Page 1

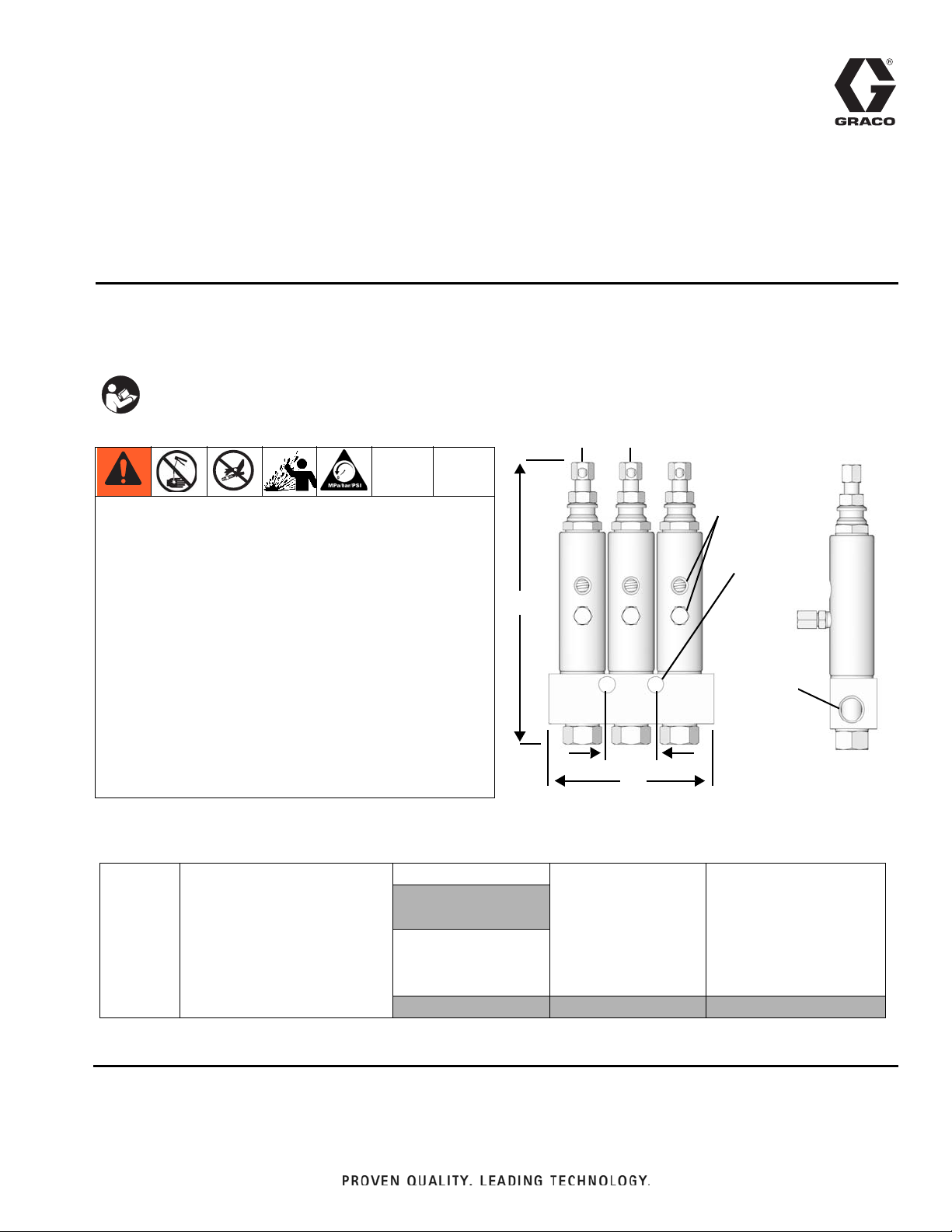

1-1/4”

7-1/16”

A

B

1/8” npt

dispense

outlet

13/32”

mounting

holes

3/8” npt

(2) supply

inlet/outlet

Model 114903 Shown

Instructions-Parts List

®

GL-1

For Single–Line Parallel Automatic Lubrication Systems.

Important Safety Instructions

Read all warnings and instructions in this manual and related automatic

lubrication system instruction manuals. Save all instructions.

SKIN INJECTION HAZARD

Fluid from the injector, leaks, or ruptured components

can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid

injected into the skin might look like just a cut, but it is a

serious injury. Get immediate surgical treatment.

Fluid splashed in the eyes or on the skin can also

cause serious injury. The equipment may be pressurized already, or it could become pressurized by an

automatic lube cycle initiated by Lubrication Controller

(timer). Disconnect power to the timer, and disconnect

the air supply to the pump module to ensure that the

system is depressurized. See the pressure relief pro-

cedure in the pump manual incuded with your automatic lubrication system.

Injectors

308953N

EN

GL-1 Injector Models

Part No. Description Dimension A Dimension B Bare Manifold Part No.

114901

114902

114903

114904

114905

117206

114909

Injector, GL–1, one point

Injector, GL–1, two point

Injector, GL–1, three point 1.25 in. (31.7 mm) 4.23 in. (107.5 mm) 114913

Injector, GL–1, four point 2.50 in. (63.4 mm) 5.47 in. (139.0 mm) 114914

Injector, GL–1, five point 3.75 in. (95.1 mm) 6.71 in. (170.5 mm) 114915

Injector, GL-1, six point 4.99 in. (126.8 mm) 7.90 in. (202.7 mm) 118206

Injector, GL–1, replacement

2.48 in. (63.0 mm) 114911

3.00 in. (76.0 mm) 114912

Page 2

Installation Instructions

Reference letters used in the following instructions, refer

to F

IG. 2.

• Group injectors to minimize feed line length.

• Install injectors in locations that allow easy and safe

servicing access.

• Install injectors in areas that minimize accidental

injector damage by moving equipment.

• Injector outputs can be combined for a common

bearing point with a large grease requirement but

the output for a single injector cannot be split into

multiple bearing points.

• Graco recommends using steel tubing instead of

pipe and hose for supply lines when possible. Pipe

is often contaminated with scale and requires

proper cleaning prior to use. Hose lines expand

under pressure which leads to longer pump cycle

time.

2. Install injectors on a flat, hard surface using mounting brackets (a).

3. Connect fluid supply line (c) to injectors.

NOTICE

To prevent rupturing supply lines due to over-pressurizing the components, only use supply lines and

fittings that meet or exceed the pressure rating of the

injectors.

4. Connect lube point feed lines (b).

5. Flush the system with low viscosity oil or mineral

spirits to remove contamination introduced during

installation.

6. Use a purge gun or run the pump until clean lubricant is dispensed at the end of each feed line to

purge the system of flushing fluid or air.

7. Run the system at full output and verify that all injectors are cycling.

1. Relieve pressure. See Pressure Relief Procedure,

in the pump instruction manual included with your

automatic lubrication system.

8. Adjust injector volume output. (See Volume Adjustment page 4.)

9. Connect feed lines to lubrication points.

2 308953N

Page 3

Injector Service Parts

2

4

9

18

11

1

13

16

19

15

6

Manifold

(not included)

9

7

17

5

12

3

8

Torque to 50-55 ft-lbs (68-74.5 N.m)

1

Torque to 35-40 ft-lbs (47-54 N.m)

2

2

1

Injector Service Parts

Item Description Qty Part No.

1

Injector body

2

Adjusting screw

3

Lock nut

4

Packing housing

5

Zerk fitting and cap assembly

6

Copper gasket

Adapter bolt

7

(used on all manifold models)

8

Indicator pin

9

Steel gasket

Fluoroelastomer o–ring (PN

11

114997)

12

Displacement piston

13

Compression spring

15

Plunger

16

Fluoroelastomer packing

17

Fluoroelastomer packing

18

Fluoroelastomer packing

19

Inlet valve

11 114906

1 114907

1 114908

1 114916

1 114918

1-

12

1

1

1

1

1

1

1

1

Included in Injector Repair Kit 241234 only

Available Kits

Use Only Genuine Graco Repair Parts

Graco Part No. 115119 . . . . . Plastisol Injector Cover

Graco Part No. 115120 . . . . . . . . . . . . . Crossover Kit

(see page 3 for installation instructions)

(for connecting the outlets of injectors

for increased output)

Graco Part No. 241234 . . . . . . . . . Injector Repair Kit

(See Kit 241234 parts in Injector Service Parts list.)

308953N 3

Page 4

Injector Cover Kit 115119

groove

21

22

Injector Cover Kit 115119

Plastisol cap for Graco GL-1 Injectors

Item Description Qty

21 Plastisol cap 1

22 O-ring 1

Installation Instructions

1. Apply a light coating of transparent lubricant to the

inside of cap (21).

2. Slide cap (21) over the indicator stem of the injector

far enough to cover the groove in the piston plug.

3. Slide the o-ring (22) down over the cap to the

groove in the piston plug, forcing the cover into the

groove to form a seal.

Volume Adjustment

*Maximum adjustment setting is when adjusting screw (2) is just making contact with the indicator pin (8) with no inlet

pressure. Turn adjusting screw clockwise (in), to reduce output. To adjust, loosen lock nut (3) and turn adjusting

screw (2) the number of turns indicated on the GL-1 Volume Adjustment Table to obtain the desired volume. Tighten

lock nut (3) when desired volume setting is reached

GL-1 Volume Adjustment Table

Description

Maximum Adjustment* 0 0.080 1.31

360° Clockwise Turn 1 0.071 1.16

360° Clockwise Turn 2 0.062 1.02

360° Clockwise Turn 3 0.053 0.87

360° Clockwise Turn 4 0.044 0.72

360° Clockwise Turn 5 0.035 0.57

360° Clockwise Turn 6 0.026 0.43

360° Clockwise Turn 7 0.017 0.28

Minimum Adjustment 8 0.008 0.13

.

Number of

Turns

in.

Volume

3

cc

4 308953N

Page 5

Injector Cover Kit 115119

Technical Data

Maximum operating pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 3500 psi (24 MPa, 241 bar)

Suggested operating pressure . . . . . . . . . . . . . . . . . . . . . . . . . 2500 psi (17 MPa, 172 bar)

Reset pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600 psi (4.1 MPa, 41 bar)

Output volume per cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . carbon steel, stainless steel, copper, fluoroelastomer

Recommended fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N.L.G.I. #2 grease down to 32° F (0° C)

adjustable*: 0.008 to 0.08 in.

3

308953N 5

Page 6

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 1999, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 308953

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised April 2015

Loading...

Loading...