Page 1

Operating Instructions

METRA HIT 1A/2A

Analog Multimeter

www.GlobalTestSupply.com

3-349-305-15

5/8.11

Page 2

6

5

3

4

1

8

7

2

1 Common connection for all measuring ranges (instrument earth)

2 METRA HIT 2A: connection for highest current measuring range 15 A

3 Connection for resistance measurement and capacitance measurement

(negative potential)

4 Connection for all voltage and current ranges

except for METRA HIT 2A: here current measuring range up to 1.5 A

5 Catch for locking the bottom part of the instrument

6 Set screw for mechanical zero setting of the pointer

7 Potentiometer knob

8 Range switch

2 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 3

Contents Page

1 Safety Features and Precautions ......................................4

2 Application ........................................................................6

3 Description ........................................................................7

4 Operation ..........................................................................8

4.1 Controls .........................................................................................8

4.2 Starting the Instrument (Ω Measurement only) .................................9

4.3 Voltage Measurement ...................................................................10

4.3.1 DC and AC Voltages up to 500 V ...................................................11

4.4 Current Measurement ...................................................................12

4.4.1 DC and AC Voltages (METRA HIT 2A: up to 1.5 A) ...........................12

4.4.2 METRA HIT 2A: Direct and Alternating Currents up to 15 A ..............13

4.5 Resistance Measurements ............................................................14

4.6 Estimated Capacitance Measurement ............................................16

4.7 Measurement of Gain and Attenuation ...........................................17

4.8 Testing Diodes and Transistors ......................................................18

5 Technical Characteristics ...............................................19

6 Maintenace .....................................................................25

6.1 Battery .........................................................................................25

6.2 Housing .......................................................................................25

6.3 Fuses ...........................................................................................25

6.4 Device Return and Environmentally Compatible Disposal .................27

7 Standard Equipment .......................................................28

8 Recalibration ...................................................................29

9 Repair and Replacement Parts Service

DKD Calibration Center

and Rental Instrument Service .......................................30

10 Product Support ..............................................................31

GMC-I Messtechnik GmbH 3

www.GlobalTestSupply.com

Page 4

1 Safety Features and Precautions

You have selected an instrument which provides you with a high

level of safety.

This instrument fulfills the requirements of the applicable European and national EC guidelines. We confirm this with the CE

marking. The relevant declaration of conformity can be obtained

from GMC-I Messtechnik GmbH.

The analog/digital multimeter has been manufactured and tested

in accordance with safety regulations IEC 61010–1:2001/

DIN EN 61010–1:2001/VDE 0411–1:2002. If used for its

intended purpose, safety of the operator, as well as that of the

instrument, is assured. However, safety cannot be guaranteed if

the instrument is used improperly or handled carelessly.

In order to maintain flawless technical safety condition, and to assure

safe use, it is imperative that you read the operating instructions thoroughly and carefully before placing your instrument into service, and

that you follow all instructions contained therein.

Observe the following safety precautions

• The instrument may only be operated by persons who are

capable of recognizing contact hazards and implementing

appropriate safety precautions. Contact hazards exist anywhere, where voltages of greater than 33 V RMS may occur.

• Avoid working alone when taking measurements which

involve contact hazards. Be certain that a second person is

present.

• Maximum allowable voltage between terminals (1), (2), (3), (3) and

ground is equal to 500 V category II.

4 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 5

• The instrument may only be used for current measurement in

power systems if the electrical circuit is protected with a fuse or a

circuit breaker with a rating of up to 20 A. In order to conform to the

CAT requirements, two fuse links have been fitted for the ranges

mA und A.

• Be prepared for the occurrence of unexpected voltages at

devices under test (e.g. defective devices). For example,

capacitors may be dangerously charged.

• Make certain that the measurement cables are in flawless

condition, e.g. no damage to insulation, no interruptions in

cables or plugs etc.

• No measurements may be performed with this instrument in

electrical circuits with corona discharge (high voltage).

• Special care is required when measurements are made in

HF electrical circuits. Dangerous pulsating voltages may be

present.

• Measurements under moist ambient conditions are not permitted.

• Be absolutely certain that the measuring ranges are not

overloaded beyond their allowable capacities. Limit values

can be found in the “Measuring Ranges” table in chapter 4

„Operation“.

GMC-I Messtechnik GmbH 5

www.GlobalTestSupply.com

Page 6

Meaning of symbols on the instrument

!

Warning concerning a point of danger

(Attention: observe documentation)

Continuous, doubled or reinforced insulation

CAT II Measuring category II instrument 500 V

Ground

Fuse

Indicates EU conformity

2 Application

The multimeter is suited for voltage, current and resistance measurements and for the rough measurement of capacitance. It is

designed for universal use in electronics, radio and television

technology and digital technology and can be used for many

measuring tasks in the field of general electrical technology. The

meter is mainly used in the DIY sector as well as in the fields of

service, eductation and vocational training.

6 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 7

3 Description

The multimeter has measuring ranges for direct and alternating

voltage, direct and alternating current and resistance. Capacitance values can be ascertained by rough measurements.

All the measuring ranges are selected by means of the central

range switch. They are clearly arranged in the rotary section of

the switch.

A mirror is placed behind the scale for accurate reading of the

measured values. The pivots of the measuring element and the

measuring range switch are located in line one above the other,

so that it is also possible to provide long scales for the Ω and dB

measurements. The rugged plastic case and the core-magnet

moving-coil measuring element with its spring-backed jewel

bearings protect the meter against damage when subjected to

rough mechanical stress.

The connection sockets are protected against accidental contact. Both the special instrument leads with shock protection (KS

17) and all measuring leads with conventional banana plugs

(4 mm diameter) can be plugged in.

GMC-I Messtechnik GmbH 7

www.GlobalTestSupply.com

Page 8

4Operation

4.1 Controls

Measuring range switch

The multimeter has only one rotary switch by which all the measuring ranges are selected. The meter can be switched from the

direct voltage ranges to the corresponding alternating voltage

ranges, or from the direct current ranges to the corresponding

alternating current ranges, without switching off the measured

value.

It must be ensured that the measuring range switch is first set to

the highest measuring range when measuring voltage and current.

The switch then has to be switched to lower ranges until the

optimum deflection is obtained.

Connection sockets

The meter has connection sockets with shock-proof protection.

Their functions are as follows:

Socket „⊥“ = common connection for all measuring ranges

Socket „+15 A

Socket „Ω“ = connection for resistance measurement and

Socket „+V,A “ =

The sockets can accommodate the instrument leads with shock-protected connection plugs as well as all measuring cables with banana

plugs (diameter 4 mm).

(instrument earth)

= METRA HIT 2A: connection for highest

current measuring range 15 A

capacitance measurement (negative potential)

connection for all voltage and current ranges

except for METRA HIT 2A: here up to 1.5 A

8 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 9

Potentiometer knob

Attention!

!

Attention!

!

The rotary knob is used to set the full deflection 0 Ω when measuring resistance as described in chapter 4.5 and capacitance

according to chapter 4.6.

4.2 Starting the Instrument (Ω Measurement only)

Inserting the battery

The bottom half must be removed from the instrument in order to

install or exchange the battery.

Before opening the instrument, the measuring leads

must be disconnected from the measuring circuit!

➭ Press the catch on the rear of the instrument, using a test

point, banana plug or similar object, in the direction of the

arrow and remove the lower section.

➭ Insert the 1.5 V mignon cell in accordance with the symbol

and pole sign.

Only use a leak-proof 1.5 V mignon cell according to

IEC LR6/R 6! (AA-Size)

➭ Place the instrument in the lower section of the housing and

gently press the two halves together until they lock into

place.

Mechanical zero point check

• Place the multimeter flat on the edge of a table. The lower

third of the instrument should project over the edge.

• Check the mechanical zero setting of the pointer.

GMC-I Messtechnik GmbH 9

www.GlobalTestSupply.com

Page 10

• If necessary, adjust the set screw on the rear of the instru-

Attention!

!

ment with a screwdriver to correct the setting.

Battery check

➭ Set the range switch to the „Ω x1“ position.

➭ Short-circuit connecting sockets „⊥“ and „Ω“ using a mea-

suring lead.

➭ Set the pointer to full deflection position 0 Ω using potenti-

ometer knob.

If it is no longer possible to set the full deflection or if the reading

does not remain constant after setting, the mignon cell is spent

or the pigtail fuse is defective.

4.3 Voltage Measurement

Regardless of the value of the measured voltage, as a

safety precaution, do not exceed the sum of 500 V

CAT II for measured voltage plus voltage against earth

when directly connecting up the multimeter!

The left-hand connection socket marked „⊥“ should be connected whenever possible and for all voltage measurements to

the point with the lowest potential against earth.

10 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 11

4.3.1 DC and AC Voltages up to 500 V

➭ Set range switch to the posi-

tion 500 V or 500 V .

➭ Plug test leads into the instru-

ment; (black) test lead to

socket „⊥“ and (red) lead to

socket „+ V, “.

For safety reasons, the test

leads with shock-protected

connection plugs should be

used.

➭ Apply the voltage measured to

the test leads. For DC voltage,

socket „⊥“ must be connected

to the negative pole of the

measured voltage and socket

„+ V,A “ to its positive pole.

➭ If the measured voltage is less than 150 V, set range switch,

in the case of DC voltage, to the lower DC voltage ranges

and, in the case of AC voltage, to the lower AC voltage

ranges, proceeding until optimum deflection is obtained.

➭ Read off the measured value: for DC voltage, on scales

0 ... 5 or 0 ... 15 V, A , for AC voltage, on scales 0 ... 5 or

0 ... 15 V, A .

GMC-I Messtechnik GmbH 11

www.GlobalTestSupply.com

Page 12

4.4 Current Measurement

Attention!

!

The multimeter must always be connected into the lead

the voltage of which is the lowest relative to earth. For

safety reasons, the voltage relative to earth must not exceed 500 V CAT II! Observe the overload limits, see tables

on page 23.

4.4.1 DC and AC Voltages (METRA HIT 2A: up to 1.5 A)

➭ Set range switch to the position

5 A or 5 A (METRA HIT

2A: 1.5 A or 1.5 A ).

➭ Plug test leads into the instru-

ment; (black) test lead to socket

„⊥“ and (red) lead to „+ V, A “.

➭ Disconnect the power supply to

the measuring circuit, and/or

the power consumer (R

discharge all capacitors, if avail-

able.

➭ Interrupt the measuring circuit

and safely connect the measur-

ing leads (without contact resis-

tance!) in series with the power consumer R

sign when measuring direct current! Negative to „⊥“ socket

and positive to „+V, A “ socket.

➭ Connect power supply to measuring circuit again.

) and

v

. Note polarity

v

12 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 13

➭ If the measuring current is less than 500 mA. set the mea-

suring range switch to lower direct current ranges in the

case of direct current, and to lower alternating current

ranges in the case of alternating current, until the optimum

deflection is obtained.

➭ Read off the measured value: METRA HIT 1A: for DC on

scale 0 ... 15 V,A , for AC on scale 0 ... 15 V,A .

METRA HIT 2A: for DC on scale 0 ... 15 V,A , for AC on

scale 0 ... 15 V,A .

4.4.2 METRA HIT 2A: Direct and Alternating Currents up to 15 A

➭ Set the range switch to the posi-

tion 15 A or 15 A .

➭ Plug the test leads into the in-

strument; (black) test lead to

socket „⊥“ and (red) test lead to

socket „+ 15 A “.

➭ Disconnect the power supply to

the test circuit or consumer (R

and discharge all capacitors, if

)

v

any.

➭ Disconnect test circuit and con-

nect test leads safely (no contact

resistance) in series to the consumer R

current, observe the correct pole signs. Negative to socket

. In the case of direct

v

„⊥“ and positive to „+ 15 A “.

➭ Re-connect the supply to the test circuit.

➭ Read off the measured value: for DC on scale 0 ... 15 V,A ,

for AC on scale 0 ... 15 V,A .

GMC-I Messtechnik GmbH 13

www.GlobalTestSupply.com

Page 14

4.5 Resistance Measurements

Resistance is measured with DC

voltage from the 1.5 V mignon cell.

The table of measuring ranges in

chapter 5 gives the maximum measuring currents for full deflection and

a battery voltage of 1.5 V.

Socket polarity is as follows:

Positive pole on socket „⊥“

Negative pole on socket „Ω“

➭ Set range switch, depending on

the measured value expected,

to one of the ranges Ω x1...

Ω x1000.

➭ Plug in the test leads to sockets

„⊥“ and „Ω“.

➭ Short-circuit the test leads.

➭ Using the potentiometer knob, set the pointer of the measur-

ing mechanism to full deflection 0 Ω. If it is no longer possi-

ble to set for full deflection or if the reading does not remain

constant after setting, the mignon cell is depleted or the pig-

tail fuse is defective.

➭ Connect resistance to be measured R

to the test leads.

x

14 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 15

Attention!

!

Only voltage-free objects may be measured. External

Note!

voltages falsify the measuring results and might also

damage the instrument!

➭ Read off the value displayed on the Ω scale and multiply by

the factor according to the adjusted measuring range.

If possible, the measuring range should be selected in such a

way as to obtain a reading in the range 5 ... 50 Ω. The measuring

error, in relation to the actual resistance value, is smallest in the

middle of the deflection range. Read off the value displayed on

the Ω scale and multiply by the factor according to the adjusted

measuring range. During resistance measurements of a longer

duration, the full deflection 0 Ω should always be checked if possible after moving the range switch from one resistance range to

another and, if necessary, it should be reset.

Contact resistances at the battery connecting terminals

may, particularly in low ohmic resistance ranges, cause

the setting of full deflection 0 Ω to fluctuate. Consequently, good contact should be ensured, for example

by removing and refitting the battery (see chapter 4.2).

GMC-I Messtechnik GmbH 15

www.GlobalTestSupply.com

Page 16

4.6 Estimated Capacitance Measurement

Capacitance values can be determined in the resistance ranges

by estimated measurement. When doing so, proceed exactly as

if measuring resistance in accordance with chapter 4.5. Resis-

is to be replaced by the capacitance to be measured,

tance R

x

after prior discharge. When the capacitor is connected, the

pointer of the instrument swings to a maximum value and then

returns to its initial position (mechanical zero point). The point of

return of the pointer deflection serves as a measure for capacitance. It is to be determined on scale 0 ... 5 V, A . The measured value can be determined using the following comparative

scale and the factor for capacitance measurement corresponding to the measuring range selected:

Measuring Range

Ω x 1000

Ω x 100

Ω x 10

Ω x 1

Factor for Capacitance

Measurement

μF x 1

μF x 10

μF x 100

μF x 1 000

Measuring Limits

2 ... 200 μF

20 ... 2 000 μ F

200... 20000 μF

2 000 ... 200 000 μF

Before measurement is repeated, the capacitor must be

recharged!

Example:

Selected measuring range:

Ω x 100

Return point of pointer: 3.3 on the upper scale 0 ... 5 V, A

Capacitance determined

via comparative scale:

50 μF

Multiplied by the factor for

capacitance measurement:

16 GMC-I Messtechnik GmbH

50 μF x 10 = 500 μF

www.GlobalTestSupply.com

Page 17

4.7 Measurement of Gain and Attenuation

C

v

1

0,89

f

Hz

----

R

i

MΩ

------

⋅⋅

-------------------------

μF⋅≈

In communications engineering, gain or attenuation is almost

exclusively given as a logarithm of the ratio between a measured

voltage and a given reference voltage in dB. In recurrent networks, it is thereby possible to determine the total gain or attenuation in a simple manner by adding or subtracting the individual

values. The reference voltage is 0.775 V (1 mW for 600 Ω);

attenuation at this voltage is 0 dB.

For gain and attenuation measurement, proceed exactly as

described in chapter 4.3.1 for AC voltage measurement; the

measured values, however, are to be read off the dB scale.

The range – 15 ... + 6 dB shown on the scale corresponds to the

AC voltage range 1.5 V. In the case of the higher voltage measuring ranges 5 V , 15 V , 50 V ..., 10 dB, 20 dB, 30 dB ...

are to be added to the value read; see the table in chapter 5

showing the voltage measuring ranges.

If a DC voltage is superposed on the AC voltage to be measured,

this can be cancelled out by using a suitable capacitor, which is

to be series-connected to the measuring input.

The operating voltage of the seriesconnected capacitor must be at least

of the same magnitude as the peak

value for the voltage applied. If there is

an additional error of 1% of the measured value, it can be calculated from the formula opposite.

In mentionned formula, R

suring instrument in the selected measuring range

is the internal resistance of the mea-

i

GMC-I Messtechnik GmbH 17

www.GlobalTestSupply.com

Page 18

Example:

Attention!

!

Note!

For a 1 kHz superposed AC voltage, a series-connected capaci-

= 0.0056 μF = 5.6 nF results for the 50 V measuring

tor of C

v

range.

The capacitor is loaded up to the value of the DC voltage component. The load can assume a magnitude that

can be lethal and retain this load for quite some time.

The capacitor must therefore be discharged after measurement!

4.8 Testing Diodes and Transistors

The resistance range Ω x 1000 is suitable for approximate functional testing of diodes and transistors. By using a resistance

measurement (see chapter 4.5) it is simple to determine a

short-circuit or interruption of current in a diode or a diode path

between base, collector and emitter in a transistor. This test also

enables the polarity of a diode and the base connection of a

transistor to be determined.

The positive pole is at socket „⊥“, the negative pole is at

socket „Ω“.

The DUT is not destroyed during this measurement as the voltage does not exceed 1.75 V, and the test current does not

exceed 100 μA.

18 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 19

5 Technical Characteristics

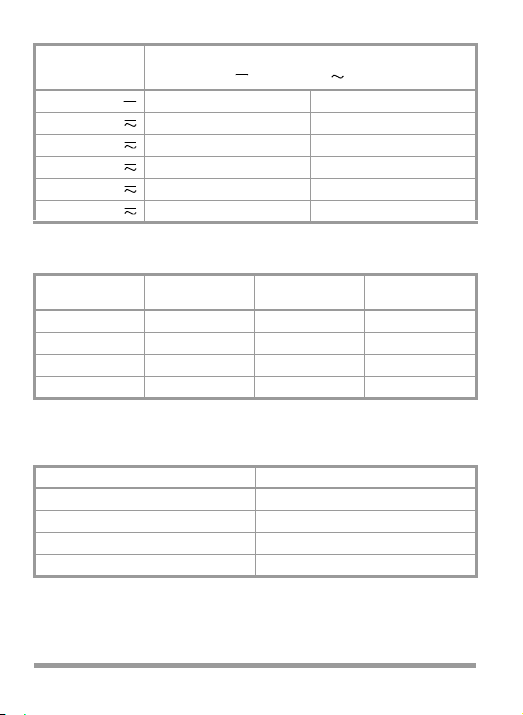

Voltage Measuring Ranges

)

Voltage Output

1

0.15 V — 3.15 kΩ —

0.50 V — 10.00 kΩ —

1.50 V –15 ... + 6 dB 31.50 kΩ 6.50 kΩ

5.00 V – 5 ... + 16 dB 100.00 kΩ 20.00 kΩ

15.00 V + 5 ... + 26 dB 315.00 kΩ 65.00 kΩ

50.00 V +15 ... + 36 dB 1.00 MΩ 200.00 kΩ

150.00 V +25 ... + 46 dB 3.15 MΩ 650.00 kΩ

500.00 V +35 ... + 56 dB 10.00 MΩ 2.00 MΩ

1)

0dB 0.775 V in the range of 1.5 V ; 0 dB 1 mW at 600 Ω

Internal Resistance approx.

Input resistance in relation to voltage for : 20.0 kΩ/V

for : 4.0 kΩ/V

METRA HIT 1A: Current Measuring Ranges

Current

50.00 μA 0.158 V —

0.50 mA 1.15 V 1.00 V

5.00 mA 1.25 V 1.25 V

50.00 mA 1.25 V 1.25 V

500.00 mA 1.85 V 1.85 V

5000.00 mA 1.73 V 1.73 V

GMC-I Messtechnik GmbH 19

www.GlobalTestSupply.com

Voltage Drop approx.

Page 20

METRA HIT 2A: Current Measuring Ranges

Current

50 μA 0.158 V —

1.5 mA 1.16 V 1.21 V

15 mA 1.25 V 1.25 V

150 mA 1.25 V 1.25 V

1.5 A 1.95 V 1.95 V

15 A 0.43 V 0.49 V

Voltage Drop approx.

Resistance Measuring Ranges

Resistance Measuring Limits

Ω x 1

Ω x 10

Ω x 100

Ω x 1000

2)

for battery voltage 1.5 V

1 Ω ... 1 kΩ

10 Ω ... 10 kΩ

100 Ω ... 100 kΩ

1kΩ ... 1 MΩ

Value at Mid-Scale

)

(R

i

18.00 Ω 83 mA

180.00 Ω 8.3 mA

1.8 0 kΩ 0.83 mA

18.00 kΩ 0.083 mA

Max. Meas. Current

2)

approx.

I

max

Capacitance Measuring Ranges

Capacitance

3)

Measuring Limits

μF x 1000 2000 ... 200 000 μF

μF x 100 200 ... 20000 μF

μF x 10 20 ... 2 000 μF

μF x 1 2 ... 200 μF

3)

Estimated measurement in the resistance measuring ranges;

determination of measured values via comparative scale, see chapter 4.6.

20 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 21

Reference Conditions

Ambient temperature +23 ° C ± 2 K

Position of use horizontal

Frequency 40 ... 60 Hz

Wave shape for : sinusoidal

Relative humidity 40 ... 60%

The instrument features half-wave rectification and is calibrated

in r.m.s. values. It evaluates the arithmetical mean of a half-wave

and indicates different values for undulatory voltage or current,

depending on the polarity of connection.

For other influencing quantities

according to IEC/EN 60 051

Ambient Conditions

Storage temperatures –25 ... 65 °C (without battery)

Relative humidity

max. 75%, no condensation allowed

METRA HIT 2A: Accuracy

(for reference conditions per IEC/EN 60 051),

Class 2.5 for and ;

maximum permissible intrinsic error in the 15 A : range: ± 2%;

1,5 V~: +1/–2,5%

Class 2.5 for Ω (error in relation to a scale length of 52 mm)

METRA HIT 2A: additional accuracy class influence and nominal ranges of use

Ambient temperatures

for : 0 ... +23 ... + 40 ° C

for : + 13 ... + 23

... +35 °C

Frequency Ranges 1.5 V ... 500 V:

35 ... 40 ... 60

... 1000 Hz

Ranges 1.5 mA ... 1.5 A:

35 ... 40 ... 60

... 1000 Hz

Range 15 A:

... 1000 Hz

Other influencing quantites

40 ... 45 ... 60

according to IEC/EN 60 051

GMC-I Messtechnik GmbH 21

www.GlobalTestSupply.com

Page 22

Power Supply

Battery for resistance

measurement 1 mignon cell 1.5 V per IEC LR6/R6

(AA-Size), leak-proof

Elektrical Safety

Protection class II per IEC/EN 61 010-1:2001/

VDE 0411-1:2002

Measuring category II

Nominal voltage 500 V

Test voltage 3.5 kV~

Contamination level 2

Fuses

replaceable

METRA HIT 1A:

F1: FF630mA/700V AC (50 kA), 6.3 x 32 (Article number: Z109J)

F2: FF6,3A/500V AC (50 kA), 6.3 x 32

(Article number: Z109K)

METRA HIT 2A:

F1: FF1,6A/700V AC (50 kA), 6.3 x 32

F2: FF16A/500V AC (50 kA), 6.3 x 32

(Article number: Z109E)

(Article number: Z109A)

pigtail fuse

750 mA/600 V AC

Electromagnetic Compatibility (EMC)

Interference emission

Interference immunity

EN 61326-1:2006 class B

EN 61326-1:2006

EN 61326-2-1:2006

22 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 23

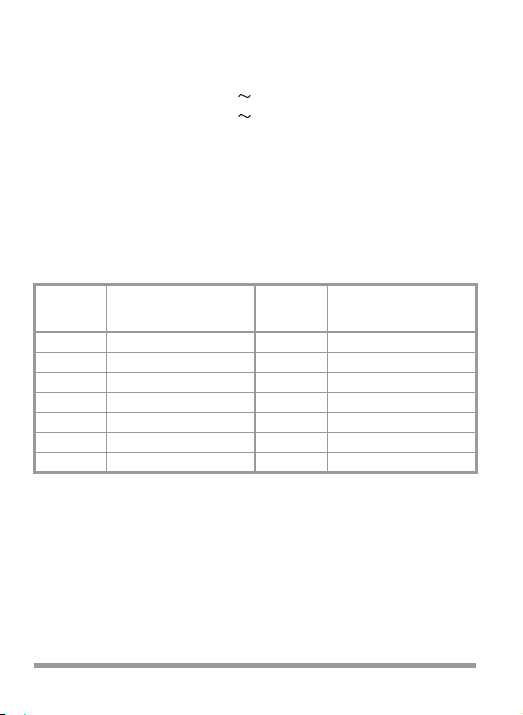

METRA HIT 1A: Overload capacity

Range loadable up to Range loadable up to

0.15 V –

0.5 V –

1.5 V –

5.0 V –

15.0 V –

50.0 V –

150.0 V –

500.0 V –

50.0 μA –

0.5 mA –

5.0 mA –

50.0 mA –

500 .0 mA –

5 000.0 mA –

20 V

50 V

100 V

150 V

250 V

250 V

300 V

500 V

1.0 mA

5.0 mA

10.0 mA

70.0 mA

500.0 mA

3.0 A

5.0 A

1)

2)

2)

2)

2)

2)

2)

2)

3)

—

—

1.5 V

5.0 V

15.0 V

50.0 V

150.0 V

500.0 V

—

0.5 mA

5.0 mA

50.0 mA

500 .0 mA

5 000.0 mA

10.0 mA

70.0 mA

500.0 mA

METRA HIT 2A: Overload capacity

Range loadable up to Range loadable up to

0.15 V –

0.5 V –

1.5 V –

5.0 V –

15.0 V –

50.0 V –

150.0 V –

500.0 V –

50 μA –

1.5 mA –

15 mA –

150 mA –

1.5 A –

15 A –

1)

Fuse F1 blows in the event of an overload

2)

These ranges are protected against overload by a PTC thermistor

3)

max. 1 min

20 V

50 V

100 V

150 V

250 V

250 V

300 V

500 V

1.0 mA

5.0 mA

20.0 mA

150.0 mA

1.2 A

1.5 A

12.0 A

15.0 A

1)

2)

2)

2)

2)

2)

2)

2)

3)

3)

—

—

1.5 V

5.0 V

15.0 V

50.0 V

150..0 V

500.0 V

—

1.5 mA

15 mA

150 mA

1.5 A

15 A

20.0 mA

150.0 mA

—

—

25 V

50 V

150 V

250 V

300 V

500 V

—

5.0 mA

3.0 A

5.0 A

—

—

25 V

50 V

150 V

250 V

300 V

500 V

—

5.0 mA

1.2 A

1.5 A

12.0 A

15.0 A

2)

2)

2)

2)

2)

2)

3)

2)

2)

2)

2)

2)

2)

3)

3)

GMC-I Messtechnik GmbH 23

www.GlobalTestSupply.com

Page 24

Mechanical Design

Scale length A, V – 0 ... 5.0: approx. 83 mm

A, V – 0 ...15.8: approx. 77 mm

A, V 0 ... 5.0: approx. 67 mm

A, V 0 ... 15.8: approx. 59 mm

Ω∞... 0: approx. 52 mm

dB – 15 ... + 6: approx. 42 mm

Dimensions 92 x 126 x 45 mm

Weight approx. 0.3 kg without battery

Protection type Housing IP 40, terminals IP 20

per EN 60529/VDE 0470 part 1

Extract from table on the significance

of IP codes

IP XY

(1st digit X)

Protection against the

penetration of solid

foreign matter

0 no protection 0 no protection

1 ≥ 50.0 mm

2 ≥ 12.5 mm

3 ≥ 2.5 mm

4 ≥ 1.0 mm

5 protection from dust 5 hoseproof

6 dustproof 6 extremely hoseproof

∅

∅

∅

∅

IP XY

(2nd digit Y)

Protection against the

penetration of water

1 vertical dripping

2 dripping (15° gradient)

3 spray-water

4 splashwater

24 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 25

6 Maintenace

Attention!

!

6.1 Battery

The state of the battery should be checked from time to time. A

discharged or decomposing battery should not be left inside the

instrument. The battery should be checked and changed in the

manner described in chapter 4.2.

6.2 Housing

No special maintenance is required for the housing. Keep outside surfaces clean. Use a slightly dampened cloth for cleaning.

Avoid the use of cleansers, abrasives or solvents.

6.3 Fuses

The instrument is fitted with two replaceable fuses F1 and F2.

For replacement: Open and close the housing as described in

chapter 4.2 under the heading „Inserting the battery“.

Disconnect the instrument completely from the measuring circuit before opening the bottom part of the housing to replace

the fuse!

Upon tripping of the fuse, eliminate the cause of overload before putting the instrument back to serviceable

condition! Make absolutely sure that only the specified fuse is

used, see chapter 5!

Using a fuse with different tripping characteristics, different nominal current or different switching capacity

involves hazards for the operator and for protective

diodes, resistances or other components. The use of

mended fuses or short-circuiting of the fuse holder is not

permitted.

GMC-I Messtechnik GmbH 25

www.GlobalTestSupply.com

Page 26

Melting Fuse F1 for the mA Range and 0.15 V Range

F2

F1

The inserted F1 melting fuse for the measuring circuit up to 0.5 A

(for METRA HIT 1A) or 1.5 A (for METRA HIT 2A) can be checked

for continuity in the resistance measuring ranges, preferrably in

the Ω x 1 range when removed from the instrument. If the fuse is

defective, ∞ is indicated. The melting fuse blows if one of the

current measuring ranges or the 0.15 V range is unduly overloaded.

Melting Fuse F2 for the A Range

The fuse can be checked for continuity in the Ω x 1 range when

removed from the instrument. If the fuse is defective, ∞ is indicated.

Location of melting fuses after

removal of the bottom part of the

housing

26 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 27

6.4 Device Return and Environmentally Compatible Disposal

Pb Cd Hg

The instrument is a category 9 product (monitoring and

control instrument) in accordance with ElektroG (German

Electrical and Electronic Device Law). This device is not

subject to the RoHS directive.

We identify our electrical and electronic devices

(as of August 2005) in accordance with WEEE

2002/96/EG and ElektroG with the symbol shown

to the right per DIN EN 50419.

These devices may not be disposed of with the trash.

Please contact our service department regarding the

return of old devices.

If you use batteries or rechargeable batteries in your instrument or accessories which no longer function properly,

they must be duly disposed of in compliance with the

applicable national regulations.

Batteries or rechargeable batteries may contain harmful

substances or heavy metal such as lead (PB), cadmium

(CD) or mercury (Hg).

They symbol shown to the right indicates that

batteries or rechargeable batteries may not be

disposed of with the trash, but must be delivered

to collection points specially provided for this purpose.

GMC-I Messtechnik GmbH 27

www.GlobalTestSupply.com

Page 28

7 Standard Equipment

Analog multimeter without battery, without cable set

28 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 29

8 Recalibration

The respective measuring task and the stress to which your

measuring instrument is subjected affect the ageing of the components and may result in deviations from the guaranteed accuracy.

If high measuring accuracy is required and the instrument is frequently used in field applications, combined with transport stress

and great temperature fluctuations, we recommend a relatively

short calibration interval of 1 year. If your measuring instrument is

mainly used in the laboratory and indoors without being exposed

to any major climatic or mechanical stress, a calibration interval

of 2-3 years is usually sufficient.

During recalibration* in an accredited calibration laboratory (DIN

EN ISO/IEC 17025) the deviations of your instrument in relation

to traceable standards are measured and documented. The

deviations determined in the process are used for correction of

the readings during subsequent application.

We are pleased to perform DKD or factory calibrations for you in

our calibration laboratory. Please visit our website at

Center or → FAQs → Calibration questions and answers).

By having your measuring instrument calibrated regularly, you

fulfill the requirements of a quality management system per

DIN EN ISO 9001.

*

Verification of specifications or adjustment services are not part of the

calibration. For products from our factory, however, any necessary adjustment is frequently performed and the observance of the relevant

specification is confirmed.

GMC-I Messtechnik GmbH 29

www.GlobalTestSupply.com

Page 30

9 Repair and Replacement Parts Service

DKD Calibration Center

and Rental Instrument Service

When you need service, please contact:

GMC-I Service GmbH

Service Center

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service in

other countries.

30 GMC-I Messtechnik GmbH

www.GlobalTestSupply.com

Page 31

10 Product Support

When you need support, please contact:

GMC-I Messtechnik GmbH

Hotline Produktsupport

Phone +49 911 8602-0

Fax +49 911 8602-709

E-Mail support@gossenmetrawatt.com

GMC-I Messtechnik GmbH 31

www.GlobalTestSupply.com

Page 32

Edited in Germany • Subject to change without notice • A pdf version is available on the Internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

www.GlobalTestSupply.com

Phone +49 911 8602-111

Fax +49 911 8602-777

info@gossenmetrawatt.com

E-Mail

www.gossenmetrawatt.com

Loading...

Loading...