Page 1

INSTRUCTIONS-PARTS

This manual contains IMPORTANT

WARNINGS AND INSTRUCTIONS

READ AND RETAIN

FOR

REFERENCE

~

LIST

a

QWO

307-863

Rev.

A

GM3500

3000

psi

(210

bar)

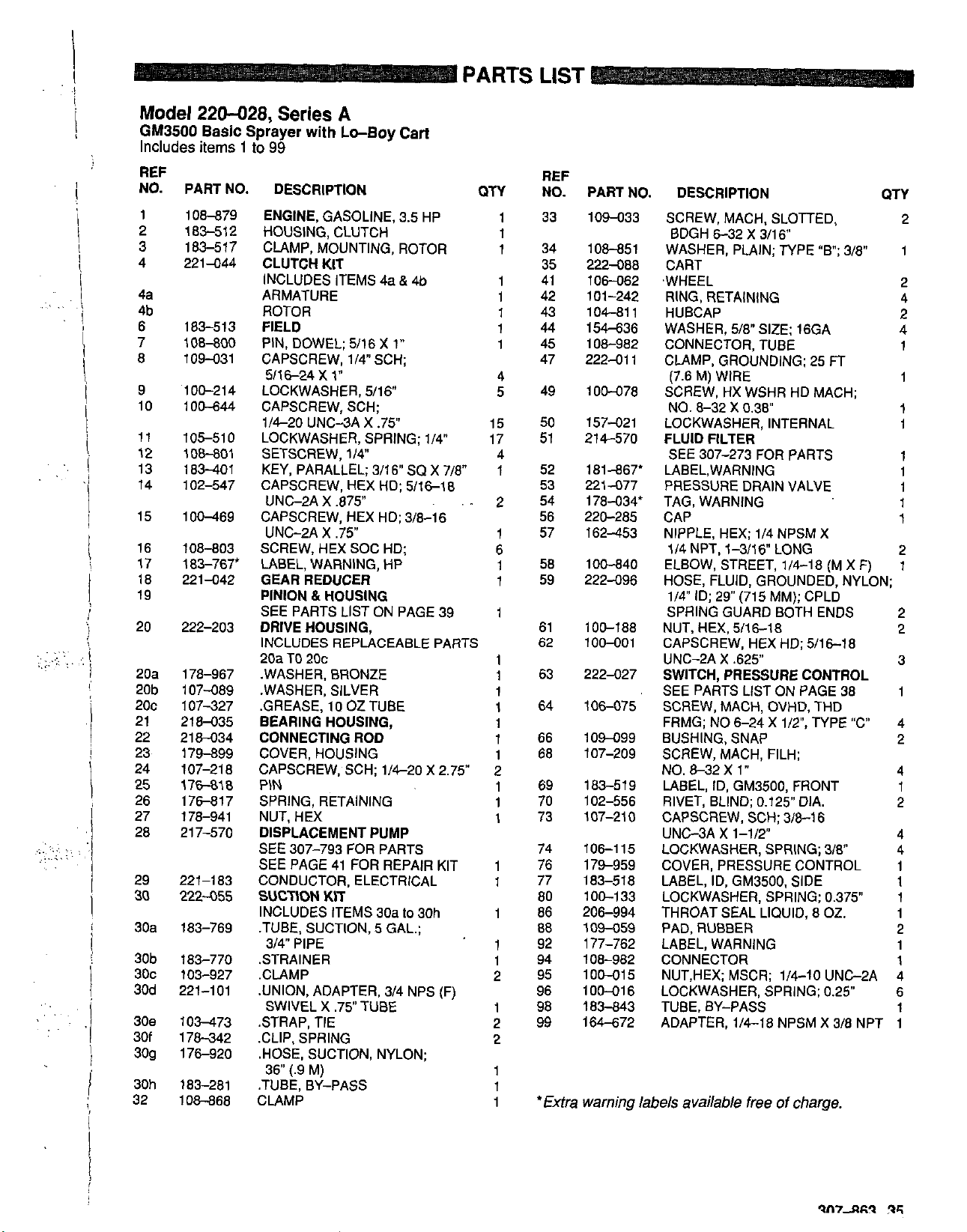

Model 220-028, Series

Lo-Boy Cart, Basic

Model 231-077

Lo-Boy Cart, Complete

Model 220-040, Series

Upright Cart, Basic

Model 231-0517

Upright Cart, Complete

SPRAYER

MAXIMUM WORKING

A

A

PRESSURE

WARNING

Hazard

Never use

such solvents in this equipment. Such use could result in a serious chemical reaction, with the possibility of explosion, which could cause death, serious bodily injury and/or substantial property damage.

Consult your fluid suppliers

Refer

of

Using Fluids Containing Halogenated Hydrocarbons

1,1,

I-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing

to

ensure that the fluids being used are compatible with aluminum and zinc parts.

to

the Technical Data

GRACO INC. P.O.

on

page

42

for more information.

BOX

1441 MINNEAPOLIS, MN 55440-1444

COPYRIGHT

1988,

GRACO INC.

Page 2

TABLE

OF

CONTENTS

Introduction

Warnings

English

French (Avertissernent)

Spanish (Advertencia) 8

Setup

Fueling

Startup

Maintenance

Flushing Guidelines

Troubleshooting Guide

Repair

Pressure Control

Pressure Control Calibration

Bearing Housing and Connecting Rod

Drive Housing

Pinion. Clutch. Field. Clam. Enaine

...............................

................................

...................

....................

...................................

..................................

..................................

.............................

.......................

....................

.......................

-

-

..........................

Pinion Housing kemo&

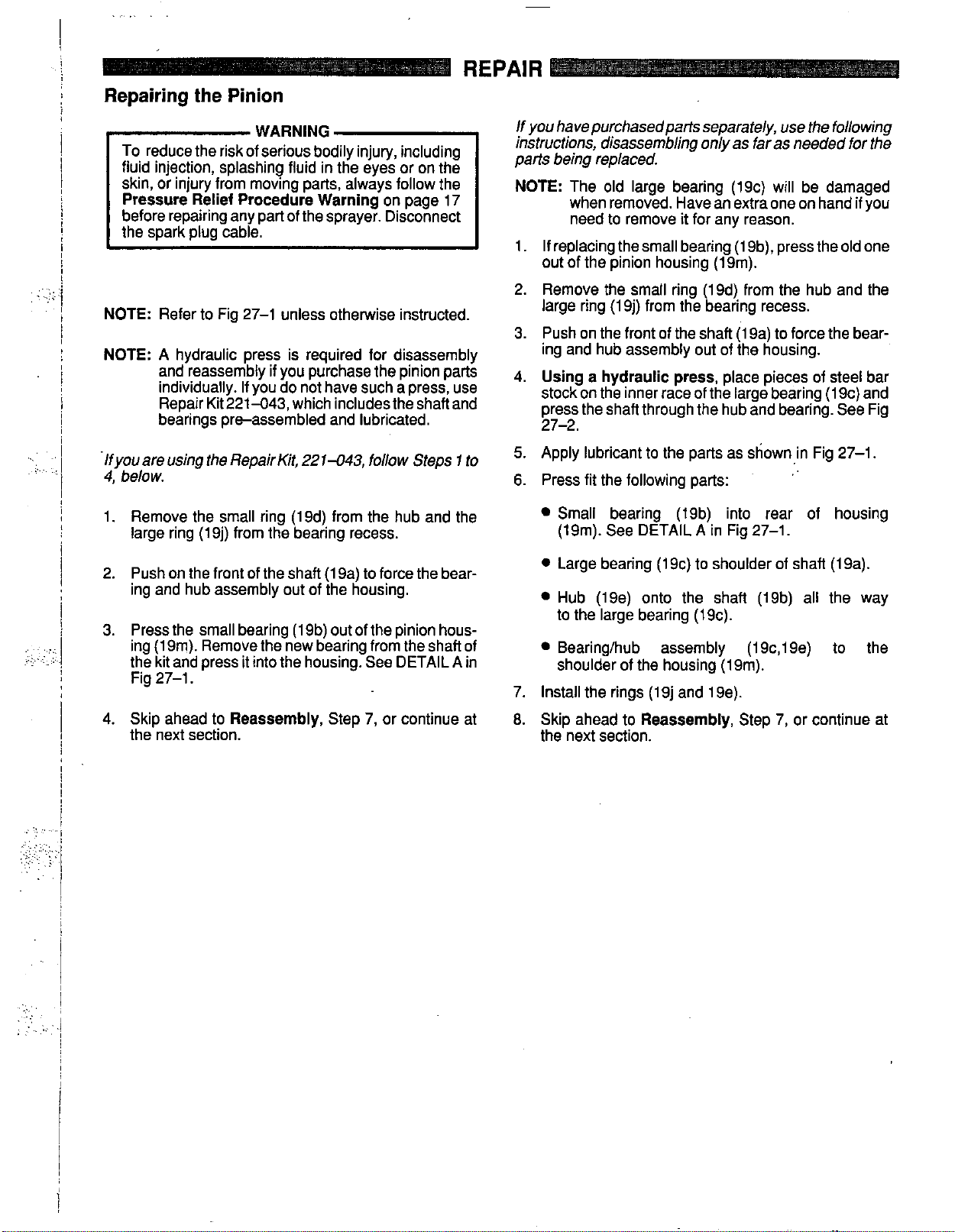

Repairing the Pinion

.................

..............

-

"

.......

..............

INTRODUCTION

2

4

6

10

11

12

14

15

17

19

21

22

24

25

26

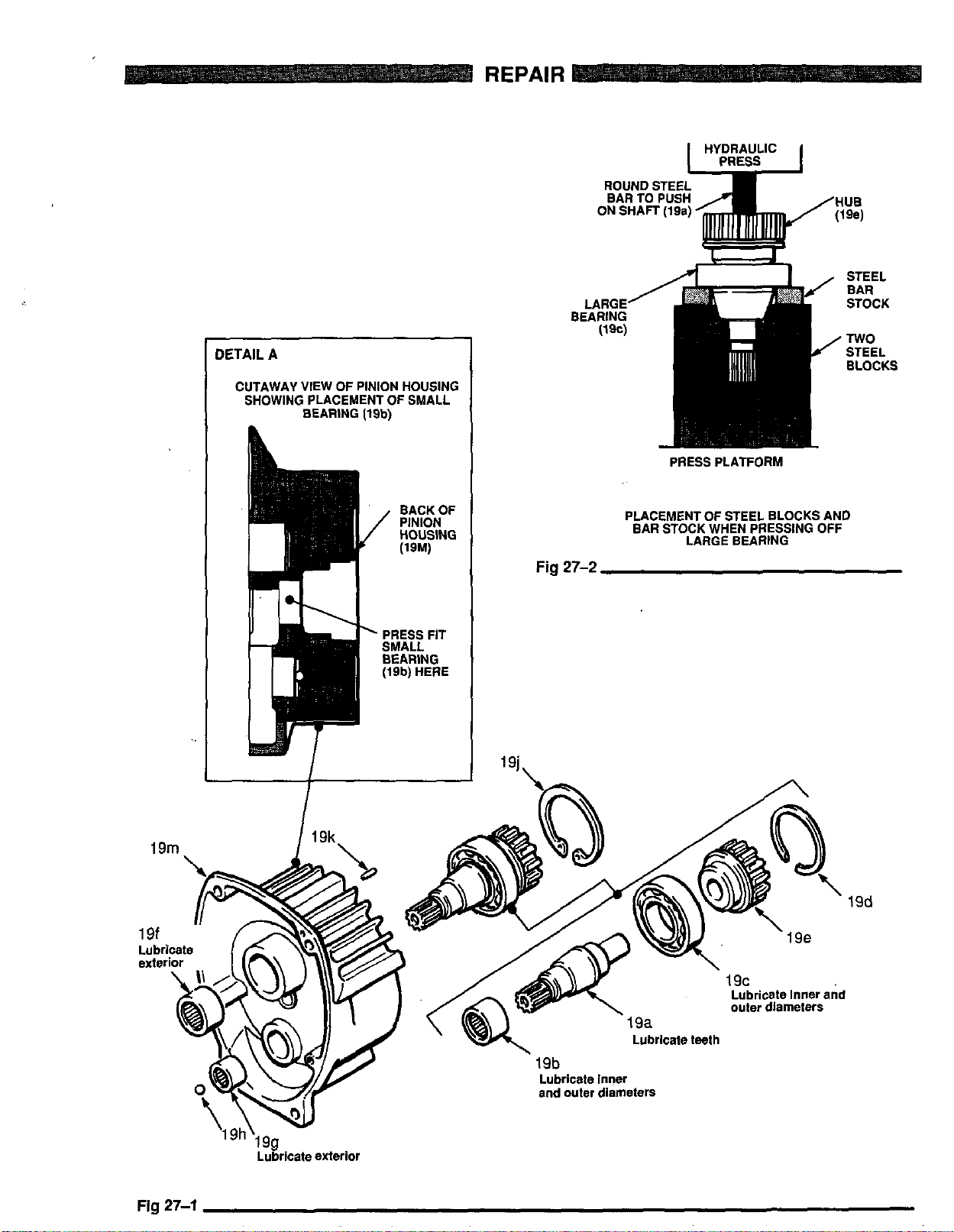

Clutch

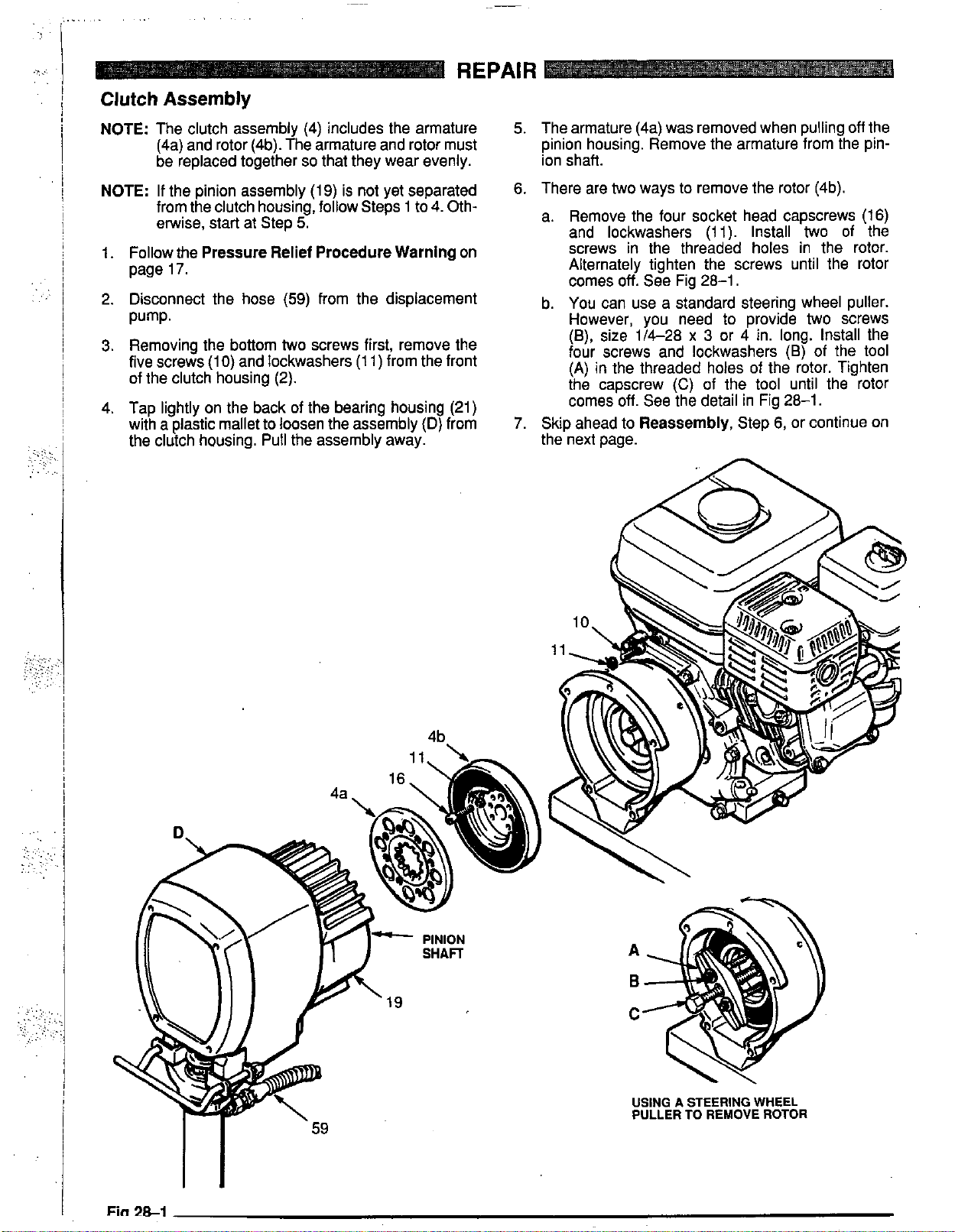

Engine

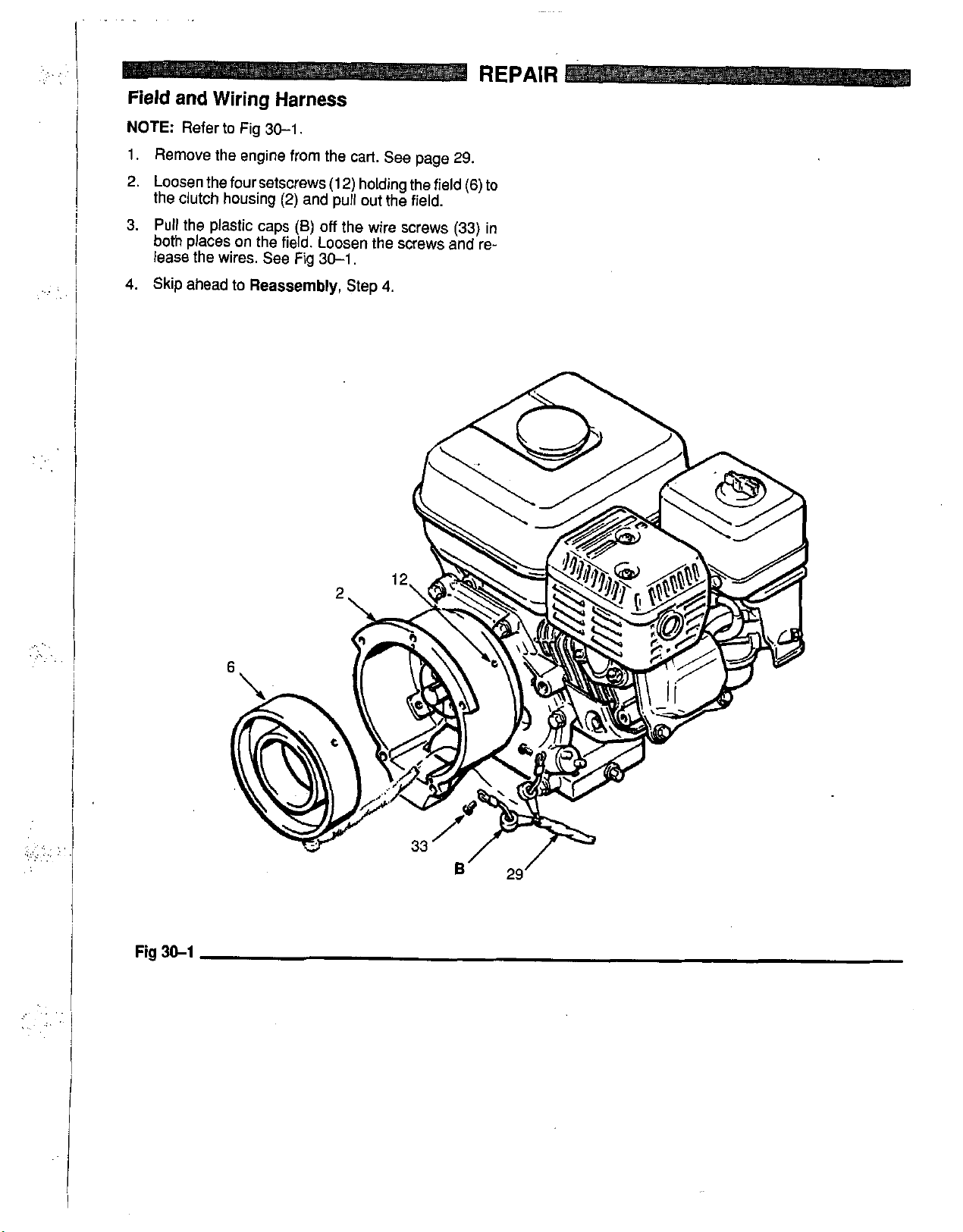

Field and Wiring Harness

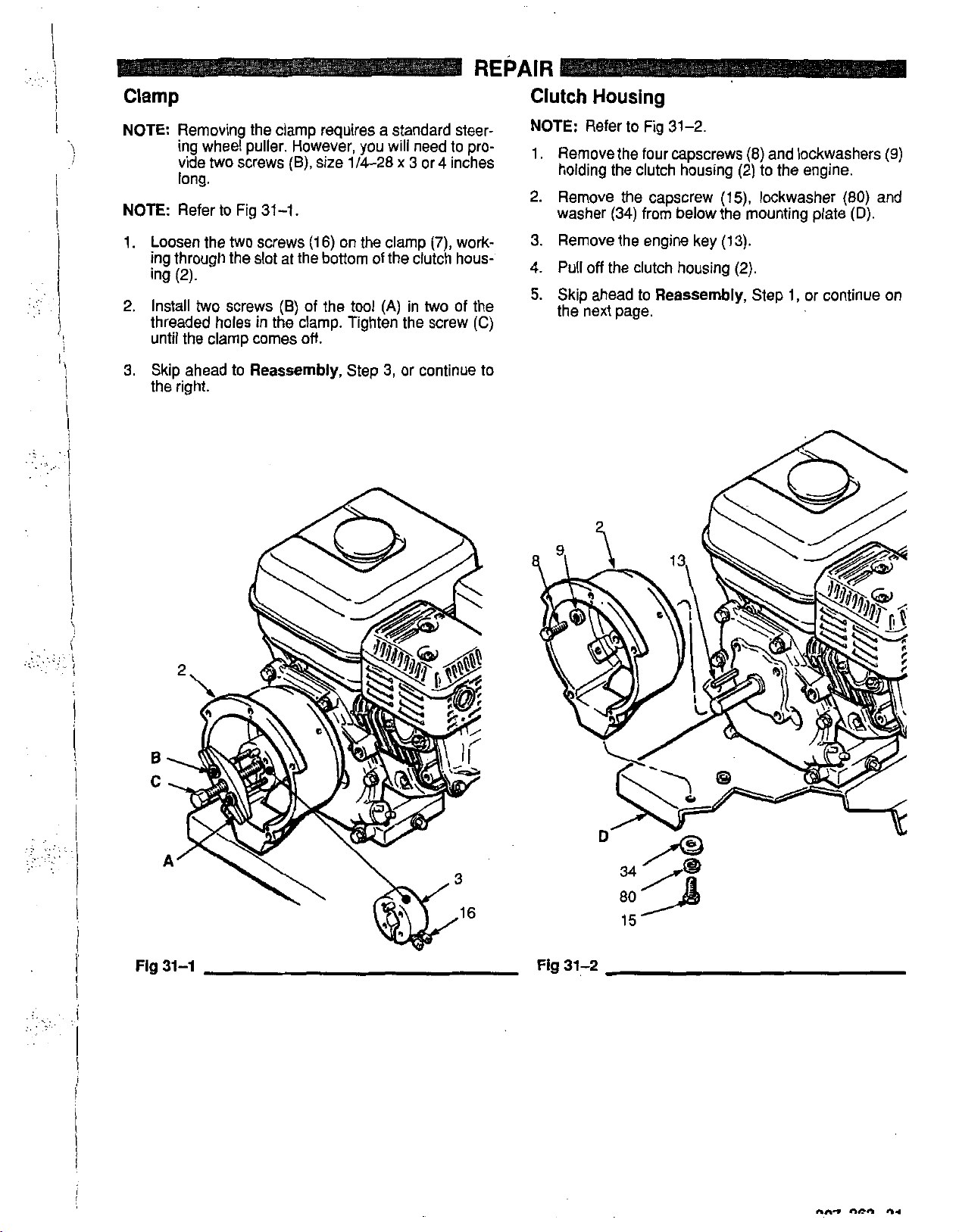

Clamp

Clutch Housing

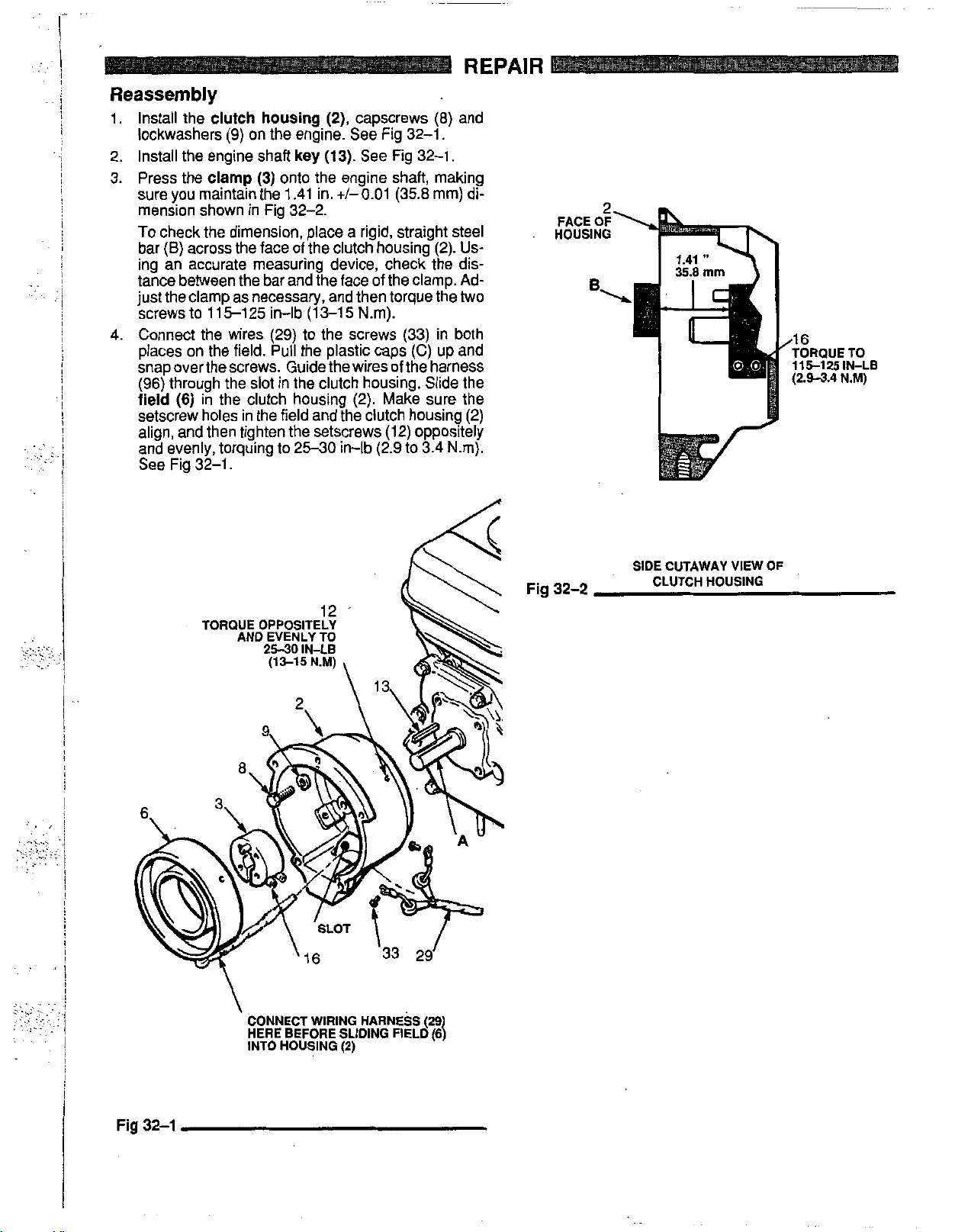

Reassembly

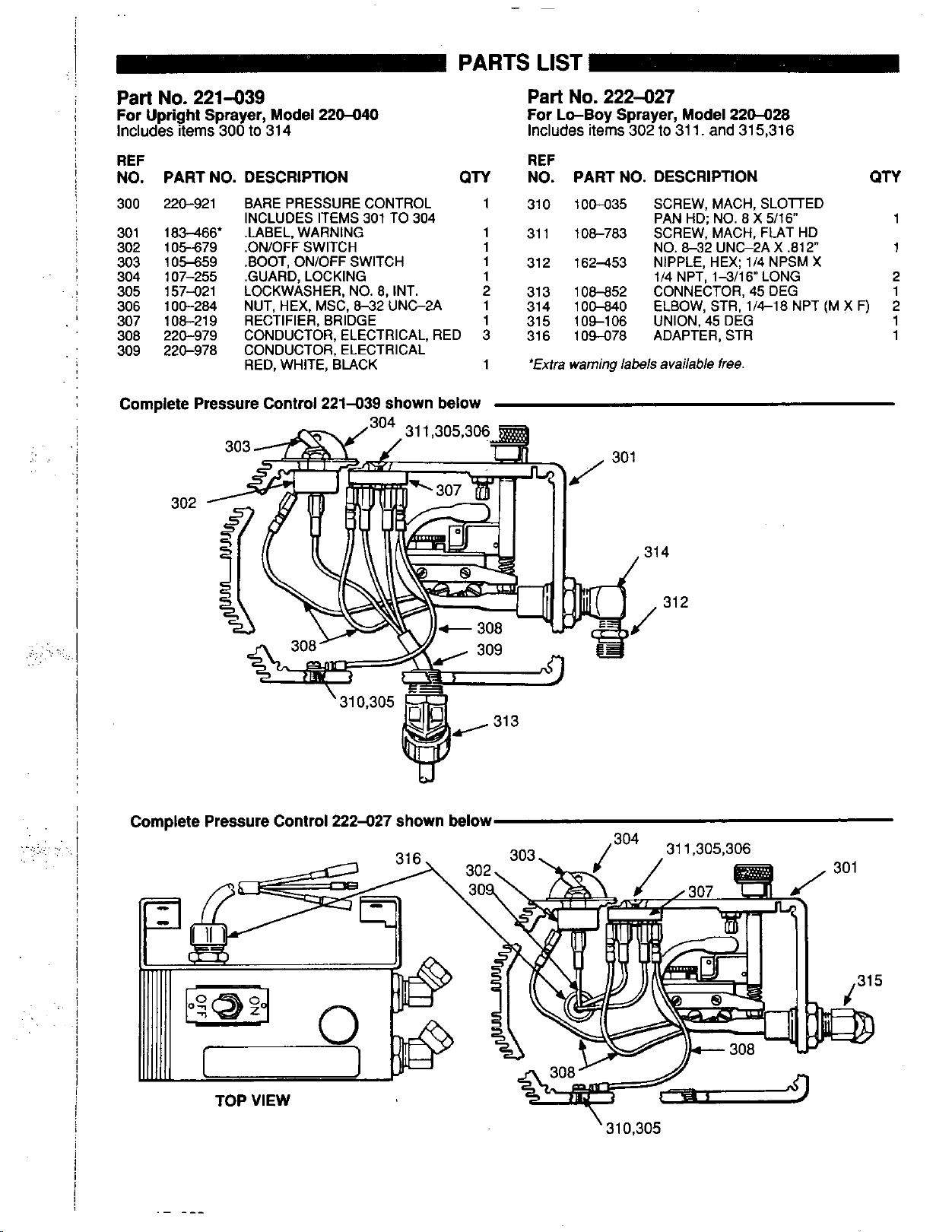

Parts Lists and Drawings

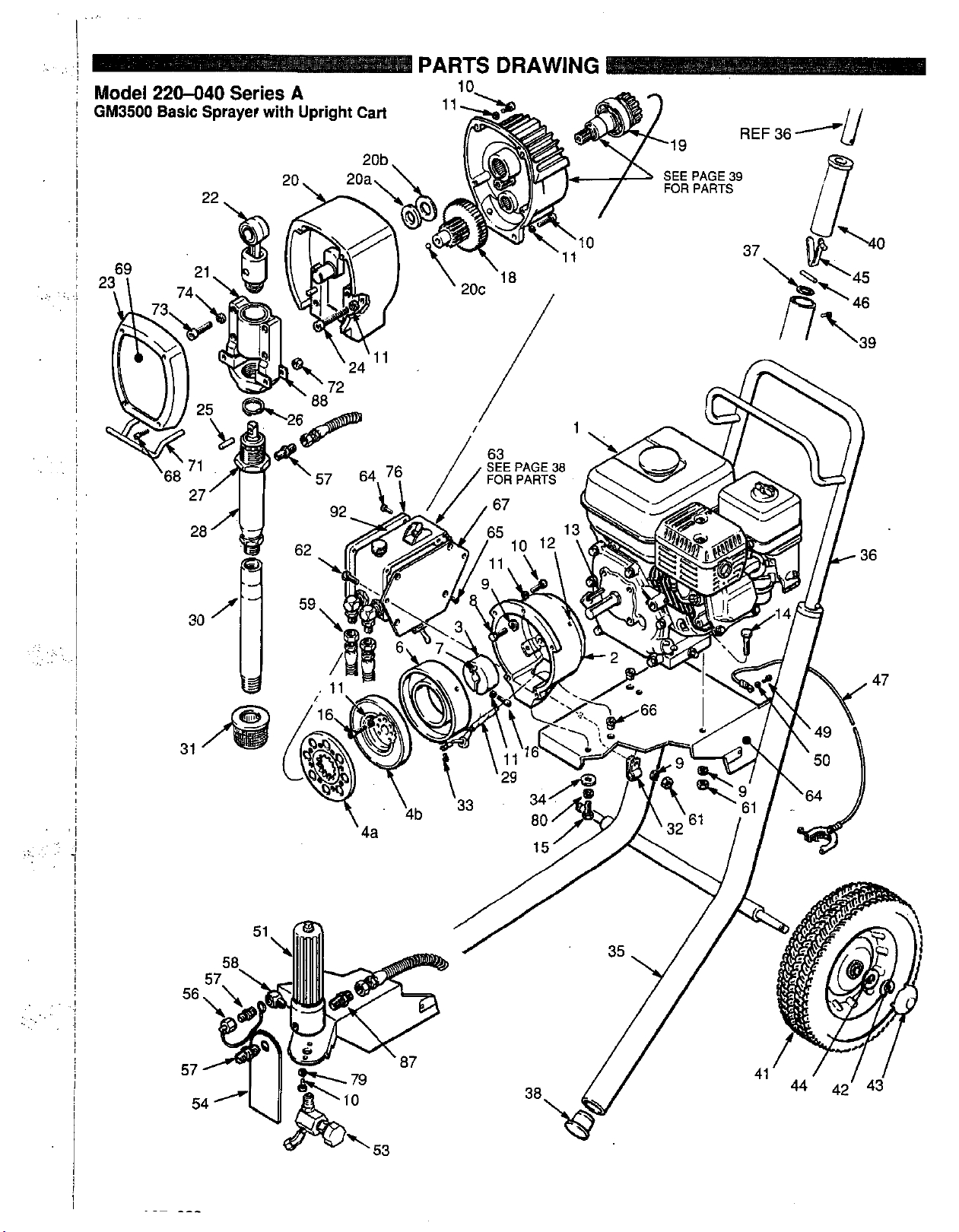

Basic Sprayer,

Lo-Bov Cart. Model 220-028

Uprighi Cart,' Model 220-040

Completre Sprayer,

Lo-Bov Cart. Model 231-077

Uprighi CartIModel 231-057

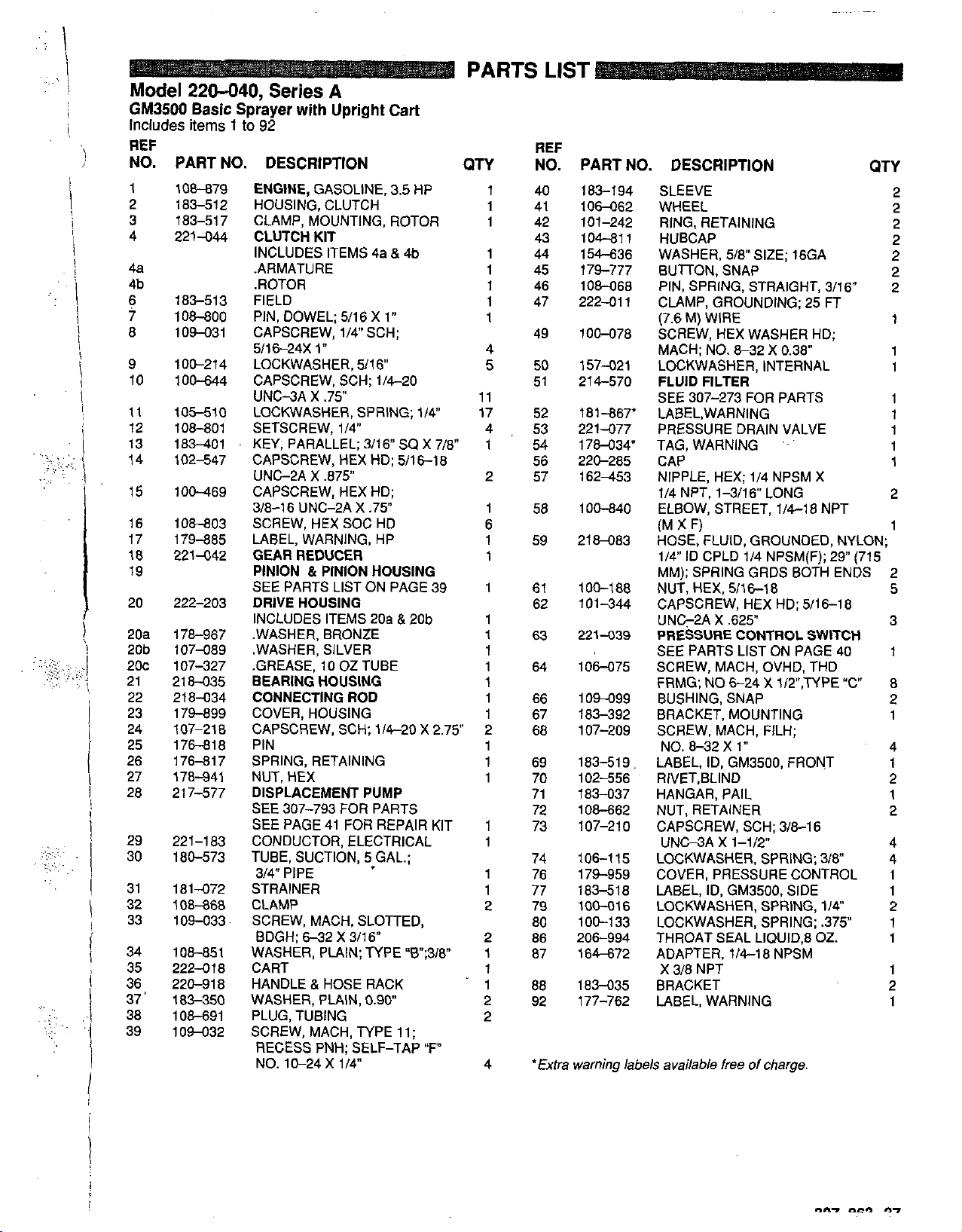

Pinion Assembly

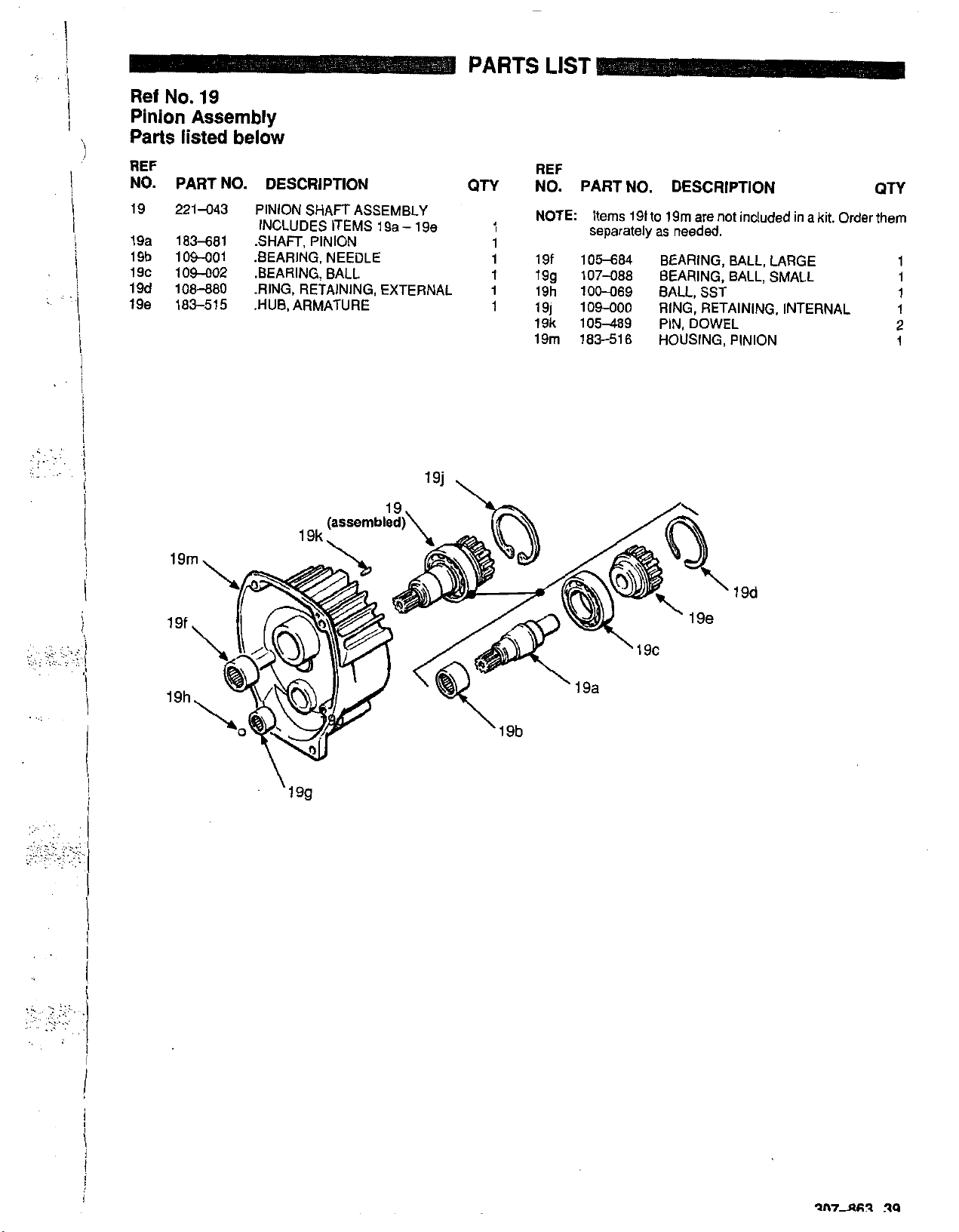

Pressure Control Assembly

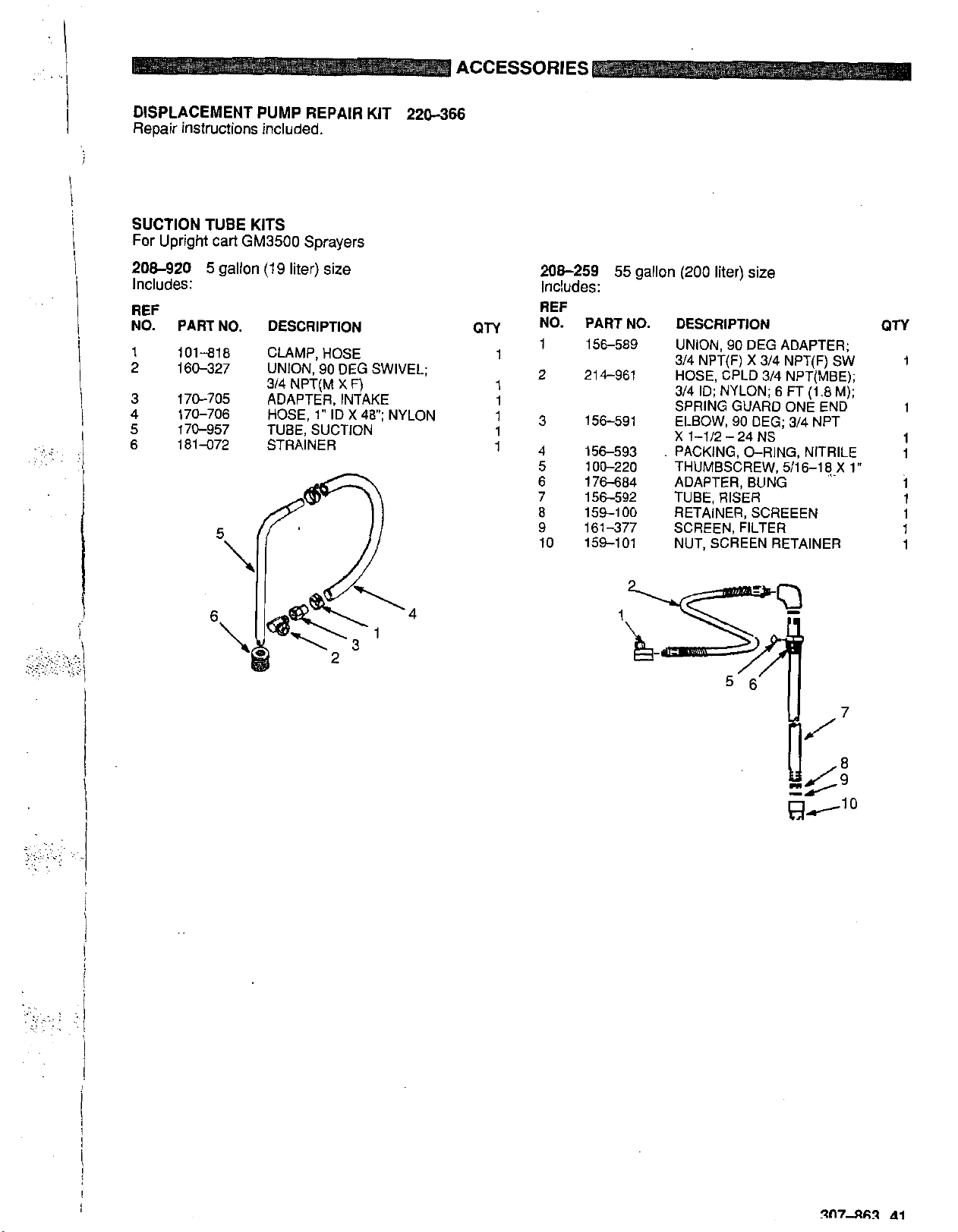

Accessories

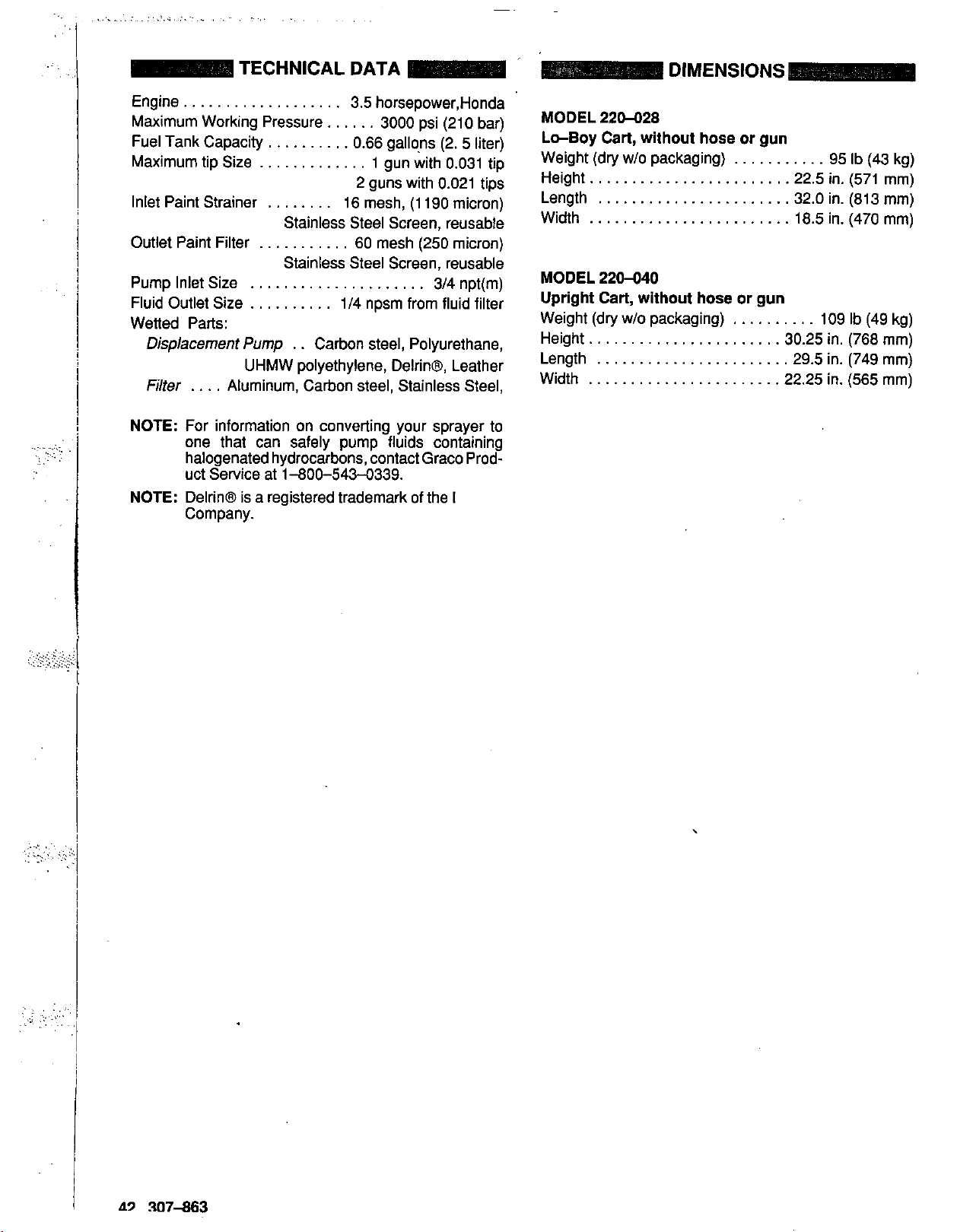

Dimensions

Technical Data

Warranty

.............................

.............................

.............................

......................

........................

........................

..............................

...............................

............................

.........................

28

29

..............

......

...........

.......

...

I

.......

................

Back Cover

30

31

31

32

34

36

38

38

39

40

41

42

42

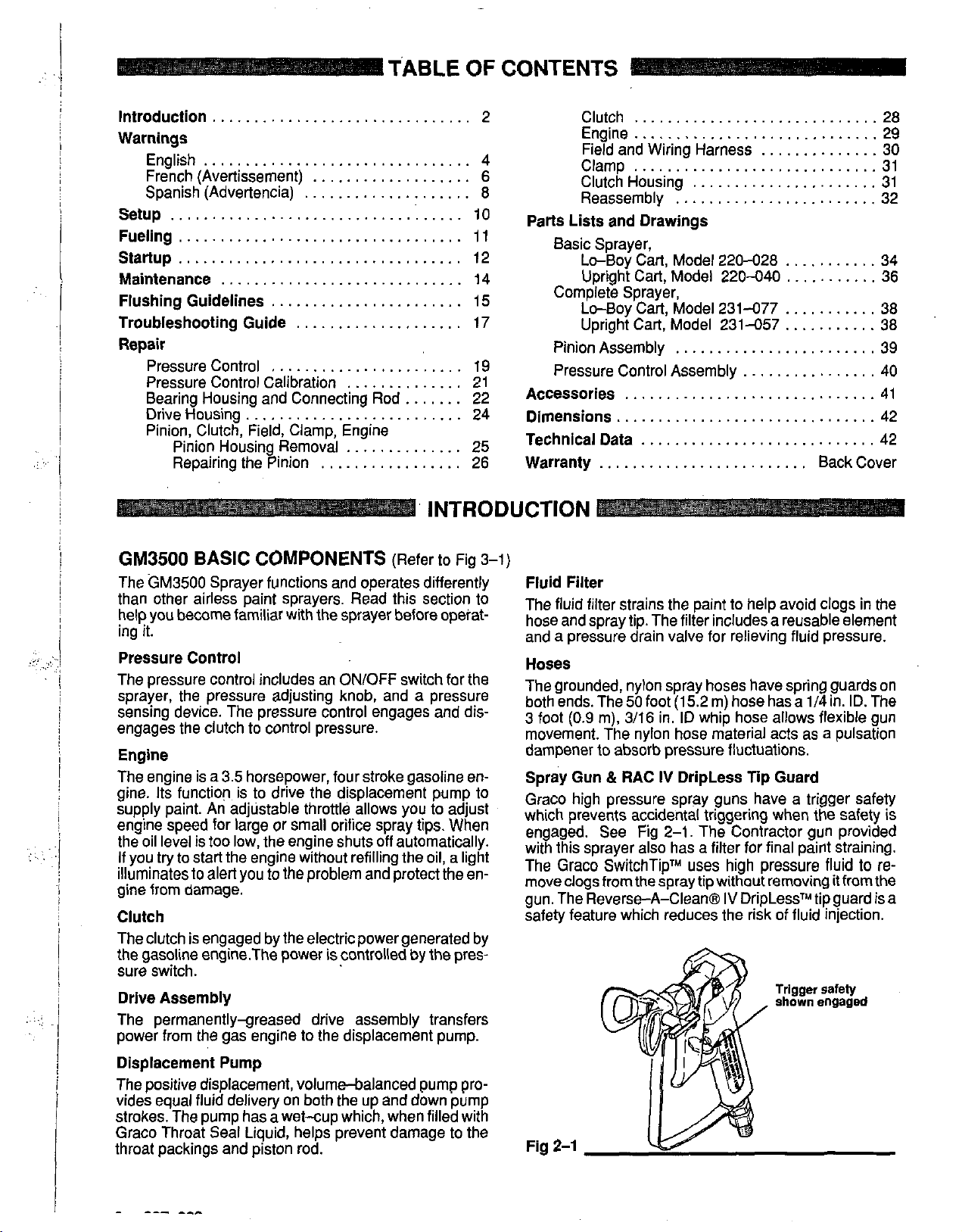

GM3500

The GM3500 Sprayer functions and operates differently

than other airless paint sprayers. Read this section to

help you become familiar with the sprayer before operating it.

Pressure Control

The pressure control includes

sprayer, the pressure adjusting knob, and a pressure

sensing device. The pressure control engages and dis-

engages the clutch to control pressure.

Engine

The engine is a 3.5 horsepower, four stroke gasoline engine. Its function is to drive the displacement pump to

supply paint. An adjustable throttle allows you to adjust

engine speed for large or small

the oil level is too low, the engine shuts

If

you try to start the engine without refilling the oil, a light

illuminates to

gine from damage.

Clutch

The clutch is engaged by the electric power generated by

the gasoline engine.The power is controlled

sure switch.

Drive Assembly

The permanentlygreased drive assembly transfers

power from the gas engine

BASIC

alert

you to the problem and protect the en-

COMPONENTS

an

ON/OFF switch for the

oritice

spray tips. When

off

to

the displacement pump.

(Refer to Fig 3-1)

automatically.

by

the pres-

Fluid Filter

The fluid filter strains the paint to help avoid clogs in the

hose and spray tip. The filter includes a reusable element

and a pressure drain valve for relieving fluid pressure.

Hoses

The grounded, nylon spray hoses have spring guards on

both ends. The 50 foot (1 5.2 m) hose has a 1/11 in. ID. The

3 foot (0.9 m), 3/16 in. ID whip hose allows flexible gun

movement. The nylon hose material acts as a pulsation

dampener to absorb pressure fluctuations.

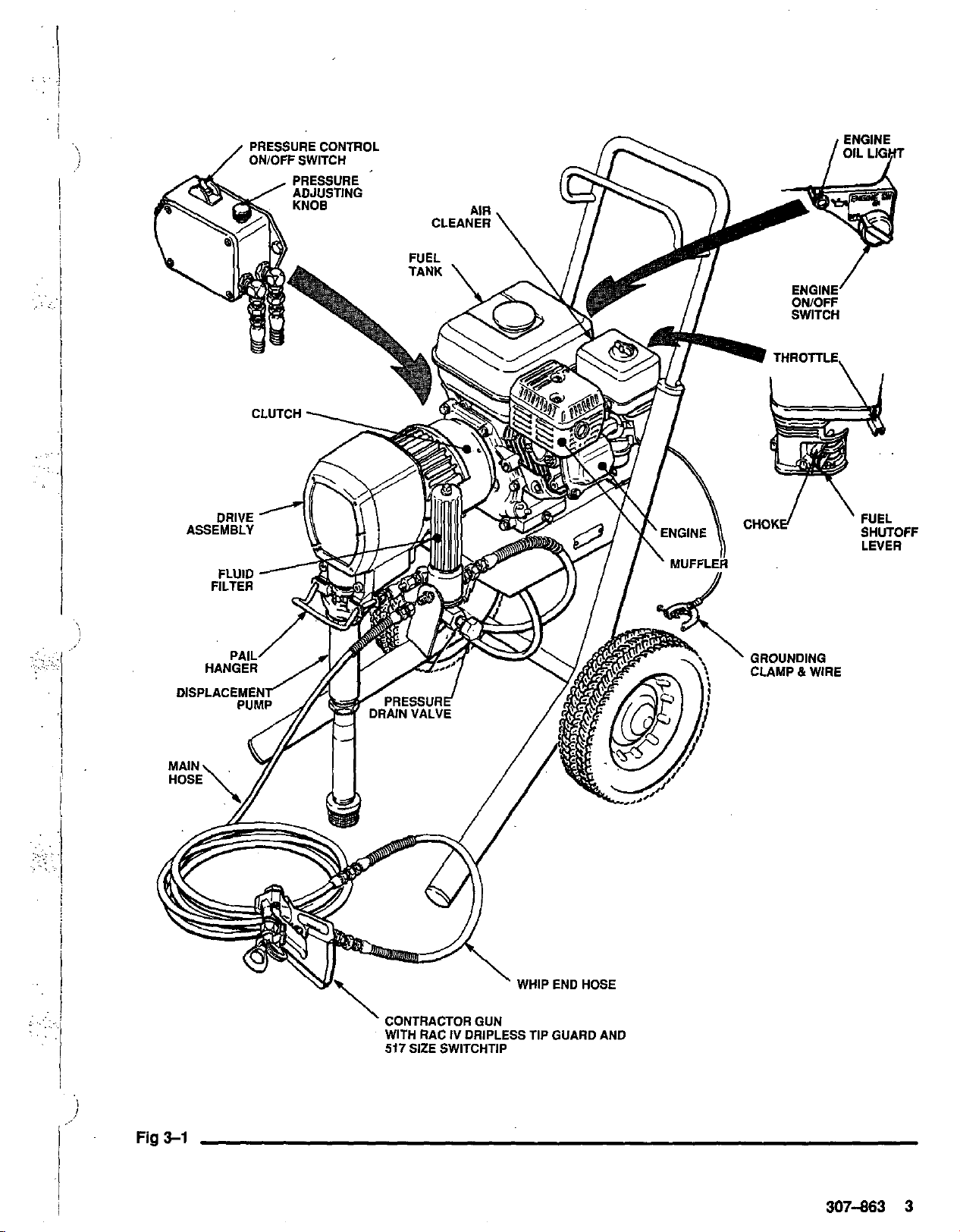

Spray Gun & RAC

Graco high pressure spray guns have a trigger safety

which prevents accidental triggering when the safety is

engaged. See Fig 2-1. The Contractor gun provided

with this sprayer also has a filter for final paint straining.

The Graco SwitchTipTM

move clogs from the spray tip without removing

gun. The Reverse-A-Clean@

safety feature which reduces the risk of fluid injection.

IV

DripLess Tip Guard

uses

high pressure fluid to

IV

DripLessTM tip guard is a

it

from the

re-

Displacement Pump

The positive displacement, volumebalanced pump provides equal fluid delivery on both the up and down pump

strokes. The pump has a wet-cup which, when filled with

Graco Throat Seal Liquid, helps prevent damage to the

throat packings and piston rod.

Page 3

..

. .

I

I

,

,.

i

'

CONTRACTOR

WITH

RAC

517

SIZE SWITCHTIP

i

Fig

3-1

i

GUN

IV

DRIPLESS TIP GUARD AND

307-863

3

Page 4

HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

FOR

PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS

Read and understand all instruction manuals before operating equipment.

FLUID INJECTION HAZARD

General

This equipment generates very high fluid pressure. Spray from

the gun, leaks or ruptured components can inject fluid through

yourskin and into your body andcauseextremely serious bodily

injury, including the need for amputation. Also, fluid injected or

splashed into the eyes or

age.

NEVERpointthespraygunatanyoneoratanypartofthebody.

NEVER put hand or fingers over the spray tip. NEVER try

"blow back" paint; this is NOT an air spray system.

ALWAYS have the tip guard in place

spraying.

ALWAYSfoliowthe Pressure Relief Procedure, below, before

cleaning or removing the spray tip or servicing any system

equipment.

NEVER try

Besureequipmentsafetydevicesareoperating

each use.

Medical Alert-Airless

If

any fluid appears

MEDICAL CARE AT ONCE.

CUT. Tell the doctor exactly what fluid was injected.

NotetoPhvsician:lniectionintheskinisatraumaticiniurv.It

is importah

Do

cern with some exotic coatings injected directly into the

blood stream. Consultation with

constructive hand surgeon may be advisable.

Spray

Be

each use. DO not remove or modify any part

cause a malfunction and result in serious bodily injury.

Safety

on

the skin can cause serious dam-

to

on

the spray gun when

to

stop or deflect leaks with your hand or body.

properly before

to

Spray

penetrate your skin, get EMERGENCY

to

treat

the

not

delay treatment

Gun

sure all gun safely devices are operating properly before

Safety

injury surgically as

to

research toxicity. Toxicity

Devices

Wounds

DO

NOT TREAT AS A SIMPLE

as

possible.

is

,~

a con-

soon

a

plastic surgeon or re-

oi

the gun-this can

,~~-

Safety

Latch

Wheneveryoustopspraying,evenforamoment,alwayssetthe

gun safety latch in the closed or "safe" position, making the gun

inoperative. Failure

tal triggering of the gun.

Diffuser

The gun diffuser breaks up spray and reduces the risk of fluid

injection when the tip is

regularly. Follow the

remove the spray tip.

gun firmly

the gun.

stream, replace the diffuser immediately.

Tip

ALWAYS have the tip guard in place

spraying. The tip guard alerts you

and helps reduce, but does not prevent, the risk of accidentally

placing your fingers or any part of your body close

tip.

Trigger

Always have the trigger guard in place

ing

dropped or bumped.

Spray

Use extreme caution when cleaning or changing spray tips.

the spray tip clogs while spraying, engage the gun safety latch

immediately, ALWAYS follow the Pressure Relief Procedure

and then remove the spray tip to clean

NEVER wipe off build-up around the spray tip until pressure is

fully relieved and the gun safety latch is engaged.

to

If

the fluid emitted is

Guard

Guard

to

reduce the risk of accidentally triggering the gun

Tip Safety

to

set the safety latch can result in acciden-

not

installed. Check diffuser operation

Pressure Relief

Aim the gun into

the pail. Using the lowest possible pressure, trigger

Procedure,

a metal pail,

not

diffused into an irregular

on

the spray gun while

to

the fluid injection hazard

on

the gun when spray-

below, then

holding the

to

the spray

if

it

is

If

it.

Pressure

To

reduce the risk of serious bodily injury, including fluid injec-

tion. splashing fluid or solvent in the eyes or

iuryfrommovingpartsorelectricshock,alwaysfollowthispro-

cedure whenever you shut

servicing any part of the spray system, when installing, cleaning or changing spray tips, and whenever you stop spraying.

1.

2.

Turn the ON/OFF switch

3.

Relief

Engage the gun safety latch.

Flip the pressure control switch

Procedure

off

the sprayer, when checking or

to

OFF.

1

on

the skin, or

to

OFF. or that pressure has

in-

2

4.

Disengage the gun safety latch. Hold a metal part of the

gun firmly

the gun

5.

Engage

6.

Open the pressure drain vaive, having a container ready

to

catch the drainage. Leave the valve open until you are

ready

7.

Disconnect the spark plug cable

lfyoususpectthatfhespraytiporhoseiscorn

stepsabove, VERY SLOWLY loosen the tip guard retaining

nut or hose end coupling and relieve pressure gradually, then

to

the side of agrounded metal pail, andtrigger

to

relieve pressure.

the

gun

safety

latch.

to

spray again.

not

been fully relieved ager fokwing the

.

Now clear the tip or hose.

letel clogged,

Page 5

I

....

,.

. .

i

!

I

!

.,

.

..

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers or other body

parts. KEEP CLEAR of moving parts when starting or operating

the sprayer. Follow the Pressure Relief Procedure on page

before checking or servicing any part ofthe sprayer, to prevent it

from starting accidentally.

4

EQUIPMENT MISUSE HAZARD

General Safety

Any misuse of the spray equipment or accessories, such as

overoressurizino. modifvino Darts. usino incomoatible chemicals'and fluids,-or using worn or damaged parts, can cause

to

them

or

property damage.

NEVER alter or modify any part of this equipment; doing

could cause it

CHECK all spray equipment regularly and repair or replace

worn or damaged parts immediately.

Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and solvent manufacturer.

rupture and result in fluid injection, splashing in the eyes

on

theskin, orother serious bod~ily injury..orfire. exolosion or

to

System Pressure

This sprayer can develop

WORKING PRESSURE. Be sure that all spray equipment and

accessories used are rated to withstand this pressure.

exceed the maximum working pressure of any component or

accessory used in the system.

Fluid

and

BE SURE that all fluids and solvents used are chemically compatible with the wetted parts shown in the TECHNICAL DATA

on page 42. Always read the fluid and solvent manufacturer's

literature before using them in this sprayer.

Solvent Compatibility

1

I.~~~.

malfunction.

~ ~~~

3000

psi (210 bar) MAXIMUM

-

DO

~ ~

so

NOT

If

High pressure fluid in the hoses can be very dangerous.

hose develops a leak, split or rupture due

damage or misuse, the high pressure spray emitted from it can

cause a fluid injection injury or other serious bodily injury or

property damage.

ALL FLUID HOSES MUST HAVE SPRING GUARDS ON

BOTH ENDS! The spring guards help protect the hose from

kinks or bends at or close

hose rupture.

TIGHTEN all fluid connections securely before each use. High

pressure fluid can dislodge a loose coupling or allow high pressure spray

NEVER use

tire hose for cuts, leaks, abrasion, bulging cover, or damage or

movement

ist. replace the hose immediately.

pressure hose or mend it with tape or any other device.

paired hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY.

hoses

and hot surfaces of the pump and

or solvents which are not compatible with the inner tube and

to

be emitted from the coupling.

a

damaged hose. Before'each use, check the en-

of

the hose couplings.

to

move equipment. Keep

to

the coupling which can result in

If

DO

hoses clear of moving

gas engine.

to

any kind of wear,

any of these conditions ex-

NOT try

to

recouple high

Do

not pull on

Do

not use fluids

the

A

re-

parts

coverofthehose.DONOTexposeGracohosetotemperatures

above

180'

F

(82'

C)

or below

Hose

Groundlng Continuity

Proper hose grounding continuity is essential to maintaining a

grounded spray system. Check the electrical resistance of your

fluid hoses at least once a week.

on

it which specifies the maximum electrical resistance,

tag

contact the'hose supplier or manufacturer for the maximum resistance limits. Use a resistance meter in the appropriate range

for your hose to check the resistance. lfthe resistance exceeds

the recommended limits, replace it immediately. An ungrounded or poorly grounded hose can make your system hazardous. Also read FIRE

OR

40' F (-40'

If

your hose does not have a

EXPLOSION HAZARD.

C).

..

,

,

...

..~

. ..

,.

..

..

.

.

..

FIRE

Static electricity is created by the flow of fluid through the pump

and hose.

grounded, sparking may occur, and the system may become

hazardous.

plugging a

Sparks can ignite fumes from solvents and the fluid being

sprayed, dust particles and other flammable substances,

whether you are spraying indoors or outdoors, and can cause a

fireor explosion and serious bodilyinjury and property damage.

If

while using this equipment, STOP SPRAYING IMMEDIATELY. Check the entire system for proper grounding.

use the system again until the problem has been identified and

corrected.

Grounding

To reduce the risk

other spray equipment used

CHECKyourlocalelectricalcodefordetailedgroundinginstruc-

lions for your area and type of equipment. BE SURE

all of this spray equipment:

.

1. Sprayer: connect a ground wire and clamp (supplied)

GASOLINE ENGINE HAZARD

NEVER

spilled

ALWAYS pour fuel in slowly

OR

NEVER operate the engine in a closed building unless the engine exhaust is piped outside. The exhaust contains carbon

monoxide, a poisonous, odorless and invisible gas which can

cause serious illness and even death

OR

EXPLOSION HAZARD

If

every part of the spray equipment is not properly

Sparking may also occur when

power supply

you experience any static sparking

of

true earth ground.

fill

the fuel tank while the engine is running or hot. fuel

on

a hot surface can ignite and cause a fire.

EXPLOSION HAZARD, above, and FUELING

cord or using a

static sparking, ground the sprayer and all

or

located in the spray area.

to

avoid spilling. Also read FIRE

plugging

gasoline engine.

or

even

if

inhaled.

in or un-

a slight shock

Do

not

to

ground

to

a

on

page 11.

2.

Fluid

hoses: use only grounded hoses with a maximum

of

500feet(l50m)combinedhoselengthtoensuregrounding

continuity. See Hose Grounding Continuity,

3.

Spraygun:obtain grounding through connection

erly grounded fluid hose and sprayer.

4.

Object being sprayed: according

5.

Fluid

supply container: according to local code.

6.

All solvent

code. Use only metal pails, which are conductive.

dace the oail on a non+onductive surface, such as oaoer

or cardboard, which interrupts the grounding continuity.

7.

To

maintain grounding continuity when flushing or relieving

pressure, always hold a metal part of the gun firmly

side of a grounded metal pail, then trigger the gun.

pails

used

when flushing, according to local

to

local code

to

a prop-

Do

to

not

the

Flushing Safety

Reduce the risk of fluid injection injury. static sparking, or

splashing by following the flushing procedure given

of

this manual. Follow the Pressure Relief Procedureon page

4, and remove the spray tip before flushing. Hold ametal part of

the gun firmly to the side of a grounded metal pail and use the

lowest possible fluid pressure during flushing.

on

page 14

IMPORTANT

United States Government safety standards have been

adopted under the Occupational Safety and Health Act. These

standards-particularly theGeneral Standards, Part 1910, and

the Construction Standards. Part 1926 -should be consulted.

.)n7

om

e

Page 6

AVERTISSEMENT

La

pulv6risation

RBserv6

exclusivement I'usage professionnel. Observer toutes

Bien lire et bien comprendre tous

B

haute

pression

peut

causer des blessures tr6s graves.

les

consignes de s6curit6.

les

manuels d'instructions avant d'utiliser

le

mat6riel.

RISQUES

D'INJECTION

Consignes g6nerales de s6curitB

Cet appareil produit un fluide B tr& haute pression. Le fluide

pulvbrisb par le pistolet ou le fluide sous pression provenant de

fuites ou de ruptures peut ptin&rer sous la peau ou

du

corps et entrainer des blessures trh graves, voir m&me une

amputation. MBme sans &re sous pression, le fluide bclabous-

Sant

ou entrant dans les yeux peut aussi entrainer des

blessures graves.

NE JAMAIS pointer le pistolet vers quelqu'un ou vers une partie quelconque du corps. NE JAMAIS mettre la main ou les

doigts sur I'ajutage du pulvbrisateur. NE JAMAIS essayer de

"refouler" la peinture. Cet appareil N'est PAS un compresseur

pneumatique.

TOUJOURS garder la protection de I'ajutage en place sur le

pistolat pendant la pulv6risation.

A

TOUJOURS observer la March

Pression donnbe plus loin, avant de nettoyer ou d'enlever

I'ajutage du pulvbrisateur, ou d'effectuer un travail quelcon-

que sur une partie de I'appareil.

NE JAMAIS essayer darrhter ou de

main ou le corps.

Avant chaque utilisation, bien s'assurer que 18s dispositifs de

dcuritb fonctionnent correctement.

Suivre pour DBtendre la

d&i&

B

I'intbrieur

les fuites avec la

Soins mBdicaux

En

cas

IMMEDIATEMENT

D'URGENCE. NE PAS SOIGNER CETTE BLESSUAE

COMME UNE SIMPLE COUPURE.

Dispositifs

Avant chaque utilisation, bien s'assure que tous 18s dispositifs

de sbcuritb du pistolet fonctionnent correctement. Ne pas

de penetration de

Avls

au medecin: La pdndirarion

esi

un

chlrurglcalement cene blessure immBdiatement.

pas reiarder le traiiemeni pour effeciuer des recherches sur

la

ioxicii.4. ceriains rev6iements exotiques soni dangereuse-

ment toxiques quand

sang.

ou

iraumaiisme.

I/

est souhaitable de consulrer

un

chirurgien sp6cialis6 dans

de

skurite du

fluide

MUS

DES

II

ils

soni injecibs directement dans le

la peau: DEMANDER

SOlNS MEDICAUX

des

fluides

sous

est

important

un

chirurgien estheiique

la

reconstruction des mains.

pistolet

de

la

peau

traiter

Ne

enlever

querait d'entrainer un mauvais fonctionnement et des

blessures graves.

A chaque fois que l'on s'arr8te de pulvtiriser, m&me s'il s'agit

d'un court instant, toujours mettre

pistolet sur la position "fermbe" ou "sbcurit6" I"safe") pour

emp&cher le pistolet de fonctionner. Si le verrou de &curite

n'est pas mis, le pistolet peut se dbclencher accidentellement.

Verrou

ni

modifier une partie quelconque du pistolet; ceci ris-

de

s6curii6

le

verrou de sbcuritb du

Diffuser

Le diffuseur du pistolet sert B diviser le jet et B rbduire les ris-

ques d'injection accidentelle quand I'ajutage n'est pas en

place. Vbrifier le fonctionnement du diffuseur rbgulibrement.

Pour cette vbrification, dtitendre la pression en observant la

Marche

loin puis enlever I'ajutage du pulvbrisateur. Pointer le pistolet

dans un seau en mbtal, en le maintenant fermement contre le

seau. Puis, en utilisant la pression

puyer sur

diffuse

le diffuseur.

Protection de l'ajutage

TOUJOURS maintenir la protection de I'ajutage en place sur le

pistolet du pulvbrisateur pendant

tion de I'ajutage attire I'attention sur les risques d'injection et

contribue

ou une partie quelconque du corps ne passent accidentelle-

ment

Consi nes de s6curitB concernant

pulvBr

Faire extrhement attention B l'occasion du nettoyage ou du

remplacement des ajutages du pulvbrisateur. Si I'ajutage se

bouche pendant la pulvbrisation, mettre immbdiatement le

verrou de sbcuritb du pistolet. TOUJOURS bien observer la

Marche

I'aiutaae du pulvbrisateur Dour le nettover.

NE

du pulvbrisateur avant que

tomb& et we le verrou de sbcuritb du pistolet ne soit engag

9

Suivre pour DBtendre

la

gachette du pistolet. Si le fluide projet6 n'esipas

sous

forme de jet irrtigulier, remplacer immediatement

B

rbduire, mais n'bvite pas le risque, que les doigts

B

proximitb immediate de I'ajutage du pulvtirisateur.

B

sateur

A

Suivre pour DBtendre

..

JAMAIS essuyer ce qui s'est accumulb autour de I'ajutar

la

la

Pression donnbe plus

la

plus faible possible, ap-

la

pulvbrisation. La protec-

I'ajutage

la

Pression puis eniever

pression ne soit complbtemel

du

38

nt

8.

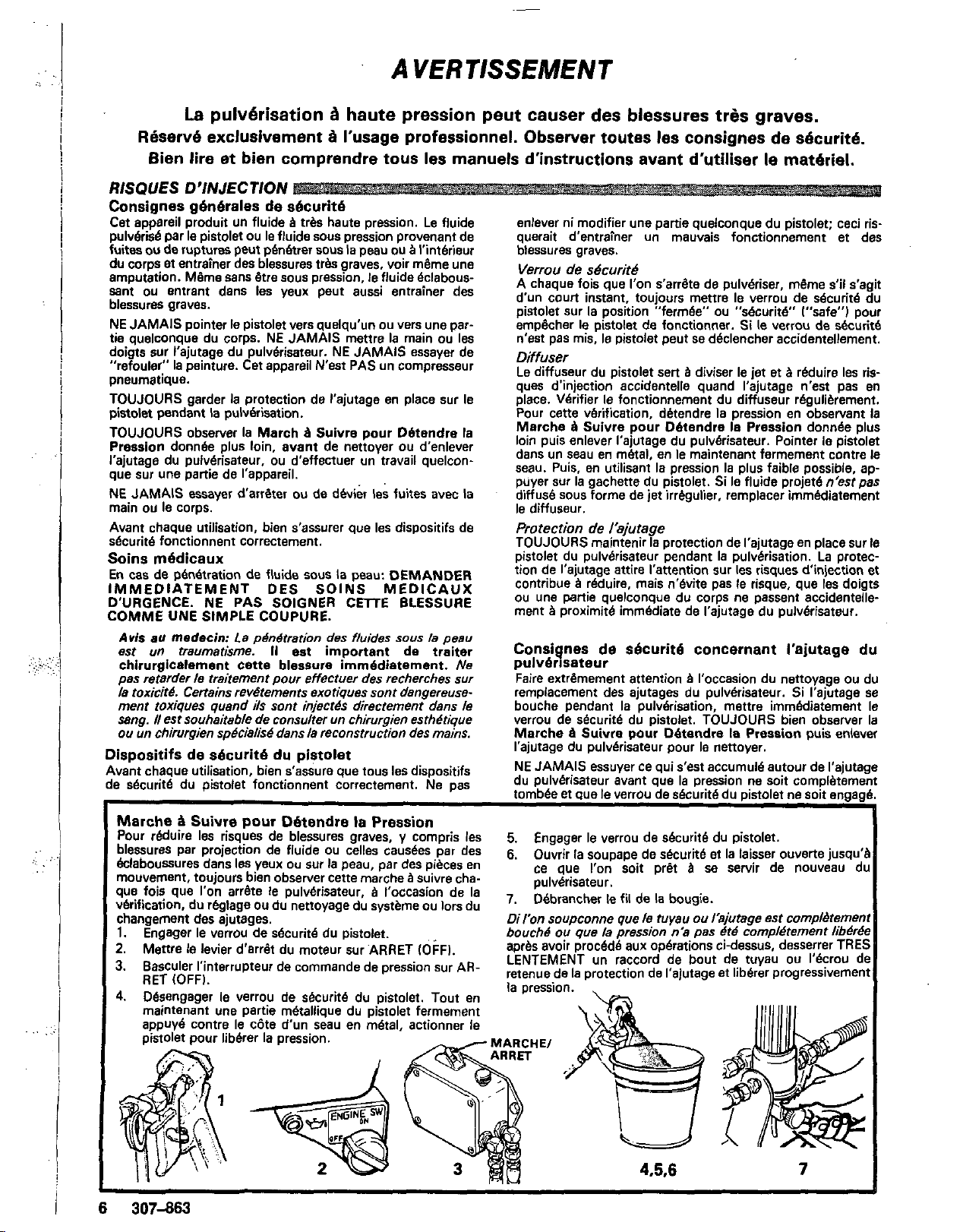

Marche B Suivre

Pour reduire Ies risques de blessures graves, y compris les

blessures Par projection de fluide

Bclaboussures dans Ies yeux ou sur la peau, par des pieces en

mouvement, toujours bien observer cette marche

que fois que I'on arrbte le pulvbrisateur,

vbrification, du rbglage ou du nettoyage du systbme ou lors du

changement des ajutages.

1.

Engager le verrou de sbcuritb du pistolet. bouch8

2.

Menre le levier d'arr€t du moteur sur ARRET IOFFI.

3.

Bascub I'interrupfeur de commande de pression sur AR-

RET IOFFI.

4.

Dbsengager le verrou de sbcuritb du pistolet. Tout en

maintenant une partie m6tallique du pistolet fermement

appuy6 contre le c6te d'un seau en mbtal, actionner le

6

307-863

pour

DBtendre

OU

libbrer la pression.

la

Pression

celles causks par des

B

Suivre cha-

B

I'occasion de la

5.

Engager le verrou de sbcuritb du pistolet.

6.

Ouvrir la soupape de sbcuritb et la laisser ouverte jusqu'i

ce que l'on soit pret

pulvbrisateur.

,,

Dbbrancher

iron

soupconne que le tuyau

aprbs avoir procbdti aux opbrations ci-dessus. desserrer TREI

LENTEMENT un raccord de bout de tuyaU ou I'bCrOU dt

retenue

ou

de

que

la

,e

fii

de

la

pression n'a

A

SB

servir de nouveau dl

la

bougie,

ou

hjutage esi complbtemen

pas

6id

comp~&ernent

de I'alutage et libbrer progressivemen

lib&&

7

Page 7

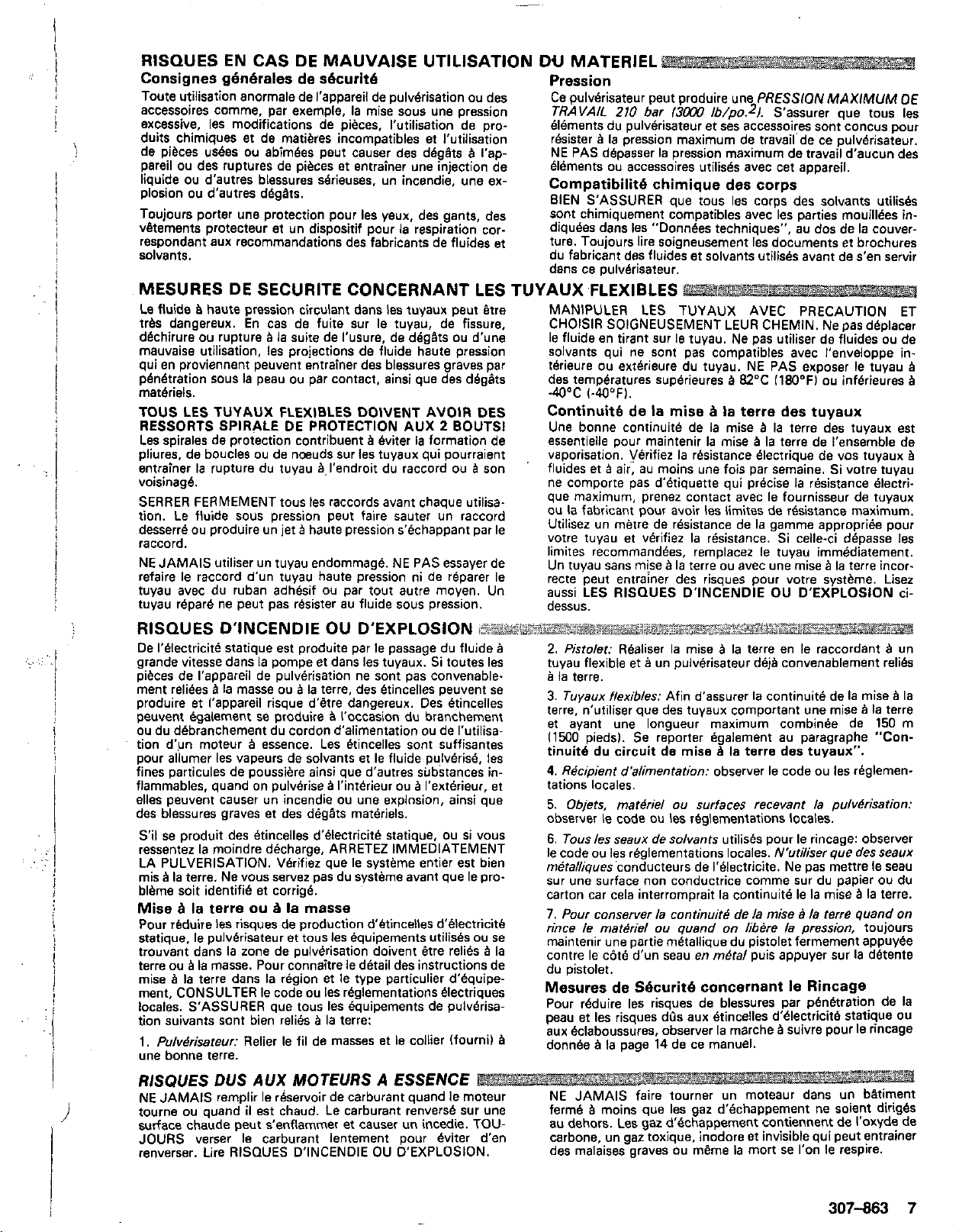

RISQUES

Consignes

Toute utilisation anormale de I'appareil de pulverisation

accessoires comme. par exemple,

excessive, 18s modifications de pieces, I'utilisation de produits chimiques et de matieres incompatibles et l'utilisation

de pieces usees ou abimees peut causer des dbgats

pareil

ou

liquide

plosion

Toujours porter une protection pour les

vdtements protecteur et un dispositif pour la respiration cor-

respondant aux recommandations des fabricants de fluides

EN

CAS DE MAUVAISE UTlLlSATlON W MATERIEL

g4n6rales

de

s4curit6

la

mise sous une pression

ou

B

des ruptures de pieces et entrainer une injection de

ou

d'autres blessures serieuses, un incendie, une ex-

ou

d'autres dbg8ts.

yeux,

des gants, des

des

I'ap-

et

Pression

Ce pulverisateur peut produire une

TRAVAIL

210

bar

13wO

Ib/po.2/.

Blements du pulverisateur et ses accessoires sont concus pour

resister

NE PAS depasser

B

la

pression maximum de travailide ce pulverisateur.

la

pression maximum de travail d'aucun des

dements ou accessoires utilises avec cet appareil.

compatibilit4

chimique

BIEN S'ASSURER que tous

sont chimiquement compatibles avec les parties mouill6es

diquees dans les "DonnBes techniques", au dos de

ture. Toujours lire soigneusement

PRESSlON

MAXlMUM

S'assurer que tous les

des

corps

Ies

corps des solvants utilis&

les

documents

et

DE

in-

la

couver-

brochures

solvants. du fabricant des fluides et solvants utilises avant de s'en servir

dans ce pulvbrisateur.

MESURES DE SECURITE CONCERNANT LES TUYAUX FLEXIBLES

B

Le fluide

haute pression circulant dans

trhs dangereux. En cas de fuite sur

B

la

dbchirure ou rupture

mauvaise utilisation,

suite de I'usure. de dbgets

les

projections de fluide haute pression

qui en proviennent peuvent entrainer des blessures graves par

la

penetration sous

peau ou par contact, ainsi que des degits

materiels. -4O'C

TOUS LES TUYAUX FLEXIBLES DOIVENT AVOlR DES

RESSORTS SPIRALE DE PROTECTION AUX 2 BOUTS1 Une bonne continuite de la mise

Les spirales de protection contribuent

pliures. de boucles ou de nceuds sur

entrainer

la

rupture du tuyau B,I'endroit du raccord ou B son fluides et d air, au moins une fois par semaine. Si votre tuyau

voisinage.

SERRER

tion,

desserrC

FERMEMENT

Le

fluide

ou

produire

sous

pression

un

jet

les

raccords

peut

a

haute pression s'echappant

raccord.

NE JAMAIS utiliser un tuyau endommage. NE PAS essayer de

refaire le raccord d'un tuyau haute pression ni de reparer le

tuyau avec du ruban adhesif ou par tout autre moyen. Un

tuyau reparb ne peut pas resister au fluide sous pression.

les

tuyaux peut atre MANIPULER LES TUYAUX AVEC PRECAUTION ET

18

tuyau, de fissure, CHOlSlR SOIGNEUSEMENT LEUR CHEMIN. Nepasdeplacer

ou

d'une

le fluide en tirant sur

le

tuyau. Ne pas utiliser de fluides

solvants qui ne sont pas compatibles avec I'enveloppe interieure ou exterieure du tuyau. NE PAS exposer le tuyau

des temperatures supdrieures

B

82°C

f180°FI

I-4O"FI.

B

Bviter

la

les

tuyaux qui pourraient

formation de

Continuit6

essentielle pour maintenir

vaporisation. Vbrifiez

de

la

mise

la

terre

des

la

B

mise B la terre de I'ensemble de

la

resistance Blectrique de vos tuyaux

tuyaux

la

terre des tuyaux est

ne comporte pas d'btiquette qui precise la resistance Blectri-

avant

faire

&que UtiliSa. que maximum. prenez contact avec le fournisseur de waux

sauter

un

raccord

par

le

ou

la fabricant pour avoir les limites de rkktance maximum.

Utilisez un metre de resistance de la gamme appropriee pour

votre tuyau et verifiez la resistance. Si celle-ci depasse les

limites recornrnand6es. remplacez le tuyau immbdiatement.

A

la

Un tuyau sans m[se

terre ou avec une mise

recte peut entrainer des risques pour votre systeme. Lisez

OU

aussi LES RlSQUES D'INCENDIE

D'EXPLOSION ci-

dessus.

ou

ou inferieures

B

la

terre incor-

de

B

B

B

De I'electricite statique est produite par le passage du fluide

la

grande vitesse dans

pompe et dans les tuyaux. Si toutes les tuyau flexible et

a

pieces de I'appareil de pulverisation ne sont pas convenable-

ment reliees

produire

peuvent

ou

du dbbranchement du cordon d'alimentation ou de I'utilisa-

a

la masse ou

et

I'appareil risque d'btre dangereux. Des etincelles

egalement

se

A

la

produire

terre. des Btincelles peuvent se

a

I'occasion

du

branchement

tion d'un rnoteur B essence. Les Btincelles sont suffisantes

pour allumer les vapeurs de solvants

et

le

fluide pulverish.

les

fines particules de poussiere ainsi que d'autres substances in-

flammables, quand on pulverise

I'intbrieur ou B I'extbrieur,

et

B

elles peuvent causer un incendie ou une explosion, ainsi que

des blessures graves et des degits materiels. observer le code ou

S'il se produit des Btincelles d'blectricitk statique. ou

reSSentez la moindre decharge,

ARRETEZ

lMMEDIATEMENT

si

vous

LA PULVERISATION. VBrifiez que le systeme entier est bien

mis

la

terre. Ne yous serve2 pas du svsteme avant que le pro-

blerne soit identifie et corrigb. carton car cela interromprait la continuite le

Mise

B

la

terre

ou B la

masse

Pour rbduire les risques de production d'6tincelles d'blectricitb

statique. le pulverisateur et tousles bquipements utilises ou se maintenir

trouvant dans

terre

ou

mise

B

ment, CONSULTER le code

locales.

la

B

zone de pulv6risation doivent atre relies

la

masse. Pour connaitre le detail des instructions de du

la

terre dans la region et le type particulier d'dquipe-

S'ASSURER

que

ou

les rbglementations Blectriques

tOUs

les

equipements

de pu~v&isa- Pour rbduire les risques de blessures par pdnbtration de la

3

la

tion suivants sont bien relies B la terre:

1.

Pu/vdrisateur:

Relier le fil de masses

et

le collier lfournil

B

2.

Pisfolef:

a

la terre.

3,

Tu,,aux

terre, n'utiliser que des tuyaux comportant une mise

et

ayant une longueur maximum combinhe de

4.

R4c;pient d'aliinenrafion:

Realiser la mise B la terre en le raccordant B un

a

un pulverisateur deja convenablement relies

flexibles:

piedsl,

du

Afin d,assurar

Se

de

la

continuite

egalement

mise

terre

observer le code ou

au

paragraphe

des

tuyaux.l,

de

18s

la

mise

B

la

terre

150

,.Con.

rbglemen-

m

tations locales.

5.

Objets, mat.4riel

6,

T~~~

Ies

le code ou les rbglementations locales.

m~ralligues'conducteurs de

sur

une

surface

7.

Pour conserver la confinuif.4 de la mise B la ferre quand

r;nce

le

le

cbte d'un

pistolet,

une

de

cOntre

Mesures

peau et les risques dds aux Btincelles d'blectricitd Statique

aux Bclaboussures, observer la marche B suivre pour

donnee

a

la

page

les

de solvants

non

ou

partie

,,,etallique

SBcurit4

14

ou

surfaces recevant la pulv.4risation:

rbglementations locales.

utilises

pour

le rincage:

~*el~~~~i~i~~,

conductrice

on

en

concernant

de

ce

manuel.

N'utiliserque desseaux

N~

pas

sur

du papier

la

la

du

puis

press;on,

fermement

appuyer

le

Rincage

mettre

mise B la terre.

sur

la

le

observer

le

ou

du

on

toujours

appuyee

detente

ou

rincage

une bonne terre.

RlSQUES

DUS

AUX

MOTEURS

A

ESSENCE

NE JAMAIS remplir le rsservoir de carburant quand le moteur NE JAMAIS faire tourner un moteaur dans un betiment

B

tourne

ou

quand

il

est chaud. Le carburant renversb sur une

surface chaude peut s'enflammer et causer

JOURS verser

renverser. Lire RISQUES D'INCENDIE

le

carburant lentement pour Bviter d'en

OU

un

incedie. TOU-

D'EXPLOSION.

feme

au dehors. Les gaz d'echappement contiennent de I'oxyde de

carbone, un gaz toxique, inodore et invisible qui peut entrainer

des malaises graves ou m&me

moins que les gaz d'echappement ne soient diriges

la

mort se I'0n le respire.

la

307-863 7

Page 8

AD

VERTENCIA

EL ROCIADO A ALTA PRESION PUEDE CAUSAR GRAVES LESIONES.

SOLO

PARA

US0

PROFESIONAL.

Lea y entienda todo

RESPETE

el

manual de instrucciones antes de rnanejar

LOS

AVISOS

DE

ADVERTENCIA.

el

equipo.

PELIGRO

DE

INVECCION

DE

FLUID0

Seguridad general

Este equipo genera un fluido a una presi6n muy aka.

rociado de la pistola,

componentes pueden inyectar fluido en la piel y el cuerpo

causar lesiones extremadamente graves, incluyendo a veces la

necesidad de amputaci6n. Tambidn, el fluido inyectado

salpicado en

NUNCA apuntar la pistola hacia alguien

cuerpo. NUNCA colocar

quilla. NUNCA tratar de "hacer retornar la pintura"; este NO

es un sistema de rociado de aire.

SIEMPRE tener colocado el protector de

pistola mientras se est6 pulverizando.

SIEMPRE seguir el procedimiento de descarga de presi6n.

dado

servicio a cualiquier equipo del sistema.

NUNCA tratar de parar

cuerpo.

Asegurar que todos

esthn funcionando bien antes de cada uso.

Tratarnianto

.

. - .

-

Si pareciera que un poco de fluido penetr6

TRATAMIENTO MEDICO DE URGENCIA

MEDIATO.

COATE.

A

vis0

se causa una lesidn iraumiltica.

quirhrgicamente la lesi6n a la brevedad posible.

demorar el tratamiento para investigar la toxicidad. La

icidad es algo de soma importancia en algunas pinturas

exdiicas cuando se inyectan directamenre al iorrenie

sanguineo. Sir4 convenienie consultar a

cirugia pldstica

10s

m6s

abjo, anies de limpiar o sacar

. . .

.

-. .

-

-

NO

DBcir al medico exactamente cua fluido fue.

a/ medico:

10s

escapes de fluido o roturas de

ojos

puede causar graves daiios.

o

la

mano

o

10s

o

desviar

10s

escapes con

10s

aparatos de seguridad del equipo

rnbdien

. . .

-

-.

-

-

TRATAR LA HERIDA COMO UN SIMPLE

Si

se llega a inyectar este fluido en la pie/

o

reconstruciiva de las menos.

alguna parte del

dedos encima de

la

boquilla en

la

boquilla o de dar

la

mano o el

la

piel, conseguir

Es

importante tretar

un

especialista en

DE

la

tox-

El

10s

y

o

bo-

la

IN-

No

Aparatos de seguridad de la pistola pulverizadora

Asegurar que todos

et6n

funcionando bien antes de cada uso. No sacar ni

modificar ninguna pieza de la pistola pues podria causar el

malfuncionamiento de la misma con las consiguientes leiones

personales.

Pestilo

Cada vez que se deje de pulverizar, aunque sea por un breve

momento, siempre colocar el pestillo de seguridad en la

posici6n "cerrada", lo que deja

hacerlo puede llevar al disparo imprevisto de la pistola.

de

seguridad

Difusor

El

difusor de

el riesgo de inyecci6n cuando no est6 instalada

Revisar con regularidad el funcionamiento del difusor. Seguir

el

procedimiento de descarga de presi6n. dado

y

despuds sacar

met6lico. sostenihdola bien firme contra

presi6n

emitido

inmediato

Protector de

SIEMPRE tener el protector de

pistola mientras se est6 pulverizando. Este protector llama

atencidn contra el peligro de inyecci6n y ayuda a reducir, per0

no evita. la colocaci6n accidental de

parte del cuerpo

Seguridad

Tener mucho cuidado al limpiar

llegara a obstruirse mientras est6 pulverizando, enganchar el

pestillo de

cedimiento

quilla para limpiarla.

NUNCA limpiar

quilla antes de que se haya descargado por completo la

presion

la

m6s

bajo posible, disparar

no

sale disperso en un chorro irregular, reemplazar de

el

difusor.

la

de

la

pistola de inmediato. SIEMPRE seouir el

de

y

el pestillo est6 enganchado.

10s

aparatos protectores de la pistola

la

pistola inoperante.

pistola dispersa el chorro pulverizado y reduce

la

boquilla. Apuntar la pistola a un balde

61.

la

pistola. Si el fluido

Utilizando la

la

boquilla.

mas

El

no

abajo,

boquilla

la

boquilla colocado en la

10s

cerca de la boquilla.

la

boquilla pulverizadora

descarga de presi6n y despubssacar la'bo-

la

acumulaci6n de pintura alrededor de la bo-

dedos o cualquier otra

o

cambiar las boquillas. Si

la

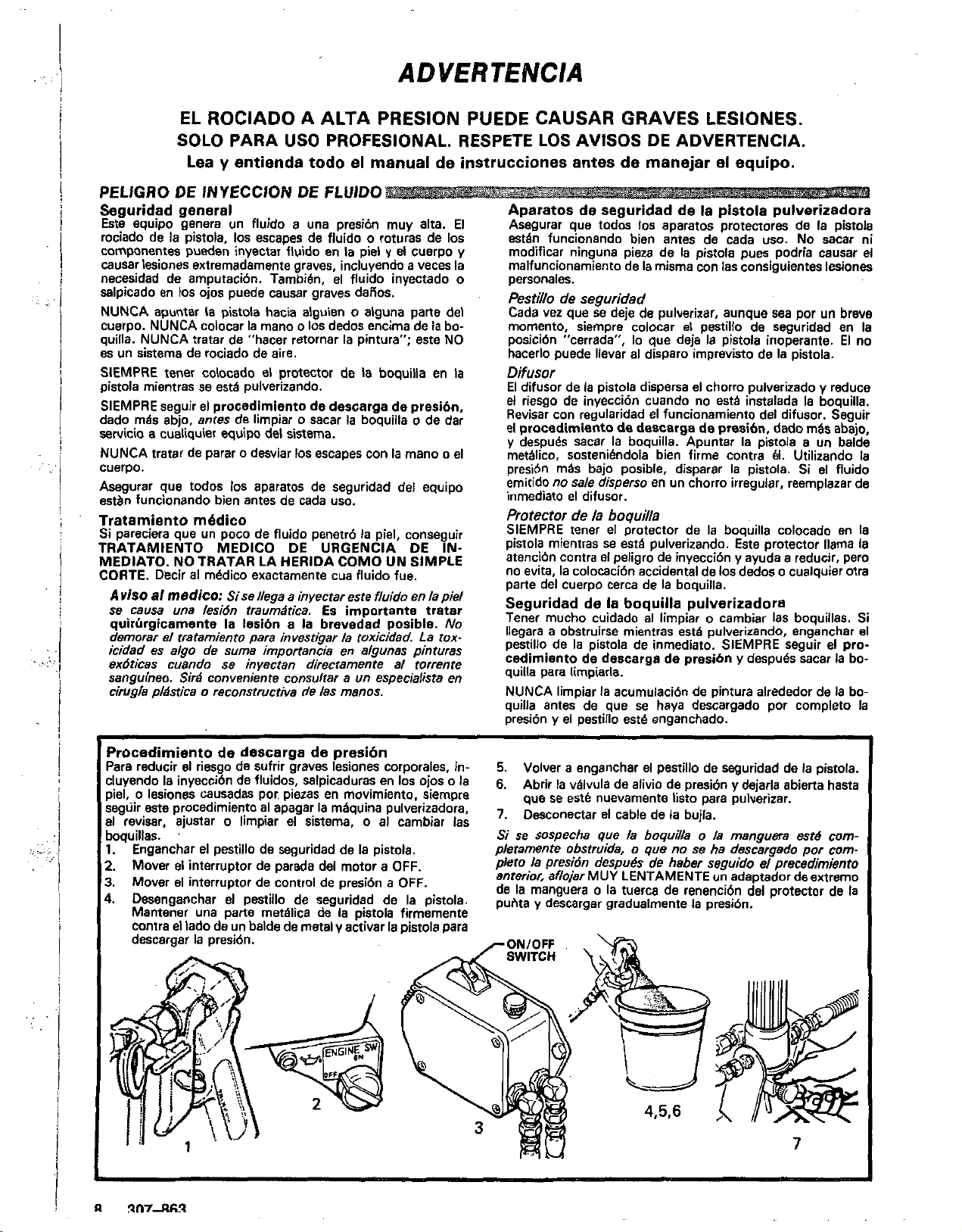

oro-

'rocedimiento

'ara reducir el riesgo de sufrir graves lesiones corporales, in:luyendo la inyecci6n de fluidos, salpicaduras en

o

lesiones causadas por. piezas en movimiento. siempre

iel,

ieguir este procedimiento

11

revisar. ajustar o limpiar el sistema, o al cambiar las

,oquillas.

I.

Enganchar el pestillo de sesuridad de la pistola.

!.

Mover

I.

Mover el interruptor de control de presi6n a

I.

Desenganchar e1 pestillo

Mantener una parte met6lica de

contra el lado de un balde de metal

descargar

de

descarga de presi6n

al

apagar la m6quina pulverizadora,

'

el

interruptor de parada del motor a

de

seguridad de la pistola.

la

y

la

presi6n.

anivar la pistola para

10s

ojos o la

OFF.

OFF.

pistola firmemente

L

5.

Volver a enganchar el pestillo de seguridad de la pistola.

6.

Abrir la vhlvula de alivio de presi6n y dejarla abiena hasta

que se est6 nuevamente list0 para pulverizar.

7.

Desconectar el cable de la bujla.

Si

se sospecha que la boquilla o la manguera est6

pleiamente obsiruida,

pleto la presidn despu6s

anterior, aflojar MUY LENTAMENTE un adaptador de extremo

de

la

manguera o la tuerca de renencibn del protector de la

puhta

descargar gradualmenfe

o

we

no

se ha descaraado

de

habw seguido eiprecedimiento

la

presi6n.

Dor

comcom-

7

Page 9

:j

,.

.::.

T

,.

..

.,

....

.. .

.,

.:

..

!

i

PELIGRO

Seguridad general

Cualquier mal us0 del equipo pulverizador

coma sobrepresurizaci6n. modificaci6n de piezhs, us0 de

materiales

de piezas daiiadas

y

causen la inyecci6n de fluido u otras lesiones corporales

graves, incendio, explosi6n

Siempre usar gafas, guantes, vestimetas protectoras

respiradero,

del solvente.

Presi6n

Esta pulverizadora puede desarrollar

PRESION

equipo pulverizador

aguantar

NO exceder la presi6n rnhxima de trabajo de ninghn componente o accesorio de este sistema.

Compatibilidad de

Siempre leer Ias instrucciones del fabricante del fluido

solvente antes de usarlos en esta pulverizadora.

SEGURIDAD EN EL

El fluido que escapa a

ser muy peligroso. Si en la manguera se desarrolla un escape,

una rotura

o

dah

causar una lesibn por inyeccion

graves

ITODAS LAS MANGUERAS PARA FLUIDOS TIENEN

QUE TENER GUARDAS DE RESORTE EN AMBOS EX.

TREMOSl Estas protegen las rnangueras contra dobleces

retorceduras en

podrian traducirse en roturas de

Antes de usarlas, APRETAR bien firmes todas las conexiones.

El fluido a aka presi6n puede desalojar un acoplamiento suelto

o

dejar que por

NUNCA usar una manguera que esth daiiada. Siempre.

revisarla en busca de cortaduras, escapes, abrasidn, cubierta

abultada,

contrarse cualquiera de estas condiciones, reemplazar de in-

mediato

aka presi6n

similar. Una manguera que ha sido remendada no aguante

fluido

MANEJAR

MANGUERAS. No tirar de las mangueras para mover el

equipo.

con el tub0 interno

las mangueras a temperaturas sobre

-40OC

Continuidad

manguera

La continuidad del circuito de puesta a tierra apropiado es

esencial para mantener conectado

pulverizador.

maxima de las mangueras de aire

vez a la semana. Si la manguera no tiene una etiqueta en

cual se especifica la resistencia elbctrica maxima, ponerse en

contact0 con el proveedor

informaci6n sobre

resistencia en

cia; si excede

mediato. Es muy arriesgado tener una manguera sin puesta a

tierra

o

bih la informacidn sobre RIESGO DE INCENDIO

SION,

POR

MAL

US0

DEL EQUIP0

o

10s

accesorios,

y

productos quimicos incompatibles, o utilizaci6n

o

desgastadas. puede hacen que se rompan

0

daiion a la propiedad.

tal

como recomiendan

del

sistema

DE

TRARAJO MAXIMA. Asegurar que todo el

y

la

presi6n mexima de trabajo de esta pulverizadora.

sus accesorios tienen la capacidad para

10s

fabricantes del fluido

210

barias

(3oW

y

psi) de

fluido

US0

DE LAS MANGUERASl

alta

presi6n por las mangueras puede

o

rajadura debido a cualquier tip0 de desgaste.

maltrato. el chorro a aka presi6n emitido por alli puede

o

daiios a la propiedad.

10s

acoplarnientos o cerca de ellos,

BI

escape un chorro a alta presi6n.

o

acoplamientos sueltos o daiiados. Si llegara a en-

la

manguera. NO intentar reacoplar una manguera de

o

enmendarla con cinta adhesiva u otro material

a

aha presi6n.

Y

PASAR CUIDADOSAMENTE LAS

No

usar fluidos o sokentes que Sean incompatibles

y

la cubierta dela manguera. NO exponer

(-40°F).

del

circuito

Es

indispensable revisar la resistencia elbctrica

10s

la

con la puesta a tierra en malas condiciones. Leer tam-

mas

arriba.

limites de resistencia. Usar un metro de

gama apropiada para comprobar

10s

limites recomendados, reemplazarla de in-

u

otras lesiones corporales

la

manguera.

de

puesta

y

de fluido por

o

fabricante de

~~~~ ~~~

@PC

(180OFi o bajo

a

tierra

a

tierra el sistema

lo

menos una

la

manguera para la

la

resisten-

0

EXPLO-

10s

de

tal

un

o

que

el

la

la

PRECAUCIONES PARA

LOS

MOTORES

DE

GASOLINA

NUNCA llenar

fundionando

SUperfiCie caliente puede encenderse

SIEMPRE verter el combustible lentamente para evitar der-

rames. Leer PELIGRO

SION.

y

NUNCA hacer funcionar el motor en un edificio cerrado sin en-

caminar

escape contienen monbxido de carbono, un gas venenoso, sin

olor e invisible que podrla causar enfermedades graves, in-

cluso la muerte, al inhalarse.

o

caliente. El combustible derramado en una

DE

10s

gases de escape hacia el aire libre.

y

INCENDIO 0 EXPLO-

provocar un incendio.

Los

gases de

PELIGRO DE INCENDIO 0 EXPLOSION

El

flujo a alta velocidad del fluido al pasar por la bomba

manguera crea electricidad esthtica. Si todas las partes del

equipo pulverizador no tienen buena tierra, pueden ocurrir

chispas. convirtiendo

y

pueden producirse chispas al enchufar

d6n elbctrico

pueden inflamar

fluido pulverizado, particulas de polvo

flamables, sea a1 aire libre o bajo techo.

una explosi6n

a

la propiedad.

Si ocurre

choque elbctrico mientras se usa el equipo, DEJAR DE

PULVERIZAR DE INMEDIATO. Revisar todo el sistema en

busca de una tierra apropiada.

hasta haber identificado

Puesta a tierra

Para reducir el riesgo de chispas esthticas, conectar a tierra la

puiverizadora

se encuentre en el lugar que

c6digo elbctrico de la localidad para las instrucciones sobre las

conexiones a tierra exigidas para

ASEGURAR de conectar

pulverizador:

1.

pulverizadora: Conectar el alambre de tierra y la abrazadera

lsuministradal

2.

Mangueras para fluidos: usar solamente mangueras con

puesta a tierra de una longitud combinada de

para asegurar buena continuidad a tierra. Referine tambibn al

perrafo sobre continuidad a tierra de

3.

Pistola: hacer

manguera.de fluido

4.

Suministrar on recipiente: de acuerdo al c6digo de la

localidad.

5.

Objeto que se est.4 rociando: de conformidad con el c6digo

local.

6.

Todos

conformidad con el cbdigo local. Usar solamente baldes de

metal, que Sean conductivos. No colocar el balde en una

superficie no conductiva, como papel

la

rumpe

7.

Para mantener la continuidad a tierra durante

descarga de presidn, siempre apoyar una parte methlica de la

pistola bien firme contra el costado de baldedemetal, despu6s

apretar el gatillo.

Seguridad

Para reducir el riesgo de que se inyecte

piel, or que ocurra una descarga de electricidad estatica, siempre seguir las INSTRUCCIONES PARA EL LAVADO, dadas en

la phina

presibn en la phgna

lavar. Apoyar una parte metdlica de

el costado de un balde de metal

posible de fluido durante el lavado.

o

0

una

chispa de electricidad esthtica o incluso

y

a

10s

baldes de solvenre usados durante el lavado, de

continuidad a tierra.

durante

14.

Seguir el procedimiento de descarga

a1

sistema en algo peligroso. Tambih,

al

usar un motor de gasolina. Estas chispas

10s

vapores de

incendio y graves lesiones corporales y daflos

y

solucionado el problema.

todo el otro equipo de pulverizar que se use

se

a

una buena conexi6n a tierra.

la

puesta a tierra conecthndola a una

y

pulverizadora bien conectadas a tierra.

el

lavado

8,

y

quitar

la

o

desenchufar el cor-

10s

solventes y el chorro de

y

otras sustancias

lo

que podria causar

un

No

usar de nuevo el sisterna

va a rociar. CONSULTAR el

la

zona y tip0 de equipo.

tierra todo este equipo

150

m

(500

la

rnanguera.

o

cart6n. que inter-

el

lavado

o

salpique fluido en la

boquilla rociadora antes de

la

pistola bien firme contra

y

usar le presi6n

mhs

y

in-

ligero

o

pies),

o

de

baia

Page 10

..

..

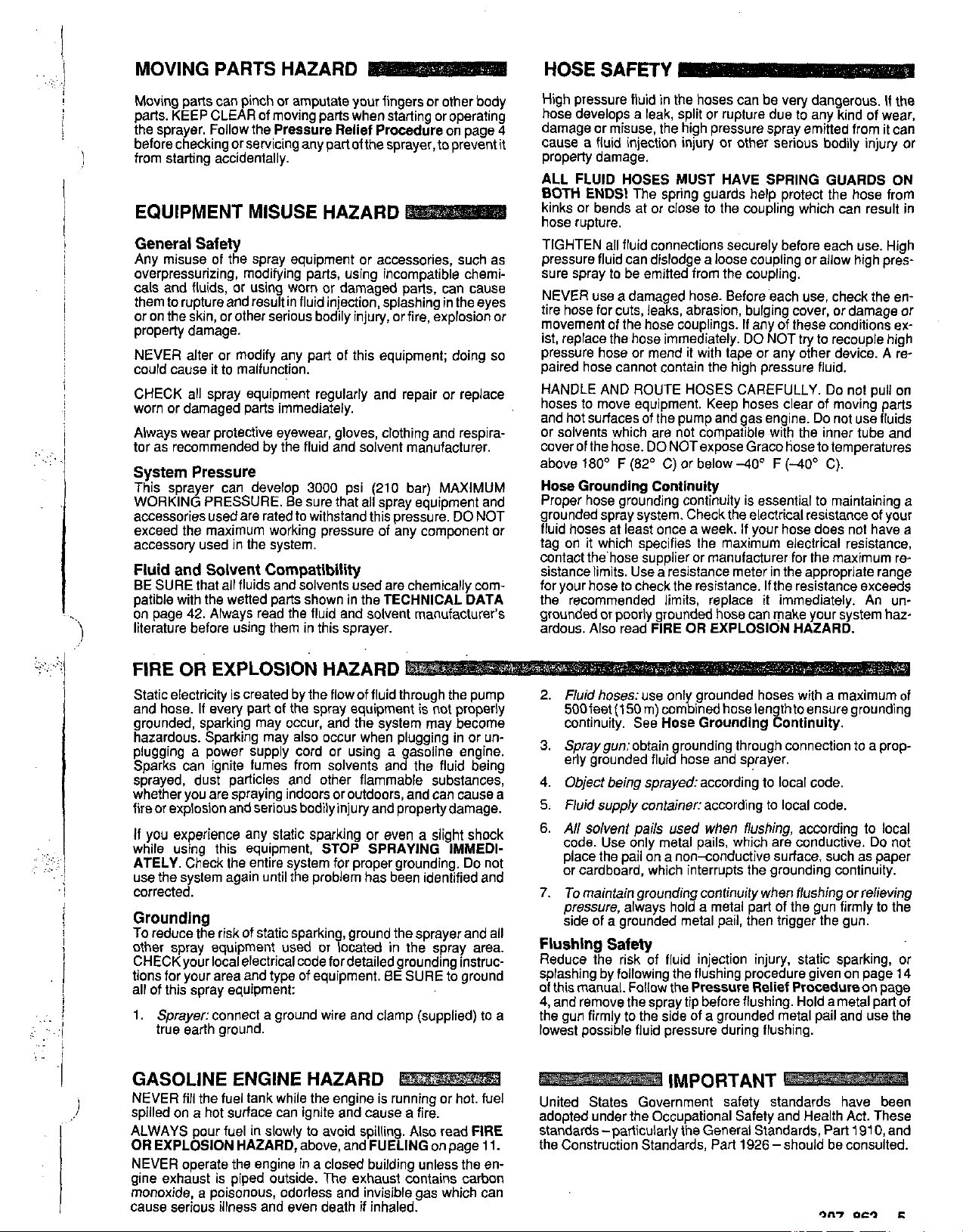

SETUP

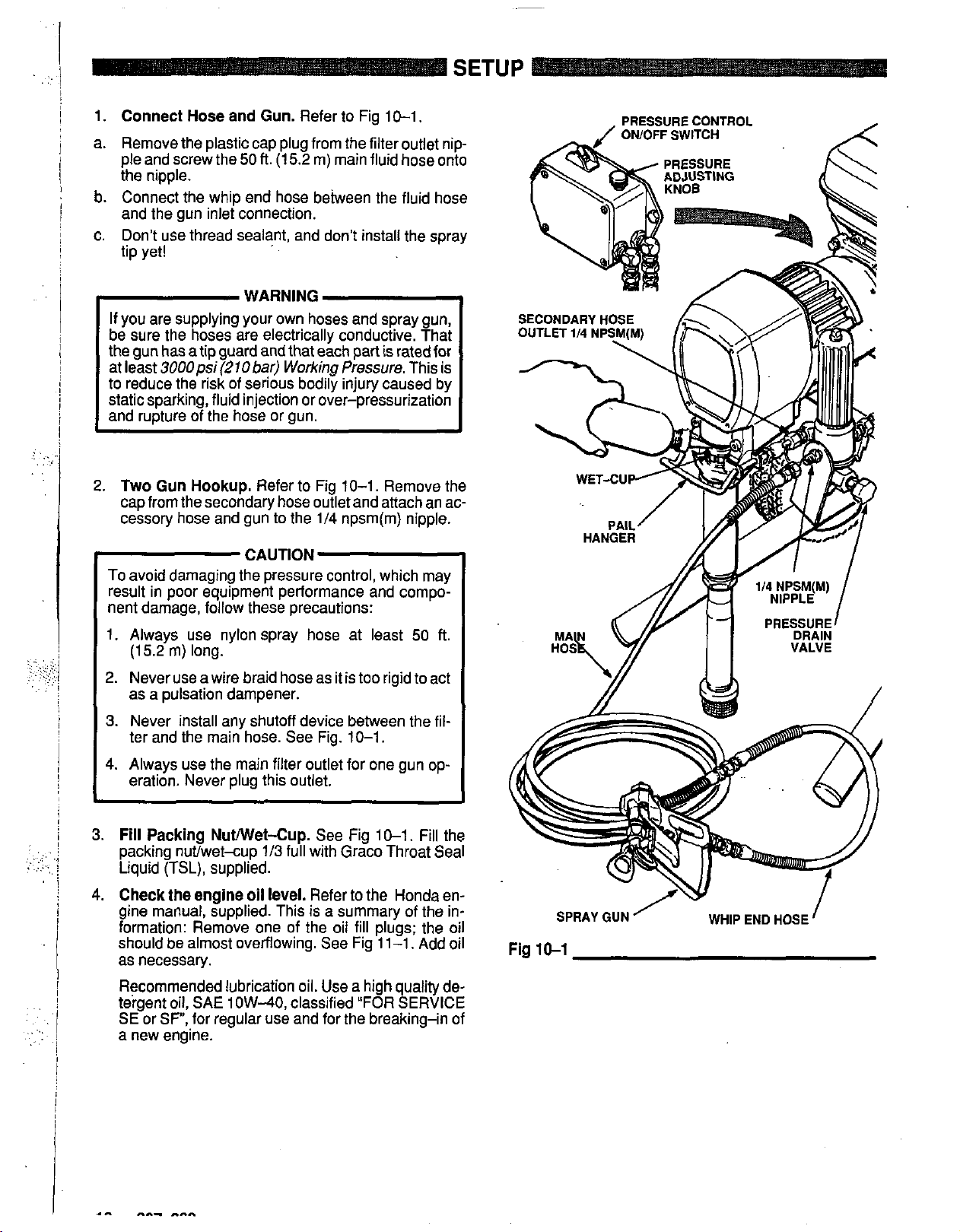

1.

Connect Hose and Gun.

a. Remove the plastic cap plug from the filter outlet nip-

ple and screw the

50

the nipple.

b. Connect the whip end hose beiween the fluid hose

and the gun inlet connection.

c. Don't use thread sealant, and don't install the spray

tip yet!

If you are supplying your own hoses and spray gun,

be sure the hoses are electrically conductive. That

the gun has a tip guard and that each part is rated

at least

3000psi(270bar)

to reduce the risk of serious bodily injury caused by

static sparking, fluid injection or over-pressurization

and rupture of the hose or gun.

2.

Two Gun Hookup.

cap from the secondary hose outlet and attach an accessory hose and gun to the 1/4 npsm(m) nipple.

Refer to Fig 10-1.

ft.

(1

5.2

m) main fluid hose onto

Working

Refer

to

Fig 10-1. Remove the

Pressure.

for

This is

..

.

.,.

..

.

.

. ....

..

.. .

..

.

.

:,:.

..

..

.. ..

..

..

CAUTION

To avoid damaging the pressure control, which may

result in poor equipment performance and compo-

nent damage, follow these precautions:

1.

Always use nylon spray hose at least

(1

5.2

m) long.

2.

Never use a wire braid hose as it is too rigid to act

50

ft.

as a pulsation dampener.

3.

Never install any shutoff device between the

ter and the main hose. See Fig.

10-1.

4. Always use the main filter outlet for one gun

fil-

op-

eration. Never plug this outlet.

3.

Fill

Packing NuWet-Cup.

packing nut/wet-cup

Liquid

(TSL),

4.

Check the engine

supplied.

oil

1/3

level.

gine manual, supplied. This

formation: Remove one of the oil

See Fig 10-1.

Fill

full with Graco Throat Seal

Refer to the Honda en-

is

a summary of the in-

fill

plugs; the oil

should be almost overflowing. See Fig 11-1. Add oil

as necessary.

Recommended

teraent oil.

SE-or

SF;

lubrication oil. Use a high

SAE

1

OW-40.

for regular

classified

use

and forthe breaking-in

"FOR

quality de-

SERVICE

a new engine.

the

of

Fig

10-1

SPRAY

GUN

'

WHIP

END

HOSE

I

Page 11

5.

Be sure your system is properly grounded be-

fore operating it.

tion,

page

6.

Fill

7.

Flush the pump

was left

a. Before using water-base paint, flush with

b. Before using oil-base paint, flush with mineral

FIRE

5.

the gas tank.

in

to

mineral spirits followed by soapy water, and

then a clean water flush.

spirits only.

Read and follow the warning sec-

OR

EXPLOSION

See the

to

protect pump parts after factory testing.

FUELING

remove the lightweight oil which

HAZARD,

section, below.

SETUP

on

I.

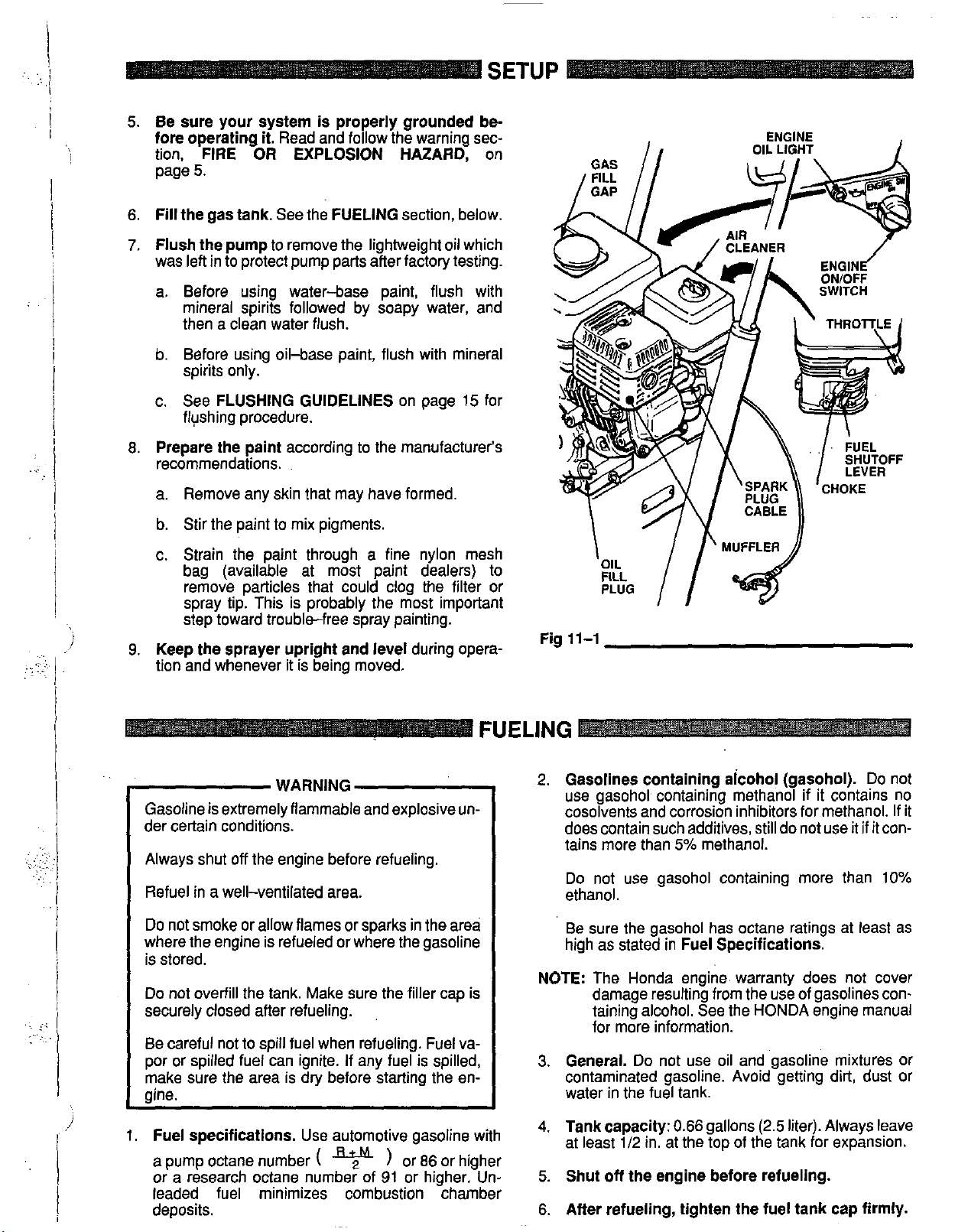

ENGINE

OIL LIGHT

.. .

c. See

8.

Prepare the paint

recommendations.

a. Remove any skin that may have formed.

b. Stir the paint to mix pigments.

c. Strain the paint through a fine nylon mesh

9.

Keep the sprayer upright and level

tion and whenever it is being moved.

Gasoline is extremely flammable and explosive under certain conditions.

Always shut

Refuel in a well-ventilated area.

FLUSHING GUIDELINES

flushing procedure.

according

bag (available at most paint dealers)

remove particles that could clog the filter or

spray tip. This is probably the most important

step toward trouble-free spray painting.

WARNING

off

the engine before refueling.

on

page 15 for

to

the manufacturer’s

during opera-

to

Fig

FUELING

2.

Gasolines containing aicohol (gasohol).

use gasohol containing methanol

cosolvents and corrosion inhibitors for methanol. If it

does contain such additives, still do

tains more than 5% methanol.

ethanol.

\

11-1

Do

not use gasohol containing more than

/

fi

MUFFLER

//

if

it contains no

not

use it

Do not

if

it con-

10%

Do

not smoke

where the engine is refueled or where the gasoline

is stored.

Do

not overfill the tank. Make sure the filler cap is

securely closed after refueling.

Be careful not to spill fuel when refueling. Fuel vapor or spilled fuel

make sure the area is dry before starting the en-

oine.

1.

Fuel specifications.

a pump octane number

or a research octane number of 91 or higher. Un-

leaded fuel minimizes combustion chamber

deposits.

or

allow flames or sparks in the area

can

ignite. If any fuel is spilled,

Use automotive gasoline with

(

or

86

or higher

Be sure the gasohol has octane ratings at least as

high as stated in

NOTE:

3.

4.

5.

6. After refueling, tighten the fuel tank cap firmly.

The Honda engine. warranty does

damage resulting from the use of gasolines containing alcohol. See the HONDA engine manual

for more information.

General.

contaminated gasoline. Avoid getting dirt, dust or

water in the fuel tank.

Tank capacity: 0.66

at least 112 in. at the top of the tank for expansion.

Shut

Do

off

the engine before refueling.

Fuel Specifications.

not

not

use oil and gasoline mixtures or

gallons (2.5 liter). Always leave

cover

Page 12

STARTUP

NOTE:

Use this procedure each time you start the sprayer to

help ensure the sprayer is ready to operate and that you

start it safely.

NOTE:

1.

2.

NOTE:

3.

4.

5.

6.

7.

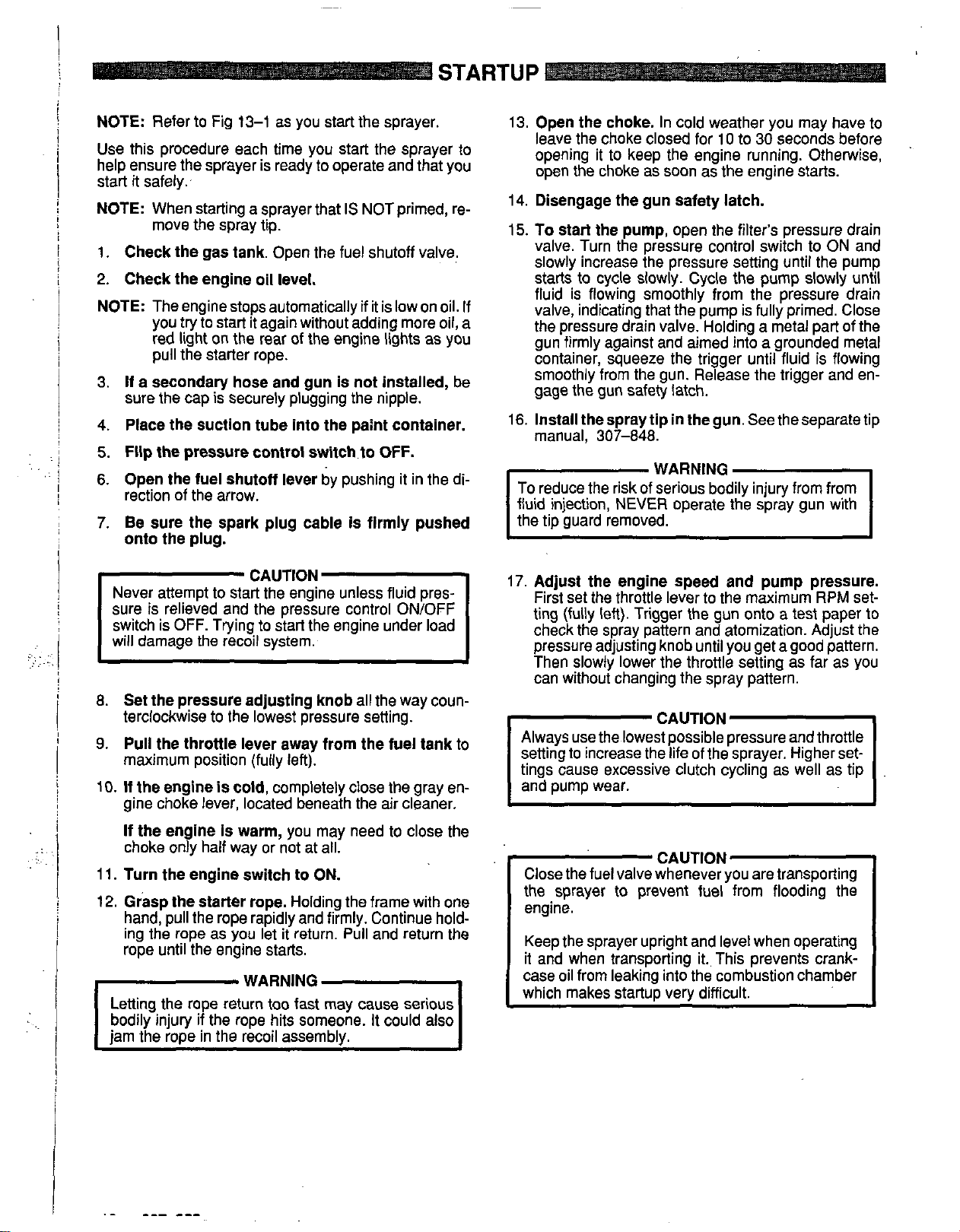

Refer to Fig 13-1 as you start the sprayer. 13.

When starting a sprayer that

move the spray tip.

Check the gas tank.

Check the engine

The engine stops automatically if it is low on oil.

you try to start it again without adding more oil, a

red light on the rear of the engine lights as you

pull the starter rope.

If

a

secondary hose and gun

sure the cap is securely plugging the nipple.

Place the suction tube into the paint container.

Flip the pressure control switch.to OFF.

Open the fuel shutoff lever

rection of the arrow.

Be sure the spark plug cable is firmly pushed

onto the plug.

Open the fuel shutoff valve.

oil

level.

IS

NOTprimed, re-

If

is

not installed,

by pushing it in the di-

be

Open the choke.

leave the choke closed for 10 to 30 seconds before

opening it to keep the engine running. Othelwise,

open the choke as soon as the engine starts.

14.

Disengage the gun safety latch.

15.

To start the pump,

valve. Turn the pressure control switch to ON and

slowly increase the pressure setting until the pump

starts to cycle slowly. Cycle the

fluid is flowing smoothly from the pressure drain

valve, indicating that the pump is fully primed. Close

the pressure drain valve. Holding a metal part of the

gun firmly against and aimed into a grounded metal

container, squeeze the trigger until fluid is flowing

smoothly from the gun. Release the trigger and engage the gun safety latch.

16.

1nstallthespraytipinthegun.Seetheseparatetip

manual, 307-848.

To reduce the risk of serious bodily injury from from

fluid

injection,

the tip guard removed.

TWARNlNGl

In cold weather you may have to

open the filter's pressure drain

pump

NEVER

operate the spray gun with

slowly until

:.

.

..

1:

',:

. .

. ..

CAUTION

Never attempt to start the engine unless fluid pres-

sure

is

relieved and the pressure control ON/OFF

switch is OFF. Trying to start the engine under load

will damage the recoil system.

I

8.

Set the pressure adjusting knob

terclockwise to the lowest pressure setting.

9.

Pull the throttle lever away from the fuel tank

maximum position (fully left).

10.

If

the engine is cold,

gine choke lever, located beneath the air cleaner.

If

the engine Is warm,

1

I

choke only half way or not at all.

11.

Turn the engine switch to ON.

12.

Grasp the starter rope.

hand, pull the rope rapidly and firmly. Continue holding the rope as you let

rope until the engine starts.

Letting the rope return too fast may cause serious

bodily injury if the rope hits someone.

iam the rope in the recoil assemblv.

IWARNINT1

completely close the gray en-

you may need to close the

Holding the frame with one

it

return. Pull and return the

all the way coun-

to

It

could also

17.

Adjust the engine speed and pump pressure.

First set the throttle lever to the maximum RPM set-

ting (fully left). Trigger the gun onto a test paper to

check the spray pattern and atomization. Adjust the

pressure adjusting knob until you get a good pattern.

Then slowly lower the throttle setting as far as you

can without changing the spray pattern.

Always use the lowest possible pressure and throttle

setting to increase the life of the sprayer. Higher settings cause excessive clutch cycling as well as tip

and pump wear.

l-cAuT1oNl

Close the fuel valve whenever

the sprayer

Keep the sprayer upright and level when operating

it and when transporting it.. This prevents crank-

case oil from leaking into the combustion chamber

which makes startup verv difficult.

to

prevent fuel

you are transporting

from flooding the

Page 13

..

..

.i

..

I

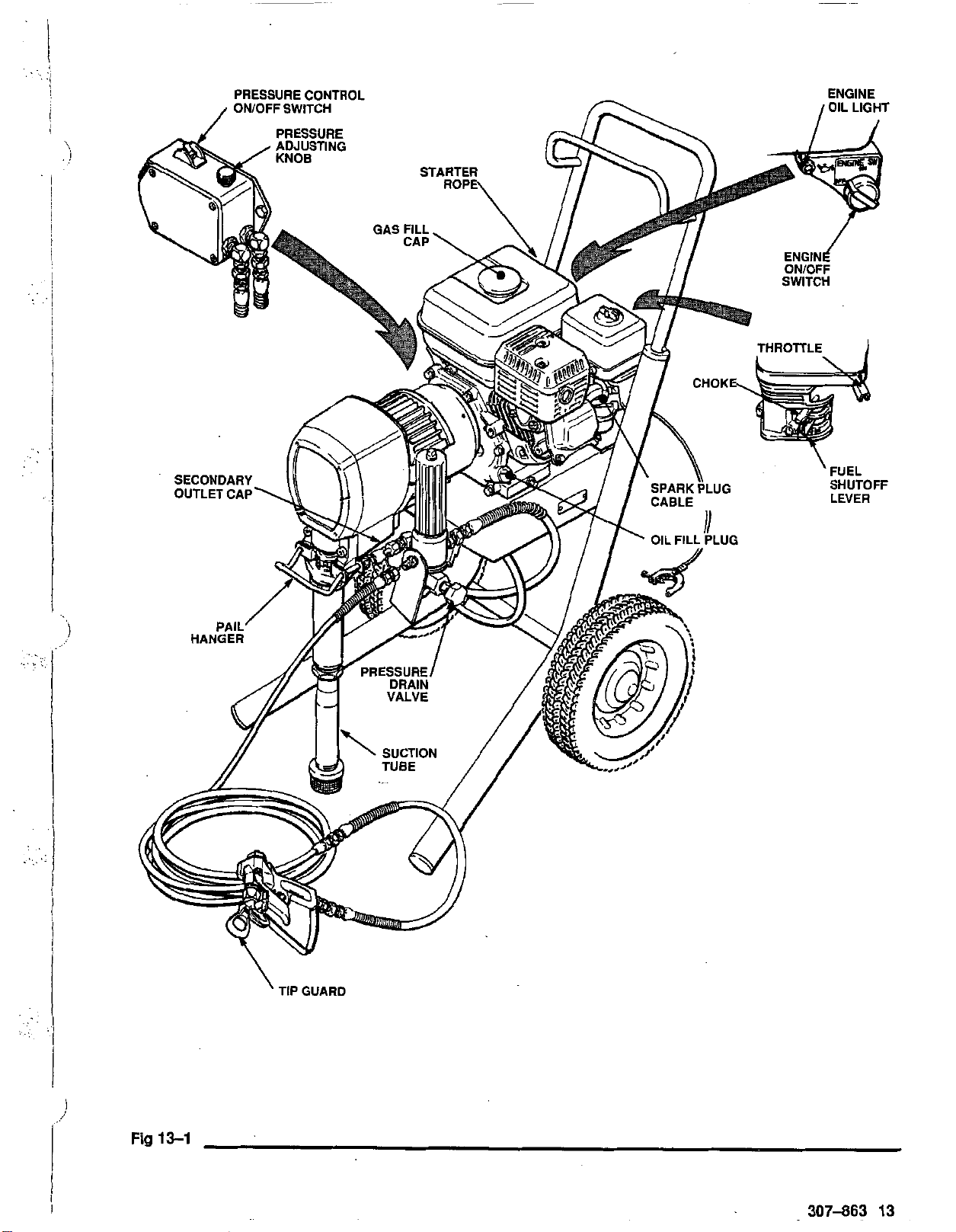

Fig

13-1

'

TIP

GUARD

307-863

13

Page 14

MAINTENANCE

1-

WARNING

-1

To reduce the risk of serious bodily injury, including

fluid injection or splashing in the eyes or on the skin,

or injury from moving parts, always follow the

I

sure Relief Procedure Warning

on page

15

before

Pres-

checking, adjusting, cleaning and shutting down the

1

sprayer. Disconnect the spark plug.

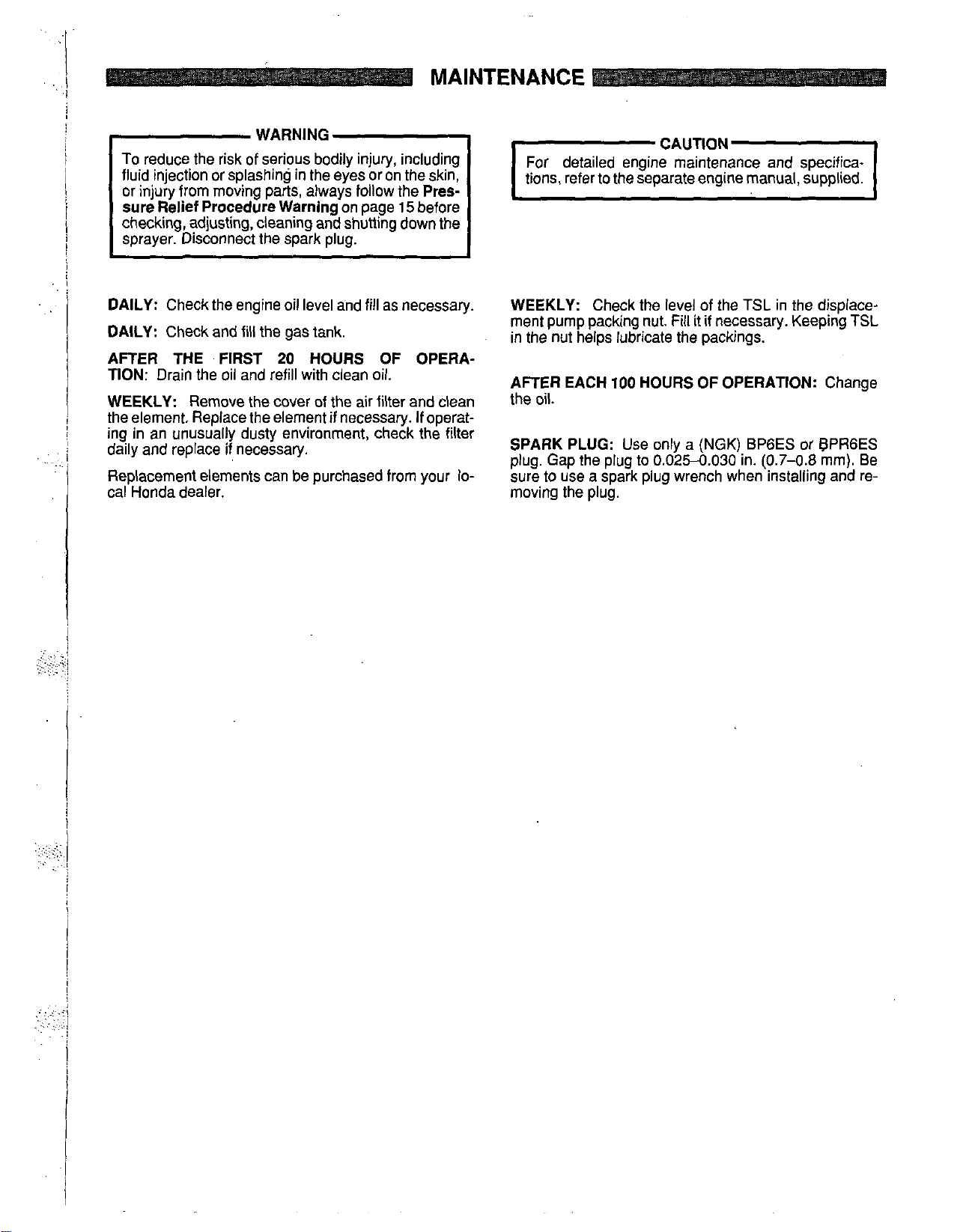

DAILY:

DAILY:

AFTER THE FIRST

TION:

WEEKLY:

the element. Replace the element

Check the engine oil level and

fill

as necessary.

Check and fill the gas tank.

20

HOURS OF OPERA-

Drain the oil and refill with clean oil.

Remove the cover of the air filter and clean

if

necessary.

If

operating in an unusually dusty environment, check the filter

daily and replace

Replacement elements can be purchased from your

if

necessary.

lo-

cal Honda dealer.

CAUTION

For

detailed engine maintenance and specifica-

tions, refer to the separate engine manual, supplied.

r

WEEKLY:

ment pump packing nut. Fill it

Check the level of the TSL in the displace-

if

necessary. Keeping TSL

in the nut helps lubricate the packings.

AFTER EACH

100

HOURS

OF

OPERATION:

Change

the oil.

SPARK PLUG:

plug. Gap the plug to

Use only a

0.0250.030

(NGK)

BPGES or

in.

BPRGES

(0.7-0.8

mm).

Be

sure to use a spark plug wrench when installing and removing the plug.

~..

~

..

:

....

:.:.

i

..

.,:.

,.

.... ..

'.,.

. . ..

,

. ~.

:.

.,

..

..

Page 15

FLUSHING GUIDELINES

WARNING

Pressure Relief Procedure

To

reduce the riskof serious bodily injury, includingfluid

injection, splashing fluid or solvent in the eyes or on the

skin, or injury from moving parts or electric shock, always follow this procedure whenever you shut

off

sprayer, when checkina or servicina any Dart of the

spray system, when i&alling, c1eGing-o; changing ready

spray tips, and whenever you stop spraying.

1.

Engage the gun safety latch.

2.

Turn the ON/OFF switch to OFF.

3.

Flip the pressure control switch to OFF.

4.

Disengage the gun safety latch. Hold a metal part of

the

and

the Engage

6.

Open the Pressure drain valve. havina a container

until you are ready

7.

Disconnect the spark plug cable

If

you

clogged, or that pressure has not been

ter following the steps above, VERY SLOWLY loosen

the tip guard retaining nut or hose end coupling and re-

lieve pressure gradually, then loosen completely. Now

clear the tip or hose.

gun

firmly

trigger

the

to

catch the drainage. Leave thij valve open

suspect that the spray tip or hose

the

the

gun

to

gun latch.

to

side

of

a

grounded

relieve

pressure,

spray again.

is

fully

metal

pail,

complete/y

relieved

af-

..

. . ..

...

.

:..,

...

'!::

..

.

..

.

.,:

..

..

1

,

,,

When

1.

to

Flush

New Sprayer.

tory tested

in

lightweight oil which was left in to pro-

Your new

GM3500

tect pump parts.

Before using water-base paint, flush with mineral

spirits followed by soapy water, and then a clean

water flush.

Before using oil-basepaint, flush with mineral spirits

2

Sprayer was fac-

CAUTION

NEVER leave water in the sprayer

if

there is the

slightest chance it could freeze. Push the water out

with mineral spirits. Water left

to

freeze in the pressure control tube prevents the sprayer from being

started and causes serious damage to the pressure

control.

only.

2.

Changing Colors.

Flush with a compatible solvent

6.

Startup after storage.

such as mineral spirits or water.

,

3.

Changing from water-base to oil-base paint.

Flush with warm, soapy water, then mineral spirits.

4.

Changing from oil-base to water-base paint.

Flush with mineral spirits, followed by warm, soapy

Before using water-base paint, flush

spirits with soapy water and then aclean water flush.

When using oil-base paint, flush

out

its with the paint to be sprayed and the sprayer

ready

to

use.

out

mineral

the mineral spir-

is

water, then a clean water flush.

5.

Storage.

Continued on page

16.

Water-base paint: flush with water, then mineral

spirits and leave the pump, hose and gun filled with

mineral spirits. Shut off the sprayer, remove the

I

spark plug cable, and open the pressure drain valve

to

relieve pressure and leave it open.

Oil4asepaint:flush with mineral spirits. Shut

off

the

sprayer, remove the spark plug cable, and open the

pressure drain valve to relieve pressure and leave it

open.

Page 16

I

I

!

,

'.

!

!

i

!

i

~

i

!

.I

:.

.I

!

i

1

!

I

.i

i

I

~

FLUSHING GUIDELINES

How

to

Flush

1.

Follow the

page

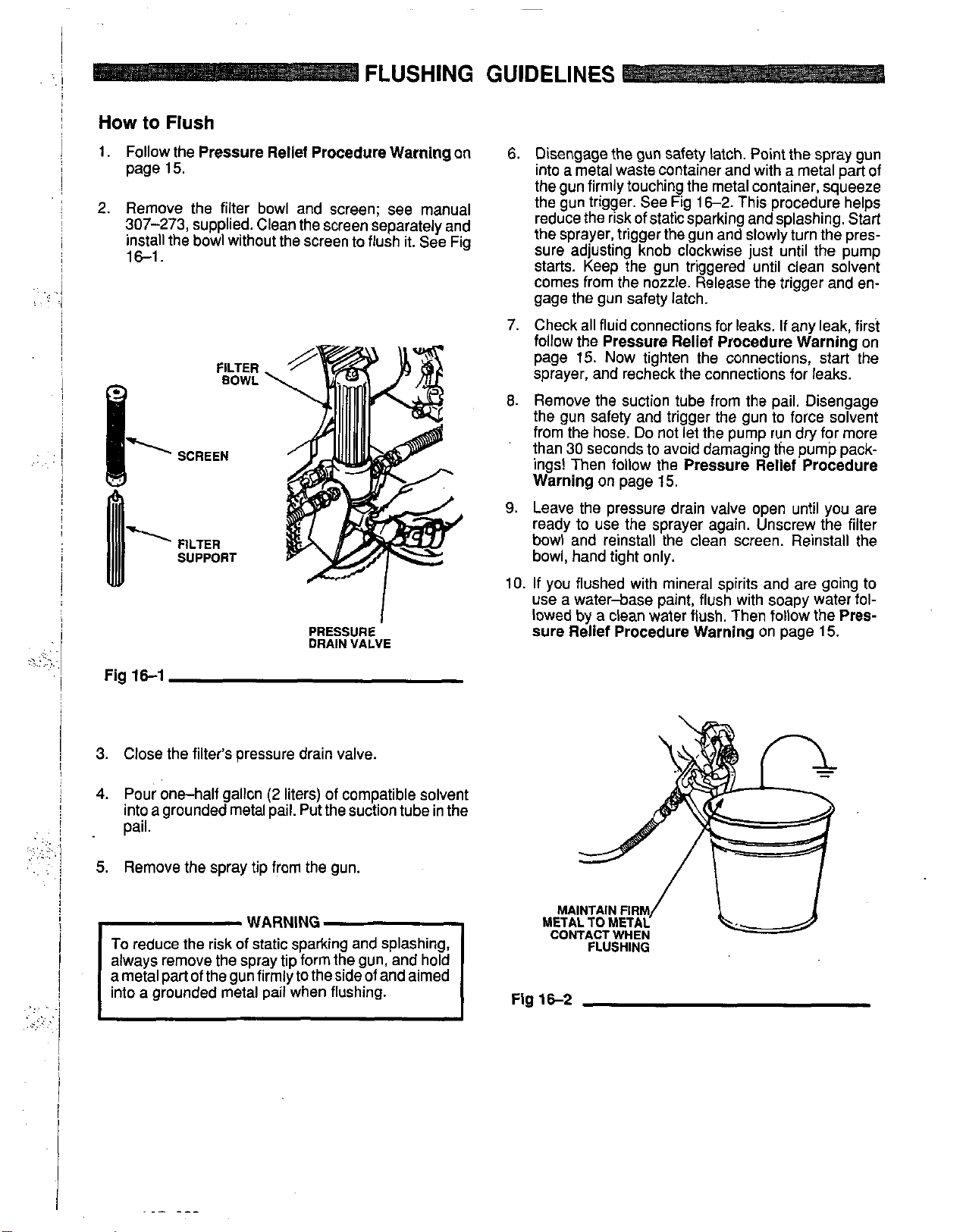

2. Remove the filter bowl and screen; see manual

307-273, supplied. Clean the screen separately and

install the bowl without the screen to flush it. See Fig

16-1.

Pressure Relief Procedure Warning

15.

FILTER

BOWL

SUPPORT

PRESSURE

DRAIN

VALVE

on

6.

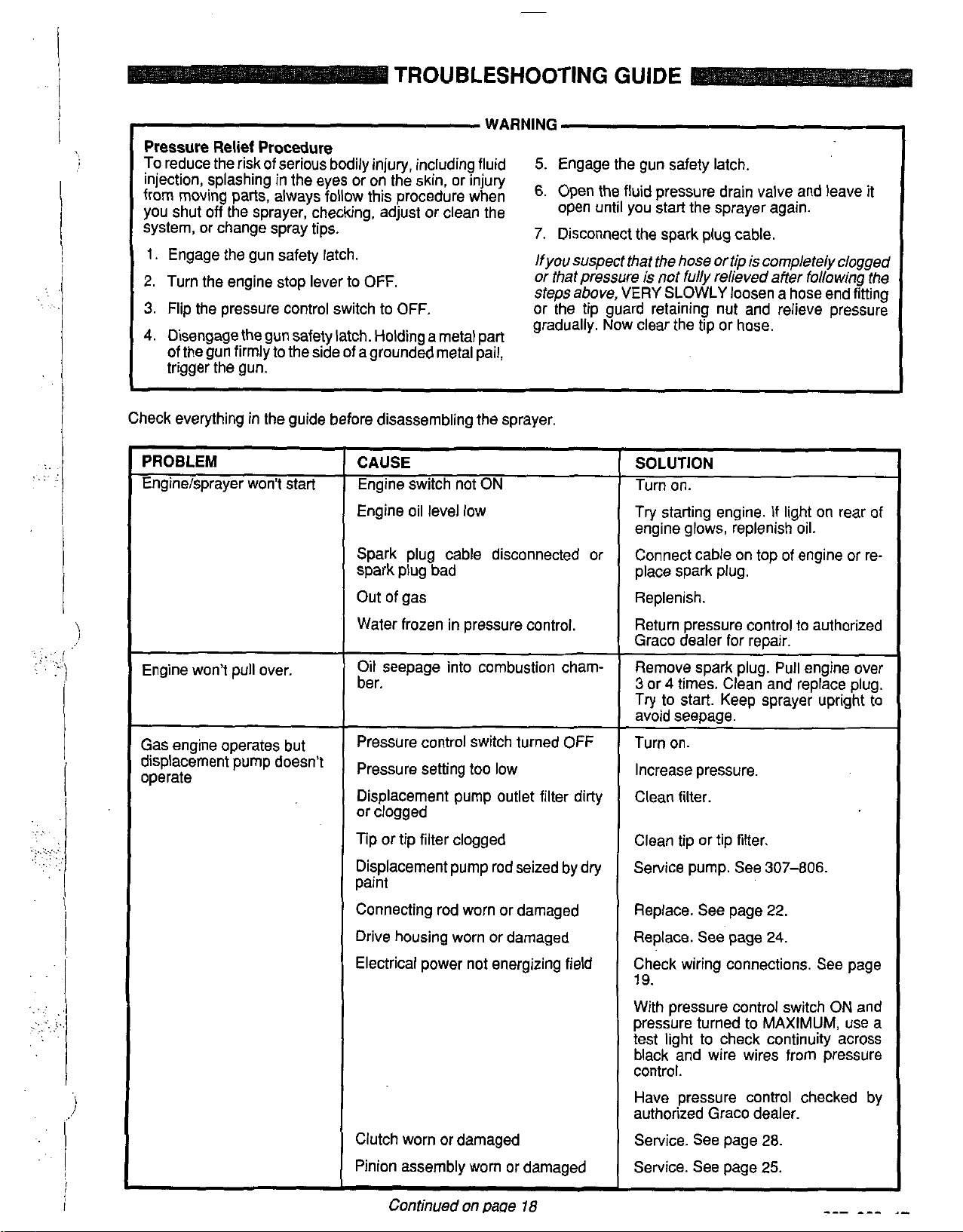

Disengage the gun safety latch. Point the spray gun

into a metal waste container and with a metal part of

the gun firmly touching the metal container, squeeze

the gun trigger. See Fig

of

reduce the risk

static sparking and splashing. Start

16-2.

This procedure helps

the sprayer, trigger the gun and slowly turn the pressure adjusting knob clockwise just until the pump

starts. Keep the gun triggered until clean solvent

comes from the nozzle. Release the trigger and engage the gun safety latch.

7. Check all fluid connections for leaks. If any leak, first

follow the

page

Pressure Relief Procedure Warning

15.

Now tighten the connections, start the

on

sprayer, and recheck the connections for leaks.

8.

Remove the suction tube from the pail. Disengage

the gun safety and trigger the gun to force solvent

from the hose.

Do

not let the pump run dry for more

than 30 seconds to avoid damaging the pump pack-

ings! Then follow the

Warning

9.

Leave the pressure drain valve open until you are

on page 15.

Pressure Relief Procedure

ready to use the sprayer again. Unscrew the filter

bowl and reinstall the clean screen. Reinstall the

bowl, hand tight only.

IO.

If you flushed with mineral spirits and are going to

use a water-base paint, flush with soapy water followed by a clean water flush. Then follow the

sure Relief Procedure Warning

on

page

Pres-

15.

Fig

161

3. Close the filter's pressure drain valve.

4.

Pour

one-half gallon

into

a

grounded metal pail. Put the suction tube in the

(2

liters)

of

compatible solvent

pail.

5. Remove the spray tip from the gun.

WARNING

To reduce the risk of static sparking and splashing,

always remove the spray tip form the gun, and hold

a metal part of the gun firmly to the side of and aimed

into a grounded metal pail when flushing.

Fig

CONTACT

162

WHEN

FLUSHING

Page 17

TROUBLESHOOTING GUIDE

WARNING

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including fluid

injection, splashing in the eyes or on the skin, or injury

from moving parts, always follow this procedure when

you shut off the sprayer, checking, adjust or clean the open until you start the sprayer again.

system, or change spray tips.

I.

Engage the gun safety latch. lfyou suspect that the hose

2. Turn the engine stop lever

3.

Flip the pressure control switch

4.

Disengage the gun safety latch. Holding a metal part

to

OFF.

to

OFF.

of the gun firmly to the side of a grounded metal pail,

trigger the gun.

Check everything in the guide before disassembling the sprayer.

5.

Engage the gun safety latch.

6.

Open the fluid pressure drain valve and leave it

7.

Disconnect the spark plug cable.

ortip

is

cornpletelyclogged

is

or that pressure

not fully relieved affer following the

steps above, VERY SLOWLY loosen a hose end fitting

or the tip guard retaining

nut

and relieve pressure

gradually. Now clear the tip or hose.

..

.

..

:

,..:.

,.:...'

..

,.

....

.,.

:

..

PROBLEM

Engine/sprayer won't start

Engine won't pull over.

Gas engine operates but

displacement pump doesn't

operate

CAUSE

Engine switch

not

ON

Engine oil level low

Spark plug cable disconnected or

spark plug bad

Out of gas

Water frozen in pressure control.

Oil seepage into combustion cham-

ber.

Pressure control switch turned

Pressure setting

too

low

OFF

Displacement pump outlet filter dirty

or clogged

Tip or tip filter clogged

Displacement pump rod seized by dry

paint

SOLUTION

Turn on.

Try starting engine.

If

light

on

rear of

engine glows, replenish oil.

Connect cable on top of engine or replace spark plug.

Replenish.

Return pressure control

to

authorized

Graco dealer for repair.

Remove spark plug. Pull engine over

3

or 4 times. Clean and replace plug.

to

Try

start. Keep sprayer upright

to

avoid seeoaoe.

Turn on.

Increase pressure,

Clean filter

Clean tip or tip filter.

Service pump. See

307-806.

Connecting rod worn or damaged

Drive housing worn or damaged

Electrical power

not

energizing field

Clutch worn or damaged

'inion assembly worn or damaged

~~ ~ ~~

Continued on Raoe

18

Replace. See page 22.

Replace.

See

page 24.

Check wiring connections. See page

19.

With pressure control switch

pressure turned

test light

to

MAXIMUM,

to

check continuity across

ON

use a

and

black and wire wires from pressure

control.

Have pressure control checked by

authorized Graco dealer.

Service. See page 28.

Service. See page 25.

Page 18

~

.(

I

..

!

PROBLEM

Displacement pump outpul

low on upstroke

Displacement pump outpu

low on downstroke or bott

strokes

Paint leaks into wetcup

TROUBLESHOOTING

~~

CAUSE

Pump inlet screen clogged

Piston ball check not seating

Piston packings worn or damaged

Displacement pump sleeve gasket

worn or damaged

Pump inlet screen clogged

Piston packings worn or damaged

Intake valve ball check not seating

properly

Engine RPM too low

Clutch worn or damaaed

~~~~~

Loose wet-cup

Throat packings worn or damaged

GUIDE

~

SOLUTION

Clean.

Service piston ball check.

Replace packings.

Replace.

Clean.

Replace packings.

Clean and service.

Increase throttle setting. See Startup,

Step 17, page 12.

Replace. See page 28.

Tighten just enough to stop leakage.

Replace packings. See 307-793.

Low fluid delivery

Spitting from gun

Displacement rod worn or

damaged

Pump inlet screen clogged

Pressure setting too low

Engine RPM too low

Dirty outlet filter, tip filter or tip

Large pressure drop in hose

Air in fluid pump or hose

Tip partially clogged

Fluid supply is low or empty

Replace. See 307-793.

Clean.

Increase pressure. See Startup, Step

17, page 12.

Increase throttle setting. See Startup,

Step 17, page 12.

Clean,

Use larger diameter hose.

Check for. loose connections at intake

and tighten. Then prime the pump.

See Startup, page

12.

Clear.

Refill and reprime the pump. See

Startup, page 12. Check fluid supply

often

to

prevent running dry.

Page 19

1

s

I

1

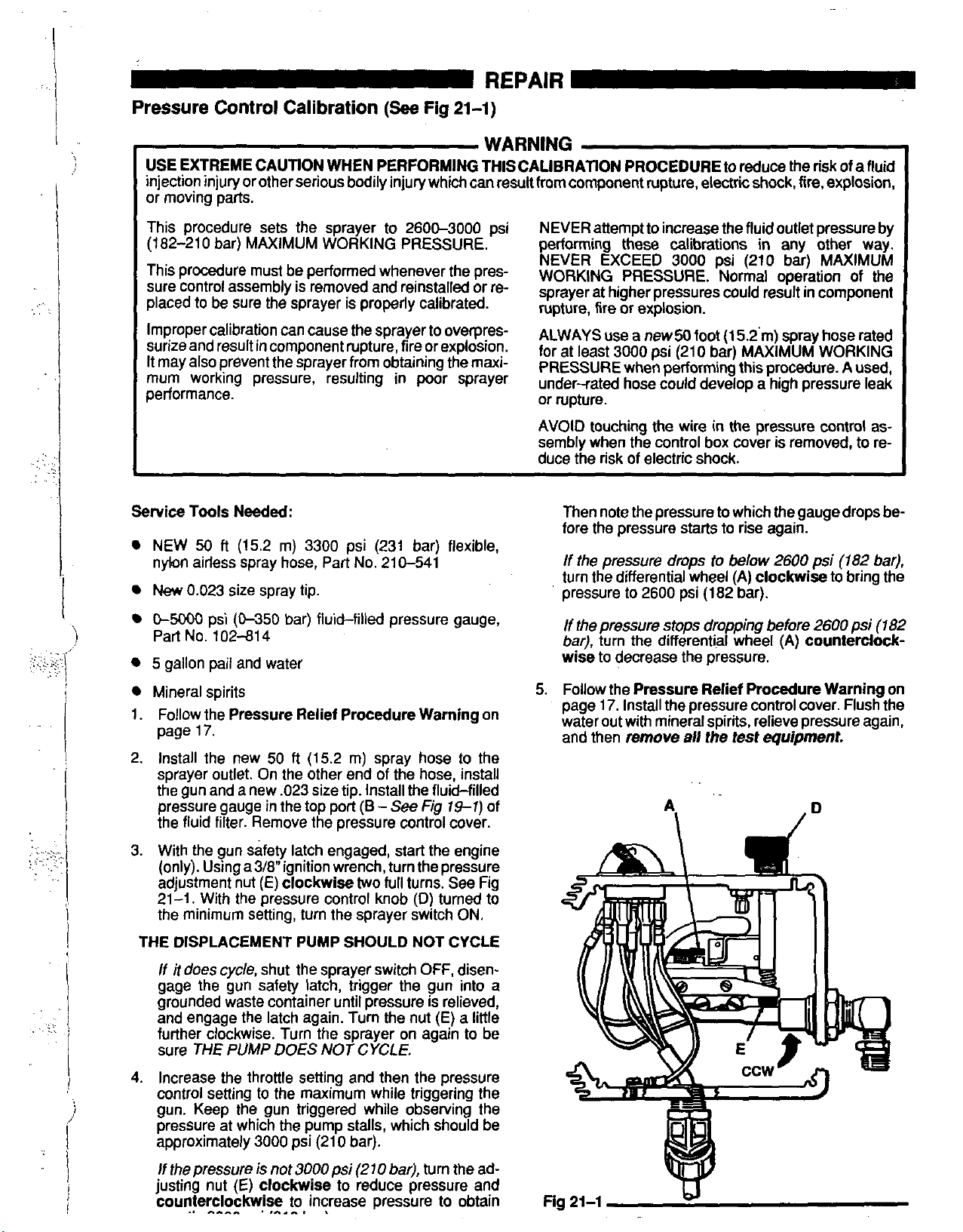

Pressure Control Replacement

REPAIR

I

..

. .. .

. .

\

To

reduce the risk of serious bodily injury, including

fluid injection or splashing in the eyes oron the skin,

or injury from moving parts, always follow the

sure Relief Procedure Warning