Page 1

Page 2

LABKON Series

GOSSEN METRAWATT LABKON Series

SWITCHING-MODE DC POWER SUPPLY

GOSSEN METRAWATT LABKON Series is a series of programmable switching-mode DC power supplies with RS232 and

USB (optional) or GPIB (optional) interfaces. The good durability, simple operation, low noise, excellent output accuracy as

well as the adjustment from 0V make this series of reliable power supplies the right choice for many applications. It provides

flexible and stable DC power for various design and test environments.

Versatile Bench-Top Features

High definition liquid crystal display

Full-featured keyboard and knobs

High-efficient switching-mode power supply

Low ripple and noise which rivals the linear power supply

Excellent line and load regulation

Up to 10 operating states storage and recall

Portable, ruggedized case and flexible system functions

Standardized RS232 interface, optional GPIB or USB

SCPI ( Standard Commands for Programmable Instruments) compatibility

Direct setting of I/O Parameters from front-panel

_________________________________________________________________________________________________

2 GMC-I Messtechnik GmbH

Page 3

LABKON Series

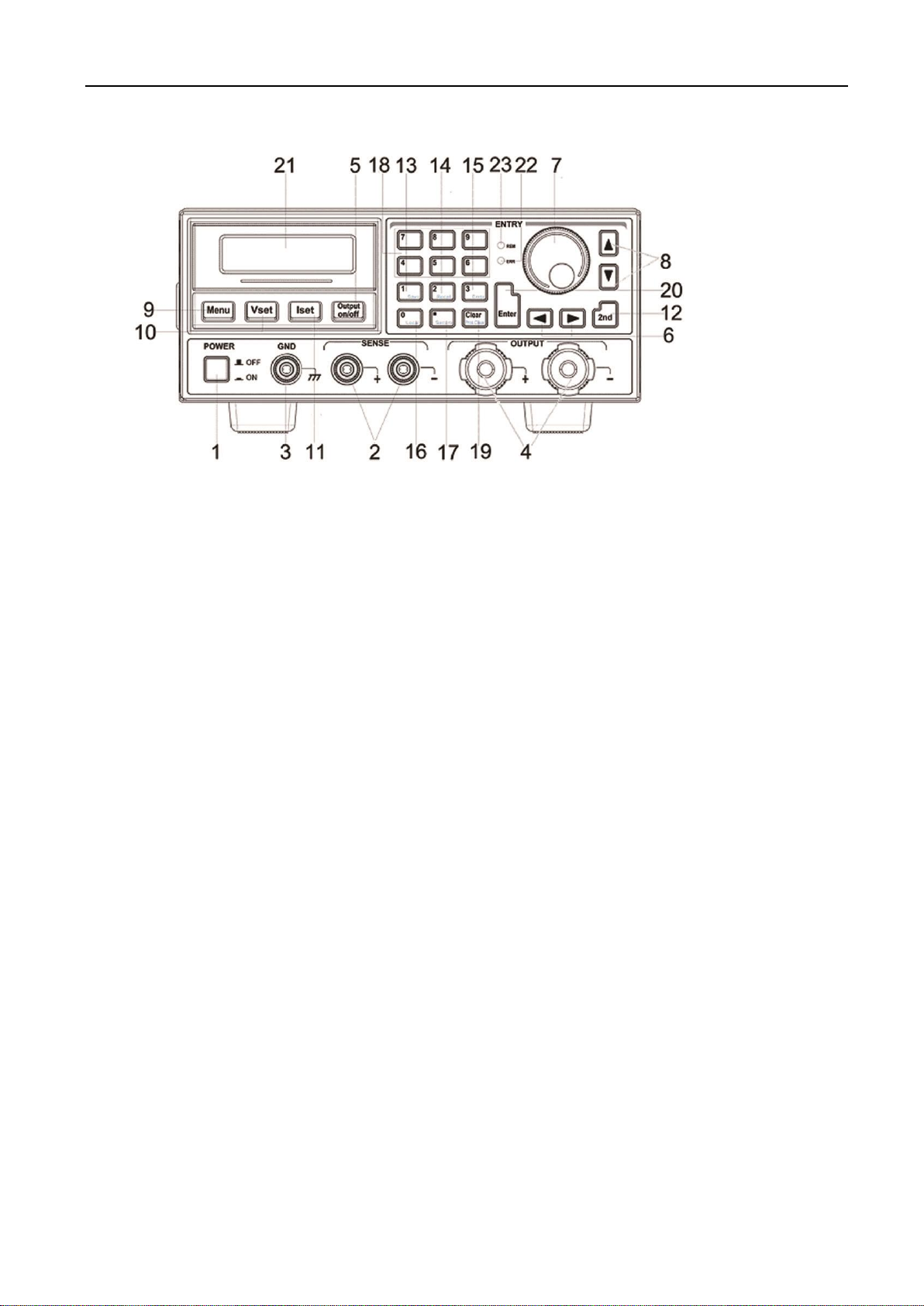

The Front Panel at a Glance

1. AC power switch 2. Sense terminals

3. Earth ground terminal 4. Supply output terminals

5. Output on/off key 6. Left/Right key

7. Control knob 8. Up/Down key

9. Menu setting key 10. Voltage setting key

11. Current setting key 12. Switch key (second menu level)

13. Store key (second menu level) 14. Recall key (second menu level)

15. Error key (second menu level) 16 Local key (second menu level)

17. Secure key (second menu level) 18. Number key

19. Clear key (second menu level) 20. Enter key

21. Display screen 22. ERR annunciator

23. REM annunciator

1. AC power switch: Turns the AC power on and off.

2. Sense terminals: Senses voltage level at device under test (DUT), the positive pole is in red, the negative pole is in

black.

3. Earth ground terminal: It is connected to the chassis and earth ground.

4. Supply output terminals: Supply output, the positive output terminal is in red, the negative output terminal is in black.

5. Output on/off key: Turns the power supply output on/off.

6. Left/Right key: Moves the blinking digit to left or right, or selects different options.

7. Control knob: Adjusts the value of the blinking digit or selects different options by turning clockwise or counter clockwise.

8. Up/Down key: Turns the menu page.

9. Menu setting key: Enters menu setting contents.

10. Voltage setting key (VSET): Displays or modifies the present voltage setting value.

11. Current setting key (ISET): Displays or modifies the present current setting value.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 3

Page 4

LABKON Series

12. Switch key for second menu level (2nd): Enables the second menu level of other keys.

13. Store key for second menu level (Save): Stores the present operating states in location “0”, “1”, … “9”.

14. Recall key for second menu level (Recall): Recalls a previously stored operating state from location “0”, “1”,…“9”.

15. Error key for second menu level (Error): Checks or reads the error codes.

16. Local key for second menu level (Local): Returns the power supply to local mode from remote control mode.

17. Secure key for second menu level (I/O config): Secures and unsecures the power supply for calibration.

18. Number key (0-9 and.): Sets values.

19. Clear key for second menu level (Clear): Clears present input value or exits current operation.

20. Enter key (Enter): Confirms present setting values or option.

21. Display screen: Shows parameters and status of power supply.

22. ERR annunciator: When some error is detected, ERR annunciator is on.

23. REM annunciator: When the power supply is in remote control mode, REM annunciator is on.

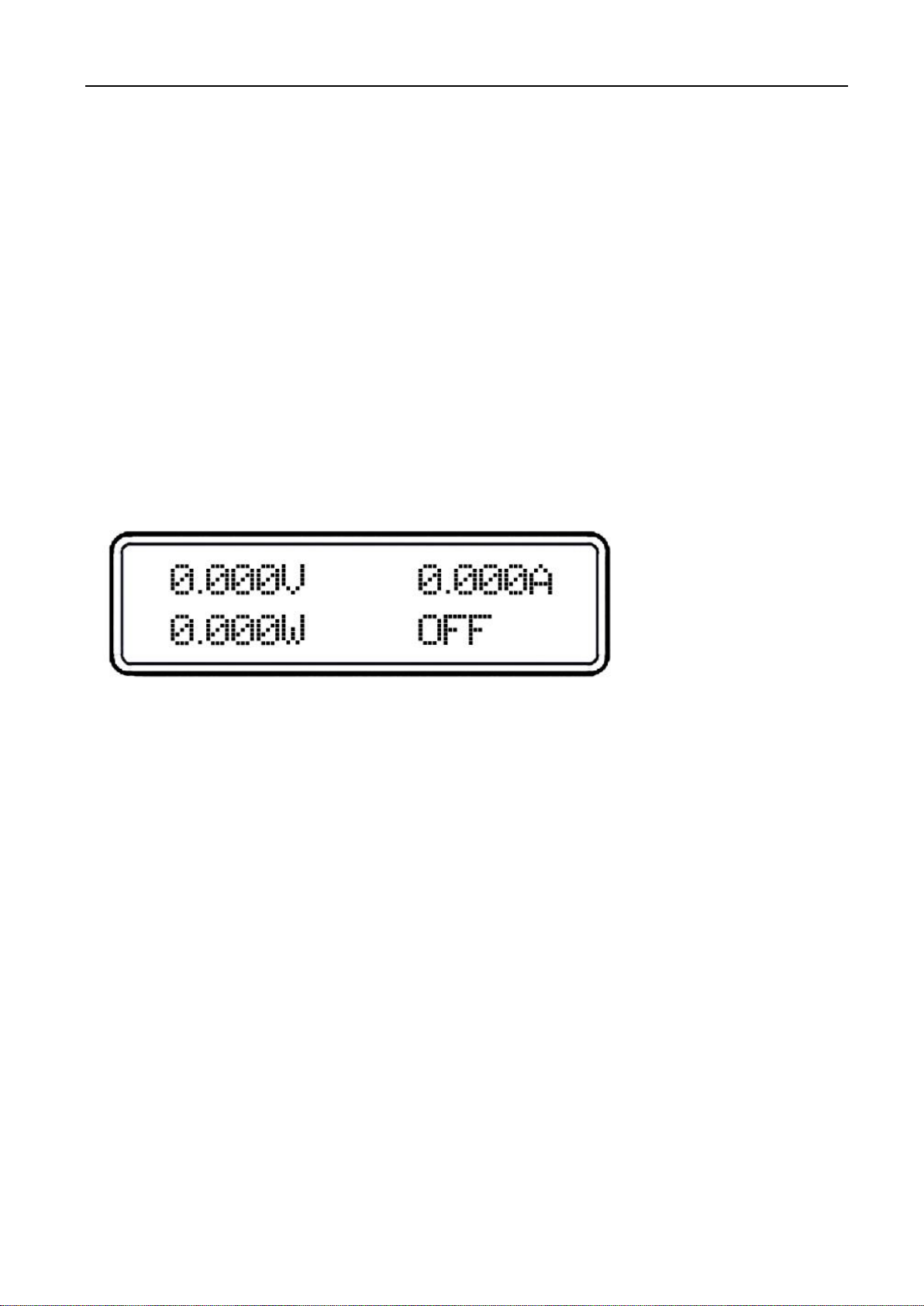

Front-Panel Display Messages

0.000V Display present voltage value.

0.000A Display present current value.

0.000W Display present power value.

OT The power supply is in over-temperature state.

OV The power supply is in over-voltage state and the supply output is disabled.

OFF The output of power supply is off.

ERROR Hardware or remote interface control commands errors are detected and the error bits have not been

cleared or read.

Unreg The present output of the power supply is unregulated. (The output is neither CV nor CC.)

CV The output of power supply is in CV mode.

CC The output of power supply is in CC mode.

_________________________________________________________________________________________________

4 GMC-I Messtechnik GmbH

Page 5

LABKON Series

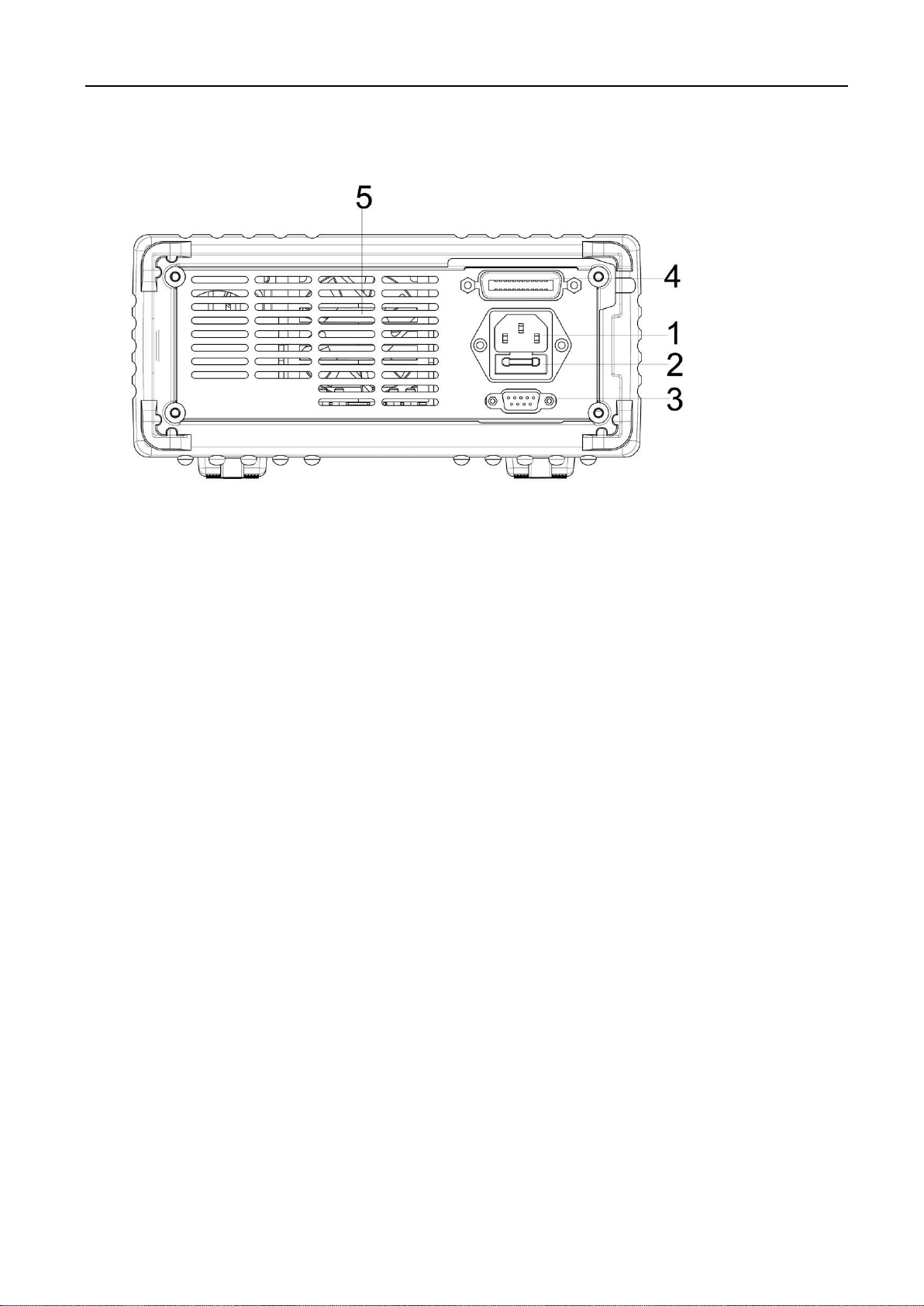

The Rear Panel at a Glance

1. AC inlet 2. Fuse holder

3. RS232 interface connector 4. GPIB interface connector (optional)

5. Fan outlet

An Introduction to this Manual

General Information

Apart from a general description of your power supply, it provides instructions for checking your power supply, selecting

power-line voltage and connecting to AC power.

Initial Operation

It ensures that the power supply develops its rated outputs and responds to operation from the front panel properly.

Front-Panel Operation

It describes the use of front-panel keys and knobs in detail and how to use them to operate the power supply from the front

panel. And it also shows how to configure the power supply for the remote interface and introduces the calibration features in

brief.

Remote Interface Reference

It contains the reference information to help you program the power supply over the remote interface, and explains how to

program for status reporting as well.

Application Programs

It provides some remote interface applications to help you develop programs for your application.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 5

Page 6

LABKON Series

Tutorial

It describes basic operation of the power supply and gives specific details on the operation and use of GOSSEN

METRAWATT LABKON Series power supplies.

Specifications

It lists the power supply’s basic specifications.

_________________________________________________________________________________________________

6 GMC-I Messtechnik GmbH

Page 7

LABKON Series

Content

An Introduction to this Manual ................................................................................................................................................ 5

General Information ........................................................................................................................................................... 5

Initial Operation .................................................................................................................................................................. 5

Front-Panel Operation........................................................................................................................................................ 5

Remote Interface Reference .............................................................................................................................................. 5

Application Programs ......................................................................................................................................................... 5

Tutorial .............................................................................................................................................................................. 6

Specifications ..................................................................................................................................................................... 6

1.1 General Information ............................................................................................................................................ 10

1.2 Safety Considerations ......................................................................................................................................... 10

1.3 Description .......................................................................................................................................................... 10

1.4 Installation .......................................................................................................................................................... 11

1.5 Initial Inspection .................................................................................................................................................. 11

1.6 Mechanical Check .............................................................................................................................................. 11

1.7 Electrical Check .................................................................................................................................................. 11

1.8 Temperature Control ........................................................................................................................................... 11

1.9 Rack Mounting .................................................................................................................................................... 11

2 Initial Operation ............................................................................................................................................................ 12

2.1 Initial Operation ................................................................................................................................................... 12

2.2 Preliminary Checkout .......................................................................................................................................... 12

2.3 Power-Line Cord ................................................................................................................................................. 12

2.4 Fuse Replacement .............................................................................................................................................. 13

2.5 Power-On Checkout ........................................................................................................................................... 14

2.6 1. Self-test started ............................................................................................................................................... 14

2.7 2. Self-test accomplished .................................................................................................................................... 14

2.8 3. Enabling the output ......................................................................................................................................... 14

2.9 Output Checkout ................................................................................................................................................. 15

2.10 Voltage Output Checkout .................................................................................................................................... 15

2.11 Current Output Checkout .................................................................................................................................... 16

3 Front Panel Operation .................................................................................................................................................. 18

3.1 Front Panel Operation Overview ......................................................................................................................... 18

3.2 Output on/off ....................................................................................................................................................... 18

3.3 Constant Voltage Output Setting ........................................................................................................................ 19

3.4 Constant Current Output Setting ......................................................................................................................... 20

3.5 Menu Setting....................................................................................................................................................... 21

3.5.1 Main Menu Description ................................................................................................................................... 21

3.6 Storing and Recalling .......................................................................................................................................... 22

3.7 Error Messages Display ...................................................................................................................................... 23

3.8 Local/ Remote Operation Switch ........................................................................................................................ 23

3.9 Protection Function ............................................................................................................................................. 23

3.9.1 Abnormal Latched State Clearance ................................................................................................................ 23

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 7

Page 8

LABKON Series

3.9.2 Over-Voltage .................................................................................................................................................. 23

3.9.3 Over-Temperature .......................................................................................................................................... 23

3.10 The Power Supply Calibration ............................................................................................................................ 24

3.11 Calibration Procedure ......................................................................................................................................... 24

3.12 CV Mode Calibration ........................................................................................................................................... 25

3.12.1 Wiring ............................................................................................................................................................. 25

3.12.2 0.5 V Calibration ............................................................................................................................................. 25

3.12.3 22 V Calibration .............................................................................................................................................. 25

3.12.4 4.5 V Calibration ............................................................................................................................................. 26

3.13 CC Mode Calibration .......................................................................................................................................... 26

3.13.1 Wiring ............................................................................................................................................................. 26

3.13.2 0.5 A Calibration ............................................................................................................................................. 26

3.13.3 6 A Calibration ................................................................................................................................................ 27

3.13.4 9 A Calibration ................................................................................................................................................ 27

3.14 OV Calibration .................................................................................................................................................... 27

4 Remote Interface Reference ................................................................................................................................ ........ 28

4.1 Remote Interface Reference ............................................................................................................................... 28

4.2 SCPI Command Summary ................................................................................................................................. 28

4.3 An Introduction to the SCPI Language ............................................................................................................... 29

4.4 Command Format Used in This Manual ............................................................................................................. 30

4.5 Command Separators ......................................................................................................................................... 30

4.6 Using the MIN and MAX Parameters .................................................................................................................. 31

4.7 Querying Parameter Settings.............................................................................................................................. 31

4.8 SCPI Command Terminators .............................................................................................................................. 31

4.9 SCPI Parameter Types ................................................................ ....................................................................... 31

4.10 Output Setting and Operation Commands .......................................................................................................... 32

4.11 Trigger Commands ............................................................................................................................................. 32

4.12 System-Related Commands ................................................................ ............................................................... 33

4.13 Calibration Commands ....................................................................................................................................... 33

4.14 Status Reporting Commands .............................................................................................................................. 33

4.15 RS232 Interface Commands............................................................................................................................... 34

4.16 Simplified Programming Overview ...................................................................................................................... 34

4.17 Using the APPLy Command ............................................................................................................................... 34

4.18 Using the Low-Level Commands ........................................................................................................................ 35

4.19 Selecting a Trigger Source ................................................................................................................................. 35

4.20 Using the APPLY Command............................................................................................................................... 35

4.21 Output Setting and Operation Commands .......................................................................................................... 36

4.22 Measurement Commands .................................................................................................................................. 36

4.23 Output on/off and Tracking Operation Commands ............................................................................................. 36

4.24 Output Setting Commands ................................................................................................................................. 37

4.25 Trigger Source Choice ........................................................................................................................................ 38

4.26 Selecting a Trigger Source ................................................................................................................................. 38

4.27 Bus (Software) Triggering ................................................................................................................................... 38

4.28 Immediate Triggering .......................................................................................................................................... 38

_________________________________________________________________________________________________

8 GMC-I Messtechnik GmbH

Page 9

LABKON Series

4.29 Trigger Commands ............................................................................................................................................. 39

4.30 System-Related Commands ............................................................................................................................... 39

4.31 Calibration Commands ....................................................................................................................................... 41

4.32 RS232 Interface Commands............................................................................................................................... 42

4.33 The SCPI Status Registers ................................................................................................................................. 42

4.34 What is an Event Register? ................................................................................................................................ 42

4.35 What is an Enable Register? .............................................................................................................................. 42

4.36 The Questionable Status Register ...................................................................................................................... 43

4.37 The Standard Event Register.............................................................................................................................. 44

4.38 The Status Byte Register .................................................................................................................................... 45

4.39 Status Reporting Commands .............................................................................................................................. 46

4.40 SCPI Conformance Information .......................................................................................................................... 47

4.41 SCPI Confirmed Commands............................................................................................................................... 47

4.42 Device-Specific Commands ................................................................................................................................ 48

5 Tutorial ......................................................................................................................................................................... 50

5.1 Tutorial ................................................................................................................................................................ 50

5.2 An Overview of GOSSEN METRAWATT LABKON Series Operation ................................................................ 50

5.3 Output Characteristics ........................................................................................................................................ 50

5.4 Unregulated State ............................................................................................................................................... 51

5.5 Unwanted Signals ............................................................................................................................................... 51

5.6 Connecting the Load ........................................................................................................................................... 52

5.7 Output Isolation ................................................................................................................................................... 52

5.8 Multiple Loads..................................................................................................................................................... 52

5.9 Considerations .................................................................................................................................................... 53

5.10 Capacitive Load .................................................................................................................................................. 53

5.11 Inductive Load .................................................................................................................................................... 53

5.12 Pulse Load .......................................................................................................................................................... 54

5.13 Reverse Current Load ........................................................................................................................................ 54

5.14 Extending the output ........................................................................................................................................... 54

5.15 Reliability ............................................................................................................................................................ 54

6 Specifications ............................................................................................................................................................... 55

6.1 Performance Specifications ................................................................................................................................ 55

6.2 Transient Response Time ................................................................................................................................... 56

6.3 Command Processing Time................................................................................................................................ 56

6.4 Supplementary Characteristics ........................................................................................................................... 56

7 APPENDIX Error Messages ........................................................................................................................................ 59

7.1 Error Messages .................................................................................................................................................. 59

7.2 Execution Errors ................................................................................................................................................. 59

7.3 Self-Test Errors ................................................................................................................................................... 61

7.4 Calibration Errors ................................................................................................................................................ 62

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 9

Page 10

LABKON Series

General Information

1.1 General Information

This chapter provides a general description of your power supply. And it also contains instructions relate to initial inspection,

selecting the power-line voltage, and connecting your power supply to AC power.

1.2 Safety Considerations

This power supply is a safety instrument with a protective earth terminal. The terminal must be connected to earth ground

through a power source with a 3-wire ground receptacle when being connected to AC power supply.

Before installation or operation, please check the power supply and read safety markings and instructions introduced in this

manual first. Please see relevant chapters for related specific information about safety operations.

1.3 Description

GOSSEN METRAWATT LABKON Series is a series of programmable switching-mode DC power supplies with stable

voltage and constant current. The excellent line and load regulation, extremely low ripple and noise make it well suited as a

high preference power system. LABKON Series, as a kind of high-efficient switching-mode supply, features wide supply

input voltage from 100 V AC to 240 V AC (LABKON P500) and/or 180 V AC to 265 V AC (LABKON P800), high power factor

and a minimum output of 0V.

Output voltage or current can be adjusted independently from front panel, or controlled via RS232 or GPIB interface,

respectively. Buttons and knobs on the front panel can be used to adjust voltage and current of the DC output; calibration is

possible without opening the housing in case of reduced precision (including change password for calibration); switch the

power supply from remote control mode to local mode; set and monitor the power supply over remote interface; monitor the

setting and output of power supply via the liquid crystal display in front panel, and all the status indication, error information

displayed during working.

When being controlled over remote interface, it can be used both as a listener and a speaker at the same time. The power

supply can be set and data can be returned over RS232, or GPIB interface by an external controller. The following functions

can be performed through RS232, or GPIB interface:

1. Voltage and current setting

2. Voltage and current readback

3. Enable or disable track mode

4. Present and stored status readback

5. Programming syntax error detection

6. Calibration

7. Output on/off

8. System self-test

This power supply is equipped with a liquid crystal display for displaying the output of voltage and current. A 5-digit voltage

and a 5-digit current could show the actual or setting value of a selected supply simultaneously. And the liquid crystal display

can show the current mode of power supply。

Connections to the power supply’s output and to chassis ground are made to binding terminals on the front panel. The Sense

terminals can remotely sample the power supply’s voltage. The positive and negative terminals of each output can be

grounded, or kept a certain voltage with the chassis ground. But voltage between each output and the chassis ground should

be kept within ± 240 V DC. The power supply is provided with a detachable 3-wire grounding type power cord. The AC line

fuse is on the rear panel. It can be extracted for replacement when needed.

The power supply can be calibrated from the front panel directly without opening the cabinet. Correction factors are stored in

non-volatile memory. You can guard against unauthorized calibration by using the “Standard” calibration protection function.

_________________________________________________________________________________________________

10 GMC-I Messtechnik GmbH

Page 11

LABKON Series

1.4 Installation

1.5 Initial Inspection

When you receive your power supply, please check it for any obvious damage that may have occurred during shipment or

resulted from other reasons. If any damage is found, contact the carrier and the Sales Office immediately in order to deal with

it in time.

Keep the original packing materials in case the power supply has to be returned to GMC-I Messtechnik for repairing in the

future. If you return the power supply for service, please attach a tag identifying the owner and model number. A brief

description of the malfuction is also needed.

1.6 Mechanical Check

This check confirms that there are no broken keys or knobs, and that the cabinet and panel surfaces are free from dents and

scratches, and that the display is not scratched or cracked as well.

1.7 Electrical Check

Please see Chapter 2 for an initial operation procedure. When successfully completed, it can be ensured that the power

supply is operating in accordance with its specifications.

1.8 Temperature Control

The power supply’s performance will not be affected when operating within the temperature range of 0°C to 40°C, within the

temperature range of 40°C to 55°C, the over-temperature protection may take effect, depending on the input voltage and

output power. A brushless fan is used to cool the power supply by drawing cool air through the two sides and exhausting the

heat through the fan outlet on the rear panel.

Sufficient space must be left at the rear and two sides of the cabinet for air circulation when the power supply is installed.

Please remove the rubber bumpers for rack mounting.

1.9 Rack Mounting

The power supply could be installed in a standard 19-inch rack.

Please remove the rubber bumpers at the front and end of power supply before installing.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 11

Page 12

LABKON Series

2 Initial Operation

2.1 Initial Operation

This chapter mainly focuses on three basic tests which should be performed before the operation of the power supply: the

preliminary check, the power-on check, and the output check. The preliminary check is to check if the power supply could run

correctly. The power-on test includes a self-test that checks the internal microprocessors and checks if the user is able to

examine the display at the front panel under the condition of applying power to the supply properly. The output check ensures

that the power supply develops its rated outputs and properly responds to operation from the front panel.

In order to make sure the power supply is in accordance with what is required and have a better command

of power supply features for later use, it is suggested that both the experienced and the inexperienced

users should read this chapter prior to operation

2.2 Preliminary Checkout

GOSSEN METRAWATT LABKON Series power supply can be used from a rated 100 V to 240 V single phase AC power

source at 47 to 63 Hz. There is an indication below the AC power inlet on the rear panel showing the rated input voltage set

for the power supply at the factory.

2.3 Power-Line Cord

The power supply is shipped ex works with a power-line cord that has a plug appropriate for continental Europe. Please

contact the nearest GMC-I MESSTECHNIK Sales and Service Office if the wrong power-line cord is included with your power

supply. Your power supply is equipped with a 3-wire grounding type power cord with a diameter of 1mm2 x3, the third

conductor is the ground lead. The power supply can operate properly only when the power-line cord is plugged into an

appropriate receptacle. Do not operate your power supply without adequate cabinet ground connection.

_________________________________________________________________________________________________

12 GMC-I Messtechnik GmbH

Page 13

LABKON Series

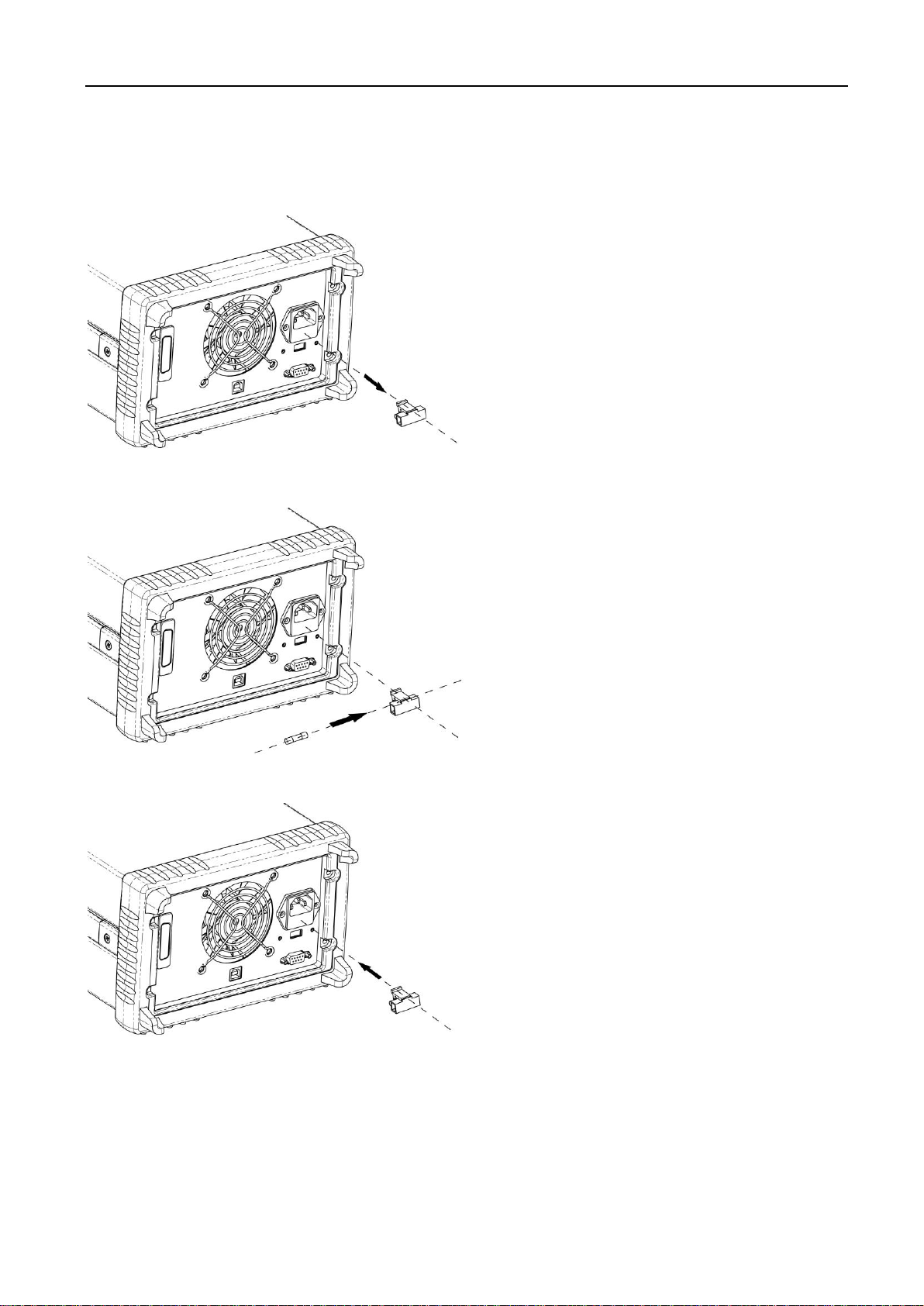

2.4 Fuse Replacement

1 Replace the fuse

Step 1: Remove the fuse-holder below AC power inlet.

Step 2: Replace the fuse with the correct one that meets the requirements.

Step 3: Put back the fuse holder.

For 115V AC operation, 10AT fuse must be used;

For 230V AC operation, 6AT fuse must be used.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 13

Page 14

LABKON Series

2.5 Power-On Checkout

The power-on test includes an automatic self-test that checks the internal microprocessors and a system self-test after the

power supply is turned on, which examines the information relate to self-test process shown on the front panel. You will

observe the following sequence on the display:

2.6 1. Self-test started

It begins with an initial operation immediately after pressing the power switch on. Then the self-test starts,

involving the test of the internal microprocessors and the whole power supply system.

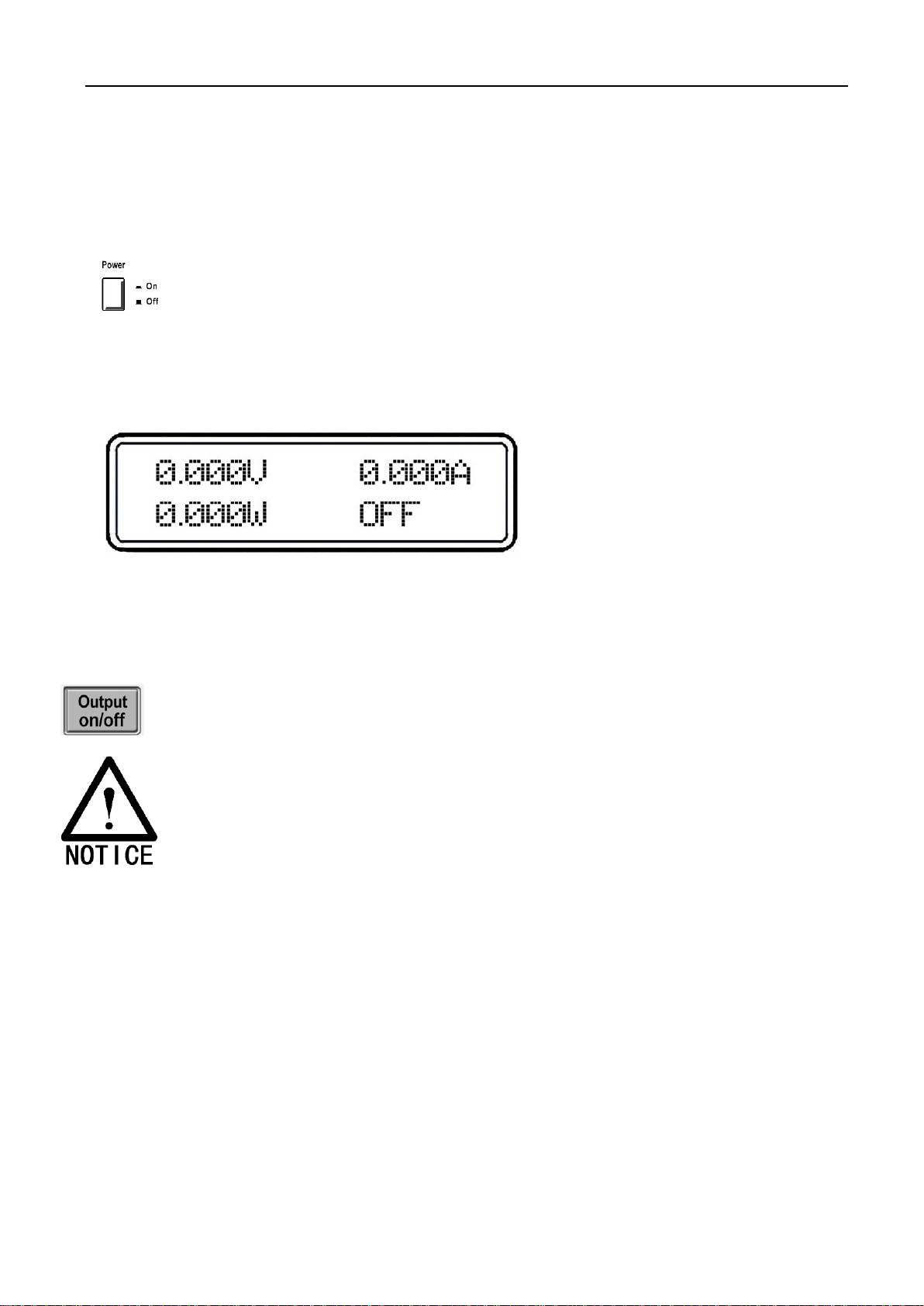

2.7 2. Self-test accomplished

If no error or abnormity has been detected during self testing, the supply will enter into power-on/reset state and the output

will be switched off.

In this figure, “OFF” indicates that the supply output is switched off.

2.8 3. Enabling the output

Press “Output on/off” to enable the output. The “OFF” annunciator on the lower right corner of the display

vanishes, while the “ON” and “CV” annunciators at the same place turn on. And the display switches to

monitor mode automatically to monitor the actual value of the output voltage and current.

If power-on self-test has detected any error or abnormity, the “ERROR”annunciator is lit. For specific

information about errors, please see related chapters in appendix.

_________________________________________________________________________________________________

14 GMC-I Messtechnik GmbH

Page 15

LABKON Series

2.9 Output Checkout

The output checkout is to ensure that the power supply develops its rated outputs and properly responds to various

operations. Specific steps are shown as followings:

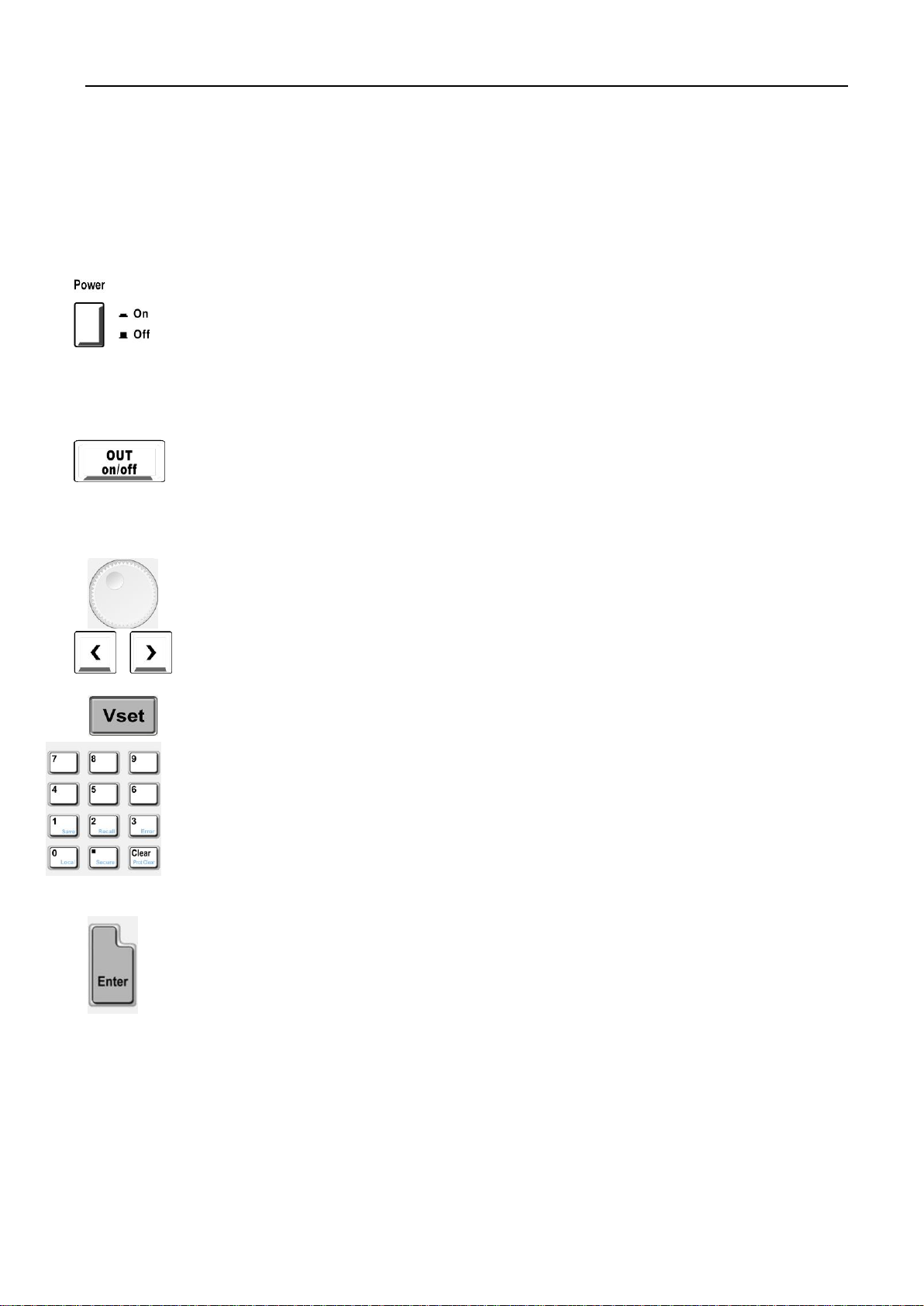

2.10 Voltage Output Checkout

1. Turn on the power supply.

Press the “Power-on” button, and let the power-on check finish. Usually the power supply will go into the

power-on / reset state automatically. “OFF” will be shown in the lower right corner of the display and both

the output voltage and current are 0.

2. Enable the outputs.

Press the “OUT on/off” button to turn on the power supply outputs. Now the display is in monitor mode; the

“CV” and “ON” annunciator in the lower right corner of the display is lit. At the same time a 5-digit voltage

meter and a 5-digit current meter are displayed, respectively showing the actual value of output voltage

and current of the power supply.

3. Check if the voltmeter properly responds to knob control on front panel of the supply.

Knob Checkout

When the power supply output is on and the display is in monitor mode, move the blinking digit to voltage

value displayed by pressing the key “Left”. Turn the knob clockwise or counter clockwise to check that the

voltmeter responds to knob control to increase or decrease and the ampmeter indicates nearly zero.

Key Checkout

When the power supply output is on and the display is in monitor mode, press key “VSET”, the voltage

setting value in the LCD will blink. Press the number keys on front panel directly to set voltage value

needed. Then press “Enter” to verify and to finish setting and go back to monitor mode. This process is to

check that the voltage value displayed responds to the key operation correctly.

4 Check if the voltage can be adjusted from zero to the maximum rated value.

Adjust the knob until the voltmeter indicates 0V and then adjust the knob gradually until the voltmeter

indicates the maximum rated value with the method explained in last step. At the same time check if the

voltmeter and output voltage changes as voltage changes.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 15

Page 16

LABKON Series

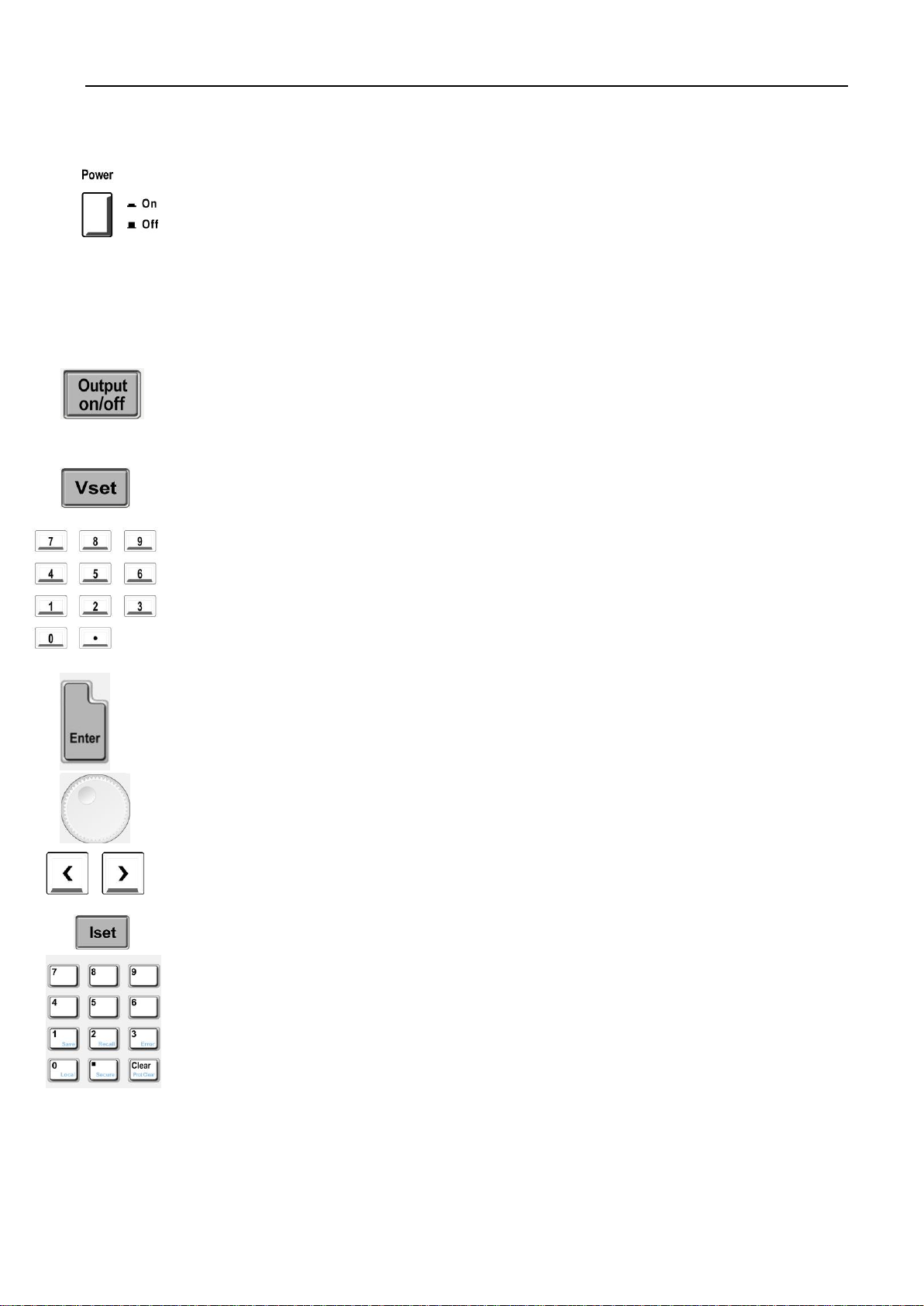

2.11 Current Output Checkout

1. Turn on the power supply.

Press “Power-on” button and finish the power-on checkout. Usually the power supply will go into the

power-on / reset state automatically and the “OFF” annunciator in the lower right corner of the LCD turns

on. Both the voltage value and current value are 0.

2. Connect a short across (+) and (-) output terminals of the supply with an insulated test lead. The

sectional area of the shorting stub should be larger than 1.5mm2.

3. Enable the outputs.

Set the supply voltage to 5V according to the voltage setting measure. Press the “OUT on/off” button, the

display is in monitor mode. At the same time a 5-digit voltage meter and a 5-digit current meter are

displayed, showing the actual value of output voltage and output current of the power supply respectively.

The CV or CC modes depend on the resistance of the test lead.

4. Adjust the voltage limit value to 1.0 V.

Adjust the voltage limit to 1.0 V to assure CC operation. Please see related chapters about voltage and

current setting from front panel in this manual for specific operations.

5. Check that the front-panel ampmeter properly responds to the key and knob operations from the front

panel.

Knob Checkout

When the output of the power supply is turned on and the display is in monitor mode, press “Right” key to

move the blinking digit to current value displayed, and turn the knob clockwise or counter clockwise to

check if the current value displayed increases or decreases as current changes.

Key Checkout

When the output of the power supply is turned on and the display is in monitor state, press “ISET” and the

current setting value is blinking. Press the number keys on front panel directly to set current value needed.

Then press “ENTER” to verify and finish setting and go back to monitor mode. This process is to check that

the current value displayed responds to the key operation correctly.

_________________________________________________________________________________________________

16 GMC-I Messtechnik GmbH

Page 17

LABKON Series

6. Ensure that the current can be adjusted from 0A to the maximum rated value.

Adjust the knob until the ampmeter indicates 0A and then until the ampmeter indicates the maximum rated

value.

If an error has been detected during the output checkout procedures, the ERROR annunciator will turn on.

Refer to the related chapters in appendix for more specific error information.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 17

Page 18

LABKON Series

3 Front Panel Operation

3.1 Front Panel Operation Overview

Output on/off

Constant Voltage setting

Constant Current setting

Menu Setting

Storing and Recalling

Error Messages Display

Local/Remote Operation switch

Protection Function

Power Supply Calibration

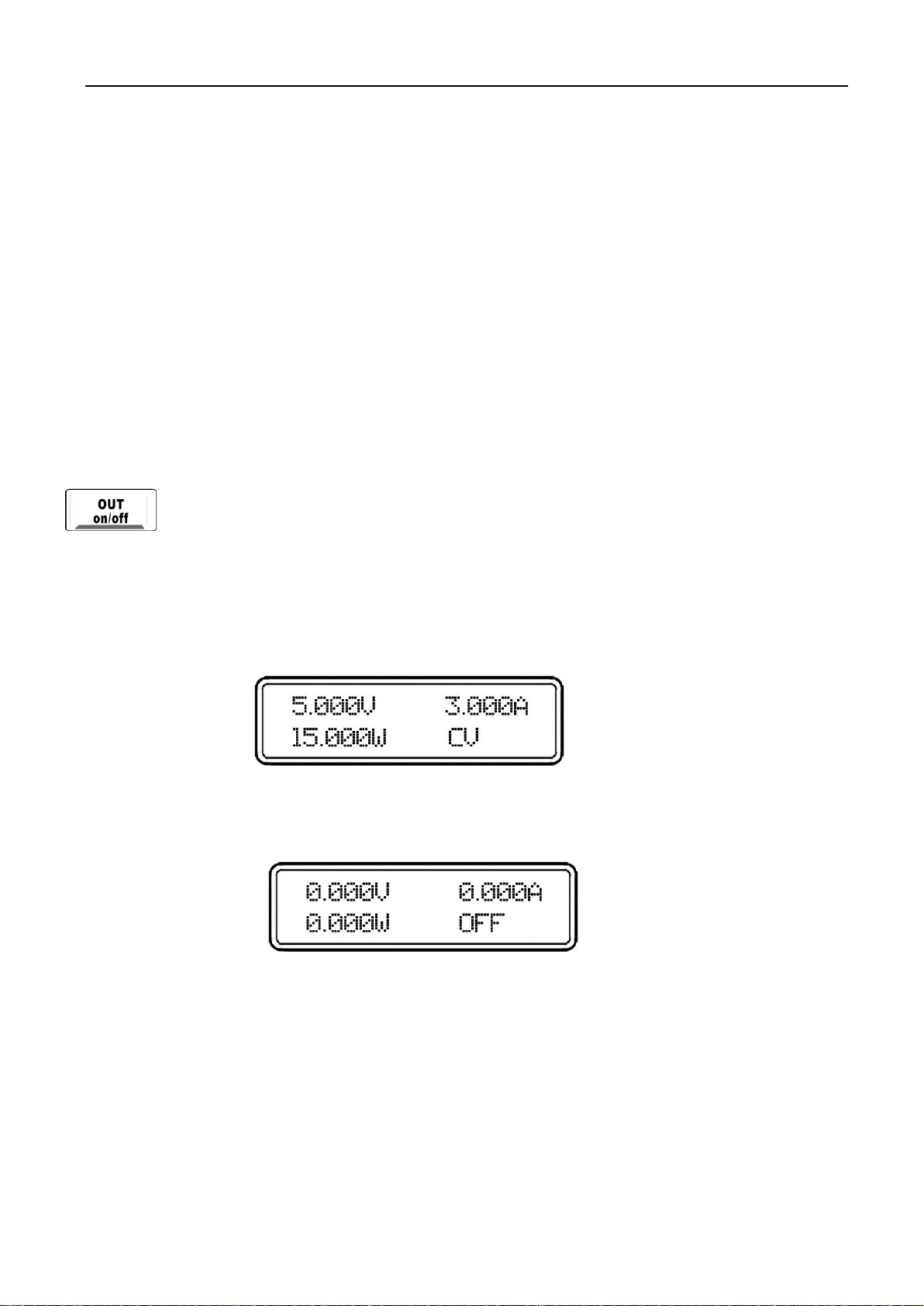

3.2 Output on/off

The output of the power supply could be switched on or off through this button.

When the output of the power supply is disabled, you can enable it by pressing “Out on/off” key, and it can

be turned off by pressing this key again.

When the output of the power supply is enabled, “CV”, “CC” or “Unreg” will be displayed in the lower right

corner of the display. “CV” indicates that the supply is in constant voltage state, “CC” indicates that the

power supply is in constant current state and “Unreg” indicates that the power supply is operating in

unstable state (Neither in constant voltage nor constant current status).

For example: if the power supply output is in constant voltage state, the actual output voltage is 5V and the

actual output current is 3A, the display will show as follows:

When the output of the power supply is off, the “OFF” annuciator in the lower left corner of the display is lit and the keys as

well as the knobs are still valid. Then the display will show as follows:

When it is operated from remote interface, entering the following command can enable or disable the output: OUTPUT

ON/OFF. You can turn on the output by selecting ON and turn off the output by selecting OFF.

_________________________________________________________________________________________________

18 GMC-I Messtechnik GmbH

Page 19

LABKON Series

3.3 Constant Voltage Output Setting

Constant voltage output is the most common output of the power supply. The voltage output has a constant value in constant

voltage output mode, and it will not change with the load while the current will. The CV annunciator in the lower left corner of

the LCD will turn on when the power supply is in constant voltage mode.

1. Connecting a load to the relevant output terminals

Turn off the power supply. Connect the load to the relevant output terminals. Connect the positive pole of the load to “+”

terminal of the output, and connect the negative pole to “-” terminal of the output.

2. Turning on the power supply

Press the “Power on/off” button in the front panel. The power supply will go into power-on/ reset state,

namely the power supply is off.

3. Setting desired output voltage

The desired output voltage can be set directly by pressing number keys or using “Left/Right” key together with the knob.

1). Using number keys and “Enter” key to enter:

① Press “Vset” to enter into voltage setting state.

② Enter the desired voltage value by pressing number keys. “Clear” key can be used to clear any wrong value.

③ Press “Enter” key to confirm the voltage setting value.

2). Using “Left/Right” keys, knob and “Enter” key to enter:

① Press “Vset” to enter into voltage setting state.

② Press “Left/Right” keys to move the blinking digit to the relevant digit of the value.

③ Increase or decrease the relevant value by turning the knob clockwise or counter clockwise. Then use “Left/Right” keys to

move to the next digit to modify.

④ Press “Enter” key to confirm the voltage setting value.

4. Setting maximum current

The maximum current can be set directly by pressing the number keys or using “Left/Right” keys together with the knob.

1). Using number keys and “Enter” key to enter:

① Press “Iset” key to enter into current setting state.

② Enter the desired current value by pressing number keys. “Clear” key can be used to clear the wrong value.

③ Press “Enter” key to confirm the current setting value.

2). Using “Left/Right” keys, knob and “Enter” key to enter:

① Press “Iset” key to enter into current setting state.

② Press “Left/Right” keys to move the blinking digit to the relevant digit of the value.

③ Increase or decrease the relevant value by turning the knob clockwise or counterclockwise, then use “Left/Right” keys to

move to the next digit to modify.

④ Press “Enter” key to confirm the current setting value.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 19

Page 20

LABKON Series

5. Enabling the outputs

Press the “Output on/off” key to enable the outputs. “CV” is displayed in the lower right corner of the display.

6. Verifying that the power supply is in the constant voltage mode

When you operate the power supply in the constant voltage (CV) mode, if “CC” is displayed in the lower left corner of the

display, it indicates that the actual output current value has reached the set value. Therefore please choose a higher current

limit value.

3.4 Constant Current Output Setting

When the power supply is in constant current mode, the current will output at a constant value, and it will not change with the

load while the voltage will. The CC annunciator in the lower right corner of the display will turn on when the power supply is in

constant current mode. The operation methods of constant current output are introduced in the following.

1. Connecting a load to the relevant output terminals

Turn off the power supply. Connect the load to the relevant terminals. Connect the positive pole of the load to “+” terminal of

the output, and connect the negative pole to “-” terminal of the output.

2. Turning on the power supply

Press the “Power on/off” button in the front panel. The power supply will go into power-on/ reset state, namely the power

supply is off.

3. Maximum output voltage setting

Maximum output voltage can be set directly by pressing number keys or using “Left/Right” key together with the knob.

1). Using number keys and “Enter” key to enter:

① Press “Vset” to enter into voltage setting state.

② Enter the desired voltage value by pressing number keys. “Clear” key can be used to clear the wrong value.

③ Press “Enter” key to confirm the voltage setting value.

2). Using “Left/Right” keys, knob and “Enter” key to enter:

① Press “Vset” to enter into voltage setting state.

② Press “Left/Right” keys to move the blinking digit to the corresponding digit of the value.

③ Increase or decrease the relevant value by turning the knob clockwise or counter clockwise, then use “Left/Right” keys to

move to the next digit to modify.

④ Press “Enter” key to confirm the voltage setting value.

4. Setting the desired output current

The desired current can be set directly by pressing the number keys or using “Left/Right” keys together with the knob.

1). Using number keys and “Enter” key to enter:

① Press “Iset” to enter into current setting state.

② Enter the desired current value by pressing number keys. “Clear” key can be used to clear the wrong value.

③ Press “Enter” key to confirm the current setting value.

_________________________________________________________________________________________________

20 GMC-I Messtechnik GmbH

Page 21

LABKON Series

Function and Parameter

Description

Current Limit:

max. 14.600 A (K148A)

Current Limit:

Current Limit Value

Voltage Limit:

max. 35.200 V (K148A)

Voltage Limit:

Voltage Limit Value

Voltage Over:

max. 36.000 V (K148A)

Voltage Over:

Over Voltage Value

Beep:

*On Off

Beep:

On Off

Knob:

*On Off

Knob:

On Off

Interface:

*RS232 GPIB

Interface Choices:

RS232 GPIB

RS232 Interface

Baud Rate

4800 *9600

Baud Rate Setting

300 600 1200 2400 4800 9600 19200 38400

Parity Check

*None Even Odd

Parity Check

None Even Odd

Data Bit:

5 6 7 *8

Data Bit:

5 6 7 *8

Stop Bit:

*1 2

Stop Bit:

*1 2

2). Using “Left/Right” keys, knob and “Enter” key to enter:

① Press “Iset” to enter into current setting state.

② Press “Left/Right” keys to move the blinking digit to the corresponding digit of the value.

③ Increase or decrease the relevant value by turning the knob clockwise or counter clockwise, then use “Left/Right” keys to

move to the next digit to modify.

④ Press “Enter” key to confirm the current setting value.

5. Enabling the outputs

Press the “Output on/off” key to enable the outputs. “CC” is displayed in the lower left corner of the display.

6. Verifying that the power supply is in the constant current mode

When the power supply is operating in the constant current mode, if the “CV” is displayed in the lower left corner of the

display, it indicates that the actual output voltage value has reached our setting value. Therefore please choose a higher

voltage limit.

3.5 Menu Setting

3.5.1 Main Menu Description

Press “Menu” key to enter into main menu, which is shown as follows:

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 21

Page 22

LABKON Series

Flow Control:

*On Off

Flow Control:

*On Off

USB Interface

None

Selecting USB

GPIB Interface

GPIB Address:

5

GPIB Address:

Address Value

Step

Operational Details

Display Information

1

Set voltage to 5V and current to 2A. Then turn on the

power supply.

5.000V 2.000A

0.000W CV

2

Press “2nd” + “Save” keys to enter into store menu.

Save:0

3

Press keys or adjust the knob to select store location as 1.

Save:1

4

Press “Enter” key to confirm and exit store menu

simultaneously.

5.000V 2.000A

0.000W CV

Step

Operational Details

Display Information

1

Set voltage to 30V. Then turn off the power supply.

30.000V 0.000A

0.000W OFF

2

Press “2nd” + “Recall” keys to enter into recall menu.

Recall:0

3

Press keys or adjust the knob to select recall location as 1.

Recall:1

4

Press“Enter” key to confirm and exit recall menu

simultaneously.

5.000V 2.000A

0.000W CV

Notes: Except the parameters about knob, key sound and interface configuration, other parameters in the main menu will not

be saved when the power supply is switched off. If you would like to store relevant parameters, please press “2nd” + “Save”

keys or make use of *sav command.

3.6 Storing and Recalling

Store and recall procedures are illustrated in the following:

1 Press “2nd” + “Save” keys to enter the electronic store menu, or press “2nd” + “Recall” keys to enter the electronic recall

menu.

2 Press keys or adjust the knob to select store or recall location (0~9).

3 Press “Enter” key to confirm and exit store or recall menu simultaneously. For a store case, voltage and current values are

saved in corresponding EEPROM and for a recall condition, the voltage and current values stored previously can be

retrieved from corresponding EEPROM and set as present values.

Example 1: Set voltage to 5V and current to 2A. Then turn on the power supply and save this state to the EEPROM specified

by Location 1.

Example 2: Based on Example 1, set voltage to 30V. Then turn off the power supply and recall the values saved in the

EEPROM specified by Location 1.

_________________________________________________________________________________________________

22 GMC-I Messtechnik GmbH

Page 23

LABKON Series

Step

Operational Details

Display Information

1

Press “2nd” +“Error” keys and the display will show the

error messages.

ERROR -103

2

If some error has been detected, repeat the first step.

3

When there is no error, “err” annunciator will be off.

Repeat the first step, then “NO ERROR” will be showed

in the display.

NO ERROR

3.7 Error Messages Display

If some error has been detected, “err” annunciator will be lit. Then you can read the error messages through front panel

operation with following steps:

1 Press “2nd” + “Error” keys and the display will show the error messages.

Example 1: if there is a wrong command, “err” annunciator will turn on. Then check the error messages with following steps:

3.8 Local/ Remote Operation Switch

If it is necessary to operate the power supply with the keys and knobs of the front panel, the power supply must be kept in

local control state. The power supply will be in this state as soon as it is switched on.

In remote control state, all keys and knobs become invalid (except “2nd” and “Local” keys). When the power source receives

the remote command (SYST:REM) through RS232 Interface or commands through GPIB Interface, REM annunciator will be

on and remote control becomes valid. In remote control state, all operations of the power supply are controlled by remote

controller. After receiving the command demanding the power supply to return to local control (eg. SYST:LOC ), the power

supply will go back to local control state and REM annunciator will be off. In remote control state, the power supply can be

returned to local control state by pressing “2nd” +“Local” keys even if it has not received the returning command.

3.9 Protection Function

There are two protections states: over-voltage protection and over-temperature protection for LABKON Series. Once

anything abnormal is detected, the corresponding state symbol in the State Register will be set; the power supply will disable

its output and beep to give an alarm; the display reveals the reason for the unusual condition and the power supply enters

into abnormal latched state. Except specific operations, the supply will stop responding to other commands. For example:

when the temperature is too high, supply output will turn off and beep to give an alarm. OT will be showed in the lower right

corner of the display and the power supply will not respond to other commands.

3.9.1 Abnormal Latched State Clearance

When the power supply enters into abnormal latched state, it fails to respond to other commands. Only when the abnormal

latched state is cleared by pressing “2nd” + “Clear” keys, can normal operations be restored. Obviously, the reason for the

abnormal latch must be solved, or the power supply will enter into abnormal latched state once again immediately.

3.9.2 Over-Voltage

The user can set the over-voltage protection value (Voltage Over) in the menu as needed. When the supply's output voltage

is higher than the set value, the system enters into over-voltage protection status and the display shows OV. This state can

be cleared by decreasing the output voltage or increasing the over-voltage protection value. Otherwise, even though you can

remove the latched state by pressing “2nd” + “Clear” keys, the system will automatically enter over-voltage protection status

once again for over-voltage.

3.9.3 Over-Temperature

If the internal temperature of the supply is above the safety limitation, over-temperature protection will be triggered; the

supply output will turn off and OT is displayed. In the meantime, OT and PS in the Questionable Status Register will be set

and keep in this state until they are reset and over-temperature state is removed. You can’t clear the abnormal latched state

until the supply temperature falls to its normal range.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 23

Page 24

LABKON Series

3.10 The Power Supply Calibration

Because various factors may cause the reduction of the power supply’s output precision after it has been used for a period of

time, the user should calibrate the power supply’s output to make the output return to the previous precision. But it is

suggested that the power should not be calibrated frequently. This section mainly introduces how to unsecure the power

supply and the detailed procedures of manual calibration.

3.11 Calibration Procedure

Caution

When calibration is conducted, the ambient temperature should be within the range of 25° C ± 2° C. All testing instruments

and the supply power must be preheated for 30 minutes before calibration.

Press the “Vset” key while switching on the power supply and the display will show as follows:

Press “secure” key after pressing “2nd” key and you will see the following graph:

Enter the password “003662”, then press “Enter” key to enter into calibration menu, which is shown as below:

Select CV, CC or OV mode calibration by direction key. If “DEF” is selected, all calibration parameters are restored to default

value. CV, CC and OV mode should be calibrated one by one, which is the correct calibration sequence. Return to calibration

menu after each mode calibration is completed. Press “Clear” key to exist calibration state.

_________________________________________________________________________________________________

24 GMC-I Messtechnik GmbH

Page 25

LABKON Series

3.12 CV Mode Calibration

In this mode, three voltage points: 0.5 V, 22 V, 34.5 V (take LABKON P500 35 V / 14.5 A, K148A as example) should be

calibrated. A complete overview of calibration checkpoints for all LABKON models is listed on page 57 of this manual.

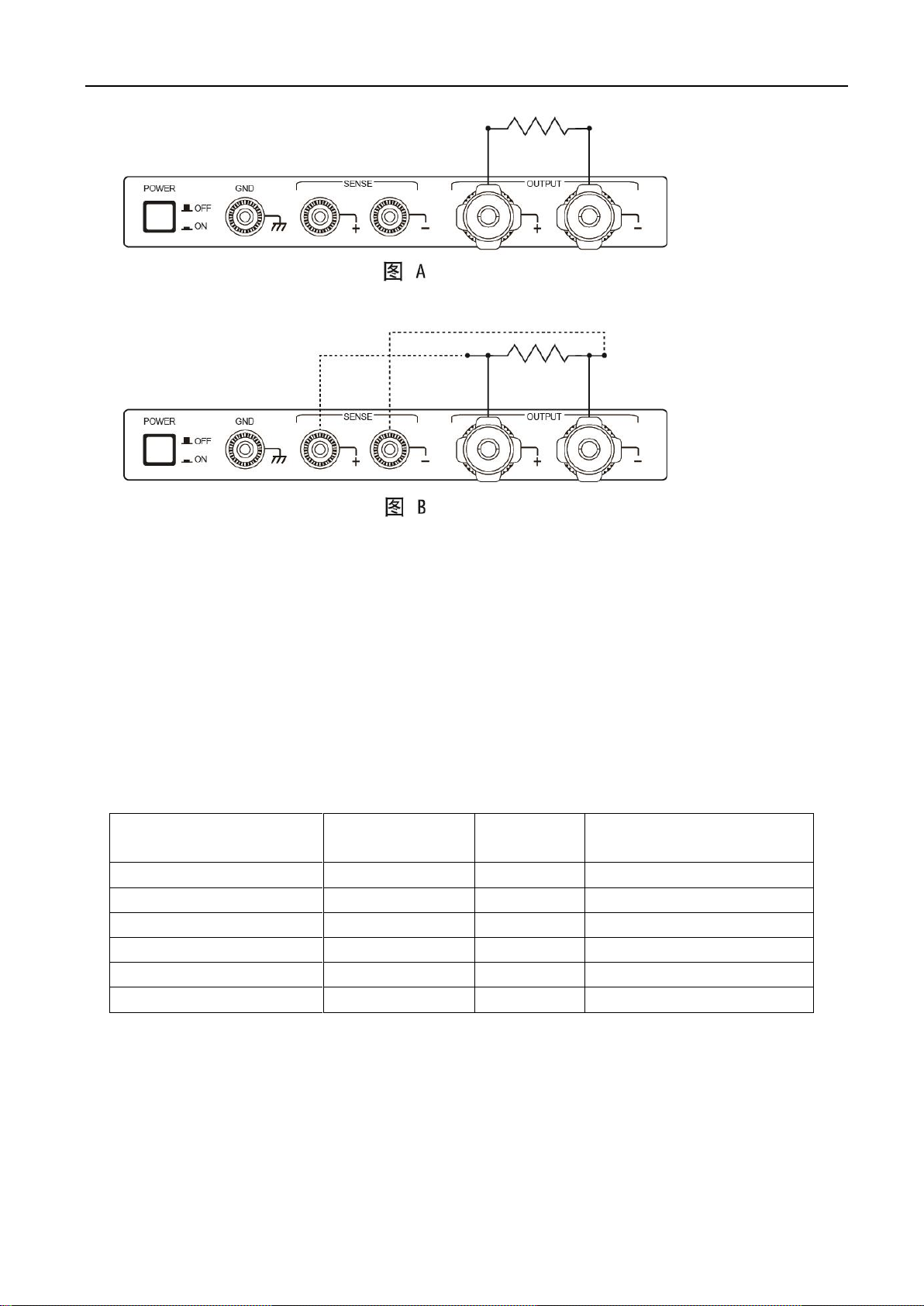

3.12.1 Wiring

3.12.2 0.5 V Calibration

Press “Enter” key, you will see the following figure in the display:

Enter the value you read from the multimeter, which is retained to four decimal places. If necessary, press the “Clear” key to

remove the wrong input value of current digit. Then press the “Enter” key to confirm.

3.12.3 22 V Calibration

Press “Enter” key to verify and then you will see the followings:

Enter the value you read from the multimeter, which is retained to four decimal places. If necessary, press the “Clear” key to

remove the wrong input value of current digit. Then press the “Enter” key to confirm.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 25

Page 26

LABKON Series

3.12.4 4.5 V Calibration

Press “Enter” key to verify and then the display will show as follows:

Enter the value you read from the multimeter, which is retained to four decimal places. If necessary, press “Clear” key to

remove the wrong input value of current digit. Then press “Enter” key to confirm and exit to calibration menu. Now, voltage

calibration is completed.

3.13 CC Mode Calibration

In this mode, three current points: 0.5 A, 6 A, 9 A (take LABKON P500 35 V/14.5 A, K148A as an example) should be

calibrated. A complete overview of calibration checkpoints for all LABKON models is listed at the end of this manual!

3.13.1 Wiring

3.13.2 0.5 A Calibration

Press “Enter” key, you will see the following figure in the display:

Enter the value you read from the multimeter, which is retained to four decimal places. If necessary, press the “Clear” key to

remove the wrong input value of present digit. Then press “Enter” key to confirm.

_________________________________________________________________________________________________

26 GMC-I Messtechnik GmbH

Page 27

LABKON Series

3.13.3 6 A Calibration

Press “Enter” key to verify and then you will see the following:

Enter the value you read from the multimeter, which is retained to four decimal places. If necessary, press the “Clear” key to

remove the wrong input value of present digit. Then press the “Enter” key to confirm.

3.13.4 9 A Calibration

Press “Enter” key to verify and then the display will show as follows:

Enter the value you read from the multimeter, which is retained to four decimal places. If necessary, press the “Clear” key to

remove the wrong input value of present digit. Then press the “Enter” key to confirm.

3.14 OV Calibration

OV calibration is a kind of automatic calibration without manual operation, which starts after the voltage calibration is

conducted and is shown in the following:

When the calibration is completed, the display will go back to the calibration menu.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 27

Page 28

LABKON Series

4 Remote Interface Reference

4.1 Remote Interface Reference

A detailed description of how to use the remote interface will be given in this chapter, which includes how to program the

power supply through the remote interface, the commands format and matters need attention.

SCPI Command Summary

Simplified Programming Overview

Using the Apply Command

Output Setting and Operation Commands

Triggering Commands

System-Related Commands,

Calibration Commands

RS232 Interface Commands

The SCPI Status Registers

Status Reporting Commands

An Introduction to the SCPI Language

Halting an Output in Progress

SCPI Conformance Information

If this is the first time you use the SCPI language, it is suggested intensely to read this chapter attentively in

order to become familiar with the language before you attempt to program the power supply.

4.2 SCPI Command Summary

This section mainly introduces the SCPI (Standard Commands for Programmable Instruments) commands available to

program the power supply. Refer to the later sections in this chapter for more complete details on the format and function of

each command.

Each SCPI command presented in this section uses the following conventional format.

1. Square brackets ([ ]) indicate optional keywords or parameters.

2. Braces ({ }) enclose parameters within a command string.

3. Triangle brackets (< >) indicate that you must substitute a value or a code for the enclosed parameter.

4. A vertical bar ( | ) separates one of two or more alternative parameters.

_________________________________________________________________________________________________

28 GMC-I Messtechnik GmbH

Page 29

LABKON Series

4.3 An Introduction to the SCPI Language

SCPI (Standard Commands for Programmable Instruments) is an ASCII-based instrument command language designed for

test and measurement instruments.

The detailed techniques used to program the power supply over the remote interface are introduced in the following sections.

SCPI commands are based on a hierarchical structure, also known as a tree system. In this system, associated commands

are grouped together under a common node or root, thus forming subsystems. A portion of the SOURce subsystem is shown

below to illustrate the tree system.

[SOURce:]

CURRent

[:LEVel]

[:IMMediate]

[:AMPLitude] {<current>|MIN|MAX}

[:AMPLitude]? [MIN|MAX]

:TRIGgered

[:AMPLitude] {<current>|MIN|MAX}

[:AMPLitude]? [MIN|MAX]

:LIMit

[:AMPLitude] {<current>|MIN|MAX}

[:AMPLitude]? [MIN|MAX]

VOLTage

[:LEVel]

[:IMMediate]

[:AMPLitude] {<voltage>|MIN|MAX}

[:AMPLitude]? [MIN|MAX]

:TRIGgered

[:AMPLitude] {<voltage>|MIN|MAX}

[:AMPLitude]? [MIN|MAX]

:LIMit

[:AMPLitude] {<voltage>|MIN|MAX}

[:AMPLitude]? [MIN|MAX]

[SOURce:] is the root keyword of the command, CURRent and VOLTage are the second-level keywords, and LIMit is the

third-level keywords. A colon ( : ) separates a command keyword from a lower-level keyword.

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 29

Page 30

LABKON Series

4.4 Command Format Used in This Manual

The format used to show commands in this manual is shown below:

CURRent {<current>|MINimum|MAXimum}

The command syntax shows that most commands are the mixture of capital and lower case letters. The capital letters

indicate the abbreviated spelling for the command. For shorter program lines, send the abbreviated form. For better program

readability, send the long form. But notice that only the complete spelling form and the capital letters are acceptable for the

keyword. Give the following example to illustrate:

In the above syntax statement, CURR and CURRENT are both acceptable forms for the keyword “CURRent”. As you can

use the mixture of capital or lower case letters for the commands, CURR, Curr, and CURr are all acceptable. Notice that the

capital letters are indispensable. For example, “CUR” is incorrect. And “CURRe”, “CURRen”, will generate an error because

of the incomplete spelling.

Braces “{ }” enclose the parameter choices for a given command string. The braces are not sent with the command string.

A vertical bar “|” separates multiple parameter choices for a given command string.

Triangle brackets “< >” indicate that you must specify a value for the enclosed parameter. For example, the above syntax

statement shows the current parameter enclosed in triangle brackets. You must specify a value for the current parameter,

which is not enclosed in the triangle bracket (such as “CURR 0.1”)..

Some parameters are enclosed in square brackets “[ ]”. The brackets indicate that the parameter is optional and can be

omitted. The brackets are not sent with the command string. If you do not specify a value for an optional parameter, a default

value will be chosen by power supply.

A colon “:” separates a command keyword from a lower-level keyword. You must insert a blank space to separate a

parameter from a command keyword. If a command requires more than one parameter, you must separate adjacent

parameters with a comma as shown below:

SOURce:CURRent:TRIGgered

APPL 3.5,1.5

4.5 Command Separators

A colon “ :” is used to separate a command keyword from a lower-level keyword as shown below:

SOURce:CURRent:TRIGgered

A semicolon “ ;” is used to separate two commands within the same subsystem as shown below:

SOUR:VOLT MIN;CURR MAX

The following two commands have the same effect as the above command.

SOUR:VOLT MIN

SOUR:CURR MAX

Use a colon and a semicolon to link commands from different subsystems.

For example, in the following command string, an error is generated if you do not use the colon and semicolon:

MEAS:VOLT?;:SOUR:CURR MIN

_________________________________________________________________________________________________

30 GMC-I Messtechnik GmbH

Page 31

LABKON Series

4.6 Using the MIN and MAX Parameters

You can substitute MINimum or MAXimum for the parameter of many commands. For example, consider the following

command:

CURRent {<current>|MIN|MAX}

Instead of selecting a specific current, you can substitute MINimum to set the current to its minimum value or MAXimum to

set the current to its maximum value.

4.7 Querying Parameter Settings

You can query the value of most parameters by adding a question mark (?) to the command. For example, the following

command sets the output current to 5A

CURR 5

You can query the value by executing:

CURR?

You can also query the minimum or maximum value allowed with the present function as follows:

CURR? MAX

CURR? MIN

4.8 SCPI Command Terminators

A command string sent to the power supply must terminate with a <new line> character. The IEEE-488 EOI (end-or-identify)

message is interpreted as a <new line> character and can be used to terminate a command string in place of a <new line>

character. A <carriage return> followed by a <new line> is also accepted.

4.9 SCPI Parameter Types

The SCPI language defines several different data formats to be used in program messages and response messages.

Numeric Parameters: Commands that require numeric parameters will accept all commonly used decimal representations of

numbers including optional signs, decimal points, and scientific notation. Special values for numeric parameters like

MINimum, MAXimum, and DEFault are also accepted. You can also send engineering unit suffixes (V, A or SEC) with

numeric parameters. If only specific numeric values are accepted, the power supply will automatically round the input

numeric parameters. The following command uses a numeric parameter:

CURR {<current>|MINimum|MAXimum}

Discrete Parameters: Discrete parameters are used to program settings that have a limited number of values (like BUS,

IMM). Query responses will always return the short form in all capital letters. The following command uses discrete

parameters:

TRIG:SOUR {BUS|IMM}

Boolean Parameters: Boolean parameters represent a single binary condition that is either true or false. For a false condition,

the power supply will accept “OFF” or “0”. For a true condition, the power supply will accept “ON” or “1”. When you query a

boolean setting, the power supply will always return “0” or “1”. The following command uses a boolean parameter:

DISP {OFF|ON}

String Parameters: String parameters can contain virtually any set of ASCII characters. A string must begin and end with

matching quotes; either with a single quote or with a double quote. You can include the quote delimiter as part of the string by

typing it twice without any characters in between. The following command uses a string parameter:

DISPlay:TEXT <quoted string>

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 31

Page 32

LABKON Series

4.10 Output Setting and Operation Commands

APPLy [{<voltage>|DEF|MIN|MAX}][,{<current>|DEF|MIN|MAX}]]

APPLy?

MEASure

:CURRent[:DC]?

[:VOLTage][:DC]?

Output

[:STATe] {OFF|ON}

[:STATe]?

:TRACk[:STATe] {OFF|ON}

: TRACk[:STATe]?

[SOURce:]

CURRent[:LEVel][:IMMediate][:AMPLitude] {<current>[MIN|MAX}

CURRent[:LEVel][:IMMediate][:AMPLitude]? [MIN|MAX]

CURRent[:LEVel]:LIMit[:AMPLitude] {<current>|MIN|MAX|DEF}

CURRent[:LEVel]:LIMit[:AMPLitude]? {MIN|MAX|DEF}

CURRent[:LEVel]:TRIGgered[:AMPLitude] {<current>[MIN|MAX}

CURRent[:LEVel]:TRIGgered[:AMPLitude]? [MIN|MAX]

VOLTage[:LEVel][:IMMediate][:AMPLitude] {<current>|MIN|MAX}

VOLTage[:LEVel][:IMMediate][:AMPLitude]? [MIN|MAX]

VOLTage[:LEVel]:LIMit[:AMPLitude] {<current>|MIN|MAX|DEF}

VOLTage[:LEVel]:LIMit[:AMPLitude]? {MIN|MAX|DEF}

VOLTage[:LEVel]:TRIGgered[:AMPLitude] {<current>[MIN|MAX}

VOLTage[:LEVel]:TRIGgered[:AMPLitude]? [MIN|MAX]

4.11 Trigger Commands

INITiate[:IMMediate]

TRIGger[:SEQuence]

:DELay {<second>|MIN|MAX}

:DELay?

:SOURce {BUS|IMM}

:SOURce?

*TRG

_________________________________________________________________________________________________

32 GMC-I Messtechnik GmbH

Page 33

LABKON Series

4.12 System-Related Commands

DISPlay[:WINDow]

[:STATe] {OFF|ON}

[:STATe]?

:TEXT[:DATA] <quoted string >

:TEXT[:DATA]?

:TEXT:CLEar

SYSTem

:BEEPer[:IMMediate]

:ERRor?

:VERSion?

*IDN?

*RST

*TST?

*SAV {1|2|3}

*RCL {1|2|3}

4.13 Calibration Commands

CALibration

:COUNt?

:CURRent[:DATA] < numeric value >

:CURRent:LEVel {MIN|MAX}

:SECure:CODE <new code >

:SECure:STATe {OFF|ON},<new code>

:SECure:STATe?

:STRing <quoted string >

:STRing?

:VOLTage[:DATA] < numeric value >

:VOLTage:LEVel {MIN|MAX}

4.14 Status Reporting Commands

STATus:QUEStionable

[:EVENt]?

:ENABle <enable value >

:ENABle?

:INSTrument[:EVENt]?

:INSTrument:ENABle <enable value>

:INSTrument:ENABle?

:INSTrument:ISUMmary<n>[:EVENt]?

:INSTrument:ISUMmary<n>:CONDition?

:INSTrument:ISUMmary<n>:ENABle <enable value>

:INSTrument:ISUMmary<n>:ENABle?

_________________________________________________________________________________________________

GMC-I Messtechnik GmbH 33

Page 34

LABKON Series

SYSTem:ERRor?

*CLS

*ESE <enable value>

*ESE?

*ESR?

*OPC

*OPC?

*PSC {0|1}

*PSC?

*SRE <enable value>

*SRE?

*STB?

*WAI

4.15 RS232 Interface Commands

SYSTem

:LOCal

:REMote

:RWLock

4.16 Simplified Programming Overview

This chapter gives an overview of the basic commands used to program the power supply over the remote interface. Some of

them are the SCPI-confirmed commands, and some are the device-specific commands. It is unnecessary to differentiate

them when using GOSSEN METRAWATT LABKON Series.

4.17 Using the APPLy Command

The APPLy command provides the most straightforward method to program the power supply over the remote interface,

such as to control one output or triple outputs of power supply, and to read the immediate output value of each supply. Give

the following example to illustrate:

APPLY 3.3,2.0 Set the supply to an output of 3.3V rated at 2.0A

APLLY 12.0,0.5 Set the supply to an output of 12.0V rated at 0.5A

_________________________________________________________________________________________________

34 GMC-I Messtechnik GmbH

Page 35

LABKON Series

4.18 Using the Low-Level Commands

The main feature of the low-level commands is to provide you with more flexibility to change or query the individual

parameters than the APPLy command. Give the following example to illustrate how to use the low-level commands to set the

supply to an output of 5.0V rated at 4.0A:

VOLT 3.3

CURR 2.0

The two commands shown in this example have the same function as the first command shown in the above example, which

shows when some individual parameter is changed, there is no need to enter the whole setting parameters as the above

example, just enter some specified parameter.

Reading a Query Response