Page 1

OM−06490−01

August 10, 2011

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

T

HANDY-SUB

SUBMERSIBLE PUMP

MODEL

SE1 1/2B3−E.33 12V

THE GORMAN-RUPP COMPANY F MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

E2011 The Gorman-Rupp Company

Page 2

Register your new

Gorman-Rupp pump online at

www.grpumps.com

Valid serial number and e-mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman-Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

Page 3

TABLE OF CONTENTS

INTRODUCTION PAGE I − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY - SECTION A PAGE A − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION − SECTION B PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREINSTALLATION INSPECTION PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP INSTALLATION PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Dimensions PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning the Pump PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Pump Installations PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PIPING PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP POWER CABLE CONNECTIONS PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION − SECTION C PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP OPERATION PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switching PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running Time PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overload Protection PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Checks PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOPPING PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage and Cold Weather Preservation PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING − SECTION D PAGE D − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL TESTING PAGE D − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment PAGE D − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cable Continuity Check PAGE D − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Breaker Check PAGE D − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On-Off Switch Check PAGE D − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP MAINTENANCE AND REPAIR - SECTION E PAGE E − 1. . . . . . . . . . . . . . . . .

PERFORMANCE CURVE PAGE E − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS LIST:

Pump Model PAGE E − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E − 4. . . . . . . . . . . . . . . . . . . . . . . . .

PUMP END DISASSEMBLY PAGE E − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strainer Removal PAGE E − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Removal PAGE E − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Removal PAGE E − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP END REASSEMBLY PAGE E − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning And Inspection Of Pump Parts PAGE E − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Installation PAGE E − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Installation PAGE E − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strainer Installation PAGE E − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOTOR DISASSEMBLY PAGE E − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

TABLE OF CONTENTS

(continued)

Cable Assembly and Motor Cover Removal PAGE E − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Circuit Breaker Removal PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Brush Removal PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOTOR REASSEMBLY PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Brush Installation PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Circuit Breaker Installation PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Assembly and Motor Cover Installation PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

SE SERIES

OM−06490

INTRODUCTION

Thank You for purchasing a Gorman-Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

This pump is an SE Series, Handy-SubT submersible model, designed to handle dirty water that

does not contain large entrained solids. Do not attempt to pump volatile, flammable or corrosive liquids that may damage the pump. The basic material of construction is aluminum, with a cast iron impeller.

The pump may be operated fully or partially submerged, but should not be operated dry for extended periods. The integral 1/3 H.P. electric motor

may be driven by any standard 12-volt DC vehicle

battery. The pump is not explosion-proof, and

should not be operated in a hazardous atmosphere.

This manual will alert personnel to known procedures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel. However,

this manual cannot possibly anticipate and provide

detailed precautions for every situation that might

occur during maintenance of the unit. Therefore, it

is the responsibility of the owner/maintenance personnel to ensure that only safe, established main-

tenance procedures are used, and that any procedures not addressed in this manual are performed

only after establishing that neither personal safety

nor pump integrity are compromised by such practices.

If there are any questions regarding the pump or

its application which are not covered in this manual or in other literature accompanying this unit,

please contact your Gorman-Rupp distributor, or

the Gorman-Rupp Company:

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901−1217

Phone: (419) 755−1011

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631−2870

The following are used to alert maintenance personnel to procedures which require special attention, to those which could damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possible damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I − 1INTRODUCTION

Page 6

SE SERIES

OM−06490

SAFETY - SECTION A

This information applies to the SE Series Handy-SubT submersible electric

motor driven pump.

Do not operate this pump where explosive vapors or flammable material exist.

Death or serious injury will result.

Check the National Electric Code

(N.E.C.) and local codes before using.

Before attempting to open or service the

pump:

1. Familiarize yourself with this manual.

2. Switch off the pump and disconnect the power cables from the vehicle battery to ensure that the

pump will remain inoperative.

3. Allow the pump to cool if overheated.

This pump is designed to handle dirty

water that does not contain large entrained solids. It is not designed to

pump volatile, flammable or corrosive

materials. Do not attempt to pump any

liquids which may damage the pump or

endanger personnel as a result of pump

failure.

casing, electrical shock could occur,

causing severe injury or death to personnel.

Always make sure the switch on the

power cables is in the OFF position before connecting the leads to the vehicle

battery. Failure to do so could cause

arcing, resulting in explosion or fire.

Never attempt to alter the length or repair any power cable with a splice. The

pump motor and cable must be completely waterproof. Damage to the pump

or personal injury may result from alterations.

After the pump has been installed, make

certain that the pump and all piping or

hose connections are secure before operation.

Do not attempt to lift the pump by the

power cables, carry handle or piping.

Attach proper lifting equipment to the

lifting eye fitted to the pump.

Do not allow the pump and vehicle to

come into contact when connecting the

power cable to the battery. If the pump

should develop an internal short to the

Obtain the services of a qualified electrician to troubleshoot, test and/or service the electrical components of this

pump.

PAGE A − 1SAFETY

Page 7

INSTALLATION − SECTION B

OM−06490SE SERIES

Review all SAFETY information in Section A.

Do not operate this pump where explosive vapors or flammable material exist.

Death or serious injury will result.

Check the National Electric Code

(N.E.C.) and local codes before using.

This section only summarizes recommended installation practices for the pump. If there are questions concerning your specific application, contact

your local distributor or the Gorman-Rupp Company.

PREINSTALLATION INSPECTION

The pump was inspected and tested before shipment from the factory. Before installation, inspect

the pump for damage which may have occurred

during shipment. Check as follows:

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious damage.

c. The standard pump is furnished with two

30-foot (3 m) long power cables. Inspect the

cables for cuts or damage.

d. Screw the lifting eye (shipped loose) into the

tapped hole in the top of the motor cover until

fully seated, and secure it with the jam nut.

e. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

as indicated.

If anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

Lubrication

The shaft seal in this pump is lubricated by the medium being pumped. The bearings in this pump

are permanently lubricated for life. No additional lubrication is required.

PUMP INSTALLATION

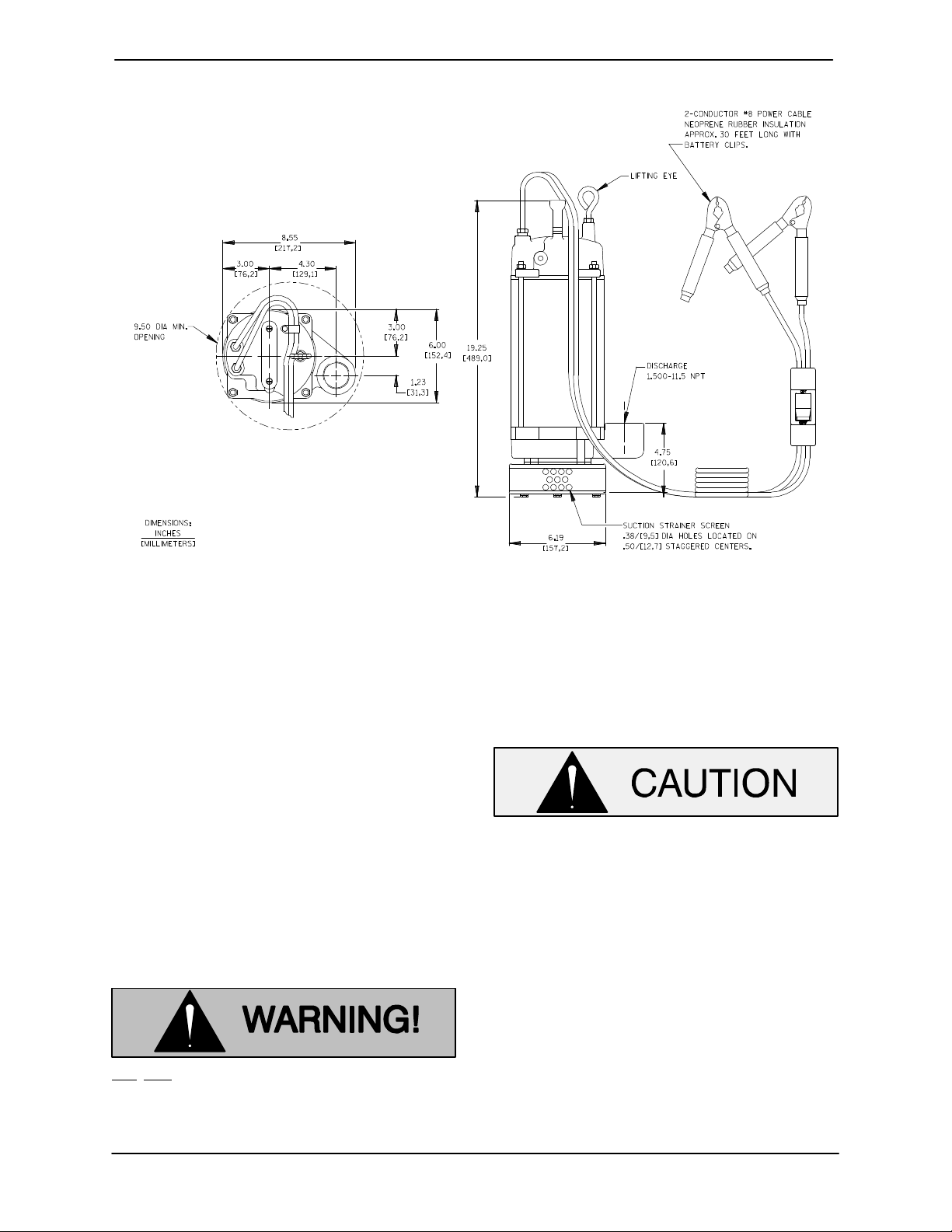

Pump Dimensions

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating surfaces.

The pump is provided with a suction strainer to prevent large solids from clogging the impeller. See

Figure 1 for the approximate physical dimensions

of the pump.

PAGE B − 1INSTALLATION

Page 8

OM−06490 SE SERIES

OUTLINE DRAWING

TOP VIEW

Figure 1. Pump Model SE1 1/2B3−E.33 12V

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer-installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

Attach a rope or chain to the lifting handle in the top

of the motor cover. Do not lift the unit by the power

cables or the discharge piping. Do not attach lifting

equipment to the carry handle. Customer installed

equipment such as rigid discharge piping must be

removed before attempting to lift.

Positioning the Pump

This pump is designed to operate fully or partially

submerged; however, it should not be operated

dry for extended periods of time.

Extended dry operation will destroy the

seal assembly.

Secure and support the pump by the lifting eye fitted on the pump. If the application involves a lot of

debris, protect the pump from excessive wear and

clogging by suspending it in a perforated barrel or

culvert pipe. If the bottom is heavily sludge-covered, rest the pump on support blocks or suspend

it from a raft or similar device near the surface of the

liquid. See Figure 2 for typical pump installations.

Do not attempt to lift the pump by the

power cables, carry handle or piping.

Attach proper lifting equipment to the

lifting eye fitted to the pump.

PAGE B − 2 INSTALLATION

The pump is provided with a suction strainer to prevent large solids from clogging the impeller. Any

spherical solids which pass through the strainer

will pass through the pump.

Page 9

OM−06490SE SERIES

BY BAIL

IN PERFORATED CULVERT PIPE

Figure 2. Typical Pump Installations

PIPING

The pump volute is equipped with a standard

1−1/2−inch NPT tapped discharge connection.

Either hose or rigid pipe may be used for the discharge connection.

For maximum pumping capacity, use non-collapsible hose or rigid piping, and keep the discharge as

short and straight as possible. If rigid piping is

used, minimize the use of elbows and fittings which

increase friction losses and reduce pump performance.

A check valve or throttling valve may be installed in

the discharge line to control siphoning or back flow

when the pump is shut off.

ON SUPPORTS

Never attempt to alter the length or repair any power cable with a splice. The

pump motor and cable must be completely waterproof. Damage to the pump

or personal injury may result from alterations.

When connecting the pump power cables to the

vehicle, first check the vehicle owner’s manual to

determine if the vehicle has a negative or a positive

grounding system.

PUMP POWER CABLE CONNECTIONS

The pump is provided with two 30-foot (3 m) power

cables. Splicing of the power cables is not recommended by the Gorman-Rupp Company due to

safety and warranty considerations.

Always make sure the switch on the

power cables is in the OFF position before connecting the leads to the vehicle

battery. Failure to do so could cause

arcing, resulting in explosion or fire.

Refer to Figure 3 for pump power cable connections, and proceed as follows:

PAGE B − 3INSTALLATION

Page 10

OM−06490 SE SERIES

1) Connect the red cable clamp from the pump

to the positive (+) terminal on negative

grounding systems, or to the negative (−) terminal on positive grounding systems.

Do not allow the pump and vehicle to

come into contact when connecting the

power cable to the battery. If the pump

should develop an internal short to the

casing, electrical shock could occur,

causing severe injury or death to personnel.

2) Connect the black cable clamp from the

pump to ground, preferrably to a solid, metallic, stationary point on the engine. The con-

nection should be made as far away from the

battery as possible.

BATTERY

Power

line to

VEHICLE ENGINE

Ground

(Black)

Ground line

from pump

pump

(Red)

HANDY-SUBT

Switch

PUMP

Figure 3. Pump Power Cable Connections

(Negative Ground System)

PAGE B − 4 INSTALLATION

Page 11

SE SERIES

OM−06490

OPERATION − SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and

decals attached to the pump.

PUMP OPERATION

Do not operate this pump where explosive vapors or flammable material exist.

Death or serious injury will result.

Check the National Electric Code

(N.E.C.) and local codes before using.

This pump is designed to handle dirty

water that does not contain large entrained solids. It is not designed to

pump volatile, flammable or corrosive

materials. Do not attempt to pump any

liquids which may damage the pump or

endanger personnel as a result of pump

failure.

Install the pump and piping as described in INSTALLATION, Section B.

Running Time

The pump draws about 30 Amps, and can be operated for about 45 minutes on a fully-charged 55

AMP-hour battery, and still permit starting of the vehicle under normal conditions. Caution should be

used when the running time exceeds 30 or 40 minutes without the engine running to recharge the

battery, particularly in cold weather when the battery efficiency is lowered. Battery size (AMP-hour

rating) and the use of other accessories such as

the lights and radio, must be taken into consideration for practical running periods without the vehicle engine running.

Do not operate an internal combustion

engine in an explosive atmosphere.

When operating internal combustion

engines in an enclosed area, make certain that exhaust fumes are piped to the

outside. These fumes contain carbon

monoxide, a deadly gas that is colorless, tasteless, and odorless.

Overload Protection

Overload protection is provided by means of a 40

Amp automatic reset circuit breaker located inside

the motor cover on top of the pump.

Operational Checks

Check the pump for proper operation when it is first

Switching

The ON-OFF switch for the pump is located on the

power cable. With the switch in the OFF position, a

safety interlock circuit eliminates arcing when the

cable is connected to the battery. Arcing may occur if the switch was left ON because the pump was

stopped after its last operation by disconnecting

the battery clips without using the switch. Always

make sure the switch is in the OFF position before

connecting to the vehicle battery.

OPERATION PAGE C − 1

started and periodically thereafter to identify minor

problems.

Check the pump for unusual noises or excessive

vibration while it is operating. If noise or vibration is

excessive, stop the pump and refer to the

troubleshooting chart for possible causes.

Check the pump strainer screen for clogging

caused by stones, sticks, or other debris. Clean

the strainer screen when required. In some cases,

stopping the pump momentarily may back flush

Page 12

OM−06490

the strainer screen, purging most of the debris

from it. If this fails to clean the screen, remove the

pump from the sump and remove the debris manually (see MAINTENANCE AND REPAIR in Section

E).

Never introduce air or steam pressure into the

pump casing or piping to remove a blockage. This

could result in personal injury or damage to the

equipment. If backflushing is absolutely necessary, liquid pressure must be limited to 50% of the

maximum permissible operating pressure shown

on the pump performance curve (see MAINTE-

NANCE AND REPAIR, Section E).

SE SERIES

Do not attempt to lift the pump by the

power cables, carry handle or piping.

Attach proper lifting equipment to the

lifting eye fitted to the pump.

Clean the strainer screen before storage. If the

application involves a lot of mud or sludge, remove

the strainer and clean the impeller before storage.

NOTE

The most common cause of failure to run is hardened mud or sludge in the impeller.

STOPPING

After stopping the pump, be sure to perform all required maintenance and preservation procedures.

Storage and Cold Weather Preservation

After stopping the pump, disconnect the power

cables from the vehicle battery, and use the rope or

chain attached to the lifting eye on the motor cover

to remove the pump from the sump. Do not lift the

unit by the power cables or the discharge piping.

Do not attach lifting equipment to the carry handle.

Customer installed equipment such as rigid discharge piping must be removed before attempting

to lift.

In freezing temperatures, the pump will not freeze

as long as it is submerged in liquid. If the pump

casing is not submerged, or if the liquid begins to

freeze, remove the pump from the sump and allow

it to dry thoroughly. Run the pump for two or three

minutes to dry the inner walls.

If the pump freezes, move it into a warm area until

completely thawed, or submerge it into the liquid. If

the liquid is near freezing, the pump must be submerged for an extended period of time. Start the

pump and check for shaft rotation. If still frozen, allow additional thawing time before attempting to

restart.

Do not attempt to thaw the pump by using

a torch or other source of flame. This could

damage gaskets, electrical components,

or motor windings.

OPERATIONPAGE C − 2

Page 13

SE SERIES OM−06490

TROUBLESHOOTING − SECTION D

Review all SAFETY information in Section A.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

MOTOR WILL NOT

RUN

MOTOR RUNS, BUT

PUMP FAILS TO

DELIVER RATED

DISCHARGE

Hardened mud or sludge in impeller. Remove strainer, check and clean.

Poor connection at battery or vehicle Check and correct connections.

ground.

Impeller binding. Check freedom of rotation. Add shims

or gaskets as required.

Damaged power cable(s). Inspect and replace as required.

Open circuit in motor windings or power Check continuity.

cable.

Loose connection in motor cover. Remove cover, check connections

and correct as required.

Bad switch or circuit breaker. Check electrical components as

described in this section and replace

as required.

Worn motor brushes or out of position Disassemble pump, check and

to make contact with armature. replace brushes as required.

Strainer clogged. Check and clean as required.

Impeller binding. Check freedom of rotation. Add shims

or gaskets as required.

Discharge line clogged or restricted; Check discharge lines; straighten

hose kinked. hose.

Liquid being pumped too thick. Dilute liquid by heating if possible.

Vehicle battery not fully charged. Start vehicle and allow to run until

battery is fully charged.

Worn impeller vanes; excessive impeller Check impeller and clearance. See

clearance. PUMP END REASSEMBLY.

Pumping entrained air. Check liquid level in sump; check

position of pump.

Damaged or unbalanced impeller. Replace impeller.

TROUBLESHOOTING PAGE D − 1

Page 14

OM−06490

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

SE SERIES

PUMP RUNS WITH

EXCESSIVE NOISE

OR VIBRATION

Pumping entrained air. Check liquid level in sump; check

Damaged impeller. Inspect and replace impeller.

Motor shaft or bearings defective. Disassemble pump and check motor

ELECTRICAL TESTING

If you suspect that pump malfunctions are caused

by defects in the power cables or electrical components, perform the following checks to help isolate

the defective part.

Obtain the services of a qualified electrician to troubleshoot, test and/or service the electrical components of this

pump.

position of pump.

and bearings.

Power Cable Continuity Check

Disconnect the power cables inside the motor cover. Use the ohmmeter to check continuity of the

cables, and replace defective cables as required.

Never attempt to alter the length or repair any power cable with a splice. The

pump motor and cable must be completely waterproof. Damage to the pump

or personal injury may result from alterations.

Always disconnect the battery clamps

from the vehicle battery when testing electrical components.

Test Equipment

A volt/amp/ohmmeter of adequate range and quality will be required to conduct the following electrical tests.

Equipment Use

Ammeter To check AC Voltage

and current (amperage)

Ohmeter To measure resistance

(ohms) to ground

Circuit Breaker Check

The circuit breaker used in this pump is normally

closed. Disconnect the wires from the breaker, and

check continuity across the terminals. If the circuit

is open, replace the breaker.

On-Off Switch Check

Disconnect red battery cable lead from circuit

breaker terminal. Check continuity between battery clamp and ring terminal on the end of the

cable. Moving ON-OFF switch from ON to OFF

should break continuity. If the switch is bad, the

continuity will remain open when the switch is in

the ON position.

TROUBLESHOOTINGPAGE D − 2

Page 15

SE SERIES OM−06490

PUMP MAINTENANCE AND REPAIR - SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

STANDARD PERFORMANCE FOR PUMP MODEL SE1 1/2B3−E.33 12V

Based on 70_ F (21_ C) clear water at sea level.

Since pump installations are seldom identical, your

MAINTENANCE & REPAIR PAGE E − 1

performance may be difference due to such factors as viscosity, specific gravity and temperature.

Page 16

OM−06490 SE SERIES

SECTION DRAWING

PARTS PAGE

Figure 1. Pump Model SE1 1/2B3−E.33 12V

MAINTENANCE & REPAIRPAGE E − 2

Page 17

SE SERIES OM−06490

PARTS LIST

Pump Model SE1 1/2B3−E.33 12V

(From S/N 1483930 Up)

If your pump serial number is followed by an N", your pump is NOT a standard production model. Contact

the Gorman-Rupp Company to verify part numbers.

ITEM

PART NAME PART

NO.

NUMBER

MAT’L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT’L

CODE

QTY

1 CASING TUBE KIT 26831−071 −−− 1

1A −CASING TUBE NOT AVAILABLE 1

1B −STUD NOT AVAILABLE 4

2 O-RING 25152−254 −−− 1

3 LOCK WASHER J04 15991 4

4 HEX HD CAPSCREW B0403−1/2 15991 4

5 PUMP CASING 26831−072 −−− 1

6 SEAL ASSY 26831−003 −−− 1

7 IMP ADJ SHIM 26831−061 −−− 7

8 IMPELLER 26831−002 −−− 1

9 CASING GASKET 26831−062 −−− 5

10 SUCTION COVER 26831−076 −−− 1

11 STRAINER 26831−064 −−− 1

12 STRAINER PLATE 26831−065 −−− 1

13 LOCK WASHER J04 14991 4

14 HEX HD CAPSCREW B0411 17000 4

15 MOTOR 26831−075 −−− 1

16 POWER CABLE ASSY 26831−073 −−− 1

17 O-RING 25152−254 −−− 1

18 MOTOR COVER 26831−074 −−− 1

19 HEX NUT D06 15991 1

20 HANDLE 26831−052 −−− 1

INDICATES PARTS RECOMMENDED FOR STOCK

21 LOCK WASHER J#10 15991 1

22 RD HD MACH SCREW X#04−02 15991 1

23 CABLE CLAMP 26831−007 −−− 1

24 GLAND NUT 26831−022 −−− 2

25 GLAND SPACER 26831−023 −−− 2

26 SEALING RING 26831−024 −−− 2

27 HEX NUT D05 15991 4

28 LOCK WASHER J05 15991 4

29 TWIST TYPE CONNECTOR26831−078 −−− 1

30 RING TERMINAL 26831−077 −−− 1

31 CIRCUIT BREAKER 26831−042 −−− 1

32 SELF-TAPPING SCREW 26831−035 −−− 2

NOT SHOWN:

MOTOR BRUSH 26831−079 −−− 2

CAUTION DECAL (LARGE) 26831−068 −−− 1

NAMEPLATE 38812−073 −−− 1

G-R DECAL GR−03 −−− 1

CAUTION DECAL 26831−081 −−− 2

OPTIONAL:

CARRYING CASE/HOSE KIT 48782−001 −−− 1

MAINTENANCE & REPAIR PAGE E − 3

Page 18

OM−06490 SE SERIES

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY

Review all SAFETY information in Section A.

Follow the instructions on all tags, label and decals attached to the pump.

The following maintenance and repair instructions

are keyed to the Pump Model sectional view (Figure 1) and the accompanying parts lists.

Before attempting to service the pump, switch off

the pump and disconnect the power cables from

the vehicle battery to ensure that the pump will remain inoperative.

Before attempting to open or service the

pump:

1. Familiarize yourself with this manual.

2. Switch off the pump and disconnect the power cables from the vehicle battery to ensure that the

pump will remain inoperative.

3. Allow the pump to cool if overheated.

Use a rope or chain attached to the handle in the

motor cover to remove the pump from the sump,

and move it to a location where the discharge line

can be removed. It is not necessary to disconnect a

flexible discharge hose before removing the pump.

If rigid discharge piping is used, disconnect the

piping before attempting to move the pump.

motor housing is to be opened, the work must be

done in a clean, well-equipped shop. All maintenance functions must be done by qualified personnel.

Obtain the services of a qualified electrician to troubleshoot, test and/or service the electrical components of this

pump.

Check the chart in TROUBLESHOOTING, Section

D, to determine the nature of the pump problem. If

the problem is mechanical in nature, such as worn

pump parts, seal replacement, etc., refer to PUMP

END DISASSEMBLY for instructions.

If the problem is electrical, complete disassembly

may not be required. Refer to Electrical Testing in

TROUBLESHOOTING, Section D, and have a

qualified electrician check the cables and electrical

components inside the motor cover. If the problem

is determined to be in electrical components, complete disassembly of the pump may not be required. See the appropriate section in MOTOR

DISASSEMBLY.

Carefully inspect any O-rings or gaskets before removal and cleaning to determine if a proper seal

and compression existed prior to disassembly. If

sealing was faulty or questionable, the cause must

be determined and corrected before reassembly.

All gaskets and most O-rings must be replaced if

disturbed. Repair gaskets and O-rings are listed on

the parts list.

Do not attempt to lift the pump by the

power cables, carry handle or piping.

Attach proper lifting equipment to the

lifting eye fitted to the pump.

Select a suitable location, preferably indoors, to

perform the degree of maintenance required. If the

PUMP END DISASSEMBLY

Strainer Removal

To remove the strainer screen (11), lay the pump

on its side and disengage the hardware (13 and

14). Remove the strainer plate (12), strainer

screen, suction cover (10) and casing gaskets (9).

If the impeller is clogged, the debris can usually be

removed without further disassembly.

MAINTENANCE & REPAIRPAGE E − 4

Page 19

SE SERIES OM−06490

Impeller Removal

Wedge a piece of wood between the vanes of the

impeller (8) and the inside of the pump casing (5).

Insert a large flat-bladed screwdriver into the slot in

the end of the shaft. Turn the shaft in a clockwise

direction to break the impeller loose. After the impeller breaks loose, remove the screwdriver and

wood block and unscrew the impeller from the

shaft. Use caution when unscrewing the impeller;

tension on the seal spring will be released.

Remove the impeller shims (7). For ease of reassembly, tie and tag the shims or measure and record their thickness.

Seal Removal

(Figures 1 and 2)

Remove the spring centering washer and spring.

Lubricate the seal area of the rotor shaft with light

oil. To easily remove the seal, disengage the hardware (3 and 4) securing the pump casing to the

motor (15). Use a soft-faced mallet to tap the pump

casing loose from the casing tube (1A).

Slide the pump casing and seal off the shaft. Press

the stationary portion of the seal out of the pump

casing from the back side.

Inspect the lower casing tube O-ring (2). If replacement is required, remove it from the pump casing.

If no further disassembly is required, proceed with

PUMP END REASSEMBLY.

NOTE

Do not disassemble the motor unless it is necessary and a clean, well-equipped shop is available. If

the motor housing components are to be serviced,

see MOTOR DISASSEMBLY in this section. Do not

reassemble the end components at this time.

during reassembly (see the parts lists for numbers).

Cleaning And Inspection Of Pump Parts

Carefully inspect any O-rings or gaskets before removal and cleaning to determine if a proper seal

and compression existed prior to disassembly. If

sealing was faulty or questionable, the cause must

be determined and corrected before reassembly.

Replace any parts as required.

Thoroughly clean all reuseable parts with a soft

cloth soaked in cleaning solvent. Remove all Orings and gaskets, and clean the sealing surfaces

of dirt or gasket material. Be careful not to scratch

gasket surfaces.

Most cleaning solvents are toxic and

flammable. Use them only in a well-ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent containers.

Inspect the rotor shaft for damaged threads, scoring, or nicks. Remove nicks and burrs with a fine

file or emery cloth to restore original contours. If the

shaft is bent or severely damaged, the motor must

be replaced as an assembly (see MOTOR DISAS-

SEMBLY).

Inspect the seal components for wear, scoring,

grooves, and other damage that might cause leakage. The shaft seal assembly should not be reused

because wear patterns on the finished faces cannot be realigned during reassembly. This could result in premature failure. If any components are

worn, replace the complete seal; never mix old

and new seal parts.

Handle a new seal with extreme care to prevent

PUMP END REASSEMBLY

NOTE

Reuse of old O-rings, gaskets, or shaft seal parts

may result in premature leakage or reduced pump

performance. It is strongly recommended that new

gaskets and a new shaft seal assembly be used

MAINTENANCE & REPAIR PAGE E − 5

damage. Be careful not to contaminate the precision finished faces; even fingerprints on the faces

can shorten seal life. If necessary, clean the faces

with a non-oil based solvent and a clean, lint-free

tissue. Wipe lightly in a concentric pattern to avoid

scratching the faces.

Install the shaft seal as illustrated in Figure 2.

Page 20

OM−06490 SE SERIES

STATIONARY

CUP SEAT

BELLOWS

SPRING

CENTERING

WASHER

PUMP

CASING

STATIONARY

ELEMENT

ROTATING

ELEMENT

ROTOR

SHAFT

BELLOWS

RETAINER

SPRING

IMPELLER

SHIMS

IMPELLER

Figure 2. Seal Assembly

Seal Installation

(Figures 1 and 2)

If a new seal assembly is to be installed, do not unwrap it until time of installation. Cleanliness of seal

components is critical, especially the seal faces.

Clean the rotor shaft and seal cavity area of the

pump casing (5). Be sure the area is dry and free of

lint and dirt. Check the seal bore for burrs or nicks

that might prevent a good seal. Apply a light coating of oil to the bore.

NOTE

When pressing seal components onto the shaft,

use hand pressure only. A push tube cut from a

length of plastic pipe will aid in installing seal components. The I.D. of the push tube should be approximately the same as the I.D. of the seal spring.

thumbs to press the assembly into the bore. Apply

equal pressure on opposite sides until the seat

contacts the bore shoulder. Remove the tissue and

inspect the seal face to ensure that it is clean and

dry. If cleaning is necessary, use a clean lint-free

cloth to wipe lightly in a concentric pattern.

Lubricate and install a new casing tube O-ring (2)

on the pump casing. Carefully slide the pump casing over the shaft and use a soft-faced mallet to tap

the casing into the casing tube (1A) until fully

seated. Secure the pump casing to the motor with

the hardware (3 and 4).

Be certain the seal face of the rotating element is

free of grit or surface damage. Apply a light coating of oil to the seal seating surface on the shaft

and the I.D. of the bellows. Inspect the seal face to

ensure that it is clean and dry. If cleaning is necessary, use a clean lint-free cloth to wipe in a concentric pattern.

Subassemble the stationary element in the stationary cup seat. Position this subassembly in the casing bore with the sealing face up, and cover the

seal face with a clean, lint-free cloth. Use your

Slide the seal rotating portion onto the lubricated

shaft as shown in Figure 2. Apply firm, steady pressure on the seal retainer until it slides down the

shaft.

MAINTENANCE & REPAIRPAGE E − 6

Page 21

SE SERIES OM−06490

Slide the seal spring over the shaft and bellows retainer, and install the spring centering washer. See

Figure 2 for the proper order of seal assembly.

Impeller Installation

Inspect the impeller (8) for cracks, broken vanes,

or wear from erosion, and replace it if damaged.

Clean the threads on the rotor shaft.

Install the same thickness of impeller adjusting

shims (7) as previously removed. Position the impeller against the shims and seal spring. Carefully

compress the spring with the impeller until the impeller can be started on the shaft threads. Screw

the impeller onto the shaft until it is fully seated.

Wedge a piece of wood between the vanes of the

impeller and the inside of the pump casing.

Insert a large flat-bladed screwdriver into the slot in

the end of the shaft. Turn the shaft in a counter-

clockwise direction to secure the impeller.

Remove the block of wood, and turn the impeller to

check for free rotation. If the impeller scrapes or

binds against the pump casing, remove the impeller and install additional shims as required. Reinstall the impeller and re-check the clearance.

MOTOR DISASSEMBLY

Disassembly of the motor is rarely required except

to replace electrical components or the motor

brushes. Do not disassemble the motor unless it is

necessary and a clean, well-equipped shop is

available.

NOTE

It is recommended that a pump with a defective motor be returned to Gorman-Rupp, or to one of the

Gorman-Rupp authorized Submersible Repair

Centers.

Obtain the services of a qualified electrician to troubleshoot, test and/or service the electrical components of this

pump.

Carefully inspect any O-rings or gaskets before removal and cleaning to determine if a proper seal

and compression existed prior to disassembly. If

sealing was faulty or questionable, the cause must

be determined and corrected before reassembly.

Replace any parts as required.

Check front impeller clearance after installing the

suction cover (10).

Strainer Installation

Inspect the strainer screen (1) and suction cover

(10) for cracks, distortion or erosion, and replace

any defective parts.

Install the same thickness of casing gaskets (9)

and position the suction cover against the gaskets.

Insert a flat-bladed screwdriver in the slot in the end

of the shaft, and turn the shaft to check for scraping

or binding. If scraping or binding occurs, install

additional gaskets.

Install the suction cover, strainer screen and strainer plate (12) and secure the parts with the hardware (13 and 14).

MAINTENANCE & REPAIR PAGE E − 7

Cable Assembly and Motor Cover Removal

Total removal of the motor assembly (15) is not always required. Disassemble and replace only the

parts proven defective by inspection or testing.

See Electrical Testing in TROUBLESHOOTING.

The electrical components may be serviced without disassembling the motor housing or pump

end.

Secure the pump in an upright position. To remove

the motor cover, disengage the hardware (27 and

28). Use a screwdriver to carefully pry the motor

cover out of the casing tube.

Carefully raise the motor cover until the electrical

components are accessible. To remove the motor

cover, unscrew the nut securing the red (positive)

power cable lead to the shorter terminal on the circuit breaker (31).

Page 22

OM−06490 SE SERIES

Unscrew the twist-type connector (29) securing

the black (negative) power cable lead to the red

motor lead. Separate the motor cover from the casing tube.

Remove the O-ring (17) from the groove in the motor cover.

To remove the power cable assembly (16), remove

the hardware (21 and 22) securing the cable clamp

(23) to the motor cover. Unscrew the gland nuts

(24) from the motor cover and pull the cables,

spacers (25) and sealing rings (26) from the motor

cover. Slide the cable clamp, sealing rings,

spacers and gland nuts off the power cables.

See Motor Cover Installation if no further disassembly is required.

Motor Circuit Breaker Removal

If electrical testing indicates a defective circuit

breaker (31), disconnect the red motor cable lead

and the red power cable lead from the circuit

breaker. Remove the self-tapping screws (32) securing the circuit breaker to the motor.

Motor Brush Removal

With the motor cover removed, the brushes (not

shown) can be easily removed. Remove the two

capscrews (not shown) in the top of the motor assembly and pry the motor casing open.

Reposition the previously separated motor casing

parts. Use caution not to pinch the motor leads and

to make sure the split grommet is properly positioned in the slot in the motor casing. Secure the

motor casing parts with the previously removed

capscrews.

Motor Circuit Breaker Installation

Secure the replacement circuit breaker (31) to the

top of the motor assembly with the self-tapping

screws (32). If a new motor assembly is being

installed, crimp the ring terminal (30) to the black

motor cable lead.

Secure the ring terminal on the black motor cable

lead to the longer terminal on the circuit breaker

with the previously removed nut.

Cable Assembly and Motor Cover Installation

If the cable assembly (16) was removed for replacement, slide the gland nuts (24), spacers (25)

and sealing rings (26) up the ends of the cable

leads approximately 12 inches (305 mm). Feed the

cable leads down through the holes in the motor

cover (18).

Lightly lubricate the upper casing tube O-ring (17)

and install it in the groove in the motor cover.

Refer to the wiring diagram in Figure 3, and use the

wire nut (29) to secure the black motor lead to the

black cable lead. Secure the ring terminal on the

red motor cable lead to the shorter terminal on the

circuit breaker with the previously removed nut.

Disengage the two small screws securing the

brush leads to the motor and remove the brushes.

There are no provisions for replacing motor parts.

Individual motor parts are not sold separately. If the

motor is damaged, the complete motor assembly

must be replaced. See the parts list on page E−3

for replacement parts.

MOTOR REASSEMBLY

Motor Brush Installation

Position the new brushes (not shown) in the brush

holders and secure the brush leads to the motor

assembly with the two previously removed screws.

RED BATTERY

RED

MOTOR

BLACK

AUX. BATT.

CIRCUIT BREAKER

(BLACK MOTOR LEAD

TO LONG TERMINAL)

WIRE

NUT

SWITCH

CLAMP

BLACK BATTERY

CLAMP

(GROUND)

Figure 3. Wiring Diagram

With the pump end components installed and the

casing tube (1A) in place, carefully pull the excess

cable leads up through the holes in the motor cover.

MAINTENANCE & REPAIRPAGE E − 8

Page 23

SE SERIES OM−06490

Position the motor cover in the casing tube with the

studs (1B) through the holes in the motor cover.

Install the hardware (27 and 28) and tighten the

nuts (27) in an alternating pattern until the motor

cover is fully seated in the casing tube. Use caution

not to cut or pinch the casing tube O-ring.

Slide the sealing rings (26) down the cable leads

and into the bores in the motor cover. Slide the

spacers (25) down the leads onto the sealing rings.

Screw the gland nuts (24) into the motor cover to

seal the cables.

Secure the cable leads to the motor cover with the

cable clamp (23) and hardware (21 and 22).

If removed, reinstall the lifting handle (20) and secure it with the jam nut (19).

Proceed with PUMP END REASSEMBLY.

MAINTENANCE & REPAIR PAGE E − 9

Page 24

For U.S. and International Warranty Information,

Please Visit www.grpumps.com/warranty

or call:

U.S.: 419−755−1280

International: +1−419−755−1352

For Canadian Warranty Information,

Please Visit www.grcanada.com/warranty

or call:

519−631−2870

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA

Loading...

Loading...