Page 1

Operating Instructions

METRACELL BT PRO

Portable Battery Tester

3-447-058-03

1/4.20

Page 2

METRACELL BT PRO GMC-I Messtechnik GmbH

Table of Contents

1 Safety Precautions..............................................................1

2 Important Information .........................................................2

2.1 Intended Use /

Use for Intended Purpose ................................................2

2.2 Use for Other than Intended Purpose...............................2

2.3 Liability and Guarantee ....................................................2

2.4 Opening the Instrument / Repairs ....................................2

3 Documentation....................................................................2

3.1 Identifiers .........................................................................2

3.2 Definition of Terms...........................................................2

4 Getting Started....................................................................3

5 The Instrument....................................................................3

5.1 Scope of Delivery............................................................. 3

5.2 Optional Accessories .......................................................3

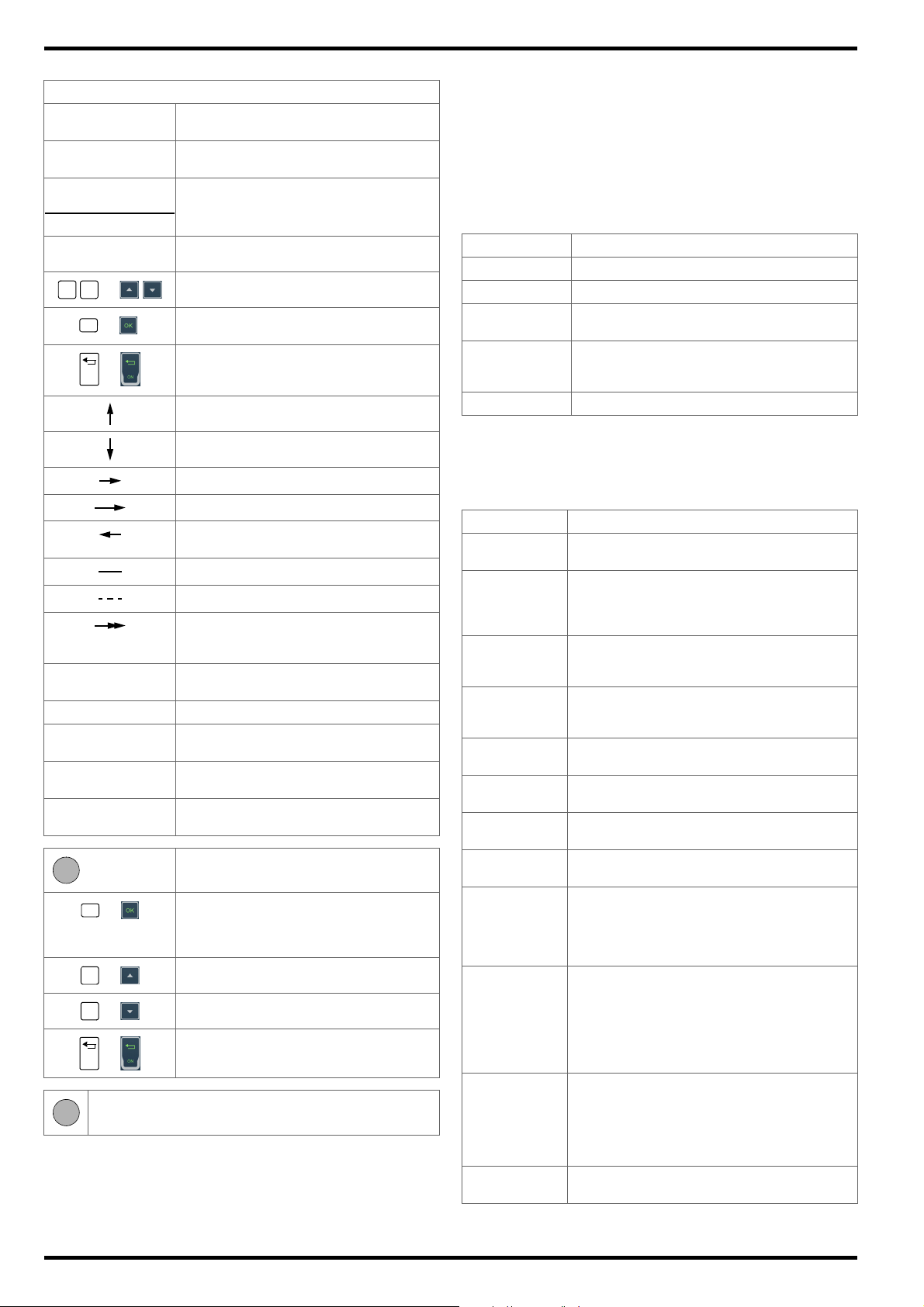

5.3 Instrument Overview ........................................................3

5.4 Relevant Standards .........................................................4

5.5 Measurement Inputs........................................................5

5.6 LCD Display.....................................................................5

5.7 Function Keys / Navigation ..............................................5

5.8 RFID Reader ....................................................................5

5.9 Attachment Options.........................................................5

5.10 Technical Data.................................................................6

5.11 Characteristic Values .......................................................6

6 Operation ............................................................................7

6.1 Power Supply (rechargeable batteries).............................7

6.2 Switching the Instrument On/Off ......................................7

6.3 System Settings...............................................................8

6.4 Establishing and Terminating Wireless Connections ......... 8

6.5 Testing the RFID Reader..................................................9

7 Menu and Functions .........................................................10

7.1 Overview........................................................................10

7.2 Display Menu.................................................................12

7.3 Measurement Menu.......................................................12

7.4 Data Menu.....................................................................15

7.5 The SETTINGS Menu.....................................................16

7.6 INFO Menu ....................................................................17

10 Performing Measurements ............................................... 30

10.1 General Information........................................................30

10.2 Multimeter Measurements..............................................32

10.3 Charge Retention Measurement.....................................33

10.4 Discharge Measurement ................................................35

10.5 Charge Measurement ....................................................37

10.6 Resistance Measurement...............................................39

10.7 Temperature Measurement............................................41

10.8 Connector Measurement ...............................................43

10.9 Interval U Measurement .................................................45

10.10 Interval U+I Measurement ..............................................47

10.11 DMA35 Measurement (IrDA)...........................................49

10.12 DMA35 Measurement (BT).............................................49

11 Viewing, Editing, Transferring and Evaluating Measured

Values ............................................................................... 50

11.1 Viewing Measured Values / Measured Value Details at the

Instrument......................................................................50

11.2 Viewing Measured Value Evaluations at the Instrument ..50

11.3 Excluding a Measurement from Transmission (deactivate

measurement)................................................................50

11.4 Deleting Measured Values..............................................50

11.5 Saving Measured Values to a PC (data backup).............50

12 Maintenance ..................................................................... 52

12.1 Firmware Update ...........................................................52

12.2 Housing and Display ......................................................52

12.3 Measurement Cables .....................................................52

12.4 Fuse...............................................................................53

12.5 Accessories ...................................................................53

13 Service and Support .........................................................53

13.1 Product Support ............................................................53

13.2 Repair and Replacement Parts Service

Calibration Center * and Rental Instrument Service ........53

14 CE Declaration ..................................................................54

15 Returns and Environmentally Sound Disposal.................. 54

8 “BT PRO Manager” PC Software.......................................18

8.1 Installation, Launching the Program and Update............18

8.2 Overview........................................................................18

8.3 Defining the Data(base) Storage Location ......................18

8.4 Managing User Accounts............................................... 19

8.5 Basic Setting: Specifying the Temperature Unit of

Measure ........................................................................20

8.6 Creating and Managing the Battery Database................ 20

8.7 Transferring the Battery Database to the Battery Tester . 23

8.8 Assigning RFID Tags to Batteries (DUTs)........................24

8.9 Importing Measurement Data......................................... 24

8.10 Viewing Measurement Series and Creating Measurement

Evaluations (reports).......................................................25

9 Preparing Measurements..................................................28

9.1 General Information (procedure).....................................28

9.2 Switching Polarity On or Off ...........................................28

9.3 Connecting Measuring Accessories ...............................28

Page 3

GMC-I Messtechnik GmbH METRACELL BT PRO

1 Safety Precautions

Observe this documentation, in particular all included safety information, in order to protect yourself and others from injury, and to

prevent damage to the instrument.

• Carefully and completely read and adhere to these operating

instructions, as well as the instrument’s condensed operating

instructions.

The respective documents can be found at

http://www.gossenmetrawatt.com. Retain these documents

for future reference.

• Use only the specified accessories with the instrument!

• Carefully and completely read and adhere to the product documentation for optional accessories. Retain these documents

for future reference.

• Tests may only be performed by a qualified electrician, or

under the supervision and direction of a qualified electrician.

The user must be instructed by a qualified electrician concerning performance and evaluation of the tests.

• Wear suitable and appropriate personal protective equipment

(PPE) whenever working with the instrument.

• Implement adequate measures for protection against electrostatic discharge (ESD).

• Observe and comply with all applicable DIN, VDE, EN, IEC and

ANSI guidelines. Inform yourself concerning the operating

company’s specifications and guidelines, as well as those of

the respective battery manufacturers.

• Batteries are electrochemical components with very high

short-circuit currents. Avoid short-circuits which endanger

yourself as a user, the entire system or operating personnel.

• If the instrument doesn’t function flawlessly, remove it from

operation and secure it against inadvertent use.

• The instrument may only be used as long as it’s in good working order.

Inspect the housing before use. Pay particular attention to any

possible cracks and the insulation around the sockets.

Damaged components must be replaced immediately.

• Accessories and cables may only be used as long as they’re

fully intact.

Inspect all cables and accessories before use. Pay particular

attention to damage, broken insulation or kinked cables.

Damaged components must be replaced immediately.

• Do not use the instrument after long periods of storage under

unfavorable conditions (e.g. humidity, dust or extreme temperature).

• Do not use the instrument after extraordinary stressing due to

transport.

• Do not use the instrument in potentially explosive atmospheres.

• Use the instrument only within the specified ambient conditions.

• Use the instrument only in accordance with the specified protection class (IP code).

• The instrument must not be exposed to direct sunlight.

• The instrument and the included accessories may only be

used for the measurements described in this manual.

• Only use accessories and the charger which are included with

the battery tester or listed as optional accessories.

• Only use the instrument and the accessories within the specified measuring category.

• The measurement cables and all external cabling must not

exceed an overall length of 1 meter.

• Plugging in the measurement cables and the power pack must

not necessitate any undue force.

• Connect the ground wire before connecting the voltage conducting cable, and disconnect the voltage conducting cable

before disconnecting the ground wire.

• Check measurement cable continuity.

• Avoid short circuits due to incorrectly connected measurement

cables.

• Never touch the conductive ends of the alligator clips, the test

probes or the Kelvin probes.

• Ensure that the alligator clips, test probes and Kelvin probes

make good contact.

• Do not move or remove the Kelvin probes during a measurement.

Unwanted sparking may otherwise occur due to test current.

• Do not remove or move the alligator clips, test probes or Kelvin

probes until measurement has been completed. Completion of

measurement is indicated by means of an acoustic acknowledgment.

• Avoid simultaneously contacting the battery and the frame or

hardware, which may be grounded.

• The battery tester is equipped with a transponder module.

Determine whether or not use of the 125 kHz frequency is permissible in your country.

• The battery tester is equipped with a Bluetooth

Determine whether or not use of the implemented frequency

range of 2.402 to 2.480 GHz is permissible in your country.

• The input at the P+ measurement jack is equipped with a fuse

link. The instrument may only be used as long as this fuse is in

flawless condition.

A defective fuse may only be replaced by our repair service.

• The instrument only works with inserted batteries.

• The battery charger may only be connected to electrical systems (TN or TT) with a maximum of 230/400 V which comply

with applicable safety regulations (e.g. IEC 60346, VDE 0100)

and are protected with a fuse or circuit breaker with a maximum rating of 16 A.

• Do not use the instrument while the internal batteries are being

charged.

• Do not use the instrument if the battery compartment cover

has been removed.

• Always create a backup copy of your measurement data.

®

module.

1

Page 4

METRACELL BT PRO GMC-I Messtechnik GmbH

Attention!

!

Note

Block

Battery

System

2 Important Information

Please read this important information!

2.1 Intended Use / Use for Intended Purpose

Periodic testing and well-organized maintenance are necessary in

order to assure the availability of stationary battery systems.

The METRACELL BT PRO is a multifunctional instrument for testing batteries and battery blocks (referred to below as “devices

under test” or “DUTs”). It can be used to determine the current status of a DUT and pinpoint concealed defects. The battery tester is

used primarily for testing DUTs in stationary battery systems.

The battery tester stores measured values internally. All recorded

measured values can be viewed on site. Individual acquired values

can be conveniently re-measured if necessary. Management of

devices under test, as well as evaluation and backup of the measured values, is handled by the included “BT PRO Manager” software. The measured values can also be transferred to an external

computer as a CSV file.

The battery tester is a portable instrument which can be held in the

hand while performing measurements.

Safety of the operator, as well as that of the instrument, is only

assured when it’s used for its intended purpose.

2.2 Use for Other than Intended Purpose

Using the instrument for any purposes other than those described

in the condensed operating instructions or these instrument operating instructions is contrary to use for intended purpose.

2.3 Liability and Guarantee

GMC-I Messtechnik GmbH assumes no liability for property damage, personal injury or consequential damage resulting from

improper or incorrect use of the product, in particular due to failure

to observe the product documentation. Furthermore, all guarantee

claims are rendered null and void in such cases.

Nor does GMC-I Messtechnik GmbH assume any liability for data

loss.

2.4 Opening the Instrument / Repairs

The instrument may only be opened by authorized, trained personnel in order to ensure flawless, safe operation and to assure

that the guarantee isn’t rendered null and void. Even original

replacement parts may only be installed by authorized, trained

personnel.

Unauthorized modifications to the instrument are prohibited.

If it can be ascertained that the battery tester has been opened by

unauthorized personnel, no guarantee claims can be honored by

the manufacturer with regard to personal safety, measuring accuracy, compliance with applicable safety measures or any consequential damages.

3 Documentation

3.1 Identifiers

The following identifiers are used in this documentation:

Identifier Meaning

Safety information that must be complied with

Warning

Important information which must be

Important

Prerequisite A condition etc. which must be fulfilled

1. Procedural step Steps of a procedure which must be

Result Result of a procedural step

• Enumeration

– Enumeration

Figure 1: Caption

Table 1: Description of the content of a table

Footnote

3.2 Definition of Terms

A block is the smallest unit. A group of two or more blocks is

called a battery. For example, this can involve several blocks connected in series (e.g. a traction battery) or a group of batteries

consisting of two or more blocks in a UPS system.

Measurements can be conducted for individual blocks or batteries. From an organizational standpoint, a device under test is

always set up in the battery tester as a battery which includes one

or more blocks which will be measured. And thus if you only want

to measure one block, set up a battery with just one block.

taken into consideration and complied

with

before a given action can be taken

completed in the specified order

Bullet lists

Description of the content of a figure

Comment

2

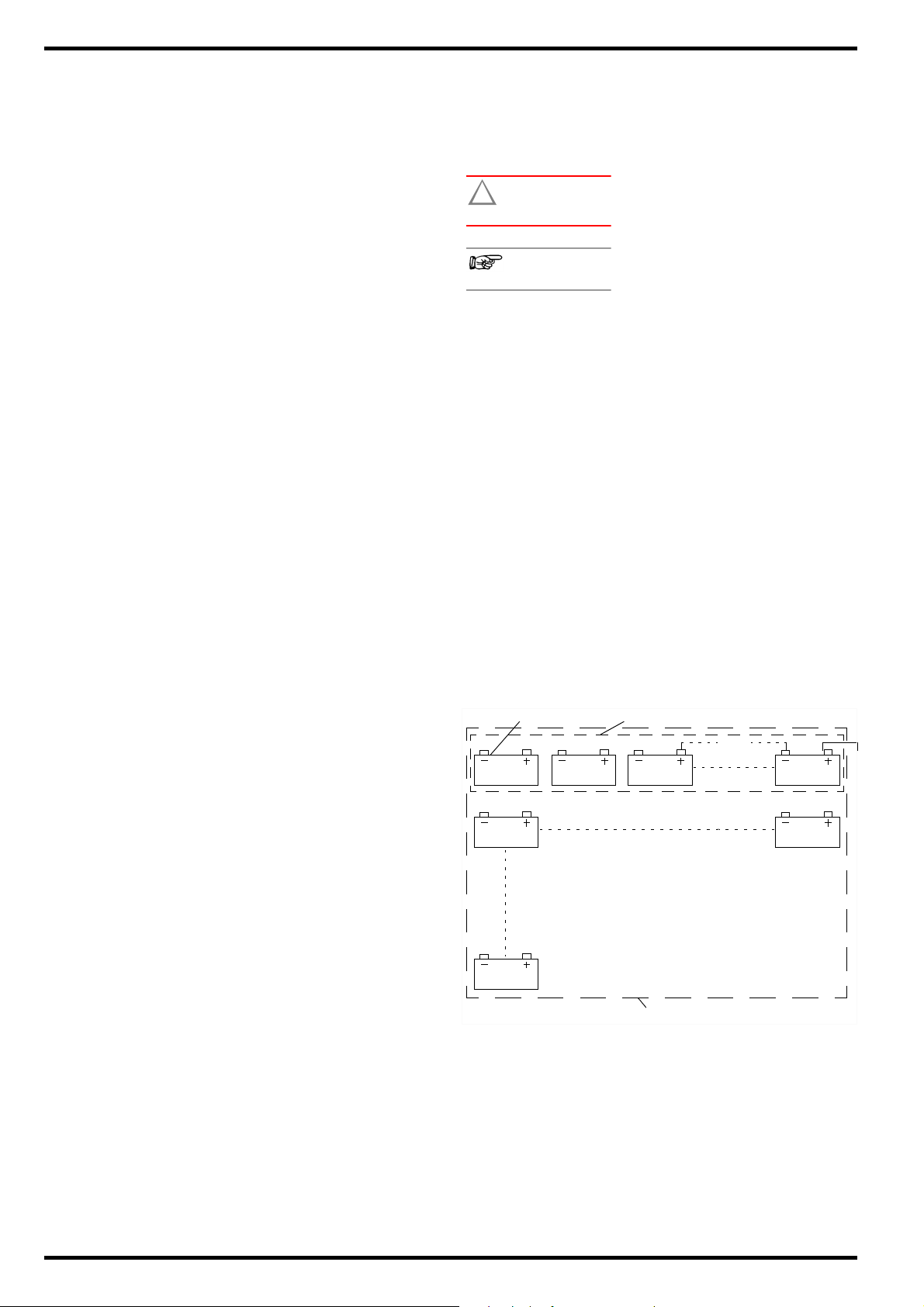

Figure 2: Example – Blocks and Battery within a System

Page 5

GMC-I Messtechnik GmbH METRACELL BT PRO

2

11

3

4

5

6

7

10

9

1

8

4 Getting Started

1. Read and adhere to the product documentation. In particular

observe all safety information in the documentation, on the

instrument and on the packaging.

“Safety Precautions”

“Important Information”

“Documentation”

2. Familiarize yourself with the battery tester.

“The Instrument” 3

“Operation”

“Menu and Functions”

3. Install BT PRO Manager software and familiarize yourself with

the program

4. Create a battery database 20.

5. Complete all required preparation in order to be able to perform measurements

6. Perform measurements

7. Evaluate your measurements “Viewing, Editing, Transferring

and Evaluating Measured Values”

7

18.

1

2

2

10

18.

30.

50.

5 The Instrument

5.1 Scope of Delivery

Please check for completeness.

1 METRACELL BT PRO

1 Rubber holster

4 1.2 V AA batteries

1Power pack

1 Set of multimeter test probes (KS29)

2 Alligator clips (KY95-3)

1 Set of Kelvin probes for 4-wire measurement (Z227D)

1 Carrying strap

1 Carrying case

1BTPRO Manager (battery tester management software)

1 Test report / factory calibration certificate

1 Condensed operating instructions

5.2 Optional Accessories

Some measurements necessitate optional accessories:

– AC/DC current clamp sensor

– CP1800 (Z204A) for measurements up to 1250 ADC or

– CP330 (Z202B) for measurements up to 300 A

– METRATHERM IR BASE temperature sensor (Z680A)

– Spring-loaded contact pins as replacement parts for the Kelvin

probes (Z227F)

Please contact our product support team for further information

on accessories

53.

DC

Values recorded by and stored at the DMA 35 portable density

meter from Anton Paar GmbH can be transferred to the battery

tester. A description of how to use the density meter with the

METRACELL BT PRO is included in these operating instructions

(

30). Please contact Anton Paar GmbH for any further infor-

mation concerning the DMA 35 density meter.

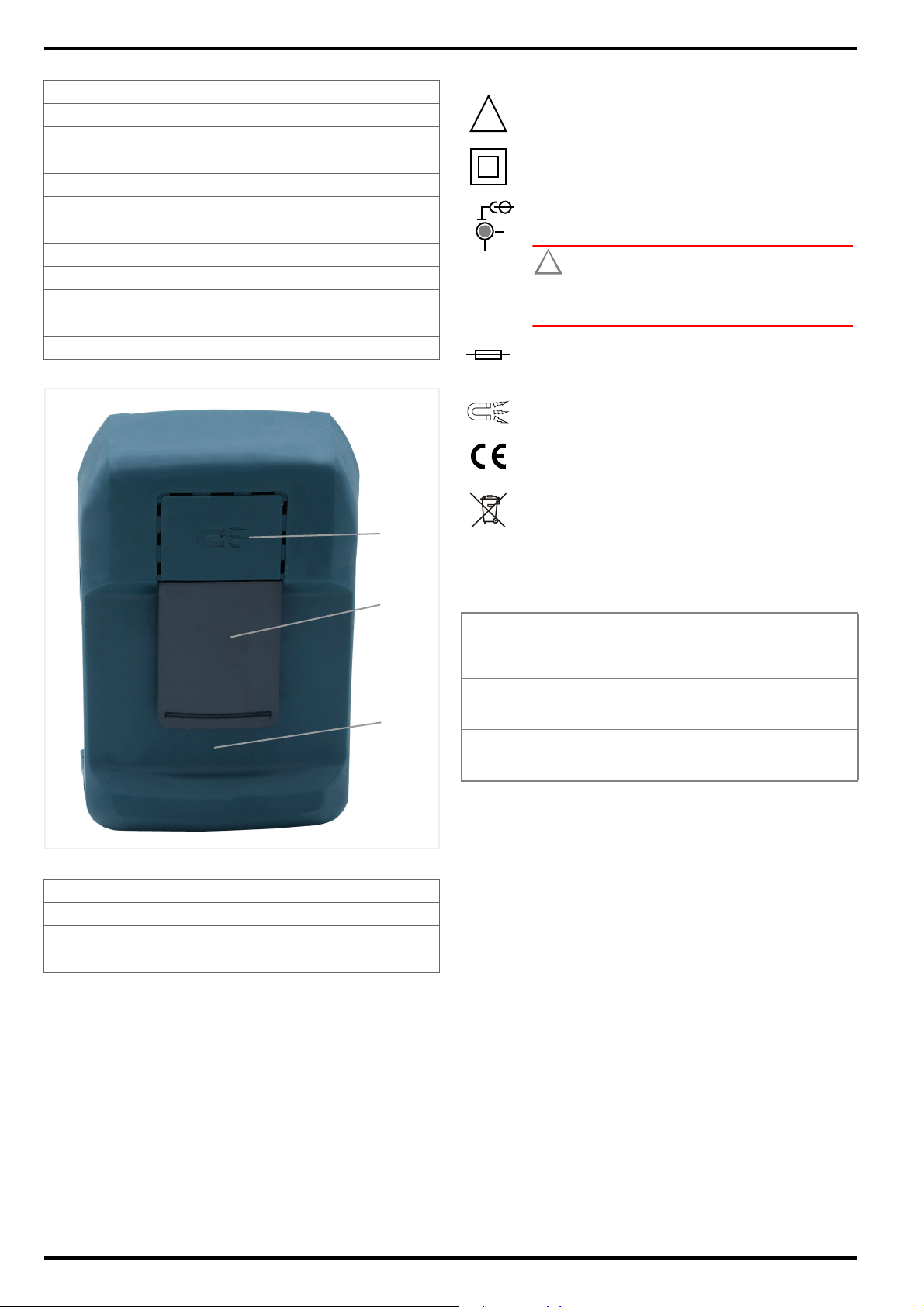

5.3 Instrument Overview

Front

Figure 3: Front Panel

3

Page 6

METRACELL BT PRO GMC-I Messtechnik GmbH

1

2

3

Attention!

!

!

Max.

6VDC

800 m

Symbols on the instrument and the included accessories:

No. Function

1 Rubber holster (removable)

2 Infrared interface

3 Charging socket (charging cable connection)

4 Measurement input S−

5 Measurement input P−/COM

6 Measurement input S+

7 Measurement input P+

8 Carrying strap eyelets

9 Function keys

10 Display

11 RFID reader

Back

IR

Infrared interface location

Warning concerning a point of danger

(attention, observe documentation!)

Double insulation (protection category II)

Charging socket location

( “Instrument Overview”

Attention!

Only rechargeable NiMH batteries may be inserted when the charger is connected.

Fuse

Static magnetic field

European conformity marking

3)

Figure 4: Back of Instrument

No. Function

1 Retaining magnet

2 Retaining clip

3 Battery compartment cover (underneath the holster)

The device may not be disposed of with household

trash “Returns and Environmentally Sound Disposal” 54.

5.4 Relevant Standards

The battery tester has been manufactured and tested in accordance with the following safety regulations:

IEC 61 010-1

EN 61 010-1

VDE 0411-1

EN 60 529

VDE 0470, part 1

DIN EN 61 326-1

VDE 0843-20-1

Safety requirements for electrical equipment

for measurement, control and laboratory use

–

General requirements

Test instruments and test procedures

Degrees of protection provided by enclosures

(IP code)

Electrical equipment for measurement, control and laboratory use – EMC requirements –

Part 1: General requirements

4

Page 7

GMC-I Messtechnik GmbH METRACELL BT PRO

Note

Attention!

!

<Date>

<Time>

BTpro

<Version>

5.5 Measurement Inputs

All measurement inputs are referenced to ground and reference

potential, P–/COM input. The measurement inputs are not electrically isolated from each other.

The measuring ranges depend on the respective measurement

inputs.

Measurement

input

S− Input for measuring DC voltage.

P−/COM Reference potential (ground potential) of all measure-

S+ Measurement input for direct and alternating voltage

P+ Current conducting cable to plus pole during resis-

Function

Measuring range: ±2450.00 mVDCResolution: 0.01 mV

Input impedance: > 10 M

Sensing lead to minus pole during resistance mea-

surement.

ment inputs.

Current conducting cable to minus pole during resistance measurement.

measurements.

Measuring

ranges: ±24.5000 V

±600.000 V

Input impedance: 1.6 M

±300.000 V

Sensing lead to plus pole during resistance measurement.

tance measurement.

Max. 24 V

Maximum test voltage must not exceed

24 V DC at input P+.

The instrument is damaged if this value is

exceed.

600 V CAT III refers to measurement inputs S+, S−

and P−/COM.

DC

Resolution: 0.1 mV

DC

Resolution: 1 mV

DC

Resolution: 10 mV

AC

5.6 LCD Display

All measured values, functions and settings can be observed at

the instrument’s display. As a rule, the display at the LCD panel

appears in two lines. Three and four-line displays are also used in

some cases, for example with measured values.

After switching the battery tester on, the initial display appears

including the instrument’s designation and the version, as well as

date and time.

Figure 5: Figure: Initial Display

After pressing any key while the initial display is shown, the battery

tester is switched to the main menu.

All other displays and information which appear at the instrument

depend on the previously selected function. The currently selected

function is always identified by a preceding arrow ->.

5.7 Function Keys / Navigation

Key Function

“Function” key

– Switch on and off ( 7)

– Press briefly: Return to next higher menu level or

cancel measurement

– Press and hold: End (

measurement

Scroll down key “▼”

Selection of menu items or digits in downward direction.

Scroll up key “▲”

Selection of menu items or digits in upward direction.

“OK” key

– Open menus

– Execute functions

– Confirm entries

– Select digits

– Proper termination of measurements

– Press and hold: repeat measurement (

30) or reactivate ( 30)

31)

5.8 RFID Reader

The display is surrounded by an RFID reader. If individual batteries

are equipped with an RFID tag (transponder), the tag can be

scanned before measurement, thus making it possible to subsequently assign the measurement data to the respective DUT automatically

125 kHz Technology

The RFID reader can only read RFID tags which use a frequency of

125 kHz. This technology offers several advantages:

• As one of the first RFID technologies, it’s widely used and easy

to obtain.

• It uses robust tags which are relatively insensitive to interfer-

ence from metals and liquids, which is crucial in battery envi-

ronments.

• Universal use (license-free ISM band)

• Minimal energy consumption (low-frequency long-wave band –

LF passive tags)

• Reading range: approx. 10 cm

• Small data transfer volumes with fast reading process (e.g.

only object ID as battery identification)

Reading RFID Tags

In order to read an RFID tag, hold the battery tester display 1 to

2 cm above the RFID tag. RF appears at display.

32.

5.9 Attachment Options

The battery tester provides acoustic feedback for all important

procedural steps, e.g. readiness to record measured values. Consequently, there’s no need to continuously observe the display.

In order to ensure freedom of movement, comfort and quick work

for the operator, the battery tester can be secured by means of

various retaining devices for the entire duration of measurement:

• Carrying strap:

The operator can use the carrying strap to suspend the battery

tester around his neck. The condensed operating instructions

include a description of how to attach the carrying strap.

• Retaining clip:

The operator can attach the battery tester to his belt with the

help of the retaining clip.

• Retaining magnet:

The battery tester can be attached to magnetic surfaces such

as battery cabinet doors with the retaining magnet.

5

Page 8

METRACELL BT PRO GMC-I Messtechnik GmbH

Note

Note

5.10 Technical Data

Power Supply Rechargeable NiMH batteries, 4 ea. 1.2 V type AA (recommended: Ansmann maxE 2500 mAh)

Input Impedance

Ambient

Conditions

Electrical Safety

Electromagnetic

Compatibility (EMC)

Mechanical

Design

Data Interfaces

Internal Memory Up to 300,000 data records

Measurement input S+: 1.6 M

Measurement input S-: > 10 M

Operating temperature: +5 ... +40 °C

Storage temperature: -20 ... +60 °C

Relative humidity: Max. 75%, no condensation allowed

Elevation: Max. 2000 m

Measuring category: 600 V CAT III

Pollution degree: 2

Protection category: II per IEC 61 010-1/EN 61010-1/VDE 0411-1

Fuse link: 1 ea. SIBA 600 V/10 A FF

Test Voltage: Test voltage at measuring connection P+ may not exceed 24 V

Interference emission: EN 61326-1:2013, class A

Interference immunity: EN 61 326-1:2013

EN 61326-2-1:2013

Protection: Housing: IP40

per DIN VDE 0470, part 1/EN 60 529

(protection against ingress of solid foreign objects:

1.0 mm dia., protection against ingress of

water: not protected)

Housing: Approx. 9.6 × 15.4 × 3.3 cm (W × H × D)

Weight: Approx. 0.45 kg (without rubber holster)

Display: LCD, monochrome, luminous

IrDA: Connection for DMA 35 density meter, version 3

RFID: Connection for RFID tag

®

Bluetooth

: Connection for PC, headset and DMA 35 density meter, version 4

DC

.

Technical data for the AC/DC current clamp sensors, the temperature sensor and the DMA 35 density meter can be found in the

respective product documentation.

5.11 Characteristic Values

Measuring Function

Multimeter/

Connector

Measured Quantity V

Display Range

Measuring Range

-2450.00 …

+2450.00 mV

-2450.00 …

+2450.00 mV

DC

Multimeter/

Float/

Discharge/Charge

V

DC

-24.5000 …

+24.5000 V

-24.5000 …

+24.5000 V

Resolution 0.01 mV 0.1 mV 1 mV 10 mV 0.01 m 0.1 °C

Input Impedance /

Test Cu r r e n t

Intrinsic Uncertainty

S+

S− •••

P+ •

Measuring

connec-

tions

P−/

COM

1)

Only applicable if the temperature sensor is connected to the battery tester.

2)

Within a frequency range of 45 to 500 Hz.

>10M 1.6 M 1.6 M 1.6 M l

±(0.05%

rdg. + 10 d)

±(0.05%

rdg. + 10 d)

• •••

• • ••••

Multimeter/

Interval U/

Internal U+I

V

DC

-600.000 …

+600.000 V

-600.000 …

+600.000 V

±(0.05%

rdg.+ 50 d)

Multimeter Resistance Temperature

V

AC

-300.000 …

+300.000 V

-300.000 …

+300.000 V

±(2.0%

rdg. + 10 d)

2)

Rel + R

ct

00.00 …

1000.00 m

°C

-230.0 …

+230.0 °C

00.10 …

1000.00 m

approx. 2 A > 10 M

p

±(3.0%

rdg. + 8 d)

1)

The characteristic values of the AC/DC current clamp sensors and the DMA 35 density meter, as well as additional characteristic

values for the temperature sensor, can be found in the respective product documentation.

6

Page 9

GMC-I Messtechnik GmbH METRACELL BT PRO

Attention!

!

Attention!

!

Note

Attention!

!

Attention!

!

Note

6 Operation

6.1 Power Supply (rechargeable batteries)

Battery Operation

The battery tester is operated with rechargeable NiMH batteries.

Pre-charged batteries are shipped loose. You have already

inserted the batteries during initial startup (

ating instructions).

Operating time is approximately 10 hours when the batteries are

fully charged. A warning is generated when battery voltage drops

to below 4.8 V. The battery tester can be operated for approximately 1 more hour after this warning is generated.

Leaking batteries can damage the device.

Check the batteries at short, regular intervals and after long

periods of storage.

Charging Process

It takes about 3½ hours to charge the batteries.

Damage to the batteries or the instrument.

When charging, use only:

- The included rechargeable batteries or the

batteries specified in the technical data

- The included charger

Always connect the battery charger to the

battery tester before connecting the charger

to the electrical outlet.

condensed oper-

The battery tester must be switched off.

All measurement cables and accessories must be removed

from the battery tester.

1. Remove the holster from the battery tester: Press against the

bottom of the holster at the front and push it back and off of

the battery tester. As soon as the lower part of the battery tester is exposed, pull the instrument completely out of the holster.

2. Place the battery tester face down on a stable surface.

3. Loosen and remove the screw from the battery compartment

cover.

4. Unlock and remove the battery compartment cover.

5. Remove any batteries from the battery compartment.

6. Insert 4 approved rechargeable batteries into the battery compartment, making sure that the plus and minus poles match up

with the provided polarity symbols.

Only the included batteries or those specified in the technical data ( 6) may be inserted and used.

7. Place the battery compartment cover onto the battery compartment and press it until it audibly clicks into place.

8. Secure the battery compartment cover with the screw.

9. Pull the holster back over the battery tester: Observe the cutouts in the holster for the front panel and the connections.

Push the battery tester into the holster at the top first as far as

it will go. Then press on the front at the bottom until the battery

tester is fully reinserted into the holster.

The batteries have now been inserted. The battery tester can

be used.

Do not switch the battery tester on during charging. The

battery tester may not be operated during charging and is

switched off automatically after 3 seconds.

The battery tester is switched off.

4 NiMH batteries are inserted

(see section on “Replacing the Batteries”

on inserting batteries).

All measurement cables and accessories must be removed

from the battery tester.

1. Insert the charger’s connector plug into the battery tester’s

charging socket “Instrument Overview”

2. Connect the charger to the 230 V mains outlet.

The batteries in the battery tester are charged.

3. Wait until the charging process has been completed.

It takes about 3½ hours to fully charge the batteries.

4. Unplug the charger from the electrical outlet.

5. Remove the connector plug from the battery tester’s charging

socket.

The batteries are charged. The battery tester can now be

used.

Replacing the Batteries

You can replace the batteries if necessary.

7 for information

3.

6.2 Switching the Instrument On/Off

Switching the Instrument On

1. Press and hold the Function key for approximately 2 seconds.

The initial display appears with the instrument’s designation

and version, as well as date and time ( “LCD Display”

2. Press any key.

The main menu appears at the display. The battery tester can

now be used.

Switching the Battery Tester Off

Normally, the battery tester is switched off manually. If the battery

tester has not been used for more than 10 minutes, it’s switched

off automatically.

1. Select POWER OFF in the main menu with the help of the ▼

key.

2. Press the OK key.

The display goes blank. The battery tester has been switched

off.

The battery tester can also be switched off by pressing the

Function key. The key must be pressed and held for approximately 10 seconds to this end.

However, it’s preferable to switch the instrument off using

the SWITCH OFF function.

5).

Risk of injury due to contact with dangerous voltages.

Only use the battery tester when the battery compartment

cover is inserted and firmly screwed into place.

Required tools: Philips screwdriver

7

Page 10

METRACELL BT PRO GMC-I Messtechnik GmbH

Note

Note

Note

Note

6.3 System Settings

You can enter basic settings to the battery tester.

Setting Date and Time

Switch back and forth between standard time and daylight

savings time manually. The battery tester is not equipped

with an automatic time change function.

Although the battery tester can be paired with several

devices via Bluetooth

eral devices via Bluetooth® is not possible.

®

Bluetooth

needed.

connections can be terminated when they’re no longer

®

, simultaneous operation with sev-

1. Switch the battery tester on 7.

2. Press the OK key.

The main menu appears.

3. Select SETTINGS from the main menu

using the ▼▲ keys.

4. Press the OK key.

The SETTINGS menu is displayed.

5. Select SYSTEM using the ▼▲ keys.

6. Press the OK key.

The SYSTEM menu is displayed.

7. Select SET TIME&DATE using the ▼▲ keys.

8. Press the OK key.

The SET TIME&DATE menu is displayed. The cursor is positioned

at the first digit of the date display (dd.mm.yy: dd = day, mm =

month and yy = year).

9. Use the ▼▲ keys to enter the first digit of the two-digit display

for the current day.

10. Press the OK key to move to the second digit.

11. Repeat steps 9. and 10. until the date has been completely

entered.

After entering and confirming the last digit for the year, the cursor jumps to the first digit of the time display (ss:mm:hh: ss =

second, mm = minute and hh = hour)

12. Set the digits for time in the same way as described for setting

the date.

After entering the last digit for current time, your settings are

saved. The SYSTEM menu is displayed.

Date and time have been set.

Language Selection

Device language can be set to either English or German.

1. Switch the battery tester on

2. Press the OK key.

The main menu appears.

3. Select SETTINGS from the main menu

using the ▼▲ keys.

4. Press the OK key.

The SETTINGS menu is displayed.

5. Select SYSTEM using the ▼▲ keys.

6. Press the OK key.

The SYSTEM menu is displayed.

7. Select SEL. LANGUAGE using the ▼▲ keys.

8. Press the OK key.

The SEL. LANGUAGE menu is displayed.

9. Select the desired language using the ▼▲ keys.

10. Press the OK key.

The device language is changed.

7.

6.4 Establishing and Terminating Wireless Connections

The battery tester can be wirelessly connected to various devices:

• To the DMA 35 density meter from Anton Paar GmbH

– DMA 35 version 3 via infrared “DMA35 Measurement

(IrDA)”

49

– DMA 35 version 4 via Bluetooth

ment (BT)”

• To a PC in order to view, evaluate and save measurement data

“Saving Measured Values to a PC (data backup)”

• To a headset for improved audibility of signals generated by the

instrument “Establishing and Testing a Bluetooth® Connection with a Headset”

49

8

®

“DMA35 Measure-

50

In case of connection problems, it may be helpful to terminate (

references to specific sections above).

Establishing and Testing a Bluetooth

Acoustic signals are used to confirm various actions before, during

and after a measuring procedure, as well as certain instrument

reactions.

The instrument can be paired with a headset, making it possible to

better hear these signals in noisy work environments. The connection can be checked in advance with a test signal.

Read and adhere to the documentation included with your

headset.

The headset supports Bluetooth

1. Switch the battery tester on

2. Press the OK key.

The main menu appears.

3. Select SETTINGS from the main menu

using the ▼▲ keys.

4. Press the OK key.

The SETTINGS menu is displayed.

5. Select BT-SETTINGS using the ▼▲ keys.

The BT-SETTINGS menu is displayed.

6. Select LINK HEADSET using the ▼▲ keys.

7. Press the OK key.

8. The PUT HEADSET IN PAIRING MODE -> prompt appears.

9. Set the headset to pairing mode. Read the documentation

included with your headset to find out how.

10. Position the headset close to the battery tester.

11. Acknowledge the PUT HEADSET IN PAIRING MODE -> prompt by

pressing the OK key.

BT PAIRING: SEARCH HEADSET! appears at the display.

12. The headset and the battery tester are connected to each

other. Pairing progress is displayed as a percentage. As soon

as the devices are successfully connected, SUCCESSFUL!

appears at the display.

13. Put on the headset.

14. Press the OK key.

The BT-SETTINGS menu is displayed.

15. Press the Function key.

The main menu appears.

16. Select SETTINGS from the main menu using the ▼▲ keys.

17. Press the OK key.

The SETTINGS menu is displayed.

18. Select SYSTEM using the ▼▲ keys.

19. Press the OK key.

The SYSTEM menu is displayed.

20. Select TEST HEADSET using the

21. Press the OK key.

A test signal is played back at the headset.

9) and reestablish Bluetooth

®

Connection with a Headset

®

profile “HSP”.

7.

▼▲ keys.

®

connections (see

8

Page 11

GMC-I Messtechnik GmbH METRACELL BT PRO

Terminating the Bluetooth® Connection

All paired devices are disconnected when the Bluetooth

tion is terminated. It’s not possible to disconnect individual

devices.

1. Switch the battery tester on 7.

2. Press the OK key.

The main menu appears.

3. Select SETTINGS from the main menu

using the ▼▲ keys.

4. Press the OK key.

The SETTINGS menu is displayed.

5. Select BT-SETTINGS using the ▼▲ keys.

The BT-SETTINGS menu is displayed.

6. Select REM. PAIRINGS using the ▼▲ keys.

7. Press the OK key.

The DO YOU REALLY WANT TO DELETE? prompt appears.

8. Press the OK key.

DELETING DATA! PLEASE WAIT appears briefly at the display.

REM. PAIRINGS appears at the display.

Bluetooth

minated.

®

connection to all paired devices has now been ter-

®

connec-

6.5 Testing the RFID Reader

The RFID reader can be tested ( 5).

A compatible RFID tag (125 kHz) is available.

1. Switch the battery tester on

2. Press the OK key.

The main menu appears.

3. Select SETTINGS from the main menu

using the ▼▲ keys.

4. Press the OK key.

The SETTINGS menu is displayed.

5. Select SYSTEM using the ▼▲ keys.

6. Press the OK key.

The SYSTEM menu is displayed.

7. Select TEST TRANSP. using the ▼ key.

8. Press the OK key.

WAITING FOR RFID – – – – –> ( ) <– – – – – appears at the display.

Furthermore, a repetitive acoustic signal indicates readiness to

read.

9. Hold the battery tester’s RFID reader roughly 1 to 2 cm above

the RFID tag.

The RFID tag is read. The RFID tag’s number appears at the

display.

7.

Refer to section on “Performing Measurements”

assign RFID tags to DUTs and read them out during measurement.

30 on how to

9

Page 12

METRACELL BT PRO GMC-I Messtechnik GmbH

Initial

Display

2 sec.

ON

OK

ON

ON

OK

ON

OK

ON

OK

ON

OK

OK

ON

OK

OK

ON

OK

OK

ON

OK

OK

ON

OK

A

OK

OK

ON

OK

ON

OK

ON

OK

OK

ON

OK

OK

ON

OK

OK

ON

OK

OK

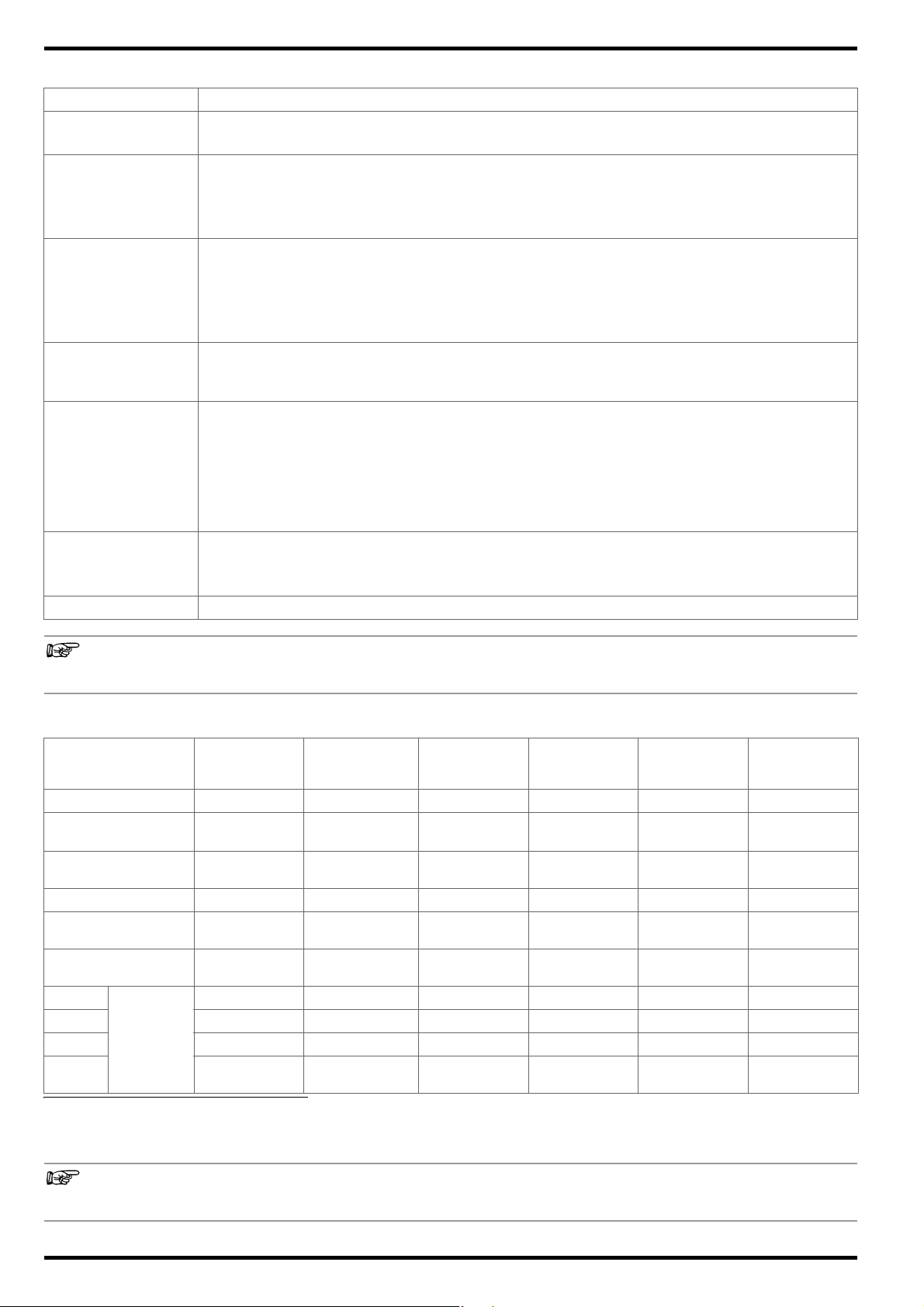

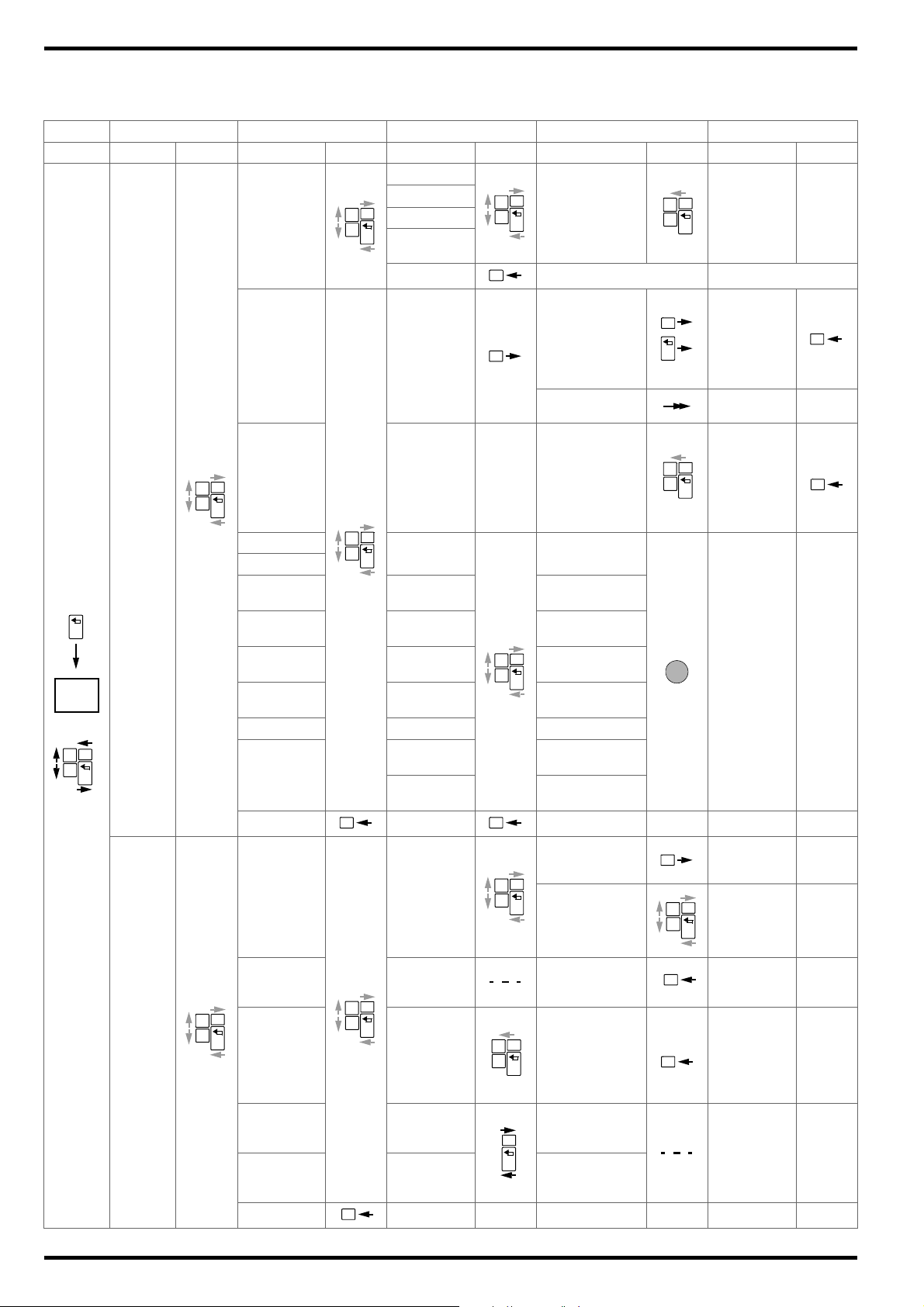

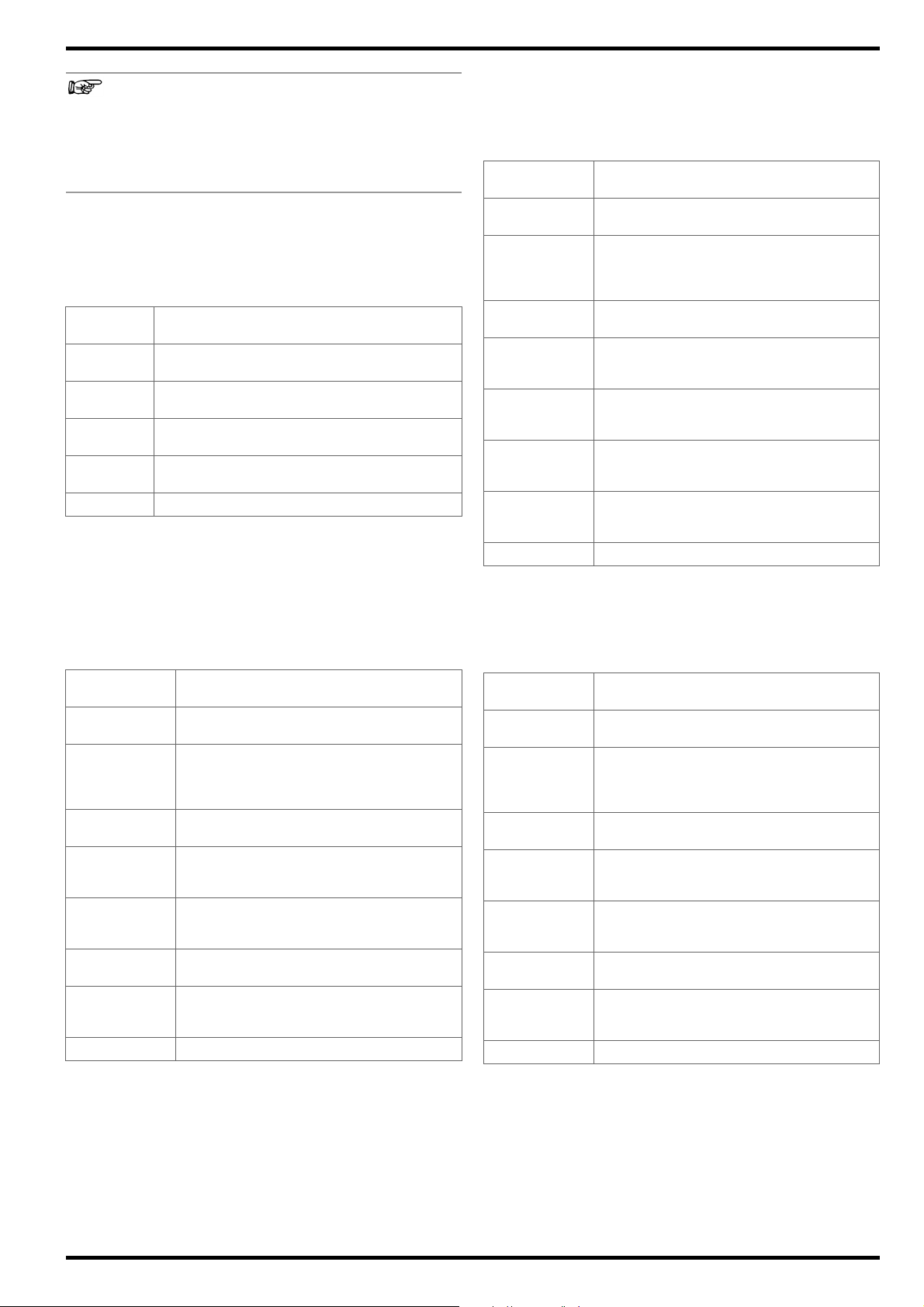

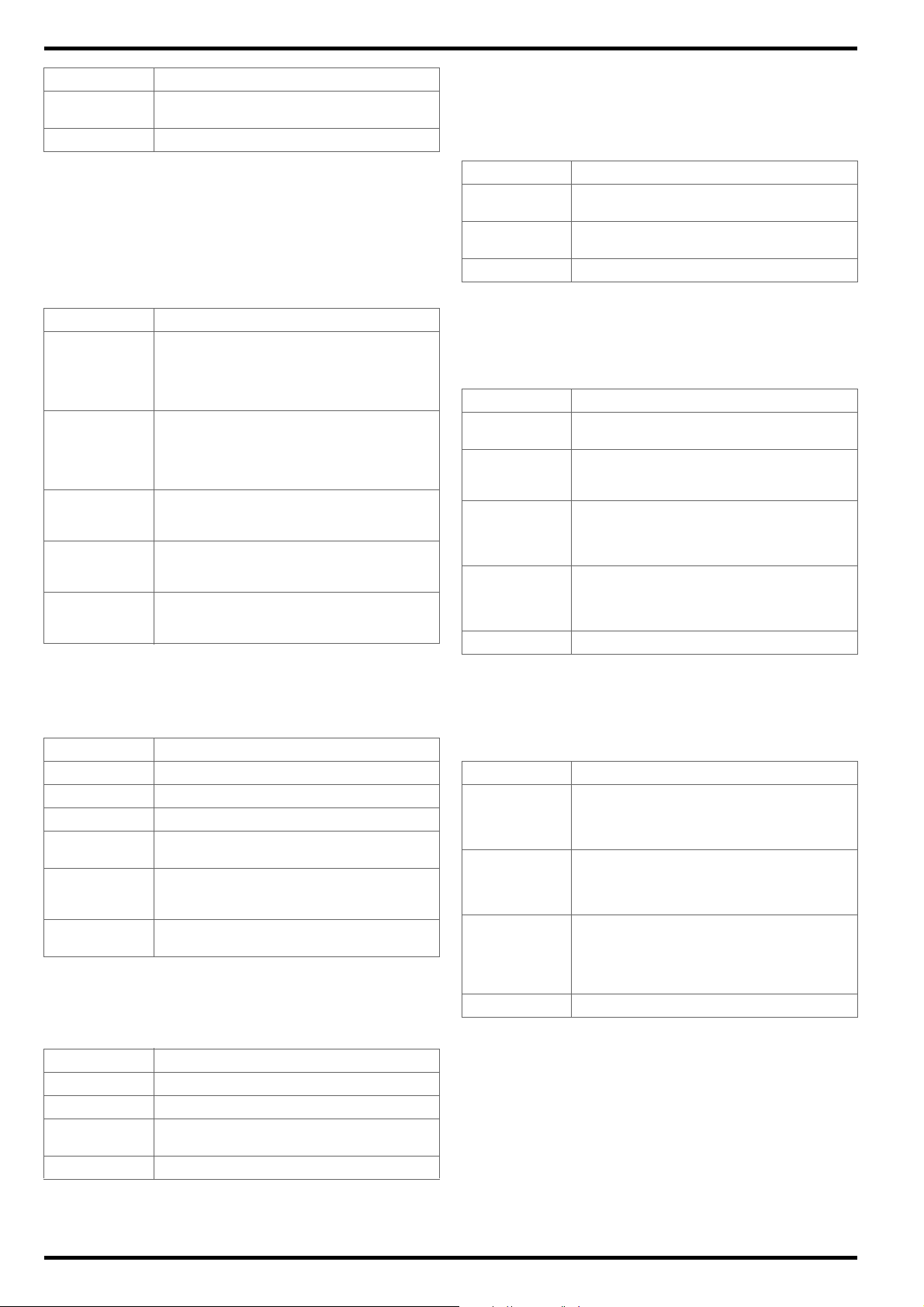

7 Menu and Functions

7.1 Overview

On Main Menu Level 1st Submenu Level 2nd Submenu Level 3rd Submenu Level 4th Submenu Level

Start Display Keys Display A Keys Display Keys Display Keys Display Keys

Start measurement

(short tone),

end measurement

(short tone), display value

Start measurement

(short tone),

end measurement

(short tone),

display value

WAITING FOR

DMA35

Battery database

display,

brief tone indicates RFID readiness to read

BATTERY: 0000

BLOCKS: 0000

MIN: 00 0 0

[U/M]

MAX: 00 0 0

[U/M]

CLAMP A: 0000

CLAMP mV: 0000

Display measured values (see

key)

Display measured value evaluation

End measured value

recording,

return to

MULTIMETER

display

WANT TO QUIT

WITH SAVING?

WANT TO QUIT

WITHOUT

SAVING?

In case of

manual selection, return to

display.

In case of

RFID, display

read result.

Repeat measurement

View evaluation via all

keys, then automatic return

For RFID

MEASUREMENT

2.45 V DC (S-)

24.5 V DC (S+)

MULTIMETER

600 V DC (S+)

300 V AC (S+)

QUIT

FLOAT START

DISCHARGE SELECT.BATT

CHARGE

RESISTANCE

TEMPERATURE

CONNECTOR

INTERVAL U

INTERVAL U+I

AREA: XXXX AREA: 0000

BATTERY:

XXXX

BLOCKS

XXXX*

MIN: XX.XXX

[U/M]

MAX: XX:XXX

[U/M]

DMA35 (IrDA) INT [s]: XXXX** INT [s]: 0000

CLAMP A:

DMA35 (BT)

XXXX ***

CLAMP mV:

XXXX ***

QUIT QUIT

Display of

measurement

SHOW DATA

with indication of measurement type,

date, time etc.

10

DATA

MENU

EXPORT (CSV)

SHOW

BAT-DEF

CLEAR DATA

CLEAR

BAT-DEF

QUIT

BT CSV

EXPORT

(CONNECT)

Battery database display,

brief tone indicates RFID

readiness to

read

DO YOU

REALLY WANT

TO DELETE?

DO YOU

REALLY WANT

TO DELETE?

DEVICE PAIRED?

EXPORT TARGET

OK?

In case of manual

selection, return

to display.

In case of RFID,

display read result.

DELETING

DATA!

PLEASE WAIT!

DELETING

DATA!

PLEASE WAIT!

For RFID

Brief tone

indicates

deletion,

return to

CLEAR DATA/

BATT. display

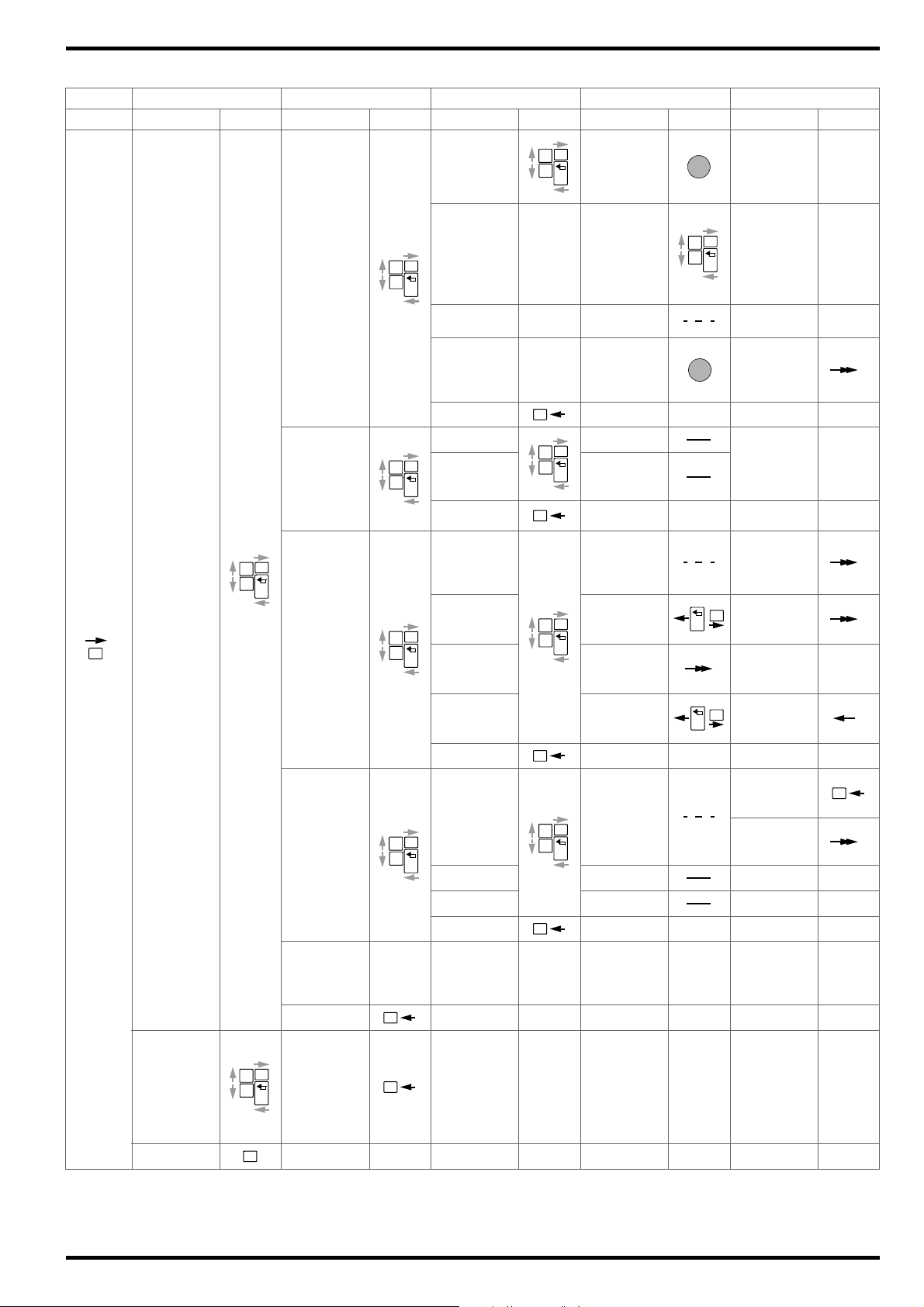

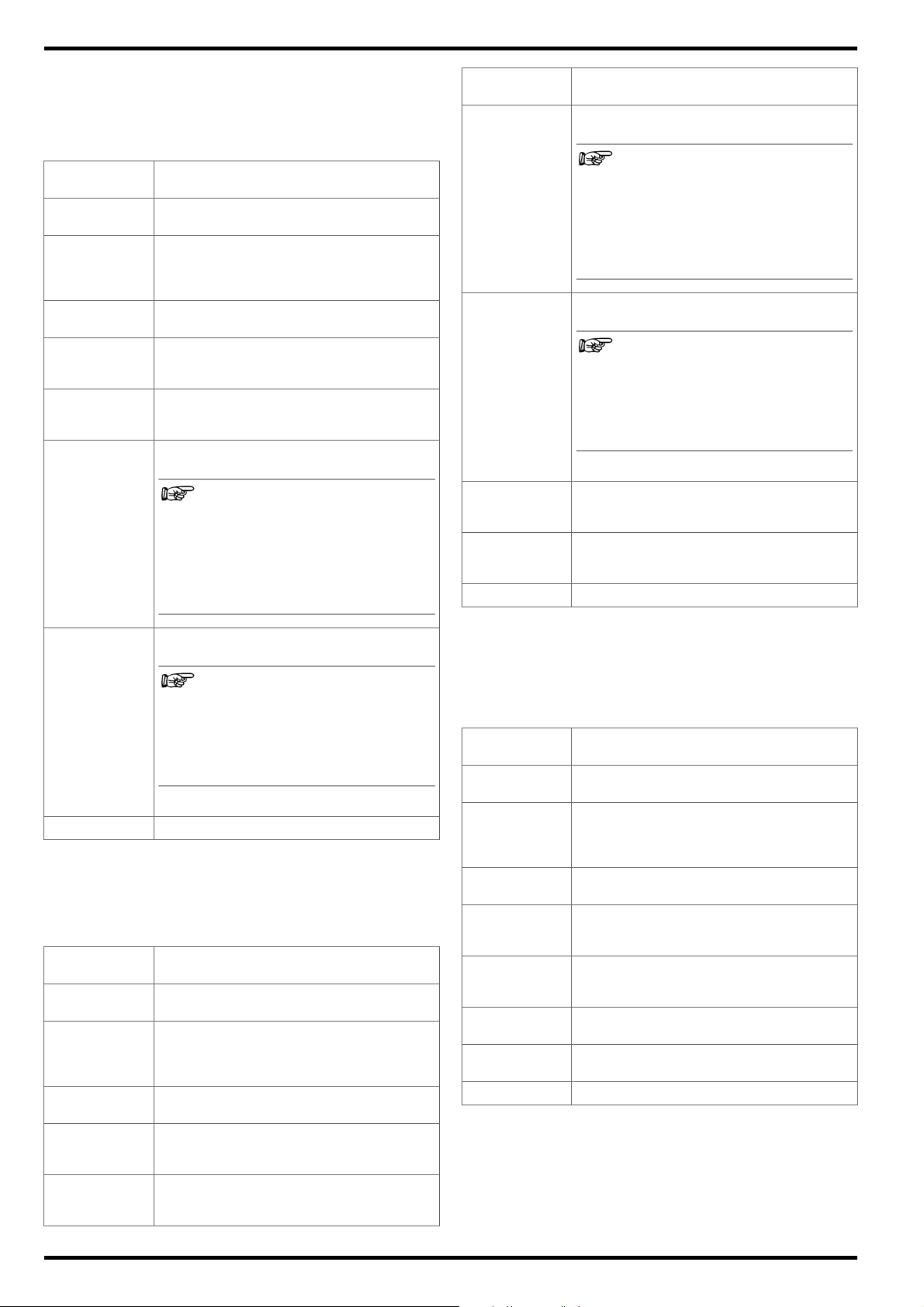

Page 13

GMC-I Messtechnik GmbH METRACELL BT PRO

OK

ON

OK

ON

OK

ON

OK

A

ON

OK

B

OK

ON

OK

ON

OK

OK

ON

OK

ON

OK

ONOKON

OK

OK

ON

OK

ON

OK

OK

OK

OK

ON

OK

OK

OK

(continued)

On Main Menu Level 1st Submenu Level 2nd Submenu Level 3rd Submenu Level 4th Submenu Level

Start Display Keys Display A Keys Display Keys Display Keys Display Keys

SETTINGS

INFO

POWER OFF

SYSTEM

MEASUREMENTS

BT-SETTINGS

CSV-EXPORT

FACTORY

ONLY

QUIT

VERSION:

VX.XX

ENTRIES:

XXX%

MEMORY:

XXX%

BATTERY:

XXX%

SET

TIME&DATE

SEL. LANGUAGE

DATE: XX.XX.X

TIME:

XX:XX:XX

ENGLISH

DEUTSCH

TEST HEADSET

Read out test

signal

WAITING

TEST TRANSP.

FOR RFID

-----> ( ) <----

-

QUIT

POLARITY ON POLARITY ON

POLARITY OFF POLARITY OFF

QUIT

BT

LINK

COMPUTER

PAIRING:

WAITING FOR

PC

PUT HEADSET

LINK HEADSET

IN PAIRING

MODE ->

LINK DMA35

V4

REM.

PAIRINGS

PLEASE DIS-

COVER BTpro

WITH DMA35

DO YOU RE-

ALLY WANT TO

DELETE?

QUIT

EXPORT

TARGET

SCANNING

FOR

BT DEVICES.

FILENA. FIXED FILENA. FIXED

FILEN. UNIQ. FILEN. UNIQ.

QUIT

FACTORY USE

ONLY

PASSWORD:

XXXXX

Menu is displayed in selected language,

return to

LANGUAGE

SEL.

display

WAITING FOR

RFID

<RFID

Number>

Brief tone signals selection,

display remains in

menu

List with

all detected

BT devices is

displayed.

BT PAIRING:

SEARCH

HEADSET

DELETING

DATA!

PLEASE WAIT!

NO BT

DEVICES

FOUND

Detected BT

devices are

listed

11

Page 14

METRACELL BT PRO GMC-I Messtechnik GmbH

=

=

OK

ON

=

A

=OK=

=

ON

=

B

7.2 Display Menu

General Key

-> MEASUREMENT

DATA

DELETING DATA

Display menu/function,

the arrow indicates the selected function.

Feedback or information after action

PLEASE WAIT

BLOCK 12.2500V

0004/4

Display measured value (example)

Display measured value evaluation

AN:0001 BN:0010

Descriptive text Explanation of measured value, parameter

and other displays

Scroll within menu levels and functions.

Start function,

submenu selection

Switch on,

termination of an action currently being executed

Move up one view in the menu.

The initial display appears after switching the battery tester on

(

7). The main menu is then displayed after pressing any key.

If you’re already in a submenu, press the FUNCTION key repeatedly

until the display is returned to the main menu.

This is the central menu from which all other hierarchically subordinate menus and functions can be accessed. All main menu functions can be selected with the help of the ▼▲ keys.

Table 10: List of Functions Available in the Main Menu

Function Description

MEASUREMENT Available measuring functions

DATA MENU Data management functions

12

15

SETTINGS Parameter settings for system, measure-

ments and data transfer

16

INFO Information concerning firmware version, bat-

tery charge level and memory occupancy

17

POWER OFF Switch off the battery tester

7.

Move down one view in the menu.

Jump to submenu level (press briefly).

Jump to submenu level (press and hold).

Jump back to higher menu level (initial position).

Remains at current position.

No action required.

Further action and displays depend on

systems to be linked or downstream systems.

0 Currently selected digit (display with black

background).

X Placeholder for one digit.

* Parameter not for measuring functions

INTERVAL U and INTERVAL U+I

** Parameters only for measuring functions

INTERVAL U and INTERVAL U+I

*** Parameters only for measuring functions

INTERVAL U and INTERVAL U+I

Set/select special key assignments for

parameters

Cursor for selecting the digit to be

changed (inverted cursor), storage takes

place after selection of the last digit, then

return to higher menu level

Increase digit

Decrease digit

Cancel entry/selection of digits without

saving, return to higher menu level

RFID tags must be held roughly 1 to 2 cm above the display

7.3 Measurement Menu

Select MEASUREMENT in the main menu and then press the OK

key in order to open the menu.

Table 11: List of Functions Available in the MEASUREMENT Menu

Measurement Description

MULTIMETER DC and AC voltage measurements without

FLOAT Periodic measurement of block voltages.

DISCHARGE Multiple measurement of block voltages at

CHARGE Multiple measurement of block voltages at

RESISTANCE Periodic measurement of the internal resis-

TEMPERATURE Measurement of block temperature with an IR

CONNECTOR Measurement of voltage drop to determine

INTERVAL U Measurement of the voltage of a battery at any

INTERVAL U + I Measurement of the voltage and current of a

DMA 35 (IrDA) Measurement of acid density and electrolyte

DMA 35 (BT) Measurement of acid density and electrolyte

QUIT Exit the MEASUREMENT menu and return to the

storing measured values

This measurement is used for quarterly recording of float voltage, for example in UPS systems.

short intervals during discharging (capacitance

test)

short intervals during charging (capacitance

test)

tance of the blocks

temperature sensor

connector loss between blocks

desired time intervals (voltage curve)

battery at any desired time intervals (voltage

and current curves)

Example: Recording of discharge current

during discharging.

temperature within a block.

Measurements are performed with the DMA 35

density meter (version 3) from Anton Paar

GmbH. Data are transferred from the sensor to

the battery tester via infrared (Infrared Data Association – IrDA).

temperature within a block.

Measurements are performed with the DMA 35

density meter (version 4) from Anton Paar

GmbH. Measured values are transferred from

the sensor to the battery tester via Bluetooth

®

main menu.

12

Page 15

GMC-I Messtechnik GmbH METRACELL BT PRO

Note

Temperature

The required parameters for the device under test must be

defined before starting a measurement. Use the battery

database to this end ( “Performing Measurements”

30

and “Transferring the Battery Database to the Battery

Tester”

23).

Manual entries should only be made in exceptional cases.

Multimeter

Select the MEASUREMENT MULTIMETER function sequence via

the main menu and press the OK key in order to open the menu.

Table 12: Possible Measuring Ranges for MULTIMETER Measure-

ment

Measuring

Range

2.45 V

DC

24.5 V

DC

600 V

DC

300 V

AC

Description

(S–) Measuring range selection for direct voltage mea-

surement via measuring socket S–

(S+) Measuring range selection for direct voltage mea-

surement via measuring socket S+

(S+) Measuring range selection for direct voltage mea-

surement via measuring socket S+

(S+) Measuring range selection for alternating voltage

measurement via measuring socket S+

QUIT Return to MEASUREMENT menu

Float, Discharge, Charge and Resistance

In order to open the menu, select one of the following function

sequences from the main menu:

MEASUREMENT FLOAT or MEASUREMENT

DISCHARGE or MEASUREMENT CHARGE or MEASUREMENT

RESISTANCE, and then press the OK key.

Table 13: Parameters and Functions for the FLOAT, DISCHARGE,

CHARGE and RESISTANCE Measurements

Function/

Setting

Description

START Measurement is started after selecting or en-

tering the battery parameters.

SELECT.BATT The menu for selecting and loading a stored

battery database is accessed via this function.

If a database exists, the stored data records

appear.

AREA: XXXX Manual assignment of a unique four-digit

number for the location of the battery system

BATTERY: XXXX Manual assignment of a unique four-digit

number as a designation of the battery in the

battery system

BLOCKS:XXXX Manual assignment a unique four-digit num-

ber identifying the number of blocks within the

battery

MIN: XX.XXX V Manual measuring range setting: lower volt-

age limit value

MAX: XX.XXX V Manual measuring range setting: upper volt-

age limit value

(max. +24.50 V)

QUIT Return to MEASUREMENT menu

Select the MEASUREMENT TEMPERATURE function sequence

via the main menu and press the OK key in order to open the menu.

Table 14: Parameters and Functions for the TEMPERATURE Mea-

surement

Function/

Setting

Description

START Measurement is started after selecting or en-

tering the battery parameters.

SELECT.BATT The menu for selecting and loading a stored

battery database is accessed via this function.

If a database exists, the stored data records

appear.

AREA: XXXX Manual assignment of a unique four-digit

number for the location of the battery system

BATTERY: XXXX Manual assignment of a unique four-digit

number as a designation of the battery in the

battery system

BLOCKS:XXXX Manual assignment a unique four-digit num-

ber identifying the number of blocks within the

battery

MIN: XXXX.X C Manual measuring range setting: lower tem-

perature limit value

(max. –230 °C)

MAX: XXXX.X C Manual measuring range setting: upper tem-

perature limit value

(max. +230 °C)

QUIT Return to MEASUREMENT menu

Start / Battery Parameters Menu for Connector Measurement

Select the MEASUREMENT CONNECTOR function sequence via

the main menu and press the OK key in order to open the menu.

Table 15: Parameters and Functions for the CONNECTOR Mea-

surement

Function/

Setting

Description

START Measurement is started after selecting or en-

tering the battery parameters.

SELECT.BATT The menu for selecting and loading a stored

battery database is accessed via this function.

If a database exists, the stored data records

appear.

AREA: XXXX Manual assignment of a unique four-digit

number for the location of the battery system

BATTERY: XXXX Manual assignment of a unique four-digit

number as a designation of the battery in the

battery system

BLOCKS:XXXX Manual assignment a unique four-digit num-

ber identifying the number of blocks within the

battery

MIN: XXXX.X mV Manual measuring range setting: lower volt-

age limit value

MAX: XXXX.X mV Manual measuring range setting: upper volt-

age limit value

(max. +2400.0 mV)

QUIT Return to MEASUREMENT menu

13

Page 16

METRACELL BT PRO GMC-I Messtechnik GmbH

Note

Note

Note

Note

Start / Battery Parameters Menu for Interval U Measurement

Select the MEASUREMENT INTERVAL U function sequence via

the main menu and press the OK key in order to open the menu.

Table 16: Parameters and Functions for the INTERVAL U Mea-

surement

Function/

Setting

START Measurement is started after selecting or en-

SELECT.BATT The menu for selecting and loading a stored

AREA: XXXX Manual assignment of a unique four-digit

BATTERY: XXXX Manual assignment of a unique four-digit

INT [s]: XXXX Manually adjustable time interval (in seconds)

MIN: XXX.XX V Manual measuring range setting: lower volt-

MAX: XXX.XX V Measuring range setting: upper voltage limit

QUIT Return to MEASUREMENT menu

Interval U + I

Select the MEASUREMENT INTERVAL U+I function sequence via

the main menu and press the OK key in order to open the menu.

Table 17: Parameters and Functions for INTERVAL U+I Measure-

Function/

Setting

START Measurement is started after selecting or en-

SELECT.BATT The menu for selecting and loading a stored

AREA: XXXX Manual assignment of a unique four-digit

BATTERY: XXXX Manual assignment of a unique four-digit

INT [s]: XXXX Manually adjustable time interval (in seconds)

Description

tering the battery parameters.

battery database is accessed via this function.

If a database exists, the stored data records

appear.

number for the location of the battery system

number as a designation of the battery in the

battery system

for recording the measured value.

(min. 1 second)

age limit value

Same as discharge cut-off voltage. If

the limit value is fallen short of, the

instrument generates an acoustic signal at regular intervals. This indicates

that the discharging process has been

completed and measurement can be

ended.

value

Same as charge cut-off voltage. If the

limit value is exceeded, the instrument

generates an acoustic signal at regular

intervals. This indicates that the

charging process has been completed

and measurement can be ended.

(max. +600 V)

ments

Description

tering the battery parameters.

battery database is accessed via this function.

If a database exists, the stored data records

appear.

number for the location of the battery system

number as a designation of the battery in the

battery system

for recording the measured value.

(min. 1 second)

Function/

Setting

MIN: XXX.XX V Manual measuring range setting: lower volt-

MAX: XXX.XX V Manual measuring range setting: upper volt-

CLAMP A: XXXX Manual measuring range setting: Current

CLAMP mV: XXXX Manual measuring range setting: Voltage

QUIT Return to MEASUREMENT menu

DMA35 (IrDA and Bluetooth

Select the MEASUREMENT DMA35 (IrDA) or DMA35 (BT) function sequence via the main menu and then press the OK key in order

to open the menu.

Table 18: Parameters and Functions for the DMA35 (IrDA) and

Function/

Setting

START Measurement is started after selecting or en-

SELECT.BATT The menu for selecting and loading a stored

AREA: XXXX Manual assignment of a unique four-digit

BATTERY: XXXX Manual assignment of a unique four-digit

BLOCKS:XXXX Manual assignment a unique four-digit num-

MIN: X.XXXX Manual measuring range setting: lower limit

MAX: X.XXXX Manual measuring range setting: upper limit

QUIT Return to MEASUREMENT menu

Description

age limit value

Same as discharge cut-off voltage. If

the limit value is fallen short of, the

instrument generates an acoustic signal at regular intervals. This indicates

that the discharging process has been

completed and measurement can be

ended.

age limit value

Same as charge cut-off voltage. If the

limit value is exceeded, the instrument

generates an acoustic signal at regular

intervals. This indicates that the

charging process has been completed

and measurement can be ended.

(max. +600 V)

value of the transformation ratio of the current

clamp

value of the transformation ratio of the current

clamp

®

)

DMA35 (BT) Measurements

Description

tering the battery parameters.

battery database is accessed via this function.

If a database exists, the stored data records

appear.

number for the location of the battery system

number as a designation of the battery in the

battery system

ber identifying the number of blocks within the

battery

value for acid density

value for acid density

14

Page 17

GMC-I Messtechnik GmbH METRACELL BT PRO

Note

7.4 Data Menu

Select DATA MENU in the main menu and then press the OK key in

order to open the menu.

Table 19: Functions in the DATA Menu

Function Description

SHOW DATA Display of stored measured values

EXPORT (CSV) Transfer of stored measured values to the PC

SHOW BATT-DEF Display of the battery database

CLEAR DATA Complete, irretrievable deletion of all stored

CLEAR BAT-DEF Complete, irretrievable deletion of a battery

QUIT Return to the main menu

Measured Values

Select the DATA SHOW DATA function sequence from the main

menu and press the OK key in order to open the MEASUREMENTS

menu.

Table 20: Information on Stored MEASUREMENTS

Designation Description

Measuring Function

[XXXXX] Meaning varies depending on measurement:

DD.MM.YY Date of measurement

HH:MM:SS Time of measurement

AN:XXXX Location number assigned to the battery sys-

BN:XXXX Battery number assigned to the battery

as CSV file

measured values

database

Designation of the measuring function

– Number of blocks over which measure-

ments have been performed

– Number of measurements (e.g. for

INTERVAL U)

tem

Designation Description

AN:XXXX Location number assigned to the battery sys-

tem

BN:XXXX Battery number assigned to the battery

Table 23: Measured RESISTANCE Values

Designation Description

BLOCK Measurement over one block

XXXX/X Battery number / number of blocks

XX.XXXX V Measured voltage value

R(el) = Measured value of the internal electrical resis-

tance of a block

R(ct) = Measured value of the internal electrochemical

resistance of a block

Table 24: Measured TEMPERATURE Values

Designation Description

BLOCK Measurement over one block

XXXX/X Battery number / number of blocks

XXXX.X C Measured temperature value

AN:XXXX Location number assigned to the battery sys-

tem

BN:XXXX Battery number assigned to the battery

Table 25: Measured CONNECTOR Values

Designation Description

BLOCK Measurement over one block

XXXX/X Battery number / number of blocks

XXXX.XX mV Measured voltage value

AN:XXXX Location number assigned to the battery sys-

tem

BN:XXXX Battery number assigned to the battery

Navigate through all of the measurements in the MEASUREMENT

VALUES menu using the ▼▲ keys. After selecting a given mea-

surement and pressing the OK key, measured values and measured value details are displayed.

If an RFID tag has been assigned to a system and the tag is

read before measurement, the RFID tag’s number is displayed instead of the AN and BN numbers in the corresponding measured values / measured value details.

Table 21: Measured FLOAT Values

Designation Description

BLOCK Measurement over one block

XXXX/X Battery number / number of blocks

X.XXXX V Measured voltage value

AN:XXXX Location number assigned to the battery sys-

tem

BN:XXXX Battery number assigned to the battery

Table 22: Measured DISCHARGE and CHARGE Value s

Designation Description

BLOCK Measurement over one block

XXXX/X Battery number / number of blocks

X.XXXX V Measured voltage value

Table 26: Measured INTERVAL U Values

Designation Description

COUNT: Number of measurements performed over a

freely defined time interval

X.XXX V Display of overall battery voltage which was

measured during a freely defined time interval

TIME. Time interval during which the battery’s overall

voltage was measured

Table 27: Measured INTERVAL U + I Values

Designation Description

COUNT: Number of measurements performed

X.XXX V Overall battery voltage measured during the

defined time interval

X.XXXX A Battery current measured during the defined

time interval

TIME. Time interval during which the battery’s overall

voltage and battery current were measured

Table 28: Measured DMA (IrDA) and DMA35 (BT) Values

Designation Description

BLOCK Measurement over one block

XXXX/X Battery number / number of blocks

X.XXX kg/l Acid density

X.XXX C Te mpe ra tu re

15

Page 18

METRACELL BT PRO GMC-I Messtechnik GmbH

Designation Description

AN:XXXX Location number assigned to the battery sys-

tem

BN:XXXX Battery number assigned to the battery

Menu for the Display of Measured Value Evaluations

In addition to individual measurements, measured value evaluations can also be displayed. Select a measurement in the SHOW

DATA menu using the ▼▲ keys. Then press and hold the OK key

until the menu with the measured value evaluations is displayed.

Complete information is available in the section on “Viewing, Editing, Transferring and Evaluating Measured Values”

50.

Table 29: Measured Value Evaluations

Designation Description

SUM: [XXXX] Sum of all measured values measured over

the blocks of a battery. The number of blocks

over which measurement has been performed

is shown in square brackets (e.g. for FLOAT or

RESISTANCE).

NUMBER [XXXX] Number of all measured values that were

measured during a multiple measurement over

a block. The number of measurements is

shown in square brackets (e.g. for TEMPERA-

).

TURE

AVER.: Mean value of the measured values measured

either over all blocks of a battery or over one

block in the case of a multiple measurement.

MIN: XXXX Smallest measured value of the measurement

with indication of the number of the block at

which the measured value was measured.

MAX: XXXX Largest measured value of the measurement

with indication of the number of the block at

which the measured value was measured.

7.5 The SETTINGS Menu

Select SETTINGS in the main menu and then press the OK key in

order to open the menu.

Table 30: SETTINGS Menu Functions

Function Description

SYSTEM System settings

MEASUREMENTS Settings for measured value recording

®

BT-SETTINGS Settings for Bluetooth

CSV EXPORT Settings for the transmission of data and mea-

sured values as a CSV file

SERVICE MENU This function is for service only ( “Service

and Support”

53). Access is restricted by

means of a password.

QUIT Exit the SETTINGS menu and return to the main

menu.

SYSTEM

Select the SETTINGS SYSTEM function sequence from the main

menu and press the OK key in order to open the SYSTEM menu.

Table 31: Functions in the SYSTEM Menu

Function Description

SET TIME&DATE Settings for device date and time

SEL. LANGUAGE User language selection

TEST HEADSET Playback of a test signal at a headset in order

to check the Bluetooth

QUIT Return to SETTINGS menu

connection

®

function

MEASUREMENTS

Select the SETTINGS MEASUREMENTS function sequence from

the main menu and press the OK key in order to open the MEASURE-

MENTS menu.

Table 32: List of Functions Available in the MEASUREMENTS Menu

Function Description

POLARITY ON Switch polarity on: the negative or positive

measured value is displayed.

POLARITY OFF Switch polarity off: the absolute value of the

measured value is displayed.

QUIT Return to SETTINGS menu

BT-SETTINGS

Select the SETTINGS BT SETTING function sequence from the

main menu and press the OK key in order to open the BT SETTINGS

menu.

Table 33: Functions in the BT SETTINGS Menu.

Function Description

LINK COMPUTER Function for establishing a Bluetooth® con-

nection between the battery tester and a PC

®

LINK HEADSET Function for establishing a Bluetooth

connection between the battery tester and a

headset

®

LINK DMA35 V4 Function for establishing a Bluetooth

connection between the battery tester and a version 4 DMA 35 density meter from Anton Paar

GmbH

®

REM. PAIRINGS Termination of the Bluetooth

connection to

all paired devices

(device connections cannot be terminated individually)

QUIT Return to SETTINGS menu

CSV EXPORT

Select the SETTINGS CSV EXPORT function sequence from the

main menu and press the OK key in order to open the CSV EXPORT

menu.

Table 34: Functions in the CSV EXPORT Menu

Function Description

EXPORT TARGET Selection of the destination (e.g. PC) for the

transmission of measured values as a CSV file

(a Bluetooth

®

connection must first be estab-

lished between the battery tester and the PC)

FILENA. FIXED Function for defining a uniform filename when

transferring measured values to a PC as a

CSV file

The file is named “BTPRO_Export.csv”.

FILEN. UNIQ. Function for generating different filenames

each time measured values are transferred to

a PC as a CSV file The file is named “BTPRO_Export_<SystemID>_<Date>_<Time>.csv”.

QUIT Return to SETTINGS menu

16

Page 19

GMC-I Messtechnik GmbH METRACELL BT PRO

7.6 INFO Menu

Select INFO in the main menu and then press the OK key in order

to open the menu.

Table 35: Information in the INFO Menu

Function Description

VERSION: The battery tester’s current firmware version

ENTRIES: Display of memory occupancy for measuring

MEMORY: Display of memory occupancy for measured

BATTERY Battery charge status (in volts)

procedures as a percentage

100% = full storage capacity available

0% = no storage capacity available

values as a percentage

100% = full storage capacity available

0% = no storage capacity available

17

Page 20

METRACELL BT PRO GMC-I Messtechnik GmbH

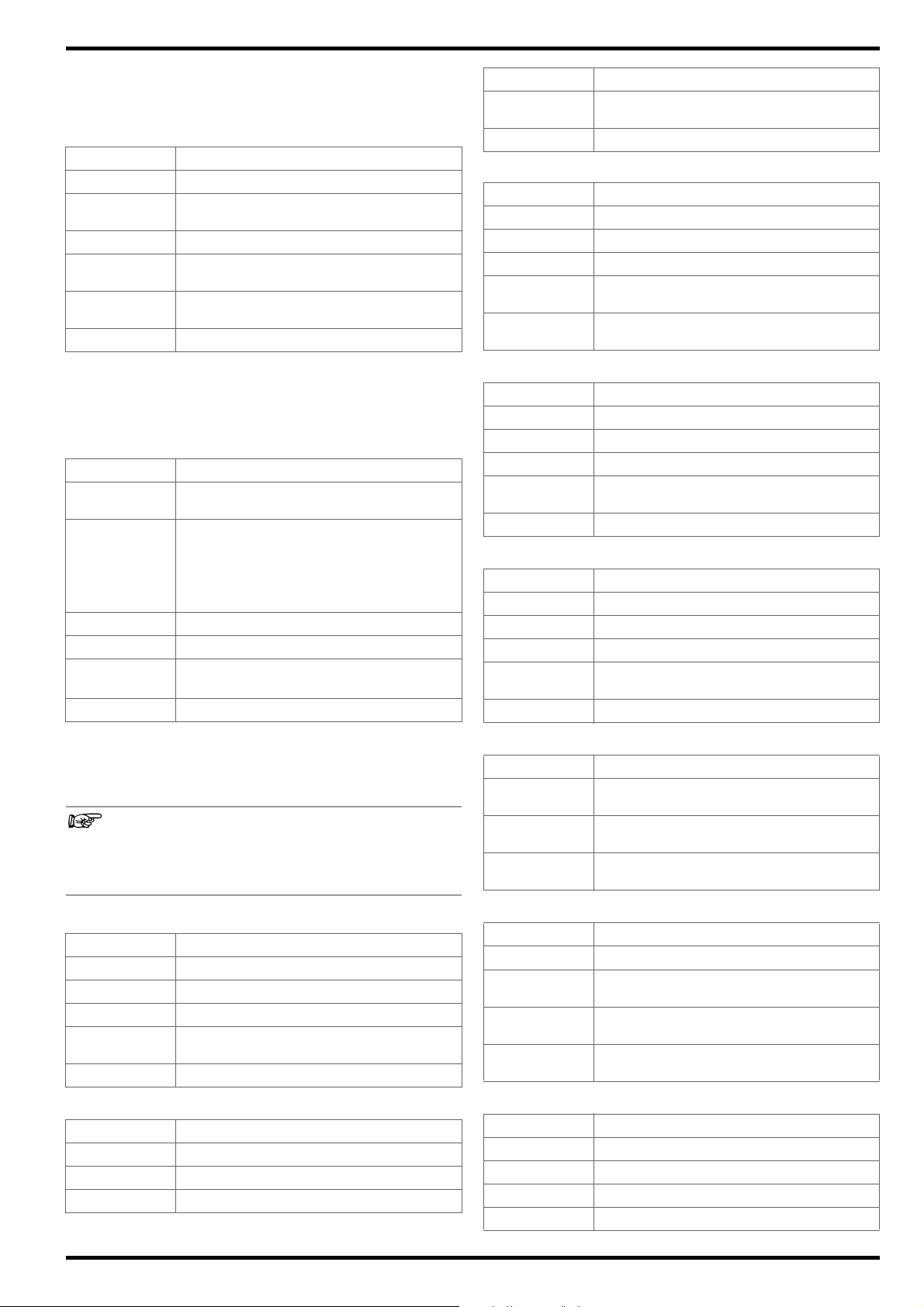

Note

2

1

3

4

5

6

910

7

8

8 “BT PRO Manager” PC Software

“BT PRO Manager” PC software is an important tool when using

the battery tester. The program can be used to:

• Create, maintain and manage the battery database (DUT management)

• Transfer and save measurement data

• View measurement results and create measurement evaluations (reports)

We strongly recommend using BT PRO Manager software!

The battery tester can be used without the software, but in

this case the important and convenient functions listed

above are unavailable.

This section provides you with all the information you’ll need to

work with BT PRO Manager.

When working with the battery tester and BT PRO Manager for the

first time, begin by following the instructions included in the sections up through “Creating the Battery Database” in the order in

which they appear.

If you’ve already performed measurements and would like to

import the measurement data into BT PRO Manager, as well as

view and create reports, go directly to “Importing Measurement

Data”

24.

8.1 Installation, Launching the Program and Update

Download

The current version of the software can be downloaded free of

charge as a ZIP file from the “myGMC” service portal on GMC-I’s

website:

http://www.gmc-instruments.de/services/mygmc/

First of all, you’ll have to register yourself and your test instrument.

You’re then provided with access to the download.

System Requirements

• PC with Microsoft Windows 7

• Screen resolution of at least 1024 × 768

• At least 2 GB available hard disk memory

• At least 8 GB RAM

Installation

You’ve already downloaded the installation file

Your system fulfills the specified requirements

1. Run the installation file.

The installation wizard appears.

2. Follow the instructions displayed by the installation wizard.

The software is installed on your PC.

Launching the Program

BT PRO Manager has been installed on your PC

The program can be launched by means of the usual Windows

procedures, e.g. by using the desktop shortcut.

Update

Software updates provide new features and bug fixes.

All settings, measurement data and the battery database are

retained when the software is updated.

1. Check to see which software version is currently available

“Download”

2. Start BT PRO Manager.

The Login dialog appears.

3. Click the

The Login dialog is closed.

4. Click the Information button.

The Information dialog appears and displays the currently

installed software version.

18.

button.

®

or higher

18.

18.

18.

5. Compare the software versions.

– If the versions differ: continue.

– If the versions are identical: no action is required.

6. Download the latest version of the software.

7. Run the installation file.

The installation wizard appears.

8. Follow the instructions displayed by the installation wizard.

The software is updated.

8.2 Overview

No. Meaning

1 Information

Shows information about the program.

2 Database status

3 Definitions

Defines batteries including all associated information

such as blocks and location

4 Display measurement series

Displays data associated with already performed measurements

5 Read in measurement series

Reads in measurement data from the battery tester or

from a stored CSV file

6 User administration

Defines user accounts for login

7 General settings

Defines general settings

8 Database settings

Defines settings for the database

9 Display selection

Elements can be selected here for which further information is displayed in the detail display area (10).

10 Detail display area

Displays detailed information about the element selected

in the display selection (9). Some of this information can

be edited or deleted.

®

8.3 Defining the Data(base) Storage Location

All data (measurement data, battery databases etc.) available in

BT PRO Manager are stored in a database.

Access is protected with the help of user accounts 19.

This database can be stored locally at a PC or remotely on a

server. The main difference between local and server-based databases is the number of user accounts: you can set up as many as

10 user accounts for a local database. Only one administrator can

be set up for a server database.

If necessary, you can create several databases and switch

amongst them. As a service provider, for example, you can create

separate databases for each customer.

A local database is created when BT PRO Manager is installed.

This is selected by default and can be used immediately.

18

Page 21

GMC-I Messtechnik GmbH METRACELL BT PRO

Note

Note

Using the Local Database

During program installation, an empty local database is created

which is included in BT PRO Manager by default. Alternatively, you

can select a different local database.

The database is located on the PC where BT PRO Manager is

installed.

The database uses the “.fdb” format.

You know the username and password for the database.

1. Start BT PRO Manager.

The Login dialog appears.

2. Click the

The Login dialog is closed.