Page 1

GOODMANS C520

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can prcduce

potentially hazardous X-RAY RADIATION.

To avoid such hazards, the high voltage

must not be above the specified limit. The

nominal value of the high voltage of this

receiver is 19K volts at zero beam

current(minimum brightness) under

230VAC power sources. The high voltage

must not, under any circumstances, exceed

22.5K volt each times a receiver requires

servicing, the high voltage should be

checked following the HIGH VOLTAGE

CHECK procedure.

It is recommended the reajing of the high

voltage be recorded as a parts of the

service record. It is important to use an

accurate and reliable high voltage meter.

2. The only source of X-RAY RADIATION in

this TV receiver is the picture tube. For

continued X-RAY RADIATION protection,

the repiacernent tube must be exactly the

same type tube as specified in the parts

list.

SAFETY PRECAUTION

1. Potentials as high as 17,000 volts are

present when this receiver is operation.

Operation of the receiver outside the

cabinet of which the back board removed

involves a shock hazard from the receiver.

1) Servicing should not be attempted by

anyone who is not thoroughly familiar with

the precautions necessary when working

on high-voltage equipment.

2) Always discharage the picture tube anode

to the receiver chassis to keep off the

shock hazard before removing the anode

cap.

3) Perfectly diseharage the high potential of

the picture tube before handling the tube.

The picture tube is highly evacuated and if

brocken, glass fragments will be violently

expelled.

2. If any fuse in this TV receiver is blown,

replace it with the FUSE specified in

Replacement parts list.

3. When replacing a high wattage resistor

(oxide metal film resistor) in circuit board

keep the resistor 10mm away from circuit

board.

4. Keep wires away from high voltage or high

temperature components.

5. This receiver must operate under AC230

voltage, 50Hz never connect to any other

DC supply or power or frequency.

Adjustments

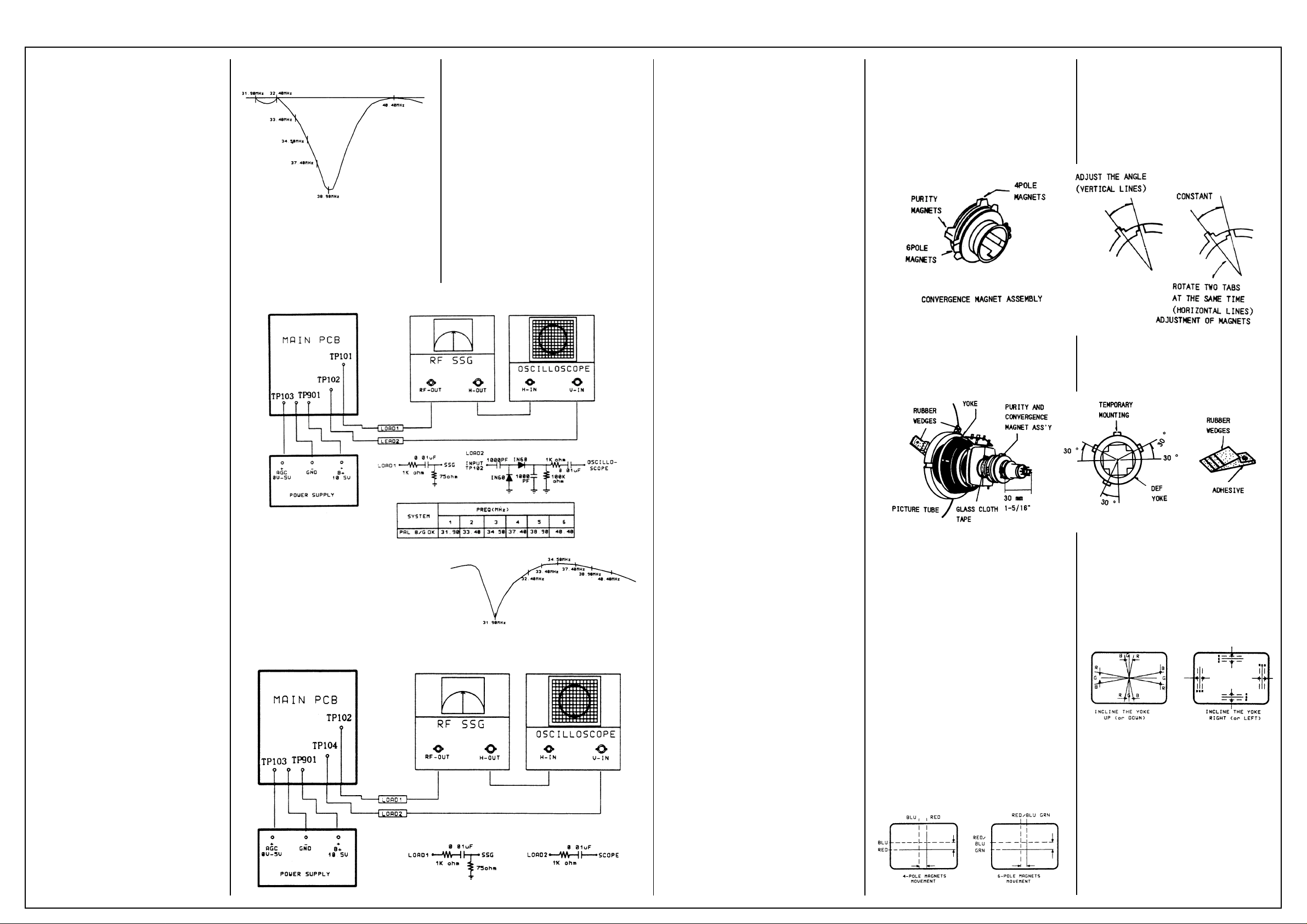

VIF DET. COIL ADJUSTMENT

1) The MEASUREMENT UNIT connect as

shown in Figure 3.

2) Set the VIP ADJUSTMENT MEASURE-

MENT UNIT from the left (FREQUENCY

(MHz) of Figure 4.)

Figure 3. The Method of the Measurement

Unit Connection (See opposite)

3) FREQUENCY(MHz) MARKER POINT adjust

the DETECTOR COIL (T103) to maximum.

Figure 4. The Wave Shape of VIP

TRAP COIL ADJUSTMENT

1) The measurement unit connect as shown in

figure 5.

2) Set the adjust measurement unit from the left

(Frequency MHz of Figure 6)

Fig 5. The method of the measurement unit

connection

3) Frequency (MHz) marker point aijust the trap

coil (T101) to maximum.

Fig 6. The wave shape of trap (See opposite)

SCREEN VOLUME ADJUSTMENT

1) Fix the video output DRIVER VOLUME VR604,

605 and the video output BIAS VOLUME

VR601, 602, 603 to the VOLUME center.

2) Adjust the BRIGHTNESS and the CONTRAST

VOLUME to minimum.

3) Change the SERVICE SWITCH SW203 to the

SERVICE position.

4) Becoming the CROSSWAY A LINE, adjust the

SCREEN VOLUME.

WHITE BALANCE ADJUSTMENT

1) Fix the SERVICE SWITCH to the SERVICE

position.

2) The CROSSWAY A LINE adjust the BIAS

VOLUME VR601, 602, 603 the white.

3) Fix the SERVICE SWITCH to the NORMAL

position.

4) Attach the LUMINANCE METER to the contrast

to maximum.

5) Adjust the BRIGHTNESS and the CONTRAST

to minimum.

6) The LED of the LUMINANCE METER adjust

the video output BIAS VOLUME to the green

color.

7) Adjust the brightness and the contrast to

minimum.

8) The LED of the luminance meter adjust the

video output bias volume to the green color.

9) Adjust again to a (5), (6), (7), (8) clauses.

FOCUS VOLUME ADJUSTMENT

1) Receive the LION PATTERN.

2) Adjust the brightness and the CONTRAST

VOLUME to maximum.

3) Adjust the focus volume to clearness.

ABL ADJUSTMENT (Automatic Brightness

Control Limit)

1) Receive the CROSS HATCH PATTERN.

2) Adjust the brightness and the CONTRAST

VOLUME to maximum.

3) Connect TPX, Y POINT with the DC VOLTMETER.

4) The voltage of TPX, Y POINT adjust the SUB

BRIGHTNESS VOLUME (SVR201) to 230 ±

5(mV).

AGC ADJUSTMENT

1) Receive the UHF Channel 21.(Then, the input

level of the RF must to be 90dB-100dB)

2) The UHF Channel 21 adjust the AGC VR

(SVR101) to be disappear the Noise.

3) The input level 100dB check to be saturated by

the VHF channel reception.

V-SIZE ADJUSTMENT

1) Receive the LION PATTERN. (When the LION

PATTERN don’t exist, use to the PATTERN with

correspondence)

2) Adjust the V-SIZE (SVR301) to be identified

with the OVER SCAN 10% of the horizonztal

3) Adjust the VERTICAL POSITION VR (SVR302)

to be identified with the CENTER POSITION of

the VERTICAL CENTER.

H-CENTER ADJUSTMENT

1) Receive the LION PATTERN.(When the LION

PATTERN doesn’t exist, use the PATTERN with

correspondence)

2) Adjust the H-CENTER VR (SVR105) to be

indentified with the center position of the

horizontal center.

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE ADJUST-

MENT on this chassis. The +11(±20) DC volt

power supply must be properly adjusted to insure

the correct high voltage.

1) Connect an accurate high voltage meter to

anode of the picture tube.

2) Turn on the receiver. Set the BRIGHTNESS

and CONTRAST controls to minimum. (zero

beam current)

3) High voltage will be measured about 19KV.

4) Rotate the BRIGHTNESS control to the both

extremes to be sure the high voltage does not

exceed the limit of 22.5KV under any conditions.

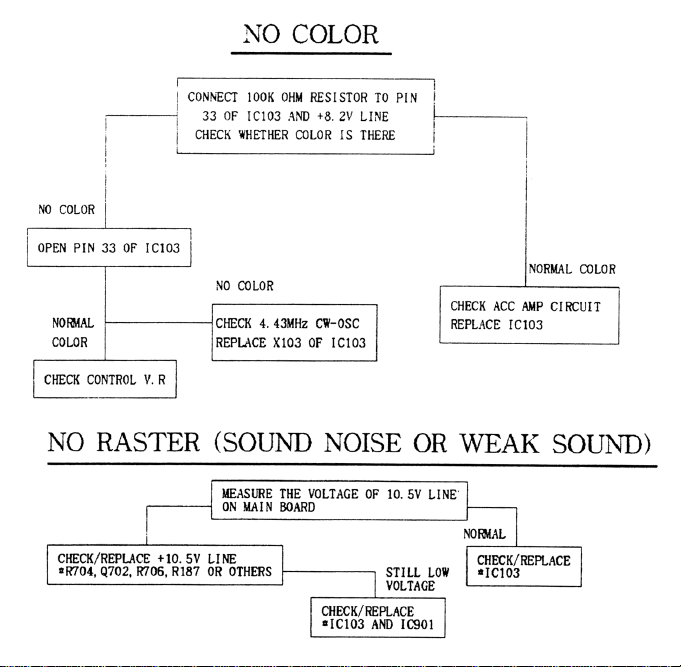

COLOR PURITY ADJUSTMENT

NOTE: Before attempting any purity adjustments,

the receiver should be operate for at least 20

minutes.

1) Demagnetize the picture using a deguassing

coil.

2) Turn the CONTRAST and BRIGHTNESS

controls to maximum.

3) Adjust RED and BLUE BIAS control (VR601

and VR603) to provide only a green raster.

Advance the GREEN BIAS control (VR602) if

necessary.

4) Loosen the clamp screw holding the yoke, and

slide the yoke backward to provide vertical

green belt (zone) in the picture screen.

5) Rotate and spread the tabs of the 1 purity

magnet (See fig 7) around the neck of the

picture tube until the green belt is in the center

of the screen. At the same time, center the

raster vertically.

6) Move the yoke slowly forward until a uniform

green screen is obtained. Tighten the Clamp

screw of the yoke temporarily.

7) Check the purity of the red and blue raster by

adjusting the BIAS controls.

8) Obtained a white raster, referring to “CRT

GRAY SCALE ADJUSTMENT.”

9) Proceed with convergence adjustment.

Fig 7. Purity and Convergence Magnets

CONVERGENCE MAGNET ASSEMBLY POSI-

TIONING

Convergence magnet assembly need mechanical

positioning following the figures.

Fig 8. Tube Assembly

CONVERGENCE ADJUSTMENTS

Note: Before attempting any convergence

adjustments, the receiver should be operated for

at least fifteen minutes.

CENTER CONVERGENCE ADJUSTMENTS

1) Receive crosshatch pattern with a color bar

signal generator

2) Adjust the BRIGHTNESS and CONTRAST

controls for well defined pattern.

3) Adjust two tabs of the 4-Pole Magnets to

change the angle between them. And superimpose red a blue vertical lines in the center area

of the picture screen.

4) Turn both tabs of the same time without

changing position between them to superimpose red and blue horizontal lines at the center

of the screen.

5) Adjust the tabs of 6-Pole Magnets to superimpose red/blue line with green one. Adjusting the

angle affects the vertical lines and rotating both

manets affects the horiaontal lines.

6) Repeat adjustments 3, 4, 5 observing

red,green and blue movement, because 4-Pole

Magnets and 6-Pole Magnets interact.

Fig 9. Center Convergence Adjustment

CIRCUMFERENCE CONVERGENCE

ADJUSTMENT

1) Loosen the clamp screw of deflection yoke

to allow the yoke to tilt.

2) Tilt front of the deflection yoke up or down

to obtain better convergence in circumference. Push the mounted wedge into the

space between picture tube and the yoke to

hold the yoke temporarily.

3) Place other wedge at bottom and remove

the cover paper to stick.

4) Tilt front of the yoke right or left to obtain

better convergence in circumference.

5) Keep the yoke positioned and put another

wedge in either upper space. Remove cover

paper and stick the wedge on picture tube to

secure the yoke.

6) Detach the temporarily mounted wedge and

put it in another upper space. Stick it on

picture tube to secure the yoke.

7) After inserting three wedges, recheck overall

convergence. Tighten the screw firmly to

hold the yoke tightly in place.

8) Place 3 adhesive tapes over, wedges as

shown in Fig 10.

9) Place a wedge temporarily. (Tempoarty

Mounting). (do not remove cover paper on

adhesive part of a new wedge).

Fig 10. Circumference Convergence

Adjustment

CRT GRAY SCALE ADJUSTMENT

1) Set the COLOR Control to minimum.

2) Adjust the BRIGHTNESS and CONTRAST

Control to obtain low light area

3) Adjust RED,GREEN and BLUE BIAS

Controls (601, 602, 603) to obtain gray

raster of low brightness.

4) Adjust the BRIGHTNESS and CONTRAST

Controls to maximum.

5) Adjust the BLUE DRIVE. (VR605) and RED

DRIVE Controls (VR604) to obtain proper

white balanced picture in high light areas.

6) Repeat step 2 through 5 for correct gray

scale.

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Loading...

Loading...