Page 1

Instruction Manual

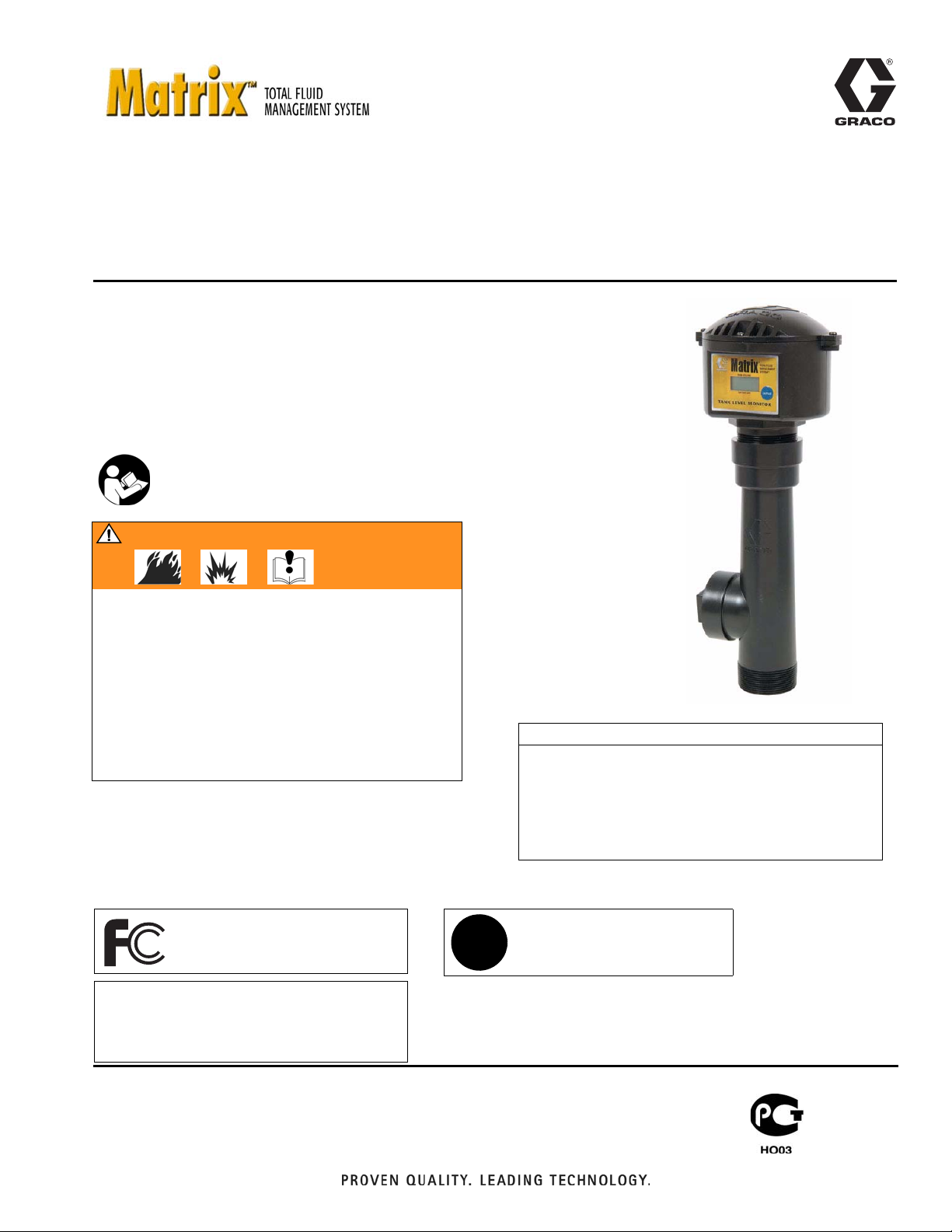

Tank Level Monitor

Part No. 119274, Series D, North America (N.A.)

Part No. 120105, Series D, (Australia)

Used to monitor tank levels for oils and anti-freeze mixtures.

The Tank Level Monitor is to be used only with Graco Matrix Software.

US Patent D484,819

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

WARNING

Not for use in hazardous locatons.

Ambient temperature range -22°F to 122°F (-30°C

to 50°C).

309500L

Do not use the Tank Level Monitor with fluids having

an auto ignition below 392° F (200° C).

Do not use the Tank Level Monitor with pressurized

tanks.

Read warnings and instructions.

The Matrix Tank Level Monitor contains an RF device with the following approvals:

FCC ID: JHIGNET

IC: 4840AGNET

Industry Canada Statement

The term “IC” before the certification/registration number only signifies that the Industry

Canada technical specifications were met.

✓

• Do not over tighten tank level monitor into

tank bung! Over tightening can cause perma-

nent damage and result in inaccurate readings.

• Do not use thread sealant or adhesive! Many

of these products are chemically incompatible

with the PC/ABS plastic.

Australian Vendor Code: N3845

CAUTION

Page 2

Notes

2 309500L

Page 3

Warnings

Warnings

The following warnings include general safety information for this equipment. More specific warnings are included in

the text where appropriate.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground equipment.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

BATTERY SAFETY

The battery may leak, explode, cause burns, or cause an explosion if mishandled:

• You must use the battery type specified for use with the equipment.

• Sparking can occur when changing batteries. Only replace the battery in a non-hazardous location,

away from flammable fluids or fumes.

• Handle and dispose of battery properly - do not short circuit, charge, force over discharge, disassemble, crush, penetrate, incinerate, or heat the battery to a temperature exceeding 185° F (85° C).

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Comply with all applicable safety regulations.

309500L 3

Page 4

Installation

Installation

WARNING

Installing and servicing this equipment requires

access to parts which may cause fire, explosion, and

serious injury if work is not performed properly. Do not

install or service this equipment unless you are trained

and qualified. Read warnings, page 3.

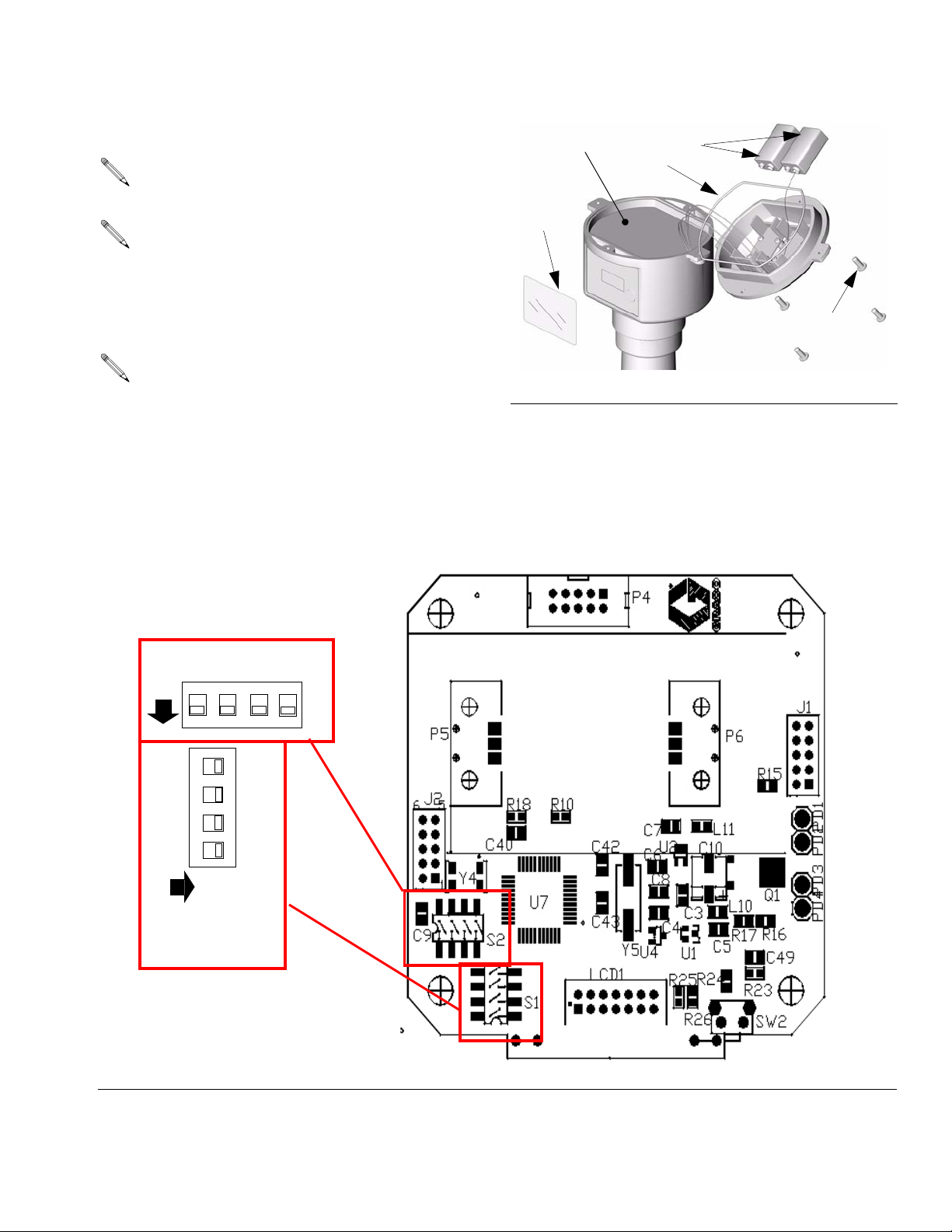

The location of the dipswitches will change to the same

settings of the Transceiver that it must communicate

with. The factory default setting for all Tank Level Monitors is (AA) using a RS232 connection. The first A refers

to the Network ID and the second A refers to the Transceiver ID. If multiple Transceivers are used or if RS422

connection is used, the factory default settings will

require changing.

Determining what settings to use

CAUTION

• Do not over tighten tank level monitor into tank

bung! Over tightening can cause permanent dam-

age and result in inaccurate readings.

• Do not use thread sealant or adhesive! Many of

these products are chemically incompatible with the

PC/ABS plastic.

TLM Dipswitch Settings

Tank Level Monitors (TLM) and Transceivers have two, 4

- position dipswitches labeled S1 and S2.

• Network ID (S1): This is the RF identification

setting assigned to a Matrix installation. All components in the system use this same Network

ID. For example, if one dealership is using Network ID (A), the dealership across the street

would require Network ID (B) to avoid RF interference between the two systems.

• Transceiver ID (S2): This is the RF identifica-

tion setting assigned to a Matrix Transceiver(s).

Matrix system components are then assigned to

the Transceiver(s) ID's as desired for RF communication. For example, if a system required

two Transceivers, some components would be

assigned to one Transceiver and other components would be assigned to the second Transceiver using the Transceiver ID dipswitch.

There are (8) Network ID's and (8) Transceiver ID's possible by changing the position of the dipswitches. The

eight positions are identified as A, B, C, D, E, F, G, and

H.

Tank Level Monitor dipswitches must be set to match

those of the transceiver the TLM will be communicating

with.

1. Remove the protective plastic cover (5) over the

Tank Level Monitor display that was used for shipping and discard. See F

2. Remove the four screws (3) holding the tank monitor

cover in place.

WARNING

Read and follow

3. Remove the cover.

4. Remove the insulating foam (4) to access the circuit

board.

5. Set the S1 and S2 settings to match those of the

transceiver that this TLM will communicate with.

Wait at least 30 seconds after the dipswitch settings

are made before installing the batteries. If you do

not wait the 30 seconds, the software will not recognize the new settings.

6. Install the (2) alkaline 9-volt batteries (1) provided.

Be sure that the batteries fully engage the mounting

clips by pushing on the bottom of the batteries with

your thumbs.

On initial power up of the TLM, it will take about 30

seconds for the monitor to display information after

pressing the blue display button. This time will

decrease thereafter to a few seconds

BATTERY SAFETY

IG. 1.

warnings, page 3.

4 309500L

Page 5

7. Replace the insulating foam (4) and reconnect the

batteries.

Make sure the o-ring (2) is not damaged and is in

the correct location.

Make sure the RF antenna wire (black formed wire

near the center of the top PC board) is not flattened against the PC board. This can result in poor

RF communication.

8. Replace cover and secure it with the four screws (3).

Installation

4

1

2

5

3

Make sure the cover screws are tightened securely

(18-22 in-lb) to avoid water leakage into the TLM

electronics. If a torque wrench is not used, verify

there are no gaps under the screw heads and no

gaps under the cover flange. This will ensure

proper compression of the o-ring for a water-tight

seal.

All dipswitches in down

or off position.

on

S2

12

4

3

2

4

3

F

IG. 1

n

1

o

S1

All dipswitches

to right or off

position.

F

IG. 2

309500L 5

Page 6

Dipswitch Setting using RS232 Connection

Dipswitch Setting using RS232 Connection

See FIG. 3 for dipswitch settings.

b

All dipswitch settings must be made without power

to the TLM (no batteries) or the settings will not be

properly communicated to the PC software.

RS232 Cable Settings

S2 Tank Level Monitor ID

F

IG. 3

A - default

on

12

3

E

on

12

3

A - default

4

3

2

1

on

S1

S2

S2

C

on

12

G

on

12

4

3

4

3

B

on

S2

4

12

4

3

F

on

S2

4

12

4

3

S2

S2

D

on

12

H

on

12

S2

4

3

S2

4

3

S1 Network ID

B

C

4

3

2

n

1

o

S1

n

o

S1

D

4

3

2

1

on

S1

E

4

3

2

1

n

o

S1

F

4

3

2

1

n

o

S1

G

4

3

2

1

n

o

S1

H

4

3

2

1

4

3

2

n

1

o

S1

6 309500L

Page 7

Dipswitch Setting using RS422 Connection:

Dipswitch Setting using RS422 Connection:

See FIG. 4 for dipswitch settings.

All dipswitch settings must be made without power

to the TLM's or the settings will not be properly

communicated to the PC software.

RS422 Cable Settings

S2 Tank Level Monitor ID

4

B

on

12

F

on

12

C

S2

4

3

S2

4

3

S1 Network ID

D

4

A

on

12

E

on

12

A

S2

4

3

S2

4

3

B

4

4

Dipswitch setting (4) of the S1 Network ID changes

position when using RS422 cable instead of

RS232 cable.

S2

S2

4

D

on

12

H

on

12

G

S2

4

3

S2

4

3

H

4

C

on

12

G

on

12

E

4

3

4

3

F

4

4

F

IG. 4

3

2

n

1

o

S1

3

2

n

1

o

S1

3

2

1

on

S1

3

2

n

1

o

S1

3

2

n

1

o

S1

3

2

n

1

o

S1

3

2

n

1

o

S1

3

2

n

1

o

S1

309500L 7

Page 8

Dipswitch Setting using RS422 Connection:

Programming Tank Level

Monitors

Graco recommends that tank monitors be programmed

prior to installation.

The PC software allows a 5 minute period to program a Tank Level Monitor

To program the tank monitors:

• Load the Matrix software to the PC and set the

Transceiver(s) dipswitches. Connect the Transceiver(s) to the PC using either RS232 or RS422

cable then supply power to the Transceiver.

• The Matrix Tank Level Monitoring PC software must

be at the Tank Monitor Setup screen and in program

mode.

1. At the Matrix Setup screen on the PC, enter all the

desired tank parameters and settings.

2. After parameters are set, program each TLM in the

system one at a time by clicking on the “Program”

action on the Matrix Setup screen.

display “Complete”. A pop-up window will appear on

the PC screen indicating the TLM is programmed.

See F

IG. 5. Label the tank name and fluid name on

the TLM. Repeat this procedure for each TLM in the

system.

4. Press the blue TLM button (A) to reset the internal

clock. If not done, the TLM will not read and report

at the scheduled time(s). When the batteries require

changing, it is not necessary to re-program the

TLM, but the blue button (A) should be pushed to

reset the internal TLM clock. If not done, the TLM

will not report at the correct scheduled times. See

Instruction Manual 309501 PC Software Guide or

Manual 309504 Tank Level Monitor Software Guide

for details.

B

3. Hold down the blue button (A) until the display (B)

reads “Program Mode.” After 5 seconds the TLM will

F

IG. 5

A

8 309500L

Page 9

Dipswitch Setting using RS422 Connection:

Installing Tank Level Monitor

CAUTION

• Do not over tighten tank level monitor into tank

bung! Over tightening can cause permanent dam-

age and result in inaccurate readings.

• Do not use thread sealant or adhesive! Many of

these products are chemically incompatible with the

PC/ABS plastic.

1. Remove the 2 in. bung fitting and screw in the TLM

hand-tight. DO NOT use a wrench to tighten as this

may damage the TLM. Do not use thread lock adhesive as this may damage the TLM.

2. The TLM must be mounted within 2 degrees of the

surface of the fluid. A level that measures degrees

should be used. Place the level on the top of the

pipe fitting on the tank. If outside the 2 degree specification, the fitting should be changed. Graco recommends that the height of the tank fitting should

not exceed 1/2 in. (1.27 cm). The fitting height can

be up to 2 in. (5.08 cm), provided the fitting is within

2 degrees of the surface of the fluid. Also, the taller

the tank, the more critical the 2 degree specification

becomes. See F

IG. 6.

CAUTION

Do not install the TLM in the tank’s fill port. Repeated

removal of the TLM will damage the unit and void the

warranty.

Port (D) is not to be used as a fill hole for oil deliveries.

See F

IG. 7.

The tank’s breather port might be the only available

location for mounting the TLM. The horizontal 2 in. npt

port (D) can be used to accommodate the breather. The

breather should be mounted in an upright position using

a 90° elbow fitting.

Do not use the horizontal port for routing pressure

relief return tubes. This can result in inaccurate

readings.

D

CAUTION

The TLM will not operate correctly if tilted more than 2°

from the surface of the tank liquid.

The TLM will not read properly when the fluid in the tank

is agitated (i.e. filling a tank with oil or anti-freeze). Be

sure to take all TLM readings when the fluid in the tank

is calm.

TLM must be mounted within 2° from perpendicular to

the surface of the fluid.

2°

F

2°

IG. 6

F

IG. 7

TI4794A

309500L 9

Page 10

Operation

Operation

Tank Level Data

The tank level monitor is equipped with an LCD display

screen (B) and a display button (A). See

The LCD display is used to view tank data. It displays:

Battery Life - the remaining life of the unit’s batteries.

Batteries should be replaced before the power remaining drops below 10%.

FIG. 9

.

Battery

100%

Nw ID - A

Tx ID - A

Version

XX.XX.XXX

First Display

Second Display

Third Display

Battery life is dependent on the number of readings

taken per day.

Network ID and Transceiver ID - displays the Network

and Transceiver ID information for 2 seconds. This ID

information relates to the dipswitch settings on the PC

board of the TLM.

Firmware - TLM version displays current firmware revision.

Fluid Level - remaining inches or cm of fluid in the tank.

Fluid Volume - the volume of fluid remaining in the tank,

based on the tank geometry defined during setup. The

TLM can be programmed to display in either gallons or

liters during programming of the TLM.

Vertical tanks use this capacity figure to calculate

tank volume. Obround and cylindrical tanks use the

tank dimensions to calculate tank volume.

No RF Signal - displays when the tank level monitor is

not receiving an RF signal from the PC transceiver. If

the tank monitor is receiving a signal or the signal is

re-established, this screen will not appear. If “No RF Signal” appears, the fluid volume and battery life data is not

being transmitted or updated at the PC. This may take

up to 15 seconds to display.

36”

Fourth Display

Fluid

100

Gallons

No RF

Signal

F

IG. 8: Example Display

After tank re-fill from an oil distributor or waste oil

tank is emptied from a waste oil service provider,

press the blue button on the TLM to ensure the

TLM will maintain the most current tank volume

status. If button is not pushed, the TLM will automatically read correctly at the next scheduled

tank reading.

Daylight Saving Time (DST) Change

The PC software automatically changes the PC time

when daylight saving time changes occur (Spring and

Fall).

When this happens the Matrix software displays a

pop-up screen instructing the administrator to re-boot

the Matrix PC. This changes the Matrix clock to match

the PC clock.

Fifth Display

(can program for liters)

Screen display when

no RF signal is

received after 10-12

seconds

The first TLM reading will be 1 hour earlier or later

(depending on the Spring or Fall daylight saving

time change), but all subsequent TLM reading will

be accurate.

10 309500L

Page 11

Viewing Data

Press and release the blue display button (A). See FIG.

9. Displays appear (B), each lasting a few seconds

before going on to the next screen. See F

Tank Level data can be viewed remotely at the PC,

using the Matrix software. See Instruction Manual

309501 PC Software Guide or Manual 309504

Tank Level Monitor Software Guide for details.

IG. 9.

Viewing Data

B

A

F

IG. 9

If the TLM reading is outside of the programmed size

parameters, the LCD display will show “Invalid Reading.”

See F

IG. 10.

F

IG. 10

Invalid

Reading

309500L 11

Page 12

Troubleshooting

Troubleshooting

Problem Cause Solution

Brand new monitor’s display is very dim.

Monitor displays “Invalid

Reading”.

Monitor will not program. Incorrect COM port selected for

Monitor has intermittent

RF communication

Unit is shipped with protective coating over display.

The TLM reading is outside of the

programmed size parameters.

transceiver.

Transceiver is not powered-up. Verify transceiver is powered-up

Attempt to program while red lights

on transceiver are lit.

Transceiver dipswitches not set cor-

rectly.

PC is not in program mode. Ensure PC is in program mode.

PC program window has expired. The PC software allows a 5-minute period to program a TLM.

TLM dipswitches settings do not

match transceiver settings.

Out of RF range.

RF obstruction.

Weak or dead batteries. Replace batteries. See Determining what settings to use,

Microprocessor not completely shut

down before installing new batteries.

RF antenna is flattened or out of

position inside the TLM.

Out of RF range.

RF obstruction.

Two TLMs are programmed to the

same address.

Weak or dead batteries. Replace batteries. See Determining what settings to use,

Remove protective coating.

Verify the programmed parameters and re-program the TLM if

necessary.

Ensure correct COM port is selected.

Wait until red lights on transceiver go blank before attempting

to program.

Ensure transceiver dipswitches are set for appropriate communication cable.

Verify settings with Transceiver (see page. 6 for dipswitch setting instructions).

Reposition Transceiver until TLM has good RF communication.

page 4.

After you have removed old batteries, wait 30 seconds to

ensure the microprocessor has completely shut down, before

installing new batteries.

Position antenna wire to suspend above the circuit board. See

7, page 5.

Reposition Transceiver until TLM has good RF communication.

Verify that each TLM is correctly programmed to a unique

address.

page 4.

12 309500L

Page 13

Problem Cause Solution

Monitor is not reporting

scheduled readings.

Monitor will not take reading when blue button is

pressed.

Monitor readings are

inaccurate.

Troubleshooting

Out of RF range.

RF obstruction.

Two TLMs are programmed to the

same address.

Weak or dead batteries. Replace batteries. See Determining what settings to use,

Microprocessor not completely shut

down before installing new batteries.

Tank Level Monitor was not programmed after scheduled times

were entered into software.

Reading is scheduled when pump is

operating.

Clock was changed on PC but the

monitor was not reprogrammed.

Weak or dead batteries. Replace batteries. See Determining what settings to use,

Batteries are not correctly seated. Ensure the batteries fully engage the mounting clips by push-

Microprocessor not completely shut

down before installing new batteries.

Monitor display is cracked. Replace monitor display.

Tank geometry incorrectly defined. See Instruction Manual 309504 Tank Level Monitor Software

Tank Level Monitor has not been

reprogrammed with latest adjustments made within Tank Setup

screen of the software.

Two TLMs are programmed to the

same address.

Fluid surface is moving while reading

is being taken.

Pipe adapters installed in the tank

bung.

Tank Level Monitor is not perpendicular to top of fluid.

Inside tank obstruction. Install in different tank bung to avoid tank obstruction.

Reposition Transceiver until TLM has good RF communication.

Verify that each TLM is correctly programmed to a unique

address.

page 4.

After you have removed old batteries, wait 30 seconds to

ensure the microprocessor has completely shut down, before

installing new batteries.

Reprogram Tank Level Monitor.

Ensure readings are scheduled at times that the pump is not

operating.

The monitor’s internal clock is synchronized with the PC clock

upon programming. Manipulating the scheduled reporting time

by changing the PC clock will cause a false indication that the

monitor is not reporting at the scheduled reporting times.

page 4.

ing on the bottom of each battery with your thumbs.

After you have removed old batteries, wait 30 seconds to

ensure the microprocessor has completely shut down, before

installing new batteries.

Guide or manual 309501 PC Software Guide for details.

Reprogram Tank Level Monitor.

Verify that each TLM is correctly programmed to a unique

address.

Ensure pump is not operating and that nothing is disturbing the

surface of the fluid during readings.

Ensure there are no adapters installed in the tank bung.

Level tank so that it is perpendicular to top of the fluid and/or

realign Tank Level Monitor.

309500L 13

Page 14

Service

Service

Once the Tank Level Monitor has been installed, no

additional maintenance or service is necessary, with the

exception of replacing batteries.

Replacing Batteries

When the tank sensor or PC battery indicator shows

that replacement of batteries is needed (before power

drops below 10%), replace the TLM batteries as follows:

1. Remove the four tank monitor cover screws.

2. Replace the batteries using alkaline 9v batteries. Be

sure the batteries fully engage the mounting clips by

pushing on the bottom of the batteries with your

thumbs.

3. Replace the cover and tighten the four cover

screws.

14 309500L

Page 15

Parts

119274 (N.A.), Tank Level Monitor

120105 (Australia), Tank Level Monitor

2

4

2

Parts

1

1

1

Remove protective cover used for shipping before programming.

2

Do not remove. This is required to maintain intrinsic safety approval.

Ref.

Part No. Description Qty

No.

1 BATTERY, 9V (purchase locally) 2

2 112343 O-RING 1

3 117467 SCREW, self tapping, HI-LO,

#10-16 x 9/16

4 117743 FOAM, insulator 1

3

4

309500L 15

Page 16

Technical Data

Technical Data

Ultrasonic Tank Depth Measurement range 0 - 30 ft. (0 - 9 m) Not for use in pressurized tanks.

Fluid Level Measurement Accuracy +/- 0.5%

Mounting Standard 2 in. (npt) bung.

Height above tank for TLM and tube mount-

ing

TLM Mounting Tube and Tank Vent Graco recommends venting the tank separately from the TLM. If not

Weight (with batteries installed) 2.34lb. (1.06 g)

Operating Temperature Range -22° F to 185° F (- 30° C to 85° C) Note: Display will not function

RF Operating Temperature Range -40°F to 185°F (-40°C to 85°C)

Storage Temperature Range -40°F to 185°F (-40°C to 85°C)

Batteries Two 9V alkaline

Battery Life 1.5 years

Enclosure IP65

Intrinsic Safety Instrinsically safe Exia for use in Class I, Division 1, Group D Haz-

15 in. (30.48 cm).

possible, the TLM mounting and vent function can be combined if

required for tanks with one hole in tank.

below 32°F (0°C).

ardous Locations when used with (2) 9-volt alkaline batteries.

• Ambient temperature range -22°F to 122°F (-30°C to 50°C).

• Temperature Code: T3.

The Matrix TLM is not to be used with materials with an auto

ignition below 392°F (200°C).

RF Communication 902-928 MHz frequency hopping, spread-spectrum (N.A.).

Totally Unobstructed RF Communication

Range (based on TLM and Transceiver

mounting and RF environment)

Unobstructed RF Communication Range

(based on building construction and RF environment)

Obstructed RF Communication Range

(based on building construction and RF environment)

Tank Geometry Vertical walled tanks, cylindrical tanks, and obround tanks.

915-928 MHz frequency hopping, spread-spectrum (Australia).

1/4 mile / 1320 ft (.4 km / 402.3 m)

300-500ft (91.0-152.0)

250-300ft (76.2-91.0 m)

•Vertical Tanks

Maximum Volume 999,999 gallons or liters

Maximum Height 30ft. (360 in.)

•Cylindrical Tanks

Maximum Volume 999,999 gallons or liters

Maximum Diameter 30ft. (360 in.)

Maximum Length Unlimited

16 309500L

Page 17

Dimensions

Dimensions

A 9.1 in (231 mm)

B 4.9 in. (124 mm)

B

A

1-1/2 in. npt

2 in. npt

TI4631A

309500L 17

Page 18

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship

on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by

Graco, Graco will, for a period of twenty-four months from the date of sale, repair or replace any part of the equipment determined

by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with

Graco's written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused

by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering,

or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the

incompatibility of Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper

design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by

Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor

for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts.

The equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose

any defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts,

labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco's sole obligation and buyer's sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no

other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or

property, or any other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within

two (2) years of the date of sale Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a

particular purpose in connection with accessories, equipment, materials or components sold but not manufactured by Graco.

These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any,

of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying

equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach

of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal

proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les

parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et

procédures judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les

procedures concernées.

Graco Phone Numbers

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 309500

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2003, Graco Inc. is registered to I.S. EN ISO 9001

www.graco.com

Revised 11/2008

Loading...

Loading...