Page 1

Replacement Parts List No. 0700051700

New 09/2015

Daikin

MagnitudeTM

Magnetic Bearing

Centrifugal Chiller

WME

1500

Vintage B

To nd your Daikin Applied parts distributor, call 1-800-377-2787 or visit www.DaikinApplied.com

Page 2

Contents

Parts List Revision History.................................................................................................................................. 3

Nomenclature

Model and Serial Number Nomenclature ..................................................................................................... 4

Model Number- Complete ....................................................................................................................... 5 - 9

Electrical Legend .............................................................................................................................................. 10

Controls

Main Control Box ........................................................................................................................................11

VFD Enclosure ........................................................................................................................................... 12

VFD Chassis ....................................................................................................................................... 13 - 14

VFD Power Supply Plate .................................................................................................................... 15 - 16

OITS- Operator Interface Touch Screen .................................................................................................... 17

Control Sensors ......................................................................................................................................... 18 - 19

Compressor

Motor/Bearing Assemblies .................................................................................................................. 20 - 21

Impeller Assembly ..................................................................................................................................... 22

Impeller Seal & Compressor Fittings .................................................................................................. 23 - 24

Discharge Housing & High Speed Shaft Seal ........................................................................................... 25

Inlet Assembly ..................................................................................................................................... 26 - 27

Unit Assembly

Relief & Shutoff Valves- Diagrams ...................................................................................................... 28 - 29

Discharge Piping Stack .............................................................................................................................. 30

Range Extension ................................................................................................................................. 31 - 32

Suction and Discharge Piping .................................................................................................................... 33

Liquid Injection ........................................................................................................................................... 34

Rotor Cooling ...................................................................................................................................... 35 - 36

Stator Cooling ..................................................................................................................................... 37 - 38

VFD Cooling ........................................................................................................................................ 39 - 40

Liquid Line ........................................................................................................................................... 41 - 42

Expansion Valve......................................................................................................................................... 43

Condenser

Diagrams .................................................................................................................................................... 44

42 Inch - Dish Head Gaskets & Hardware ................................................................................................. 45

42 Inch - Water Box Head Gaskets & Hardware ........................................................................................ 46

Sight Glass, Shut Off Valve & Gasket, Charge Valve ................................................................................ 47

Evaporator

Diagrams .................................................................................................................................................... 48

48 Inch - Dish Head Gaskets & Hardware ................................................................................................. 49

48 Inch - Water Box Head Gaskets & Hardware ........................................................................................ 50

Sight Glass, Charge Valve ......................................................................................................................... 51

Critical Parts List............................................................................................................................................... 52

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 2

Page 3

Parts List Revision History

Revision Date Description

New 09/2015 New

Daikin Applied, 13600 Industrial Park Blvd., P.O. Box 1551, Minneapolis, MN 55440 (763) 553-5330

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 3

Page 4

Model and Serial Number Nomenclature

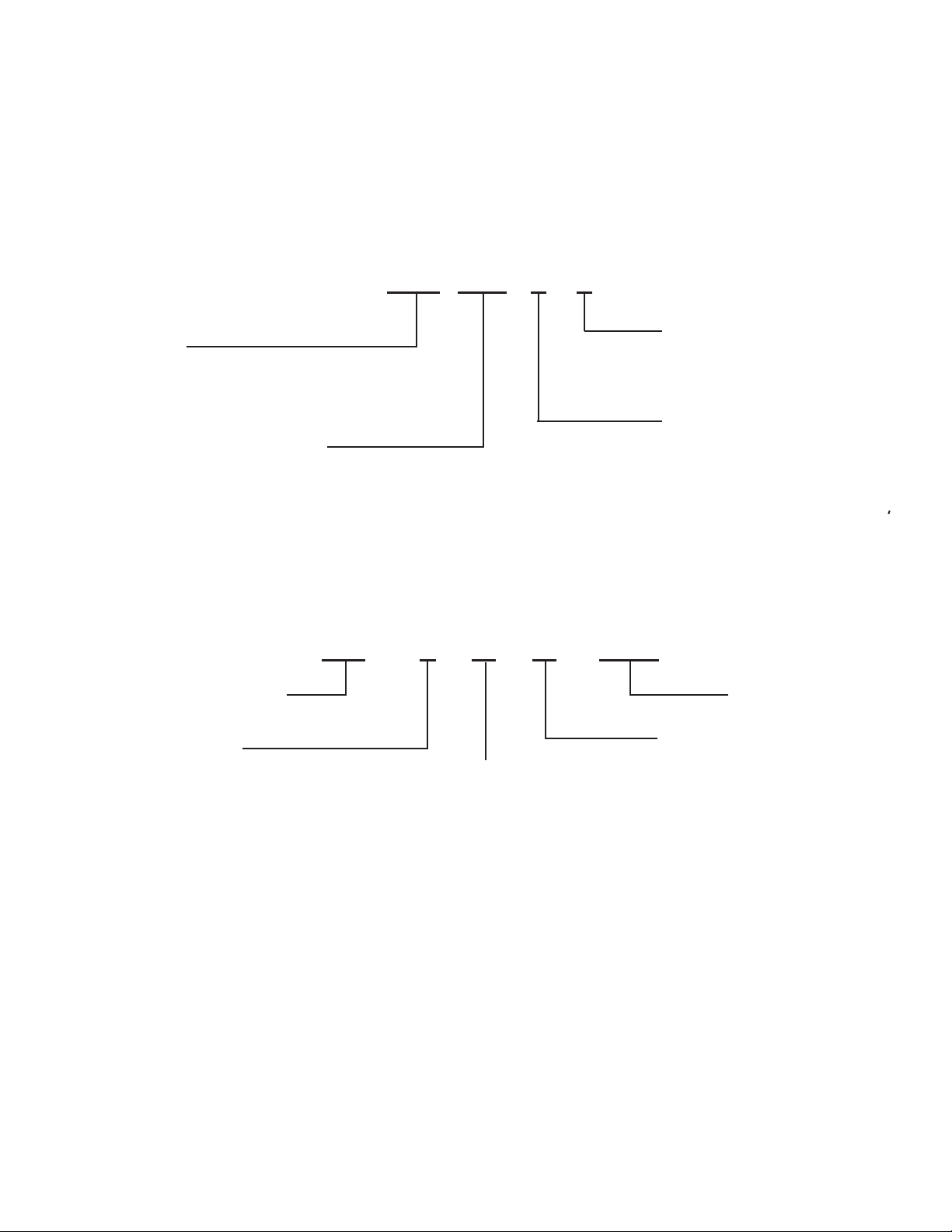

Model Number Nomenclature

Unit Type:

WME = Magnetic Bearing Centrifugal Chiller,

Water Cooled

Unit Size:

1000 Nominal Tons

Nomenclature

WME 1500 D B

Vintage

Number of Compressors

D = Dual Compressor

Plant Identication

STN = Staunton, VA

U = Unit

Serial Number Nomenclature

STN U 15 05 04810

Year of Manufacture

14 = 2014

15 = 2015

16 = 2016

17 = 2017

etc.

Serial Number

(Build Sequence)

Month of Manufacture

01 = January

02 = February

03 = March

04 = April

05 = May

06 = June

07 = July

08 = August

09 = September

10 = October

11 = November

12 = December

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 4

Page 5

Nomenclature

Model Number- Complete

Code: WME 1500D B SN M3 00460 H6 D C E4816 GB 2 C DK L 2 V C N C

Code No.: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

4 440F 00580 C C N A C4216 GB 2 C DR N N N NN L 2 V

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

C N D 4 1050F 00725 C C N N NN A A 0150 A 0700 E7 EA E N

40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

N A 01020 M D N N S N N R S H N B 1 5 A N N N

60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

F N N E A A N J 000 U Y N 0 A N S S U A 12345

81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

NNNNNNNNNNN NN NNNNN VFDM400 D NNNN N C3 04V

101 102 103 104 105 106 107 108 109

1. Model Type

WME= Magnetic Bearing Centrifugal Chiller, Water Cooled

2. Unit Size / Number of Compressors

1500D= 1500 Tons, Dual Compressor

3. Vintage

B= Vintage B

4. Chiller Conguration

SN= Single Refrigerant Circuit w/o Economizer

5. Motor Code

M4= 6 Winding, 6PH, 380-480V

6. Power Supply Voltage

00380= 380V; 00400= 400V; 00415= 415V; 00440= 440V; 00460= 460V; 00480= 480V; 00575= 575V

7. Power Supply Hertz

H5= 50 Hertz; H6= 60 Hertz

8. Always D

9. Compressor Model Revision

C= Revision C

10. Evaporator Shell Size

E4816= Evaporator, 48" Diameter/16' Long

11. Evaporator Tube Count and Conguration

GB= Design B, 3/4" Diameter Tube, Qty=963

HB= Design B, 3/4" Diameter Tube, Qty=863

JB= Design B, 3/4” Diameter Tube , Qty=757

SD= Design D, Mixed Tubes, Qty= 553 of 3/4" + 222 of 1"

TD= Design D, Mixed Tubes, Qty= 499 of 3/4" + 200 of 1"

VE= Design E, 1” Diameter Tube, Qty=509

WE= Design E, 1” Diameter Tube, Qty=459

YE= Design E, 1” Diameter Tube, Qty=392

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 5

Page 6

Nomenclature

Model Number- Complete, Continued

12. Evaporator Tube Wall Thickness

2= 0.025"

3= 0.028"

5= 0.035"

13. Evaporator Tube Type

C= CU

N= CN90/10

14. Evaporator Tube Model

15. Evaporator Inlet Nozzle Location

L= Left

R= Right

16. Evaporator Water Passes

1= 1 Pass

2= 2 Pass

3= 3 Pass

17. Evaporator Inlet Nozzle Connection Type

V= Groove

F= Flanged

18. Evaporator Inlet Nozzle Conguration

A= Dish, End; 1-Pass

B= Dish, End; 2 or 3 Pass

D= Water Box, Top; 1-Pass

E= Water Box, Rear; 1-Pass

H= Water Box, Rear; 2 or 3 Pass

19. Evaporator Hinged Type

N= None

H= Standard Hinges on Both Ends

20. Evaporator Refrigerant Design Pressure

C= 200 PSIG

27. Evaporator Model Revision

A= Revision Level A

28. Condenser Shell Size

C4216= Evaporator, 42” Diameter/16’ Long;

29. Condenser Tube Count and Conguration

GB= Design B, 3/4” Diameter Tube, Qty=1365

HB= Design B, 3/4” Diameter Tube, Qty=1221

JB= Design B, 3/4” Diameter Tube , Qty=1090

VE= Design E, 1” Diameter Tube, Qty=810

WE= Design E, 1” Diameter Tube, Qty=732

YE= Design E, 1” Diameter Tube, Qty=645

30. Condenser Tube Wall Thickness

2= 0.025”

3= 0.028”

5= 0.035”

31. Condenser Tube Type

C= CU

N= CN90/10

S= Stainless Steel

T= Titanium

32. Condenser Tube Model

33-36. Future Use

37. Condenser Inlet Nozzle Location

L= Left

R= Right

38. Condenser Water Passes

1= 1 Pass

2= 2 Pass

3= 3 Pass

21. Evaporator Water Side Design Pressure

4= 150 PSIG, Non-ASME Code

39. Condenser Inlet Nozzle Connection Type

V= Groove

F= Flanged

22. Evaporator Leaving Water Temperature

Example: 440= 44.0 °F

23. Evaporator GPM

Example: 00580= 580 GPM

24. Evaporator Tube Sheet Coating/ Material

C= Carbon Steel

E= Enecon Coating; Outside of Tube Sheet

25. Evaporator Head/ Water Box Coating/ Material

C= Carbon Steel

E= Enecon Coating; Inside of Head

D= Devcon Coating; Inside of Head

26. Evaporator Head Tube Cleaning System

N= None

40. Evaporator Inlet Nozzle Conguration

A= Dish, End; 1-Pass

B= Dish, End; 2 or 3 Pass

D= Water Box, Top; 1-Pass

E= Water Box, Front; 1-Pass

H= Water Box, Front; 2 or 3 Pass

41. Condenser Hinged Type

N= None

H= Standard Hinges on Both Ends

42. Condenser Refrigerant Design Pressure

D= 225 PSIG

43. Evaporator Water Side Design Pressure

4= 150 PSIG, Non-ASME Code

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 6

Page 7

Nomenclature

Model Number- Complete, Continued

44. Condenser Leaving Water Temperature

Example: 1050= 105.0 °F

45. Condenser GPM

Example: 00725= 725 GPM

46. Condenser Tube Sheet Coating/ Material

C= Carbon Steel

E= Enecon Coating; Outside of Tube Sheet

M= Monel Clad

S= Stainless Steel Clad

T= Titanium Steel Clad

47. Condenser Head/ Water Box Coating/ Material

C= Carbon Steel

E= Enecon Coating; Inside of Head

D= Devcon Coating; Inside of Head

48-49. Future Use

50. Condenser Tube Cleaning System

NN= None

51. Condenser Model Revision

A= Revision level A

52. Pressure Vessel Code

A= ASME

53. Unit Tons

Example: 0150= 150 Tons

62. Input Rated Load Amps (RLA) - Compressor #1

Example: 01020= 102.0 Amps

63. Starter Box #

M= Multiple Point - Dual Starter Boxes

64. Power Connection Type

D= Disconnect Switch

65. EMI Filter

N= None

4= 400A Input Current EMI Filter

66. Surge Protection

N= None

67. Short Circuit Current Ratings

S= SCCR 35KA

H= SCCR 65KA

V= SCCR 100KA

L= SCCR 25KA (For 575V only)

M= SCCR 50KA

68. Ground Fault Protection

N= None

F= With Ground Fault Protection Relay

69. Harmonic Filter

N= None

1= 300 HP

2= 350 HP

3= 400 HP

54. Refrigerant Type

A= Refrigerant 134A

55. Refrigerant Weight

Example: 0700= 700 Pounds

56. Electronic Expansion Valve Circuit #1

E7= Electronic Valve Size 7

57. Controller Type

EA= MicroTech-E (Rev. A)

58. Controller Language

E= English - English Units

59. Controller Rapid Restore

N= None

60. Controller Communications

N= None

B= BACnet (MS/TP, IP/Ethernet)

L= Lonmark

M= Modbus

61. Starter Box & Unit Controller Box Type

A= NEMA 1

70. Range Extension

R= Range Extension System

71. Compressor Sound Reduction

Sound Reduction Pkg - Sound Insulation on Dchrg Line

72. Evaporator Insulation

N= None

H= 3/4" Insulation on Evap. Shell, Suction Piping,

and Compressor Inlet

3= 1-1/2" Insulation on Evap. Shell, Suction Piping,

and Compressor Inlet

73. Head Insulation

N= None

2= Evap. Return and Connection Heads Insulated

74. Factory Water Flow Indicatior

B= Both Evaporator and Condenser Flow Control

75. Unit Paint

1= Standard Painting

76. Shipping/ Packaging

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 7

Page 8

Nomenclature

Model Number- Complete, Continued

77. Refrigerant Charge

A= Full Factory Refrigerant Charge

C= Holding Charge - Nitrogen

78. Special

V= None

X= Special

79. Low Lift Conditions

N= None

80. Knockdown

N= None

A= Type A; Bolted Construction, Shipped Together

B= Type B; Bolted Construction, Shipped as Parts

81-83. Testing

GF= Ground Fault Detection Relay; YY= None

84. Agency Listing

E= ETL/cETL

N= None

85. AHRI Listing

A= AHRI

N= None

86. ASHRAE Listing

A= ASHRAE

N= None

87. OSP-IBC Listing

S= OSP-IBC

N= None

88. Unit Label

J= Daikin

89. Coolant Rating

000= Water on both Evaporator and Condenser

E00= Ex: E10= 10% Ethylene on Evaporator or Condenser or Both

P00= Ex: P10= 10% Propylene on Evaporator or Condenser or Both

90. Startup

91. First Year Warranty

Y= Entire Unit Parts and Labor

P= Entire Unit Parts Only

92. Extended Chiller Warranty

A= 1 year of Extended Warranty on parts only

B= 1 year of Extended Warranty on parts and labor

C= 2 year of Extended Warranty on parts only

D= 2 year of Extended Warranty on parts and labor

E= 3 year of Extended Warranty on parts only

F= 3 year of Extended Warranty on parts and labor

G= 4 year of Extended Warranty on parts only

H= 4 year of Extended Warranty on parts and labor

N= None

93. Refrigerant Warranty

0= None

B= 1 Year

D= 2 Year

F= 3 Year

H= 4 Year

K= 5 Year

94. Delayed Warranty Start

A= 12-18; Additional Months = none

B= 12-20; Additional Months = 2

C= 12-22; Additional Months = 4

D= 12-24; Additional Months = 6

E= 12-26; Additional Months = 8

F= 12-28; Additional Months = 10

G= 12-30; Additional Months = 12

95. Extended Chiller Warranty

A= 1 year of Ext Warranty on compressor parts only

B= 1 year of Ext Warranty on compressor parts & labor

C= 2 year of Ext Warranty on compressor parts only

D= 2 year of Ext Warranty on compressor parts & labor

E= 3 year of Ext Warranty on compressor parts only

F= 3 year of Ext Warranty on compressor parts & labor

G= 4 year of Ext Warranty on compressor parts only

H= 4 year of Ext Warranty on compressor parts & labor

N= None

96. Ship

S= Standard Ship

96-97. Bill of Materials

99. Unit Model Revision

A= Revision Level A

100. Unit kW

101. Stock Unit Modications

NNNNNNNNNNN= None

* * * * * * * * * * *= WME Stock Unit Part Number

102. Expansion Valve #2

NN= None

103. Input Rated Load Amps (RLA) - Compr #2 Only

NNNNN= None

* * * * *= Example: 01020= 102.0 Amps

104. VFD Type and Size

VFDM400= 400A - VFD Max Output Amps - 6 Phase

VFDM450= 450A - VFD Max Output Amps - 6 Phase

VFDM500= 500A - VFD Max Output Amps - 3 Phase

105. Power Assembly

S= Single Power Assembly- 3 Phase

D= Dual Power Assembly - 6 Phase

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 8

Page 9

Nomenclature

Model Number- Complete, Continued

106. Transformer Type

NNNN= None

40SD= 400A AutoTransformer - 3 Phase (SD400-6)

60SU= 600A AutoTransformer - 3 Phase (SU600-6)

50SD= 500A Stepdown AutoTransformer - 6 Phase (SD500-12)

73ST= 730A AutoTransformer - 6 Phase (ST730-12)

73Su= 730A Stepup AutoTransformer - 6 Phase (SU730-12)

107. Power Meter

N= None

M= 7350 Power Meter

108. Cabinet Size

C1= Large Cabinet w/Transformer

C2= Small Cabinet w/o Transformer

C3= Large Cabinet w/o Transformer

109. Circuit Breaker Rating

04V= 380-480V / 400A, 100KA Breaker

05S= 380-480V / 500A, 35KA Breaker

05H= 380-480V / 500A, 65KA Breaker

06S= 380-480V / 600A, 35KA Breaker

06H= 380-480V / 600A, 65KA Breaker

06V= 380-480V / 600A, 100KA Breaker

08S= 380-480V / 800A, 35KA Breaker

08H= 380-480V / 800A, 65KA Breaker

08V= 380-480V / 800A, 100KA Breaker

04L= 575V / 400A, 25KA Breaker

04M= 575V / 400A, 50KA Breaker

06L= 575V / 600A, 25KA Breaker

06M= 575V / 600A, 50KA Breaker

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 9

Page 10

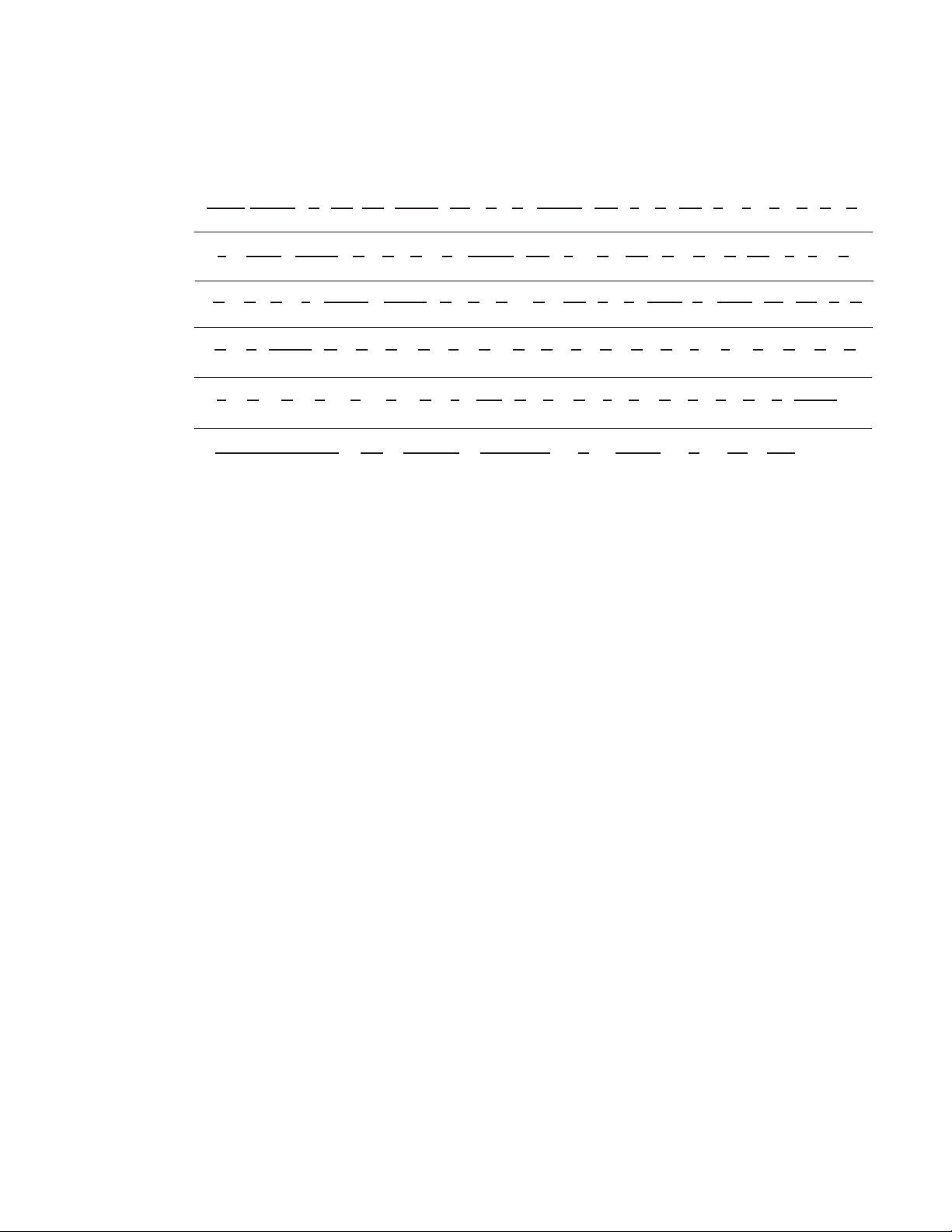

Electrical Legend

Sch. Sym. Description Location

BAS Communication Card Main Control Box

CB1 Circuit Breaker- TX2 Primary VFD Power Supply Plate

CB2- 4 Circuit Breaker- Fans VFD Power Supply Plate

CB4 Circuit Breaker- MCB Trip, Power Meter, ELR, Solenoid VFD Power Supply Plate

CFT1- CFT2 Cooling Fan Control VFD Power Supply Plate

CT1- 6 Current Transducers VFD Chassis

CPU Main Control Board Main Control Box

D1 Diode VFD Chassis

ES Switch- Ethernet Main Control Box

ELR Relay- Earth Leakage VFD Power Supply Plate

EMC EMC Filter VFD Enclosure

EXV1 Electronic Expansion Valve Liquid Line

F1- F2 Fuse- Controls Transformer, 2A 600VAC VFD Power Supply Plate

F3- F5 Fuse- IPS, 6A 600VAC VFD Power Supply Plate

F6- F7 Fuse- 150VDC to DC Power Supply, 10A 600VAC VFD Power Supply Plate

F8- F10 Fuse- Power Meter, 10A 600VAC VFD Power Supply Plate

INPUT I/O Board Main Control Box

IPS Intermediate Power Supply VFD Enclosure

L1- 3 Chopper Chokes/Inductors VFD Chassis

LCD LCD Touch Screen Monitor (OITS) Evaporator

LR Line Reactor VFD Enclosure

MCB Main Circuit Breaker VFD Enclosure

P1- P14 DC Power Distribution Terminals VFD Power Supply Plate

PM Power and Current Meter VFD Power Supply Plate

PS2- PS4 Power Supply- VFD VFD Power Supply Plate

PS5 Power Supply- Chiller I/O VFD Power Supply Plate

PS6 Power Supply- Compressor I/O VFD Power Supply Plate

PS7- PS8 Power Supply- Magnetic Bearings VFD Power Supply Plate

Q1- 3 Chopper/IGBT Driver VFD Chassis

Q4- 6 Steering Bridge IGBT VFD Chassis

R1- 4 Resistors VFD Chassis

S01 Sensor- Evaporator Entering Water Temperature Evaporator Inlet

S02 Sensor- Evaporator Leaving Water Temperature Evaporator Outlet

S04 Switch- Evaporator Entering Flow Evaporator Inlet

S05 Sensor- Condenser Entering Water Temperature Condenser Inlet

S06 Sensor- Condenser Leaving Water Temperature Condenser Outlet

S07 Sensor- Condenser Refrigerant Pressure Condenser

S08 Switch- Condenser Entering Flow Condenser Inlet

S09 Sensor- Liquid Line Temperature Liquid Line

S10 Sensor- Compressor Suction Temperature Compressor

S11 Sensor- Compressor Suction Pressure Compressor

S12 Sensor- Compressor Discharge Temperature Compressor Discharge Housing

S13 Sensor- Compressor Discharge Pressure Compressor Discharge Housing

S14 Sensor- Motor Gap Temperature Compressor

S15 Switch- High Pressure Discharge Piping

SW1 Switch- Compressor #1 Main Control Box

SW3 Switch- Remote Start/Stop Remote Mounting

SW4 Switch- Mode Remote Mounting

SW5 Switch- Unit Enable Main Control Box

TDM1- 3 Diode/Thyristor Module VFD Chassis

TS1 Thermal Switch VFD Chassis

TH1, 2 Thermistors VFD Chassis

TX2 Transformer- 480/240/120 VAC, 500A VFD Power Supply Plate

VFD1 VFD Chassis Assembly VFD Enclosure

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 10

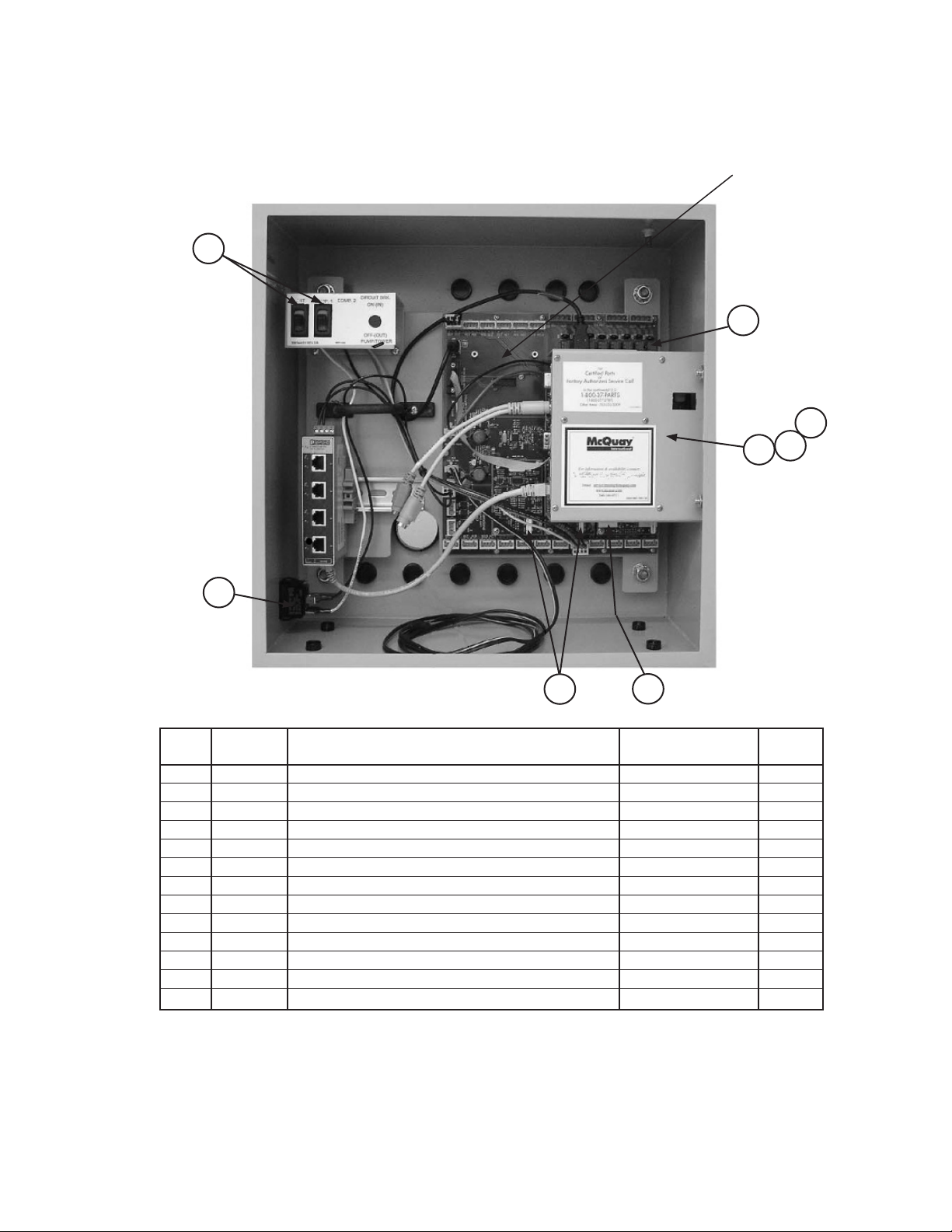

Page 11

24

Controls

Main Control Box

Communication Card

Location

4

9

8

7

18

13

Ref. Schem.

No. Sym. Description Part No. Qty.

4 Board- Chiller I/O Backplane 300047099 1

7 CPU Board- Chiller Controller 300047102 1

N/S Connector, Chiller Controller, Beige 300048948 21

N/S Connector, Chiller Controller, Orange 300048949 4

8 Board- Digital I/O 333568101 1

9 Board- Analog Output 333568201 1

11 Board- IGV Stepper Motor 333568302 1

13 Board- Analog Input 333568401 2

18 SW5 Switch- Unit Enable 300047109 1

24 SW1 Switch- Unit and Compressor #1 300047110 2

N/S BAS BACnet MS/TP/E Installation Kit 2 332356961 1

N/S BAS Lonmark Installation Kit 2 332356952 1

N/S BAS Modbus Installation Kit 2 332356953 1

N/S= Not Shown on Diagram.

2

Includes the Communication Card and Installation Manual.

11

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 11

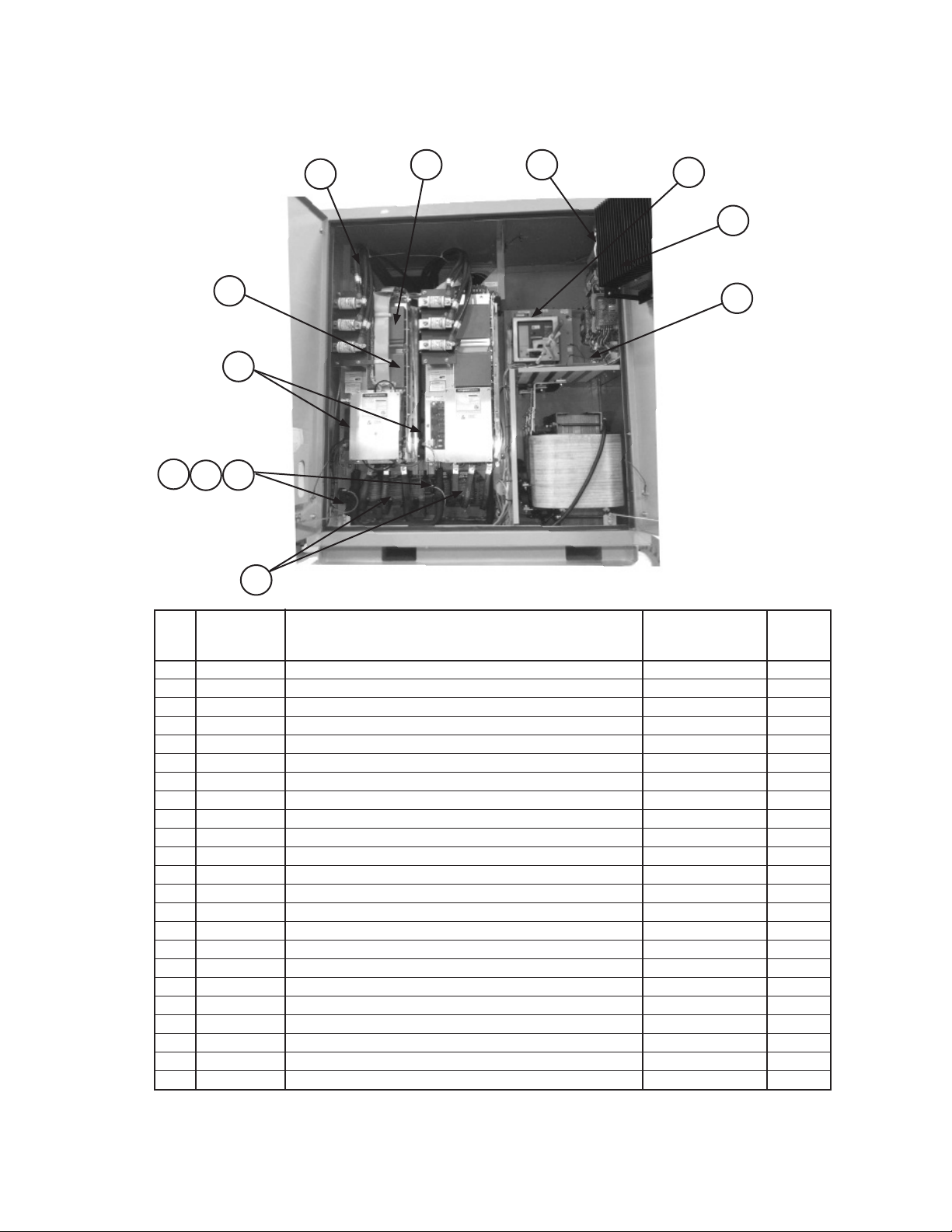

Page 12

Controls

VFD Enclosure

5C

5B

3

4

5A

1

13

8

7

10

6

Ref. Schem.

No. Sym. Description Part No. Qty.

1 Fan 120 VAC 600 CFM 300047091 2

3 VFD1 VFD Chassis Assembly- Phases 1- 3 1 300047093 1

4 Fuse 20A/1000VAC 300047094 2

5A Valve- Solenoid 331796001 2

5B Valve- Coil 120/60, 10 watt 331796051 2

5C Repair Kit- Solenoid Valve 300052079 2

6 LR Line Reactor 3PH 300047096 2

7 IPS Intermediate Power Supply 300047097 1

8 MCB CBKR Molded Case 25KAIC 600V 400A 300048927 1

CBKR Molded Case 25KAIC 600V 600A 300048929 1

CBKR Molded Case 35KAIC 480V 500A 300047098 1

CBKR Molded Case 35KAIC 600V 500A 300047071 1

CBKR Molded Case 35KAIC 600V 600A 300047100 1

CBKR Molded Case 35KAIC 600V 800A 300048924 1

CBKR Molded Case 50KAIC 600V 400A 300048928 1

CBKR Molded Case 50KAIC 600V 600A 300048930 1

CBKR Molded Case 65KAIC 600V 500A 300047088 1

CBKR Molded Case 65KAIC 600V 600A 300047108 1

CBKR Molded Case 65KAIC 600V 800A 300048925 1

CBKR Molded Case 100KAIC 480V 400A 300047069 1

CBKR Molded Case 100KAIC 480V 600A 300048923 1

CBKR Molded Case 100KAIC 480V 800A 300048926 1

10 Surge Suppressor 480V 300047076 1

1

Refer to VFD Chassis Assembly detail on the following pages.

2

Quantity per VFD Enclosure.

2

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 12

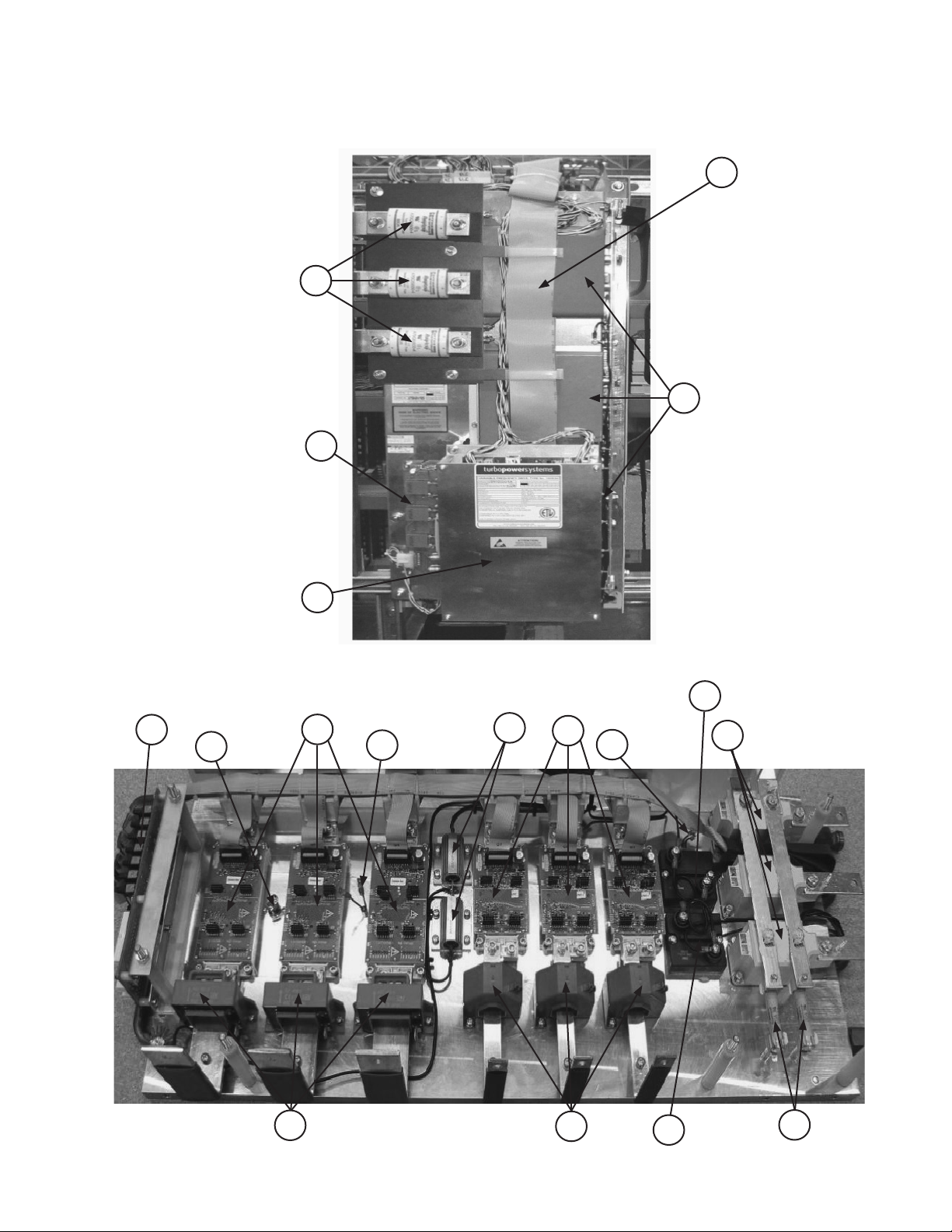

Page 13

Controls

VFD Chassis- Diagrams

16

1

4

3

2

15

5

12

6

13

14

7

13

8

11

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 13

10

15

9

Page 14

Controls

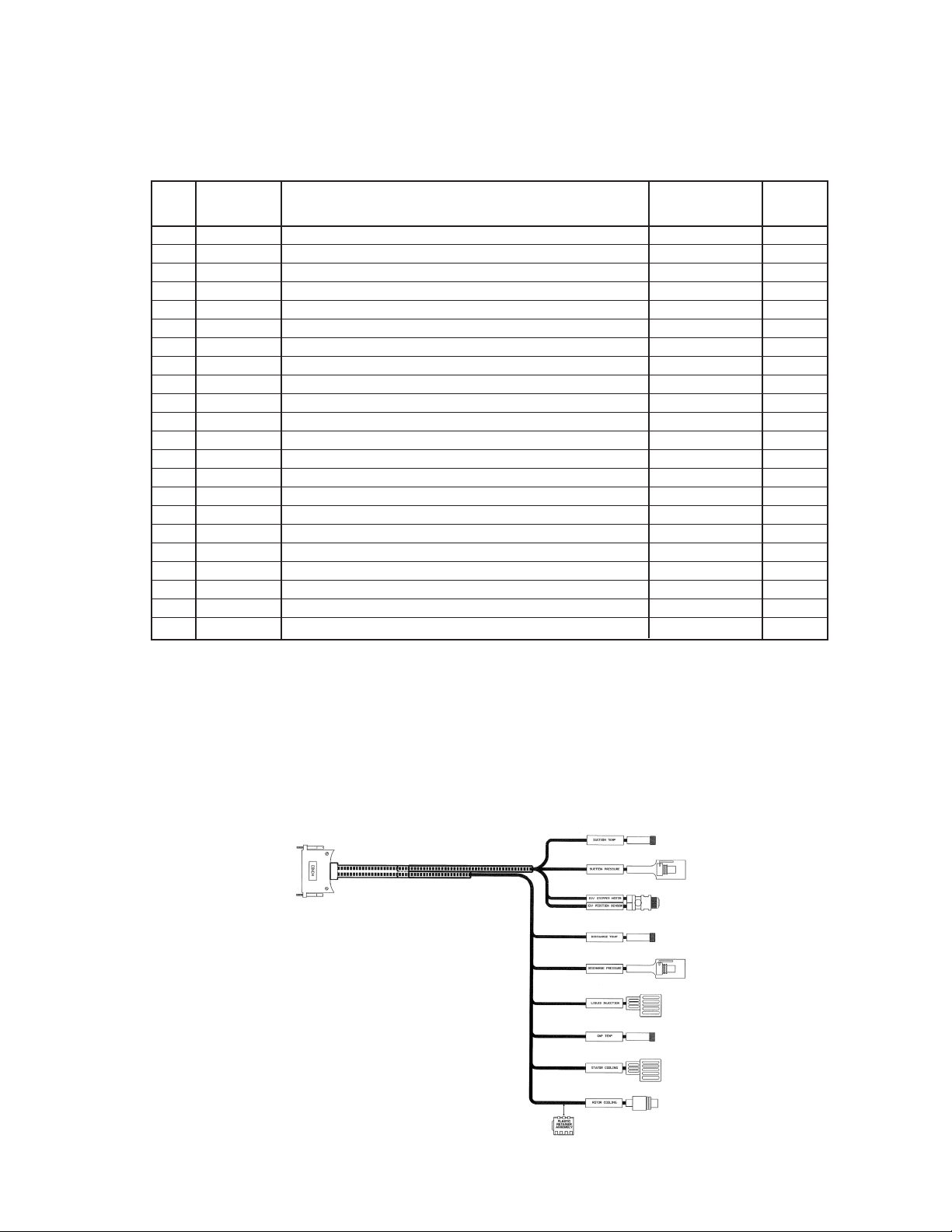

VFD Chassis- Components & Compressor Wiring Harness

VFD Chassis- Components

Ref. Schem.

No. Sym. Description Part No. Qty.

1 Fuse 600A, 700V 300047092 3

2 VFD Controller Assembly 300048932 1

Backup Battery for VFD Controller 334295801 1

3 Voltage Transducer Interface Board 300048950 1

4 Link Capacitor 1200uF, 700V 300048939 3

5 Connector Interface 300048934 1

6 Q4- 6 Steering Bridge IGBT Assy. 300048937 3

7 Q1- 3 Chopper IGBT Assy. 300048936 3

8 TDM1- 3 Diode Thyristor Module 300049088 3

9 Fuse 20A, 800V 300048941 2

10 CT1- 3 Current Transducer 300048942 3

11 CT4- 6 Current Transducer 300048943 3

12 TS1 Thermal Switch 300048945 1

13 TH1, 2 Thermistor 300048944 2

14 R3, 4 Resistor 2K2, 75W 300049089 2

15 R1, 2 Resistor 150R, 250W 300048938 2

16 Wire Harness/Cable Kit 2 300055446 1

N/S L1- 3 Chopper Chokes/Inductors 300048952 3

N/S Thyristor Driver Board 300048933 1

N/S Snubber Board 300048935 1

N/S Snubber Capacitors 1uF, 1200V 300048940 6

N/S D1 Diode 300048951 1

N/S= Not Shown on Diagram.

1

Quantity PER Chassis Assembly

2

Kit contains ribbon cables and harnesses. Connections include: Q1-J10; Q2-J11; Q3-J12; Q4-J7; Q5-J8; Q6-J9; J1-J6;

and J1-J14.

1

Compressor Wiring Harness

Part Number 331795503

Available as a complete assembly only. One per compressor.

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 14

Page 15

Controls

VFD Power Supply Plate- Diagram

21

20

19

11

22

12

7

4

8

6

9

5

13

13

14

2

3

18

17

15

14

16

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 15

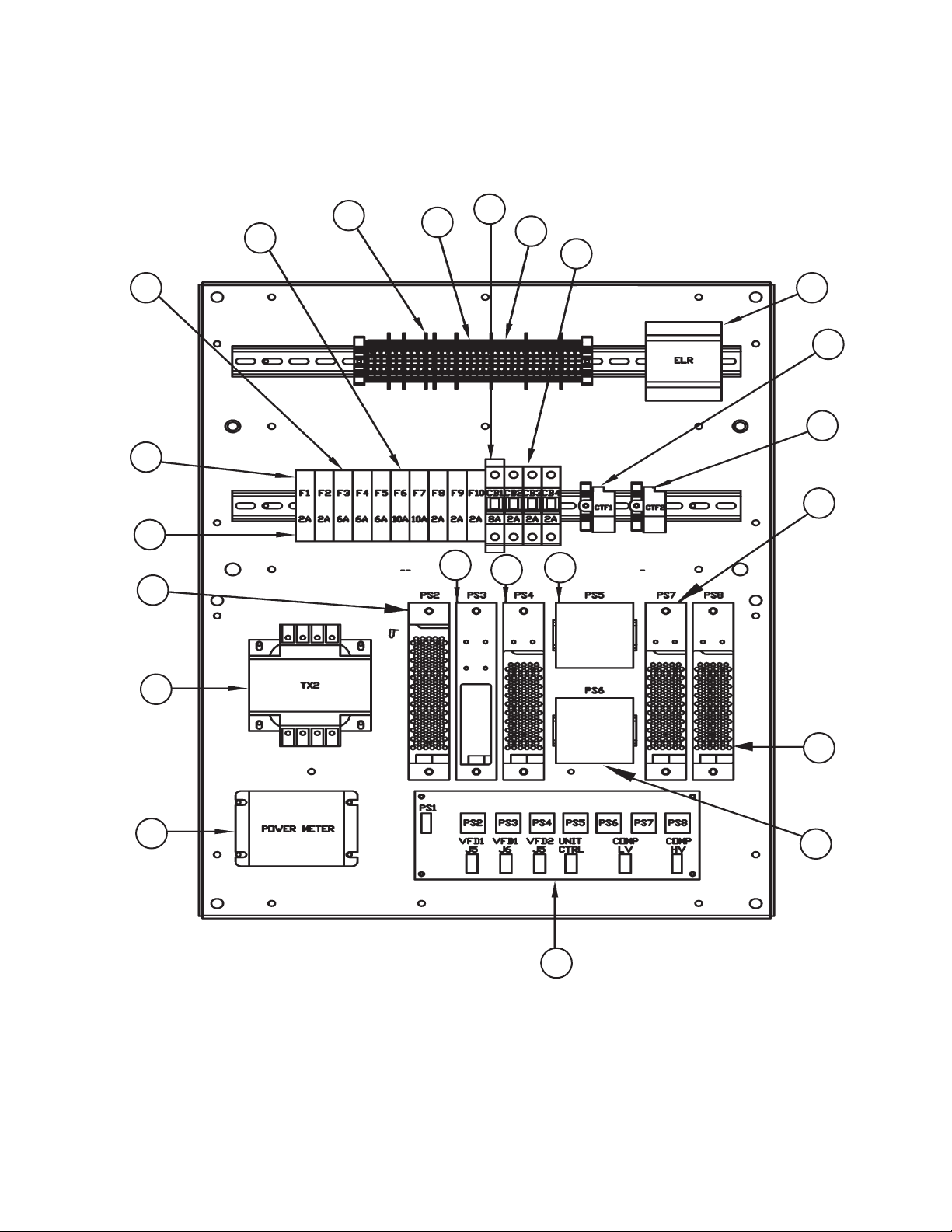

Page 16

Controls

VFD Power Supply Plate- Components

Ref. Schem.

No. Sym. Description Part No. Qty.

2 Plate- Partition Gray 300047073 17

3 Terminal Block Gray 300047074 36

4 Terminal Block- Ground Green-Yellow 300047075 9

5 Bracket- End, Snap on 300047190 7

6 ELR Relay- Earth Leakage 300047078 1

7 CB1 Circuit Breaker- Primary 8A 300047079 1

8 CB2- 4 Circuit Breaker- 2 Fans & MCB trip 2A 300047080 3

9 Switch- Fan Failure 331578601 2

11 DC power supply +15 VDC 100 watts 300047081 1

12 DC power supply 15 VDC 25 watts 300047082 1

13 DC power supply +24 VDC 77 watts 300047083 2

14 DC power supply +24 VDC 100 watts 300047084 2

15 DC power supply +12 VDC 72 watts 300047085 1

16 DC Distribution Board 300047086 1

17 PM Monitor- Voltage, Power and Current 300047087 1

18 TX2 Transformer 480/240/120V 500VA 349939804 1

19 F1- 10 Fuse holder 300047088 7

20 F1-2, F8-10 Fuse 300047089 2

21 F3- 5 Fuse 300047090 3

22 F6-7 Fuse 300046902 2

1

Quantity per VFD Power Supply Plate.

1

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 16

Page 17

Controls

OITS- Operator Interface Touch Screen

Swivel Bracket

15

Swivel Pins

1

1

Main Control Box

18

16

Ref.No. Description Part No. Qty.

15 Monitor- 15" LCD Touchscreen, Black 330276502 1

16 LCD Support Arm Assembly, Black 1 330815411 1

18 OITS/Unit Control Box Support Block 330406501 2

1

The LCD Support Arm Assembly includes the Swivel Bracket, the Swivel Pins, and the mounting hardware (screws, washers and

nuts). These items are not available separately.

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 17

Page 18

Top View

Front View

S07

Control Sensors

Sensor Location Diagrams

S15

S14

S10

S13

S12

S11

End View

S02

S01

S04

S09

Out

In

Evaporator

Condenser

Out

In

S06

S05

S08

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 18

Page 19

Control Sensors

Components

Ref. Description Part Qty.

No. Number

S01 Sensor- Evaporator Entering Water Temperature 073007203 1

S02 Sensor- Evaporator Leaving Water Temperature 073007203 1

S04 Switch- Evaporator Entering Flow 331796201 1

N/S Cable- Evaporator Entering Flow Switch (5 Meter Lg.) 330571403 1

S05 Sensor- Condenser Entering Water Temperature 073007203 1

S06 Sensor- Condenser Leaving Water Temperature 073007203 1

S07 Sensor- Condenser Refrigerant Pressure 071568621 1

S08 Switch- Condenser Entering Flow 331796201 1

N/S Cable- Condenser Entering Flow Switch (5 Meter Lg.) 330571403 1

S09 Sensor- Liquid Line Temperature 073007203 1

S10 Sensor- Compressor Suction Temperature 331582801 2 2

S11 Sensor- Compressor Suction Pressure 071568521 2

N/S Cable- Compressor Suction Pressure Sensor 331796801 2

S12 Sensor- Compressor Discharge Temperature 331582801 2 2

S13 Sensor- Compressor Discharge Pressure 071568621 2 2

S14 Sensor- Motor Gap Temperature 331795205 2 2

S15 Switch- High Pressure 074796301 2

N/S= Not Shown on Diagram

2

The Cable for this Sensor is part of the Compressor Wiring Harness and is not available separately. Refer to the Compressor Wiring

Harness section.

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 19

Page 20

Compressor

Motor/Bearing Assemblies

Part No. Description Application Voltage

333507101 MBAW6/6 (Code 05= M4) 380 - 575V

Note: The Compressor Magnetic Bearing, Rotor, and Stator components are not eld

replaceable. If replacement is required, the entire assembly must be replaced. For

Compressor Motor/Bearing Assembly eld serviceable components see the following

page.

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 20

Page 21

Compressor

Motor/Bearing Assembly Components

1

6

2

8A

8B

Front View Bottom View

11

Back View

Ref.

No. Description Part No. Qty.

1 Kit- Electronics Cover Assy. 1 300047066 1

2 Controller- Compressor 300047067 1

6 Kit- Electronics Cover Gasket 2 300047068 1

8A Kit- Connector Plate with Gasket 300047070 1

8B Kit- Connector Plate with Gasket & 3 Cables 300047070 1

11 Plug- Hex Head 300047072 1

1

Kit includes Cover, Gasket & Insulator.

2

Kit includes Gasket & Insulator. Included in Electronics Cover Assy Kit 300047066.

3

Quantity per Motor/Bearing Assembly.

3

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 21

Page 22

407

Compressor

Impeller Assembly

402

403

405

404

406

418

416

417

415

Ref.

No. Description Part No. Qty.

402 Washer- Impeller 735043467 1

403- 406 Kit- Shim Washers, Impeller 1 300049084 1

407 Impeller Assembly 2 331347211 1

415 Volute Insert 331439602 1

416 Pin- Volute Insert .50 x .09" 735038039 1

417 O-Ring 3 330198639 1

418 Ring- Retaining 331438804 1

4

1

The shim combination is unique to each compressor. The kit contains quantities of four shim sizes.

2

Available as an assembly only.

3

Included in Compressor O-Ring Kit p/n 300049073. One kit per Compressor.

4

Quantity per Impeller Assembly.

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 22

Page 23

Impeller Seal & Compressor Fittings- Diagrams

See Compressor

Inlet Assembly

Compressor

506

504

502

503

609

608

602

605

606

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 23

607

Page 24

Compressor

Impeller Seal & Compressor Fittings- Components

Ref.

No. Description Part No. Qty.

502 Seal- Impeller (1 pair) 332027502 1

503 O-Ring 3 070194967 1

504 O-Ring 3 070194999 1

506 Screw, Stainless Steel 3/8-16 x 2.0" 331353705 24

602 Fitting- Elbow 2 332471617 1

O-Ring, ORFS 1 070194968 1

O-Ring, SAE 1 070194980 1

605 Fitting- Elbow 070789307 1

O-Ring, ORFS 1 735073650 1

O-Ring, SAE 1 735073625 1

606 Fitting- Elbow 070789368 1

O-Ring, ORFS 1 735073640 1

O-Ring, SAE 1 735073625 1

607 Fitting- Straight 070789383 1

O-Ring, ORFS 1 300047193 1

O-Ring, SAE 1 070194970 1

608 Fitting- Run Tee 070789392 1

O-Ring, ORFS 1 070194968 2

O-Ring, SAE 1 070194980 1

609 Well, Temperature Sensor 331795204 1

1

O-Ring(s) are furnished standard with all ttings. Order additional O-Rings if needed. ORFS Style

O-Rings seat on the face end of the tting. SAE style O-Rings seat at the base of the tting.

2

The well for this tting is integrated into the Discharge Housing and is not available separately.

3

Included in Compressor O-Ring Kit p/n 300049073. One kit per Compressor.

4

Quantity per Compressor.

4

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 24

Page 25

315

307

313

311

Compressor

Discharge Housing & High Speed Shaft Seal

316

507

304

306

307

312

314

508

302

303

305

Ref.

No. Description Part No. Qty.

302 Discharge Housing 331553803 1

303 O-Ring 2 070194978 1

304 Screw, Stainless Steel #.38-16 x 2.0" 331353705 12

305 Screw, Stainless Steel #.38-16 x 3.0" 331353706 6

306 Ring- Liquid Injection 331552901 1

307 Screw #10 x .50" 735034921 12

311 Pin .50 x .09" 735038039 1

312 Seal- High Speed Shaft 1.5" 331351101 1

313 Shim- High Speed Shaft Seal 331347501 1

314 Spring- Wave, High Speed Shaft 735049886 1

315 Retainer- High Speed Shaft Seal 331353301 1

316 Pin- Locator 331584501 1

415 Dowel .25 x .875 735038038 1

416 Plug 735017102 1

O-Ring, SAE 1 735073623 1

507 Well, Temp Sensor 331582701 1

508 Valve- Access 070229306 1

1

O-Ring(s) are furnished standard with all ttings. Order additional O-Rings if needed.

2

Included in Compressor O-Ring Kit p/n 300049073. One kit per Compressor.

3

Quantity per Compressor.

415

416

3

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 25

Page 26

Compressor

Inlet Assembly- Diagrams

201

201

202

206

203

204

205

213

210

211

212

220

221

222

219

218

207

209

208

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 26

Page 27

Compressor

Inlet Assembly- Components

Ref. Description Part

No. Number Qty.

Complete Compressor Inlet Assembly 331553412 1

201 Inlet Housing 331587903 1

202 Gear- Face 331553201 1

203 Inlet Vane 331553002 11

204 Gear- Spur 331438202 11

205 Pin- Spur Gear .313 x .58" 735038065 11

206 Ring- Retaining Spur Gear 735049890 11

207 IGV Actuator Assembly, Complete 331583401 1

208 O-Ring 1 070194996 2

209 Screw- Stainless Steel .50-13 x 1.50" 331353704 2

210 Plug- Sensor Magnet 331438401 1

211 Magnet 331353802 1

212 Sensor 331352831 1

213 Bracket- Sensor 331352701 1

218 Ring- Vane Stop 331553301 1

219 Ring- Retaining Vane Stop 331438805 1

220 Valve- Access 070229306 1

221 Connector- Male 8 Pole 331795401 1

222 Well- Temperature Sensor 331582701 1

1

Included in Compressor O-Ring Kit p/n 300049073. One kit per Compressor.

2

Quantity per Inlet Assembly.

2

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 27

Page 28

020

Unit Assembly

Relief & Shutoff Valves- Diagrams

022

024

021

081

082

080

083

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 28

020

Page 29

Unit Assembly

Relief & Shutoff Valves- Components

Ref.

No. Description Part No. Qty.

020 Fitting- 90 Degree Elbow 332471635 3

O-Ring 1 070194963 3

021 Valve- Shut Off (on Condenser) 735039964 1

O-Ring, SAE 1 070194980 1

022 Valve- Relief (on Evaporator) 200# 735045817 2

024 Valve- Relief (on Condenser) 225# 735045829 2

080 Valve- Angle 332471701 2

O-Ring, ORFS 1 735043662 2

O-Ring, SAE 1 735073624 2

081 Cap- Tube End 070789347 2

082 Fitting 735043925 2

083 Fitting- Swivel 735043954 2

1

O-Ring(s) are furnished standard with all ttings. Order additional O-Rings if needed. ORFS Style O-Rings seat on the

face end of the tting. SAE style O-Rings seat at the base of the tting.

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 29

Page 30

Unit Assembly

Discharge Piping Stack

See Suction Piping

136

135

126

132

022 147

127

022 128

125 126

Qty.=2

Ref.

No. Description Part No. Qty.

022 Nut 735029626 24

125 Valve- Check 8.0" 333283103 1

126 Gasket 070199040 3

127 Weld Flange 735031835 2

128 Screw .75 x 8.5" 735034137 8

132 Elbow- 90 Degree 8.0" 331554301 1

135 Nozzle- Discharge 331553702 1

136 O-Ring 330198643 1

147 Bolt 3/4-10 x 3.25" 735033966 8

1

Quantity per Discharge Piping Stack.

1

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 30

Page 31

Unit Assembly

Range Extension

024

026

022

020

034

004

003

002

020

022

024

026

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 31

Page 32

Unit Assembly

Range Extension

Ref.

No. Description Part No. Qty.

002 Core- Schrader Valve 026541100 4

003 Valve- Schrader 071100801 4

004 Cap- Schrader Valve 032943500 4

020 Kit- Flange 2 735016403 4

022 Adapter 735049702 4

024 Gasket- Flange 070199112 4

026 Screw- Flange .62 x 2.50" 735033864 16

034 Valve- Expansion 250T 330386205 2

Motor- Expansion Valve 330386209 2

Sight Glass- Expansion Valve 300043182 2

2

The Flange Kit does NOT contain a gasket. If a gasket is required, order Ref # 024 p/n 070199112.

Also, DO NOT use the screws that come with this Flange Kit. If screws are required, order 4pc. of

Ref # 026 p/n 735033864.

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 32

Page 33

084

088

086

085

087

Unit Assembly

Suction and Discharge Piping

092

136

093

094

Ref.

No. Description Part No. Qty.

084 Screw M10- 1.5 x 50mm 735036546 18

085 Screw- Stainless Steel .38 -16 x 1.75" 331353707 12

086 Elbow- Suction 90 Degree 331352003 1

087 O-Ring 1 070194992 1

088 O-Ring 1 350233017 1

092 Screw .50 x 3.5" 735033967 8

093 Washer 040500313 8

094 Nut 735029626 8

136 O-Ring 330198643 1

1

Included in Compressor O-Ring Kit p/n 300049073. One kit per Compressor.

2

Quantity per Suction & Discharge Piping.

2

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 33

Page 34

027

002

Unit Assembly

Liquid Injection

022

021

003

004

029

003

002

031

004

Ref.

No. Description Part No. Qty.

002 Core- Schrader Valve 026541100 2

003 Valve- Schrader 071100801 2

004 Cap- Schrader Valve 032943500 2

021 Fitting- ORFS to Braze Sleeve 070789351 1

O-Ring 1 070194968 1

022 Nut- Braze Sleeve 070789354 1

027 Valve- Solenoid .875" 735048473 1

N/S Coil- Solenoid Valve 24VDC 331796054 1

029 Strainer 735030501 1

031 Valve- Ball .875" 330286084 1

1

O-Ring(s) are furnished standard with each tting. Order additional O-Rings if needed.

2

Quantity per Liquid Injection Line.

2

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 34

Page 35

Unit Assembly

Rotor Cooling

111

112

111

112

120

112

115

160

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 35

Page 36

Unit Assembly

Rotor Cooling Components

Ref. Description Part

No. Number Qty.

111 Fitting- ORFS to Braze Sleeve 070789351 2

O-Ring 1 070194968 2

112 Nut- Braze Sleeve 070789354 3

115 Fitting- Reducer Sleeve 070789391 1

O-Ring 1 070194968 1

120 Valve- Solenoid 331796003 1

160 Valve- Ball .375" 330286001 1

1

O-Ring(s) are furnished standard with each tting. Order additional O-Rings if needed.

2

Quantity per Rotor Cooling Line.

2

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 36

Page 37

Unit Assembly

Stator Cooling

023

026

022

020

028

029

045

002

004

Stator Cooling Return

003

036

045046

046

045

046

Stator Cooling Supply

003

002

004

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 37

030

052

Page 38

Unit Assembly

Stator Cooling- Components

Ref. Description Part

No. Number Qty.

002 Core- Schrader Valve 026541100 2

003 Valve- Schrader 071100801 2

004 Cap- Schrader Valve 032943500 2

020 Fitting- Elbow ORFS to SAE 332471617 1

O-Ring, ORFS 1 070194968 1

O-Ring, SAE 1 070194980 1

022 Fitting- ORFS to Braze Sleeve 070789351 1

O-Ring 1 070194968 1

023 Nut- Braze Sleeve 070789354 1

026 Valve- Solenoid 331796002 1

N/S Coil- Solenoid Valve 24VDC 331796052 1

028 Fitting- Sleeve ORFS 070789361 1

O-Ring, ORFS 1 735073640 1

029 Fitting- Nut 070789360 1

030 Filter Drier 735028828 1

036 Valve- Ball .625" 330286003 1

045 Fitting- ORFS to Braze Sleeve 070789316 3

O-Ring, ORFS 1 735073650 3

046 Fitting- Nut ORFS 070789310 3

O-Ring, ORFS 1 735073650 3

052 Valve- Ball .875" 330286084 1

1

O-Ring(s) are furnished standard with each tting. Order additional O-Rings if needed. ORFS Style

O-Rings seat on the face end of the tting. SAE style O-Rings seat at the base of the tting.

2

Quantity per Stator Cooling Line.

2

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 38

Page 39

Unit Assembly

VFD Cooling

031

021 022

003 004

002

VFD Cooling Return

031

003 004

002

012

002

003 004

021 022

021 022

002

003

004

002

003

004

VFD Cooling Supply

021 022

031

018

012

002

003

004

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 39

Page 40

Unit Assembly

VFD Cooling

Ref. Description Part Qty.

No. Number

002 Core- Schrader Valve 026541100 6

003 Valve- Schrader 071100801 6

004 Cap- Schrader Valve 032943500 6

012 Valve- Ball 1.375" 330286086 4

018 Strainer 1.375" 735030536 2

021 Fitting- ORFS to Braze Sleeve 070789351 4

O-Ring 1 070194968 2

022 Nut- Braze Sleeve 070789354 4

031 Valve, Ball .875 330286084 4

1

O-Ring(s) are furnished standard with each tting. Order additional O-Rings if needed.

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 40

Page 41

Unit Assembly

Liquid Line- Diagrams

060B

060A

060E

060D

060C

022

080

021

081

101

102

100

See

Expansion

Valve

section

022

020

024

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 41

104

021

Page 42

Unit Assembly

Liquid Line- Components

Ref. Description Part Qty.

No. Number

020 Coupling- Adapter 071901601 1

021 Flange 071992102 2

022 Gasket 735073403 2

024 Strainer 070977802 1

060A Saddle- Sight Glass 330743304 1

060B Cap- Sight Glass 330508701 1

060C Valve- Schrader 071100801 1

060D Core- Schrader Valve 026541100 1

060E Cap- Schrader Valve 032943500 1

080 Coupling Adapter 071900701 1

081 Bolt .625 x 3.25" 735033966 4

100 O-Ring 735073630 1

101 Screw .75 x 3.0" 735033878 4

102 Washer, Lock 048164816 4

104 Screw .75 x 3.5" 735033967 4

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 42

Page 43

Unit Assembly

Expansion Valve

115

121

105

103

127

125

126

Ref. Description Part Qty.

No. Number

102 Bearing 735014129 2

103 Seal 735234327 1

105 Check Valve 735040316 1

112 Flex Coupling 332778402 1

115 Motor, Stepper/IGV 331353601 1

119 Site Glass (on Motor Cover) 015997816 1

121 O-Ring 735043639 1

125 Expansion Valve Body 332935601 1

126 Site Glass (on Body) 332674501 1

127 O-Ring (between Body and Base) 735073633 1

128 O-Ring (between Base and Motor Cover) 735043674 1

102

102

128

119

112

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 43

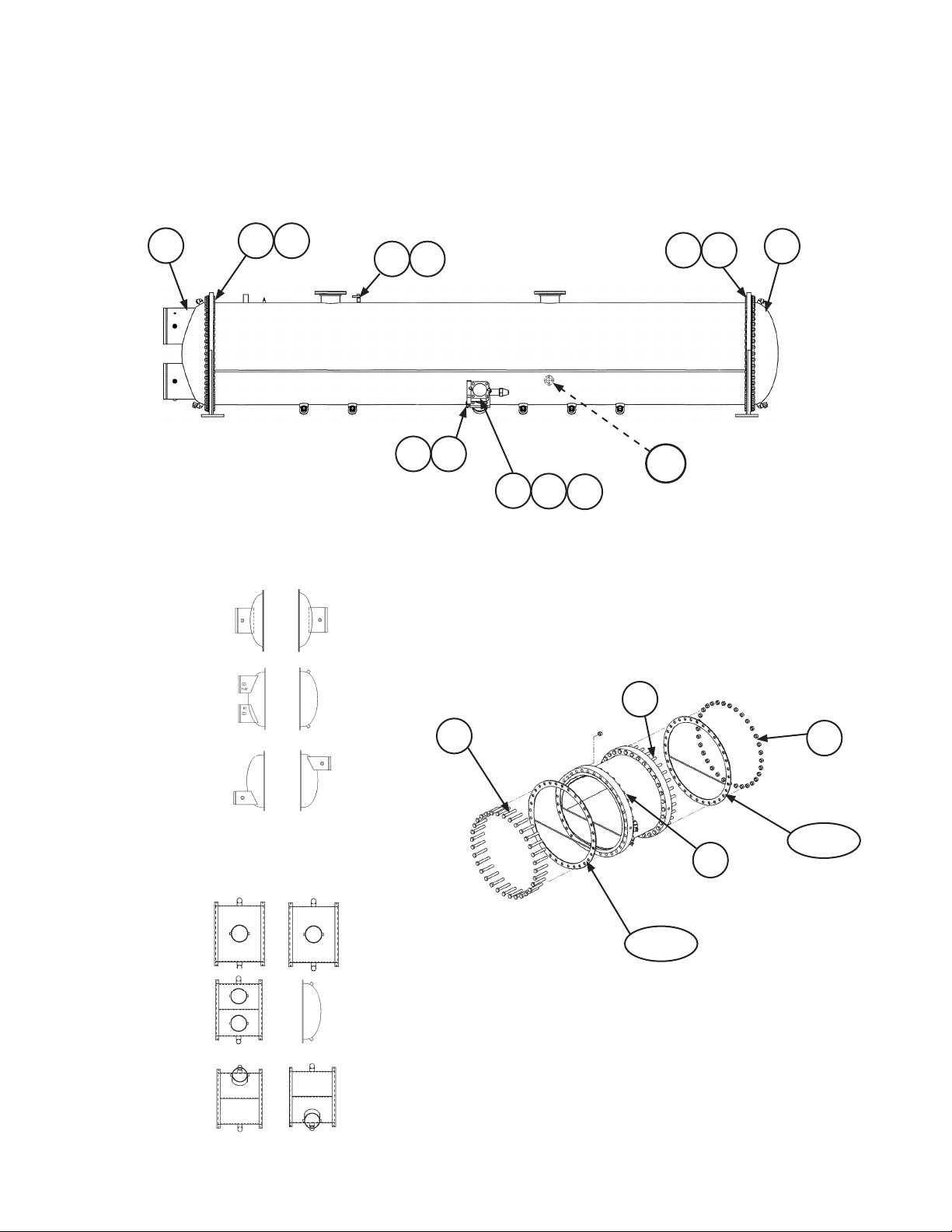

Page 44

352

353 354

Condenser

Diagrams

2-Pass Condenser shown

Rear View

331330

353 354

355

Dish Head, Grooved

Entering

Return

1- Pass

2- Pass

3- Pass

Water Box Head, Grooved

Entering

Return

331330

Screw

353

251

252

110A

253

Water Box Head

Screw

353

(Located on the front side

of the Condenser)

Condenser End

354

Nut

352/355

354

Nut

Gasket

Cover End

1- Pass

352/355

Gasket

2- Pass

3- Pass

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 44

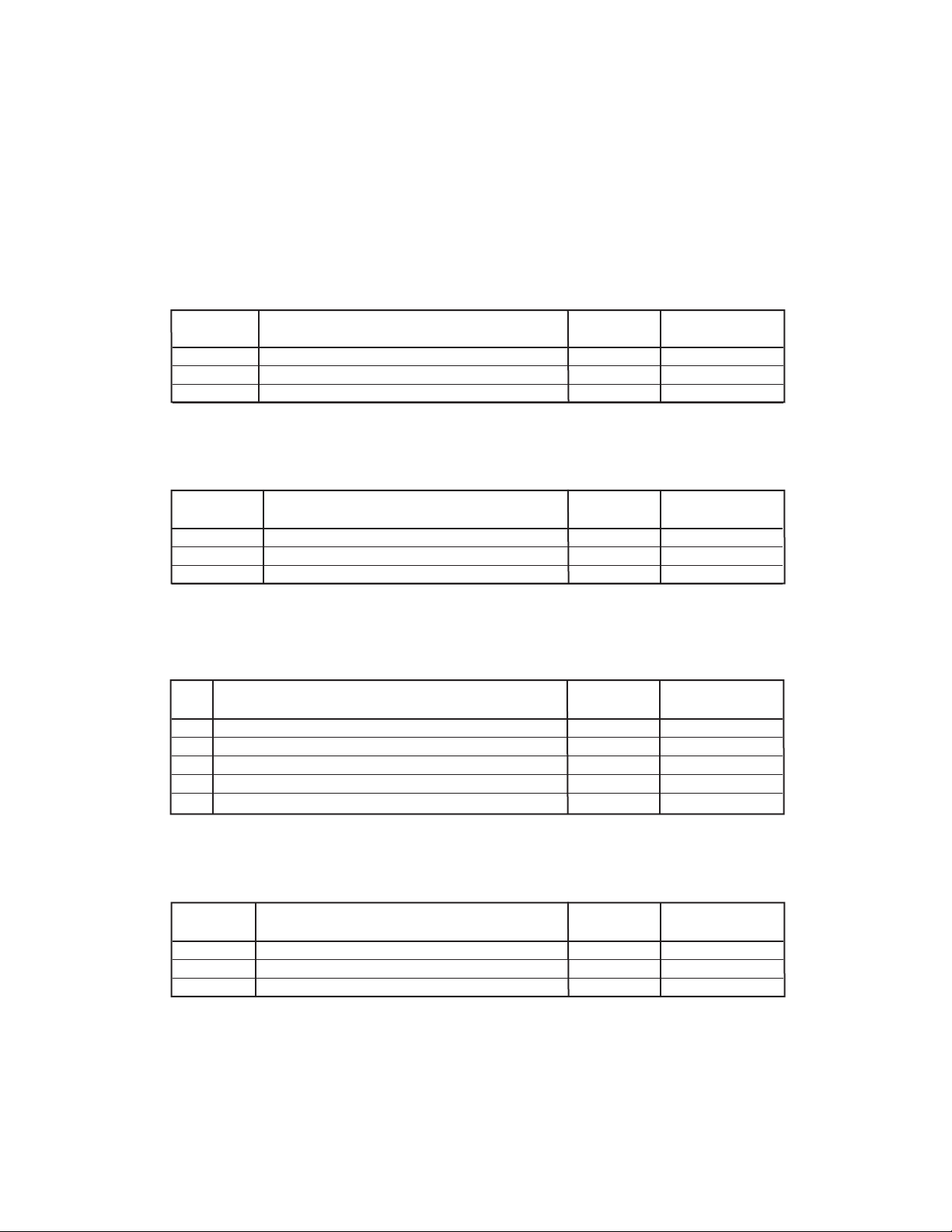

Page 45

Condenser

42 Inch - Dish Head Gaskets & Hardware

150 PSIG non-ASME (Code 43=4)

Carbon Steel tube sheet and heads (Codes 46 & 47 = C)

1 Pass, Dish Heads

Ref. Description Part Quantity

No. Number

352/355 Gasket - Dish Head 334721707 2

353 Screw .75 x 3.5" 735033966 80 per head

354 Nut 735029626 80 per head

2 Pass, Dish Heads

Ref. Description Part Quantity

No. Number

352 Gasket - Dish Head, Entering Side 334825861 1

353 Screw .75 x 3.5" 735033966 80 per head

354 Nut 735029626 80 per head

355 Gasket- Dish Head, Return Side 334721707 1

3 Pass, Dish Heads

Ref. Description Part Quantity

No. Number

352/355 Gasket - Dish Head 334825861 2

353 Screw .75 x 3.5" 735033966 80 per head

354 Nut 735029626 80 per head

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 45

Page 46

Condenser

42 Inch - Water Box Head Gaskets & Hardware

150 PSIG non-ASME (Code 43=4)

Carbon Steel tube sheet and heads (Codes 46 & 47 = C)

1-Pass, Water Box Heads with Top Nozzle (Code 40=D)

Ref. Description Part Quantity

No. Number

352/355 Gasket - Water Box Head 334721707 4

353 Screw .75 x 6.0" 735033972 80 x 4

354 Nut 735029626 80 x 4

1-Pass, Water Box Heads with Front Nozzle (Code 40=F)

Ref. Description Part Quantity

No. Number

352/355 Gasket - Water Box Head 334721707 4

353 Screw .75 x 6.0" 735033972 80 x 4

354 Nut 735029626 80 x 4

1

1

1

1

2-Pass, Water Box Heads with Front Nozzle (Code 40=J)

Ref. Description Part Quantity

No. Number

352 Gasket - Water Box Head, Entering Side 334825863 2

353 Screw for Water Box Head .75 x 6.0" 735033972 80 x 2

1

Screw for Dished Head .75 x 3.5" 735033966 56

354 Nut 735029626 80 x 3

1

355 Gasket- Dished Head, Return Side 334721707 1

3-Pass, Water Box Heads with Front Nozzle (Code 40=J)

Ref. Description Part Quantity

No. Number

352/355 Gasket - Water Box Head 334825863 4

353 Screw .75 x 6.0" 735033972 80 x 4

354 Nut 735029626 80 x 4

1

Each Water Box Head has 2 sets of screws and nuts. There are 80 screws + 80 nuts for the water box cover,

and 80 screws + 80 nuts at the connection of the head to the condenser. See Condenser diagrams.

1

1

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 46

Page 47

Condenser

Sight Glass, Shut Off Valve & Gasket,

Charge Valve

Sight Glass, Shut Off Valve & Gasket, Charge Valve & Cap

Ref. Description Part Qty.

No. Number

110A Sight Glass 1.0" MPT 350229502 1

251 Valve- Shut Off (King Valve) 4.0" 735039809 1

252 Screw- Shut Off Valve .75 x 7.0 735033974 4

253 Gasket- Shut Off Valve 070199106 1

330 Valve- Charge 332480201 2

O-Ring for Charge Valve 735073634 2

331 Cap- Charge Valve 073243901 2

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 47

Page 48

Evaporator

Diagrams

2-Pass Evaporator shown

Rear View

352

Dish Head, Grooved

353 354 353 354

Entering

1- Pass

Return

331330

110A

(Located on the front side

of the Evaporator)

Water Box Head

355

331330

2- Pass

3- Pass

Water Box Head, Grooved

Entering

Return

1- Pass

2- Pass

3- Pass

Screw

353

Cover end

Screw

353

352/355

Gasket

354

Nut

Condenser end

354

Nut

352/355

Gasket

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 48

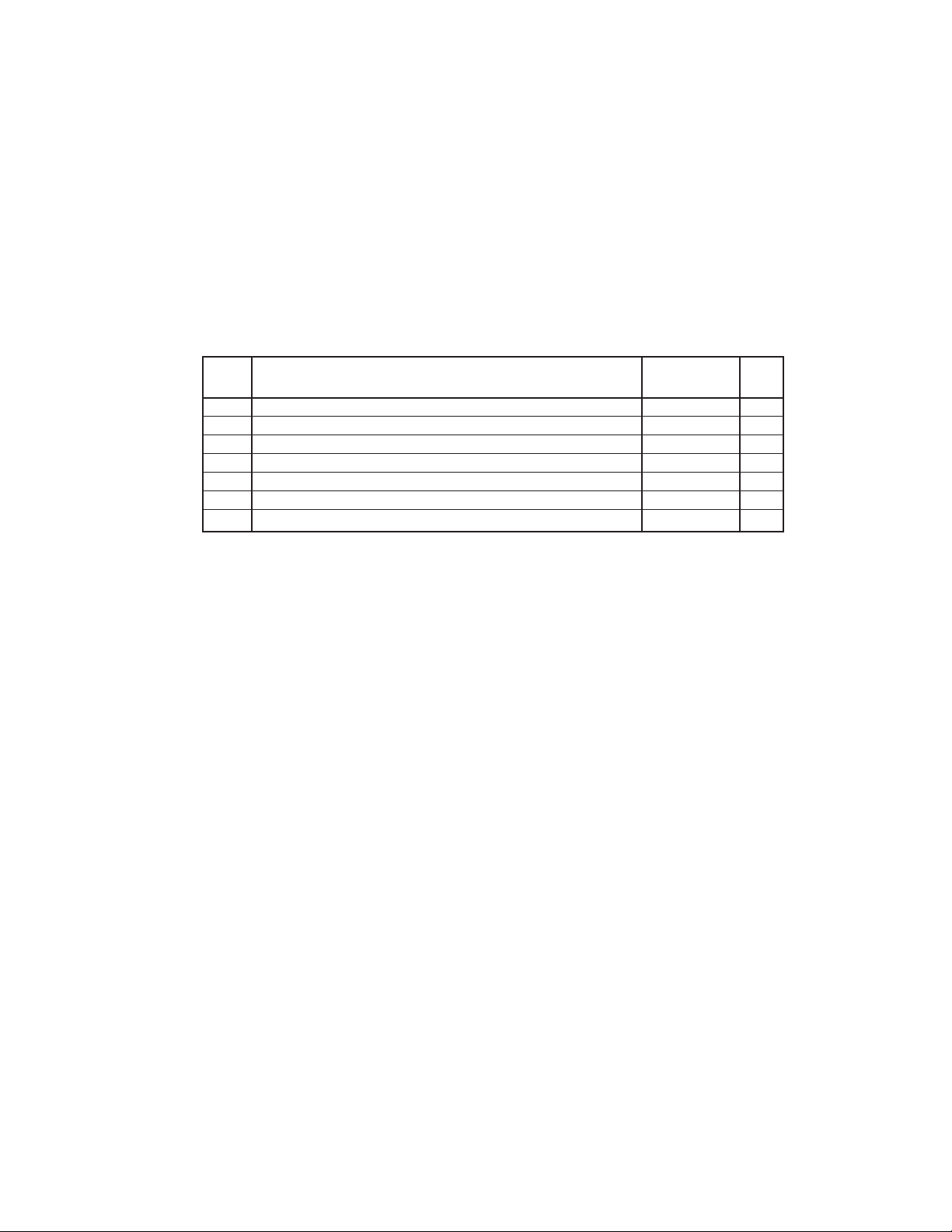

Page 49

Evaporator

48 Inch - Dish Head Gaskets & Hardware

150 PSIG non-ASME (Code 21=4)

Carbon Steel tube sheet and heads (Codes 24 & 25 = C)

1 Pass, Dish Heads

Ref. Description Part Quantity

No. Number

352/355 Gasket - Dish Head 334721708 2

353 Screw .75 x 3.5" 735033967 96 per head

354 Nut 735029626 96 per head

2 Pass, Dish Heads

Ref. Description Part Quantity

No. Number

352 Gasket - Dish Head, Entering Side 334825871 1

353 Screw .75 x 3.5" 735033967 96 per head

354 Nut 735029626 96 per head

355 Gasket- Return Head 334721708 1

3 Pass, Dish Heads

Ref. Description Part Quantity

No. Number

352/355 Gasket - Dish Head 334825871 2

353 Screw .75 x 3.5" 735033967 96 per head

354 Nut 735029626 96 per head

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 49

Page 50

Evaporator

48 Inch - Water Box Head Gaskets & Hardware

150 PSIG non-ASME (Code 21=4)

Carbon Steel tube sheet and heads (Codes 24 & 25 = C)

1-Pass, Water Box Heads with Top Nozzle (Code 18=D)

Ref. Description Part Quantity

No. Number

352/355 Gasket - Water Box Head 334721708 4

353 Screw .75 x 6.5" 735033973 96 x 4

354 Nut 735029626 96 x 4

1-Pass, Water Box Heads with Rear Nozzle (Code 18=E)

Ref. Description Part Quantity

No. Number

352/355 Gasket - Water Box Head 334721708 4

353 Screw .75 x 6.5" 735033973 96 x 4

354 Nut 735029626 96 x 4

1

1

1

1

2-Pass, Water Box Heads with Rear Nozzle (Code 18=H)

Ref. Description Part Quantity

No. Number

352 Gasket - Water Box Head, Entering Side 334825872 2

353 Screw for Water Box Head .75 x 6.5" 735033973 96 x 2

1

Screw for Dished Head .75 x 3.5" 735033967 96

354 Nut 735029626 96 x 3

1

355 Gasket- Dished Head, Return Side 334721708 1

3-Pass, Water Box Heads with Rear Nozzle (Code 18=H)

Ref. Description Part Quantity

No. Number

352 Gasket - Water Box Head, Entering Side 334825872 2

355 Gasket - Water Box Head, Opposite Side 334825873 2

353 Screw .75 x 6.5" 735033973 96 x 4

354 Nut 735029626 96 x 4

1

Each Water Box Head has 2 sets of screws and nuts. There are 96 screws + 96 nuts for the water box cover,

and 96 screws + 96 nuts at the connection of the head to the evaporator. See Evaporator diagrams.

1

1

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 50

Page 51

Evaporator

Sight Glass & Charge Valve

Sight Glass, Charge Valve & Cap

Ref. Description Part Qty.

No. Number

110A Sight Glass 1.0" MPT 350229502 1

330 Valve- Charge 332480201 2

O-Ring for Charge Valve 735073634 2

331 Cap- Charge Valve 073243901 2

WME1500DB- Water Cooled Chiller New 09/15 RPL 7000517 / Page 51

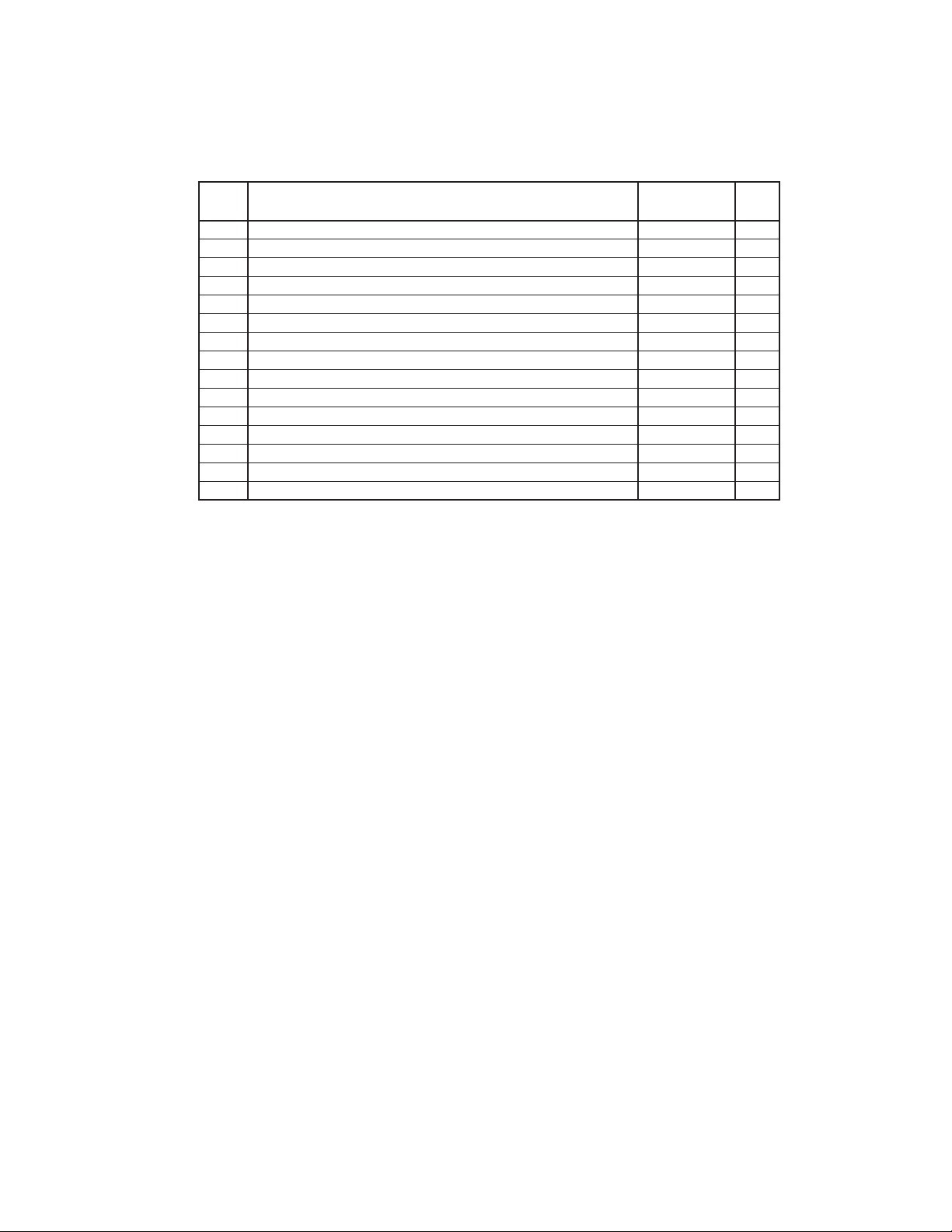

Page 52

Critical Daikin Applied OEM Parts

Are What Your HVAC Unit Needs!

Daikin MagnitudeTM Centrifugal Chiller

WME

1500

Critical Components UNIT SIZE Voltage Part Number

Sensors

S01 - Evap Entering Water Temp 1500 ALL 073007203

S02 - Evap Leaving Water Temp 1500 ALL 073007203

S05 - Cond Entering Water Temp 1500 ALL 073007203

S06 - Cond Leaving Water Temp 1500 ALL 073007203

S07 - Cond Refrigerant Pressure 1500 ALL 071568621

S09 - Liquid Line Temp 1500 ALL 073007203

S10 - Compr Suction Temp 1500 ALL 331582801

S11 - Compr Suction Pressure 1500 ALL 071568521

S12 - Compr Discharge Temp 1500 ALL 331582801

S13 - Compr Discharge Pressure 1500 ALL 071568621

S14 - Motor Gap Temp 1500 ALL 331795205

Switches

S04 - Switch, Evap Entering Flow 1500 ALL 331796201

S08 - Switch, Cond Entering Flow 1500 ALL 331796201

S15 - Switch, High Pressure 1500 ALL 074796301

VFD Controls

Wire Harness/Cable Kit 1500 ALL 300055446

Fuse, 20A/1000VAC 1500 ALL 300047094

Fuse, 600A/700V 1500 ALL 300047092

Fuse, 20A/800V 1500 ALL 300048941

Fuse, Power Supply Plate F1-2, F8-10 1500 ALL 300047089

Fuse, Power Supply Plate F3-5 1500 ALL 300047090

Fuse, Power Supply Plate F6-7 1500 ALL 300046902

Compressor O-Ring Kit

Compressor O-Ring Kit (one kit per compr) 1500 ALL 300049073

Call Your Local Daikin Applied Parts Distributor For All Your Parts Needs.

To Locate A Distributor, Go To www.DaikinApplied.com or Call 1-800-37PARTS

7000516 New 09/2015 CPL Page 1 of 1

Loading...

Loading...