Page 1

!NSTRUCTlONS

AND PARTS

LIST

FORM:306-704

10

GALLON

PRESIDENT

HYDRA-SPRAY

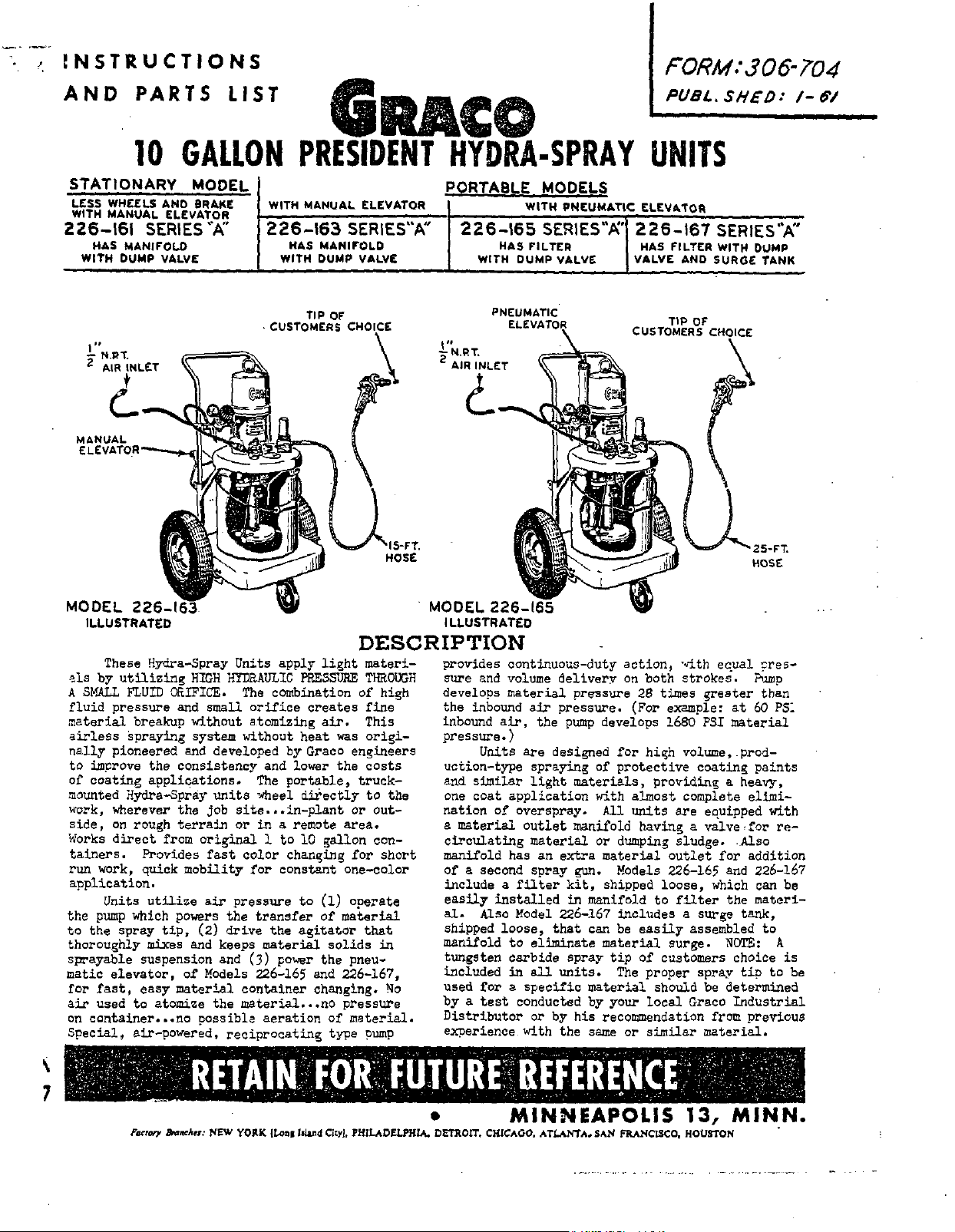

STATIONARY MODEL PORTABLE MODELS

LESS WHEELS AND BRAKE WITH MANUAL ELEVATOR

WlTN MANUAL ELEVATOR

226-161

HAS

WITH

SERIES"A"

MANIFOLD

DUMP VALVE

226-163

HAS MAHIrOLD

WITH DUMP VALVE

CUSTOMERS CHOLCE

TIP

OF

SERIES'A"

226-165

WlTN DUMP VALVE

WITH PHCUMATIC ELEVPITOR

SERIES"6'

HAS FILTER

PNEUMATIC

ELEVATOR

\

UNITS

226-167

HAS FILTER WITH

VALVE AND SURGE TANK

TIP

CUSTOMERS

SERIES"A"

DUMP

OF

CHOICE

ILLUSTRATED

DESCRIPTION

These Hdi-a-Sorav Units aoulv lieht materi-

+Is

by

A

fluid pressure

material breakup without

airless Spraying system without heat

nally pioneered and developed by Graco ensbeers

to

of

mounted HydraSpray units wheel directly to the

work, viterever the job

side,

Works

tainers. Rovides

run

application.

the pump wllich powers the transfer of material

to the spray

thoroughly mixes and keeps material solids

sgayable suspension and

matic elevator,

for

air

on

Special, air-powered, reciprocatinp type

utili& HkH-HYDilAULIC'

SMALL

FLUID

CEIFICE.

and

improve the consistency and lower the costs

coating applications. The portable, truck-

The cmbination

small

orifice creates fine-

atomizing

site

on roqh terrain

direct from original

work,

quick mobility for constant one-color

Units utuize

tip,

or

fast

color changing

air

pressure to

(2)

drive the agitator

(3)

of

fast,

easy material container changing.

used to atomise the material...no pressure

container...no possible aeration

Xodels 226-165 and 2.26-167,

...in-

in

a

remote area.

1

to

pomr

&SS&

air.

was

plant

10

gallon con-

(1)

the pneu-

of

TwtOuGH

of

hich

This

origi-

or

out-

for

short

operate

that

in

No

material.

pump

ILLUSTRATED

provides continuous-duty action,

sure and volume deliver7

develops material pressure

the

inbound

inbound air, the pump develops 1680

pressure.)

Units are desiged

uction-type spraying of protective coating paints

similar

and

one coat application with almost complete elimi-

nation

a

material outlet

circulating

manifold

of

a

second

include

eaSuy installed in manifold to filter

al.

Also

shipped loose, that can be easily assembled to

manifold to eliminate material surge.

tungsten carbide spray tip of customers choice

included

used for

by a test conducted by your local Graco Industrial

Distributor

experience with the

air

pressure.

light naterials, providins a heavy,

of

overspray.

manifold

material

has

an extra

spray

a

filter

Model

in

a

specific material should

qm.

kit,

226-167

all

units. The proper spray tip

or

by

his

on

(For

for

All

units

or

dumping sludge.

material outlet

Models 226-165 and 226-167

shipped loose, which can be

includes a surge tank,

recommendation from previous

same

or

.4th

both strokes. amp

28

times greater than

example:

hiqh volume,~prod-

havins a valve,for re-

similar

equal ?res-

at

PSI

material

are equipped

.Also

for

addition

the

NOTE:

be

determined

material.

60

PS:

with

materi-

A

is

to

be

..

Page 2

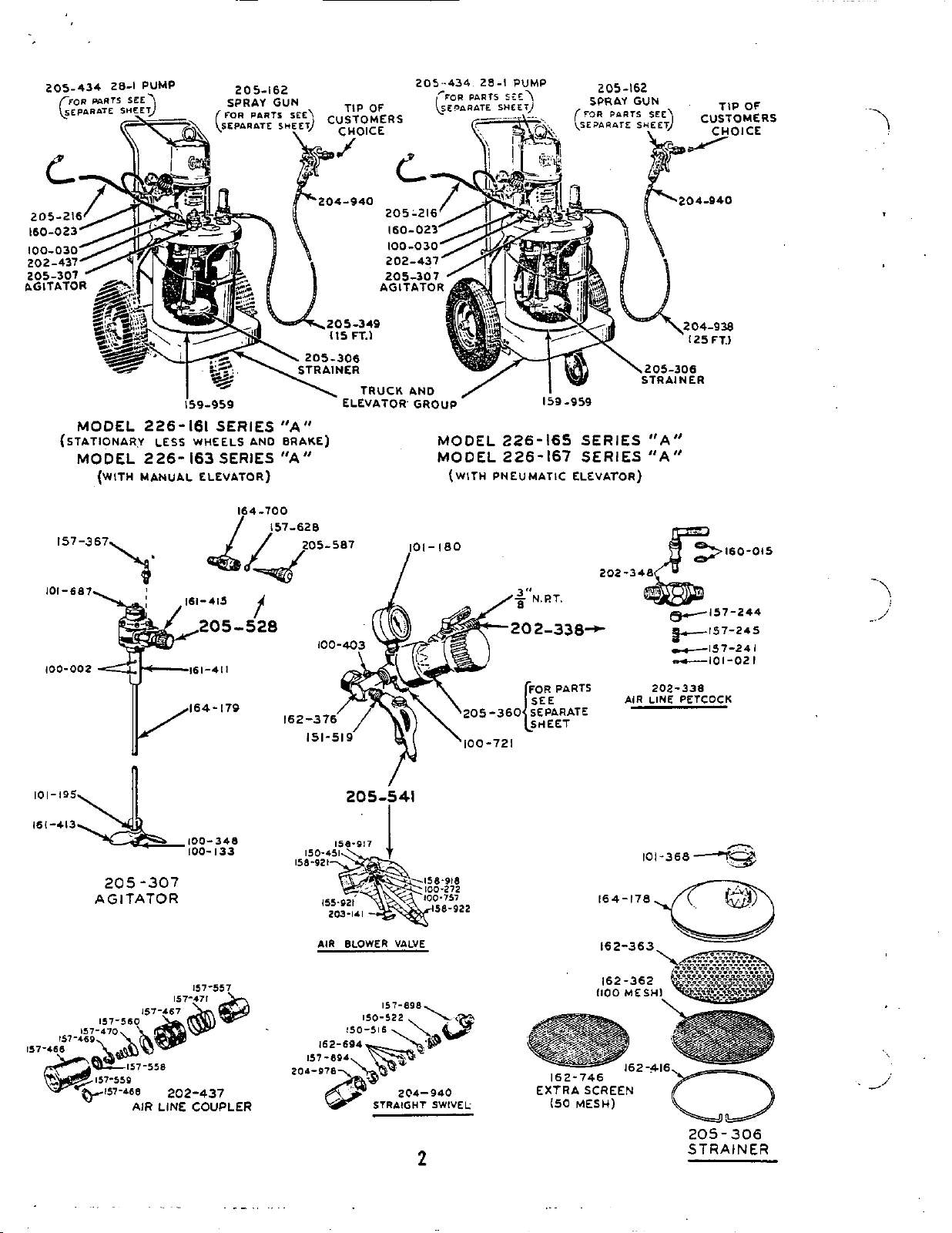

MODEL 226-161 SERIES

(STATIONARY LESS WHEELS AND BRAKE)

MODEL

(WITH

226-

MANUAL

163

SERIES

ELEVATOR)

"A"

"A"

164-700

MODEL 226-165 SERIES

MOOEL 226-167 SERIES

(WITH

PNEUMATIC

ELEVATOR)

"A"

"A"

157-367

AGITATOR

205

-301

157557

AIR

BLOWER VALVE

101-160

,a

./a

3''N.RT.

202-338'

202-3

-157-245

-157-241

nc101-021

202-338

blR LINE PETCOCK

I

AIR LINE COUPLER

.

204-978

204-940

STRbIGHT

SWIVEL

2

162-746

205-306

STRAINER

Page 3

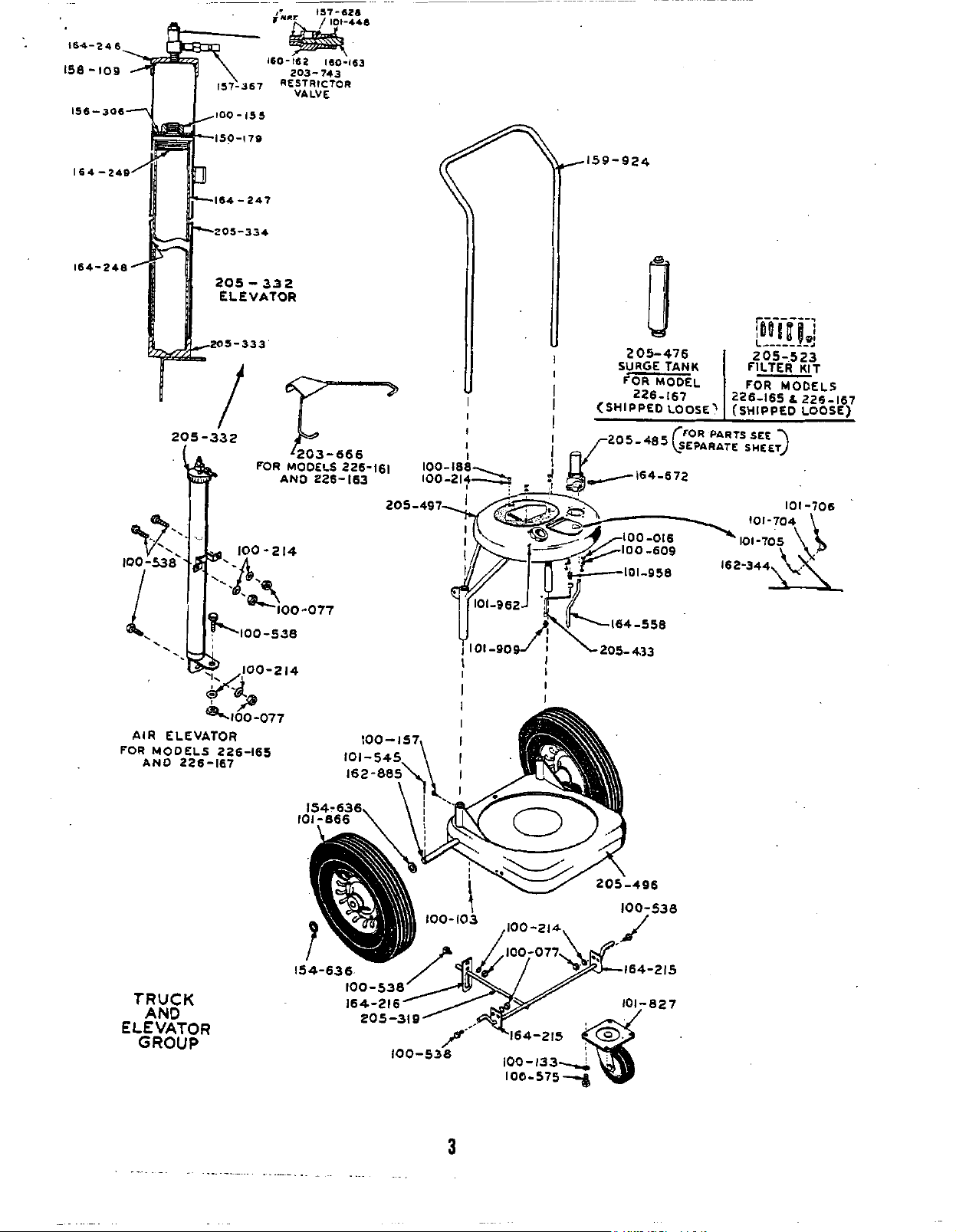

205-332

I

I

I

I

I

I

205-476

SURGE

<SHIPPED

TANK

FORMODEL

226-167

LOOSE\

TRUCK

AND

ELEVATOR

GROUP

3

Page 4

This

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

tured to exacting

ranted against defective

manship

Excessive

corrosive

not be construed

within the limitations of

equipment

as

set

wear

materials

has

GRACO

forth

in

due to passage of abrasive

through

as

indication of defective parts ing pressures and operating speeds.

IMPORTANT

. ..

been carefully manufacstandards.

materials

the

GRACO

It

is

and/or uork- from

WW-

WARRANTT.

or

this

equipment

this

warranty. require actual

shall

NOTES

Air

x)

than

100

h-ing

c.f.m.

agitator.

per

AIR

REQUIREMENTS

pressures required to owrate

to

1oo.s.i.

lb. of air Dressure to ODerate

continuous operation,

CAUTION:

Do

not

at

nod

this

air

gun

delivery of approxhatew

plus

3

c.f.m.

for

continuous

PmP

range

use

more

PWP.

m-k-

dt

use

h

of

"

WPPH

CARE.

such

as

Air

hire to effectively ground the

tional

be

air

of

the sane type.

materkl

GRACO

sharp

khking,

supply hose 205-216 Includes

hose

WARRANTI

does not cover abuse conditions compressor should delivery 25% me

crimping

is

expensive.

or

unit.

supply hose

is

required,

HANDLE

crushing.

a

static

If

addi-

it

should

To provide reserve capacity for

than

required

ment which

N&:

since

in

ed to atomize the

for

it

is

Consumtion of compressed

this Hvdra-Sorap process air

PREPARATION FOR OPERATION

1.

the hire-braided hpont " lined

hose 205-349 (15')

164-672 protruding

205-485. Connect the end, without swivel 2QL-9LO 162-376 as shorn

attached, to nipple 164-672. See

connect swivel 204-940, attached to other end

this hose, to spray

THREAD

Remove contents arton

or

204-938 (25' ) to nipple separately for removing foreign

from

material outlet manifold entering

gun

at

this

SEM

AT

ANY

WIVF,L

CONNECTION.

Fig.

time.

and

cokzct before reaching unit.

material

1.

DO

DO

NOT

NOT

of

USE

strainer

2OL-999 (accessory) may be purchased

the

205-216--

unit. Attaches to

normal

to

serve.

paint.

in

Fig.

I

e'

NBT

2

operation

NOTE:

2.

A

Graco

matter

air

*THESE

peak

Of

all

air

is

not need-

air

line

from

manifold

ARC

bCCtSSCUIU

load

equip-

is

lm,

air

air

NOTE:

...

it

is

in

2. For operation

purchase these accessories separately...two

high

pressure

a second hose 205-349 (15')

second swivel 2OL-940,

and

a

move nipple 16L-672 and plug from manFfold to raise, apply a little grease to exterior

M5-485, and qonnect valves and hoses

in

Fig.

3. Attaah one end

205-216

end

Of

162-376.' Refer to Fig.

threaded

(drain

Snch location

Check

dump

should be closed. When closed,

a

horizontil position. Refer to

valve of

of

material

second spray tip of

..

2.

to

smce of air Supply and screw other attached to end of air hose 160-023,

hose

into

shutoff valves 205-583.

a

second spray

of

air manifold swivel adapter fitting

1.

NET.

Install a

or

bleed typelin the air supply

that

air

can be turned

manifold

a

second sprav

or

2OL-938 (25'),

customers

15

foot air supply hose elevator, disconnect

205-485

its

knob

Fig.

1.

mn

(2)

~. .

.~

ep

choice.

as

a

205-162 merated elevator,

Re-

shorn faces of handle ends.

NOTE:

equipped with

vith foot

to back of truck base and guide rod into notch at

bottom of bracket.

L.

If

hook over handle.

If

Model 226-165

in

Kale hose studs are line fitting

master

air valve

line

on

and off

in

1.

With air admitted to unit, elevator will raise

unit and hold

disconnected.

Models 226-163. 226-165 & 226-167 are

a

brake-to set brakes push

on

rod protruding from bracket attached

Model 226-161

lift

NOTE:

or

air

agitator 205-307 and connect to

157-367.atop

it

there until air hose

or

226-163 with hand-

up

on

elevator hanger and

If

elevator

226-167 with air-operated

line coupler 202-417,

elevator as shown

4

is

from

160621

down

difficult

sur-

ab line

air

in

Fix.

is

Page 5

5.

vided. Wipe clean

material stirred

consistency

terial

thoroughly making sure there

concentration

container. The pigments must be well dispersed

prevent them from clogging the

strainer

ed into the container of material.

gallon can. the material intake strainer

removed

the agitator propellor into the container.

relation

fluid intake strainer. When

are held

the feet

port the perforated

Fig.

Remove from base the

its

and

or

place a smaller container

inside the

205-306

NOTE:

in

order to

6.

Check

to

in

of

10

or

cake formed

when

Fa

a

small

get

the

position

the perforated plate 162-363

position by the retaining ring 162-Ll6,

foot valve body

plats

3.

PUMP

FOOT

interior

thinned

gallon pail. Stir material

the

10

qallon pail pro-

and

pour

to

the proper spray

is

no

heavy pigcent

on

the bottom

fluid

pump

container, such

the

lower

of

the

must

162-361 as show

intake

is

initially lower-

pump housing and

Poot valve feet

plate and screen

contact and

<ntO

of

of

as

a one

must

of

ma-

pump

SUp-

in

it

the

be

in

should

fice openings.

manual elevator, unhook hanger to lower.

with

air hose 160-023

Refer to Fig.

to

bv air,

necessary, loosen lock

valve 203-743 and turn reetrictor screw'cloclcwise

to decrease

screw

completed. Airrestrictor valve 203-743

ed atop elevator tube. Refer to

a filter kit

refer to illustrated

Form 306-696

205485

ing hose into a waste container. Start pump

opening

ting regulator 205-360 at

Allow pump to operate until all traces

inhibiting

removed. Stop pump and discard.materia1 pumped.

be

used

with

spray

tips

havin$

7.

Lower pump into

Dneumatic elevator, loner by disconnecting

from

material.

elevator air line fitting.

larger

If

1.

NOTE:

8.

9.

The speed at which

is

set

at

factory.

nut

or

in

to a filter

ON-OFT

pg~e~c~o&+.~e to

place with lock

If

unit includes a filter kit

205-523

.~

for

easy conversion

Insert delivery end

pump

nut

and a surqe tank 205-476,

inrt.ruetions

or

a

filter-surp

air petcock 202-338 and set-

30

oil,

with which pump

unit

If

of

is

adjustment

air

restrictor

&rcase.

when adjustment

1.

Fig.

in

senarate

-~

~.

of

manifold

chkaher.

of

material dispens-

p.s.i.

was

Refer

treated,

ori-

unit

with

elevated,

is

Lock

is

is

locat-

205-521

'~~

-

~"

by

Fie

of

rust

is

or

1.

FIG.3

NCrPE:

strainer 205-306 can be removed and reulaced

the extra, more coarse

plied. Refer to Fig.

If

desired, the

-

100

mesh screen

50

mesh screen i62-746 sup-

3.

This

50

mesh

screen

in

with

OPERATION

IMPORTANT

1.

For most satisfactory operating conditions, locate pump and

not

be

sub,iected to temperatures below 65" F.

2.

taininq

particles. Coarse gsind, coagulated, contaminat-

ed and skinned

through

being used, without clogging, can not

factorily sprayed.

OrVice diameter

terial

important that particle's which could plug this

orifice are not present

Sprayed.

and clean filter,

relieved, remove

strainer

light

Fig.

Do no.t attemut to surav materials con-

heaw fillers.

dirt

materials

the openings

in

Due

in

must

be forced under pressure,

3.

Dailp,

4.

&l~,

20L-959

oil

to screen cavity

spray tip through which

before starting to spray, remove

if

used,

wit> air pressure

and

clean screen

(accessol-g),

4.

NOTES

material

that

size

to

in

so

or

other coame

vill

of screen

the extremely

the

material to

of

spray

if

used.

in

strainer nut. See

that thev

not pass freely

or

filters

be

satis-

small

ma-

it

is

very

be

gun.

shut

off

air

and

line

Add

in

NOTE:

unit

for

valves 205-583 and

waste container before starting pump. Refer to

Fin.

2.

.-

10.

end

of

,

inlet

rrill

5..

cates necessary,

"P

VAL'?

move and clean filter cartridge

used. Refer

6.

material

check to be

with feet

7.

screen, tips,

be sprayed

solvent of a twe rec&mended

material beme snrayed. Use of the

may

cause

ents which-could-cause clogging

filter and spray

CLEA"JER.

If

accessories have been added to

two

gun

operation, open material shutoff

insert

Connect swivel 204-940, attached to free

material dispensins hose;

Dailv

or

more often

WITH

OmN

TO

RELEEVE

ends

if

PLMP

DEACTIVATED

MATERIAL

of

to

emerience

or

to

Fig.

1.

w,

intake strainer 205-306. men replacing,

When

remove and clean screen

sure

of

jellinn

that plate 162-363

pump foot

thinning materia1;cleaning filters,

etc.; changing types of material to

or

flushing unit; be sure to

valve.

or

separation of

pn

tip.

Refer to Fig. 3.

bv

manufacturer

of

W

NOT

5

both hoses into

spray

gun

Ldi-

AND

PRESSRE,

screen,

is

wrong

material

strainer,

USE

FILTER

if

in

pump

in

contact

we

CLEAW

solvent

compo-

COMMCN

re-

Of

CLW

Page 6

Nm:

0-nd a specific type

atability

he material by dropping a single drop

1

into a

laterial drop clouds

.ent

is

'orm

a ball, the solvent

.efinitely should not be used.

Thorouah agitation of material should be

lccomolished prior to

E.

1.

;ator

lefer to Fig.

nore turns to the left to

notor. Refer to Fig.

nay be adjusted to

,P

material used.

speed may cause vibration and foaming

he moderate agitation speeds

This

light

progress

is

extremely important that

suspension and held there dbring the entire spray

operation.

5.

hile unit

1.

.fter material has been circulated sufficiently

nd before attempting to spray. When closed,

nob

of

If

manufacturer

of

the solvent to.be used

small

container

or

compatible.

If

AGITATION

Agitation can best be obtained

Snap

air

line coupler

air

2.

fitting

Wn

and agitator

1.

agitator

suit

N.WTE:

3.

Open

manifold dump valve and

permits pump circulate the material under

of

material does not re-

of

solvent, check the com-

of

".he solvent.

disperses readily, the

drop tends to string

is

not compatible

OF

MATERIAL

~umpinn

air

1.

material to soray

valve

start

Speed

the particular viscosity

Excessive agitation

at

for

as

202437

WFU

be

x)5-528,

agitator

of

agitation

all

thinning

of

the

If

and

follows:

onto agi-

energized.

t'm

air

of

material.

times.

start

or

pump.

load.

1.

Lift

hinped inspection plate and examine

of

agitaiion through hie

all

Allow

agitator to continua operation

is

supplying

material

SUPPLYING MATERtAL

Stop pump and close manifold dump valve

dump valve

is

in

a

horizontal position.

in

cover.

solids are

to spray

TO

GUN

DUt

gun.

materi-

the

sol-

or

It

in

inbound air pressure.

100

0.s.i.

5.

hold spray

surface to be sprayed, with

U

spray

Hydra-Spray technique

ventional spraying with air, except

greater distance spray tip should be held

work surface, the

duced which results

and the positive action used when triggering gun.

in this Instruction Sheet

cating troubles which may occur during spraying.

Also

spec'ific information pertaining to the spray

pump, regulator and manifold

While spraying be sure at

gun

perpendicular (approx.

inches

from

will

NOTE:

refer to separate Instruction Sheets

surface

cover satisfactorilg. NOTE: Good

Refer to the

Do

not

set

hieher than

all

its

greater

similar

spray tip

if

or

is

very

for

larger

coatinq thichss pro-

in

less pattern overlapping

SERVTCE

for

DIAGNOSIS

assistance

or

filter.

times to

90")

12

the

material

to

con-

the

from

in

for

to

to

CHART

10-

gun,

SAFETY PRECAUTIONS

The Hydra-Spray equipment develops extremely

high

material

until relieved by shutting off the

and releasing the material pressure by opening

manifold dump valve.

high pressure stream

spray

gun

with the hand

penetrate the

HANDLE

YOU

WULU

lowing safety precautions should be observed:

a

Nevar

the spray tip. (Use

is

recommended.)

Never place

in contact with

pressure which

is

allowed to come

or

any

skin

and cause physical harm.

THE

HYDFA-SPRAY

ANYGUN:

point

put the hand

gun

the

any

LO-

part

remains

In

operation,

of

material released from

in

part

of

human body

GUN

OR

UNLOADED.

directly at the face.

or

fingers directly over

of

protective leather gloves

tip

or

gun

of

the body.

in

the system

air

to pump

if

the fine

direct contact

it

AS

CAUTIOUSLY

The

nozzle directly

could

AS

fol-

2.

@en

accessory),

.alve body when open. Refer

3.

92-38.

:losed

-

.he

mmp

iqueezing trigger

itarts

ressure, from

and

air

is

pump operating, forcing material, under

4.

;o

obtain desired breakup and spray pattern

naterial.

naterial,orFfice diameter and fan angle

;ip.

TO

justing knob

:o

iecrgaze pressure turn

JOTE:

1ump

'orced through the orifice

levelops material pressure

The amount

determines

material

if

used. Handles are parallel to

open ON-OFF

With petcock open, mifold dumu valve

air

pressure admitted, the pumping action of

controlled by operation

regulator

gun

Adjust pump to pressure required

This

setting

increase air pressure to pump, turn

of

regulator

the

shutoff valves

pump

air

205-360

of

spray

spray tip.

will

205-360

it

of

air

pressure supplied to the

pressure

205-583

to

Fig.

2.

control petcock

set to control

of

spray

gun

open automatically

vary due to viscosity

clocMse and

gagniegc&o+&e.

of

the material

in

spray tip. Pmp

28

times that

gun.

of

of

of

spray

ad-

the

-

lieve material pressure

ing

to

gun

for

a

a

fully

prevent leaks

as pressurized stream

tip.

Always

the material'to spray

to prevent sparking. The high velocity

material through the spray tip may cause static

electricity to be developed. Use

braid

material dispensing hoses

tected hose.

proper grounding out

shut

off

air pressure to pump and re-

in

remove

and

gun

tip

service.

remove tip from

tighten threaded connections care-

securely, and handle hose carefully to

that

could cause physical harm same

be sure that the equipment supplying

Also

be

of

system before attempt-

or

screen and/or removing

gun

to clean

COD~Q

gun

sure

fiom

orifice

is

properly grounded

only

or

to provide

the compressor.

static pro-

for

flow

metal

6

..

it.

in

the

gun

of

Page 7

PREVENTIVE MAINTENANCE

At

least twice daily and durine any lenethy:

of

interruption

relieved: remove and clean

filter

manufacturer

parts

nozzle

~.

dry

in

~ ~ ~~

in

sprayinq,

clean

solvent

of the material beine smayed. Blow

with

air

clean

pressure.

solvent during shut

with

material

gun

spray tip and tip

of

a

type recommended by

_.

Also

kerse

down

pressure

.

gun

periods.

SHUTDOWN PROCEDURE

To

maintain

this

shutdown procedure

day's spraying must be diligently followed:

each

1.

ON-OFF

Handle

closed.

and spray

This

to

terial has stopped draining, remwe and clean

Shut off air to pump

air

is

at right angle to petcock body when

2.

Relieve material pressure in

gun

will

drain

allow

back into material container.

efficient operation of unit,

at the completion

by

control petcock

by

opening

the material trapped in the system

drump

closing pump

202-338.

valve of -ifold.

See Fig.

pump,

of

After

filter cartridge

valve.

3.

Remove spray tip and filter,

i'rom

spray

type solvent and

bristled brush.

205-541

air through tip

open end

spray

cotmuended

spraying again.

em

from dispensine hose unless the unit

completely flushed. Keeping

with material

1.

flushing

gun.

attached to air manifold

of

forward end submerged

gun

type

..

unit.

m:

hose , final flushing with solvent

of

all external moving pump

rusting

unit

ma-

follow

paragraph entitled

of

or

screen,

Immerse

wash

Using the air blower valve

from

filter.

solvent

NOTE:

will

Water based paints

the wetted parts. To completely flush

the procedure outlined

in

thoroughly with a fine

front to back and through

Refer to Fig.

until ready

Do

not remove the swaq

minimize~the

FLUSHINC

if

used. Close

clean

recornended

162-376,

1.

in

&&

to

unit

fully

necessity for

will

DAILY

and also

parts

to prevent the

in

UNIT.

drain

if

used,

blov

Keep

re-

start

is

to be

charged

requke a

Oiling

subsequent

-SERVICE

TROUBLESOME

Fump

fails

Pump operates, but insufficient material discharge.......

Excessive surge

Insufficient material breakup..

Tails

Spray

Too

heavy a coating thic.ess

CHECK

to operate,

at

in

spray pattern............

gun

spitting.............

POINT

NO.

l........

2

........

3........

L........

5........

6

........

7........

e........

9........

lo........

ll........

12........

l?........

U......,.

no

material

spray

.............................

gun

............................

mssmm

Restricted

Insufficient air capacity.

Air

valve closed

Air

regulator inoperative

Air

regllator set too high.

Material too viscous

Insufficient

Clogged materid intake strainer.

Clogged material filter, tip

Hish flow rate-tip orifice too large.

Improper

Surge chamber inactive,

Worn,

Worn

ak.

material

or

worn

damaged

or

obstructed pump valves

DIAGNOSIS

sIMPpOM.5

discharge.

..........................

.......................

..........................

CAUSES

supply line.

or

clogged.

in

spray

gun

or

obstructed

if

.............

or

set too

container.

or

tip filter.

tip.

used.

gun

parts.

or

packings.

low.

CHECK

POINT

1-3-4-6-6-9

2-4-7-Y,

1-2-9-10-12

1-2-3-4-6-9-11

1-24-6-ll

13

5-10-11

NOS.

-

MAINTENANCE

IMPORTANT NOTES

1.

solvent. and material

particles rbich could clog strainer screens andl

or

and smav

clean

ready to

when not in use, shut

Keev unit, mixine container. thinner,

plug the small orifice

2.

Keep lower

head immersed

mn

solvent after

start

sprayine again.

-3.

TO

reliive-unit

CLEAV

and free

in

spray tip.

vump

Assembl-f filled nith

in

flushin4

off

recommended type

unit and until

Of

unnecessary pressure

air pressure to pump

of

foreisn

and relieve material pressure

dump valve

dicates necessar , drain filter

more

~

and close dump valve.

4.

Daily

filter

of

manifold

or

cart:idne

more often

7

..

....................

or

or

in

filter.

if

screen.

system by opening

experience

or

surge tank, re-

if

used, and

in-

Page 8

5.

If

out

filter

as often as experience indicates necessary. Stop

pump and open dump valve. After material has

drained completely

6.

cressure

156-967

llsed). Daily,

edd

light oil to screen cavity

fer to Fig.

suree tank

Darts

Shut off air pressure to unit and relieve

in

air line, before removins screen 9. Eecirculate solvent

in

air

line

clean

L.

205-L76

installed,

from

tank, close dump valve.

strainer 20k-999 (accessory

this screen and at reassembly

is

beine used with- trigger of spray

it

should be drained

in

nut 156-944. Re-

if

FLUSHING UNIT

The frequency vith which unit should be flush-

ed deoends upon

generil operating conditions, and usage of unit.

It

is

wi5e to establish a re&= flushing scheU-

In

ule.

flush unit dailv while

~~ ~~ ~~~~~

flushing may prbve satisfactory. unit

flushed

17

commended for use with the material,

if

ed

.type

connect ak'hose to agitator and connect

elevator to raise unit

hook hanger over truck ha.ndle. manifold

spray

operatink by squeezing trigger of spray

rrill

system

flushed Out as much Daterial as possible, Stop

and open manifold dump valve.

a1

stopped draining, close manifold dump valve.

position

mately

into pail of solvent.

direct

to

pressure through the system, flushing the internal

cavities of manifold and filter

solvent appears at

in

clean

separate Instruction Sheet for the spray

spray

to hose again.

solvent and

202-338.

through system and back into pail

10

lower immersion pump.

aP.d connect material hose to spray

some instances

at

flush

unit with thinner

1.

Remove Spray tip and

used,

from

solvent.

2.

With

3.

With

gun

pump air, forcing the material out

back into container. When the

from

all

L.

Remove container

in

2

gallons'

5.

Set air to pump at approxhately

gun

start

pump.

system and remove spray

6.

Remove spray

in

accordance with procedure outlined in

gun

7.

Direct end

to

15

minutes. Wash

8.

After thoroughly flushing unit stop pump

type

or

types

of

material pumped, chamber, close

it

may be desirable to

in

other cases less freouent

must2

the end of each wurkine

or

spray

Sun

and

soak

air

SUPPlY

PmP

into

material container and

loops

in

to

unit

or

manually

air petcock

hose. After material has

of

its

dace a pail containine. approxi-

of

comGtible solvent: Loxer pump

to material container and trigger

Runp

will

move the solvent, under

gun,

stop

ppn.

gun

from

head immersed

start

Allow

thinner

in

solvent until attached

of

material hose into pail of

pump by opening air line petcock

or

solvent to circulate

material

week.

solvent

glm

202-338

Drain

material from base and

pump,

hose and thorou5hly

of

as

follows:

filter cartridge, using thinner oi'solvent may be necessary.

in

clean recommend-

turned

or

for

from

On,

raise and

open, direct Tvith a removable

start

air

excess materi-

surge tank. When

release pressure

a period

exterior of

gun.

Thorough-

type re-

dis-

it

to

pump

gun.

Unit

of

the

has Agitator air motor 101-687

Pump

20

p.s.i.,

gun

gun.

Keep

of

Squeeze overflowing with kerosene.

'gun

start

pump.

fill

hose and spray qn with solvent.

filled with solvent OVerniQht

readv to soray aeain.

,

Pior to char&% anit with material.

10.

operating, by squeezing trigger of spray

and continue ooeratinn until most

been blown

from loops

if

used. After draining tank of

11.

lower pump into container, connect

agitator and charge unit with properly mixed

material.

NOTE:

tmes of material, flush

EVER,

a

be required-and

-

Also

if

to be sprayed recommends usins

thinner

the

first

the possibility of separation

terial components. The sur3e tank

thoroughly scrubbed clean. Surge

Allow

Close Spray

out

in

hose and fnter

Replace container of material upon base,

When chansins colors

lonaer circulation oeriod

manufacturer of another

or

solvent, the thinner

flushing

or

filter should be removed and par.ts

and open air

pump

to operate long enough

gun

and raise pump. Start

of

sysiem.

its

dump valve.

Drain excess solvent

unit

in

some casks a second flushing

must

be flushed out to eliminate

plur:

to

facilitate

line

or

breekend until

for

about 5 minutes

of

solvent has

or

surge chamber.

filier

air

or

incompatible

as described,

will

type

of

a

different trpe

or

solvent used

or

jelling of

or

tank

cleaning.

AGITATOR

must

be properly

ofled with a light

is

shutdorm

Of

8

hours

some moisture and

lubricated before shutdown,

oil

motor:

1.

2.

3.

Air

than to be oiled. However,

has been used

have been followed

imwhich case

follows:

1.

or

or

Remove oiler screw from air motor top.

Apply 3 to

Replace oiler screw and run motor

about

motor should require

161-41

Remove exhaust muffler

air

motor

oil,

whenever

is

not to

more.

if

1/2

minute.

or

other improper oiling practices

air

motor should be flushed

be operated

All

compressed air oontains

air

motor

is

not

rust

may

L

droos

of oil to oiler.

no

attention other

if

too heavy an oil

guming

FIG.

of rotor

OILER

5

for

~ ~ .~

may

SCREW

161-415.

~~~l~~~

muffler.

a

petcock to

to

~~~p

unit

gun

~ ~~ ~~

or

sur&

hose to

HOW-

necessarilv

-

material

of

in

ma-

tank of

is

equipped

a

period

nrouerlv

.-~~

result." To

for

result,

as

Fill to

.,

Page 9

'

PTFEPTFEPTFE

2.

Remove

5.

3.

Fill

dllow a

,

>.

Pig.

.

then start ab motor.

smooth operation has been achieved

been

blown

screw and

NOTE:

MUl'a.

If

oiler from

oiler

with

soaking

from

a*haUSt. stop

fFu

oiler with a light

MAgE

NO

ATPMPT

air

motor top cap. See

kerosene. Replace oiler.

period of, 5 to

Run

motor

slowly.

and

LUOtOr,

M

DISASSMBLB

kerosene

remove ouer

air

motor

it should need repab, contact

10

minutes,

After

oil.

ADl

pour

nearest Graco Authorized %mice Depot.

FLUID SHUTOFF VALVE

205-583

Worn

"0"

rings,

valve to fail to operate.

air

shut off

supply, relieve

(ACCESSORY\

ball

seat

If

or

ball

sesvice

fluid

pressure

may

cause

is

necessary,

and

move valve. Place valve body in a vise and drive

in

valve

the two pina out of holes

from

valve cap

body

being

careful not to

body.

as this would shear off the locating pins in

body.

worn

"On

moving

handle shaft down

See

Fig.

6.

or

damaged parts. NOTE:

ring

15L,-7lJ

ball

162-831.

Disassemble and replace

can be best removed

from

intb

body

cavity in valve

With

and then pushing

Runwe

turn cap

valve

any

handle removed,

by

first re-

body'.

has

LUERICATION

pressure,

re-

inner carity of cup leather

oil.

exposed surface of elevator guide tube

See parts illustration for location of parts.

structions and parts identification.

..

fIG.6

ELEVATOR

2

Every

to 6 weeks

unscrew

Replace cap. Raise elevator

PUMP. REGULATOR,

FILTER OR SURGE CHAMBER

Refer to separate sheet

with

and

remove cap

elevator free

&-ab.

150-179

SPRAY

for

maintenance

of

Fill

vith

SdE

and

lubricate

1&-7A7.

GUN AND

air

20

in-

REPAIRING HYDRA-SPRAY HOSE

dra-Spray hose

" inner

wire braid

lining

Outer

and should be handled with care.

becane damaged it can be salvaged

Couplings to

the

Graco detachable

Of two parts. the female Mvel stud

the sleeve

162-366.

in the following

NUTE:

F-20898

A hose coupling fixture Graco

specifically designed to facilitate the

assembly of couplbgs upon this tppe of hose

be obtained

from

of a thu piece assembly block and

as

shown

tool

1.

hose

With

be cut

and

in

Position the two piece assembly block on.

plain side of block

clamp

Cut off With a fine tooth hand

is

constructed of tiupont

tube with stainless steal

CWer. This hose

broken

and

ends

reusable couplings consist

is

exoensive

If

hose should

by

of

assembling

hose sections.

201.-937

and

and are assembled upon hose

manner:

No.

factory. This fixture consists

may

an

assembly

Fig.

7,

8

and

.

in

a dse

9.

toward hose end to holding block

as

shown

in

Fig.

7.

hack saw.

3. Add a drop of oil to the end

vires, position assembly.block

vith

of

Its

the

groovad

side toward end of hose just cut and slide block

onto hose until

an

of

. . ~

,jvW

inch beyond the end of hose. See

ASSEMW

no.

4.

ap the threaded e.nd

ass&ly twl

or

rmrunc

F-20198

protrudes about

moL

as

shown

in

in

place

on

hose, insert end of tool

1/32

to

Fig.

CIUIION-

DO

NOT

CRUSH

HO5L

of

sleeve 162-366

Fig. 8 and while

it

into hose and end of sleeve into groove.

1/16

8.

2.

about

2

inches

not crush the hose-apply

Remove hose

from

from

block

end just cut.

only

and

grip

In

CAUTION:

vise

00

enough pressure

on the viae jaws to hold while forcing the sleeve

onto hose.

9

5.

While twisting sleeve

vith a wrench apply

as

td and

sleeve

body

is

forced onto hose

block to slide back. After about & inch

hose

is

covered, remove the block and continue

back

and

pressure to

forth

assembly

allow

Of

to force sleeve onto the hose until end of hose

reaches the

Fig.

10.

shoulder

in

sleeve. Refer to

Loading...

Loading...