Page 1

Replacement Parts List No. 700029400

Revision B 10/2015

Daikin

Magnitude™

Magnetic Bearing Compressor

Centrifugal Chiller

WMC

125S, 145S, 200S

145D, 150D, 225D, 250D, 275D, 290D

Vintage C

To nd your Daikin Applied parts distributor, call 1-800-377-2787 or visit www.DaikinApplied.com

Page 2

Contents

Parts List Revision History ..................................................................................................................... 3

Complete Model Nomenclature ........................................................................................................ 4 - 6

Electrical Legend ................................................................................................................................... 7

Unit Components .............................................................................................................................. 8 - 9

Magnetic Bearing Compressor ..................................................................................................... 10 - 14

Piping - Discharge ............................................................................................................................... 15

Piping - Liquid Line and Motor Cooling................................................................................................ 16

Condenser- Dish Heads ............................................................................................................... 17 - 19

Condenser- Water Box Heads ...................................................................................................... 20 - 22

Evaporator- Dish Heads .............................................................................................................. 23 - 25

Evaporator- Water Box Heads ..................................................................................................... 26 - 30

Evaporator Insulation ........................................................................................................................... 31

Unit Controls:

Operator Interface Panel ............................................................................................................. 32

Unit Control Box ................................................................................................................... 33 - 34

Power Panel ......................................................................................................................... 35 - 38

Control Box Label ........................................................................................................................ 39

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 2

Page 3

Parts List Revision History

Revision Date Description

NEW 10/2014 New

A 09/2015 Pages 4-6: Added Tube Counts to Codes 11 & 29, causing other codes to expand

onto other pages.

Page 34: Corrected description for p/n 350147407, was BACnet w/RS485 Ethernet.

B 10/2015 Pages 18,19,21,22,24,25,27-30: Added note to contact D. A. for coated Heads.

Daikin Applied, 13600 Industrial Park Blvd., P.O. Box 1551, Minneapolis, MN 55440 (763) 553-5330

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 3

Page 4

Complete Model NomenclatureComplete Model Nomenclature

WMC 250D C SN 15 00460 H6 D D E2609 HB 2 C DK L 2 V C N C 4

Code 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 etc.

02 Size (in nominal tons)

125S= 125 Tons, Single Compressor

145S= 145 Tons, Single Compressor

145D= 145 Tons, Dual Compressors

150D= 150 Tons, Dual Compressors

200D= 200 Tons, Single Compressor

225D= 225 Tons, Dual Compressors

250D= 250 Tons, Dual Compressors

275D= 275 Tons, Dual Compressors

290D= 290 Tons, Dual Compressors

03 Vintage

C= Vintage C

04 Conguration

SN= Single Refrigerant Circuit w/o Economizer

05 Compessor Size

13= Unit sizes 145D, 150D

14= Unit sizes 125S, 225D, 275D

15= Unit sizes 145S, 250D, 290D

25= Unit size 200S

06 Power Supply Voltage

00380= 380V

00400= 400V

00415= 415V

00460= 460V

00575= 575V

07 Power Supply Hertz

H5= 50 Hertz

H6= 60 Hertz

12 Evaporator Tube Thickness

2= 0.025

3= 0.028

5= 0.035

13 Evaporator Tube Type

C= Copper

N= CuproNickel 90/10

14 Evaporator Tube Model

15 Evaporator Inlet Nozzle Location

L= Left

R= Right

16 Evaporator Water Passes

1= 1 Pass

2= 2 Pass

3= 3 Pass

17 Evaporator Inlet Nozzle Connection Type

V= Groove

F= Flanged

18 EvaporatorInletNozzleConguration

A= Dish, End (Non-Directional Flow)

C= Dish, End (Over/Under Flow)

D= Water Box, Top (Non-Directional Flow)

E= Water Box, Rear (Non-Directional Flow)

F= Water Box, Front (Non-Directional Flow)

H= Water Box, Rear (Over/Under Flow)

J= Water Box, Front (Over/Under Flow)

08 Always D

09 Compressor Model Revision

D= Compressor Revision D

10 Evaporator Shell Diameter & Length

E2209= 22" Diameter, 9' Length

E2212= 22" Diameter, 12' Length

E2609= 26" Diameter, 9' Length

E2612= 26" Diameter, 12' Length

11 EvaporatorTubeConguration&Count

22" Evap Diameter

HB=140 (3/4" all)

RD=159 (3/4"=qty of 130, 1"=qty. of 29)

UD=109 (3/4"=qty of 66, 1"=qty. of 43)

YE=72 (1" all)

26" Evap Diameter

HB=196 (3/4" all)

RD=203 (3/4"=qty of 152, 1"=qty. of 51)

TD=176 (3/4"=qty of 125, 1"=qty. of 51)

UD=151 (3/4"=qty of 100, 1"=qty. of 51)

YE=106 (1" all)

19 Evaporator Hinged Type

N= None

H= Standard Hinged on Both Ends

20 Evaporator Refrigerant Design Pressure

C= 200 PSIG

21 Evaporator Water Side Design Pressure

4= 150 PSIG - Non-ASME Code

22 Evaporator Leaving Water Temperature

Example: 440F = 44.0 degrees F

23 Evaporator GPM

Example: 00580 = 580 GPM

24 Evaporator Tube Sheet Coating/Material

C= Carbon Steel

E= Enecon Coating - Outside of Tube Sheet

25 Evaporator Head/Water Box Coating/Material

C= Carbon Steel

E= Enecon Coating - Inside of Head

D= Devcon Coating - Inside of Head

26 Always N

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 4

Page 5

Complete Model Nomenclature

27 Evaporator Model Revision

28 Condenser Shell Diameter & Length

C2009= 20" Diameter, 9' Length

C2012= 20" Diameter, 12' Length

C2209= 22" Diameter, 9' Length

C2212= 22" Diameter, 12' Length

29 CondenserTubeConguration&Count

20" Cond Diameter

GB=248 (3/4" all)

HB=214 (3/4" all)

JB=150 (3/4" all)

22" Cond Diameter

GB=300 (3/4" all)

HB=263 (3/4" all)

26" Cond Diameter

GB=426 (3/4" all)

HB=381 (3/4" all)

30 Condenser Tube Thickness

2= 0.025

3= 0.028

5= 0.035

31 Condenser Tube Type

C= Copper

N= CuproNickel 90/10

S= Stainless Steel

T= Titanium

32 Condenser Tube Model

33-35 Always N

36 Always NN

37 Condenser Inlet Nozzle Location

L= Left

R= Right

38 Condenser Water Passes

1= 1 Pass

2= 2 Pass

3= 3 Pass

39 Condenser Inlet Nozzle Connection Type

V= Groove

F= Flanged

40 CondenserInletNozzleConguration

A= Dish, End (Non-Directional Flow)

C= Dish, End (Over/Under Flow)

E= Water Box, Rear (Non-Directional Flow)

F= Water Box, Front (Non-Directional Flow)

H= Water Box, Rear (Over/Under Flow)

J= Water Box, Front (Over/Under Flow)

41 Condenser Hinged Type

N= None

H= Standard Hinged on Both Ends

42 Condenser Refrigerant Design Pressure

C= 200 PSIG

43 Condenser Water Side Design Pressure

4= 150 PSIG - Non-ASME Code

44 Condenser Leaving Water Temperature

Example: 1050F = 105.0 degrees F

45 Condenser GPM

Example: 00725 = 725 GPM

46 Condenser Tube Sheet Coating/Material

C= Carbon Steel

E= Enecon Coating - Outside of Tube Sheet

M= Monel Clad

S= Stainless Steel Clad

T= Titanium Clad Steel

47 Condenser Head/Water Box Coating/Material

C= Carbon Steel

E= Enecon Coating - Inside of Head

D= Devcon Coating - Inside of Head

48-49 Always N

50 Always NN

51 Condenser Model Revision

52 Pressure Vessel Code

A= ASME

53 Unit Tons

Example: 0150= 150 Tons

54 Refrigerant

A= Refrigerant 134a

55 Refrigerant Weight

example: 0700= 700 Pounds

56 Expansion Valve

S1= Electronic Expansion Valve, single actuator, 150T

S3= Electronic Expansion Valve, single actuator, 300T

57 Controller Type

3L= Microtech II, pCO3 (Large)

58 Controller Language

E= English

59 Controller Rapid Restore

N= None

R= Rapid Restore

60 Controller Communications

N= None

B= BACnet MS/TP

L= LonMark

M= ModBus

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 5

Page 6

Complete Model Nomenclature

61 Power Box & Unit Controller Box Type

A= NEMA 1

62 Rated Load Amps (RLA) - Compressor

Example: 01020= 102.0 Amps

63 Power Box - Box Type

S= Single Point, Single Box w/Metal Compressor Conduits

M= Multi Point, Single Box w/Metal Compressor Conduits

64 Power Connection Type

D= Disconnect Switch

P= Power Block

65 EMI Filter

N= None

P= EMI Filter

66 Always N

67 Short Circuit Ratings

S= Standard Short Circuit Current Rating, 35KA

H= High Short Circuit Current Rating, 65KA

68 Ground Fault Protection

Y= None

F= With Ground Fault Protection

69 Harmonic Filter

N= None

M= Unit Mounted Harmonic Filter

91-95 Warranty

96-98 Miscellaneous

99 Unit Model Revision

B= Revision Level B

100 Unit kW

Example: 02487= 248.7 kW

101 Miscellaneous

102 Isolation Valves

WV= With Suction Shut-off Valves

and Discharge Check Valve

70 Part Load Balancing Valve

N= None

B= Part Load Balancing Valve

71 Always N

72 Evaporator Insulation - Shell Insulation

N= None

H= 3/4" insulation on Evap Shell, Suction Piping,

Compressor Inlet, Motor Barrel

3= 1-1/2" insulation on Evap shell, Suction

Piping, Compr Inlet, Mtr Barrel

73 Evaporator Insulation - Head Insulation

N= None

2= Evaporator Return and Connection Heads Insulated

74 Factory Water Flow Indication

B= Both Evaporator and Condenser Flow Control

75-77 Miscellaneous

78 Special

N= None

X= Special

79-90 Miscellaneous

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 6

Page 7

Electrical Legend

A ....................................Alarm

B .................................... Analog Input Connections

CB.................................. Circuit Breaker

CF .................................. Condenser Flow Switch

CNT ............................... Contactor

CP1, 2............................ Condenser Pump Cycling Relay

CPB ............................... Capacitor Bank

CT1-4............................. Cooling Tower Relay Stages 1-4

CTB1 ............................. Terminal Block

CWI ................................ Condenser Water Interlocks

DS.................................. Disconnect Switch

EFS................................ Evaporator Flow Switch

EMI ................................ Electro-Magnetic Interference Filter

EP1, 2 ............................ Evap Pump Cycling Relay 1, 2

EWI ................................ Evaporator Water Interlocks

EXV ............................... Electronic Expansion Valve

EXVB ............................. Electronic Expansion Valve Board

F .................................... Fuse

FB .................................. Fuse Block

GFP ............................... Ground Fault Protector

GND ............................... Ground

HF .................................. Harmonic Filter

ID ................................... Digital Input Connections

IR ................................... Isolation Relay

I/O CM ........................... Input/Output Compr Module

K1T ................................ Time Delay Relay

K1V

................................ Surge Relay

K1R................................ Harmonic Filter 1 Relay

K2R................................ Harmonic Filter 2 Relay

LBV

....................................Load Balance Valve

LR ......................................Line Reactor

...................................High Ambient Fan

M1T

OILR ..................................Optically Isolated Line Repeater

R1V....................................Surge Absorber

S1T

....................................High Ambient Fan Thermostat

SPPB .................................Single Point Power Block

...................................Unit Start/Stop Switch

SW1

SW2 ...................................Compressor Manual Stop Switch

SW3 ...................................Remote Start/Stop Switch

SW4

...................................Mode Switch

SW5 ...................................Emergency Stop Switch

......................................Transformer (120VAC)

T1

T2 ......................................Transformer (24VAC)

T3

......................................Transformer (24VAC)

......................................Transformer (24VAC)

T4

T5

......................................Transformer (24VAC) / Isolation

...................................Terminal Block

TB1

TRTS .................................Trap Reactor Thermal Switch

UC

.....................................Unit Controller

..................................Unit Communication Module

UCM

UTB1

.................................Terminal Block

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 7

Page 8

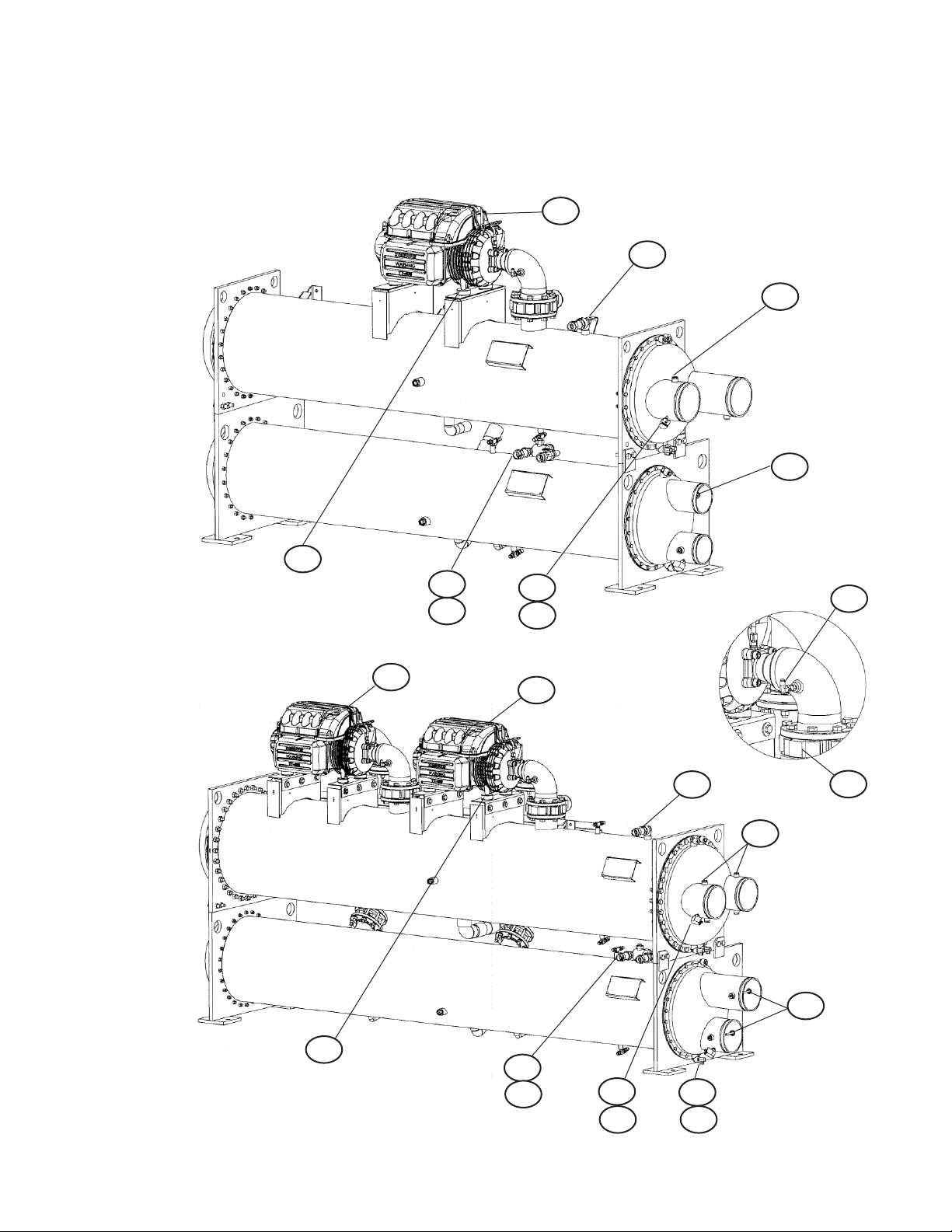

Unit Components

001

F033

H030

H030

Single Circuit

WMC145S

A020

001

F021

F034

H020

H021

001

F033

F030

A050

H030

H030

Dual Circuit

WMC 290D shown

A020

F021

F034

H020

H021

H020

H021

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 8

Page 9

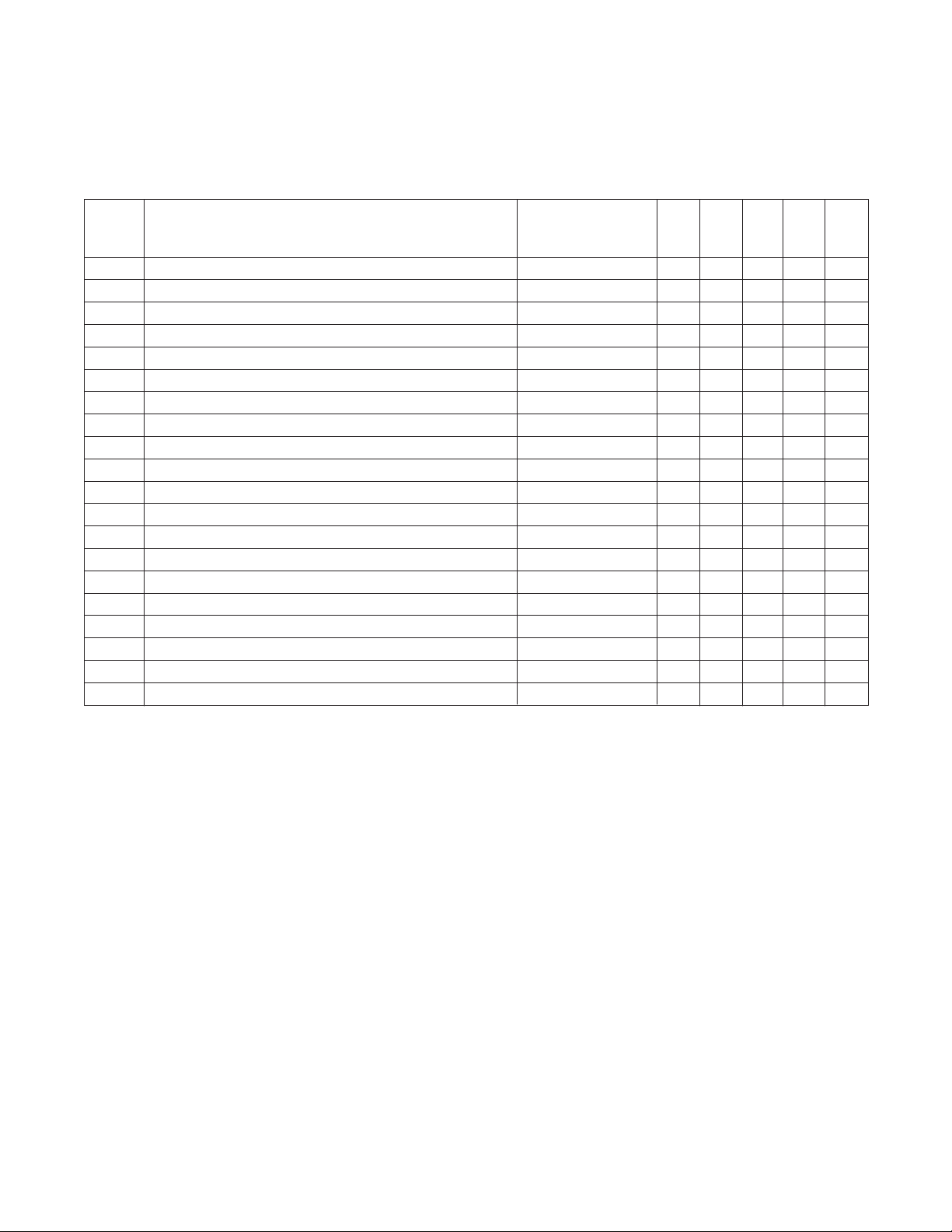

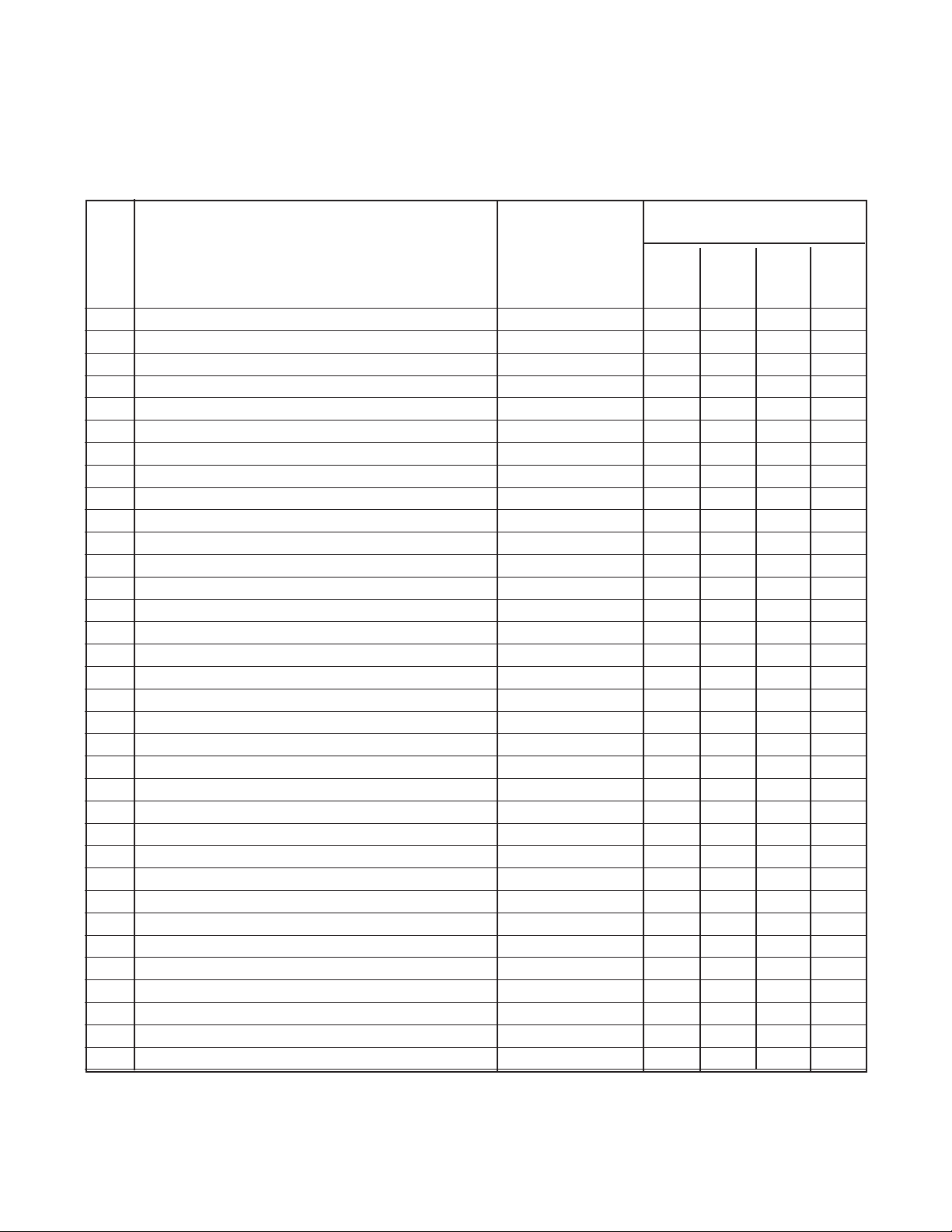

Unit Components

125S 225D

145S 250D

Ref. # Description Part Number 200S 145D 150D 275D 290D

001 Compressor See Note

A020 Compressor Isolator 330527701 4 8 8 8 8

A050 Buttery Valve 073062121 1 2 2 2 2

F021 Shut Off Valve 735039964 1 1 1 1 1

F030 Relief Valve, 200#, Angle 735045818 1 2 2 2 2

F033 Relief Valve, 200# 735045817 1 1 1 1 1

F034 Relief Valve, 200# 735045817 2 2 2 2 2

H020 Flow Sensor 330571401 2 2 2 2 2

H021 Cable, Flow Sensor 330571402 2 2 2 2 2

H030 Sensor Well 047441511 4 4 4 4 4

Note: Contact Daikin Applied with the compressor model, compressor part number, compressor serial number

and BMCC revision. On dual compressor units, provide same information on other compressor to ensure

BMCC compatibility.

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 9

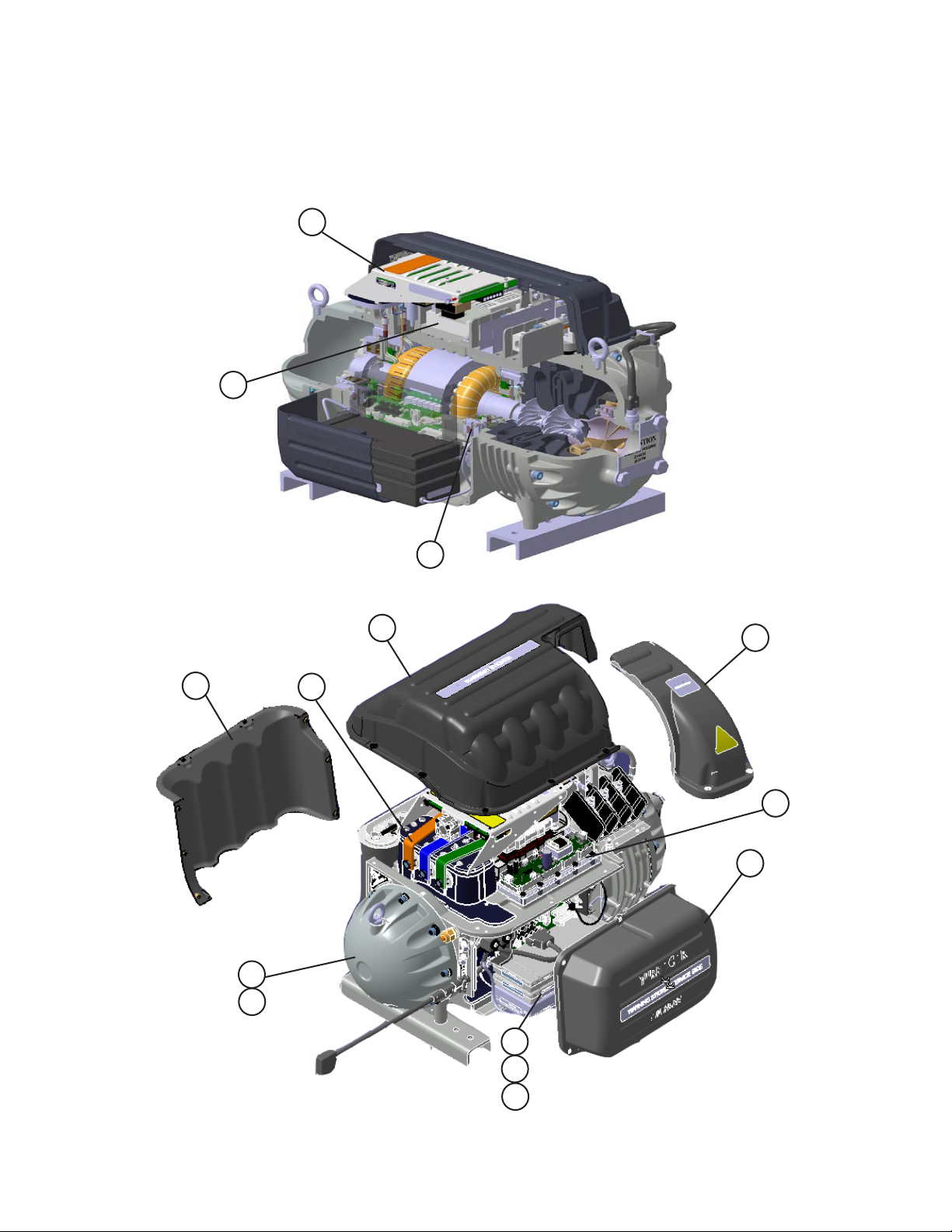

Page 10

017

Magnetic Bearing Compressor

013

011

006

007

016

008

004

010

003

009

002

012

014

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 10

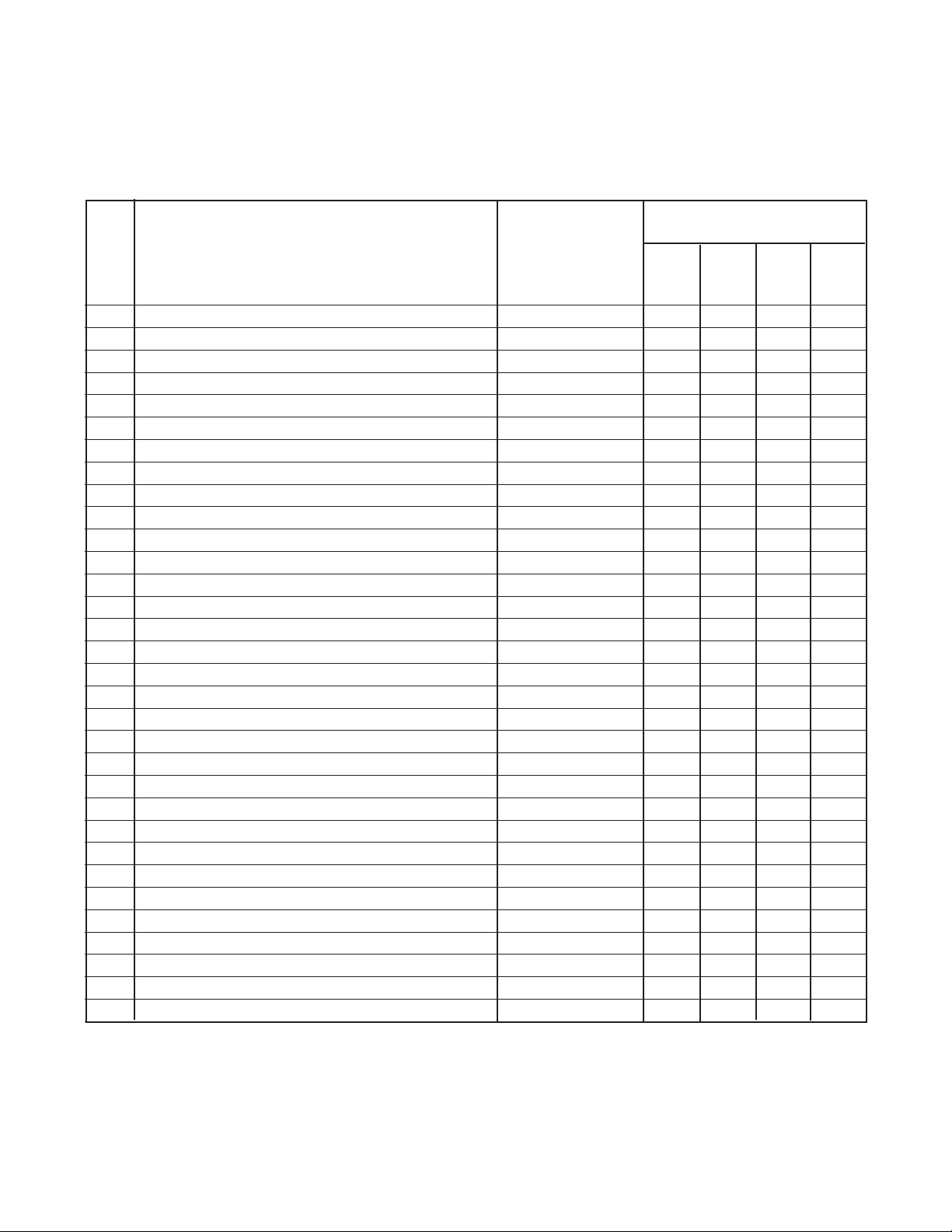

Page 11

Magnetic Bearing Compressor

Ref # Description Part Number

145D 125S 145S

150D 200S 225D 250D

275D 290D

002 Kit, Module, Bearing PWM 300040127 1 1 1 1

003 Kit, DC/DC Converter Assy, 380V 300053303 1 1 1 1

003 Kit, DC/DC Converter Assy, 400-460V 300042897 1 1 1 1

003 Kit, DC/DC Converter Assy, 575V 300048726 1 1 1 1

004 Kit, Module, Backplane Assy 300042899 1 1 1 1

006 Kit, End Cap Assy 300048171 1 1 1 1

007 Kit, Insulation Cover, End Bell 300043829 1 1 1 1

008 Kit, Cover, Top Assy 300040136 1 1 1 1

009 Kit, Cover, Service Side Assy 300040137 1 1 1 1

010 Kit, Cover, Mains Input Assy 300040138 1 1 1 1

011 Kit, Cover, Capacitor Assy 300040139 1 1 1 1

012 Kit, Module Serial Driver 300043064 1 1 1 1

013 Kit, Module, Softstart, 380V 300053304 1 1 1 1

013 Kit, Module, Softstart, 400V 300043853 1 1 1 1

013 Kit, Module, Softstart, 460V 300043245 1 1 1 1

013 Kit, Module Softstart, 575V 300051438 1 1 1 1

014 Kit, Bearing Motor Compressor Control (BMCC) See Note

016 Kit, Input Mains Buss Bars 100416 1 1 1

017 Kit, IGBT Manifold Cooling, w/o DC/DC Converter 300040931 1

017 Kit, IGBT Manifold Cooling, w/o DC/DC Converter 300043315 1 1 1

017 Kit, IGBT Manifold Clg, w/DC/DC Converter, 460V 300043246 1 1 1

NS Kit, Soft Start Cooling Fan Assembly 300049137 1 1 1 1

NS Kit, PCB Assy, Compressor Interface Connector 300043882 1 1 1 1

NS Kit, Terminal Power Block Assy 300043928 1

NS Kit, Terminal Power Block Assy 300043983 1 1 1

NS Kit, Cover Plate Assy 300049175 1 1 1 1

NS Kit, Sensor Assy, Temperature, Motor Rotor 300050440 1 1 1

NS Kit, Sensor Assy, Temperature, Motor Rotor 300053305 1

NS Kit, Tube, Connection to IGBT 300048170 1 1 1 1

NS Kit, Capacitor, IGBT Snubber 300043447 1 1 1 1

NS Kit, Sensor, Pressure Temp Suction (blue dot) 300040130 1 1 1 1

NS Kit, Sensor, Pressure Temp Discharge (red dot) 300040131 1 1 1 1

Quantity per

compressor

Note: Contact Daikin Applied with the compressor model, compressor part number, compressor serial number and BMCC

revision. On dual compressor units, provide same information on other compressor to ensure BMCC compatibility.

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 11

Page 12

Magnetic Bearing Compressor

Ref # Description Part Number

145D 125S 145S

150D 200S 225D 250D

275D 290D

NS Kit, Diode Rectiers 300043875 1

NS Kit, Diode Rectiers 300044087 1 1 1

NS Kit, Sensor Heatsink Diode Rectiers Dual Cool 300047204 1 1 1

NS Kit, Flange, Economizer 300048175 1

NS Kit, Flange, Economizer 300053307 1 1 1

NS Kit, Flange, Suction, Brass 300046266 1 1 1

NS Kit, Flange, Suction, Steel 300048959 1 1 1

NS Kit, Flange, Suction, Brass 300053306 1

NS Kit, Flange, Discharge, Brass 300053308 1

NS Kit, Flange, Discharge, Brass 300046267 1 1 1

NS Kit, Flange, Discharge, Steel 331387401 1 1 1

NS Kit, O-Ring, IGBT Assy 300043869 1 1 1 1

NS Kit, O-Ring, Ports Connection 300043968 1 1 1 1

NS Kit, O-Ring, IGV Assy 300043877 1 1 1 1

NS Kit, O-Ring, End Cap Assy 300043878 1 1 1 1

NS Kit, O-Ring, Service Side Small O-Rings 300043879 1 1 1 1

NS Kit, O-Ring, Cover Plate Assy 300043880 1 1 1 1

NS Kit, O-Ring, Suction Port Only 300048180 1 1 1 1

NS Kit, Cable Harness, Compressor DC Bus 200140 1 1 1 1

NS Kit, Cable Harness Assy, Compressor Interface 300047144 1 1 1 1

NS Kit, Cable Harness, Softstart SCR Gate 300044089 1 1 1 1

NS Kit, Cable Harness, Mtr Cooling & Coil Assy 300040132 1

NS Kit, Cable Harness, Mtr Cooling & Coil Assy 300048754 1 1 1

NS Kit, Cable Harness, Compressor Controller 300044030 1 1 1 1

NS Kit, Cable Harness, Front Bearing Sensor 300047965 1 1 1 1

NS Kit, Cable Harness, Rear Bearing Sensor 300047966 1 1 1 1

NS Kit, Cable Harness, Mtr Driver (IGBT to Backplane) 300044114 1 1 1 1

NS Kit, Cable Harness, Softstart AC/DC, Fused 300040953 1

NS Kit, Cable Harness, Softstart AC/DC 300044098 1 1 1

NS Cable Harness, DC/DC to Backplane 300047244 1 1 1 1

NS Line Reactor, 140A, 5% 300047659 1

NS Line Reactor, 180A, 5% 300045658 1 1

NS Line Reactor, 240A, 5% 300048177 1 1 1

NS Line Reactor, 140A, 10% 300044143 1

Quantity per

compressor

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 12

Page 13

Magnetic Bearing Compressor

Ref # Description Part Number

145D 125S 145S

150D 200S 225D 250D

275D 290D

NS EMI/EMC Filter, CE, 185A 300048760 1 1 1

NS EMI/EMC Filter, CE, 322A 300048960 1 1 1

NS Kit, Fuse, Class T, Fast Acting 300045202 1

NS Fuse, Slo Nano SMF 0.25A, 125V 300046528 1 1 1 1

NS Fuse, Slo Nano SMF 0.2A, 600V, Midget,Time Delay 300044083 1 1 1 1

NS Kit, Fuse 2A, 1000V, HVA, 3” 300045312 1 1 1 1

NS Kit, Fuses, Softstart 300046521 1 1 1 1

NS Kit, Fuse Nano SMF 1.0A, 125V 300046530 1 1 1 1

NS Kit, IGV Motor Service 300048085 1 1 1 1

NS Kit, Buss Bar Assy and Capacitors, 400V 300043831 1

NS Kit, Buss Bar Assy and Capacitors, 460V 300046429 1

NS Kit, Buss Bar Assy and Capacitors, 380V/400V 300047251 1 1 1

NS Kit, Buss Bar Assy and Capacitors, 460V 300043832 1 1 1

NS Kit, Buss Bar Assembly and Capacitors, 575V 300049168 1

NS Kit, Buss Bar Assembly and Capacitors, 575V 300053309 1

NS Kit, Buss Bar Diode 300048955 1

NS Kit, Buss Assy Conn Motor IGBT 300045215 1

NS Kit, Buss Assy Conn Motor IGBT 300048961 1 1 1

NS Kit, Suction Strainer 300048957 1

NS Kit, Compressor Cooling Adaptor w/Strainer 300050352 1 1 1 1

NS Kit, Strainer for Cooling Adapter 300053310 1 1 1 1

NS Kit, Compressor Mounting 300040125 1 1 1 1

NS Kit, Screws for Covers, M5, Stainless Steel 300046932 1 1 1 1

NS Dielectric Grease 300045661 1 1 1 1

NS Kit, Cooling Valves Assy 300043892 1

NS Kit, Cooling Valves Assy (380V, 400V, 460V) 300047112 1

NS Kit, Cooling Valves Assy (575V) 300053311 1

NS Kit, Cooling Valves Assy (380V) 300053312 1

NS Kit, Cooling Valves Assy (400V, 460V) 300053313 1

NS Kit, Cooling Valves Assy 300053313 1

Quantity per

compressor

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 13

Page 14

Magnetic Bearing Compressor

Ref # Description Part Number

145D 125S 145S

150D 200S 225D 250D

275D 290D

NS Kit, IGV Housing Assembly and O-Rings 300043626 1

NS Kit, IGV Housing Assembly and O-Rings 300053314 1

NS Kit, IGV Housing Assembly and O-Rings 300046822 1

NS Kit, IGV Housing Assembly and O-Rings 300045254 1

NS Kit, Bracket Mains Input Plate, 2.0" Diameter 300049942 1 1 1 1

NS Kit, Bracket Mains Input Plate, 2.5” Diameter 300049943 1 1 1 1

NS Kit, Bracket Mains Input Plate, 3.0” Diameter 300049944 1 1 1 1

NS Kit, Bracket Mains Input Plate, 3.5” Diameter 300049945 1 1 1 1

NS Kit, Heatsink Cooling Manifold SCR Assy 300049070 1

NS Kit, Heatsink Cooling Manifold SCR Assy 300050154 1 1 1

NS Kit, Hermetic Feedthrough IGV - 4 Pin 300049261 1 1 1 1

NS Kit, Hermetic Feedthru, Rear Bearing, 6-Pin 300043473 1 1 1 1

NS Kit, Hermetic Feedthru, Front Bearing, 4-Pin 300046599 1 1 1 1

NS Kit, Hermetic Feedthru, Bearing Sensor, 9-Pin 300045720 1 1 1 1

NS Kit, Hermetic Feedthru High Power 300045214 1 1 1 1

Quantity per

compressor

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 14

Page 15

Piping - Discharge

C044

C031

WMC290D shown

125S 225D

Ref. # Description Part Number 145S 145D 150D 250D 290D

200S 275D

C031 Gasket, 6.88 OD 070199120 3 6 6 6 6

C044 Check Valve 331684001 1 2 2 2 2

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 15

Page 16

B030

Piping - Liquid Line and Motor Cooling

E022

B012

B017

B030

E040

Motor Cooling Line

290D shown

B041

B012

B041

B012

E022

Liquid Line

145D shown

Liquid Line

250D shown

125S 225D

Ref. # Description Part Number 145S 145D 150D 200S 250D 290D

275D

B012 Gasket, 2.84 OD 070199112 2 2 2 1 1 1

B017 Gasket, 4.15 OD 070199104 1 1 1

B030 Electronic Expansion Valve, 126 Ton 330386206 1 1 1

B030 Electronic Expansion Valve, 250 Ton 330386207 1 1 1

B041 Ball Valve, 1.63 330296045 1 1 1

B041 Ball Valve, 2.12 330296046 1 1 1

E022 Ball Valve, .625 330296041 2 4 4 2 4 4

E040 Filter Drier, .625 735028827 1 2 2 1 2 2

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 16

Page 17

Condenser- Dish Heads

Head

Gasket

351

352

Connection

End

331

330

110

Return

Shown: 2-Pass, Grooved Connection, Dish Heads

Ref. # Description Part Number Qty.

110 Sight Glass Clear w/Ball 350229502 1

330 Shut-Off Valve 735039929 2

331 Cap, Flare 073243901 2

Code 38 Code 39 Code 40

#Passes ConnectionType NozzleConguration

1=1 Pass V = Grooved A = Dish, End (Non-directional Flow)

2=2 Pass F = Flanged C = Dish, End (Over/Under Flow)

3=3 Pass

End

355

350

Gasket

Head

Head Types

Dish Grooved Dish Flanged

Connection

Return

Connection

Return

1- Pass

2- Pass

3- Pass

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 17

Page 18

Condenser - Dish Heads

20 Inch

Heads listed are non-coated. For coated heads (Code 47 = D or E), contact Daikin Applied.

1 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Connection Head

with anged connection (Code 39=F) 330959213 2

with grooved connection (Code 39=V) 330958101 2

352/355 Gasket, Head 070304644 1 per head

NS Screw, H5, 0.50 x 2.5 735033851 22 per head

NS Nut, 0.50-13 735029625 22 per head

2 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350 Assembly, Return Head 330685102 1

351 Assembly, Connection Head

with anged connection (Code 39=F) 330959223 1

with grooved connection (Code 39=V) 330958223 1

352 Gasket Kit, Connection Head 333849804 1

355 Gasket, Return Head 070304644 1

NS Screw, H5, 0.50 x 2.5 735033851 22 per head

NS Nut, 0.50-13 735029625 22 per head

3 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Connection Head

with anged connection (Code 39=F) 330959333 2

with grooved connection (Code 39=V) 330958333 2

352/355 Gasket Kit, Head 333849804 1 per head

NS Screw- H5, 0.50 x 2.5 735033851 22 per head

NS Nut- 0.50-13 735029625 22 per head

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 18

Page 19

Condenser - Dish Heads

22 Inch

Heads listed are non-coated. For coated heads (Code 47 = D or E), contact Daikin Applied.

1 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Connection Head

with anged connection (Code 39=F) 330959214 2

with grooved connection (Code 39=V) 330958301 2

352/355 Gasket, Head 070304645 1 per head

NS Screw- H5, 0.50 x 2.5 735033851 26 per head

NS Nut- 0.50-13 735029625 26 per head

2 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350 Assembly, Return Head 330958302 1

351 Assembly, Connection Head

with anged Connection (Code 39=F) 330959224 1

with grooved Connection (Code 39=V) 330958224 1

352 Gasket Kit, Connection Head 333849805 1

355 Gasket, Return Head 070304645 1

NS Screw, H5, 0.50 x 2.5 735033851 26 per head

NS Nut, 0.50-13 735029625 26 per head

3 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Connection Head

with anged connection (Code 39=F) 330959334 2

with grooved connection (Code 39=V) 330958334 2

352/355 Gasket Kit, Head 333849805 1 per head

NS Screw, H5, 0.50 x 2.5 735033851 26 per head

NS Nut, 0.50-13 735029625 26 per head

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 19

Page 20

Condenser- Water Box Heads

366

Water Box

Cover Gasket

Water Box to

Shell Gasket

Head

351

Connection

End

352

331

330

330

110

Return

End

355

Gasket

350

Shown: 2-Pass, Grooved Connection, Water Box Head

Ref. # Description Part Number Qty.

110 Sight Glass Clear w/Ball 350229502 1

330 Shut-Off Valve 735039929 2

331 Cap, Flare 073243901 2

Code 38 Code 39 Code 40

#Passes ConnectionType NozzleConguration

1=1 Pass V = Grooved E = Water Box, Rear (Non-directional Flow)

2=2 Pass F = Flanged F = Water Box, Front (Non-directional Flow)

3=3 Pass H = Water Box, Rear (Over/Under Flow)

J = Water Box, Front (Over/Under Flow)

Head

Head Types

Water Box Grooved Water Box Flanged

Connection

Return

Connection

Return

1- Pass

2- Pass

3- Pass

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 20

Page 21

Condenser- Water Box Heads

20 Inch

Heads listed are non-coated. For coated heads (Code 47 = D or E), contact Daikin Applied.

1 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Water Box Head

with anged connection (Code 39=F) 330960513 2

with grooved connection (Code 39=V) 330958513 2

352/366 Gasket, Head 070304644 2 per end

NS Screw- H5, 0.50 x 3.5 735033941 44 per end

NS Nut- 0.50-13 735029625 44 per end

2 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350 Assembly, Return Head 330658102 1

351 Assembly, Water Box Head

with anged connection (Code 39=F) 330971523 1

with grooved connection (Code 39=V) 330961523 1

352 Gasket Kit, Water Box to Shell 333850004 1

355 Gasket, Return Head 070304644 1

366 Gasket Kit, Water Box Cover 333850004 1

NS Screw- H5, 0.50 x 3.5, Return Head 735033941 22

NS Screw- H5, 0.50 x 3.5, Water Box Head 735033941 44

NS Nut- 0.50-13, Return Head 735029625 22

NS Nut- 0.50-13, Water Box Head 735029625 44

3 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty

350/351 Assembly, Water Box Head

with anged connection (Code 39=F) 330971633 2

with grooved connection (Code 39=V) 330961633 2

352 Gasket Kit, Water Box to Shell 333850004 2

366 Gasket Kit, Water Box Cover 333850004 2

NS Screw- H5, 0.50 x 3.5, Return Head 735033941 44 per end

NS Nut- 0.50-13, Water Box Head 735029625 44 per end

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 21

Page 22

Condenser- Water Box Heads

22 Inch

Heads listed are non-coated. For coated heads (Code 47 = D or E), contact Daikin Applied.

1 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Water Box Head

with anged connection (Code 39=F) 330960514 2

with grooved connection (Code 39=V) 330958514 2

352/366 Gasket, Head 070304645 2 per end

NS Screw- H5, 0.75 x 3.5, Water Box to Shell 735033967 26 per end

NS Screw- H5, 0.50 x 3.5, Water Box Cover 735033941 26 per end

NS Nut- 0.75-10, Water Box to Shell 735029626 26 per end

NS Nut- 0.50-13, Water Box Cover 735029625 26 per end

2 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350 Assembly, Return Head 330958302 1

351 Assembly, Connection Head

with anged connection (Code 39=F) 330971524 2

with grooved connection (Code 39=V) 330961524 2

352 Gasket Kit, Water Box to Shell 333850005 1

355 Gasket, Return Head 070304645 1

366 Gasket Kit, Water Box Cover 333850005 1

NS Screw, Return Head 735033941 26

NS Screw- H5, 0.75 x 3.5, Water Box to Shell 735033967 26

NS Screw- H5, 0.50 x 3.5, Water Box Cover 735033941 26

NS Nut, Return Head 735029625 26

NS Nut- 0.75-10, Wtr Box to Shell 735029626 26

NS Nut- 0.50-13, Water Box Cover 735029625 26

3 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Connection Head

with anged connection (Code 39=F) 330971634 2

with grooved connection (Code 39=V) 330961634 2

352 Gasket Kit, Water Box to Shell 333850005 2

366 Gasket Kit, Water Box Cover 333850005 2

NS Screw- H5, 0.75 x 3.5, Wtr Box to Shell 735033967 26 per head

NS Screw- H5, 0.50 x 3.5, Water Box Cover 735033941 26 per end

NS Nut- 0.75-10, Wtr Box to Shell 735029626 26 per end

NS Nut- 0.50-13, Water Box Cover 735029625 26 per end

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 22

Page 23

Evaporator- Dish Heads

Head

Gasket

351

352

Connection

End

330

331

Return

End

355

350

Shown: 2-Pass, Grooved Connections, Dish Heads

Ref. # Description Part Number Qty.

330 Shut-Off Valve 735039929 2

331 Cap, Flare 073243901 2

Code 16 Code 17 Code 18

#Passes ConnectionType NozzleConguration

1=1 Pass V = Grooved A = Dish, End (Non-directional Flow)

2=2 Pass F = Flanged C = Dish, End (Over/Under Flow)

3=3 Pass

Gasket

Head

Head Types

Dish Grooved Dish Flanged

Connection

Return

Connection

Return

1- Pass

2- Pass

3- Pass

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 23

Page 24

Evaporator - Dish Heads

22 Inch

Heads listed are non-coated. For coated heads (Code 25 = D or E), contact Daikin Applied.

1 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Connection Head

with anged connection (Code 17=F) 330959214 2

with grooved connection (Code 17=V) 330958301 2

352/355 Gasket, Head 070304645 1 per head

NS Screw, H5, 0.50 x 2.5 735033851 26 per head

NS Nut, 0.50-13 735029625 26 per head

2 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350 Assembly, Return Head 330958302 1

351 Assembly, Connection Head

with anged connection (Code 17=F) 330959224 1

with grooved connection (Code 17=V) 330958224 1

352 Gasket Kit, Connection Head 333849805 1

355 Gasket, Return Head 070304645 1

NS Screw, H5, 0.50 x 2.5 735033851 26 per head

NS Nut, 0.50-13 735029625 26 per head

3 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Head, Connection

with anged connection (Code 17=F) 330959334 2

with grooved connection (Code 17=V) 330958334 2

352/355 Gasket Kit, Head 333849805 1 per head

NS Screw- H5, 0.50 x 2.5 735033851 26 per head

NS Nut- 0.50-13 735029625 26 per head

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 24

Page 25

Evaporator - Dish Heads

26 Inch

Heads listed are non-coated. For coated heads (Code 25 = D or E), contact Daikin Applied.

1 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Connection Head

with anged connection (Code 17=F) 330959215 2

with grooved connection (Code 17=V) 330958501 2

352/355 Gasket, Head 070304646 1 per head

NS Screw, H5, 0.75 x 3.0 735033878 32 per head

NS Nut, 0.75-10 735029626 32 per head

2 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350 Assembly, Return Head 330958502 1

351 Assembly, Connection Head

with anged connection (Code 17=F) 330959225 1

with grooved connection (Code 17=V) 330958225 1

352 Gasket Kit, Connection Head 333849806 1

355 Gasket, Return Head 070304646 1

NS Screw, H5, 0.75 x 3.0 735033878 32 per head

NS Nut, 0.75-10 735029626 32 per head

3 Pass, 150 PSI, Dish Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Connection Head

with anged connection (Code 17=F) 330959335 2

with grooved connection (Code 17= V) 330958335 2

352/355 Gasket Kit, Head 333849806 1 per head

NS Screw- H5, 0.75 x 3.0 735033878 32 per head

NS Nut- 0.75-10 735029626 32 per head

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 25

Page 26

Evaporator- Water Box Heads

Water

Box

Cover

Gasket

Water Box to Shell

Head

366

351

Gasket

Ref. # Description Part Number Qty.

330 Shut-Off Valve 735039929 2

331 Cap, Flare 073243901 2

Code 16 Code 17 Code 18

#Passes ConnectionType NozzleConguration

1=1 Pass V = Grooved D = Water Box, Top (Non-directional Flow)

2=2 Pass F = Flanged E = Water Box, Rear (Non-directional Flow)

3=3 Pass F = Water Box, Front (Non-directional Flow)

H = Water Box, Rear (Over/Under Flow)

J = Water Box, Front (Over/Under Flow)

Connection

End

352

330

331

Return

End

355

350

Shown: 2-Pass, Grooved Connections, Water Box Head

Gasket

Head

Head Types

Water Box Grooved Water Box Flanged

Connection

Return

Connection

Return

1- Pass

(Front Nozzle Shown)

2- Pass

3- Pass

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 26

Page 27

Evaporator- Water Box Heads

22 Inch

Heads listed are non-coated. For coated heads (Code 25 = D or E), contact Daikin Applied.

1 Pass, Top Nozzle Connection (Code 18 = D), 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Water Box Head

with anged connection (Code 17=F) 330960414 2

with grooved connection (Code 17=V) 330958414 2

352/366 Gasket, Head 070304645 2 per end

NS Screw, H5, 0.75 x 3.5, Water Box Head 735033967 26 per end

NS Screw, H5, 0.50 x 2.5, Return Head 735033941 26 per end

NS Nut, 0.75-10, Water Box Head 735029626 26 per end

NS Nut, 0.50-13, for Return Head 735029625 26 per end

1 Pass, Front or Rear Nozzle Connection (Code 18 = E, F), 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350 / 351 Assembly, Water Box Head

with anged connection (Code 17=F) 330960514 2

with grooved connection (Code 17=V) 330958514 2

352 / 366 Gasket, Head 070304645 2 per end

NS Screw, H5, 0.75 x 3.5, Water Box Head 735033967 26 per end

NS Screw, H5, 0.50 x 2.5, Return Head 735033941 26 per end

NS Nut, 0.75-10, Water Box Head 735029626 26 per end

NS Nut, 0.50-13, Return Head 735029625 26 per end

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 27

NS = Not Shown

Page 28

Evaporator- Water Box Heads

22 Inch

Heads listed are non-coated. For coated heads (Code 25 = D or E), contact Daikin Applied.

2 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350 Assembly, Return Head 330958302 1

351 Assembly, Water Box Head

with anged connection (Code 17=F) 330960624 1

with grooved connection (Code 17= V) 330958624 1

352 Gasket Kit, Water Box to Shell 333850005 1

355 Gasket, Return Head 070304645 1

366 Gasket Kit, Water Box Cover 333850005 2

NS Screw, H5, 0.50 x 2.5, Return Head 735033941 26

NS Screw, H5, 0.75 x 3.5, Water Box to Shell 735033967 26

NS Screw, H5, 0.50 x 2.5, Water Box Cover 735033941 26

NS Nut, 0.50-13, Return Head 735029625 26

NS Nut, 0.75-10, Water Box to Shell 735029626 26

NS Nut, 0.50-13, Water Box Cover 735029625 26

3 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Water Box Head

with anged connection (Code 17=F) 330960734 2

with grooved connection (Code 17= V) 330958734 2

352 Gasket Kit, Water Box to Shell 333850005 2 per end

366 Gasket Kit, Water Box Cover 333850005 2 per end

NS Screw, H5, 0.75 x 3.5, Water Box to Shell 735033967 26 per end

NS Screw, H5, 0.50 x 2.5, Water Box Cover 735033941 26 per end

NS Nut, 0.75-10, Water Box to Shell 735029626 26 per end

NS Nut, 0.50-13, Water Box Cover 735029625 26 per end

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 28

Page 29

Evaporator- Water Box Heads

26 Inch

Heads listed are non-coated. For coated heads (Code 25 = D or E), contact Daikin Applied.

1 Pass, Top Nozzle Connection (Code 18 = D), 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Water Box Head

with anged connection (Code 17= F) 330960415 2

with grooved connection (Code 17= V) 330958415 2

352/366 Gasket, Head 070304646 2 per end

NS Screw, H5, 0.75 x 4.5 735033969 64 per end

NS Nut, 0.75-10 735029626 64 per end

1 Pass, Front or Rear Nozzle Connection (Code 18 = E, F), 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Water Box Head

with anged connection (Code 17= F) 330960515 2

with grooved connection (Code 17= V) 330958515 2

352/366 Gasket, Head 070304646 2 per end

NS Screw, H5, 0.75 x 4.5 735033969 64 per end

NS Nut, 0.75-10 735029626 64 per end

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 29

Page 30

Evaporator- Water Box Heads

26 Inch

Heads listed are non-coated. For coated heads (Code 25 = D or E), contact Daikin Applied.

2 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350 Assembly, Return Head 330958502 1

351 Assembly, Water Box Head

with anged connection (Code 17= F) 330960625 1

with grooved connection (Code 17= V) 330958625 1

352 Gasket Kit, Water Box to Shell 333850006 1

355 Gasket, Return Head 070304646 1

366 Gasket Kit, Water Box Cover 333850006 1

NS Screw, H5, 0.75 x 4.5, Return Head 735033969 32

NS Screw, H5, 0.75 x 4.5, Water Box Head 735033969 64

NS Nut, 0.75-10, Return Head 735029626 32

NS Nut, 0.75-10, Water Box Head 735029626 64

3 Pass, 150 PSI, Water Box Heads, non-ASME

Ref. # Description Part Number Qty.

350/351 Assembly, Water Box Head

with anged connection (Code 17= F) 330960735 1

with grooved connection (Code 17= V) 330958735 1

352 Gasket Kit, Water Box to Shell 333850006 1

366 Gasket Kit, Water Box Cover 333850006 1

NS Screw, H5, 0.75 x 4.5 735033969 64 per end

NS Nut, 0.75-10 735029626 64 per end

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 30

Page 31

Evaporator Insulation

Single Insulation

Description Part Number Quantity

22 inch, 9 ft. Evaporator: (125S, 145D)

Insulation, 3/4", Evaporator Shell 047662050 80 square ft

Insulation, 3/4", Evaporator Head 047662050 15 square ft per head

Insulation, 3/4", Suction 047662050 17 square ft per suction line

22 inch, 12 ft. Evaporator: (150D)

Insulation, 3/4", Evaporator Shell 047662050 100 square ft

Insulation, 3/4", Evaporator Head 047662050 15 square ft per head

Insulation, 3/4", Suction 047662050 17 square ft per suction line

26 inch, 9 ft. Evaporator: (200S, 225D, 250D)

Insulation, 3/4", Evaporator Shell 047662050 100 square ft

Insulation, 3/4", Evaporator Head 047662050 19 square ft per head

Insulation, 3/4", Suction 047662050 17 square ft per suction line

26 inch, 12 ft. Evaporator: (275D, 290D)

Insulation, 3/4", Evaporator Shell 047662050 125 square ft

Insulation, 3/4", Evaporator Head 047662050 19 square ft per head

Insulation, 3/4", Suction 047662050 17 square ft per suction line

Double Insulation

Description Part Number Quantity

22 inch, 9 ft. Evaporator: (125S, 145D)

Insulation, 3/4", Evaporator Shell 047662050 175 square ft

Insulation, 3/4", Evaporator Head 047662050 30 square ft per head

Insulation, 3/4", Suction 047662050 28 square ft per suction line

22 inch, 12 ft. Evaporator: (150D)

Insulation, 3/4", Evaporator Shell 047662050 205 square ft

Insulation, 3/4", Evaporator Head 047662050 30 square ft per head

Insulation, 3/4", Suction 047662050 28 square ft per suction line

26 inch, 9 ft. Evaporator: (200S, 225D, 250D)

Insulation, 3/4", Evaporator Shell 047662050 205 square ft

Insulation, 3/4", Evaporator Head 047662050 37 square ft per head

Insulation, 3/4", Suction 047662050 28 square ft per suction line

26 inch, 12 ft. Evaporator: (275D, 290D)

Insulation, 3/4", Evaporator Shell 047662050 255 square ft

Insulation, 3/4", Evaporator Head 047662050 37 square ft per head

Insulation, 3/4", Suction 047662050 28 square ft per suction line

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 31

Page 32

Unit Controls

Operator Interface Panel (OITS)

15

16

Power Panel

WMC 150D shown

Ref. Description Part Qty.

No. Number

15 Operator Interface Panel (OITS) w/cables, 15” Black 330276502 1

Cable, Power, Operator Interface 300040768 1

Cable, Serial, Operator Interface 300043345 1

Cable Kit (includes Power, Serial & VGA cords) 300043289 1

16 Support Arm Assy, Black (includes swivel pin, washers, & nut) 330815411 1

Unit Control Box

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 32

Page 33

105

Unit Controls

Unit Control Box

102

104

109

103

112

108

110

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 33

Page 34

Unit Controls

Unit Control Box

Ref. # Schem. Description Part Number Qty.

102 SW1 Rocker Switch, Unit 300042181 1

102 SW6, SW7 Rocker Switch, Compressor 300042181 2

103 SW10 Rocker Switch, Emergency Shut-down 300042962 1

104 CB Circuit Breaker, 10A, 250V 300042182 1

105 EXV EXV Driver Board 330277803 1

108 PC OITS Circuit Board Assy 331620003 1

Power Supply for Ckt Brd - OITS 331620053 1

Memory Card 331620093 1

109 UCM Comm Module Board 330275202 1

110 MOD1, MOD2 PCB Assy 300042958 2

112 UC Unit Controller, MTII 332608311 1

Serial Card for Unit Controller 300047238 1

NS US05 Sensor- 30 ft. 073007303 1

NS US02, US03, US04 Sensor- 30 ft. 073007203 3

NS US10 Sensor- 30 ft. 073007203 1

NS = Not Shown

400

Ref. # Description Part Number Qty.

400 LonMark Serial Interface 332608501 1

400 ModBus RS485 Serial Network Board 332608801 1

400 RS232 Serial Gateway / Modem Board 332608701 1

400 BACnet with IP Ethernet 350147406 1

NS BACnet with MS/TP 350147407 1

NS = Not Shown

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 34

Page 35

Unit Controls

Power Box

GFS1

Single Point

Conguration

(Code 63= S)

T2, T3

CB1

EMI1

LR1

GFR1

400

CB2

DS1 or PB

EMI2

T1, F13

LR2

Multiple Point

Conguration

(Code 63= M)

GFS1

CB1

EMI1

LR1

GFS2

GFR1, GFR2

CB2

T2, T3

EMI2

T1, F13

LR2

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 35

Page 36

Unit Controls

Power Box

Schem. Description RLA Range Part Number Quantity

(Code 62)

GFS1, GFS2 Ground Fault Sensor All 300052035 1

GFR1, GFR2 Ground Fault Relay All 300053857 1

Standard Short Circuit Current Rating Code 67= S

DS1 Main Disconnect Switch w/Handle, 150A 40-53 300053323 1

DS1 Main Disconnect Switch w/Handle, 200A 54-69 300053324 1

DS1 Main Disconnect Switch w/Handle, 225A 70-76 300053325 1

DS1 Main Disconnect Switch w/Handle, 250A 77-92 300053326 1

DS1 Main Disconnect Switch w/Handle, 400A 93-138 300053327 1

DS1 Main Disconnect Switch w/Handle, 600A 139-199 300053328 1

DS1 Main Disconnect Switch w/Handle, 800A 200-214 300053329 1

High Short Circuit Current Rating Code 67= H

DS1 Main Disconnect Switch w/Handle, 150A 40-53 300053330 1

DS1 Main Disconnect Switch w/Handle, 200A 54-69 300053331 1

DS1 Main Disconnect Switch w/Handle, 225A 70-76 300053332 1

DS1 Main Disconnect Switch w/Handle, 250A 77-92 300053333 1

DS1 Main Disconnect Switch w/Handle, 400A 93-138 300053334 1

DS1 Main Disconnect Switch w/Handle, 600A 139-199 300053335 1

DS1 Main Disconnect Switch w/Handle, 800A 200-214 300053336 1

PB Main Power Block, 175A 40-78 300053337 1

PB Main Power Block, 380A 79-169 193446303 1

PB Main Power Block, 760A 170-214 193446302 1

CB1, CB2 Branch Disconnect Switch, 70A 40-46 300053338 2

CB1, CB2 Branch Disconnect Switch, 80A 47-53 300053339 2

CB1, CB2 Branch Disconnect Switch, 90A 54-60 300053340 2

CB1, CB2 Branch Disconnect Switch, 100A 61-66 300053341 2

CB1, CB2 Branch Disconnect Switch, 125A 67-83 300053342 2

CB1, CB2 Branch Disconnect Switch, 150A 84-100 300053343 2

CB1, CB2 Branch Disconnect Switch, 175A 101-116 300053344 2

CB1, CB2 Branch Disconnect Switch, 200A 117-133 300053345 2

CB1, CB2 Branch Disconnect Switch, 225A 134-150 300053346 2

CB1, CB2 Branch Disconnect Switch, 250A 151-166 300053347 2

CB1, CB2 Branch Disconnect Switch, 300A 167-199 300053348 2

CB1, CB2 Branch Disconnect Switch, 400A 200-214 300053349 2

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 36

Page 37

Unit Controls

Power Box

Schem. Description RLA Range Part Number Quantity

(Code 62)

EMI1, EMI2 EMI Filter, 90A, 380-460V 40-72 300053350 2

EMI1, EMI2 EMI Filter, 120A, 380-460V 73-96 300053351 2

EMI1, EMI2 EMI Filter, 150A, 380-460V 97-120 300053352 2

EMI1, EMI2 EMI Filter, 180A, 380-460V 121-144 300053353 2

EMI1, EMI2 EMI Filter, 250A, 380-460V 145-200 300053354 2

EMI1, EMI2 EMI Filter, 320A, 380-460V 201-214 300053858 2

EMI1, EMI2 EMI Filter, 120A, 575V 40-92 300053355 2

EMI1, EMI2 EMI Filter, 150A, 575V 93-120 300053356 2

EMI1, EMI2 EMI Filter, 180A, 575V 121-144 300053357 2

EMI1, EMI2 EMI Filter, 250A, 575V 145-200 300053358 2

LR1, LR2 Line Reactor, 380-460V 40-77 300053359 2

LR1, LR2 Line Reactor, 380-460V 78-100 300053360 2

LR1, LR2 Line Reactor, 380-460V 101-125 300053361 2

LR1, LR2 Line Reactor, 380-460V 126-144 300053362 2

LR1, LR2 Line Reactor, 380-460V 145-192 300053363 2

LR1, LR2 Line Reactor, 575V 40-79 300053364 2

LR1, LR2 Line Reactor, 575V 80-100 300053365 2

LR1, LR2 Line Reactor, 575V 101-115 300053366 2

LR1, LR2 Line Reactor, 575V 116-154 300053367 2

F14-16, 24-26 * Main Power Fuse (not used on 145D, 150D) 100-140 300053389 6

F14-16, 24-26 * Main Power Fuse (not used on 145D, 150D) 141-214 300053390 6

F11-12, 21-22 * Control Power Fuse All 300053391 4

IR * Interlock Relay, 380V All 300053392 1

IR * Interlock Relay, 400V All 300053859 1

IR * Interlock Relay, 460V All 300050946 1

IR * Interlock Relay, 575V All 300053860 1

T1 Control Transformer All 099477103 1

F13 Control Fuse All 300053393 1

S1T * Temperature Switch 150-214 300053394 1

M1F * Fan Motor 150-214 300053395 1

* Not shown on diagram.

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 37

Page 38

Unit Controls

Power Box

Schem. Description RLA Range Part Number Quantity

(Code 62)

K1V * Surge Relay All 300053396 1

K1T * Time Delay Relay All 300053397 1

T2 Transformer, OITS All 330386105 1

T3 Transformer, Chiller Controller All 330386105 1

R1V * Surge Absorber All 300053398 1

HF1, HF2 Harmonic Filter **

* Not shown on diagram.

** Contact Daikin Applied with the Power Box Serial No. and Power Box Part No.

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 38

Page 39

Unit Controls

Power Box Label

For other control components, please contact Daikin Applied with the Power Box Serial Number

and Power Box Part Number. These numbers are located on the Power Box rating label (see example below). This label is found on the inside of the panel door.

Sales Order:

Daikin G.O.:

Power Box

Serial Number

Power Box

Part Number

Serial: W10006025-00001

Daikin Ref. No.:

Benshaw Part No.: WMCZCZ154Z154D4606ASDPNSNNNS

Daikin Part No.:

Daikin Code String:

BOX-ELEC,BEN-WMC_400D_C_TT500_01540_TT500_01540_D_00460_H6_A_S_D_P_N_S_N_N_N_S_R0

System HP: N/A System Voltage: 460

Frequency: 60 Phase: 3

Type: 1

SCCR Ka RMS: 35

System RLA: 308 Max RLA: N/A

Sytem LRA: 339 Max LRA: N/A

Interrupt Rating: 35

Daikin P.O.:

Magnetic Bearing Compr. Chiller; WMC 125S-290D, Vint. C Rev. B 10/2015 RPL 700029400 / Page 39

Loading...

Loading...