Grasslin DTMV40 Series, DTMV40, DTQMV40, DTMV40-IM, DTMV40-M Operating Instructions Manual

...

• Disconnectpoweratthecircuitbreaker(s)ordisconnectswitch(es)beforebeginning

installationorservicing.

• Morethanonecircuitbreakerordisconnectswitchmayberequiredtode-energizethe

equipmentbeforeservicing.

• Donotusethemanualoffpositionofthetimerforequipmentservicing.Alwaysdisconnectthepoweratthecircuitbreaker(s)ordisconnectswitch(es).

• UseCOPPERconductorsONLY.

• For40amploads,use#8AWGwire,rated90˚Cmin.

• Wireinaccordancewithnationalandlocalelectricalcoderequirements.

DTMV40 Series

TimeInitiated,Temperature,

PressureorTimeTerminatedMulti-Voltage

40ADefrostTimers

WARNING

Risk of Fire or Electric Shock

• Rotatetimerdialclockwiseonly.

CAUTION

Risk of Damage to Timer

1

Paragon Precision

TIME INITIATED, TIME TERMINATED

Grasslin

Mode Selection Wiring Diag.

TIME INITIATED, PRESSURE TERMINATED

(Separate Pressure Switch Required (see instructions)

TIME INITIATED, REMOTE TEMPERATURE OR

PRESSURE TERMINATED

STARTUP PROCEDURE

1. Determine model to be replaced (Grasslin or Competitors)

from table below.

2. Set Mode Selection (S1 BLUE DIP Switch

– Fig. A) See table below and instructions

on page 5.

3. Apply corresponding Terminal

Identification and Door labels –see retrofit

kit instructions.

4. Set correct input voltage (S2 RED DIP

Switch – Fig. B).

5. Follow installation and programming instructions.

The DTMV40 can be configured for

either 120 or 208/240VAC. Locate RED

DIP Switch to the right of timer module.

For:

• 120VAC slide DIP switch UP

• 208/240VAC slide DIP switch DOWN

TImer Mechanism

Step 2

Interior

Protective

Cover

Step 1

Ground Lug

2-1/2”

6-1/8”

INSTALLATION

Note: For outdoor locations, raintight, or wet location conduit

hubs that comply with requirements of UL 514B (standard for

fittings for conduit and outlet boxes) are to be used.

1. Open door and then remove interior protective cover by

releasing spring clip on bottom.

2. Remove timer mechanism by releasing spring clip on bottom.

3. Select knockouts to be used. Remove inner 1/2” knockout

by inserting a screwdriver in the slot and carefully punch

knockout loose. Remove slug. If 3/4” knockout is required,

remove the outer ring with pliers after removing the 1/2”

knockout. Smooth edges with knife if necessary.

4. Place enclosure in desired mounting location and mark the

three mounting holes (refer to diagram below). Start by

placing set screw on top and attaching enclosure over

keyhole: then screw in remaining two screws on bottom.

5. Connect conduit hubs to conduit before connecting the

hubs to the enclosure. After inserting hubs into enclosure,

carefully tighten hub lock nut. Do not over-torque.

6. Verify voltage selection. 120VAC – position switch UP;

208/240VAC – position switch DOWN (refer to Fig. B).

7. Wire in accordance with National and Local

Codes.

8. Gr

ounding: Terminate all ground wires to ground lug on

bottom of enclosure.

9. Replace interior protective cover.

UL TYPE 3R Enclosure

Bracket Mount

Input Voltage Switch (S2)

Mode Selection Switch (S1)

http://waterheatertimer.org/Intermatic-Defrost-timers-and-manuals.html

8

7

A

M

Models Non-Enclosure Mount

DTMV40-M 24-hour, Mechanism Only

DTQMV40-M 24-hour w/Battery Backup, Mechanism Only

DTMV40-P 24-hour, Panel Mount

DTMV40-B 24-hour, Bracket Mount

DTQMV40-B 24-hour w/Battery Backup, Bracket Mount

PROGRAMMING (Synchronous and Quartz

Models)

Setting the Time:

Turn the minute hand clockwise until the time of day (and AM

or PM) on the outer dial is aligned with the triangle marker on

the inner dial.

Note: All units with Battery Backup provide up to a week of

reserve carryover.

Setting Defrost Initiation Time:

Move a white tab (tripper) on the outer dial outward at each

desired initiation time. For example, to set defrost initiation

times at 6:00AM, 11:30AM, 4:30PM and 11:00PM, move the

tab adjacent to the “M” in AM on the dial (6:00AM), the tab that

lies between 11:30AM and 11:45 AM, the tab between 4:30PM

and 4:45PM, and the tab adjacent to the 11:00–11:15PM

marks. (See note for 8243/6243 replacement.)

Setting Maximum Defrost Duration:

Different defrost durations may be set for each defrost initiation

setting. Each white tab (tripper) provides a 15 minute interval.

The tabs that set the initiation time provide a minimum of 15 minutes of defrost. For longer defrost duration, move additional tabs

(following in time) from the initiation tab. For example, if a 45

minute defrost is to start at 7:00AM, move the tab outward that

lies between 7:00 and 7:15

on the AM side of the dial, and the

tabs adjacent to 7:15-7:30 and 7:30-7:45.

(3 tabs moved outward). The defrost will

initiate at 7:00AM and time terminate at

7:45AM (if temperature termination does

not occur first.)

For electronic models, refer to separate programming instructions.

DO NOT ROTATE MINUTE HAND COUNTER-CLOCKWISE

Model Designation

Models Enclosure Mount

DTMV40 24-hour, Outdoor UL TYPE 3R Enclosure

DTQMV40 24-hour w/Battery Backup,

Outdoor UL TYPE 3R Enclosure

DTMV40-IM 24-hour, Indoor Metal UL TYPE 1 Enclosure

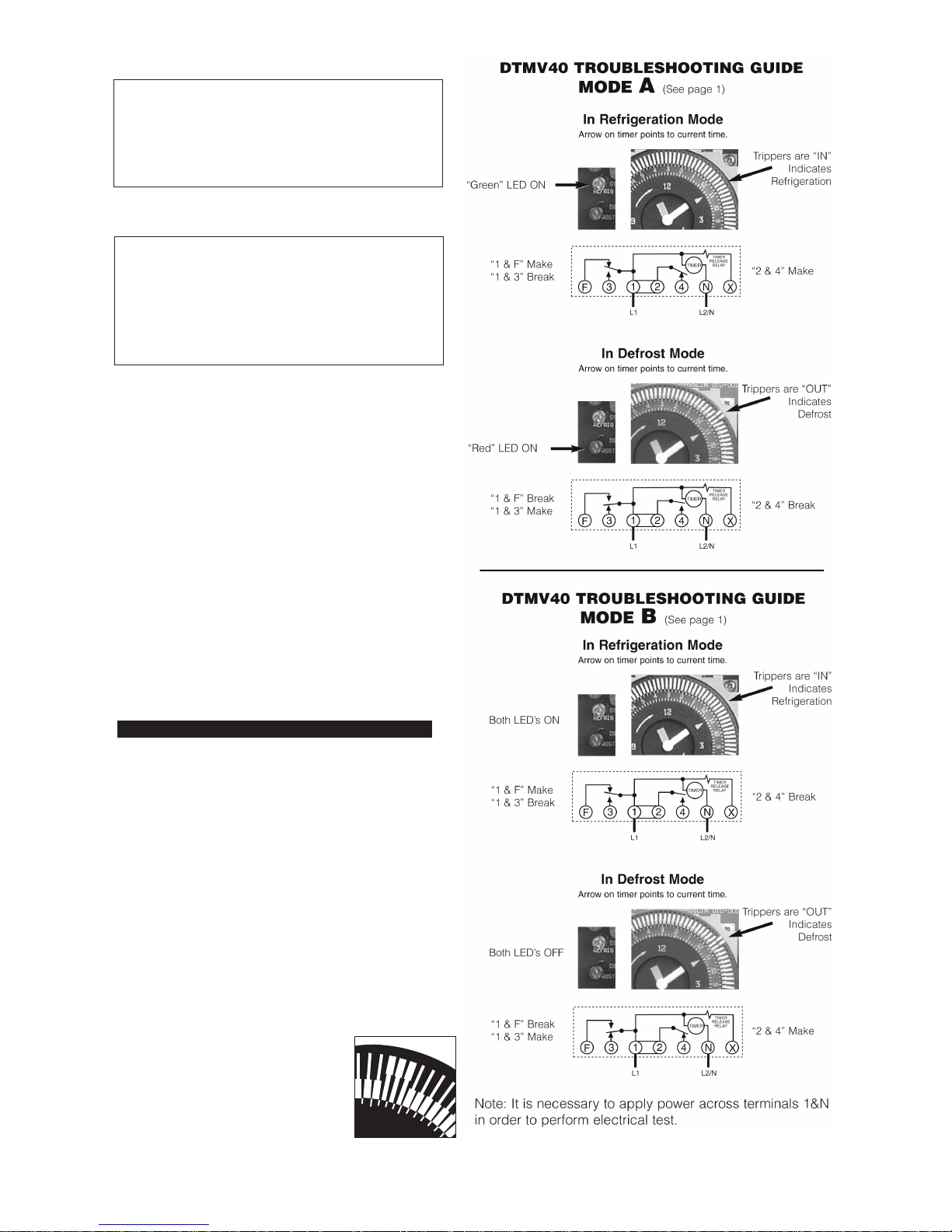

Note: It is necessary to apply power across terminals 1&N

in order to perform electrical test.

2

8141 Replacement

Mode A with 8141 Label Applied

7

L1

L2

TERMINATION

THERMOSTAT

W/FAN DELAY

2

4

X

N

8143 Replacement

Mode B with 8143 Label Applied

8

8143

LABEL

TIMER

RELEASE

RELAY

TIMER

LINE

CONNECT ACROSS

COMPRESSOR

THERMOSTA

T

FAN

HOT

GAS

VALVE

1

*See Note 1, page 5

3

L1

L2

TERMINATION

THERMOSTAT

2

X

8143 Replacement–Double Pole Switching

Mode B with 8143 Label Applied

9

8143

LABEL

TIMER

RELEASE

RELAY

TIMER

3

DEFROST

HEATER

LINE

SOLENOID

VALVE

OR

CONTACTOR

1

4

N

DTMV40 - TYPICAL WIRING DIAGRAMS

All switch positions are shown in refrigeration cycle operation, and change position upon initiation of a defrost.

8045 Replacement

Mode A with 8045 Label Applied

1

THERMOSTAT

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACT

OR COIL

DEFROST

HEATER

L1

L2

TIMER

TIMER

RELEASE

RELAY

1

2

4 X

8041 Replacement

Mode A with 8041 Label Applied

2

8041

LABEL

3

LINE

FAN

N

L1

L2

2

4

N

3

8043 Replacement

Mode B with 8043 Label Applied

3

8043

LABEL

TIMER

RELEASE

RELAY

TIMER

LINE

CONNECT ACROSS

COMPRESSOR

THERMOSTA

T

HOT

GAS

VALVE

F

1

L1

L2

2

2

8047 Replacement–Double Pole Switching

Mode B with 8047 Label Applied

4

8047

LABEL

TIMER

RELEASE

RELAY

TIMER

3

DEFROST

HEATER

LINE

SOLENOID

VALVE

OR

CONTACTOR

N

4

1

THERMOSTAT

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACT

OR COIL

DEFROST

HEATER

L1

N

120V

TIMER

TIMER

RELEASE

RELAY

TERMINATION

THERMOSTAT

W/FAN

1

2

4

X

120V Fan & Defrost Heater; 240V Compressor

Mode A - No Label Required

6

3

N

F

FAN

120V

240V

L2

8245 Replacement

Mode A with 8245 Label Applied

10

*See Note 2, page 5

COMPRESSOR

L1

L2

TIMER

TIMER

RELEASE

RELAY

F

3

2

4

LINE

8243 Replacement

Mode B with Trippers Reversed

11

PRESSURE

SWITCH

1-N

p

Xp

LABEL

8243

L1

L2

4

8247 Replacement–Double Pole Switching

Mode B with 8247 Label Applied

12

8247

LABEL

TIMER

RELEASE

RELAY

TIMER

3

DEFROST

HEATER

LINE

SOLENOID

VALVE

OR

CONTACTOR

N

2

1

p

PRESSURE

SWITCH

Xp

DELAY

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACTOR COIL

FAN

MOTOR

DEFROST

HEATER

L1

L2

TIMER

TIMER

RELEASE

RELAY

F

3

1-N

2

4 X

LINE

THERMOSTAT

8045

LABEL

THERMOSTAT

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACT

OR COIL

DEFROST

HEATER

L1

L2

TIMER

TIMER

RELEASE

RELAY

TERMINATION

THERMOSTAT

W/FAN DELAY

1

2

X

8141

LABEL

3

LINE

FAN

N

4

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACTOR COIL

FAN

MOTOR

DEFROST

HEATER

L1

L2

TIMER

TIMER

RELEASE

RELAY

PRESSURE

SWITCH

F

3

1-N

2

4

LINE

THERMOSTAT

Xp

p

LABEL

8245

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACTOR COIL

FAN

MOTOR

DEFROST

HEATER

L1

L2

TIMER

TIMER

RELEASE

RELAY

TERMINATION

THERMOSTAT

W/FAN DELAY

F

3

1

2

4XN

LINE

8145 Replacement

Mode A - No Label Required

5

THERMOSTAT

DEFAULT (Out of the Box)

3

4

R EPLACING EXISTING DEFROST TIMERS

The DTMV40 will replace all models of Paragon 8040,

8140, 8240 Series or Precision 6040, 6140, 6240

Series.

TERMINAL IDENTIFICATION:

The standard DTMV40 terminal identification is identical

to the Paragon 8145 with the addition of the “F” terminal.

Terminal identification labels are provided for the other

models to be placed over the printed numbers on the

printed circuit board. From the table on page 4, select the

proper label, apply to printed circuit board, and wire per

the original wiring or the wiring diagrams indicated.

MODE SELECTION (Light Blue DIP Switch):

First determine what model is being replaced (Grasslin or

Competitors). The mode selector DIP switch (located at

lower right side of the board) determines the configuration of terminals 2&4. In position “A”, the terminals are

normally closed (only when the timer is energized), and

will open during a defrost. In position “B”, terminals 2&4

are normally open, and will close during a defrost. Select

proper position from table below and wiring diagrams

indicated. To select mode simply slide the

switch as fol-

lows:

Mode

Mode

A – position switch to left;

B – position

switch to right;

Note: When Mode “B” is selected the

DTMV40 will operate as follows:

Refrigeration Mode – RED &

GREEN LED’s will turn OFF (1&3

and 2&4 break while 1&F make)

Defrost Mode – RED & GREEN

LED’s will turn ON (1&3 and 2&4

make while 1&F break)

8045 REPLACEMENT:

The DTMV40 with 8045 terminal ID label applied differs

from the 8045 in that terminals 1 and N are combined.

This means that the DTMV40 model must be the same

voltage as the defrost circuit (defrost heater, contactor

coil, or hot gas valve). If used in an application where the

defrost circuit is 120V and the refrigeration circuit is 240V,

the DTMV40 must be configured for 120V application

(RED DIP Switch Down) with 120V power connected to 1-

N and X.

Note 1 – (8143 Replacement): When replacing a

Paragon 8143 or Precision 6143, wire the

termina-

tion thermostat to terminal N of the DTMV40 and

the adjacent blank terminal. The Paragon and

Precision timers are wired to terminal N and the

blank terminal. If the termination thermostat is

wired to terminal N of the DTMV40 (with the 8143

label attached), temperature termination will not

occur and may result in burnout of the DTMV40.

See wiring diagrams 8 & 9.

8240/6240 SERIES REPLACEMENT: The DTMV40 may

be used to replace the Paragon 8240 or Precision 6240

series defrost timers with integral pressure termination

by the addition of a remote pressure switch wired to ter-

minals Xp and p of the DTMV40 (with an 8240 series ter-

minal label applied). There must be no external voltage

connected to the pressure switch. Set pressure switch

cut-in to the same value as set on the Paragon or

Precision defrost timer being replaced. Set cut-out 6 to

14psi below cut-in. See wiring diagrams 10, 11, and 12.

Recommended Pressure Switches: Johnson/Penn P170,

Ranco 010 series, or Danfoss KP1 series. Pressure

range approximately 35-110psi, CUT-IN ON

PRESSURE

RISE.

NOTE 2 – (8243 Replacement): When replacing a

Paragon 8243 or Precision 6243, the DTMV40

white tabs (trippers) for setting defrost time and

defrost duration must be reversed. Pull ALL tabs

outward for refrigeration. Press the tabs inward at

the desired defrost initiation times, and for desired

duration.

Please Note: The DTMV40 replaces all prior Grasslin

defrost timer models such as DT040, DT140, DTMV, and

DTSX.

SPECIFICATIONS

Maximum Contact Switch Rating:

40A Resistive @ 120VAC, 208~240VAC

2HP @ 208~240VAC; 1HP @ 120VAC

16FLA, 90LRA @ 120VAC

12FLA, 52LRA @ 240VAC

“F” Terminal: 30A Resistive @ 120~240VAC

1HP @ 120VAC; 2HP @ 208~240VAC

Wiring Connections: Screw box lug terminals.

Up to one #8 AWG wire

Environmental Ratings:

Operating Temperature Range: –40°F to 131°F (–40°C to 55°C)

Operating Humidity: 0 - 95% RH, non-condensing

Dimensions: 8.795” x 6.631” x 2.935” (H x W x D)

Shipping Weight: 3 lbs.

Agency Approvals: UL Listed

5

LIMITED ONE YEAR WARRANTY

If within the warranty period specified, this product fails due to a defect in material or workmanship, Intermatic Incorporated will repair or

replace it, at its sole option, free of charge. This warranty is extended to the original purchaser only and is not transferable. This warranty

does not apply to: (a) damage to units caused by accident, dropping or abuse in handling, acts of God or any negligent use; (b) units which

have been subject to unauthorized repair, opened, taken apart or otherwise modified; (c) units not used in accordance with instructions;

(d) damages exceeding the cost of the product; (e) sealed lamps and/or lamp bulbs, LED’s and batteries; (f) the finish on any portion of the

product, such as surface and/or weathering, as this is considered normal wear and tear; (g) transit damage, initial installation costs, removal

costs, or reinstallation costs.

INTERMATIC INCORPORATED WILL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS OR IMPLIED WARRANTIES. ALL

IMPLIED WARRANTIES, INCLUDING THE WARRANTY OF MERCHANTABILITY AND THE WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE, ARE HEREBY MODIFIED TO EXIST ONLY AS CONTAINED IN THIS LIMITED WARRANTY, AND SHALL BE OF THE SAME

DURATION AS THE WARRANTY PERIOD STATED ABOVE. SOME STATES DO NOT ALLOW LIMITATIONS ON THE DURATION OF AN

IMPLIED WARRANTY, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

This warranty service is available by either (a) returning the product to the dealer from whom the unit was purchased, or (b) completing a

warranty claim on line at www.intermatic.com. This warranty is made by: Intermatic Incorporated, Customer Service 7777 Winn Rd. Spring

Grove, Illinois 60081-9698. For warranty service go to: http://www.intermatic.com or call 815-675-7000.

6

158--01071-REV2

DTMV40 Series

Time Initiated, Temperature, Pressure or Time

Terminated Multi-Voltage 40 A Defrost Timers

SPECIFIERS GUIDE

Furnish and install a Grasslin DTMV40 defrost control which is

eld adjustable for 120V or 240V operation and shall have defrost

initiation times settable to the quarter hour via captive trippers at 15

minute intervals. The defrost timer shall be housed in a UL TYPE 3R

indoor/outdoor plastic enclosure. The relay output will be rated for

40A Resistive, 2HP @ 240VAC. Defrost termination to be by time (and

by a remote temperature or pressure switch).

SPECIFICATIONS:

Maximum Contact Switch Rating:

40A Resistive @ 120VAC, 208~240VAC

2HP @ 208~240VAC; 1HP @ 120VAC

16FLA, 90LRA @ 120VAC

12FLA, 52LRA @ 240VAC

“F” TERMINAL:

30A Resistiv e @ 120~240V AC

1HP @ 120VAC; 2HP @ 208~240VAC

WIRING CONNECTIONS:

Screw box lug terminals. Up to one #8 AWG wire

ENVIR ONMENTAL RATINGS:

Operating Temperatur e Range: –40 °F to 131°F (–40°C to 55°C)

Operating Humidity: 0 - 95% RH, non-condensing

ELECTRICAL LIFE:

50,000 Operations at Full Load

DIMENSIONS:

8.795” x 6.631” x 2.935” (H x W x D)

SHIPPING WEIGHT:

AGENCY APPROVALS: UL LISTED

3 lbs.

FEATURES

• DTMV40 replaces over 40 competitive models

• Multi-Voltage eld adjustable for 120, or 208/240VAC

• Mounts in existing enclosures, no tools required

• Box lug terminals

• Defrost times settable on quarter hour with captive trippers

• UL TYPE 3R outdoor enclosure

• 40 Amp, 2HP Rating

• Moisture resistant conformal coated board

• LED indications for defrost and refrigeration cycles

• Compact outdoor UL TYPE 3R enclosure

• Defrost cycles are programmed independently

• “Real-time” clock for quick, easy and accura

te setting

NO TOOLS

REQUIRED!

Our “GUTS” simply snap

into existing enclosures

Moisture Resistant

Conformal Coated Board

Ground Lug Termination

Red and Green LED

Lights Indicate

Defrost or Run Cycle

Large Screw

Terminals for Easy Wiring

Up to one #8 AWG wire

40 Amp Rated

Contacts

Captive Trippers

Can’t Be Lost

Independently

Adjustable Trippers

Allow For Full or

Partial Defrost Cycles

on 15 Minute Intervals

True Clock Face

New Compact

UL TYPE 3R

Outdoor Enclosure

Replaces All Metal

Enclosures

Easy Multi-Voltage

Field Adjustable

DIP Switch for

120 or 208/240 VAC

Loading...

Loading...