Page 1

PUBLICATION NUMBER

OM-06629-01

April 17, 2013

Rev. B 01‐13‐14

SF SERIES

EXPLOSION‐PROOF PUMPS

THE GORMAN‐RUPP COMPANY D MANSFIELD, OHIO

www.grpumps.com

GORMAN‐RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

e2013 The Gorman‐Rupp Company

Page 2

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

Page 3

TABLE OF CONTENTS

INTRODUCTION PAGE I - 1.................................................

SAFETY ‐ SECTION A PAGE A - 1............................................

INSTALLATION - SECTION B PAGE B - 1....................................

GENERAL INFORMATION PAGE B - 1..................................................

PREINSTALLATION INSPECTION PAGE B - 1............................................

LUBRICATION PAGE B - 1.............................................................

PUMP MOTOR SPECIFICATIONS PAGE B - 1............................................

PUMP INSTALLATION PAGE B - 2......................................................

Lifting PAGE B - 2.................................................................

Impeller Rotation PAGE B - 2.......................................................

Positioning the Pump (Guide Rail Application) PAGE B - 3.............................

Positioning the Pump (Stand Application) PAGE B - 3.................................

Piping PAGE B - 3................................................................

ELECTRICAL CONNECTIONS PAGE B - 3...............................................

Field Wiring Connections (Incoming Power) PAGE B - 3...............................

Dual Voltage PAGE B - 4...........................................................

Motor Cable Grounding Test PAGE B - 4.............................................

Control Box Connections PAGE B - 4...............................................

Liquid Level Devices PAGE B - 5....................................................

OPERATION - SECTION C PAGE C - 1......................................

GENERAL INFORMATION PAGE C - 1..................................................

Pump Performance PAGE C - 1.....................................................

Control Box PAGE C - 1...........................................................

PUMP OPERATION PAGE C - 1........................................................

Liquid Temperature And Overheating PAGE C - 1.....................................

STARTING, STOPPING AND OPERATIONAL CHECKS PAGE C - 2.........................

Starting PAGE C - 2...............................................................

Stopping PAGE C - 2..............................................................

Operational Checks PAGE C - 2....................................................

COLD WEATHER PRESERVATION PAGE C - 3...........................................

LUBRICATION PAGE C - 3.............................................................

Draining Oil PAGE C - 3...........................................................

Condition of Oil PAGE C - 3........................................................

Adding Oil PAGE C - 3............................................................

TROUBLESHOOTING - SECTION D PAGE D - 1..............................

ELECTRICAL TESTING PAGE D - 3.....................................................

Test Equipment PAGE D - 3........................................................

Voltage Imbalance PAGE D - 3.....................................................

Motor and Power Cable Continuity PAGE D - 3.......................................

Insulation Resistance PAGE D - 4...................................................

i

Page 4

TABLE OF CONTENTS

(continued)

PUMP MAINTENANCE AND REPAIR ‐ SECTION E PAGE E - 1.................

GENERAL INFORMATION PAGE E - 1..................................................

Lifting PAGE E - 1.................................................................

Pump Serial Numbers PAGE E - 1..................................................

PARTS LISTS:

Pump Model SF4A-X PAGE E - 3..................................................

PUMP END DISASSEMBLY AND REASSEMBLY PAGE E - 4...............................

PUMP END DISASSEMBLY PAGE E - 4.................................................

Preparing Pump for Disassembly PAGE E - 4........................................

Suction Head and Wear Ring Removal PAGE E - 5....................................

Pump Casing Removal PAGE E - 5.................................................

Draining Oil From Seal Cavity PAGE E - 5............................................

Impeller Removal PAGE E - 5......................................................

Seal Removal PAGE E - 6..........................................................

PUMP END REASSEMBLY PAGE E - 6..................................................

Hardware Torque Values PAGE E - 6................................................

Cleaning and Inspection of Pump Parts PAGE E - 6...................................

Seal Installation PAGE E - 7........................................................

Impeller Installation PAGE E - 8.....................................................

Suction Head and Wear Ring Installation PAGE E - 8..................................

Pump Casing Installation PAGE E - 8................................................

Impeller Face Clearance Adjustment PAGE E - 9.....................................

Final Assembly PAGE E - 9........................................................

LUBRICATION PAGE E - 9.............................................................

Seal Cavity PAGE E - 9............................................................

ii

Page 5

OM-06629 SF SERIES X‐PROOF PUMPS

INTRODUCTION

Thank You for purchasing a Gorman‐Rupp SF

Series explosion‐proof pump. Read this manual

carefully to learn how to safely install and operate

your pump. Failure to do so could result in personal

injury or damage to the pump.

This manual contains essential information on in

stalling and operating the pump, and on making

electrical connections. However, since pump in

stallations are seldom identical, some of the infor

mation only summarizes general recommenda

tions and practices required to inspect, position,

and arrange the pump and piping.

This manual provides troubleshooting and mainte

nance instructions required to properly diagnose

operational problems, and to service the pump hy

draulic components only. Pump motor mainte

nance may be performed only by a Gorman‐Rupp

authorized repair facility, or the factory. Otherwise,

the pump warranty will be negated, and damage

to the pump, and injury or death to personnel can

result. Contact the factory for the authorized repair

facility closest to you.

The motor powering this pump is approved by

either CSA and/or FM for Class 1, Division 1,

Groups C and D environments. Refer to the name

plate on your pump for agency approval informa

tion. All repairs to the pump, other than seal, impel

ler and other hydraulic components, must be per

formed by a Gorman‐Rupp authorized repair facil

ity or the factory. Any repairs to the motor assembly

performed by the customer or an unauthorized re

pair facility negates the agency approval and the

motor warranty, and damage to the pump, and in

jury or death to personnel can result. If the motor

is dual‐voltage, the pump is shipped from the fac

tory wired only for the voltage shown on the name

plate. If desired to have the voltage changed, re

turn the pump to the factory or to a Gorman‐Rupp

authorized repair facility.

The pump motor must be operated through an ap

propriate control box matching the voltage and

other characteristics of the motor. The control box

must provide for proper operation of the motor pro

tection devices, such as the integral moisture and

thermal switches. Control boxes and other control

devices not integral to the pump are not covered

in this manual.

Pump construction is cast iron, with stainless steel

shaft and hardware.

These pumps may be equipped with a guide shoe

for mounting on guide rails in a wet well. A guide

rail system, controls and liquid level devices are

available from the factory as optional equipment.

If there are any questions regarding the pump

which are not covered in this manual or in other lit

erature accompanying the unit, please contact

your Gorman‐Rupp distributor or the Gorman‐

Rupp Company:

The Gorman‐Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-1217

Phone: (419) 755-1011

or:

Gorman‐Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631-2870

RECORDING MODEL AND

SERIAL NUMBERS

Please record the pump model, serial number, volt

age, and motor impeller diameter in the spaces

provided below. Your Gorman‐Rupp distributor

needs this information when you require parts or

service.

Pump Model:

Serial Number:

Voltage:

Impeller Diameter:

WARRANTY INFORMATION

The warranty provided with your pump is part of

Gorman‐Rupp's support program for customers

who operate and maintain their equipment as de

scribed in this and the other accompanying litera

ture. Please note that should the equipment be

abused or modified to change its performance be

yond the original factory specifications, the war

ranty will become void and any claim will be de

nied.

PAGE I - 1INTRODUCTION

Page 6

OM-06629SF SERIES X‐PROOF PUMPS

HAZARD AND INSTRUCTION

DEFINITIONS

The following are used to alert personnel to proce

dures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

Hazards or unsafe practices which COULD

result in minor personal injury or product or

property damage. These instructions de

scribe the requirements and the possible

damage which could result from failure to

follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I - 2 INTRODUCTION

Page 7

OM-06629 SF SERIES X‐PROOF PUMPS

SAFETY - SECTION A

The following information applies

throughout this manual to Gorman‐

Rupp SF Series explosion‐proof sub

mersible pumps.

When installing or servicing the pump

or controls, follow all requirements for

the installation of wiring or electrical

equipment in hazardous locations as

outlined in the National Electric Code.

Before attempting to install, operate, or

service this pump, familiarize yourself

with this manual, and with all other liter

ature shipped with the pump. Unfamil

iarity with all aspects of pump operation

covered in this manual could lead to de

struction of equipment, injury, or death

to personnel.

When entering the pump wet well for in

stallation or service, follow all safety re

quirements for confined space entry.

Failure to observe these requirements

could result in injury or death to person

nel.

The motor powering this pump is ap

proved by either CSA and/or FM for

Class 1, Division 1, Groups C and D en

vironments. Refer to the nameplate on

your pump for agency approval inform

ation. Any liquid level devices used with

the pump must be intrinsically safe for

use in these environments.

Any control box used to operate the

pump must meet all applicable local

and national codes for the application.

If the control box is to be installed in an

explosive environment, it must be a

Nema 7 rating or better. If a non‐explo

sion proof control box is used, it must be

located outside the explosive environ

ment. Improper location of a non‐explo

sion proof control box could result in de

struction of equipment, injury, or death

to personnel.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Obtain the services of a qu

alified electrician to make all electrical

connections.

Do not connect the pump motor directly

to the incoming power lines. The pump

motor is designed to operate through a

control box which provides overload

protection and power control; other

wise, the pump warranty will be voided.

Make certain that the pump and control

box are properly grounded, and that the

incoming power matches the require

ments of the pump and controls. Install

and operate the control box in accor

dance with the National Electric Code

and all local codes. Failure to follow

these could result in injury or death to

personnel.

PAGE A - 1SAFETY

Page 8

SF SERIES X‐PROOF PUMPS OM-06629

ing equipment to the lifting bail fitted on

the pump. Lift the pump or component

only as high as necessary and keep per

This pump is not designed to pump vol

sonnel away from suspended objects.

atile, flammable, or corrosive liquids.

The maximum temperature of the liquid

being pumped should not exceed 104_F

(40_C); do not apply the pump at higher

temperatures. Do not attempt to pump

any liquids which may damage the

pump or endanger personnel as a result

of pump failure.

This pump was wired at the factory only

for the voltage shown on the nameplate.

Do not attempt to change the voltage on

a dual‐voltage motor. If desired to have

the voltage changed, return the pump to

the factory or to an authorized Gorman‐

Rupp repair facility only; otherwise, the

pump warranty will be negated, and

The following precautions should be

taken before attempting to service the

damage to the pump, and injury or death

to personnel can result.

pump; otherwise, injury or death could

result.

1. Familiarize yourself with this man

ual and with all other literature

shipped with the pump.

2. Lock out incoming power to the

pump or control box to ensure that

the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

If the pump is used to handle liquids

which may cause illness or disease

through direct exposure, take neces

sary precautions during maintenance

and repair to prevent personal contami

nation.

4. Close the discharge valve (if

used).

The motor powering this pump is ap

Death or serious personal injury and

damage to the pump or components

can occur if proper lifting procedures

are not observed. Make certain that

hoists, chains, slings or cables are in

good working condition and of suffi

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Do not attempt to

lift this pump by the motor or control

cables, or the piping. Attach proper lift

PAGE A-2 SAFETY

proved by either CSA and/or FM for Class

1, Division 1, Groups C and D environ

ments. Refer to the nameplate on your

pump for agency approval information. All

repairs to the pump, other than seal, impel

ler and other hydraulic components, must

be performed by a Gorman‐Rupp autho

rized repair facility or the factory. Any re

pairs to the motor assembly performed by

the customer or an unauthorized repair fa

cility negates the agency approval and the

motor warranty.

Page 9

OM-06629 SF SERIES X‐PROOF PUMPS

Loose connections can result in damage to

equipment and serious injury to personnel.

After the pump has been installed, make

certain that the pump and all piping or hose

connections are secure before operation.

PAGE A - 3SAFETY

Page 10

OM-06629 SF SERIES X‐PROOF PUMPS

INSTALLATION - SECTION B

GENERAL INFORMATION

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section is intended only to summarize general rec

ommendations and practices required to inspect,

position, and arrange the pump and piping. If there

are any questions concerning your specific instal

lation, contact your Gorman‐Rupp distributor or

the Gorman‐Rupp Company.

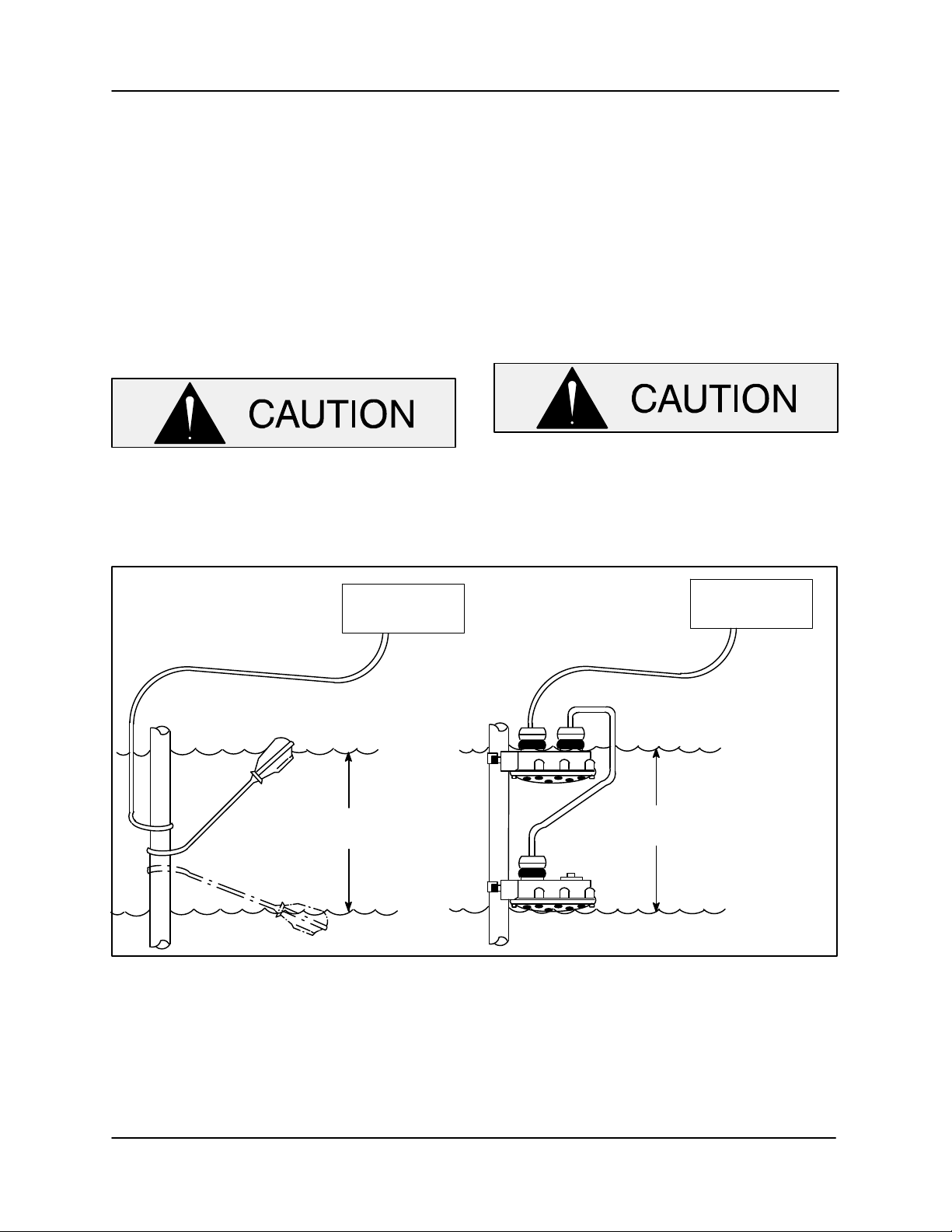

The pump motor is not designed to be

operated in air for more than 10 minutes

without overheating. The pump must be

operated through a liquid level control de

signed to cut off power when liquid falls be

low the midpoint of the motor housing

(single pump operation), or below the dis

charge flange (duplex, alternating pump

operation).

Controls, liquid level devices, and a guide rail sys

tem are available from Gorman‐Rupp as optional

equipment. For more information on installing and

operating these options, refer to the other literature

accompanying the option(s).

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

check for damage which may have occurred dur

ing shipment. Check as follows:

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious dam

age.

b. Check for loose attaching hardware. Since

gaskets tend to shrink after drying, check for

loose hardware at the mating surfaces.

c. Inspect the power cable for cuts or any other

obvious damage.

d. Check that amperes, phase, voltage and

hertz indicated on the name plate match the

ratings on the control box and incoming pow

er.

e. Carefully read all tags, decals, and markings

on the pump, and perform all duties indicated.

f. Check for oil leaks. If there is any indication of

an oil leak, see LUBRICATION at the end of

this manual.

LUBRICATION

These pumps are equipped with two separate

mechanical seals.

The seals prevent the liquid being pumped from

entering the seal housing cavity from the pump

end, and at the same time prevents the oil in the

seal housing from leaking into the motor housing.

The upper pump seal is lubricated by oil in the seal

housing (see LUBRICATION at the end of this

manual). The lower seal is lubricated by the medi

um being pumped.

There is no other lubrication required for these

pumps.

Pump Motor Specifications

The motor furnished with this pump is an air‐filled,

60 Hz., Squirrel Cage, Induction Start model;

NEMA Class H Insulation Rated 356_F (180_C),

104_F (40_C) ambient, plus 252_F (140_C) tem

perature rise. The motor is approved for Class 1,

Division 1, Group C and D locations.

See Table B‐1 for motor specifications for each

motor frame size.

PAGE B - 1INSTALLATION

Page 11

SF SERIES X‐PROOF PUMPS OM-06629

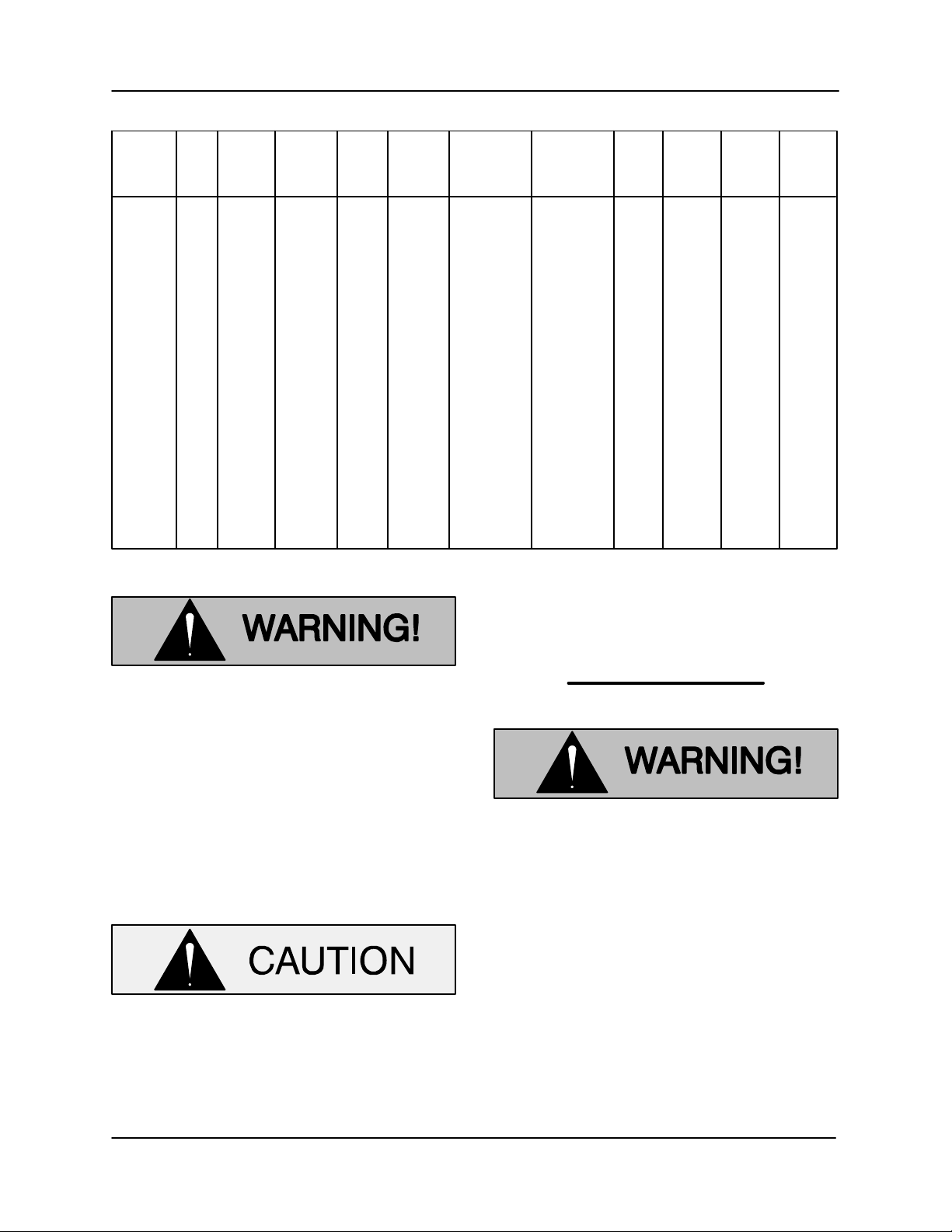

Table B‐1. Pump Motor Specifications

G‐R Full Locked LR

Motor HP Volts PH Hz RPM Load Rotor Code Start Design Service

Frame Amps Amps kVA Factor

4A 15 208 3 60 1750 46.8 416 L 149.9 A 1.15

4A 15 230 3 60 1750 42.4 376 L 149.8 A 1.15

4A 15 460 3 60 1750 21.2 188 L 149.8 A 1.15

4A 15 575 3 60 1750 17.0 150 L 149.4 A 1.15

4A 20 208 3 60 1750 58.6 416 J 149.9 A 1.15

4A 20 230 3 60 1750 53.0 376 J 149.8 A 1.15

4A 20 460 3 60 1750 26.5 188 J 149.8 A 1.15

4A 20 575 3 60 1750 21.2 150 J 149.4 A 1.15

4A 24 208 3 60 1750 63.4 416 G 149.9 A 1.0

4A 24 230 3 60 1750 61.6 376 G 149.8 A 1.15

4A 24 460 3 60 1750 30.8 188 G 149.8 A 1.15

4A 24 575 3 60 1750 24.6 150 G 149.4 A 1.15

5A 30 460 3 60 1750 36.6 246 H 196.0 B 1.15

5A 30 575 3 60 1750 29.3 197 H 196.2 B 1.15

6A 50 460 3 60 1750 60.0 425 H 338.6 A 1.15

6A 50 575 3 60 1750 48.0 340 H 338.6 A 1.15

7A 75 460 3 60 1750 86.0 542 G 431.8 B 1.15

7A 75 460 3 60 1750 69.0 434 G 432.2 B 1.15

PUMP INSTALLATION

When installing or servicing the pump

or controls, follow all requirements for

the installation of wiring or electrical

equipment in hazardous locations as

outlined in the National Electric Code.

When entering the pump wet well for in

stallation or service, follow all safety re

quirements for confined space entry.

Failure to observe these requirements

could result in injury or death to person

nel.

Do not allow the free end of the power

cable to enter the liquid being pumped.

The free end of the cable must be kept dry

to prevent liquid from wicking through the

cable and into the motor.

NOTE

Refer to the performance curve on the pump Spe

cification Data Sheet when determining the most ef

ficient piping installation. The recommended

maximum submergence depth is 65 feet.

Lifting

Death or serious personal injury and

damage to the pump or components

can occur if proper lifting procedures

are not observed. Make certain that

hoists, chains, slings or cables are in

good working condition and of suffi

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Do not attempt to

lift this pump by the motor or control

cables, or the piping. Attach proper lift

ing equipment to the lifting bail fitted on

the pump. Lift the pump or component

PAGE B - 2 INSTALLATION

Page 12

OM-06629 SF SERIES X‐PROOF PUMPS

only as high as necessary and keep per

sonnel away from suspended objects.

Pump unit weights will vary depending on the

pump application. Check the shipping tag on the

unit packaging for the actual weight, and use lifting

equipment with appropriate capacity. Drain the

pump and remove all customer‐installed equip

ment such as discharge hoses or piping before at

tempting to lift existing, installed units.

Impeller Rotation

Check impeller rotation as follows before installing

the pump on rails or in a wet well.

While checking impeller rotation, secure

the pump to prevent the motor power

cable from coiling.

Suspend the pump by the lifting handle. Apply

power briefly and note the direction of pump kick

back. As viewed from the top, the pump should

kick in a counterclockwise direction; this will indi

cate that impeller rotation is correct.

If the pump kicks in a clockwise direction, impeller

rotation is incorrect. If the pump is powered by a

three‐phase motor, have a qualified electrician in

terchange the control box connections of any two

pump motor power leads. Re‐check pump kick

back; it should now be in a counterclockwise direc

tion.

If rotation is incorrect on a single‐phase motor, con

tact the factory before installing the pump.

Positioning the Pump (Guide Rail Application)

If the pump is to be installed where flam

mable vapors may be present, the guide

rail system must be of a non‐sparking

design suitable for explosion‐proof ser

vice. Failure to observe this require

ment could result in injury or death to

personnel.

The pump may equipped with a guide shoe for

mounting on optional guide rails. A discharge el

bow/baseplate is also available as optional equip

ment.

Use a suitable lifting device attached to the lifting

handle to lift the pump. Engage the guide shoe at

the top of the guide rails, and lower the pump into

the sump. When lowered into place, the guide

shoe connects to the optional discharge elbow/

baseplate, and the pump is automatically and se

curely sealed to the piping system; the pump can

be removed or installed without personnel entering

the wet well.

For information on installing the guide rails, see the

literature accompanying the rails. Be sure the in

stallation allows the pump to slide without binding

on the rails or baseplate.

NOTE

When engaging the guide shoe and elbow/base

plate, make sure that the connection is not impeded

by mounting hardware, and that the guide shoe is

fully seated in the baseplate.

Reel in any slack control cable so that it is not

dragged into the pump suction.

Positioning the Pump (Stand Application)

Secure a discharge hose to the pump discharge

connection, and use a suitable lifting device at

tached to the lifting handle to lower the pump into

the wet well. The recommended maximum sub

mergence depth is 65 feet.

Make certain that the pump and stand sit level in

the wet well.

Reel in any slack control cable so that it is not

dragged into the pump suction.

Piping

The optional discharge elbow/baseplate is drilled

for connection to a discharge flange for slide rail

applications. Either hose or rigid pipe may be used

to make discharge connections.

If rigid discharge piping is installed, the line must

be independently supported to avoid vibration and

strain on the pump. For maximum pumping capac

ity, keep the line as short and straight as possible.

Elbows and fittings used in discharge lines in

crease friction loss; minimize their use.

PAGE B - 3INSTALLATION

Page 13

SF SERIES X‐PROOF PUMPS OM-06629

It is recommended that a check valve or throttling

valve be installed in the discharge line to control si

phoning or back flow when the pump is shut off.

ELECTRICAL CONNECTIONS

Install and operate this pump in accor

dance with the National Electrical Code

and all local codes. Have a qualified

electrician perform all checks and con

nections in this section.

Never attempt to alter the length of the

pump motor cable or to repair it with a

splice. The power cable and pump mo

tor must be kept completely waterproof.

Serious damage to the pump and injury

or death to personnel can result from

any alteration to the cable.

Field Wiring Connections (Incoming Power)

Do not connect the pump motor directly

to the incoming power lines. The pump

motor is designed to operate through a

control box which provides overload

protection and power control; other

wise, the pump warranty will be voided.

Make certain that the pump and control

box are properly grounded, and that the

incoming power matches the require

ments of the pump and controls. Install

and operate the control box in accor

dance with the National Electric Code

and all local codes. Failure to follow

these could result in injury or death to

personnel.

Field wiring is not provided with this pump, and

must be supplied by the user. The field wiring must

be of the proper size and type to ensure an ade

quate voltage supply to the pump. Voltage avail

able at the motor must be within the range indi

cated in Table B‐2.

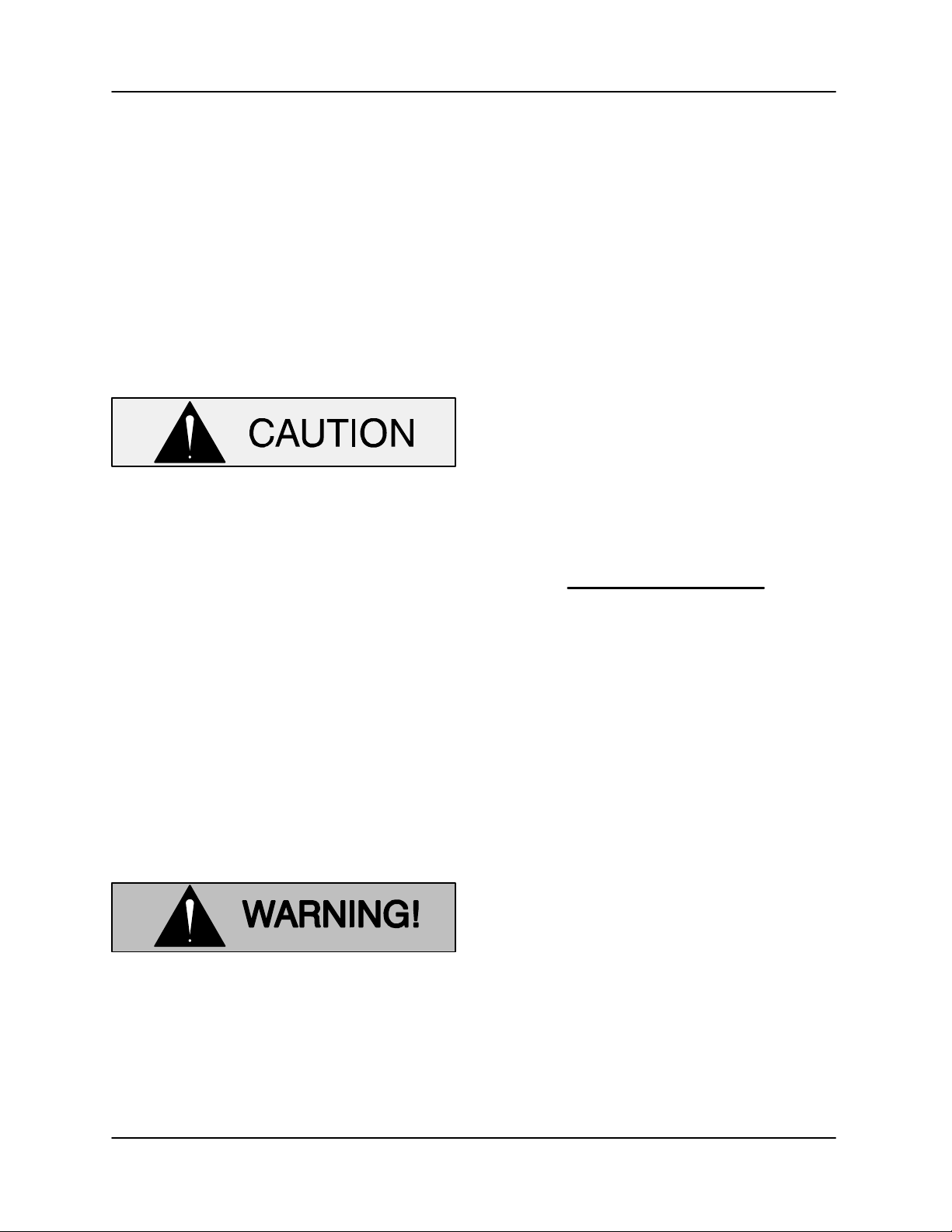

Table B‐2. Pump Voltage Requirements

NOMINAL

VOLTAGE

230

460

Use conduit cable clamps to secure the incoming

field wiring to the control box. Make certain all con

nections are tight. If necessary, support the cable

weight to prevent excessive strain on cable clamps

and cable.

Refer to the wiring diagrams at the end of this sec

tion for field wiring connections.

Dual Voltage

PHASE

3208 187 229

3

3

3575 517 632

MINIMUM

VOLTAGE

207

414

MAXIMUM

VOLTAGE

253

506

This pump was wired at the factory only

for the voltage shown on the nameplate.

Do not attempt to change the voltage on

a dual‐voltage motor. If desired to have

the voltage changed, return the pump to

the factory or to an authorized Gorman‐

Rupp repair facility only; otherwise, the

pump warranty will be negated, and

damage to the pump, and injury or death

to personnel can result.

Motor Cable Grounding Test

Do not connect the pump control cable

to the control box or incoming voltage

before verifying the pump ground;

otherwise, personnel will be exposed to

serious injury or death.

Connect one lead of a lamp, bell or similar testing

device to the motor cable green/yellow ground

lead (s). Connect the second test lead to an unin

sulated point on the pump body. The test circuit

should close.

PAGE B - 4 INSTALLATION

Page 14

OM-06629 SF SERIES X‐PROOF PUMPS

If the test circuit does not close, there is a defect in

the cable or motor which must be corrected.

Control Box Connections

The motor powering this pump is ap

proved by both CSA and FM for Class 1,

Division 1, Groups C and D environ

ments. Any liquid level devices used

with the pump must be intrinsically safe

for use in these environments.

Any control box used to operate the

pump must meet all applicable local

and national codes for the application. If

the control box is to be installed in an ex

plosive environment, it must be a Nema

7 rating or better. If a non‐explosion

proof control box is used, it must be lo

cated outside the explosive environ

ment. Improper location of a non‐explo

sion proof control box could result in de

struction of equipment, injury, or death

to personnel.

This pump is shipped completely wired for the volt

age shown on the nameplate and is ready for op

eration through an approved control box.

Ground the control box in accordance with the in

structions accompanying it.

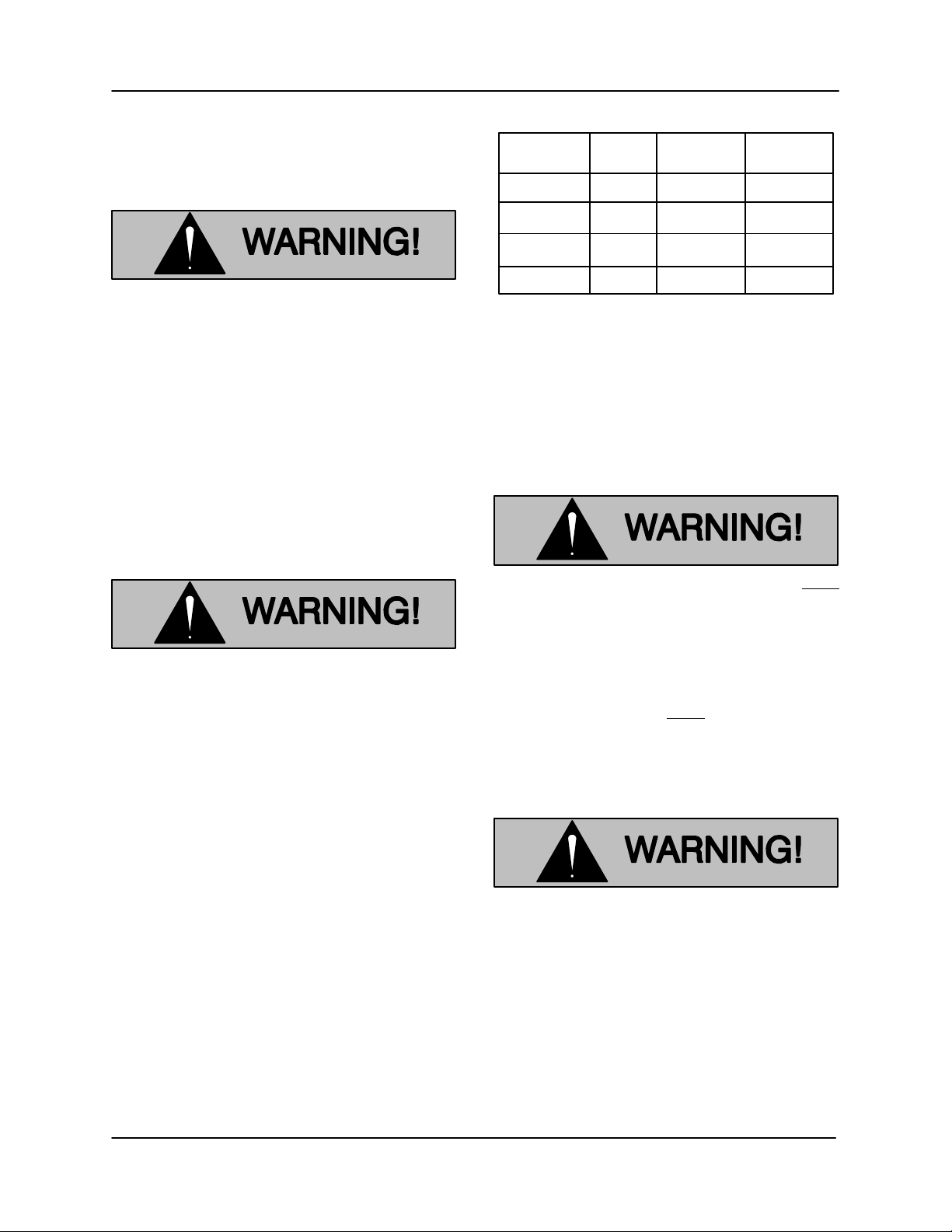

Refer to Figure B-1 and connect the pump motor

cable to the control box.

Figure B-1. Three Phase Power

Cable Connections

Control leads P1 and P2 provide the motor with

thermal protection. Control leads W1 and W2 pro

vide the motor with moisture protection. Refer to

Figure B-2 and connect the pump control cable to

the control box.

Ground the pump to the control box using the pow

er cable ground(s) and ground check wire (if so

equipped). Secure the ground wire(s) and ground

check wire (if so equipped) to the grounding lug(s)

inside the control box to ensure a thorough ground

for the pump.

Ground the pump using the power cable

ground wire(s) before applying line po

tential. Failure to properly ground the

pump could result in damage to the

pump or control and/or injury or death to

personnel.

Figure B-2. Control Cable Connections

The thermal protection contacts will auto

matically re‐close when the motor cools to

the established safe operating tempera

ture. Whenever automatic restarting is not

desirable, connect only to controls which

are wired for manual restart.

PAGE B - 5INSTALLATION

Page 15

SF SERIES X‐PROOF PUMPS OM-06629

Refer to the appropriate wiring diagram accompa

nying the control box when making electrical con

nections.

Liquid Level Devices

Optional controls available from Gorman‐Rupp

may provide a means to automatically regulate the

liquid level. These control boxes may be con

nected to the following sensing devices which per

form either filling or dewatering functions (see Fi

gure B-3).

The internal wiring of the sensing devices

are different for filling and dewatering func

tions. Be sure to follow the instructions in

cluded with the option before making con

nections.

S Diaphragm Type: two fixed‐position sen

sors (upper and lower) each contain a dia

phragm which flexes with changes in liquid

level, thus activating an enclosed miniature

switch.

S Bulb (Float) Type: a bulb raises or lowers

(floats) with the liquid level, thus activating

an enclosed miniature switch.

Other types of liquid level devices may also be

used. Consult the factory for the liquid level device

best suited for your application.

Liquid level devices must be positioned far

enough to allow 6 minutes between starts.

If the pump motor cycles more than 10

starts per hour, it will over‐heat, resulting in

damage to the motor windings or control

box components.

PUMP

CONTROL BOX

TO LEVEL CONTROL CIRCUIT

IN MAIN CONTROL

BOX

LIQUID LEVEL

RANGE

OFF

DEWATERING

ON (FILLING)

BULB (FLOAT TYPE)

Figure B-3. Liquid Level Devices

TO LEVEL CONTROL CIRCUIT

IN MAIN CONTROL

BOX

LIQUID LEVEL

RANGE

DEWATERING

ON (FILLING)

DIAPHRAGM TYPE

PUMP

CONTROL BOX

OFF

PAGE B - 6 INSTALLATION

Page 16

OM-06629 SF SERIES X‐PROOF PUMPS

OPERATION - SECTION C

GENERAL INFORMATION

Review all SAFETY information in Section A.

This pump is not designed to pump vol

atile, flammable, or corrosive liquids.

The maximum temperature of the liquid

being pumped should not exceed 104_F

(40_C); do not apply the pump at higher

temperatures. Do not attempt to pump

any liquids which may damage the

pump or endanger personnel as a result

of pump failure.

Follow the instructions on all tags, labels and de

cals attached to the pump.

Pump Performance

Refer to the pump Specification Data Sheet for the

specific performance for your pump.

Control Box

The motor powering this pump is ap

proved by either CSA and/or FM for

Class 1, Division 1, Groups C and D en

vironments. Refer to the nameplate on

your pump for agency approval inform

ation. Any liquid level devices used with

the pump must be intrinsically safe for

use in these environments

Any control box used to operate the

pump must meet all applicable local

and national codes for the application.

If the control box is to be installed in an

explosive environment, it must be a

Nema 7 rating or better. If a non‐explo

sion proof control box is used, it must be

located outside the explosive environ

ment. Improper location of a non‐explo

sion proof control box could result in de

struction of equipment, injury, or death

to personnel.

See the operating instructions furnished with the

control box, and with other optional accessories

and controls, before attempting to start the pump.

PUMP OPERATION

Liquid Temperature and Overheating.

Overheated pumps can cause severe

burns and injury. If the pump becomes

overheated:

1. Stop the pump immediately.

2. Lock out the power to the control

panel to ensure that the pump will

remain inoperative.

2. Allow the pump to completely cool

if overheated.

3. Close the discharge valve (if

used).

4. Refer to instructions in this manual

before restarting the pump.

Overheating can occur if the pump is misapplied;

if it is started more than 10 times within one hour;

if the control box fails to provide overload or ther

mal protection, or if the pump is operated against

a closed discharge valve for an extended period of

time.

The submersible motor is cooled by the liquid be

ing pumped. To minimize the chance of over‐heat

ing when installed in a simplex application, it is

recommended that at least one‐half of the motor

remain immersed in the liquid.

PAGE C - 1OPERATION

Page 17

SF SERIES X‐PROOF PUMPS OM-06629

tempt to handle or service the pump un

less all power to the motor has been

shut off and locked out at the control

Do not start the pump more than 10 times

per hour. If the motor does not cool be

tween starts it will overheat, resulting in

damage to the motor windings or control

box components.

When installed in a standard alternating duplex

application, where one pump runs while the other

is shut down, the pump may be operated continu

ously until fully exposed. The shut down cycle will

provide sufficient time for the motor to cool.

box; otherwise, serious personal injury

could result.

During motor shutoff by the thermal

overload device, control box circuits re

main live. Do not attempt to service any

control box components unless incom

ing power has been shut off.

After stopping the pump, be sure to perform all re

quired maintenance and preservation procedures.

Operational Checks

STARTING, STOPPING, AND

OPERATIONAL CHECKS

Starting

Do not attempt to operate the pump until

impeller rotation has been checked; im

proper rotation will affect pump perform

ance and may damage the pump.

Follow the instructions accompanying the control

box, start the pump, and run any recommended

checks.

Stopping

Follow the instructions accompanying the control

box for stopping the pump.

To detect minor problems, check the pump for

proper operation when it is first started, and at peri

odic intervals during operation.

To avoid serious damage to the pump,

check for unusual noises or excessive vi

bration while the pump is running. If noise

or vibration is excessive, stop operation

and refer to the troubleshooting chart in

Section D.

The suction inlet or impeller may become clogged

with debris. In some cases, stopping the pump

momentarily may backflush this blockage. If back

flushing does not clear the debris, remove the

pump from the sump or wet well and clear manu

ally.

Never introduce air or steam pressure

The integral thermal overload device

will shut off the motor if the temperature

rises above design limits. When the

pump cools and the temperature falls

below these limits, the motor will restart

automatically. To avoid the hazards of

an unexpected motor start‐up, do not at

PAGE C - 2 OPERATION

into the pump casing to remove a block

age. This could result in personal injury

or damage to the equipment. If back

flushing is absolutely necessary, limit

liquid pressure input to 50% of the maxi

mum permissible operating pressure

shown in the pump performance curve

Page 18

OM-06629 SF SERIES X‐PROOF PUMPS

(refer to the pump Specification Data

Sheet).

Check the pump for overheating. Overheating can

occur if the pump is misapplied, required to start

repeatedly, if the control box fails to provide over

load or thermal protection, or if the pump is oper

ated against a closed discharge valve for an ex

tended period of time.

Do not start the pump more than 10 times

per hour. If the motor does not cool be

tween starts it will overheat, resulting in

damage to the motor windings or control

box components.

Do not attempt to thaw the pump by us

ing a torch or other source of flame. This

could damage O‐rings or heat the oil in

the seal housing above critical tempera

tures, causing the pump to rupture or

explode.

LUBRICATION

Before installing or removing the lubrica

tion plugs, always make sure the pump is

completely cool, and clean the area

around the plugs to prevent contamination

of the oil.

Check the oil level in the seal cavity before initial

startup, after the first two weeks of operation, and

every month thereafter.

Check the oil level only when the pump

is cool. If the oil level plug is removed

when the pump is hot, pressure in the

seal cavity can cause hot oil to be

ejected as the plug is removed.

Draining Oil

Lay the pump flat on a work surface with one of the

lubrication plugs facing up. Remove the plug slow

ly to release any pressure in the seal housing.

COLD WEATHER PRESERVATION

The pump will not freeze as long as the casing is

submerged in liquid. If the casing is not sub

merged, or if the liquid begins to freeze, remove the

pump from the sump or wet well and dry it thor

oughly. Run the pump for two or three minutes to

dry the inner walls.

If the pump does freeze while it is out of the liquid,

submerge it until thawed; if the liquid is near freez

ing, the pump must be submerged for an extended

period of time. Check thawing by starting the pump

and checking that the shaft rotates freely. If the

pump remains frozen, allow additional thawing

time before attempting to restart.

If submerging does not thaw the pump, move it

into a warm area until completely thawed.

Place a clean container under the other (lower)

plug. Remove the plug and roll the pump on its side

to drain the seal housing.

Condition Of Oil

Check the condition of the oil drained from the

pump. Clear oil indicates that the lower pump seal

is functioning properly. If the oil is milky or contains

water, the lower seal must be changed before the

pump is put back in operation.

Adding Oil

Remove the lubrication plugs as indicated in

Draining Oil. Position the pump upright and add

premium quality submersible pump oil through

one of the plug holes until the oil reaches the bot

tom of the hole. Clean and re‐install the plugs.

PAGE C - 3OPERATION

Page 19

SF SERIES X‐PROOF PUMPS OM-06629

The grade of lubricant used is critical to the opera

tion of this pump. Use premium quality hydraulic oil

as specified in Table C-1.

Table C-1. Pump Oil Specifications

Specifications:

Type Premium high viscosity index, anti‐wear hydraulic oil..............................

Viscosity @ 100_F (38_C) 110 to 155...............................................

Viscosity @ 210_F (99_C) 40 to 50..................................................

Dielectric 26,000 (volts‐min)........................................................

Recommended supplier:

Gulf Oil Company Gulf Harmony HVI AW 26..........................................

Acceptable alternate suppliers:

Gulf Oil Company Gulf Harmony 32 AW..............................................

Texas Oil Company Rando HD 32 or HD AZ 32........................................

Sun Oil Company Sunvis 816 or 916.................................................

British Petroleum Oil Company Energol‐HLP 32........................................

Shell Oil Company Tellus 32, Tellus T‐23 or T32.......................................

ARCO Duro 32...................................................................

Exxon Nuto H 32...................................................................

PAGE C - 4 OPERATION

Page 20

OM-06629 SF SERIES X‐PROOF PUMPS

TROUBLESHOOTING - SECTION D

Review all SAFETY information in Section A.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

The following precautions should be

taken before attempting to service the

pump; otherwise, injury or death could

result.

opening any covers, plates or

plugs.

4. Close the discharge valve (if

used).

1. Familiarize yourself with this man

ual and with all other literature

shipped with the pump.

2. Lock out incoming power to the

pump or control box to ensure that

Many of the probable remedies listed below re

quire use of electrical test instruments; for specific

procedures, see ELECTRICAL TESTING following

the chart.

NOTE

the pump will remain inoperative.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP FAILS TO

START

No power to motor. Check for blown fuse or open

circuit breaker.

Impeller jammed. Check Impeller; disassemble and

repair as necessary.

Motor, voltage or control box incompat‐ Check ratings on pump nameplate

ible; defective connections. and control box; check incoming

voltage; check connections.

Motor cable damaged. Check (see Electrical Testing).

Control box current interrupting or Check control box; check for leaking

moisture‐sensing devices tripped. shaft seals, cut O‐rings, or moisture

wicking through cable.

Open circuit in motor windings or. Check continuity (see Electrical

cable. Testing).

Motor overheated, thermal switches Allow motor to cool.

tripped.

TROUBLESHOOTING PAGE D - 1

Page 21

SF SERIES X‐PROOF PUMPS OM-06629

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

MOTOR RUNS BUT

FAILS TO DELIVER

RATED FLOW OR

PRESSURE

PUMP STARTS

THEN SHUTS OFF

Pump running backwards. Check and correct impeller rotation

(see Rotation in Installation and

Operation Manual).

Voltage too low or too high; excessive Check incoming voltage; check

voltage drop between pump and control. cable length.

Discharge head too high. Reduce discharge head, or install

staging adaptor and additional pump.

Discharge throttling valve partially Open discharge valve; check piping

closed; check valve improperly installed. installation.

Impeller or discharge line clogged. Check and clear as necessary.

Liquid being pumped too thick. Dilute liquid if possible.

Impeller worn or damaged. Replace.

Insufficient liquid in wet well. Stop pump until liquid level rises;

install liquid level devices.

Clogged suction port or impeller Clear blockage; reset overload

causing motor to overload. device in control box.

EXCESSIVE

NOISE OR VIBRA

TION

Motor overheated; thermal switch Allow pump to cool.

tripped.

Moisture sensing device tripped. Return pump to factory or authorized

repair facility.

Motor bearings defective. Return pump to factory or authorized

repair facility.

Motor cable damaged. Check (see Electrical Testing).

Insufficient liquid in wet well. Stop pump until liquid level rises;

install liquid level devices.

Pump operating outside designed Check discharge head and flow;

operating range. adjust as required to meet perform‐

ance specifications.

Impeller clogged. Clear blockage.

Impeller loose or damaged. Check impeller; replace if necessary.

Motor shaft or bearings defective. Replace.

Pumping entrained air. Check wet well liquid level; install

baffles if required.

TROUBLESHOOTINGPAGE D - 2

Page 22

OM-06629 SF SERIES X‐PROOF PUMPS

ELECTRICAL TESTING

Make the electrical checks which follow to deter

mine if pump malfunctions are being caused by

problems in the motor or in the power cable.

Test Equipment

A volt/amp/ohmmeter and megohmmeter of ade

quate range and quality are required to conduct

the electrical tests which follow. Use commercially

available equipment as listed below.

Equipment Use

Ammeter To check AC Voltage

and current (amperage)

Ohmeter To measure resistance

(ohms) to ground

can be measured. If possible, measure the

voltage at the control box with:

1. The pump off.

2. The pump running in air.

3. The pump submerged and running under

full load.

The voltage measured under each condition must

be the same.

b. If voltage is balanced when the pump is off but

is imbalanced when the pump is running,

thoroughly check the power source, all inter

connecting cables, and the pump motor to

isolate the defect.

c. Use an Amprobe or equivalent instrument to

measure the current draw (amperage) of

each phase while the pump is running under

full load, and with no load. In each condition,

the amperage readings for all three phases

must match as closely as can be measured.

Normal amperage values are listed in Table 1,

Section B; these values apply only when the

voltage at the site is the normal voltage listed.

Refer to the wiring diagram(s) accompany

ing the motor and control box before re

connecting any electrical leads which have

been disconnected. Connections to the

wrong terminals may damage the motor

and/or control devices.

Voltage Imbalance

Use a voltmeter to read each phase of the incom

ing 3‐phase power. Each phase must balance with

the other two as closely as can be measured with a

commercial instrument. If the phases are out of

balance, contact your power company. If the

phases are balanced, check out the motor as de

scribed in the following steps:

a. Use a voltmeter, Amprobe, or equivalent in

strument to read the voltage of incoming

power lines 1 and 2, 2 and 3, and 1 and 3 at the

control box. Voltage must match as closely as

TROUBLESHOOTING PAGE D - 3

Motor and Power Cable Continuity

Set the megohmmeter at R x 1 scale and zero‐

balance it. Test as follows:

a. Shut off incoming power to the control box,

and disconnect the motor power cable leads.

Connect the megohmmeter test leads to any

two power cable leads, and note the megohm

meter reading. A high resistance reading indi

cates an open or broken circuit in the power

cable or motor windings, or a bad connection

between the motor and cable.

b. Repeat Step a. with each set of leads. The

three readings should be as close as can be

measured.

c. If readings indicate that continuity problems

exist in the motor or power cable, the motor

must be returned to the factory or to a Gor

man‐Rupp authorized repair facility.

Page 23

SF SERIES X‐PROOF PUMPS OM-06629

Insulation Resistance

Set the megohmmeter at R x 100, and zero‐ba

lance it. Test as follows:

a. Shut off incoming power to the control box,

and disconnect the motor power cable leads.

Connect one megohmmeter test lead to the

motor cable green/yellow ground lead. Touch

the other test lead to each of the motor cable

leads in turn. Note the readings.

b. Readings will indicate resistance values in

both the power cable and motor windings.If

resistance reads infinity (1), insulation is

good. If resistance reads between infinity (1),

and 1 megohm, insulation is acceptable but

should be rechecked regularly. If resistance

reads less than 1 megohm, insulation should

be checked more closely and frequently.

c. If readings indicate that a ground exists, the

motor must be returned to the factory or to a

Gorman‐Rupp authorized repair facility.

TROUBLESHOOTINGPAGE D - 4

Page 24

PUMP MAINTENANCE AND REPAIR - SECTION E

OM-06629SF SERIES X‐PROOF PUMPS

GENERAL INFORMATION

Review all SAFETY information in Section A.

Do not attempt to service the pump as

sembly unless all power to the motor

has been shut off at the control box;

otherwise, injury or death could result.

Select a suitable location, preferably indoors, to

perform required maintenance. All work must be

performed by qualified personnel.

The motor powering this pump is ap

proved by either CSA and/or FM for Class

1, Division 1, Groups C and D environ

ments. Refer to the nameplate on your

pump for agency approval information. All

repairs to the pump, other than seal, impel

ler and other hydraulic components, must

be performed by a Gorman‐Rupp autho

rized repair facility or the factory. Any re

pairs to the motor assembly performed by

the customer or an unauthorized repair fa

cility negates the agency approval and the

motor warranty.

Check TROUBLESHOOTING, Section D to deter

mine causes and remedies of pump problems.

This section of the manual provides maintenance

instructions required to properly service the pump

hydraulic components only. Pump motor mainte

nance may be performed only by a Gorman‐Rupp

authorized repair facility, or the factory. Otherwise,

the pump warranty will be negated, and damage

to the pump, and injury or death to personnel can

result. Contact the factory for the authorized repair

facility closest to you.

Lifting

Death or serious personal injury and

damage to the pump or components

can occur if proper lifting procedures

are not observed. Make certain that

hoists, chains, slings or cables are in

good working condition and of suffi

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Do not attempt to

lift this pump by the motor or control

cables, or the piping. Attach proper lift

ing equipment to the lifting bail fitted on

the pump. Lift the pump or component

only as high as necessary and keep per

sonnel away from suspended objects.

Pump unit weights will vary depending on the

pump application. Check the shipping tag on the

unit packaging for the actual weight, and use lifting

equipment with appropriate capacity. Drain the

pump and remove all customer‐installed equip

ment such as discharge hoses or piping before at

tempting to lift existing, installed units.

Pump Serial Numbers

Pumps in the following serial number range are

covered in this section.

(From S/N 1531245 Up)

If your pump serial number is followed by an “N”,

your pump is NOT a standard production model.

Contact the Gorman‐Rupp Company to verify part

numbers.

PAGE E - 1MAINTENANCE AND REPAIR

Page 25

PARTS PAGE

SF SERIES X‐PROOF PUMPSOM-06629

ILLUSTRATION

Figure E-1. SF4A-X Pump Model Assembly

MAINTENANCE AND REPAIRPAGE E - 2

Page 26

SF4A-X Pump Model Assembly

ITEM

PART NAME PART

NO.

1 PUMP CASING

. -ANSI SEE NOTE BELOW 1

. -DIN SEE NOTE BELOW 1

2 IMPELLER SEE NOTE BELOW 1

3 IMPELLER WASHER 31514-017 17000 1

4 SOCKET HD CAPSCREW MBD1020 17000 1

5 WEAR RING 38691-368 11010 1

6 O‐RING 25152-277 --- 1

7 LOCK WASHER MJ12 17000 14

8 ADJUSTING SCREW MB1235 17000 4

8A HEX HD CAPSCREW MB1235 17000 8

9 SUCTION HEAD

-ANSI 38246-619 10000 1

-DIN 38246-620 10000 1

10 O‐RING 25152-276 --- 1

11 HEX HD CAPSCREW MB1245 17000 8

12 NAME PLATE NOT AVAILAABLE

13 DRIVE SCREW NOT AVAILAABLE

14 MOTOR ASSY CONSULT FACTORY

15 TERM HOUSING ASSY NOT AVAILAABLE

16 LOCK WASHER NOT AVAILAABLE

17 HEX NUT NOT AVAILAABLE

18 HEX HD CAPSCREW MB1230 17000 2

19 LIFTING BAIL ASSY 44713-048 17040 1

20 JAM NUT MAT12 17000 4

21 SEAL PLATE 38272-536 10000 1

22 O‐RING 25152-379 --- 1

23 FLAT HD CAPSCREW MF0520 17000 4

24 SHAFT SLEEVE O‐RING 25154-022 --- 1

25 SHAFT SLEEVE 31441-030 1706H 1

26 SEAL ASSY 25285-856 --- 1

27 SPRING RETAINER 31161-042 17000 1

28 IMP ADJ SHIM SET 37J 17090 1

29 . PIPE PLUG P04 17000 2

NOT SHOWN:

INFINITY DECAL 38811-435 --- 1

G‐R DECAL GR-03 --- 1

NUMBER

MAT'L

CODE

Parts List

QTY ITEM

NO.

OPTIONAL:

OM-06629SF SERIES X‐PROOF PUMPS

PART NAME PART

NUMBER

ANSI SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-559 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT 48156-024 --- 1

ALIGNMENT KIT 48786-551 --- 1

BASEPLATE KIT

-SHORT 48156-603 --- 1

-LONG 48156-604 --- 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

DIN SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-560 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT CONSULT FACTORY 1

ALIGNMENT KIT 48786-552 --- 1

BASEPLATE KIT

-SHORT CONSULT FACTORY 1

-LONG CONSULT FACTORY 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

ANSI TRASH VERSION

STAND KIT 48786-209 --- 1

DISCH ELBOW KIT 48135-102 --- 1

INCREASER KIT 48135-502 --- 1

DIN TRASH VERSION

STAND KIT 48786-213 --- 1

DISCH ELBOW KIT 48135-106 --- 1

LIQUID LEVEL DEVICES:

DIAPHRAGM TYPE GRP48-03 --- 1

GRP48-06 --- 1

FLOAT TYPE 27471-180 --- 1

120V LIQUID LEVEL

CONTROL RELAY 27521-321 --- 1

MAT'L

CODE

QTY

. INCLUDED W/ANSI REPAIR PUMP CASING ASSY 46472-912 --- 1

. INCLUDED W/DIN REPAIR PUMP CASING ASSY 46472-919 --- 1

INDICATES PARTS RECOMMENDED FOR STOCK

NOTE: WHEN ORDERING A REPLACEMENT IMPELLER, PROVIDE THE FACTORY WITH THE PUMP MODEL, S/N AND IMPELLER

DIAMETER (FROM NAMEPLATE)

PAGE E - 3MAINTENANCE AND REPAIR

Page 27

ILLUSTRATION

SF SERIES X‐PROOF PUMPSOM-06629

Figure E-2. SF4B-X Pump Model Assembly

MAINTENANCE AND REPAIRPAGE E - 4

Page 28

SF4B-X Pump Model Assembly

ITEM

PART NAME PART

NO.

1 PUMP CASING

. -ANSI SEE NOTE BELOW 1

. -DIN SEE NOTE BELOW 1

2 IMPELLER SEE NOTE BELOW 1

3 IMPELLER WASHER 31514-017 17000 1

4 SOCKET HD CAPSCREW MBD1020 17000 1

5 WEAR RING 38691-368 11010 1

6 O‐RING 25152-277 --- 1

7 SUCTION HEAD

-ANSI 38246-619 10000 1

-DIN 38246-620 10000 1

8 LOCK WASHER MJ12 17000 14

9 ADJUSTING SCREW MB1235 17000 4

9A HEX HD CAPSCREW MB1235 17000 8

10 O‐RING 25152-276 --- 1

11 HEX HD CAPSCREW MB1245 17000 8

12 NAME PLATE NOT AVAILAABLE

13 DRIVE SCREW NOT AVAILAABLE

14 MOTOR ASSY CONSULT FACTORY

15 TERM HOUSING ASSY NOT AVAILAABLE

16 LOCK WASHER NOT AVAILAABLE

17 HEX NUT NOT AVAILAABLE

18 HEX HD CAPSCREW MB1030 17000 2

19 LIFTING BAIL ASSY 44713-048 17040 1

20 JAM NUT MAT12 17000 4

21 SEAL PLATE 38272-536 10000 1

22 FLAT HD CAPSCREW MF0520 17000 4

23 O‐RING 25152-379 --- 1

24 SHAFT SLEEVE O‐RING 25154-022 --- 1

25 SHAFT SLEEVE 31441-030 1706H 1

26 SEAL ASSY 25285-856 --- 1

27 SPRING RETAINER 31161-042 17000 1

28 IMP ADJ SHIM SET 37J 17090 1

29 . PIPE PLUG P04 17000 2

NOT SHOWN:

INFINITY DECAL 38811-435 --- 1

G‐R DECAL GR-03 --- 1

NUMBER

MAT'L

CODE

Parts List

QTY ITEM

NO.

OPTIONAL:

OM-06629SF SERIES X‐PROOF PUMPS

PART NAME PART

NUMBER

ANSI SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-559 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT 48156-024 --- 1

ALIGNMENT KIT 48786-551 --- 1

BASEPLATE KIT

-SHORT 48156-603 --- 1

-LONG 48156-604 --- 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

DIN SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-560 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT CONSULT FACTORY 1

ALIGNMENT KIT 48786-552 --- 1

BASEPLATE KIT

-SHORT CONSULT FACTORY 1

-LONG CONSULT FACTORY 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

ANSI TRASH VERSION

STAND KIT 48786-209 --- 1

DISCH ELBOW KIT 48135-102 --- 1

INCREASER KIT 48135-502 --- 1

DIN TRASH VERSION

STAND KIT 48786-213 --- 1

DISCH ELBOW KIT 48135-106 --- 1

LIQUID LEVEL DEVICES:

DIAPHRAGM TYPE GRP48-03 --- 1

GRP48-06 --- 1

FLOAT TYPE 27471-180 --- 1

120V LIQUID LEVEL

CONTROL RELAY 27521-321 --- 1

MAT'L

CODE

QTY

. INCLUDED W/ANSI REPAIR PUMP CASING ASSY 46472-912 --- 1

. INCLUDED W/DIN REPAIR PUMP CASING ASSY 46472-919 --- 1

INDICATES PARTS RECOMMENDED FOR STOCK

NOTE: WHEN ORDERING A REPLACEMENT IMPELLER, PROVIDE THE FACTORY WITH THE PUMP MODEL, S/N AND IMPELLER

DIAMETER (FROM NAMEPLATE)

PAGE E - 5MAINTENANCE AND REPAIR

Page 29

ILLUSTRATION

SF SERIES X‐PROOF PUMPSOM-06629

Figure E-3. SF4C-X Pump Model Assembly

MAINTENANCE AND REPAIRPAGE E - 6

Page 30

SF4C-X Pump Model Assembly

ITEM

PART NAME PART

NO.

1 PUMP CASING

. -ANSI SEE NOTE BELOW 1

. -DIN SEE NOTE BELOW 1

2 IMPELLER SEE NOTE BELOW 1

3 IMPELLER WASHER 31514-039 17000 1

4 SOCKET HD CAPSCREW MBD1225 17000 1

5 WEAR RING 38691-368 11010 1

6 O‐RING 25152-277 --- 1

7 SUCTION HEAD

-ANSI 38246-619 10000 1

-DIN 38246-620 10000 1

8 LOCK WASHER MJ12 17000 14

9 ADJUSTING SCREW MB1235 17000 4

9A HEX HD CAPSCREW MB1235 17000 4

10 O‐RING 25152-276 --- 1

11 HEX HD CAPSCREW MB1245 17000 8

12 NAME PLATE NOT AVAILAABLE

13 DRIVE SCREW NOT AVAILAABLE

14 MOTOR ASSY CONSULT FACTORY

15 TERM HOUSING ASSY NOT AVAILAABLE

16 LOCK WASHER NOT AVAILAABLE

17 HEX NUT NOT AVAILAABLE

18 HEX HD CAPSCREW MB1630 17000 2

19 LIFTING BAIL ASSY 44713-051 17040 1

20 JAM NUT MAT12 17000 4

21 SEAL PLATE 38272-537 10000 1

22 FLAT HD CAPSCREW MF0520 17000 4

23 O‐RING 25152-379 --- 1

24 SHAFT SLEEVE O‐RING 25154-031 --- 1

25 SHAFT SLEEVE 31441-031 1706H 1

26 SEAL ASSY 25285-860 --- 1

27 SPRING RETAINER 31161-042 17000 1

28 IMP ADJ SHIM SET 8499 17000 1

29 . PIPE PLUG P04 17000 1

NOT SHOWN:

INFINITY DECAL 38811-435 --- 1

G‐R DECAL GR-03 --- 1

NUMBER

MAT'L

CODE

Parts List

QTY ITEM

NO.

OPTIONAL:

OM-06629SF SERIES X‐PROOF PUMPS

PART NAME PART

NUMBER

ANSI SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-559 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT 48156-024 --- 1

ALIGNMENT KIT 48786-551 --- 1

BASEPLATE KIT

-SHORT 48156-603 --- 1

-LONG 48156-604 --- 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

DIN SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-560 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT CONSULT FACTORY 1

ALIGNMENT KIT 48786-552 --- 1

BASEPLATE KIT

-SHORT CONSULT FACTORY 1

-LONG CONSULT FACTORY 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

ANSI TRASH VERSION

STAND KIT 48786-209 --- 1

DISCH ELBOW KIT 48135-102 --- 1

INCREASER KIT 48135-502 --- 1

DIN TRASH VERSION

STAND KIT 48786-213 --- 1

DISCH ELBOW KIT 48135-106 --- 1

LIQUID LEVEL DEVICES:

DIAPHRAGM TYPE GRP48-03 --- 1

GRP48-06 --- 1

FLOAT TYPE 27471-180 --- 1

120V LIQUID LEVEL

CONTROL RELAY 27521-321 --- 1

MAT'L

CODE

QTY

. INCLUDED W/ANSI REPAIR PUMP CASING ASSY 46472-912 --- 1

. INCLUDED W/DIN REPAIR PUMP CASING ASSY 46472-919 --- 1

INDICATES PARTS RECOMMENDED FOR STOCK

NOTE: WHEN ORDERING A REPLACEMENT IMPELLER, PROVIDE THE FACTORY WITH THE PUMP MODEL, S/N AND IMPELLER

DIAMETER (FROM NAMEPLATE)

PAGE E - 7MAINTENANCE AND REPAIR

Page 31

ILLUSTRATION

SF SERIES X‐PROOF PUMPSOM-06629

Figure E-4. SF4D-X Pump Model Assembly

MAINTENANCE AND REPAIRPAGE E - 8

Page 32

SF4D-X Pump Model Assembly

ITEM

PART NAME PART

NO.

1 PUMP CASING

. -ANSI SEE NOTE BELOW 1

. -DIN SEE NOTE BELOW 1

2 IMPELLER SEE NOTE BELOW 1

3 IMPELLER WASHER 31514-040 17000 1

4 SOCKET HD CAPSCREW MBD1235 17000 1

5 WEAR RING 38691-363 11010 1

6 O‐RING 25152-383 --- 1

7 SUCTION HEAD

-ANSI 38246-619 10000 1

-DIN 38246-622 10000 1

8 LOCK WASHER MJ12 17000 14

9 ADJUSTING SCREW MB1640 17000 4

9A HEX HD CAPSCREW MB1640 17000 4

10 O‐RING 25152-279 --- 1

11 HEX HD CAPSCREW MB1655 17000 8

12 NAME PLATE NOT AVAILAABLE

13 DRIVE SCREW NOT AVAILAABLE

14 MOTOR ASSY CONSULT FACTORY

15 TERM HOUSING ASSY NOT AVAILAABLE

16 LOCK WASHER NOT AVAILAABLE

17 HEX NUT NOT AVAILAABLE

18 HEX HD CAPSCREW MB1630 17000 2

19 LIFTING BAIL ASSY 44713-052 17040 1

20 JAM NUT MAT16 17000 4

21 SEAL PLATE 38272-720 10000 1

22 FLAT HD CAPSCREW MF0520 17000 4

23 O‐RING 25152-383 --- 1

24 SHAFT SLEEVE O‐RING 25154-034 --- 1

25 SHAFT SLEEVE 31441-032 1706H 1

26 SEAL ASSY 25285-816 --- 1

27 IMP ADJ SHIM SET 48261-062 17000 1

28 . PIPE PLUG P08 17000 3

29 . PIPE PLUG P04 17000 2

NOT SHOWN:

INFINITY DECAL 38811-435 --- 1

G‐R DECAL GR-03 --- 1

NUMBER

MAT'L

CODE

Parts List

QTY ITEM

NO.

OPTIONAL:

OM-06629SF SERIES X‐PROOF PUMPS

PART NAME PART

NUMBER

ANSI SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-559 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT 48156-024 --- 1

ALIGNMENT KIT 48786-551 --- 1

BASEPLATE KIT

-SHORT 48156-603 --- 1

-LONG 48156-604 --- 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

DIN SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-560 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT CONSULT FACTORY 1

ALIGNMENT KIT 48786-552 --- 1

BASEPLATE KIT

-SHORT CONSULT FACTORY 1

-LONG CONSULT FACTORY 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

ANSI TRASH VERSION

STAND KIT 48786-209 --- 1

DISCH ELBOW KIT 48135-102 --- 1

INCREASER KIT 48135-502 --- 1

DIN TRASH VERSION

STAND KIT 48786-213 --- 1

DISCH ELBOW KIT 48135-106 --- 1

LIQUID LEVEL DEVICES:

DIAPHRAGM TYPE GRP48-03 --- 1

GRP48-06 --- 1

FLOAT TYPE 27471-180 --- 1

120V LIQUID LEVEL

CONTROL RELAY 27521-321 --- 1

MAT'L

CODE

QTY

. INCLUDED W/ANSI REPAIR PUMP CASING ASSY 46472-915 --- 1

. INCLUDED W/DIN REPAIR PUMP CASING ASSY 46472-922 --- 1

INDICATES PARTS RECOMMENDED FOR STOCK

NOTE: WHEN ORDERING A REPLACEMENT IMPELLER, PROVIDE THE FACTORY WITH THE PUMP MODEL, S/N AND IMPELLER

DIAMETER (FROM NAMEPLATE)

PAGE E - 9MAINTENANCE AND REPAIR

Page 33

ILLUSTRATION

SF SERIES X‐PROOF PUMPSOM-06629

Figure E-5. SF6B-X Pump Model Assembly

MAINTENANCE AND REPAIRPAGE E - 10

Page 34

SF6B-X Pump Model Assembly

ITEM

PART NAME PART

NO.

1 PUMP CASING

. -ANSI SEE NOTE BELOW 1

. -DIN SEE NOTE BELOW 1

2 IMPELLER SEE NOTE BELOW 1

3 IMPELLER WASHER 31514-040 17000 1

4 SOCKET HD CAPSCREW MBD1235 17000 1

5 WEAR RING 38691-366 11010 1

6 O‐RING 25152-383 --- 1

7 SUCTION HEAD

-ANSI 38246-616 10000 1

-DIN 38246-621 10000 1

8 LOCK WASHER MJ16 17000 18

9 ADJUSTING SCREW MB1640 17000 6

9A HEX HD CAPSCREW MB1640 17000 6

10 O‐RING 25152-282 --- 1

11 HEX HD CAPSCREW MB1655 17000 8

12 NAME PLATE NOT AVAILAABLE

13 DRIVE SCREW NOT AVAILAABLE

14 MOTOR ASSY CONSULT FACTORY

15 TERM HOUSING ASSY NOT AVAILAABLE

16 LOCK WASHER NOT AVAILAABLE

17 HEX NUT NOT AVAILAABLE

18 HEX HD CAPSCREW MB1630 17000 2

19 LIFTING BAIL ASSY 44713-052 17040 1

20 JAM NUT MAT16 17000 4

21 SEAL PLATE 38272-719 10000 1

22 FLAT HD CAPSCREW MF0520 17000 4

23 O‐RING 25152-386 --- 1

24 SHAFT SLEEVE O‐RING 25154-034 --- 1

25 SHAFT SLEEVE 31441-032 1706H 1

26 SEAL ASSY 25285-816 --- 1

27 IMP ADJ SHIM SET 48261-062 17000 1

28 . PIPE PLUG P04 17000 2

NOT SHOWN:

INFINITY DECAL 38811-435 --- 1

G‐R DECAL GR-03 --- 1

NUMBER

MAT'L

CODE

Parts List

QTY ITEM

NO.

OPTIONAL:

OM-06629SF SERIES X‐PROOF PUMPS

PART NAME PART

NUMBER

ANSI SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-559 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT 48156-024 --- 1

ALIGNMENT KIT 48786-551 --- 1

BASEPLATE KIT

-SHORT 48156-603 --- 1

-LONG 48156-604 --- 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

DIN SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-560 --- 1

-GUIDE SHOE SEAL 31513-054 19020 1

SLIDE RAIL KIT CONSULT FACTORY 1

ALIGNMENT KIT 48786-552 --- 1

BASEPLATE KIT

-SHORT CONSULT FACTORY 1

-LONG CONSULT FACTORY 1

LIFTING CABLE KIT

-36' 48151-502 --- 1

-50' 48151-504 --- 1

ANSI TRASH VERSION

STAND KIT 48786-209 --- 1

DISCH ELBOW KIT 48135-102 --- 1

INCREASER KIT 48135-502 --- 1

DIN TRASH VERSION

STAND KIT 48786-213 --- 1

DISCH ELBOW KIT 48135-106 --- 1

LIQUID LEVEL DEVICES:

DIAPHRAGM TYPE GRP48-03 --- 1

GRP48-06 --- 1

FLOAT TYPE 27471-180 --- 1

120V LIQUID LEVEL

CONTROL RELAY 27521-321 --- 1

MAT'L

CODE

QTY

. INCLUDED W/ANSI REPAIR PUMP CASING ASSY 46472-916 --- 1

. INCLUDED W/DIN REPAIR PUMP CASING ASSY 46472-923 --- 1

INDICATES PARTS RECOMMENDED FOR STOCK

NOTE: WHEN ORDERING A REPLACEMENT IMPELLER, PROVIDE THE FACTORY WITH THE PUMP MODEL, S/N AND IMPELLER

DIAMETER (FROM NAMEPLATE)

PAGE E - 11MAINTENANCE AND REPAIR

Page 35

ILLUSTRATION

SF SERIES X‐PROOF PUMPSOM-06629

Figure E-6. SF6C-X Pump Model Assembly

MAINTENANCE AND REPAIRPAGE E - 12

Page 36

SF6C-X Pump Model Assembly

ITEM

PART NAME PART

NO.

1 PUMP CASING

. -ANSI SEE NOTE BELOW 1

. -DIN SEE NOTE BELOW 1

2 IMPELLER SEE NOTE BELOW 1

3 IMPELLER WASHER 31514-039 17000 1

4 SOCKET HD CAPSCREW MBD1225 17000 1

5 WEAR RING 38691-368 11010 1

6 O‐RING 25152-277 --- 1

7 SUCTION HEAD

-ANSI 38246-619 10000 1

-DIN 38246-620 10000 1

8 LOCK WASHER MJ12 17000 14

9 ADJUSTING SCREW MB1235 17000 4

9A HEX HD CAPSCREW MB1235 17000 4

10 O‐RING 25152-276 --- 1

11 HEX HD CAPSCREW MB1245 17000 8

12 NAME PLATE NOT AVAILAABLE

13 DRIVE SCREW NOT AVAILAABLE

14 MOTOR ASSY CONSULT FACTORY

15 TERM HOUSING ASSY NOT AVAILAABLE

16 LOCK WASHER NOT AVAILAABLE

17 HEX NUT NOT AVAILAABLE

18 HEX HD CAPSCREW MB1630 17000 2

19 LIFTING BAIL ASSY 44713-051 17040 1

20 JAM NUT MAT12 17000 4

21 SEAL PLATE 38272-537 10000 1

22 FLAT HD CAPSCREW MF0516 17000 4

23 O‐RING 25152-379 --- 1

24 SHAFT SLEEVE O‐RING 25154-031 --- 1

25 SHAFT SLEEVE 31441-031 1706H 1

26 SEAL ASSY 25285-860 --- 1

27 SPRING RETAINER 31161-042 17000 1

28 IMP ADJ SHIM SET 8499 17000 1

29 . PIPE PLUG P04 17000 1

NOT SHOWN:

INFINITY DECAL 38811-435 --- 1

G‐R DECAL GR-03 --- 1

NUMBER

MAT'L

CODE

Parts List

QTY ITEM

NO.

OPTIONAL:

OM-06629SF SERIES X‐PROOF PUMPS

PART NAME PART

NUMBER

ANSI SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-561 --- 1

-GUIDE SHOE SEAL 31513-055 19020 1

SLIDE RAIL KIT 48156-025 --- 1

BASEPLATE KIT

-SHORT 48156-605 --- 1

-LONG 48156-606 --- 1

LIFTING CABLE KIT

-36' 48151-505 --- 1

-50' 48151-506 --- 1

DIN SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-562 --- 1

-GUIDE SHOE SEAL 31513-055 19020 1

SLIDE RAIL KIT CONSULT FACTORY 1

BASEPLATE KIT

-SHORT CONSULT FACTORY 1

-LONG CONSULT FACTORY 1

LIFTING CABLE KIT

-36' 48151-505 --- 1

-50' 48151-506 --- 1

ANSI TRASH VERSION

STAND KIT 48786-211 --- 1

DISCH ELBOW KIT 48135-103 --- 1

INCREASER KIT 48135-503 --- 1

DIN TRASH VERSION

STAND KIT 48786-215 --- 1

DISCH ELBOW KIT 48135-107 --- 1

LIQUID LEVEL DEVICES:

DIAPHRAGM TYPE GRP48-03 --- 1

GRP48-06 --- 1

FLOAT TYPE 27471-180 --- 1

120V LIQUID LEVEL

CONTROL RELAY 27521-321 --- 1

MAT'L

CODE

QTY

. INCLUDED W/ANSI REPAIR PUMP CASING ASSY 46472-917 --- 1

. INCLUDED W/DIN REPAIR PUMP CASING ASSY 46472-924 --- 1

INDICATES PARTS RECOMMENDED FOR STOCK

NOTE: WHEN ORDERING A REPLACEMENT IMPELLER, PROVIDE THE FACTORY WITH THE PUMP MODEL, S/N AND IMPELLER

DIAMETER (FROM NAMEPLATE)

PAGE E - 13MAINTENANCE AND REPAIR

Page 37

ILLUSTRATION

SF SERIES X‐PROOF PUMPSOM-06629

Figure E-7. SF6D-X Pump Model Assembly

MAINTENANCE AND REPAIRPAGE E - 14

Page 38

SF6D-X Pump Model Assembly

ITEM

PART NAME PART

NO.

1 PUMP CASING

. -ANSI SEE NOTE BELOW 1

. -DIN SEE NOTE BELOW 1

2 IMPELLER SEE NOTE BELOW 1

3 IMPELLER WASHER 31514-017 17000 1

4 SOCKET HD CAPSCREW MBD1020 17000 1

5 WEAR RING 38691-368 11010 1

6 O‐RING 25152-277 --- 1

7 SUCTION HEAD

-ANSI 38246-619 10000 1

-DIN 38246-620 10000 1

8 LOCK WASHER MJ12 17000 18

9 ADJUSTING SCREW MB1235 17000 4

9A HEX HD CAPSCREW MB1235 17000 4

10 O‐RING 25152-276 --- 1

11 HEX HD CAPSCREW MB1245 17000 8

12 NAME PLATE NOT AVAILAABLE

13 DRIVE SCREW NOT AVAILAABLE

14 MOTOR ASSY CONSULT FACTORY

15 TERM HOUSING ASSY NOT AVAILAABLE

16 LOCK WASHER NOT AVAILAABLE

17 HEX NUT NOT AVAILAABLE

18 HEX HD CAPSCREW MB1030 17000 2

19 LIFTING BAIL ASSY 44713-048 17040 1

20 JAM NUT MAT12 17000 4

21 SEAL PLATE 38272-536 10000 1

22 FLAT HD CAPSCREW MF0516 17000 4

23 O‐RING 25152-379 --- 1

24 SHAFT SLEEVE O‐RING 25154-022 --- 1

25 SHAFT SLEEVE 31441-030 1706H 1

26 SEAL ASSY 25285-856 --- 1

27 IMP ADJ SHIM SET 37J 17090 1

28 . PIPE PLUG P04 17000 2

NOT SHOWN:

INFINITY DECAL 38811-435 --- 1

G‐R DECAL GR-03 --- 1

NUMBER

MAT'L

CODE

Parts List

QTY ITEM

NO.

OPTIONAL:

OM-06629SF SERIES X‐PROOF PUMPS

PART NAME PART

NUMBER

ANSI SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-561 --- 1

-GUIDE SHOE SEAL 31513-055 19020 1

SLIDE RAIL KIT 48156-025 --- 1

BASEPLATE KIT

-SHORT 48156-605 --- 1

-LONG 48156-606 --- 1

LIFTING CABLE KIT

-36' 48151-505 --- 1

-50' 48151-506 --- 1

DIN SLIDE RAIL VERSION

GUIDE SHOE KIT 48156-562 --- 1

-GUIDE SHOE SEAL 31513-055 19020 1

SLIDE RAIL KIT CONSULT FACTORY 1

BASEPLATE KIT

-SHORT CONSULT FACTORY 1

-LONG CONSULT FACTORY 1

LIFTING CABLE KIT

-36' 48151-505 --- 1

-50' 48151-506 --- 1

ANSI TRASH VERSION

STAND KIT 48786-211 --- 1

DISCH ELBOW KIT 48135-103 --- 1

INCREASER KIT 48135-503 --- 1

DIN TRASH VERSION

STAND KIT 48786-215 --- 1

DISCH ELBOW KIT 48135-107 --- 1

LIQUID LEVEL DEVICES:

DIAPHRAGM TYPE GRP48-03 --- 1

GRP48-06 --- 1

FLOAT TYPE 27471-180 --- 1

120V LIQUID LEVEL

CONTROL RELAY 27521-321 --- 1

MAT'L

CODE

QTY

. INCLUDED W/ANSI REPAIR PUMP CASING ASSY 46472-917 --- 1

. INCLUDED W/DIN REPAIR PUMP CASING ASSY 46472-924 --- 1

INDICATES PARTS RECOMMENDED FOR STOCK

NOTE: WHEN ORDERING A REPLACEMENT IMPELLER, PROVIDE THE FACTORY WITH THE PUMP MODEL, S/N AND IMPELLER

DIAMETER (FROM NAMEPLATE)

PAGE E - 15MAINTENANCE AND REPAIR