Gorenje OTG 50 SM, OTG 100 SM, OTG 80 SM, OTG 120 SM, TGR 30-120 SM User Manual

OTG 50-120 SM

22

Dear buyer, thank you for purchasing our product.

Prior to the installation and first use of the electric water heater, please read these

instructions carefully.

THIS APPLIANCE IS NOT INTENDED FOR USE BY PERSONS (INCLUDING

CHILDREN) WITH REDUCED PHYSICAL, SENSORY OR MENTAL CAPABILITIES, OR

LACK OF EXPERIENCE AND KNOWLEDGE, UNLESS THEY HAVE BEEN GIVEN

SUPERVISION OR INSTRUCTIONS CONCERNING THE USE OF THE APPLIANCE BY

A PERSON RESPONSIBLE FOR THEIR SAFETY.

CHILDREN SHOULD BE SUPERVISED TO ENSURE THAT THEY DO NOT PLAY WITH

THE APPLIANCE.

In accordance with the latest guidelines, we have developed for our more demanding

customers the electric water heater OTG equipped with an intelligent electronic regulator

allowing the setting of the temperature of water in the heater as well as smart "ECOS"

mode of operation. The heater records your habits and after a while, it calculates the

optimal operating mode that enables minimal use of electric energy necessary to meet

your warm water needs.

This water heater has been manufactured in compliance with the relevant standards and

tested by the relevant authorities as indicated by the Safety Certificate and the

Electromagnetic Compatibility Certificate. The technical characteristics of the product are

listed on the label affixed between the inlet and outlet pipes. The installation must be

carried out by qualified staff. All repairs and maintenance work within the water heater, e.g.

lime removal or inspection/replacement of the protective anticorrosion anode, must be

carried out by an authorised maintenance service provider.

INSTALLATION

The water heater shall be installed as close as possible to the outlets. When installing the

water heater in a room with a bathtub or shower, take into account the requirements

defined in IEC Standard 60364-7-701 (VDE 0100, Part 701). It has to be fitted to the wall

using appropriate wall screws with a minimum diameter of 8 mm. A wall with a poor loadbearing capacity must be properly reinforced where the heater will be installed. The water

heater may only be fixed upon the wall vertically. We recommend the distance between the

water heater and the ceiling is large enough to allow simple replacement of the MG anode

(see dimension G in the Installation Drawing), in order to avoid unnecessary dismounting

of the heater during the servicing intervention.

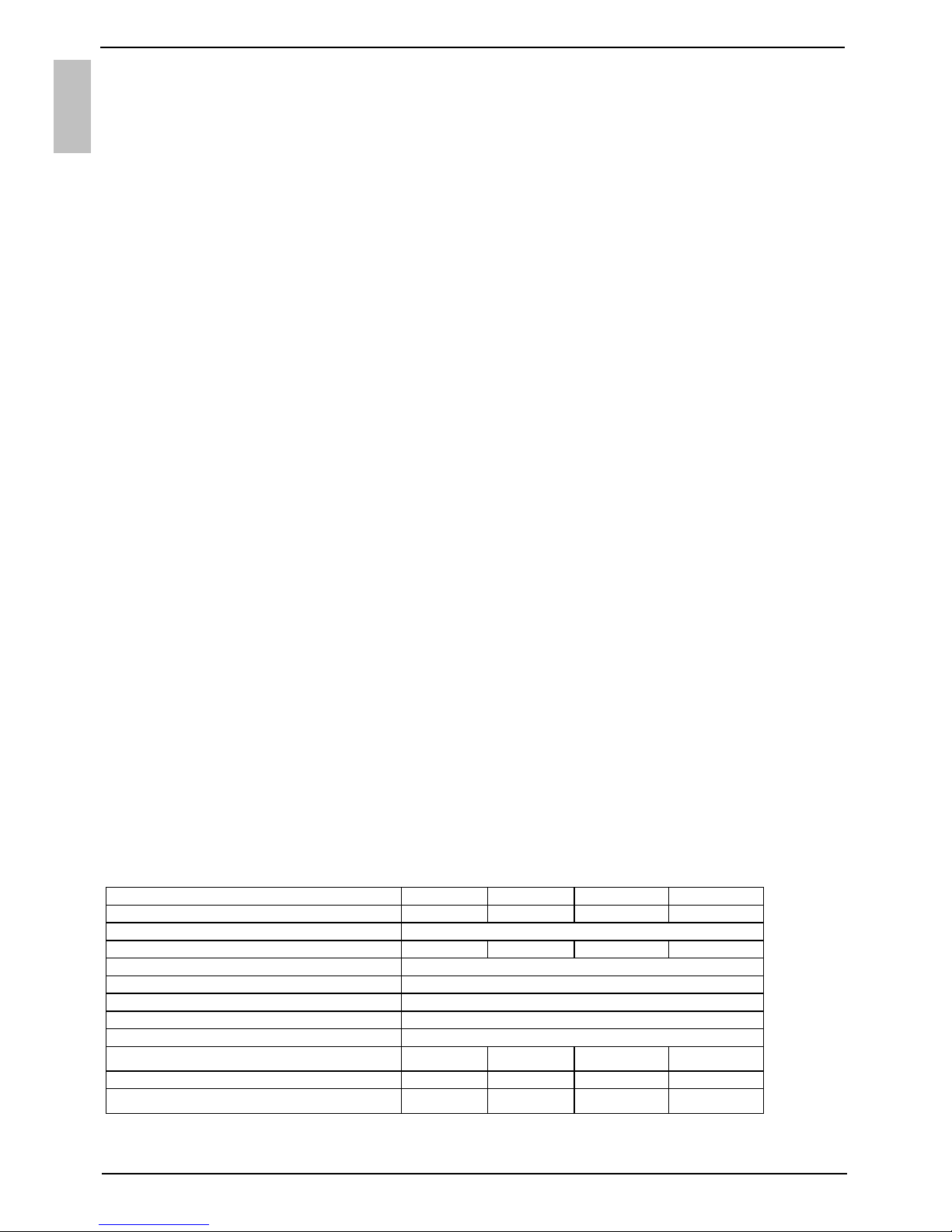

TECHNICAL PROPERTIES OF THE APPLIANCE

Type OT

G 50 SM OTG 80 SM OTG 100 SM OTG 120 SM

Volume [l]

50 80 100 120

Rated pressure [MPa (bar)]

0,6 (6) / 0,9 (9)

Weight / Filled with water [kg] 24/74 31/111 36/136 41/161

Anti-corrosion of tank enamelled & Mg Anode

Power of electrical heater [W]

2000

Connection voltage [V~]

230

Protection class I

Degree of protection IP24

Duration of heating to 75 °C 1) [h]

155 305 355 435

Quantity of mixed water at 40 °C [l]

94 148 194 226

Energy consumption 2) [kWh/24h]

0,99 1,26 1,71 1,81

1) Time for heating the whole content of heater if the initial temperature of cold water from water

supply is 15 °C.

EN

23

2) Energy consumption to maintain the temperature of water in the water heater at 65 °C if the

surrounding temperature is 20 °C, measured according to EN 60379.

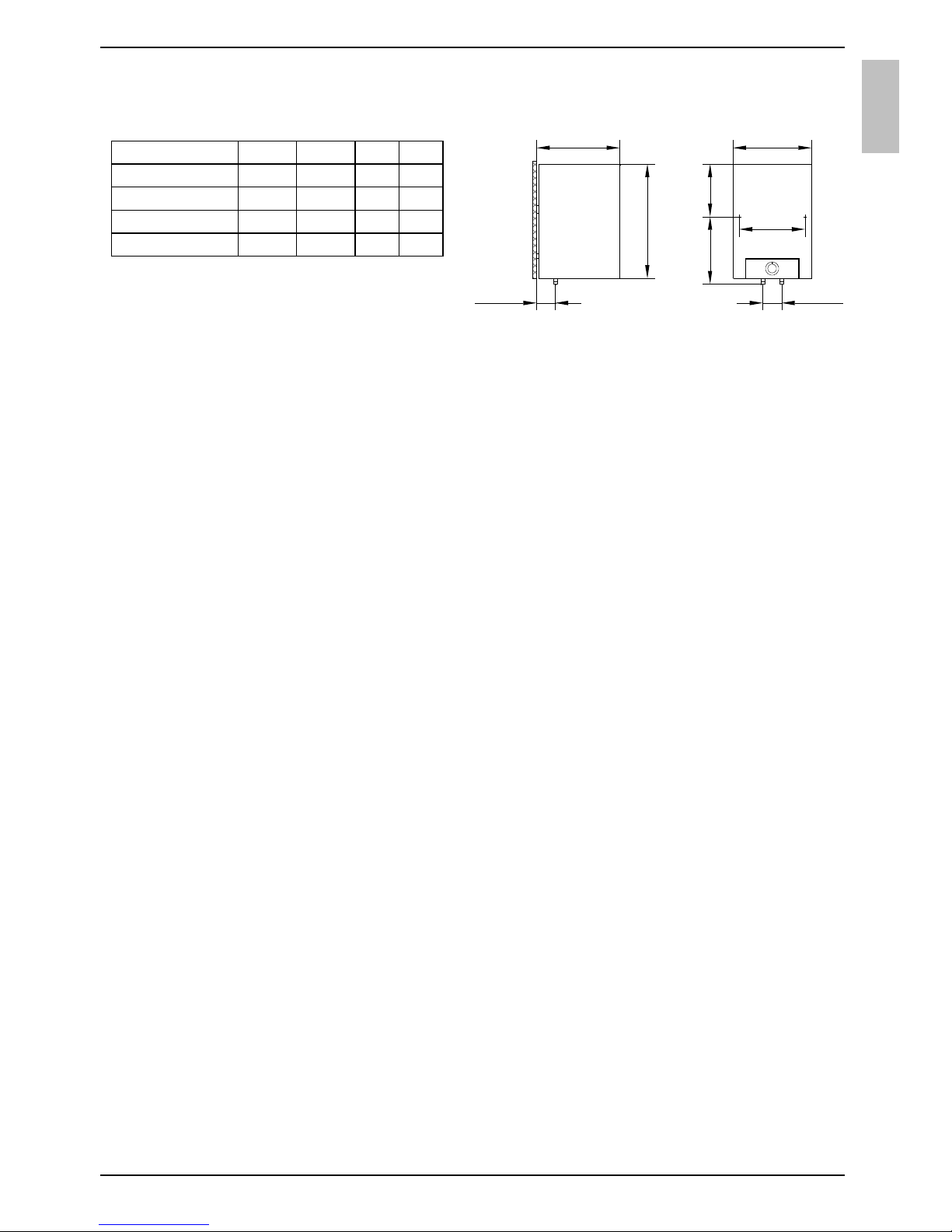

A B C G

OTG 50 SM 690 470 250 210

OTG 80 SM 950 735 245 360

OTG 100 SM 1125 900 255 360

OTG 120 SM 1300 900 430 510

Connection and installation

dimensions of the water heater [mm]

CONNECTION TO THE WATER SUPPLY

The water heater connections for the inlet and outlet of water are colour-coded. The inlet of

cold water is marked with blue colour, while the hot water outlet is marked with red colour.

The water heater can be connected to the water supply in two ways. The closed-circuit

pressure system enables several points of use, while the open-circuit gravity system

enables a single point of use only. The mixer taps must also be installed in accordance

with the selected installation mode.

The open-circuit gravity system requires the installation of a non-return valve in order to

prevent the water from draining out of the tank in the event of the water supply running dry

or being shut down. This installation mode requires the use of a cross-flow mixer tap. As

the heating of water expands its volume, this causes the tap to drip. The dripping cannot

be stopped by tightening it further; on the contrary, the tightening can only damage the tap.

The closed-circuit pressure system requires the use of pressure mixer taps. For safety

reasons the supply pipe must be fitted with a safety valve or alternatively, a valve of the

safety class that prevents the pressure in the tank from exceeding the nominal pressure by

more than 0.1 MPa (1 bar). The outlet opening on the relief valve must be equipped with

an outlet for atmospheric pressure.

The heating of water in the heater causes the pressure in the tank to increase to the level

set by the safety valve. As the water cannot return to the water supply system, this can

result in dripping from the outlet of the safety valve. The drip can be piped to the drain by

installing a catching unit just below the safety valve. The drain installed below the safety

valve outlet must be piped down vertically and placed in an environment that is free from

the onset of freezing conditions.

In case the existing plumbing does not enable you to pipe the dripping water from the

safety valve into the drain, you can avoid the dripping by installing a 3-litre expansion tank

on the inlet water pipe of the boiler.

In order to provide correct operation of the safety valve, periodical inspections of the relief

valve must be carried out by the user to eliminate any limescale and check if the safety

valve is blocked. To check the valve, open the outlet of the safety valve by turning the

handle or unscrewing the nut of the valve (depending on the type of the valve). The valve

is operating properly if the water comes out of the nozzle when the outlet is open.

EN

445

100

A

350

B

C

420

100

Loading...

Loading...