Page 1

Centrifugal Compressor Water Chillers Catalog 605-5

Models WSC, WDC, WCC, HSC

Page 2

Contents

Modbus

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview of Water-Cooled Product Line . . . . . . . . 3

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . 4

World-Class Design Leader . . . . . . . . . . . . . . . 4

Design Features. . . . . . . . . . . . . . . . . . . . . . . . 4

Dual Compressor Centrifugal Chillers . . . . . . . . . . 6

Heat Recovery Models . . . . . . . . . . . . . . . . . . . . . . . 9

Templifier Heat Pump Water Heaters . . . . . . . 9

Heat Recovery Models . . . . . . . . . . . . . . . . . . . . . . 10

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

MicroTech® II Controls . . . . . . . . . . . . . . . . . 11

Application Considerations. . . . . . . . . . . . . . . . . . 14

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Starters and VFDs . . . . . . . . . . . . . . . . . . . . . . . . . 26

Motor Starters . . . . . . . . . . . . . . . . . . . . . . . . 26

Variable Frequency Drives (VFD) . . . . . . . . . 26

Selection Procedures . . . . . . . . . . . . . . . . . . . . . . 28

IPLV/NPLV Defined . . . . . . . . . . . . . . . . . . . 29

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . 49

Options and Accessories . . . . . . . . . . . . . . . . . . . 52

Refrigerant Recovery Units and Monitors . . . . . 54

Pump Out Units. . . . . . . . . . . . . . . . . . . . . . . 54

Refrigerant Monitors . . . . . . . . . . . . . . . . . . . 54

Retrofit Disassembly (Knockdown Options) . . . 55

Specifications (WSC) . . . . . . . . . . . . . . . . . . . . . . 59

Specifications (WDC) . . . . . . . . . . . . . . . . . . . . . . 65

Specifications (WCC) . . . . . . . . . . . . . . . . . . . . . . 71

Starter Types and Descriptions . . . . . . . . . . . 26

Hazard Identification

DANGER

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage, severe personal injury, or death if not avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or equipment damage if not avoided.

On the cover: WSC 087, 600 Tons, with Compressor VFD

Document:

Issue Date: October 1999

Revision Date:

Replaces:

CAT 605-5

September 2015

August 2015

© 2015 Daikin Applied. Illustrations and data cover the Daikin product at the time of publication and we reserve the right to make changes in

design and construction at anytime without notice. ™® The following are trademarks or registered trademarks of their respective companies:

LEED is a registered trademark of the U.S. Green Building Council; BACnet from ASHRAE; LONMARK, LonTalk, LONWORKS, and the

LONMARK logo are managed, granted and used by LONMARK International under a license granted by Echelon Corporation; Modbus from

Schneider Electric; MicroTech II, Open Choices from Daikin.

2 Cat 605-5

Page 3

Engineered for flexibility and performance

Centrifugal Compressor Water Chillers Catalog 605-2

Models WSC, WDC, WCC, HSC

Includes Higher Voltage (10/11kV) WDC/WCC models

Introduction

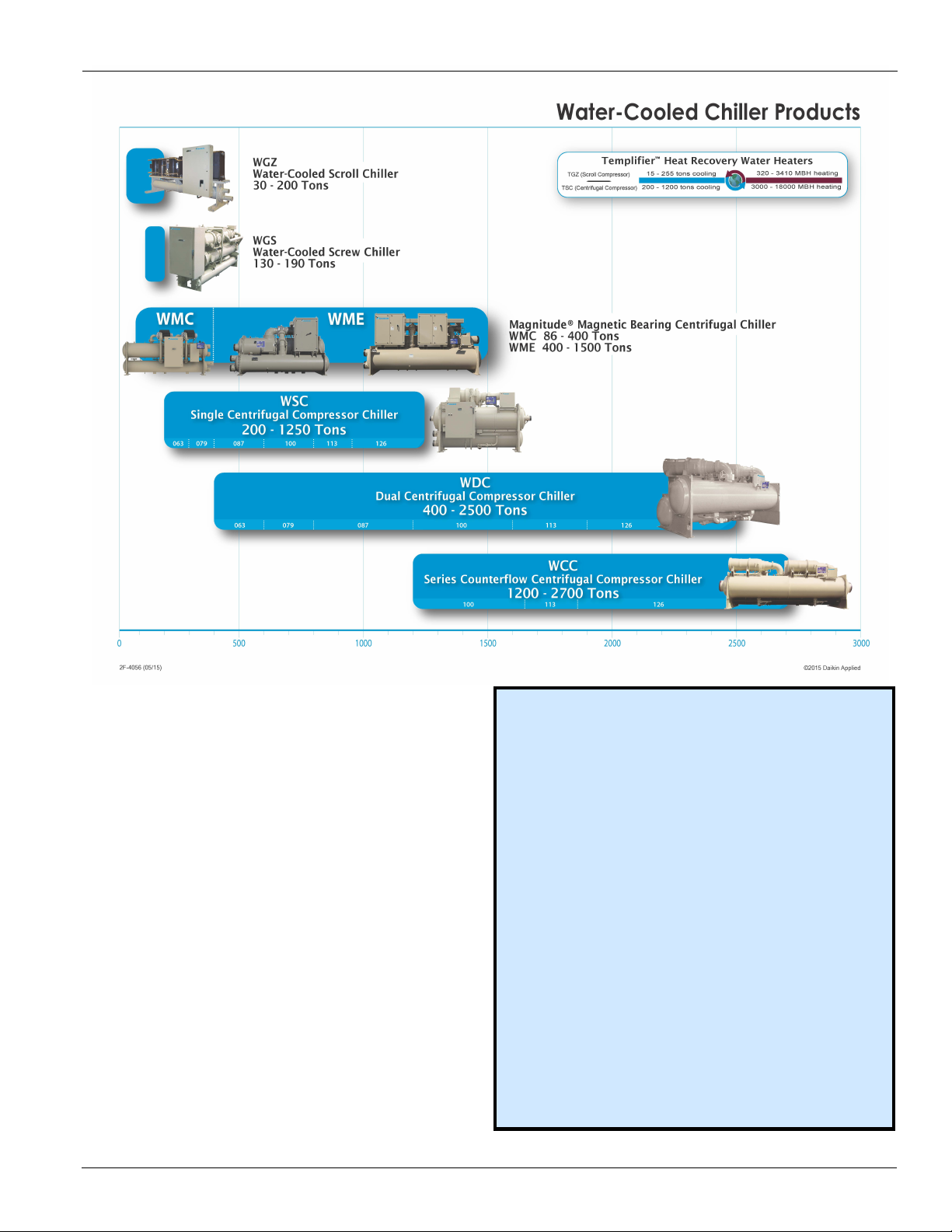

Overview of Water-Cooled Product Line

Introduction

Included in this manual:

Centrifugal Products included in separate manuals:

Model WSC

• Capacity: 200-1250 tons (AHRI conditions)

• Excellent full load performance

Model WDC

• Capacity: 400-2500 tons (AHRI conditions)

• Outstanding part load performance

• Redundancy for increased reliability

• Some sizes available with 10/11kV50Hz power option

Model WCC

• Capacity: 1200-2700 tons (AHRI conditions)

• Two refrigerant circuits for true counterflow

• Outstanding full load performance

• Some sizes available with 10/11kV50Hz power option

Magnitude™ Magnetic Bearing Compressor Chillers

Magnitude™ Model WMC

• Capacity: 145-400 tons

• Oil-free, frictionless compressor

• Excellent part-load performance

• See CAT 602 for more information

Magnitude™ Model WME

•

Capacity: 400-1500 tons

• Oil-free, frictionless compressor

• Outstanding efficiency

• See CAT 604 for more information

Templifier™ Model TSC Water Heater

• Recovers waste heat from process applications

• 5,000 - 19,000 MBH

Model HSC

• Recycles heat normally lost in cooling towers

• Hot water - 140

•

See Templifier CAT 614 for more information

o

; COP as high as 7

• Produces simultaneous heating and cooling

Cat 605-5 3

Page 4

Features and Benefits

Features and Benefits

World-Class Design Leader

As part of Daikin Industries, a Fortune 1000 company, Daikin

is the second largest air conditioning, heating, ventilating and

refrigeration company in the world. We have earned a

worldwide reputation for providing a full line of quality

products and expertise to meet the demands of our customers.

The engineered flexibility of our products allows you to fine

tune your HVAC system to meet the specific requirements of

your application. You benefit from lower installed and

operating costs, high energy efficiency, quiet operation,

superior indoor air quality (IAQ) and low cost maintenance

and service.

Daikin Centrifugal Compressor Water Chillers are

engineered for flexibility and performance - offering choices,

options and features that provide the

right solution for your

specific application-and have been doing so for over fifty

years. Some highlights of our world-class centrifugal design

are:

Design Features

Excellent Performance

Daikin offers a wide range of centrifugal vessel and

component combinations to provide the right solution for your

specific application. The single compressor WSC offers

excellent full load performance, however, in most

applications, chillers spend about 99% of their operating hours

at part-load condidtions. Our dual compressor WDC chillers

offer many attractive benefits, including outstanding part-load

efficiency, and system redundancy similar to two separate

chillers, with a lower total installed cost. WCC models also

offer the dual compressor advantage but with counterflow

vessels, and a separate refrigerant circuit for each compressor.

WCC chillers excel at full load efficiency. Contact your

Daikin representative for detailed information to decide which

model is right for your job requirements.

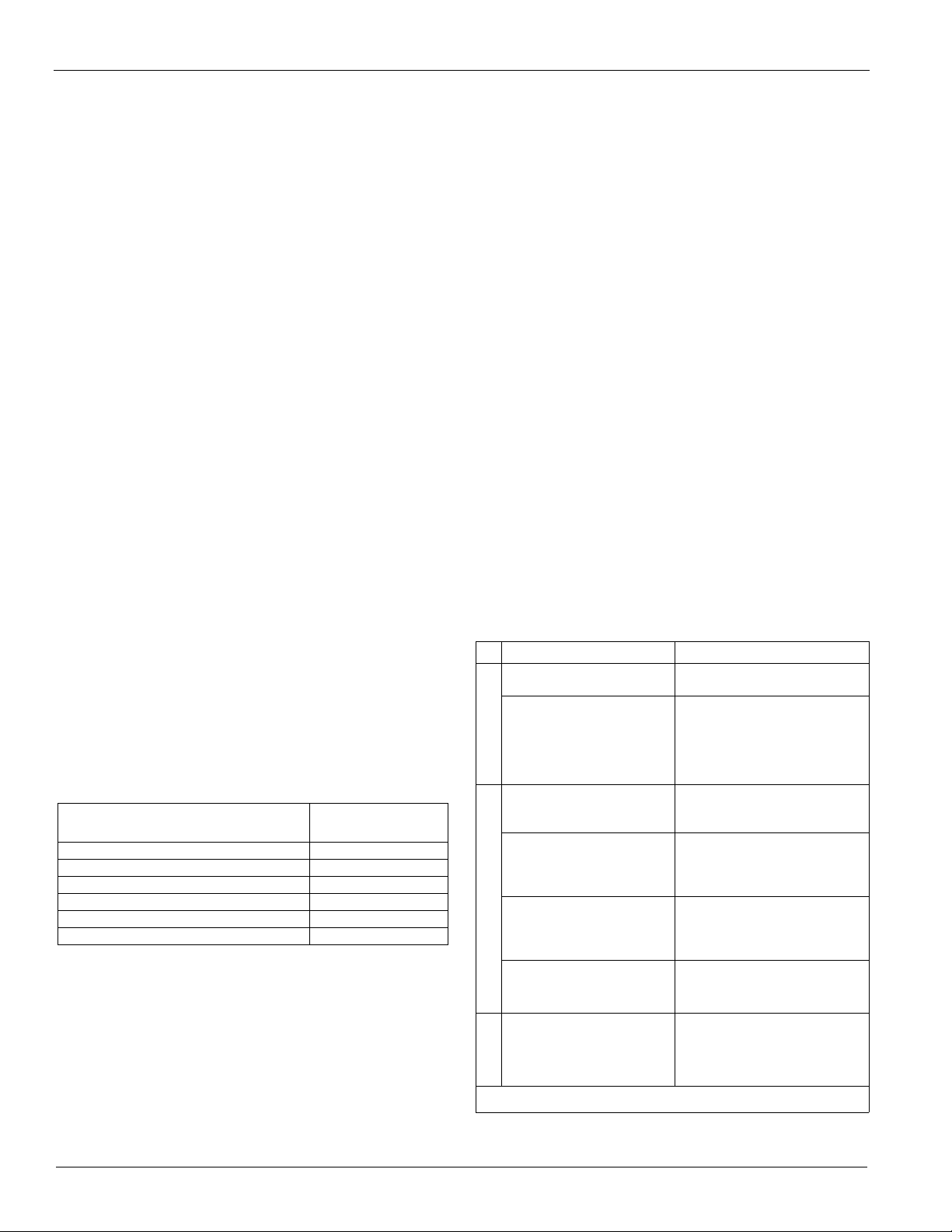

Table 1: Centrifugal Models & Possible Applications

Application

Cooling <1250 tons, most hours at full load WSC

Cooling >1250 tons, most hours at full load WCC

Cooling, most hours at part load WDC

Heating Application TSC Templifier™

Simultaneous Cooling and Heating HSC

Optimized Part Load Performance Optional VFD

Positive Pressure Design

Positive pressure systems offer numerous advantages over

ve pressure design. In a negative pressure system, leaks

negati

allow air, moisture, and other contaminants to seep into

system, which will gradually decrease performance, as well as

cause corrosion which must be removed. The Daikin positive

pressure design eliminates this worry, providing sustainable

performance and trouble-free ownership for the life of the unit

under normal operation.

Daikin Model

Gear Driven Advantage

Daikin’s precision-engineered gear driven design allows for

lighter components, less vibration, and ability to

select gear

ratios that will provide the optimum impeller speed for your

application. Older direct-drive designs must use large, heavy

impellers to reach similar tip speeds, which cause more

vibration and greater stress on shaft and motor during

unexpected electrical interruptions.

The compact design and lighter weight components allow for

efficient hydrodynamic bearings to be used. This means that

operation, the shaft is supported on a film of lubricant,

during

with no shaft-to-bearing contact, providing theoretical infinte

life bearings under normal circumstances. The design

simplicity of the Daikin centrifugal compressors provides

increased durability and reliable performance.

Smart Refrigerant

HFC-134a refrigerant contains no chlorine and has zero Ozone

Depletion Potential (ODP), making it an environmentally

superior alternative to other refrigerants such as HCFC-123. It

also has an A1 ASHRAE Safety Classificiation - the lowest

toxicity and flammability rating. R-134a provides the

assurance of a safe, smart, and sustainable solution.

R-123 requires about 6 times the gas flow rate (cfm/ton) of R134a, which means that the suction and discharge

piping must

also be six times larger. Using R-134a allows Daikin to

provide you with a smaller footprint chiller.

Table 2: Refrigerant Comparison

HFC-134a HCFC-123

No Ozone Depletion

Potential

No Refrigerant Phase Out

Date

ENVIRONMENTAL

Physically smaller, requiring

less mechanical room space.

In the event of a small leak,

refrigerant escapes, allowing

easy detection and repair

No purge unit required

No oil change is required

INSTALLATION AND MAINTENANCE

A1 ASHRAE Safety

Classification -

lowest

toxicity/flammability

SAFETY

RefrigerantResourceCenter for references and more information.

rating

See www.DaikinApplied.com /Daikin/DesignSolutions/

Ozone-depleting substance

Montreal Protocol requires

phase out in new equipment by

2020; production cease by 2030

Requires larger refrigerant flow

rate, with subsequent increase in

component and unit size.

In the event of a small leak, air

leaks into the chiller, making

detection and repair difficult. Can

degrade efficiency

Added cost and additional space

for a purge unit. Must

periodically purge unit to remove

contaminants

Annual oil change is

recommended

B1 ASHRAE Safety

Classification- higher toxicity

level

4 Cat 605-5

Page 5

Features and Benefits

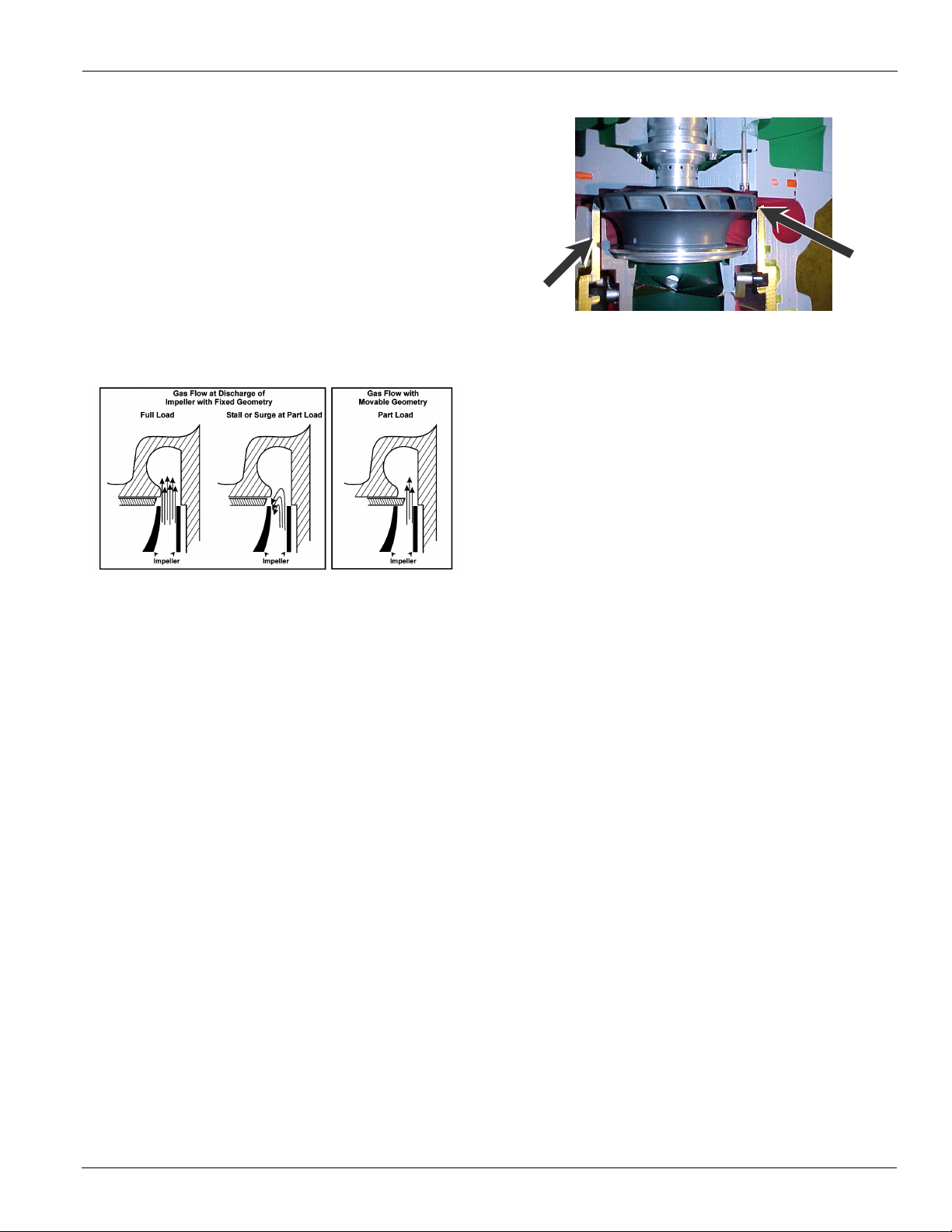

Unmatched Unloading

Daikin pioneered the use of moveable discharge geometry to

lower the surge point of centrifugal

which the compressor enters a stall or surge condition

generally limits compressor unloading. Chillers with a fixed

discharge will experience stall or surge at low loads due to

refrigerant re-entering the impeller. When in a stall condition,

the refrigerant gas is unable to enter the volute due to its low

velocity and remains stalled in the impeller. In a surge

condition the gas rapidly reverses direction in the impeller

causing excessive vibration and heat. Daikin compressors

reduce the discharge area as load decreases to maintain gas

velocity and greatly reduce the tendency to stall or surge.

Figure 1: Fixed vs. Movable Discharge Geometry

In Figure 1, above, the drawing on the left shows a crosssection view of the operation at full load of a unit with a fixed

compressor discharge. At full load, a large quantity of gas is

discharged with a fairly uniform discharge velocity as

indicated by the arrows.

The center drawing shows a fixed compressor discharge at

reduced capacity. Note that the velocity is not uniform and the

refrigerant tends to reenter the impeller. This is caused by low

velocity in the discharge area and the high pressure in the

condenser, resulting in unstable surge operation and with noise

and vibration generated.

The following cutaway picture shows the unique Daikin

movable discharge geometry. As the capacity reduces, the

movable unloader piston travels inward, reducing the

discharge cross section area and maintaining the refrigerant

velocity. This mechanism

capacity reduction.

allows our excellent unloading

compressors. The point at

Figure 2: Movable diffuser closes impeller discharge area

as load decreases.

Controls Flexibility

MicroTech II® controls with our Open ChoicesTM feature

allow easy integration with the BAS of choice using

LonTalk®, BACnet® or Modbus® protocol

Retrofit Flexibility

Easy to retrofit with flexible knock-down options. See page 55

for details.

Trouble-Free Startup

All Daikin chillers are factory tested on AHRI qualified

computer-controlled test stands. Each chiller is run-tested

under load conditions for a minimum of one hour with

evaporator and condenser water flow at job conditions

(excluding glycol applications). Operating controls are

checked and adjusted, and the refrigerant charge is adjusted for

optimum operation and recorded on the unit nameplate. Units

operating with 50-Hz power are tested with a 50-Hz power

supply. The testing helps ensure correct operation prior to

shipment, and allows factory calibration of chiller operating

controls.

All domestic Daikin centrifugal chillers are commissioned by

Daikin Factory Service personnel, or by authorized and

experienced

ensure that proper starting and checkout procedures are

employed and helps in a speedy commissioning process,

giving you confidence that your chiller is operating as

expected.

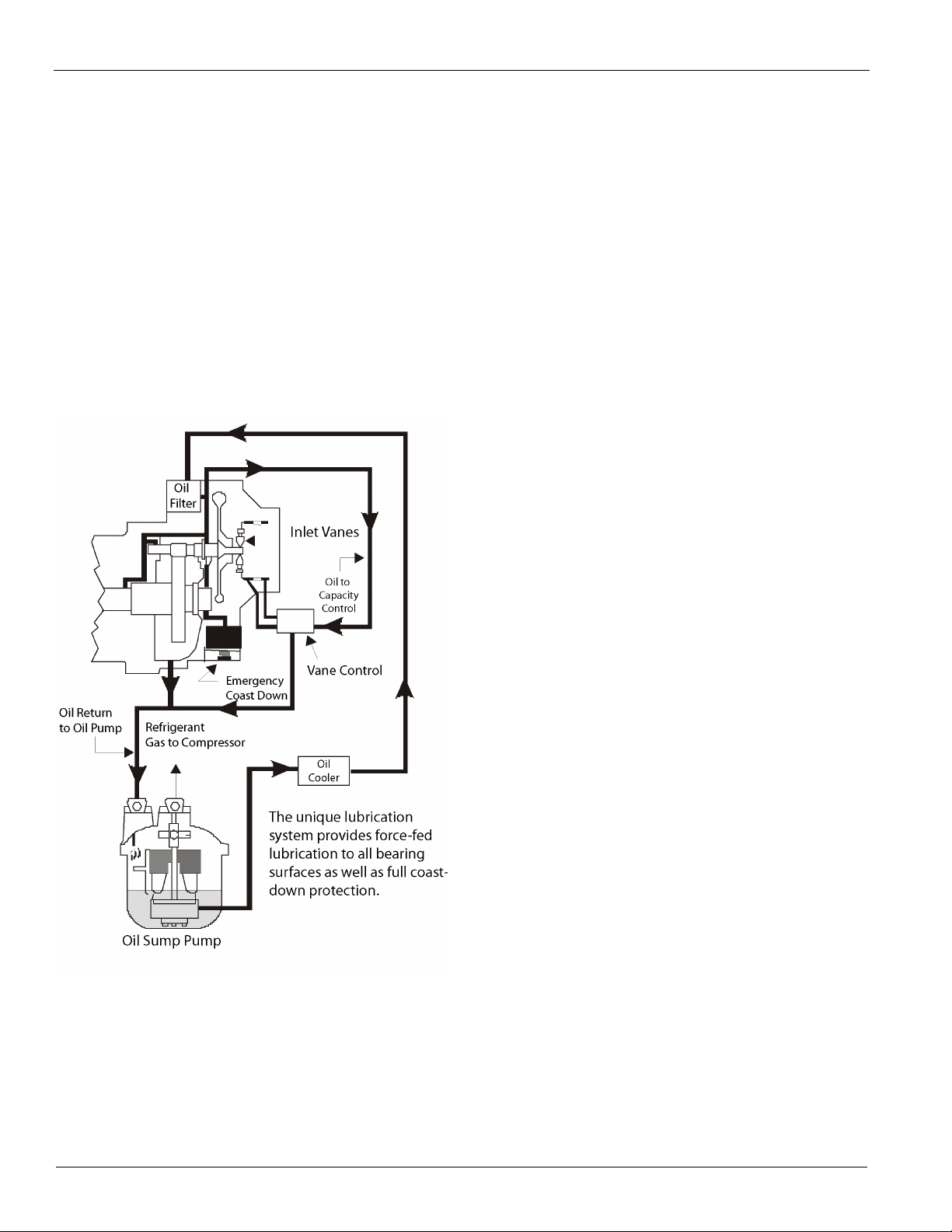

Lubrication System

A separately driven electric oil pump assembly supplies

lubrication at controlled temperature and pressure to all

bearing surfaces and is the source of hydraulic pressure for the

capacity control system.

Daikin startup technicians. This procedure helps

The control system will not allow the compressor to start until

oil pressure, at the proper temperature, is established. It also

allows the oil pump to operate after compressor shutdown to

provide lubrication during coast-down. Lubricant from the

pump is supplied to the compressor through a water-cooled,

brazed-plate heat exchanger and single or dual five-micron oil

filters internal to the compressor. All bearing surfaces are

Cat 605-5 5

Page 6

Dual Compressor Centrifugal Chillers

pressure lubricated. Drive gears operate in a controlled

lubricant mist atmosphere that efficiently cools and lubricates

them.

Lubricant is made available under pressure from the

compressor oil filter to the unit capacity control system and is

used to position the inlet guide vanes in response to changes in

leaving chiller water temperature.

If a power failure occurs, an emergency oil reservoir provides

adequate lubrication flow under pressure, and prevents damage

that could occur during the coast-down period with the oil

pump stopped.

Since the Daikin chillers are positive pressure, there is no

need to change the lubricant or filter on a regular basis. As

with any equipment of

this type, an annual oil check is

recommended to evaluate the lubricant condition.

Figure 3: Lubrication System Schematic

is gas rapidly reversing direction through the impeller). A

number of things can contribute to this condition including

inadequate maintenance of condenser tube cleanliness, a

cooling tower or control malfunction, or unusual ambient

temperatures among others.

For these abnormal conditions, Daikin compressor

designers have developed a protective control system that

senses the potential for a surge, looks at the entire chiller

system operation and takes corrective action if possible;

or

stops the compressor, to help prevent any damage from

occurring. This protection is provided as standard on all

Daikin centrifugal compressors.

Dual Compressor Centrifugal Chillers

Dual Compressor Experience

Daikin is the expert when it comes to dual centrifugal

compressor technology. We

have been successfully building

dual compressor centrifugal chillers since 1971. Daikin is the

only company that builds them with either a single refrigerant

circuit (Model WDC) or two refrigerant circuits (Model

WCC).

Benefits of Dual Compressor Chillers

Superior Efficiency

When coupled with a variable frequency drive, the extremely

efficient Dual Compressor Chillers are considerably more

efficient than single compressor chillers in the same size range,

with IPLVs (Integrated Part Load Value) as low as 0.3 kW per

ton. IPLV conditions are set by AHRI and subject to stringent

testing. Insist on AHRI-certified IPLV efficiency when making

efficiency comparisons.

Enhanced Surge Protection

When centrifugal compressors operate at part load, the volume

of refrigerant gas entering the impeller is reduced. At the

reduced flow, the impeller's capacity to develop the peak load

head is also reduced. At conditions of low refrigerant flow and

high compressor head (pressure difference), stall and/or surge

can occur (a stall is gas static in the impeller, a surge condition

The Redundancy Feature

Daikin dual centrifugal chillers have two of everything

connected to the evaporator and condenser - two

compressors, two lubrication systems, two control systems,

and two starters.

If any component on a compressor system fails, the component

can be removed or repaired without shutting down the other

compressor; providing an automatic back-up with at least 60

percent of the chiller design capacity available on WDC units

and 50 percent on WCC units.

Redundancy is also built into the distributed control system,

which consists of a unit controller, a compressor controller for

each compressor and an operator interface touch screen. The

chiller will operate normally without the touch screen being

functional. If a compressor controller is unavailable, the other

compressor will operate normally and handle as much of the

load as possible.

Lower Installed Costs

The redundancy feature pays off in lower installed costs. An

example of how to incorporate dual compressor chillers into a

system requiring redundancy:

6 Cat 605-5

Page 7

Dual Compressor Centrifugal Chillers

WSC Single Compressor Chillers WDC Dual Compressor Chillers

(2)

600 ton (2100 kW) On Line Units

(2)

750 ton (2100 kW) Units with

+(1)

600 (2100 kW ) t on Standby Unit 1,200 (4200 kW ) On Line tons

*

1,800 ton (6300 kW) Installed Capacity 1500 ton (52 50 kW ) Ins ta lled Capacit y

Job requirement: 1,200 tons (4200 kW), 50% Backup

*One 750-ton (2100 kW) dual chiller running on two compressors for 750 tons (2100

kW), plus one 750-ton (2100 kW) dual chiller running on one compressor for 60% of 750

tons (2100 kW) = 450 tons (1575 kW), for a total of 1200 tons (4200 kW) on any 3 of the

4 total compressors.

The elimination of the extra pumps, valves, piping, controls,

rigging, and floor space can result in as much as a 35%

reduction in the installation cost for a chiller plant, plus the

savings on the chillers themselves.

Dual Compressor Chiller Overview

There are subtle but important differences between the single

circuit WDC and two circuit WCC chillers.

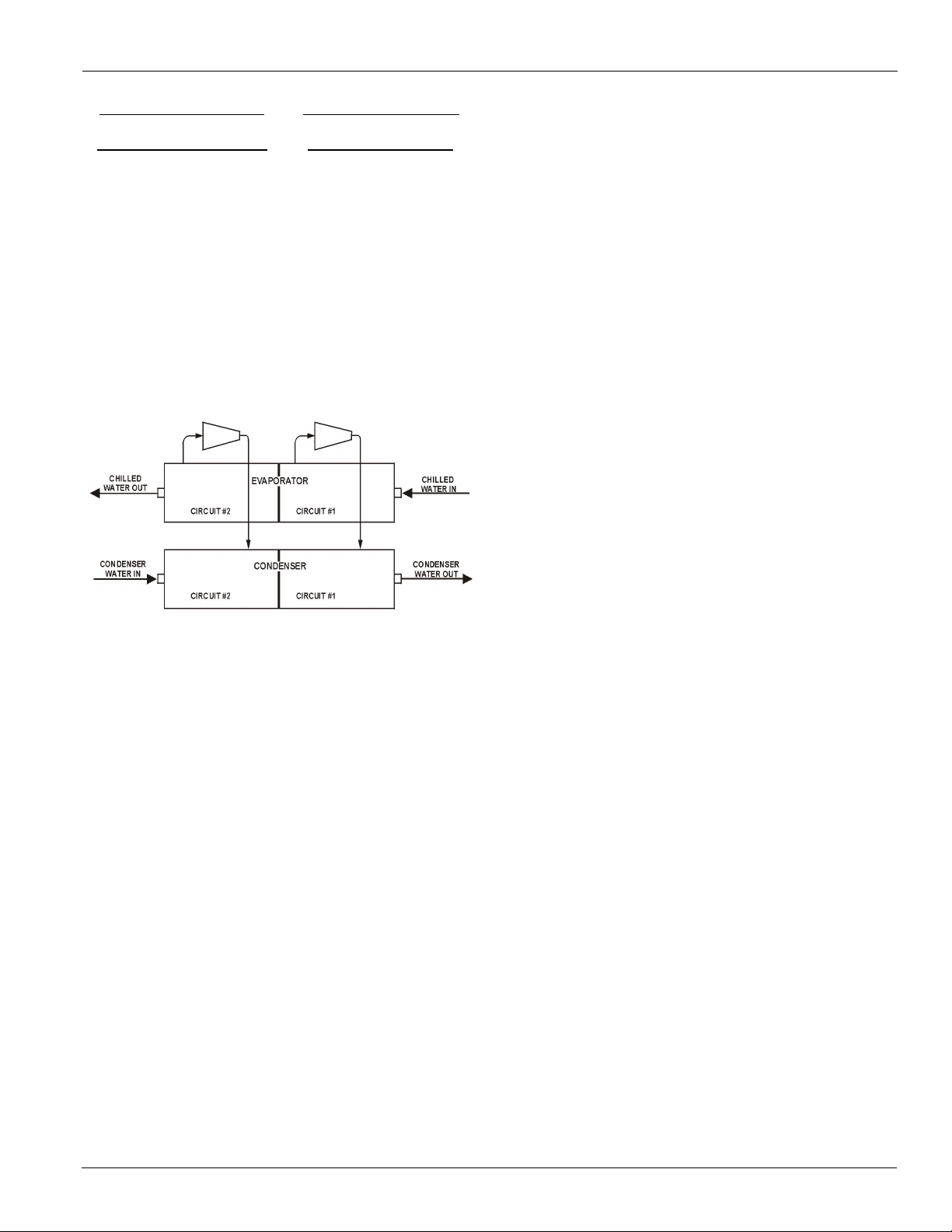

Dual Circuit WCC Counterflow Chillers

These chillers have a separate refrigerant circuit for each

compressor. They are available in single pass only. They

provide the high full load efficiency advantage of two separate

chillers arranged for counterflow operation in a single,

compact unit.

Single Circuit WDC Chillers

These chillers have a single-refrigerant circuit for the

evaporator and condenser with two compressors running in

parallel and are available in one, two or three-pass

configurations. Their salient feature is that at singlecompressor, part load operation, the running compressor can

utilize the entire chiller's heat transfer surface, providing

outstanding part load performance.

Application of Dual Compressor Chillers

Designers and owners must decide which chiller type, or

combination of chiller types, is best for their installation.

Considerations include first cost, system efficiency, system

reliability, space requirements, and total owning costs.

Use WCC chillers when:

• Project requirement is lowest kW per ton performance at full

load with high electrical demand charges.

• Project has a large central plant where cycling chillers for

system capacity reduction is expected (three or more

chillers).

• High chilled water delta-T and low water pressure drops are

desired.

• Built-in redundancy is required. A single compressor will

provide 50% of the unit's full load capacity.

• High efficiency and large capacity is required with series

flow. Use two WCC units in series-counterflow in the 3,000

to 4,000 ton range.

Use WDC chillers when:

• Project requirement is overall lowest energy consumption

with best part load performance.

• Project has smaller chilled water plant where unit unloading

is expected versus cycling of chillers associated with large

multi-chiller plants.

• Floor space is limited (16-foot vessel length compared to 20foot for WCC).

• Two or three pass vessels are required, typical of retrofit

applications.

• Built-in redundancy is required. A single compressor will

provide 60% of the unit's full load capacity.

Use a combination of WDC and WCC chillers when:

• Peak overall system efficiency is important; for example,

use three WCC and one WDC chiller, all in parallel. The

WCC units are optimized for running at full load and the

WDC is optimized for part load operation. The WCC units

cycle on and off and the WDC unit (consider variable

frequency drives on this unit) trims the load, running

between five and one hundred percent capacity.

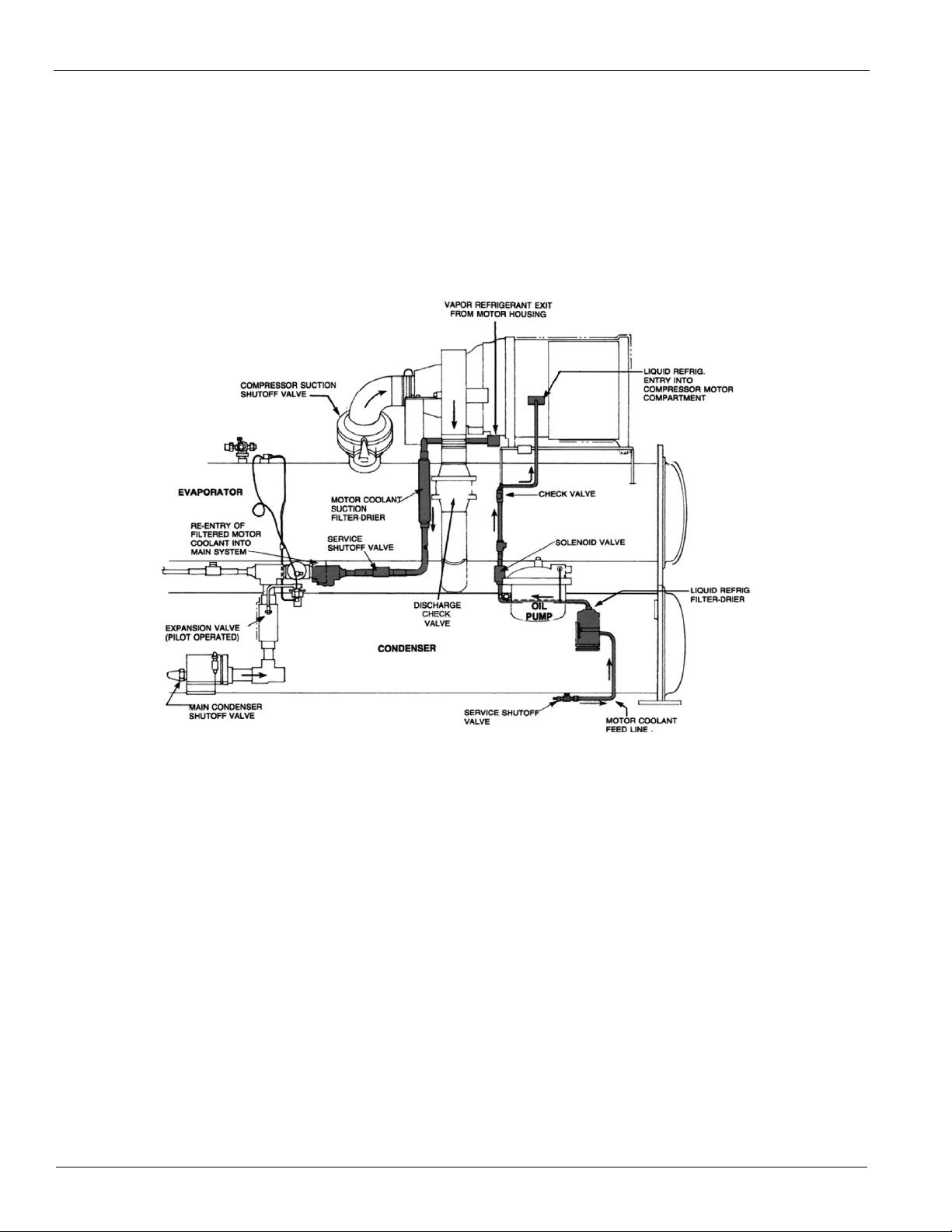

Why a Compressor Motor Failure Will Not Contaminate the

Common Refrigerant Circuit on WDC dual chillers

Some people are concerned with the result of a motor burnout

on a single-circuit dual compressor chiller. This is not a

problem on the Daikin WDC chillers because of compressor

construction and chiller layout.

The compressor motor is isolated from the main refrigerant

flow circuit so that any contaminants generated by a motor

failure will not pass into the main refrigerant circuit. Moisture,

acid and/or carbon particles will be automatically trapped

within the compressor's dedicated coolant feed and exit lines.

Internally, the compressor motor compartment is separated and

sealed from the main refrigerant compression chamber. A

double shaft seal on the motor side of the gear housing

prevents cross flow of refrigerant along the motor shaft. The

motor coolant feed line is equipped with both a solenoid valve

and a check valve. These mechanical components, plus the

higher pressure of the liquid refrigerant, prevent back feed into

the main refrigerant system. Refrigerant vapor exiting the

motor compartment must pass through a high pressure drop

filter-drier, sized to immediately plug up and seal off the motor

compartment. Both the coolant feed and return lines are

equipped with manual shutoff valves to permit component

service.

Cat 605-5 7

Page 8

Dual Compressor Centrifugal Chillers

Over 30 years of field experience have proven the reliability of

these compressor motors. Despite the reliability inherent in the

motor design and the protective control, electrical distribution

system faults and lightning strikes can occur that are beyond

the control of the most conscientious designer. The coolant

protective system protects the unit charge from being

contaminated.

Special WDC Warranty: In the unlikely event of a motor

burnout, the chiller refrigerant charge will not be

Figure 4: Motor Cooling

contaminated. This is so well proven that it is guaranteed for

five years. In areas supported by Daikin Factory Service, if a

motor burnout occurs in one compressor and contaminates the

refrigerant circuit, any resultant damage to the other

compressor will be repaired and the refrigerant charge replaced

at no cost to the customer for parts and labor. The terms of the

original chiller warranty apply to the original burned out

compressor.

Efficiency

Chillers usually spend 99% of their operating hours under part

load conditions, and most of this time at less than 60% of

design capacity. One compressor of a dual WDC chiller

operates with the full heat transfer surface of the entire unit.

For example, one 500-ton (1,750 kW) compressor on a 1,000

ton (3,500 kW) dual chiller utilizes 1,000 tons (3500 kW) of

evaporator and condenser surface. This increases the

compressor's capacity and also results in very high efficiency.

Typical efficiencies for a WDC dual chiller, taken from a

selection computer run, look like this:

Full load efficiency: 0.550 kW per ton (6.5 COP)

60% load, one compressor: 0.364 kW per ton (9.6 COP)

IPLV: 0.415 kW per ton (8.5 COP)

The addition of VFDs to the WDC dual

produces an astonishing AHRI certified IPLV of 0.340 for the

above case. Specific selections can vary up or down from this

example. IPLV is defined in the Selection section of this

manual beginning on page 28 .

8 Cat 605-5

compressor chiller

WCC chillers, with their counterflow design, excel at full load

efficiency. Each of the two compressors operates at a lower

head (pressure differential) than single compressor chillers in

parallel. With any pump or compressor, lower head means

lower power for a given flow. As shown on the right, the #2

(downstream compressor) makes 42 F water but has only 89 F

condenser water leaving instead of 95 F typical of a single

compressor unit. The #1 compressor has 95 F condenser water

leaving, but only has to make 47.6 F chilled water.

The Replacement Market Advantage

• Bolt-together construction on single and dual compressor

chillers along with factory disassembly available as an

option simply the tough entrance situations.

• Put 20% or more tons in the same footprint.

• Add dual compressor redundancy.

• Greatly reduce chiller energy consumption.

• Install a refrigerant with no phase-out date.

• Opens many options for multiple chiller plants using WSC,

WDC and WCC combinations.

Page 9

Heat Recovery Models

EVAPORATOR

TOW E R

COND ENSER

RE COV E RY

COND E N SE R

AUXILI ARY

HE ATER

HEAT L OAD

TCTCCOO LI N G

LOAD

OPEN

CI RC UI T

TOWER

HEAT REC OVERY

CHI LLER

LEGEND

TC TEMPERATURE CONTROL POINT

PUMP

Typical Building Types

Hotels/Motels

Health Care

Athletic Facilities

Resorts

Schools

Food Service

Nursing Homes

Typical Applications

Space Heating

Outside Air Heating

Reheat

Service Hot Water

Laundries

Kitchens

G

TOWER

)

G

HEATER

R

R

CONDENSER

R

COOLING

R

90° F

(35°C)

F

CHILLER

TC

TC

C

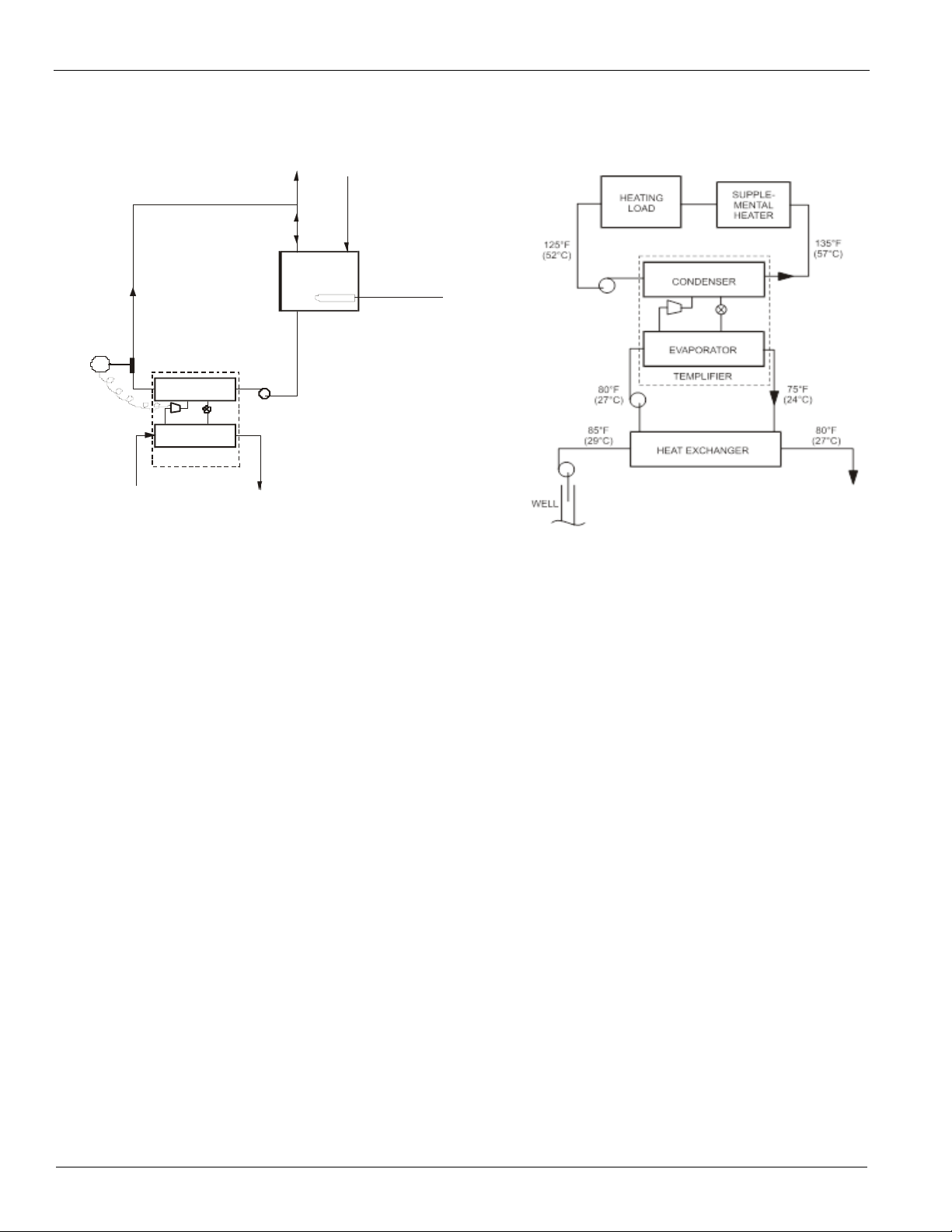

Heat Recovery Models

Heat Recovery Models

For decades, Daikin has pioneered the use of heat recovery

chillers and the unique Daikin

Water Heater to reduce energy costs. These products have

become more important than ever with the current emphasis

on total building efficiency. ASHRAE Efficiency Standard

90.1 mandates the use of heat recovery equipment of this

type in a wide range of buildings.

Heat Recovery Chillers

Model HSC heat recovery chillers, with a single compressor,

have a single condenser with split bundles, i.e., two separate

water passages divided by separate water heads as shown in

the photograph to the right. The inboard water connections are

connected to the cooling tower, the other water side is

connected to the heating system.

The economic feasibility of hot water generated with these

units depends on heating and cooling load profiles and on the

relative cost of the available energy sources. A compressor's

kW per ton is heavily influenced by the pressure head it is

pumping against. During heat recovery operation, the entire

cooling load is operating against the high head required by the

Templifier Heat Pump

hot water temperature. For this reason, it is desirable to

maximize the percentage of the

total rejected heat used for the

heating load. Daikin's economic evaluation program, Energy

Analyzer , available on CD from your local Daikin sales

office, is the perfect tool to determine the economic feasibility

of using this proven technology.

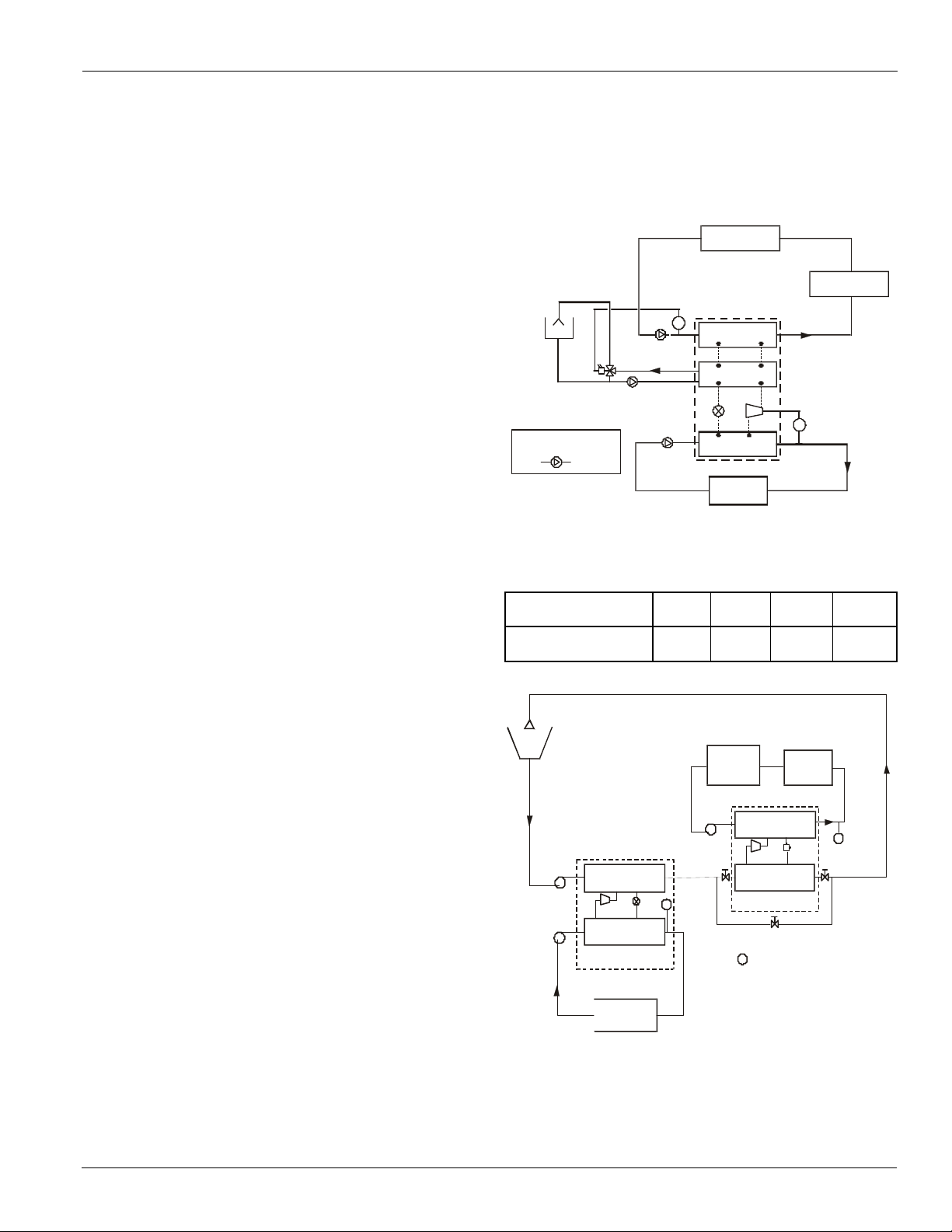

Figure 5: Heat Recovery Chiller Piping Schematic

Templifier Heat Pump Water Heaters

Model TSC: 5,000 to 19,000 MBH

The Model TSC Templifier was developed in the 1970s, after

the 1973 oil embargo, as a device to replace fossil-fired water

heaters with electric heaters. The concept was simple; direct a

stream of warm waste heat to the evaporator of a refrigeration

unit, amplify the temperature of the heat through the

compression cycle, and then deliver the heat from the

condenser, at a higher useful temperature, to a heating load.

The flow diagram shown to the left illustrates just how the

Templifier unit is placed

decision to include a Templifier water heater is almost always

a financial one. Evaluation of load profiles, energy costs, and

owning costs is made simple by using the Daikin Energy

Analyzer evaluation program to determine if the return on

investment meets the owner's requirements.

When there is sufficient waste heat available, Templifier units

can be very attractive where fossil fuels are not available, or

where their use is restricted due to pollution problems or other

reasons. Compared to electric resistance heating, the energy

cost for a Templifier unit to heat domestic water, for example,

could be 7 to 8 times less!

Where to Use Templifier Water Heaters:

in a chilled water system. The

Table 3: Typical COP’s

Hot Water

Temperatures

COP (Based on 85F

off Chiller to Templifier)

110F 120F130F 140F

8.3 6.8 6.0 4.5

Figure 6: Templifier Heat Pump Water Heater Schematic

COOLI N

85°

(29°C)

55°F

(13°C)

EVAPO RATO

12 5°F

(52°C

45°F

(7 ° C )

95 °F

HEATIN

LOAD

TEMPLI FI ER HEAT

PUMP WAT ER HEATE

T

SUPPLE-

MENTAL

CONDE NSE

EVAPORAT O

TEMPE RATURE CONTRO L

13 5°F

(57°C)

(32° )

Cat 605-5 9

LOA D

Page 10

Heat Recovery Models

Intermediate Heat Exchanger

Ground Water Heat Source

Service Hot Water Piping

CONDENSER

EVAPORATOR

ST OR AG E

TA N K

140°F

(60°C)

TEMPLIFIER

HEAT

SOURCE

140°F

(60°C)

140°F

(60°C)

RETURN /

MAKEUP

OUTP UT

STANDBY /

A UXI LI AR Y HE AT

T- C

Figure 7: Typical Templifier Applications

Heat Recovery Models

10 Cat 605-5

Page 11

Controls

Controls

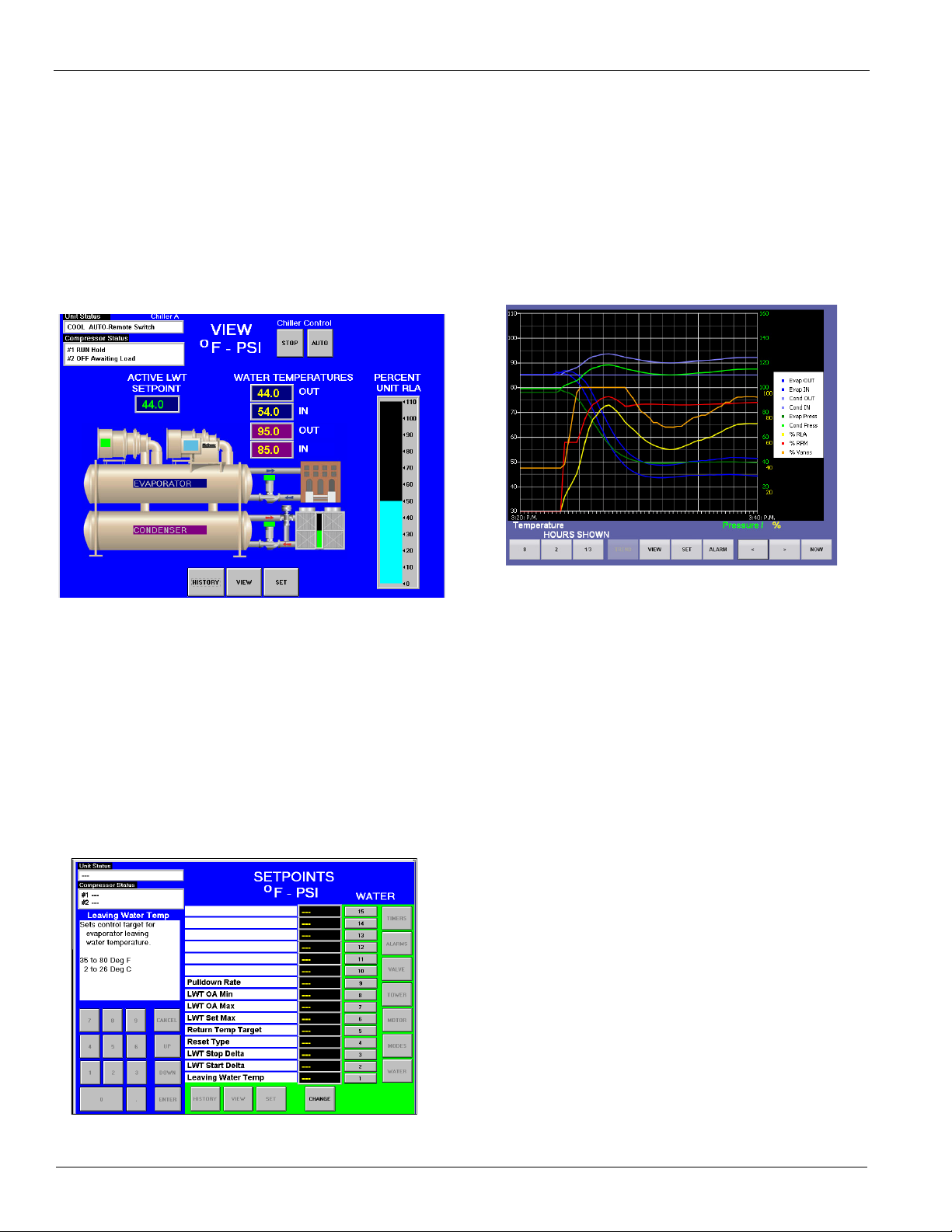

MicroTech® II Controls

Daikin Centrifugal chillers are equipped with the proven

reliability of the MicroTech® II controls system with touchscreen interface. The control system is designed for easy and

intuitive operation, and configured for efficient and reliable

operation. Plus, Daikin's Open Choices™ feature allows

integration with your building automation system (BAS)

through an optional communication module

(see Options and Accessories section, page 52).

Designed with the System Operator in Mind

Reliable, economic use of any chiller depends on an easy

operator interface. That's why operation simplicity was one of

the primary considerations

MicroTech® II controller and Operator Interface Touch-Screen

(OITS). The 15-inch color touch-screen is mounted on a fully

adjustable arm. The chiller is graphically displayed, with key

operating parameters viewable on the screen. Alarm history

and operation setpoints are easily accessed through intuitive

touch-screen buttons. The chiller operating manual is also

viewable on the touch screen and can be downloaded via USB.

MicroTech® II Controls Enhance Operating Economy

Many features have been integrated into MicroTech II controls

to ensure optimum operating economy. In addition to replacing

normal relay logic circuits, we've enhanced the controller's

energy saving capabilities with the following features:

• Direct control of water pumps Optically isolated, digital

output relays provide automatic lead-lag of the evaporator

and condenser pumps, permitting pump operation only when

required.

• User-programmable compressor soft loading Prevents

excessive power draw during pull down from high chilled

water temperature conditions.

in the development of the

• Chilled-water reset Reset the leaving water temperature

based on the return water temperature. Raising the chilled

water setpoint during periods of light loads dramatically

reduces power consumption.

• Demand limit control Maximum motor current draw can be

set on the panel, or can be adjusted from a remote 4-20ma or

1-5 VDC BAS signal. This feature controls maximum

demand charges during high usage periods.

• Condenser water temperature control Capable of four

stages of tower fan control, plus an optional analog control

of either a three-way tower-bypass valve or variable speed

tower-fan motor. Stages are controlled from condenser-water

temperature. The three-way valve can be controlled to a

different water temperature or track the current tower stage.

This allows optimum chilled water plant performance based

on specific job requirements.

• Staging Options (Multiple Chiller Installations) The

MicroTech® II controller is capable of compressor

staging decisions and balancing compressor loads

between up to four WSC,WDC or WSC Daikin chillers

using defaults or operator-defined staging.

• Plotting Historic Trends Past operation of the chiller can be

plotted as trend lines and even downloaded to a spreadsheet

for evaluation and analysis.

Proactive Controls

MicroTech® II controls constantly monitor chiller status, and

automatically take

proactive measures to relieve abnormal

conditions or shut the unit down if a fault occurs. For example,

if a problem occurs in the cooling tower and discharge

pressure starts to rise, the controller will automatically hold the

load point and activate an alarm signal. A further rise in

pressure will initiate compressor unloading in an effort to

maintain the setpoint pressure. If the pressure continues to rise,

the unit will shut off at the cutout pressure setting to protect

the unit.

Table 4: Daikin MicroTech® II Controls Features and Benefits

FEATURE BENEFIT

Open Choices™ Option

Touch-screen Interface

Alarm/Fault History and Trend Logging Historical trend data can be downloaded from an onboard USB port

Precise 0.2 F chilled water controls Provides stability in chilled water system

Proactive Controls

Integrated lead/lag pump control

Condenser Water Temperature Control Provides tower fan control /modulation based on system conditions

Multiple language capability -

Metric or IP units of measure

Cat 605-5 11

Easy integration into a building management system via a factory or field-installed

module communicating with BACnet , LONMARK or Modbus protocols.

Easy to read, adjustable, large 15-inch, color touch screen;

See chiller operation at a glance; easily view and change setpoints

Proactive correction of “unusual conditions” allows chiller to stay online; activates

alarm and modifies chiller operation to provide maximum possible cooling

Automatic control of chilled water and condenser water pumps; permits pump

operation only when required

Great asset for world-wide applications

Page 12

Controls

Alarm History for Easy Troubleshooting

The controller memory can retain and display the cause of the

current fault and the last twenty-five fault conditions. This

feature is extremely useful for troubleshooting and

maintaining an accurate record of unit performance and

history.

The Home Screen shown below is the primary viewing screen

on the Operator Interface Touch Screen (OITS). It gives realtime data on unit status, water temperatures, chilled water

setpoint and motor amp draw.

Figure 8: OITS Home Screen

Trend Logging

Ever wonder how your chiller performed last night? Were you

holding the correct chilled water temperature? What kind of

cooling load did the chiller have? The Daikin MicroTech® II

controller can provide the answers, thanks to its huge

memory, and plot water temperatures, refrigerant pressures,

and motor load data. These values can also be downloaded

through a convenient USB port (located on the unit control

panel) into a spreadsheet for detailed evaluation and analysis.

Figure 10: OITS Trend History Screen

If an alarm occurs, a red button appears on the screen that

leads to the Active Fault Screen whichgives complete fault

information so that the fault can be corrected and cleared.

Changing Setpoints

Changing setpoints is easy with the MicroTech II control. For

example, to change the chilled water setpoint, press SET

button from any screen, then press WATER and this screen

appears, now press button #1, Leaving Water Temperature, and

you are ready to input a password and a new value. (The

controller features a three-level password security system to

provide protection against unauthorized use.)

Figure 9: OITS Setpoint Screen

WDC/WCC Chiller Controls

Dual compressor model centrifugal chillers feature a

MicroTech® II unit controller and a separate controller for

each compressor. This distributed control scheme allows the

operation of each compressor in

Performance data for each compressor is monitored separately

by each controller, and can be controlled and monitored on the

interface panel.

Compressor staging and the load balance function are standard

features

the compressor with the fewest number of starts first, and will

only start remaining compressors when sufficient load has

been established. The staging function will stop the

compressor with the most run-hours as the load decreases to

single compressor range. During two-compressor operation,

the load balance function will equalize the load between each

compressor, providing optimum unit efficiency.

Versatile Communications For Even More Control

For flexibility there are three ways to interface with the

MicroTech® II controller:

• Direct entry via Operator Interface Touch-Screen.

• Direct entry as above, plus remote digital and analog input/

of MicroTech® II controllers. Smart scheduling starts

output signals for certain functions such as enable run input,

alarm signal output, chilled water reset and load limiting,

outputs for pump and tower fan control, for variable speed

tower fan and/or tower bypass valve.

dependently from the other.

12 Cat 605-5

Page 13

Controls

• Interface with a building automation system (BAS) with

optional modules, communicating directly with BACnet,

have received LONMARK certification with the optional

LONWORKS communication module.

LONMARK or Modbus protocols.

Protocol Options

Building Automation Systems

All MicroTech II®

controllers are capable of communication

with BAS, providing seamless integration and comprehensive

monitoring, control, and two-way data exchange with industry

standard protocols such as LONMARK , Modbus or BACnet .

•BACnet MS/TP

•BACnet IP

• BACnet Ethernet

• LONWORKS (FTT-10A)

• Modbus RTU

Open Choices Benefits

• Easy to integrate into your building automation system

• Factory- or field-installed communication modules

The BAS communication module can be ordered factorymounted with your chiller, or can be field-installed at any time

after the chiller is installed.

• Comprehensive point list for system integration, equipment monitoring and alarm notification

• Comprehensive data exchange

Electric Power Options

In order for the BAS to read the full complement of power data

on low and medium voltage solid state, across-the-line, and

Integration Made Easy

Daikin unit controllers strictly conform to the interoperability

guidelines of the LONMARK Interoperability Association

and the BACnet Manufacturers Association. They

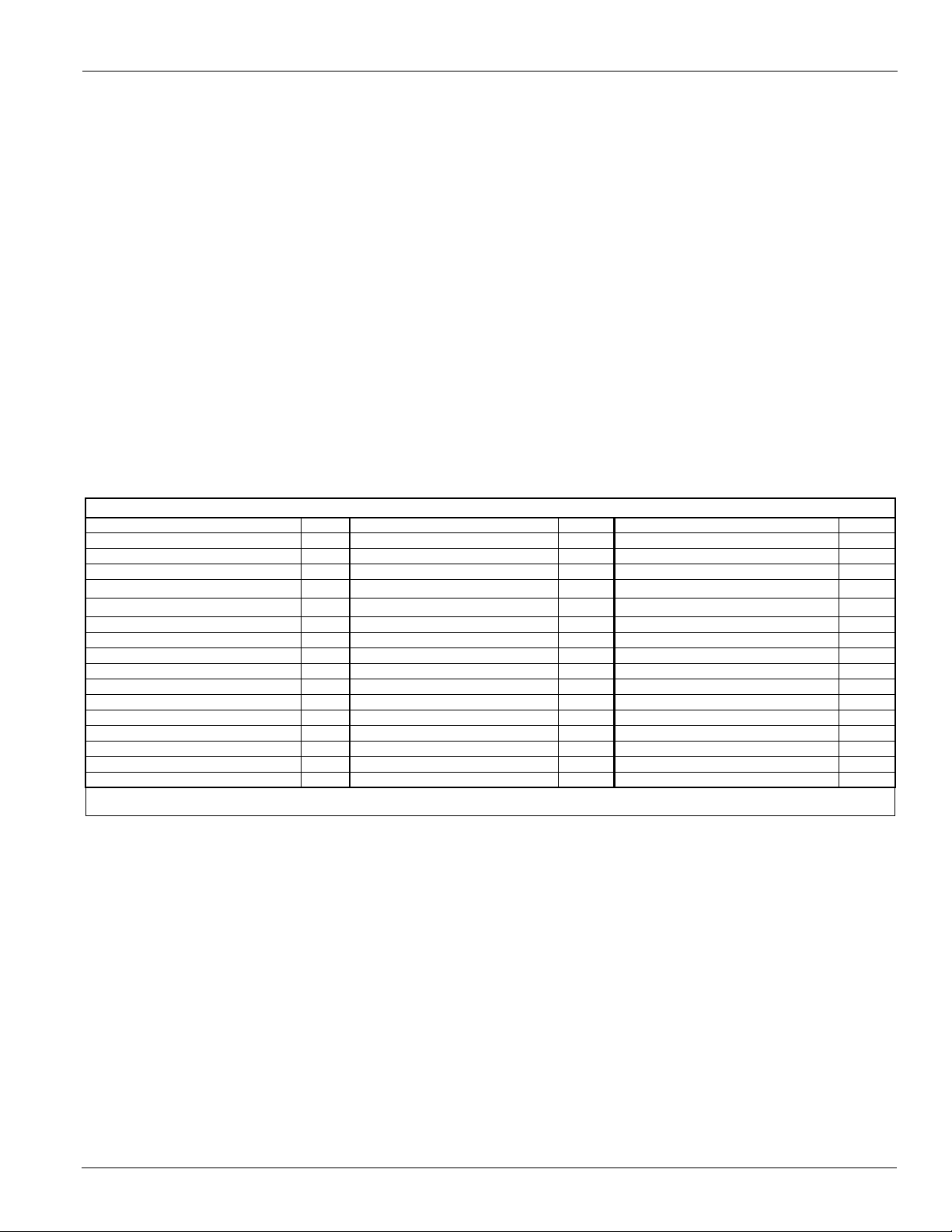

Table 5: Typical BAS Read/Write Data Points

Typical Data Points

Active Setpoint R Cond EWT R Evap Water Pump Status R

Actual Capacity R Cond Flow Switch Status R Heat Recovery EWT R

Capacity Limit Output R Cond LWT R Heat Recovery LWT R

Capacity Limit Setpoint W Cond Pump Run Hours R Heat Setpoint W

Chiller Enable W Cond Refrigerant Pressure

Chiller Limited R Cond Sat. Refrigerant Temp

Chiller Local/Remote R Cond Water Pump Status R Liquid Line Refrigerant Temp R

Chiller Mode Output R Cool Setpoint W Maximum Send Time W

Chiller Mode Setpoint W Current Alarm R Minimum Send Time W

Chiller On/Off R Default Values W Network Clear Alarm W

Chiller Status R Evap EWT R Oil Feed Pressure R

Compressor Discharge Temp R Evap Flow Switch Status R Oil Feed Temp R

Compressor Percent RLA R Evap LWT for Unit R Oil Sump Pressure R

Compressor Run Hours R Evap LWT for Compressor R Oil Sump Temp R

Compressor Select W Evap Pump Run Hours R Outdoor Air Temp

Compressor Starts R Evap Refrigerant Pressure R2 Pump Select W

Compressor Suction Line Temp R Evap Sat. Refrigerant Temp R2 Run Enabled R

1.) Data points available are dependent upon options selected

2.) Per compressor

wye-delta starters, the optional Field Metering Package must

be ordered with the chiller. Otherwise the BAS will only read

the average unit amps. This power data is not available to a

BAS on all other starter voltages and types.

1

(W = Write, R = Read)

2

Ice Setpoint W

R

2

Liquid Line Refrigerant Pressure

R

Cat 605-5 13

Page 14

Application Considerations

Application Considerations

Location

These chillers are intended only for installation in an indoor or

weather protected area consistent with the NEMA 1 rating on

the chiller, controls, and electrical panels. If indoor subfreezing temperatures are possible, special precautions must be

taken to avoid equipment damage. Equipment room

temperature for operating and standby conditions is 40°F-

122°F (4.4°C-50°C)

CAUTION

Daikin Centrifugal Chillers are intended only for installation in indoor

areas protected from temperature extremes. Failure to comply may

result in equipment damage and may void the manufacturer warranty.

Operating/Standby Limits

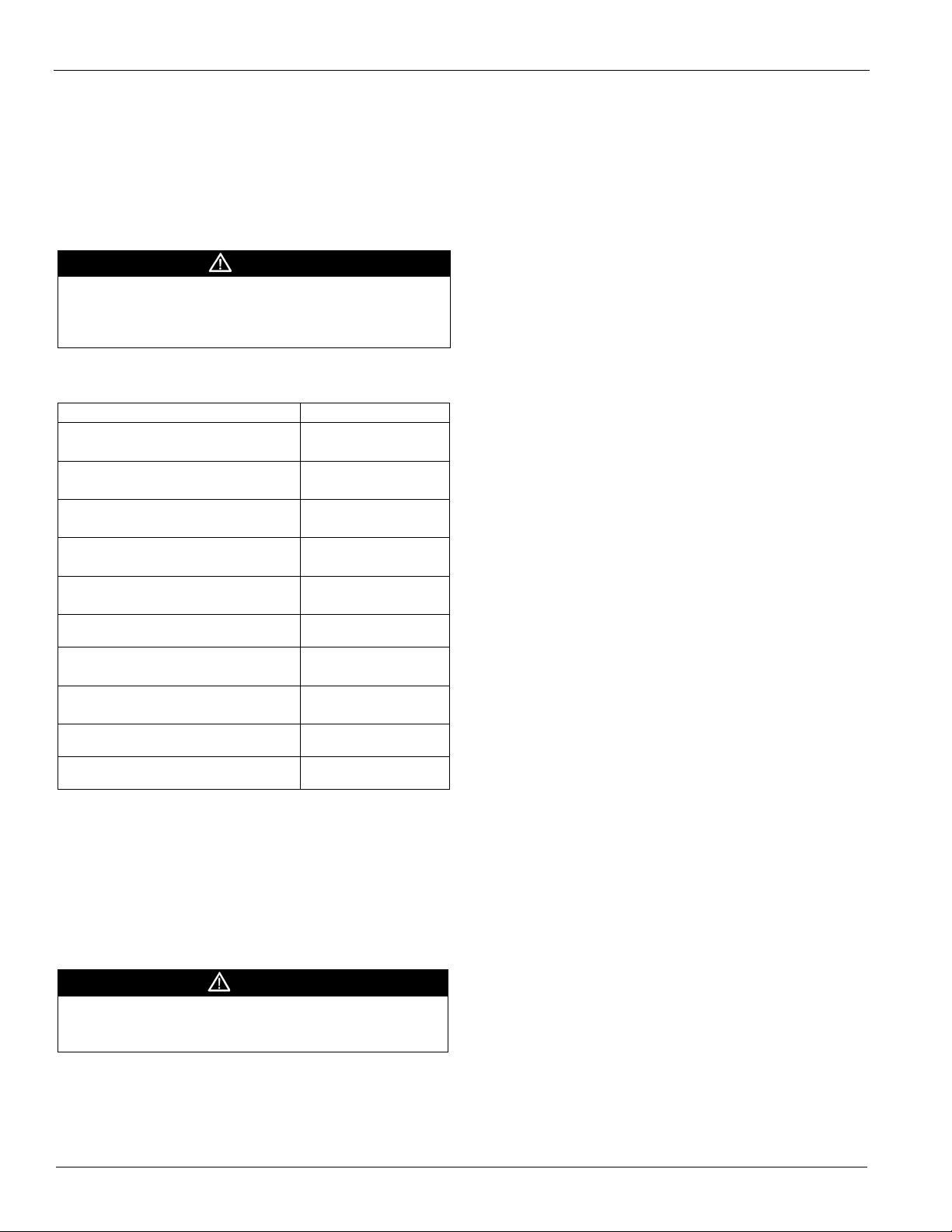

Table 6: Operating/Standby Limits

Equipment room operating temperature: 40°-104°F (4.4°-40°C)

Equipment room temperature, standby,

with water in vessels and oil cooler:

Equipment room temperature, standby,

without water in vessels and oil cooler:

Maximum entering condenser water

temperature, startup:

Maximum entering condenser water

temperature, operating:

Minimum entering condenser water

temperature, operating:

Minimum leaving chilled water

temperature:

Minimum leaving chilled fluid temperature

with correct anti-freeze fluid:

Maximum entering chilled water

temperature, operating:

Maximum oil cooler entering

temperature:

Minimum oil cooler entering

temperature:

Piping

Piping must be adequately supported to remove weight and

strain on the chiller's fittings and connections. Do not use

PVCor CPVC piping. Be sure piping is adequately insulated.

Install a cleanable 20-mesh water strainer upstream of the

evaporator and condenser. Install enough shutoff valves to

permit draining water from the evaporator or condenser

without draining the complete system.

CAUTION

Freeze Notice: The evaporator and condenser are not selfdraining. Both must be blown out to completely remove water

to help prevent freeze-up

.

Include thermometers and pressure gauges at the chiller inlet

and outlet connections and air vents at the high points of

piping. The water heads can be interchanged (end for end),

allowing water connections to be made at either end of the

40°-104°F (4.4°-40°C)

0°F-122F (-18°C-50°C)

design + 5°F (2.7°C)

job-specific design

temperature

see this page.

38°F (3.3°C)

15°F (9.4°C)

90°F (32.2°C)

80°F (26.7°C)

42°F (5.6°C)

unit. Use new head gaskets when interchanging water heads.

When water pump noise is objectionable, use rubber isolation

sections at both the inlet and outlet of the pump. Vibration

eliminator sections in the condenser inlet and outlet water lines

are not normally required. Where noise and vibration are

critical and the unit is mounted on spring isolators, flexible

piping and conduit connections are necessary. If not factory

installed, a flow switch or pressure differential switch must be

installed in the leaving chilled water line in accordance with

the flow switch manufacturer's instructions.

Note: Victaulic connections are AWWA C-606. Field supply

transitions if Victaulic brand AGS® (Advanced Groove

System) type grooves are used on the field piping.

Optimum Water Temperatures and Flow Rates

A key to improving energy efficiency for any chiller is

minimizing the lift, or pressure difference, between the

compressor suction and discharge pressures. Reducing the lift

reduces the compressor work, and hence its energy

consumption per unit of output. The chiller typically has the

largest motor of any component in a chilled water system.

Higher leaving chilled water temperatures

Warmer leaving chilled water temperatures will raise the

compressor's suction pressure and decrease the lift, improving

efficiency. Using 45 F (7.0 C) leaving water instead of 42 F

(5.5 C) will make a significant improvement.

Evaporator temperature drop

The industry standard has been a ten-degree temperature drop

in the evaporator. Increasing the drop to 12 or 14 degrees will

improve the evaporator heat transfer, raise the suction

pressure, and improve chiller efficiency. Chilled water pump

energy will also be reduced.

Condenser entering water temperature

As a general rule, a one-degree drop in condenser entering

water temperature will reduce chiller energy consumption by

two percent. Cooler water lowers the condensing pressure and

reduces compressor work. One or two degrees can make a

noticeable difference. The incremental cost of a larger tower

can be small and provide a good return on investment.

Minimum Condenser Water Temperature Operation

When ambient wet bulb temperatures are lower than design,

the condenser water temperature can be allowed to fall. Lower

temperatures will improve chiller performance.

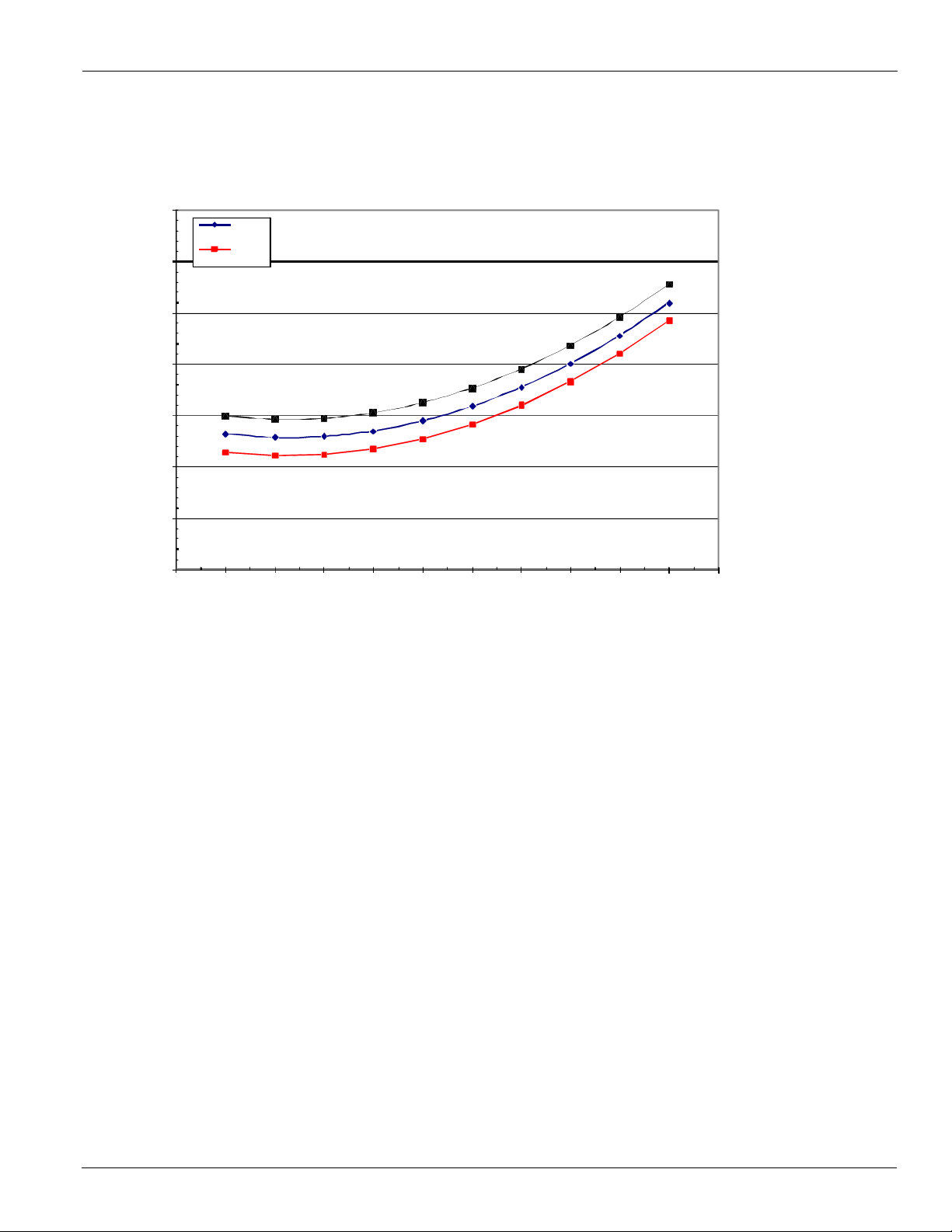

Up to 600 Tons

Daikin centrifugal chillers up to 600 Tons are equipped with

electronic expansion valves (EXV) and will start and run

with entering

condenser water temperatures as low as shown

in Figure 11 (based on a 10 degree F condenser Delta-T) or

as calculated from the following equation on which the

curves are based

14 Cat 605-5

Page 15

Application Considerations

LChWT

42

LChWT

Min. ECWT = 5.25 + 0.88*(LWT) - DT

FL*

(PLD/100) + 22 *(PLD/1 00)2

ECWT = E nt erin g c ond en ser water te mperat ur e

LWT = Leaving chilled water temperature

DT

FL

= Ch ille d Wate r D elta -T at full l oad

PL D = The pe rc ent ch ille r load poin t to b e chec ked

For example; at 44F LWT, 10 degree F Delta-

water temperature could be as low as 44.5F. This provides excellent operation with watereconomizer systems.

Figure 11: Minimum Entering Condenser Water Temperature (With Electronic Expansion Valve)

Minimum Entering Condenser Water Temperature - 10 F Range

65.0

60.0

55.0

50.0

F

,

T

W

C

E

45.0

40.0

35.0

30.0

0 10 20 30 40 50 60 70 80 90 100 110

44

Percent Load

T, and 50% full load operation, the entering condenser

Cat 605-5 15

side

Page 16

Application Considerations

44

LChW

T

Over 600 Tons

Chillers over approximately 600 Tons are equipped with

thermal expansion valves (TXV) and will start and run with

entering condenser water temperatures as low as calculated by

the following equation and shown in the chart following.

"ECWT = Entering condenser water temperature

"LWT = Leaving chilled water temperature

"DTFL = Chilled Water Delta-T at full load

"PLD = The percent chiller load point to be checked

Min. ECWT = 7.25 + LWT- 1.25* DTFL(PLD/100) +

65. 0

60. 0

55. 0

50. 0

45.0

40. 0

2

Minimu m Ent er ing C ond ens er Wate r Temp er atur e - 10 F R an ge

42

LChWT

22*(PLD/100)

Figure 12: Minimum Entering Condenser Water Temperature (Thermal Expansion Valve)

F

,

T

W

C

E

35. 0

30. 0

0 102030405060708090100110

Percen

t Load

For example; at 44 F LWT, 10 degree F Delta-T, and 50% full

load operation, the entering condenser water temperature could

be as low as 50.5 F. This provides excellent operation with

water-side economizer systems.

Depending on local climatic conditions, using the lowest

possible entering condenser water temperature may be more

costly in total system power consumed than the expected

savings in chiller power would suggest, due to the excessive

fan power required.

Cooling tower fans must continue to operate at 100% capacity

at low wet bulb temperatures. As chillers are selected for lower

kW per ton, the cooling tower fan motor power becomes a

higher percentage

of the total peak load chiller power.

Daikin's Energy Analyzer program can optimize the chiller/

tower operation for specific buildings in specific locales.

Even with tower fan control, some form of water flow control,

such as tower bypass, is recommended.

Condenser water temperature rise

The industry standard of 3 gpm/ton or about a 9.5-degree

delta-T works well for most applications. Reducing condenser

water flow to lower pumping energy will increase the water

temperature rise, resulting in an increase in the compressor's

condensing pressure and energy consumption. This is usually

not a productive strategy.

System analysis

Although Daikin is a proponent of analyzing the entire

system, it is generally effective to place the

chiller in the most

efficient mode because it is, by far, a larger energy consumer

than pumps. The Daikin Energy Analyzer program is an

excellent tool to investigate the entire system efficiency,

quickly and accurately. It is especially good at comparing

different system types and operating parameters. Contact your

local Daikin sales office for assistance on your particular

application.

For Best Chiller Efficiency

The designer must determine the proper chiller efficiency for a

given application. The most efficient chiller is not always the

best. A life cycle analysis (as performed by Daikin's Energy

Analyzer program, for example) is the only way to be sure of

the best selection. Utility costs, load factors, maintenance

costs, cost of capital, tax bracket; in other words, all the factors

affecting owning cost, must be considered.

Generally, the attempts to save the last few full load kW are

very costly. For example, the cost to go from 0.58 to 0.57 kW/

16 Cat 605-5

Page 17

Application Considerations

ton could be very costly because of the large number of copper

tubes that would have to be added to the heat exchangers.

Table 7:

Vessel Activity Example

Evaporator

Evaporator

Evaporator Lower flow rates

Condenser

Condenser

Higher leaving water

Temperatures

Higher water temperature

drops

Lower entering water

temperature

Higher flow rates (3.0 gpm/

ton or higher)

44F instead of 42F

12°F instead of 10°F

2.4 gpm/ton instead of

3.0 gpm/ton

84F instead of 85F

3.0 gpm/ton instead of

2.5 gpm/ton

Mixing Single and Dual Compressor Chillers

WDC dual compressor chillers excel at part load operation,

while single compressor chillers usually have better full load

efficiency. A good chiller plant strategy is to install one dual

and one or more single compressor units. Run the dual until it

is fully loaded, then switch to the single compressor unit and

run it only at full load, using the dual to trim the load.

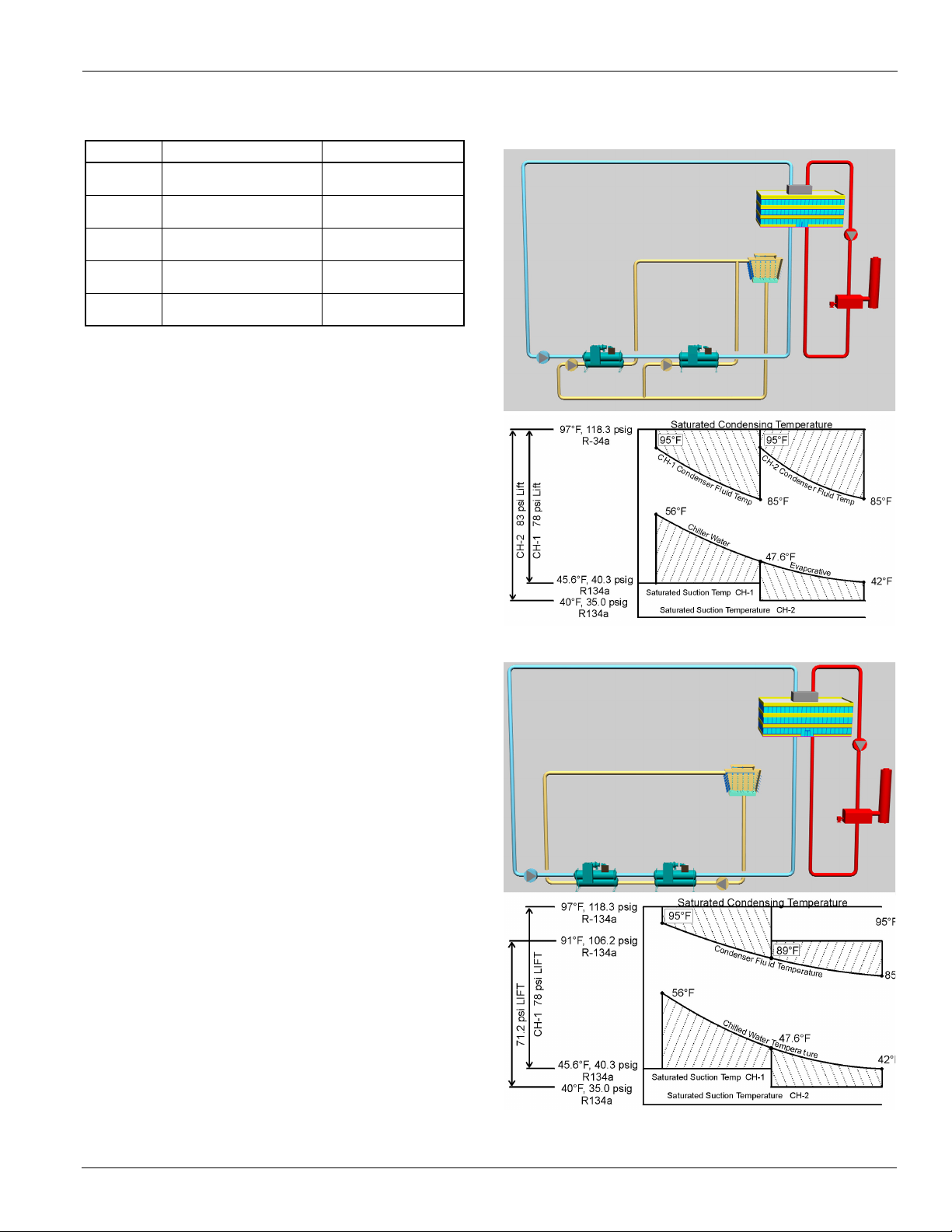

Series Counterflow and Series Parallel Chillers

The design of piping systems can greatly impact chiller

performance. A popular system is to place the evaporators in

series with the chilled water flowing from one evaporator to

the next as shown in Figure 13 and Figure 14. Two different

condenser water piping arrangements can be used. Parallel

flow (Figure 13) divides the total condenser flow between the

two condensers. The counterflow system (Figure 14) puts all

of the condenser water through the condenser of the lag chiller

(chiller producing the coldest evaporator leaving water) and

then through the lead chiller (chiller seeing the warmest

evaporator water temperatures).

tons) combines counterflow design into one unit. See page 6

for details.

Figure 13: Series Parallel Flow

Figure 14: Series Counterflow Flow

Typically, since the lead machine will see the warmest

evaporator water, it will have the greater capacity and larger

portion of the total system evaporator temperature drop. Again

referring to Figure 13 and Figure 14, the lead machine has an

8.4 degree drop (56.0

degree drop (47.6

°F-47.6°F) and the lag machine has a 5.6

°F - 42.0°F).

Condenser water flow is important to overall system

efficiency. With parallel flow (Figure 13), the condensers have

identical flow conditions (95 to 85 degrees in this example)

with the compressor lift shown. With counterflow arrangement

the lift on the lead machine is significantly lower, reducing

compressor work and making the overall system efficiency

about 2% better. Even though the chiller performance is

different, it is good practice to use the same chiller models.

Both the WSC and WDC chillers are suitable for series

counterflow arrangement and include controls specifically

designed for series chillers. For more information, please refer

to Application guide AG -31-003: Chiller Plant Design.

Daikin's model WCC dual compressor chiller (1200 to 2700

Cat 605-5 17

Page 18

Application Considerations

CHILLER

OIL COOLER

STOP

VALVE

STRAI NER

MAX. 40 MESH

SOLENO ID

VA LV E

DRA IN VALVE

OR PLUG

PUMP

OPEN

DRAIN VALVE

OR PLUG

SOL EN OID

VA LVE

OIL COOLE R

STRAINE R

MAX. 40

MESH

DISCHARGE ABOVE

HI GH EST POSSIBLE

WATER LEVEL

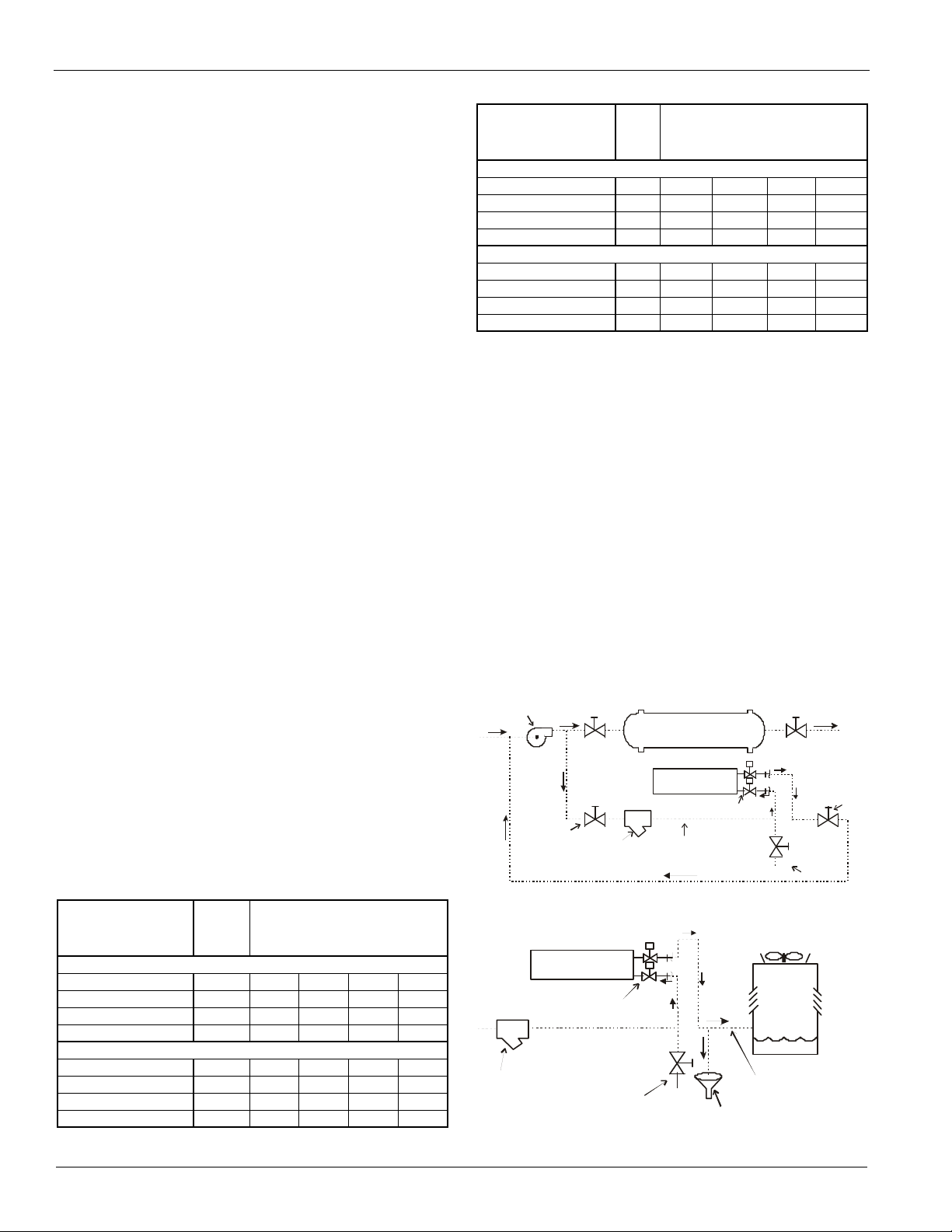

Oil Coolers

Daikin centrifugal chillers have a factory-mounted, watercooled oil cooler with a temperature controlled water

regulating v

Cooling water connections are located at the rear of the unit,

near the compressor and are shown on the specific unit

certified drawings. Models WDC 063 through 087 and all

WCC have the cooling water connections in the lower portion

of one tube sheet.

WDC 063, 079, 087, 100 and 126 dual compressor chillers are

equipped as above, but the water piping for the two oil coolers

is factory piped to a common inlet and outlet connection.

Field water piping to the inlet and outlet connections must be

installed according to good piping practices and must include

stop valves to isolate the cooler for servicing. A 1" minimum

cleanable filter (40 mesh maximum) and drain valve or plug

must also be field installed. The water supply for the oil cooler

must be from the chilled water circuit, or from an independent

clean source such as city water. When using chilled water, it is

important that the water pressure drop across the evaporator is

greater than the pressure drop across the oil cooler or

insufficient oil cooler flow will result. If the pressure drop

across the evaporator is less than the oil cooler, the oil cooler

must be piped across the chilled water pump, provided that its

pressure drop is sufficient. The water flow through the oil

cooler will be adjusted by the unit's regulating valve so that the

temperature of oil supplied to the compressor bearings

(leaving the oil cooler) is between 90

C).

43

NOTE: The system must be designed for the highest cooling

water temperature possible, which may occur for a short time

during startup.

alve and solenoid valve for each compressor.

F and 110F (32C and

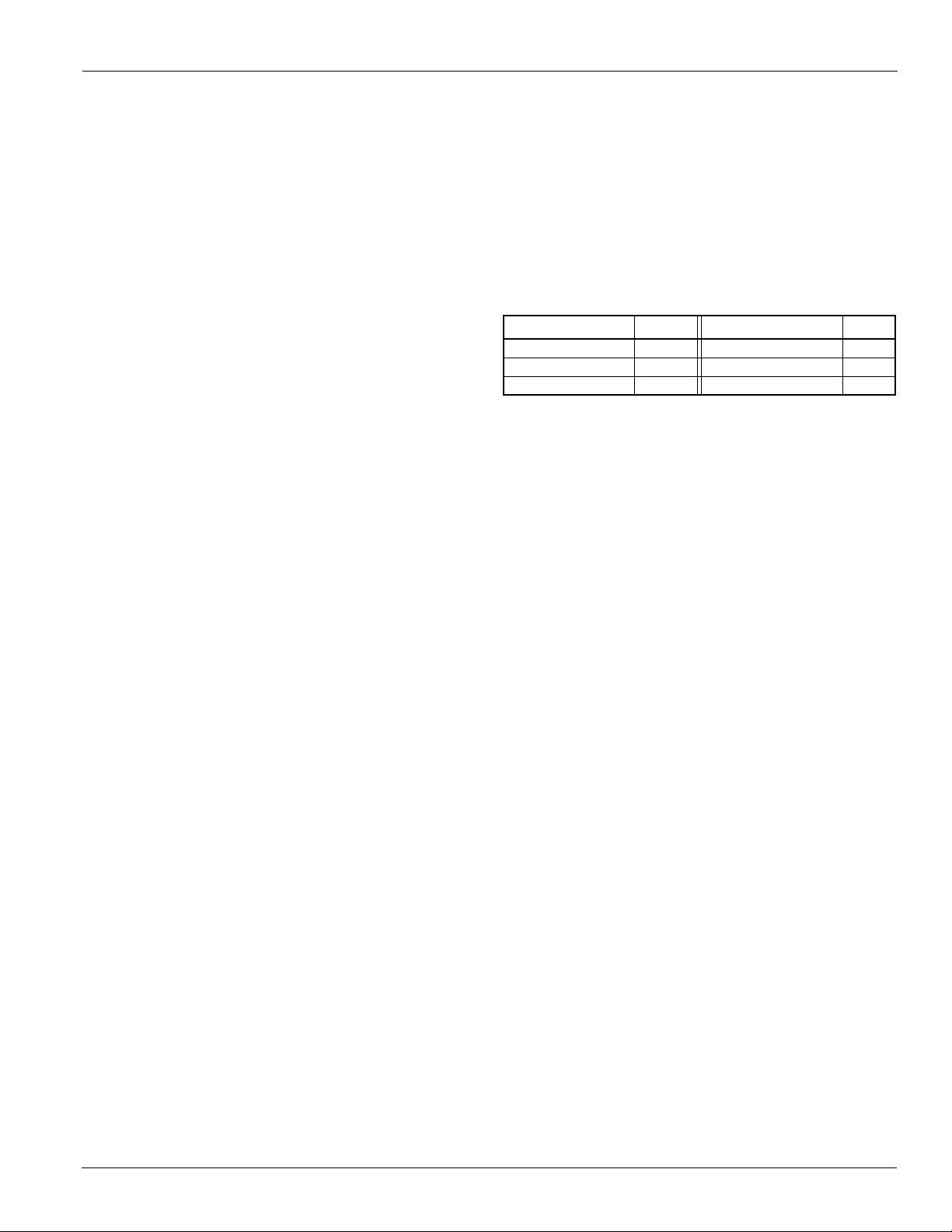

Table 9: WSC with VFD Oil Cooler Data

Hot

Side

POE

Lub.

Cold Side Water

WSC/HSC 063 - 087

Flow, gpm 9.9 13.4 4.0 2.9 2.3

Inlet Temperature, F 118.0 80.0 65.0 55.0 45.0

Outlet Temp., F 100.0 90.3 99.6 103.1 105.6

Pressure Drop, ft. - 30.5 6.7 4.8 3.6

WSC/HSC 100 - 126

Flow, gpm 15.8 24.4 7.0 5.0 4.0

Inlet Temp., F 120.0 80.0 65.0 55.0 45.0

Outlet Temp., F 100.0 89.8 100.1 103.6 106.2

Pressure Drop, ft. - 30.6 15.7 11.4 9.3

NOTES:

1WDC and WCC units have twice the cooling water flow rate

of the comparable WSC chiller.

2

Pressure drops include valves on the unit.

When supplied with city water, the oil piping must discharge

through a trap into an open drain to prevent draining the cooler

by siphoning. The city water can also be used for cooling

tower makeup by discharging it into the tower sump from a

point above the highest possible water level.

Note: Particular attention must be paid to chillers with variable

chilled water flow through the evaporator. The pressure

drop available at low flow rates can very well be

insufficient to supply the oil cooler with enough water. In

this case an auxiliary booster pump can be used or city

water employed.

Cooling Water Connection Sizes: WDC/WCC 100/126 have 11/2 in. FPT connections, all other WDC and WSCs are 1 in.

FPT.

Figure 15: Oil Cooler Piping Across Chilled Water Pump

Compressors using chilled water for oil cooling will often start

with warm "chilled water" in the system until the chilled water

loop temperature is pulled down. With cooling water in the

F to 55F (4C to 13C) range, considerably less water will

40

R

S

be used and the pressure drop will be greatly reduced. The

following table contains oil cooler data at various inlet water

temperatures.

Table 8: WSC Oil Cooler Data

Hot

Side

POE

Lube

Cold Side Water

WSC 063 - 087

Flow, gpm 9.9 11.9 2.9 2.0 1.54

Inlet Temperature, F 118.0 80.0 65.0 55.0 45.0

Outlet Temp., F 100.0 87.3 94.5 98.3 101.4

Pressure Drop, psi - 4.3 0.3 0.14 0.09

WSC 100 - 126

Flow, gpm 15.8 21.9 5.11 3.5 2.7

Inlet Temperature, F 120.0 80.0 65.0 55.0 45.0

Outlet Temp., F 100.0 87.0 95.0 99.0 102.3

Pressure Drop, psi - 3.78 0.23 0.11 0.07

18 Cat 605-5

Figure 16: Figure 17, Oil Cooler Piping With City Water

R

S

COOLING TOWER

COOLING TOWER MAKEUP

DRA IN

STOP

VALU E

Page 19

Application Considerations

5.0

2

....

2

2

2

1

n

DDD

Common

D

Pumps

Model WSC, WDC and WCC chiller compressor motors

operate at 3600 rpm on 60 Hz power (3000 rpm on 50 Hz).

When VFDs are employed, the hertz/speed can be reduced by

70%. To avoid the possibility of objectionable harmonics in

the system piping, 4-pole, 1800/1500 rpm system pumps

should be used. The condenser water pump(s) must be cycled

off when the last chiller of the system cycles off. This will

keep cold condenser water from migrating refrigerant to the

condenser. Cold liquid refrigerant in the condenser can make

start-up difficult. In addition, turning off the condenser water

pump(s) when the chillers are not operating will conserve

energy.

Include thermometers and pressure gauges at the chiller inlet

and outlet connections and air vents at the high points of

piping. The water heads can be interchanged (end for end),

allowing water connections to be made at either end of the

unit. Use new head gaskets when interchanging water heads.

When water pump noise is objectionable, use rubber isolation

sections at both the inlet and outlet of the pump. Vibration

eliminator sections in the condenser inlet and outlet water lines

are not normally required. Where noise and vibration are

critical and the unit is mounted on spring isolators, flexible

piping and conduit connections are necessary. If not factory

installed, a flow switch or pressure differential switch must be

installed in the leaving chilled water line in accordance with

the flow switch manufacturer's instructions.

Victaulic connections are AWWA C-606 on 14-inch and larger

sizes. Field supply transitions if Victaulic brand AGS®

(Advanced Groove System) type grooves are used on the field

piping.

Filtering and Treatment

Owners and operators must be aware that if the unit is

operating wit

cooling tower is required. Make sure tower blow-down or

bleed-off is operating. Atmospheric air contains many

contaminants, which increases the need for water treatment.

The use of untreated water will result in corrosion, erosion,

slime buildup, scaling, or algae formation. A water treatment

service should be used. Daikin is not responsible for damage

or faulty operation from untreated or improperly treated

water.

Machine Room Ventilation

In the market today, centrifugal c

either hermetic or open type motors. Hermetic motors are

cooled with refrigerant and dissipate their heat through the

cooling tower. On the other hand, open motors circulate

equipment room air across themselves for cooling and reject

the heat to the equipment room. Daikin chillers have hermetic

motors and DO NOT require additional ventilation.

For chillers with open-drive type, air-cooled motors, good

engineering practice dictates that the motor heat be removed to

h a cooling tower, cleaning and flushing the

hillers are available with

prevent high equipment room temperatures. In many

applications this requires a large volume of ventilation air, or

mechanical cooling to properly remove this motor heat.

EXAMPLE: 1000 tons x 0.6 kW/Ton x 0.04 motor heat loss x

0.284 Tons/kW = 7 tons (24 kW) cooling

The energy and installation costs of ventilation or mechanical

cooling equipment must be considered when evaluating

various chillers. For a fair comparison, the kW used for the

ventilation fans, or if mechanical cooling is required, the

additional cooling and fan energy must be added to the open

motor compressor energy when comparing hermetic drives.

Additionally, significant costs occur for the purchase,

installation, and maintenance of the ventilation or air handling

units.

Equipment room ventilation and safety requirements for

various refrigerants is a complex subject and is updated from

time to time. The latest edition of ASHRAE 15 should be

consulted.

Thermal Storage

Daikin chillers are designed for use in thermal storage

systems. The chillers

must be considered. The first is normal air-conditioning

The second condition occurs during the ice making process

when leaving fluid temperatures are in the 22

(-5.6

°C to -3.3°C) range.

The MicroTech II control system will accommodate both

operating points. The ice mode can be started or stopped by an

input signal to the microprocessor from a BAS or through a

chilled water reset signal. When a signal is received to change

from the ice mode to the normal operating mode, the chiller

will shut down until the system fluid temperature rises to the

higher setpoint. The chiller will then restart and continue

operation at the higher leaving fluid temperature. When

changing from normal cooling to the ice mode, the chiller will

load to maximum capacity until the lower setpoint is reached.

Computer selections must be made to check that the chiller

will operate at both conditions. If the "ice mode" is at night,

the pressure differentials between the evaporator and

condenser are usually similar to normal cooling applications.

The leaving fluid temperature is lower, but the condensing

temperature is also lower because the cooling tower water is

colder. If the ice mode can also operate during the day, when

cooling tower water temperatures are high, a proper selection

becomes more difficult because the two refrigerant pressure

differentials are significantly different.

A three-way condenser water control valve is always required.

have two operating conditions that

duty where leaving

evaporator fluid

temperatures range

from 40

(4.4

°F to 45°F

°C to 7.2°C).

°F to 26°F

Cat 605-5 19

Page 20

Application Considerations

Variable Speed Pumping

Variable speed pumping involves changing system water

flow relative to cooling load change

chillers are designed for this duty with two limitations.

First, the rate of change in the water flow needs to be slow, not

greater than 10% of the change per minute. The chiller needs

time to sense a load change and respond.

Second, the water velocity in the vessels must be 3 to 10 fps

(0.91 and

occurs which reduces heat transfer. Above 10 fps (3.0 m/sec),

excessively high pressure drops and tube erosion occur.

These flow limits can be determined from the Daikin

selection program.

We recommend variable flow only in the evaporator because

there is virtually no change in chiller efficiency compared to

constant flow. In other words, there is no chiller energy

penalty. Although variable speed pumping can be done in the

condenser loop, it is usually unwise. The intent of variable

flow is to reduce pump horsepower. However, reducing

condenser water flow increases the chiller's condensing

pressure, increasing the lift that the compressor must overcome

which, in turn, increases the compressor's energy use.

Consequently, pump energy savings can be lost because the

chiller operating power is significantly increased.

Low condenser flow can cause premature tube fouling and

subsequent increased compressor power consumption.

Increased cleaning and/or chemical use can also result.

Vibration Mounting

Every Daikin chiller is run tested and compressor vibration is

measured and limited to a maximum rate

second, which is considerably more stringent than other

available compressors. Consequently, floor-mounted spring

isolators are not usually required. Rubber mounting pads are

shipped with each unit. It is wise to continue to use piping

flexible connectors to reduce sound transmitted into the pipe

and to allow for expansion and contraction.

AHRI Standard 575 Sound Ratings

Sound data in accordance with AHRI Standard 575 for

individual units are available from your local Daikin

representative. Due to the large number of

combinations and variety of applications, sound data is not

included in this catalog.

3.0 m/sec). Below 3 fps (0.91 m/sec), laminar flow

s. Daikin centrifugal

of 0.14 inches per

component

Discharge Line Sound Packages

For extremely sensitive projects, an optional discharge line

sound package is offered consisting of sound insulation

installed on the unit's discharge line. An additional 2 to 4 dbA

reduction normally occurs.

System Water Volume

All chilled water systems need adequate time to recognize a

load change, respond to that load change and stabilize, without

undesirable short cycling of the compressors or loss of control.

In air conditioning systems, the potential for short cycling

usually exists when the building load falls below the minimum

chiller plant capacity or on close-coupled systems with very

small water volumes.

Some of the things the designer should consider when looking

at water volume are the minimum cooling load, the minimum

chiller plant capacity during the low load period and the

desired cycle time for the compressors.

Assuming that there are no sudden load changes and that the

chiller plant has reasonable turndown, a rule of thumb of

"gallons of water volume equal to two to three times the

chilled water gpm flow rate" is often used.

A properly designed storage tank should be added if the

system components do not provide sufficient water volume.

Relief Valves

Relief valve connection sizes are 1-inch

quantity shown in Table 10 for the evaporator and condenser.

In addition, there is a relief valve (3/8 inch flare) on the top of

the oil sump of all units.

All relief valves (including the oil sump) must be piped to the

outside of the building in accordance with ANSI/ASHRAE 15-

2001. The new 2001 standard has revised the calculation

method compared to previous issues.

Twin relief valves, mounted on a transfer valve, are used on

the condenser so that one relief valve can be shut off and

removed for testing or replacement, leaving the other in

operation. Only one of the two valves is in operation at any

time. Where 4 valves are shown, on some large vessels, they

consist of two relief valves mounted on each of two transfer

valves. Only two relief valves of the four are active at any

time.

FPT and are in the

20 Cat 605-5

Page 21

Application Considerations

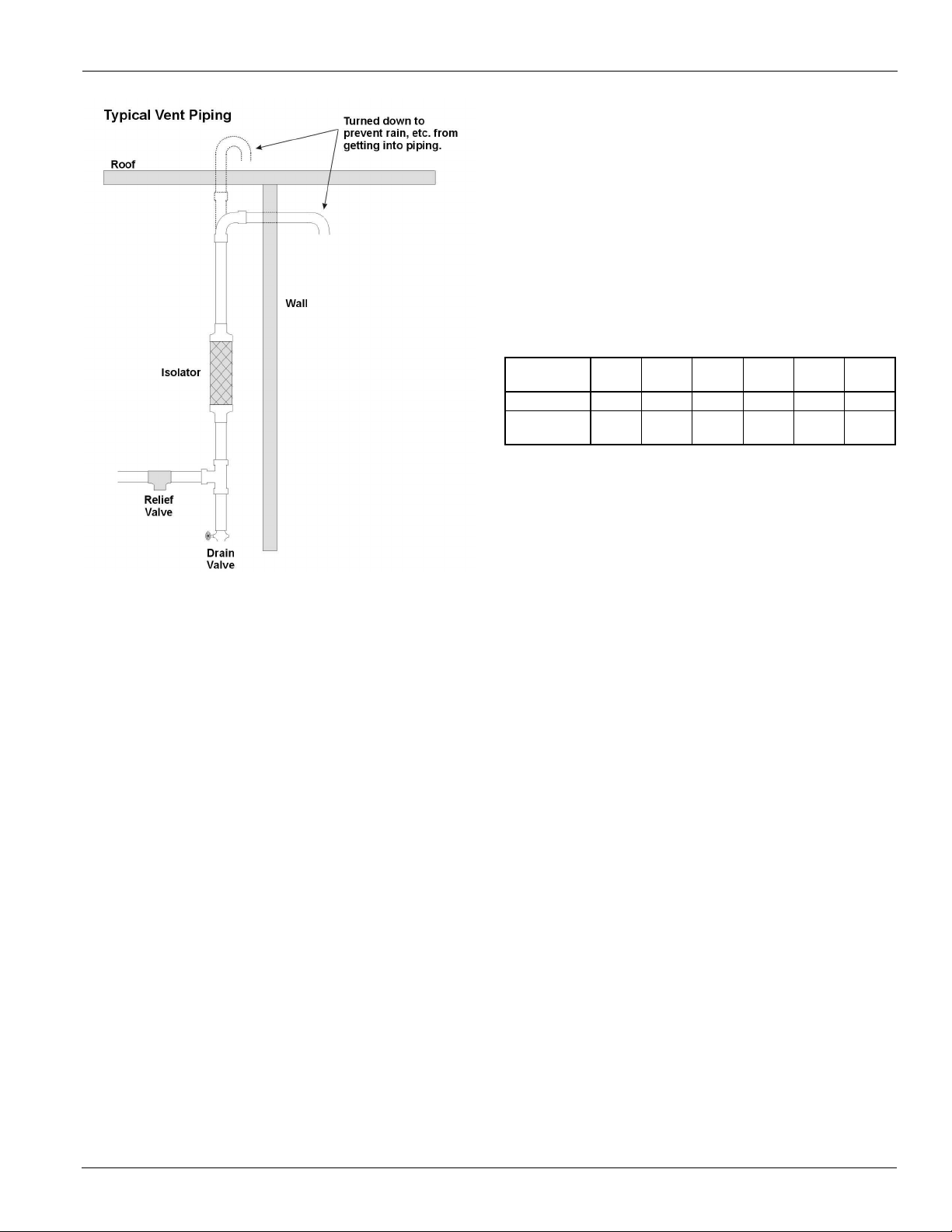

Figure 17: Typical Vent Piping

Vent piping is sized for only one valve of the set since only one

can be in operation at a time.

Relief Pipe Sizing (ASHRAE Method)

Daikin centrifugal chillers have the following relief valve

settings and discharge capacity:

• WSC/WCC evaporator (1 valve) and condenser (2 valves

piped together to common vent pipe) = 200 psi, 75.5 lb of

air/min

• WDC evaporator (1) = 180 psi, 68.5 lb of air/min

• WDC condenser(2) = 225 psi, 84.4 lb of air/min

• Note: some large condensers have 4 relief valves

Since the pressures and valve size are fixed for Daikin

chillers, the ASHRAE equation can be reduced to the simple

tabl

e shown below.

Table 10: Relief Valve Piping Sizes

Pipe Size inch

(NPT)

Moody Factor

Equivalent

length (ft)

Note: A 1-inch pipe is too small to handle these valves. A pipe

increaser must be installed at the valve outlet.

1.25 1.5 2 2.5 3 4

0.0209 0.0202 0.0190 0.0182 0.0173 0.0163

2.2 18.5 105.8 296.7 973.6 4117.4

Per ASHRAE Standard 15, the pipe size cannot be less than

the relief device. The discharge from more than one relief

valve can be run into a common header, the area of which shall

not be less than the sum of the areas of the connected pipes.

For further details, refer to ASHRAE Standard 15.

The above information is a guide only. Consult local codes

and/or latest version of ASHRAE Standard 15 for sizing data.

Relief valve pipe sizing is based on the discharge capacity for

the given evaporator or condenser and the length of piping to

be run.

Cat 605-5 21

Page 22

Application Considerations

MODEL CODE EXAM PLE: W S C - 063M - AQ - 18S / E2012- E - 2 * A / C1812- B L Y Y - 2 * A Y Y Y R / 134B

Packaged Water Cooled

Centrifugal Chiller

S = Single Compressor

D = D ual Compressor

C = Dual Counterflow

Hermet ic Co mpressor Model

Compressor/Impeller Code

Gear Ratio

Motor/Voltage Code

Evaporator Shell Description

[Diameter (in.), Length (ft.)]

Tube Count Code

Tube Type Code

Number of Passes (1, 2, 3)

Water Inlet Location (R = Right Inlet; L = Left Inlet)

Connection Type

Condenser Shell Description [Diameter (in.), Length (ft.)]

Tube Count Code

Type Type Code

Tube Count Code (Heat Recovery Condenser)

Tube Type Code (Heat Recovery Conderser)

Number of Passes (1, 2, 3)

Water Inlet Location (R = Right Inlet; L = Left Inlet)

Connection Type

Number of Passes (Heat Recovery Condenser)

Water Inlet Location (Heat Recovery Condenser)

Connection Type (Heat Recovery Condenser)

Motor Manufacturer

Refrigeration Type (134 = HFC-134a)

COMPRESSOREVAPORATOR

CONDENSER

R

Figure 18: Chiller Identification (Code String Index)

22 Cat 605-5

Page 23

Electrical Data

Wiring and Conduit

Wire sizes must comply with local and state electrical codes.

Where total amperes require larger conductors than a single

conduit would permit, limited by dimensions of motor terminal

box, two or more conduits can be used. Where multiple

conduits are used, all three phases must be balanced in each

conduit. Failure to balance each conduit will result in

excessive heating of the conductors and unbalanced voltage.

An interposing relay can be required on remote mounted

starter applications when the length of the conductors run

between the chiller and starter is excessive.

Note: On WDC and WCC dual compressor units, dual power

leads are standard, requiring separate power leads properly

sized and protected to each compressor starter or VFD.