Page 1

INSTRUCTIONS–P

This

manual contains IMPORT

W

ARNINGS AND INSTRUCTIONS

READ AND RET

AIN FOR REFERENCE

ARTS LIST

ANT

55 Gallon (200 Liter) Drum Size

306–934

Rev. K

Supersedes H

AIR–POWERED

150

psi (10.5 bar) MAXIMUM INBOUND AIR PRESSURE

RAM

Model 207–279, Series J

For

use with high pressure extrusion pumps (see page 3).

Model 223–634, Series A

For

use with Check–Mate 450 pumps

with Displacement Pump 222–790 (see page 3).

TABLE OF CONTENTS

Safety Warnings 2.

Pump

Selection Chart3. . . . . . . . . . . . . . . . . . . . . .

Installation 4–6

Operation 7

Troubleshooting

Service 9–12

Parts

Model 207–279 14, 15

Model

Accessories 18

Dimensional

Technical

Warranty Back

Toll–Free

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drawings and Lists

223–634 16, 17

Data

.

. . . . . . . . . . . . . . . . . . . . . .

Graco Phone Numbers

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart8. . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drawing

.

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

.

.

Back Cover

Cover

Back Cover

19.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

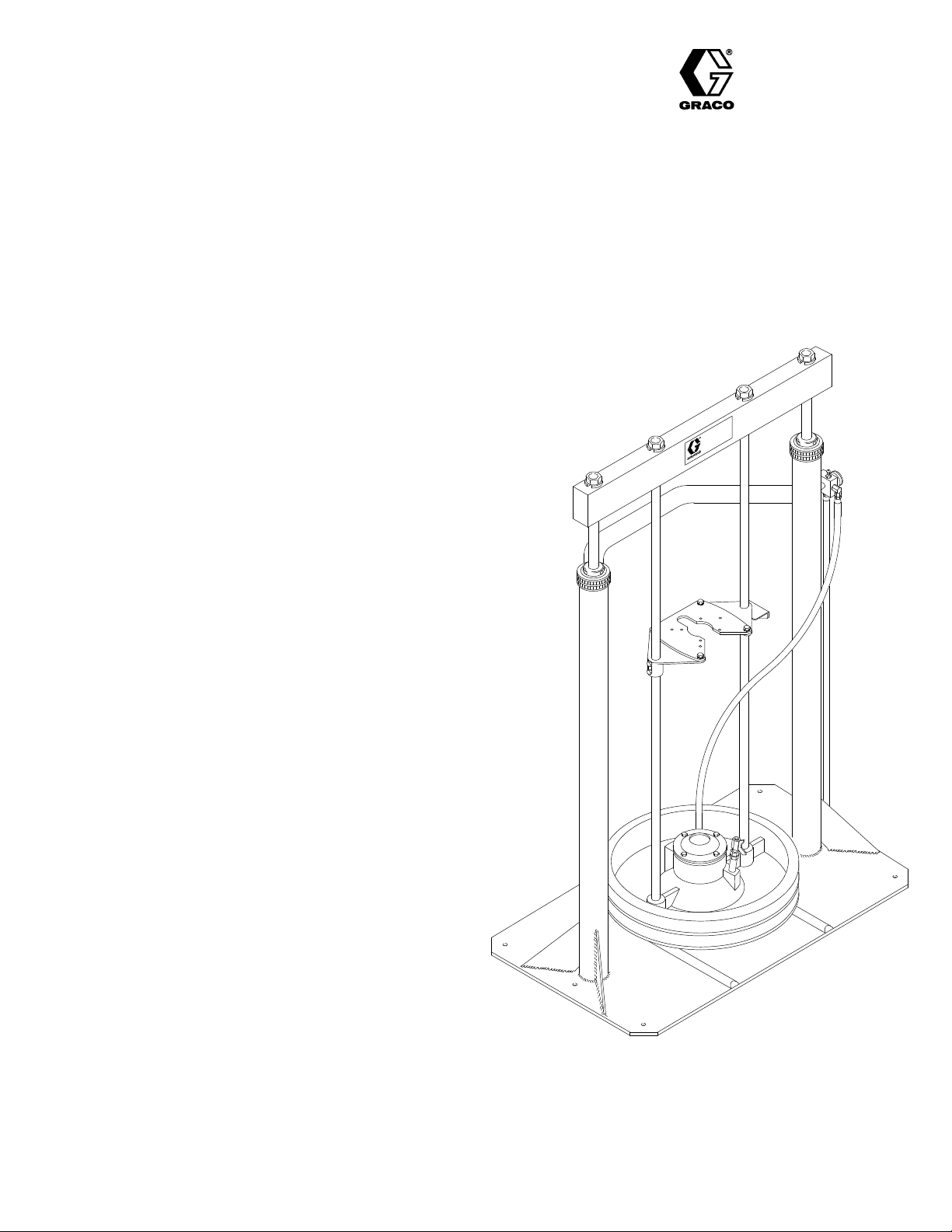

Model

207–279 Shown

Page 2

SAFETY

W

FOR PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS.

Read and understand all instruction manuals before operating equipment.

EQUIPMENT MISUSE HAZARD

General

Any

ing parts, or using worn or damaged parts, can cause them to rupture and

result

DO

SURE

NEVER

function

CHECK

parts

ALWAYS

instruction

Safety

misuse of the ram or accessories, such as overpressurizing, modify

in serious bodily injury or property damage.

NOT exceed 150 psi (10.5 bar)

to the ram.

alter or modify any part of the ram; doing so could cause it to mal

and make it dangerous to operate.

all equipment regularly and repair or replace worn or damaged

immediately

use the ram only for its intended purpose as

.

manual.

MAXIMUM INBOUND AIR PRES

described in this

-

-

-

ARNINGS

Pressure

To

reduce the risk of serious bodily injury

in the eyes or on the skin, or injury from moving parts, always relieve

ing

all

air and fluid pressure in the system before checking or repairing the

ram

1. Shut

2.

3.

4. T

5.

6. Leave

MOVING PARTS HAZARD

Moving

ram plate/pump fluid inlet moves when the ram is in operation. Keep

hands

fluid container when raising or lowering the ram. Keep clear of all moving

parts when starting or operating the ram or pump. Before checking or

servicing the ram or pump, always follow the Pressure Relief

Procedure,

Relief Procedure

, including fluid injection, splash

or any other part of the system and

of

f the air to the pump and ram.

Open the bleed–type master air valve to relieve trapped air

Shut of

f the ram director valve.

rigger the gun/dispensing valve to relieve fluid pressure.

Open all fluid drain valves in the system.

the drain valves open until you are ready to

again.

parts can pinch or amputate your fingers

and fingers away from the ram plate, pump fluid inlet, and lip of the

above.

when shutting down the system.

.

spray/dispense

or other body parts. The

-

Page 3

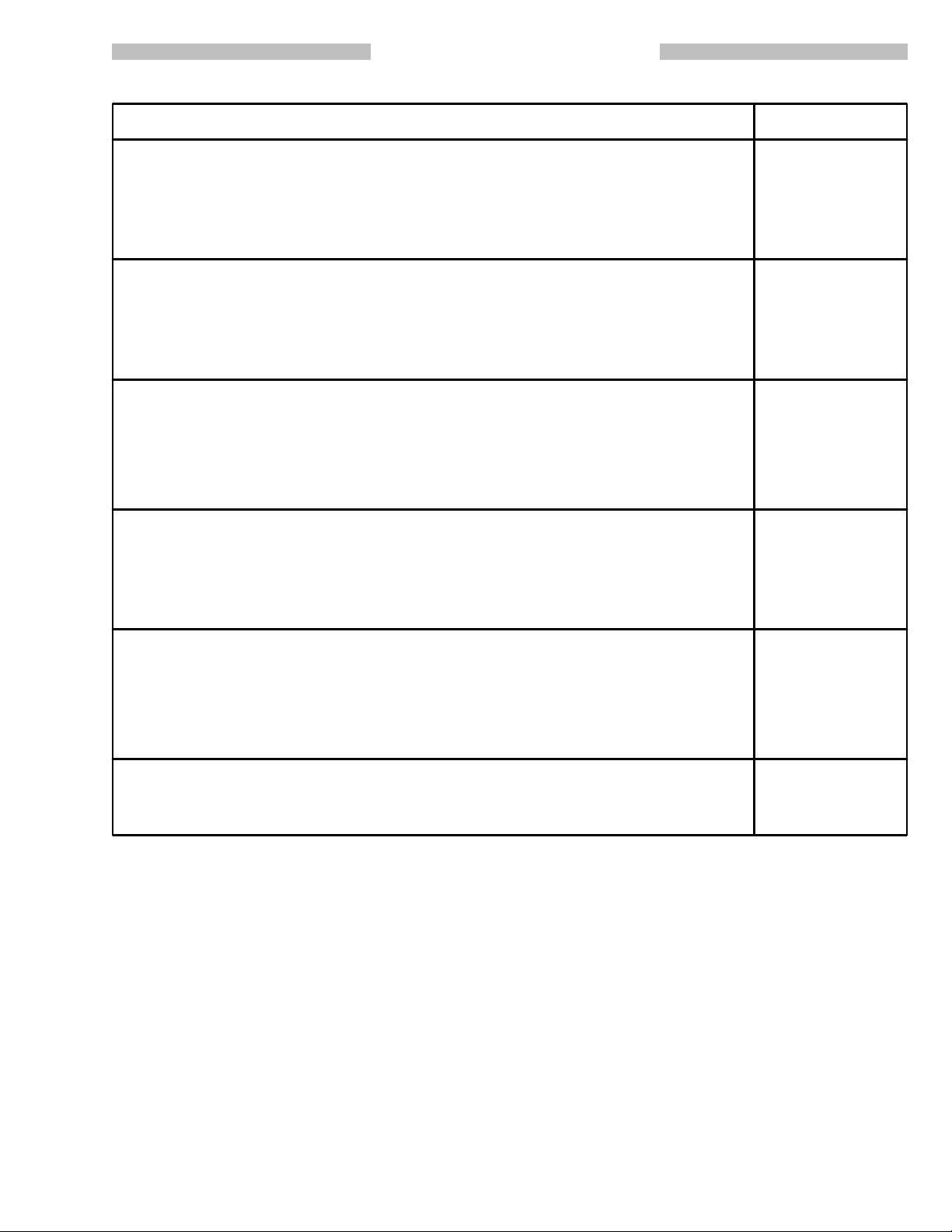

For

Pump Model and Description

PUMP SELECTION CHART

Use Ram Model

10:1 Monark, Model 222–770, with Severe–Duty Check–Mate 450 Displacement Pump

20:1 President, Model 222–768, with Severe–Duty Check–Mate 450 Displacement Pump

34:1 Senator

55:1 Bulldog, Model 222–778, with Severe–Duty Check–Mate 450 Displacement Pump

15:1 Senator

15:1 Senator

25:1 Senator

25:1 Senator

10:1 Bulldog, Model 222–526, with Severe–Duty Displacement Pump

10:1 Bulldog, Model 204–287, with Nitralloy Displacement Pump

10:1 Bulldog, Model 207–172, with Stainless Steel Displacement Pump

25:1 Bulldog, Model 222–527, with Severe–Duty Displacement Pump

25:1 Bulldog, Model 217–565, with Nitralloy Displacement Pump

40:1 Bulldog, Model 222–535, with Severe–Duty Displacement Pump

40:1 Bulldog, Model 220–448, with Nitralloy Displacement Pump

, Model 222–769, with Severe–Duty Check–Mate 450 Displacement Pump

, Model 222–518, with Severe–Duty Displacement Pump

, Model 222–489, with Nitralloy Displacement Pump

, Model 222–525, with Severe–Duty Displacement Pump

, Model 222–519, with Nitralloy Displacement Pump

223–634*

223–634*

223–634*

223–634*

207–279

207–279

207–279

207–279

207–279

207–279

207–279

or

954–285**

207–279

207–279

207–279

207–279

20:1 King, Model 222–539, with Severe–Duty Displacement Pump

20:1 King, Model 222–248, with Nitralloy Displacement Pump

20:1 King, Model 220–648, with Stainless Steel Displacement Pump

55:1 King, Model 222–545, with Severe–Duty Displacement Pump

55:1 King, Model 217–566, with Nitralloy Displacement Pump

Mounting Kit 222–776 is required to mount a Check–Mate 450 Pump on Model 223–634 Ram.

*

**

Stainless Steel Ram 954–285 does not include ram plate or tie rods.

NOTE: Model

207–279 Ram is shipped with optional seals (51 and 75), seal plates (76), an intake adapter (55), and

a mounting plate (58) for use with pumps not listed above (see the

installation

Technical

information regarding pumps

Assistance at 1–800–543–0339.

not listed in this chart, contact your Graco representative or Graco

parts

list on page 15). For application and

207–279

207–279

207–279

or

954–285**

207–279

207–279

Page 4

TYPICAL INSTALLATION

26, 27

35

57,

D

J

3

Y

B

A

C

EFG

H

4

66

KEY

A Air

B Bleed–T

C

D

E

F

G Bleed–T

H

J

Y

3

4 Ram Director Valve

26, 27

35 Mounting Bracket Setscrews

57

66

Line Filter

(required, for pump)

ype Master Air V

Pump Air Regulator

Air Manifold

Air Supply Hose (for ram)

Ram Air Regulator

ype Master Air V

(for accessories)

Main Air Supply Line

Drum Clamps

Ground Wire (required)

Support Beam

Pump Mounting Hardware

Pump Mounting Brackets

Air Manifold Mounting Bracket

alve

alve

air–powered ram extruder forces high viscosity flu

This

ids

into the intake valve of the fluid pump. Wiper rings

and

other accessory equipment for use with this ram are

in the ACCESSORIES section.

listed

NOTE: To convert the ram from air to hydraulic opera-

tion, install piston kit 220–501 (see page 18).

Contact

your Graco representative for details.

Locating the Ram

NOTE: Refer

1. Select a convenient location for the equipment.

Check

the pump and ram when the ram is

position. Make sure the air regulators for the pump

and

2.

Level the base of the ram, using metal shims.

3. Using

1/2

anchors which are long enough to prevent the unit

from tipping. Refer to the Dimensional Drawing on

page

4. Mount

procedure

to the Dimensional Drawing on page 19

ram

mounting and clearance dimensions.

that there is suf

ficient overhead clearance

in

the fully raised

ram are fully accessible.

the holes in the base as a guide, drill holes for

in. (13 mm) anchors. Bolt the ram to

the floor with

19.

the pump on the ram, following the applicable

on page 5 or 6.

for

for

-

Installing Accessories and Connecting Air

Lines

1. Install

2. Install

3. Install an air manifold (D) on the mounting bracket

4. Install a second bleed–valve (G) upstream from all

an air line filter (A) on the air supply line to re

move harmful moisture and contaminants from the

compressed

air supply

.

a bleed–type master air valve (B)

from

the pump air regulator (C).

WARNING

bleed–type master air valve (B)

The

is required in

your system to relieve air trapped between this

valve

and the pump after the pump air regulator is

closed. Trapped air can cause the pump to cycle

unexpectedly,

injury,

including splashing in the eyes or on the

and

injury from moving parts.

Connect a suitable air hose (E)

(66).

let

port of the air manifold

which could result in serious bodily

between an out

and the air inlet of the ram

air regulator (F).

accessories,

Connect

to isolate the

accessories for servicing.

the main air supply line (H) to the manifold

(D).

-

downstream

skin

-

Page 5

INSTALLATION

Mounting the Pump (Model 207–279 Ram)

NOTE: The

Mount

tion

on page 4.

1. Remove

those pumps listed in the chart on page 3. Position

the mounting brackets (57) so that the top of the

pump

on the mounting brackets (57) with the air inlet

toward

the mounting brackets with the screws (27) and

washers

2. Remove the four screws (25) and washers (31)

holding

(63)

Leave the bottom seal plate (62) and gasket (61) in

place.

Pump Selection Chart on page

commonly

mounted on this

ram. Installing other

3 lists pumps

pumps on the ram may require alternate parts,

which are packed in separate plastic bags. For

information, contact your Graco representative

or Graco Technical Assistance at

1–800–543–0339.

the pump as follows. Refer to the T

ypical Installa

the mounting plate (58); it is not required

will clear the support beam (3). Set the pump

the ram director valve (4). Attach the pump to

(26) provided.

the standard seal plates (62) to the ram

plate

and remove the top seal plate (62) and seal (56).

See Fig 1.

for

3.

For

15:1 and 25:1 ratio Senator

, 25:1 and 40:1

Bulldog, and 55:1 ratio King standard extrusion

pumps,

slide the top seal plate (62) up over the pump

intake valve and push the seal (56) onto the pump

intake

housing. Then continue with step 4.

For

10:1 ratio Bulldog and 20:1 ratio

a flanged intake housing,

discard the top seal plate

King pumps with

(62) and seal (56). Remove and discard the bottom

-

seal plate (62). Align the holes in the intake valve

flange with those in the gasket (61) and ram plate

(63).

Then continue with step 4.

4. Loosen the mounting bracket setscrews (35), and

carefully

low

5.

If applicable for your installation,

down

lower the pump until the intake valve is

the gasket (61), then tighten the setscrews.

push the seal (56)

firmly against the bottom seal plate (62).

6. Align the holes in the top seal plate or pump intake

flange

(as applicable)

with the holes in the ram plate

(63). Secure tightly to the ram plate with the four

screws

(25) and washers (31).

ratio

be

-

PUMP

62

62

Fig 1

INT

AKE

HOUSING

ST

ANDARD EXTRUSION

PUMPS

56

25, 31

61

63

10:1 BULLDOG AND 20:1 KING PUMPS,

WITH FLANGED INT

AKE HOUSING

INTAKE

HOUSING

FLANGE

25, 31

61

63

306-934ą5

Page 6

INSTALLATION

Mounting the Pump (Model 223–634 Ram)

NOTE: Model

1.

Place the gasket (K) from Mounting Kit 222–776 on

the

ram plate. See Fig 2. Lower the Check–Mate

223–634 Ram is only for use with

Mate 450 Pumps having a 222–790 Displacement

Pump. The Pump Selection Chart on page

3

lists

the Check–Mate 450 Pumps which can be

mounted

This

See

on this ram.

installation requires Mounting Kit 222–776.

Accessories on page 18.

Check–

450

pump

onto the gasket

intake

flange

to the plate with the screws (L) and lugs

(M)

included in the mounting kit.

2.

For Senator and Bulldog Check–Mate 450 Pumps

only:

Position the mounting brackets (57) under the

base

of the air motor

page 4. Attach the motor to the mounting brackets

with

the screws (27)

mounting brackets (57) are not used with Monark

and

President Check–Mate 450 Pumps.

and plate. Secure the pump’

. See the Typical Installation on

and washers (26) provided. The

s

RAM PLA

M

TE

L

CHECK–MA

INT

AKE FLANGE

K

TE 450 PUMP

Fig 2

Page 7

OPERATION

WARNING

Follow

the

Pressure Relief Procedure

before

checking

part of the system and when shutting down the

system.

Keep

hands and fingers away from the ram plate,

fluid

pump inlet,

raising or lowering the ram to reduce the risk of

pinching

or amputating hands or fingers.

or repairing the ram or any other

and lip of the fluid container when

on page 8

Before Pumping Fluid

1. Turn the director valve knob (17) to OFF. Close the

ram

air regulator and main air control valve.

2. Turn

3. Set

NOTE: Do

the

director valve knob to UP

control

valve and ram air regulator until the ram starts

to

move upward. Let the ram rise to its full height.

a full drum of fluid on the ram base, slide it back

against the tube stop, and center it under the ram

plate.

See the T

Accessories

and properly align the drum with the ram. Then

hold,

remove the drum cover and smooth the surface of

the

fluid with a straightedge.

not use drums that

dents with this ram. Rough bung openings or

large dents will damage the wipers or stop the

ram

plate, resulting in a runaway pump.

ypical Installation on page

section for drum clamps (J) that center

. Open the main air

4 and the

have side bungs or large

5. Turn the director valve knob to the DOWN position,

lower

the ram plate until all air is forced out and

comes

out of the vent

valve

knob to OFF and close the vent valve (23).

6. Set

NOTE: Increase

the air pressure to the ram at 50 psi (4 bar). Turn

the

director valve knob to the DOWN position. Start

the

pump (open the bleed–type master air valve and

fluid dispensing valve). Let the pump run until the

system is primed and all air is forced out. Close the

bleed–type

to

stop the pump.

not prime properly with heavier fluids. If fluid is

forced

too high and the air pressure should be decreased.

master air valve or

air pressure to the ram if the pump does

out

around the top wiper

opening. Then turn the director

fluid dispensing valve

, ram pressure is

How to Use the Ram

1. To pump fluid from the drum, turn the director valve

knob to the DOWN position and start the pump. Always

use the lowest air pressure possible to both the

pump

,

2. To

and ram.

change drums, stop the pump and turn the air di

rector

valve knob to UP

ton

(14) in and hold until the ram plate clears the

of the drum. When the ram reaches its maximum

height,

remove the empty drum and put a full drum in

its

place. Follow

ing

Fluid”, at left.

. Push the air assist valve but

the procedure under “Before Pump

fluid

-

-

top

-

4. Turn the director valve knob to the DOWN position

and

lower the ram until

enter the drum, then turn the valve to OFF. Reposition the drum so the wipers will not hit the drum lip,

then

open the vent valve (23) on the ram plate.

14

17

14

17

the ram plate is just ready to

Ram Air Controls

(Model 207–279)

Shutdown

1. T

urn the director valve knob (17) to OFF

2. Shut

of

f the air supply to the ram and pump and

the Pressure Relief Procedure

23

.

follow

on page 8.

Fig 3

Ram Air Controls

(Model 223–634)

Ram Plate and V

(Model 207–279 Shown)

ent V

alve

306-934ą7

Page 8

TROUBLESHOOTING

WARNING

Pressure

To reduce the risk of serious bodily injury, including

fluid

injury

pressure in the system before checking or repairing

the

ting

1.

Relief Procedure

injection, splashing in the eyes or on the skin,

from moving parts, always relieve all air and fluid

ram or any other part of the system

down the system.

Shut of

f the air to the pump and ram.

and when shut

or

CHART

Shut of

3.

4. T

-

fluid pressure.

5.

Open all fluid drain valves in the system.

f the ram director valve.

rigger the gun/dispensing valve to relieve

2. Open the bleed–type master air valve to relieve

trapped

PROBLEM CAUSE SOLUTION

Ram won’t raise or lower

Ram raises or lowers too fast Air pressure too high

Air leaks around cylinder

packing nuts (46)

Fluid squeezes past

ram plate wipers

Pump won’t prime properly or

pumps air

air.

Closed air valve or clogged air line

Not enough air pressure

W

orn or damaged piston

Director valve closed or clogged

Loose packing nut or worn packingsTighten, replace

Air pressure too high

W

orn or damaged wipers

Closed air valve or clogged air line

Not enough air pressure

6. Leave

spray/dispense

the drain valves open until you are ready to

again.

Open, clear

Increase

Replace

Open, clear

Decrease

Decrease

Replace

Open, clear

Increase

Air director valve won’t hold

drum down or push plate up

8ą306-934

W

orn or damaged piston

Director valve closed or clogged

Air director valve dirty

or damaged

Closed air valve or clogged air line

Not enough air pressure

V

alve passage clogged

, worn

Replace

Open, clear

Clean, service

Open, clear

Increase

Clean

Page 9

SERVICE

Air Director Valve Cleaning and Service

(Model 207–279 Ram)

1. Follow

2.

3. Screw

4. Remove the knob (17), and take the stud (18) and

the

Pressure Relief Procedure W

page

8.

Pry out the button plug (16). See Fig 4.

the stud (18) out of the housing (19), holding

your hand under the director valve to catch the ball

gland (74) and v–packing (7).

(6),

springs

o–rings (1

(10 and 12) out of the knob. Check the stud

1) for damage.

arning

on

14

20

15

8

11

21

13

196

1017

5. Clean

and inspect all parts for wear

place

as needed.

or damage. Re

Air Assist Valve Service

(Model 207–279 Ram)

1. Follow

2. Screw the seat (15) out of the housing (19). Check

3. Remove

4.

5. Clean

the

Pressure Relief Procedure W

page

8.

the

gasket (8) and

the poppet (21) and spring (13).

Pull the stem (20) out of the seat (15).

and inspect all parts for wear

place

as needed.

o–ring (1

1) for damage. See Fig 4.

or damage. Re

arning

on

-

Fig 4

-

1118

16

12

74 7

5

Page 10

SERVICE

Air Director Valve Cleaning or Service

(Model 223–634 Ram)

1. Follow

2.

3. Screw

4. Remove the knob (17), and take the stud (18) and

5. Loosen the jam nut (15), unscrew the needle (20),

6. Clean

the

Pressure Relief Procedure W

page

8.

Pry out the button plug (16). See Fig 5.

the stud (18) out of the housing (19), holding

your hand under the director valve to catch the ball

and seal (7).

(6)

springs

o–rings (1

and

place

(10 and 12) out of the knob. Check the stud

1) for damage.

check the o–ring (9).

and inspect all parts for wear

as needed.

arning

or damage. Re

on

Air Assist Valve Service

(Model 223–634 Ram)

1. Follow

2. Screw

3. Remove

4.

5. Clean

-

the

Pressure Relief Procedure W

page

8.

the stud (94) out of the housing (93). See Fig

6.

the poppet (89) and spring (92).

Pull the stem (88) out of the stud (94).

and inspect all parts for wear

place

as needed.

arning

or damage. Re

on

-

10ą306-934

Loading...

Loading...