Page 1

Instructions

306556S

Topper Units

Grease dispense unit with pneumatic pump elevator for easy drum replacement. For

professional use only.

EN

Model 226013

50:1 Ratio Fire-Ball® Pump

5000 psi (34.5 MPa, 345 bar) Maximum Working Pressure

100 PSI (0.68 MPa, 6.89 bar) Maximum Air Pressure

Model 226018

50:1 Ratio President® Pump

4000 psi (27.6 MPa, 276 bar) Maximum Working

Pressure

80 PSI (0.55 MPa, 5.5 bar) Maximum Air Pressure

Model 244637

75:1 Ratio President® Pump

4000 psi (27.6 MPa, 276 bar) Maximum Working

Pressure

80 PSI (0.55 MPa, 5.5 bar) Maximum Air Pressure

Model 204490, Elevator and Inductor

without pump or hose kit

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Page 2

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 5

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing a Drum . . . . . . . . . . . . . . . . . . . . . . . . 10

Removing a Drum . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Removing the Pump . . . . . . . . . . . . . . . . . . . . . 12

Reinstalling the Pump . . . . . . . . . . . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 20

2 306556S

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

306556S 3

Page 4

Warnings

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

• Know the specific hazards of the fluid you are using.

• Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state, and national guidelines.

• Always wear protective eye wear, gloves, clothing, and respirator as recommended by the fluid and

solvent manufacturer.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, hearing loss,

inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

4 306556S

Page 5

Installation

Installation

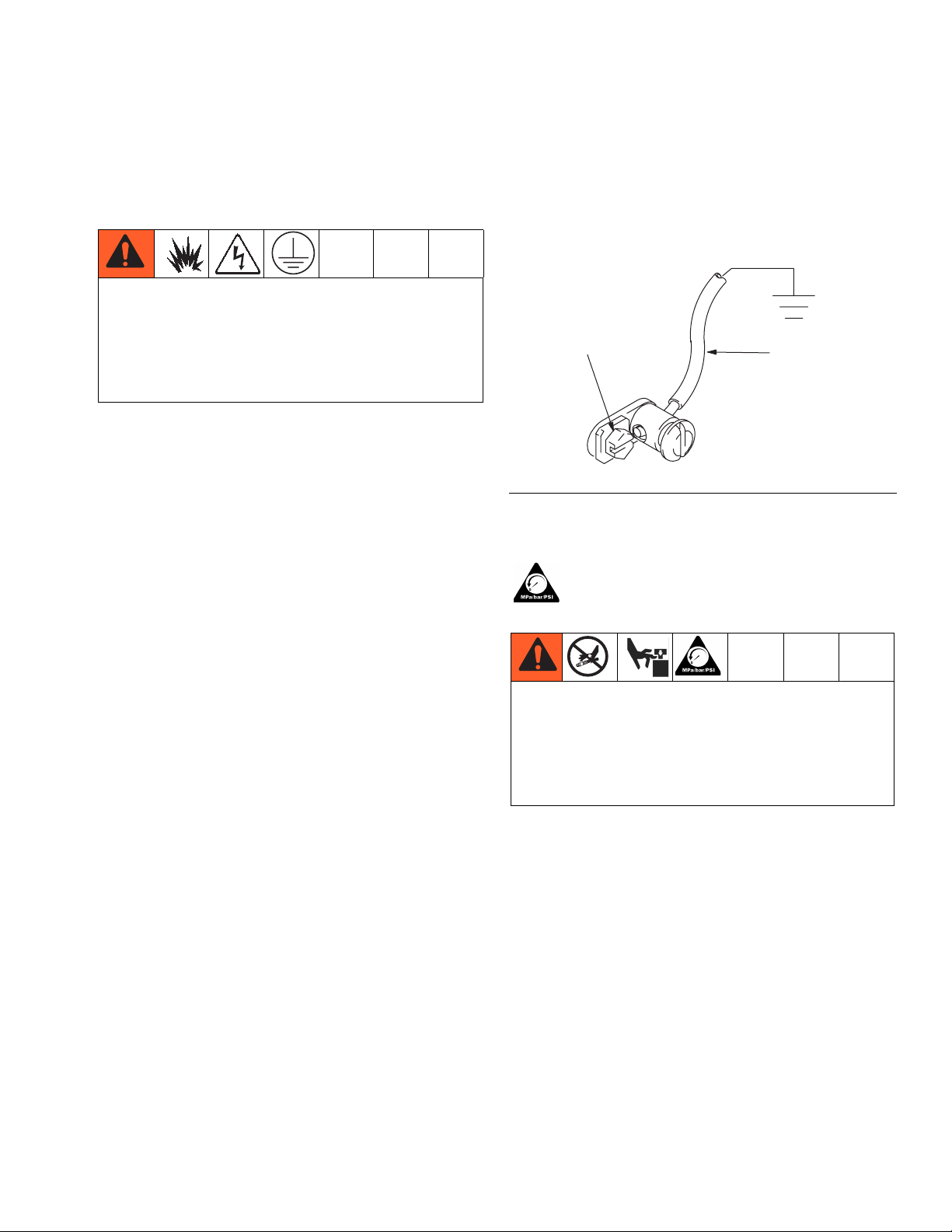

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

• Pump: Use a ground wire and clamp as shown in

Fig 1.

• Air and fluid hoses: Use only electrically conductive

hoses.

• Air Compressor: Follow manufacturer’s recommendations.

• Spray fun and dispensing valve: Ground through

connection to a properly grounded fluid hose and

pump.

3. Connect the other end of the ground wire to a true

earth ground. (Fig 1).

Z

FIG. 1

Y

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

• Fluid supply container: Follow your local code.

• Truck bed or platform: Follow your local code.

• Solvent pails used when flushing: Follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the pail

on a nonconductive surface, such as paper or cardboard, which interrupts the grounding continuity.

• To maintain grounding continuity when flushing or

relieving pressure: Hold a metal part of the dispensing valve firmly to the side of a grounded metal pail,

then trigger the valve.

Grounding the Pump

1. Remove the ground screw (Z) and insert through

the eye of the ring terminal at the end of ground wire

(Y).

2. Fasten the ground screw back into the pump and

tighten securely.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Close the pump’s air regulator.

2. Close the supply pump’s bleed-type master air valve

(required in this system).

3. Hold a metal part of the dispensing valve firmly to a

grounded metal waste container and open the dispensing valve until pressure is fully relieved.

If you suspect that the dispensing valve, extension, or

grease fitting coupler is clogged, or that pressure has

not been fully relieved after following the steps above,

VERY SLOWLY loosen the coupler or hose end coupling and relieve pressure gradually, then loosen completely and clear the clog.

306556S 5

Page 6

Installation

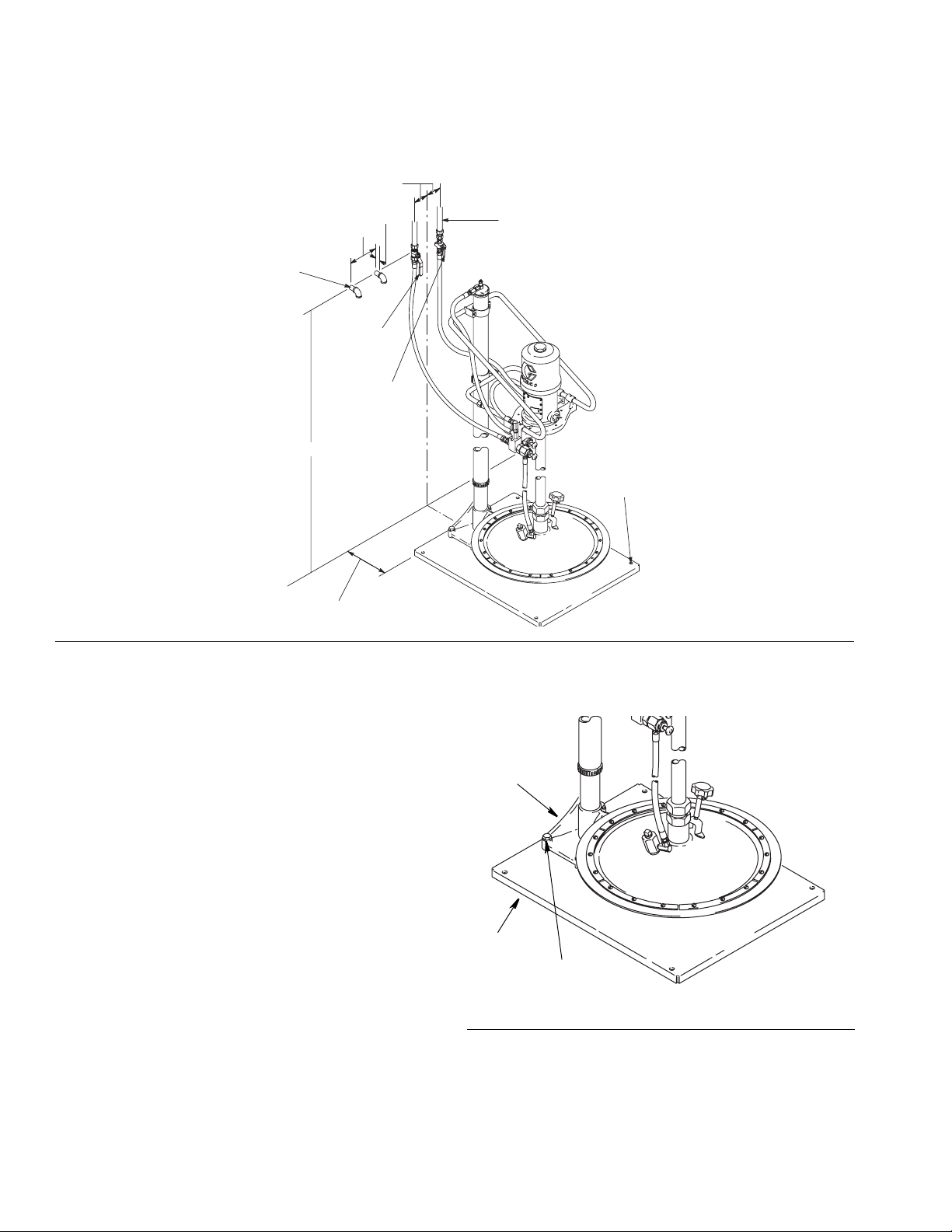

Typical Installation

3” (76 mm)

FIG. 2

supply lines

(through wall)

5’ (1524 mm)

6” (152.4 mm)

master air valve

fluid shutoff valve

clearance

for plumbing

1” (25 mm)

bleed-type

high pressure

supply lines

(from ceiling)

mounting

holes

The Typical Installation (shown in fig 2) is only a guide

for selecting and installing this system. It is not an actual

system design. Contact your local Graco representative

for assistance in designing a system to suit your particular needs.

Positioning the Elevator

1. Position the elevator where the ceiling is at least 8 ft

(2.6 m) high. The elevator is 90 in (2.4 m) when fully

raised.

2. Provide adequate space in front of the elevator for

changing drums and in back and on the side for

plumbing.

Mounting the Elevator

1. Secure the elevator base (A) to the mounting base

(102) using screws (104), lockwashers (103), and

nuts (105). (Fig 3)

2. Bolt the mounting base (102) to the floor for stability.

3. Verify the elevator is level. Loosen on or two screws

(104) on the elevator base and place shims under

the base, if necessary.

4. Place the inductor plate (2, 18, or 22) on the mounting base (102).

A

102

103

104

105

FIG. 3

5. Loosen the screws (68) of both support brackets

(83). Slide the support (64) down far enough to

allow installation of the pump in the inductor plate.

Tighten the bracket screws lightly.

6 306556S

Page 7

Installation

Mounting the Pump

Models 226013, 226018, 244637

1. Mount the pump support bracket (86). (F

FIG. 4

2. Remove inductor plate nut (11 or 24), locking ring (8

or 23) and o-ring (9). (F

IG. 5)

3. In order, slide inductor plate nut (11 or 24), locking

ring (8 or 23) and o-ring (9) on pump riser tube.

(F

IG. 5)

IG. 4)

86

5. Tighten the lock nut (11 or 24) securely. Continue

with Step 4 below.

DETAIL

8 or 23

2 or 22

pump riser

tube

11 or 24

pump intake

slots

0.12” (3.2 mm)

FIG. 5

NOTE: The full length of the pump intake slots must be

just below the bottom of the inductor cone.

Model 204490

Refer to F

IG. 6 for Steps 1-3 below.

1. Lubricate the o-ring (20) in the inductor plate (18)

with light, waterproof grease. (F

IG. 6)

2. Mount the pump on the pump support (64) so the

fluid outlet faces front.

4. Adjust the inductor plate on the pump so that the

pump intake is 0.12 in. (3.2 mm) above the mounting base.

3. Guide the pump intake valve as far as possible into

the inductor plate, then tighten the set screws (19).

Continue with Step 4 below.

20

18

19

FIG. 6

306556S 7

Page 8

Installation

All Models

Refer to F

IG. 7 for the following Steps.

4. Loosen the pump support clamps again and raise

the support (64) until it meets the pump base.

5. Secure the President or Fire-Ball pump to the pump

support mounting plates from the underside with the

screws (68).

6. Tighten screws (68) on lower pump bracket (83).

7. Slide the upper support bracket (83) up or down (the

tubing of the pump support (64) will flex slightly)

until the pump is in a true vertical position.

8. Tighten the screws (68) on the upper bracket.

68

64

4. Connect one end of the 36 in. (914 mm) hose into

the adapter and the other hose end into the

snap-over valve’s (27) union (82). (F

IG. 8)

The bleed-type master air valve is required in your

system to relieve air trapped between this valve and

the pump after the air is shut off. Trapped air can

cause the pump to cycle unexpectedly and cause

serious injury, including splashing in the yes or on the

skin. Position the valve close to the pump.

85

89

83

FIG. 7

Installing the Hoses and Valves

NOTE: Use thread sealant on all male threads except at

the swivel unions.

1. Remove the plug from the top of the elevator cap

and screw it into the air inlet (E) in the elevator base.

(F

IG. 8)

1. Screw the restrictor valve assembly (42) into the

elevator cap.

2. Screw the 1/4 x 1/8 npt adapter (85) into the restrictor valve. (F

IG. 8)

27

E

FIG. 8

5. Route the hose inside the arms of the pump support

(64). (F

IG. 7)

6. Screw the hex nipple (115 or 99) from the outlet

hose kit (91 or 97) to the pump outlet. (See Parts

Drawing on Page 16.)

7. Connect the kit’s swivel union (96) to the adapter

with the opening in the valve (94) facing down. (See

Parts Drawing on Page 18.)

3. Install the 1/4 x 3/8 npt adapter (89). (F

8 306556S

IG. 8)

Page 9

8. Install a bleed-type master air valve on the pump’s

air supply line.

9. Install a fluid shutoff valve on the fluid supply line to

shut off fluid to the pump.

10. Finish assembling the hoses and fittings as shown

on Parts Drawing Page 16.

Installation

306556S 9

Page 10

Operation

46

Operation

NOTICE

Always close the ball valve (65) as soon as the

inductor plate reaches the bottom of the drum, indicating the drum is empty. Allowing the pump to run

without fluid will cause damage to the pump.

Installing a Drum

Refer to FIG. 9 for the following instructions.

1. Relieve the pressure, see Pressure Relief Procedure, page 5.

2. Close the ball valve (65). The handle will be at a 90°

angle to the valve body.

3. Open the bleed-type master air valve (F).

4. Open the inductor plate vent by turning the knob

(10) counter clockwise.

5. Pull open the snap-over valve (27) to raise the elevator.

NOTE: To adjust the elevator speed, turn the restrictor

valve screw (46) clockwise to decrease the speed or

counter clockwise to increase the speed.

6. Center an opened 400 lb (181.4 kg) drum under the

inductor plate so the drum bottom touches the elevator base (A).

7. Make the top of the fluid concave by scooping fluid

from the center to the sides of the container.

8. Loosen the setscrews (73), holding pump mounting

plates to the mounting bracket (C). Align the pump

and inductor plate with the drum.

NOTE: Keep your fingers and hands away from the

sides of the drum or inductor plate to avoid pinching

them when raising and lowering the pump.

9. Push in the snap-over valve (27) to lower the pump

while guiding the inductor plate into the drum.

10. Press down the pump and rock it back and forth to

seat the inductor plate. This helps eliminate air

trapped beneath the plate. Continue this action until

fluid appears at the vent opening (D).

11. Be sure that the pump is aligned vertically and

tighten the set screws (73).

FIG. 9

47

65

F

73

94

C

27

A

10

D

12. Close the inductor plate vent by turning the knob

(10) clockwise.

13. For Models 226013, 226018, and 244637 only

a. Open the bleeder valve (94) at the pump outlet

by turning the thumbscrew counter clockwise.

b. Open the ball valve (65) until all air trapped in

the pump and under the plate are pumped

through the valve.

c. Close the ball valve and the bleeder valve.

d. Regulate the pump speed with the ball valve

handle.

14. All Models:

pressure necessary for good delivery. Higher pressures cause premature pump wear and usually do

not produce better results.

Always use the lowest possible pump

:

10 306556S

Page 11

Removing a Drum

1. Relive pressure, see Pressure Relief Procedure,

page 5.

2. Press in and hold the air-assist valve (47) until the

inductor plate rises above the drum. Release the

valve. (F

3. Open the snap-over valve (27) and raise the elevator to full height. (F

NOTE: If you lose air pressure when reaching the drum

chime, continue holding the air-assist valve and slowly

pull out the snap-over valve until the chime is passed.

Then, immediately close the snap-over valve to prevent

raising the drum off the floor.

IG. 9)

IG. 9)

Operation

306556S 11

Page 12

Maintenance

Maintenance

Refer to FIG. 10 for reference numbers.

NOTE: To avoid contaminating the fluid in the supply

container, keep the pump intake and the inductor plate

clean during the servicing operations. Place the parts on

clean paper or rags.

Removing the Pump

1. Relieve Pressure, see Pressure Relief Procedure,

page 5.

2. Remove the drum. Disconnect the air-assist hose

(41).

For Model 204490: Loosen the inductor plate set

screws (19).

For Models 226013, 226018, and 244637: Unscrew

the locking nut (11 or 24), taking note of the number

of turns needed.

3. Push the snap-over valve (27) to lower the pump.

4. Relieve pressure in the pump and disconnect the

hoses.

5. Disconnect the pump from the mounting bracket

and remove it.

Reinstalling the Pump

1. Connect the pump to the mounting bracket.

FIG. 10

41

27

11 or 24

2. Attached hoses to pump.

3. Pull the snap-over valve (27) to raise the pump.

4. Attach drum. See Installing a Drum, page 10.

NOTE: When attaching the pump to the inductor plate,

turn the locking nut (11 or 24) the same number of turns

noted in Removing the Pump, Step 2, or until you feel it

settle in.

12 306556S

Page 13

Troubleshooting

Problem Cause Solution

Troubleshooting

Low flow or air sucked into pump or

under inductor plate.

Failure of snap-valve or air-assist

valve

1. Open inductor plate vent

2. Loose inductor plate sleeve locking nut

3. Worn inductor seals

Worn o-rings or seals

1. Close the inductor plate.

2. Tighten the locking nuts.

3. Replace seals; See Parts Drawing Page 16.

Remove valve, place in vise, disassemble and replace parts as

needed.

306556S 13

Page 14

Parts

Parts

Model 204490

Elevator and Inductor Plate Assembly

Includes items 17, 25, 90, and 101

Ref

Parts

No.

No. Description Qty.

17 204405 INDUCTOR PLATE ASSEMBLY

See parts on page 14

25 204461 WISHBONE SUPPORT ASSEMBLY

See parts on page 16

90 204385 PNEUMATIC ELEVATOR

See manual 306287 for parts

101 205339 ELEVATOR BASE

See parts below

Model 226013

Pump, Elevator, and Inductor Plate Assembly

Includes items 1, 25, 89, 90, 91 and 101

Ref

No. Part No. Description Qty.

1 204353 INDUCTOR PLATE ASSEMBLY

See parts on page 14

25 204461 WISHBONE SUPPORT ASSEMBLY

See parts on page 16

89 239888 50:1 RATIO FIRE-BALL PUMP

See manual 308883 for parts

90 204385 PNEUMATIC ELEVATOR

See manual 306287 for parts

91 204467 HOSE KIT

See parts on page 18

101 205339 ELEVATOR BASE

See parts below

Model 226018

Pump, Elevator, and Inductor Plate Assembly

Includes items 21, 25, 90, 97, 101, and 106

1

1

1

1

Model 244637

Pump, Elevator, and Inductor Plate Assembly

Includes items 21, 25, 90, 97, 101, and 107

Ref

No. Part No. Description Qty.

21 205669 INDUCTOR PLATE ASSEMBLY

See Parts on Page 14

25 204461 WISHBONE SUPPORT ASSEMBLY

See parts on page 16

90 204385 PNEUMATIC ELEVATOR

See manual 306287 for parts

97 205102 HOSE KIT

See parts on page 18

101 205339 ELEVATOR BASE

See parts below

107 239730 75:1 RATIO PRESIDENT PUMP

See manual 308777 for parts

Ref No. 101: Part No. 205339

Elevator Base Assembly

Includes items 102 - 105

1

Ref

1

No. Part No. Description Qty.

102 205340 BASE, elevator 1

1

103 100018 LOCKWASHERS, spring, 1/2” 4

104 100096 SCREW, hex hd cap, 1/2-13 x 2” 4

1

105 100321 NUT, 1/2-13 4

1

1

90

89, 106, or 107

1

1

1

1

1

1

Ref

No. Part No. Description Qty.

21 205699 INDUCTOR PLATE ASSEMBLY

See part on page 14

25 204461 WISHBONE SUPPORT ASSEMBLY

See parts on page 16

90 204385 PNEUMATIC ELEVATOR

See manual 306287 for parts

97 205102 HOSE KIT

See parts on page 18

101 205339 ELEVATOR BASE

See parts below

106 205395 50:1 RATIO PRESIDENT PUMP

See manual 306674 for parts

14 306556S

1

102

1

1

1

1

1

103

104

105

91 or 97

1, 17, or 21

Page 15

Parts

Ref No. 1: Part No. 204353

Inductor Plate Assembly: 400 lb Drum size

Fits 50:1 Fire-Ball In-Line Pump; Includes items 2-16

Ref No.Part No. Description Qty.

2 204502 PLATE, inductor, bare 1

3 100015 NUT, hex, mscr, 1/4-20 UNC-2a 1

4 100021 CAPSCREW, hex hd, 1/4-20 UNC-2a x 1” 1

5 104663 PLUG, pipe, 3/4 npt (f) 1

6 100799 SCREW, mach, rd hd, 1/4-20 x 1/2” 18

7 100859 SCREW, headless, full dog point, No.

10-24 x 1/4”

8 101644 SLEEVE, coupling 1

9 158776 O-RING 1

10 160865 KNOB, vent 1

11 161107 NUT, locking 1

12 161162 SEAL, rubber 1

13 161287 WIPER, inductor plate 1

14 161288 SEGMENT, full barrel 6

15 164432 CAP, vent 1

16 164497 ROD, vent release 1

Ref No. 17: Part No. 204405

Inductor Plate Assembly: 400 lb Drum size

Fits Monarch and President In-Line Pumps

Includes items 3 - 7, 10, 12 - 16, 18 - 20

Ref No.Part No. Description Qty.

3 100015 NUT, hex, mscr, 1/4-20 UNC-2a 1

4 100021 CAPSCREW, hex hd, 1/4-20 UNC-2a x 1” 1

5 104663 PLUG, pipe, 3/4 npt (f) 1

6 100799 SCREW, mach, rd hd, 1/4-20 x 1/2” 18

7 100859 SCREW, headless, full dog point, No.

10-24 x 1/4”

10 160865 KNOB, vent 1

12 161162 SEAL, rubber 1

13 161287 WIPER, inductor plate 1

14 161288 SEGMENT, full barrel 6

15 164432 CAP, vent 1

16 164497 ROD, vent release 1

18 204507 PLATE, inductor, bare 1

19 100556 SETSCREW, sq hd cup point, 5/16-18 x

3/8”

20 160721 O-RING, nitrile rubber 1

10

4

3

16

15

7

1

11

8

9

6

14

Tapered

shoulder

faces up

5

12

13

2

10

4

3

Ref No. 1

6

14

16

15

7

20

1

12

5

19

13

2

18

Ref No. 17

Ref No. 21: Part No. 205699

Inductor Plate Assembly: 400 lb Drum size

Fits 50:1 President In-Line Pumps

Includes items 3 - 7, 10, 12 - 16, and 22 - 24

Ref No.Part No. Description Qty.

3 100015 NUT, hex, mscr, 1/4-20 UNC-2a 1

4 100021 CAPSCREW, hex hd, 1/4-20 UNC-2a x 1” 1

5 104663 PLUG, pipe, 3/4 npt (f) 1

6 100799 SCREW, mach, rd hd, 1/4-20 x 1/2” 18

7 100859 SCREW, headless, full dog point, No.

10-24 x 1/4”

10 160865 KNOB, vent 1

12 161162 SEAL, rubber 1

13 161287 WIPER, inductor plate 1

14 161288 SEGMENT, full barrel 6

15 164432 CAP, vent 1

16 164497 ROD, vent release 1

22 205698 PLATE, inductor, bare 1

23 196219 RING, locking 1

24 164962 NUT, collet 1

410

3

16

24

23

15

7

1

12

22

6

14

9

Large taper

5

Ref No. 21

faces up

13

306556S 15

Page 16

Parts

aa

Ref. No. 42

Restrictor Valve Assembly

Includes items 43 to 46

44

45

1/8 npt

62

61

89

85

83

68

Ref. No. 27

Snap-Over Valve Assembly

Includes items 28 to 40

43

29

36

35

46

28

40

34

37

32

39

31

0729 0730

42

69

70

83

64

86

73

33

38

30

41

65

88

87

1/4 npt

90

47

63

79

82

84

77

62

78

27

3/8 npt

52

66

51

74

49

60

59

0732B

Ref. No. 47

Air Assist Valve Assembly

Includes items 48 to 60

50

56

58

55

48

54

57

53

0731

16 306556S

Page 17

Ref No. 25: Part No. 204461

Wishbone Support Assembly

Parts

Ref

No. Part No. Description Qty.

27 202295 SNAP-OVER VALVE ASSEMBLY

Includes items 28 - 40

28 100272 LOCKWASHER, int. shkprf, No. 6 1

29 104560 SCREW, oval hd, 6-32 3/8” 1

30 154519 KNOB 1

31 154526 WASHER 1

32 154570 WASHEr 1

33 154594 O-RING, buna-N 1

34 155500 O-RING, nitrile rubber 1

35 155811 SEAL, valve, nitrile rubber 1

36 155921 SEAL, valve, nitrile rubber 1

37 157160 HOUSING, valve 1

38 157161 GUIDE, valve 1

39 161129 STEM, valve, large 1

40 161132 STEM, valve, small 1

41 205418 HOSE, air, cpld 1/2 npt(m) 1/2” (13mm)

ID, 6’ (1.8 m) long

42 203743 RESTRICTOR VALVE ASSEMBLY

Includes items 43 - 46

43 101448 NUT, jam, 3/8-24 1

44 157628 O-RING, nitrile rubber 1

45 160162 HOUSING, valve 1

46 160163 NEEDLE VALVE 1

47 203842 AIR ASSIST VALVE ASSEMBLY

Includes items 48 - 60

48 100063 PIN, cotter, 1/6” dia x 1/2” 1

49 100068 LOCKWASHERS, spring, No. 6 1

50 100072 NUT, hex, No. 6-32 1

51 150902 SPRING, compression 1

52 153348 GASKET, copper 1

53 154519 KNOB 1

54 154594 O-RING, buna-N 1

55 155500 O-RING, nitrile rubber 1

56 155811 SEAL, valve, nitrile rubber 1

57 157161 GUIDE, valve 1

58 160401 STEM, valve 1

59 160402 HOUSING, valve 1

60 160404 STUD, valve 1

Ref

No. Part No. Description Qty.

61 204560 HOSE, air, cpld 3/8 npt (m) 3/8”

62 204561 HOSE, air, cpld 3/8 npt (m) 3/8”

63 205610 SUPPORT, pump, lower 1

64 205611 SUPPORT, pump, upper 1

65 208393 BALL VALVE 1

66 100016 LOCKWASHER, spring, 1/4” 4

68 100057 CAPSCREW, hex hd, 5/16-18 x 3/4” 11

69 100181 NUT, square, 6/16-18 4

70 100214 LOCKWASHERS, 5/16” 4

71 100333 CAPSCREW, hex hd, 1/4-20 x 1/2” 4

72 100469 CAPSCREW, hex hd, 3/8-16 x 3/4” 4

73 100421 SETSCREW, socket hd, cup point,

74 100377 SCREW, hex socket hd, 1/4-20 x 5/8” 2

1

76 150718 CLAMP, drum 4

77 151243 ADAPTER, 1/8 npt(m) 1

1

78 155541 UNION, 90° street, 1/4 npt (m x f)

79 155677 UNION, 90° adapter, 3/8 npt (f) 1

80 155699 ELBOW, street, 3/8 npt (m x f) 1

81 156580 ADAPTER, 3/8 npt(f) x 1/8 npt(m) 1

82 156823 UNION, 1/4 npt(m x f) swivel 1

1

83 158271 BRACKET, elevator riser tube, 1/8 npt 2

84 158962 ELBOW, 90° street, 1/4 npt(f) x 1/8 npt

85 159840 ADAPTER, pump mounting, 1/4 npt(f) x

86 189211 BRACKET, pump mounting 2

87 161466 MANIFOLD, air 1

88 162505 UNION, swivel, 3/8 npt(m) x 1/2

89 150287 ADAPTER, 1/4 npt(m) x 3/8 npt(f) 1

90 158256 UNION, swivel, 1/2 npt(m) x 3/8

(9.6mm) ID, 18” (457 mm) long

(9.6mm) ID, 36” (914 mm) long

5/16” x 3/8”

swivel

(m)

1/8 npt(m)

npsm(f) swivel

npsm(f) swivel (used with model

226018 President pump only)

1

2

4

1

1

1

1

1

MOUNTING and CONNECTING PARTS

0733

0734

1/8 npt 3/8 npt

REF. NO.

QTY.

306556S 17

81 80 76 68 71 72

114 1144

Page 18

Parts

Ref No. 91: Part No. 204467

Fire-Ball Delivery Hose Kit

Includes items 92 - 94, 96, and 115

Ref

No. Part No. Description Qty.

92 100206 BUSHING, 1/2 npt(m) x 1/4 npt(f) 1

93 109150 HOSE, fluid, cpld 1/4 npt(m)), 1/4”

(6.4mm) ID, 6’ (1.83 m) long

94 205528 VALVE, bleeder 1

96 160878 UNION, 90°, 1/4 npt(f) swivel 1

115 156971 NIPPLE, 1/4 x 1/4 npt(m) 1

1/2 npt9394

115

1/4 npt 96

92

Ref No. 97: Part No. 205102

President Delivery Hose Kit

Includes items 94, 96, 98, 99, and 110

Ref

No. Part No. Description Qty.

94 205528 VALVE, bleeder 1

96 160878 UNION, 90°, 1/4 npt(f) swivel 1

1

98 109163 HOSe, cpld 3/8 npt(m), 3/8”

(9.6mm) ID, 6’ (1.83 m) long

99 156849 NIPPLE, hex, 3/8 npt(m) 1

110 100081 BUSHING, pipe, 1/2 npt(m) x 3/8

npt(f)

94

3/8 npt 96

98

1/2 npt

1

1

99

110

Dimensions

90” (2.3 m) Maximum Height

56” (1.4 m) Minimum Height

30” (762 mm)

24” (610 mm)

18 306556S

Page 19

Technical Data

See the pump instruction manual for Technical Data including Wetted Parts, Port Sizes, and so on.

.

Topper Units

US Metric

Maximum fluid working pressure

50:1 Ratio Fire-Ball Pump 5000 psi 34.5 MPa, 345 bar

50:1 Ratio President Pump 4000 psi 28 MPa, 280 bar

75:1 Ratio President Pump

Maximum air pressure

50:1 Ratio Fire-Ball Pump 100 psi 0.7 MPa, 7bar

50:1 Ratio President Pump 80 psi 0.6 MPa, 6 bar

75:1 Ratio President Pump

Weight

Model 226013

50:1 Ratio Fire-Ball Pump

Model 226018

50:1 Ratio President Pump

Model 244637

75:1 Ratio President Pump

Model 204490

Elevator and Inductor

Maximum sound pressure tested at 100 psi (0.7 MPa, 7 bar) at 40 cycles per minute

Model 226013

50:1 Ratio Fire-Ball Pump

Maximum sound pressure tested at 100 psi (0.7 MPa, 7 bar) at 15 cycles per minute

Model 226018

50:1 Ratio President Pump

Model 244637

75:1 Ratio President Pump

Maximum sound power lever tested in accordance with ISO 9614-2

Model 226013

50:1 Ratio Fire-Ball Pump

Maximum sound power lever tested in accordance with ISO 9614-2

Model 226018

50:1 Ratio President Pump

Model 244637

75:1 Ratio President Pump

4000 psi

80 psi

122 lb 55 kg

136 lb 61 kg

136 lb 61 kg

90 lb 41 kg

28 MPa, 280 bar

0.6 MPa, 6 bar

77.8 dB(A)

80.9 dB(A)

80.9 dB(A)

85.6 dB(A)

94.6 dB(A)

94.6 dB(A)

Technical Data

306556S 19

Page 20

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective par ts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 1956, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 306556

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised November 2012

Loading...

Loading...