Page 1

Instructions-Parts List

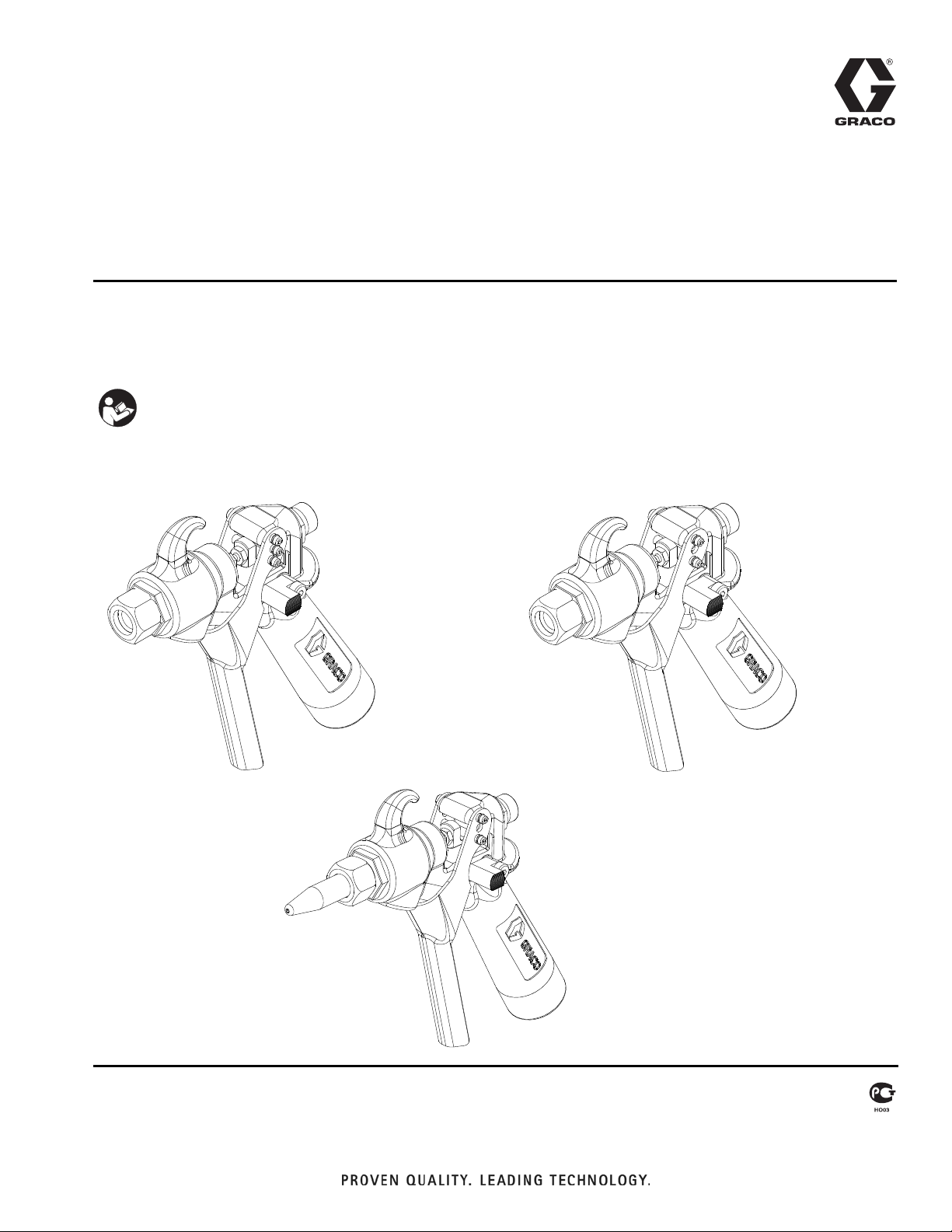

Pistol Grip Flow Gun

For dispensing ambient temperature sealants and adhesives.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 2 for part numbers and maxumum working pressure.

309739D

Model 12004X

Models 12004 and 12005

Model 12006

Page 2

Models

Models

Pistol Grip, Base Seal Pistol Grip, Tip Seal

Part Number Model Description

2500 psi (17.2 MPa, 172 bar) maximum working pressure

C27020 12004 Standard base seal

C27031 12004X Two stage, easy pull

C27067 12005 Balanced piston

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Grounding and Electrical Requirements . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 5

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Models 12004, 12004X . . . . . . . . . . . . . . . . . . . . 8

Model 12005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Model 12006 . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Models 12004 & 12004X . . . . . . . . . . . . . . . . . . 12

Model 12005 . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Model 12006 . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 16

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 16

Part Number Model Description

2000 psi (13.79 MPa, 137.9 bar) maximum working pressure

C27078 12006 Pistol Grip, Tip Seal

2 309739

Page 3

Warnings

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

• Connect only to grounded power source.

SKIN INJECTION HAZARD

High pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

Warnings

Warning

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure on page 5 if the nozzle clogs and before cleaning, checking or

servicing equipment.

TOXIC FLUID HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on the skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers and dispose of it according to applicable guidelines.

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause death or serious injury.

• Do not exceed maximum working pressure or temperature rating of lowest rated system component.

See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturers warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses away from traffic areas, sharp edges, moving parts and hot surfaces.

• Do not use hoses to pull equipment.

309739 3

Page 4

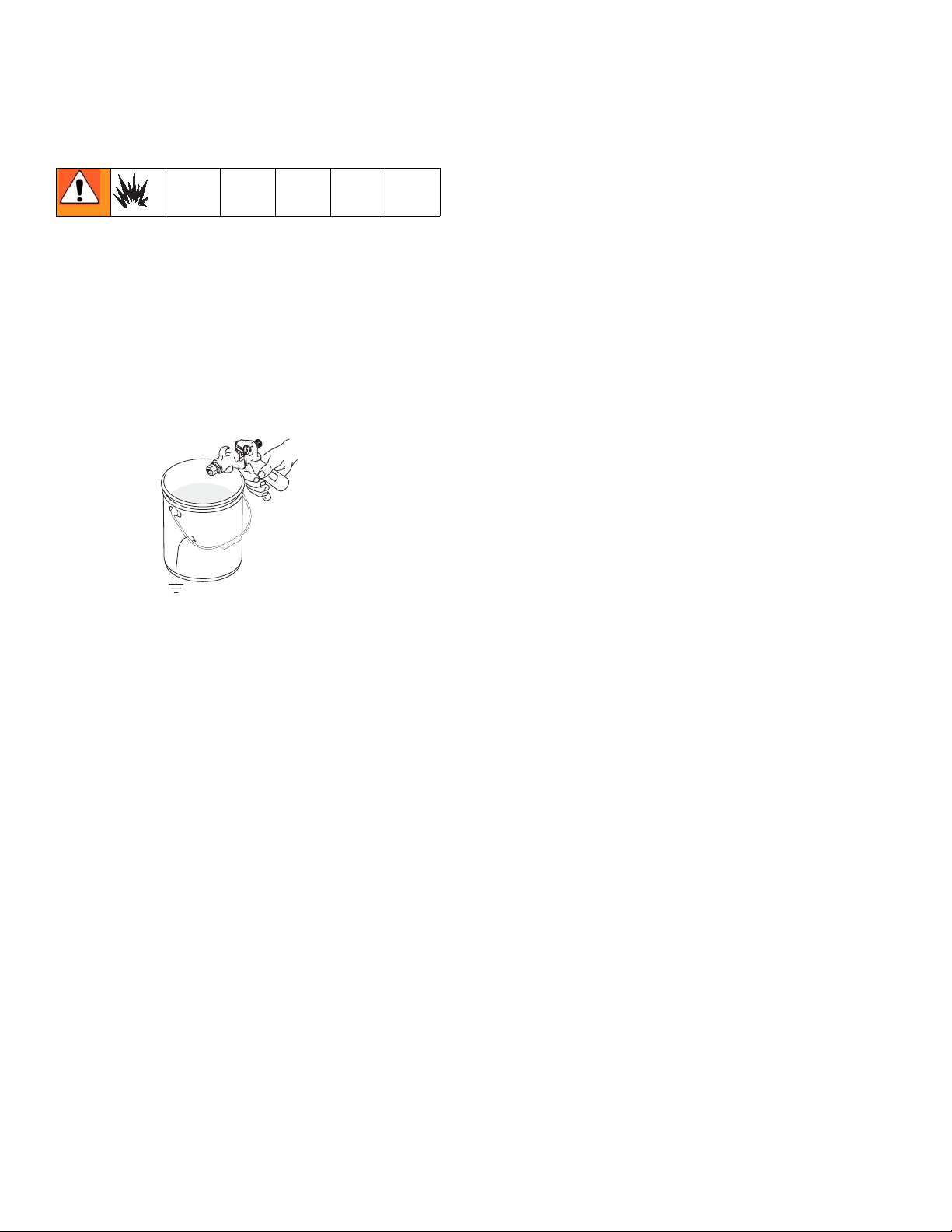

Grounding and Electrical Requirements

Grounding and Electrical Requirements

1. Pump: connect a ground wire and clamp to a true

earth ground as shown in pump manual.

2. Applicator: ground through motor cable assembly.

The following are minimum requirements for a basic dispensing system. Your system may include other equipment or objects that must be grounded. Check your local

electrical code for detailed grounding instructions for

your area and type of equipment.

To maintain grounding continuity when flushing or relieving pressure, always hold a metal part of spray gun

firmly to side of a grounded metal pail. Then trigger

spray gun.

ti3795a

3. Fluid and air hoses: only use electrically conduc-

tive material and air hoses.

4. Dispense gun: ground through connection of hose

or cable.

5. Air compressor: follow manufacturer’s recommen-

dations.

6. Object being sprayed: refer to local code.

7. Fluid supply container: refer to local code.

8. Solvent pails used for flushing: refer to local

code.

4 309739

Page 5

Installation

Installation

Inspect flow gun for shipping damage. If damage is

found notify the carrier immediately.

If material hose will be suspended by a hanger or

tool balancer, route hose through the suspension

device before

1. Connect flow gun to any standard Graco hose

assembly.

2. Connect the opposite end of the heated hose

assembly to any fluid supply system. See Model

table, page 2 for maximum fluid working pressure

for your gun model.

3. Tighten fluid connections.

4. Before operating gun, squeeze and release trigger a

few cycles. Observe action of cartridge assembly.

securing each end of material hose.

Pressure Relief Procedure

To help prevent injuries, follow this procedure

when you shut off the flow gun and before checking or adjusting any part of gun.

If you suspect the tip/nozzle or hose is completely

clogged or that pressure has not been fully relieved after

following the above steps, VERY SLOWLY loosen the

retaining nut or hose end coupling to relieve pressure

gradually. Then loosen it completely. Clear tip/nozzle or

hose.

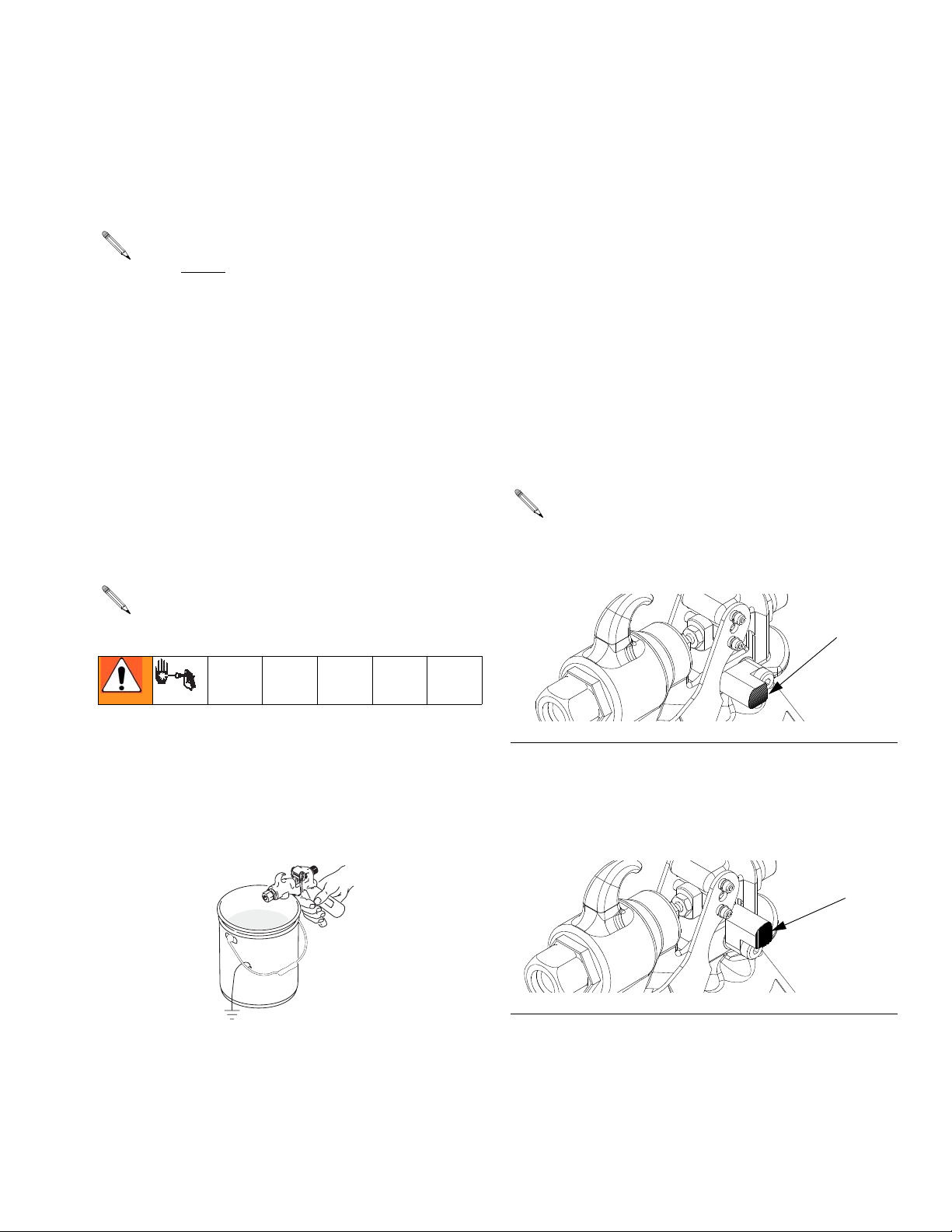

Trigger Lock

Always engage trigger lock when you stop dispensing to

prevent gun from being triggered accidentally by hand or

if dropped or bumped.

To engage trigger lock, release trigger and rotate lock

downward. See Fig. 1.

Do not try to force trigger valve open with trigger

lock engaged. This could result in component failure.

Trigger Lock

Engaged

1. Shut off air to pump.

2. Close bleed-type master air valve (required in your

system).

3. Hold metal part of spray gun firmly to side of

grounded metal pail. Trigger gun to relieve pressure.

ti3795a

4. Open drain valve and/or pump bleeder valve having

a container ready to catch the drainage.

5. Leave drain valve open until you are ready to

spray/dispense again.

F

IG. 1: Trigger Lock Engaged

To disengage trigger lock, rotate it upward. See Fig. 2.

Trigger Lock

Disengaged

F

IG. 2: Trigger Lock Disengaged

309739 5

Page 6

Troubleshooting

Troubleshooting

Problem Cause Solution

Gun fails to dispense when trigger is

actuated

Gun fails to dispense when trigger is

engaged

Seal leakage Packing adjustment nut not snug Follow Pressure Relief Procedure,

Material leaks from gun inlet swivel Worn seals Replace seals.

Material lodged in nozzle Follow Pressure Relief Procedure,

page 5. Clear nozzle of blockage.

Material supply, hose, passages,

clogged

Tension of trigger needs adjustment Check spring tension adjustment at

Needle and seat adapter loose or

worn

Worn seals and packings Rebuild gun as necessary.

Check material supply settings,

hoses, etc. for proper material supply.

Verify integrity of trigger pin through

yoke. Repair or replace cartridge

assembly as necessary.

rear of gun. Spring tension should be

adjusted to allow approximately 1/32

in. of free play on trigger.

Verify integrity of trigger pin through

yoke. Repair or replace cartridge

assembly as necessary.

Check that seat adapter is tightened

firmly and flush to gun body.

Needle and seat adapter worn.

Replace components as necessary.

page 5. Tighten packing adjustment

nut.

6 309739

Page 7

Troubleshooting

309739 7

Page 8

Service

Service

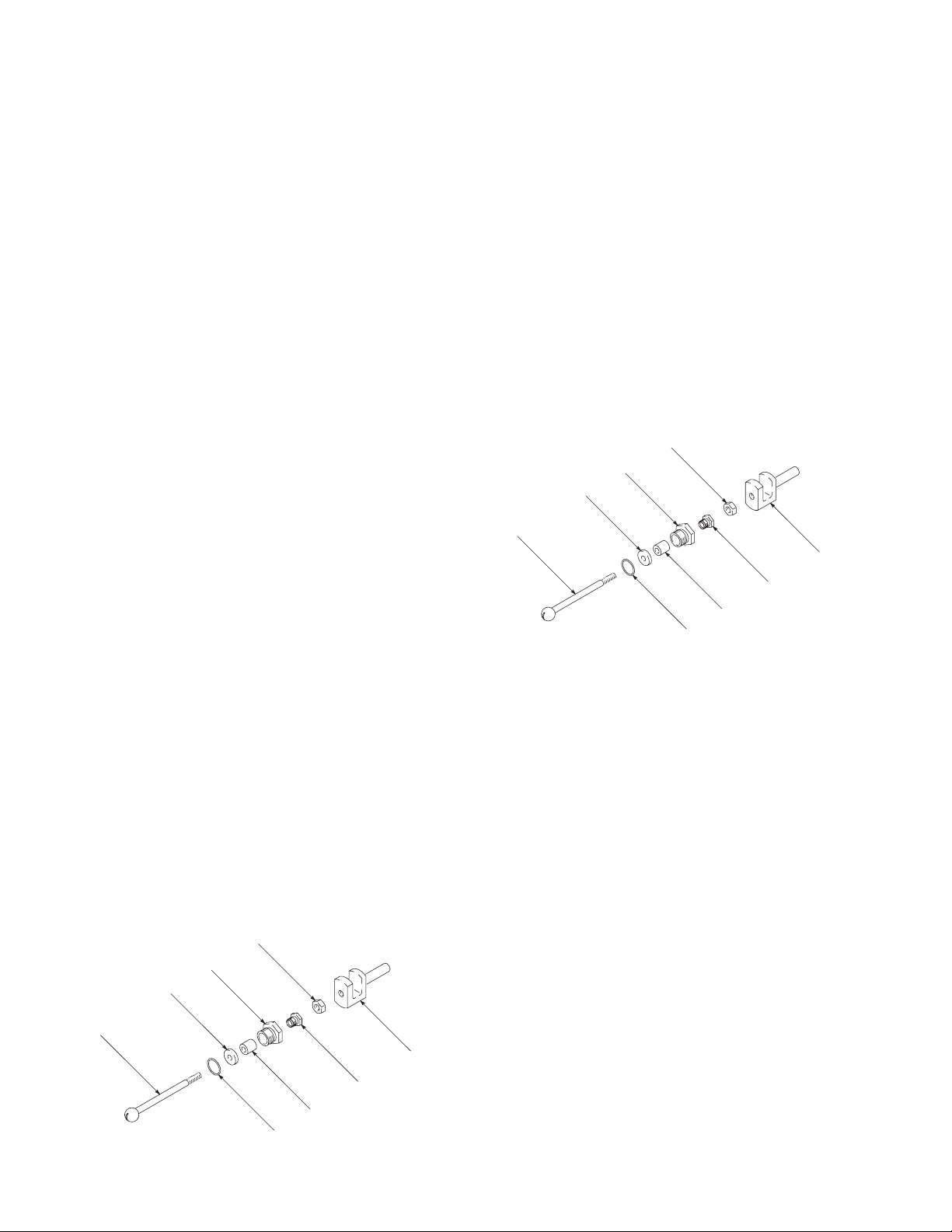

Models 12004, 12004X

Disassembly

1. Actuate gun to purge material and relieve pressure

in gun. Pressure Relief Procedure, page 5.

2. Disconnect material supply line from gun handle.

3. Hold adapter (9) stationary and unscrew nozzle and

collar (16).

4. With trigger depressed, unscrew adapter (9) from

gun body (17).

5. Remove o-ring (10) from adapter (9).

6. Loosen lock nut (14).

7. Carefully unscrew and remove spring retainer (15)

and spring (13) from the gun body (17).

8. Remove screw (11) and lock washer (23) from side

of trigger (18).

9. Pull trigger pins (12) from gun body (17) and remove

trigger (18).

10. Unscrew packing nut (5) from gun body (17).

11. Remove cartridge assembly through side of gun

handle.

Cartridge Disassembly Procedure

1. Remove o-ring (4) from groove on packing nut (5).

2. Loosen lock nut (14) on cartridge while holding yoke

(1) in a soft

3. Separate needle/ball (8) from yoke (1) using the slot

in needle/ball to unscrew the yoke.

4. Remove adjusting screw (3) from packing nut (5).

Then, separate needle/ball (8) from packing support

(7).

5. Push seals (6) out of packing nut (5).

Nut

Packing Nut

Packing Support

Needle/ball

Yok e

Reassembly

Clean all parts thoroughly before reassembling. Check

them carefully for damage or wear, replacing parts as

needed. For best results replace the original parts with

new parts in repair kits.

Prior to assembly, lubricate all seals and o-rings with

PARKER-O-LUBE or an equivalent lubricant.

1. Push seals (6) in the packing nut (5).

2. Screw adjusting screw (3) into packing nut (5).

Insert needle/ball (8) into packing support (7).

Nut

Packing Nut

Packing Support

Needle/ball

Yok e

Adjusting Screw

Seal

O-Ring

ti3810a

3. Attach needle/ball (8) to yoke (1) using slot in the

yoke to screw needle/ball.

4. Secure yoke in soft jawed vice. Tighten lock nut to

cartridge.

5. Install o-ring (4) onto groove in packing nut (5).

6. Insert cartridge assembly through front of gun handle.

7. Screw packing nut (5) in gun body (17).

8. Install trigger (18) and insert trigger pins (12) in gun

body (17). Secure using screws (11) and lock washers (23).

9. Install snap rings (11) from top to bottom to secure

trigger pins (12).

10. Install spring (13) and spring retainer (15) into the

gun body (17). Adjust spring retainer to allow

approximately 1/32 in. of free play on trigger.

11. Tighten lock nut (14).

12. Install o-ring (10) to adapter (9).

Adjusting Screw

Seal

O-Ring

8 309739

ti3810a

13. With trigger retracted, screw adapter (9) into gun

body (17).

Page 9

Service

14. Hold adapter (9) stationary and screw nozzle and

collar (16) into adapter. Do not over tighten collar.

15. Reconnect flow gun to material supply line.

16. Turn on material supply line.

17. Return flow gun to normal operating condition.

Model 12005

Disassembly

1. Actuate gun to purge material and relieve pressure

in gun. Pressure Relief Procedure, page 5.

2. Disconnect material supply line from gun handle.

3. Hold adapter (9) stationary and unscrew nozzle and

collar (16).

4. With trigger depressed, unscrew adapter (9) from

gun body (17).

5. Remove o-ring (10) from adapter (9).

6. Loosen lock nut (14).

7. Carefully unscrew and remove spring retainer (15)

8. Remove screws (11) and lock washers (28) from

trigger pins (12).

9. Pull trigger pins (12) from gun body (17) and remove

trigger (18).

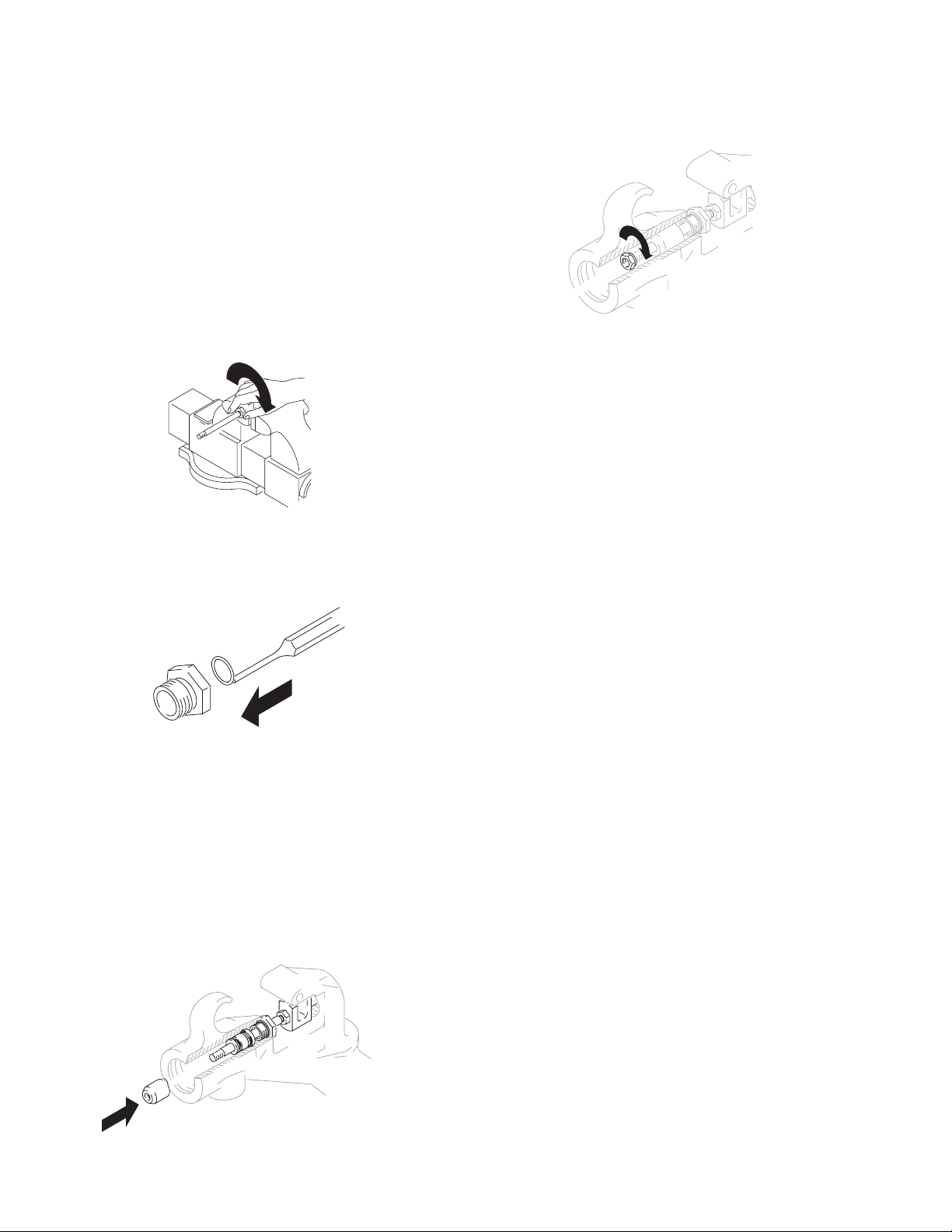

Cartridge Disassembly Procedure

1. Remove guide (22) from needle (8).

ti4035a

2. Remove two o-rings (23) from guide (22).

ti4036a

3. Unwind spiral PTFE o-ring backup (21) from

guide(22).

4. Loosen adjustment screw (3) while holding packing

nut (5).

5. Extract needle (8) from packing nut (5).

6. Remove o-ring (4) from groove in packing nut (5).

7. Remove adjustment screw (3).

8. Push three seal-needles (6) out of packing nut (5)

with soft rod or dowel.

10. Remove piston valve (20) from front of gun.

11. Unscrew packing nut (5) from gun body (17).

12. Remove cartridge assembly from gun.

ti4039a

9. Hold yoke (1) in soft-jawed vice. Unlock stop nut (2).

ti4040a

10. Separate needle (8) from yoke (1).

309739 9

Page 10

Service

Reassembly

Clean all parts thoroughly before reassembling. Check

them carefully for damage or wear, replacing parts as

needed. For best results replace the original parts with

new parts in repair kits.

Prior to assembly, lubricate all seals and o-rings with

PARKER-O-LUBE or an equivalent lubricant.

1. Connect needle (8) and stop nut (2) to yoke (1).

2. Secure yoke (1) in soft jawed vise. Lock stop nut (2)

against yoke.

ti4043a

3. Insert needle (8) into packing nut (5).

4. Push three seal needles (6) in packing nut (5) using

soft rod or dowel. Orient as shown below

12. Tighten nut (19) on needle (8).

ti4051a

13. Adjust screw (3) to tighten packings.

14. Install trigger (18). Align yoke (1) in gun body (17).

15. Press trigger pin (12) into gun body.

16. Secure trigger pins (12) using screws (11) and lock

washers (28).

17. Install spring (13) and spring retainer (15) into gun

body (17).

18. Adjust spring retainer to allow approximately 1/32 in.

of free play on trigger.

19. Tighten stop nut (14).

20. Install o-ring (10) on adapter (9).

ti4045a

5. Install o-ring (4) on groove of packing nut (5).

6. Install guide (22) on needle (8).

7. Rewind spiral o-ring backup (21) on guide (22).

8. Install two o-rings (23) on guide (22).

9. Insert cartridge assembly in gun body (17) from rear

of gun.

10. Screw packing nut (5) into gun body (17).

11. Insert valve (20) through front of gun on needle (8).

21. With trigger retracted screw adapter (9) on gun body

(17).

22. While holding adapter (9) stationary, screw collar

(16) and nozzle into adapter. Do not over tighten

collar.

23. Reconnect flow gun to material supply line.

24. Turn on material supply line to gun.

25. Return flow gun to normal operating condition.

ti4050a

10 309739

Page 11

Service

Model 12006

Disassembly

1. With trigger (20) depressed, remove collar (17)

securing nozzle (18) to gun.

2. Remove nozzle (18), holding adapter (10) firmly to

prevent it from turning.

3. Remove gasket (9). Clean and inspect for damage.

4. Remove adapter (10) from gun body.

5. Remove both screws (12) and lock washers (25) on

one side of trigger (20) and push both trigger pins

(13) out of body.

6. Loosen lock nut (15) at rear of gun.

7. Unthread spring retainer (16) and remove spring

(14).

8. Loosen and remove adjustment screw (6) on packing nut (3) and pull needle assembly from rear of

gun. Inspect for damage, replace if needed.

9. Remove packing assembly from gun.

10. Unthread packing nut (3) from body.

11. Remove adjustment screw (6) and o-ring (5) and

seals (4).

Reassembly

Clean all parts thoroughly before reassembling. Check

them carefully for damage or wear. Replace parts as

needed. For best results replace the original parts with

new parts in repair kits.

Prior to assembly, lubricate all seals and o-rings with

PARKER-O-LUBE or an equivalent lubricant.

1. Replace o-ring (5) and seals (4) in packing nut (6).

Nut

Packing Nut

Packing Support

Needle

Yok e

Adjusting Screw

Seal

O-Ring

ti4057a

2. Thread packing nut (3) into gun body.

3. Install packing assembly through rear of gun.

4. Install needle assembly through rear of gun.

5. Install spring (14) and spring retainer (16) into gun

body. Adjust spring retainer to allow approximately

1/32 in. of free play on trigger.

6. Tighten lock nut (15).

7. Install trigger (20) and insert trigger pins (13) in gun

body.

8. Secure trigger pins (13) using screws (12) and lock

washers (25).

9. Replace o-ring (11). Lubricate with petroleum jelly to

aid in reassembly.

10. With trigger (20) retracted, screw adapter (10) into

gun body.

11. Insert gasket (9) in collar (17).

12. While holding adapter stationary, screw collar (17)

and nozzle (18) into adapter. Do not overtighten collar.

13. Reconnect flow gun to material supply line.

14. Turn on material supply line.

15. Return flow gun to normal operating condition.

309739 11

Page 12

Parts

Parts

Models 12004 & 12004X

13

1

2

3

5

6

7

4

14

10

9

16

12

8

18

Item Part No. Description Qty

1 C27052 YOKE 1

2 100284 NUT, hex (model 12004) 1

C19284 NUT, hex (model 12004-X) 1

3 C27061 SCREW, adjustment 1

4 106555 PACKING, o-ring 1

5 C27058 PACKING, nut 1

6 C27060 SEAL, needle 3

7 C27053 SUPPORT, packing 1

8 C27038 NEEDLE 1

9 C27063 ADAPTER, ball seat 1

10 C20102 PACKING, o-ring 1

11 C19950 SCREW, cap, sch

(model 12004) 2

(model 12004-X) 3

12 15X116 PIN, trigger (model 12004) 2

(model 12004-X) 3

15

21

19

20

17

11

23

Item Part No. Description Qty

13 C00020 SPRING 1

14 C27036 NUT, lock 1

15 C27037 RETAINER, spring 1

16 C00004 COLLAR 1

17 C27049 BODY, flow gun 1

18 C27051 TRIGGER, hot melt 1

19 C34009 TRIGGER, lock 1

20 108483 SCREW, shoulder, sch 1

21 C20565 WASHER, spring 1

22 070269 SEALANT, anaerobic

23 C19208 LOCKWASHER

(model 12004) 2

(model 12004-X) 3

24 101369 WRENCH, hex key, 3/32 in.

(not shown)

1

12 309739

Page 13

Model 12005

16

19

20

21

Parts

13

1

2

10

9

22

23

12

8

6

4

3

5

14

15

27

24

25

17

18

Item Part No. Description Qty

1 C27052 YOKE 1

2 C19284 NUT, hex 1

3 C27061 SCREW, adjustment 1

4 106555 PACKING, o-ring 1

5 C27058 PACKING, nut 1

6 C27060 SEAL, needle 3

8 C27071 NEEDLE 1

9 C27077 FITTING, adapter 1

10 C20102 PACKING, o-ring 1

11 C19950 RING, snap 2

12 15X116 PIN, trigger 2

13 C00020 SPRING 1

14 C27036 NUT, lock 1

15 C27037 RETAINER, spring 1

28

11

Item Part No. Description Qty

16 C00004 COLLAR 1

17 C27049 BODY, flow gun 1

18 C27051 TRIGGER, hot melt 1

19 C27076 NUT 1

20 C27072 VALVE, piston 1

21 C27074 PACKING, PTFE o-ring 1

22 C27075 GUIDE 1

23 103337 PACKING, o-ring 2

24 C34009 TRIGGER, lock 1

25 108483 SCREW, shoulder, sch 1

26 C20565 WASHER, spring 1

27 070269 SEALANT, anaerobic

28 C19208 LOCKWASHER 2

29 101369 WRENCH, hex key, 3/32 in.

(not shown)

1

309739 13

Page 14

Parts

14

Model 12006

16

10

8

7

6

18

9

11

13

1

2

5

3

4

15

16

24

21

22

20

Item Part No. Description Qty

1 C27080 NEEDLE 1

2 C27053 SUPPORT, packing 1

3 C27058 PACKING, nut 1

4 C27060 SEAL, needle 3

5 106555 PACKING, o-ring 1

6 C27061 SCREW, adjustment 1

7 C19284 NUT, hex 1

8 C27052 YOKE 1

9 C02064 GASKET 1

10 C27063 ADAPTER, ball seat 1

25

Item Part No. Description Qty

12

11 C20102 PACKING, o-ring 1

12 C19950 RING, snap 2

13 15X116 PIN, trigger 2

14 C00020 SPRING 1

15 C27036 NUT, lock 1

16 C27037 RETAINER, spring 1

17 C00004 COLLAR 1

18 C27086 NOZZLE 1

19 C27049 BODY, flow gun 1

20 C27051 TRIGGER, hot melt 1

21 C34009 TRIGGER, lock 1

22 108483 SCREW, shoulder, sch 1

23 C20565 WASHER, spring 1

24 070269 SEALANT, anaerobic

25 C19208 LOCKWASHER 2

26 101369 WRENCH, hex key, 3/32 in.

(not shown)

1

14 309739

Page 15

Technical Data

Technical Data

Maximum fluid working pressure . . . . . . . . . . . . . . . . . . . Models 12004X, 12004, and 12005: 2500 psi (17.2 MPa,

172 bar)

Model 12006: 2000 psi (13.79 MPa, 137.9 bar)

Inlet port size on gun housing . . . . . . . . . . . . . . . . . . . . . 1/2-14 NPT

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Models 12004X, 12004, and 12005: 1.4 lb (.64 kg)

Model 12006: 1.6 lb (.73 kg)

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Height: 7 in. (178 mm)

Width: 2 in. (51 mm)

Length:

Models 12004X, 12004, and 12005: 7 in. (178 mm)

Model 12006: 9 in. (229 mm)

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Models 12004 and 12004X: aluminum, fluorocarbon

rubber, carbon steel, tool steel, brass, tetrafluoroethylene

Model 12005: aluminum, fluorocarbon rubber, carbon

steel, brass, fluoroelastomer, stainless steel, PTFE,

tetrafluoroethylene

Model 12006: aluminum, fluorocarbon rubber, carbon

steel, brass, tetrafluoroethylene

CE Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Models 12004X, 12004, and 12005: Yes

Model 12006: No

309739 15

Page 16

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211, Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 309739

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2002, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 1/2009

Loading...

Loading...