Page 1

Engineered for flexibility and performance™

Magnitude™ Magnetic Bearing Centrifugal Chillers Catalog 602-2

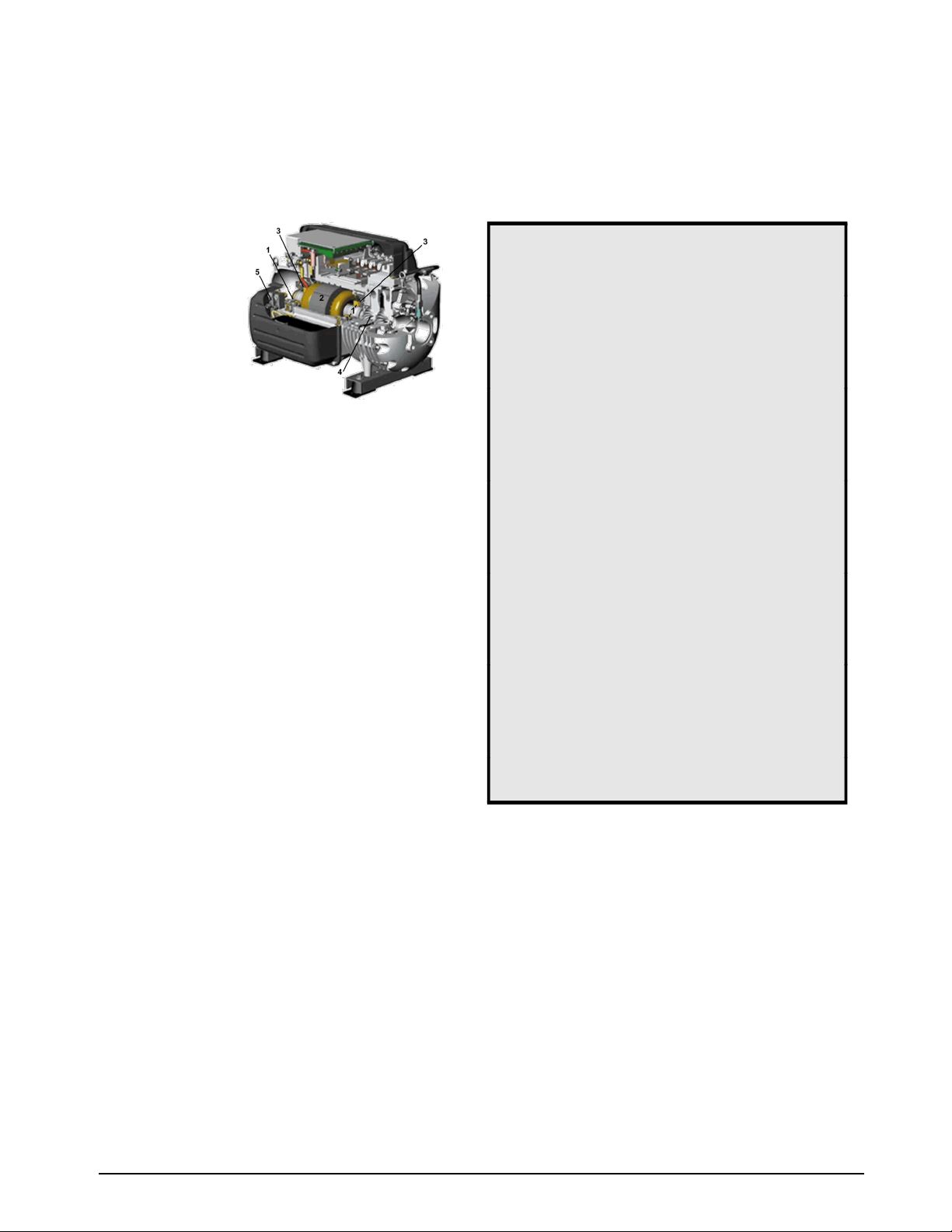

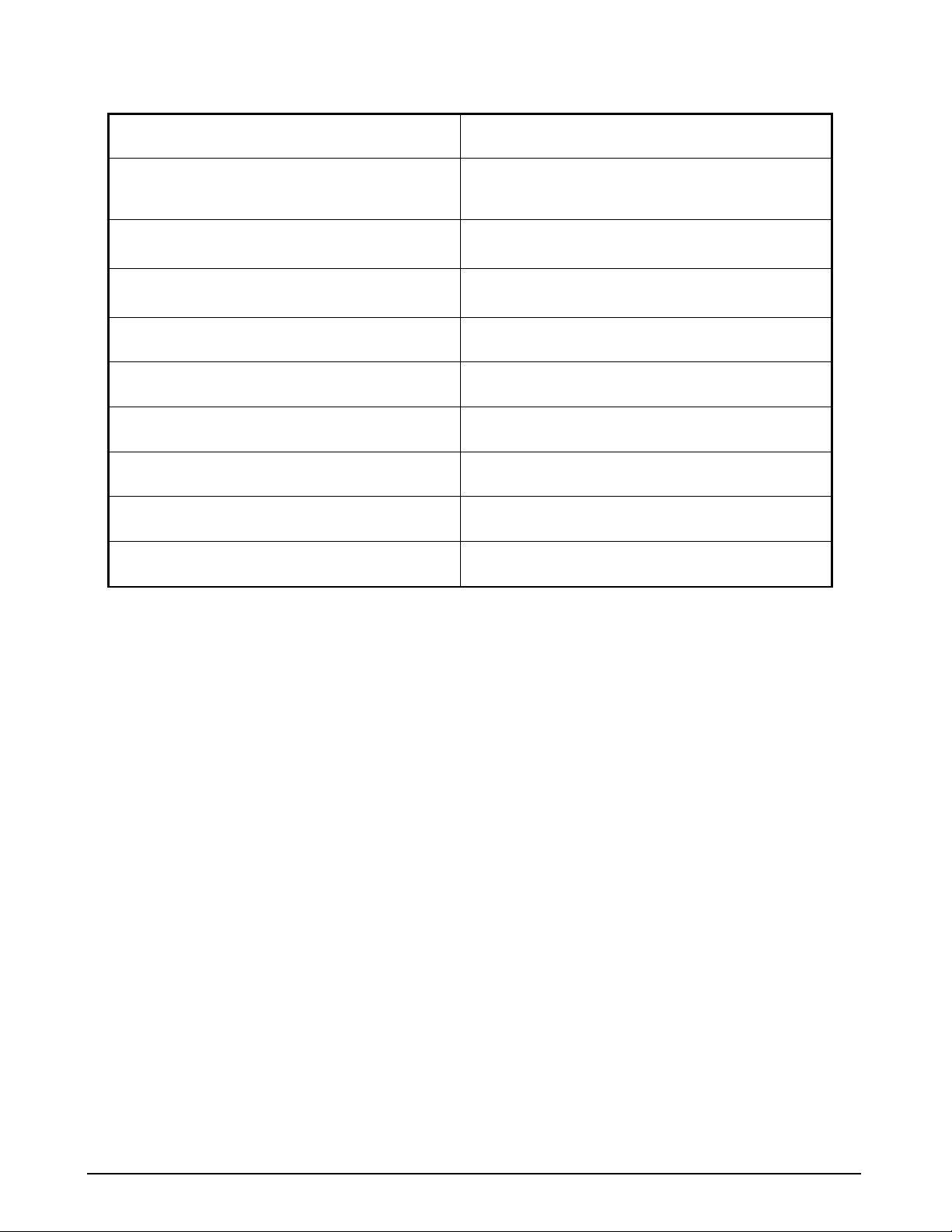

Model WMC, B Vintage • 145 to 400 tons • 500 to 1400 kW • R-134a

Page 2

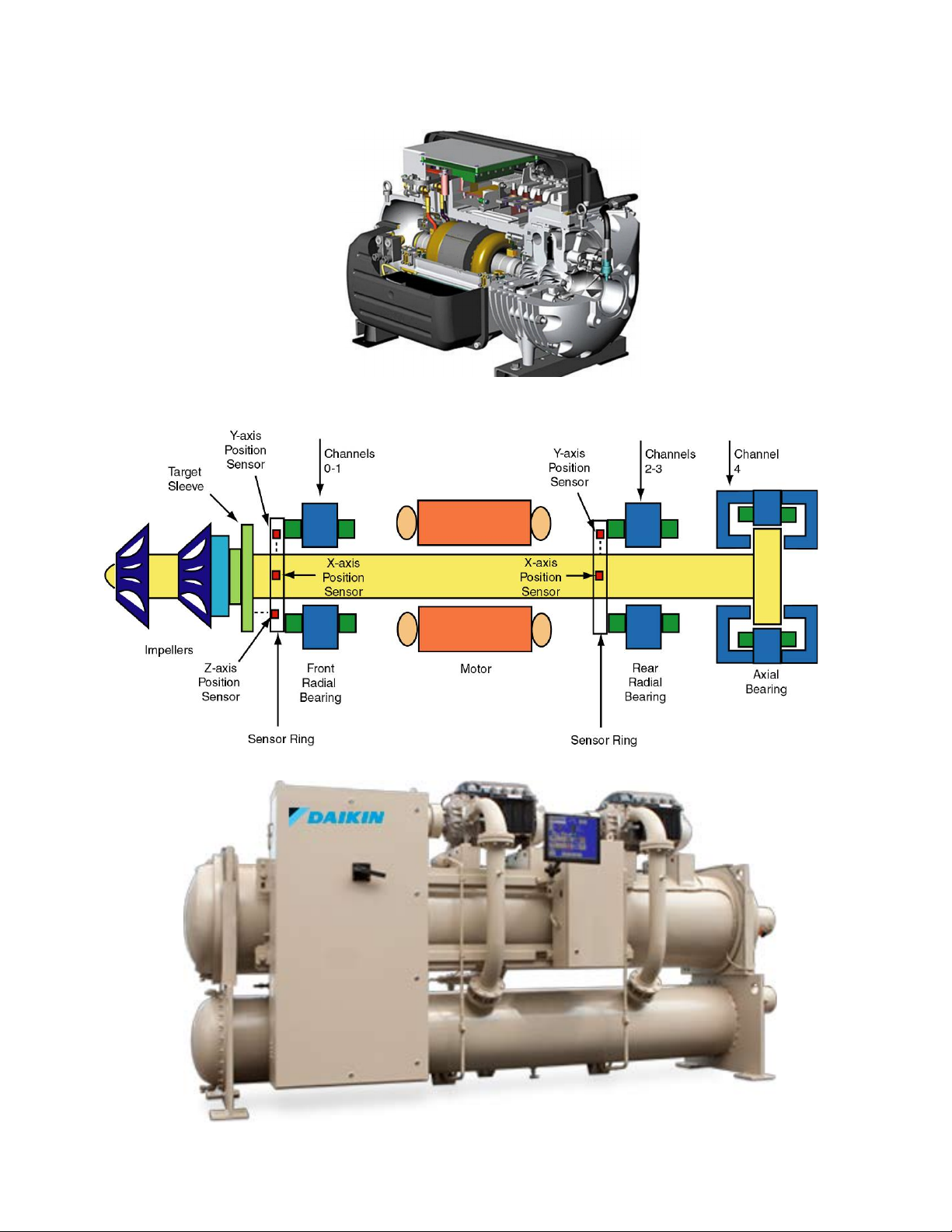

Cutaway View of Magnetic Bearing Compressor

Compressor Major Running Gear Components

MicroTech II® Controller Operator Interface, Home Screen

Page 3

Table of Contents

Manufactured in an ISO Certified Facility

Document: Catalog 602-2

Modbus™

Applies to 60 HZ only

The New Compressor Technology ........................................................................................................................ 4

Benefit Summary ............................................................................................................................................ 4

The Compressor Technology .......................................................................................................................... 5

Low Operating Costs ...................................................................................................................................... 6

Environmental Responsibility ........................................................................................................................ 6

Unit Control Features ..................................................................................................................................... 7

MicroTech II ® Control Features and Benefits ................................................................................................ 8

Unit Design Features ........................................................................................................................................... 12

Chiller Identification ........................................................................................................................................... 16

Sound Data ........................................................................................................................................................... 17

One-Third Octave Band ................................................................................................................................ 17

Dimensions ........................................................................................................................................................... 19

Marine Water Box Dimensions ..................................................................................................................... 25

Physical Data and Weights ................................................................................................................................. 27

Physical Data ................................................................................................................................................ 28

Relief Valves ......................................................................................................................................................... 29

Electrical Data ..................................................................................................................................................... 30

Power Factor Correction ............................................................................................................................... 40

VFD Line Harmonics ................................................................................................................................... 40

Application Considerations ................................................................................................................................ 42

Location ........................................................................................................................................................ 42

Optimum Water Temperatures and Flow ...................................................................................................... 42

System Water Volume ................................................................................................................................... 44

Pump Control ................................................................................................................................................ 44

Retrofit Knockdown ..................................................................................................................................... 45

Pressure Drop Curves ................................................................................................................................... 46

Options and Accessories...................................................................................................................................... 49

Refrigerant Recovery Units ................................................................................................................................ 51

Refrigerant Monitors .......................................................................................................................................... 52

Specifications ....................................................................................................................................................... 54

*Unit Controllers are LONMARK certified with an optional LONWORKS communication module.

Original Issue Date: February 2009

Revision Issue Date: May 2013

Replaces: February 2013

Software Version V08.20

©2013 Daikin Applied. Illustrations and data cover the Daikin product at the time of publication and we reserve the right to make

changes in design and construction at anytime without notice. ™® The following are trademarks or registered trademarks of their

respective companies: BACnet from ASHRAE; LONMARK, LonTalk, LONWORKS, and the LONMARK logo are managed, granted and

used by LONMARK International under a license granted by Echelon Corporation; Modbus from Schneider Electric; MicroTech II,

Open Choices from Daikin.

Catalog 602-2 3

Applies to 60 HZ only

Page 4

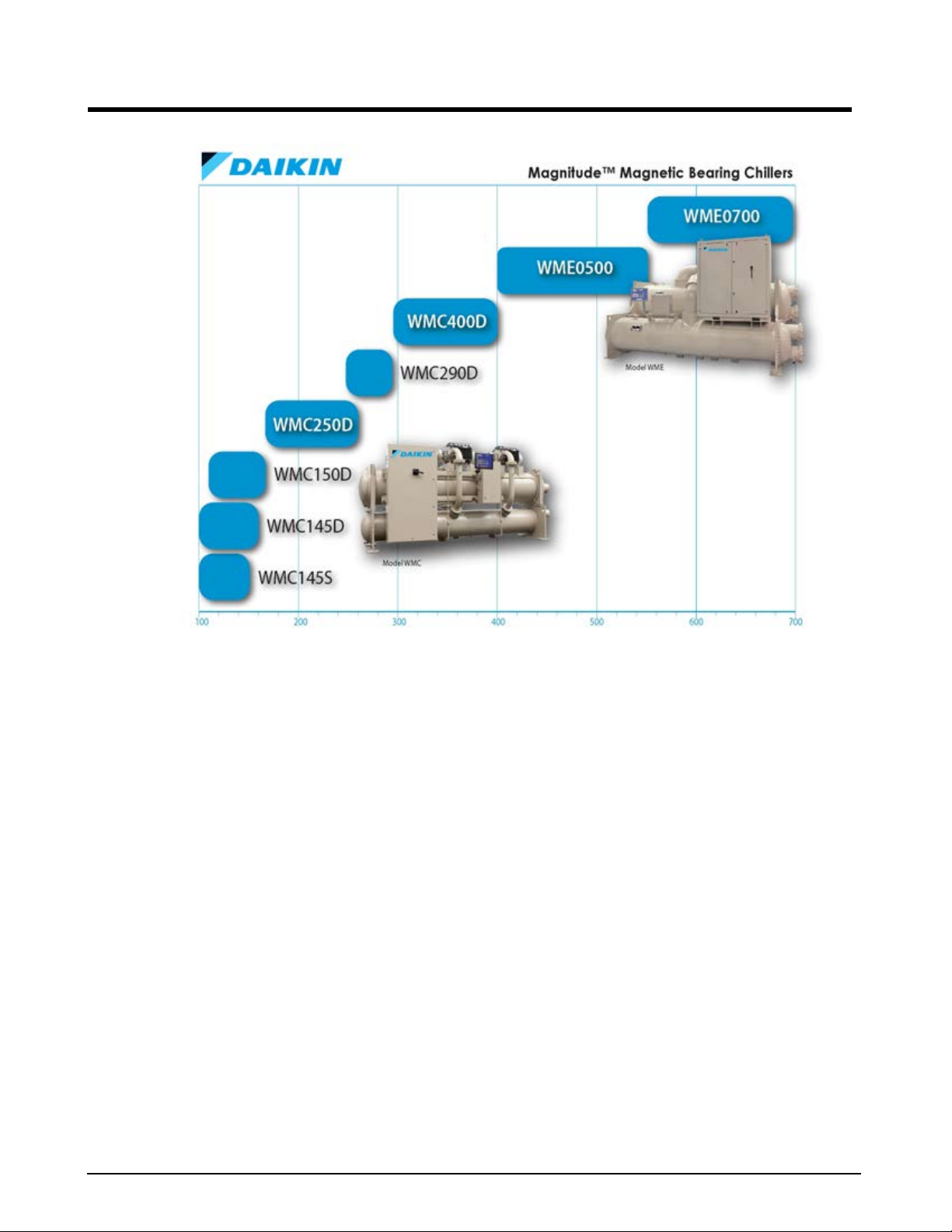

The New Compressor Technology

For Magnitude™ Model WME information see Catalog 604

Next Generation Centrifugal -

Here Today

The industry’s next generation of centrifugal chillers

is here today with Daikin Magnitude chillers. The new

technology begins with centrifugal compressors

utilizing frictionless magnetic bearings for oil-free

operation, integral variable-frequency drives, and

high-speed direct drive technology. The high

efficiency compressor is matched with highly efficient

heat exchanges to make an impressive chiller. The

control system is based on Daikin’s MicroTech II

family to provide the optimum chiller control system.

We invite you to look at how the features and benefits

compare to older compressor technologies.

Benefit Summary

• Highest Efficiency- in its size range; as low as

0.328 kW/ton.

•

Increased Reliability This frictionless

magnetic bearing design needs no oil. With no

oil to coat the heat transfer surfaces, a gain in

heat exchanger efficiency can be realized.

•

Ultra Quiet A compressor sound level as low

as 76 dBA, with virtually no structure-borne

vibration, eliminates the need for expensive sound

attenuation accessories.

• Sustainable Performance All oil-lubricated

chillers will deposit oil on heat transfer surfaces

and eventually lose some efficiency. Since the

Magnitude chiller uses a positive pressure

refrigerant and has no oil, its industry-leading

efficiency is maintained for the life of the

chiller. Additionally, over time negative

pressure chillers may draw air and moisture into

the system, which can significantly increase

energy consumption.

•

Smart refrigerant choice The compressor is

optimized for HFC 134a, the positive pressure

refrigerant with no phase-out schedule and no

ozone depletion.

•

Smart controls. The compressor is self-

correcting and incorporates a system of

sophisticated self-diagnostics, monitoring and

controls.

event of a power failure, the compressor motor

acts as a generator, providing power for the

bearing control system during coast down. It

also has a system to gently de-levitate the shaft.

Safe power interruption In the

4 Catalog 602-2

Page 5

Oil-Free Design Benefits

Totally Oil-Free Operation = Greater Efficiency

With no oil to coat the heat tr ansfer surfaces, a gain in

heat exchanger efficiency can be realized.

No Oil Loss = Sustainable Performance

With no possibility of oil loss at light loads or due to worn

seals, the original energy saving efficiency can be

maintained for the life of the chiller.

No Oil Handling Equipment = Greater Reliability

With magnetic bearings operating in a magnetic electrical

field instead of oil-lubricated bearings, the oil handling

equipment is removed. No need for:

oil pumps

oil reservoi rs

oil coolers

oil filters

water r egulating valves

oil relief valves

oil system controls, starter, piping, heaters, etc...

that are needed to maintain oil quality. These devices can

be a fault source in tr aditional chillers, and removing

them significantly increases unit and system reliability.

No Oil System = Reduced Maintenance Costs

With oil removed from the system, oil samples, oil

changes, oil system maintenance, oil f ilter changes and

leaks are eliminated.

The Compressor Technology

The advanced, magnetic bearing, permanent

magnet synchronous motor technology used in

Magnitude chillers offers many owner benefits.

Figure 1, Compressor Cutaway

Magnetic Bearings and

11..

Bearing Sensors

Permanent Magnet

22..

Synchronous Motor

Touchdown Bearings

33..

Shaft and Impellers

44..

Compressor Cooling

55..

VFD

66..

VFD = Ultra-Low IPLV

The well-proven energy performance advantages

of large central plant type variable-speed

centrifugal chiller compressors now benefit

mainstream, middle-market applications through

the use of high-speed, centrifugal compression

with integral variable-speed drive.

The compressor speed reduces as the condensing

temperature and/or cooling load reduces,

optimizing energy performance through the entire

operating range. Movable inlet guide vanes

redirect gas flow into the first stage impeller

during low loads, after the compressor has reached

minimum speed.

Ultra-Smart Controls

The chillers utilize digital control electronics to

proactively manage unit operation and providing

control of external chilled water and cooling tower

pumps.

Greater Reliability

Oil Handling Equipment Removed

With magnetic bearings operating in a magnetic

electrical field instead of oil lubricated ball or roller

friction type bearings as the basis of design, the oil

handling equipment is removed.

Catalog 602-2 5

Page 6

Exceptional Control

User-Friendly Touch Screen Panel

Every Magnitude chiller is provided with the userfriendly operator interface touch screen panel

mounted on the moveable positioning arm for easy

viewing and operation.

View chiller status, clear faults and change

parameters by merely touching the screen.

For added convenience, the unit operating and

maintenance manual is viewable on the screen and

can be downloaded and printed via the USB port

located in the control panel.

Low Operating Costs

Shrink Your Utility Costs with Ultra Efficient Part-Load Performance

The Magnitude chiller Integrated

Part Load Value (IPLV) is as low

as 0.328 kW/Ton. Compare this

with most screw compressor

chillers - approximately 0.575

kW/Ton. There is a potential for

up to 40% energy savings at part

load compared to other chillers.

Virtually Eliminate Maintenance Costs

Oi

l samples, oil change-outs, oil

system maintenance, oil filter

changes are eliminated. The

bearing system, shafting and

impellers are shown here.

Flexible BAS Interface Modules

Every Magnitude chiller with MicroTech®II

controls and the Open Choices™ feature can be

provided with L

Modbus communications modules for an easy, low

cost connection to the building automation system of

your choice. Expensive and complex interface

gateways are not required.

Modules can also be easily retrofitted after

installation.

ONWORKS, BACnet, or

Variable Frequency Drives

Compressor unloading and subsequent chiller

capacity reduction is accomplished by a

compressor-mounted variable frequency drive. It

operates in conjunction with the inlet guide vanes.

The VFDs are a key factor in providing the

tremendous energy savings at part load operation.

Seismic Certification Option

WMC units are OSHPD Pre-Approved and so

labeled. (California only).

WMC units are certified to IBC 2009

nvironmental Responsibility

E

Long Term Refrigerant Solution

The Magnitude chiller uses R-134a refrigerant,

which does not have a phase-out date and does not

attack the ozone layer.

Ultra Quiet Sound Levels

The Magnitude chiller is the quietest chiller in the

industry for its size range. It is perfect for sound

sensitive applications. See ratings on page 17.

The best way to appreciate how quiet these units are

is to hear one operate. It is important to compare the

sound data in this catalog to other offerings.

Remember that a sound pressure difference of only

two to three dBA is a very noticeable difference. A

number of owners have asked for a large indicating

light on the unit so they can tell when it’s on!

6 Catalog 602-2

Page 7

Extremely Low Vibration Levels

As a result of the magnetic bearings and low

inertia design, the compressor vibration levels are

extremely low, minimizing vibration that could be

transmitted to the structure.

The unit is shipped with rubber mounting pads and

spring vibration isolators are not required.

Unit Control Features

Magnitude Chillers Feature MicroTech

It is only fitting that the world’s most

revolutionary chiller design be matched with

the advanced Daikin MicroTech control

technology to give you the ultimate in chiller

performance and control. The control includes

many energy-saving features and interface

enhancements not found in any other unit controller

system on the market today. MicroTech controller's

innovative design will help keep your chiller

running efficiently . . . day in, day out, for years to

come.

Control Architecture

The Magnitude chiller takes advantage of Daikin

International’s 30 years of experience in designing

and manufacturing the highly regarded WDC line of

conventional, dual centrifugal compressor chillers.

The operator interface panel is a 15-inch Super

VGA touch-screen, utilizing graphics to provide

clear and concise information on the chiller status,

(see page 9) alarms, trends, and setpoint

adjustment. Should the touch-screen become

inoperable, the unit controller will continue

uninterrupted operation of the chiller.

The controller minds those functions that are

common to the chiller as a whole (pumps, cooling

tower, valves, etc.) and is the interface point for

BAS connection and other control inputs to the

chiller, as well as outputs such as operation of the

electronic expansion valve.

The control panel contains a USB port for

downloading the unit’s fault history, major

parameter trends, and the unit operating manual that

is stored in the microprocessor.

Catalog 602-2 7

Page 8

energy conservation

MicroTech II ® Control Features and Benefits

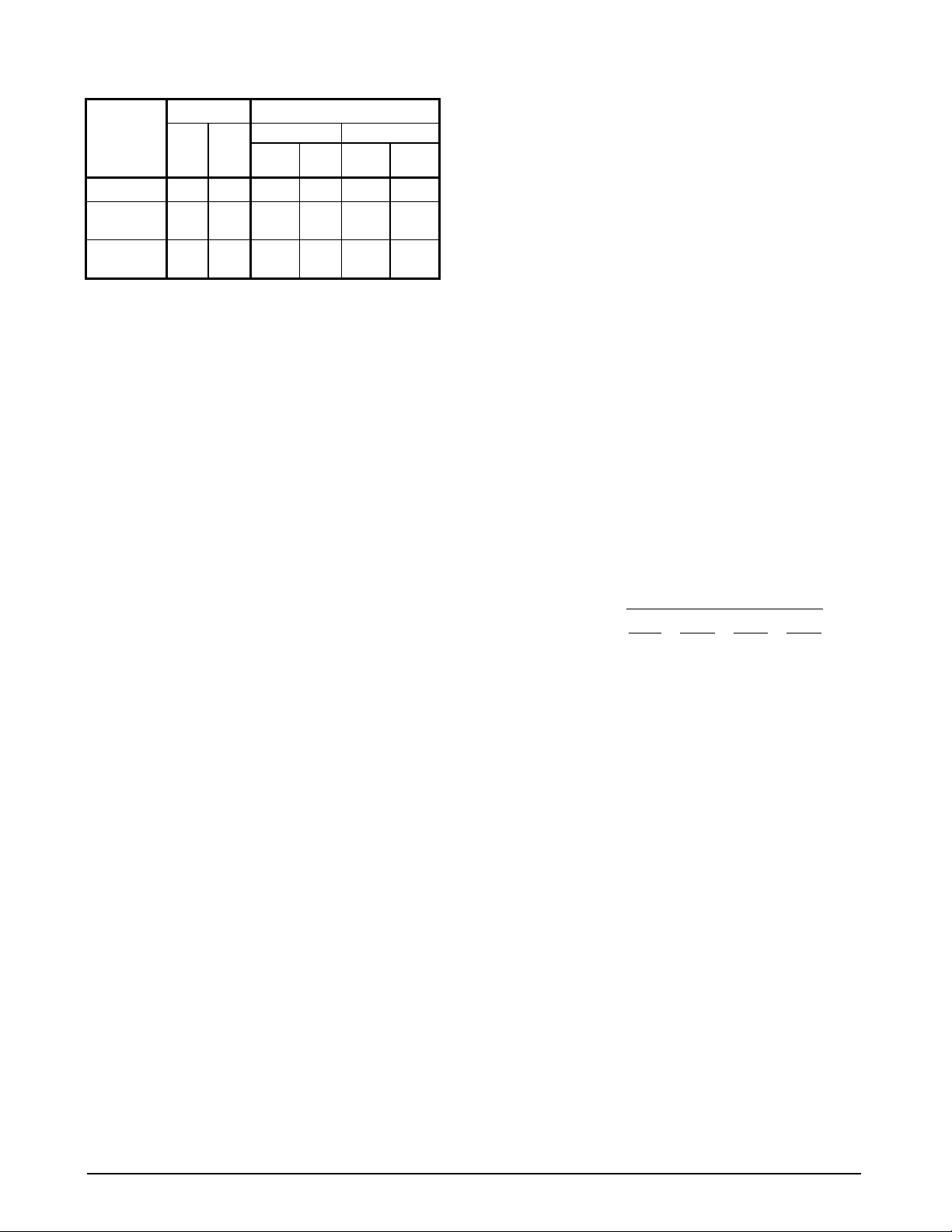

FEATURE BENEFIT

Easy integration into Building Automation System

(BAS) via the exclusive Open Choice™

communication module

Easy to read, adjustable, 15 inch, Super VGA color

touch screen operator interface

Historic trend data-downloadable

Precise ± 0.2 °F chilled water control

Proactive pre-shutdown correction of “unusual

conditions” allows chiller to stay online

Automatic control of chilled water and condenser

water pumps

Controls up to four stages of tower fans and

modulation of tower fan and/or bypass valve

Twenty-five previous alarm descriptions are stored

in memory

Up to four WMC chillers* can be interconnected

for coordinated operation

Designed with the Operator in Mind

Reliable, economic use of any chiller depends

largely on an easy operator interface. That’s why

operation simplicity was one of the main

considerations in the development of the

MicroTech controller. The operator’s interface

with the chiller is through a 15-inch, Super VGA

color monitor with touch-screen capability. The

operator can clearly see the entire chiller

graphically displayed with the key operating

parameters viewable on the screen. Pressing a

single on-screen button will access the set screens

where setpoints can be reviewed and changed, if

necessary. Other screens, such as alarm history,

are easily accessed through touch screen buttons.

See the following page for some typical screens.

By constantly monitoring chiller status, the

MicroTech controller will automatically take

proactive measures to relieve abnormal conditions

or shut the unit down if a fault occurs. For

example, if a problem occurs in the cooling tower

and discharge pressure starts to rise, the controller

will automatically hold the load point and activate

an alarm signal. A further rise in pressure will

initiate compressor unloading in an effort to

maintain the setpoint pressure and stay online. If

the pressure continues to rise, the unit will shut off

at the cutout pressure setting.

Designer can select any BAS supplier using standard

open protocols and know the MicroTech II control will

interface with it.

Provides stability in chilled water system

Valuable asset for trouble shooting

Simplifies multi-chiller installations

Operators can observe chiller operation and easily

select various data screens and change setpoints

Water temperatures, refrigerant pressures, and motor

load plots can provide valuable information for

Activates alarm and modifies chiller operation to

provide maximum possible cooling

Integrated lead/lag and automatic engagement of

backup pump

Optimum integrated, efficient, control of cooling tower

water based on system conditions

The MicroTech controller's memory retains a

record of faults and the time/date stamp. The

controller's memory (no batteries required) can

retain and display the cause of the current fault and

the last twenty-five fault conditions. This method

for retaining the fault is extremely useful for

trouble shooting and maintaining an accurate

record of unit performance and history. The

controller features a two-level password security

system to provide protection against unauthorized

use.

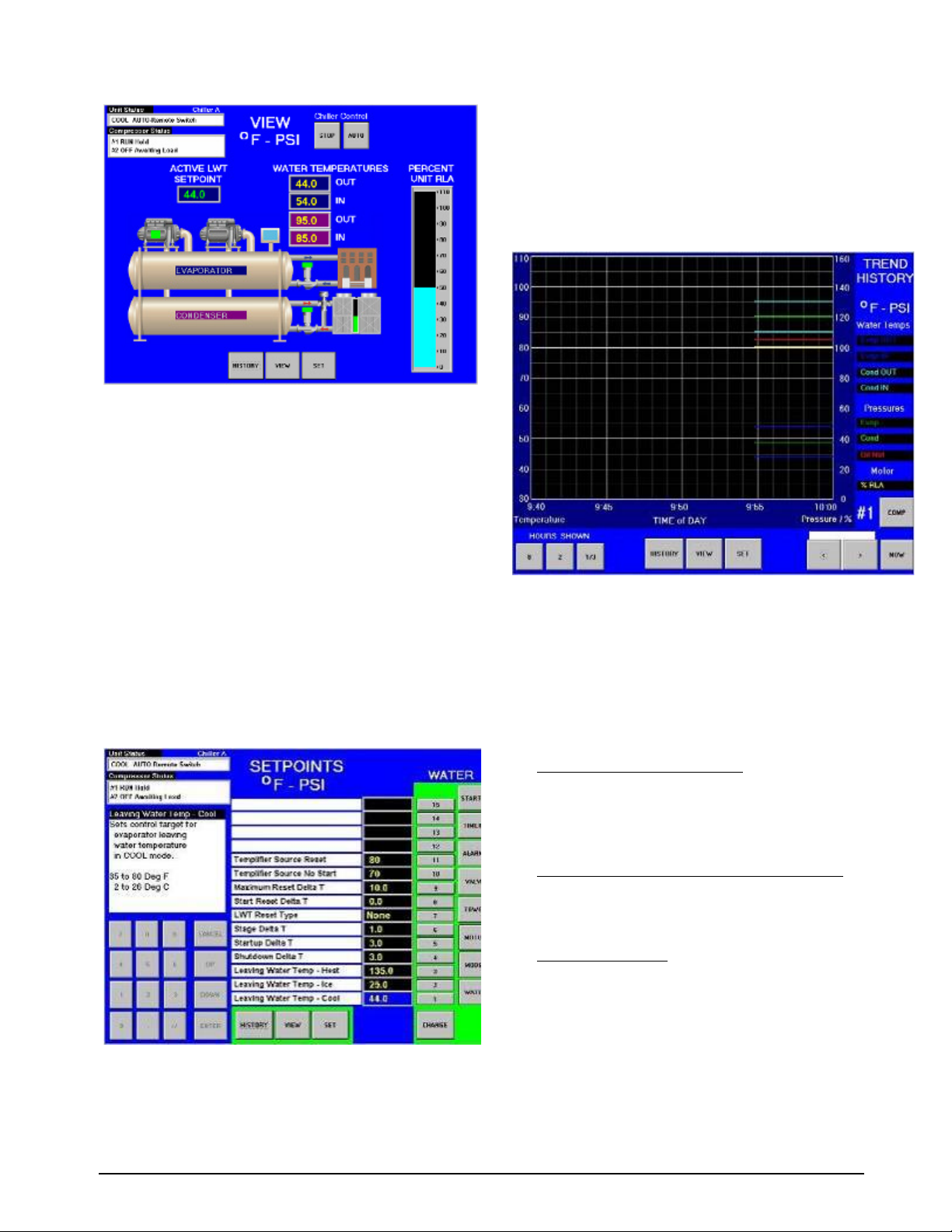

The Home Screen shown in Figure 2 is usually

used as the primary viewing screen. It provides real

time data on unit status, water temperatures, chilled

water set point and motor amp draw. In other

words, it very clearly answers the vital question: is

the chiller doing what it is supposed to do?

*Note: WMC B-vintage chillers may not be interconnected with any

other model, including WMC A-vintage models. See IM 10292 for more information.

8 Catalog 602-2

Page 9

Figure 2, MicroTech II Home Screen

an alarm occurs, a red button appears on the

If

screen (a remote signal is also available). Pressing

this button immediately accesses the Active Fault

Screen that gives complete fault information. The

problem can be fixed and the fault can be quickly

and easily cleared at this point.

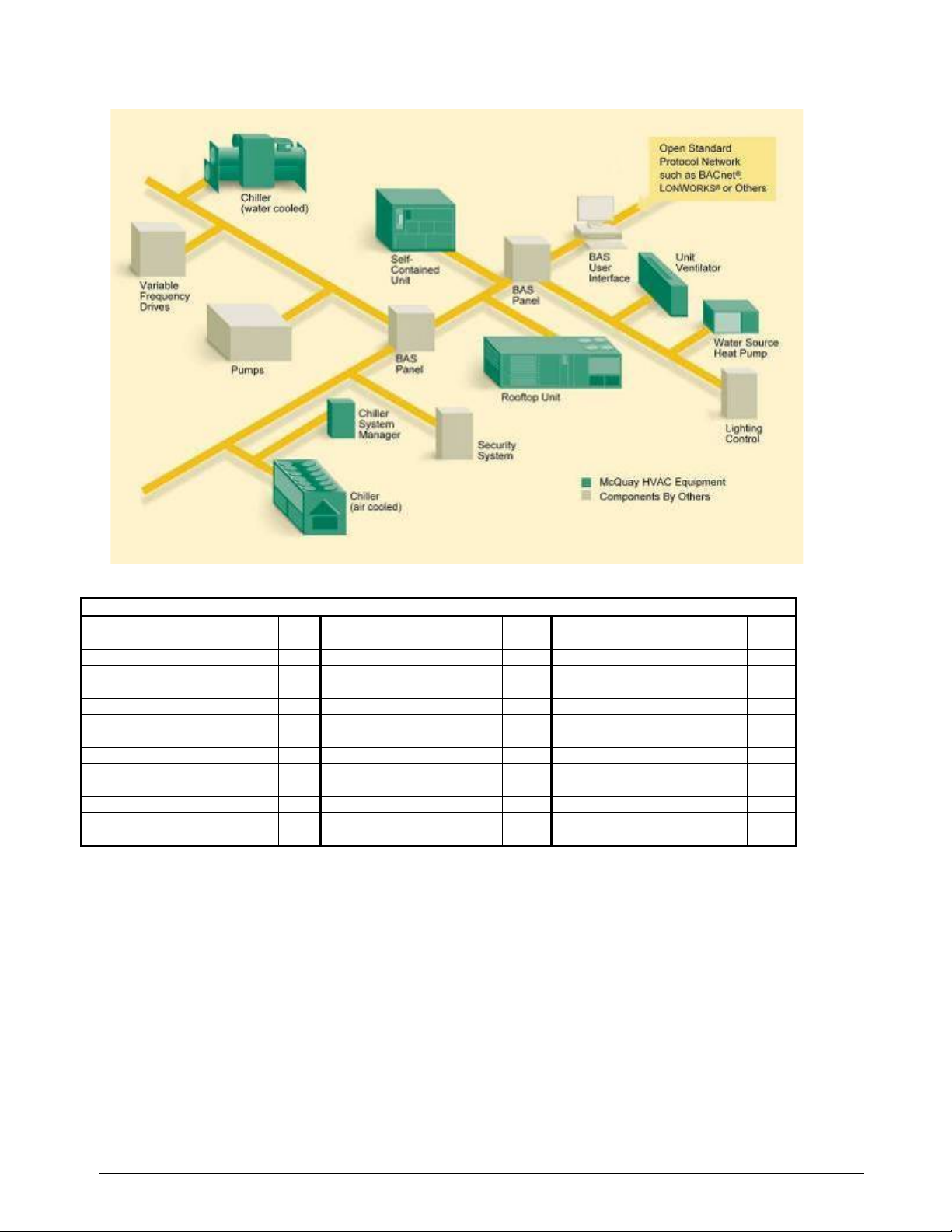

Changing Setpoints

The mystery of changing set points is a thing of

the past. Look at how easy the job becomes with

the Daikin MicroTech. For example, to change the

chilled water set point, press SET from any screen,

then press the WATER button and this screen

appears, press button #1, Leaving Water

Temperature, and you are ready to input a new

value. Selected setpoints can also be changed by

the BAS.

Fi

gure 3, MicroTech II Setpoints Screen

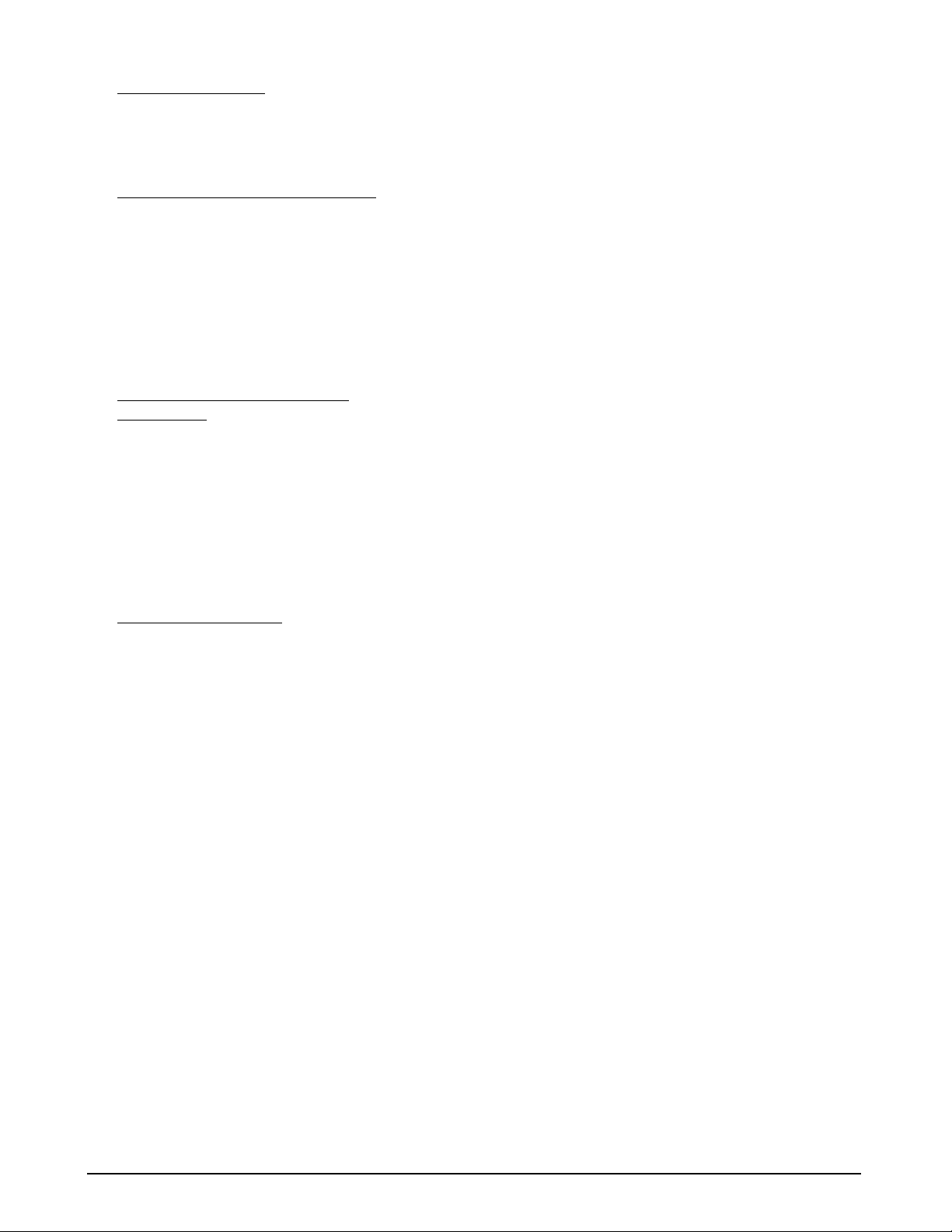

The Daikin MicroTech controller can record and

plot water temperatures, refrigerant pressures, and

motor load in order to trend performance. These

values can also be downloaded through a

convenient USB port in the control panel, and

exported into a spreadsheet for further evaluation

and record purposes.

Figure 4, Trend Logging Screen

MicroTech Controller Increases Chiller Operating Economy

Many standard features have been incorporated

into MicroTech control in order to maintain the

operating economy of Daikin centrifugal chillers.

In addition to replacing normal relay logic

circuits, we’ve enhanced the controller's energy

saving capabilities with the following features:

• Direct control of water pumps. Optically

isolated, digital output relays provide automatic

lead-lag of the evaporator and condenser

pumps, permitting pump operation only when

r

equired.

• User-programmable compressor soft loading.

Prevents excessive power draw during pull

down from high unoccupied chilled water

temperature conditions.

• Chilled-water reset. Accomplished directly on

he unit by resetting the leaving water

t

temperature based on the return water

temperature. A remote 4-20 ma or 1-5 VDC

BAS signal can also be used to reset th

eaving water. Raising the chilled water

Trend Logging

Ever wonder how your chiller performed last

week? Were you holding the required chilled water

temperature? What kind of cooling load did the

chiller have?

Catalog 602-2 9

l

setpoint during periods of light loads

dramatically reduces electrical consumption.

e

Page 10

• Demand limit control. Maximum motor current

draw can be set on the panel, or can be adjusted

from a remote 4-20 ma or 1-5 VDC BAS

signal. This feature controls maximum demand

charges during high usage periods.

• Condenser water temperature control. Capable

of four stages of tower fan control plus an

optional analog control of either a three-way

tower-bypass valve or variable speed tower-fan

motor. Stages are controlled from condenserwater temperature. The three-way valve can be

controlled to a different water temperature or

track the current tower stage. This allows

optimum chilled water plant performance

based upon specific job requirements.

• Staging Options (Multiple Chiller

Installations). Lead-lag and load-balance: the

MicroTech II controller is capable of

compressor lead-lag decisions and balancing

compressor loads between two compressors on

one unit or two separate Magnitude chillers,

using defaults or operator defined staging. For

example, in the 30 to 60 percent load segment,

one compressor running on each of two chillers

will provide better efficiency than two

compressors running on one chiller.

• Plotting Historic Trends. Past operation of the

chiller can be plotted as trend lines and even

downloaded to spread sheets for evaluation - a

valuable tool for optimizing efficiency.

Versatile Communications Capabilities Give You Even More Control

For complete flexibility there are four ways to

interface with the MicroTech II controller:

1. Direct entry and readout locally at the operator

interface panel on the unit.

2. Direct entry as above plus digital and analog

input/output signals for certain functions such

as: enable run input, alarm signal output, 4-20

ma or 0-5 VDC inputs for chilled water reset

and load limiting, pump and tower fan control,

analog output for variable speed fan and tower

bypass.

3. Interface with BACnet, L

ONWORKS, or

Modbus.

4. Direct communication between three

Magnitude WMC chillers (not compatible with

WME models).

Building Automation Systems

All MicroTech II controllers are capable of

communications providing seamless integration

and comprehensive monitoring, control, and twoway data exchange with industry standard

protocols Lon Talk

Open Choice Benefits

• Easy to integrate into your building automation

system supplier of choice

• Factory- or field-installed communications

module

• Provides efficient equipment operation

• Integrated control logic for factory options

• Easy-to-use local user interface

• Owner/designer can select the BAS that best

meets building requirements

• Comprehensive data exchange

®

or BACnet or Modbus.

10 Catalog 602-2

Page 11

Capacity Limit Output

R

Cond EWT

R

Evap Water Pump Status

R

Chiller Enable

W

Cond LWT

R

Run Enabled

R

Chiller Local/Remote

R

Cond Refrigerant Pressure

R

Liquid Line Refrigerant Temp

R

Chiller Mode Setpoint

W

Cond Water Pump Status

R

Minimum Send Time

R

Chiller Status

R

Evap Flow Switch Status

R

Cool Setpoint

W

Compressor Percent RLA

R

Evap LWT for Compressor

R

Default Values

W

Compressor Select

W

Evap Refrigerant Pressure

R

Actual Capacity

R

BACnet MS/TP

LonTalk (FTT-10A)

BACnet IP

Modbus RTU

BACnet Ethernet

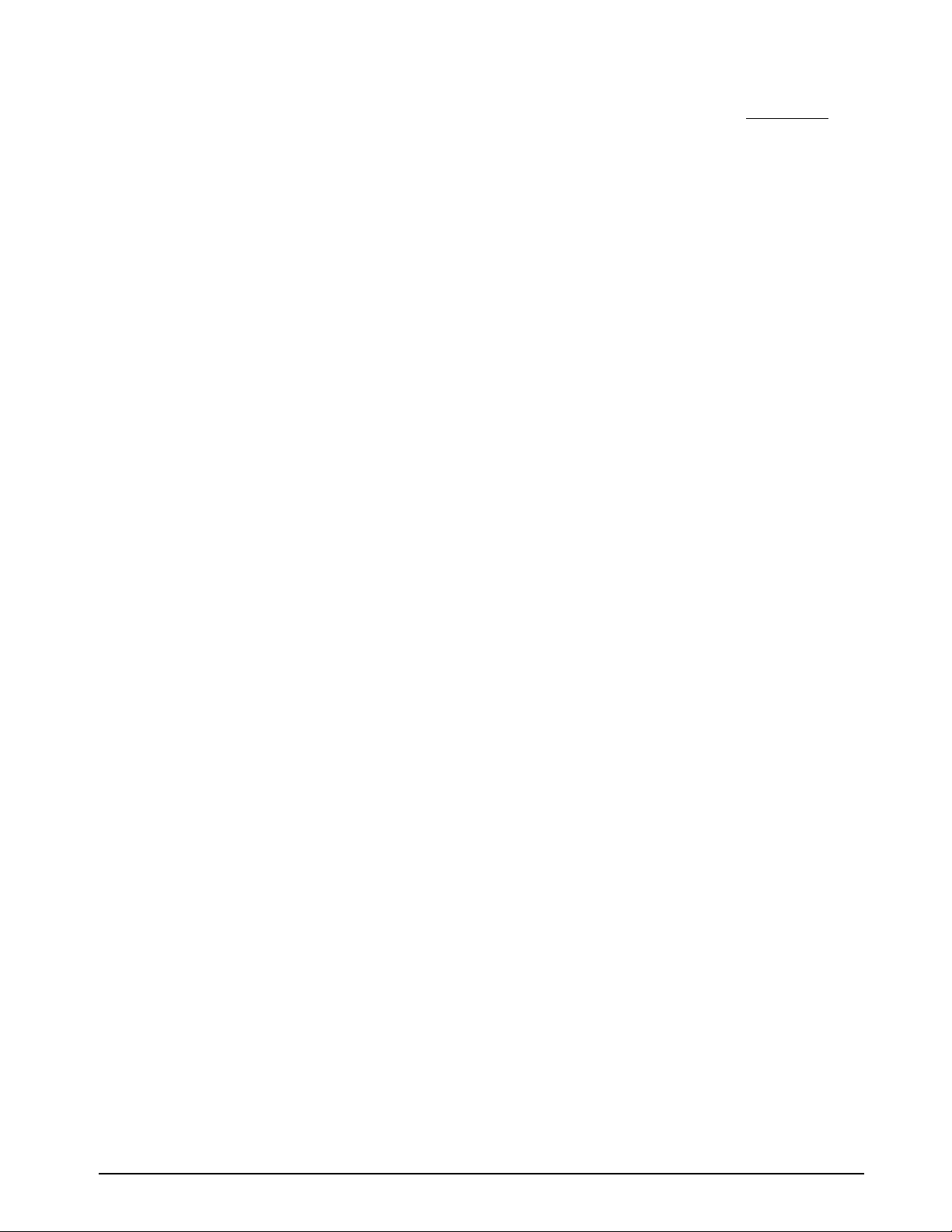

Figure 5, Sample System Architecture

Table 1, Typical Data Point Availability

Typical Data Points

Capacity Limit Setpoint W Cond Flow Switch Status R Pump Select W

Chiller Limited R Cond Pump Run Hours R Liquid Line Refrigerant Pressure R

Chiller Mode Output R Cond Sat. Refrigerant Temp R Maximum Send Time W

Chiller On/Off R Evap EWT R Network Clear Alarm W

Compressor Discharge Temp R Evap LWT for Unit R Current Alarm R

Compressor Run Hours R Evap Pump Run Hours R Active Setpoint R

Compressor Starts R Evap Sat. Refrigerant Temp R Compressor Suction Line Temp R

Notes: Data points available are dependent upon options selected

1

(W = Write, R = Read)

Network Protocol Options

Catalog 602-2 11

Page 12

Unit Design Features

Variable Frequency Drive

Efficiency: The standard variable frequency drive

is a technology that has been used for decades to

control motor speed on a wide variety of motordrive applications. When applied to centrifugal

compressor motors, significant gains in part load

performance can be realized. The improvement in

efficiency and reduction of annual energy cost is

maximized when there are long periods of part

load operation, combined with low compressor lift

(lower condenser water temperatures).

The attributes of VFD and the compressor

technology produces one of the industry's most

efficient chiller based on the all-important IPLV

value. See “IPLV/NPLV Defined” on page 14 for

details on the AHRI IPLV efficiency rating.

Starting Inrush: The use of a VFD on centrifugal

chillers also provides an excellent method of

reducing motor starting inrush-even better than

"solid state" starters. Starting current can be

closely controlled since both the frequency and

voltage are regulated. This can be an important

benefit to a building's electrical distribution

system. The low inrush feature, combined with two

one-half size compressors having a staggered start,

is particularly attractive where chillers will be

asked to operate on emergency generators. Since

inrush has much to do with sizing the generators,

much smaller generators can be used.

Optional Harmonic Filter

An optional field-mounted harmonic filter is

available. See page 40 for details.

HFC-134a

Daikin Positive Pressure Design:

• No

• No Vacuum Prevention System

• No Contaminants

HFC-134a operates above atmospheric pressure in

the entire refrigerant circuit and at normal

temperatures. All Daikin centrifugal chillers use a

positive pressure refrigerant, with the following

benefits:

• N

circuit

• No breakdown of motor insulation, refrigerant

or lubricant

• No increase in operating cost due t

d

condensables

Purge

o absorption of impurities into the refrigerant

o

isplacement of heat transfer surface by non-

• No crevice corrosion and tube failure due t

m

oisture in the system

• No annual service expense to maintain a

rebuild purge unit

• No abnormal annual service expense for oil

ilter, and refrigerant replacement

f

• No periodic emissions of refrigerant into the

atmosphere

o

nd

,

Heat Exchangers

Daikin Magnitude chillers are equipped with

high performance heat exchangers. The unique

design greatly increases heat transfer and

reduces unit footprint and refrigerant charge.

Vessels are designed, constructed and tested in

accordance with ASME Section VIII, ASHRAE

Standard 15 requirements and TEMA

recommendations.

T

he replaceable water tubes are internally rifled

and externally enhanced copper, and are

mechanically bonded to steel tube sheets. Standard

tubes are 0.025-inch wall thickness. Consult

factory for other options.

Vessels are available for 1, 2 or 3 pass water flow.

A 3/4" or 1-1/2 thick layer of vinyl/nitrate polymer

evaporator insulation is optional. All seams are

glued to form an effective vapor barrier. Detailed

information on the insulation can be found under

“Physical Data” on page 27.

Pumpdown

Pumpout systems provide a means to collect and

contain the refrigerant charge without loss when

access to internal chiller components is required

for service.

Daikin condensers and evaporators are sized to

hold the entire unit refrigerant charge when not

more than 90% full and at 90°F (32°C) ambient

temperature. They are equipped with valves in

the compressor discharge lines, suction lines, and

in the liquid line. These valves, coupled with the

vessel design, satisfy the stringent requirements

of the U.S. Department of Transportation for

refrigerant shipping containers, as well as ASME

vessel codes. When service is required, the

refrigerant charge can be pumped down into

either the condenser or evaporator by compressor

operation and use of a refrigerant transfer unit.

12 Catalog 602-2

Page 13

Elimination of the cost and space requirements of

an external pumpout system on most jobs is a

major Daikin advantage.

Electronic Expansion Valve

Controlled refrigerant flow over the entire capacity

range saves energy and dollars. Cooling loads and

condenser water temperatures can change

constantly. On Magnitude chillers, a modern

electronic expansion valve meters refrigerant flow

in direct response to the unit controller input,

which looks at unit kW and lift (discharge minus

suction pressure) to set the valve position. The

controller then balances suction superheat and

liquid subcooling to reach the optimum efficienc y,

regardless of changing load or condensing

temperatures. In doing so, full utilization of

compressor, evaporator, and condenser efficiency

over the entire operating range is achieved.

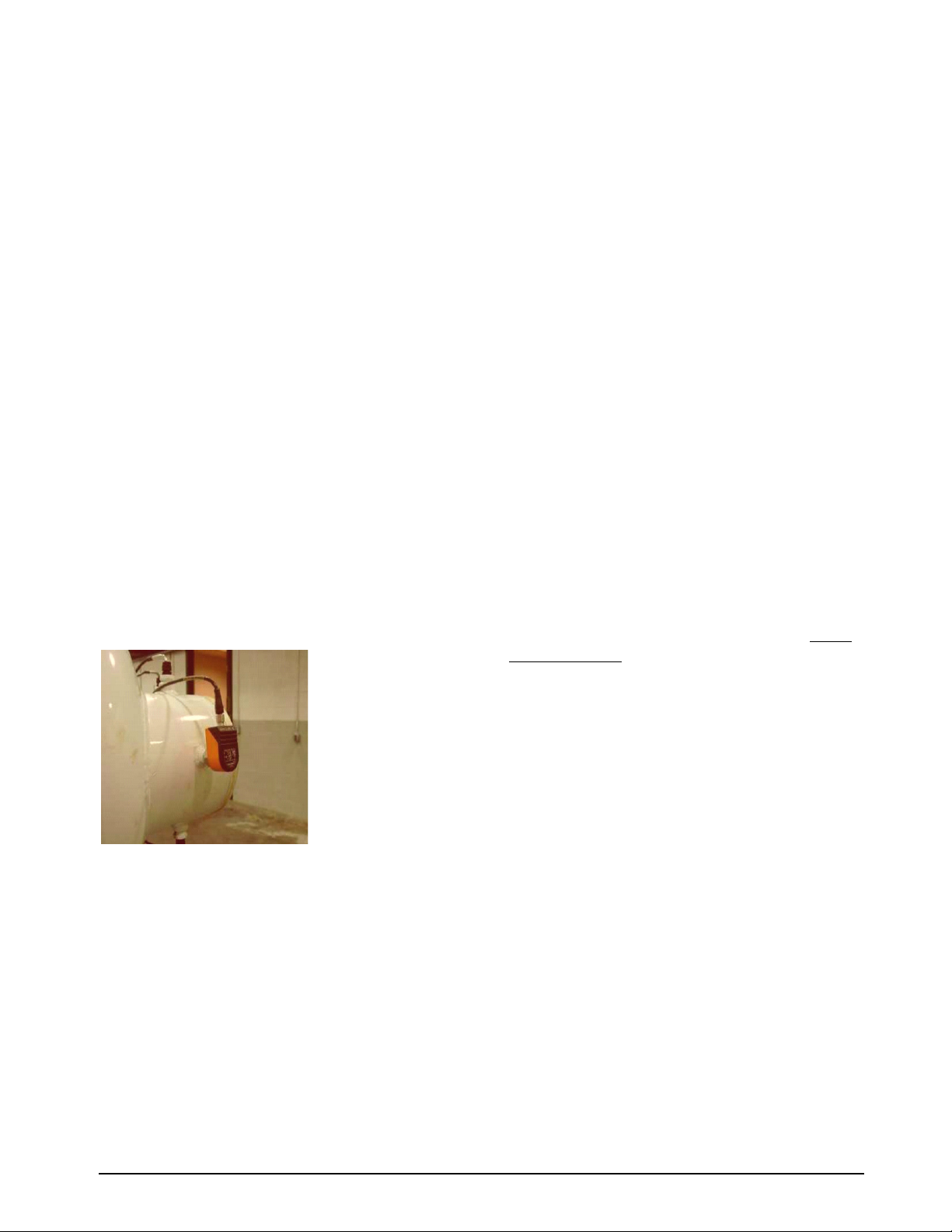

Flow Switch

All chiller units must be provided with flow

switches for the evaporator and condenser.

Daikin furnishes factory-installed and wired,

thermal dispersion-type flow switches as standard

equipment on Magnitude chillers. This eliminates

the expense of field mounting and wiring

conventional paddle or differential pressure

switches.

e flow switches

Th

prevent the unit

from starting

without sufficient

water flow through

the vessels. They

also serve to shut

down the unit in

the event that

water flow is

interrupted to

guard against evaporator freeze-up or excessive

discharge pressure.

Optional Witness Test

A factory engineer oversees the testing in the

presence of the customer or their designate and

translates the test data onto an easy-to-read

spreadsheet. Tests are run to AHRI tolerances of

capacity and power. 50 Hertz units are tested using

an on-site 50 Hertz generator.

Daikin Factory Service Startup

All Daikin centrifugal chillers are commissioned

by local Daikin Factory Service personnel or by

authorized Daikin startup technicians. This

procedure helps assure that proper starting and

checkout procedures are employed and helps speed

up the commissioning process.

Part Load Efficiency

According to ASHRAE, chillers usually spend

99% of their operating hours under part load

conditions and most of this time at less than 60%

of design capacity. One compressor of a dual

chiller operates with the full heat transfer surface

of the entire unit. For example, one 75-ton

compressor on a 150-ton dual chiller utilizes 150

tons of evaporator and condenser surface. This

results in very high unit efficiency and also

increases the compressor’s capacity.

The inclusion of VFDs, as standard, to the dual

compressor chiller can produce astonishing AHRI

Certified IPLVs,

selections can vary from this example.

as low as 0.328 kW/ton. Specific

Compliance with ASHRAE Std. 90.1

With the Magnitude chiller capacity range of 145

to 400 tons, they fall into three ASHRAE Std. 90.1

efficiency groups and revisions.

Additionally, for a higher margin of protection,

normally open auxiliary contacts in the pump

starters can be wired in series with the flow switches

as shown in the Field Wiring Diagram.

Optional Certified Test

A factory engineer oversees the testing, certifies the

accuracy of the computerized results, and translates

the test data onto an easy-to-read spreadsheet. The

tests are run to AHRI tolerance of capacity and

power. 50 Hertz units are tested using an on-site 50

Hertz generator.

Catalog 602-2 13

Page 14

Table 2, ASHRAE 90.1 Requirements (kW/ton)

Path A

Path B

Load-

Load-

150 Tons

< 300 Tons

300 Tons

600 Tons

DCBA

IPLVorNPLV

12.0

+

45.0

+

42.0

+

01.0

1

=

DCBAIPLVorNPLV 12.0+45.0+42.0+01.0=

Std. 90.1

Capacity

Range

< 150 Tons 0.703 0.669

≥

≥

<

NOTE: Beginning in 2010, the 90.1 efficiency

requirements have been divided into two groups,

designated as Path A and Path B. Path B is a new

category created for units with VFD compressor drives

that by nature have superior part-load efficiencies. WMC

Pre 2010 Starting in 2010

Full

IPLV

Load

0.634 0.596 0.634 0.596 0.639 0.450

0.576 0.549 0.576 0.549 0.600 0.400

Full

IPLV

0.634 0.596

Full

IPLV

0.639 0.450

Magnitude chillers, with their built-in VFDs, fall into

Path B.

The Path B IPLV values for 2010 are about 30 percent

less than the 2007 equivalent values. Also beginning in

2010, the minimum efficiency values are formula derived

instead tabular so that they can take flows and

temperatures other than AHRI standard into account.

AHRI Certification

Daikin has an on-going commitment to supply

chillers that perform as specified. To this extent,

Daikin centrifugal chillers are part of the AHRI

Certification Program. On-going performance

verification of chiller capacity and power input

plus AHRI certified computerized selection

output provide the owner with specified

performance in accordance with the latest version

of AHRI Standard 550/590.

All c

hillers that fall within the scope of the

certification program have an AHRI certification

label at no cost to the owner. Equipment covered

by the AHRI certification program includes all

water-cooled centrifugal and screw water chilling

packages rated up to 2500 tons (8800 kW) at AHRI

standard rating conditions, hermetic or open drive,

with electric driven motor not exceeding 5000

volts, and cooling water (not glycol).

Published certified ratings verified through testing

by AHRI include:

and performance tolerances of all units that fall

within the application rating conditions.

Leaving chilled water temp.: 40°F to 48°F (44°F

standard)

Entering condenser water temp.: 60°F to 95°F

Leaving chilled water temp.: 44°F

Evap. waterside field fouling allowance: 0.0001

Chilled water flow rate: 2.4 gpm/ton

Entering condenser water temp.: 85°F

Condenser waterside field fouling allowance:

0.00025

Condenser water flow rate: 3.0 gpm/ton

IPLV/NPLV Defined

Part load performance can be presented in terms of

Integrated Part Load Value (IPLV), which is based

on AHRI standard rating conditions (listed above),

or Non-Standard Part Load Values (NPLV), which

is based on specified or job site conditions. IPLV

and NPLV are based on the following weighting

equation from AHRI 550/590:

Us

ing kW/ton:

Wher

e:

A = kW/ton at 100%

B = kW/ton at 75%

C = kW/ton at 50%

D = kW/ton at 25%

Or

, using COP values:

Where:

A = COP at 100%

B = COP at 75%

C = COP at 50%

D = COP at 25%

The AHRI Standard 550/590 for Centrifugal or

Screw Water-Chilling Packages and associated

manuals define certification and testing procedures

14 Catalog 602-2

• Capacity, tons (kW)

• Power, kW/ton (COP)

• Pressure drops, ft. of water (kPa)

• Integrated Part Load Value (IPLV) or Non-

Standard Part Load Value (NPLV)

Page 15

% . ( . % )

%

Tolerance x FL

DTFLx FL

= − +

10 5 0 07

1500

Weighting

The percent of annual hours of operation at the

four load points are as follows:

ton (kW/ton), and heat balance is:

100% Load at 1%

75% Load at 42%

50% Load at 45%

25% Load at 12%

Note that the vast majority of hours are at the operating

range where dual compressor chillers excel.

Tolerances

The AHRI test tolerance, per AHRI Standard

550/590-98, for capacity (tons), power input per

Where:

FL = Full Load

DTFL = Chilled Water Delta-T at Full Load

This formula results in a ±5% tolerance on tons

and kW/ton at the 100% load point and AHRI

conditions.

Catalog 602-2 15

Page 16

MODEL CODE EXAMPLE:

Packaged Water Cooled

M = Magnetic

Centrifugal Compressor Model

Unit Model Code

Motor/Voltage Code

Evaporator Shell Description

Tube Count Code

Tube Type Code

Number of Passes (1, 2, 3)

Water Inlet Location (R = Right Inlet; L = Left Inlet)

Connection Type

Condenser Shell Description [Diameter (in.), Length (ft.)]

Tube Count Code

Tube Type Code

Tube Count Code (Heat Recovery Condenser)

Tube Type Code (Heat Recovery Condenser)

Number of Passes (1, 2, 3)

Wate

r Inlet Location (R = Right Inlet; L = Left Inlet)

Connection Type

Number of Passes (Heat Recovery Condenser)

Water Inlet Location (Heat Recovery Condenser)

Motor Manufacturer

N/A

N/A

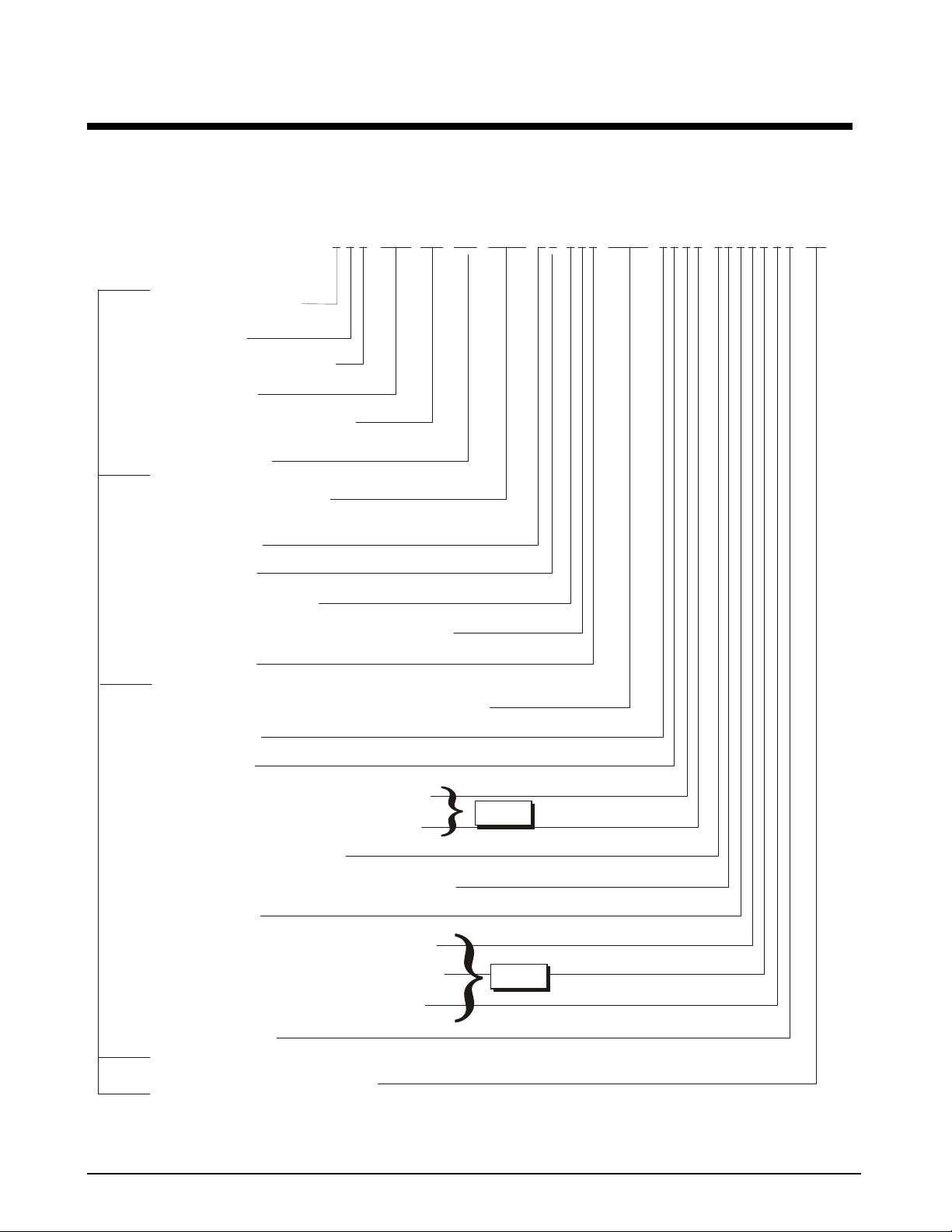

Chiller Identification

Magnitude centrifugal chillers are selected by computer and identified by their components on the selection

printout as a Model #. The unit model code is as follows:

Figure 6, Chiller Identification

C

O

M

P

R

E

S

S

Vintage/Single Refrigerant Circuit

O

R

E

V

[Diameter (in.), Length (ft.)]

A

P

O

R

A

T

O

R

W M C - 150D - BS - 13R / E2212 - B E - 2 RA / C2012 - B L Y Y - 2 R A Y Y Y R 134

C

O

N

D

E

N

S

E

R

Connection Type (Heat Recovery Condenser)

Refrigeration Type (134 = HFC-134a)

16 Catalog 602-2

Page 17

63 Hz

125 Hz

250 Hz

500 Hz

1 kHz

2 kHz

4 kHz

8 kHz

75

78.0

Octave Band

63 Hz

125 Hz

250 Hz

500 Hz

1 kHz

2 kHz

4 kHz

8 kHz

100

37.5

49.5

56.0

65.0

72.0

70.0

66.5

64.0

75.5

75

39.5

48.5

55.0

61.0

69.5

64.5

64.0

60.0

72.5

25

36.0

48.5

54.5

57.5

65.5

60.5

57.5

52.0

68.0

Octave Band

63 Hz

125 Hz

250 Hz

500 Hz

1 kHz

2 kHz

4 kHz

8 kHz

100

37.5

51.5

59.5

72.0

75.0

72.5

76.5

75.0

81.5

75

37.0

50.5

62.5

66.5

70.0

69.5

74.0

70.5

78.0

50

75.0

25

37.5

49.0

59.0

63.0

65.0

66.0

69.5

64.0

73.5

Octave Band

63 Hz

125 Hz

250 Hz

500 Hz

1 kHz

2 kHz

4 kHz

8 kHz

100

83.5

25

44.5

51.5

61.0

64.5

67.5

73.0

73.0

62.0

77.0

50

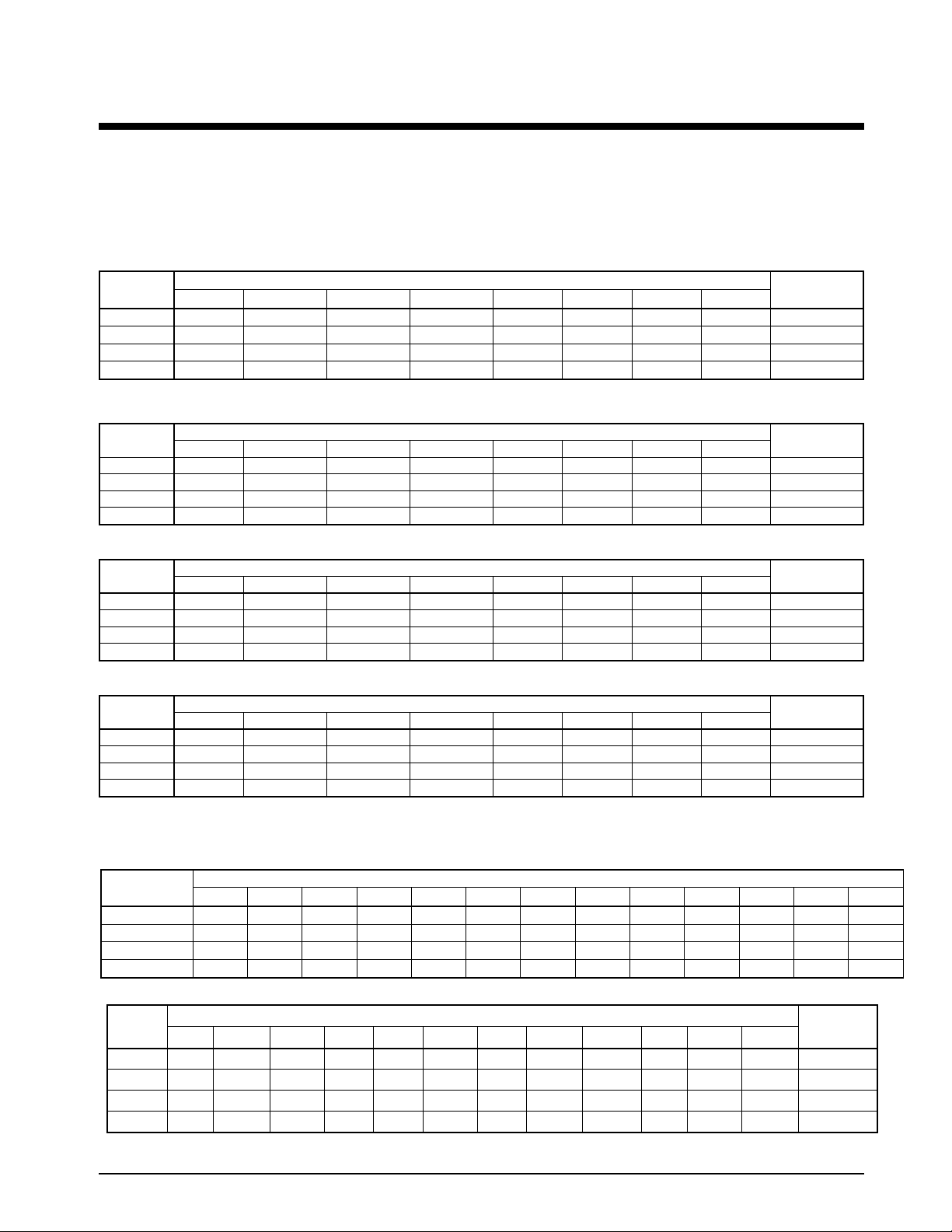

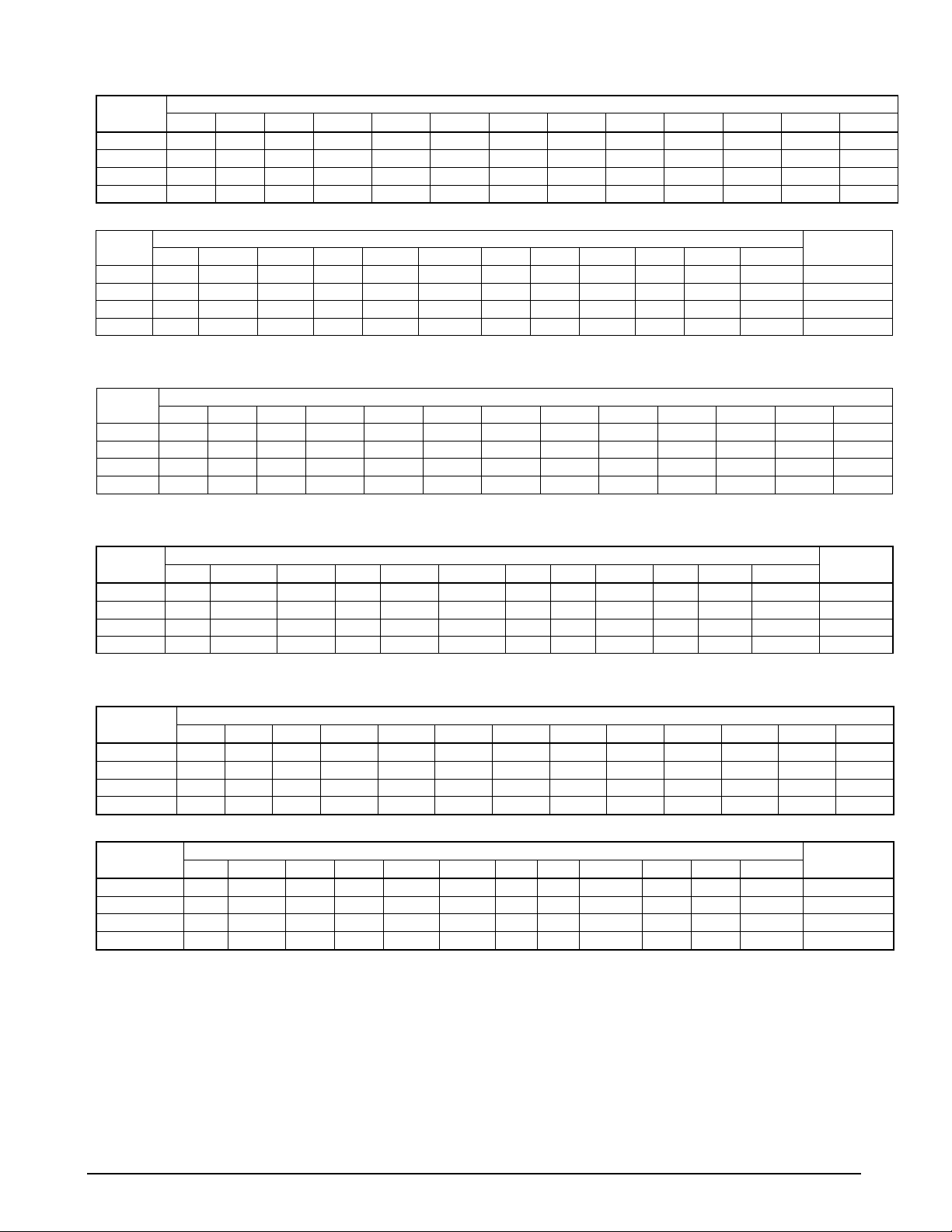

Sound Data

The following sound pressure ratings are for

measurements one meter from the unit and in

accordance with ANSI/AHRI Standard 575. The

ratings are for the various part loads shown and at

lowering of sound level as the units unload.

Ratings are “A” weighted measured at one-meter

from the unit. The 25 percent values are with one

compressor running.

the center bands. Note that there is a considerable

Table 3, WMC 145S Sound Pressure (dB), 50/60 Hz

Percent

Load

100

50

25

37.0 50.0 61.0 67.0 74.5 71.5 73.0 75.5

39.5 49.0 60.5 66.0 72.5 69.0 71.0 72.0

37.0 47.5 60.0 64.5 66.5 68.0 69.5 68.0

38.0 50.0 58.0 66.5 68.5 70.0 69.5 70.0

Octave Band

Table 4, WMC 145D/150D, Sound Pressure (dB), 50/60 Hz

Percent

Load

50

35.5 48.0 54.5 58.0 66.0 61.0 58.5 53.5

Table 5, WMC 250D/290D, Sound Pressure (dB), 50/60 Hz

Percent

Load

A-Weighted

80.5

75.0

76.5

A-Weighted

68.5

A-Weighted

37.5 50.0 60.0 65.0 65.5 66.0 71.5 66.0

Table 6, WMC 400D, Sound Pressure (dB), 50/60 Hz

Percent

Load

46.0 55.5 65.5 70.5 74.5 76.0 80.0 74.5

75

50

45.5 55.5 65.5 69.5 73.5 76.5 79.0 72.5

45.0 54.5 64.0 69.0 71.0 74.5 77.5 70.0

One-Third Octave Band

Table 7, WMC 145S, One-Third Octave Band Sound Ratings

Percent

Load

100

75

25

50 Hz 63 Hz 80 Hz 100 Hz 125 Hz 160 Hz 200 Hz 250 Hz 315 Hz 400 Hz 500 Hz 630 Hz 800 Hz

33.5 32.0 30.5 38.0 46.5 46.5 49.0 59.0 56.0 60.5 63.0 63.0 69.5

34.0 36.0 33.0 39.0 45.0 45.5 49.5 58.5 54.5 58.5 60.0 63.5 71.0

31.5 33.5 31.5 37.5 44.5 43.5 48.0 58.5 54.0 53.0 57.0 63.5 58.0

32.0 32.5 34.5 37.0 47.0 46.5 49.5 55.5 53.0 55.0 59.0 65.0 59.5

Table 7, continued

Percent

Load

1 kHz 1.25 kHz 1.6 kHz 2 kHz 2.5 kHz 3.15 kHz 4 kHz 5 kHz 6.3 kHz 8 kHz 10 kHz 12.5 kHz

100

75

50

25

64.0 72.5 66.0 67.5 66.5 66.5 68.0 69.5 72.0 71.0 69.5 67.5

64.0 65.5 64.5 65.5 63.0 64.0 66.0 68.0 69.5 66.5 64.5 62.0

60.5 64.0 63.5 64.5 61.0 61.5 65.5 65.5 65.5 62.5 60.0 58.5

62.5 66.5 65.0 66.5 64.0 63.5 65.0 66.0 67.0 64.5 62.5 60.0

Octave Band

Octave Band

A-Weighted

82.5

81.0

A- Weighted

80.5

78.0

75.0

76.5

Catalog 602-2 17

Page 18

Load

Octave Band

50 Hz

63 Hz

80 Hz

100 Hz

125 Hz

160 Hz

200 Hz

250 Hz

315 Hz

400 Hz

500 Hz

630 Hz

800 Hz

100

32.5

32.0

34.0

38.0

48.0

42.0

46.0

53.5

51.0

53.0

62.5

60.5

61.0

75

32.0

32.0

37.5

37.0

47.0

41.0

45.5

52.5

50.0

53.5

58.0

55.5

62.5

50

26.5

30.5

33.0

36.5

47.0

39.0

43.5

52.5

48.5

52.0

53.5

54.5

62.0

25

100

70.5

65.0

68.0

62.0

63.0

62.5

61.0

61.5

60.0

59.0

59.0

58.0

75.5

Load

Octave Band

50 Hz

63 Hz

80 Hz

100 Hz

125 Hz

160 Hz

200 Hz

250 Hz

315 Hz

400 Hz

500 Hz

630 Hz

800 Hz

100

32.0

32.5

33.0

38.0

49.0

47.5

50.5

56.0

56.0

70.0

65.5

65.0

71.0

75

32.0

32.5

32.5

37.5

48.0

46.0

48.5

54.0

61.5

60.5

58.0

64.0

63.0

50

33.0

33.0

32.0

37.0

48.5

43.5

47.5

53.0

58.5

52.5

57.5

64.0

57.5

25

Load

Octave Band

Weighted

1 kHz

1.25 kHz

1.6 kHz

2 kHz

2.5 kHz

3.15 kHz

4 kHz

5 kHz

6.3 kHz

8 kHz

10 kHz

12.5 kHz

100

67.0

71.0

68.0

67.0

68.5

69.5

71.5

73.0

71.0

72.0

67.0

64.5

81.5

75

66.0

65.5

64.5

64.5

64.5

67.5

69.5

70.5

66.5

67.0

63.5

60.5

78.0

50

75.0

25

58.5

62.0

60.5

61.0

62.0

63.5

66.0

64.5

59.5

61.0

55.5

54.4

73.5

Octave Band

75

Octave Band

Table 8, WMC 145D/150D, One-Third Octave Band Sound Ratings

Percent

31.5 30.5 32.0 36.5 47.5 40.5 43.5 52.5 49.5 50.5 52.5 54.5 57.5

Table 8, continued

Percent

Load

1 kHz 1.25 kHz 1.6 kHz 2 kHz 2.5 kHz 3.15 kHz 4 kHz 5 kHz 6.3 kHz 8 kHz 10 kHz 12.5 kHz

Octave Band

A- Weighted

75

50

25

67.5 61.5 59.5 58.5 60.5 59.0 60.0 58.0 55.0 54.0 56.5 57.5

57.5 62.5 57.0 55.5 55.5 54.5 55.5 50.0 48.0 45.5 51.0 50.5

63.5 58.0 56.5 56.0 54.0 53.5 54.0 49.5 48.0 45.0 47.5 48.0

Table 9, WMC 250D/290D, One-Third Octave Band Sound Ratings

Percent

33.0 33.0 31.5 35.5 48.0 42.0 45.5 56.0 56.0 49.5 58.5 61.0 59.0

Table 9, continued

Percent

60.0 63.0 60.5 61.0 62.0 65.0 68.5 66.5 62.0 62.0 59.0 57.5

Table 10, WMC 400D, One-Third Octave Band Sound Ratings

Percent

Load

100

50

25

50 Hz 63 Hz 80 Hz 100 Hz 125 Hz 160 Hz 200 Hz 250 Hz 315 Hz 400 Hz 500 Hz 630 Hz 800 Hz

36.0 42.5 42.5 45.5 52.0 52.0 56.0 60.0 63.5 64.5 65.5 67.0 69.5

35.5 42.5 42.0 45.5 51.5 52.0 55.5 60.0 63.5 64.0 65.0 65.0 70.5

34.0 41.5 42.0 43.5 49.0 52.5 56.0 61.5 58.5 63.5 65.0 64.0 66.0

34.0 41.5 41.0 41.5 45.5 50.0 57.0 55.5 55.5 58.5 59.0 61.0 62.0

72.5

68.5

68.0

A-

Table 11, continued

Percent Load

100

75

50

25

1 kHz 1.25 kHz 1.6 kHz 2 kHz 2.5 kHz 3.15 kHz 4 kHz 5 kHz 6.3 kHz 8 kHz 10 kHz 12.5 kHz

71.0 68.5 70.0 72.0 72.0 72.0 75.0 77.5 71.5 69.5 66.0 63.0

68.0 67.5 69.5 71.0 73.5 72.0 74.5 75.5 69.5 68.0 65.0 61.5

65.5 66.5 68.0 69.0 71.5 70.0 73.0 74.5 67.0 65.0 63.5 57.5

62.0 63.5 65.5 71.5 64.5 66.0 71.0 64.0 59.5 57.0 53.5 49.0

18 Catalog 602-2

A-Weighted

83.5

82.5

81.0

77.0

Page 19

6.2

157

14.7

375

112.1

2846

101.6

2579

128.3

3259

5.3

TYP.BOTH

ENDS

133

29.3

CONDENSER

RELIEF

VALVES

744

58.3

EVAPORATOR

RELIEFVALVE

1480

134.7

(UNITOVERALL)

3421

18.0

458

11.1

283

17.1

435

FRONT

END

BOX

UNIT

CTRL

BOX

EVAPORATOR

CONDENSER

COMPRESSOR

FRONTVIEW

X

Y

5,7,8

3

3

3

3

114.8

2916

57.5

1460

22.5

EVAPORATOR

RELIEFVALVE

571

22.6

SUCTION

RELIEF

VALVE

574

26.9

CONDENSER

RELIEF

VALVES

684

TOPVIEW

RB

RF

LF

LB

Z

X

4

3

3,4

3,4

5,13

5,13,14

5,7,8

4.0

102

26.5

673

34.5

876

10.0

254

32.7

8

31

37.8

960

44.3

(OVERALLWIDTH)

1126

16.8

425

44.8

1137

65.9

TOP UNIT

CTRL BOX

1675

74.3

TOP FRONT

ENDBOX

1887

81.0

TOP

COMPR.

2058

69.8

SUCTION

RELIEF

VALVE

1774

O.I.T.S.

IN

IN

OUT

OUT

RIGHTVIEW

Y

Z

5

5

5,10,12

5

4

5

5

5.6

INLET

142

5.6

OUTLET

142

8.0

NOM.

TYP.(2X)

203

EVAPORATORHEAD2-PASS

VICTAULIC150 PSI WATERSIDE

C

L

C

L

OUT

IN

7,8

13.0

INLET

330

19.0

OUTLET

483

5.6

OUTLET

143

5.6

INLET

143

6.0

NOM.

TYP.(2X)

152

CONDENSERHEAD2-PASS

VICTAULIC150 PSI WATERSIDE

C

L

C

L

IN

OUT

7,8

13.0

INLET/

OUTLET

330

11.3

287

114.8

2916

34.5

876

1.13

MTG. HOLE

(TYP.)

29

6.3

160

8.9

225

16.0

407

31.9

809

34.0

864

9.0

230

14.0

357

13.8

352

8.0

203

8.0

203

MOUNTING

FOOT(TYP.)

ELECTRICAL

CONNECTIONS

FRONTEND BOX

UNITCTRL BOX

ALLDIMENSIONSAREIN DECMAL

INCHESAND [MILLIMATERS]

SEEDRAWING332835001FORNOTES

RB

LB

LF

RF

5,13,14

5,13

WMC145SBS

332834001 00 NONE

DRAWINGNUMBER REV. SCALE

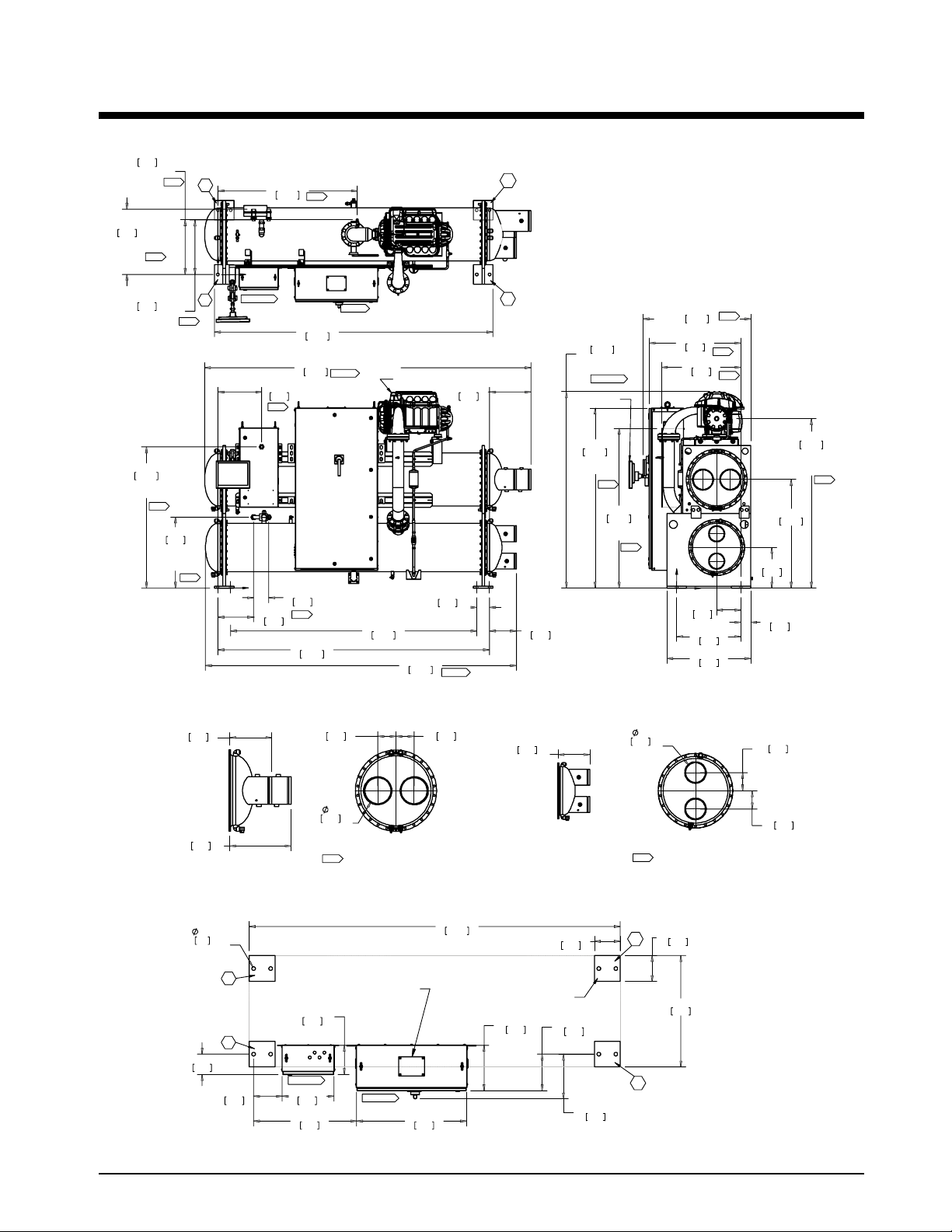

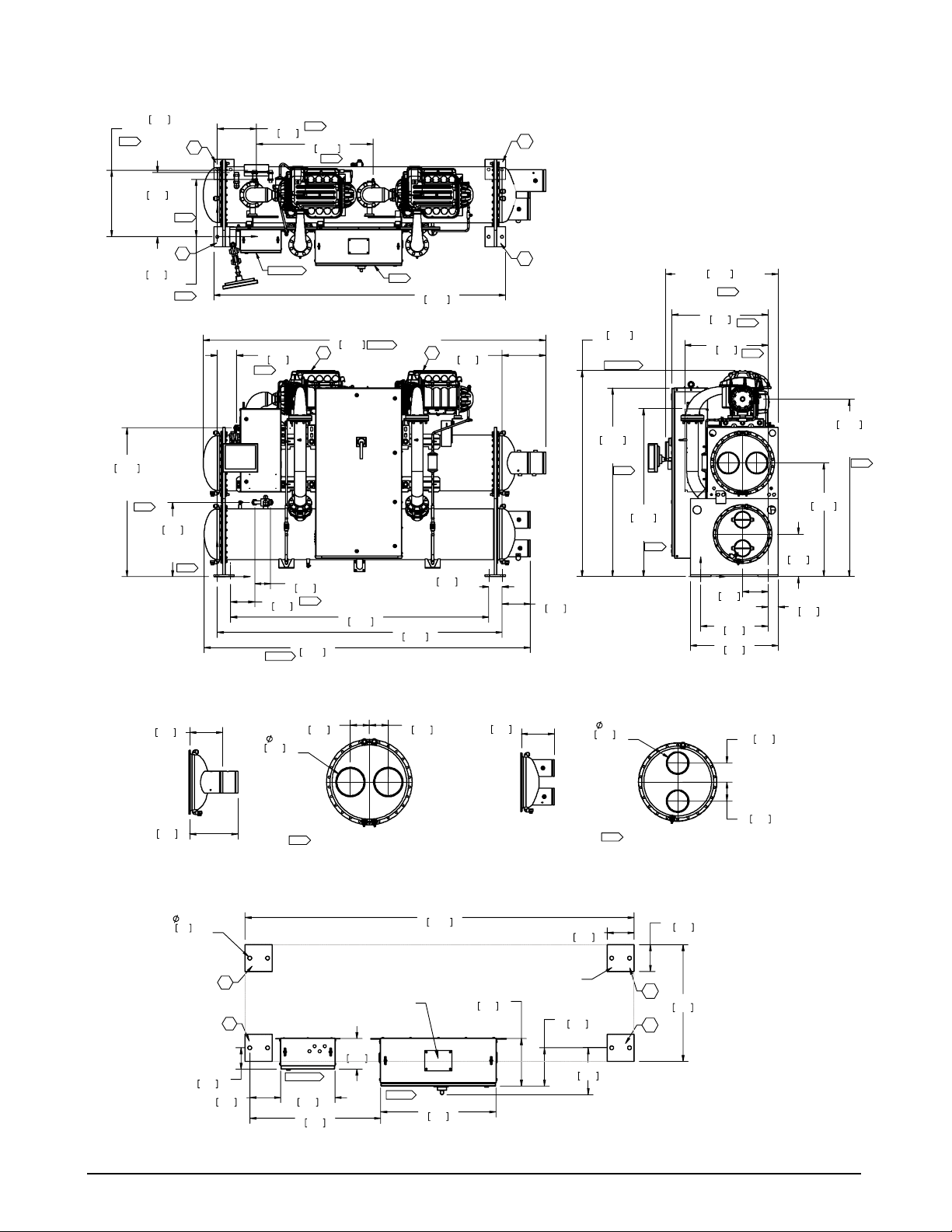

Dimensions

Figure 7, WMC 145S (B-vintage), 2-Pass, Right-hand (See page 26 for notes.)

Catalog 602-2 19

Page 20

7.6

194

6.2

157

9.5

241

101.6

2579

112.1

2846

5.3

TYPICAL

BOTH ENDS

133

128.3

3259

29.2

CONDENSER

RELIEF

VALVES

742

58.6

EVAPORATOR

RELIEF

VALVES

1487

134.7

(UNITOVERALL)

3421

17.1

435

11.1

283

UNIT

CTRL

BOX

FRONT

END

BOX

CONDENSER

EVAPORATOR

FRONTVIEW

#1 #2

3

3

3

3

5

5,7,8

Y

X

114.8

2916

15.4

391

46.0

1168

22.6

SUCTION

RELIEF

VALVE

574

25.3

EVAPORATOR

RELIEF

VALVE

643

26.3

CONDENSER

RELIEF

VALVES

667

TOPVIEW

4

4

3,4

3,4

5,13,14

5,13

RB

RF

LF

LB

5,7,8

3

X

Z

34.5

876

26.5

673

10.0

254

44.3

(OVERALLWIDTH)

1126

37.8

960

69.8

SUCTION

RELIEF

VALVES

1774

74.3

TOP FRONT

ENDBOX

1887

81.1

TOP

COMPR.

2060

4.0

102

44.8

1137

16.8

425

66.1

TOP UNIT

CTRLBOX

1678

32.7

831

IN

RIGHTVIEW

IN

OUT

5,10,12

5

5

5

5

4

OUT

Y

Z

5.6

OUTLET

143

5.6

INLET

143

6.0

NOM.

TYP.(2X)

152

CONDENSERHEAD 2-PASS

VICTAULIC150PSI WATERSIDE

OUT

IN

7,8

13.0

INLET/

OUTLET

330

5.6

142

5.6

142

8.0

NOM.

TYP.(2X)

203

EVAPORATORHEAD2-PASS

VICTAULIC150PSI WATERSIDE

OUT

IN

7,8

13.0

INLET

330

19.0

OUTLET

483

114.8

2916

34.5

876

8.0

203

8.0

203

11.3

287

14.0

357

34.0

864

38.6

981

9.1

232

16.0

407

6.3

160

9.0

230

1.13

MTG.HOLE

(TYP.)

29

13.8

352

FRONTENDBOX

UNITCTRL BOX

MOUNTING

FOOT(TYP.)

ELECTRICAL

CONNECTIONS

ALLDIMENSIONSAREIN DECIMAL

INCHESAND [MILLIMETERS]

SEEDRAWING 332835001 FORNOTES

TOPVIEW

LB

LF

RF

RB

5,13,14

5,13

WMC145DBS

332834101 00 NONE

DRAWINGNUMBER REV. SCALE

Figure 8, WMC 145D (B-vintage), 2-Pass, Right-hand (See page 26 for notes)

20 Catalog 602-2

Page 21

136.4

3466

146.9

3732

5.3

TYP.BOTH

ENDS

133

163.2

4145

11.1

283

169.6

(UNITOVERALL)

4307

17.1

435

15.5

393

15.9

405

6.2

157

29.2

CONDENSER

RELIEF

VALVES

742

58.2

EVAPORATOR

RELIEF

VALVES

1479

FRONTVIEW

#1

#2

FRONT

END

BOX

UNIT

CTRL

BOX

CONDENSER

EVAPORATOR

X

Y

5,7,8

3

3

3

3

46.6

1184

46.0

1168

146.9

3732

22.6

SUCTION PIPE

RELIEF VALVES

574

21.8

EVAPORATOR

RELIEF VALVES

554

26.3

CONDENSER

RELIEF VALVES

667

TOPVIEW

RB

RF

LF

LB

Z

X

4 4

3

3,4

3,4

5,13,14

5,13

5,7,8

16.8

425

44.8

1137

74.3

TOP

FRONT

END BOX

1887

81.1

TOP

COMPR.

2060

69.8

SUCTION

RELIEF

VALVES

1774

44.3

(OVERALLWIDTH)

1126

37.8

960

32.8

833

66.0

TOP UNIT

CTRL BOX

1677

10.0

254

4.0

102

26.5

673

34.5

876

RIGHTVIEW

IN

IN

OUT

OUT

O.I.T.S.

Y

Z

5

5

5

5

5

4

5,10,12

149.7

3802

34.5

876

8.0

203

8.0

203

1.13

MTG.HOLES

(TYP.)

29

11.4

289

34.0

864

82.6

2098

16.0

407

14.0

357

9.0

230

6.3

160

11.3

287

13.8

352

MOUNTING

FOOT(TYP.)

TOPVIEW

ELECTRICAL

CONNECTION

FRONTEND BOX

UNITCTRL BOX

SEEDRAWING332835001 FORNOTES

LB

LF

RF

RB

5,13 5,13,14

5.6

INLET

142

5.6

OUTLET

142

8.0

NOM.

TYP.(2X)

203

EVAPORATOR HEAD 2-PASS

VICTAULIC150PSI WATERSIDE

IN

OUT

7,8

13.3

INLET

337

19.3

OUTLET

489

5.6

OUTLET

143

5.6

INLET

143

6.0

NOM.

TYP.(2X)

152

CONDENSER HEAD 2-PASS

VICTAULIC150PSI WATERSIDE

OUT

IN

7,8

13.3

INLET/

OUTLET

337

WMC150DBS

ALLDIMENSIONSAREIN DECIMAL

INCHESAND [MILLIMETERS]

332834201

DRAWINGNUMBER

NONE

SCALE

00

REV.

Figure 9, WMC 150D (B-vintage), 2-Pass, Right-hand (See page 26 for notes)

Catalog 602-2 21

Page 22

112.1

2846

134.7

3421

17.1

435

11.1

283

11.1

283

29.2

CONDENSER

RELIEF

VALVES

742

61.2

EVAPORATOR

RELIEF

VALVE

1555

135.7

(OVERALLUNIT)

3447

6.2

157

5.3

TYP.BOTH

ENDS

133

8.1

206

101.6

2579

9.5

241

FRONTVIEW

#1 #2

FRONT

END

BOX

UNIT

CTRL

BOX

CONDENSER

EVAPORATOR

X

Y

5,7,8

3

3

3

15.9

403

46.0

1168

24.2

SUCTION

RELIEF

VALVES

615

114.8

2916

28.9

EVAPORATOR

RELIEF VALVES

735

27.9

CONDENSER

RELIEF VALVES

708

TOPVIEW

RB

RF

LF

LB

Z

X

4

4

3

3,4

3,4

5,13,14

5,13

5,7,8

12.0

305

30.1

765

4.0

102

38.1

968

15.8

400

45.8

1162

72.8

SUCTION

RELIEF

VALVES

1850

74.0

TOP

FRONT

ENDBOX

1881

84.0

TOP OF

COMPR.

2134

41.5

1054

48.0

(OVERALLWIDTH)

1220

65.7

TOP UNIT

CTRL BOX

1669

36.4

925

RIGHTVIEW

IN

IN

OUT

OUT

O.I.T.S.

Y

Z

5

5

5

5

5

4

5,10,12

8.0

203

8.0

203

38.1

968

114.8

2916

9.1

232

16.0

407

9.0

230

14.0

357

11.4

289

38.9

987

34.0

864

1.13

MTG.HOLE

TYP.

29

13.9

353

MOUNTINGFEET

TOPVIEW

ELECTRICAL

CONNECTION

FRONTENDBOX

UNITCTRL BOX

SEEDRAWING332835001 FORNOTES

LB

LF

RF

RB

5,13

5,13,14

7.1

INLET

180

7.1

OUTLET

180

8.6

NOM.

TYP.(2X)

219

EVAPORATORHEAD 2-PASS

VICTAULIC150PSI WATERSIDE

IN

OUT

13.3

INLET

337

13.3

OUTLET

337

5.6

OUTLET

142

5.6

INLET

142

8.6

NOM.

TYP.(2X)

219

CONDENSERHEAD 2-PASS

VICTAULIC150PSI WATERSIDE

OUT

IN

19.3

INLET/

OUTLET

489

WMC250DBS

ALLDIMENSIONSAREINDECIMAL

INCHES AND [MILLIMETERS]

332834301

DRAWINGNUMBER

NONE

SCALE

00

REV.

Figure 10, WMC 250D (B-vintage), 2-Pass, Right-hand (See page 26 for notes)

22 Catalog 602-2

Page 23

146.9

3732

136.4

3466

61.2

EVAPORATOR

RELIEF

VALVES

1554

170.6

(UNITOVERALL)

4333

15.5

393

5.9

151

6.2

157

17.1

435

5.3

TYPICAL

BOTH ENDS

133

11.1

283

29.2

CONDENSER

RELIEF

VALVES

742

163.6

4155

FRONTVIEW

#1

#2

FRONT

END

BOX

UNIT

CTRL

BOX

CONDENSER

EVAPORATOR

X

Y

5,7,8

3

3

3

3

24.2

SUCTION

RELIEF

VALVE

615

27.9

EVAPORATOR

RELIEF

VALVE

708

149.7

3802

23.4

CONDENSER

RELIEF

VALVES

595

49.1

1247

46.0

1168

TOPVIEW

RB

RF

LF

LB

Z

X

4 4

3

3,4

3,4

5,13,14

5,13

5,7,8

12.0

305

30.1

765

4.0

102

38.1

96

8

15.8

400

45.8

1162

72.8

SUCTION

RELIEF

VALVES

1850

74.1

TOP

FRONT

ENDBOX

1881

84.0

TOP OF

COMPR.

2134

65.9

TOP UNIT

CTRL BOX

1673

36.5

927

41.5

1054

48.0

(OVERALLWIDTH)

1220

RIGHTVIEW

IN

IN

OUT

OUT

O.I.T.S.

Y

Z

5

5

5

5

5

4

5,10,12

8.0

203

8.0

203

38.1

968

149.7

3802

1.13

MTG.HOLE

TYP.

29

11.4

289

34.0

864

11.4

289

82.6

2098

16.0

407

14.0

357

9.0

230

6.4

162

13.9

353

MOUNTINGFEET

TOPVIEW

ELECTRICAL

CONNECTION

FRONTENDBOX

UNITCTRL BOX

SEEDRAWING332835001 FORNOTES

LB

LF

RF

RB

5,13

5,13,14

7.1

INLET

180

7.1

OUTLET

180

8.0

NOM.

TYP.(2X)

203

EVAPORATORHEAD 2-PASS

VICTAULIC150PSI WATERSIDE

IN

OUT

13.3

INLET

337

13.3

OUTLET

337

5.6

OUTLET

142

5.6

INLET

142

8.0

NOM.

TYP.(2X)

203

CONDENSERHEAD 2-PASS

VICTAULIC150PSI WATERSIDE

OUT

IN

19.3

INLET/

OUTLET

489

WMC290DBS

ALLDIMENSIONSAREINDECIMAL

INCHES AND [MILLIMETERS]

332834401

DRAWINGNUMBER

NONE

SCALE

00

REV.

Figure 11, WMC 290D (B-vintage), 2-Pass, Right-hand (See page 26 for notes.)

Catalog 602-2 23

Page 24

136.4

3466

6.2

157

5.9

151

5.3

TYPICAL

BOTH ENDS

133

146.9

3732

164.4

4174

35.0

CONDENSER

RELIEF

VALVES

888

72.0

EVAPORATOR

RELIEF

VALVE

1829

15.5

393

11.1

283

14.1

359

168.7

(UNITOVERALL)

4285

FRONTVIEW

CONDENSER

EVAPORATOR

FRONT

END

BOX

UNIT

CTRL

BOX

#1 #2

X

Y

5,7,8

5,7,8

3

3

3

3

47.1

1197

46.0

1168

149.7

3802

28.9

EVAPORATOR

RELIEF

VALVES

734

29.0

SUCTION

RELIEF

VALVES

737

33.4

CONDENSER

RELIEF

VALVES

847

TOPVIEW

LB

LF

RB

Z

X

4 4

3

3,4

3,4

5,13

5,13,14

RF

13.1

332

36.0

914

4.0

102

44.0

1

118

19.5

495

54.5

1385

83.4

RELIEF

VALVES

2117

73.4

TOP

UNIT

CTRL

BOX

1864

81.6

TOP

FRONT

END

BOX

2074

94.5

TOP OF

COMPR.

2401

50.8

(OVERALLWIDTH)

1289

44.2

1123

39.2

996

IN

IN

OUT

OUT

RIGHTVIEW

O.I.T.S.

Y

Z

5

5

5

5

5

3

5,10,12

149.7

3802

11.4

289

34.0

864

82.6

2098

16.0

407

8.2

208

14.0

357

9.0

230

3.2

81

8.0

203

8.0

203

1.13

MTG. HOLE

(TYP.)

29

10.8

273

44.0

1118

MOUNTING

FOOT(TYP.)

ELECTRICAL

CONNECTIONS

TOPVIEW

FRONTEND BOX

UNITCTRL BOX

WMC400DBS

332834501 00

SCALE

DRAWINGNUMBER

REV

.

NONE

ALLDIMENSIONSAREIN DECIMAL

INCHESAND[ MILLIMETERS]

SEEDRAWING332835001FORNOTES

LF

LB

RB

RF

5,13

5,13,14

7.1

OUTLET

180

7.1

INLET

180

8.0

NOM.

TYP.(2X)

203

CONDENSERHEAD2-PASS

VICTAULIC150 PSI WATERSIDE

C

L

C

L

IN

OUT

7,8

13.0

INLET/

OUTLET

330

8.1

INLET

207

8.1

OUTLET

207

10.0

NOM.

TYP(2X)

255

EVAPORATORHEAD2-PASS

VICTAULIC150 PSI WATERSIDE

C

L

IN

OUT

7,8

16.0

INLET/

OUTLET

406

C

L

Figure 12, WMC 400D (B-vintage), 2-Pass, Right-hand (See page 26 for notes.)

24 Catalog 602-2

Page 25

Marine Water Box Dimensions with Victaulic or Flanged Connections

REAR FACING ONLY

REAR FACING ONLY

REAR FACING ONLY

Marine water boxes are an available option on all evaporator and condenser sizes. Caution: There is some

nomenclature confusion in the industry. We refer to our standard dished heads as “dished heads”. Some

manufacturers refer to them, or similar devices as “water boxes”. They are not “marine water boxes” with

removable end covers as illustrated below.

150 PSI Non-ASME - Victaulic Connection

Evap.

Cond.

Notes:

1. Dimensions in inches.

2. Flanges are ANSI raised face. Mating flanges by others.

3. Some condensers with flanges can have staggered connections due to flange interference. Consult factory.

4. Flanges add 0.5 inches to the distance from the vertical centerline to the flange face compared to Victaulic.

Catalog 602-2 25

1 PASS 2 PASS 3 PASS

Dia.

'AAA' 'BBB' 'CCC 'DDD' 'EEE' 'AAA' 'BBB' 'CCC' 'DDD' 'EEE' 'FFF' 'GGG' 'AAA' 'BBB' 'CCC' 'DDD' 'EEE' 'FFF'

E22

10.75 17.00 21.25 20.00 10.00 8.625 17.00 21.00 20.00 10.00 5.59 23.00 5.563 17.00 21.25 20.00 10.00 7.12

E26

10.75 19.00 21.25 20.00 10.00 8.625 19.00 21.25 20.00 10.00 7.07 19.00 6.625 19.00 21.25 20.00 10.00 8.07

E30

14.00 21.00 28.50 26.50 13.25 10.75 21.00 28.50 26.50 13.25 8.13 21.00 6.625 21.00 28.50 26.50 13.25 10.19

1 PASS 2 PASS 3 PASS

Dia.

'AAA' 'BBB' 'CCC 'DDD' 'EEE' 'AAA' 'BBB 'CCC' 'DDD' 'EEE' 'FFF' 'GGG' 'AAA' 'BBB' 'CCC' 'DDD' 'EEE' 'FFF'

C20

8.62 16.00 19.00 18.00 9.00 6.625 16.00 19.00 18.00 9.00 5.63 16.00

C22

10.75 17.00 21.25 20.00

C26

10.75 19.00 21.25 20.00

10.00 8.625 17.00 21.00 20.00 10.00 5.59 23.00

10.00 8.625 19.00 21.25 20.00 10.00 7.07 19.00

Consult Daikin Sales Office

Page 26

Drawing Notes

NOTES:

1. All dimensions are in inches and [millimeters] unless noted otherwise.

2. Final connections must allow for .500 inch +/- [12.7mm] manufacturing tolerances.

3. 1.00-inch FPT [25.4 mm] evaporator and condenser relief valves must be piped per ANSI / ASHRAE

15. Number of relief valves is 1 per evaporator and 2 per condenser.

4. .375 inch [9 mm] suction nozzle relief valve must be piped per ANSI / ASHRAE 15.

5. Clearances:

Ends 108 inches (2743 mm) on WMC 145S/D and WMC 250D at one end

144 inches (3658 mm) on WMC 150D, WMC 290, and WMC 400D at one end

plus 36 inches (910 mm) is required at the opposite end. If tube pull and cleaning

clearance is at the connection end, do not block tube access with piping, pumps, etc.

Sides 36 inches (914 mm) is recommended on all other sides and top for service clearance

except unit front electric panels. See below..

Electric Panels Most codes require 48 inches (1219 mm) clearance in front of the control boxes and

electrical panels.

6. 3.25-inch [83mm] diameter lifting holes are provided at the upper corners of each vessel. See

installation manual for lifting instructions.

7. All water connections are given in standard U.S. pipe sizes. Standard Victaulic® connections are also

suitable for welding.

8. The water connection shown is for the default configuration; your unit may be configured differently.

Orientation (left/right) is determined while facing the control panel. Consult the Item Summary sheet

for exact configuration. Unit shown has standard right-hand water connections. Left-hand connections

are available for either vessel. For left hand evaporator the inlet and outlet nozzles are reversed. ANSIflanged connections are available upon request. When using ANSI-flanged connections add .500 inch

[13 mm] to each flanged end.

9. Dimensions shown are for units (evaporator / condenser) with standard design pressures. The

refrigerant side design pressure is 200 PSI {1380 kPa} and the waterside design pressure is 150 PSI

{1034 kPa}. Consult the factory for unit dimensions with higher design pressures.

10. The unit vibration isolator pads are provided for field installation. When fully loaded are 0.250 inches

[6 mm] thick.

11. These values are for units with standard wall thickness copper tubing only.

12. The shipping skid adds 6.0 inches [152 mm] to the overall unit height.

13. All-power wiring is brought into the top of the compressor power panel (Front End Box). Field control

wiring is brought into the Unit Control Box.

14. The unit is shipped with an operating charge of refrigerant.

15. Optional marine water box connections are available upon request.

26 Catalog 602-2

Page 27

"LL"

"LW"

MFL

MFW

X

Z

RF

RB

LB

LF

OH

OW

OL

332834901

DRAWINGNUMBER

00

REV.

NONE

SCALE

Physical Data and Weights

Lifting and Mounting Weights

Catalog 602-2 27

Page 28

Unit Refrigerant

lb. (kg)

Evaporator

Volume, gal (L)

Insulation

sq. ft. (m2)

Number of

Valves

145S

E2209

9 ft.

550 (250)

38 (145)

66 (6.1)

1

150D

E2212

12 ft.

800 (363)

45 (170)

90 (8.3)

1

290D

E2612

12 ft.

1100 (500)

72 (273)

102 (9.4)

1

Maximum

Capacity lb. (kg)

Water

gal. (L)

145S, 145D

C2009

9 ft.

728 (330)

47 (147)

2

150D

C2012

12 ft.

971 (440)

62 (236)

2

250D

C2209

9 ft.

883 (401)

50 (223)

2

290D

400D

Physical Data

Evaporator

Refrigerant-side design pressure is 200 psi

(1379 kPa). Water-side is 150 psi (1034 kPa).

Approximate total square footage of insulation

surface required for individual packaged chillers is

Table 12, Evaporator Physical Data

tabulated by evaporator code and can be found

below. The suction elbow and compressor also

require insulation.

WMC

Model

250D

400D

Notes:

1. Refrigerant charge is approximate since the actual charge will depend on other variables. Actual charge will be shown on the

unit nameplate and is tabulated above.

2. Water capacity is based on standard tube configuration and standard dished heads.

Evaporator

Model

E2609 9 ft. 600 (272) 61 (231) 76 (7.1) 1

E3012 12 ft. 1240 (562) 88 (336) 114 (11) 1

Tube

Length

Charge

Water

Area

Relief

Condenser

With positive pressure systems, the pressure

variance with temperature is always predictable

and the vessel design and pressure relief

protection are based upon pure refrigerant

characteristics. R-134a requires ASME vessel

design, inspection and testing and uses springloaded pressure relief valves. When an over-

Table 13, Condenser Physical Data

WMC

Model

Condenser

Model

Tube

Length

Pumpdown

pressure condition occurs, spring-loaded relief

valves purge only that quantity of refrigerant

required to reduce system pressure to the valve’s

set pressure, and then close.

Refrigerant-side design pressure is 200 psi (1380

kPa). Water-side design is 150 psi (1034 kPa).

Volume

Number of

Relief Valves

C2212 12 ft. 1174 (533) 72 (273) 2

C2612 12 ft. 1676 (760) 111 (419) 2

Notes:

1. Condenser pumpdown capacity based on 90% full at 90°F.

2. Water capacity based on standard configuration and standard heads and can be less with lower tube counts.

3. See Relief Valves section for additional information.

28 Catalog 602-2

Page 29

Relief Valves

As a safety precaution and to meet code requirements, each chiller is equipped with pressure relief valves

located on the condenser and evaporator for the purpose of relieving excessive refrigerant pressure (caused by

equipment malfunction, fire, etc.) to the atmosphere. Most codes require that relief valves be vented to the

outside of a building and this is a desirable practice for all installations. Relief piping connections to the relief

valves must have flexible connectors.

Note: Remove plastic shipping plugs (if installed) from the inside of the valves prior to making pipe

connections. Whenever vent piping is installed, the lines must be run in accordance with local code

requirements; where local codes do not apply, the latest issue of ANSI/ASHRAE Standard 15 code

recommendations must be followed.

• Condensers have two relief valves as a set with a three-way valve separating the two valves. One valve

remains active at all times and the second valve acts as a standby.

• Evaporators have a single valve. Each valve has a 1.0-inch female NPT connection.

• Each suction line on dual compressor units has a single 200 psig relief valve rated at 6.9 lb/min air with a

3/8-inch flare connection.

Vessel valve capacity is 75.5 lb/min air.

Figure 13, Typical Vent Piping

Catalog 602-2 29

Page 30

Electrical Data

CAUTION

MCA

Disconnect switch will also be a circuit breaker for short circuit protection.

the power block or disconnect switch .

POWER

[Amp]

79 - 80

110 1 99 - 100

175

150

3

3 GA

81 - 88

110 1 101 - 110

175

150

3

2 GA

89 - 92

110 1 111 - 115

200

150

3

2 GA

93 - 99

110 1 116 - 123

200

150

3

1 GA

100