Page 1

Operation - Parts - Repair

Protective Coating

Hand-Held Paint Sprayer

- For portable spray applications of protective coatings

- For professional use only -

- Not approved for use in explosive atmospheres or hazardous locations -

- DO NOT SPRAY ZINC COATINGS OR MATERIALS WITH AGGREGATE.

ACCELERATED PUMP WEAR WILL OCCUR -

4000 psi (27.6 MPa, 276 bar) Maximum Working Pressure

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

Model

16H960 ✓

16N654 ✓

16N927

16N655 ✓

16N656 ✓

3A2308C

EN

-

ti19340a

Page 2

Table of Contents

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Charger Status Indicator Lights . . . . . . . . . . . . . . . . . . 7

Sprayer Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . 8

Common Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adjusting Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Starting a New Job . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

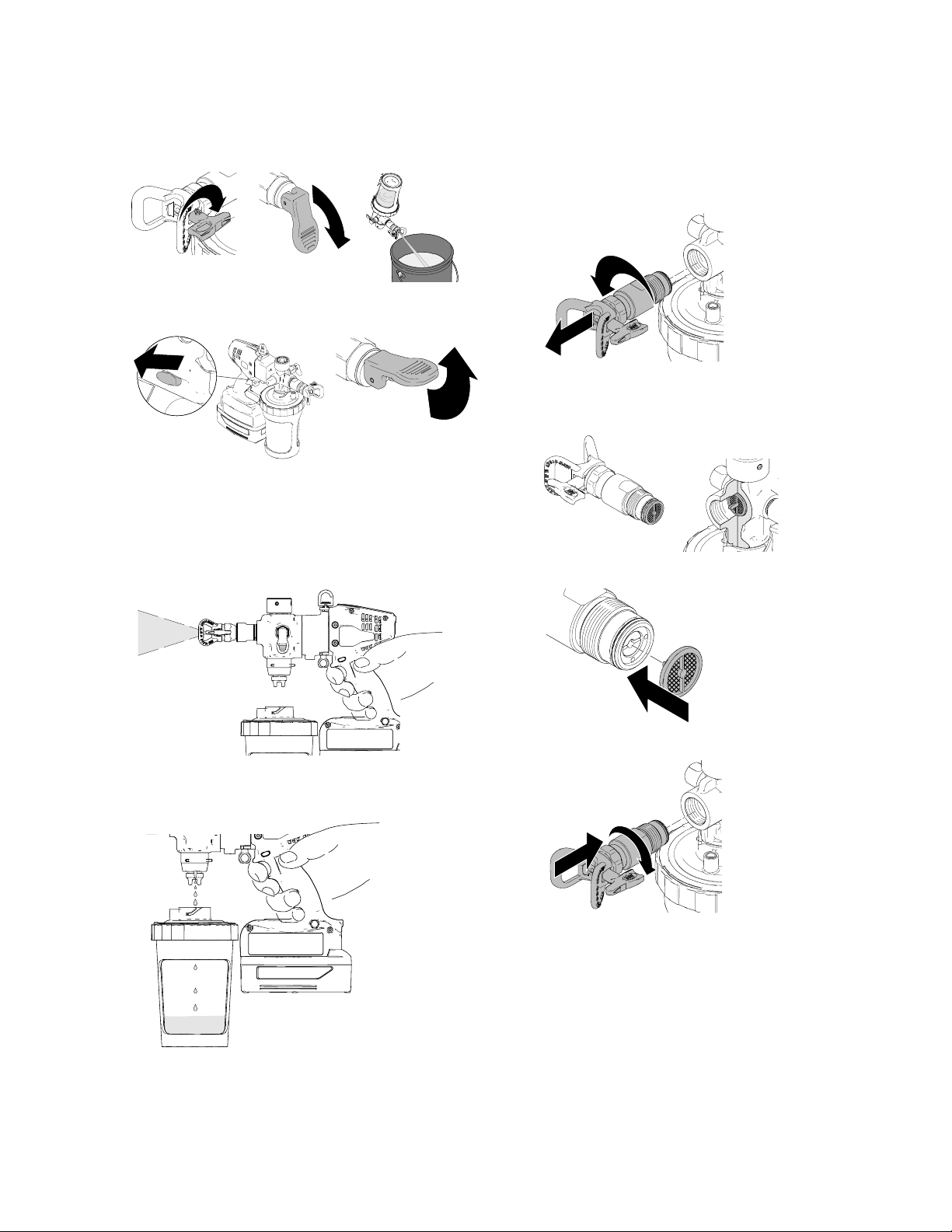

Install/Service Filter (if needed) . . . . . . . . . . . . . . . . . 13

Install Tip/Guard Assembly (if not installed) . . . . . . . . 14

Filling and Installing Cup . . . . . . . . . . . . . . . . . . . . . . 14

Priming Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setting Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Getting Started with Basic Techniques . . . . . . . . . . . 17

Triggering Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Aiming Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Unclogging Spray Tip/Guard Assembly . . . . . . . . . . . 18

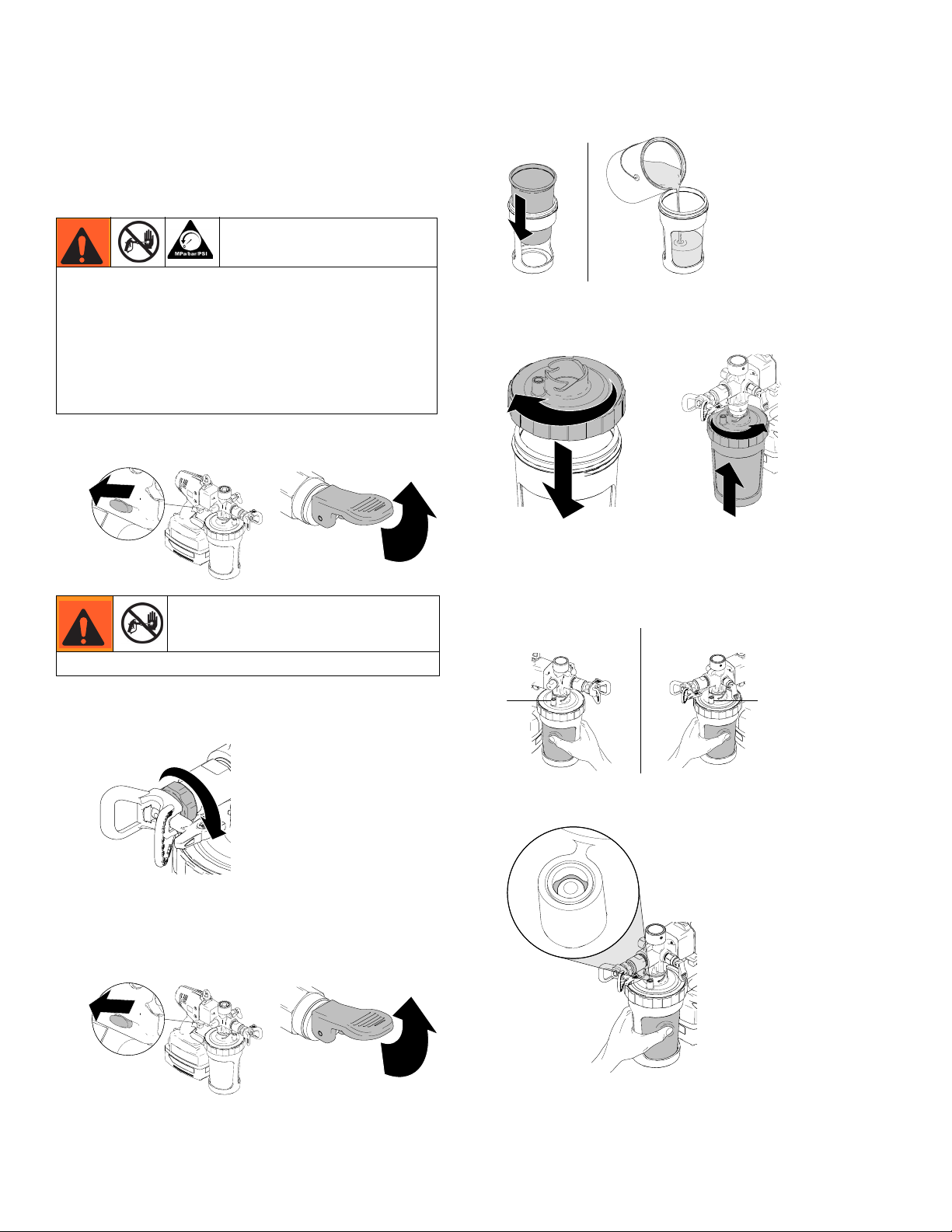

Shutdown and Cleaning . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning Sprayer Exterior . . . . . . . . . . . . . . . . . . . . . 21

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Spray Pattern Diagnostics . . . . . . . . . . . . . . . . . . . . . 26

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Inlet Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Outlet Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pressure Control Knob . . . . . . . . . . . . . . . . . . . . . . . . 30

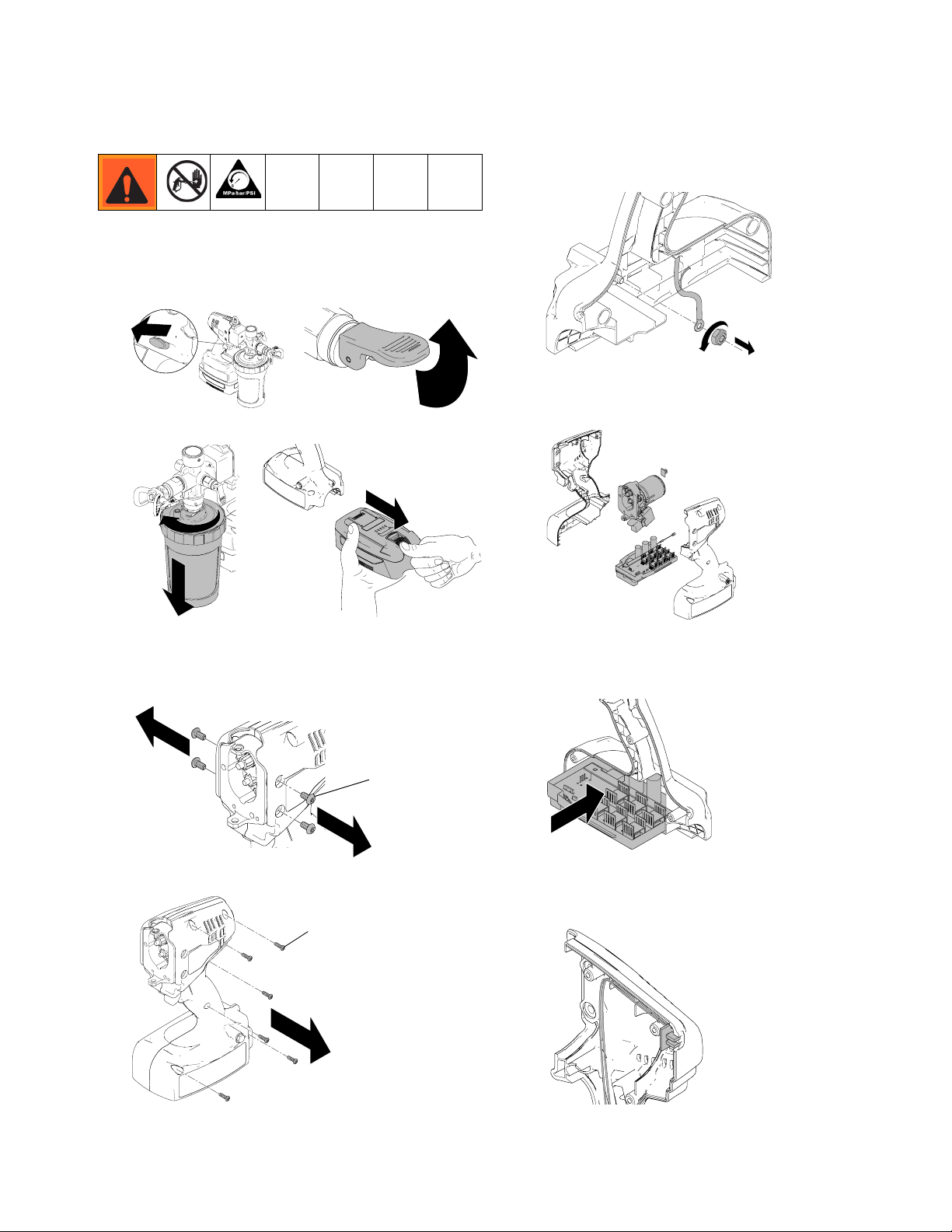

Pump Module/Drive Module . . . . . . . . . . . . . . . . . . . . 31

Pump Rebuild Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Clamshell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Motor/Control Board Replacement Kit . . . . . . . . . . . . 35

Switch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Gear Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

FCC Declaration for Battery Charger . . . . . . . . . . . . . . . 41

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . 44

Important User Information

Before using your sprayer read this Operation Manual for complete instructions on proper use and safety warnings.

DO NOT RETURN THIS SPRAYER TO THE STORE!

If you experience problems, contact Graco Product Support at 1-888-541-9788 or visit www.graco.com.

Before using this equipment, be sure to read and follow the information on your container label and ask for a Material Safety

Data Sheet (MSDS) from your supplier. The container label and MSDS will explain the contents of the material and the

specific precautions related to it.

Paints, coatings and clean-up materials generally fit into one of the following 3 basic categories:

WATER-BASED:

Your sprayer is compatible with this type of material. Your sprayer is NOT compatible with harsh cleaners such as

chlorine bleach.

OIL-BASED:

mineral spirits or paint thinner. The MSDS must indicate that the flash point of the material is above 100° F. Your

sprayer is compatible with this type of material. Use oil-based material outdoors or in a well-ventilated indoor area

with a flow of fresh air. See the safety warnings in this manual.

FLAMMABLE:

thinner, acetone, denatured alcohol, and turpentine. The container label should indicate that this material is

FLAMMABLE. Your sprayer is compatible with this type of material. Use flammable materials outdoors or in a

well-ventilated indoor area with a flow of fresh air. See the safety warnings in this manual.

The container label should indicate that the material can be cleaned up with soap and water.

The container label should indicate that the material is COMBUSTIBLE and can be cleaned up with

This type of material contains flammable solvents such as xylene, toluene, naphtha, MEK, lacquer

2 3A2308C

Page 3

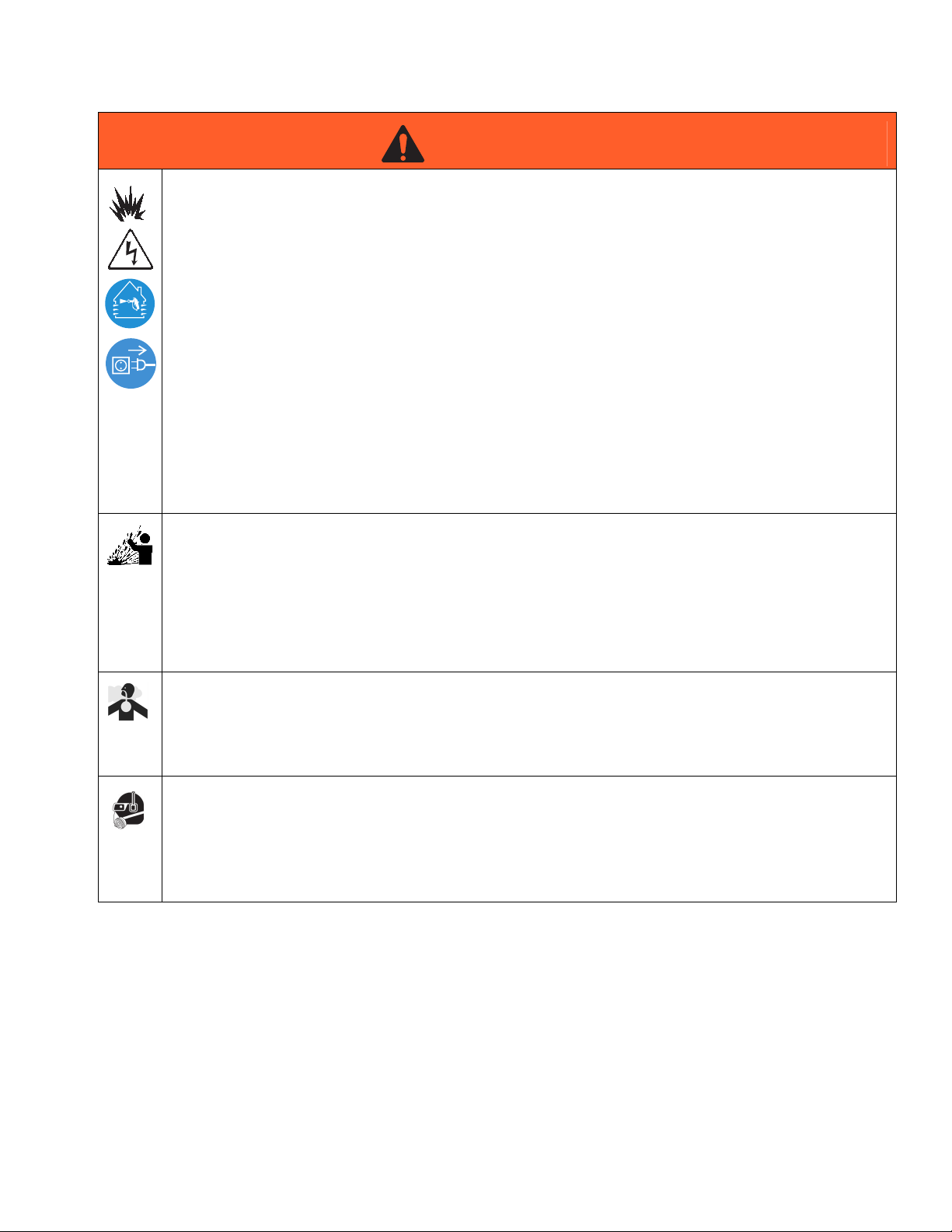

Warnings

Warnings

The following warnings are for the setup, use, maintenance, and repair of this equipment. The exclamation point

symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these

symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

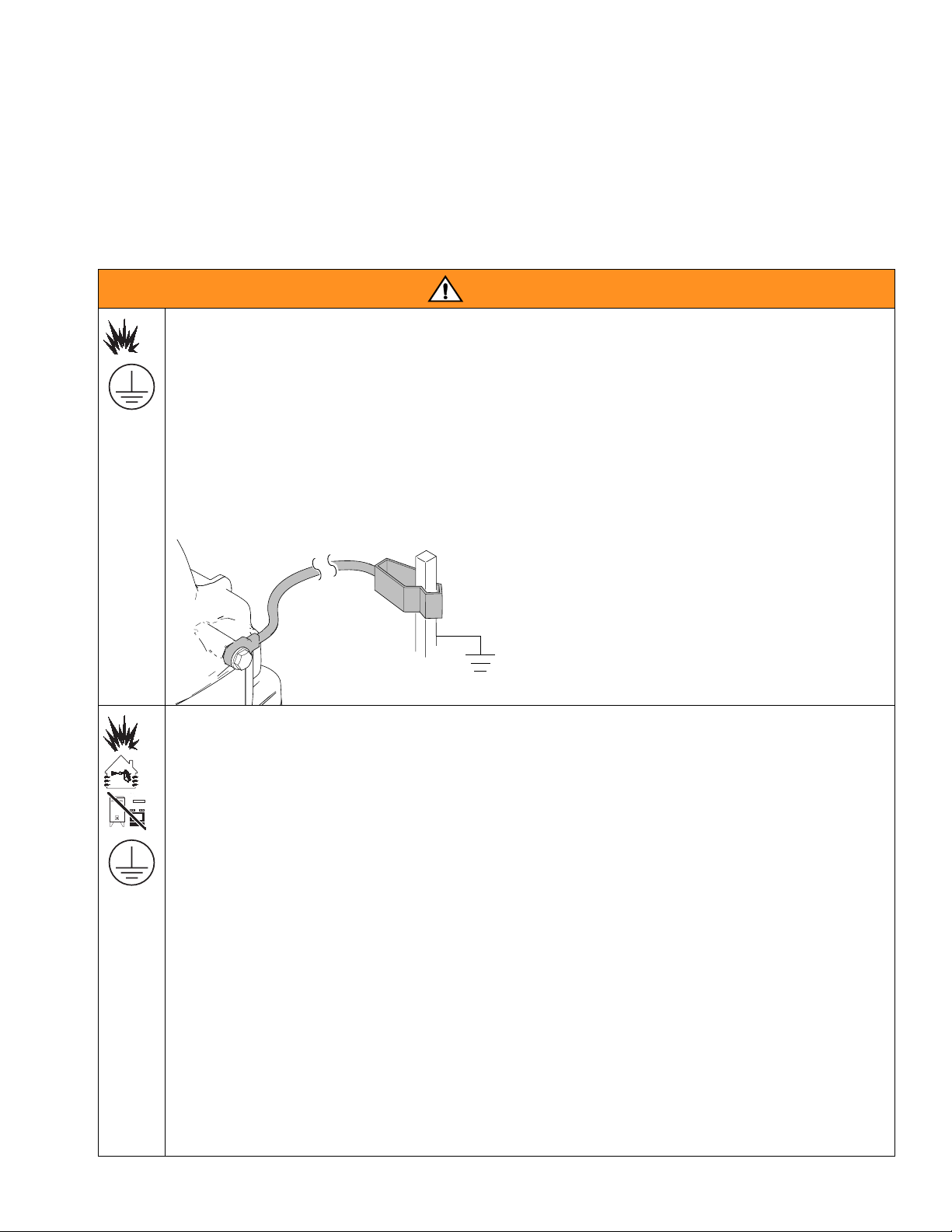

WARNING

FIRE AND EXPLOSION HAZARD (GROUNDING)

Some oil-based and flammable materials generate static electricity when sprayed. Static electricity creates

an explosion and fire risk. Your sprayer has a ground wire that will conduct the static electricity to earth

ground. The sprayer and all objects in spray area must be properly grounded to protect against static

discharge, sparks or shocks.

• Connect the ground wire when spraying flammable or static producing oil-based materials.

• If there is static sparking or if you feel a shock, stop spraying immediately and connect the sprayer to

earth ground with the ground wire provided.

GROUNDING INSTRUCTIONS

Clamp sprayer ground wire to earth ground.

ti19343a

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Do not spray flammable or combustible liquids in a confined area.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area.

• Paint or solvent flowing through the sprayer is able to result in static electricity. Static electricity creates

a risk of fire or explosion in the presence of paint or solvent fumes. The sprayer and all objects in spray

area shall be properly grounded to protect against static discharge, sparks, or shocks.

• Always connect the ground wire provided when spraying flammable materials or static producing

oil-based materials. See Grounding Instructions above.

• If there is static sparking or you feel a shock, stop operation immediately and connect sprayer to earth

ground with the ground wire provided.

• Do not spray flammable or combustible materials near open flame or sources of ignition such as

cigarettes, external motors, and electrical equipment.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Do not smoke in the spray area.

• Keep spray area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets

(MSDS) and container labels provided with the paints and solvents. Follow the paint and solvents

manufacturer’s safety instructions.

• Fire extinguisher equipment shall be present and working.

3A2308C 3

Page 4

Warnings

WARNING

WARNINGWARNINGWARNING

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

• Do not aim the sprayer at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any

part of the body.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Always use the spray tip guard. Do not spray without spray tip guard in place.

• Use caution when cleaning and changing spray tips. In the case where the spray tip clogs while spraying,

follow the Pressure Relief Procedure for relieving the pressure before reversing or removing the spray tip

to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, follow the

Pressure Relief Procedure and engage the trigger lock.

• Check parts for signs of damage. Replace any damaged parts with genuine Graco parts.

• This system is capable of producing 4000 psi. Use replacement parts or accessories that are rated a minimum of 4000 psi.

• Do not carry the sprayer with a finger on the trigger.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Disconnect the battery before servicing.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Use only in dry locations. Do not expose to water or rain.

• Use in well-lit areas.

• Always replace cracked, broken or missing parts immediately with genuine Graco parts. See Parts List,

page 23.

BATTERY HAZARD

The battery may leak, explode, cause burns, or cause an explosion if mishandled. Contents of an open battery

can cause severe irritation and/or chemical burns. If on skin, wash with soap and water. If in eyes, flush with

water for at least 15 minutes and seek immediate medical attention.

• Replace battery only in a well-ventilated area and away from flammable or combustible materials; including paints and solvents.

• When battery is not in use, keep it away from metal objects like keys, nails, screws or other metal objects

that can short circuit the battery terminals.

• Do not throw into fire.

• Charge only with Graco-approved charger as listed in this manual.

• Do not store at temperatures below 32° or above 113° F (0° to 45° C).

• Do not use at temperatures below 40° or above 90° F (4° to 32° C).

• Do not expose battery to water or rain.

• Do not disassemble, crush, or penetrate the battery.

• Do not charge a battery that is cracked or damaged.

• Follow local ordinances and/or regulations for disposal.

4 3A2308C

Page 5

Warnings

WARNING

WARNINGWARNINGWARNING

CHARGER ELECTRIC SHOCK, FIRE AND EXPLOSION HAZARD

Improper setup or usage can cause electric shock, fire, and explosion.

• Charge only in a well-ventilated area and away from flammable or combustible materials, including paints

and solvents.

• Do not charge on a combustible or flammable surface.

• Do not leave battery unattended while charging.

• Immediately unplug charger and remove battery when charging is complete.

• Charge only Graco batteries listed in this manual; other batteries may burst.

• Use only in dry locations. Do not expose to water or rain.

• Do not use a charger that is cracked or damaged.

• If the supply cord is damaged, replace the charger or cord, depending on model.

• Never force the battery into the charger.

• When operating a charger outdoors, always provide a dry location and use an extension cord suitable for

outdoor use.

• Disconnect the charger from the outlet before cleaning.

• Ensure that the outside surface of the battery is clean and dry before plugging into the charger.

• Do not attempt to charge non-rechargeable batteries.

• Do not disassemble the charger. Take charger to authorized service center when service or repair is

required.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for

compatibility.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited

to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A2308C 5

Page 6

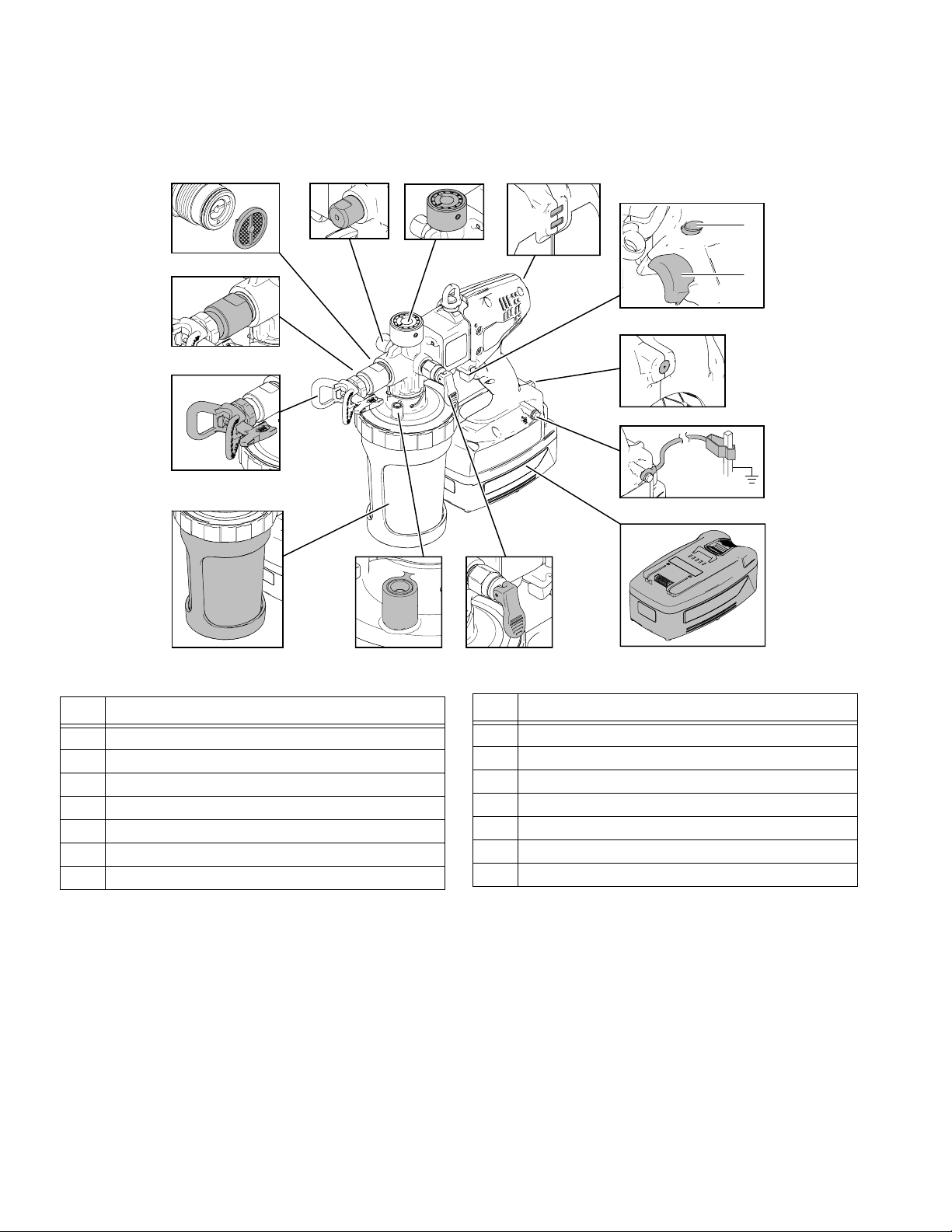

Component Identification

Component Identification

M

A

R

P

N

K

B

C

D

E

F

G

H

J

Ref. Description

A Accumulator

B Pressure Control Knob

C Sprayer Status Indicator

D Trigger Lock

E Trigger

F Static Wick

G Ground Wire Assembly with Clamp

ti19345a

Ref. Description

H Battery

J Pressure Relief Valve / Prime Valve

KCheck Valve

M Material Cup

N Spray Tip Assembly

P Front Shut-Off Valve

R Material Filter

6 3A2308C

Page 7

Operation

Operation

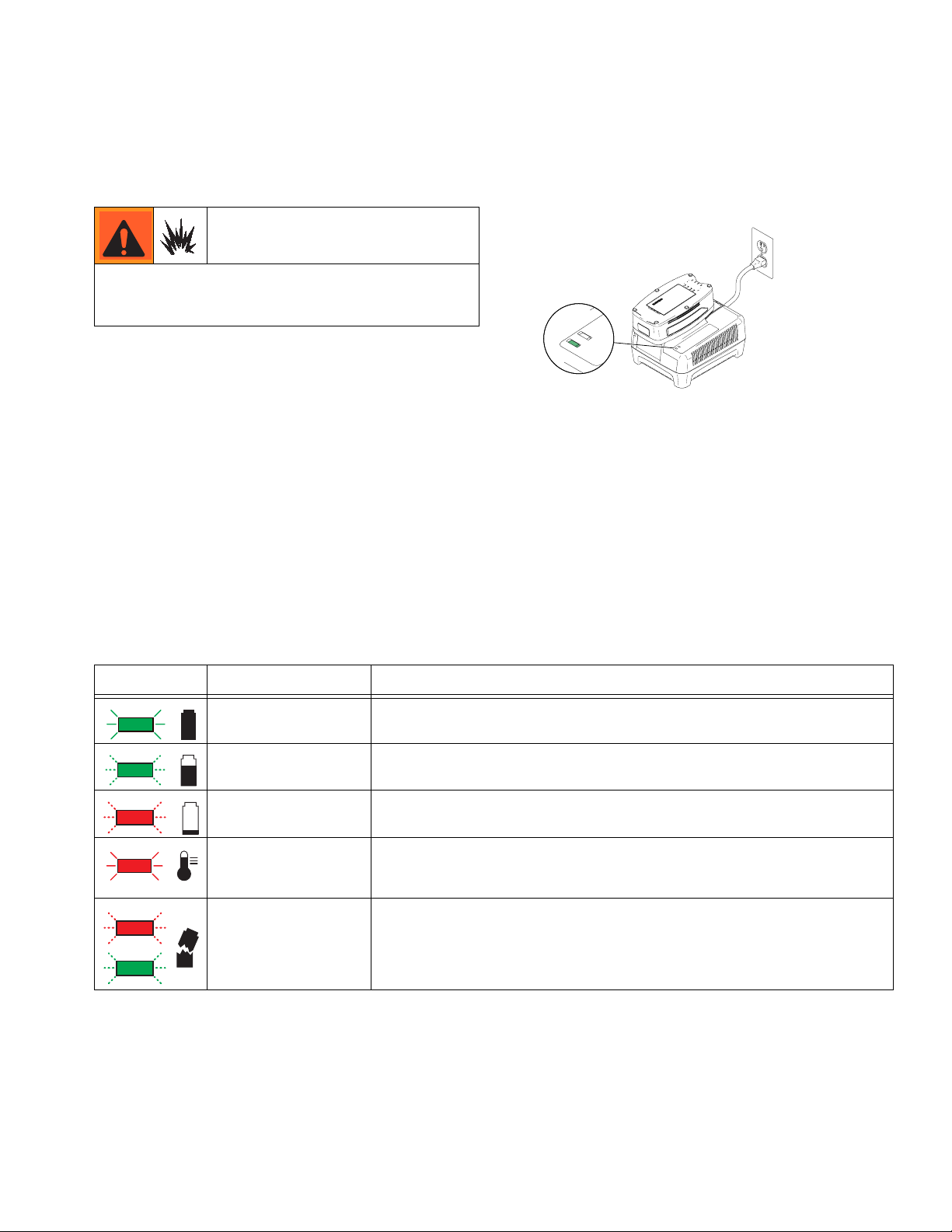

Charging the Battery

Replace and charge battery only in a well-ventilated

area and away from flammable or combustible materials, including paints and solvents.

Batteries are initially 50% charged to provide optimum

battery life and require charging before first use. It takes

approximately 50 minutes to charge a dead battery to

80%, at which point it can be used. It will take approximately 75 minutes to fully charge a dead battery.

1. Place charger in a dry, well-ventilated area and

away from flammable or combustible materials,

including paints and solvents.

2. Plug charger into an electrical outlet and slide battery into charger as shown (light will turn on in 5

seconds).

ti19341a

3. When battery becomes fully charged, immediately

unplug the charger from the power supply and

remove the battery from the charger.

NOTE: The amount sprayed with each battery varies

depending on material, spray tip size, battery charge,

and battery temperature. One battery fully charged will

spray up to one gallon. Amount sprayed will be less

depending on spray tip size, material sprayed, life of

battery, temperature, and other environmental factors.

Charger Status Indicator Lights

Label Appearance Description

Solid green light Indicates a full charge. Battery can be used.

Flashing green light

Flashing red light

Solid red light

Both lights Battery has internal fault or has experienced damage. Do not use.

Battery is charging, indicates 80% charge.

Battery can be used.

Battery is charging, indicates less than 80% charge.

Do NOT use battery.

Battery is too hot or too cold to charge. Remove battery and allow to cool or

warm up before charging. Battery temperature must be between

50° F - 113° F (10° C - 45° C) to charge.

3A2308C 7

Page 8

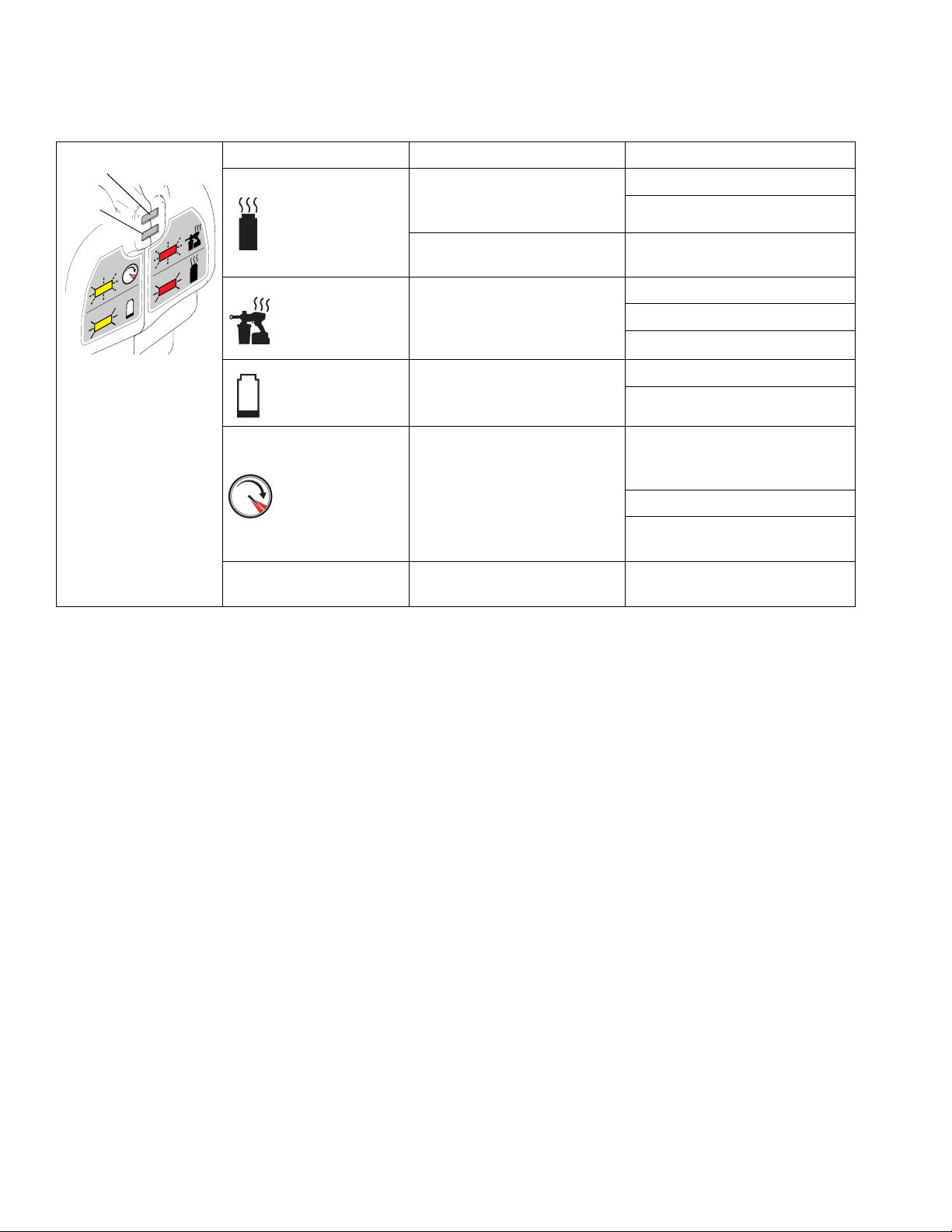

Sprayer Status Indicator

Operation

Red

Yellow

ti19361a

No light Normal operation. No action required.

Battery is too hot. Unit will

shut down until battery has

Solid Red

Flashing Red

Solid Yellow

Flashing Yellow

Solid red and solid yellow Locked motor.

cooled.

Liquid has contacted control

board.

Motor is too hot and will shut

down if heavy use continues.

Unit will shut down until motor

has cooled.

Battery is low or

battery is too cold.

High pressure signal. Gun will

shut down after 1.5 seconds.

Change battery.

Allow battery to cool.

Allow unit to dry.

Increase tip size.

Turn down pressure.

Let unit cool down.

Charge battery.

Warm up battery.

Turn pressure control

counter-clockwise to reduce

pressure.

Increase tip size.

Material is too thin--do not thin

as much.

Bring sprayer in to service center for diagnostics.

*NOTE: The sprayer status indicator light is visible for 10 seconds after the trigger is released.

8 3A2308C

Page 9

Operation

Common Procedures

Trigger Lock

Follow the Pressure Relief Procedure whenever

you see this symbol.

Always engage the trigger lock when you stop spraying

to prevent the sprayer from being triggered accidentally

by hand, or if dropped or bumped.

ti14994a

ti14995a

ti19350a

Trigger Locked

Pressure Relief Procedure

Do not operate or spray near children. Do not aim the

sprayer at, or spray any person or animal. Keep hands

and other body parts away from the discharge. For

example, do not try to stop the paint flow with any part

of the body.

This sprayer builds up an internal pressure of 4000 psi

during use. This equipment stays pressurized until

pressure is manually relieved. To help prevent serious

injury from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Engage trigger lock.

ti19374a

Trigger Unlocked

(red ring is visible)

Prime/Pressure Relief Valve Position

ti19347a

ti14999a

(For priming and releasing

UP position

pump pressure)

ti19346a

DOWN position

(Ready to spray)

ti19350a

2. Put prime/pressure relief valve UP to release pressure.

ti14999a

ti19347a

Spray Tip Position

Always perform Pressure Relief Procedure before

adjusting spray tip position.

ti19371a

ti14985a

Tip Forward

(SPRAY position)

ti19370a

ti14991a

Tip Reversed

(UNCLOG position)

ti15510a

ti15510a

3A2308C 9

Page 10

Adjusting Pressure

NOTE: Spraying water, solvents, and thin materials

(low viscosity materials) at high pressure (setting “2” or

higher with yellow light flashing) can result in temporary

pump leaking. To avoid, read and follow instructions

(Quick Guide or Manual) on how to properly adjust

pressure.

NOTE: To reduce overspray and extend battery life,

always spray at lowest pressure that results in an

acceptable spray pattern.

Operation

4. You MUST start with dial at “1” and gradually

increase by increments of “1” or less until desired

spray pattern is achieved. Put pressure relief handle

in UP position to turn pressure control knob, then

return handle to DOWN position to spray.

ti19353a

ti19372a

1. Put the pressure relief valve UP to relieve pressure.

ti19347a

2. Turn pressure control knob:

Clockwise to INCREASE pressure, or

Counter-clockwise to DECREASE pressure.

THIN

MATERIAL

THICK

MATERIAL

ti19407a

ti19408a

0 1 2 3 4 5 6 7 8 9 10 11

3. Dial in pressure by spraying material on a scrap

material.

ti19409a

10 3A2308C

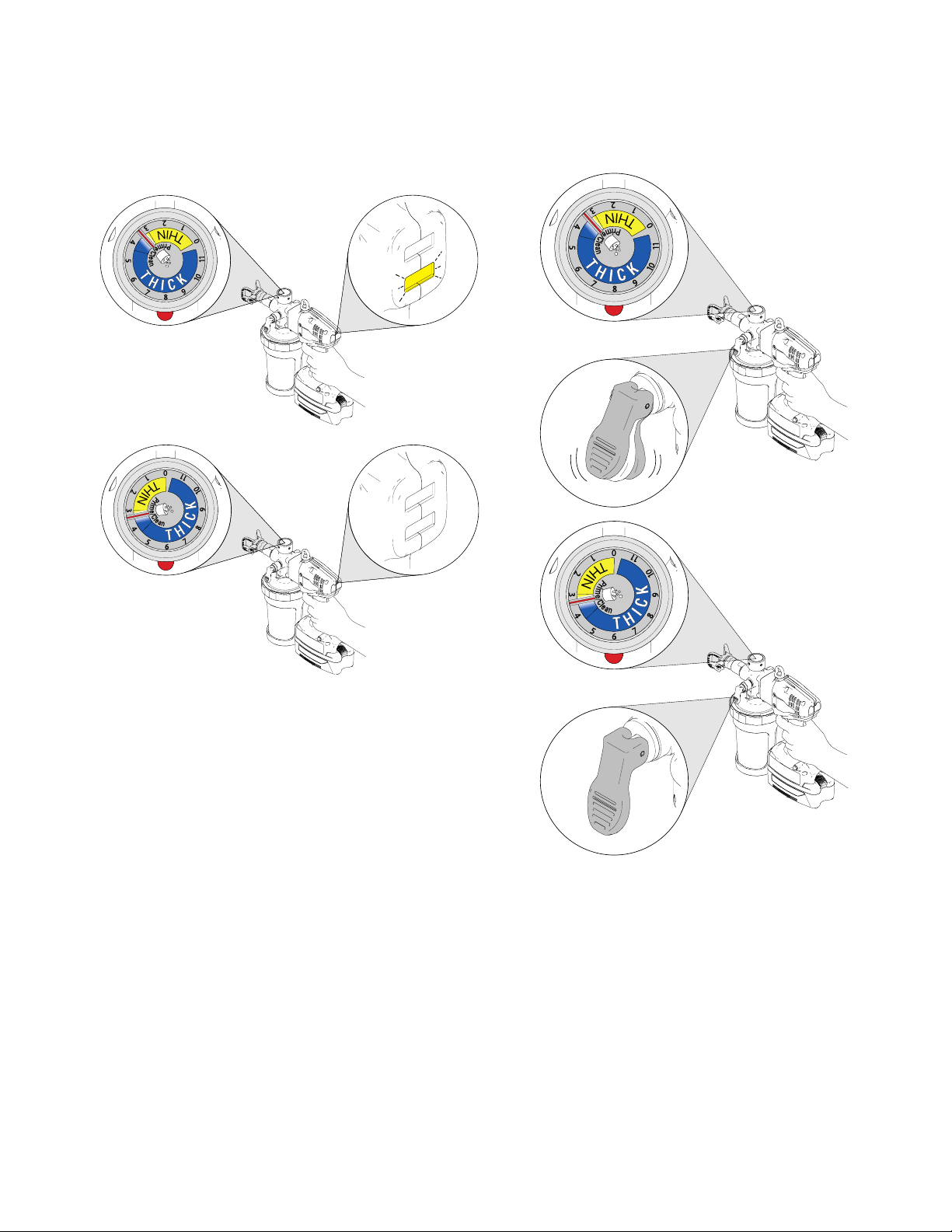

Page 11

Operation

5. If yellow light is flashing while triggering, pressure is

set too high. You MUST turn down pressure until

yellow light no longer flashes, increase tip size, or

do not thin material as much.

ti19655a

6. If pressure relief valve is vibrating, pressure is set

too high. You MUST turn down pressure, increase

tip size, or do not thin material as much.

ti19656a

ti19654a

ti19653a

NOTE: Thin materials will generally require a low

setting and thick materials will generally require a

high setting.

IMPORTANT!

After storage, the piston seals need to be energized

prior to next use to prevent leakage. To energize, follow

steps below:

1. Prime system with flushing fluid.

2. Spray at low pressure setting “1” for 10 seconds.

3. Drain fluid. You are now ready to spray.

3A2308C 11

Page 12

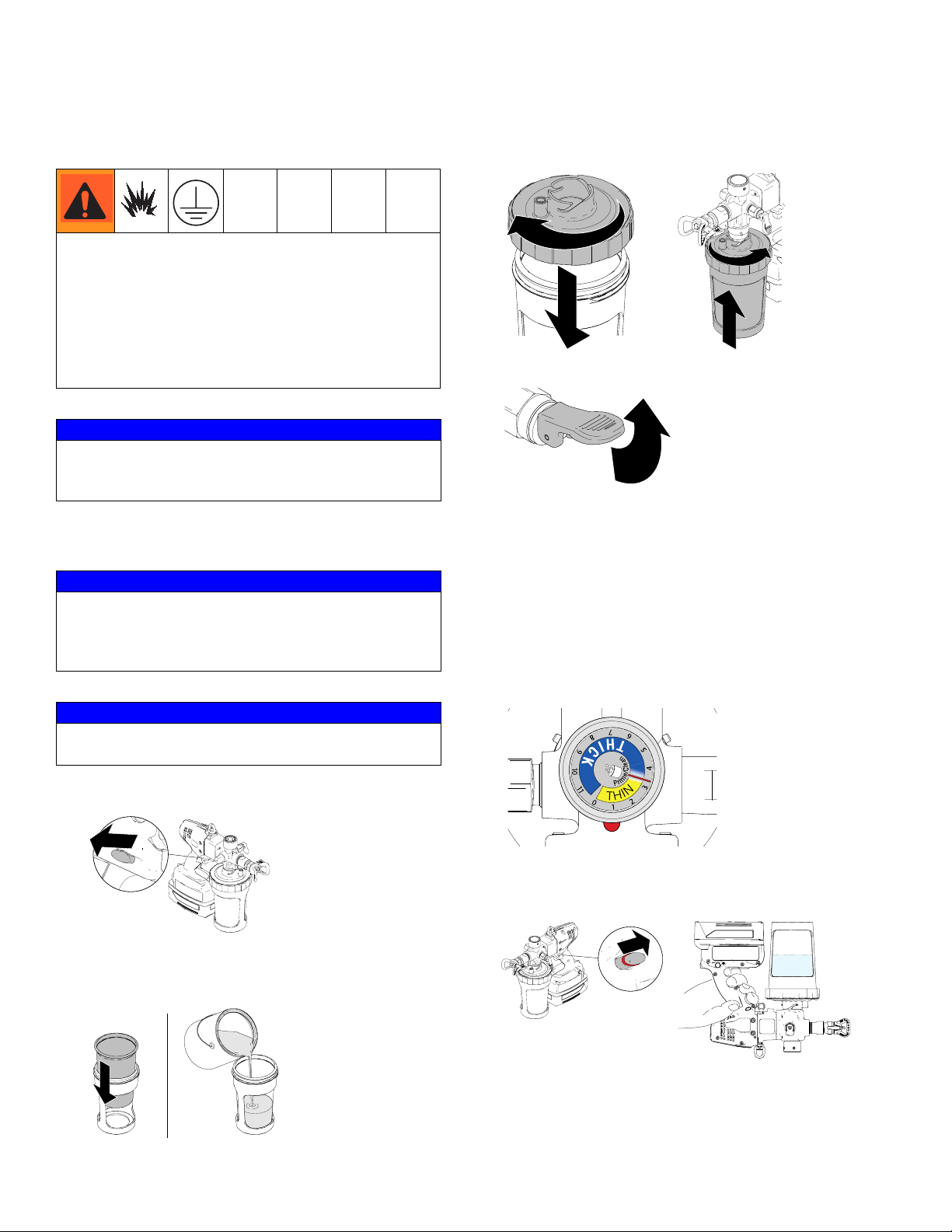

Setup

Flammable fumes (such as solvent and paint fumes) in

work area can ignite or explode.

See Grounding Instructions, page 3.

Do not spray flammable or combustible liquids in a confined area.

Keep spray area well-ventilated. Keep a good supply

of fresh air moving through the area.

NOTICE

Your sprayer is NOT compatible with harsh cleaners

such as chlorine bleach. Using these cleaners will

cause damage to the sprayer.

Starting a New Job

NOTICE

Always flush any cleaning material from the previous

use before starting a new job. If the new spraying

material is not compatible with leftover material in the

pump, adverse reactions could ruin new material.

Operation

3. Thread lid onto cup and connect cup to sprayer.

ti19354a

ti19384a

4. Put prime/pressure relief valve in UP position.

ti19347a

NOTE: After storage, the piston seals need to be

energized prior to next use to prevent leakage. To

energize, follow steps below:

a. Prime system with flushing fluid.

b. Spray at low pressure setting “1” for 10 sec-

onds.

c. Drain fluid. You are now ready to spray.

NOTICE

Do NOT spray zinc coatings or materials with

aggregate. Accelerated pump wear will occur.

1. Engage trigger lock.

ti19350a

2. Install liner into cup and fill liner 1/2 full with appropriate cleaning fluid for material about to be

sprayed.

ti19348a

5. You MUST set pressure control to setting “1”.

6. Disengage trigger lock, turn sprayer upside-down

and trigger for approximately 5 seconds to recirculate material.

ti19374a

12 3A2308C

Page 13

Operation

7. Reverse tip to UNCLOG position. Put prime/pressure relief valve DOWN to spray position and trigger

sprayer through tip into waste area for 1- 2 seconds.

ti19370a

ti19346a

ti14995a

ti19366a

8. Engage trigger lock and put prime/pressure relief

valve UP to release pressure.

ti19347a

ti19350a

9. Remove material cup.

10. Disengage trigger lock, put prime/pressure relief

valve DOWN to spray position, hold sprayer slightly

above material cup and pull trigger to discharge fluid

from pump.

Install/Service Filter (if needed)

1. Perform Pressure Relief Procedure, page 9.

2. Unthread front valve housing from sprayer.

ti19362a

3. Filter should come out of pump housing with valve.

If filter remains in housing, remove it by hand or with

pliers if necessary.

ti19342a

4. Install properly-sized filter (if needed).

ti19403a

11. Put prime/pressure relief valve UP and pull trigger to

finish flushing material.

ti19401a

12. Properly discard any material in cup.

ti19349a

5. Reassemble valve housing to pump.

ti19364a

3A2308C 13

Page 14

Operation

Install Tip/Guard Assembly (if not installed)

NOTE: Only use Graco Tip/Guard assemblies.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the

Pressure Relief Procedure when you stop spraying

and before cleaning, checking, or servicing the

equipment.

1. Engage trigger lock and put prime/pressure relief

valve UP to relieve pressure.

ti19350a

ti19347a

2. Install liner into material cup and fill with material.

ti19348a

3. Thread lid onto material cup and connect cup to

sprayer. NOTE: Do not squeeze sides of cup while

threading lid onto cup.

ti19354a

ti19384a

NOTE: Check valve can be oriented in three locations when attached to cup. If squeezing liner with

left hand, position check valve on left side. If

squeezing liner with right hand, position check valve

on right side.

Do NOT place hands in front of tip.

2. Screw Tip/Guard Assembly onto sprayer. Tighten

retaining nut until completely engaged with sprayer.

Do not overtighten nut.

ti19369a

Filling and Installing Cup

1. Engage trigger lock and put prime/pressure relief

valve UP to relieve pressure.

ti19350a

ti19347a

ti19355a

4. Squeeze liner to purge air through check valve until

material is present at check valve.

ti19367a

NOTE: To purge the maximum amount of air out of

the liner, slightly tilt the sprayer so the check valve is

the highest point.

14 3A2308C

Page 15

Operation

Priming Pump

1. Put prime/pressure relief valve UP to priming position.

ti19347a

2. Turn pressure control knob to prime/clean position

in line with red indicator dot.

ti19357a

3. Disengage trigger lock and trigger sprayer for three

seconds, then release trigger.

Setting Pressure

NOTE: Spraying water, solvents, and thin materials (low

viscosity materials) at high pressure (setting “2” or

higher with yellow light flashing) can result in temporary

pump leaking. To avoid, read and follow instructions

(Quick Guide or Manual) on how to properly adjust pressure.

1. To reduce overspray and extend battery life, always

spray at lowest pressure that produces an acceptable spray pattern.

2. Dial in pressure by spraying material on a scrap

material.

3. You MUST start with dial at “1” and gradually

increase by increments of “1” or less until desired

spray pattern is achieved. Put pressure relief handle

in UP position to turn pressure control knob, then

return handle to DOWN position to spray.

ti19374a

ti19359a

4. Turn pressure control knob counter-clockwise to

lowest position. Put prime/relief valve to DOWN

position to spray.

ti19346a

ti19351a

NOTE: A small amount of air may be introduced into

the cup from the pump while priming. Slightly tip unit

and squeeze liner to purge final amount of air if

desired.

ti19353a

ti19409a

ti19408a

NOTE: After storage, the piston seals need to be

energized prior to next use to prevent leakage. To

energize, follow steps below:

a. Prime system with flushing fluid.

b. Spray at low pressure setting “1” for 10 sec-

onds.

c. Drain fluid. You are now ready to spray.

3A2308C 15

Page 16

Operation

4. If yellow light is flashing while triggering, pressure is

set too high. You MUST turn down pressure until

yellow light no longer flashes, increase tip size, or

do not thin material as much.

ti19655a

5. If pressure relief valve is “popping”, pressure is set

too high. You MUST turn down pressure, increase

tip size, or do not thin material as much.

ti19656a

ti19654a

ti19653a

NOTE: If not enough pressure can be achieved for

an acceptable pattern, reduce tip orifice size and

repeat steps. If acceptable pattern is still not

achieved, material might need to be thinned or

heated (see material manufacturing data sheet for

thinning and heating instructions).

16 3A2308C

Page 17

Operation

Getting Started with Basic Techniques

Use a piece of scrap cardboard to practice these basic

spraying techniques before you begin spraying the surface.

Hold sprayer 10 in. (25 cm) from surface and aim

straight at surface. Tilting sprayer to direct spray angle

causes an uneven finish.

(25 cm)

10 in.

even

finish

Flex wrist to keep sprayer pointed straight. Fanning

sprayer to direct spray at angle causes uneven finish.

even finish

thick

thin

thin

uneven

finish

thick

ti19391a

thin

Triggering Sprayer

Pull trigger after starting stroke. Release trigger before

end of stroke. Sprayer must be moving when trigger is

pulled and released.

ti19393a

Start Moving

Pull Trigger

Release Trigger

Aiming Sprayer

Aim tip of sprayer at bottom edge of previous stroke,

overlapping each stroke by half.

ti19387a ti19392a

NOTE: How fast you move the sprayer will affect spray

application. If material is pulsating (see below), you are

moving too fast. If material runs, you are moving too

slow. See Troubleshooting, page 24.

Pulsating Material

ti19388a

ti19389a

ti19390a

3A2308C 17

Page 18

Operation

Unclogging Spray Tip/Guard Assembly

Always perform the Pressure Relief Procedure

(page 9) before unclogging spray tip.

1. To unclog tip obstruction, engage trigger lock and

put prime/pressure relief valve UP to relieve pressure.

ti19347a

ti19350a

2. Reverse spray tip to UNCLOG position.

5. Disengage trigger lock, put prime/pressure relief

valve DOWN to spray position, and resume spraying.

ti19374a

ti19346a

6. If tip is still clogged, it may be necessary to repeat

steps 1 - 5 and rotate the tip from SPRAY to

UNCLOG several times. Repeat step 1 to release

pressure, remove and clean filter, or replace with

new tip assembly.

ti19349a

ti19370a

3. Aim sprayer at waste area, disengage trigger lock,

and put prime/pressure relief valve DOWN to spray

position. Pull trigger to clear clog.

ti19374a

ti19346a

4. Engage trigger lock. Put prime/pressure relief valve

UP to relieve pressure and rotate spray tip back to

SPRAY position.

ti19347a

ti19350a

ti19371a

7. When obstruction is cleared, engage trigger lock

and rotate arrow-shaped handle back to SPRAY

position.

ti19350a

ti19371a

18 3A2308C

Page 19

Operation

Shutdown and Cleaning

NOTICE

Failure to properly clean sprayer after each use will

result in hardened materials, damage to the sprayer, and

the warranty will no longer be valid. Do not store solvents

other than mineral spirits in sprayer.

Flushing Sprayer

Do not spray solvents through the spray tip. Clean the tip

in a bucket of compatible solvent.

Keep spray area well-ventilated. Keep a good supply of

fresh air moving through the area.

NOTICE

Protect the internal parts of this sprayer from water.

Do not submerge the sprayer in cleaning fluid. Openings

in shroud allow cooling of mechanical parts and electronics inside. If water or cleaning fluid gets into these openings, the sprayer could malfunction or become

permanently damaged.

3. Remove cup from sprayer.

ti19360a

4. Remove lid from cup.

ti19363a

5. Remove material liner and lid from cup and properly

dispose. Properly dispose any excess material left

in the liner.

1. Engage trigger lock and put prime/pressure relief

valve UP to release pressure.

ti19350a

ti14994a

ti19347a

2. Turn pressure control knob to prime/clean position.

ti19357a

ti15000a

ti19352a

6. Insert a new liner into cup and fill 1/2 full with appropriate flushing fluid. Screw on lid and attach cup to

sprayer. Shake sprayer to move flushing fluid

around and clean all wetted areas inside cup.

ti19365a

3A2308C 19

Page 20

Operation

7. Disengage trigger lock, turn sprayer upside-down

and trigger for approximately 15 seconds to

recirculate material.

ti19374a

ti14994a

To avoid serious injury or damage to equipment, do not

expose the sprayer electronics to flushing solvents.

Keep sprayer at least 10 in. above the rim of the con-

tainer when flushing.

ti19798a

11. Remove cup and properly dispose contaminated

fluid.

ti19385a

12. Refill liner 1/2 full. Disengage trigger lock, turn

sprayer upside-down and trigger sprayer for

approximately 15 seconds to recirculate material.

ti19374a

ti19358a

13. Put prime/pressure relief valve DOWN to spray

position. Spray the remaining amount of cleaning

fluid through the front of the sprayer.

Keep spray area well-ventilated. Keep a good supply

of fresh air moving through the area. When flushing

with solvents, always ground the sprayer and waste

container.

8. Reverse tip to UNCLOG position. Put prime/pressure relief valve DOWN to spray position and trigger

sprayer through tip into waste area for 1- 2 seconds.

ti19370a

ti19346a

ti14995a

ti19366a

9. Engage trigger lock. Put prime/pressure relief valve

in UP position.

ti19350a

ti19347a

10. Unthread tip/guard from sprayer and soak in appropriate flushing fluid.

ti19346a

ti19404a

14. If sprayer is not completely clean, repeat steps 11

and 12.

15. Engage trigger lock and put prime/pressure relief

valve UP to release pressure.

ti19350a

ti19347a

16. Remove material liner and lid and properly dispose.

Properly dispose used fluid.

ti19385a

17. Clean Spray Tip/Guard assembly with clean flushing fluid. Use a soft brush to loosen and remove

dried material if needed.

ti19386a

ti19344a

20 3A2308C

Page 21

Operation

Cleaning Sprayer Exterior

Wipe paint off outside of sprayer using a soft cloth

moistened with water or flushing fluid. Do NOT submerge the sprayer or pump.

ti19400a

This sprayer is equipped

with a static wick that

reduces the build up of

static charge to reduce the

risk of fire and explosion.

KEEP THIS SURFACE

CLEAN OF OVERSPRAY.

ti19405a

Storage

3. Disengage trigger lock, turn sprayer upside-down

and trigger for approximately 10 seconds to recirculate material.

ti19374a

ti19358a

4. Reverse tip to UNCLOG position. Put prime/pressure relief valve DOWN to spray position and trigger

sprayer through tip into waste area for 1- 2 seconds.

ti19370a

ti19346a

ti19366a

5. Properly dispose of used storage fluid from material

cup.

6. Recharge battery to full charge before storage. See

Charging the Battery, page 7.

7. Store sprayer indoors in a cool, dry place. Never

store sprayer with material in the cup.

1. Fill material cup 1/3 full with mineral spirits solvent

or dilute a 4 oz. bottle of Pump Armor concentrate

with an additional 4 oz. of water in material cup and

liner.

2. Connect cup to sprayer, put prime/pressure relief

valve to UP position.

ti19347a

ti19384a

3A2308C 21

Page 22

Parts

Parts

59

57

16

32

31

51

50

52

15

7

30

24

18

55

53

54

35

63

38

3

56

60

58

18

39

33

3434

22

49

20

25

26

27

28

29

42

40

11

41

21

44

17

61

19

4

2

10

47

13

6

37

36

46

65

48

62

64

43

45

ti19153a

22 3A2308C

Page 23

Parts

Parts List

Ref. Part Description Qty.

2 16P165 KIT, lid, liner, 25 pack 1

3 16P166 KIT, lid, 25 pack 1

4 16P167 KIT, plug, cup (6 pack) 1

6 16P169 KIT, cup 1

7 16P170 KIT, filter, 30 mesh, 10 pack 1

16P171 KIT, filter, 60 mesh, 10 pack 1

16P172 KIT, filter, 100 mesh, 10 pack 1

10 16P173 KIT, battery, 28V, lithium-ion 1

11 KIT, module, drive

16P174 Models 16H960, 16N927 1

16P175 Models 16N654, 16N655, 16N656 1

13 KIT, charger, battery

*16P177 120V Models 16H960, 16N654 1

**16P178 240V Models 16N927, 16N655, 16N656 1

15 16P179 KIT, pump, rebuild 1

16 16P180 KIT, accumulator, replacement 1

17 16P181 KIT, prime valve, replacement 1

18 16P182 KIT, front shutoff valve, replacement 1

19 262601 KIT, replacement, handle, prime valve 1

20 16M558 SCREW, thumb 1

21 16P284 SCREW, cap, socket head 1

22 16P669 SWIVEL 1

24 16P451 KIT, repair, intake valve 1

25 16N586 GUIDE, ball, inlet 1

26 15R867 SPRING, compression 1

27 16N589 BALL, stainless steel 1

28 109450 PACKING, o-ring 1

29 16N848 HOUSING, intake 1

30 LTX517 TIP, spray 517, RAC X 1

31 16P452 KIT, repair, outlet valve 1

32 16P935 KIT, repair, pressure knob 1

33 16P894 LABEL, control 1

34 16P285 SCREW, set, cup, socket, HD 2

35 16P164 KIT, pump, replacement, HD 1

36 16P183 KIT, motor, replacement 1

37 KIT, repair, clamshell

16P962 Models 16H960, 16N927 1

16P961 Models 16N654, 16N655, 16N656 1

38 246215 GUARD, RAC X 1

39 246453

40 16P966 STRAP, shoulder 1

41 237686 WIRE, ground assembly with clamp 1

OneSeal

™

, RAC X (5 pack)

Ref. Part Description Qty.

42 124165 SCREW, BHCS, M5, 0.8 x 10, ss 4

43 119236 SCREW, mach, torx pan hd 10

44 112161 SCREW, mach, hex, washer, hd 1

45 278345 SWITCH, assembly 1

46 115263 SCREW, cap, socket, head 3

47 POWER CORD 1

16N441 U.S.

16N442 Europe

16P074 Australia

16P076 Italy

16P077 Denmark

16P078 Swiss

16P411 UK

48 16N510 GEAR, reducer 1

49 24P203 HOUSING, drive 1

50 109450 PACKING, o-ring 1

51 111116 PACKING, o-ring, seat 1

52 102982 PACKING, o-ring 1

53 16M574 SEAT, assembly 1

54 104319 PACKING, o-ring 1

55 16M569 NEEDLE, assembly, HD 1

56 111603 PACKING, o-ring, PTFE 1

57 16M571 CAP, needle 1

58 16C354 SPRING, compression 1

59 16P303 PACKING, o-ring 1

60 16M572 RETAINER, spring 1

61 16N602 DISK, toggle knob 1

62 121817 SCREW, cap, socket HD, m4 1

63 248936 KIT, accessory, RAC X 1

64 109575 SCREW, flange, hex HD 2

65 16N180 HOUSING, gear, machining 1

*** Warning Label Kit (Not Shown)

16T263 ENG/FRA/SPA Models 16H960, 16N654

16T264 SPA/POR/ITA Model 16N927

16T265 EU Model 16N655

16T266 ASIA/ANZ Model 16N656

*** Includes 16N441

*** Includes 16N441, 16N442, 16P074

1

***

Replacement Danger and Warning labels are

available at no cost.

3A2308C 23

Page 24

Troubleshooting

Problem Cause Solution

Troubleshooting

Check everything in this Troubleshooting Table before

you bring the sprayer to an authorized service center.

Sprayer makes no sound when

trigger is pulled

Sprayer makes sound but no material

is sprayed when trigger is pulled

Trigger is locked. Disengage trigger lock. See page 9.

Status Indicator Light is solid YELLOW

when triggering, indicating that the battery charge is low, or the battery is too

cold.

Status Indicator Light is solid RED

when triggering, indicating that the battery is too hot to operate.

Battery is not installed or is damaged. Install battery or replace.

Prime/Pressure Relief valve is in UP

position.

Tip is not in SPRAY position. Turn tip to SPRAY position.

Pump is clogged, frozen, or has debris

inside.

Sprayer is not primed or air is in

material cup.

Tip is clogged. See Unclogging Tip/Guard

Tip filter is clogged. Remove and clean tip filter. See

No or low material in liner. Refill liner with material and prime the

Inlet ball is stuck from material

residue left in sprayer.

Outlet ball is stuck from material residue left in sprayer.

Pressure setting too low. Turn pressure control knob clockwise

Replace with charged battery and

place old battery in charger, or allow

battery to warm up.

Allow battery to cool.

Put valve DOWN to spray position.

See Repair manual.

Prime the pump. See Starting a new

Job (or Refilling the Cup), page 12.

Assembly, page 18.

Install/Service Filter, page 13.

pump.

Use a pencil or thin rod to lightly push

on inlet valve to make sure it moves up

and down freely.

Use a thin rod to lightly push outlet

valve ball to make sure it moves freely.

Outlet valve is visible when filter is

removed. See Install/Service Filter,

page 13.

to increase pressure.

24 3A2308C

Page 25

Troubleshooting

Problem Cause Solution

Sprayer sprays with poor results Tip is partially clogged See Unclogging Tip/Guard

Assembly, page 18.

Tip filter is partially clogged or damaged.

Material being sprayed is aerated

because it was shaken.

Material being sprayed is too cold to

spray.

Pressure adjustment is not set correctly.

Material being sprayed is too thick. Thin material with proper reducer rec-

Incorrect tip for application of material. Change tip size.

Tip is worn or damaged. Replace tip.

Tip is not in correct position. Rotate tip to SPRAY position.

Inlet or outlet valves are worn. See Repair manual.

Prime/Pressure Relief valve is worn

out.

Accumulator is frozen and not functioning properly.

Battery is discharged but charger still

displays green light when battery is

inserted.

Battery does not last long. Battery life varies with material, tip size,

Prime/relief valve is moving and

making a popping noise while spraying.

Pump keeps losing prime. Air is getting into the bag system Ensure lid is tight.

Damaged battery. Replace battery.

pressure, and speed setting.

Tip is clogged. Unclog tip.

Pressure is too high Turn pressure control knob counter-

Front valve housing is clogged. Remove front valve housing and clean.

Tip is not in correct position. Rotate Tip to SPRAY position.

Accumulator is frozen and not functioning properly.

Material is too thick. Properly mix material to shear thin the

Prime/Pressure Relief valve is not

properly sealed.

Clean or replace filter. See page 13.

Do NOT shake material. Stir the material or check the manufacturer’s recommendation for the material being

sprayed.

Warm material.

Readjust pressure setting. See Setting

Pressure, page 15.

ommended by material manufacturer.

Replace Prime/Pressure Relief valve.

Check to see if accumulator moves

when spraying. If frozen, replace accumulator.

See Charging the Battery, page 7.

clockwise.

Increase tip size.

Check to see if accumulator moves

when spraying. If frozen, replace accumulator.

Ensure liner is not pinched and creating

an air leak path.

Change lid and liner. Retry.

material.

Warm up material to reduce viscosity.

Thin material with proper reducing

agent.

Make sure Prime/Pressure Relief valve

is fully assembled with thread sealant

applied to threads.

3A2308C 25

Page 26

Problem Cause Solution

Troubleshooting

Paint leaks from bottom of pump

module.

Water or thin cleaning fluids drip from

bottom of pump module.

Piston seal failure. Replace pump module. See Repair

manual.

Replace piston seals. See Repair

manual.

Thin fluids commonly drip while

spraying at high pressure.

After storage, the piston seals need

to be energized prior to next use to

prevent leakage. To energize, follow

steps below:

a. Prime system with flushing fluid.

b. Spray at low pressure setting “1”

for 10 seconds.

c. Drain fluid. You are now ready to

spray.

Cannot squeeze bag to extinguish air

out of liner with a new lid.

Sprayer shuts down after 1.5 seconds

of spraying and yellow light flashes.

Liquid is squirting out of accumulator. Accumulator is worn out. Replace accumulator.

O-ring has set in check valve. Lightly poke bottom of check valve on

underside of lid to release valve.

O-ring in check valve is enlarged from

solvents.

Check valve is frozen from cured

material.

Pressure is too high. Turn pressure control knob counter-

Replace lid.

Replace lid.

clockwise.

Increase tip size.

Spray Pattern Diagnostics

Problem Cause Solution

Spray pattern is pulsating:

Spray pattern has tails:

ti15526a

Operator is moving too fast while spraying. Slow speed of movement.

Tip or tip filter is clogged. Unclog tip or clean tip filter, page 18.

Pressure control is too low. Turn up pressure control.

Incorrect tip for application of

material.

Inlet or outlet valves are worn. See Repair manual.

Change tip.

26 3A2308C

Page 27

Troubleshooting

Problem Cause Solution

Spray pattern has dripping:

Spray pattern is too narrow:

ti15523a

ti15523a

Spray pattern is too wide:

ti15527a

ti15527a

Spray pattern “spits” at the

end or beginning:

Sprayer is moving too slow for material. Move sprayer faster while spraying.

Sprayer is too close to target surface. Move sprayer away from surface 10 in.

(25 cm)

Holding trigger while changing spray

Release trigger when changing directions.

direction.

Incorrect tip for application of

Replace tip.

material.

Pressure control is too high. Turn down pressure control.

Tip is worn or damaged. Replace tip.

Sprayer is too close to target surface. Move sprayer away from surface 10 in.

(25 cm)

Incorrect tip for application of material. Replace tip.

Tip is worn or damaged. Replace tip.

Sprayer is too far away from target sur-

Move sprayer closer to surface.

face.

Incorrect tip for application of material. Replace tip.

Excess material has accumulated on

See Shutdown and Cleaning, page 19.

Spray Tip/Guard Assembly.

ti15525a

ti15525a

Tip continues to drip or ooze

material after trigger is

released:

ti15528a

ti15528a

Tip filter is partially clogged or damaged. Clean or replace filter. See page 13.

Front valve is slow to react. Clean front valve.

Front valve is damaged or worn out. Replace front valve.

Filter is partially clogged or damaged. Clean or replace filter. See page 13.

Tip/Guard Assembly not threaded com-

See Install Tip/Guard Assembly, page 14.

pletely onto sprayer.

Seat is worn. Replace front valve seat housing.

3A2308C 27

Page 28

Repair

Inlet Valve

Removal

1. Engage trigger lock and put prime/pressure relief

valve in UP position to relieve pressure.

ti19350a

2. Remove material cup and battery.

ti19347a

Repair

Installation

1. Insert ball guide (25) with smaller diameter inserted

first.

25

ti19615a

2. Use a thin wire to assemble spring into inlet cavity.

ti19360a

ti19617a

3. Hold sprayer upside-down and use wrench or

socket to loosen fitting. Remove inlet fitting (29),

inlet ball (27), spring, and ball guide (25).

NOTE: Use needle-nose pliers to remove spring

and ball guide if needed.

29

25

27

ti19619a

4. Clean as much excess material from inlet cavity as

possible.

ti19612a

3. Make sure prime/pressure relief valve is in UP

position. Insert ball (27) and assemble inlet fitting

(29) using wrench or socket. Tighten to 140 in-lb

(15.8 N•m).

ti19347a

29

ti19663a

27

ti19664a

ti19613a

28 3A2308C

Page 29

Repair

Outlet Valve

Removal

1. Engage trigger lock and put prime/pressure relief

valve in UP position to relieve pressure.

5. Clean as much excess material from outlet valve

cavity as possible.

ti19614a

ti19350a

ti19347a

2. Remove material cup and battery.

ti19360a

ti19617a

3. Loosen set screws (34) from pressure control knob

and remove knob.

34

ti19620a

Installation

NOTE: Inlet valve must be fully installed before outlet

valve can be installed.

1. Make sure prime/pressure relief valve is in UP position. Use a thin screwdriver or allen wrench and turn

outlet valve (31) counter-clockwise to install.

31

ti19347a

ti19623a

2. Thread outlet valve in until it touches inlet ball.

DO NOT TIGHTEN. Outlet valve should only be

threaded until inlet ball does not move when

touched.

4. Use thin screwdriver or allen wrench to turn outlet

valve (31) clockwise and remove.

ti19616a

3. Install pressure control knob. Turn knob fully

counter-clockwise until it stops (“0” setting will line

31

up with red dot). Torque set screws (34) to 40 in-lb

(4.5 N•m).

34

ti19626a

ti19620a

3A2308C 29

ti19351a

Page 30

Pressure Control Knob

Removal

1. Engage trigger lock and put prime/pressure relief

valve in UP position to relieve pressure.

Repair

Installation

NOTE: Inlet valve must be fully installed before outlet

valve can be installed.

1. Make sure prime/pressure relief valve is in UP position. Use a thin screwdriver or allen wrench to turn

outlet valve counter-clockwise until it touches inlet

ball. DO NOT TIGHTEN. Outlet valve should only

be threaded until inlet ball does not move when

touched.

ti19350a

ti19347a

2. Loosen two set screws (34) from pressure control

knob and remove knob.

34

ti19620a

ti19347a

ti19616a

2. Install pressure control knob. Turn knob fully counter-clockwise (“0” setting will line up with red dot).

Torque set screws (34) to 40 in-lb (4.5 N•m).

34

ti19620a

ti19351a

30 3A2308C

Page 31

Repair

Pump Module/Drive Module

Removal

1. Engage trigger lock and put prime/pressure relief

valve in UP position to relieve pressure.

5. Remove pump module (35) from drive module (11).

11

35

ti19625a

Installation

ti19350a

ti19347a

2. Remove material cup and battery.

ti19360a

ti19617a

3. Unscrew swivel bolt (22) by pressing down and

turning it counter-clockwise. Use tool if needed.

22

ti19621a

4. Unscrew bolt (20). Use tool if needed.

1. Engage trigger lock and remove battery from unit.

ti19350a

ti19617a

2. Assemble pump module (35) to drive module (11).

Gears must properly engage for assembly. Slightly

rotate pump assembly as needed for proper

engagement.

11

35

ti19624a

3. Assemble swivel bolt (22) and bolt (20). Partially

thread both bolts before tightening either bolt. Use

tool to tighten and make sure bolts are secure.

NOTE: Make sure there is no gap between the two

housings when assembling bolts.

22

20

ti19618a

20

ti19622a

3A2308C 31

Page 32

Pump Rebuild Kit

Removal

Repair

Installation

1. Hold rebuild kit (15) and insert wobble drive into piston pocket and connect together.

1. Remove pump module from drive module. See

Pump Module/Drive Module, page 31.

2. Remove outlet valve from pump module and set

aside. See Outlet Valve, page 29.

3. Remove inlet valve from pump module and set

aside. See Inlet Valve, page 7.

4. Remove accumulator (16), front valve (18), and

prime valve (17) from pump module and set aside.

16

18

ti19645a

17

5. Remove four bolts (21) from pump module.

21

ti19646a

6. Separate pump portions as shown below.

15

ti19642a

2. Install four bolts (21). Torque to 60 in-lb (6.7 N•m).

21

ti19643a

3. Install accumulator (16). Torque to 140 in-lb

(15.8 N•m). Apply thread sealant to prime valve (17)

and install. Torque to 140 in-lb (15.8 N•m). Install

front valve (18) fully tighten.

16

18

17

ti19644a

4. Install inlet valve to pump module. See Inlet Valve,

page 7.

ti19647a

5. Install outlet valve to pump module. See Outlet

7. Inspect wobble drive assembly. If bearing race is

visible as shown below, replace wobble drive

assembly.

ti19863a

32 3A2308C

Valve, page 29.

6. Install pump module to drive module. See Pump

Module/Drive Module, page 31.

Page 33

Repair

Clamshell

Removal

1. Engage trigger lock and put prime/pressure relief

valve in UP position to relieve pressure.

6. Remove nut from ground stud. Remove ring terminal and unscrew second nut from ground stud.

Remove ground stud from clamshell.

ti19638a

ti19350a

ti19347a

2. Remove material cup and battery.

ti19360a

ti19617a

3. Remove pump module from drive module. See

Pump Module/Drive Module, page 31.

4. Remove screws (42) from motor housing.

42

7. Carefully remove motor, motor housing, switch, control board, indicator lights, trigger lock, and static

wick from clamshell.

ti19639a

Installation

1. Insert control board into right half of clamshell.

ti19636a

ti19627a

2. Install two LED lights into designated slot in right

5. Remove screws (43) from clamshell.

half of clamshell. Push wire bundle into slots in

clamshell.

43

ti19637a

3A2308C 33

ti19628a

Page 34

Repair

3. Set motor housing into right half of clamshell and

loosely install two bolts (42) to motor housing as

shown below.

42

ti19629a

4. Route wires from motor down the handle.

ti19630a

7. Press ground stud into left half of clamshell. Tighten

nut onto stud. Install ground terminal to stud and

tighten second nut onto stud. Install wire up along

handle.

ti19633a

8. Insert static wick into right half of clamshell and

install left clamshell to right clamshell.

5. Install trigger over top of wires. Route trigger wires

behind trigger.

ti19631a

6. Insert trigger lock over trigger with o-ring facing out.

ti19632a

ti19634a

NOTICE

Wires can become damaged when pinched between

clamshell halves. Make sure no wires are pinched

during reassembly.

9. Install bolts (42) to motor housing and install screws

(43) to connect clamshell halves. Make sure LED

lights and static wick are securely in place. Tighten

bolts (42) to 50 in-lb (5.6 N•m) and screws (43)

to 9 in-lb (1 N•m).

43

42

ti19635a

10. Install pump module to drive module. See Pump

Module/Drive Module, page 31.

34 3A2308C

Page 35

Repair

Motor/Control Board Replacement Kit

6. Unscrew nut from ground stud and remove ring

Removal

1. Engage trigger lock and put prime/pressure relief

valve in UP position to relieve pressure.

terminal. Leave other nut secured to ground stud.

ti19640a

ti19350a

ti19347a

2. Remove material cup and battery.

ti19360a

ti19617a

3. Remove pump module from drive module. See

Pump Module/Drive Module, page 31.

4. Remove four bolts (42) from motor housing.

42

7. Remove motor, motor housing, switch, control

board, indicator lights, trigger lock, and static wick

from clamshell.

ti19639a

Installation

1. Insert control board into right half of clamshell.

ti19627a

5. Remove screws (43) from clamshell.

ti19636a

2. Install two LED lights into designated slot in right

half of clamshell. Push wire bundle into slots in

clamshell.

43

ti19637a

ti19628a

3A2308C 35

Page 36

Repair

a

3. Set motor housing into right half of clamshell and

loosely install two bolts (42) to motor housing as

shown below.

42

ti19629a

4. Route wires from motor down the handle.

ti19630a

5. Assemble trigger over top of wires. Route trigger

wires behind trigger.

7. Install ground terminal to stud and tighten second

nut onto stud. Install wire up along handle.

ti19641a

8. Insert static wick into right half of clamshell and

install left clamshell to right clamshell.

ti19634a

NOTICE

Wires can become damaged when pinched between

clamshell halves. Make sure no wires are pinched

during reassembly.

ti19631a

6. Insert trigger lock over trigger with o-ring facing out.

ti19632a

9. Install two bolts (42) to motor housing and install

screws (43) to connect clamshell halves. Make sure

LED lights and static wick are securely in place.

Tighten bolts (42) to 50 in-lb (5.6 N•m) and screws

(43) to 9 in-lb (1 N•m).

43

42

ti19635

10. Install pump module into drive module. See Pump

Module/Drive Module, page 31.

36 3A2308C

Page 37

Repair

Switch Assembly

5. Remove eight screws (43) from clamshell.

Removal

1. Engage trigger lock and put prime/pressure relief

valve in UP position to relieve pressure.

ti19347a

ti19350a

2. Remove material cup and battery.

ti19617a

ti19360a

3. Remove pump module from drive module. See

Pump Module/Drive Module, page 31.

43

ti19637a

6. Remove trigger lock from assembly.

ti19649a

7. Remove trigger switch from clamshell and loosen

screws connecting wires to switch.

4. Remove four bolts (42) from motor housing.

ti19650a

42

ti19636a

3A2308C 37

Page 38

Installation

Repair

1. Insert wires and tighten screws to connect wires into

slots 1 and 2 of trigger switch.

ti19648a

2. Install trigger over top of wires. Route trigger wires

behind trigger.

3. Install trigger lock over trigger with o-ring facing out.

ti19632a

4. Install bolts (42) into motor housing and install

screws (43) to connect the clamshell halves. Make

sure LED lights and static wick are properly in place.

Tighten all four bolts (42) to 50 in-lb (5.6 N•m) and

screws (43) to 9 in-lb (1 N•m).

43

42

ti19631a

ti19635a

5. Install pump module into drive module. See Pump

Module/Drive Module, page 31.

38 3A2308C

Page 39

Repair

Gear Replacement

Removal

1. Remove pump module from drive module. See

Pump Module/Drive Module, page 31.

4. Remove four screws holding clamshells together

and two bolts connecting drive to clamshell.

ti19625a

2. If unit has accessible retaining bolt shown below,

proceed to step 3. If unit does not have accessible

retaining bolt, proceed to step 4.

ti19858a

3. Unscrew retaining bolt until gear (48) is no longer

retained. Remove gear from drive. Proceed to

Installation.

ti19877a

ti19861a

5. Pull the clamshell up and unscrew retaining bolt

until gear (48) is no longer retained. Remove gear

from drive. Proceed to Installation.

ti19878a

48

ti19860a

Installation

1. Engage trigger lock and remove battery from unit.

ti19859a

ti19350a

48

ti19860a

ti19617a

3A2308C 39

Page 40

Repair

2. If unit has accessible retaining bolt shown below,

proceed to step 3. If unit does not have accessible

retaining bolt, proceed to step 5.

ti19858a

3. Install new gear into drive housing. Screw retaining

bolt into drive housing to retain gear. Torque to 30

in-lb (3.4 N•m).

ti19857a

5. Install new gear into drive housing. Pull the clamshell up and screw in retaining bolt to retain gear.

Torque to 30 in-lb (3.4 N•m).

ti19860a

ti19879a

6. Install two bolts connecting drive to clamshell.

Torque to 50 in-lb (5.6 N•m). Install four screws

connecting clamshell halves. Torque to 9 in-lb

(1.0 N•m).

ti19860a

ti19862a

ti19880a

4. Install pump module to drive module. See Pump

Module/Drive Module, page 31.

7. Install pump module to drive module. See Pump

Module/Drive Module, page 31.

ti19624a

40 3A2308C

Page 41

Technical Data

Technical Data

Models 16H960, 16N654, 16N927, 16N655, 16N656

U.S. Metric

Sprayer:

Adjustable Pressure Range 1000 to 4000 psi 69 to 276 bar, 6.9 to 27.6 MPa

Maximum Working Pressure 4000 psi 276 bar, 26.7 MPa

Weight 8.6 lb 3.9 kg

Dimensions:

Length 14.5 in. 36.8 cm

Width 5.6 in. 14.2 cm

Height 12.8 in. 32.5 cm

Storage Temperature Range ◆❖ 32° to 113° F 0° to 45° C

Operating Temperature Range ✔ 40° to 90° F 4° to 32° C

Battery Charging Temperature Range 50° to 113° F 10° to 45° C

Storage Humidity Range 0% to 95% relative humidity, non-condensing

Sound Pressure Level LpA = 79.0 dB, Sound Power = LWA = 90.0

Vibration Level Acceleration

Wetted Parts Brass, aluminum, 301 sstl, 440c sstl, carbide, FKM, TFE, PTFE, LDPE,

Charger:

Charging Time 50 minutes to 80%, 75 minutes to 100%

Power Source 120 VAC / 240 VAC

Battery:

Voltage 28 VDC, Lithium Ion

Capacity 2.4 Ah, 67 Wh

Less than 8.2 feet/s

UHMWPE, Polypropylene, Nylon 6/6

2

2.5 m/s2††

Pump damage will occur if fluid freezes in pump.

◆

Damage to plastic parts may result if impact occurs in low temperature conditions.

❖

Changes in coating viscosity at very low or very high temperatures can affect sprayer performance.

✔

per ISO 3744 measured at 3.1 feet (1m)

†

per ISO 5349, no load condition

††

FCC Declaration for Battery Charger

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

WARNING:

operate the equipment.

NOTE:

These limits are designed to provide reasonable protection against harmful interference in a residential installation. The equipment generates,

uses and can radiate radio frequency energy and, if not installed an used in accordance with the instructions, may cause harmful interference to

radio communications. However, there si no guarantee that interference will not occur in a particular installation. If this equipment does not cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measure:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help

3A2308C 41

Changes or modifications to this unit not expressly approved by the party responsible for compliance could void the user’s authority to

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

Page 42

Notes

Notes

42 3A2308C

Page 43

Notes

Notes

3A2308C 43

Page 44

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions.

This manual contains English. MM 3A2308

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision C - April 2013

Loading...

Loading...