Page 1

Page 2

Page 3

Page 4

CONTENTS MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

I

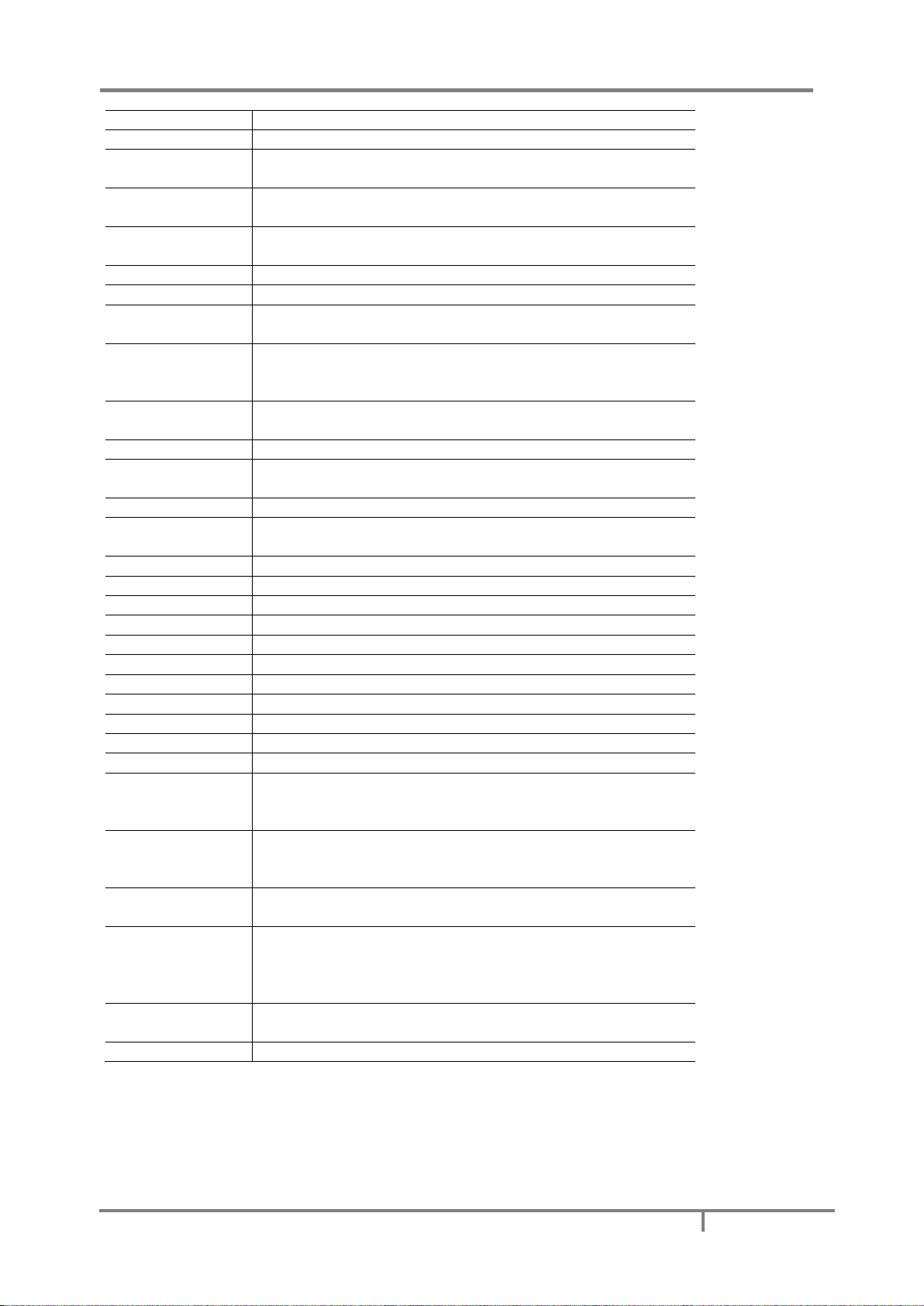

Contents

POWER QUALITY ANALYZER MAVOLOG PRO ..................................................................... 1

WARNINGS, INFORMATION AND NOTES REGARDING DESIGNATION OF PRODUCT ........... 2

BEFORE SWITCHING THE DEVICE ON ................................................................................. 3

DEVICE SWITCH OFF WARNING ......................................................................................... 3

HEALTH AND SAFETY ......................................................................................................... 4

REAL TIME CLOCK .............................................................................................................. 4

DISPOSAL .......................................................................................................................... 5

OPENING OF EQUIPMENT / REPAIR ................................................................................... 5

BASIC DESCRIPTION AND OPERATION ............................................................................... 6

Contents ......................................................................................................................... 6

Description of the MAVOLOG PRO Power Quality Analyzer .......................................... 7

Abbreviation/Glossary .................................................................................................... 8

Purpose and use of the MAVOLOG PRO Power Quality Analyzer ................................ 10

Device application and benefits ................................................................................... 11

Main Features, supported options and functionality of MAVOLOG PRO Power

Quality analyzer ............................................................................................................ 12

CONNECTION 17

Mounting ...................................................................................................................... 18

Electrical connection for MAVOLOG PRO Power Quality Analyzer .............................. 19

Connection of input/output modules .......................................................................... 21

Communication connection ......................................................................................... 24

Connection of Real Time Synchronization module C ................................................... 24

Connection of aux. Power supply ................................................................................. 26

FIRST STEPS 27

Installation wizard ........................................................................................................ 27

Notification icons .......................................................................................................... 29

LCD Navigation ............................................................................................................. 30

SETTINGS 31

MAVO-View software ................................................................................................... 31

Devices management ...................................................................................................... 32

Device settings ................................................................................................................ 34

Real time measurements ................................................................................................ 35

Page 5

MAVOLOG PRO – Waveform and Transient Recorder CONTENTS

II

GMC-I Messtechnik GmbH

Data analysis ................................................................................................................... 37

My Devices ...................................................................................................................... 37

Upgrade .......................................................................................................................... 37

Software upgrading ........................................................................................................ 38

Setting procedure ............................................................................................................ 40

General Settings ........................................................................................................... 41

Description & Location .................................................................................................... 41

Average interval .............................................................................................................. 41

Language ......................................................................................................................... 41

Currency .......................................................................................................................... 41

Temperature unit ............................................................................................................ 41

Date format ..................................................................................................................... 42

Date and time ................................................................................................................. 42

Real Time Synchronization Source .................................................................................. 42

Time zone ........................................................................................................................ 42

Auto Summer/Winter time .............................................................................................. 42

Maximum demand calculation (MD mode) .................................................................... 43

Thermal function ............................................................................................................. 43

Fixed window .................................................................................................................. 43

Sliding windows ............................................................................................................... 44

MD Time constant (min) ................................................................................................. 45

Maximum demand reset mode ....................................................................................... 46

Min/Max reset mode ...................................................................................................... 46

Starting current for PF and PA (mA) ................................................................................ 46

Starting current for all powers (mA) ............................................................................... 46

Starting voltage for SYNC ................................................................................................ 46

Harmonics calculation ..................................................................................................... 46

Reactive power & energy calculation .............................................................................. 46

LCD navigation ................................................................................................................ 47

Connection ................................................................................................................... 48

Connection mode ............................................................................................................ 48

Setting of current and voltage ratios .............................................................................. 48

Neutral line Primary/Secondary current (A) .................................................................... 48

Used voltage/current range (V/A) ................................................................................... 48

Frequency nominal value (Hz) ......................................................................................... 48

Max. demand current for TDD (A) ................................................................................... 48

Wrong connection warning ............................................................................................. 48

Energy flow direction ...................................................................................................... 49

CT connection .................................................................................................................. 49

LCD navigation ................................................................................................................ 49

Communication ............................................................................................................ 50

Push Data Format ........................................................................................................... 50

Push Response Time (sec)................................................................................................ 50

(Push) Time Synchronization ........................................................................................... 50

USB Communication ........................................................................................................ 50

Ethernet communication ................................................................................................. 50

Device Address ................................................................................................................ 51

IP Address ........................................................................................................................ 51

IP Hostname .................................................................................................................... 51

Local port ........................................................................................................................ 51

Subnet Mask .................................................................................................................... 52

Gateway Address ............................................................................................................ 52

NTP Server ....................................................................................................................... 52

Push communication settings ......................................................................................... 52

MAC Address ................................................................................................................... 53

Firmware version ............................................................................................................. 53

Communication modes ................................................................................................... 53

Page 6

CONTENTS MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

III

LCD navigation ................................................................................................................ 55

Display .......................................................................................................................... 56

Contrast/Black light intensity .......................................................................................... 56

Saving mode (min) .......................................................................................................... 56

Demo cycling period (sec) ............................................................................................... 56

Custom screen 1/2/3 ....................................................................................................... 56

LCD navigation ................................................................................................................ 57

Security ......................................................................................................................... 57

Password - Level 0 >PL0) ................................................................................................. 57

Password - Level 1 >PL1) ................................................................................................. 57

Password - Level 2 >PL2) ................................................................................................. 57

A Backup Password->BP)................................................................................................. 57

Password locks time >min) .............................................................................................. 58

Password setting ............................................................................................................. 58

Password modification .................................................................................................... 58

Password disabling .......................................................................................................... 58

Password and language .................................................................................................. 58

LCD navigation ................................................................................................................ 58

Energy ........................................................................................................................... 59

Active Tariff ..................................................................................................................... 59

Common Energy Counter Resolution............................................................................... 59

Common Energy Cost Exponent ...................................................................................... 59

Counter divider ................................................................................................................ 59

Common Tariff Price Exponent ........................................................................................ 59

1 kWh Price in Tariff (1,2,3,4) .......................................................................................... 60

1 kvarh Price in Tariff (1,2,3,4) ........................................................................................ 60

1 kVAh Price in Tariff (1,2,3,4) ......................................................................................... 60

LED Energy Counter ......................................................................................................... 60

LED Number of pulses ..................................................................................................... 60

LED Pulse Length (ms) ..................................................................................................... 60

Measured Energy ............................................................................................................ 60

Individual counter Resolution .......................................................................................... 60

Tariff Selector .................................................................................................................. 60

Tariff Clock ...................................................................................................................... 61

Holidays/Holiday date 1-20 ............................................................................................. 62

LCD navigation ................................................................................................................ 62

Inputs and outputs ....................................................................................................... 63

Introduction ..................................................................................................................... 63

I/O Modules options ........................................................................................................ 63

I/O Modules..................................................................................................................... 63

Analogue output module ................................................................................................ 63

Analogue input module ................................................................................................... 64

Pulse output module ....................................................................................................... 65

Digital input module ........................................................................................................ 65

Pulse input module .......................................................................................................... 65

Tariff input module.......................................................................................................... 65

Bistable alarm output module......................................................................................... 65

Alarm Output .................................................................................................................. 66

Status (Watchdog) and Relay output module ................................................................. 66

Auxiliary I/O Modules A & B ............................................................................................ 66

RTC Synchronization module C ........................................................................................ 67

LCD navigation ................................................................................................................ 68

Alarms ........................................................................................................................... 69

Alarms PUSH functionality .............................................................................................. 69

Push data to link .............................................................................................................. 69

Pushing period ................................................................................................................. 69

Page 7

MAVOLOG PRO – Waveform and Transient Recorder CONTENTS

IV

GMC-I Messtechnik GmbH

Pushing time delay .......................................................................................................... 70

Alarms group settings ..................................................................................................... 70

Alarm statistics reset ....................................................................................................... 70

MD Time constant (min) ................................................................................................. 70

Compare time delay (sec) ................................................................................................ 70

Hysteresis (%) .................................................................................................................. 70

Response time ................................................................................................................. 71

Individual alarm settings ................................................................................................. 71

Advanced recorders ...................................................................................................... 72

Logical Inputs and Logical Functions ............................................................................... 73

Triggers ........................................................................................................................... 74

Recorders ........................................................................................................................ 93

Conformity of voltage with EN 50160 standard ......................................................... 104

General PQ settings ....................................................................................................... 104

Monitoring mode .......................................................................................................... 104

Electro energetic system ............................................................................................... 104

Monitoring voltage connection ..................................................................................... 105

Nominal supply voltage ................................................................................................. 105

Nominal power frequency ............................................................................................. 105

Flicker calculation function ........................................................................................... 105

Monitoring period (weeks) ............................................................................................ 105

Monitoring start day ..................................................................................................... 105

Flagged events setting .................................................................................................. 105

Sending Reports and Report Details .............................................................................. 106

EN 50160 parameters settings ...................................................................................... 107

Reset ........................................................................................................................... 108

Reset energy counter .................................................................................................... 108

Reset energy counter Cost ............................................................................................. 108

Reset MD values ............................................................................................................ 108

Reset last period MD ..................................................................................................... 108

Synchronize MD ............................................................................................................. 108

Alarm relay [1/2/3/4] Off .............................................................................................. 109

Reset Min/Max values ................................................................................................... 109

Reset alarm statistic ...................................................................................................... 109

LCD navigation .............................................................................................................. 109

MEASUREMENTS 110

Online measurements ................................................................................................ 110

Interactive instrument ................................................................................................ 111

Supported measurements .......................................................................................... 112

Available connections ................................................................................................. 112

Selection of available quantities ................................................................................. 112

Explanation of basic concepts .................................................................................... 117

Sample factor MV .......................................................................................................... 117

Average interval MP ...................................................................................................... 117

Sample frequency .......................................................................................................... 117

Average interval ............................................................................................................ 117

Average interval for measurements and display........................................................... 117

Average interval for min/max values ............................................................................ 117

Average (storage) interval for recorders ....................................................................... 117

Average (aggregation) interval for PQ parameters ...................................................... 117

Power and energy flow ................................................................................................. 118

Calculation and display of measurements ................................................................. 119

Keyboard and LCD display presentation ..................................................................... 119

Measurements menu organization ............................................................................ 120

Page 8

CONTENTS MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

V

Measurements menu MAVOLOG PRO ....................................................................... 120

Present values ............................................................................................................ 121

Present values on LCD and TFT display ...................................................................... 121

Voltage .......................................................................................................................... 121

Current .......................................................................................................................... 122

Active, reactive and apparent power ............................................................................ 122

Power factor and power angle ...................................................................................... 122

Frequency ...................................................................................................................... 123

Energy counters ............................................................................................................. 123

MD values ..................................................................................................................... 123

Harmonic distortion ...................................................................................................... 123

Harmonic distortion parameters ................................................................................... 124

Flickers evaluation ......................................................................................................... 124

Flickers .......................................................................................................................... 124

Customized screens ....................................................................................................... 124

Min/Max values .......................................................................................................... 125

Average interval for min/max values ............................................................................ 125

Display of min/max values on MAVOLOG PRO ............................................................. 125

Display of min/max values – MAVO-View software...................................................... 126

Alarms ......................................................................................................................... 127

Survey of alarms ......................................................................................................... 128

Demo cycling .............................................................................................................. 129

Harmonic analysis ....................................................................................................... 129

Display of harmonic parameters ................................................................................... 130

Harmonic analasis – MAVO-View ................................................................................. 131

PQ Analysis ................................................................................................................. 134

LCD navigation .............................................................................................................. 142

PQDIF and COMTRADE files on MAVOLOG PRO – concept description ..................... 143

Working with PQDIF and COMTRADE files on the device .......................................... 143

Accessing PQDIF files ..................................................................................................... 143

Accessing COMTRADE files ............................................................................................ 149

PQDiffractor - PQDIF and COMTRADE file viewer ......................................................... 150

TECHNICAL DATA 153

Accuracy ..................................................................................................................... 153

Measurement inputs .................................................................................................. 155

Connection ................................................................................................................. 156

Communication .......................................................................................................... 156

Input/Output modules ............................................................................................... 157

Safety .......................................................................................................................... 160

Time synchronization input ........................................................................................ 160

Universal Power Supply .............................................................................................. 161

Mechanical ................................................................................................................. 161

Ambient conditions .................................................................................................... 161

Real time clock ............................................................................................................ 162

Operating conditions .................................................................................................. 162

Dimensions ................................................................................................................. 163

APPENDICES 165

APPENDIX A: MODBUS communication protocol....................................................... 165

APPENDIX B: DNP3 communication protocol ............................................................. 174

APPENDIX C: Equations............................................................................................... 182

APPENDIX D: XML Data format ................................................................................... 186

Page 9

MAVOLOG PRO – Waveform and Transient Recorder CONTENTS

VI

GMC-I Messtechnik GmbH

APPENDIX E: PQDIF and COMTRADE recorder data storage organization ................. 188

APPENDIX F: IEC61850 protocol support overview .................................................... 191

Page 10

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

1

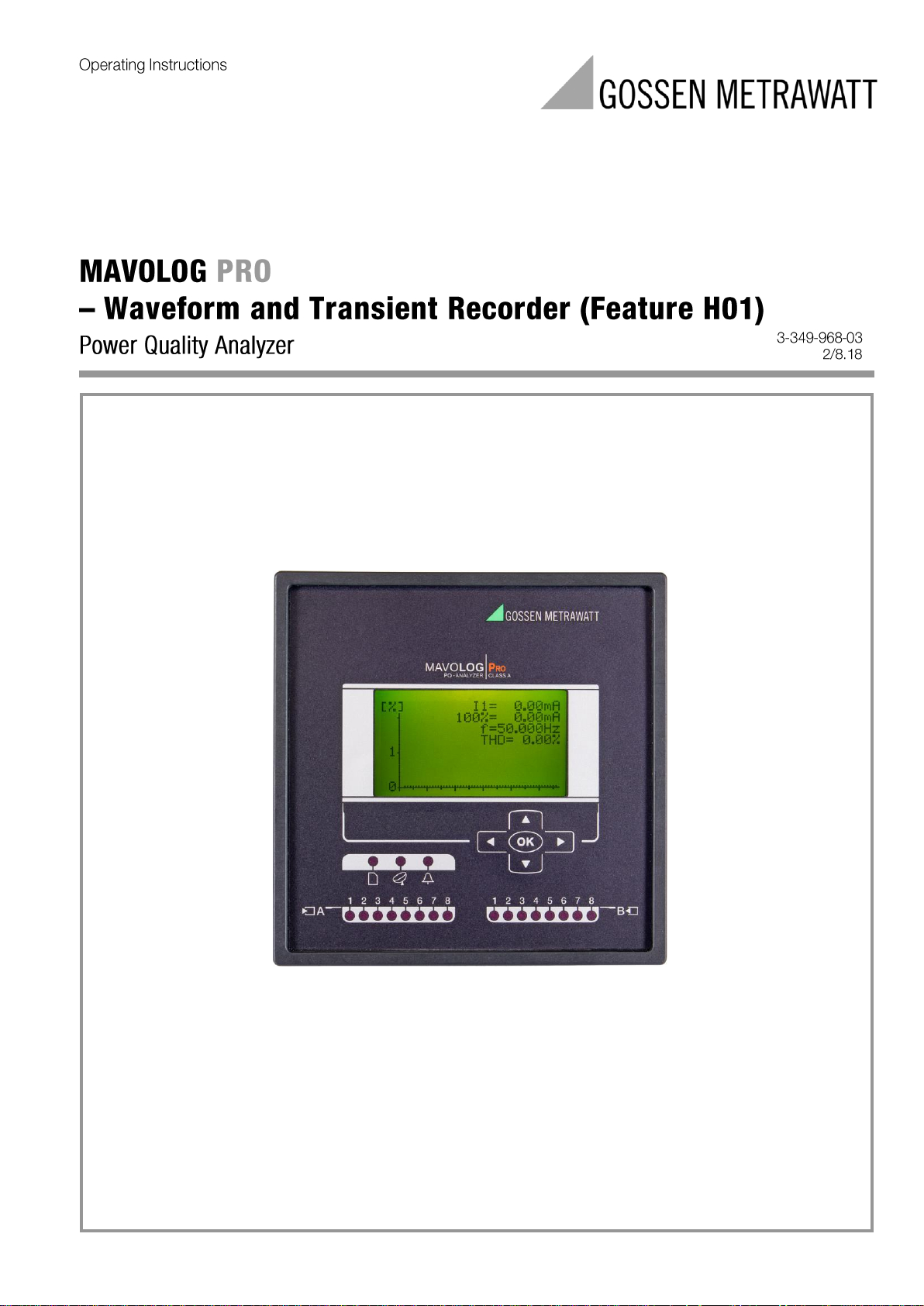

MAVOLOG PRO

- Waveform and Transient Recorder (Feature H01)

MAVOLOG PRO with Feature H01

Page 11

MAVOLOG PRO – Waveform and Transient Recorder

2

GMC-I Messtechnik GmbH

WARNINGS, INFORMATION AND

NOTES REGARDING DESIGNATION

OF PRODUCT

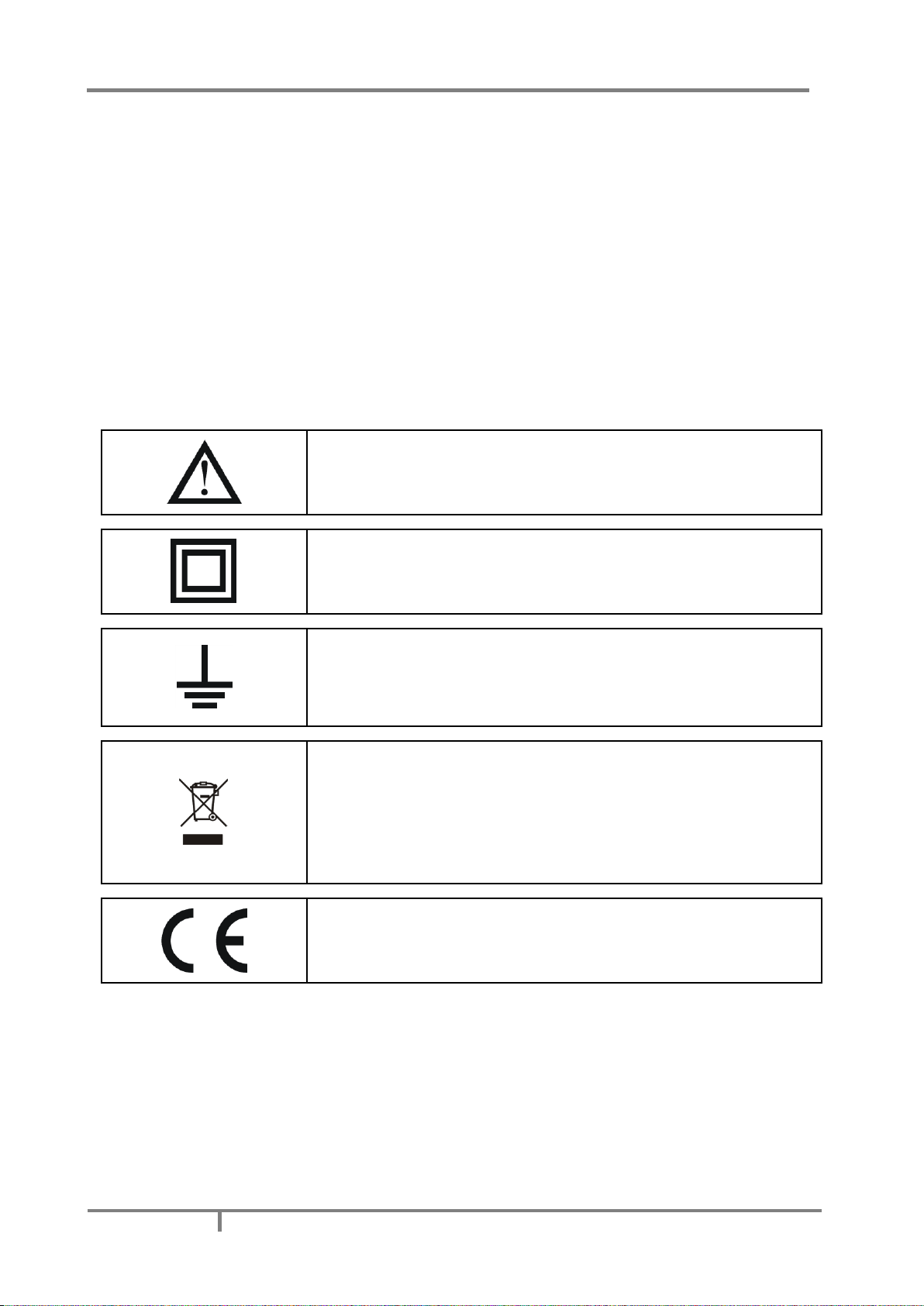

Used symbols:

See product documentation.

Double insulation in compliance with the EN 61010−1 standard.

Functional ground potential.

Note: This symbol is also used for marking a terminal for protective ground

potential if it is used as a part of connection terminal or auxiliary supply

terminals.

Compliance of the product with directive 2012/19/EU, as first priority, the

prevention of waste electrical and electronic equipment (WEEE), and in

addition, the reuse, recycling and other forms of recovery of such wastes so as

to reduce the disposal of waste. It also seeks to improve the environmental

performance of all operators involved in the life cycle of electrical and

electronic equipment.

Compliance of the product with European CE directives.

Page 12

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

3

BEFORE SWITCHING THE DEVICE ON

Check the following before switching on the device:

Nominal voltage,

Supply voltage,

Nominal frequency,

Voltage ratio and phase sequence,

Current transformer ratio and terminals integrity,

Protection fuse for voltage inputs (recommended maximal external fuse size is 6 A)

External switch or circuit-breaker must be included in the installation for disconnection of the devices’

aux. power supply. It must be suitably located and properly marked for reliable disconnection of the

device when needed.

Integrity of earth terminal

Proper connection and voltage level of I/O modules

Important: A current transformer secondary should be short circuited before connecting the device.

WARNING!

Feature A01 only (no more available): Auxiliary power supply can be LOW range (19-70VDC, 48-77VAC). Connecting device

with LOW power supply to higher voltage will cause device malfunction. Check devices’ specification before power on!

DEVICE SWITCH OFF WARNING

Auxiliary supply circuits for (external) relays can include capacitors between supply and ground. In order to

prevent electrical shock hazard, the capacitors should be discharged via external terminals after having

completely disconnected auxiliary supply (both poles of any DC supply).

Page 13

MAVOLOG PRO – Waveform and Transient Recorder

4

GMC-I Messtechnik GmbH

HEALTH AND SAFETY

The purpose of this chapter is to provide a user with information on safe installation and handling with the

product in order to assure its correct use and continuous operation.

We expect that everyone using the product will be familiar with the contents of chapter »Security Advices and

Warnings«.

If equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment

may be impaired.

REAL TIME CLOCK

As a backup power supply for Real time clock super-cap is built in. Support time is up to 2 days (after each

power supply down).

Page 14

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

5

DISPOSAL

It is strongly recommended that electrical and electronic equipment is not deposit as municipal waste. The

manufacturer or provider shall take waste electrical and electronic equipment free of charge. The complete

procedure after lifetime should comply with the Directive 2012/19/EU about restriction on the use of certain

hazardous substances in electrical and electronic equipment.

OPENING OF EQUIPMENT / REPAIR

The equipment may be opened only by authorized service personnel to ensure the safe and correct operation

of the equipment and to keep the warranty valid.

Even original spare parts may be installed only by authorized service personnel.

In case the equipment was opened by unauthorized personnel, no warranty regarding personal safety,

measurement accuracy, conformity with applicable safety measures or any consequential damage is granted by

the manufacturer.

Page 15

MAVOLOG PRO – Waveform and Transient Recorder

6

GMC-I Messtechnik GmbH

BASIC DESCRIPTION AND

OPERATION

This chapter presents all relevant information about the instrument required to understand its purpose,

applicability and basic features related to its operation.

Apart from this, it also contains navigational tips, description of used symbols and other useful information for

understandable navigation through this manual.

Regarding the options of this instrument, different chapters should be considered since a particular sub variant

might vary in functionality. More detailed description of device functions is given in chapters Main Features,

Supported options and Functionality.

The MAVOLOG PRO Advanced Power Quality Analyzer is available in 144 mmx144 mm panel mounting

enclosure. Specifications of housing and panel cut out for housing is specified in chapter

Contents

Contents and size of a packaging box can slightly vary depending on type of consignment.

Single device shipment or a very small quantity of devices is shipped in a larger cardboard box, which offers

better physical protection during transport. This type of packaging contains the following items:

Measuring instrument

Fixation screws

Pluggable terminals for connection of inputs, aux. Power supply and I/O modules

Short installation manual

When larger quantities of devices are sent they are shipped in smaller cardboard boxes for saving space and

thus reducing shipment costs. This type of packaging contains:

Measuring instrument

Fixation screws

Pluggable terminals for connection of inputs, aux. power supply and I/O modules

Short installation manual

All related documentation on this product can be found at www.gossenmetrawatt.com. The instrument

desktop based setting software – MAVO-View, together with accompanying drivers can be found on our web

page www.gossenmetrawatt.com. Due to environmental reasons, all this information is longer provided on a

separate CD.

CAUTION

Please examine the equipment carefully for potential damage which might have occurred during transport!

Page 16

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

7

Description of the MAVOLOG PRO Power Quality Analyzer

The MAVOLOG PRO Advanced Power Quality Analyzer is a comprehensive device intended for permanent

monitoring of power quality from its production, transmission, distribution all the way to the final consumers,

who are most affected by inadequate voltage quality. It is mostly applicable in medium and low voltage

applications.

Lack of information regarding supplied voltage quality can lead to unexplained production problems and

malfunction or can even damage equipment being used during factory production process. Therefore, this

device can be used for the needs of electrical utilities (evaluation against standards) as well as for industrial

purposes (e.g. for monitoring the level of supplied power quality).

Page 17

MAVOLOG PRO – Waveform and Transient Recorder

8

GMC-I Messtechnik GmbH

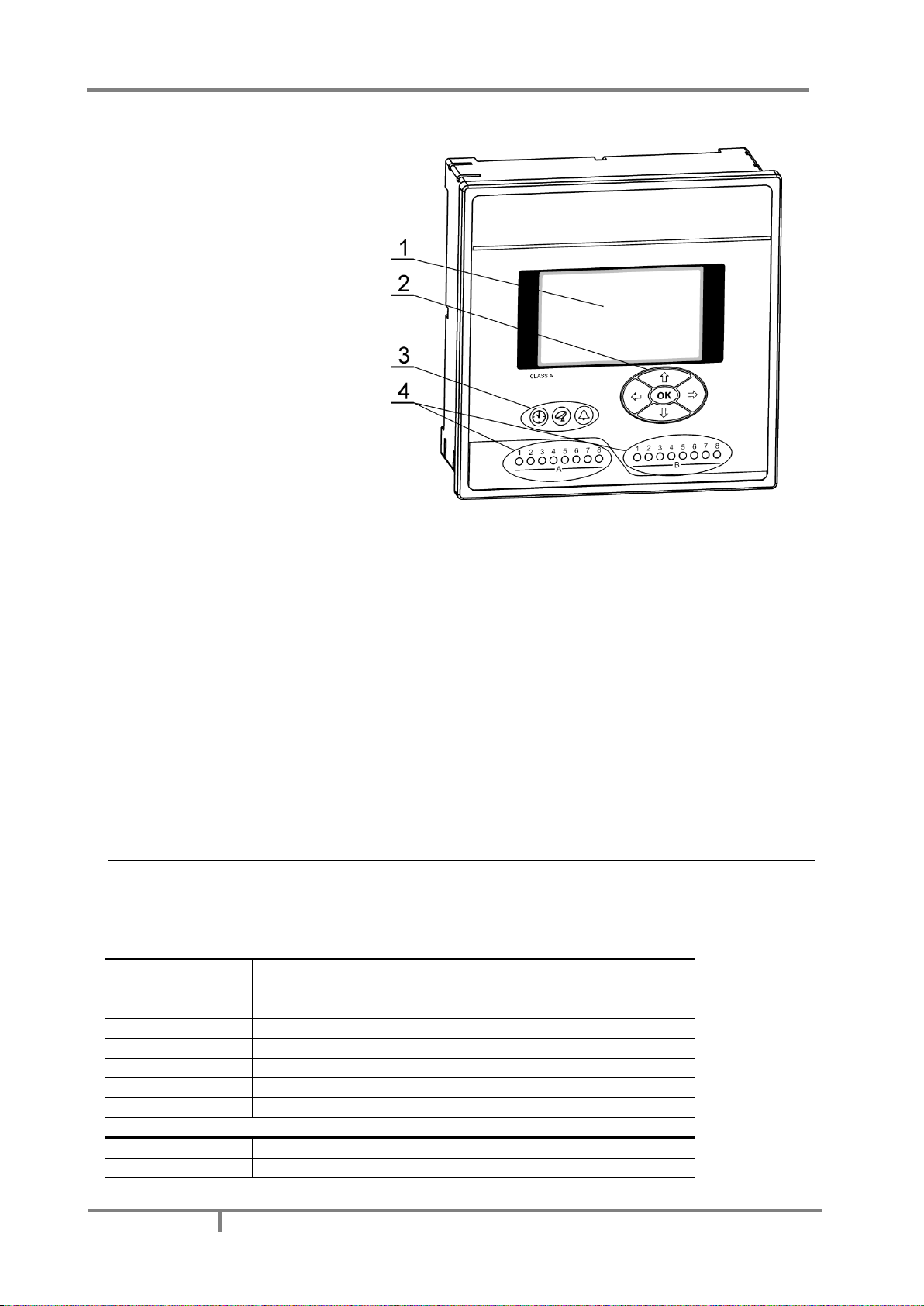

Appearance

1 – Graphical LCD

2 – Navigation keyboard

3 – General operation LED indicators

(clock synchro./comm./alarm)

4 – I/O status LED indicators

Graphical LCD:

A graphical LCD with back-light is used for displaying measuring quantities and for a display of selected

functions when setting the device.

Navigation keyboard:

The "OK" key is used for confirming the settings, selecting and exiting the display. Direction keys are

used for shifting between screens and menus.

LED indicators:

There are two types of LED indicators positioned on the front panel. General operation LED indicators

and I/O status LED indicators.

General operation LED indicators warn on certain device status. The left-most (red) indicator indicates

that the device internal clock is synchronized (via GPS, IRIG-B or NTP protocol). The middle (green) one

is blinking when transmitting MC data via communication to the server. The right-most (red) one is

blinking when any of the alarm conditions is fulfilled.

I/O state LED indicators are in operation when additional Modules A and/or B are built-in. These

modules can have the functionality of Digital input or Relay output. They are indicating the state of a

single I/O. Red LED is lit in either of the following conditions:

Relay output is activated

Signal is present on Digital input

Abbreviation/Glossary

Abbreviations are explained within the text where they appear the first time. Most common abbreviations and

expressions are explained in the following table:

Term

Explanation

RMS

Root Mean Square value

Flash

Type of a memory module that keeps its content in case of power

supply failure

Ethernet

IEEE 802.3 data layer protocol

MODBUS / DNP3

Industrial protocol for data transmission

Memory card

Multimedia memory card. Type MMC and SD supported.

MAVO-View

Setting Software for GOSSEN METRAWATT

PA total

Power Angle calculated from total active and apparent power

Term

Explanation

PA

phase

Angle between fundamental phase voltage and phase current

PF

phase

Power factor, calculated from apparent and active power (affected

Page 18

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

9

by harmonics)

THD (U, I)

Total harmonic distortion

TDD (I)

Total demand distortion (according to IEEE Std. 519-1992). Indicates

harmonic distortion at full load.

K factor (I)

Indicates a weighting of the harmonic load currents according to

their effects on transformer heating. (according to IEEE C57.110)

CREST factor (I)

Indicates a ratio between the peak amplitude of the waveform and

the RMS value of the waveform.

MD

Max. Demand; Measurement of average values in time interval

FFT graphs

Graphical display of presence of harmonics

Harmonic voltage −

harmonic

Sine voltage with frequency equal to integer multiple of basic

frequency

InterHarmonic

voltage −

interharmonics

Sine voltage with frequency NOT equal to integer multiple of basic

frequency

Flicker

Voltage fluctuation causes changes of luminous intensity of lamps,

which causes the so-called flicker

RTC

Real Time Clock

Sample factor

Defines a number of periods for measuring calculation on the basis of

measured frequency

Mp − Average interval

Defines frequency of refreshing displayed measurements

Hysteresis [%]

Percentage specifies increase or decrease of a measurement from a

certain limit after exceeding it.

IRIG-B

Serial Inter-range instrumentation group time code

GPS

Satellite navigation and time synchronization system

PO

Pulse output module

TI

Tariff input module

RO

Relay output module

BO

Bistable alarm output module

AO

Analogue output module

DI

Digital input module

PI

Pulse input module

AI

Analogue input module

WO

Status (watchdog) module – for supervision of proper operation

PQDIF

Power Quality Data Interchange Format, which is a binary file format

(according to IEEE Std 1159.3-2003) that is used to exchange power

quality data among different SW products.

COMTRADE

Common format for Transient Data Exchange for power systems is a

file format for storing oscillography and status data related to

transient power system disturbances.

Waveform

Represents the detailed time-dependent shape and form of a

voltage, current or logical input signal

Transient

Represents power quality disturbances that involve destructive high

magnitudes of current and voltage or even both. They exist in a very

short duration from less than 50 nanoseconds to as long as 50

milliseconds.

Disturbance

These are used for monitoring long-term disturbances. Every half/full

cycle, RMS value is calculated, based on the previous cycle.

PQ

Power Quality

List of common abbreviations and expressions

Page 19

MAVOLOG PRO – Waveform and Transient Recorder

10

GMC-I Messtechnik GmbH

Purpose and use of the MAVOLOG PRO Power Quality

Analyzer

This instrument performs measurements in compliance with regulatory requested standard EN 61000-4-30 and

evaluates recorded parameters for analysis according to parameters defined in European power quality

standard EN50160. It enables storage of a wide variety of highly detailed oscillography data in 8GB of internal

flash memory based on a sophisticated trigger settings mechanism. Data can be stored in standardized PQDIF

(IEEE 1159-3) and COMTRADE (IEEE C37.111) file formats which can easily be exchanged with third party PQ

analysis SW systems.

Moreover the MAVOLOG PRO stores measurements and quality reports in internal memory for further

analysis. By accessing recorded or real time values from multiple instruments installed on different locations it

is possible to gain the overall picture of the complete systems’ behavior. This can be achieved with regard to

MAVOLOG PRO accurate internal real time clock and wide range of synchronization sources support, which

assure accurate, time-stamped measurements from dislocated units.

Stored data can then be transferred to a PC or server for post analysis. The simplest way this is done is by

directly connecting a PC with installed MAVO-View Setting Studio SW via USB cable. In cases where multiple

devices are used the MAVO-Database system server usage is recommended where all relevant data from all

system connected instruments is always available from a centralized database through the push XML

communication mechanism. To save server space high precision data can also be transferred from a selected

device on-demand using FTP.

The following characteristics are measured and recorded:

Monitored Power Quality indices as defined by EN 50160

Phenomena

PQ Parameters

Frequency variations

Frequency distortion

Voltage variations

Voltage fluctuation

Voltage unbalance

Voltage changes

Rapid voltage changes

Flicker

Voltage events

Voltage dips

Voltage interruptions

Voltage swells

Harmonics & THD

THD

Harmonics

Inter-harmonics

Signaling voltage

Page 20

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

11

Device application and benefits

The MAVOLOG PRO Quality Analyzer can be used as a standalone PQ monitoring device for detection and

analysis of local PQ deviations, transients, alarms and periodic measurements. For this purpose it is normally

positioned at the point-of-common-coupling (PCC) of industrial and commercial energy consumers to monitor

quality of delivered electric energy or at medium or low voltage feeders to monitor, detect and record possible

disturbances caused by operation of consumers.

Identifying relevant fixed measuring points is the most important task prior to complete system installation.

The implementation of a PQ system itself will not prevent disturbances in network but rather help diagnose

their origins and effects by comparing and scrutinizing data from multiple time synchronized measurement

points.

Therefore the most extensive benefits are achieved when the MAVOLOG PRO is used as a part of a PQ

monitoring system comprising of strategically positioned meters connected to the MAVO-Database software

solution. This three-tier middleware software represents a perfect tool for utility companies, energy suppliers

and other parties on both ends of supply-demand chain. MAVO-Database data collector with “push”

communication system allows automatic recording of all predefined measured parameters in the device. All

sent data are stored in the MAVO-Database, while leaving a copy of the same parameters stored locally in

device memory of each device as a backup copy. Database records can be analyzed, searched as well as viewed

in tabelaric and graphic form using the native MAVO-Database web client application or other third-party

software. (e.g. SCADA systems, OPC server, PQ analysis established software…) At the same time device data

can also be visualized and analyzed on-demand by means of the powerful freely-downloadable MAVO-View

setting studio SW.

Server database records (with a copy in device memory) include numerous parameters of three-phase systems,

which have been setup in the device (PQ parameters, over 700 evaluated electrical quantities, I/O module

related physical parameters (e.g. temp., pressure, wind speed…). On the other hand the database also holds

data on alarms and detailed time-stamped transient, waveform, disturbance PQ data and fast trend trigger

records with complete oscillography data in standardized PQDIF/COMTRADE file formats.

Page 21

MAVOLOG PRO – Waveform and Transient Recorder

12

GMC-I Messtechnik GmbH

Main Features, supported options and functionality of

MAVOLOG PRO Power Quality analyzer

MAVOLOG PRO Advanced Power Quality Analyzer is a perfect tool for monitoring and analyzing medium or low

voltage systems in power distribution and industrial segments. It can be used as a standalone PQ monitoring

device for detection of local PQ deviations. For this purpose it is normally positioned at the point-of-commoncoupling (PCC) of small and medium industrial and commercial energy consumers to monitor quality of

delivered electric energy or at medium or low voltage feeders to monitor, detect and record possible

disturbances caused by (unauthorized) operation of consumers.

User can select different hardware modules that can be implemented in device. Wide range of variants can

cover practically every user’s requirements.

MAVOLOG PRO Advanced Power Quality Analyzer is a compact, user friendly and cost effective device that

offers various features to suit most of the requirements for a demanding power system management:

o Evaluation of the electricity supply quality in compliance with EN50160 with automatic report generation

o Instantaneous evaluation of over 700 electrical measurement quantities values including PQ related

parameters, harmonics (voltage/current THDs, TDDs, up to 63rd current voltage/current harmonics, voltage

phase-phase and inter-harmonics)

o Class A (0.1%) accuracy in compliance with EN61000-4-30

o Oscillography capability for recording waveforms with up to 625 samples/cycle sampling frequency

o Recording of disturbance, trend and Power Quality (PQ) events in trigger related recorders

o All trigger related recorder data available on-demand through FTP and automatically on the MAVO-

Database server via autonomous push communication or on demand

o A sophisticated triggering mechanism to register and record events of various nature:

Transient event generated triggers based on hold-off time (in ms), absolute peak value (%) and fast

change (in %Un/µs)

PQ event generated triggers based on the following events: voltage dip, voltage swell, voltage

interruption, end of voltage interruption, rapid voltage change and inrush current

External Ethernet triggers enabling trigger events with up to 8 different devices within the network

External digital triggers based on logical/digital inputs

Up to 16 combined triggers enabling logical operation on previously configured triggers of various

nature

o Recording a wide variety of data in the internal device 8GB flash memory based on trigger settings:

All activated triggers together with timestamp, duration, condition as well as a reference to an

(optionally) generated transient, waveform, disturbance and fast trend record

Waveform recorder with PQDIF/COMTRADE data format selection, selectable recorded channels

(4×Voltage, 4×Current, 16×Digital input), 19 samp./cycle to 625 samp./cycle resolution, pretrigger

time from 0,01s up to 1s, posttrigger time from 0,01s up to 40s (20s for 625 samp./cycle)

Disturbance recorder with PQDIF/COMTRADE data format selection, selectable recorded channels

(4×P-N Voltage, 3×P-P Voltage, 4×Current, 8×Logical inputs), half/full cycle averaging interval, pretrigger time up to 3000 cycles, post trigger time up to 60000 cycles

Periodic measurements in 4 standard trend recorders A through D each containing up to 32 arbitrarily

evaluated (maximum, minimum, average, maximum demand, minimum demand, actual) quantities

with periods ranging from 1min to 60min

Periodic measurements in advanced fast trend recorders 1 through 4 each containing over 700

arbitrarily evaluated (maximum, minimum, average, actual) quantities with periods ranging from 1s to

60min. The recorder can be set to PQDIF data format selection

32 adjustable alarms in 4 alarm groups each containing up to 8 alarms. Alarms relate to a particular

quantity over/under threshold and serve the purpose of controlling on-device relay outputs as well as

informing the server about the occurrence of alarm events

Recording and on-board evaluation of PQ anomalies and PQ reports based on EN50160

Page 22

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

13

o Four quadrant energy measurement in 8 programmable counters with class 0.2S accuracy with up to four

tariffs and an advanced tariff clock. Every Counters’ resolution and range can be defined. The counter

content can be configured as:

Active energy (Wh) import

Active energy (Wh) export

Reactive energy (varh) import

Reactive energy (varh) export

Total absolute active energy (Wh)

Total absolute reactive energy (varh)

Total absolute apparent energy (VAh)

Custom settings (phase dependent, four quadrant – P/Q/import/export selection)

o Automatic range selection of 4 current and 4 voltage channels (max. 12.5 A and 1000 VRMS) with 32 kHz

sampling rate

o Measurements of 40 minimal and maximal values in different time intervals (from 1 to 256 periods)

o Frequency range from 16 Hz to 400 Hz

o Ethernet and USB 2.0 communication support

o Communication - MODBUS, DNP3, FTP, upgradeable to EN 61850 (optionally – see Appendix F)

o Support for GPS, IRIG-B (modulated and digital) and NTP real time clock synchronization

o Up to 20 inputs/outputs (analogue inputs/outputs, digital inputs/outputs, alarm/watchdog outputs, pulse

input/outputs, tariff inputs, bistable outputs)

o MAVO-View Setting studio User-friendly setting and analysis software with FTP communication feasibility

for seamless device settings and single device advanced analysis

o MAVO-Database system SW support for automatic (via autonomous push XML communication) as well as

on demand data transfer (via FTP) from multiple instruments to the server through which relevant recorder

data from each device in the system is available

o On-board Web server support for basic measurement overview

o Multilingual support

o Universal power supply (two voltage ranges)

o 144 mm square panel mounting

o Available with:

128x64 pixel display

o USB memory stick slot (optional)

Page 23

MAVOLOG PRO – Waveform and Transient Recorder

14

GMC-I Messtechnik GmbH

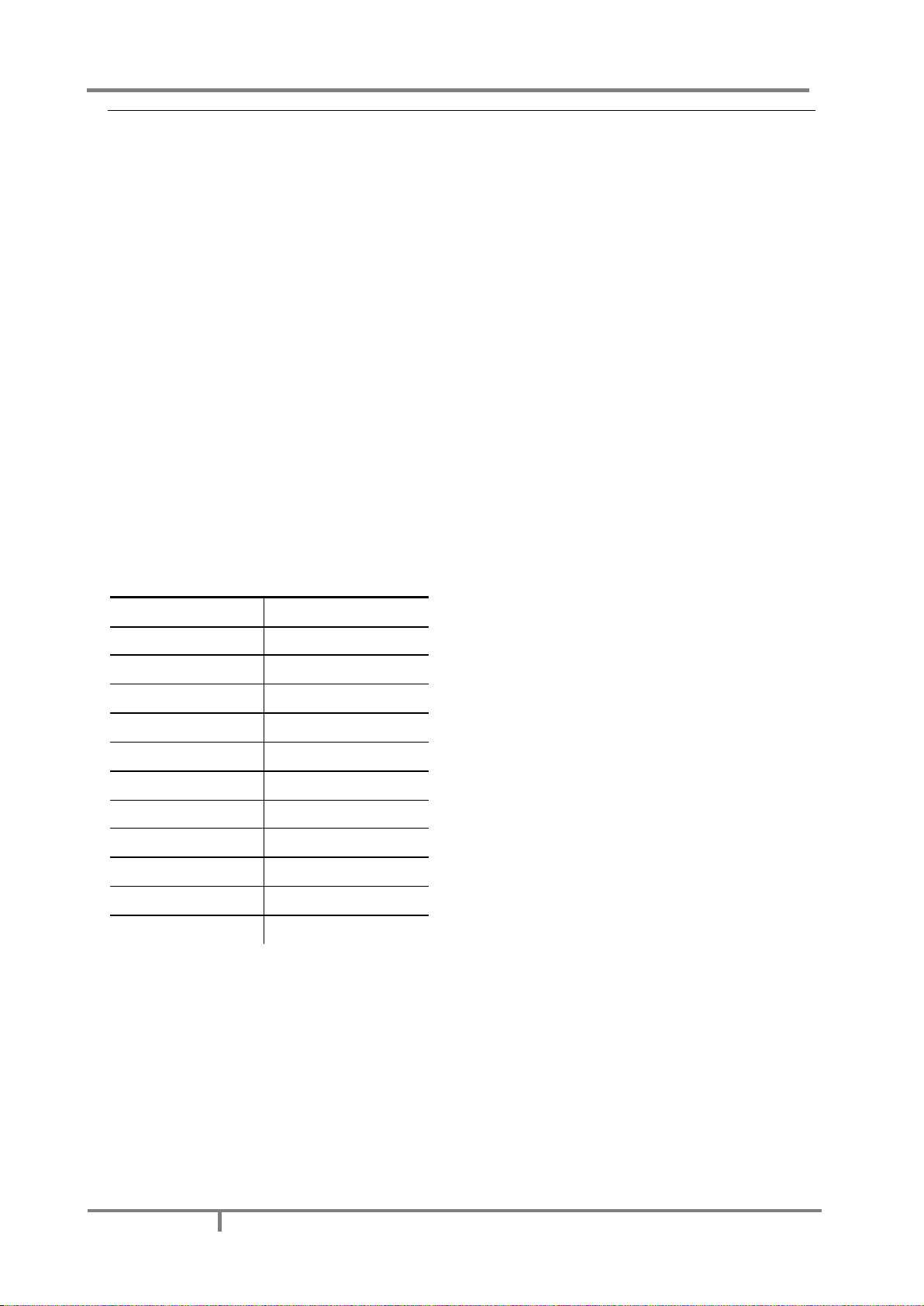

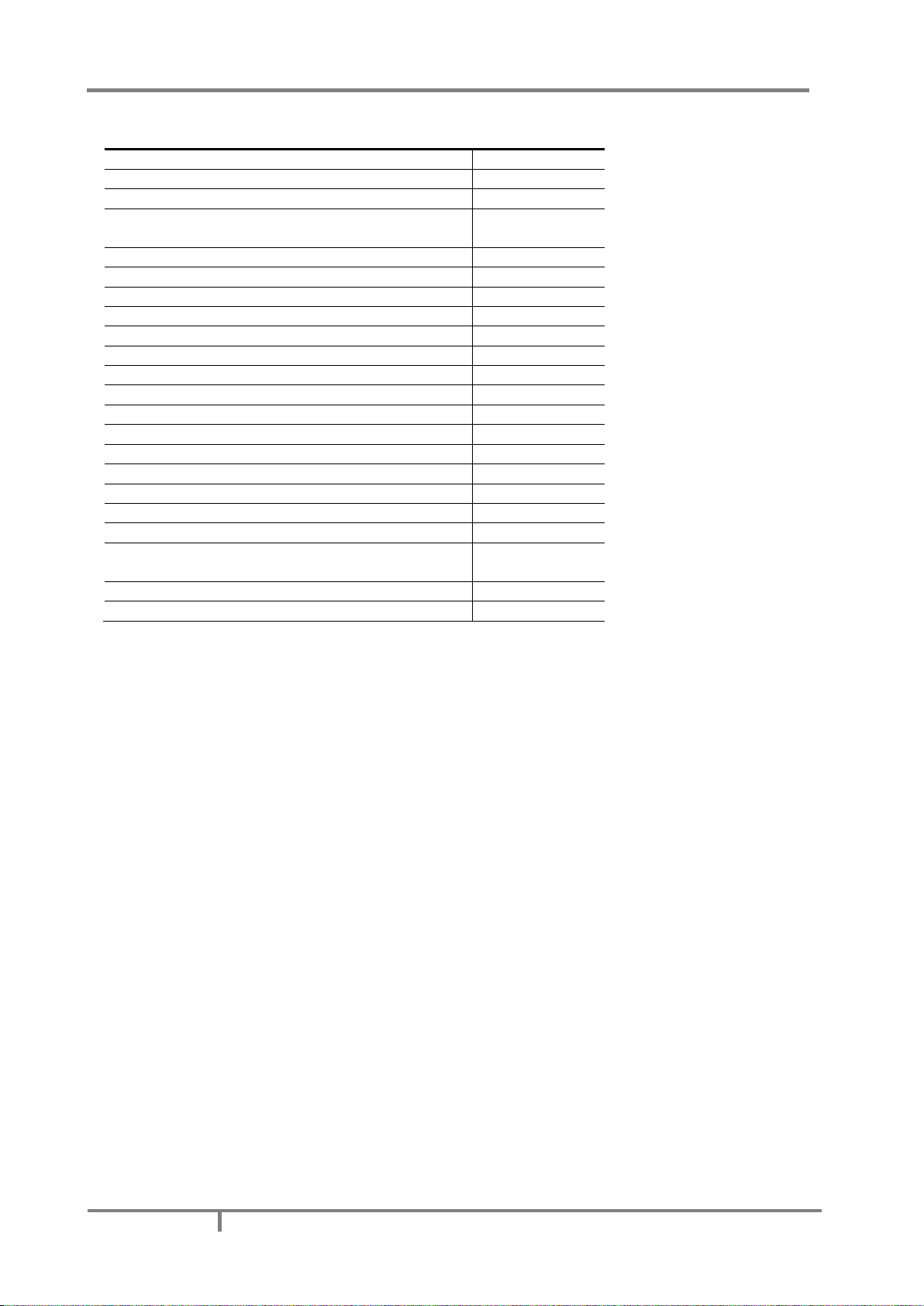

General hardware Features

Default / Optional

General

Class A measuring accuracy (0.1%) according to EN 61000-4-30 Ed.3

●

Voltage auto range up to 1000Vp-p

RMS

●

Current auto range up to 12.5 A

●

4 voltage and 4 current channels with 32 us sampling time

●

Universal power supply type High / Low

● / ○

Two independent communication ports (see data below)

○

Support for GPS / IRIG-B / NTP real time synchronization

● / ● / ●

Up to 20 additional inputs and outputs (see data below)

○

Internal flash memory (8MB+8GB)

●

Real time clock (RTC)

●

standard 144 mm DIN square panel mounting

●

Front panel

Graphical LCD display with back light

●

LED indicator (sync/com./alarm)

●

I/O status LED indicator

●

Control keys on front panel (5 keys)

●

Communication

COM1: Ethernet +USB

●

COM2: Serial (RS232/ RS485 on slot C if other synchronization modes are in use)

●

● − Function is supported (default)

○ − Optional (to be specified with an order)

Page 24

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

15

General hardware Features

Default / Optional

Input and output modules

Input / output module 1

2×AO / 2×AI / 2×RO / 2×PO / 2×PI / 2×TI / 1×BO / 2×DI / WO+RO

○/○/○/○/○/○/○/○/○

Input / output module 2

2×AO / 2×AI / 2×RO / 2×PO / 2×PI / 2×TI / 1×BO / 2×DI / WO+RO

○/○/○/○/○/○/○/○/○

Auxiliary input / output module A

I/O A

(1-8) DI / RO

○ / ○

Auxiliary input / output module B

I/O B

(1-8) DI

○

Synchronization module C

I/O C

GPS + 1pps / IRIG-B / COM2

● / ● / ●

●

Function is supported (default)

○

Optional (to be specified with an order)

PO

Pulse output module

TI

Tariff input module

RO

Relay output module

BO

Bistable relay output module

AO

Analogue output module

DI

Digital input module

PI

Pulse input module

AI

Analogue input module – U, I or R (PT100/1000)

WO

Status (watchdog) module – for supervision of proper operation

Page 25

MAVOLOG PRO – Waveform and Transient Recorder

16

GMC-I Messtechnik GmbH

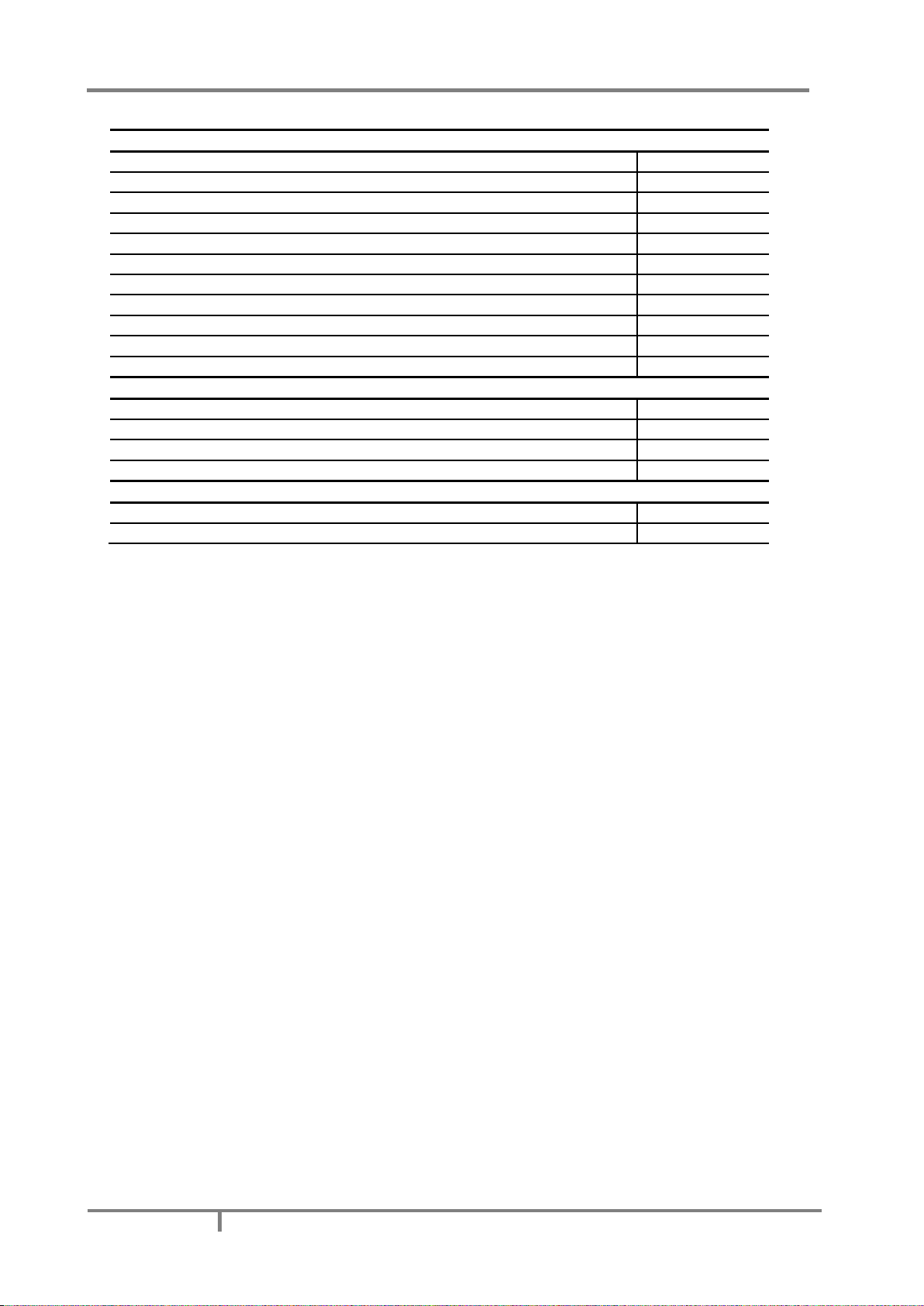

General software Features

Default / Optional

EN 50160 power quality evaluation

●

Automatic PQ report generation

●

Disturbance, trend & PQ event recording

●

Waveform recorder with programmable sampling time

(max 625 samples / period)

●

Standardized PQDIF and COMTRADE format support

●

MAVO-View user friendly setting & analysis software

●

Setup wizard

●

Wrong connection warning

●

Custom screen settings (3 user defined screens on LCD)

●

Demonstration screen cycling

●

Programmable refresh time

●

MODBUS and DNP3 communication protocols

●

Tariff clock

●

MD calculation (TF, FW, SW)

●

Wide frequency measurement range 16 – 400 Hz

●

Programmable alarms (32 alarms)

●

Alarms recording

●

Measurements recording (128 quantities)

●

Measurements graphs (time / FFT)

●

Evaluation of voltage quality in compliance with EN

50160

●

Real time clock synchronization (GPS/IRIG-B/NTP)

●

EN61850 Server

○

● − Function is supported (default)

○ − Optional (to be specified with an order)

Page 26

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

17

CONNECTION

This chapter deals with the instructions for measuring instrument connection. Both the use and connection of

the device includes handling with dangerous currents and voltages. Connection shall therefore be performed

ONLY a by a qualified person using an appropriate equipment. GOSSEN METRAWATT d.d. does not take any

responsibility regarding the use and connection. If any doubt occurs regarding connection and use in the

system which device is intended for, please contact a person who is responsible for such installations.

A person qualified for installation and connection of a device should be familiar with all necessary precaution

measures described in this document prior to its connection.

Before use:

Before use please check the following:

Nominal voltage (U

P-Pmax

= 1000 V

ACrms

; U

P-Nmax

= 600 V

ACrms

),

Supply voltage (rated value),

Nominal frequency,

Voltage ratio and phase sequence,

Current transformer ratio and terminals integrity,

Protection fuse for voltage inputs (recommended maximal external fuse size is 6 A)

External switch or circuit-breaker must be included in the installation for disconnection of the devices’ aux. power

supply. It must be suitably located and properly marked for reliable disconnection of the device when needed.

See CAUTION below.

Integrity of earth terminal

Proper connection and voltage level of I/O modules

WARNING!

Wrong or incomplete connection of voltage or other terminals can cause non-operation or damage to the device.

WARNING!

It is imperative that terminal 12 which represents fourth voltage measurement channel is connected to earth pole ONLY.

This terminal should be connected to EARTH potential at all times! This input channel is used only for measuring voltage

between neutral end earth line.

CAUTION

Aux. Supply inrush current can be as high as 20A for short period of time (<1 ms). Please choose an appropriate MCB for

disconnection of aux. supply.

PLEASE NOTE

After connection, settings have to be performed via a keyboard on the front side of the device that reflect connection of

device to voltage network (connection mode, current and voltage transformers ratio …). Settings can also be done via

communication or a memory card (where available).

Page 27

MAVOLOG PRO – Waveform and Transient Recorder

18

GMC-I Messtechnik GmbH

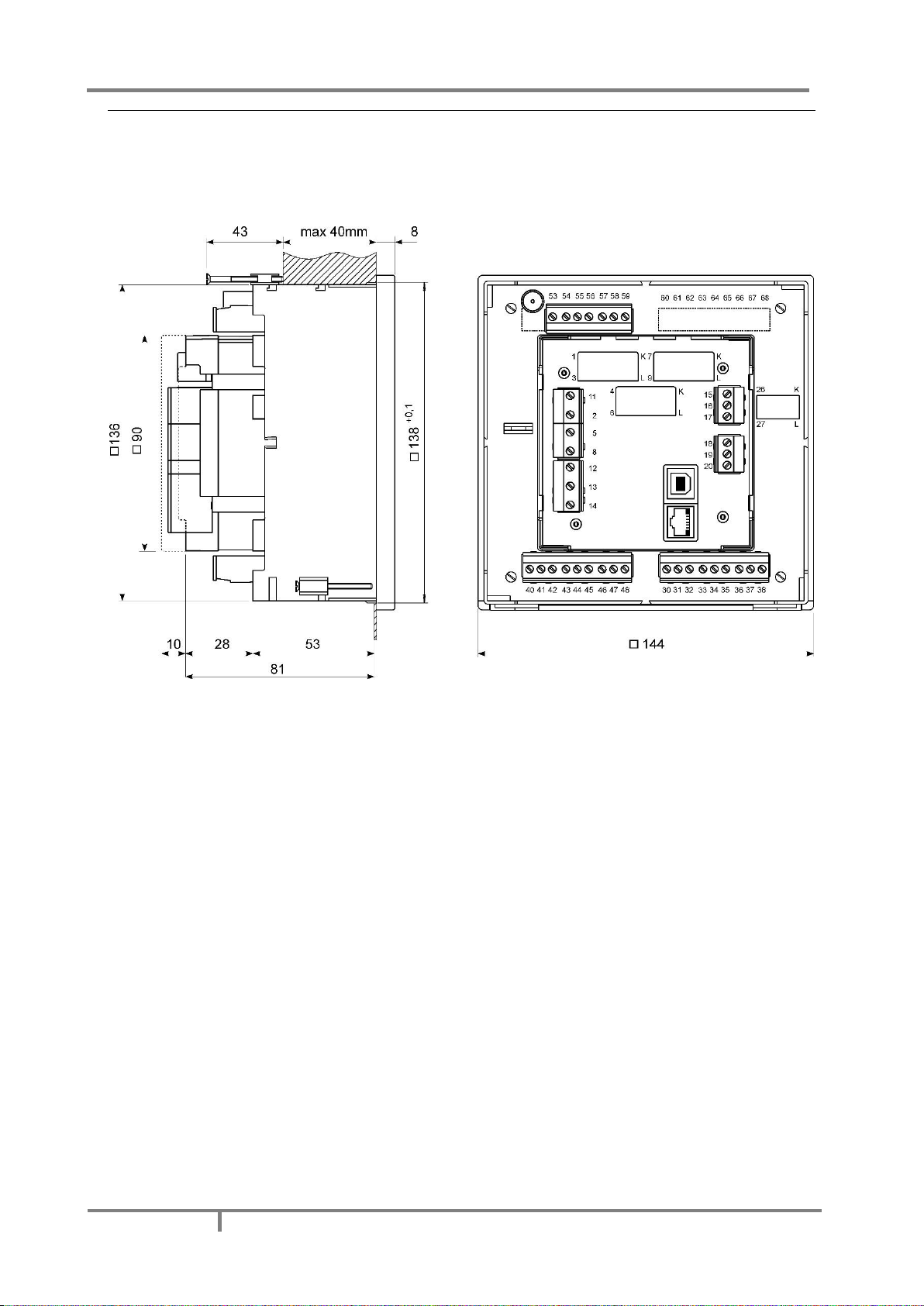

Mounting

MAVOLOG PRO Advanced Power Quality Analyzer is intended only for panel mounting. Pluggable connection

terminals allow easier installation and quick replacement should that be required.

This device is not intended for usage as portable equipment and should be used only as a fixed panel mounted

device.

Dimensional drawing and rear connection terminals position

Recommended panel cut out is:

138 x 138 mm + 0.8

Please remove protection foil from the screen.

Page 28

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

19

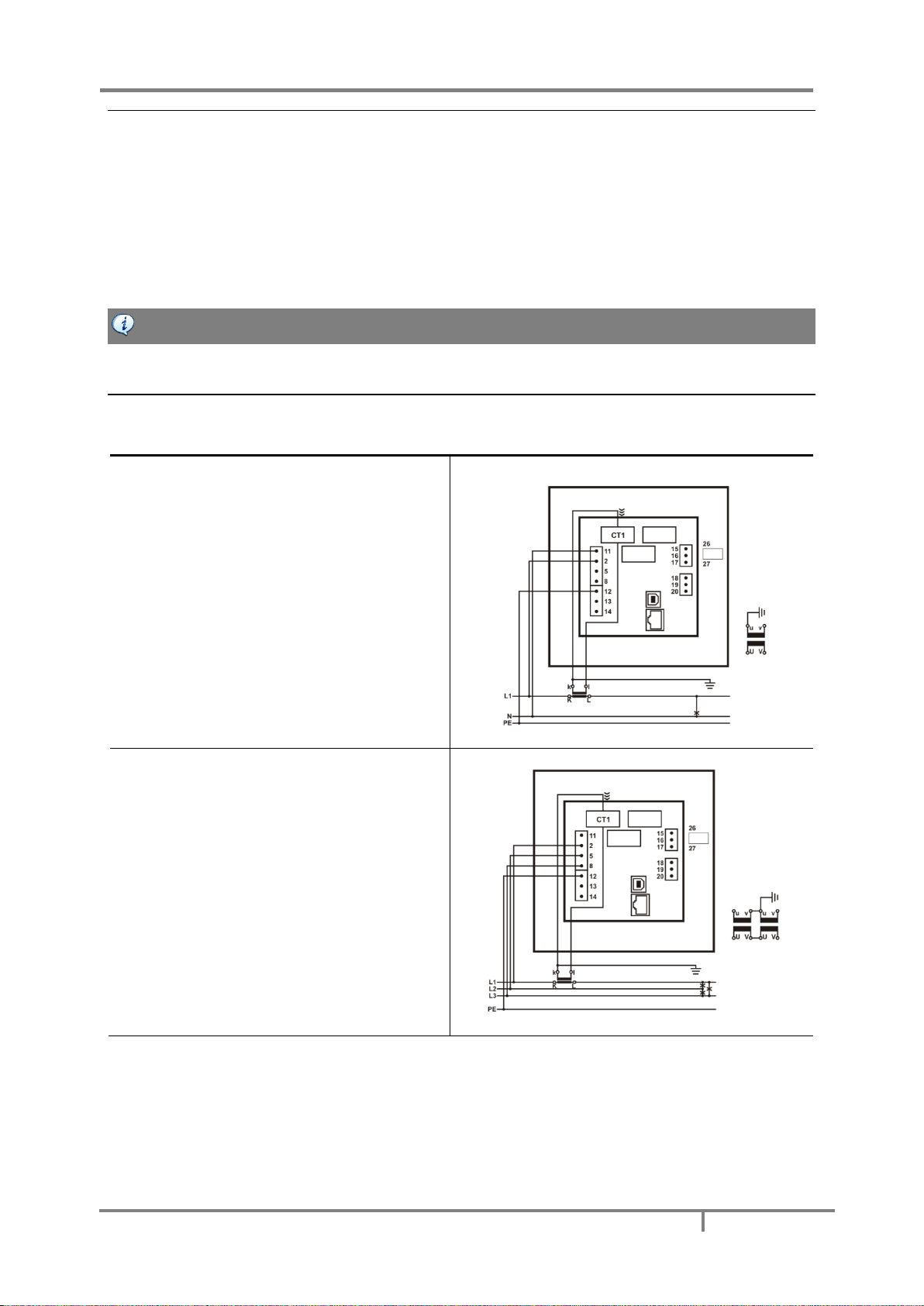

Electrical connection for MAVOLOG PRO Power Quality

Analyzer

Voltage inputs of a device can be connected directly to low-voltage network or via a voltage measuring

transformer to a high-voltage network.

Current inputs of a device are led through a hole in current transformers to allow uninterrupted current

connection. Connection to network is performed via a corresponding current transformer.

Choose corresponding connection from the figures below and connect corresponding voltages and currents.

Information on electrical consumption of current and voltage inputs is given in a chapter

CAUTION

For accurate operation and to avoid measuring signal crosstalk it is important to avoid driving voltage measuring wires close

to current measuring transformers.

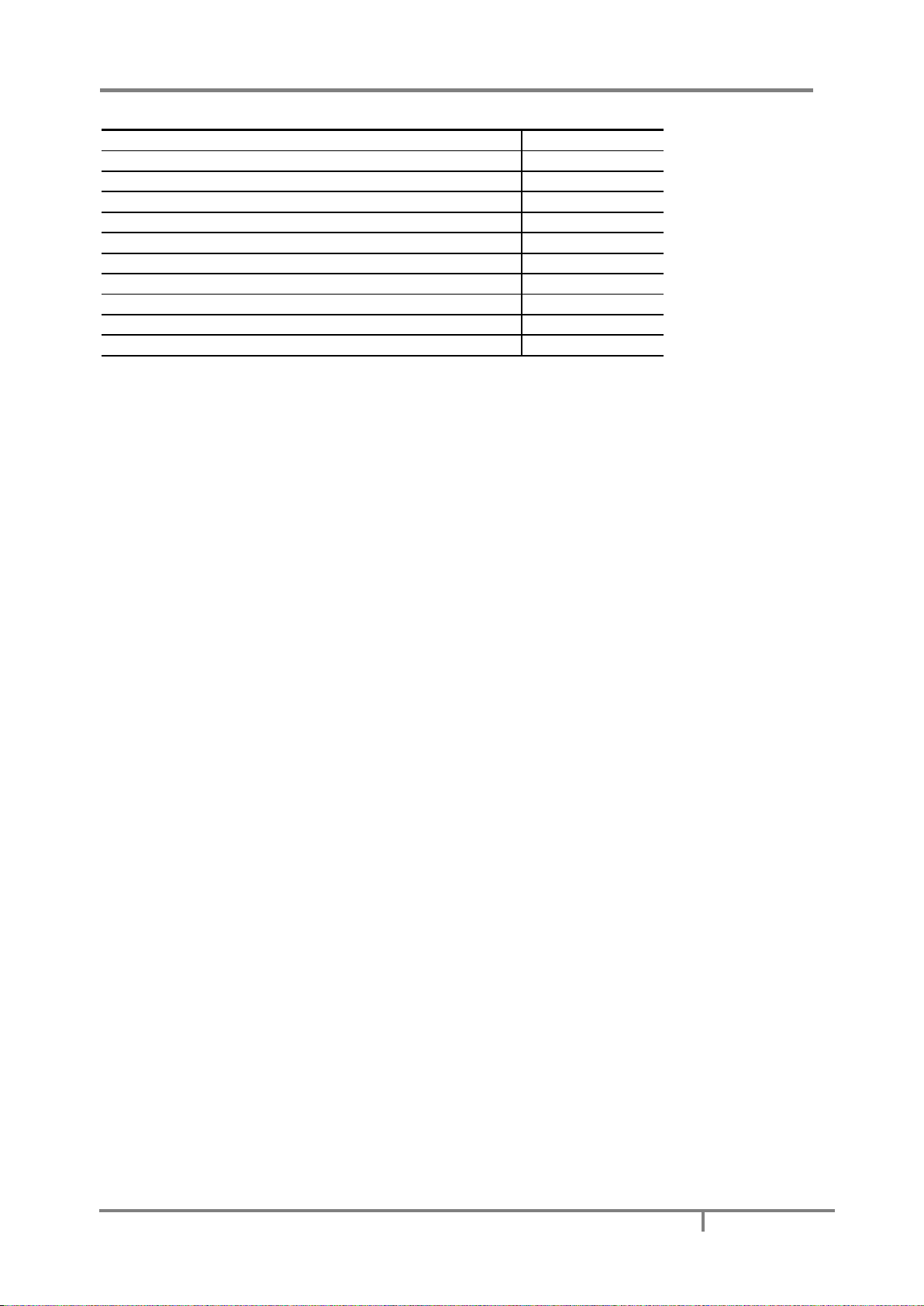

System/ connection Terminal assignment

Connection 1b (1W)

Single-phase connection

Connection 3b (1W3)

Three-phase – three-wire connection

with balanced load

Page 29

MAVOLOG PRO – Waveform and Transient Recorder

20

GMC-I Messtechnik GmbH

Connection 3u (2W3)

Three-phase – three-wire connection

with unbalanced load

Connection 4b (1W4)

Three-phase – four-wire connection

with balanced load

Connection 4u (3W4)

Three-phase – four-wire connection

with unbalanced load

PLEASE NOTE

With all connection schemes must be terminal 12 (PE) ALWAYS connected. Fourth voltage channel is dedicated for

measuring voltage between EARTH (PE, terminal 12) and NEUTRAL (N, terminal 11).

Page 30

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

21

Connection of input/output modules

WARNING!

Check the module features that are specified on the label, before connecting module contacts. Wrong connection can cause

damage or destruction of module and/or device.

PLEASE NOTE

Examples of connections are given for device with built in two input/output modules and Ethernet/USB communication.

Connection does not depend on a number of built-in modules and communication, and is shown on the devices’ label.

Connect module contacts as specified on the label. Examples of labels are given below and describe modules

built in the device. Information on electrical properties of modules is given in a chapter Technical Data –

Input/output modules.

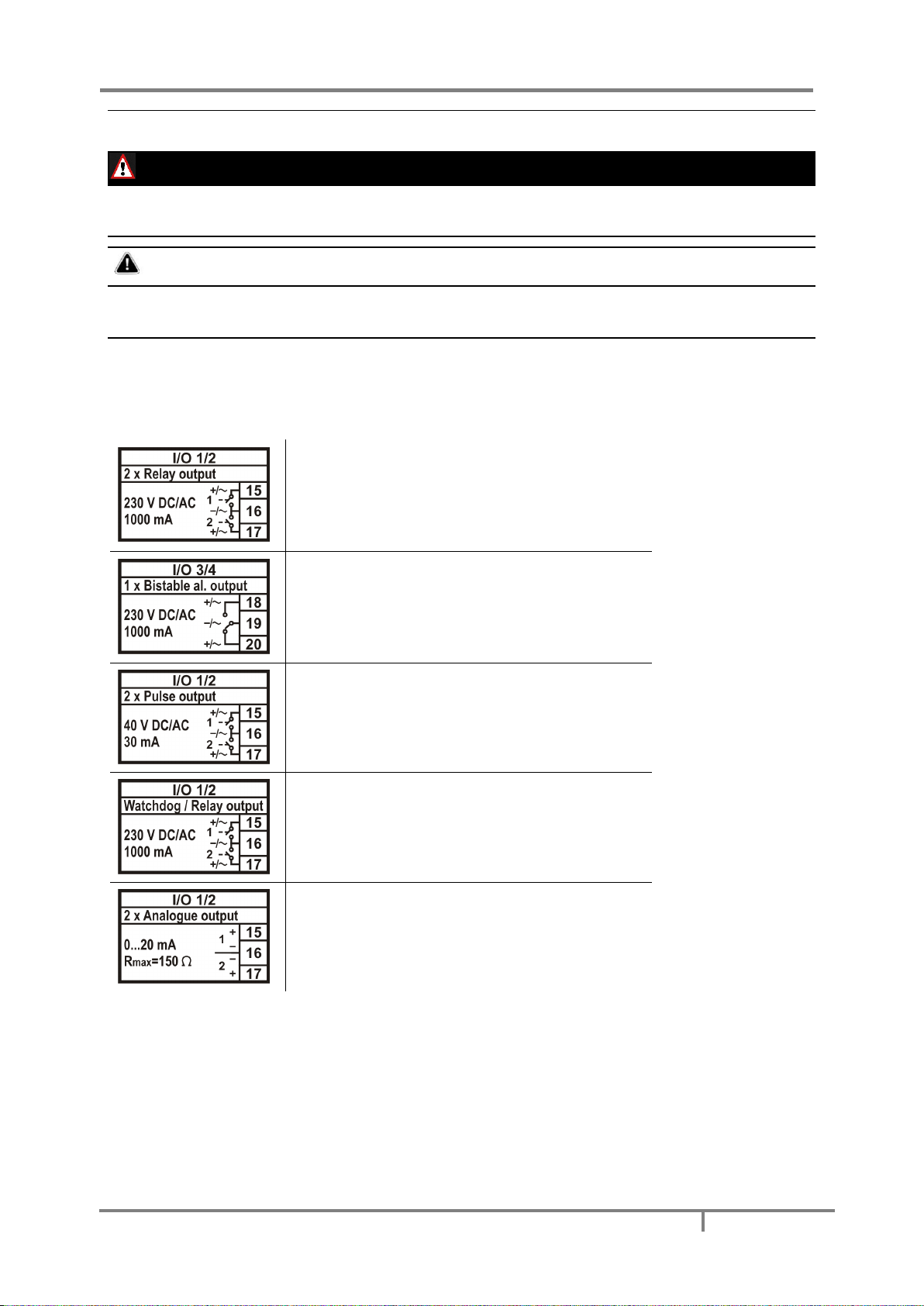

I/O module 1 and 2 (terminal numbers 15-20) – output options

Alarm (relay) output module with two outputs.

Bistable alarm output module; keeps the state

also in case of device power supply failure.

Pulse output (solid state) module with two pulse

outputs for energy counters.

Status (watchdog) output module enables proper

device operation supervision on one output (WD)

and alarm output functionality on the other.

Analogue output module with two analogue

outputs (0…20mA), proportional to measured

quantities.

Page 31

MAVOLOG PRO – Waveform and Transient Recorder

22

GMC-I Messtechnik GmbH

I/O module 1 and 2 (terminal numbers 15-20) – input options

Tariff input module with two tariff inputs for

changeover between up to four tariffs.

Digital input module with two digital inputs

enables reception of impulse signals.

Pulse input module enables reception of pulses

from various counters (water, gas, heat, flow

Analogue input module enables measurements of

DC U, I, R or temp. (PT100, PT1000) values from

external sources. Modules have different

hardware, so programming is possible within one

quantity.

WARNING

In case when only one resistance-temperature analogue input is used, the other must be short-circuited.

Auxiliary I/O module A and B – output options

Digital output relay module with

eight digital outputs enables

alarm functionality.

Auxiliary I/O module A and B – input options

Digital input module with eight

digital inputs enables reception

of digital signals.

Page 32

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

23

Synchronization module C

Synchronization module is equipped with support for two different

synchronization methods IRIG-B and GPS modem.

When modulated IRIG-B signal is used it should be connected to BNC

terminal. When level-shift IRIG-B signal is used it should be connected

to 1PPS terminal.

In case of GPS modem, 1pps signal should be connected to 1PPS

terminal and serial RS232 signal should be connected to RS232

terminals.

When IRIG-B (modulated or level-shift) or 1PPS signal is used for time

synchronization serial communication interface (RS232 or RS485) can

be used as a devices’ secondary communication port (COM2).

PLEASE NOTE

Communication port on Module C is primarily dedicated to receive serial coded date and time telegram from a GPS receiver

in order to synchronize internal real time clock (RTC). When other methods are used for synchronizing RTC this

communication port can be used as a secondary general purpose communication port.

Please note that either RS232 or RS485 should be used and not both at a time. Connector terminals that are not used

should remain unconnected otherwise the communication could not work properly.

CAUTION

RTC synchronization is essential part of Class A instrument. If no proper RTC synchronization is provided device operates as

Class S instrument.

CAUTION

Max consumption of +5V supply terminal is 100mA. When GPS with consumption greater the 100mA is used it is advisable

to use external power supply.

Page 33

MAVOLOG PRO – Waveform and Transient Recorder

24

GMC-I Messtechnik GmbH

Communication connection

Primary communication interface (COM1) type is normally specified when placing an order. Device supports

Ethernet communication designed as standard RJ-45 terminal and USB communication designed as standard

USB-B type terminal

Beside primary communication port the device has built in a secondary communication port (COM2) as a part

of a real time synchronization module C. Its operation is described in a chapter referring to a real time

synchronization Serial communication via Synchronization module C (COM2).

Connect a communication line by means of a corresponding terminal. Communication parameters are stated

on the device label, regarding the selected/equipped type of communication. Connector terminals are marked

on the label on a devices’ rear side. More detailed information on communication is given in chapter Settings –

Communications.

Example of a label for Ethernet/USB

communication module equipped

with RJ−45 and USB-B type

connector

Survey of communication connection

Connector

Terminals

Description

Ethernet

RJ−45 100BASE-T CAT5 cable recommended

USB

USB-B

Standard USB 2.0 compatible cable recommended (Type B plug)

Connection of Real Time Synchronization module C

Synchronized real-time clock (RTC) is an essential part of any Class A analyzer for proper chronological

determination of various events. To distinct cause from consequence, to follow a certain event from its origin

to manifestation in other parameters it is very important that each and every event and recorded

measurement on one instrument can be compared with events and measurements on other devices. Even if

instruments are dislocated, which is normally the case in electro distribution network events have to be timecomparable with accuracy better than a single period.

Synchronization module is used to synchronize RTC of the device and to maintain its accuracy for correct

aggregation intervals and time stamps of recorded events appearing in monitored electro distribution network.

Different types of RTC synchronization are possible:

IRIG-B modulated; 1 kHz modulation with <1ms resolution.

IRIG-B unmodulated (level shift)

1PPS + RS232 Date & Time telegram (from GPS)

PLEASE NOTE

For safety purposes it is important that all three wires (Line, Neutral and Protective Earth) are firmly connected. They

should be connected only to the designated terminals as shown on the label above as well as on the front foil.

GPS time synchronization:

1pps and serial RS232 communication with NMEA 0183 sentence support. GPS interface is designed as 5 pole

pluggable terminal (+5V for receiver supply, 1pps input and standard RS232 communication interface).

Proposed GPS receiver is GARMIN GPS18x+

Page 34

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

25

IRIG time code B (IRIG-B):

Unmodulated (DC 5V level shift) and modulated (1 kHz) serial coded format with support for 1pps, day of year,

current year and straight seconds of day as described in standard IRIG-200-04. Supported serial time code

formats are IRIG-B007 and IRIG-B127

Interface for modulated IRIG-B is designed as BNC-F terminal with 600 Ohm input impedance. Interface for

unmodulated IRIG-B is designed as pluggable terminal.

Network time protocol (NTP):

Synchronization via Ethernet requires access to a NTP server.

PLEASE NOTE

NTP can usually maintain time to within tens of milliseconds over the public Internet, but the accuracy depends on

infrastructure properties - asymmetry in outgoing and incoming communication delay affects systematic bias. It is

recommended that dedicated network rather than public network is used for synchronization purposes.

CAUTION

RTC synchronization is essential part of Class A instrument. If no proper RTC synchronization is provided device operates as

Class S instrument.

Survey of synchronization connection

Terminals

Connector type

BNC for modulated IRIG-B

and

Pluggable screw terminals for level-shift IRIG-B, GPS modem or

serial RS232 or RS485

Connector

Position

Data direction

Description

BNC connector

600 Ohm input impedance: standard Coaxial cable (55 Ohm) recommended

Screw terminal

53

1PPS (GPS) or

IRIG-B (level shift)

Synchronization pulse

54

To/From (A)

RS485

55

To/From (B)

RS485

56

To

Data reception (Rx)

57

GND

Grounding

58

From

Data transmission (Tx)

59

+5V

AUX voltage +5V

(supply for GPS modem)

When IRIG-B or 1PPS signal is used for time synchronization serial communication interface (RS232 or RS485)

can be used as a devices’ secondary communication port (COM2).

More information regarding use of Synchronization module C please see chapter Inputs and Outputs – RTC

Synchronization module C.

Page 35

MAVOLOG PRO – Waveform and Transient Recorder

26

GMC-I Messtechnik GmbH

Connection of aux. Power supply

Device can be equipped with either of two types of universal (AC/DC) switching power supply.

Feature A00 (Standard): 80...300 V DC

80...276 V AC;

40...65 Hz

Feature A01 (no longer aivailable): 19...70 V DC

48...77 V AC;

40...65 Hz

Power supply voltage depends on ordered voltage. Information on electric consumption is given in chapter

Technical Data – Universal Power Supply. Regarding power supply voltage specification on the label, choose

and connect the power supply voltage:

Feature A00: Connection of universal power supply

type High to terminals 13 and 14.

Feature A01: Connection of universal power supply

type Low to terminals 13 and 14.

WARNING!

Feature A01 only:

Auxiliary power supply can be LOW range (19-70VDC, 48-77VAC). Connecting device with LOW power supply to higher

voltage will cause device malfunction. Check devices’ specification before turn it on!

CAUTION

Aux. supply inrush current can be as high as 20A for short period of time (<1 ms). Please choose an appropriate MCB for

connection of aux. supply.

Page 36

MAVOLOG PRO – Waveform and Transient Recorder

GMC-I Messtechnik GmbH

27

FIRST STEPS

Programming device is very transparent and user friendly. Numerous settings are organized in groups

according to their functionality.

Programming device can be performed using the keypad and display on the front panel. Due to representation

of certain settings not all settings can be programmed this way. All settings can be programmed using MAVOView software.

In this chapter you will find basic programming steps which can be accessed by using keypad and display.

Installation wizard

MAVOLOG PRO

After installation and electrical connection, basic parameters have to be set in order to assure correct

operation. The easiest way to achieve that is use the Installation wizard. When entering the Installation menu,

settings follow one another when the previous one is confirmed. All required parameters shall be entered and

confirmed. Exit from the menu is possible when all required settings are confirmed or with interruption (key

several times) without changes.

Installation wizard menu may vary, depending on built in communication modules. In description below is

marked which menu appears for specific option.

PLEASE NOTE!

All settings that are performed through the Installation wizard can be subsequently changed by means of the Settings menu

or via MAVO-View software.

When entering installation wizard following display is shown:

Installation

Welcome to the

Installation Wizard.

Press OK to continue.

< Main menu

Language

Set device language.

Date

Set device date.

Time

Set device time. If instrument is connected to one of supported time synchronization sources, date and time

are automatically set.

Connection mode

Choose connection from a list of supported connection modes.

Primary voltage

Set primary voltage of monitored system if a device is connected indirectly by means of a voltage transformer.

If device is connected to directly to a low voltage enter this value.

Page 37

MAVOLOG PRO – Waveform and Transient Recorder

28

GMC-I Messtechnik GmbH

Secondary voltage