Page 1

OM-06617-01

March 1, 2013

INSTALLATION AND OPERATION

MANUAL

SE SERIES

MODELS

SE1 1/2D

SE1 1/2E

SE2M

THE GORMAN‐RUPP COMPANY D MANSFIELD, OHIO

GORMAN‐RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

www.grpumps.com

E2012 The Gorman‐Rupp Company

Page 2

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information if you have warranty questions.

Pump Model:

Serial Number:

Page 3

SE SERIES OM-06617

INTRODUCTION

Thank You for purchasing a Gorman‐Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

These pumps are SE Series submersible models.

The basic material of construction is cast iron. They

are designed to handle most non‐volatile, non‐

flammable liquids that do not contain large en

trained solids. Do not attempt to pump volatile or

flammable liquids that may damage the pump.

The pumps are powered by integral, thermally‐pro

tected electric motors which are not explosion‐

proof. Do not operate the pumps in hazardous at

mospheres.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed in

structions and precautions for every aspect of

each specific application. Therefore, it is the re

sponsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety nor pump integrity are com

promised by the installation. Pumps and related

equipment must be installed and operated ac

cording to all national, local and industry stan

dards.

The following are used to alert maintenance per

sonnel to procedures which require special atten

tion, to those which could damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possi

ble damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

1INTRODUCTION

Page 4

SE SERIES OM-06617

SAFETY

Because pump installations are seldom

identical, this manual cannot possibly pro

vide detailed instructions and precautions

for each specific application. Therefore, it

is the owner/installer's responsibility to en

sure that applications not addressed in this

manual are performed only

ing that neither operator safety nor pump

integrity are compromised by the installa

tion.

Before attempting to open or service the

pump:

after establish

1. Familiarize yourself with this man

ual.

2. Unplug the power cable from its re

ceptacle to ensure that the pump

will remain inoperative.

3. Allow the pump to completely cool

if overheated.

5. Close the discharge valve (if

used).

Never attempt to alter the length or repair

any power cable with a splice. The pump

motor and cable must be completely water

proof. Injury or death may result from alter

ations.

All electrical connections must be in accor

dance with The National Electric Code and

all local codes. If there is a conflict between

the instructions provided and N.E.C. Speci

fications, N.E.C. Specifications shall take

precedence. All electrical equipment sup

plied with this pump was in conformance

with N.E.C. requirements in effect on the

date of manufacture. Failure to follow appli

cable specifications, or substitution of elec

trical parts not supplied or approved by the

manufacturer, can result in severe injury or

death and void warranty.

This pump is designed to handle dirty water

that does not contain large entrained sol

ids. This pump is not

atile, explosive, or flammable materials. Do

not attempt to pump any liquids for which

you pump is not approved, or which may

damage the pump or endanger personnel

as a result of pump failure.

The electrical power used to operate this

pump is high enough to cause injury or

death. Make certain that the power cable re

ceptacle is properly grounded before

installation. Make certain that the plug on

the pump power cable is disconnected from

its receptacle before servicing.

SAFETY

designed to pump vol

After the pump has been installed, make

certain that the pump and all piping or hose

connections are secure before operation.

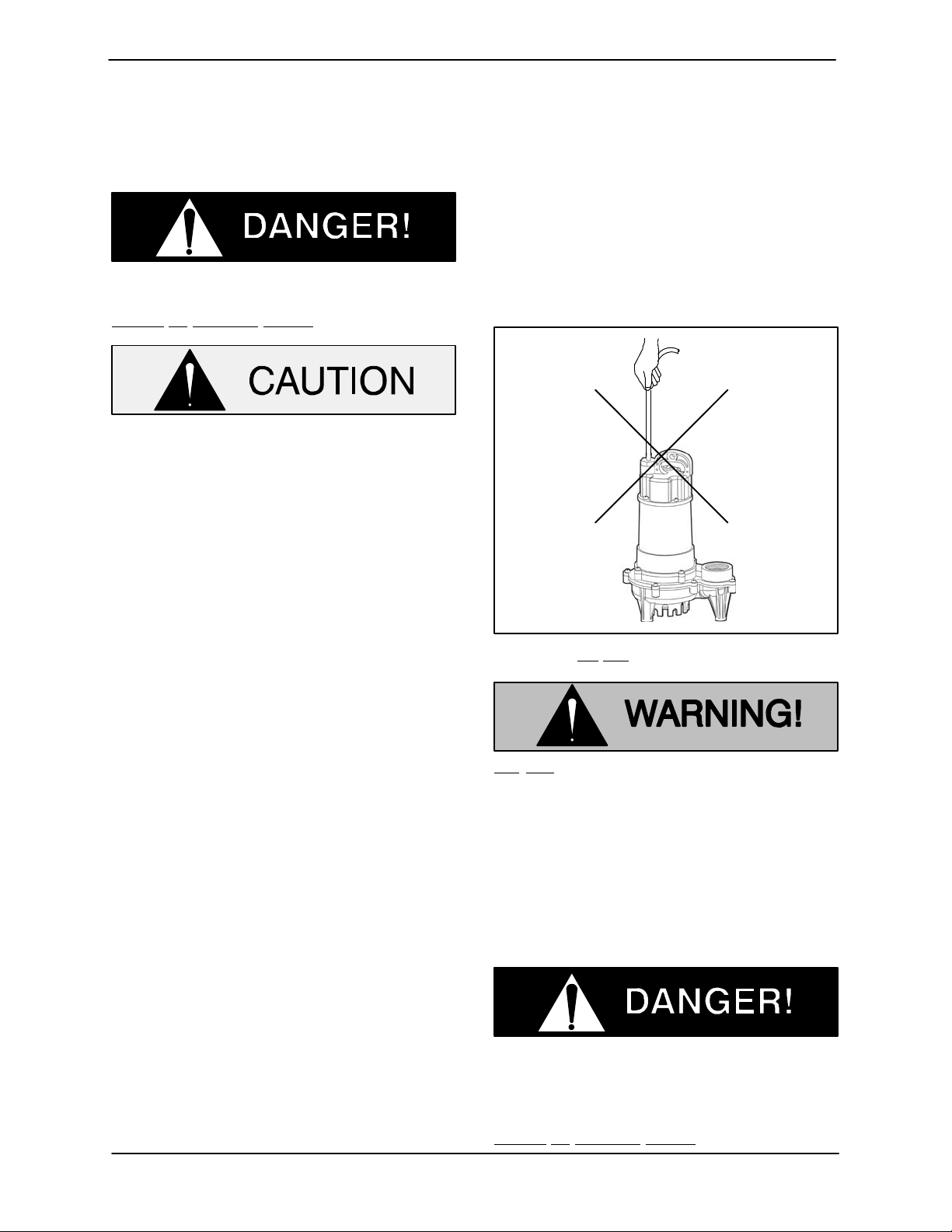

Do not attempt to lift the pump by the motor

power cable or discharge hose. Attach

proper lifting equipment to the lifting device

fitted to the pump.

Pumps and related equipment must be

installed and operated according to all nation

al, local and industry standards.

2

Page 5

INSTALLATION

OM-06617SE SERIES

Review all SAFETY information in Section A.

Do not operate this pump where explo

sive vapors or flammable material exist.

Death or serious injury will result.

Pumps and related equipment must be in

stalled and operated according to all na

tional, local and industry standards.

PREINSTALLATION INSPECTION

Before installation, inspect the pump for damage

which may have occurred during shipment. Check

as follows:

charge hoses or piping before attempting to lift ex

isting, installed units.

If necessary, attach a rope or chain to the lifting

handle on the top of the pump. Do not lift the unit

by the power cable or the discharge piping. Cus

tomer‐installed equipment such as rigid discharge

piping must be removed before attempting to lift.

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious dam

age.

b. Check for and tighten loose attaching hard

ware.

c. The pump is furnished with a 50‐foot (15 me

ter) long power cable. Inspect the cable for

cuts or damage.

d. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

as indicated.

If anything appears to be abnormal, contact your

Gorman‐Rupp distributor to determine the repair

or updating policy. Do not put the pump into serv

ice until appropriate action has been taken.

PUMP INSTALLATION

Lifting

Pump unit weights will vary depending on the mod

el. Check the shipping tag on the unit packaging

for the actual weight. Drain the pump and remove

all customer‐installed equipment such as dis

Figure 1. Do Not Lift Pump by Power Cable

Do not attempt to lift the pump by the

power cable or piping. Attach proper

lifting equipment to the handle on the

pump.

Installation

Before installing the pump, clear the sump basin of

any debris or sediment. See Figure 4 for a typical

pump installation.

The sump basin must be vented in ac

cordance with local plumbing codes.

Do not operate this pump where explo

sive vapors or flammable material exist.

Death or serious injury will result.

3INSTALLATION

Page 6

OM-06617 SE SERIES

The pump must be installed in a suitable gas‐tight,

properly vented basin which is at least 24 inches

(610 mm) deep and is at least 18 inches (457 mm)

wide for pumps fitted with wide angle (ball type) on/

off switches, and at least 14 inches (356 mm) wide

for pumps fitted with vertical on/off switches.

The pump must be placed on a hard surface in a

sump that has been cleared of all debris. Never

place the pump on clay, earth or gravel surfaces. It

is suggested that the pump be positioned on two

bricks approximately 2 inches (51 mm) apart.

Connect the discharge pipe, fittings and check

valve (if desired) to the discharge port of the pump.

It is recommended that the discharge pipe diamet

er be equal to or larger than the discharge size of

the pump.

The pump will handle 3/8 inch (9,5 mm) diameter

spherical solids.

Piping

precedence. All electrical equipment sup

plied with this pump was in conformance

with N.E.C. requirements in effect on the

date of manufacture. Failure to follow appli

cable specifications, or substitution of elec

trical parts not supplied or approved by the

manufacturer, can result in severe injury or

death and void warranty.

Always use a three‐prong grounded re

ceptacle. It is strongly recommended

that a Ground Fault Interrupter (GFI)

type receptacle (or equivalent) be used.

Either hose or rigid PVC, galvanized steel or cop

per pipe may be used for the discharge connec

tion.

For maximum pumping capacity, use non‐collaps

ible hose or rigid piping, and keep the discharge as

short and straight as possible. If rigid piping is

used, minimize the use of elbows and fittings which

increase friction losses and reduce pump perform

ance.

All piping must be clean and free of all foreign mat

ter to prevent clogging.

A check valve or throttling valve may be installed in

the discharge line to control siphoning or back flow

when the pump is shut off.

ELECTRICAL CONNECTIONS

All electrical connections must be in accor

dance with The National Electric Code and

all local codes. If there is a conflict between

the instructions provided and N.E.C. Speci

fications, N.E.C. Specifications shall take

Figure 2. Always Use a Grounded Receptacle

Verify that the voltage and frequency

shown on the pump name plate corres

ponds to those available at the recept

acle. The installer must make certain

that the electrical system is grounded in

accordance with code.

The receptacle into which the pump is to be

plugged must be connected to a separate 15 amp

circuit breaker or fuse block. Plugging into existing

outlets may cause low voltage at the motor, which

could cause tripped circuit breakers or blown

fuses in the service panel, tripping of the motor

overload or a burned out motor. When in doubt, call

an electrician.

A permanent ground connection from the recept

acle to the grounding bar at the service panel is

mandatory. These pumps are equipped with a

grounding conductor and a grounding‐type plug.

4 INSTALLATION

Page 7

OM-06617SE SERIES

Never cut off the ground pin or use an adaptor fit

ting. Do not use an extension cord. For maximum

safety, connect the pump to a circuit equipped with

a ground fault interrupter (GFI) type receptacle.

The plug and receptacle should be protected from

moisture and flooding. Protect the plug and power

cable from heat and sharp edges.

Figure 3. Always Keep Plug End Dry

PRECAUTIONS

The following may cause severe damage to the

pump and will void the pump warranty.

1. Using an extension cord.

2. Cutting off the ground pin or using an adaptor

fitting.

3. Working on the pump or switch while the

pump is plugged into the receptacle.

4. Removing the motor housing, unscrewing the

impeller, or removing the pump seal.

5. Running the pump continuously.

6. Pumping chemicals or corrosive liquids.

7. Pumping petroleum products or other flam

mable liquids.

Figure 4. Typical Sump Pump Installation

5INSTALLATION

Page 8

OM-06617

SE SERIES

OPERATION

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and

decals attached to the pump.

PUMP OPERATION

Do not operate this pump where explo

sive vapors or flammable material exist.

Death or serious injury will result.

This pump is designed to handle dirty

water that does not contain large en

trained solids. It is not designed to

pump volatile, flammable or corrosive

materials. Do not attempt to pump any

liquids which may damage the pump or

endanger personnel as a result of pump

failure.

Always keep the plug end dry.

Figure 1. Always Keep Plug End Dry

For manual operation, simply plug the power cable

into any 115 volt grounded receptacle. It is strong

ly recommended that a Ground Fault Interrupter

(GFI) type receptacle (or equivalent) be used (see

Figure 2).

Always use a three‐prong grounded re

ceptacle. It is strongly recommended

that a Ground Fault Interrupter (GFI)

type receptacle (or equivalent) be used.

Install the pump and piping as described in IN

STALLATION.

Operation of Pumps Without Integral Float

System

Each pump is provided with a 50‐foot (15 meter)

power cable. Never splice the power cable due to

safety and warranty considerations.

Never attempt to alter the length or re

pair any power cable with a splice. The

pump motor and cable must be com

pletely waterproof. Damage to the pump

or personal injury may result from alter

ations.

Figure 2. Always Use a Grounded Receptacle

Automatic Operation (Ball Type Float System)

Some units are equipped for automatic operation

with either a vertical slide or a ball type float system.

For automatic operation with a ball type float, al

ways make sure the float hangs free. It should not

come into contact with the bottom or side of the

sump.

OPERATION6

Page 9

SE SERIES

OM-06617

Plug the pump cable into a grounded receptacle.

It is strongly recommended that a Ground Fault In

terrupter (GFI) type receptacle (or equivalent) be

used (see Figure 2).

Operational Checks

Check the pump for proper operation when it is first

started and periodically thereafter to identify minor

problems.

Check the pump for unusual noises or excessive

vibration while it is operating. If noise or vibration is

excessive, stop the pump and refer to the

troubleshooting chart for possible causes.

Check the pump strainer screen for clogging

caused by stones, sticks, or other debris. Clean

the strainer screen when required. In some cases,

stopping the pump momentarily may back flush

the strainer screen, purging most of the debris

from it. If this fails to clean the screen, unplug the

pump, remove it from the sump, and remove the

debris manually.

Never introduce air or steam pressure into the

pump casing or piping to remove a blockage. This

could result in personal injury or damage to the

equipment.

STOPPING

To stop the pump when in manual mode, simply

unplug it from the receptacle. After stopping the

pump, be sure to perform all required maintenance

and preservation procedures.

This pump is equipped with automatic

thermal overload protection which will stop

the pump if overheating occurs. Unplug

the pump and allow it to cool before at

tempting to service the pump.

When operated in the automatic mode, the pump

will stop and start as the liquid level rises and falls.

For service or extended stopping, unplug the

pump from the receptacle.

Storage and Cold Weather Preservation

After stopping the pump, use the rope or chain at

tached to the lifting handle on the pump to remove

the pump from the sump. Do not lift the unit by the

power cable or the discharge piping. Customer in

stalled equipment such as rigid discharge piping

must be removed before attempting to lift.

Each of these pumps has a built‐in thermal protec

tion switch in the motor. The pump will stop if over

heating occurs. The pump will restart automatically

after it has cooled down.

Do not attempt to lift the pump by the

power cable or piping. Attach proper

lifting equipment to the handle on the

pump.

Clean the strainer screen before storage. If the

The integral thermal overload switch

will shut off the motor if the temperature

application involves a lot of mud or sludge, remove

the strainer and clean the impeller before storage.

rises above design limits. When the

pump cools and the temperature falls

below these limits, the motor will restart

automatically. To avoid the hazards of

The most common cause of failure to run is hard

ened mud or sludge in the impeller.

NOTE

an unexpected motor start‐up, unplug

the power cable from the receptacle be

fore attempting to handle the pump;

otherwise, serious personal injury

could result.

OPERATION 7

In freezing temperatures, the pump will not freeze

as long as it is submerged in liquid. If the pump

casing is not submerged, or if the liquid begins to

freeze, remove the pump from the sump and allow

Page 10

OM-06617

it to dry thoroughly. Run the pump for two or three

minutes to dry the inner walls.

If the pump freezes, move it into a warm area until

completely thawed, or submerge it into the liquid. If

the liquid is near freezing, the pump must be sub

merged for an extended period of time. Start the

pump and check for shaft rotation. If still frozen, al

low additional thawing time before attempting to

restart.

SE SERIES

Do not attempt to thaw the pump by using

a torch or other source of flame. This could

damage gaskets, electrical components,

or motor windings.

OPERATION8

Page 11

SE SERIES

TROUBLESHOOTING

Review all SAFETY information in Section A.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

OM-06617

PUMP WILL NOT

RUN (MANUAL

MODE)

PUMP WILL NOT

RUN (AUTOMATIC

MODE)

MOTOR RUNS, BUT

PUMP FAILS TO

DELIVER WATER

Power cable loose in receptacle. Check.

GFI or circuit breaker tripped, fuse Check and reset GFI or breaker;

blown. replace fuse.

Hardened mud or sludge in pump. Check and clean.

Damaged power cable. Inspect and replace as required.

Liquid level device fouled with mud Clean liquid level device(s).

or foreign material.

Float type sensing device tangled or Check installation for free movement

obstructed. of float.

Strainer clogged. Check and clean as required.

Discharge line clogged or restricted; Check discharge lines; straighten

hose kinked. hose.

Liquid being pumped too thick. Dilute liquid by heating if possible.

Discharge check valve installed Check installation (arrow on valve

Backward. Should point in direction of flow).

Pumping entrained air. Check liquid level in sump; check

position of pump.

Pump is air locked. Start and stop pump several times by

plugging and unplugging cord.

Check for clogged vent hole in pump

casing.

Vertical pumping distance is too high. Reduce distance or change the

discharge fittings of the pump.

PUMP RUNS BUT

WILL NOT STOP

PUMP RUNS BUT

ONLY DELIVERS A

SMALL AMOUNT

OF WATER

TROUBLESHOOTING 9

Float stuck in up position. Check to ensure float operates

freely.

Pump is air locked. Start and stop pump several times by

plugging and unplugging cord.

Check for clogged vent hole in pump

casing.

Page 12

OM-06617

TROUBLESHOOTING (Cont'd)

Review all SAFETY information in Section A.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

SE SERIES

PUMP RUNS BUT

ONLY DELIVERS A

SMALL AMOUNT

OF WATER

CIRCUIT BREAKER

TRIPS OR FUSE

BLOWS WHEN

PUMP STARTS

MOTOR RUNS, BUT

PUMP FAILS TO

DELIVER WATER

MOTOR RUNS FOR

A SHORT TIME,

THEN STOPS

Vertical pumping distance is too high. Reduce distance or change the

discharge fittings of the pump.

Strainer clogged. Check and clean as required.

Hardened mud or sludge in pump. Check and clean.

Damaged power cable. Inspect and replace as required.

Liquid level device fouled with mud Clean liquid level device(s).

or foreign material.

Float type sensing device tangled or Check installation for free movement

obstructed. of float.

Strainer or impeller clogged. Check and clean as required.

Circuit breaker or fuse too small. Check (must be 15 amps).

Strainer or impeller clogged. Check and clean as required.

TROUBLESHOOTING10

Page 13

Page 14

For U.S. and International Warranty Information,

Please Visit www.grpumps.com/warranty

or call:

U.S.: 419-755-1280

International: +1-419-755-1352

Loading...

Loading...