Page 1

ACU

OM‐06259‐01

March 31, 2009

Rev. A 05‐15‐12

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

SUBMERSIBLE PUMPS

MODELS

S8B1-E100 460/3

and

S8B1-E100 575/3

THE GORMAN‐RUPP COMPANY MANSFIELD, OHIO

www.grpumps.com

GORMAN‐RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

2009 The Gorman‐Rupp Company

Page 2

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

Page 3

TABLE OF CONTENTS

INTRODUCTION PAGE I - 1.................................................

SAFETY ‐ SECTION A PAGE A - 1............................................

INSTALLATION - SECTION B PAGE B - 1....................................

GENERAL INFORMATION PAGE B - 1..................................................

PUMP SEAL PAGE B - 1..............................................................

LUBRICATION PAGE B - 1.............................................................

PUMP INSTALLATION PAGE B - 1......................................................

Pump Motor Specifications PAGE B - 2..............................................

Pump Dimensions PAGE B - 2.....................................................

Lifting PAGE B - 2.................................................................

Positioning the Pump PAGE B - 3...................................................

Piping PAGE B - 3................................................................

ELECTRICAL CONNECTIONS PAGE B - 4...............................................

Field Wiring Connections (Incoming Power) PAGE B - 4...............................

Grounding Methods PAGE B - 5....................................................

Pump Power Cable Connections PAGE B - 6.........................................

Control Box Specifications PAGE B - 7..............................................

Motor Cable Grounding Test PAGE B - 7.............................................

Control Box Connections PAGE B - 7...............................................

Liquid Level Devices PAGE B - 7....................................................

WIRING DIAGRAMS PAGE B - 8.......................................................

OPERATION - SECTION C PAGE C - 1......................................

GENERAL INFORMATION PAGE C - 1..................................................

Pump Performance PAGE C - 1.....................................................

Control Box PAGE C - 1...........................................................

PUMP OPERATION PAGE C - 1........................................................

Liquid Temperature And Overheating PAGE C - 1.....................................

Impeller Rotation PAGE C - 2.......................................................

STARTING, STOPPING AND OPERATIONAL CHECKS PAGE C - 3.........................

Starting PAGE C - 3...............................................................

Stopping PAGE C - 3..............................................................

Operational Checks PAGE C - 3....................................................

COLD WEATHER PRESERVATION PAGE C - 4...........................................

LUBRICATION PAGE C - 4.............................................................

Draining Oil PAGE C - 5...........................................................

Condition of Oil Oil PAGE C - 5.....................................................

Adding Oil PAGE C - 5............................................................

TROUBLESHOOTING - SECTION D PAGE D - 1..............................

PREVENTIVE MAINTENANCE PAGE D - 3...............................................

PUMP MAINTENANCE AND REPAIR ‐ SECTION E PAGE E - 1.................

STANDARD PERFORMANCE CURVE PAGE E - 1........................................

i

Page 4

TABLE OF CONTENTS

(continued)

PARTS LISTS:

Pump Assemblies PAGE E - 3......................................................

Terminal Housing and Cable Assemblies PAGE E - 5..................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E - 6.........................

PUMP END DISASSEMBLY PAGE E - 7.................................................

Strainer Removal PAGE E - 7.......................................................

Draining Oil From Seal Cavity PAGE E - 7............................................

Draining Oil From Motor Cavity PAGE E - 7..........................................

Positioning Pump For Disassembly PAGE E - 7.......................................

Strainer Plate and Suction Head Removal PAGE E - 7.................................

Impeller Removal PAGE E - 7......................................................

Lower Seal Removal PAGE E - 8....................................................

Upper Seal Removal PAGE E - 8...................................................

PUMP END REASSEMBLY PAGE E - 8..................................................

Cleaning and Inspection of Pump Parts PAGE E - 8...................................

Upper Seal Installation PAGE E - 9..................................................

Lower Seal Installation PAGE E - 10..................................................

Impeller Installation PAGE E - 11.....................................................

Suction Head and Strainer Plate Installation PAGE E - 11...............................

Strainer Screen and Base Plate Installation PAGE E - 12................................

MOTOR DISASSEMBLY PAGE E - 12....................................................

Terminal Housing and Power Cable Removal and Disassembly PAGE E - 12..............

Intermediate and Motor Housing Disassembly PAGE E - 13.............................

Rotor and Bearing Removal PAGE E - 13.............................................

Stator Removal PAGE E - 14........................................................

Relief Valve PAGE E - 14............................................................

Hoisting Bail PAGE E - 15...........................................................

MOTOR REASSEMBLY PAGE E - 15.....................................................

Stator Installation PAGE E - 15......................................................

Bearing Installation PAGE E - 16.....................................................

Rotor and Intermediate Reassembly PAGE E - 17......................................

Terminal Housing and Power Cable Reassembly and Installation PAGE E - 17.............

Sealing Terminal Housing Connections With Silicone Adhesive PAGE E - 18..............

Sealing Terminal Housing Connections With Potting Compound PAGE E - 19.............

Terminal Housing Installation PAGE E - 20............................................

FINAL ASSEMBLY PAGE E - 20.........................................................

VACUUM TESTING PAGE E - 21........................................................

LUBRICATION PAGE E - 22.............................................................

Seal Cavity PAGE E - 22............................................................

Motor Housing Cavity PAGE E - 22...................................................

ii

Page 5

INTRODUCTION

OM-06259S SERIES PUMPS

Thank You for purchasing a Gorman‐Rupp S Se

ries Pump. Read this manual carefully to learn

how to safely install and operate your pump. Fail

ure to do so could result in personal injury or dam

age to the pump.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed in

structions and precautions for every aspect of

each specific application. Therefore, it is the re

sponsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety nor pump integrity are com

promised by the installation. Pumps and related

equipment must be installed and operated ac

cording to all national, local and industry stan

dards.

The pump motor must be operated through the

control box furnished with the pump as standard

equipment. For control box information, consult

the separate control box manual accompanying

the unit.

Pump construction is aluminum, with ductile iron

wearing parts. The pump may be operated fully or

partially submerged. Neither the pump nor the

control box are explosion‐proof, and should not be

operated in a hazardous atmosphere.

RECORDING MODEL AND

SERIAL NUMBER

Please record the pump model and serial number

in the spaces provided on the inside front cover of

this manual. Your Gorman‐Rupp distributor needs

this information when you require parts or service.

WARRANTY INFORMATION

The warranty provided with your pump is part of

Gorman‐Rupp's support program for customers

who operate and maintain their equipment as de

scribed in this and the other accompanying litera

ture. Please note that should the equipment be

abused or modified to change its performance be

yond the original factory specifications, the war

ranty will become void and any claim will be de

nied.

The following are used to alert personnel to proce

dures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel:

If there are any questions regarding the pump

which are not covered in this manual or in other lit

erature accompanying the unit, please contact

your Gorman‐Rupp distributor or the Gorman‐

Rupp Company:

The Gorman‐Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-1217

Phone: (419) 755-1011

or:

Gorman‐Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631-2870

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

PAGE I - 1INTRODUCTION

Page 6

OM-06259

S SERIES PUMPS

damage which could result from failure to

follow the procedure.

Hazards or unsafe practices which COULD

result in minor personal injury or product or

property damage. These instructions de

scribe the requirements and the possible

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I - 2 INTRODUCTION

Page 7

OM-06259 S SERIES PUMPS

SAFETY - SECTION A

This information applies to the S Series

submersible motor driven pumps indi

cated on the front cover of this manual.

Before connecting any cable to the con

Because pump installations are seldom

identical, this manual cannot possibly

provide detailed instructions and pre

cautions for each specific application.

Therefore, it is the owner/installer's re

sponsibility to ensure that applications

not addressed in this manual are per

formed only after establishing that nei

ther operator safety nor pump integrity

are compromised by the installation.

trol box, be sure to ground the control

box. Refer to the Control Box Manual for

the suggested grounding methods.

The pump motor is designed to be oper

ated through the control box furnished

with the pump. The control box provides

overload protection and power control.

Do not connect the pump motor directly

to the incoming power lines.

Before attempting to open or service the

pump:

1. Familiarize yourself with this man

ual.

2. Lock out incoming power to the

control box to ensure that the

pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Close the discharge valve (if

used).

This pump is not designed to pump vol

atile, explosive, or flammable materials.

Do not attempt to pump any liquids for

which you pump is not approved, or

which may damage the pump or endan

ger personnel as a result of pump fail

ure. Consult the factory for specific ap

plication data.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Obtain the services of a

qualified electrician to make all electri

cal connections. Make certain that the

pump and enclosure are properly

grounded; never use gas pipe as an

electrical ground. Be sure that the in

coming power matches the voltage and

phase of the pump and control before

connecting the power source. Do not

run the pump if the voltage is not within

the limits. If the overload unit is tripped

during pump operation, correct the

problem before restarting the pump.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Make certain that the control

handle on the control box is in the OFF

PAGE A - 1SAFETY

Page 8

S SERIES PUMPS OM-06259

position and locked out, or that the pow

er supply to the control box has been

otherwise cut off and locked out, before

attempting to open or service the pump

assembly. Tag electrical circuits to pre

vent accidental start‐up.

Never attempt to alter the length or re

pair any power cable with a splice. The

pump motor and cable must be com

pletely waterproof. Injury or death may

result from alterations.

All electrical connections must be in ac

cordance with The National Electric

Code and all local codes. If there is a

conflict between the instructions pro

vided and N.E.C. Specifications, N.E.C.

Specifications shall take precedence.

All electrical equipment supplied with

this pump was in conformance with

N.E.C. requirements in effect on the

date of manufacture. Failure to follow

applicable specifications, or substitu

tion of electrical parts not supplied or

approved by the manufacturer, can re

sult in severe injury or death and void

warranty.

After the pump has been installed, make

certain that the pump and all piping or

hose connections are secure before op

eration.

trician to troubleshoot, test and/or ser

vice the electrical components of this

pump.

Approach the pump cautiously after it

has been running. Although the motor is

cooled by the liquid being pumped, nor

mal operating temperatures can be high

enough to cause burns. The tempera

ture will be especially high if operated

against a closed discharge valve. Never

operate against a closed discharge

valve for long periods of time.

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an over

heated pump. Vapor pressure within the

pump can cause parts being disen

gaged to be ejected with great force. Al

low the pump to completely cool before

servicing.

Do not attempt to lift the pump by the

motor power cable or the piping. Attach

proper lifting equipment to the lifting

device fitted to the pump. If chains or

cable are wrapped around the pump to

lift it, make certain that they are posi

tioned so as not to damage the pump,

and so that the load will be balanced.

Pumps and related equipment must be

installed and operated according to all na

Obtain the services of a qualified elec

PAGE A-2 SAFETY

tional, local and industry standards.

Page 9

S SERIES PUMPS

OM-06259

INSTALLATION - SECTION B

GENERAL INFORMATION

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section is intended only to summarize general rec

ommendations and practices required to inspect,

position, and arrange the pump and piping. If there

are any questions concerning your specific instal

lation, contact your Gorman‐Rupp distributor or

the Gorman‐Rupp Company.

Liquid level devices are available from Gorman‐

Rupp as optional equipment. For information on

installing and operating these items, refer to the lit

erature accompanying them.

Pump Model Designation

Following is a description of the model numbering

system for S Series pumps. These submersible

pumps are available in a range of sizes. Refer to the

following chart to identify the size of your specific

pump model.

ratings on the control box and incoming pow

er.

e. Carefully read all tags, decals, and markings

on the pump, and perform all duties indicated.

f. Check for oil leaks. If there is any indication of

an oil leak, see LUBRICATION at the end of

this manual.

PUMP SEAL

There are two shaft seals in the pump. The lower

seal prevents liquid from entering the intermediate

cavity at the impeller end. The upper seal prevents

oil leakage from the motor housing cavity and acts

as back‐up protection in the event of lower seal fail

ure.

LUBRICATION

These pumps utilize two lubrication cavities. The

motor housing cavity provides lubrication to the

motor assembly and bearings, while the intermedi

ate cavity provides lubrication to the pump seal.

Pump Model

S

Series

3 C 1 E 230/3- 6.2

Pump Construction

Discharge Size

Pump Hydraulics

Voltage/Phase

H.P.

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

check for damage which may have occurred dur

ing shipment. Check as follows:

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious dam

age.

b. Check for loose attaching hardware. Since

gaskets tend to shrink after drying, check for

loose hardware at the mating surfaces.

c. Inspect the power cable for cuts or any other

obvious damage.

d. Check that amperes, phase, voltage and

hertz indicated on the name plate match the

The pumps are fully lubricated when shipped from

the factory. However, lubrication levels must be

checked before installing the pump (see LU

BRICATION in MAINTENANCE AND REPAIR SECTION E). An additional quart (0,9 liter) of oil is

provided to “top off” the oil level in the pump motor

cavity. If the oil level is abnormally low, determine

the cause before putting the pump into service.

Due to differences in pump design, the quantity of

oil and manner in which oil is to be added to the

seal cavity varies between pump models. Refer to

Table B‐2 for oil capacities and positions for filling

the seal cavity in each pump. Motor cavities requir

ing lubrication should always be positioned verti

cally for filling. Refer to LUBRICATION, Section C

for lubrication specifications and intervals.

PUMP INSTALLATION

When installing or servicing the pump

or controls, follow all requirements for

the installation of wiring or electrical

PAGE B - 1INSTALLATION

Page 10

OM-06259 S SERIES PUMPS

equipment as outlined in the National

Electric Code. Follow all safety require

ments. Failure to observe these require

ments could result in injury or death to

personnel.

Do not allow the free end of the power

cable to enter the liquid being pumped.

The free end of the cable must be kept dry

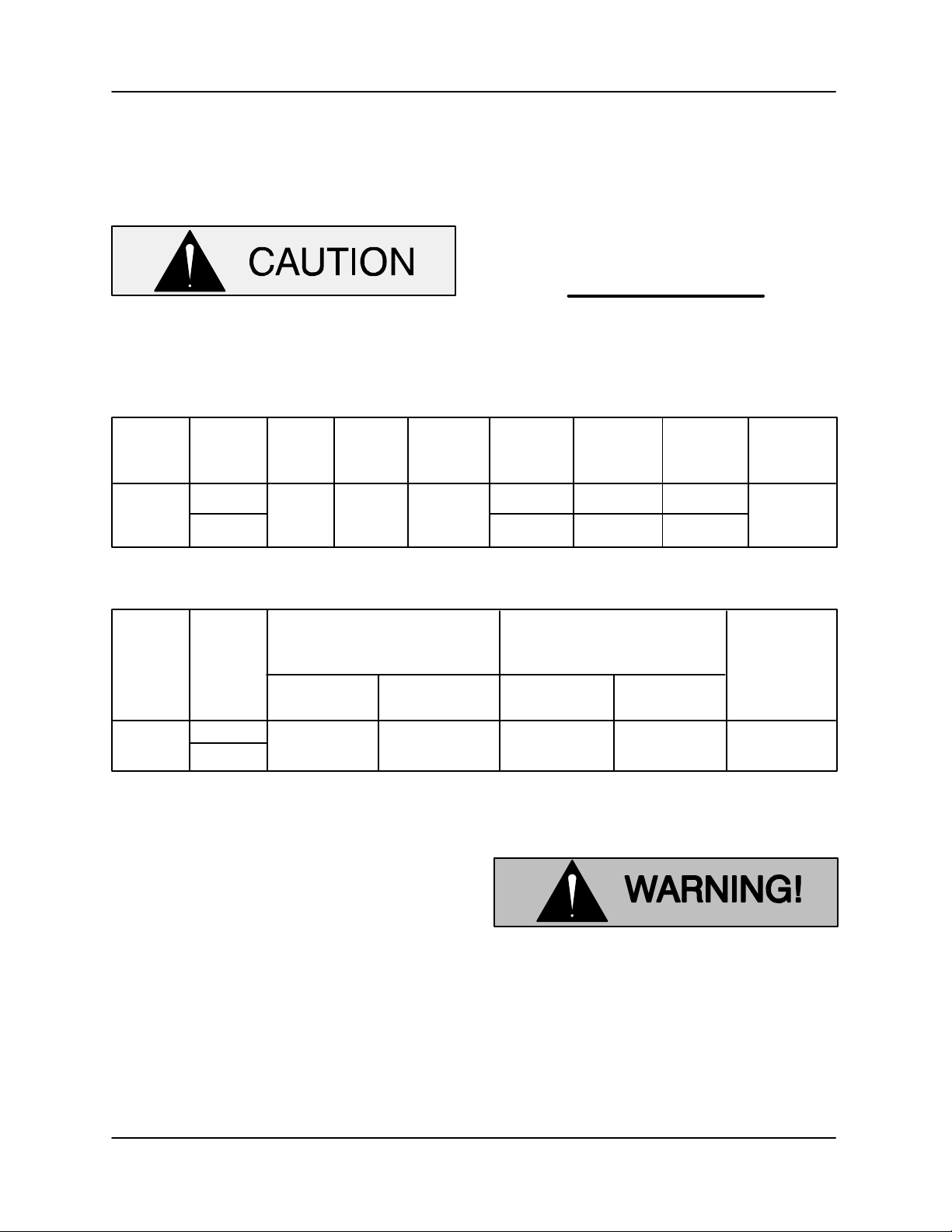

Table B‐1. Pump Specifications

Model Voltage/

Phase

460/3

S8B

575/3

Dual

Voltage

NO 8 INCH100 HP 1750

Pump

HP/

KW

Motor

Speed

(RPM)

to prevent liquid from wicking through the

cable and into the motor.

NOTE

Refer to the performance curve in Maintenance

and Repair - Section E when determining the

most efficient piping installation. The recom

mended maximum submergence depth is 65

feet.

Pump Motor Specifications

See Table B‐1 for pump specifications.

Full

Load

Amperes

135

108

No

Load

Amperes

40.3

30.9

Locked

Rotor

Amperes

715

556

Discharge

Size

(NPT)

Table B‐2. Additional Specifications

Approximate

Weight - Lbs. (kg)

Pump

Model

S8B

Pump Dimensions

For the approximate physical dimensions of your

pump, refer to the pump specification data sheet

or contact your Gorman‐Rupp distributor or the

Gorman‐Rupp Company.

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

Voltage/

Phase

460/3

575/3

Pump

870 (395) 105 (48) 224 (6,6) 768 (22,7) V

50 Ft. Cable

Oil Capacity

Ounces (Liters)

Seal

Cavity

Refer to Table B-2 for the approximate maximum

weight for your pump.

Motor

Cavity

Seal Cavity

Filling

Position

(H)orizontal

(V)ertical

Do not attempt to lift the pump by the

motor power cable or the piping. Attach

proper lifting equipment to the lifting

device fitted to the pump. If chains or

cable are wrapped around the pump to

lift it, make certain that they are posi

tioned so as not to damage the pump,

and so that the load will be balanced.

PAGE B - 2 INSTALLATION

Page 11

S SERIES PUMPS

OM-06259

Positioning the Pump

NOTE

Before installing and operating the pump, check

the direction of impeller rotation to ensure that the

pump is properly wired at the control box. See IM

PELLER ROTATION, Section C.

The pump is designed to operate fully or partially

submerged. The rotating parts are oil lubricated,

and the motor is cooled by a constant flow of liquid

or air discharged through internal passages.

As a safeguard against rupture or explosion due to

heat, models equipped with oil‐lubricated motors

are fitted with a pressure relief valve which will open

if vapor pressure within the pump motor reaches a

critical point.

The pump will operate if positioned on its side, but

this is not recommended because the motor

torque could cause the pump to roll during opera

tion.

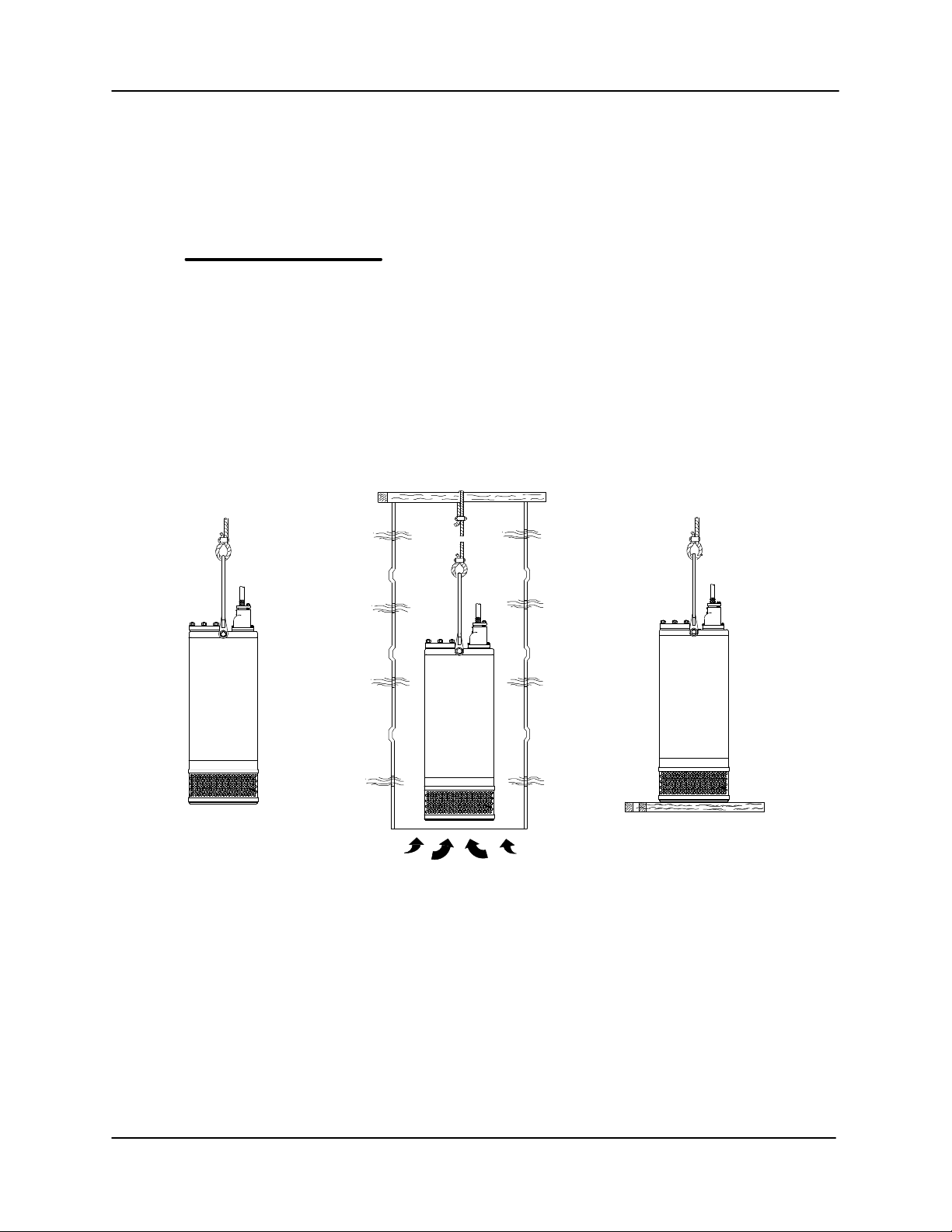

The pump should be independently secured and

supported by the lifting device fitted on the pump.

If the application involves a lot of debris, protect the

pump from excessive wear and clogging by sus

pending it in a perforated barrel or culvert pipe. If

the bottom is heavily sludge‐covered, rest the

pump on support blocks or suspend it from a raft

or similar device near the surface of the liquid. See

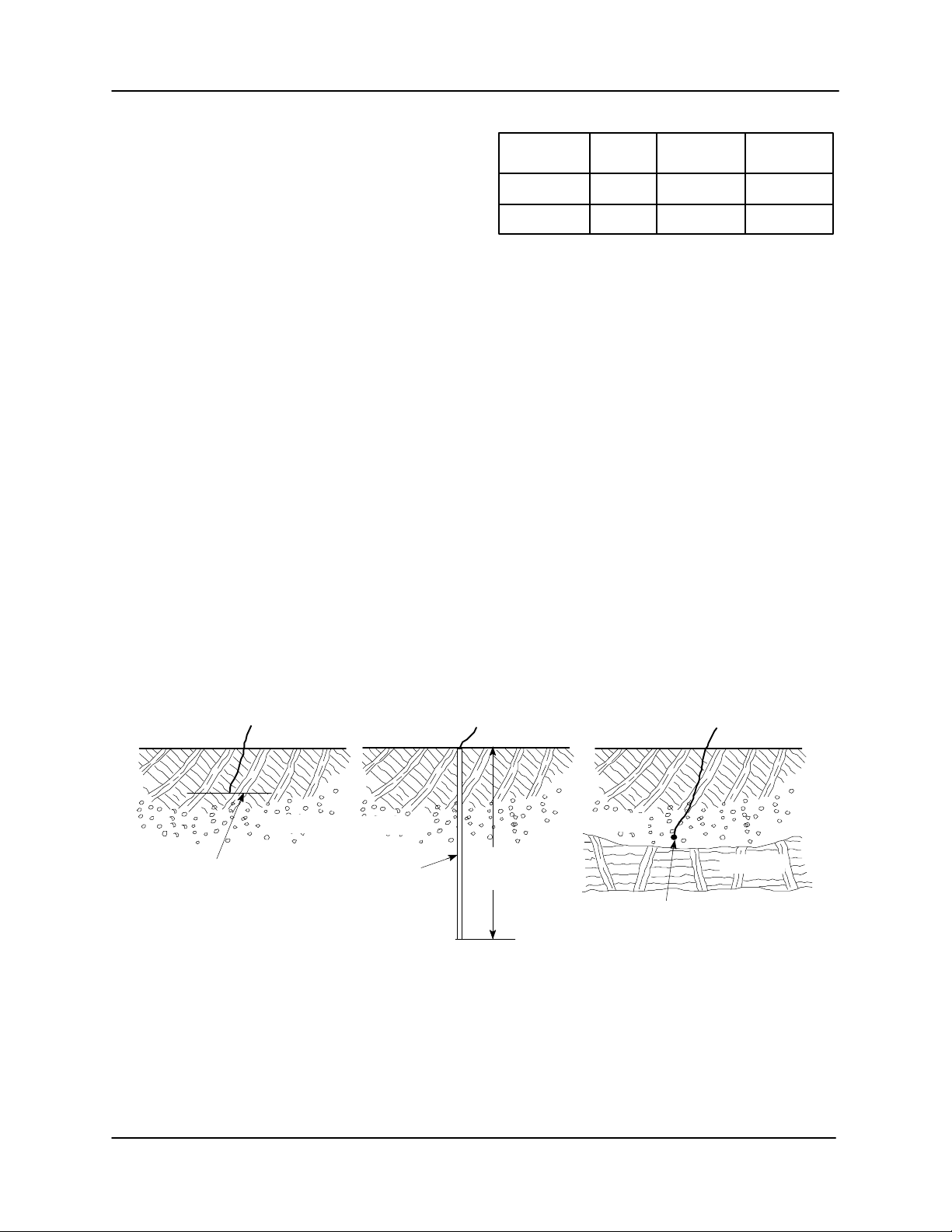

Figure B-1 for typical pump installations.

All liquid entering the pump must pass through a

strainer screen. Any spherical solids which pass

through the screen will pass through the pump.

BY BAIL IN PERFORATED CULVERT PIPE ON SUPPORTS

Figure B-1 Typical Pump Installations

Piping

No suction piping is required in a standard installa

tion.

These pumps are provided with a suction strainer

to prevent large solids from clogging the impeller.

If required, the strainer can be removed and the

pump suction “staged” to the discharge of another

pump, allowing one pump to feed the other on high

discharge head applications.

To determine the size of the discharge connection,

see Table B-1, Pump Specifications. Either

hose or rigid pipe may be used. To facilitate mobil

ity and maintenance, it is recommended that the

discharge line be fitted with a quick disconnect fit

PAGE B - 3INSTALLATION

Page 12

OM-06259 S SERIES PUMPS

ting near the pump. The discharge line must be in

dependently supported to avoid strain and vibra

tion on the pump.

Either hose or rigid pipe may be used to make dis

charge connections. For maximum pumping ca

pacity, keep the line as short and straight as pos

sible. Elbows and fittings used in discharge lines

increase friction loss, minimize their use.

It is recommended that a check valve or throttling

valve be installed in the discharge line to control si

phoning or back flow when the pump is shut off.

ELECTRICAL CONNECTIONS

Install and operate this pump in accor

dance with the National Electrical Code

and all local codes. Have a qualified

electrician perform all checks and con

nections in this section.

Never attempt to alter the length of the

pump motor cable or to repair it with a

splice. The power cable and pump mo

tor must be kept completely waterproof.

Serious damage to the pump and injury

or death to personnel can result from

any alteration to the cable.

Control Box Installation

sible to the operator, and located close enough to

the pump to avoid excessive voltage drop due to

cable length (see Pump Power Cable Connec

tion). After the box is installed, make certain the

front cover latches properly.

Failure to mount the control box vertically

on a level surface may affect operation of

the pump controls.

Field Wiring Connections (Incoming Power)

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Obtain the services of a

qualified electrician to make all electri

cal connections. Make certain that the

pump and enclosure are properly

grounded; never use gas pipe as an

electrical ground. Be sure that the in

coming power matches the voltage and

phase of the pump and control before

connecting the power source. Do not

run the pump if the voltage is not within

the limits.

Do not connect the pump motor directly

The pump is designed to be operated

through the control box furnished with

the pump. The control box provides

overload protection and power control.

Do not connect the pump motor directly

to the incoming power lines.

The control box is a rainproof enclosure with a pad

lockable front cover. The enclosure is not de

signed to be watertight, and should not be sub

merged. Refer to the control box manual for enclo

sure dimensions and parts.

Secure the control vertically on a level surface,

above flood level. The box should be easily acces

PAGE B - 4 INSTALLATION

to the incoming power lines. The pump

motor is designed to operate through a

Gorman‐Rupp approved control box

which provides overload protection and

power control; otherwise, the pump

warranty will be voided. Make certain

that the pump and control box are prop

erly grounded. Install and operate the

control box in accordance with the Na

tional Electric Code and all local codes.

Failure to follow these could result in in

jury or death to personnel.

Field wiring is not provided with the pump, and

must be supplied by the user. The field wiring must

Page 13

S SERIES PUMPS

OM-06259

be of the proper size and type to ensure an ade

quate voltage supply to the pump. Voltage avail

able at the motor must be within the range indi

cated in Table B‐3.

To calculate the voltage available at the motor, pro

ceed as follows:

a. Measure the voltage across the incoming

lines (1 & 2 for single phase, 1 & 2, 2 & 3, and 1

& 3 for three phase) while the pump is oper

ating at full capacity. Refer to the literature

supplied with the control box for power supply

connections.

b. Next, subtract the motor cable voltage drop

(see Table 4, Pump Power Cable Specifica

tions).

c. Do not continue to operate the pump if this

voltage is not within the recommended limits.

Obtain the services of a qualified electrician to

determine the correct field wiring size and oth

er details to ensure an adequate voltage sup

ply to the pump.

Table B‐3. Pump Voltage Requirements

NOMINAL

VOLTAGE

575 3 520 630

Make certain all connections are tight and that

cable entry points are rainproof. Support the cable

weight, if required, to prevent excessive strain on

cable clamps and cable.

Grounding Methods

Electrically ground the installation before connect

ing the field wiring to the control box. Install a

grounding terminal to the enclosure and connect

it to a properly embedded electrode.

The material used for the electrode must be an ex

cellent conductor of electricity, such as copper. If

iron or steel is used, it must be galvanized or other

wise metal plated to resist corrosion. Do not coat

the electrode with any material of poor conductiv

ity, such as paint or plastic.

The electrode must conform to the recommenda

tions of N.E.C. ARTICLE 250. Follow all installation

requirements of the N.E.C., and all applicable

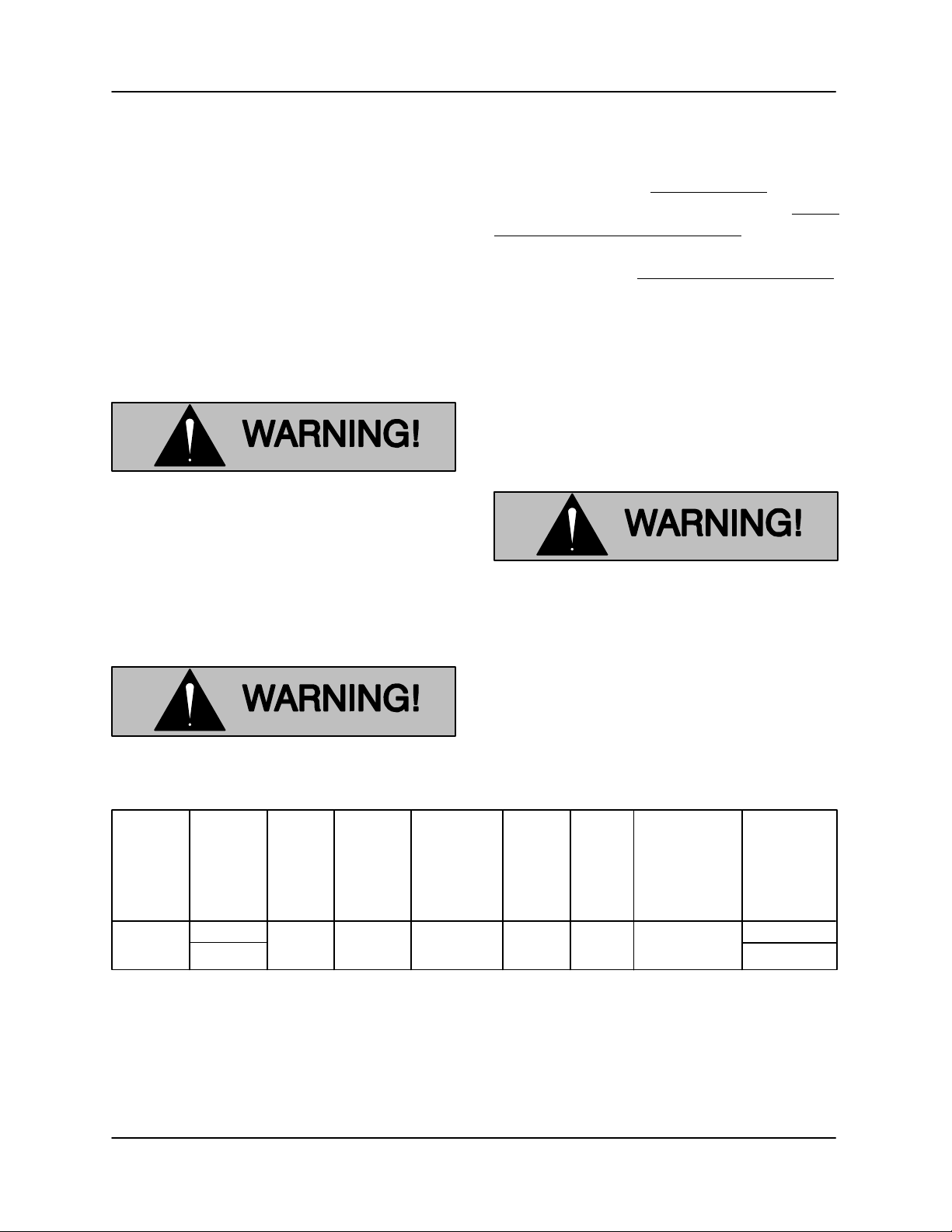

codes. See Figure B-3 for some suggested

grounding methods.

PHASE

3460 420 500

MINIMUM

VOLTAGE

MAXIMUM

VOLTAGE

a) PLATE ELECTRODE b) DRIVEN ELECTRODE c) BURIED ELECTRODE

SOIL

1/4 INCH (6,4 MM)

STEEL PLATE 2 SQ.

FEET (1858,1 SQ. CM)

SURFACE AREA

(MINIMUM)

Figure B-3. Suggested Grounding Methods

a. Plate Electrode: An iron or steel plate, 1/4

inch (6,4 mm) thick, completely impeded in

the ground. The plate must present a surface

area of at least 2 square feet (1858,1 sq. cm.).

SOIL

3/4 INCH (19,1

MM) NOMINAL

DIAMETER

(MINIMUM)

8 FEET

(2,4 M)

b. Driven Electrode: A rod or pipe, 3/4 inch

(19,1 mm) in diameter minimum, 8 feet (2,4 m)

long, completely driven into the ground.

SOIL

3/4 INCH (19,1 MM)

NOMINAL DIAMETER

(MINIMUM) 8 FEET

(2,4 M) LONG

ROCK

PAGE B - 5INSTALLATION

Page 14

OM-06259 S SERIES PUMPS

c. Buried electrode: If rock or stone prevents

embedding the full 8 foot (2,4 m) length of the

ground rod, bury it horizontally in a trench.

Space the ground rod or plates at least 6 feet

(1,8) from any other electrode or ground rod,

such as those used for signal circuits, radio

grounds, lightning rods, etc.

The earth surrounding the ground rod or plate

must contain enough moisture to make a

good electrical connection. In dry or sandy

areas, pour water around the rod, or consult

qualified personnel to devise a method of im

proving the connections.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Make certain that the control

box is properly grounded after installa

tion.

Refer to the literature accompanying the control

box for field wiring connections.

Pump Power Cable Connections

this pump is high enough to cause inju

ry or death. Obtain the services of a

qualified electrician to make all electri

cal connections. Make certain that in

coming power to the control box is in the

OFF position and locked out, or that the

power supply to the control box has

been otherwise cut off and locked out,

before connecting power or accessory

cables.

The pump is provided with a 50 ft. (15,2 m) power

cable (see Table B-4 for standard power cable

specifications). If a longer cable is required, an op

tional cable assembly must be ordered from the

factory. Splicing of the power cable is not recom

mended by the Gorman‐Rupp Company due to

safety and warranty considerations.

Never attempt to alter the length or re

pair any power cable with a splice. The

pump motor and cable must be com

pletely waterproof. Injury or death may

result from alternations.

The electrical power used to operate

Table B‐4. Pump Power Cable Specifications

DC

Amp

Cable

A.W.G

Pump

Model

S8B

NOTE: * Amp Rating at 30C (86F) Canada Use Type SOW Cable

When necessary to change or connect the pump

power cable to the control box, make certain the in

coming power is OFF and LOCKED OUT, Make

certain the control box is PROPERLY GROUNDED

PAGE B - 6 INSTALLATION

Voltage/

Phase

460/3

575/3

** Amp Rating at 40C (104F)

Cable

Size

1 1.51 (38) 0.38 (9,6) 161** GGC 0.13

O.D.

Inches

(mm)

Conductor

Dia.

Inches

(mm)

Rating

(See

Note

Below)

and that the electrical data on the control matches

the motor name plate data.

Cable

Type

Resistance

(ohms) at

25C (77F)

per 1000 ft.

(305 m)

Voltage

Drop

per 100 ft.

(30,5m) at

Max. Load

3.51

2.81

Page 15

S SERIES PUMPS

OM-06259

Connect the pump power cable to the control box

as shown in the wiring diagrams in the control box

manual. Use conduit or cable clamps to secure the

power cable to the control box. Make certain that

all connections are tight and that cable entry points

are rainproof.

NOTE

The power cable furnished with the pump includes

three electrical conductors (white, red, and black),

two grounding conductors (green) and one ground

check conductor (yellow). The yellow ground

check lead is used in conjunction with customer‐

supplied ground monitoring equipment. If this

equipment is not used, the yellow lead should be

used as a ground conductor.

Control Box Specifications

Any control box used to operate the

pump must be approved by the Gor

man‐Rupp Company for the application.

Motor Cable Grounding Test

NOTE

For reference, internal motor wiring connections

are shown in Maintenance and Repair - Section

E.

Liquid Level Devices

The standard pump is not furnished with a means

to automatically regulate liquid level. However, the

pump may be controlled to perform filling or dewa

tering functions by using either of the following op

tional sensing devices (see Figure B-4):

Diaphragm Type: two fixed‐position sen

sors (upper and lower) each contain a dia

phragm which flexes with changes in liquid

level, thus activating an enclosed miniature

switch.

Bulb (Float) Type: a bulb raises or lowers

(floats) with the liquid level, thus activating

an enclosed miniature switch.

The liquid level circuitry may be prewired as a fac

tory option, or easily added to the standard control

box in the field by qualified personnel. The unit is

complete except for the remote float switches. For

installation and operation, see the detailed instruc

tions included with the optional package.

Do not connect the pump control cable

to the control box or incoming voltage

before verifying the pump ground;

otherwise, personnel will be exposed to

serious injury or death.

Using a volt‐ohm meter, connect one lead to the

motor cable green/yellow ground lead. Connect

the other lead to an uninsulated point on the pump

body. The test circuit should close.

If the test circuit does not close, there is a defect in

the cable or motor which must be corrected.

Control Box Connections

This pump is shipped completely wired for the volt

age shown on the name plate, and is ready for op

eration through an approved control box.

Ground and wire the control box in accordance

with the instructions accompanying it.

Liquid level devices must be positioned far

enough apart to allow 10 minutes between

starts. If the pump motor cycles more than

6 starts per hour, it will over‐heat, resulting

in damage to the motor windings or control

box components.

Other types of liquid level devices may also be

used. Consult the factory for the liquid level device

best suited for your application.

If the pump requires liquid level devices,

install the liquid level devices and connect

them to the control box in accordance with

the instructions accompanying the de

vices.

PAGE B - 7INSTALLATION

Page 16

OM-06259 S SERIES PUMPS

PUMP

CONTROL BOX

TO LEVEL CONTROL CIRCUIT

IN MAIN CONTROL BOX

LIQUID LEVEL

RANGE

OFF

DEWATERING

ON (FILLING)

BULB (FLOAT TYPE)

Figure B-4. Liquid Level Devices

PUMP

CONTROL BOX

TO LEVEL CONTROL CIRCUIT

IN MAIN CONTROL BOX

LIQUID LEVEL

RANGE

OFF

DEWATERING

ON (FILLING)

DIAPHRAGM TYPE

cluded with the option before making wir

ing connections.

WIRING DIAGRAMS

The internal wiring of the sensing devices

are different for filling and dewatering func

tions. Be sure to follow the instructions in

Refer to the appropriate wiring diagram in the liter

ature accompanying the control box when making

electrical connections.

PAGE B - 8 INSTALLATION

Page 17

S SERIES PUMPS OM-06258

OPERATION - SECTION C

GENERAL INFORMATION

Review all SAFETY information in Section A.

The pump motor and control box are not

designed to be explosion‐proof. Do not

operate in an explosive atmosphere.

Any control box used to operate the

This pump is designed to handle most

non‐volatile, non‐flammable liquids. Do

not attempt to pump any liquids for

which your pump is not approved, or

which may damage the pump or endan

ger personnel as a result of pump fail

ure. Consult the factory for specific ap

plication data.

Follow the instructions on all tags, labels and de

cals attached to the pump.

Pump Performance

pump must be approved by the Gor

man‐Rupp Company for the application.

Improper location of a non‐explosion

proof control box could result in de

struction of equipment, injury or death

to personnel.

See the operating instructions furnished with the

control box, and with other optional accessories

and controls, before attempting to start the pump.

PUMP OPERATION

Liquid Temperature and Overheating.

Since operation of the pump motor is de

pendent upon the quality and performance

of the electrical controls, the pump warran

ty is valid only when controls have been

specified or provided by The Gorman‐

Rupp Company.

Refer to the performance curve in Maintenance

and Repair - Section E for the specific perfor

mance for your pump.

Control Box

A control box is provided to facilitate operation of

the pump. It contains controls for starting and stop

ping the pump, and provides overload protection

for the pump motor. The pump control may be

equipped with an optional automatic liquid level

sensing device, in which case those circuits are

also contained within the control box.

Overheated pumps can cause severe

burns and injury. If the pump becomes

overheated:

1. Stop the pump immediately.

2. Lock out the power to the control

panel to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Close the discharge valve (if

used).

5. Refer to instructions in this manual

before restarting the pump.

Overheating can occur if the pump is misapplied;

if it is started more than 6 times within one hour; if

the temperature of the liquid being pumped ex

ceeds the temperature for which the pump was de

signed, if the control box fails to provide overload

PAGE C - 1OPERATION

Page 18

OM-06258 S SERIES PUMPS

or thermal protection, or if the pump is operated

against a closed discharge valve for an extended

period of time.

Do not start the pump more than 6 times

per hour. If the motor does not cool be

tween starts it will overheat, resulting in

damage to the motor windings.

As a safeguard against rupture or explosion due to

heat, models equipped with oil‐lubricated motors

are fitted with a pressure relief valve which will open

if vapor pressure within the pump motor reaches a

critical point. Always terminate power to the pump

and control before investigating pump or control

box problems.

4. Check the temperature before ser

vicing.

5. Vent the pump slowly and cau

tiously

6. Refer to instructions in this manual

before restarting the pump.

It is recommended that the pressure relief valve as

sembly be replaced at each overhaul, or any time

the pump motor overheats and activates the valve.

Never replace this valve with a substitute which

has not been specified or provided by the Gorman‐

Rupp Company.

Impeller Rotation

Check impeller rotation as follows before operation

to ensure that the impeller is rotating in the correct

direction.

Approach the pump cautiously after it

has been running. Although the motor is

cooled by the liquid being pumped, nor

mal operating temperatures can be high

enough to cause burns. The tempera

ture will be especially high if operated

against a closed discharge valve. Never

operate against a closed discharge

valve for long periods of time.

If overheating does occur, stop the pump immedi

ately and allow it to cool before servicing it. Ap

proach any overheated pump cautiously.

Overheated pumps can cause severe

burns and injuries. If overheating of the

pump occurs:

While checking impeller rotation, secure

the pump to prevent the power cable from

coiling.

Suspend the pump from the lifting device fitted on

the pump. Apply power briefly and note the direc

tion of pump kickback. As viewed from the top, the

pump should kick in a counterclockwise direc

tion; this will indicate that impeller rotation is cor

rect.

If the pump kicks in a clockwise direction, impeller

rotation is incorrect. If the pump is powered by a

three‐phase motor, have a qualified electrician in

terchange the control box connections of any two

pump motor power leads. Re‐check pump kick

back; it should now be in a counterclockwise direc

tion.

If rotation is incorrect on a single‐phase motor, con

tact the factory before installing the pump.

1. Stop the pump immediately.

2. Ventilate the area.

3. Allow the pump to completely cool.

PAGE C - 2 OPERATION

The electrical power used to operate

Page 19

S SERIES PUMPS OM-06258

this pump is high enough to cause inju

ry or death. Make certain that incoming

power is off and locked out before inter

changing motor leads.

Never start the pump more than 6 times per

hour. If the pump motor does not cool be

tween starts, it will over‐heat, resulting in

damage to the motor windings.

Stopping

DIRECTION OF

KICKBACK

AT STARTUP

Figure C-1. Checking Pump Rotation

STARTING, STOPPING, AND

OPERATIONAL CHECKS

Starting

Follow the instructions accompanying the control

box for stopping the pump.

On pumps equipped with a motor ther

mal protector, the integral thermal over

load device will shut off the motor if the

temperature rises above design limits.

When the pump cools and the tempera

ture falls below these limits, the motor

will restart automatically. To avoid the

hazards of an unexpected motor start‐

up, do not attempt to handle or service

the pump unless all power to the motor

has been shut off and locked out at the

control box; otherwise, serious person

al injury could result.

During motor shutoff by the thermal

overload device, control box circuits re

main live. Do not attempt to service any

control box components unless incom

ing power has been shut off.

Do not attempt to operate the pump until

impeller rotation has been checked; im

proper rotation will affect pump perform

ance and may damage the pump.

Follow the instructions accompanying the control

box, start the pump, and run any recommended

checks.

To stop the pump, turn the control handle OFF,

thereby opening the circuit breakers. This does

not terminate incoming power through the field

wiring connected to the control box.

After stopping the pump, be sure to perform all re

quired maintenance and preservation procedures.

Operational Checks

To detect minor problems, check the pump for

proper operation when it is first started, and at peri

odic intervals during operation.

PAGE C - 3OPERATION

Page 20

OM-06258 S SERIES PUMPS

COLD WEATHER PRESERVATION

To avoid serious damage to the pump,

check for unusual noises or excessive vi

bration while the pump is running. If noise

or vibration is excessive, stop operation

and refer to the troubleshooting chart in the

maintenance and repair manual.

Do not attempt to thaw the pump by us

ing a torch or other source of flame. This

could damage gaskets, O‐rings or heat

the oil in the seal housing above critical

temperatures, causing the pump to rup

The suction inlet or impeller may become clogged

with debris. In some cases, stopping the pump

momentarily may backflush this blockage. If back

flushing does not clear the debris, remove the

pump from the sump or wet well and clear manu

ally.

Never introduce air or steam pressure

into the pump casing to remove a block

age. This could result in personal injury

or damage to the equipment. If back

flushing is absolutely necessary, limit

ture or explode.

The pump will not freeze as long as the casing is

submerged in liquid. If the casing is not sub

merged, or if the liquid begins to freeze, remove the

pump from the sump or wet well and dry it thor

oughly. Run the pump for two or three minutes to

dry the inner walls.

If the pump does freeze while it is out of the liquid,

submerge it until thawed; if the liquid is near freez

ing, the pump must be submerged for an extended

period of time. Check thawing by starting the pump

and checking that the shaft rotates freely. If the

pump remains frozen, allow additional thawing

time before attempting to restart.

liquid pressure input to 50% of the maxi

mum permissible operating pressure

shown in the pump performance curve

If submerging does not thaw the pump, move it

into a warm area until completely thawed.

(refer to the accompanying Parts List

Manual).

LUBRICATION

Check the pump for overheating. Overheating can

occur if the pump is misapplied, required to start

repeatedly, if the control box fails to provide over

load or thermal protection, or if the pump is oper

ated against a closed discharge valve for an ex

tended period of time.

Do not remove plates, covers, gauges,

pipe plugs or fittings from an over

heated pump. Vapor pressure within the

pump can cause parts being disen

gaged to be ejected with great force. Al

low the pump to completely cool before

Do not start the pump more than 6 times

servicing.

per hour. If the motor does not cool be

tween starts it will overheat, resulting in

damage to the motor windings.

Check the oil level(s) as indicated in the following

LUBRICATION section.

PAGE C - 4 OPERATION

On a new pump, check the oil level in both seal and

motor cavities before initial startup, and drain and

replace the oil after the first 200 hours of operation.

Following this, check the oil level in the seal cavity

after the first two weeks of operation, and every

Page 21

S SERIES PUMPS OM-06258

month thereafter. Check the motor lubrication level

any time the pressure relief valve is activated, and

replace the oil annually.

Before installing or removing the lubrication

plug(s), always clean the area around the plug(s)

to prevent contamination.

Draining Oil

Refer to the Parts List in Maintenance and Repair

- Section E for drain plug location.

Remove the drain plug slowly to release any pres

sure. Install a short pipe nipple in the hole. Place a

clean container under the plug and, using a hoist,

tilt the pump at an angle of approximately 60.

Repeat the procedure for the motor housing oil.

Condition Of Oil

Adding Oil

Refer to Table B-2 in INSTALLATION for oil ca

pacities and positions for filling the seal cavity in

your pump. Motor cavities requiring lubrication

should always be positioned vertically for filling.

The grade of lubricant used is critical to the opera

tion of this pump. Use premium quality submers

ible pump oil as specified in the following table. Oil

must be stored in a clean, tightly closed container

in a reasonably dry environment.

When lubricating the seal cavity, remove the lu

brication plug as indicated in Draining Oil, and

position the pump as indicated in Table B-2. Add

premium quality submersible pump oil through

this plug hole. If the pump is to be positioned verti

cally or at an angle, fill the cavity to the bottom of

the plug hole. If the pump is to be positioned hori

zontally, completely fill the cavity.

Install and tighten the lubrication plug.

Check the condition of the oil drained from the

pump. Clear oil indicates that the pump seal(s) are

functioning properly. If the oil is milky or contains

a small amount of water, it must be changed.

If the oil contains a large amount of water, it must

be changed, and the seal(s) must be checked be

fore the pump is put back in operation (refer to

Maintenance and Repair, Section E).

When lubricating the motor cavity, add oil through

the hole for the pressure relief valve. If the pump is

equipped with a motor lubricant level plug, remove

this plug and fill the cavity until oil escapes through

the hole. If the pump is not equipped with a motor

lubricant level plug, fill the cavity to the top of the

hole.

Reinstall the pressure relief valve.

PAGE C - 5OPERATION

Page 22

OM-06258 S SERIES PUMPS

Table C-1. Pump Oil Specifications

Specifications:

Type Premium high viscosity index, anti‐wear hydraulic oil..............................

Viscosity @ 100F (38C) 110 to 155...............................................

Viscosity @ 210F (99C) 40 to 50..................................................

Dielectric 26,000 (volts‐min)........................................................

Recommended supplier:

Gulf Oil Company Gulf Harmony HVI AW 26..........................................

Acceptable alternate suppliers:

Gulf Oil Company Gulf Harmony 32 AW..............................................

Texas Oil Company Rando HD 32 or HD AZ 32........................................

Sun Oil Company Sunvis 816 or 916.................................................

BP (Also Boron) Energol‐HLP 32.....................................................

Shell Oil Company Tellus 32, Tellus T‐23 or T32.......................................

ARCO Duro 32...................................................................

Exxon (Also Esso) Nuto H 32........................................................

Petro‐Canada Harmony HVI 22......................................................

PAGE C - 6 OPERATION

Page 23

TROUBLESHOOTING - SECTION D

Review all SAFETY information in Section A.

NOTE

Many of the probable remedies listed in the TROU

BLESHOOTING CHART require use of electrical

test instruments; for specific procedures, see

ELECTRICAL TESTING at the end of the chart.

TROUBLESHOOTING CHART

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

S SERIES PUMPSOM-06259

PUMP FAILS TO

START, OVER

LOAD UNIT NOT

TRIPPED (MANU

AL MODE).

PUMP FAILS TO

START, OVER

LOAD UNIT NOT

TRIPPED (AUTO

MATIC MODE).

Power source incompatible with con

trol box.

No voltage at line side of circuit

breaker.

Open circuit in motor windings or

power cable.

Defective motor power cable. Replace cable.

Defective motor. Check for and replace defective mo

Liquid level device or control circuits

improperly connected to main con

trol box.

Level sensing device(s) improperly

positioned.

Level sensing device(s) fouled with

mud or foreign material.

Float type sensing device(s) tangled

or obstructed.

Defective liquid level sensing de

vice(s) or control panel.

Correct power source.

Check power source for blown fuse,

open circuit breaker, broken lead or

loose connections.

Check continuity.

tor components.

Check wiring diagrams: cor

rect or tighten connections.

Position device(s) at proper

level.

Clean sensing device(s).

Check installation for free

movement of float.

Repair or replace defective unit(s).

OVERLOAD UNIT

TRIPS

TROUBLESHOOTING

Low or high voltage, or excessive

voltage drop between pump and

control box.

Defective insulation in motor wind

ings or power cable; defective wind

ings.

Impeller jammed due to debris or in

sufficient clearance.

Bearing(s) frozen. Disassemble pump and check bear

Measure voltage at control box.

Check that wiring is correct type,

size, and length (see Field Wiring

Connection, Section B).

Check insulation resistance; check

continuity.

Disassemble pump and check im

peller.

ing(s).

PAGE D - 1

Page 24

TROUBLESHOOTING CHART (cont'd)

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

OM-06259S SERIES PUMPS

MOTOR RUNS,

BUT PUMP FAILS

TO DELIVER

RATED DIS

CHARGE.

Discharge head too high. Reduce discharge head or install

staging adaptor and additional

pump.

Low or incorrect voltage. Measure control box voltage, both

when pump is running and when

shut off.

Discharge throttling valve partially

closed; check valve installed improp

erly.

Discharge line clogged or restricted;

hose kinked.

Liquid being pumped too thick. Dilute liquid if possible.

Strainer screen or impeller clogged. Clear clog(s). Stop pump; back flow

Insufficient liquid in sump or tank. Stop pump until liquid level rises.

Worn impeller vanes; excessive im

peller clearance.

Pump running backwards. Check direction of rotation. If incor

Open discharge valve fully; check

piping installation.

Check discharge lines; straighten

hose.

may flush away debris.

Check impeller and clearance (see

PUMP END REASSEMBLY in

Maintenance and Repair, Section

E).

rect, interchange any two motor

leads at the control box (see Pump

Rotation, Section C).

PUMP RUNS

WITH EXCES

SIVE NOISE OR

VIBRATION

Pumping entrained air. Check liquid level in sump; check

position of pump and liquid level

sensing device(s).

Damaged or unbalanced impeller. Replace impeller.

Discharge piping not properly sup

ported.

Impeller jammed or loose. Check impeller.

Motor shaft or bearings defective. Disassemble pump and check mo

Pump is cavitating. Reduce discharge head or restrict

Check piping installation.

tor and bearings.

flow on low head applications.

PAGE D - 2

TROUBLESHOOTING

Page 25

S SERIES PUMPSOM-06259

ELECTRICAL TESTING

Make the electrical checks which follow to deter

mine if pump malfunctions are being caused by

problems in the motor or in the motor cable.

Test Equipment

A volt/amp/ohmmeter and megohmmeter of ade

quate range and quality are required to conduct

the electrical tests which follow.

Equipment Use

Ammeter To check AC Voltage

and current (amperage)

Ohmeter To measure resistance

(ohms) to ground

3. The pump submerged and running under

full load.

The voltage measured under each condition

must be the same.

b. If voltage is balanced when the pump is off but

is imbalanced when the pump is running,

thoroughly check the power source, all inter

connecting cables, and the pump motor to

isolate the defect.

c. Use an Amprobe or equivalent instrument to

measure the current draw (amperage) of

each phase while the pump is running under

full load, and with no load. In each condition,

the amperage readings for all three phases

must match as closely as can be measured.

Normal amperage values are listed in Table 1,

Section B; these values apply only when the

voltage at the site is the normal voltage listed.

Motor and Power Cable Continuity

Refer to the wiring diagram(s) accompany

ing the motor and control box before re

connecting any electrical leads which have

been disconnected. Connections to the

wrong terminals may damage the motor

and/or control devices.

Voltage Imbalance

Use a voltmeter to read each phase of the incom

ing 3 phase power. Each phase must balance with

the other two as closely as can be measured with a

commercial instrument. If the phases are out of

balance, contact your power company. If the

phases are balanced, check out the motor as de

scribed in the following steps:

a. Use a voltmeter, Amprobe, or equivalent in

strument to read the voltage of incoming

power lines 1 and 2, 2 and 3, and 1 and 3 at the

control box. Voltage must match as closely as

can be measured. If possible, measure the

voltage at the control box with:

1. The pump shut off.

2. The pump running in air.

Set the megohmmeter at R x 1 scale and zero‐ba

lance it. Test as follows:

a. Shut off incoming power to the control box,

and disconnect the motor power cable leads.

Connect the megohmmeter test leads to any

two power cable leads, and note the

megohmmeter reading. A high resistance

reading indicates an open or broken circuit in

the power cable or motor windings, or a bad

connection between the motor and cable.

b. Repeat Step a. with each set of leads. The

three readings shall be as close as can be

measured.

c. If readings indicate that continuity problems

exist in the motor or motor cable, the motor

must be returned to the factory or to a U/L‐ap

proved facility.

Insulation Resistance

Set the megohmmeter at R x 100, and zero‐ba

lance it. Test as follows:

a. Shut off incoming power to the control box,

and disconnect the motor power cable leads.

Connect one megohmmeter test lead to the

motor cable green/yellow ground lead. Touch

TROUBLESHOOTING

PAGE D - 3

Page 26

OM-06259S SERIES PUMPS

the other test lead to each of the motor cable

leads in turn. Note the readings.

b. Readings will indicate resistance values in

both the power cable and motor windings.If

resistance reads infinity (1), insulation is

good. If resistance reads between infinity (1),

and 1 megohm, insulation is acceptable but

should be rechecked regularly. If resistance

reads less than 1 megohm, insulation should

be checked more closely and frequently.

c. If readings indicate that a ground exists, test

the stator and motor power cable separately.

Replace as required.

PAGE D - 4

TROUBLESHOOTING

Page 27

OM-06259 S SERIES PUMPS

PUMP MAINTENANCE AND REPAIR - SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

STANDARD PERFORMANCE FOR PUMP MODELS S8B1-E100 460/3 AND S8B1-E100 575/3

Based on 70F (21C) clear water at sea level

with minimum suction lift. Since pump installations

are seldom identical, your performance may be dif

ferent due to such factors as viscosity, specific

gravity, elevation, temperature, and impeller trim.

Contact the Gorman‐Rupp Company to verify per

formance or part numbers.

Pump speed and operating condition

If your pump serial number is followed by an “N”,

your pump is NOT a standard production model.

points must be within the continuous per

formance range shown on the curve.

PAGE E - 1MAINTENANCE AND REPAIR

Page 28

S SERIES PUMPS OM-06259

SECTION DRAWING

PARTS PAGE

Figure E-1. S8B1-E100 460/3 And S8B1-E100 575/3 Pump Assemblies

MAINTENANCE AND REPAIRPAGE E - 2

Page 29

OM-06259 S SERIES PUMPS

S8B1-E100 460/3 And S8B1-E100 575/3 Pump Assemblies

Parts List

(From S/N 1432260 Up)

If your pump serial number is followed by an “N”, your pump is NOT a standard production model. Contact

the Gorman‐Rupp Company to verify part numbers.

ITEM

PART NAME PART

NO.

1 DIFFUSER 38632-023 11030 1

2 IMPELLER 38623-526 11030 1

3 LOWER SEAL ASSY 12430A --- 1

4 UPPER SEAL ASSY S1934 --- 1

5 STRAINER SCREEN 10090 1599V 1

6 SUCTION HEAD GSKT 38683-817 20000 1

7 DIFFUSER GSKT 38682-812 20000 1

8 SEAL PLATE O‐RING S2207 --- 1

9 SEAL DRAIN PLUG P06 17000 1

10 MOTOR DRAIN PLUG P06 17000 1

11 SEAL FILL PLUG P06 17000 1

12 HEX HD CAPSCREW B0608 15991 4

13 LOCKWASHER J06 15991 4

14 BEARING CAP GSKT 10085G 20000 1

15 MOTOR HOUSING GSKT 38684-703 20000 1

16 MOTOR HOUSING GSKT 10038G 20000 1

17 BEARING CAP 10085 10010 1

18 MOTOR HOUSING ASSY 42822-014 24130 1

19 MOTOR CAVITY OIL P06 17000 1

LEVEL PLUG

20 BAIL BUSHING 10045 15071 2

21 HOISTING BAIL 10039 2400V 1

22 HEX HD CAPSCREW B1210 15991 2

23 LOCKWASHER J12 15991 2

24 FLAT WASHER K12 15991 2

25 DISCH FLANGE GSKT 1759G 18000 1

26 DISCHARGE FLANGE 1759 10010 1

27 PIPE CAP V16 11999 1

28 STREET TEE ASSY 14138 --- 1

29 PRESS RELIEF VALVE 14139 --- 1

30 CLOSE PIPE NIPPLE THA1614 15079 1

31 UPPER BALL BEARING S1077 --- 1

32 DISCH FLANGE STUD C1211 15991 8

33 HEX NUT D12 15991 8

34 FILL TUBE ASSY 10040 24040 1

35 RETAINING RING S245 --- 1

36 TERMINAL HOUSING 47367-028 --- 1

AND CABLE ASSY

37 STUD C0607 15991 6

38 DEFORM LOCKNUT DD06 15991 6

39 ROTOR/SHAFT ASSY 47112-083 --- 1

40 STATOR ASSY

-460V 47113-087 --- 1

-575V 47113-088 --- 1

41 NAME PLATE 2613CY 17020 1

42 DRIVE SCREW BM#04-03 17000 6

43 MOTOR HOUSING GSKT 10062G 20000 1

NUMBER

MAT'L

CODE

QTY ITEM

NO.

44 STUD 10443 17000 12

45 HEX NUT D10 17000 12

46 LOCKWASHER J10 17000 12

47 LOWER BALL BEARING 23425-611 --- 1

48 INTERMEDIATE 38261-020 13040 1

49 SEAL PLATE 38272-708 10010 1

50 DIFFUSER GSKT 38682-813 20000 1

51 SOC HD CAPSCREW BD0503 17000 6

52 HEX HD CAPSCREW B1216 15991 20

53 HEX NUT D12 15991 20

54 LOCKWASHER J12 15991 20

55 SPACER 31413-026 15079 6

56 BASE PLATE 10036 13080 1

57 HEX HD CAPSCREW B1024 15991 6

58 STUD C1211 17000 8

59 HEX NUT D12 17000 8

60 LOCKWASHER J12 17000 8

61 SUCTION HEAD 38246-033 10010 1

62 IMPELLER WASHER 11199 17000 1

63 IMPELLER NUT AT20S 17000 1

64 WEAR RING 38691-309 14000 1

65 WEAR RING 38691-309 14000 1

NOT SHOWN:

OPTIONAL:

LIQUID LEVEL DEVICES:

PART NAME PART

NUMBER

CONTROL BOX

-460/3 27515-506 --- 1

-575/3 27515-516 --- 1

1 QT SUB MOTOR OIL 9568 --- 1

MOTOR VOLTAGE TAG

-460/3 6588BL --- 1

-575/3 6588BM --- 1

IMP KNOCKER 2177C 14070 1

HEATER PACK

-460/3 27521-213 --- 1

-575/3 27521-212 --- 1

REPAIR GASKET SET 11000V --- 1

HEAT‐SHRINK TUBE & 48315-004 --- 1

ADHESIVE KIT

TERM POTTING KIT 12442A --- 1

ANODE PLATE ASSY 42116-002 --- 1

DIAPHRAGM TYPE GRP48-03 --- 1

GRP48-06 --- 1

FLOAT TYPE 27471-155 --- 1

LIQ LEV CONTRL RELAY 27521-321 --- 1

MAT'L

CODE

QTY

INDICATES PARTS RECOMMENDED FOR STOCK

PAGE E - 3MAINTENANCE AND REPAIR

Page 30

S SERIES PUMPS OM-06259

SECTION DRAWING

Figure E-2. Terminal Housing And Cable Assembly

MAINTENANCE AND REPAIRPAGE E - 4

Page 31

OM-06259 S SERIES PUMPS

Terminal Housing And Cable Assembly

Parts List

ITEM

NO.

1 TERMINAL POST 38724-009 14100 3

2 TERMINAL COLLAR 10052A 14100 3

3 HEAT‐SHRINK TUBE 31417-030 19530 3

4 T‐TYPE LOCKWASHER AK06 15991 2

5 RD HD MACH SCREW X0603 14990 2

6 TERMINAL 27214-062 --- 1

7 TERMINAL WASHER 31133-110 15991 1

8 GLAND BUSHING 31144-001 19100 1

9 INFORMATION PLATE 38816-047 17990 1

10 DRIVE SCREW BM#04-03 17000 4

11 CABLE GRIP 11227H --- 1

12 TERMINAL GLAND 10658 13040 1

13 POWER CABLE 10325L --- 1

14 HEX NUT D08 15991 2

15 STUD C0808 15991 2

16 TERMINAL HOUSING 10088B 13040 1

17 TERMINAL S1550 --- 1

18 AL HD SETSCREW GA0602 14990 3

19 TERMINAL PLT ASSY 11163 24010 1

20 DYNA SEAL WASHER S1586 --- 3

21 AL HD SETSCREW GA0501 1/2 14990 3

PART NAME

PART

NUMBER

MAT'L

CODE

QTY

NOT SHOWN:

RTV SEALANT 18771-106 --- 2

INDICATES PARTS RECOMMENDED FOR STOCK

PAGE E - 5MAINTENANCE AND REPAIR

Page 32

S SERIES PUMPS OM-06259

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY

Review all SAFETY information in Section A.

Do not attempt to service the pump as

sembly unless all power to the motor

has been shut off at the control box;

otherwise, injury or death could result.

Use a lifting device with sufficient ca

pacity. If slings or chains are used to

move the pump or components, make

sure that the load is balanced; other

wise serious personal injury or death

could result.

The maintenance and repair instructions in this

manual are keyed to the sectional views, Figures

E-1 and E-2, and the corresponding parts lists.

Select a suitable location, preferably indoors, to

perform required maintenance. All work must be

performed by qualified personnel.

All repairs to the pump motor must be per

formed by a Gorman‐Rupp authorized

Submersible repair facility or the factory.

Any repairs to the motor assembly per

formed by the customer or an unautho

rized repair facility negates the warranty.

This section provides maintenance instructions re

quired to properly service the pump components.

Pump motor maintenance may be performed only

by a Gorman‐Rupp authorized Submersible repair

facility, or the factory. Otherwise, the pump warran

ty will be negated, and damage to the pump, and

injury or death to personnel can result. Contact the

factory for the authorized repair facility closest to

you.

Use the hoisting bail to remove the pump from the

wet well or sump, and move it to a location where

the discharge line can be removed. It is not neces

sary to disconnect a flexible discharge hose before

removing the pump. If rigid discharge piping is

used, disconnect the piping before attempting to

move the pump.

Do not attempt to lift the pump by the

motor power cable or the piping. Attach

proper lifting equipment to the lifting

device fitted to the pump. If chains or

cable are wrapped around the pump to

lift it, make certain that they are posi

tioned so as not to damage the pump,

and so that the load will be balanced.

Check the chart in TROUBLESHOOTING, Section

D of this manual, to determine the nature of the

pump problem. If the problem is mechanical in na

ture, such as worn pump parts, seal replacement,

lubrication, etc., refer to PUMP END DISASSEM

BLY for instructions.

If the problem is electrical, complete disassembly

may not be required. Refer to Electrical Testing in

TROUBLESHOOTING, Section D, and have a

qualified electrician check the control box, cable

and terminal housing. If the problem is determined

to be in the motor, proceed with PUMP END DIS

ASSEMBLY, followed by MOTOR DISASSEMBLY.

Otherwise, see Terminal Housing And Power Ca

ble Disassembly.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Make certain that the control

handle on the control box is in the off po

sition and locked out, or that the power

supply to the control box has been

otherwise cut off and locked out, before

attempting to open or service the pump

assembly. Tag electrical circuits to pre

vent accidental start‐up.

Carefully inspect any O‐rings or gaskets before re

moval and cleaning to determine if a proper seal

and compression existed prior to disassembly. If

sealing was faulty or questionable, the cause must

be determined and corrected before reassembly.

All gaskets and most O‐rings must be replaced if

MAINTENANCE AND REPAIRPAGE E - 6

Page 33

OM-06259 S SERIES PUMPS

disturbed. Repair gaskets and O‐rings are listed in

the Parts List.

PUMP END DISASSEMBLY

Strainer Removal

(Figure E-1)

To remove the strainer assembly (5), raise the

pump slightly, or lay it on its side and disengage

the hardware (55 and 57) securing the strainer and

base plate (56) to the diffuser (1). If the impeller (2)

is clogged, the debris can usually be removed

without further disassembly.

Draining Oil From Seal Cavity

(Figure E-1)

If any further disassembly is to be performed on the

pump, the seal oil cavity must be drained.

Positioning Pump For Disassembly

(Figure E-1)

It is recommended that the pump be positioned

upside‐down during disassembly. To hold the

pump in the inverted position, rest the pump se

curely on blocks. Be careful not to damage the ter

minal housing and cable assembly (36) while in

this position. Use adequate equipment and per

sonnel to safely handle the pump until it is secured.

If inverting the pump is not practical, lay the pump

on its side and secure it to prevent rolling.

Suction Head And Diffuser Removal

(Figure E-1)

Remove the hardware (59 and 60) securing the

suction head (61) to the diffuser (1). Pull the suction

head from the diffuser and remove the suction

head gasket (6). Remove the hardware (52, 53 and

54) securing the diffuser (1) to the intermediate

(48). Tap around the parting surfaces with a soft‐

faced mallet and separate the assemblies. Re

move and discard the diffuser gaskets (7 and 50).

Let the pump cool before removing the

seal cavity drain plug. Pressure built up

within a hot pump could cause the oil to

spray out when the plug is removed. Re

move the plug slowly and permit pressure

to vent to atmosphere.

Lay the pump on its side with the pipe plugs (9 and

10) facing up. Clean any dirt from around the

plugs. Remove the seal cavity drain plug (9), and

install a short 3/8‐inch NPT nipple in the hole. Tip

the pump and drain the seal oil into a clean con

tainer. Inspect the oil for water, dirt, or cloudy condi

tion which could indicate lower seal failure or poor

gasket seal.

Draining Oil From Motor Cavity

(Figure E-1)

If motor problems are suspected, remove the mo

tor cavity drain plug (10), and install a short nipple

in the hole. Tip the pump and drain the motor oil

into a clean container. Inspect the oil for dark color

which could indicate motor overheating, water or

dirt contamination. The presence of dirt or water

could indicate a breakdown in the waterproof in

tegrity of the motor cavity, probably due to poor

gaskets or seals.

Inspect the wear ring (64) for excessive wear or

scoring and replace as required. The wear ring is a

press fit into the suction head. To remove the wear

ring, drill two small holes horizontally through the

ring 180 apart. Use a small chisel or mechanical

cutting device to complete the cuts through the

wear ring.

Use caution not to damage the suction

head when removing the wear ring.

Impeller Removal

(Figure E-1)

NOTE

The impeller hub is drilled and tapped with two 3/8

- 16 UNC screw holes for use with an impeller pull

er (not furnished) if desired.

Insert a 3/4 inch square X 36 inch long (19,1 mm

square X 914,4 mm long) rod between the vanes of

the impeller (2) to prevent impeller rotation. Re

move the impeller nut (63) and washer (62). Screw

the impeller knocker (not shown, supplied with

pump) onto the rotor shaft.

PAGE E - 7MAINTENANCE AND REPAIR

Page 34

S SERIES PUMPS OM-06259

NOTE

The rotor shaft is tapered and forms a friction fit with

the impeller. Screw the impeller knocker onto the

shaft until it bottoms out.

Use two pry bars to exert pressure on the back of

the impeller and strike the knocker sharply until the

impeller breaks loose.

Do not use excessive force when striking

the knocker. It is possible to drive the rotor

and lower ball bearing (47) out of position

during impeller removal. If this occurs, the

motor must be disassembled and the low

er bearing must be pressed back into

place to achieve proper impeller clear

ances (see Motor Disassembly and Mo

tor Reassembly).

After the impeller is free; remove the impeller

knocker and slide the impeller off the shaft. Use

caution when removing the impeller; tension on

the seal spring will be released. Inspect the impel

ler for excessive wear or damage and replace as

required.

If no further disassembly is required, proceed to

the appropriate areas in PUMP END REASSEMB

LY.

press fit into the seal plate. To remove the wear

ring, drill two small holes horizontally through the

ring 180 apart. Use a small chisel or mechanical

cutting device to complete the cuts through the

wear ring.

Use caution not to damage the seal plate

when removing the wear ring.