Page 1

User manual

E-Clip 1 / E-Clip 2

Current Clamps

20 751 208

3-349-447-03

1/12.07

Page 2

E-Clip 1 / E-Clip 2 Current Clamps

Table of contents

1. WARNINGS ..............................................................................................................2

2. DESCRIPTION OF CURRENT CLAMPS................................................................. 3

3. MAINTENANCE........................................................................................................3

3.1. INSPECTION .............................................................................................................3

3.2. CLEANING................................................................................................................4

3.3. SERVICE AND CALIBRATION .......................................................................................4

4. CURRENT CLAMP OPERATION ............................................................................ 4

4.1. SUBSTITUTE ELECTRIC MODEL FOR CURRENT CLAMPS.................................................4

4.2. TYPICAL APPLICATIONS ............................................................................................. 5

5. SPECIFICATIONS....................................................................................................6

5.1. GENERAL PURPOSE CURRENT CLAMP WITH CURRENT OUTPUT ..................................... 6

5.2. SENSITIVE CURRENT CLAMPS WITH CURRENT OUTPUT ................................................. 6

5.3. GENERAL (ALL TYPES) ..............................................................................................7

1. Warnings

To ensure a high level of operator's safety during using of current clamps the following warnings

have to be considered:

♦ Do not use the current clamp if any damage is noticed!

♦ Do not leave open nodes of the current clamp with current output (E-Clip 1, E-Clip 2)

during measurement to avoid damage and electric shock on secondary side, never

enclose conductor in the jaw unless the clamp is connected to measuring instrument!

♦ Only a competent, authorized person is allowed to carry out service intervention!

♦ Consider all generally known precautions in order to avoid risk of electric shock

while dealing with electric installations!

♦ Do not extend hands over safety barrier to prevent of electric shock! Only handles are

allowed to be touched during measurement!

♦

♦

♦ If the current clamp is used in a manner not specified in this User manual, the

Symbol on the current clamp indicates the possibility to use the current clamp on

non-insulated conductors.

Symbol on the current clamp indicates the possibility of a hazardous live

!

condition if the operator ignores the required safety measures.

provided protection can be impaired!

2

Page 3

E-Clip 1 / E-Clip 2 Current Clamps

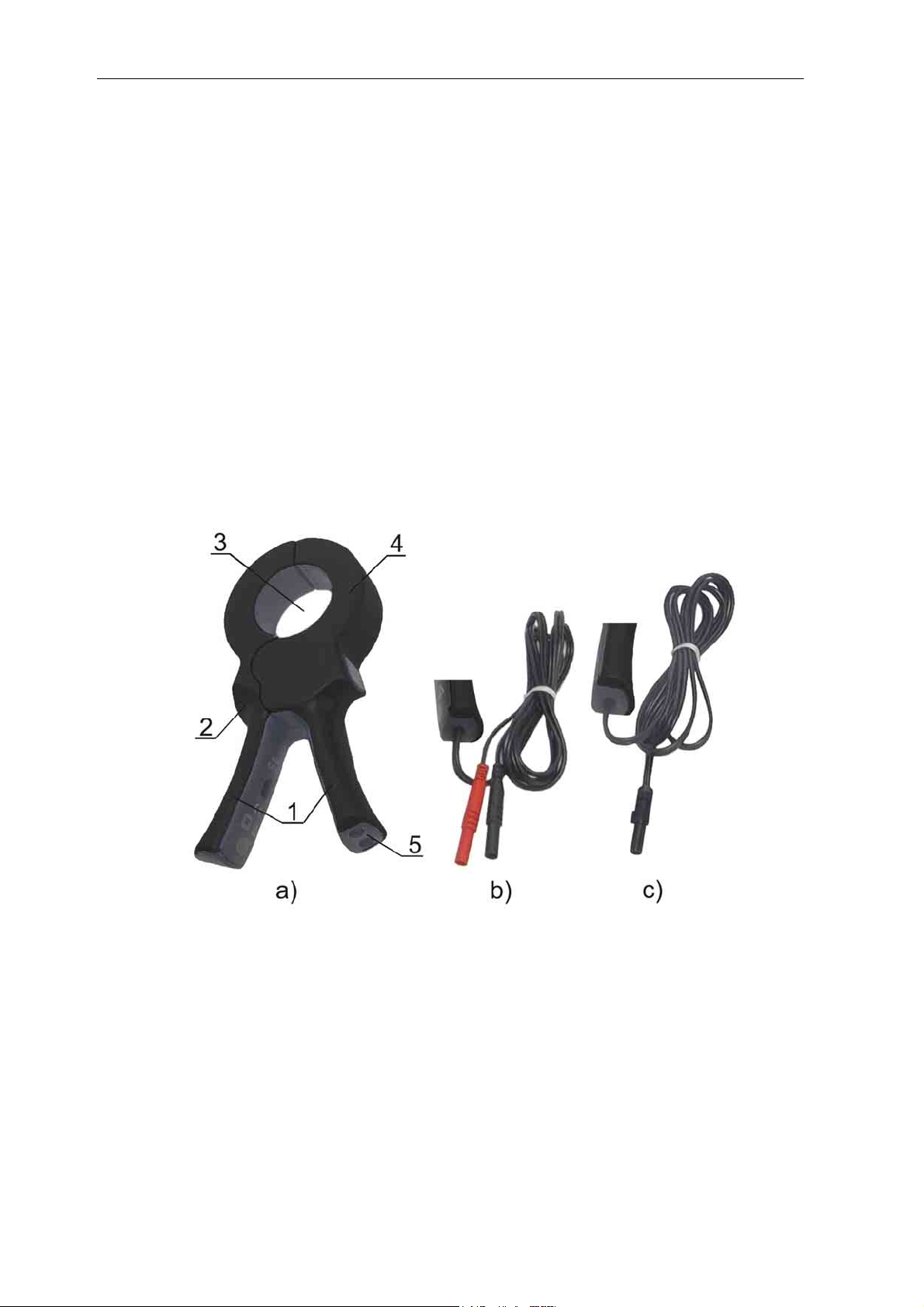

2. Description of current clamps

The E-Clip 1and E-Clip 2 are 1000/1 ratio current clamps for measuring alternating currents in

the range from 1 mA to 1000 A (depending on the type).

They can be connected to any power analyzer, energy analyzer, harmonics analyzer,

multimeter, earth resistance meters, electrical installation testers and other measuring

instruments with compatible voltage or current inputs.

In chapter 4 some typical current clamp applications are described.

The current transducer is housed in a plastic case that maintains the protection class defined in

technical specifications. It consists of:

1. Handles,

2. Safety barrier,

3. Conductor opening,

4. Current transformer,

5. Connection with:

a) Safety banana sokets (E-Clip 2),

b) Cable connection (length = 1.5 m) with safety banana terminals

(E-Clip 1),

3. Maintenance

3.1. Inspection

To maintain operator safety and ensure reliability of the current clamp it is good practice to

inspect it on a regular basis. Check that the enclosure and optional connection are without

defects such as scratches or breaks.

Jaw surface must be clean. Pollution on jaw surfaces reduces the current clamp sensitivity.

3

Page 4

E-Clip 1 / E-Clip 2 Current Clamps

)

3.2. Cleaning

Use a soft cloth moistened with soapy water or alcohol to clean non-metallic surface of the

current clamps and leave them to dry totally before using it.

Notes!

• Do not use liquids based on petrol or hydrocarbons!

• Do not spill cleaning liquid over the current clamps!

To clean jaw cut surfaces use slightly oiled soft cloth.

3.3. Service and calibration

It is essential that your clamp is regularly calibrated in order to guarantee the technical

specification listed in this User manual. We recommend 2-year calibration interval.

Metrel encloses an original calibration certificate with every new instrument and clamp.

For recalibration and repairs under or out of warranty time please contact your distributor for

further information.

4. Current clamp operation

4.1. Substitute electric model for current clamps

Equivalent circuit diagram for current clamp measurement:

Is

Im

Im

Symbols on circuit diagrams have following meaning:

Im Measured (AC) current, primary current

Is Measured current, current transformer secondary current

N1 Number of primary turns - normally N1=1 for current clamps

N2 Number of secondary turns (1000 for all types)

I A-meter

Measuring resistor

R

L

U V-meter

N1

N2

Clamp

current transformer

N1

N2

Clamp

current transformer

Is

a)

R

L

b

I

U

4

Page 5

E-Clip 1 / E-Clip 2 Current Clamps

Clamp current transformer must always have a low impedance load on its secondary side. This

loading is realized with an A-meter (for current sensors with current output). Current clamp with

voltage output already contains the load resistor and its output voltage is proportional to

measured current.

The N1:N2 ratio (primary to secondary winding turns ratio) defines the step-down current ratio

and sensitivity of current clamps. For N2 = 1000 the sensitivity is defined as

1 mA / 1 A, i.e.: 1 mA of output current is generated from 1 A primary current for

N1 = 1. The general formula for sensitivity are given below:

N

= for current output, and

1

II

mS

N

2

N

1

N

R

Lm

2

IU

= for voltage output.

N1 is always integer and means number of passes of conductor carrying measured current

through conductor opening of current clamp.

4.2. Typical applications

Some typical applications of current measurement for standard sensitive current clamps

(E-Clip 2) in combination with appropriate measuring instrument:

- Harmonic analysis,

- Measuring electrical power,

- Measuring current and energy consumption,

- Functional testing of appliances, machines,

- Measuring equipment inrush current, etc.

Additional applications related to low current measurements can be covered with high sensitive

type current clamps (E-Clip 1):

- Measurement of PE leakage current,

- Measurement of differential current and/or current difference,

- Contactless measurement of earth resistance,

- Determining problems in lighting and grounding systems.

5

Page 6

E-Clip 1 / E-Clip 2 Current Clamps

5. Specifications

5.1. General purpose current clamp with current output

Type: E-Clip 2

Rated current: 1000 A

Current ratio : 1000:1

Output:1 mA/A, safety banana sockets

Electrical characteristics (at R = 1 Ω):

Measuring range: 0.2 A ÷ 1200 A

Output signal: 0.2 mA ÷ 1.2 A (0.2 A ÷ 1200 A)

Accuracy and phase error:

Primary current [A] 0.1 ÷ 10 10 50 200 1000 1200

Accuracy of output current [%]

Phase error [°]

Frequency range: 40 Hz ÷ 5 kHz

Continuity of measurements:

Load impedance:

Working voltage: 600 V max.

Influence of neighbor conductor: <1 mA/A at 50 Hz

Influence of conductor position <0.3 % at f < 400 Hz

Influence of loading:

Influence of DC current offset: <2.5 % for I

5.2. Sensitive current clamps with current output

Φ

4 mm

≤2.5 ≤2 ≤1.5 ≤0.9 ≤0.7 ≤0.7

n.a.

1000 A r.m.s. (f < 1 kHz) continuous

1200 A r.m.s. (40 min / 20 min intermitted)

≤10 Ω

2 Ω to 10 Ω: 1 % and 1 °

≤3 ≤1.7 ≤0.9 ≤0.7 ≤0.7

< 30 A

DC

Type: E-Clip 1

Rated current: 1000 A

Current ratio : 1000:1

Output: 1 mA/A, safety banana plugs

Electrical characteristics (R = 1 Ω)

Current measuring range: 0.001 A ÷ 1200 A

Output signal: 1 μA ÷ 1.2 A (1 mA ÷ 1200 A)

Accuracy and phase error

Primary current [A]

Accuracy of output current

[%]

Phase error [°]

Frequency range: 40 Hz..5 kHz

Continuity of measurements: 1000 A r.m.s. (f < 1kHz) continuous

Load impedance:

Working voltage: 600 V max.

Influence of neighbor conductor: <1 mA/A at 50 Hz

Φ

4mm

0.1m ÷ 100m 0.1 ÷ 1 1 ÷ 10 10 ÷ 100 100 ÷ 1200

≤3 ≤2 ≤1.2 ≤1 ≤0.5

n.a. n.a.

1200 A r.m.s. (40 min / 20 min intermitted)

≤10 Ω

≤2.2 ≤1 ≤0.7

6

Page 7

E-Clip 1 / E-Clip 2 Current Clamps

Influence of conductor position <0.3 % at f < 400 Hz

Influence of loading:

Influence of DC current offset: <2.5 % for I

2 Ω to 10 Ω: 1 % and 1°

< 15 A

DC

5.3. General (all types)

Safety specification

Over voltage category: 600 V CAT III,

Pollution degree: 2

Double insulation

Mechanical data

Jaw opening: 52 mm

Maximum conductor sizes:

cable: Φ 50 mm

Environment conditions

Working temperature: -10 °C ÷ 50 °C

Storage temperature: -30 °C ÷ 70 °C

Humidity: 0 % ÷ 85 %, linearly decreasing for T

> 35 °C

Altitude: working 0 to 2000 m

Applied standards

Safety: EN/IEC 61010-1

EN/IEC 61010-2-32

bar: 1 bar 50 mm x 5 mm,

4 bars 30 mm x 5 mm

Flammability of plastic housing:

UL94 – UV1

Dimension: 220 mm x 120 mm x 48 mm

Weight: 600 g

Other outputs availability

Contact manufacturer or local distributor for

further information.

7

Page 8

Repair and Replacement Parts Service

DKD Calibration Lab

and Rental Instrument Service

When you need service, please contact:

GMC-I Gossen-Metrawatt GmbH

Service-Center

Thomas-Mann-Straße 20

90471 Nürnberg ● Germany

Phone +49 911 8602-0

Fax +49 911 8602-253

E-Mail service@gossenmetrawatt.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service in other countries.

Product Support

When you need support, please contact:

GMC-I Gossen-Metrawatt GmbH

Product Support Hotline

Phone +49 911 8602-112

Fax +49 911 8602-709

E-Mail support@gossenmetrawatt.com

GMC-I Gossen Metrawatt GmbH

Thomas-Mann-Str. 16-20

90471 Nürnberg • Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail info@gossenmetrawatt.com

www. gossenmetrawatt.com

Loading...

Loading...