GORMAN-RUPP PUMPS SE1 1/2D, SE1 1/2E, SE Series, SE2M Installation And Operation Manual

OM-06617-01

March 1, 2013

INSTALLATION AND OPERATION

MANUAL

SE SERIES

MODELS

SE1 1/2D

SE1 1/2E

SE2M

THE GORMAN‐RUPP COMPANY D MANSFIELD, OHIO

GORMAN‐RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

www.grpumps.com

E2012 The Gorman‐Rupp Company

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information if you have warranty questions.

Pump Model:

Serial Number:

SE SERIES OM-06617

INTRODUCTION

Thank You for purchasing a Gorman‐Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

These pumps are SE Series submersible models.

The basic material of construction is cast iron. They

are designed to handle most non‐volatile, non‐

flammable liquids that do not contain large en

trained solids. Do not attempt to pump volatile or

flammable liquids that may damage the pump.

The pumps are powered by integral, thermally‐pro

tected electric motors which are not explosion‐

proof. Do not operate the pumps in hazardous at

mospheres.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed in

structions and precautions for every aspect of

each specific application. Therefore, it is the re

sponsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety nor pump integrity are com

promised by the installation. Pumps and related

equipment must be installed and operated ac

cording to all national, local and industry stan

dards.

The following are used to alert maintenance per

sonnel to procedures which require special atten

tion, to those which could damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possi

ble damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

1INTRODUCTION

SE SERIES OM-06617

SAFETY

Because pump installations are seldom

identical, this manual cannot possibly pro

vide detailed instructions and precautions

for each specific application. Therefore, it

is the owner/installer's responsibility to en

sure that applications not addressed in this

manual are performed only

ing that neither operator safety nor pump

integrity are compromised by the installa

tion.

Before attempting to open or service the

pump:

after establish

1. Familiarize yourself with this man

ual.

2. Unplug the power cable from its re

ceptacle to ensure that the pump

will remain inoperative.

3. Allow the pump to completely cool

if overheated.

5. Close the discharge valve (if

used).

Never attempt to alter the length or repair

any power cable with a splice. The pump

motor and cable must be completely water

proof. Injury or death may result from alter

ations.

All electrical connections must be in accor

dance with The National Electric Code and

all local codes. If there is a conflict between

the instructions provided and N.E.C. Speci

fications, N.E.C. Specifications shall take

precedence. All electrical equipment sup

plied with this pump was in conformance

with N.E.C. requirements in effect on the

date of manufacture. Failure to follow appli

cable specifications, or substitution of elec

trical parts not supplied or approved by the

manufacturer, can result in severe injury or

death and void warranty.

This pump is designed to handle dirty water

that does not contain large entrained sol

ids. This pump is not

atile, explosive, or flammable materials. Do

not attempt to pump any liquids for which

you pump is not approved, or which may

damage the pump or endanger personnel

as a result of pump failure.

The electrical power used to operate this

pump is high enough to cause injury or

death. Make certain that the power cable re

ceptacle is properly grounded before

installation. Make certain that the plug on

the pump power cable is disconnected from

its receptacle before servicing.

SAFETY

designed to pump vol

After the pump has been installed, make

certain that the pump and all piping or hose

connections are secure before operation.

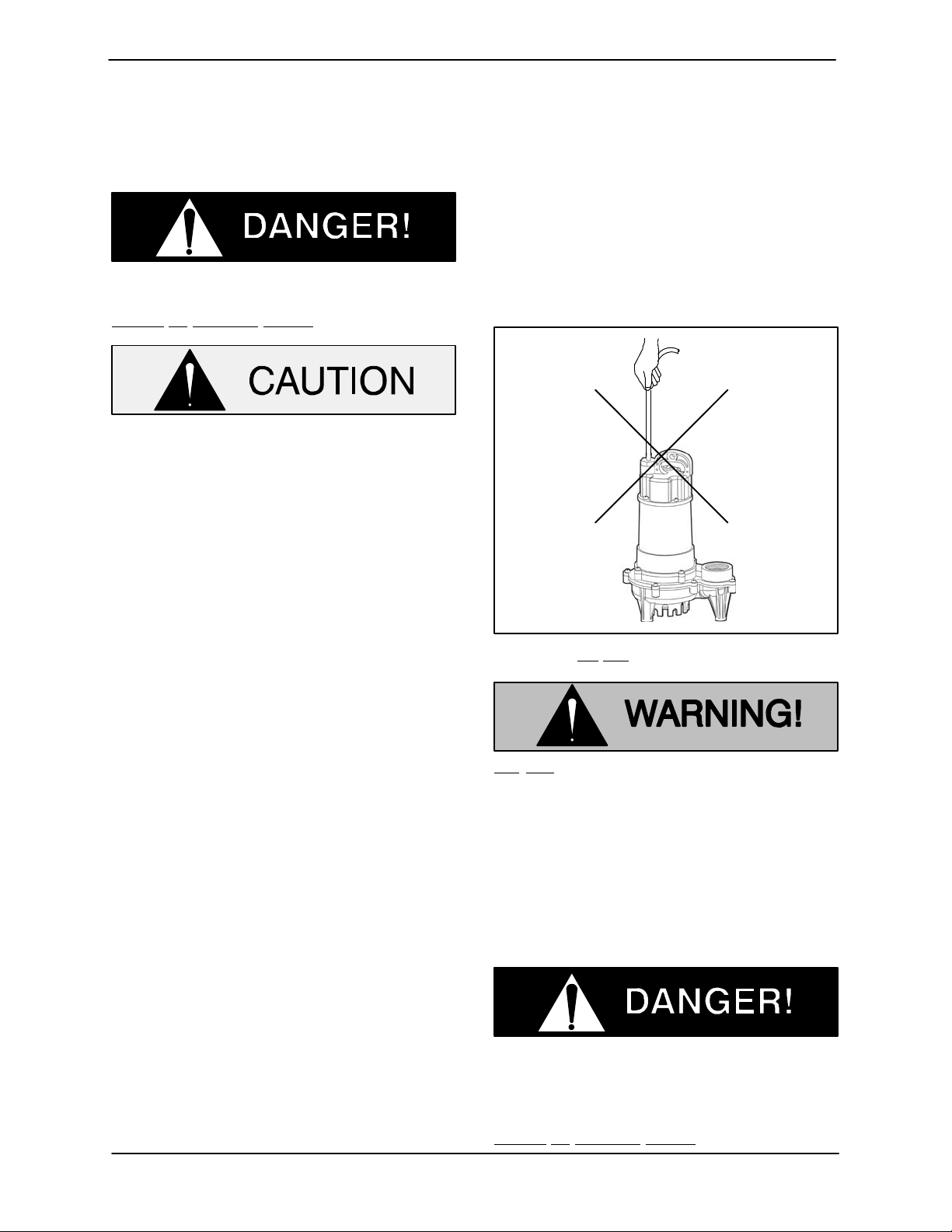

Do not attempt to lift the pump by the motor

power cable or discharge hose. Attach

proper lifting equipment to the lifting device

fitted to the pump.

Pumps and related equipment must be

installed and operated according to all nation

al, local and industry standards.

2

INSTALLATION

OM-06617SE SERIES

Review all SAFETY information in Section A.

Do not operate this pump where explo

sive vapors or flammable material exist.

Death or serious injury will result.

Pumps and related equipment must be in

stalled and operated according to all na

tional, local and industry standards.

PREINSTALLATION INSPECTION

Before installation, inspect the pump for damage

which may have occurred during shipment. Check

as follows:

charge hoses or piping before attempting to lift ex

isting, installed units.

If necessary, attach a rope or chain to the lifting

handle on the top of the pump. Do not lift the unit

by the power cable or the discharge piping. Cus

tomer‐installed equipment such as rigid discharge

piping must be removed before attempting to lift.

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious dam

age.

b. Check for and tighten loose attaching hard

ware.

c. The pump is furnished with a 50‐foot (15 me

ter) long power cable. Inspect the cable for

cuts or damage.

d. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

as indicated.

If anything appears to be abnormal, contact your

Gorman‐Rupp distributor to determine the repair

or updating policy. Do not put the pump into serv

ice until appropriate action has been taken.

PUMP INSTALLATION

Lifting

Pump unit weights will vary depending on the mod

el. Check the shipping tag on the unit packaging

for the actual weight. Drain the pump and remove

all customer‐installed equipment such as dis

Figure 1. Do Not Lift Pump by Power Cable

Do not attempt to lift the pump by the

power cable or piping. Attach proper

lifting equipment to the handle on the

pump.

Installation

Before installing the pump, clear the sump basin of

any debris or sediment. See Figure 4 for a typical

pump installation.

The sump basin must be vented in ac

cordance with local plumbing codes.

Do not operate this pump where explo

sive vapors or flammable material exist.

Death or serious injury will result.

3INSTALLATION

Loading...

Loading...