Page 1

Instructions-Parts

Color and Catalyst

Change Valve Stacks

For color/catalyst changing or distribution of industrial paints and coatings or fluids.

Important Safety Instructions

Read all warnings and instructions in this manual.

For complete warnings and instructions see your

proportioning system manual. Hazard symbols refer

to specific procedure risks. Save all instructions.

See page 3 for model information, including maximum working pressure.

312783B

TI11668A

Low Pressure Valve Stack 15V813

TI11665A

High Pressure Valve Stack 15V817

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Low Pressure Valve Stacks . . . . . . . . . . . . . . . . . 3

High Pressure Valve Stacks . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Low Pressure Color/Catalyst Valve Stacks . . . . . 6

Technical Data, Low Pressure Stacks . . . . . . . . . 6

Low Pressure Valve Part Quantity Chart . . . . . . . 7

High Pressure Color/Catalyst Valve Stacks . . . . 8

Technical Data, High Pressure Stacks . . . . . . . . 8

High Pressure Valve Part Quantity Chart . . . . . . 9

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Low Pressure Valve Stack Dimensions . . . . . . . 10

High Pressure Valve Stack Dimensions . . . . . . 11

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 12

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 12

Related Manuals

See the following manuals for additional information on

the color and catalyst change valve stacks.

Manual Description

312775 ProMix 2KS Manual System Installation

312776 ProMix 2KS Manual System Operation

312777 ProMix 2KS Manual System Repair-Parts

312778 ProMix 2KS Automatic System Installation

312779 ProMix 2KS Automatic System Operation

312780 ProMix 2KS Automatic System

Repair-Parts

312782 Dispense Valve

312787 Color Change Module Kit

2 312783B

Page 3

Models

Low Pressure Valve Stacks

300 psi (2.1 MPa, 21 bar) Maximum Fluid Working Pressure

Models

Valve Stack

Part No. Series Valve Stack Description

256994

15V812 2 color/catalyst change 3

256290 3 color/catalyst change 4

15V813 4 color/catalyst change 5

256292 5 color/catalyst change 6

256293 6 color/catalyst change 7

15V814 7 color/catalyst change 8

256295 8 color/catalyst change 9

256296 9 color/catalyst change 10

256297 10 color/catalyst change 11

256298 11 color/catalyst change 12

15V815 12 color/catalyst change 13

256300 13 color/catalyst change 14

256301 14 color/catalyst change 15

256302 15 color/catalyst change 16

256303 16 color/catalyst change 17

256304 17 color/catalyst change 18

256305 18 color/catalyst change 19

256306 19 color/catalyst change 20

256307 20 color/catalyst change 21

256308 21 color/catalyst change 22

256309 22 color/catalyst change 23

256310 23 color/catalyst change 24

256311 24 color/catalyst change 25

256312 25 color/catalyst change 26

256313 26 color/catalyst change 27

256314 27 color/catalyst change 28

256315 28 color/catalyst change 29

256316 29 color/catalyst change 30

256372 30 color/catalyst change 31

A

1 color

Valve Part

No.

15X304

Quantity◆

Valve

2

◆ Each stack includes one additional valve for solvent.

312783B 3

Page 4

Models

High Pressure Valve Stacks

3000 psi (21 MPa, 210 bar) Maximum Fluid Working Pressure

Valve Stack

Part No. Series Valve Stack Description

256995

15V816 2 color/catalyst change 3

256339 3 color/catalyst change 4

15V817 4 color/catalyst change 5

256341 5 color/catalyst change 6

256342 6 color/catalyst change 7

256343 7 color/catalyst change 8

256344 8 color/catalyst change 9

256345 9 color/catalyst change 10

256346 10 color/catalyst change 11

256347 11 color/catalyst change 12

256348 12 color/catalyst change 13

256349 13 color/catalyst change 14

256350 14 color/catalyst change 15

256351 15 color/catalyst change 16

256352 16 color/catalyst change 17

256353 17 color/catalyst change 18

256354 18 color/catalyst change 19

256355 19 color/catalyst change 20

256356 20 color/catalyst change 21

256357 21 color/catalyst change 22

256358 22 color/catalyst change 23

256359 23 color/catalyst change 24

256360 24 color/catalyst change 25

256361 25 color/catalyst change 26

256362 26 color/catalyst change 27

256363 27 color/catalyst change 28

256364 28 color/catalyst change 29

256365 29 color/catalyst change 30

256371 30 color/catalyst change 31

A

1 color

Valve Part

No.

15X303

Quantity◆

Valve

2

◆ Each stack includes one additional valve for solvent.

4 312783B

Page 5

Installation

Installation

1. Connect 5/32 in. (4 mm) OD air actuation tubes

from the valve solenoids to the air inlets (A) of each

valve. See F

NOTE: The high pressure color change valve uses a

spring-operated valve closure vent (20) which does not

require a second air actuation line. If you are installing a

bare valve, remove the elbow fitting from the top port

and install the breather vent which is shipped loose.

2. Connect fluid supply lines to the 1/4 npt(f) inlet (B) of

each valve adapter. Supply solvent to one valve (S)

at the top of the stack.

NOTE: Paint Circulating System

The color change valves have two fluid ports for each

individual valve. If you are circulating paint, plumb the

valves in one port and out the other.

Another option is to use a tee fitting to circulate.

Verify that all unused fluid ports on the color change

valve stack are plugged before operation. An open

port will leak fluid.

IG. 1.

NOTICE

20

A

S

B

C

High Pressure Valve Stack

A

TI11665A

S

3. Connect the gun fluid supply line to the fluid outlet

port (C) of the color change manifold.

NOTICE

A check valve is recommended on all dead head

valves to prevent color crossover if two valves are

open at the same time.

A

C

Low Pressure Valve Stack

FIG. 1. Valve Stack Connections

B

TI11668A

312783B 5

Page 6

Parts

Parts

Low Pressure Color/Catalyst Valve Stacks

16

10

8

9

3

4

2

*15

7

11

1

2

Ref.

No. Part No. Description Qty

1 15X304 VALVE, low pressure; includes item

15; see manual 312782

2 --- SCREW; 5/16-24 x 5/8 in. (16 mm) ◆

3 15T436 ADAPTER, manifold ◆

4 101970 PLUG, pipe ◆

6 15T793 MANIFOLD, fluid port 1

7 15T574 SEAT, valve needle ◆

8 110004 O-RING; ptfe ◆

9 15T792 MANIFOLD, body ◆

10 15T794 MANIFOLD, end cap 1

11 15X129 PLUG, housing ◆

12 109450 O-RING; ptfe ◆

15* --- O-RING; ptfe ◆

16 --- SCREW, cap, socket-head; 1/4-20

x 5/8 in. (16 mm)

8

12

◆ See the Low Pressure Valve Part Quantity Chart

on page 7 to determine the quantity of each part in

◆

your valve stack.

* Part included in Seal Kit 15W621 (purchase sepa-

rately). Kit includes additional parts; see Dispense

Valve manual 312782.

--- These parts are not available separately.

6

Technical Data, Low Pressure

Stacks

Maximum Fluid Working

◆

Pressure 300 psi (2.1 MPa, 21 bar)

Wetted Parts 303 sst, tungsten carbide,

ptfe, acetal

Color Change Valves: see

manual 312782

Weight see page 7

TI11669A

6 312783B

Page 7

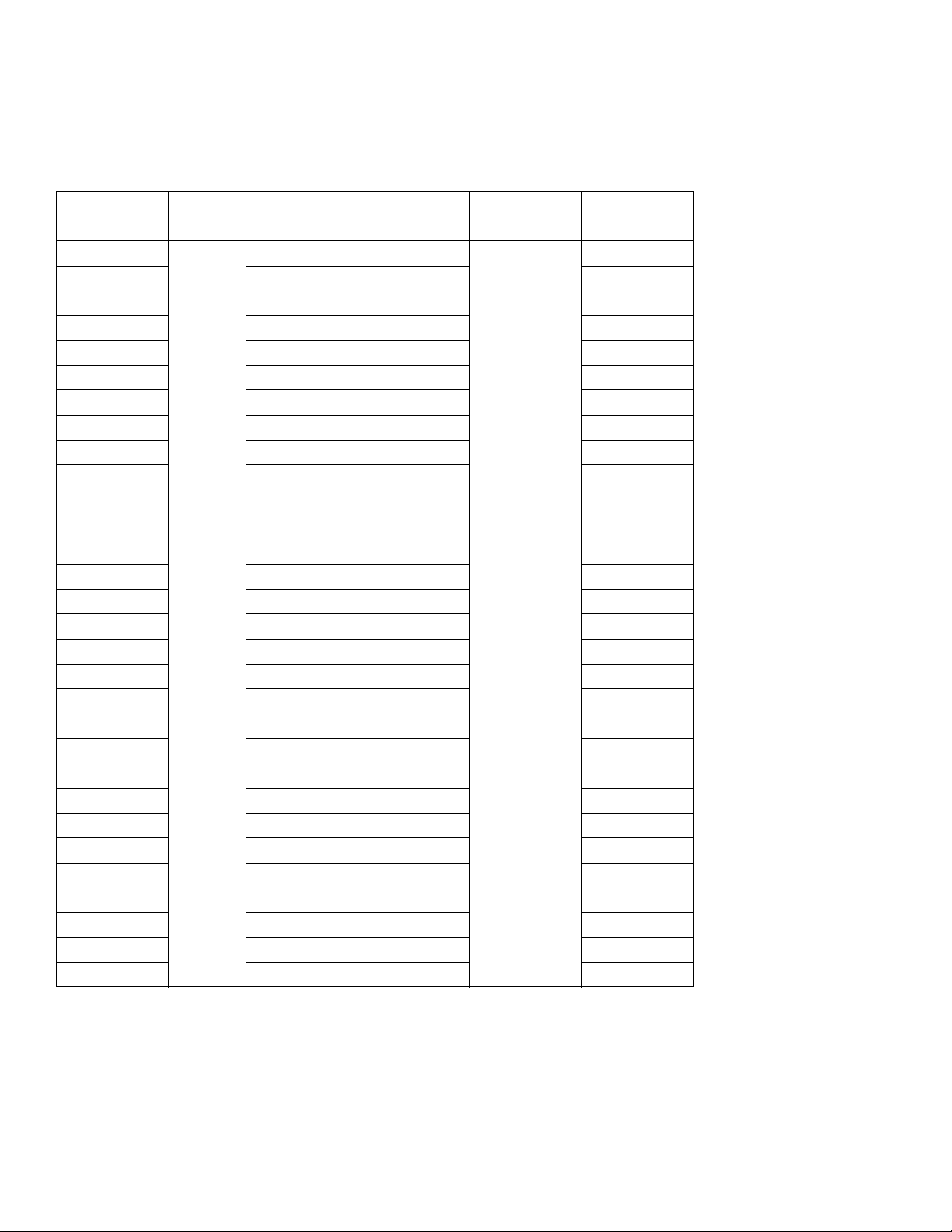

Low Pressure Valve Part Quantity Chart

Find your Valve Stack Part No. in the left column and the desired reference number in the top row to find the part

quantity used in your valve stack.

Parts

Valve

Stack

Part No.

256994 2 4 2 2 2 2 1 0 0 2 4 2.35 (1.07)

15V812 3 8 3 3 3 3 2 1 1 3 6 4.05 (1.84)

256290 4 8 4 44320046 4.70 (2.13)

15V8135125554311586.40 (2.90)

256292 6 12 6 6 6 4 3 0 0 6 8 7.05 (3.20)

256293 7 16 7 7 7 5 4 1 1 7 10 8.75 (3.97)

15V81481688854008109.40 (4.26)

256295 9 20 9 99651191211.10 (5.03)

256296 10 20 10 10 10 6 5 0 0 10 12 11.75 (5.33)

256297 11 24 11 11 11 7 6 1 1 11 14 13.45 (6.10)

256298 12 24 12 12 12 7 6 0 0 12 14 14.10 (6.40)

15V815 13 28 13 13 13 8 7 1 1 13 16 15.80 (7.17)

256300 14 28 14 14 14 8 7 0 0 14 16 16.45 (7.46)

256301 15 32 15 15 15 9 8 1 1 15 18 18.15 (8.23)

256302 16 32 16 16 16 9 8 0 0 16 18 18.80 (8.53)

256303 17 36 17 17 17 10 9 1 1 17 20 20.50 (9.30)

256304 18 36 18 18 18 10 9 0 0 18 20 21.15 (9.59)

256305 19 40 19 19 19 11 10 1 1 19 22 22.85 (10.36)

256306 20 40 20 20 20 11 10 0 0 20 22 23.50 (10.66)

256307 21 44 21 21 21 12 11 1 1 21 24 25.20 (11.43)

256308 22 44 22 22 22 12 11 0 0 22 24 25.85 (11.73)

256309 23 48 23 23 23 13 12 1 1 23 26 27.55 (12.50)

256310 24 48 24 24 24 13 12 0 0 24 26 28.20 (12.80)

256311 25 52 25 25 25 14 13 1 1 25 28 29.90 (13.56)

256312 26 52 26 26 26 14 13 0 0 26 28 30.55 (13.86)

256313 27 56 27 27 27 15 14 1 1 27 30 32.25 (14.63)

256314 28 56 28 28 28 15 14 0 0 28 30 32.90 (14.92)

256315 29 60 29 29 29 16 15 1 1 29 32 34.60 (15.70)

256316 30 60 30 30 30 16 15 0 0 30 32 35.25 (15.99)

256372 31 64 31 31 31 17 16 1 1 31 34 36.95 (16.76)

Reference Numbers

Weight

lb (kg)123478911121516

312783B 7

Page 8

Parts

High Pressure Color/Catalyst Valve Stacks

16

10

8

9

‡7

‡5

3

4

2

1

20

‡5

*‡15

11

Ref.

No. Part No. Description Qty

1 15X303 VALVE, high pressure; includes

item 15; see manual 312782

2 --- SCREW; 5/16-24 x 5/8 in. (16 mm) ◆

3 15T436 ADAPTER, manifold ◆

4 101970 PLUG, pipe ◆

5‡ --- O-RING; ptfe ◆

6 15T869 MANIFOLD, fluid port 1

7‡ --- SEAT, valve needle; sst ◆

8 110004 O-RING; ptfe ◆

9 15T872 MANIFOLD, body ◆

10 15T871 MANIFOLD, end cap 1

11 15T873 PLATE, blank ◆

12 109450 O-RING; ptfe ◆

15*‡ --- O-RING; ptfe ◆

16 --- SCREW, cap, socket-head; 1/4-20

x 5/8 in. (16 mm)

20 15V818 VENT, breather ◆

8

12

2

◆ See the High Pressure Valve Part Quantity Chart

on page 9 to determine the quantity of each part in

◆

your valve stack.

‡ Parts included in Valve Seat Kit 24A861 (purchase

separately). (Optional Carbide Seat Kit 15U932 is

available separately.)

* Part included in Seal Kit 15U933 (purchase sepa-

rately). Kit includes additional parts; see Dispense

Valve manual 312782.

--- These parts are not available separately.

6

Technical Data, High Pressure

Stacks

◆

Maximum Fluid Working

Pressure 3000 psi (21 MPa, 210 bar)

Wetted Parts 303 sst, tungsten carbide,

ptfe

Color Change Valves: see

manual 312782

Weight see page 9

TI11666A

8 312783B

Page 9

High Pressure Valve Part Quantity Chart

Find your Valve Stack Part No. in the left column and the desired reference number in the top row to find the part

quantity used in your valve stack.

Parts

Valve

Stack

Part No.

256995 2 4 2 2 4 2 2 1 0 0 2 4 2 2.60 (1.18)

15V816 3 8 3 3 6 3 3 2 1 1 3 6 3 5.05 (2.29)

256339 4 8 44843200464 5.20 (2.36)

15V817512551054311585 7.65 (3.47)

256341 6 12 6 6 12 6 4 3 0 0 6 8 6 7.80 (3.54)

256342 7 16 7 7 14 7 5 4 1 1 7 10 7 10.25 (4.65)

256343 8 16 8 8 16 8 5 400810810.40 (4.72)

256344 9 20 9 9 18 9 6 511912912.85 (5.83)

256345 10 20 10 10 20 10 6 5 0 0 10 12 10 13.00 (5.90)

256346 11 24 11 11 22 11 7 6 1 1 11 14 11 15.45 (7.01)

256347 12 24 12 12 24 12 7 6 0 0 12 14 12 15.60 (7.08)

256348 13 28 13 13 26 13 8 7 1 1 13 16 13 18.05 (8.19)

256349 14 28 14 14 28 14 8 7 0 0 14 16 14 18.20 (8.26)

256350 15 32 15 15 30 15 9 8 1 1 15 18 15 20.65 (9.37)

256351 16 32 16 16 32 16 9 8 0 0 16 18 16 20.80 (9.43)

256352 17 36 17 17 34 17 10 9 1 1 17 20 17 23.25 (10.55)

256353 18 36 18 18 36 18 10 9 0 0 18 20 18 23.40 (10.61)

256354 19 40 19 19 38 19 11 10 1 1 19 22 19 25.85 (11.73)

256355 20 40 20 20 40 20 11 10 0 0 20 22 20 26.00 (11.79)

256356 21 44 21 21 42 21 12 11 1 1 21 24 21 28.45 (12.90)

256357 22 44 22 22 44 22 12 11 0 0 22 24 22 28.60 (12.97)

256358 23 48 23 23 46 23 13 12 1 1 23 26 23 31.05 (14.08)

256359 24 48 24 24 48 24 13 12 0 0 24 26 24 31.20 (14.15)

256360 25 52 25 25 50 25 14 13 1 1 25 28 25 33.65 (15.26)

256361 26 52 26 26 52 26 14 13 0 0 26 28 26 33.80 (15.33)

256362 27 56 27 27 54 27 15 14 1 1 27 30 27 36.25 (16.44)

256363 28 56 28 28 56 28 15 14 0 0 28 30 28 36.40 (16.51)

256364 29 60 29 29 58 29 16 15 1 1 29 32 29 38.85 (17.62)

256365 30 60 30 30 60 30 16 15 0 0 30 32 30 39.00 (17.69)

256371 31 64 31 31 62 31 17 16 1 1 31 34 31 41.45 (18.80)

Reference Numbers

Weight

lb (kg)123457891112151620

312783B 9

Page 10

Dimensions

Dimensions

NOTE: Mounting bracket 15U927 is available to mount

the color valve stack to a ProMix 2KS Fluid Station. See

manual 312787 for mounting instructions.

Low Pressure Valve Stack Dimensions

G

F

A

B

FIG. 2. Low Pressure Valve Stack Dimensions

A

(manifold cap

and screws)B(manifold)C(fluid port)

0.5 in.

(13 mm)

2.061 in.

(52.3 mm)

1.07 in.

(27.2 mm)

E

D

(A+total of B+C)

Example shown with

three manifolds:

7.75 in.

(197 mm)

E

(width)

8.43 in.

(214.1 mm)

B

B

C

F

(mounting

hole

dimension)

2.061 in.

(52.3 mm)

D

TI13553a

G

(mounting

hole size)

1/4-20

10 312783B

Page 11

High Pressure Valve Stack Dimensions

G

F

Dimensions

A

B

FIG. 3. Hign Pressure Valve Stack Dimensions

A

(manifold cap

and screws)B(manifold)C(fluid port)

0.62 in.

(15.7 mm)

2.25 in.

(57.2 mm)

1.07 in.

(27.2 mm)

E

D

(A+total of B+C)

Example shown with

three manifolds:

8.44 in.

(214 mm)

E

(width)

10.16 in.

(258.1 mm)

B

B

C

F

(mounting

hole

dimension)

2.25 in.

(57.2 mm)

D

TI13554a

G

(mounting

hole size)

1/4-20

312783B 11

Page 12

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 312783

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2008, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 1/2009

Loading...

Loading...