Page 1

INSTRUCTIONS AND PARTS LIST

10

GALLON

STATIONARY MODEL

LESS WHEELS AND SRAKC

WITH MANUAL ELEVATOR

226-161 SERIES "A"

HAS MANIFOLD

WITH DUMP VALVE

PRESIDENT

WITH MANUAL ELEVATOR

226-163 SERIES"A"

HAS MANIFOLD

WITH DUMP VALVE

HYDRA-SPRAY

PORTABLE MODELS

WITH PNEUMATIC ELEVATOR

226-165 S£R1ES"A"

HAS FILTER

WITH DUMP VALVE

UNITS

226-167 SERtES"A"

HAS FILTER WITH DUMP

VALVE AND SURGE TANK

FORM:306-704

PUBL.SH£D: /-£/

TIP OF

CUSTOMERS CHOICE

r*

~ N.BT.

^ AIR INLET

MANUAL

ELEVATOR

I5“FT.

HOSE

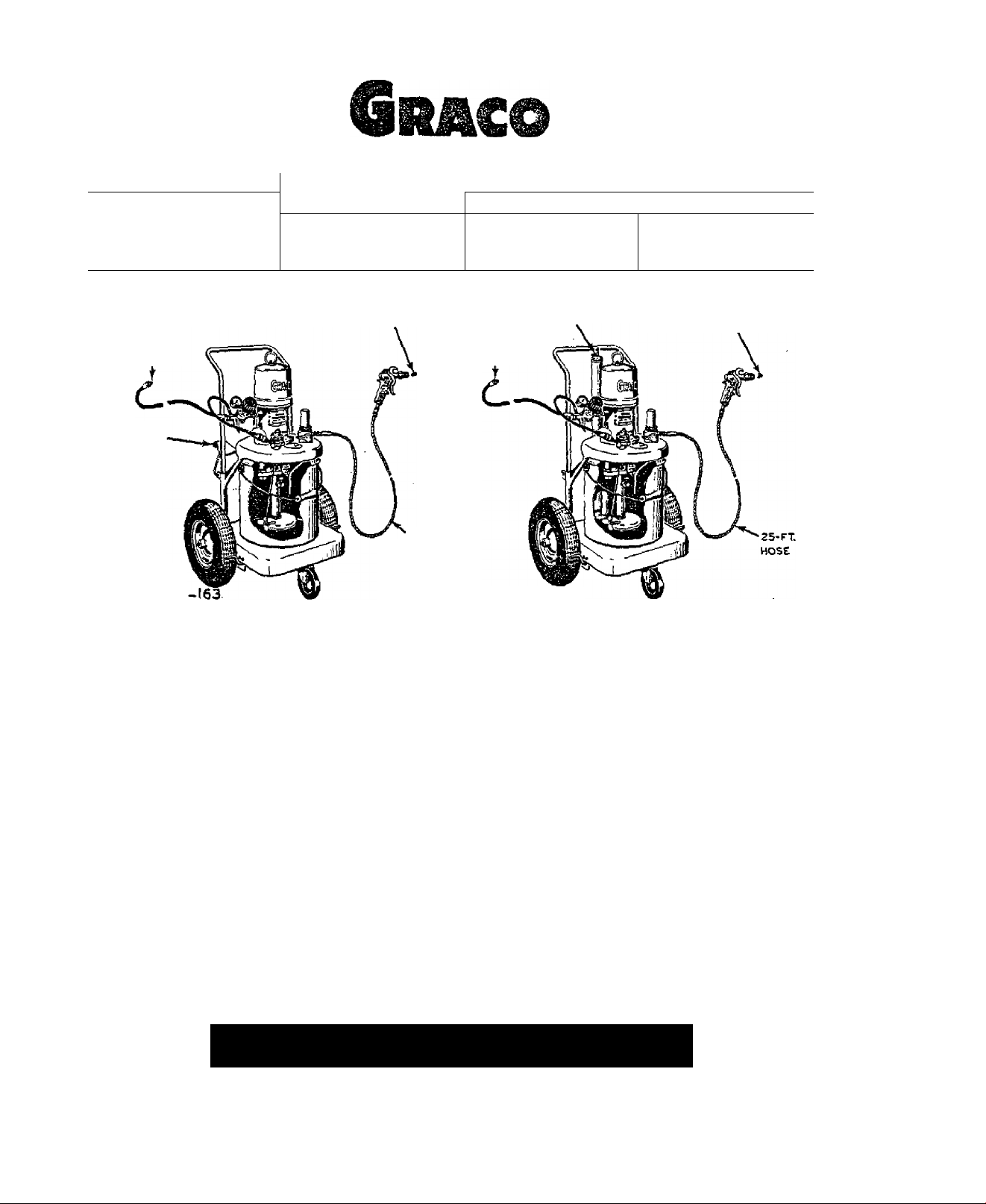

MODEL 226

ILLUSTRATED

DESCRIPTION

These Hydra-Spray Units apply light materi

als by utilizing HI&H HYDRAULIC PRESSURE THROUGH

A SMALL FLUID ORIFICE. The combination of high

fluid pressure and small orifice creates fine

material breakup without atomizing air. This

airless spraying system without heat was origi

nally pioneered and developed by Graco engineers

to improve the consistency and lower the costs

of coating applications. The portable, truckmounted Hydra-Spray units wheel directly to the

work, wherever the job site...in-plant or out

side, on rough terrain or in a remote area.

Works direct from original 1 to 10 gallon con

tainers. Provides fast color changing for short

run work, quick mobility for constant one-color

application.

Units utilize air press\ire to (l) operate

the pump which powers the transfer of material

to the spray tip, (2) drive the agitator that

thoroughly mixes and keeps material solids in

sprayable suspension and (3) power the pneu

matic elevator, of Models 226-165 and 226-167,

for fast, easy material container changing. No

air used to atomize the material...no pressure

on container...no possible aeration of material.

Special, air-powered, reciprocating type pump

PNEUMATIC

ELEVATOR

I"

^N.RT.

AIR INLET

MODEL 226-165

ILLUSTRATED

provides continuous-duty action, ’.dth equal pres

sure and volume delivery on both strokes. Pump

develops material pressure 28 times greeter than

the inbound air pressure. (For example: at 60 PSl

inbound air, the pump develops 1680 PSI material

pressure.)

Units are designed for high volumeprod

uction-type spraying of protective coating paints

and similar light materials, providing a heavy,

one coat application with almost complete elimi

nation of overspray. All units are equipped with

a material outlet manifold having a valve > for re

circulating material or dumping sludge. -.Also

manifold has an exrtra material outlet for addition

of a second spray gun. Models 226-165 and 226-167

include a filter kit, shipped loose, which can be

easily installed in manifold to filter the materi

al. Also Model 226-167 includes a surge tank,

shipped loose, that can be easily assembled to

manifold to eliminate material surge. NOTE: A

tungsten carbide spray tip of customers choice is

included in all units. The proper spray tip to be

used for a specific material should be detennined

by a test conducted by your local Graco Industrial

Distributor or by his recommendation from previous

experience with the same or similar material.

TIP OF

CUSTOMERS CHOICE

7

RETAlNlFOlii-UtU^REFERENtE

• MINNEAPOLIS T3, MINN.

facterji anuKha; NEW YORK {Loa| Iilind Citri, PHILADELPHIA. DETROIT. CHICAGO. ATLANTA, SAN FRANCISCO, HOUSTON "

Page 2

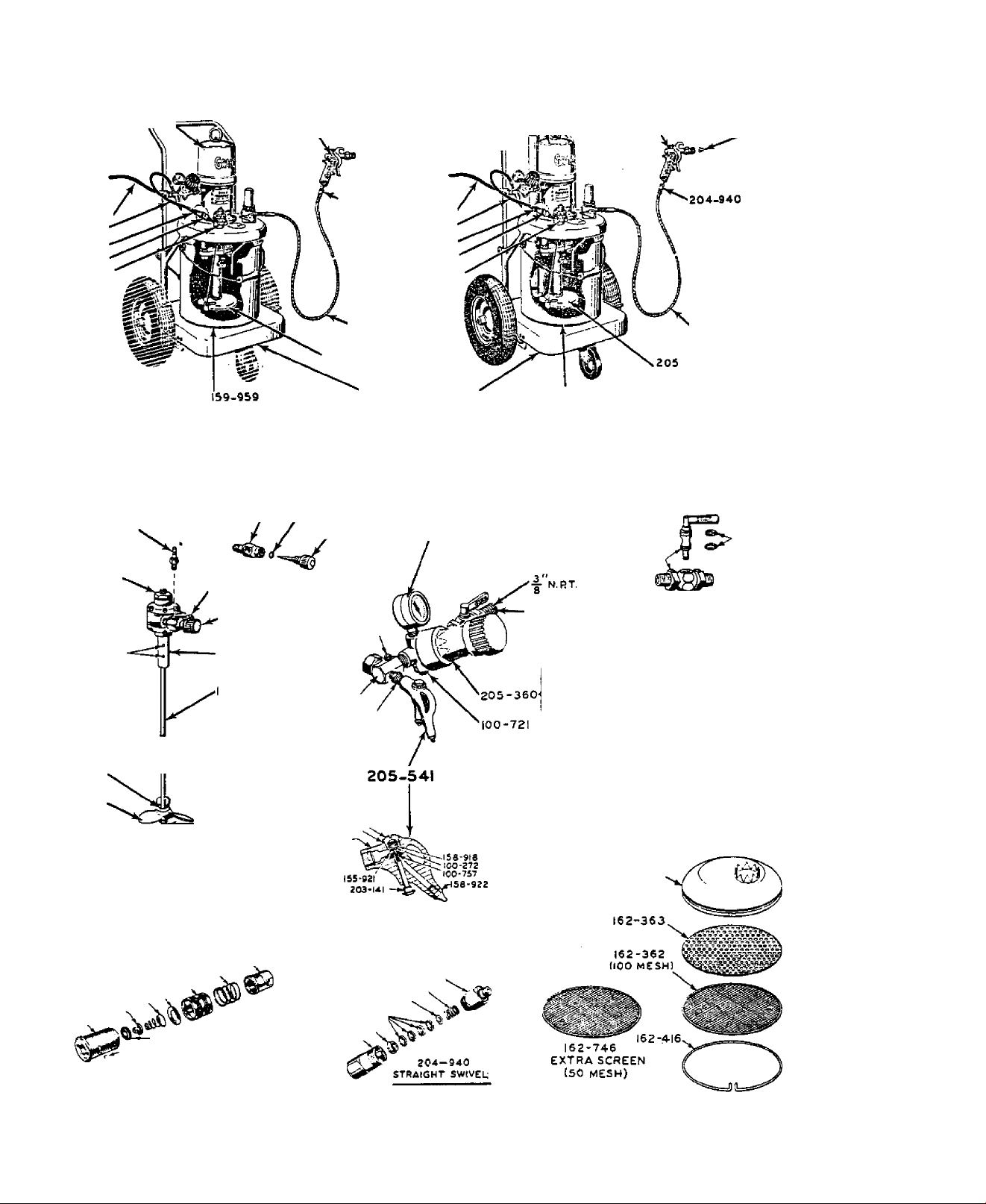

205-434 2S-I PUMP

f FOR BAHTS

\^epAHATE SHEET^

205-162

SPRAY GUN

f FOR PARTS see'.

I^sepahate sheets

TIP Of

customers

CHOICE

/

205-434 Z8-1 PUMP

(''for parts s-:e'\

Uepabate eheet_J

205-162

SPRAY GUN

( FOR PARTS SEE>

^separate sheev

TIP OF

CUSTOMERS

CHOICE

205-216

160-023

100-030

202-437

205-307

agitator

MODEL 236-161 SERIES "A"

(stationary less wheels and brake)

MODEL 2 26- 163 SERIES "A"

(with manual elevator)

157-367

101-687

100-002

I6I-4IS j,

205.526

161-411

64-179

STRAINER

164.700

/ 157-628

162-376

204-940

205-349

lISFT.l

205-306

205-507

100-403

151-519

205-216

160-023

100-030

202-437

205-307

agitator

TRUCK AND

elevator GROUP

101-180

STRAINER

159-959

MODEL 226-165 SERIES "A‘

MODEL 226-167 SERIES "A‘

(with PNEUMATIC elevator)

202-340

202-338-

FOR parts

SEE

SEPARATE

SHEET

202-338

AIR LINE PETCOCK

204-938

125 FT)

306

——157-244

___

157-245

M

----

137-241

^

----

101-02 I

160-015

y

I0I-I9S'

161-413

IS7-4S9

205 -307

AGITATOR

157-467

IS7-560

157-470

157-469

-157-558

-157-559

'■^157-460 202-437

AIR LINE COUPLER

100-346

100-133

IS7-S57

157-471

156-917

150-451 ‘

158-921

AIR BLOWER VALVE

I62-6S4,

157-894^

204-978-

150-522 ,

ISO-516 ■

tOI-368

164-170

157-898,

205-306

STRAINER

Page 3

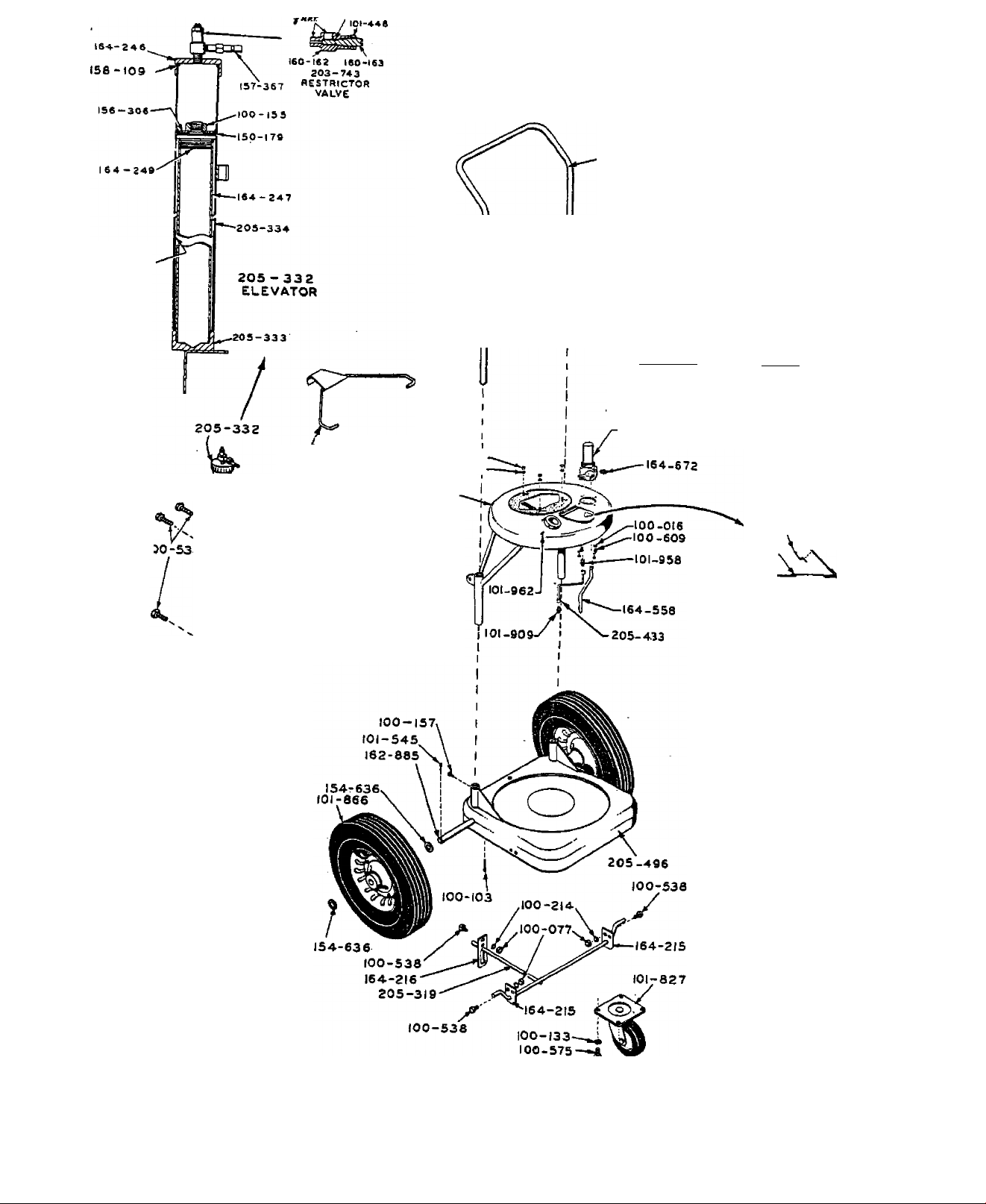

164-346

)57-eea

IS9-9a4

K a

AIR ELEVATOR

FOR MODELS 226-165

AND 226-167

g

^100-077

Si.

203-666

FOR MODELS 226-161

AND 226-163

100-214

100-077

I00-S38

100-214

205-497-

100-188

100-214

205-476

SURGE TANK

FOR MODEL

226-167

(SHIPPED LOOSE''

205 485 r‘’ARTS SEE

^°^"^^\^SEPABATE SHEEtJ

162-344

2Ö5-52’3

filter kit

FOR MODELS

226-165 t 226-167

(SHIPPED LOOSE)

101-706

31-706

lot-704

101-705

TRUCK

AND

ELEVATOR

GROUP

Page 4

This equipment has been carefully manufac

tured to exacting CHACO standards. It is war

ranted against defective materials and/or work

manship as set forth in the GRACO WARRANTT.

Excessive wear due to passage of abrasive or

corrosive materials through this equipment shall

not be construed as indication of defective parts

within the limitations of this warranty.

IMPORTANT NOTES

•*PTFE * material hose is expensive. HAHPLE

WITH Cakjs. GRACO WARRANTY does not cover abuse

such as sharp kinking, crimping or crushing.

Air supply hose 205-216 includes a static

wire to effectively ground the unit. If addi

tional air supply hose is required, it should

be of the same type.

PREPARATION FOR OPERATION

1, Remove contents from carton and connect

the wire-braided Dupont ’’PTFE*’ lined material

hose 205-3A9 (15') or 20A-yja ^25’) to nipple

161-672 protnidtng from material outlet manifold

205-485. Connect the end, without swivel 204-940

attached, to nipple 164-672. See Fig. 1. DO NOT

connect swivel 204-940, attached to other end of

this hose, to spray gun at this time. DO NOT USE

THREAD SEALER AT ANY SWIVEL CONNECTION.

AIR REQUIREMENTS

Air pressures required to operate pump range

from 20 to 100 p.s.i. CAUTION; Do not use more

than 100 lb. of air pressure to operate pump.

During continuous operation, at norTnal work

ing pressures and operating speeds, this unit will

reqviire actual air delivery of approximatelY ^

c.f.m. per gun plus 3 c.f.m. for continuous use of

agitator.

To provide reserve capacity for peak load

conditions compressor shovdd delivery 25% more air

than required for normal operation of all equip

ment vdiich It is to serve.

NOTE; Consumption of compressed air Is low.

since in this Hydra-Spray process air is not need

ed to atomise the paint.

before reaching unit. NOTE; A Graco air line

strainer 204-999 (accessory) may be purchased

separately for removing foreign matter from air

entering the unit. Attaches to air manifold

162-376 as shown in Fig. 2.

,205-216--^VpT

157-367

THESE ARE accessories

202-338

'^^^^205-360

104-038 125

FIG. I 305-307

HORIZONTAL (CLOSED».

NOTE: Check dump valve of manifold 205-485

...it should be closed. When closed, its knob

is in a horizontal position. Refer to Fig. 1.

2. For operation of a second spray gun

purchase these accessories separately...two (2)

high pressure material shutoff valves 205-583,

a second hose 205-349 (15') 204-938 (25*), a

second swivel 204-940, a second spray gun 205-162

and a second spray tip of customers choice. Re

move nipple 164-672 and plug from manifold

205-485, and qormect valves and hoses as shown

in Fig. 2. ' '

3. Attach one end of 15 foot air supply hose

205-216 to soiH-ce of air supply and screw other

end of hose into air manifold swivel adapter

162-376.'' Refer to Fig. 1. Male hose studs are

threaded ^ NPT. Install a master air valve

(drain or bleed type)in the air supply line in

such location that air can be turned on and off

OR

05-349115

205-583

NOTE: Models 226-163. 226-165 & 226-167 are

equipped with a brake—to set brakes push down

with foot on rod protruding from bracket attached

to back of truck base and guide rod into notch at

bottom of bracket.

4. If Model 226-161 or 226-163 with hand

operated elevator, lift up on elevator hanger and

hook over handle. NOTE: If elevator is difficult

to raise, apply a little grease to exterior svirfaces of handle ends.

If Model 226-165 or 226-I67 with air-operated

elevator. disconnect air line coupler 202-437,

attached to end of air hose 160-023, from air line

fitting in agitator 205-307 and connect to air

line fitting 157-367 atop elevator as shown in Fig.

1, With air admitted to unit, elevator will raise

unit and hold it there until air hose 160-023 Ls

disconnected. '

Page 5

5. Remove from base the 10 gallon pail pro

vided. Wipe clean its interior and potiT into it

material stirred and thinned to the proper sprayconsistency or place a smaller container of ma

terial inside the 10 gallon pail. Stir material

thoroughly making sure there is no heavy pigment

concentration or cake formed on the bottom of the

container* The pigments must be well dispersed to

prevent them from clogging the fluid intake

strainer 205-306 v4ien the pump is initially lower

ed into the container of material.

ROTBs For a small container, such as a one

gallon can, the material intake strainer must be

removed in order to get the lower pump housing and

the agitator propeller into the container.

6. Check the position of foot valve feet in

relation to the perforated plate 162-363 of pump

fluid intake strainer. When the plate and screen

are held in position by the retaining ring 162-416,

the feet of foot valve body must contact and sup

port the perforated plate 162-363 as shown in

Fig. 3*

should be used with spray tips having larger ori

fice openings.

7* Lower pump into material. If unit with

manual elevator, unhook hanger to lower. If unit

with pneumatle elevator, lower by disconnecting

air hose 160-023 from elevator air line fitting*

Refer to Fig. 1*

NOTE; The speed at which unit is elevated^

bv air, is set at factory. If adjustment is

necessary, loosen lock nut of air restrictor

valve 203-743 and turn restrictor screw clockwise

to decrease or cqunterolo^kwi^e to increase * Lock

screw in place with lock nut when adjustment is

completed. Air.restrictor valve 203-743 is locat

ed atop elevator tube. Refer to Fig. 1.

8, If unit includes a filter kit 205-523 or

a filter kit 205-523 and a surge taniT 205-4767

refer to illustrated instructions in separate

Form 306-696 for easy conversion of manifold

205-485 to a filter or a filter-surge chaaiber. .

9- Insert delivery end of material dispens

ing hose into a xiraste container. Start pump by

opening CM-OFF punro air petcock 202-338 and set

ting regulator 205-360 at 30 p.s.i. Refer Fig. I.

Allow pimip to operate until all traces of rust

inhibiting oil, with vrfiich pump was treated, is

removed. Stop pump and discard material pumped.

NOTE: If desired, the 100 mesh screen in

strainer 205-306 can be removed and replaced -with

the extra, more coarse 50 mesh screen 162-746 sup

plied. Refer to Fig. 3- This 50 mesh screen

IMPORTANT NOTES

1. For most satisfactory operating condi

tions, locate pump and material so that they will

not be subjected to temperatures below 65° F.

2. Do no.t attempt to spray materials con

taining hea-gy fillers, dirt or other coarse

particles> Coarse grind, coagulated, con-taminated and skinned materials that will not pass freely

through the openings in sice of screen or filters

being used, without clogging, can not be satis

factorily sprayed. Due to the extremely small

orifice diameter in spray tip through vdiich ma

terial must be forced under pressure, it is very

Impor-bant that particle's which could plug this

orifice are not present in the material to be

sprayed.

3. Daily, before starting to spray, remove

and clean filter, if used, of spray gun.

Paily. with air pressure shut off and

relieved, remove and clean screen in air line

s-fcrainer 204-999 (accessory), if used. Add

light oil to screen cavity in strainer nut. See

Fig. 4.

NOTE: If accessories have been added to

-unit for two gun operation, open material shutoff

valves 205-583 and insert ends of both hoses Into

-waste container before starting pump. Refer to

Fig. 2.

10. Connect swivel 204-940, at-tached to free

end of material dispensing hose, to spray gun

inlet.

OPERATION

5.. Dally or more often if experience indi

cates necessary. WITH PUMP DEACTIVATED AMD FILTER

DUMP VALVE OPEN TO RELIEVE MATERIAL PRESSURE, re

move and clean filter cartridge or screen, if

used. Refer to Fig. 1.

6. Dally, remove and clean screen in pump

material intake strainer 205-306. When replacing,

check to be sure that plate 162-363 is in contact

with feet of pwmp foot -valve. Refer to Fig. 3

7* When thinning material;cleaning filters,

screen, tips, etc.; changing types of material to

be sprayed or flushing unit; be sure to tise CLEAN

solvent of a type recommended b.y manufacturer of

material being sprayed. Use of the wrong solvent

may cause jelling or separation, of material oompo-

ents which could cause clogging of strainer,

filter and spray gun tip. DO NOT USE COMMON GUN

CLEANER.

Page 6

НОТЕ: If manufacturer of material does not reommend a specific type of solvent, check the comatability of the solvent to-be used for thinning

he material by dropping a single drop of the materi1 into a small container of the solvent. If the

laterial drop clouds or disperses readily, the sol-

■ent is compatible. If drop tends to string or

orm a ball, the solvent is not compatible and

.efinitely should not be used. •

AGITATION OF MATERIAL

Thorough agitation of material should be

lecomplished prior to Dumping material to spray

Agitation can best be obtained as follows ;

am

1. Snap air line coiçler 202-437 onto agi:ator air fitting and agitator will be energised,

lefer to Fig. 1.

2. Turn agitator air valve 205-528, two or

nore turns to the left to start agitator air

notor. Refer to Fig. 1. Speed of agitation

nay be adjusted to suit the particular viscosity

3f material used. NOTE: Excessive agitation

speed may cause vibration and foaming of material,

dse moderate agitation speeds at all times.

3. Open manifold dung) valve and start pump.

This permits pump circulate the material under

light load.

4" Lift hinged inspection plate and examine

progress of agitation through hole in cover. It

is extr^^maly impcirtant that all solids are put in

suspension and held there dbring the entire spray

operation.

5. Allow agitator to continuev operation .

hüe unit is supplying material to spray gun.

SUPPLYING MATERIAL TO GUN

1. Stop puag) and close manifold dump valve

iter material has been circulated sufficiently

jid before attempting to spray. When closed,

ïiob of dump valve is in a horizontal position.

inbound air pressure. Do not set higher than

100 p.B.i.

5- While spraying be sure at all times to

hold spray gun perpendicular (approx. 90“) to '

surface to be sprayed, with its spray tip 12 to

14 inches from surface or greater if the material

spray will cover satisfactorily. NOTE: Good

Hydra-Spray technique is very similar to con

ventional spraying with air, except for the

greater distance spray tip should be held from

work surface, the larger coating thickness pro

duced which results in less pattern overlapping

and the positive action used vdien triggering gun.

NOTE: Refer to the SERVICE DIAGNOSIS CHART

in this Instruction Sheet for assistance in lo

cating troubles which may occur during spraying.

Also refer to separate Instruction Sheets for

specific information pertaining to the spray gun,

pump, regulator and manifold or filter.

SAFETY PRECAUTIONS

The Ifydra-Spray equipment develops extremely

high material pressure which remains in the system

until relieved by shutting off the air to pump

and releasing the material pressure by opening

manifold dump valve. In operation, if the fine

high pressure stream of material released from

spray gun is allowed to come in direct contact

with the hand or any part of human body it could

penetrate the skin and cause physical harm.

HANDLE THE HYDRA-SPRAY GUN AS CAPTIOUSLY AS

YOU WOULD ANY GUN: LOADED CR UNLOADED. The fol

lowing safety precautions should be observed;

Never point gun directly at the face.

Never put the hand or fingers directly over

the spray tip. (Use of protective leather gloves

is recommended.)

Never place the tip or gun nozzle directly

in contact with any part of the body.

2. Open material shutoff valves 205-583

accessory), if used. Handles are parallel to

■alve body when open. Refer to Fig. 2*

3. Open ON-OFF pump air control petcock

102-338. With petcock open, manifold dump valve

losed and air regulator 205-360 set to control

ihe air pressure admitted, the pumping action of

lump is controlled by operation of spray gun.

iqueezing trigger of spray gun open automatically

(tarts pump operating, forcing material, under ^

iressure, from gun spray tip.

4* Adjust pump to minimum pressure required

;o obtain desired breakup and spray pattern of

aaterial. This setting will vary due to viscosity

daterial, orifice diameter and fan angle of spray

;ip. To increase air pressure to pump, turn ad

justing knob of regulator 205-360 clockwise and

pressure turn it counterclockwise.

JOTE: The amount of air pressure supplied to the

dump determines the pressure of the material

Torced through the orifice in spray tip. Pump

ievelops material pressure 28 times that of the

Always shut off air pressure to pump and re

lieve material pressure in system before attempt

ing to remove gun tip or screen and/or removing

gun for service.

Always remove tip from gun to clean it.

Always tighten threaded connections care

fully and securely, and handle hose carefully to

prevent leaks that could cause physical harm same

as pressurized stream coming from orifice in gun

tip.

Always be sure that the equipment supplying

the material to spray gun is properly grounded

to prevent sparking. The high velocity flow of

material through the spray tip may cause static

electricity to be developed. Use only metal

braid material dispensing hoses or static pro

tected hose. Also be sure to provide for the

proper grounding out of the compressor.

6

Page 7

PREVENTIVE MAINTENANCE

At least twice daily and during any lengthy

interruption of spraying, with material pressure

relievedi remove and clean gun spray tip and tip

filter in clean solvent of a type recommended by

manufacturer of the material being sprayed. Blowparts dry with air pressure. Also inmerse gun

nozale in clean solvent during shut down periods.

SHUTDOWN PROCEDURE

To maintain efficient operation of unit,

this shutdown procedTu:e at the completion of

each day’s spraying must be diligently followed:

1. Shut off air to pump by closing p-ump

ON-OFF air control petcock 202-338« See Fig. 1.

Handle is at right angle to petcock body vdien

closed.

2. Relieve material pressure in p\unp, hose

and spray gun by opening drump valve of manifold.

This will allow the material trapped in the system

to drain back into material container. After ma

terial has stopped draining, remove and clean

'SERVICE DIAGNOSIS'

filter cartridge or screen. If used. Close drain

valve.

3. Remove spray tip and filter, if used,

from spray gun. Immerse in clean recommended

type solvent and wash thoroughly with a fine

bristled brush. Using the air blower valve

205-5W- attached to air manifold 162-376, blow

air through tip from front to back and through

open end of filter. Refer to Fig. 1. Keep

spray gun forward end submerged in clean re

commended type solvent until ready to start

spraying again. NOTE: Do not remove the spray

gim from dispensing hose unless the unit is to be

completely flushed. Keeping unit fully charged

with material will minimize the necessity for

flushing unit.

CAUTION! Water based paints will recpiire a

final flushing with solvent DAILY and also oiling

of all external moving pump parts to prevent the

rusting of the wetted parts. To completely flush

unit follow the procedure outlined in subsequent

paragraph entitled FLUSHING UNIT.

TROUBLESOME SYMPTOMS

Pump fails to operate, no material discharge

Pump operates, but insufficient material discharge.

Excessive surge at spray gun..............................................................

Insufficient material breakup

Tails In spray pattern..........................................................................

Spray gun spitting

Too heavy a coating thickness

CHECK POINT N0.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

..............................................................................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

.............................................................

...........................................................

Restricted air supply line.

Insufficient air capacity.

Air valve closed or clogged.

Air regulator inoperative or set too low.

Air regulator set too high.

Material too viscous

Insvifficlent material in container.

Clogged material intake strainer.

Clogged material filter, tip or tip filter.

High flow rate—tip orifice too large.

Improper or worn spray gun tip.

Surge chamber inactive, if used.

Worn, damaged or obstructed gun parts.

Worn or obstructed pump valves or packings.

MAINTENANCE

IMPORTANT NOTES

1. Keep unit, mixing container, thinner.

solvent, and material CLEAN and free of foreign

particles i-ihich could clog strainer screens and/

or plug the small orifice in spray tip.

2. Keep lower pump Assembly filled with

and spray gun head immersed in recommended type

clean solvent after flushing unit and until

ready to start spraying again.

3. To relieve unit of unnecessarT pressure

vdien not in use, shut off air pressure to pump

.....................................

POSSIBLE CAUSES

and relieve material pressure in system by opening

dxunp valve of manifold or filter.

dicates necessary, drain filter or surge tank, re

move filter cartridge or screen, if used, and

clean. Before draining tank and removing filter

cartridge or screen, shut off air pressure to pump

and relieve matf>r-i.al pressure bv opening dump

valve. Replace cartridge or screen after cleaning

and close d-ump valve.

CHECK POINT NOS.

1- 3-A-6-8-9

2- 4-7-U

1-2-9-10-12

1-2-3-4-6-9-11

1-2^-6-H

13

5-10-11

4. Daily or more often if experience in

Page 8

5, Tf surge tank 205-/4.76 is being used with

out filter parts installed, it should be drained

as often as experience indicates necessary. Stop

pump and open dump valve. After material has

drained completely from tank, close dump valve.

6. Shut off air pressure to unit and relieve,

nrpssure in air line, before removing screen

156-967 in air linestrainer 204-999 (accessory if

used). Daily, clean this screen and at reassembly

add light oil to screen cavity in nut 156-944. Re

fer to Fig. 4.

FLUSHING UNIT

The freouency with which unit should be flush

ed depends upon type or types of material pumped,

general operating conditions, and usage of unit.

It Is wise to establish a regular flushing sched

ule. In some instances it may be desirable to

flush unit daily while in other cases less freouent

flushing may prove satisfactory. Unit must be

flushed at the end of each working week. Thorough

ly flush unit with thinner or solvent of type re

commended for use with the material, as follows;

1. Remove spray tip and g'jn filter cartridge.

If used, from spray gun and soak in clean recommend

ed .type solvent.

2. With air supply to unit turned on, dis

connect air hose to agitator and connect it to

elevator to raise unit or manually raise and

hook hanger over truck handle.

3. With pump air petcock 202-338 open, direct

spray gun into material container and start pump

operating by squeezing trigger of spray gun. Unit

v/ill pump air, forcing the material out of the

system back into container. When the air has

flushed out as much material as possible, stop pump

and open manifold dump valve. Drain excess materi

al from all loops in hose. After material has

stopped draining, close manifold dump valve.

4. Remove container of material from base and

position in its place a pail containing- approxi

mately 2 gallons of compatible solvent. Lower pump

into pail of solvent.

5. Set air to pump at approximately 20 p.s.i.,

direct gun to material container and trigger gun

to start pump. Pump will move the solvent, under

pressure through the system, flushing the internal

cavities of manifold and filter or surge tank. When

solvent appears at gun, stop pump, release pressure

in system and remove spray gun.

6. Remove spray gun from hose and thoroughly

clean in accordance with procedure outlined in

separate Instruction Sheet for the spray gun. Keep

spray gun head immersed in solvent until attached

to hose again.

7. Direct end of material hose into pail of

solvent and start pump by opening air line petcock

202-338. Allow thinner or solvent to circulate

through system and back into pail for a period of

10 to 15 minutes. Wash material from exterior of

lower immersion pump.

3. After thoroughly flushing unit stop pump

an.d connect material hose to spray gun. Squeeze

trigger of spray gun and open air line petcock to

start pump. Allow pump to operate long enough to

fill hose and spray gun with solvent. Keep unit

filled -ivlth solvent overnight or weekend until

ready to spray again.

9* Recirculate solvent for about 5 minutes

prior to charging unit with material.

10. Close spray gun and raise pump. Start

pump operating, by squeezing trigger of spray gun

and continue operating until most of solvent has

been blown out of system. Drain excess solvent '

from loops in hose and filter or surge chamber,

if used. After draining tank of filter or surge

chamber, close its dump valve.

11. Replace container of material upon base,

lower pump into container, connect air hose to

agitator and charge unit with properly mixed

material,

NOrS; When changing colors or incompatible

types of material, flush unit as described, HOW

EVER, a longer circulation period will necessarily

be required and in some cases a second flushing

using clean thinner or solvent may be necessary.

^Iso ii manufacturer of another type of material

to be sprayed recommends using a different type of

thinner or solvent, the thinner or solvent used in

the first flushing must be flushed out to eliminate

the possibility of separation or jelling of ma

terial components. The surge tank or tank of

manifold or filter should be removed and parts

thoroughly scrubbed clean. Surge tank is equipped

id-th a removable plug to facilitate cleaning.

AGITATOR

Agitator air motor 101-687 must be properly

oiled with a light air motor oil, whenever unit

is shutdown or is not to be operated for a period

of 8 ho\irs or more. All compressed air contains

some moisture and if air motor is not properly

lubricated before shutdown, rust may result. To

oil motor;

1. Remove oiler screw from air motor top.

2. Apply 3 to 4 drops of oil to oiler. ■

3. Replace oiler screw and run motor for

' about 1/2 minute.

Air motor should require no attention other

than to be oiled. However, if too heavy an oil

has been used or other improper oiling practices

have been followed gumming of rotor may result,

in-i4iich case air motor should be flushed as

follows;

OILER SCREW

161-415

\ ^

IS

8. , »J

FIG. 5

1. Remove exhaust muffler 161-415. Fill to

overflowing with kerosene. Replace muffler.

Page 9

' 2. Remove oiler from a±r motor top cap. See

?ig. 5. Fill oiler vdth kerosene. Replace oiler.

3. Allow a soaking period of 5 to 10 minutes,

then start air motor. Run motor slowly. After

smooth operation has been achieved and kerosene has

been hlown from exhaust, stop motor, remove oiler

screw and fill oiler with a light air motor oil.

NOTE: MASK N0 ATTEMPT TO DISASSEMBLE AIR

MOTCR. If it should need repair, contact your

nearest Grace Authorized Service Depot.

FLUID SHUTOFF VALVE

205-583 iACCESSORY)

BOOY-

562-833 SEAT

LDBRICATION

ORIVf PfNS

I62-B34 BALL

FIG.6

ELEVATOR

Worn ”CF* rings, ball seat or ball may cause

valve to fail to operate. If service is necessary,

shut off air supply, relieve fluid pressure and re

move valve. Place valve body in a vise and drive

the two pins out of holes in valve body. Remorve

valve cap firom body being careful not to turn cap

as this would shear off the locating pins in valve

body. See Fig. 6. Disassemble and replace any

worn or damaged parts. NOTE; With handle removed,

nO” ring 15L-741 can be beat removed by first re

moving ball 162-83L from body and then pushing

handle shaft down Into cavity in valve body.

REPAIRING HYDRA-SPRAY HOSE

Hvdra-Spray hose is constructed of Dupont

"PTFE^ inner lining tube with stainless steel

wire oraid outer cover. This hose is expensive

and should be handled with care. If hose should

become damaged it can be salvaged by assembling

couplings to the broken ends of hose sections.

Graco detachable and reusable couplings consist

of two parts, the female swivel stud 20Д.-937 and '

the sleeve 162-366, and are assembled upon hose

in the following manner;

MOTE: A hose coupling fixture Graco No.

F-20898 specifically designed to facilitate the

assembly of couplings upon this type of hose may

be obtained from factory. This fixture consists

of a two piece assembly block and an assembly

tool as shown in Fig. 7,

_ 1. Position the two piece assembly block on

hose with plain side of block toward hose end to

be cut and clamp in a vise as shown in Pig. 7.

Cut off with a fine tooth hand hack saw.

S and 9.

Every 2 to 6 weeks with elevator free of air

pressure, unscrew and remove cap l6iii-2ii.6. Fill

inner cavity of cup leather 150-179 'with SAE 20

oil. Replace cap. Raise elevator and lubricate

exposed surface of elevator guide tube I6i4.-2L7.

See parts illustration for location of parts.

PUMP. REGULATOR, SPRAY GUN AND

FILTER OR SURGE CHAMBER

Refer to separate sheet for maintenance in-

■ structions and parts identification.

3. Add a drop of oil to the end of the

wires, position assembly block with its grooved

side toward end of hose just cut and slide block

onto hose until it protrudes about 1/32 to I/I6

of an inch beyond the end of hose. See Fig. 8.

ASSEMlLf TOOL

OF FiXTUHL

if. sup the threaded end of sleeve 162-366

over assembly tool as shown In Fig. 8 and while

holding block in place on hose, insert end of tool

into hose and end of sleeve into groove.

OIL LIOHTlT

CAUTION-

DO NOT CRUSH

H05C

2. Remove hose from block and grip in vise

about 2 inches from end just cut. CAUTION; Do

not crush the hose—apply only enough pressure

on the vise jaws to hold while forcing the sleeve

onto hose.

5* While twisting sleeve back and forth

with a wrench apply body pressure to assembly

tool and as sleeve is forced onto hose allow

block to slide back. After about i inch of

hose is covered, remove the block and continue

to force sleeve onto the hose until end of hose

reaches the shoulder in sleeve. Refer to

Fig. 10.

Loading...

Loading...