Gorman-Rupp Pumps SE2D3 User Manual

OM-06494-01

August 11, 2011

Rev. A 12‐13‐12

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

SE SERIES PUMP

MODEL

SE2D3 115V 1P

THE GORMAN‐RUPP COMPANY MANSFIELD, OHIO

GORMAN‐RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

www.grpumps.com

2011 The Gorman‐Rupp Company

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

TABLE OF CONTENTS

INTRODUCTION PAGE I - 1.................................................

SAFETY ‐ SECTION A PAGE A - 1............................................

INSTALLATION - SECTION B PAGE B - 1....................................

GENERAL INFORMATION PAGE B - 1..................................................

PREINSTALLATION INSPECTION PAGE B - 1............................................

PUMP SEAL PAGE B - 1..............................................................

LUBRICATION PAGE B - 1.............................................................

PUMP INSTALLATION PAGE B - 2......................................................

Pump Motor Specifications PAGE B - 2..............................................

Pump Dimensions PAGE B - 2.....................................................

Lifting PAGE B - 2.................................................................

Positioning the Pump PAGE B - 2...................................................

Piping PAGE B - 3................................................................

ELECTRICAL CONNECTIONS PAGE B - 3...............................................

Grounding Methods PAGE B - 4....................................................

Pump Power Cable Connections PAGE B - 5.........................................

Control Box PAGE B - 5...........................................................

OPERATION - SECTION C PAGE C - 1......................................

GENERAL INFORMATION PAGE C - 1..................................................

Pump Performance PAGE C - 1.....................................................

Pump Controls PAGE C - 1........................................................

PUMP OPERATION PAGE C - 2........................................................

Impeller Rotation PAGE C - 2.......................................................

STARTING, STOPPING, AND OPERATIONAL CHECKS PAGE C - 3.........................

Starting And Stopping PAGE C - 3..................................................

Operational Checks PAGE C - 3....................................................

LIQUID LEVEL PAGE C - 4............................................................

COLD WEATHER PRESERVATION PAGE C - 4...........................................

LUBRICATION PAGE C - 4.............................................................

Draining Oil PAGE C - 4...........................................................

Condition Of Oil PAGE C - 5........................................................

Adding Oil PAGE C - 5............................................................

TROUBLESHOOTING - SECTION D PAGE D - 1..............................

ELECTRICAL TESTING PAGE D - 2.....................................................

Test Equipment PAGE D - 2........................................................

Voltage Imbalance PAGE D - 3.....................................................

Motor And Motor Power Cable Continuity PAGE D - 3.................................

Insulation Resistance PAGE D - 3...................................................

Capacitor PAGE D - 4.............................................................

Wiring Diagram PAGE D - 4........................................................

PUMP MAINTENANCE AND REPAIR ‐ SECTION E PAGE E - 1.................

STANDARD PERFORMANCE CURVE PAGE E - 1........................................

PUMP MODEL S2D3 115V 1P PARTS LIST PAGE E - 3...................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E - 4.........................

i

TABLE OF CONTENTS

(continued)

PUMP END DISASSEMBLY PAGE E - 4.................................................

Strainer And Impeller Cover Removal PAGE E - 5.....................................

Draining Oil From Seal Cavity PAGE E - 5............................................

Positioning Pump For Disassembly PAGE E - 5.......................................

Impeller Removal PAGE E - 5......................................................

Seal Removal PAGE E - 5..........................................................

PUMP END REASSEMBLY PAGE E - 6..................................................

Cleaning And Inspection Of Pump Parts PAGE E - 6..................................

Seal Installation PAGE E - 6........................................................

Impeller Installation PAGE E - 8.....................................................

Impeller Clearance PAGE E - 8.....................................................

Strainer Installation PAGE E - 8....................................................

MOTOR DISASSEMBLY PAGE E - 9....................................................

Head And Power Cable Removal PAGE E - 9.........................................

Rotor And Shaft Removal PAGE E - 10...............................................

Bearing Removal PAGE E - 10.......................................................

Centrifugal Switch Actuator Removal PAGE E - 10.....................................

Stator Removal PAGE E - 10........................................................

MOTOR REASSEMBLY PAGE E - 11.....................................................

Stator Installation PAGE E - 11......................................................

Centrifugal Switch Actuator Installation PAGE E - 12...................................

Bearing Installation PAGE E - 12.....................................................

Rotor And Shaft Installation PAGE E - 12.............................................

Head And Power Cable Installation PAGE E - 12.......................................

VACUUM/PRESSURE TESTING PAGE E - 14.............................................

LUBRICATION PAGE E - 14.............................................................

Seal Cavity PAGE E - 14............................................................

Motor Cavity PAGE E - 15...........................................................

ii

SE SERIES OM-06494

INTRODUCTION

Thank You for purchasing a Gorman‐Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

This is an SE Series submersible pump. The basic

material of construction is cast iron, with stainless

steel hardware and fittings. The pump is light

weight and portable, making it ideally suited to

many domestic and industrial applications where

low capacity dewatering or irrigation is required.

The pump is powered by an integral, thermally‐

protected electric motor which is not explosion‐

proof. The pump may be operated fully or partially

submerged. Do not operate the pump in a hazard

ous atmosphere.

All repairs to the pump motor must be performed

by a Gorman‐Rupp authorized submersible repair

facility or the factory. Any repairs to the motor as

sembly performed by the customer or an unautho

rized repair facility negates the warranty.

Gorman‐Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631-2870

The following are used to alert maintenance per

sonnel to procedures which require special atten

tion, to those which could damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed in

structions and precautions for every aspect of

each specific application. Therefore, it is the re

sponsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety nor pump integrity are com

promised by the installation. Pumps and related

equipment must be installed and operated ac

cording to all national, local and industry stan

dards.

If there are any questions regarding the pump or

its application which are not covered in this man

ual or in other literature accompanying this unit,

please contact your Gorman‐Rupp distributor, or

The Gorman‐Rupp Company:

The Gorman‐Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-1217

Phone: (419) 755-1011

or:

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possi

ble damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I - 1INTRODUCTION

SE SERIES OM-06494

SAFETY - SECTION A

This information applies to SE Series

submersible motor driven pumps.

Because pump installations are seldom

identical, this manual cannot possibly

provide detailed instructions and pre

cautions for each specific application.

Therefore, it is the owner/installer's re

sponsibility to ensure that applications

not addressed in this manual are per

formed only after establishing that nei

ther operator safety nor pump integrity

are compromised by the installation.

Before attempting to open or service the

pump:

1. Familiarize yourself with this man

ual.

2. Make certain the control box or

switch is in the OFF or STOP posi

tion, or that the power supply to the

control box has been otherwise cut

off and locked out to ensure that

the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

5. Close the discharge valve (if

used).

If the power cable is wired into an op

tional manual starting switch or control

box, make sure that the enclosure is

grounded. See Section B for recom

mended grounds.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Make certain the control box

or switch is in the OFF or STOP position,

or that the power supply to the control

box has been otherwise cut off and

locked out. Tag electrical circuits to pre

vent accidental start‐up.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Obtain the services of a

qualified electrician to make all electri

cal connections.

This pump is not designed to pump vol

atile, explosive, or flammable materials.

Do not attempt to pump any liquids for

which you pump is not approved, or

which may damage the pump or endan

ger personnel as a result of pump fail

ure. Consult the factory for specific ap

plication data.

SAFETY

Never attempt to alter the length or re

pair any power cable with a splice. The

pump motor and cable must be com

pletely waterproof. Injury or death may

result from alterations.

All electrical connections must be in ac

cordance with The National Electric

Code and all local codes. If there is a

PAGE A - 1

OM-06494 SE SERIES

conflict between the instructions pro

vided and N.E.C. Specifications, N.E.C.

Specifications shall take precedence.

All electrical equipment supplied with

this pump was in conformance with

N.E.C. requirements in effect on the

date of manufacture. Failure to follow

Obtain the services of a qualified elec

trician to troubleshoot, test and/or ser

vice the electrical components of this

pump.

applicable specifications, or substitu

tion of electrical parts not supplied or

approved by the manufacturer, can re

sult in severe injury or death and void

warranty.

Do not attempt to lift the pump by the

motor power cable or discharge hose.

Attach proper lifting equipment to the

lifting device fitted to the pump.

After the pump has been installed, make

certain that the pump and all piping or

hose connections are secure before op

eration.

Pumps and related equipment must be

installed and operated according to all na

tional, local and industry standards.

PAGE A - 2 SAFETY

OM-06494 SE SERIES

INSTALLATION - SECTION B

GENERAL INFORMATION

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section is intended only to summarize general rec

ommendations and practices required to inspect,

position, and arrange the pump and piping. If there

are any questions concerning your specific instal

lation, contact your Gorman‐Rupp distributor or

the Gorman‐Rupp Company.

Nuts, bolts and screws used on this pump

are metric and do not match standard SAE

measurement threads. If any threaded

hardware is replaced, it must be replaced

with metric type. Attempting to force in a

fastener with SAE threads will damage the

mating threads. An optional discharge

adaptor is available to convert the metric

pipe threads in the discharge flange to the

SAE threads.

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

check for damage which may have occurred dur

ing shipment. Check as follows:

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious dam

age.

e. Carefully read all tags, decals, and markings

on the pump, and perform all duties indicated.

f. Check for oil leaks. If there is any indication of

an oil leak, see LUBRICATION at the end of

this manual.

g. If the pump has been stored for more than 12

months, some of the components or lubri

cants may have exceeded their maximum

shelf life. These must be inspected or re

placed to ensure maximum pump service.

If the maximum shelf life has been exceed, or if

anything appears to be abnormal, contact

your Gorman‐Rupp distributor or the factory

to determine the repair or updating policy. Do

not put the pump into service until appropri

ate action has been taken.

PUMP SEAL

The pump is equipped with a single faced seal as

sembly. It is designed to prevent the liquid being

pumped from entering the lubrication cavity at the

impeller end. A lip seal is used to prevent moisture

or lubrication oil from entering the motor housing

cavity at the motor end.

The seal is lubricated by premium quality submers

ible pump oil.

LUBRICATION

The pump utilizes one lubrication cavity, located

between the pump casing and the motor housing.

It is filled with premium quality submersible pump

oil which lubricates the pump seal. The motor oper

ates in and is cooled by air, therefore it requires no

lubrication.

b. Check for and tighten loose attaching hard

ware. Since gaskets tend to shrink after dry

ing, check for and tighten loose hardware at

the mating surfaces.

c. Inspect the power cable for cuts or any other

obvious damage.

d. Check that amperes, phase, voltage and

hertz indicated on the name plate match the

ratings on the control box and incoming pow

er.

This pump was fully lubricated when shipped from

the factory. However, lubrication levels must be

checked before installing the pump (see LU

BRICATION in the MAINTENANCE AND REPAIR

MANUAL). If the oil level is abnormally low, deter

mine the cause before putting the pump into ser

vice.

Refer to Table B‐2 for the oil capacity and position

for filling the seal cavity in the pump. Refer to LU

BRICATION, Section C for lubrication specifica

tions and intervals.

PAGE B - 1INSTALLATION

SE SERIES

PUMP INSTALLATION

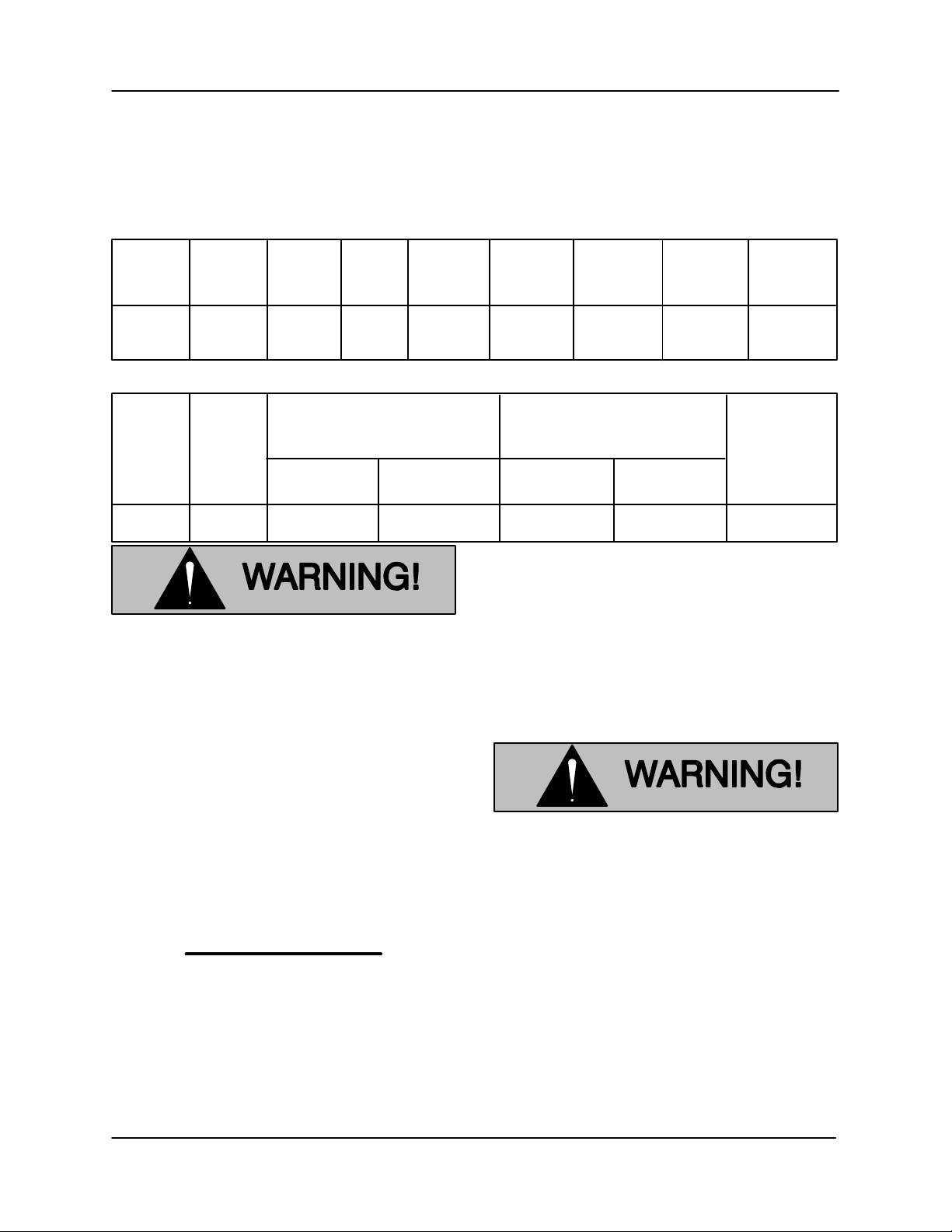

Pump Motor Specifications

See Tables B‐1 and B‐2 for pump specifications.

Table B‐1. Pump Specifications

OM-06494

Model Voltage/

Phase

SE2D3 115/1 NO 8.6 1.0 50.61 HP 3450

Pump

Model

Voltage/

Phase

115/1SE2D3

Liquid

Level

Control

Pump

78 (42) 6 (3) 7 (0,2) HORIZONTAL

Pump

HP/

KW

Table B‐2. Additional Specifications

Approximate

Weight - Lbs. (kg)

Motor

Speed

(RPM)

50 Ft. Cable

When installing or servicing the pump

or controls, follow all requirements for

the installation of wiring or electrical

equipment as outlined in the National

Electric Code. Follow all safety require

ments. Failure to observe these require

ments could result in injury or death to

personnel.

Full

Load

Amperes

Ounces (Liters)

Seal

Cavity

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

No

Load

Amperes

Oil Capacity

Locked

Amperes

Motor

Cavity

---

Rotor

Discharge

Size

(NPT)

2 INCH

w/BARBED

ADAPTOR

Seal Cavity

Filling

Position

(H)orizontal

NOTE

Refer to the performance curve in Section E, Main

tenance and Repair when determining the most

efficient piping installation. The recommended

maximum submergence depth is 23 feet. Great

er depths could result in damage to the pump

Pump Dimensions

For the approximate physical dimensions of your

pump, refer to the pump specification data sheet

or contact your Gorman‐Rupp distributor or the

Gorman‐Rupp Company.

PAGE B - 2 INSTALLATION

Do not attempt to lift the pump by the

motor power cable or the piping. Attach

proper lifting equipment or a rope to the

lifting device fitted to the pump.

Positioning the Pump

The pump is designed to operate fully or partially

submerged. The rotating parts are oil lubricated,

and the motor is cooled by a constant flow of liquid

or air discharged through internal passages.

The pump will operate if positioned on its side, but

this is not recommended because the motor

torque could cause the pump to roll during opera

tion.

OM-06494 SE SERIES

The pump should be independently secured and

supported by the lifting device fitted on the pump.

If the application involves a lot of debris, protect the

pump from excessive wear and clogging by sus

pending it in a perforated barrel or culvert pipe. If

the bottom is heavily sludge‐covered, rest the

pump on support blocks or suspend it from a raft

or similar device near the surface of the liquid. See

Figure B‐1 for typical pump installations.

All liquid entering the pump must pass through a

strainer screen. Any spherical solids which pass

through the screen will pass through the pump.

BY BAIL IN PERFORATED CULVERT PIPE ON SUPPORTS

Figure B‐1. Typical Pump Installations

Piping

No suction piping is required in a standard installa

tion. This pump is provided with a suction strainer

to prevent large solids from clogging the impeller.

To determine the size of the discharge connection,

see Table B‐1. Either hose or rigid pipe may be

used. To facilitate mobility and maintenance, it is

recommended that the discharge line be fitted with

a quick disconnect fitting near the pump. The dis

charge line must be independently supported to

avoid strain and vibration on the pump.

Either hose or rigid pipe may be used to make dis

charge connections. For maximum pumping ca

pacity, keep the line as short and straight as pos

sible. Elbows and fittings used in discharge lines

increase friction loss, minimize their use.

It is recommended that a check valve or throttling

valve be installed in the discharge line to control si

phoning or back flow when the pump is shut off.

ELECTRICAL CONNECTIONS

Install and operate this pump in accor

dance with the National Electrical Code

and all local codes. Have a qualified

electrician perform all checks and con

nections in this section.

Never attempt to alter the length of the

pump motor cable or to repair it with a

splice. The power cable and pump mo

tor must be kept completely waterproof.

Serious damage to the pump and injury

PAGE B - 3INSTALLATION

SE SERIES

OM-06494

or death to personnel can result from

any alteration to the cable.

Field Wiring Connections (Incoming Power)

The pump is designed to operate with a 115 volt,

1 phase, 60 hertz power supply. The voltage avail

able at the motor must be within the range indi

cated in Table B‐3.

To calculate the voltage available at the motor, pro

ceed as follows:

a. Measure the voltage while the pump is oper

ating at full capacity. See wiring diagrams at

the end of this section.

b. Next, subtract the motor cable voltage drop

(see Table B‐5, Pump Power Cable Specifi

cations).

c. Do not continue to operate the pump if this

voltage is not within the recommended limits.

Obtain the services of a qualified electrician to

determine the correct field wiring size and oth

er details to ensure an adequate voltage sup

ply to the pump.

Table B‐3. Pump Voltage Requirements

NOMINAL

VOLTAGE

Grounding Methods

If the power cable will be wired into an optional

manual switch or control box, ground the enclo

sure before installing the wiring. In any of these

cases, the electrical circuit must be grounded to a

properly imbedded electrode.

The material used for the electrode must be an ex

cellent conductor of electricity, such as copper. If

iron or steel is used, it must be galvanized or other

wise metal plated to resist corrosion. Do not coat

the electrode with any material of poor conductiv

ity, such as paint or plastic.

The electrode must conform to the recommenda

tions of N.E.C. ARTICLE 250. Follow all installation

requirements of the N.E.C., and all applicable local

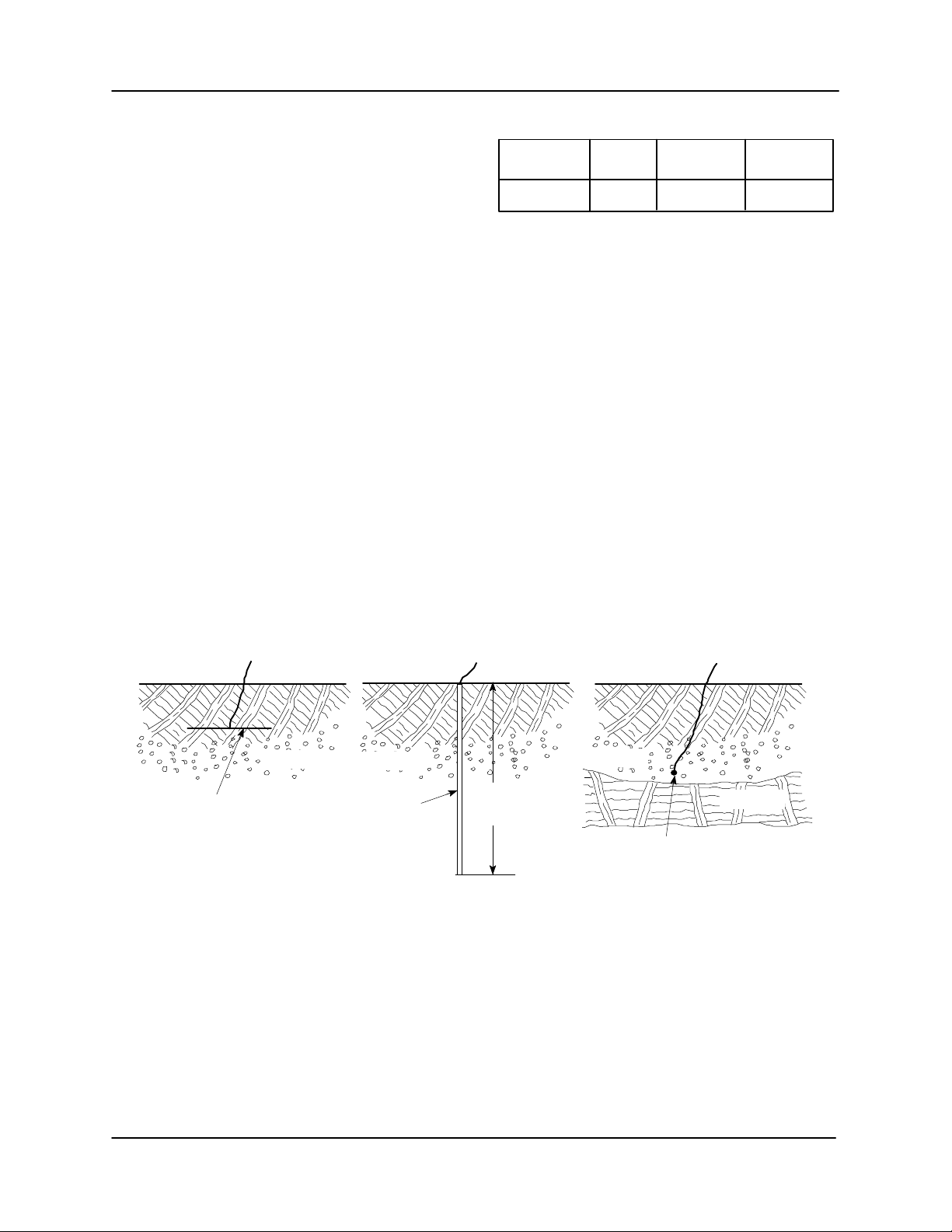

codes. See Figure B‐2 for some suggested

grounding methods.

PHASE

1115 110 120

MINIMUM

VOLTAGE

MAXIMUM

VOLTAGE

a) PLATE ELECTRODE b) DRIVEN ELECTRODE c) BURIED ELECTRODE

SOIL

1/4 INCH (6,4 MM)

STEEL PLATE 2 SQ.

FEET (1858,1 SQ. CM)

SURFACE AREA

(MINIMUM)

Figure B‐2. Suggested Grounding Methods

a. Plate Electrode: An iron or steel plate, 1/4

inch (6,4 mm) thick, completely impeded in

the ground. The plate must present a surface

area of at least 2 square feet (1858,1 sq. cm.).

b. Driven Electrode: A rod or pipe, 3/4 inch

(19,1 mm) in diameter minimum, 8 feet (2,4 m)

long, completely driven into the ground.

SOIL

3/4 INCH (19,1

MM) NOMINAL

DIAMETER

(MINIMUM)

8 FEET

(2,4 M)

c. Buried electrode: If rock or stone prevents

embedding the full 8 foot (2,4 m) length of the

ground rod, bury it horizontally in a trench.

Space the ground rod or plates at least 6 feet

(1,8) from any other electrode or ground rod,

such as those used for signal circuits, radio

grounds, lightning rods, etc.

SOIL

3/4 INCH (19,1 MM)

NOMINAL DIAMETER

(MINIMUM) 8 FEET

(2,4 M) LONG

ROCK

PAGE B - 4 INSTALLATION

OM-06494 SE SERIES

The earth surrounding the ground rod or plate

must contain enough moisture to make a

good electrical connection. In dry or sandy

areas, pour water around the rod, or consult

qualified personnel to devise a method of im

proving the connections.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Make certain that the recep

tacle or optional enclosure is properly

grounded after installation.

Pump Power Cable Connections

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Obtain the services of a

qualified electrician to make all electri

cal connections. Make certain that the

pump and receptacle or optional enclo

sure are properly grounded.

The pump is provided with a 50 ft. (15,2 m) power

cable (see Table B‐4 for standard power cable

specifications) with one end wired into the pump

head. The other end terminates in separate leads

which must be connected to a control box or switch

box.

Optional rainproof starting switches are available

from the factory (see the parts list, Section E).

NOTE

The optional rainproof starting switch listed in the

Parts List is not designed to be watertight and must

not be used in submerged applications.

Splicing of the power cable is not recommended

by the Gorman‐Rupp Company due to safety and

warranty considerations. If a longer power cable is

required, it should be of continuous length and

should replace the existing cable. Any replace

ment cable must be to Gorman‐Rupp standards,

and must be approved by Gorman‐Rupp.

Never attempt to alter the length or re

pair any power cable with a splice. The

pump motor and cable must be com

pletely waterproof. Injury or death may

result from alternations.

Table B‐4. Pump Power Cable Specifications

Cable

A.W.G

Pump

Model

When necessary to change or connect the pump

power cable to a control box, make certain the in

coming power is OFF and LOCKED OUT. Make

certain the control box is PROPERLY GROUNDED

and that the electrical data on the control matches

the motor name plate data.

Connect the pump power cable to the control

switch as shown in the wiring diagram at the end

Voltage/

Phase

115/1

Cable

Size

16 13* SO 7.72SE2D3 0.43 (11) 0.06 (1,5) 4.49

O.D.

Inches

(mm)

Conductor

Inches

(mm)

Dia.

DC

Amp

Rating

(See

Note

Below)

of this section. Make certain that all connections

are tight and that cable entry points are rainproof.

Control Box

Cable

Type

Resistance

(ohms) at

225_C (77_F)

per 1000 ft.

(305 m)

Voltage

Drop

per 100 ft.

(30,5m) at

Max. Load

Any control box used to operate the

PAGE B - 5INSTALLATION

Loading...

Loading...