Page 1

Instructions -- Parts List

GH 733 Hydra--Spray

r

307616ZAB

Sprayer

3500 psi (240 bar, 24 MPa) Maximum Working Pressure

Model 231733, Series E

Sprayer only. Has Severe-Duty* Displacement Pump

Model 230975

Includes Sprayer 231733, Hose, Swivel, Gun,

RACr X, DripLesst Tip Guard and SwitchTipt

*Severe-duty displacement pumps have an abrasion and corrosion-resistant displacement rod and

sleeve. Refer to the Technical Data in manual 311762.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

EN

9089c

Page 2

Table of Contents

Warnings 2......................................

Component Identification 5........................

Setup 5.........................................

Flushing 8.......................................

Operation 10....................................

Maintenance 12..................................

Troubleshooting 13...............................

Displacement Pump Service 16....................

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

Complete Sprayer Parts Drawing 17................

GH733 Sprayer Parts Drawing 18..................

GH733 Sprayer Parts List 21......................

Accessories 23..................................

Technical Data 23................................

Graco Phone Number 24..........................

Graco Warranty 24...............................

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

equipment if you do not follow the instructions.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

Technical Data on page 23 for the maximum working pressure of this equipment.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Do not use hoses to pull equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82_C (180_F) or below --40_C(--40_F).

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Wear hearing protection when operating this equipment.

D Do not use 1,1,1--trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

3076162

Page 3

WARNING

SKIN INJECTION HAZARD

Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely

serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also

cause serious injury.

D Fluid injected into the skin may look like just a cut, but it is a serious injury. Get immediate surgi-

cal treatment.

D Do not point the gun at anyone or at any part of the body.

D Do not put your hand or fingers over the spray tip.

D Do not stop or deflect leaks with your hand, body, glove or rag.

D Do not “blow back” fluid; this is not an air spray system.

D Always have the tip guard and the trigger guard on the gun when spraying.

D Check the gun diffuser operation weekly. Refer to the gun manual.

D Be sure the gun trigger safety operates before spraying.

D Lock the gun trigger safety when you stop spraying.

D Follow the Pressure Relief Procedure on page 10 if the spray tip clogs and before cleaning,

checking or servicing the equipment.

D Tighten all fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do not

repair high pressure couplings; you must replace the entire hose.

D Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

FUEL HAZARD

The fuel used in this unit is combustible and when spilled on a hot surface can ignite and cause a fire.

D Do not fill the fuel tank while the engine is running or hot.

EXHAUST HAZARD

The exhaust contains poisonous carbon dioxide which is colorless and odorless.

D Do not operate this equipment in a closed building.

3307616

Page 4

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D If there is any static sparking or you feel an electric shock while using this equipment, stop spray-

ing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

D Keep the spray area free of debris, including solvent, rags, and gasoline.

D Disconnect all electrical equipment in the spray area.

D Extinguish all open flames or pilot lights in the spray area.

D Do not smoke in the spray area.

D Do not turn on or off any light switch in the spray area while operating or if fumes are present.

D Do not operate a gasoline engine in the spray area.

D Ground the sprayer to a true earth ground with the ground wire and clamp (supplied).

D Use only electrically conductive hoses.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers.

D Keep clear of all moving parts when starting or operating the sprayer.

D Before servicing the equipment, follow the Pressure Relief Procedure on page 10 to prevent the

equipment from starting unexpectedly .

NOTE: This is an example of the DANGER label on your sprayer. This label is available in other languages, free of

charge. See page 23 to order.

FIRE AND

EXPLOSION HAZARD

Spray painting, flushing or cleaning equipment with flammable

liquids in confined areas can result in fire or explosion.

Use outdoors or in extremely well ventilated areas. Ground

equipment, hoses, containers and objects being sprayed.

Avoid all ignition sources such as static electricity from plastic

drop cloths, open flames such as pilot lights, hot objects such as

cigarettes, arcs from connecting or disconnecting power cords

or turning light switches on and off.

Failure to follow this warning can result in death or serious injury.

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

Liquids can be injected into the body by high pressure airless

spray or leaks -- especially hose leaks.

Keep body clear of the nozzle. Never stop leaks with any part of the

body. Drain all pressure before removing parts.Avoid accidental

triggering of gun by always setting safety latch when not spraying.

Never spray without a tip guard.

In case of accidental skin injection, seek immediate

“Surgical Treatment”.

Failure to follow this warning can result in amputation or serious

injury.

SKIN INJECTION

HAZARD

3076164

Page 5

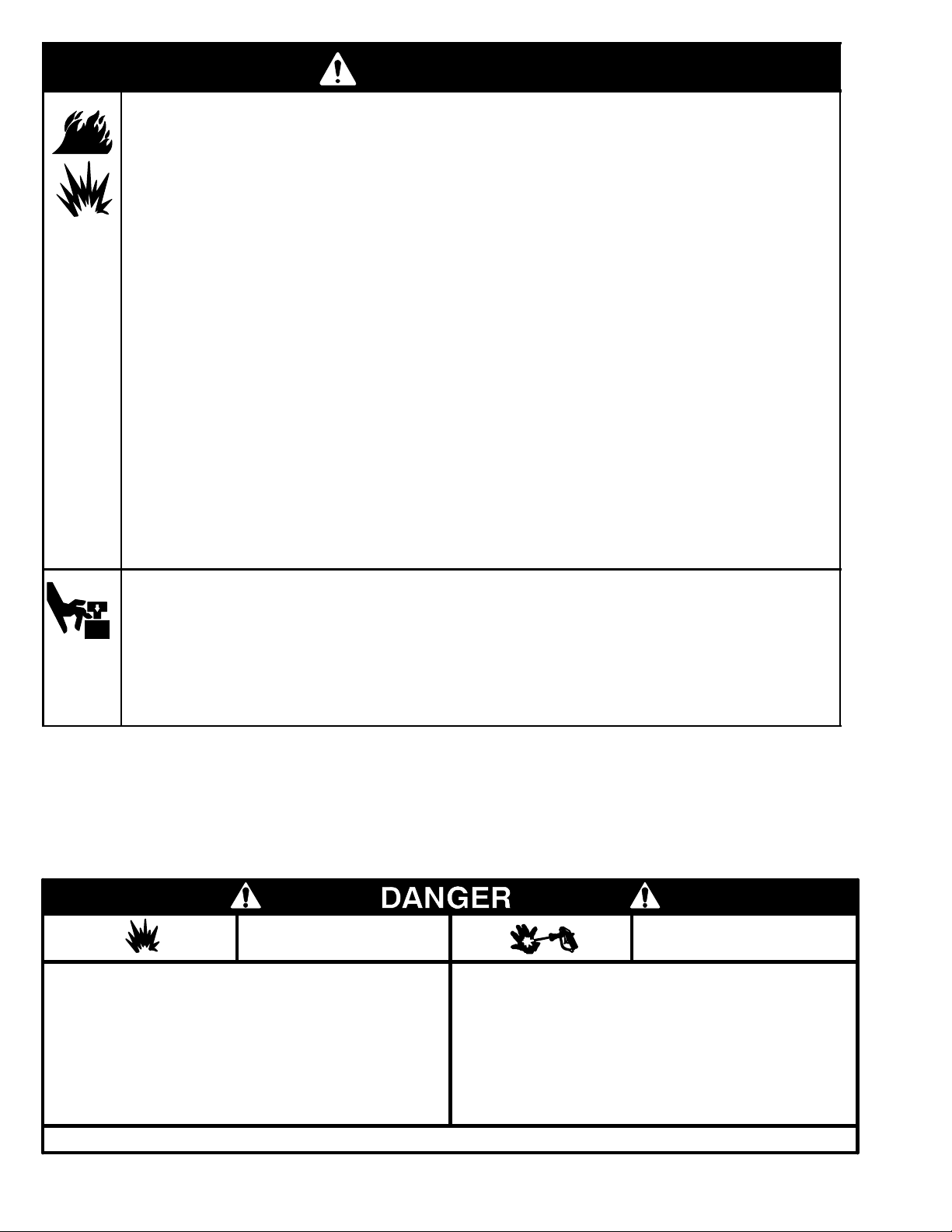

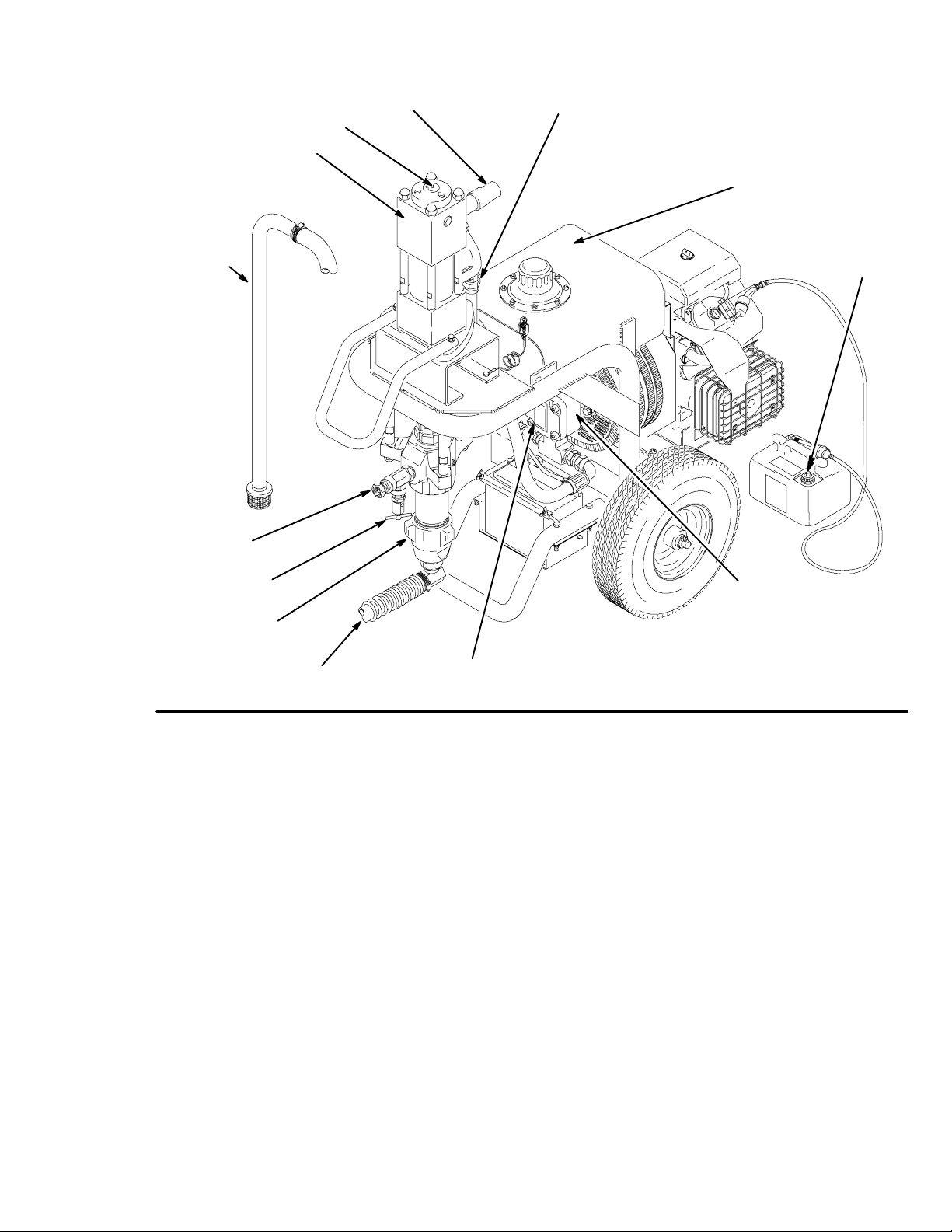

Component Identification

YDRA

H

SUCTION TUBE

ULIC RETURN LINE TO MOTOR

MOTOR RESET BUTTON

HYDRAULIC MOTOR

OUTLET

FITTING

HYDRAULIC SUPPLY LINE TO MOTOR

HYDRAULIC

RESERVOIR

GASOLINE

FILL CAP

PRESSURE

DRAIN VALVE

DISPLACEMENT PUMP

SUCTION HOSE

Fig 1

1. Connect the Hose and Gun

a. Remove the plastic cap plug from the outlet

tee and screw an accessory, conductive or

grounded spray hose onto the 1/4 npsm(f) outlet fitting. See Fig 1.

b. Connect a small diameter, 3 ft (0.9 m) whip

hose between the main hose and a spray gun,

if desired, for more flexible gun movement.

HYDRAULIC

PUMP

9089d

PRESSURE

CONTROL KNOB

Setup

c. Don’t use thread sealant on the swiveling nut

of the hose couplings, and don’t install the

spray tip yet.

NOTE: Use thread sealant on all male threads except at

swivel unions. Swivel unions are made to self-seal, and using thread sealant prevents the

swivel from turning freely.

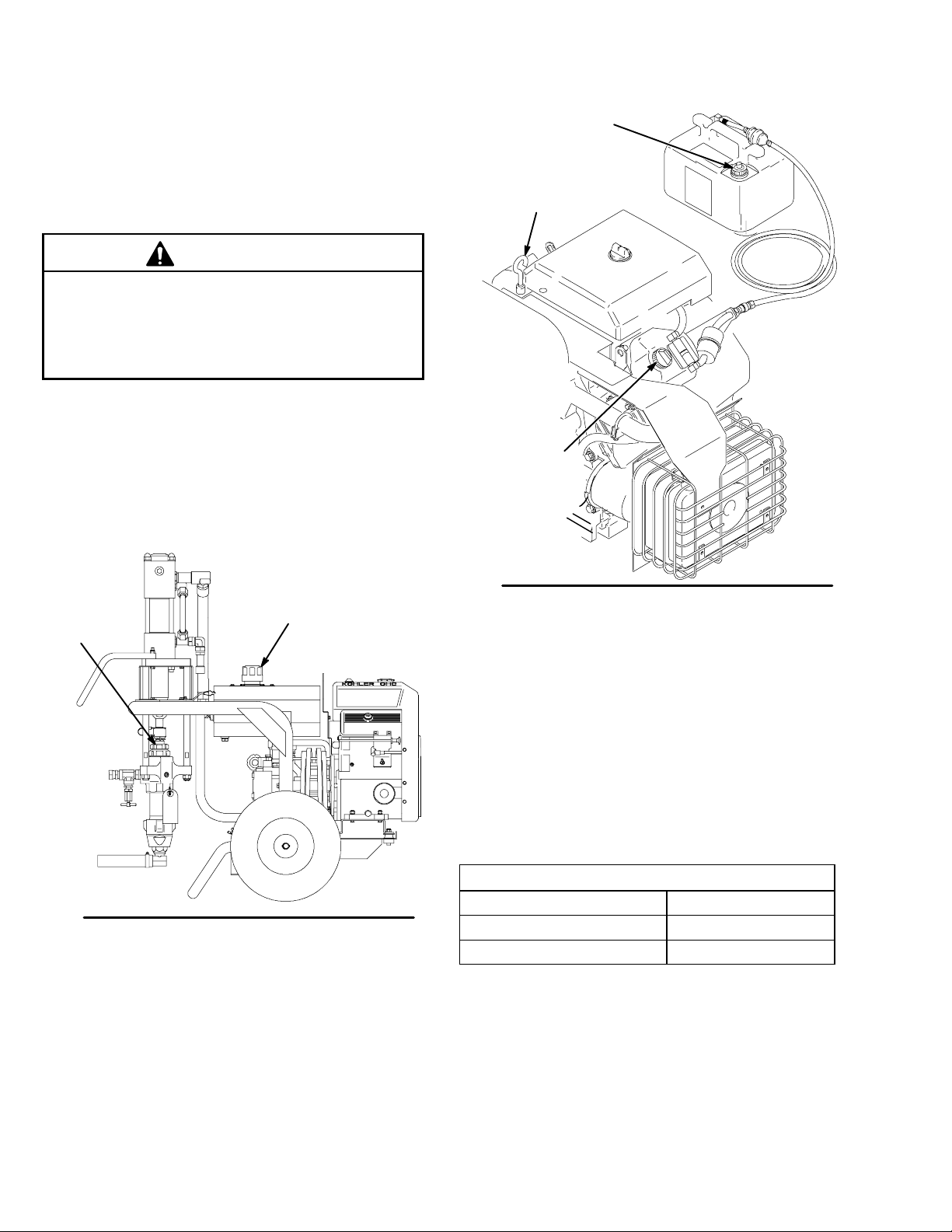

2. Fill the Packing Nut/Wet Cup 1/3 full with Graco

Throat Seal Liquid (TSL), supplied. See Fig. 2.

5307616

Page 6

3. Check the Hydraulic Oil Level

a. Unscrew the hydraulic oil fill cap. See Fig 2.

The dipstick is attached to the cap. The oil

should be up to the full line on the dipstick.

CAUTION

To prevent damage to the cooling system and

hydraulic pump, use only Graco Hydraulic Oil,

169236 (5 gal./20 liter) or 207428 (1 gal/3.8 liter).

Other types of hydraulic oil may damage the hydraulic components.

b. Add oil as needed to the proper level. A

completely full hydraulic system contains

about 5 gallons (20 liters) of oil.

Setup

GASOLINE

FILL CAP

OIL DIPSTICK

ENGINE OIL

FILL PLUG

PACKING

NUT/ WET

CUP

Fig 2

HYDRAULIC OIL

FILL CAP

7871b

7872b

Fig 3

4. Check the Engine Oil Level

a. Remove the dipstick. See Fig 3.

b. Check to be sure the oil is up to the full mark

on the dipstick.

c. If oil is needed, see the chart below for the

recommended oil type and weight.

d. Crank case capacity with filter: 2.1 quarts (2.0

liters).

RECOMMENDED LUBRICATION OIL: Use a high

quality detergent oil of American Petroleum Institute

(API) service class SG or SH for regular use and for

breaking in a new engine.

GRADE OF OIL CHART

SEASON OR TEMPERATURE GRADE OF OIL

Spring, Summer, Autumn SAE 10W--30

30_Fto0_,Winter SAE 5W--20 or 5W--30

3076166

Page 7

Setup

5. Fill the Fuel Tank

WARNING

FIRE AND EXPLOSION HAZARD

Fuel spilled on a hot surface can cause

a fire or explosion and serious bodily

injury and property damage. Shut off

engine and let it cool before filling the

tank. Carefully follow steps 5.a. to 5.c.,

below, being sure not to spill any fuel.

a. Close the fuel shutoff valve. See Fig 3.

b. Use only clean, fresh, well-known brands of

unleaded regular grade gasoline.The

minimum octane requirements are 87 octane

in the U.S.A. and 96 octane elsewhere.

c. Remove the gasoline fill cap and fill the tank.

Be sure the air vent in the fill cap is not

plugged so gasoline can flow to the carburetor,

then replace the cap. See Fig 3.

d. External fuel tank capacity: 6.0 gallons (22.7

liters)

e. Gasoline consumption at the maximum oper-

ating speed of 2900 RPM is about 1.3 gallons/

hour (4.9 liters/hour).

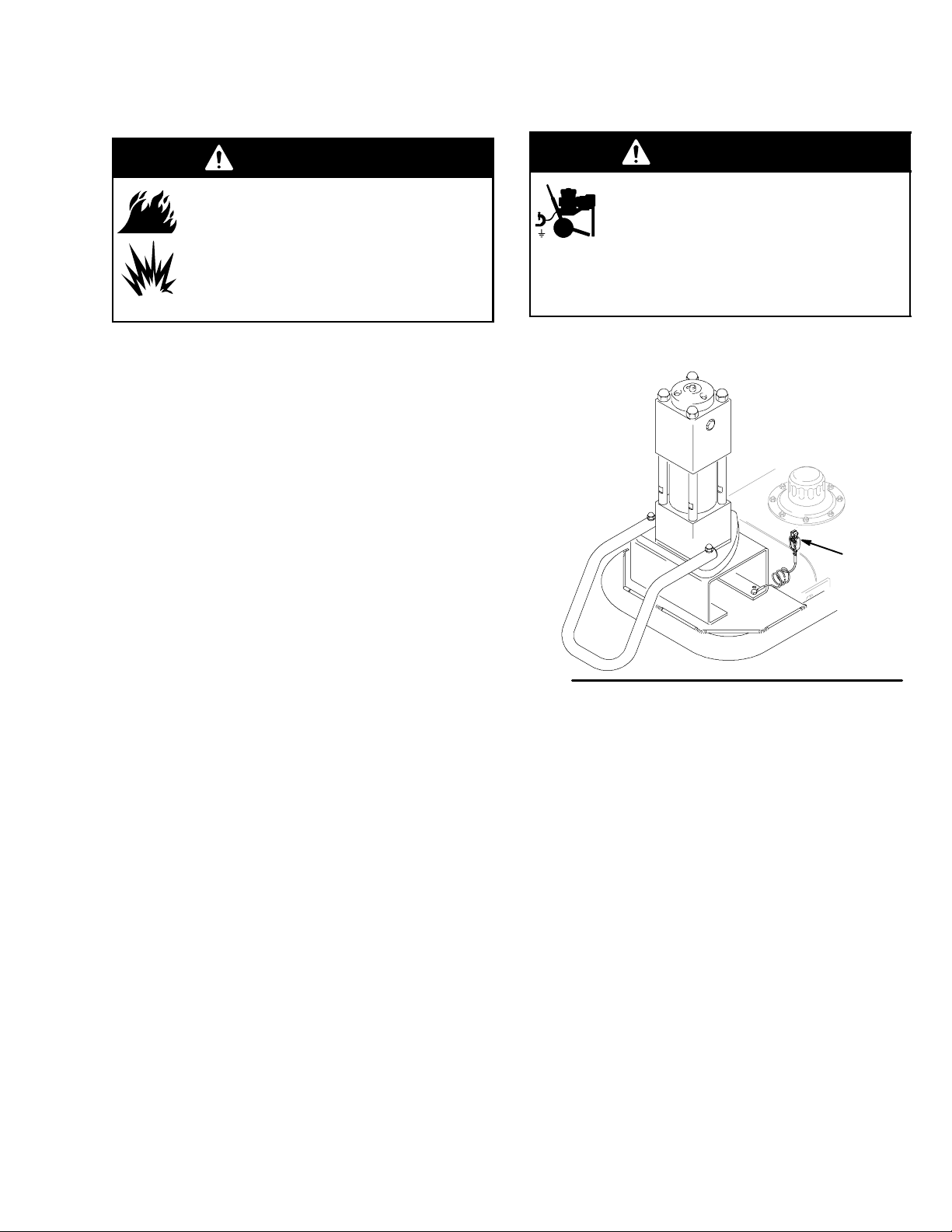

6. Grounding

WARNING

FIRE AND EXPLOSION HAZARD

To reduce the risk of static sparking, fire

or explosion which can result in serious

bodily injury and property damage,

ground the sprayer, all system components, and

the object being sprayed as instructed under FIRE

OR EXPLOSION HAZARD on page 3.

Connect the ground wire and clamp (provided) to a

true earth ground. See Fig 4.

CLAMP

Fig 4

7. Flush the sprayer to remove the oil which was left

in the pump after factory testing to protect the

pump from corrosion. See Flushing.

8. Battery Maintenance

Always charge a new battery or a battery that has not

been in use for a long period.

7873B

7307616

Page 8

Flushing

When to Flush

1. New sprayer. Y our new sprayer was factory tested

with lightweight oil which was left in to protect

pump parts from corrosion.

Before using oil - base paint, flush with mineral

spirits only.

Before using water- base paint, flush with

mineral spirits, followed by soapy water, then a

clean water rinse.

2. Changing colors. Flush with a compatible solvent

such as mineral spirits.

3. Changing from water--base to oil--base paint.

Flush with soapy water, then mineral spirits.

How to Flush

WARNING

SKIN INJECTION HAZARD

Follow the Pressure Relief Procedure

Warning on page 10. Remove the spray

tip before flushing.

4. Changing from oil--base to water-- base paint.

Flush with mineral spirits, followed by soapy water,

then a clean water flush.

5. Storage.

Water- base paint: flush with water, then mineral

spirits and leave the pump, hose and gun filled

with mineral spirits. Follow the Pressure Relief

Procedure Warning, page 10.

Oil - base paint: flush with mineral spirits. Follow

the Pressure Relief Procedure Warning, page

10.

6. Startup after storage.

Before using water- base paint, flush out mineral

spirits with soapy water and then clean water.

When using oil - base paint, flush out mineral

spirits with fluid to be sprayed.

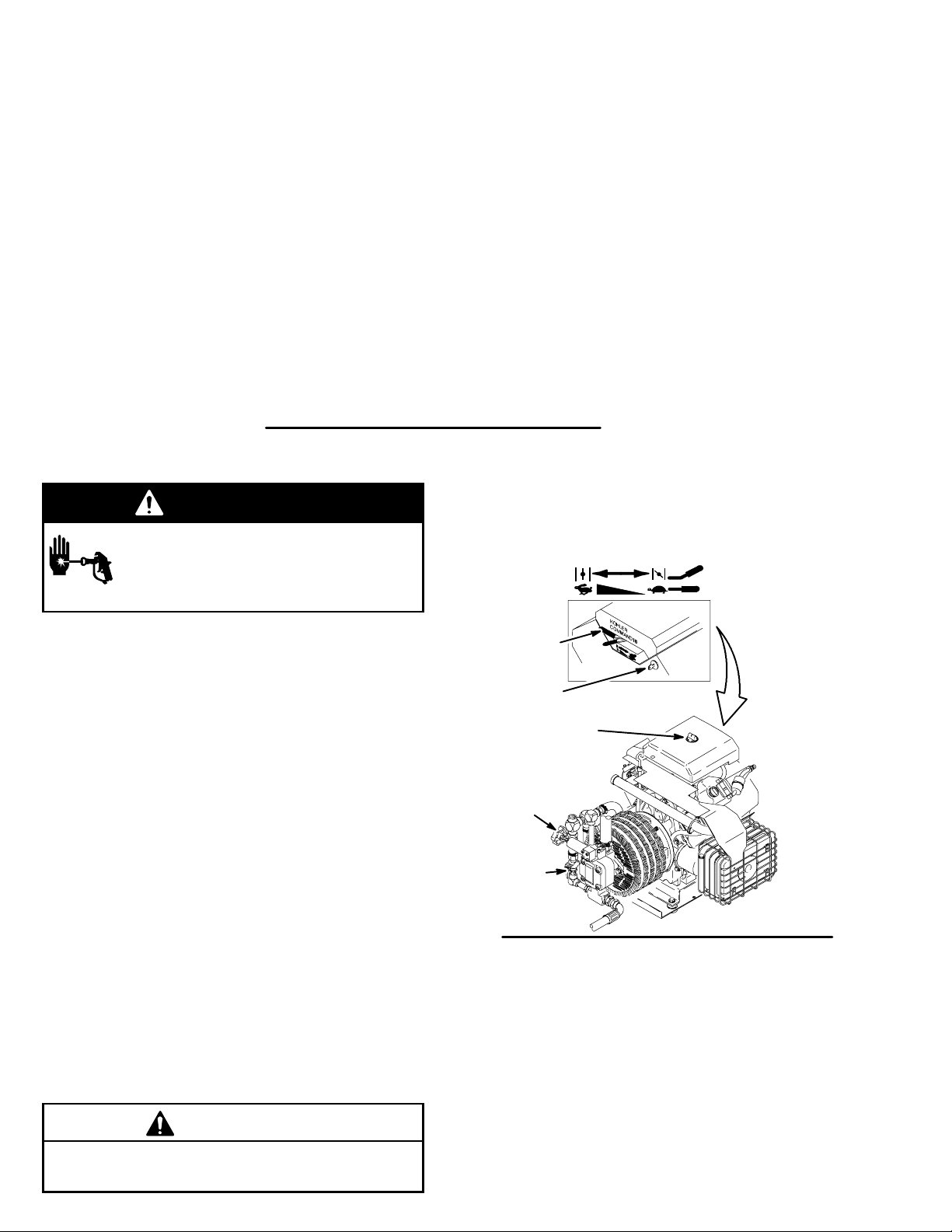

8. Turn and hold the ignition key to START until you

hear the engine “catch”, then release the key to RUN.

See Fig 5. If the engine does not start, open the

choke a little (move lever). If the engine floods, open

the choke all the way and try again.

1. Engage the gun safety latch. Remove the spray tip

from the gun.

2. Pour enough clean, compatible solvent to fill the

pump and hoses into a large, grounded metal pail.

3. Place the suction tube into the pail or tilt the

sprayer back (it will support itself) and place the

pail under the pump. Then tilt the sprayer forward

to lower the pump into the pail.

4. Turn the pressure control knob counterclockwise

until all spring tension is relieved. Y ou will be able

to feel it. The sprayer is now set at the lowest

pressure setting. Turning the knob further will

remove it. Tighten the knob locknut to set. See Fig

5.

5. Open the bypass valve. The valve lever will be

parallel to the body of the valve. See Fig 5.

6. Attach fuel hose from tank to engine.

7. Close the choke by moving the choke lever. See

Fig 5.

CHOKE

ON/OFF

SWITCH

AIR FILTER

PRESSURE

CONTROL

KNOB

BYPASS

VALVE

Fig 5

9. After the engine is warm, gradually open the choke

lever (move lever) and close the bypass valve.

See Fig 5.

10. Point the gun into the grounded metal pail and hold

a metal part of the gun firmly against the pail.

7874b

CAUTION

The bypass valve must be opened when starting the

sprayer to prevent damaging the starter.

3076168

NOTE: T o save the fluid in the pump and hose, trigger

the gun into the paint container or a separate

clean container. At the same time, slowly turn the

pressure control knob clockwise just enough to

start the pump. When solvent appears, release

the trigger and continue as below.

Page 9

WARNING

Flushing

12. Circulate the solvent until the system is thoroughly

flushed.

FIRE AND EXPLOSION HAZARD

To reduce the risk of static sparking and

splashing when flushing, always remove

the spray tip from the gun and hold a

metal part of the gun firmly to the side of a

grounded metal pail.

1 1. Making firm metal-to-metal contact, hold the gun

firmly to the side of the grounded solvent pail.

Trigger the gun. At the same time, slowly turn the

pressure control knob clockwise just enough to

start the pump.

13. Release the trigger and engage the gun safety

latch.

14. If you are going to start spraying, place the

pump or suction tube into the supply container.

Follow the Pressure Relief Procedure on page

10. Engage the gun safety latch until you are ready

to prime the pump. See Step 3, page 9.

15. If you are going to store the sprayer, be sure

your final flush is with an oil--based solvent, such

as mineral spirits. Remove the suction tube or

pump from the solvent pail. Follow the Pressure

Relief Procedure on page 10. Engage the gun

safety latch, but leave the drain valve open.

9307616

Page 10

Operation

Pressure Relief Procedure

WARNING

SKIN INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. T o reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D install or clean the spray tip.

1. Engage the gun safety latch.

2. Open the bypass valve.

2. Starting the Sprayer

a. Open the bypass valve to make startup easier.

In the open position, the valve lever is parallel

to the body of the valve. See Fig 6. Close the

filter drain valve.

b. Turn the pressure control knob counterclock-

wise until all spring tension is relieved. You will

be able to feel it. The sprayer is now set at the

lowest pressure setting. Turning the knob fur-

ther will cause it to fall off.

c. Attach fuel hose from tank.

d. If the engine is cold, close the choke by mov-

ing the choke lever. See Fig 6.

3. Turn and hold the ignition key to START until you

hear the engine “catch”, then release the key to

RUN. See Fig 6. If the engine does not start,

open the choke a little (move lever). If the engine

floods, open the choke all the way and try again.

e. After the engine is warm, gradually open the

choke lever (move choke lever) and close the

bypass valve. See Fig 6.

3. Turn the ignition key to OFF.

4. Disengage the gun safety latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail, and trigger the gun to relieve pressure.

5. Engage the gun safety latch.

6. Open the pressure drain valve, having a container

ready to catch the drainage. Leave the valve open

until you are ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved after

following the steps above, wrap a rag around the tip

guard retaining nut or hose end coupling and VERY

SLOWLY loosen the part to relieve pressure gradually,

then loosen completely. Now clear the tip or hose.

1. Prepare the Fluid

CHOKE

ON/OFF

SWITCH

AIR FILTER

PRESSURE

CONTROL

KNOB

BYPASS

VALVE

Fig 6

NOTE: In cold weather, run the engine for about 15

minutes with the bypass valve open before

starting the displacement pump, to help avoid

hydraulic motor stalling.

f. Follow the Pressure Relief Procedure

Warning on page 10, to shut off the sprayer.

7874b

a. Prepare the fluid according to the fluid manu-

facturer’s recommendations.

b. Place the pump or suction tube into the fluid

container.

30761610

WARNING

To stop the engine in an emergency, turn OFF

the ignition key. Close the bypass valve if possible.

See Fig 6. Then follow the Pressure Relief Proce-

dure Warning on page 10.

Page 11

Operation

If the motor stalls during operation, turn OFF the igni-

tion key. With your hand, firmly press straight down on

the motor reset button. Now try to restart the sprayer. If

it will not start, refer to the separate motor manual,

307158.

CAUTION

CAUTION

The engine throttle has been set to a maximum of

3000 RPM. The sprayer warranty will be voided and

the hydraulic pump life shortened if this adjustment is

changed.

Never use a hammer to depress the reset button, as

it could cause serious internal motor damage.

4. Prime the Pump

a. Be sure the gun safety latch is engaged.

b. Don’t install the spray tip yet!

c. If the engine has not been started, follow the

procedure in Step 2., page 10.

d. Disengage the gun safety latch.

e. Point the gun into a grounded metal pail and

hold a metal part of the gun firmly against the

pail. See the WARNING below.

f. Squeeze the trigger and slowly turn the pres-

sure control knob clockwise just enough to

start the pump. See Fig 6.

g. Operate the pump until all air is purged from

the pump and hoses and the fluid is flowing

freely from the gun.

h. Release the trigger and engage the safety

latch.

i. Turn the pressure control knob counterclock-

wise until all spring tension is relieved. You will

be able to feel it. The sprayer is now at the

lowest pressure setting. Turning the knob

further will remove it.

j. Follow the Pressure Relief Procedure on

page 10. Then install the spray tip in the gun

as instructed in the separate gun or tip instruc-

tion manual. If you are using the RAC IV

supplied with this sprayer, see manual 308644.

5. Adjusting the Pressure

a. Turn the pressure control knob clockwise to

increase and counterclockwise to decrease the

pressure. Tighten the knob locknut to set.

b. Always use the lowest pressure that is neces-

sary to completely atomize the fluid.

CAUTION

Operating the sprayer at a higher pressure than

necessary wastes fluid, causes early tip wear, and

shortens the sprayer life.

6. Cleaning a Clogged Tip

WARNING

SKIN INJECTION HAZARD

To reduce the risk of a fluid injection

injury , NEVER hold your hand, body or a

rag in front of the spray tip when

cleaning or checking for a cleared tip. To reduce

the risk of a fire or explosion, always hold the gun

firmly against the side of a grounded metal waste

container when checking to see if the tip was

cleared or when using a self--clearing tip.

a. Follow the Pressure Relief Procedure

Warning on page 10.

b. Clean the front of the tip frequently during the

day to keep the fluid from building up and clogging the tip. To clean, and to clear a tip if it

clogs, refer to your separate gun instruction

manual. If you are using the RAC IV tip guard

and SwitchTip, refer to manual 308644.

7. Shutting Off the Sprayer

a. Whenever you stop spraying, even for a short

break, follow the Pressure Relief Procedure

Warning on page 10.

b. Clean the tip and gun as recommended in your

separate gun or tip manual.

c. Flush the sprayer at the end of each work day

if using water--based fluid or if it could harden

in the sprayer over night. See FLUSHING,

page 8. Use a compatible solvent to flush,

then fill the pump and hoses with solvent such

as mineral spirits to help prevent pump corrosion. Relieve pressure!

d. For long term shutdown or storage, always fill

the sprayer with mineral spirits to prevent

pump corrosion. Relieve pressure!

8. Adjusting the Intake Valve Ball Travel.

c. If more coverage is needed, use a larger tip

rather than increasing the pressure.

d. Check the spray pattern. The tip size and

angle determines the pattern width and flow

rate. See the separate manual received with

your gun.

a. The pump is set to handle medium volume,

low viscosity fluid. To adjust the pump for

higher flow or heavier viscosity fluid, disassemble the intake valve as instructed in

manual 311762 and move the ball stop pin to a

higher set of holes. This increases the ball

travel.

11307616

Page 12

Maintenance

1. Always stop the pump at the bottom of its

stroke when you take a break and at the end of

the day. This helps keep fluid from drying on the

rod and damaging the packings.

2. Keep the displacement pump packing nut/wet

cup 1/3 full of TSL at all times. The TSL helps

protect the packings and rod.

3. Check the tightness of the packing nut daily . It

should be tight enough to stop leakage but no

tighter.

CAUTION

Proper engine and hydraulic oil level is important to

prevent costly damage to the sprayer. Check it as

often as recommended in Steps 4 and 5., below.

4. Check the hydraulic oil level weekly. The oil

must be up to the top mark on the dipstick. Use

only Graco Hydraulic Oil.

5. Check the engine oil level at least weekly . The

oil must be up to the FULL mark on the dipstick.

The engine should not use more than one ounce

of oil per hour of operation. Consult the engine

manual, supplied, for additional recommended

maintenance.

9. To change the hydraulic oil:

a. Follow the Pressure Relief Procedure

Warning on page 10.

b. Place a waste container under the drain plug

of the hydraulic reservoir. See Fig 7. Unscrew

the plug and drain the reservoir. Reinstall the

plug before proceeding.

c. Remove the nuts and reservoir cover.

d. Remove the return line filter and install a new

filter assembly.

e. Inspect the inlet filter and replace it if needed.

f. Install the reservoir cover and nuts. Then pour

in five gallons (19 liters) of Graco Hydraulic Oil

through the intake filter. See Fig 7. Install the

fill cap.

NUTS

HYDRAULIC

OILFILLCAP

COVER

INLET

FILTER

ENGINE

OIL

FILL PLUG

6. Inspect the return line filter frequently for clogging. Replace it after every 500 hours of operation

or every 6 months, whichever comes first. A

clogged or worn out filter reduces filter capability

and will damage the hydraulic pump.

7. Change the hydraulic oil after every 2000

hours of operation or every 12 months, whichever

comes first. For continuous operation in temperatures above 85_F(30_C), change the oil after

every 1000 hours or 6 months of use. See Step 9.

for the procedure.

CAUTION

Cleanliness is essential when servicing the hydraulic

system. Use special care to avoid getting dust or dirt

into the hydraulic system to prevent damage to the

hydraulic components.

8. Change engine oil and filter every 100 hour of

use. Use 30W detergent oil.

RETURN

LINE

FILTER

Fig 7

HYDRAULIC OIL

DRAIN

PLUG LOCATED

UNDER RESERVOIR

30761612

Page 13

Troubleshooting

WARNING

SKIN INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 10.

Check everything in the troubleshooting chart before disassembling the sprayer.

PROBLEM CAUSE SOLUTION

Gas engine doesn’t work properly. Consult engine manual, supplied.

Gas engine will not start. Check battery.

Gas engine operates, but

displacement pump doesn’t

operate.

Displacement pump operates, but

output is low on upstroke.

Displacement pump operates but

output is low on downstroke and/

or on both strokes.

Paint leaks into wetcup Loose wet--cup

Excessive leakage around

hydraulic motor piston rod wiper.

Hydraulic motor stalled.

Pressure setting too low.

Displacement pump outlet filter (if

used) is dirty or clogged.

Tip or tip filter (if used) is clogged.

Hydraulic fluid too low.

Hydraulic pump worn or damaged.

Hydraulic motor worn or damaged.

Displacement pump rod seized by

dried paint.

Piston ball check not seating properly.

Piston packings worn or damaged.

Piston packings worn or damaged.

Intake valve ball check not seating

properly.

Throat packings worn or damaged.

Piston rod seal worn or damaged. Replace these parts. See manual 307158.

Turn the ignition key to OFF. Firmly press

straight down on motor reset button. Restart

sprayer, see page 10. If it doesn’t start, see

manual 307158.

Increase pressure. See page 11.

Clean the filter.

Remove tip and/or filter and clean.

Shut off sprayer and add fluid immediately*. See

page 5.

Return sprayer for repair.

Return sprayer for repair.

Service pump. See manual 311762.

Service piston ball check. See manual 311762.

Replace packings. See manual 311762.

Replace packings. See manual 311762.

Service intake valve ball check. See manual

311762.

Tighten just enough to stop leakage.

Replace packings. See manual 311762.

Fluid delivery is low. Pressure setting too low.

Displacement pump outlet filter (if

used) is dirty or clogged.

Hydraulic pump is worn or damaged.

Hydraulic motor is worn or damaged.

Large pressure drop in fluid hose.

The sprayer overheats. Cooler or blower is worn or damaged. Replace. See page 15.

Spitting from gun. Air in fluid pump or hose.

Fluid supply is low or empty.

*Check hydraulic fluid level often. Do not allow it to become too low. Use only Graco approved hydraulic fluid. See pages 5 and 20.

Increase pressure. See page 11.

Clean filter

Return sprayer for repair.

Return sprayer for repair.

Use larger diameter hose.

Check for loose connections on siphon

assembly, tighten, then reprime pump.

Refill supply container.

13307616

Page 14

Replacing the Hydraulic Pump

1. Follow the Pressure Relief Procedure Warning

on page 10. Let the hydraulic system cool before

beginning the service procedure.

9. Pull the pump straight off the pump support.

10. Loosen the setscrews (108) on the pump half of

the coupler (109). See Fig 9.

2. Unscrew the reservoir drain plug (51), having a

container ready to catch the draining fluid.

3. Disconnect the hose (7) from the bypass valve (9)

by loosening the hose clamp (8). See Fig 8.

4. Loosen the hose clamp (8) and pull the hose (85)

off the hose insert (5) near the elbow (3). See Fig

8.

5. Loosen the hose clamp (54) on the hose (53) just

above the hydraulic pump (107). See Fig 8.

6. Loosen the tube fitting nut (18) of hose (22). See

Fig 8.

7. Remove the two capscrews (150), lockwashers

(66) and washers (64) holding the pump (107) to

the support (1 17). See Fig 8.

8. Fill oil pump case with hydraulic oil and run for

10--15 minutes at low engine speed to evacuate air

from system. Cycle paint pump slow to clear air

from motor.

1 1. Remove all fittings from the old pump and install

them on the new pump in the same order.

12. Check Dimension A as shown in Fig 9. When the

dimension is correct, tighten the setscrews (108),

slide the new pump assembly onto the pump

support (117) and recheck the dimension.

CAUTION

The correct coupling dimension is critical to avoid

improper coupler engagement to the coupler spider

which will damage the coupler and make the sprayer

inoperable.

13. Reconnect the hoses. Reinstall the reservoir plug

(51), and refill the reservoir with clean, Graco

approved hydraulic oil.

Fig 8

113

85

8

5

3

152

4

7

8

9

22

53

54

117

52

18

112

150,66,64

107

49,66

115

114

7876c

108

109

30761614

Page 15

Replacing the Cooler and Blower

1. Follow the Pressure Relief Procedure Warning

on page 10. Let the hydraulic system cool before

beginning the service procedure.

2. Remove the hydraulic pump as instructed in the

previous section.

3. Disconnect the cooler to reservoir return hose (7.)

by loosening the hose clamp (8). See Fig 8.

4. Remove the cooler capscrews (49) and lockwashers (66). See Fig 8.

c. Pull the pump support and blower off far

enough for the blower to fall out of the bottom

of the housing.

d. Install a new blower. Secure the pump support

(117) to the engine. See Fig 8.

e. Check Dimension A as shown in Fig 9 and

tighten the coupler setscrews (108). Butt the

blower hub up to the coupler half, keeping the

blower in full contact with the coupler, and

tighten the blower setscrews (B).

5. Remove the fan guard (23). See Fig 8.

6. Pull the cooler (115) straight out.

7. Inspect the rubber pad (116) for wear and replace

if necessary. See Fig 9.

8. Inspect the blower wheel (114) for wear. See Fig 8.

If it needs to be replaced, follow Steps 8a--8e.

a. Unscrew the setscrews (108) from the engine

half of the coupler (109). Unscrew the blower

setscrews (B). See Fig 9.

b. Remove t he capscrews (112) and lockwashers

(113) holding the pump support (117) to the

engine and pull the support off. See Fig 8.

108

115

23

117

CAUTION

The correct coupling dimension is critical to avoid

improper coupler engagement to the coupler spider

which will damage the coupler and make the sprayer

inoperable.

9. Install the cooler.

10. Fold the flaps of the pad (116) toward the cooler

fins and install the fan guard (23), capscrews (49)

and lockwashers (66). See Fig 8.

1 1. Reinstall the hydraulic pump and reconnect all

hoses.

ENGINE

Fig 9

A

DIMENSION A

0.05 in. ± 0.010

(1.27 mm ± --0.254)

A

107

109

108

116

TOP VIEW

15307616

Page 16

Displacement Pump Service

Disconnect the Displacement Pump

1. Flush the pump if possible. Stop the pump on the

down stroke.

2. Follow the Pressure Relief Procedure Warning

on page 10.

3. Remove the suction tube and fluid hose from the

displacement pump.

4. Unscrew the three tie rod locknuts (48). See

GH733 Sprayer Parts Drawing.

5. Unscrew the shouldered nut (35). Pull the

displacement pump (46) off the tie rods (47).

6. Screw the jam nut (90) up onto the connecting rod

(91).

7. Remove t he lower cotter pin (89) and unscrew the

connecting rod (91) from the displacement rod (A).

8. Refer to separate manual 311762 for displacement

pump repair instructions.

Reconnecting the Displacement Pump

1. Screw the connecting rod (91) into the displacement rod (A) and replace the lower cotter pin (89).

Screw the jam nut (90) all the way down. See

GH733 Sprayer Parts Drawing.

2. Mount the displacement pump (46) onto the tie

rods (47).

3. Screw the shouldered nut (35) onto the hydraulic

motor (29). Screw the tie rod locknuts (48) onto

the tie rods (47) and torque to 35--50 ft-lb (47--68

N.m).

4. Reattach the hoses to the displacement pump.

5. If the grounding wire was disconnected before

service, be sure to reconnect it before operating

the sprayer.

6. Start the pump and operate it slowly to check the

tie rods for binding. Adjust the tie rod locknuts, if

necessary to eliminate binding.

30761616

Page 17

Complete Sprayer Parts Drawing

Model 230975, GH 733 Sprayer

Includes items 501 to 510

REF

NO. PART NO. DESCRIPTION QTY

501 231733 GH 733 SPRAYER 1

505 277251 .HOSE, fluid, nylon, 3/8 in. ID, 3

506 156849 .NIPPLE, 3/8 ntp(m) 3

(See parts list on page 19)

3/8 npsm(fbe); 50 ft (15m) long

505

509

510

507

51 1

REF

506

508

39

505

505

507 155665 .ADAPTER, 3/8 npt(m) x 3/8 npsm swivel 1

508 164672 .ADAPTER, 1/4 npsm x 3/8 npt(m) 1

509 277249 .HOSE, fluid, nylon, 1/4 in. ID, 1

1/4--18 npsm(fbe), 3 ft (0.9 m) long

510 246240 .AIRLESS SPRAY GUN 1

see manual 309740 for parts

511 100505 BUSHING, pipe, 3/4 x 3/8 in. 1

*Install this adapter in place of the fluid outlet nipple in the fluid

filter.

REF 38

See page 18 for

continuation

ti10624A

506

506

506

17307616

Page 18

GH733 Sprayer Parts Drawing

Model 231733, Series D

30

29

34

178

32

82

177

79

7776

E

31

22

A

49

33

47

103

91

36

35

89

31

39

See page 17 for

continuation

150

38

144

143

48

37

46

43

9086B

30761618

Page 19

GH733 Sprayer Parts Drawing

19307616

Page 20

GH733 Sprayer Parts Drawing

74

28

Ref 77

78

93

153

96

97

98

95

50

51

94

5

108

3

141

4

5

8

85

117

8

5

54

8

7

53

112

113

2

152

Ref 111

105

106

54

25

52

138

8

142

66

49

110

9

10

107

15

17

16

18

30761620

64

65

137

Ref 22

109

115

23

109

110

108

7879b

24

114

7879A

Page 21

GH733 Parts List

REF

NO. PART NO. DESCRIPTION QTY

1 107074 BREATHER, fill cap 1

2 106114 STRAINER, inlet 1

3 107053 ELBOW, pipe, 90_, 1/2 x 3/8 npt 1

4 107128 TEE, service 1

5 107050 INSERT, hose, 1/2 npt(f) 3

7 178859 HOSE, rubber, 5 in. (125 mm) 1

8 102473 CLAMP, hose 6

9 210658 VALVE, ball 3/8 npt(m) 1

10 165472 ELBOW, pipe, 90_, 3/8 npt(f) 1

11 106039 WHEEL 2

12 106123 CAPSCREW, hex hd, 1/2 x 4 in. 4

13 100018 LOCKWASHER, spring, 1/2 in. 4

14 100321 NUT, hex, 1/2 in. thread 4

15 158979 NIPPLE, pipe, reducing, 3/8 x 1/2 npt 1

15 188344 NIPPLE, pipe, reducing, 3/8 x 1/2 npt 1

16 103475 TEE, pipe, 1/2 npt(f) 1

17 158491 NIPPLE, short, 1/2 npt 1

18 107052 FITTING, tube, flared 1

19 115753 BATTERY, 12 volt, “L” style terminals 1

20 107069 CLAMP, battery 1

21 101354 PIN, straight, spring 2

22 513575 HOSE, hydraulic supply, nylon, 3/4 in. ID,

cpld 1 --1/16 in. fbe, 30 in. (762 mm) 1

23 178751 GUARD, fan 1

24 179714 SPACER 1

25 100213 NIPPLE, pipe, 3/8 npt x 3 in. 1

26 217469 FRAME, pump 1

27 101578 CAPSCREW, hex head, 8--32 x 0.38 in. 4

28 100214 LOCKWASHER, spring, 5/16 in. 18

29 217022 MOTOR, hydraulic

see manual 307158 for parts 1

30 177755 LABEL, identification 1

31 110838 NUT, lock, 5/16--16 6

32 106212 CAPSCREW, 3/8--16 x 2.75 in. 2

33 177765 PLUG 2

34 177652 HANDLE 1

35 244819 COUPLING, assy 1

36 197340 COUPLING, cover 1

37 158586 BUSHING, 1 x 3/4 in. 2

38 111337 TEE, 3/4 in. npt(f) 1

39 157785 SWIVEL, 3/4 in. m x f 1

41 107073 CABLE, battery, positive, 23 in., 6 awg 1

43 245468 TUBE, suction, inlet 1

46 L250C1 PUMP, displacement 1

see manual 311762 for parts

47 198592 ROD, tie, 14.59 in. (371 mm) 3

48 101712 NUT, lock, type “E” 5/8 in.-- 11 3

49 100101 CAPSCREW, hex head, 3/8--16 x 1 in. 5

50 104444 O--RING, fluoroelastomer 1

51 104126 PLUG, box, 3/4 in. 1

52 107049 INSERT, hose, 3/4 npt(f) 1

53 178791 HOSE, suction, 1 in. ID, 3 ft (9.9 m) 1

54 101818 CLAMP, hose, 13/16 in. to 1--1/2 in. OD 2

55 178773 LEG, frame 1

56 177641 WASHER, flat 2

57 177570 AXLE 1

58 113951 CABLE, battery, negative, 18 in. , 6 awg 1

59 107068 HOOK, bolt, 1/4 in. thread 1

60 15C713 PLATE, engine 1

61 216141 SUPPORT, engine 1

63 246015 MOUNT, motor 1

64 100023 WASHER, 3/8 in. 14

67 100678 CAPSCREW, hex hd, 5/16 x 1.75 in. 4

68 290386* LABEL, WARNING 1

71 218125 RESERVOIR KIT 1

72 185951* LABEL, DANGER 1

73 185285* LABEL, DANGER 1

74 100188 NUT, heavy hex, 5/16 --18 unc--2a 10

75 177807 LABEL, identification 1

76 106053 ELBOW, 90_, 1--1/16 in. thread 1

77 513574 HOSE, hyd rtn, 1 in. x 20.75 in. 1

78 107127 ADAPTER, male, 1--5/16 in. x 3/4 in. 1

79 620188 ADAPTER, 1 in. (m) x 3/4 x 1/2 x 3/8 (f) 1

82 105430 NUT, seal, 1 in. npt 1

83 15C712 SHIELD, heat 1

85 178795 HOSE, cooler, 0.625 in., 10.5 in. lg 1

87 177808 LABEL, identification 1

88 178935 LABEL, caution 1

89 244820 CLIP, hairpin, with lanyard 1

91 197341 ROD, adapter 1

93 107125 ELBOW, 90_ street, 3/4 npt(m) 1

94 105429 NUT, seal, 3/4 npt 1

95 178750 FITTING, return, 1 in. npt(m) x 3/4 npt(f) 1

96 178794 FILTER, fluid 1

97 500054 BUSHING, hex hd 1

98 107067 O--RING, buna--n 1

103 112798 SCREW, mach, hex washer hd, 8 x 3/8 in.1

105 219099 KNOB, pump 1

106 100187 NUT, hex, 5/16 in. 1

107 178872 PUMP, vane, hydraulic 1

108 100421 SETSCREW, 5/16 in. x 3/8 in. 2

109 106063 COUPLER 2

110 605358 KEY, 1/4 in. 1

111 113287 ENGINE, 18 HP, OHC 1

112 107143 CAPSCREW, sch, 7/16 x 1.25 in. 4

113 100052 LOCKWASHER, spring, 7/16 in. 4

114 178792 BLOWER 1

115 178788 COOLER 1

116 178861 PAD 2

117 178786 SUPPORT, pump 1

118 102169 CAPSCREW, hex hd, 5/16 x 1.5 4

119 100016 LOCKWASHER, spring, 1/4 in. 4

120 100011 WING NUT, 1/2 in. 2

122 100015 NUT, hex, 1/4 --10 unc 2

123 178787 SHELF, battery 1

130 106229 NIPPLE 1

131 206994 TSL, 8 oz. not shown 1

132 185016 LABEL, Caution 1

137 100004 CAPSCREW, hex hd, 3/8--16 in. x 1.25 in. 2

138 107032 ELBOW, 90_ street, 3/8 npt (mxf) 1

139 158683 ELBOW, 90_, 3/8 npt(mxf) 1

140 108426 O-- RING, buna-- n 1

141 183574 HOSE, rubber tube, 4.5 in. 1

142 183575 NIPPLE, barbed hose, 3/8--18 npt(f) 1

143 237686 GROUND WIRE & CLAMP 1

144 245143 VALVE, pressure drain 1

145 158233 WASHER, flat 2

150 100505 BUSHING, 3/4 x 3/8 in. 1

167 110838 LOCKNUT, 5/16 in. 4

168 191958 BRACKET, switch 1

169 191959 GUARD, muffler 1

170 112179 SCREW, thread forming, (M5 x .8 mm) 3

171 113819 NUT, 1/4 in. 2

172 100022 SCREW, cap, 1/4 in. 4

173 100016 WASHER, lock 2

176 070401 TUBING, electrical, 13 in. 1

177 100101 SCREW, cap, hex hd, 1 x 3/8-- 16 in. 4

unc-2a

178 625057 BRACKET, motor, hydraulic 1

180 195516 SPACER 4

181 191863 GUARD, hose 1

182 113372 COUPLING, fuel line 1

183 192228 BRACKET, gas line 1

184 801971 CLAMP, hose 2

185 801959 PROTECTOR, terminal black 1

186 801958 PROTECTOR, terminal red 1

187 118423 COVER, debris 1

188 238681 FUEL TANK ASSY, 6 gallon 1

*DANGER and WARNING labels are available at no charge.

21307616

Page 22

Notes

30761622

Page 23

Technical Data

Accessories

Engine KOHLER Model CH18 OHV 4 cycle...............

twin cylinder, air cooled, 18 HP, (13.4 kW)

Gasoline 6.0 gallon (22.7 liter capacity)...................

consumes 1.3 gal/hr (4.9 liter/hr)

Hydraulic Fluid Sump 5 gallon (19 liters)..................

Hydraulic Pressure 1300 psi (89 bar)....................

10.2 gpm (39 l/min)

Displacement Pump 3500 psi (240 bar, 24 MPa)..........

Maximum Working Pressure

3 gpm (11.4 lpm) output,

15 cycles/gallon

Pump Fluid Outlet Size 1 in. npt(f).......................

Wetted Parts:

Displacement Pump Steel, Nitralloy,...................

Tungsten Carbide, PTFE, Leather

Filter Aluminum, Carbon Steel, Stainless Steel,..........

Weight (dry w/o packaging) 480 lb (217 kg)...............

Height 50.5 in. (1.3 m).................................

Length 48.5 in. (1.2 m).................................

Width 29 in. (736 mm).................................

Sound Levels*:

Sound Pressure 91 dB(A)............................

Sound Power 106 dB(A)..............................

* Measured at maximum normal load conditions.

Must be purchased separately.

GRACO--APPROVED HYDRAULIC OIL

169236 5 Gallons (20 liters)

207428 1 Gallon (3.8 liters)

DANGER LABELS

The English language DANGER label shown on

page 4 is also on your sprayer. If you have painters

who do not read English, order one of the following

labels to apply to your sprayer. The drawing below

shows the best placement of these labels for good

visibility.

Order the labels directly from Graco, free of

charge. Toll Free: 1--800--328--0211

French 186956

Spanish 185961

German 186041

Greek 186045

Korean 186049

English 185593

Apply other

language here

7871b

23307616

Page 24

Graco Warranty

Graco warrants all equipment listed in this manual which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special extended or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repairor replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shallGraco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance or structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipmentwill be returned to the original purchaser transportation prepaid. If inspection of theequipmentdoes notdisclose anydefect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

Graco’ssole obligation and buyer’s sole remedyfor any breach of warranty shall be as setforth above. The buyer agrees that no other

remedy (including, but not limited to, incidentalor consequentialdamages for lost profits, lost sales,injury to person orproperty, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be broughtwithin two (2) years of the

date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE IN CONNECTION WITH ACCESSORIES, EQUIPMENT,MATERIALS OR COMPONENTS SOLD BUT

NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, gas engines,

switches,hose, etc.), are subject to the warranty,if any, of their manufacturer. Graco will provide purchaser with reasonableassistance

in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, s pecial or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The partiesacknowledge that they have required that the present document,as well as alldocuments, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport,directement ou indirectement, avec les procédures concernées.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty

Program”.

Graco Phone Number

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1--800--690--2894 Toll Free.

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents

Original instructions. This manual contains English. MM 307616

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

GRACO INC. AND SUBSIDIARIES P.O. BOX 1441 MINNEAPOLIS, MN 55440--1441 USA

Copyright 1983, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revised October 2014

30761624

Loading...

Loading...