Page 1

Operating Instructions

MINITEST⏐MASTER⏐PRO⏐BASE

Testers per DIN VDE 0701 and 0702

3-349-358-15

4/7.07

Page 2

2 GMC-I Gossen-Metrawatt GmbH

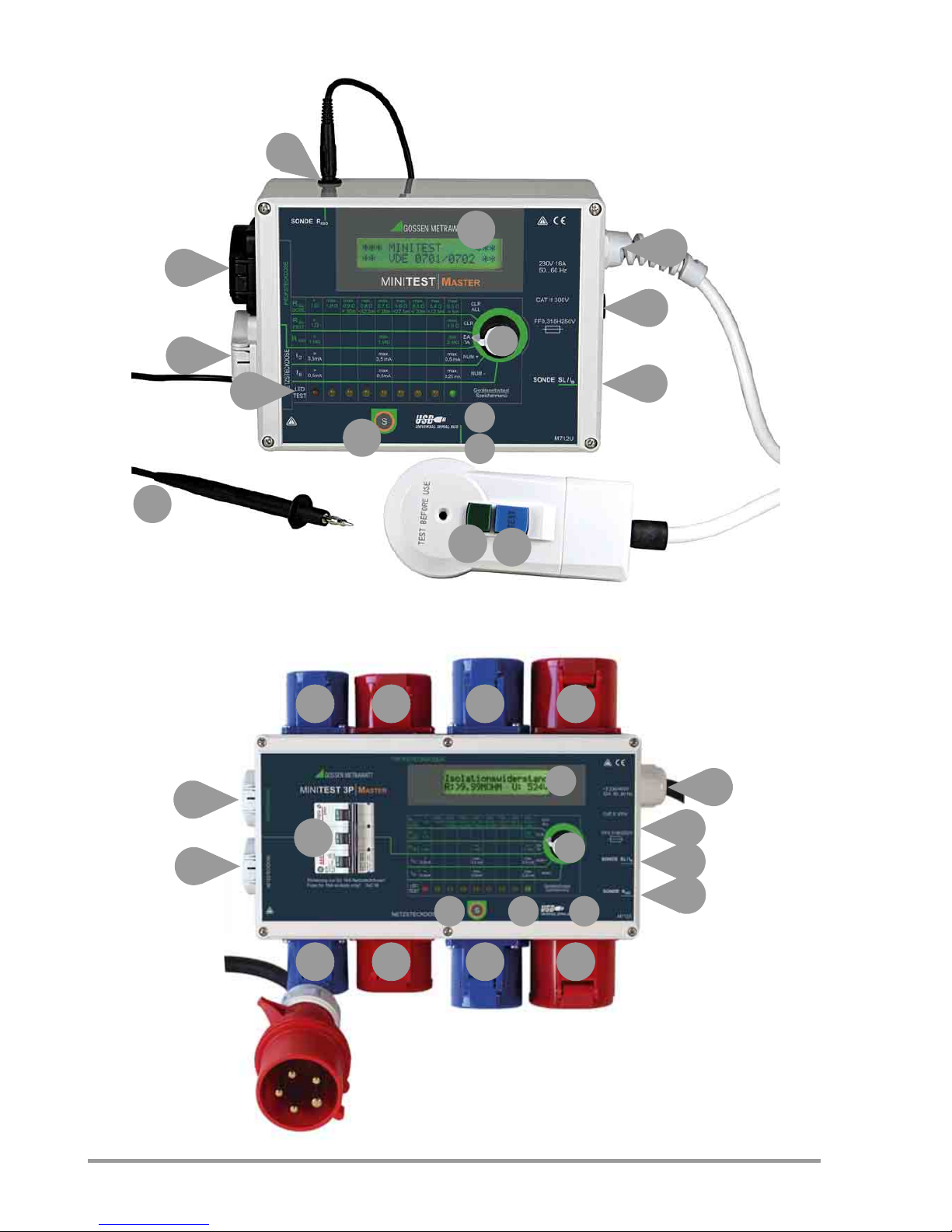

11

6

4

12

5

1

9

8

2

3

7

1

0

13

23

24

18171615

22212019

9

8

1

2

3

14

10

4

5236

11

Page 3

GMC-I Gossen-Metrawatt GmbH 3

1 Mains power cable

2 Fuse (for protecting the probe (3))

3 Probe connector socket for measuring

protective conductor current (PE) or

contact current (I

C

)

4 Rotary switch for selecting the desired

measuring function

5USB port *

6 Send key * for data transmission or

storage

7 LEDs for indicating adherence to, or

violation of limit values

8 Earthing contact mains outlet

9 Earthing contact test socket

10 Probe connector socket for insulation

resistance measurement

(only necessary for Safety Class II)

11 LCD *

12 POWER ON key *

13 RCCB test/POWER OFF key *

14 Fuse for 16 A mains outlets

and mains switch

15 CEE test socket 1P+N+PE 16 A-6h

16 CEE test socket 3P+N+PE 16 A-6h

17 CEE test socket 1P+N+PE 32 A-6h

18 CEE mains socket 3P+N+PE 32 A-6h

19 CEE mains socket 1P+N+PE 16 A-6h

20 CEE mains socket 3P+N+PE 16 A-6h

21 CEE mains socket 1P+N+PE 32 A-6h

22 CEE mains socket 3P+N+PE 32 A-6h

23 Barcode scanner connection

(9-pin, subminiature plug) **

24 Probe cable

*not for MINITEST⏐BASE

** MINITEST⏐MASTER and MINITEST 3P⏐MASTER only

* as from series launched in March 2007

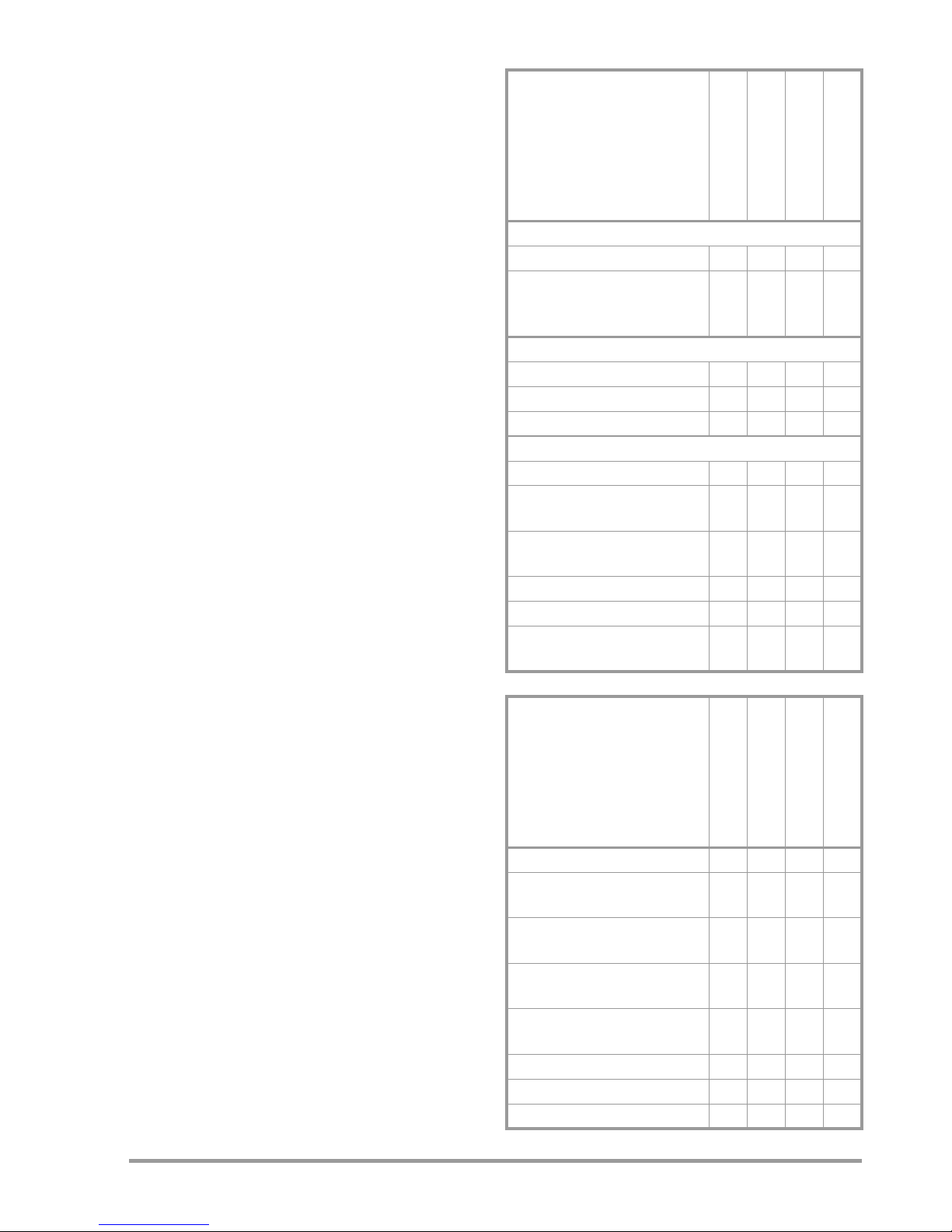

Features of MINITEST⏐...

series

MINITEST 3P⏐MASTER

MINITEST⏐MASTER

MINITEST⏐PRO

MINITEST⏐BASE

Connection types

Tests on monophase DUTs

✘✘✘✘

Tests on 3-phase DUTs

via additional test sockets

CEE 16A / CEE 32A

✘ –––

Fusing devices

Fuse for probe connection

✘✘✘✘

RCCB in mains plug

– ✘✘ –

Miniature circuit breaker

✘ –––

Report functions

Illuminated two-line LCD *

✘✘✘–

Memory for 2,000 tests

(10 measured values per test)

✘✘––

Key for transmission of

measured values

✘✘✘–

Key for storing measured values

✘✘––

Data interface (USB port)

✘✘✘–

Barcode scanner connection

(9 pin, subminiature plug)

✘✘––

Standard equipment

accessories of MINITEST⏐...

series

MINITEST 3P⏐MASTER

MINITEST⏐MASTER

MINITEST⏐PRO

MINITEST⏐BASE

Probe cable with test probe

✘✘✘✘

Adapter for earthing contact plug

to CEE coupling 3P+N+PE 32 A-6h

✘ –––

Adapter for plug 1P+N+PE 16 A

to CEE coupling 3P+N+PE 32 A-6h

✘ –––

Adapter for plug 3P+N+PE 16 A

to

CEE coupling 3P+N+PE 32 A-6h

✘ –––

Adapter for plug 1P+N+PE 32 A

to

CEE coupling 3P+N+PE 32 A-6h

✘ –––

USB connector cable

✘✘✘–

PC analysis software programs on CD-ROM

✘✘✘–

Operating instructions

✘✘✘✘

Page 4

4 GMC-I Gossen-Metrawatt GmbH

Table of Contents

1 Applications ...............................................4

2

Safety Features and Precautions .......................4

3 Initial Start-Up ............................................6

4 Test Sequence ...........................................6

5

Descriptions of Individual Measurements .........8

5.1 Measurements at the Test Outlet(s) ........................8

5.2 Measurements at the Mains Outlet(s) .....................9

6 Report Functions ......................................10

6.1 Transmission Mode (Transmission only while

Program MINITEST is Active) ...............................10

6.2

Permanent Transmission (Transmission only while

Program MINITEST is Active) ................................... 10

6.3

Memory Mode (Read-Out only with

Program

MINITEST⏐MASTER

) ................................ 10

6.3.1 Activate Memory Menu .......................................10

6.3.2 Selecting Memory Function .................................10

6.3.3 Exiting the Memory Menu ....................................11

6.3.4 Reading out Stored Measured Values at the PC ....11

6.3.5 Barcode Scanner Function ...................................11

6.3.6 Switching Off Safely ............................................11

7 PC Analysis Software Programs ..............11

7.1 Program „MINITEST“ ........................................11

7.2 Program „MiniTEST Master“ ............................11

8 Technical Data .........................................12

9 Maintenance ............................................14

9.1 Housing .............................................................14

9.2 Replacing the Fuse .............................................14

9.3 Calibration Intervals ............................................14

9.4

Return and Environmentally Sound Disposal .................. 14

10 Accessories ..............................................15

10.1 Standard Equipment ...........................................15

10.2 Order Information for Available

Accessories ........................................................15

11 Repair and Replacement Parts Service

DKD Calibration Laboratory and Rental

Instrument Service ..........................................16

12 Product Support .......................................16

1 Applications

The test instrument is used to test the electrical safety of monophase and 3-phase

electrical devices. The test instrument allows

for the measurement of protective conductor

resistance, insulation resistance and differential current and/or contact current in

accordance with DIN VDE 0404.

2 Safety Features and Precautions

The test instrument has been manufactured

and tested in accordance with the following

safety regulations:

IEC 61010-1 / DIN EN 61010-1 / VDE 0411-1,

DIN VDE 0413 parts 2 and 4.

When used for its intended purpose, the

safety of the user, the test instrument and

the device under test (electrical equipment

or electrical medical device) is assured.

Read the operating instructions carefully and

completely before placing your test instrument

into service. Follow all instructions contained

therein. Make sure that the operating instructions

are available to all users of the instrument.

Tests may only be performed by a qualified

electrician, or under the supervision and

direction of a qualified electrician. The user

must be instructed by a qualified electrician

in the execution and evaluation of tests.

Safety Precautions for MINITEST 3P⏐M

ASTER

The instrument is intended for connection

with a 3-phase system up to 32 A.

MINITEST 3P⏐MASTER can also be connected

to all customary CEE and earthing contact

outlets via the adapters included in the standard equipment.

Attention!

!

The instrument may only be connected to the mains via the adapters

included in the standard equipment.

Attention!

!

All mains sockets and/or test sockets are connected in parallel:

Only one DUT at a time may therefore be

connected to a socket.

Page 5

GMC-I Gossen-Metrawatt GmbH 5

Observe the following safety precautions:

• MINITEST⏐M

ASTER⏐PRO⏐BASE:

The instrument may only be connected

to electrical systems with a maximum of

230 V which are protected with a fuse or

circuit breaker with a maximum rating of

16 A.

• Measurements within electrical systems

are prohibited.

• Be prepared for the occurrence of

unexpected voltages at devices under

test (for example, capacitors may be

dangerously charged).

• Make certain that the measurement

cables are in flawless condition, e.g. no

damage to insulation, no cracks in

cables or plugs etc.

• Insulation Resistance Measurement R

ISO

Testing is conducted with up to 500 V.

Current limiting is utilized (I < 3.5 mA),

but if the terminals (L or N) are touched,

electrical shock may occur which could

result in consequential accidents.

• Differential Current Measurement I

D

/

Contact Current Measurement I

C

It is absolutely essential to assure that

the device under test is operated with

line voltage during performance of the

differential current and/or contact current

measurement. Exposed conductive

parts may conduct dangerous contact

voltage during testing, and may not

under any circumstances be touched

(MINITEST⏐M

ASTER⏐PRO:

mains power is disconnected if leakage

current exceeds approx. 15 mA).

• The function test may only be performed

after the device under test has

successfully passed the safety test while

connected to the test socket!

The measuring and test instrument may not be

used:

• if it demonstrates visible damage

• with damaged connector cables and

measuring cables

• if it no longer functions properly

• after extraordinary stresses due to transport

• MINITEST 3P⏐MASTER: with other adapters

than those included in the standard

equipment.

In such cases, the instrument must be

removed from operation and secured

against unintentional use.

Meanings of Symbols on the Instrument

The symbols on the instrument have the

following meanings:

Warning concerning a point of

danger (attention: observe

documentation!)

Indicates EC conformity

The device may not be disposed

of with the trash. Further information regarding the WEEE mark

can be accessed on the Internet

at www.gossenmetrawatt.com

by entering the search term

WEEE.

!

Page 6

6 GMC-I Gossen-Metrawatt GmbH

3 Initial Start-Up

Connection

Connect the test instrument’s mains plug to

the mains power outlet.

MINITEST 3P⏐M

ASTER:

The instrument can be connected to all customary CEE sockets by means of the mains

connection adapter (standard equipment).

Switching the MINITEST 3P⏐M

ASTER On:

The instrument is switched on via the 3-pole

miniature circuit breaker (m.c.b.).

Switching the MINITEST⏐MASTER⏐PRO⏐BASE On

The test instrument can be switched on with

the green power-on switch located on the

integrated residual current protective device.

It can be switched back off again with the

blue test key.

Switching the MINITEST⏐B

ASE On

The test instrument is switched on and off

with the help of the mains plug.

4 Test Sequence

Testing for electrical safety always begins

with a visual inspection. The measurements

are then conducted in the order in which

they appear next to the selector switch on

the test instrument, from top to bottom.

For each type of measurement, the test

instrument evaluates the measured values

and indicates whether or not limit values in

accordance with DIN VDE 0701 or 0702

have been adhered to by means of an LED

array.

The number and type of required measurements are determined according to the classification of the device under test:

Indication Meaning

Green

LED

The measured value is better than the

strictest limit value.

Red

LED

The measured value is worse than the most

lenient limit value.

Yellow

LED

The limit value is in-between the strictest

and the most lenient limit values. Whether

or not the DUT passes testing depends upon

the device’s classification.

Evaluation should be conducted by a

qualified electrician.

Page 7

GMC-I Gossen-Metrawatt GmbH 7

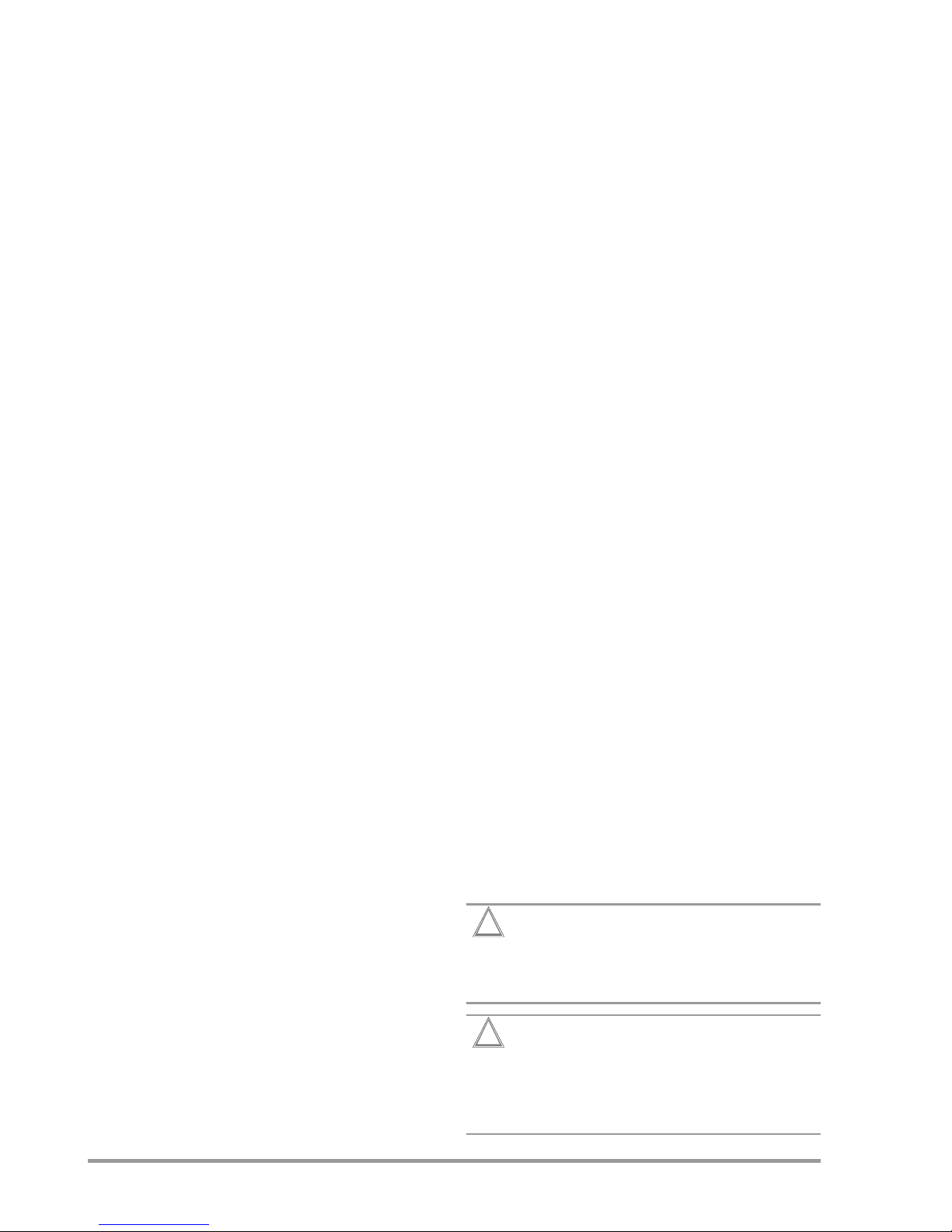

* MINITEST 3P⏐MASTER only

Device Under Test

Connect DUT to the test socket. Connect DUT to mains outlet.

– Switch the DUT on.

Protective

conductor

resistance

Probe socket

PE/ I

C

Protective

conductor

resistance

Permanent,

probe socket

PE/ I

C

Insulation

resistance

No probe

required

Insulation

resistance

Probe

socket R

ISO

Differential

current

No probe

required

Contact current

Probe socket

PE/ I

C

Safety class I

Earth contact plug

Without

exposed parts

✘✘

✘

Test with the

mains plug

poled in both

directions.

With exposed

parts, not

connected

with PE

✘

✘

Test with the

mains plug

poled in both

directions.

✘

Test with the

mains plug

poled in both

directions.

CEE plug *

Without exposed parts

✘✘✘

With exposed

parts, not

connected

with PE

✘✘✘✘

Permanently

connected DUT

✘

✘

Safety class II

With European

earth contact plug

✘

✘

Test with the

mains plug

poled in both

directions.

Use of mains outlet number depending on the mains terminal

(all test sockets as well as mains outlets No. 8 and 19 can always be used

regardless of which mains adapters are used)

Mains outlet number

20 21 22

Mains connection with mains plug 3P+N+PE 32 A

✘✘✘

Connection with earthing contact plug adapter to CEE coupling 3P+N+PE 32 A-6h

–

✘

max. 16 A

–

Connection with adapter for plug 1P+N+PE 16 A to CEE coupling 3P+N+PE 32 A-6h

–

✘

max. 16 A

–

Connection with adapter for plug 3P+N+PE 16 A to CEE coupling 3P+N+PE 32 A-6h

✘

✘

max. 16 A✘max. 16 A

Connection with adapter for plug 1P+N+PE 32 A to CEE coupling 3P+N+PE 32 A-6h

– ✘ –

Page 8

8 GMC-I Gossen-Metrawatt GmbH

5 Descriptions of Individual Measurements

5.1 Measurements at the Test Outlet(s)

Protective Conductor Resistance, R

PE

SOCKET

The probe must be plugged into the

PROBE PE/I

C

socket for the measurement of

protective conductor resistance. Measurement is performed between the protective

conductor terminal at the test outlet and the

PROBE PE/I

C

socket.

Protective Conductor Resistance, R

PE

FIX

This measurement is used for testing the

protective conductor at permanently connected devices. The test instrument must be

connected to the same supply circuit as the

device under test during measurement.

Attention!

!

Good test results may be obtained

with parallel ground connections,

although the protective conductor is

interrupted.

The probe must be plugged into the

PROBE PE/IC socket for the measurement of

protective conductor resistance. Measurement is performed between the protective

conductor terminal at the mains connection

and the PROBE PE/I

C

socket.

Testing is performed up through a resistance

value of approximately 1.3 Ω with automatic

polarity reversal.

The earthing contact resistance and the test

current are indicated on the LCD (not for

MINITEST⏐BASE).

Checking the Zero Point and the Fuse

The zero point and the internal fuse can be

checked by inserting the plug attached to

the test probe cable into the PROBE R

ISO

socket and the tip of the test probe into the

PROBE PE/IC socket with the selector switch in

the R

PE

SOCKET or RPE FIX setting. The dis-

played value should not exceed 100 mΩ.

Note: If a current of 0 mA is indicated, the

fuse is usually defective. Test and replace it,

if required.

Attention!

!

It is absolutely essential to insert the

tip of the test probe into the

PROBE PE/IC socket for this test!

Attention!

!

Use only the probe cable which is

included with the test instrument. If a

different probe cable is used:

– The measured value may be

distorted.

– The test instrument may be

damaged.

– Malfunctioning may occur.

Insulation Resistance, R

ISO

Various test types are provided for the measurement of insulation resistance.

The test type is selected automatically when

the test probe is plugged into the probe

connector socket (10).

The original test probe cable must be used

in order to take advantage of this function.

Test type switching cannot be assured if

other test probe cables are used.

• For safety class I DUTs without exposed

conductive parts:

Test insulation between L/N and PE at

the test outlet.

The test probe cable may not be plugged into

the PROBE R

ISO

socket for this test!

• For safety class II DUTs, or for safety

class I DUTs with exposed conductive

parts which are not connected to the

protective conductor:

Test between L/N at the test outlet and

the PROBE R

ISO

socket.

The test probe must be plugged into the

PROBE R

ISO

socket for this test!

The insulation resistance and the test voltage are indicated on the LCD (not for MINIT-

EST⏐BASE).

Page 9

GMC-I Gossen-Metrawatt GmbH 9

Discharging the Device Under Test

The device under test is automatically

discharged when the insulation test is

switched off (turn switch to R

PE

or ID).

The LEDs light up rapidly, one after the other

from left to right, during discharging.

Furthermore, residual voltage appears at the

display (not for MINITEST⏐B

ASE).

Leave the DUT connected to the test

instrument during the discharging sequence.

5.2 Measurements at the Mains Outlet(s)

Differential current and/or contact current

measurements are performed at the mains

outlet(s). The DUT must be unplugged, and

plugged back in again. In the case of mains

plugs which are not polarity protected, testing

must be conducted with the mains plug poled in

both directions.

Attention!

!

The mains outlet(s) always conduct(s) voltage as soon as the test instrument has been switched on.

Note!

Make sure that the device under test

is switched off before plugging it into

the mains outlet.

The device under test must be switched on during

testing.

The device under test must be switched

back off before it is unplugged from the

mains outlet.

Differential Current Measurement, I

D

Total current from all phase conductors is

measured during differential current measurement. For safety class I devices, this

corresponds to the amount of current which

is conducted by the protective conductor.

Differential current is displayed in mA at the

LCD (not for MINITEST⏐BASE).

Evaluating the Measured Values

Measured values of less than 0.5 mA are

indicated by means of a green LED.

Measured values of greater than 3.5 mA are

indicated by means of a red LED. These

devices may be dangerous, however, for

example for 3-phase current devices, there may

be higher admissible limit values of e.g. 1 mA per

kW up to 10 mA, depending on the manufacturer’s specifications. These cases are all indicated with the red LED. Evaluation must be

conducted by a qualified electrician in this

case.

Measured values of between 0.5 and 3.5 mA

are indicated by means of a yellow LED. An

evaluation of electrical safety should be conducted by a qualified electrician in this case.

Contact Current Measurement, I

C

When measuring contact current, current is

measured which is conducted via the probe

at the PROBE PE/I

C

socket to the protective

conductor terminal at the device under test.

Evaluating the Measured Values

Measured values of less than 0.25 mA are

indicated by means of a green LED. There is

no danger in touching these parts.

Measured values of greater than 0.5 mA are

indicated by means of a red LED. Devices

which demonstrate these values are

dangerous because persons who touch

them are startled, which may result in

consequential accidents.

These devices may not be placed back into

service.

Measured values of between 0.25 and

0.5 mA are indicated by means of a yellow

LED. Current within this range is not

dangerous, but the threshold of perception

is approximately 0.1 mA depending upon

sensitivity, which causes mild tingling. This is

unpleasant for some people, for which

reason devices of this sort should be

examined.

Self-Test

A device self-test is conducted when the

selector switch is turned to the LED Test

position.

Testing is indicated by the LEDs which light

up one after the other from left to right.

Page 10

10 GMC-I Gossen-Metrawatt GmbH

6 Report Functions

Depending on the selected operating mode,

the measured values and the result of each

test can be transmitted to a PC via USB port

for onward processing or stored to the internal device memory. The transmission or

storage process of measured values is indicated by all LEDs lighting briefly up from

right to left.

Selection of Operating Mode

The corresponding PC analysis software

programs have to be installed and started

for the three different operating modes in

order to receive data, see table above.

Press key „S“ (6) when switching on the

instrument to set the requested operating

mode. The following operating modes are

shown in subsequent order:

• „Transmission mode“, siehe chapter 6.1

• „Permanent transmission“, see chapter 6.2

• „Memory mode“, see chapter 6.3

The operating mode which is indicated when

releasing key „S“ (6) is selected. This setting

remains active even after switching off the

instrument.

6.1 Transmission Mode (Transmission only

while Program MINITEST is Active)

To transmit the current measured value, key

„S“ must be pressed in operating mode

„Transmission mode“ .

6.2 Permanent Transmission (Transmission

only while Program MINITEST is Active)

If operating mode „Permanent transmission“

is activated, each measured value is transmitted via the USB port.

6.3

Memory Mode (Read-Out only with

Program MINI

TEST⏐MASTER

)

In the test instruments MINITEST⏐MASTER or

MINITEST 3P⏐MASTER a maximum of 2,047

DUTs with 10 measured values per DUT can

be stored. If an attempt is made to store

more than 10 measured values for one DUT,

the additional values are ignored and the red

LED lights up briefly.

6.3.1 Activate Memory Menu

After selecting memory mode (see above) you

have to set the rotary switch to position

Gerä-

teselbsttest/Speichermenü (

Self-test/Memory

Menu)

. Activate the memory menu by pressing

key „S“ (6). The following is shown on the LCD:

** MEMORY MENU ** SELECTION -> SWITCH.

You may now select the requested memory

function via the rotary switch.

6.3.2 Selecting Memory Function

➭ Key NUM – > Menu DUT NUM –

The number of the current memory location

is reduced by one each time key „S“ (6) is

pressed. The lowest possible value is „1“.

The letter „D“ in front of the number signifies

that data are already available for this memory location.

➭ Key NUM + > Menu DUT NUM+

The number of the current memory location

is increased by one each time key „S“ (6) is

pressed. The highest possible value is

„2,047“, i.e. a maximum of 2,047 DUTs can

be tested. The letter „D“ in front of the number signifies that data are already available

for this memory location.

➭ Key DATA > Menu MEASURED VALUE NO.

In this switch position all measured values of

a DUT are shown in a consecutive, numerical sequence in the order of their recording.

Operating mode selected

at the test instrument

MINITEST 3P⏐MASTER

MINITEST⏐MASTER

MINITEST⏐PRO

PC

analysis

software

depending on the

operating

mode

Transmission mode

(Transmission of individual

measured values)

✘✘✘

MINITEST

Permanent transmission

(Continuous transmission of

measured values)

✘✘✘

MINITEST

Memory mode

(Internal measured value

memory)

✘✘

—MiniTEST

Master

Page 11

GMC-I Gossen-Metrawatt GmbH 11

➭ Key CLR > Menu DUT DEL ?

Pressing key „S“ (6) deletes the current

memory location, i.e. all data for the selected

DUT. As a preventive measure against accidental deletion you have to keep key „S“ (6)

pressed for about half a second before the

deletion process is started. The red LED

lights up during the deletion.

➭

Key CLR ALL > Menu DELETE MEMORY ?

Pressing key „S“ (6) deletes the entire device

memory. As a preventive measure against

accidental deletion you have to keep key „S“

(6) pressed for about 1 to 2 seconds before

the deletion process is started. The red LED

lights up during the deletion.

6.3.3 Exiting the Memory Menu

Set the rotary switch to position Geräteselbsttest/Speichermenü (Self-test/Memory

Menu) and press key „S“ (6) to exit the memory menu.

In operating mode „Memory mode“ the last

measured value indicated after a measurement is shown when pressing key „S“ (6).

The storage operation - as well as transmision of the values via USB port - is indicated

by a flickering of the LEDs. If more than 10

values are stored for one DUT, the red LED

lights up additionally for approx. half a second, thus signalling that it was not possible

to store the measured values.

6.3.4 Reading out Stored Measured Values

at the PC

Prerequisite: The test instrument may not be

set to Geräteselbsttest/Speichermenü

(Memory Menu or Self-test).

The stored measured values can be transmitted from the test instrument to a PC via

the analysis software and the USB port

where they can be evaluated and documented.

6.3.5 Barcode Scanner Function

Connect the barcode scanner to jack 23.

Only barcode scanners by GMC-I Gossen-

Metrawatt GmbH may be used, e. g. type

B3261.

Barcode scanners with USB port are not

suitable.

In function „NUM+“ and „NUM-“ a text comprising a maximum of 24 characters which

has been scanned with the barcode scanner

is recorded as a description of the DUT. The

text is shown in the second line of the LCD

and stored.

6.3.6 Switching Off Safely

You have to exit the memory menu before

switching off the test instrument or disconnecting it from the mains. Set the rotary

switch (4) to position Geräteselbsttest/Speichermenü (Self-test/Memory Menu) and

press key „S“ (6) for approx. half a second.

7 PC Analysis Software Programs

Two PC software programs for the adoption

and evaluation of data with the following features are available on the attached CD ROM:

7.1 Program „MINITEST“

• Automatic adoption of measured values:

Start test, display measurement results,

save results

• Customer data management

• Other functions:

– Selection between

VDE 0701 and 0702

– Establishing the test cycle

– Automatic adoption of the contractor’s

data in the test report

• Transmit measurement results to a word

processing program

7.2 Program „MiniTEST Master“

• Read-out of device memory

• Presentation of measurement data in

tabular form

• Exporting the table to Excel

• Preparation of test reports

Page 12

12 GMC-I Gossen-Metrawatt GmbH

8 Technical Data

*With automatic polarity reversal

Intrinsic Error and Measuring Error

Influencing Quantities and Influence Error

Measured Quantity Measuring Range Reso-

lution

U

no-load

R

i

I

K

I

N

Protective conductor resistance 0 … 1.30 Ω

1.0 … 99.9 Ω

10 mΩ

100 m

Ω

< 5 V −

< 5 V −

> 200 mA *

Insulation resistance 0 … 9.99 MΩ 10 kΩ 520 V − approx.

50 kΩ

< 3.5 mA > 1 mA

Contact current measurement

(verification of absence of voltage)

0 … 9.99 mA ∼ 10 μA1 kΩ

Differential current

MINITEST⏐M

ASTER⏐PRO⏐BASE

0.1 . . . 9.99 mA~

10 μA

Differential current

MINITEST 3P⏐MASTER

0.2 . . . 9.99 mA~ 10 μA

Measured Quantity Intrinsic Error Measuring Error

Protective conductor resistance ± (5% rdg. + 4 d) ± (10% rdg. + 6 d)

Insulation resistance ± (7% rdg. + 2 d) ± (10% rdg. + 5 d)

Contact current measurement

(verification of absence of voltage)

± (5% rdg. + 4 d) ± (10% rdg. + 5 d)

Differential current

MINITEST⏐M

ASTER⏐PRO⏐BASE

± (5% rdg. + 6 d) ± (10% rdg. + 6 d)

Differential current

MINITEST 3P⏐M

ASTER

± (5% rdg. + 10 d) ± (10 % rdg. + 10 d)

Influencing Quantity /

Sphere of Influence

Designation per

DIN VDE 0404

Influence Error

± … % of Measured Value

Change of position E1 —

Change to test equipment supply

voltage

E2 2.5

Temperature fluctuation

E3

Specified influence error valid starting

with

temperature changes as of 10 K:

0 … 21° C and 25 … 40° C 1 for protective conductor resistance

0.5 for all other measuring ranges

Amount of current at DUT E4 2.5

Low frequency magnetic fields E5 2.5

DUT impedance E6 2.5

Capacitance during insulation

measurement

E7

2.5

Waveshape of measured current

E8

49 … 51 Hz 2 with capacitive load

(for equivalent leakage current)

45 … 60 Hz 1 (for contact current)

2.5 for all other measuring ranges

Page 13

GMC-I Gossen-Metrawatt GmbH 13

Reference Conditions

Ambient temperature

+23° C ±2K

Relative humidity 40 ... 60%

Line voltage

MINITEST⏐M

ASTER⏐PRO⏐BASE: 230 V ±1%

MINITEST 3P⏐M

ASTER: 230 V/400 V ±1%

Measured quantity

frequency 50 Hz ±0.2%

Measured quantity

waveshape Sine (deviation

between RMS and

rectified value:

±0.5%)

Ambient Conditions

Operating temp. 0 to + 40° C

Storage temp. range –20 to +70° C

Humidity Max.75%, no con-

densation allowed

Elevation to 2000 m

Power Supply

Line voltage

MINITEST

⏐MASTER⏐PRO⏐BASE

:

230 V 50 Hz

MINITEST 3P

⏐MASTER: 230V/400V50Hz

Throughput rating

MINITEST

⏐MASTER⏐PRO⏐BASE

:

max. 3700 VA

MINITEST 3P⏐MASTER: max. 38.4 kVA

depending upon load at the mains outlet

Electrical Safety

Safety class I

Nominal line voltage 230 V

Tes t v ol ta ge

Mains + PE (mains) to

test outlet,

probe socket PE/IC or

R

ISO

: 1.5 kV∼

Mains to PE (mains):

3 kV

∼

Measuring category 300 V CAT II

Contamination degree 2

Fuse FF0,315H1000V

or FF0,315H500V

or FF0,315H250V

MINITEST 3P⏐M

ASTER

only:

3 x C16A

Residual current

protective device

(

MINI

TEST

⏐MASTER⏐PRO

)

30 mA with

undervoltage trigger

and inhibiting of

automatic restart

Display and Indicating Devices

LCD (not for MINITEST⏐B

ASE)

Dot matrix display, two lines of 20 characters

each

LEDs

9 LEDs for indicating compliance with or

violation of limit values:

1 red, 7 yellow and 1 green

Mechanical Design

Dimensions/weight

MINITEST

⏐MASTER⏐PRO⏐BASE:

W x H x D: 200 mm x 1mm x 77 mm

(without integrated outlets, grommets and

rotary switch)

Weight approx. 1.5 kg

MINITEST 3P⏐M

ASTER

W x H x D: 350 mm x 160 mm x 125 mm

(without surface-type outlets, grommets, circuit breaker and rotary switch)

(overall dimensions without cables)

Weight approx. 3.3 kg

Protection housing IP 44,

terminals IP 20

Table excerpt regarding significance of the

IP code

s

Electromagnetic Compatibility (EMC)

Generic Standard EN 61326-1: 1997

EN 61326: 1997/A1:

1998

IP XY

(1

st

digit X)

Protection

against foreign

object entry

IP XY

(2nd

digit Y)

Protection

against the

penetration of

water

2 ≥ 12.5 mm dia.

0 not protected

4 ≥ 1.0 mm dia.

4 splashing water

Page 14

14 GMC-I Gossen-Metrawatt GmbH

9 Maintenance

9.1 Housing

No special maintenance is required for the

housing. Keep outside surfaces clean. Use a

slightly dampened cloth for cleaning. Avoid

the use of cleansers, abrasives or solvents.

9.2 Replacing the Fuse

Instructions on checking the zero point and

fuse are given in chapter 5.1.

Attention!

!

Disconnect the instrument from the

measuring circuit before removing

the fuse for replacement!

Eliminate the cause of the overload after the

fuse has blown before putting the instrument

back into service!

The fuse holder is situated between the

mains power cable and the probe connector

socket. The characteristic value of the fuse

is indicated on the front plate or in chapter 8.

Attention!

!

Please make absolutely sure that

only the specified fuse is inserted!

If fuses with other blowing characteristics, other current ratings or other

breaking capacities are used, the operator is placed in danger, and protective diodes, resistors and other

components may be damaged.

The use of mended fuses or short-circuiting

the fuse holder is prohibited.

The defective fuse can be disposed of with

the trash.

9.3 Calibration Intervals

According to DIN VDE 0702, measuring

instruments used for periodic testing must

be tested and calibrated in accordance with

the manufacturer’s specifications on a

regular basis. Depending upon usage, the

manufacturer recommends an interval of 1

to 3 years for this test instrument.

Note:

These tests can be performed on-site with

the SECU-cal 10 calibration adapter accessory.

9.4 Return and Environmentally Sound Disposal

The test instrument is a category 9 product

(monitoring and control instrument) in accordance with ElektroG (German electrical and

electronic device law). This device is not

subject to the RoHS directive.

We identify our electrical and electronic devices (as of August 2005)

in accordance with WEEE 2002/

96/EC and ElektroG with the symbol shown to the right per

DIN EN 50419.

These devices may not be disposed of with

the trash.

Please contact our service department

regarding the return of old devices (see

chapter 11).

Page 15

GMC-I Gossen-Metrawatt GmbH 15

10 Accessories

10.1 Standard Equipment

Please refer to page 3 for the standard

equipment accessories.

CD ROM (not for MINITEST⏐B

ASE)

System requirements

MS WINDOWS XP SP2

➭ USB port 1.1 or 2.0.

10.2 Order Information for Available

Accessories

The accessories available for your measuring instrument are regularly examined for

compliance with the currently applicable

safety standards and are extended to include new application fields, if necessary.

The suitable, up-to-date accessories for

your measuring instrument are shown on our

website www.gossenmetrawatt.com with

the associated photo, order number, description and, depending on the scope of

the accessories, datasheet and operating instructions.

Description Type Article

number

Probe for measuring protective conductor

resistance, e.g. at rotating devices under

test

Brush

probe Z745G

Calibration adapter for test instruments per

DIN VDE 0701/0702/0751 (max. 200 mA

)

SECUcal 10 Z715A

Test adapter for electrical devices and

extension cables with CEE plug-andsocket devices

VL2 E Z745W

Barcode scanner

B3261

GTZ

3261

000

R0001

Barcode and label printer including

software

Z721D Z721D

Label set for printer Z721D

(quantity x width: 3x24/1x18/1x9mm,

each 8 m long)

Z722D Z722D

Label set for printer Z721D (5 ribbons,

each 18 mm wide and 8 m long)

Z722E Z722E

PC software for the generation of reports

and lists as supplement to MS-Word/EXCEL (language version German/English/

French/Finnish/Polish (Exception: EXCEL

only in German/English)

PC.docWORD

™/EXCEL™ Z714A

Case for MINITEST⏐MASTER,

MINITEST⏐PRO

and MINITEST⏐BASE

Case Z740B

Universal carrying pouch for

MINITEST⏐MASTER,

MINITEST⏐PRO

and MINITEST⏐BASE

F2000 Z700D

Universal carrying pouch big

for MINITEST 3P⏐MASTER

F2010 Z700F

Page 16

Edited in Germany • Subject to change without notice • A pdf version is available on the Internet

GMC-I Gossen-Metrawatt GmbH

Thomas-Mann-Str. 16-20

90471 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail info@gossenmetrawatt.com

www.gossenmetrawatt.com

11 Repair and Replacement Parts Service

DKD Calibration Laboratory* and Rental

Instrument Service

If required please contact:

GMC-I Gossen-Metrawatt GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nürnberg · Germany

Phone: +49 911 8602-0

Fax: +49 911 8602-253

E-mail

service@gossenmetrawatt.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service in other countries.

*

Calibration Laboratory for Measured

Electrical Quantities: DKD – K – 19701,

accredited per DIN EN ISO/IEC 17025:

2005

Accredited quantities: direct voltage, direct current

value, direct current resistance, alternating voltage,

alternating current value, AC active power, AC apparent

power, DC power, capacitance, frequency and temperature

Competent Partner

GMC-I Gossen-Metrawatt GmbH is certified

in accordance with DIN EN ISO 9001:2000.

Our calibration laboratory is accredited per

DIN EN ISO/IEC 17025 by the PhysikalischTechnischen Bundesanstalt (German

Federal Institute of Physics and Metrology)

and the Deutscher Kalibrierdienst (German

Calibration Service) under registration number DKD–K–19701.

We offer a complete range of expertise in the

field of metrology: from test reports and fac-

tory calibration certificates, right on up to DKD

calibration certificates.

Our spectrum of offerings is rounded out

with free test equipment management.

Our service department includes an on-site

DKD calibration bench. If errors are discovered

during calibration, our specialized personnel

are capable of completing repairs using

original replacement parts.

As a full service calibration lab, we can calibrate instruments from other manufacturers

as well.

12 Product Support

If required please contact:

GMC-I Gossen-Metrawatt GmbH

Product Support Hotline

Phone: +49 911 8602-112

Fax: +49 911 8602-709

E-mail

support@gossenmetrawatt.com

Loading...

Loading...