Page 1

PRODUCT SPECIFICATIONS

PCB

COMMERCIAL SERIES

50 Hz

SELF-CONTAINED

PACKAGE AIR CONDITIONER

7½, 10, AND 15 TON

[26.4 kW to 52.8 kW]

COOLING CAPACITY:

90,000 TO 180,000 BTU/H

The PCB Commercial 50 Hz self-contained

packaged air conditioner is designed for

ground-level or rooftop application.

Standard Features

Dual high-effi ciency scroll compressors with

•

internal motor protection (2-stage cooling;

three compressors on 15-ton units)

Compressor grommets for vibration isolation

•

Time delay for compressor sequencing

•

Fully charged systems

•

High- and low-pressure controls on all systems

•

Mild ambient switch

•

Two independent condenser coils for

•

2-stage operation

Totally enclosed, permanently lubricated ball-

•

bearing outdoor fan motors

Enhanced copper tube/aluminum fi n coils

•

Expansion valve evaporator coil

•

Vertical discharge with removable grilles

•

Galvanized steel, powder-coated drain pan with

•

3/4” (19mm) NPT condensate connection

Belt-driven, variable-pitch sheave permits multi-

•

speed adjustment

Centrifugal fan for quiet and effi cient operation

•

Filters (2” [50.8mm] disposable) provided

•

with unit

Operates up to 125°F ambient temperature

•

Cabinet Features

Heavy-gauge, zinc-coated steel cabinet with

•

weather-resistant powder-paint fi nish

Fully insulated with blankets of insulation

•

Built-in fi lter rack

•

Factory wiring conveniently arranged for

•

installation of accessories

Control box and compressors easily accessible

•

from side access panels

Accessory Heat Kit Features

Control circuitry arranged to readily

•

permit staging

Rust-resistant nickel chromium heating elements

•

Primary and secondary limit protection

•

Factory-installed one-time fuses on all models

•

Accessories

Room thermostat; Low-ambient control

•

Rooftop Lift Kit; Roof curb

•

Economizers (horizontal and vertical)

•

Manual/motorized fresh air damper

•

Horizontal Duct Kit (Downfl ow to Horizontal

•

Conversion)

Electric heat capacities 15 kW-30 kW @ 415V

•

50 Hz (fi eld-installed accessory)

Panel Louver Kit

•

SS-PCB50 www.goodmanmfg.com 6/06

Supersedes 12/05

Page 2

P

RODUCT

S

PECIFICATIONS

SPECIFICATIONS

PCB090-5 PCB120-5 PCB180-5

Total Cooling - BTU/h (kW) 88,400 (25.9) 118,600 (34.8) 172,000 (50.4)

Sensible Cooling - BTU/h¹ (kW) 67,100 (19.7) 89,200 (26.1) 131,000 (38.4)

EER² 8.9 9.7 8.5

Indoor Blower (Qty.) 2 2 2

Type Belt Belt Belt

Size - D x W (mm) 12 x 12 (305 x 305) 12 x 15 (305 x 381) 12 x 15 (305 x 381)

Motor Horsepower (kW) 2 (1.49) 3 (2.24) 5 (3.73)

Indoor CFM Nominal (L/S) 3000 (1416) 4000 (1888) 5600 (2643)

Evaporator Coil (Qty.) 1 1 1

Face Area - Ft.² (m²) 9.3 (0.86) 14.0 (1.3) 14.0 (1.3)

Rows/FPI (FPM) 3/16 (630) 3/16 (630) 3/16 (630)

Tube Diameter (mm)/Material 3/8” (9.5)/Copper 3/8” (9.5)/Copper 3/8” (9.5)/Copper

16” x 25” x 2”

Filter Size/Qty. (mm)

Outdoor Fan (Qty.) 2 2 4

Fan Diameter (mm) 24” (610) 24” (610) 22” (559)

Motor Horsepower (kW) 1/2 (0.37) 1/2 (0.37) 1/2 (0.37)

Outdoor CFM Nominal (L/S) 4300 (2030) 6100 (2880) 7000 (3300)

Condenser Coil (Qty.) 1 1 1

Face Area Total - Ft.² (m²) 15.6 (1.45) 23.8 (2.21) 23.8 (2.21)

Rows/FPI (FPM) 2/21 (827) 2/21 (827) 3/16 (630)

Tube Diameter (mm)/Material 3/8 (9.5)/Copper 3/8 (9.5)/Copper 3/8 (9.5)/Copper

Number of Compressors 2 2 3

Volts-Phase 380-415-3 380-415-3 380-415-3

Compressor RLA/LRA 6.7/47.5 9.5/73.0 9.5/73.0

Blower FLA - Indoor/Outdoor 3.4/1.7 4.2/1.7 7.3/1.7

Minimum Circuit Ampacity³ 23.6 31.3 49.5

Maximum Fuse Size 30 50 60

Ship Weight - lbs. (kg) 990 (449.5) 1215 (551.6) 1460 (662.8)

¹ Sensible capacity is gross, with no deduction for indoor motor heat

² BTU/Watt @ 80/67°F (26.7/19.4°C) inside - 95°F (35°C) outside air

³ Wire size should be in accordance with Local Electrical Codes. Extensive wire runs will require larger wire sizes.

25” x 25” x 2”

(635 x 635 x 8.51)/3

(406 x 635 x 51)/3

20” x 25” x 2”

(508 x 635 x 51)/3

16” x 25” x 2”

(406 x 635 x 51)/3

20” x 25” x 2”

(508 x 635 x 51)/3

NOMENCLATURE

PCB 090 - 5

2 SS-PCB50

E

LECTRICAL DESIGNATOR

5 - 380/415 VAC, 3ph, 50Hz

OMINAL COOLING CAPACITY

N

090 - 90,000 BTU/h

120 - 120,000 BTU/h

180 - 180,000 BTU/h

U

NIT TYPE

PCB - Package Cool

Page 3

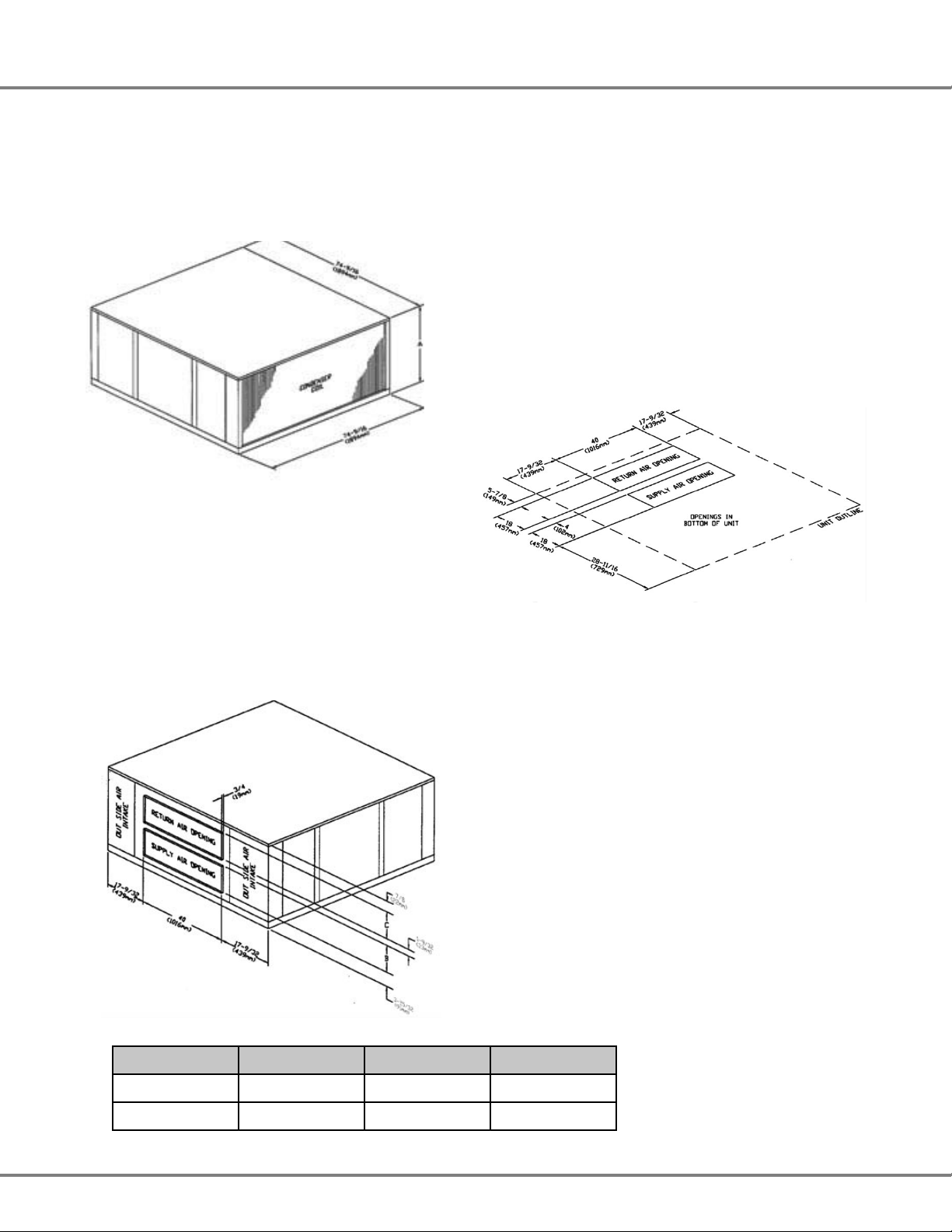

DIMENSIONS

All dimensions in inches and millimeters. Drawings are not to scale.

FIGURE 1. VERTICAL DISCHARGE

See curb details for connection of duct work to

curb. Duct work is not intended to be connected

to unit.

P

RODUCT

S

PECIFICATIONS

FIGURE 2. HORIZONTAL DISCHARGE

Note: The Horizontal Conversion Kit is required to convert

a factory duct confi guration (downfl ow) to a horizontal

duct confi guration, as shown in Figure 2.

UNIT SIZE A - HEIGHT B - SUPPLY AIR C - RETURN AIR

090 36” (914 mm) 12½” (318 mm) 179/16” (446 mm)

120,180 52” (1321 mm) 20¼” (514 mm) 2513/16” (656 mm)

SS-PCB50 3

Page 4

P

RODUCT

S

PECIFICATIONS

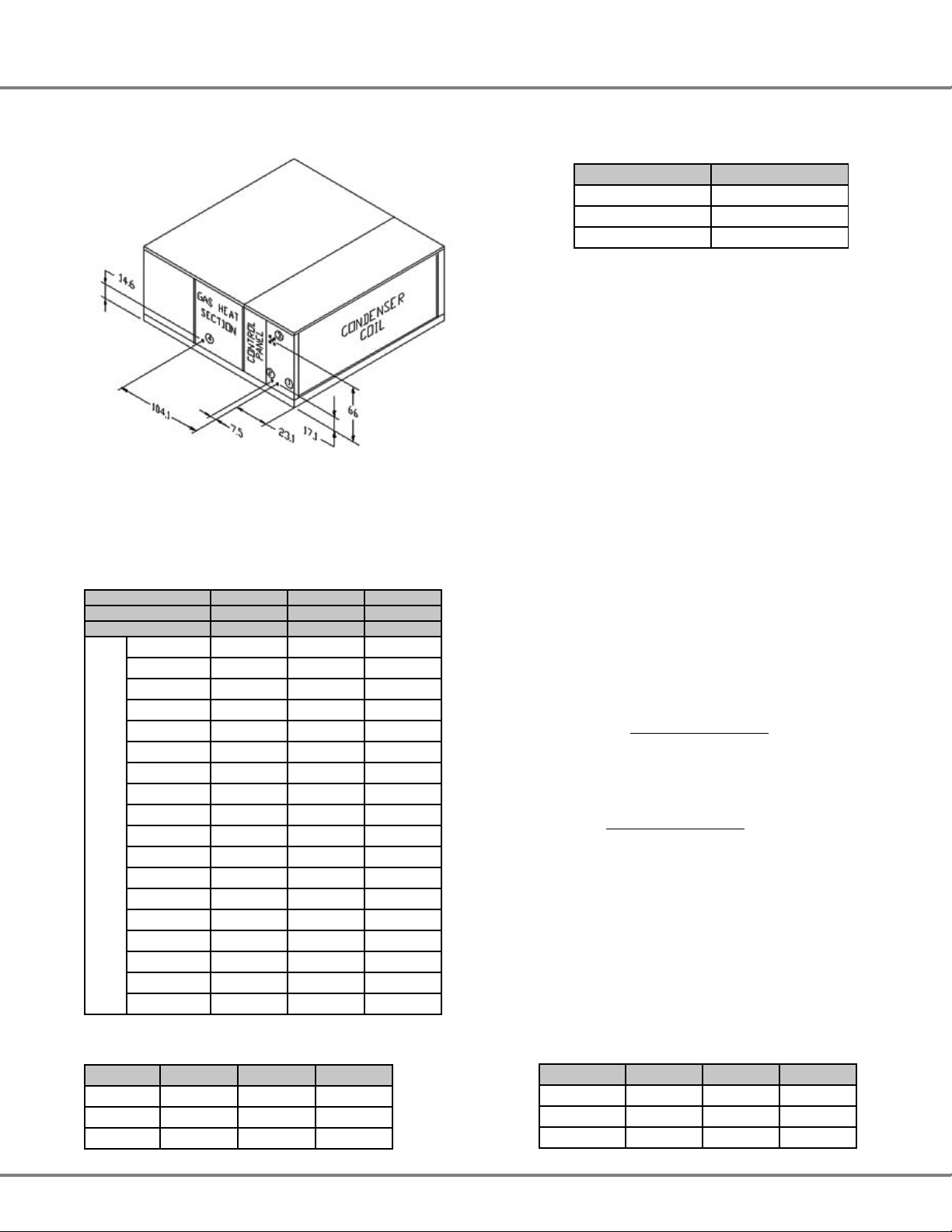

ELECTRICAL CONNECTIONS

Main power entrance location (with electric heat

1–

installed)

Control wiring entrance location

2–

Main power entrance location (without electric heat

3–

installed)

Note: Single-point wiring is available at location #1

when heat kit is installed. See installation instructions

for heat kits.

FIGURE 3. ELECTRICAL HEAT UNITS

MODEL B

PCB090-5 7⅞” (200 mm)

PCB120-5 23⅞” (606 mm)

PCB180-5 23⅞” (606 mm)

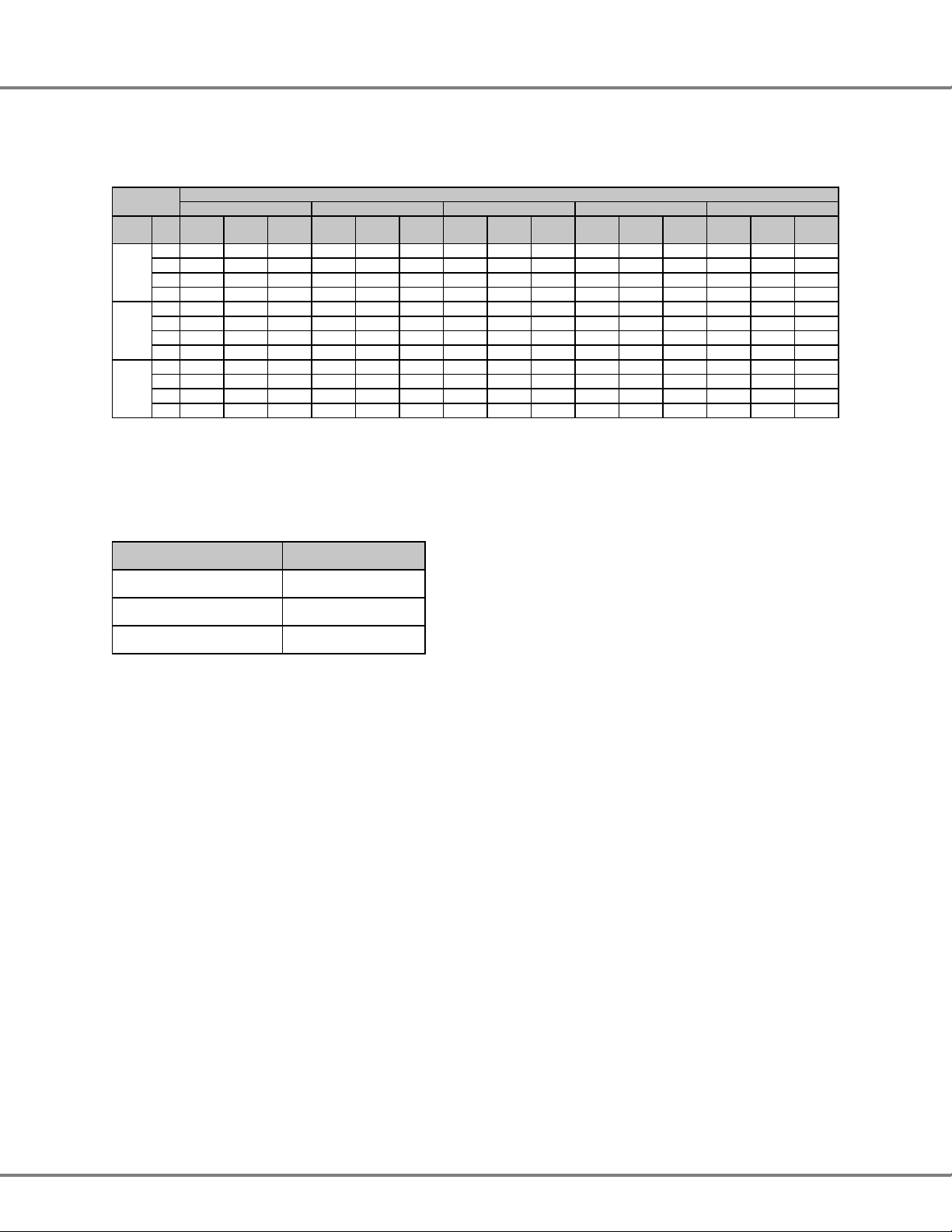

ELECTRIC HEAT

ELECTRIC HEAT AIR TEMPERATURE RISE @ NOMINAL VOLTAGE

Heater Model HKCB20 HKCB30 HKCB40

No. Stages 2 2 2

Output MBH (W) 67.5 (19.8) 101.3 (29.7) 135.0 (39.6)

2600 (1227) 24.2 (13.4) 36.2 (20.1) -

2800 (1320) 22.5 (12.5) 33.6 (18.7) -

3000 (1415) 21.0 (11.7) 31.4 (17.4) -

3200 (1510) 19.7 (10.9) 29.4 (16.3) 39.3 (21.8)

3400 (1605) 18.5 (10.3) 27.7 (15.4) 37.0 (20.6)

3600 (1700) 17.5 (9.7) 26.2 (14.6) 34.9 (19.4)

3800 (1793) 16.5 (9.2) 24.8 (13.8) 33.1 (18.4)

4000 (1888) 15.7 (8.7) 23.5 (13.1) 31.4 (17.4)

CFM

4200 (1982) 15.0 (8.3) 22.4 (12.4) 29.9 (16.6)

&

4400 (2076) 14.3 (7.9) 21.4 (11.9) 28.6 (15.9)

(L/S)

4600 (2171) 13.7 (7.6) 20.5 (11.4) 27.3 (15.2)

4800 (2265) 13.1 (7.3) 19.6 (10.9) 26.2 (14.6)

5000 (2360) 12.6 (7.0) 18.8 (10.4) 25.2 (14.0)

5200 (2454) 12.1 (6.7) 18.1 (10.1) 24.2 (13.4)

5400 (2548) 11.6 (6.4) 17.4 (9.7) 23.3 (12.9)

5600 (2643) 11.2 (6.2) 16.8 (9.3) 22.5 (12.5)

5800 (2737) 10.8 (6.0) 16.2 (9.0) 21.7 (12.1)

6000 (2832) 10.5 (5.8) 15.7 (8.7) 21.0 (11.7)

Notes:

1. Maximum air temperature rise of 40°F (22.2°C) must not be

exceeded.

2. See Electric Heater Availability table for various unit sizes.

3. Air temperature rise is for total heating capacity: Temperature rises

at other conditions may be calculated by using the formula:

Temperature Rise = Output Capacity - BTU/h

1.08 x ft³/min. Airfl ow

Note: Temperature rises must be calculated in other than nominal volt-

age conditions.

4. For altitudes over 2,000’, air temperature rise must be calculated

using the formula:

Temperature Rise = Output Capacity - BTU/h

14.4 x ft³/Min. Airfl ow x Specifi c Weight of Air

5. Operation at less than nominal voltages must be de-rated by the

following factors: 415 volt-0.75; 380 volt-0.63.

NOMINAL VOLTAGE FOR HKCB

@ 480V @ 415V @ 380V

HKCB20-4 19.8 kW 14.9 kW 12.5 kW

HKCB30-4 29.7 kW 22.3 kW 18.7 kW

HKCB40-4 39.6 kW 29.7 kW 25.0 kW

ELECTRIC HEATER AVAILABILITY

Unit Size HKCB20 HKCB30 HKCB40

7½XXX

10XXX

15XXX

4 SS-PCB50

Page 5

FAN PERFORMANCE DATA

P

RODUCT

S

PECIFICATIONS

FIGURE 4. FAN CURVE - PCB 090

SUPPLY FAN PERFORMANCE - PCB090

EXTERNAL STATIC PRESSURE (INCHES W.C.) SEE NOTE (3)

CFM

2600 669 0.44 816 0.59 916 0.75 1004 0.92 1084 1.09 1157 1.28 1226 1.47 1291 1.67

2800 734 0.53 847 0.69 944 0.85 1030 1.03 1109 1.21 1181 1.40 1249 1.60 1312 1.91

3000 770 0.62 877 0.79 973 0.97 1053 1.15 1135 1.34 1206 1.54 1273 1.75 1336 1.96

3200 807 0.73 909 0.91 1002 1.10 1086 1.29 1162 1.49 1232 1.70 1298 1.91 1360 2.12

3400 845 0.85 942 1.04 1032 1.24 1114 1.44 1159 1.65 1259 1.87 1324 2.09 1384 2.31

Notes:

•

Selections in ITALICS require a fi eld drive change. See following table below for drive ranges.

Table includes all internal pressure drops including cabinet losses. See Pressure Drops table that must be considered as part of

•

external static pressure drop.

DO NOT SELECT IN SHADED AREAS (FOR INTERPOLATION ONLY).

•

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

SUPPLY FAN DRIVE DATA - PCB090

MOTOR SHEAVE - ADJUSTABLE FACTORY SETTING

FAN SHEAVE - FIXED 2 TURNS OPENS

MOTOR SHEAVE TURNS OPEN 0 1 2 3 4 5

FAN RPM 2.0 HP MOTOR 1209 1146 1082 1018 955 891

Note: Allow ±5% variation in blower RPM due to pulley manufacturing tolerances.

Conversion Factor:

1 CFM = 0.472 L/S

1” W.C. = 2.5 M Bar

1 HP = 0.747 kW

SS-PCB50 5

Page 6

P

RODUCT

S

PECIFICATIONS

FAN PERFORMANCE DATA (CONT.)

FIGURE 5. FAN CURVE - PCB 120

SUPPLY FAN PERFORMANCE - PCB120

External Static Pressure (INCHES W.C.)

CFM

3400 679 0.73 781 0.98 873 1.26 957 1.58 1034 1.91 1105 2.26 1171 2.26 1233 2.99

3600 706 0.83 805 1.10 894 1.39 975 1.71 1051 2.05 1121 2.41 1188 2.78 1249 3.17

3800 733 0.95 829 1.23 916 1.53 995 1.85 1069 2.20 1139 2.57 1204 2.95 1266 3.36

4000 761 1.07 855 1.37 938 1.68 1016 2.01 1088 2.36 1156 2.74 1221 3.14 1282 3.55

4200 790 1.21 880 1.52 961 1.84 1037 2.18 1108 2.54 1175 2.93 1239 3.33 1299 3.75

4400 818 1.36 906 1.68 985 2.01 1059 2.36 1128 2.73 1194 3.13 1257 3.54 1316 3.97

Notes:

Selections in ITALICS require a fi eld drive change. See following table below for drive ranges.

•

Table includes all internal pressure drops including cabinet losses. See Pressure Drops table that must be considered as part of

•

external static pressure drop.

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

SUPPLY FAN DRIVE DATA - PCB120

Motor Sheave - Adjustable Factory Setting

Fan Sheave - Fixed Two Turns Opens

Motor Sheave Turns Open 0 1 2 3 4 5

Fan RPM 3.0 HP Motor 1242 1186 1129 1073 1016 960

Note: Allow ±5% variation in blower RPM due to pulley manufacturing tolerances.

Conversion Factor:

1 CFM = 0.472 L/S

1” W.C. = 2.5 M Bar

1 HP = 0.747 kW

6 SS-PCB50

Page 7

FAN PERFORMANCE DATA (CONT.)

P

RODUCT

S

PECIFICATIONS

FIGURE 6. FAN CURVE - PCB180

SUPPLY FAN PERFORMANCE - PCB180

External Static Pressure (Inches W.C.) See Last Note

CFM

4000 784 1.14 876 1.44 959 1.76 1036 2.10 1108 2.47 1176 2.86 1239 3.26 1300 3.67

4200 814 1.29 903 1.60 983 1.93 1058 2.28 1129 2.66 1195 3.05 1258 3.46 1318 3.89

4400 844 1.45 930 1.78 1008 2.12 1081 2.48 1150 2.86 1215 3.26 1277 3.68 1337 4.12

4600 874 1.63 957 1.97 1034 2.32 1105 2.69 1172 3.08 1236 3.49 1297 3.92 1356 4.37

4800 904 1.82 986 2.17 1060 2.54 1129 2.92 1195 3.32 1258 3.74 1318 4.17 1375 4.63

5000 932 2.02 1014 2.39 1086 2.77 1159 3.16 1218 3.57 1280 4.00 1338 4.44 1395 4.91

5200 966 2.24 1043 2.62 1113 3.01 1179 3.42 1242 3.84 1302 4.27 1360 4.73 1416 5.20

5400 997 2.48 1071 2.87 1141 3.28 1205 3.70 1267 4.12 1326 4.57 1382 5.03 1437 5.51

5600 1029 2.74 1101 3.14 1168 3.56 1231 3.99 1291 4.43 1394 4.88 1405 5.36 1458 5.85

Notes:

Selections in ITALICS require a fi eld drive change. See following table below for drive ranges.

•

Table includes all internal pressure drops including cabinet losses. See Pressure Drops table that must be considered as part of

•

external static pressure drop.

DO NOT SELECT IN SHADED AREAS (FOR INTERPOLATION ONLY).

•

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

SUPPLY FAN DRIVE DATA - PCB180

Motor Sheave - Adjustable Factory Setting

Fan Sheave - Fixed 2 Turns Opens

Motor Sheave Turns Open 012345

Fan RPM 5.0 HP Motor 1400 1446 1273 1209 1146 1082

Note: Allow ±5% variation in blower RPM due to pulley manufacturing tolerances.

Conversion Factor:

1 CFM = 0.472 L/S

1” W.C. = 2.5 M Bar

1 HP = 0.747 kW

SS-PCB50 7

Page 8

P

RODUCT

S

PECIFICATIONS

FAN PERFORMANCE DATA (CONT.)

COMPONENT PRESSURE DROPS

MODEL CFM WET COIL ELEC. HEAT MED. EFF. FILTERS

ECONO. RETURN AIR DAMP-

ER

2600 0.06 0.03 0.03 0.14

090

3000 0.06 0.04 0.04 0.14

3400 0.07 0.05 0.05 0.18

3600 0.05 0.05 0.03 0.14

120

4000 0.05 0.06 0.04 0.14

4400 0.05 0.08 0.04 0.14

5000 0.13 0.10 0.06 0.18

180

5400 0.13 0.12 0.06 0.21

5600 0.16 0.13 0.08 0.23

COOLING CAPACITY DATA

PCB090-5 (SI UNITS)

INDOOR

AIR

L/S WB

22.2 32.77 15.48 8.36 30.67 14.52 9.29 28.56 13.56 10.23 26.46 12.60 11.17 24.35 11.64 12.10

19.4 30.23 18.70 7.82 28.17 17.90 8.73 26.11 17.10 9.64 24.05 16.31 10.55 21.99 15.51 11.46

1203

16.7 27.52 23.00 7.46 26.07 21.73 8.30 24.62 20.45 9.14 23.17 19.18 9.98 21.72 17.91 10.82

13.9 26.59 24.96 7.18 24.98 23.20 8.06 23.38 21.43 8.94 21.77 19.67 9.83 20.17 17.91 10.71

22.2 34.17 17.16 8.63 31.91 16.15 9.58 29.65 15.14 10.53 27.39 14.14 11.48 25.13 13.13 12.43

19.4 31.36 21.95 8.08 29.28 20.81 9.01 27.20 19.66 9.93 25.12 18.52 10.86 23.03 17.38 11.78

1416

16.7 28.62 26.83 7.53 26.96 25.02 8.49 25.30 23.20 9.44 23.65 21.39 10.40 21.99 19.58 11.35

13.9 28.62 26.83 7.53 26.96 25.02 8.49 25.30 23.20 9.44 23.65 21.39 10.40 21.99 19.58 11.35

22.2 35.01 18.42 8.82 32.73 17.46 9.77 30.46 16.50 10.73 28.18 15.54 11.69 25.90 14.59 12.64

19.4 32.19 24.67 8.28 30.10 23.35 9.21 28.00 22.04 10.14 25.91 20.72 11.07 23.81 19.40 11.99

1628

16.7 30.24 28.49 7.89 28.44 26.54 8.86 26.64 24.60 9.84 24.84 22.65 10.81 23.03 20.71 11.78

13.9 30.24 28.49 7.89 28.44 26.54 8.86 26.64 24.60 9.84 24.84 22.65 10.81 23.03 20.71 11.78

Sensible heat capacities shown are based on 26.7°C DB entering air at the evaporator coil. For sensible heat capacities at other

than 26.7°C DB, deduct 44.32 W per 47 L/S of evaporator coil air for each degree below 26.7°C, or add 44.32 W per 47 L/S of

evaporator coil air per degree above 26.7°C.

23.9°C 29.4°C 35.0°C 40.6°C 46.1°C

Total

Cap.

Sens

Cap.

Kw

Total

Cap.

Sens

Cap.

CONDENSER AIR TEMPERATURE

Total

Cap.

Sens

Cap.

Kw

Kw

Total

Cap.

Sens

Cap.

Kw

Total

Cap.

Sens

Cap.

Kw

PCB090-5 (ENGLISH UNITS)

INDOOR

AIR

SCFM WB

72 111.8 52.8 8.36 104.6 49.6 9.29 97.5 46.3 10.23 90.3 43.0 11.17 83.1 39.7 12.10

67 103.2 63.8 7.82 96.1 61.1 8.73 89.1 58.4 9.64 82.1 55.6 10.55 75.0 52.9 11.46

2550

62 93.9 78.5 7.46 89.0 74.1 8.30 84.0 69.8 9.14 79.1 65.5 9.98 74.1 61.1 10.82

57 90.7 85.2 7.18 85.2 79.1 8.06 79.8 73.1 8.94 74.3 67.1 9.83 68.8 61.1 10.71

72 116.6 58.5 8.63 108.9 55.1 9.58 101.2 51.7 10.53 93.5 48.2 11.48 85.7 44.8 12.43

67 107.0 74.9 8.08 99.9 71.0 9.01 92.8 67.1 9.93 85.7 63.2 10.86 78.6 59.3 11.78

3000

62 97.6 91.6 7.53 92.0 85.4 8.49 86.3 79.2 9.44 80.7 73.0 10.40 75.0 66.8 11.35

57 97.6 91.6 7.53 92.0 85.4 8.49 86.3 79.2 9.44 80.7 73.0 10.40 75.0 66.8 11.35

72 119.5 62.9 8.82 111.7 59.6 9.77 103.9 56.3 10.73 96.2 53.0 11.69 88.4 49.8 12.64

67 109.9 84.2 8.28 102.7 79.7 9.21 95.6 75.2 10.14 88.4 70.7 11.07 81.3 66.2 11.99

3450

62 103.2 97.2 7.89 97.0 90.6 8.86 90.9 83.9 9.84 84.7 77.3 10.81 78.6 70.7 11.78

57 103.2 97.2 7.89 97.0 90.6 8.86 90.9 83.9 9.84 84.7 77.3 10.81 78.6 70.7 11.78

Sensible heat capacities shown are based on 80°F DB entering air at the evaporator coil. For sensible heat capacities at other

than 80°F DB, deduct 84 BTU/h per 100 CFM of evaporator coil air for each degree below 80°F, or add 84 BTU/h per 100 CFM of

evaporator coil air per degree above 80°F.

75°F 85°F 95°F 105°F 115°F

Total

Kbtuh

Sens

Kbtuh

Kw

Total

Kbtuh

Sens

Kbtuh

8 SS-PCB50

CONDENSER AIR TEMPERATURE

Total

Kw

Kbtuh

Sens

Kbtuh

Kw

Total

Kbtuh

Sens

Kbtuh

Kw

Total

Kbtuh

Sens

Kbtuh

Kw

Page 9

COOLING CAPACITY DATA (CONT.)

PCB120-5 (SI UNITS)

P

RODUCT

S

PECIFICATIONS

INDOOR

AIR

L/S WB

22.2 43.67 21.02 9.95 41.04 19.52 11.27 38.41 18.03 12.59 35.78 16.54 13.91 33.15 15.04 15.23

19.4 40.29 25.44 9.31 37.70 24.09 10.59 35.11 22.74 11.86 32.52 21.38 13.14 29.93 20.03 14.41

1605

16.7 36.65 31.24 8.89 34.88 29.22 10.07 33.11 27.19 11.25 31.34 25.17 12.43 29.57 23.14 13.61

13.9 35.42 33.85 8.54 33.43 31.17 9.78 31.44 28.49 11.01 29.45 25.82 12.24 27.45 23.14 13.47

22.2 45.54 23.30 10.28 42.71 21.72 11.62 39.87 20.13 12.96 37.04 18.55 14.30 34.20 16.96 15.64

19.4 41.79 29.83 9.62 39.18 27.99 10.92 36.57 26.14 12.22 33.97 24.29 13.52 31.36 22.45 14.82

1888

16.7 38.12 36.41 8.95 36.07 33.63 10.29 34.03 30.85 11.62 31.98 28.07 12.95 29.93 25.29 14.29

13.9 38.12 36.41 8.95 36.07 33.63 10.29 34.03 30.85 11.62 31.98 28.07 12.95 29.93 25.29 14.29

22.2 46.65 25.03 10.50 43.81 23.49 11.85 40.96 21.94 13.20 38.11 20.39 14.55 35.26 18.84 15.90

19.4 42.90 33.53 9.86 40.28 31.41 11.17 37.66 29.29 12.48 35.04 27.18 13.78 32.41 25.06 15.09

2170

16.7 40.29 38.65 9.39 38.05 35.67 10.75 35.82 32.70 12.11 33.59 29.72 13.46 31.36 26.75 14.82

13.9 40.29 38.65 9.39 38.05 35.67 10.75 35.82 32.70 12.11 33.59 29.72 13.46 31.36 26.75 14.82

23.9°C 29.4°C 35.0°C 40.6°C 46.1°C

Total

Cap.

Sens

Cap.

Kw

Total

Cap.

Sens

Cap.

CONDENSER AIR TEMPERATURE

Total

Cap.

Sens

Cap.

Kw

Kw

Total

Cap.

Sens

Cap.

Kw

Total

Cap.

Sens

Cap.

Kw

Sensible heat capacities shown are based on 26.7°C DB entering air at the evaporator coil. For sensible heat capacities at other

than 26.7°C DB, deduct 44.32 W per 47 L/S of evaporator coil air for each degree below 26.7°C, or add 44.32 W per 47 L/S of

evaporator coil air per degree above 26.7°C.

PCB120-5 (ENGLISH UNITS)

INDOOR

AIR

SCFM WB

3400

4000

4600

Kbtuh

72 149.0 71.7 9.95 140.0 66.6 11.27 131.1 61.5 12.59 122.1 56.4 13.91 113.1 51.3 15.23

67 137.5 86.8 9.31 128.6 82.2 10.59 119.8 77.6 11.86 111.0 73.0 13.14 102.1 68.4 14.41

62 125.1 106.6 8.89 119.0 99.7 10.07 113.0 92.8 11.25 106.9 85.9 12.43 100.9 79.0 13.61

57 120.9 115.5 8.54 114.1 106.4 9.78 107.3 97.2 11.01 100.5 88.1 12.24 93.7 79.0 13.47

72 155.4 79.5 10.28 145.7 74.1 11.62 136.1 68.7 12.96 126.4 63.3 14.30 116.7 57.9 15.64

67 142.6 101.8 9.62 133.7 95.5 10.92 124.8 89.2 12.22 115.9 82.9 13.52 107.0 76.6 14.82

62 130.1 124.2 8.95 123.1 114.7 10.29 116.1 105.3 11.62 109.1 95.8 12.95 102.1 86.3 14.29

57 130.1 124.2 8.95 123.1 114.7 10.29 116.1 105.3 11.62 109.1 95.8 12.95 102.1 86.3 14.29

72 159.2 85.4 10.50 149.5 80.1 11.85 139.8 74.9 13.20 130.0 69.6 14.55 120.3 64.3 15.90

67 146.4 114.4 9.86 137.5 107.2 11.17 128.5 100.0 12.48 119.6 92.7 13.78 110.6 85.5 15.09

62 137.5 131.9 9.39 129.9 121.7 10.75 122.2 111.6 12.11 114.6 101.4 13.46 107.0 91.3 14.82

57 137.5 131.9 9.39 129.9 121.7 10.75 122.2 111.6 12.11 114.6 101.4 13.46 107.0 91.3 14.82

75°F 85°F 95°F 105°F 115°F

Total

Sens

Kbtuh

Kw

Total

Kbtuh

Sens

Kbtuh

Sensible heat capacities shown are based on 80°F DB entering air at the evaporator coil. For sensible heat capacities at other

than 80°F DB, deduct 84 BTU/h per 100 CFM of evaporator coil air for each degree below 80°F, or add 84 BTU/h per 100 CFM of

evaporator coil air per degree above 80°F.

CONDENSER AIR TEMPERATURE

Total

Kw

Kbtuh

Sens

Kbtuh

Kw

Total

Kbtuh

Sens

Kbtuh

Kw

Total

Kbtuh

Sens

Kbtuh

Kw

PCB180-5 (SI UNITS)

INDOOR

AIR

L/S WB

22.2 64.17 29.53 16.42 60.17 28.00 18.63 56.17 26.48 20.83 52.17 24.95 23.04 48.17 23.43 25.25

19.4 59.19 35.59 15.36 55.27 34.49 17.50 51.35 33.39 19.63 47.42 32.29 21.76 43.50 31.20 23.89

2246

16.7 53.86 43.83 14.67 51.14 41.88 16.64 48.42 39.93 18.61 45.69 37.99 20.59 42.97 36.04 22.56

13.9 52.05 47.66 14.10 49.01 44.75 16.15 45.97 41.85 18.21 42.93 38.94 20.27 39.90 36.04 22.33

22.2 66.90 32.71 16.97 62.61 31.14 19.21 58.31 29.56 21.45 54.01 27.99 23.68 49.71 26.42 25.92

19.4 61.40 41.82 15.87 57.44 40.10 18.05 53.48 38.39 20.22 49.53 36.68 22.40 45.57 34.96 24.57

2643

16.7 56.02 51.22 14.77 52.89 48.26 17.00 49.76 45.30 19.23 46.63 42.34 21.46 43.50 39.38 23.68

13.9 56.02 51.22 14.77 52.89 48.26 17.00 49.76 45.30 19.23 46.63 42.34 21.46 43.50 39.38 23.68

22.2 68.54 35.09 17.33 64.22 33.66 19.59 59.89 32.22 21.85 55.57 30.78 24.11 51.24 29.34 26.37

19.4 63.03 47.01 16.27 59.05 45.02 18.46 55.07 43.02 20.64 51.09 41.02 22.83 47.11 39.03 25.01

3039

16.7 59.20 54.38 15.49 55.79 51.20 17.76 52.38 48.02 20.03 48.98 44.84 22.30 45.57 41.66 24.57

13.9 59.20 54.38 15.49 55.79 51.20 17.76 52.38 48.02 20.03 48.98 44.84 22.30 45.57 41.66 24.57

23.9°C 29.4°C 35.0°C 40.6°C 46.1°C

Total

Cap.

Sens

Cap.

Kw

Total

Cap.

Sens

Cap.

Sensible heat capacities shown are based on 26.7°C DB entering air at the evaporator coil. For sensible heat capacities at other

than 26.7°C DB, deduct 44.32 W per 47 L/S of evaporator coil air for each degree below 26.7°C, or add 44.32 W per 47 L/S of

evaporator coil air per degree above 26.7°C.

SS-PCB50 9

CONDENSER AIR TEMPERATURE

Total

Cap.

Sens

Cap.

Kw

Kw

Total

Cap.

Sens

Cap.

Kw

Total

Cap.

Sens

Cap.

Kw

Page 10

P

RODUCT

S

PECIFICATIONS

COOLING CAPACITY DATA (CONT.)

PCB180-5 (ENGLISH UNITS)

INDOOR

AIR

SCFM WB

72 219.0 100.8 16.42 205.3 95.6 18.63 191.7 90.4 20.83 178.0 85.1 23.04 164.4 79.9 25.25

67 202.0 121.4 15.36 188.6 117.7 17.50 175.2 113.9 19.63 161.8 110.2 21.76 148.4 106.5 23.89

4760

62 183.8 149.6 14.67 174.5 142.9 16.64 165.2 136.3 18.61 155.9 129.6 20.59 146.6 123.0 22.56

57 177.6 162.6 14.10 167.2 152.7 16.15 156.9 142.8 18.21 146.5 132.9 20.27 136.1 123.0 22.33

72 228.3 111.6 16.97 213.6 106.3 19.21 199.0 100.9 21.45 184.3 95.5 23.68 169.6 90.1 25.92

67 209.5 142.7 15.87 196.0 136.9 18.05 182.5 131.0 20.22 169.0 125.2 22.40 155.5 119.3 24.46

5600

62 191.1 174.8 14.77 180.5 164.7 17.00 169.8 154.6 19.23 159.1 144.5 21.46 148.4 134.4 23.68

57 191.1 174.8 14.77 180.5 164.7 17.00 169.8 154.6 19.23 159.1 144.5 21.46 148.4 134.4 23.68

72 233.9 119.7 17.33 219.1 114.8 19.59 204.4 109.9 21.85 189.6 105.0 24.11 174.9 100.1 26.37

67 215.1 160.4 16.27 201.5 153.6 18.46 187.9 146.8 20.64 174.3 140.0 22.83 160.7 133.2 25.01

6440

62 202.0 185.6 15.49 190.4 174.7 17.76 178.8 163.9 20.03 167.1 153.0 22.30 155.5 142.1 24.57

57 202.0 185.6 15.49 190.4 174.7 17.76 178.8 163.9 20.03 167.1 153.0 22.30 155.5 142.1 24.57

Sensible heat capacities shown are based on 80 °F DB entering air at the evaporator coil. For sensible heat capacities at other

than 80 °F DB, deduct 84 BTU/h per 100 CFM of evaporator coil air for each degree below 80 °F, or add 84 BTU/h per 100 CFM of

evaporator coil air per degree above 80 °F.

75°F 85°F 95°F 105°F 115°F

Total

Kbtuh

Sens

Kbtuh

Kw

Total

Kbtuh

Sens

Kbtuh

CONDENSER AIR TEMPERATURE

Total

Kw

Kbtuh

Sens

Kbtuh

Kw

Total

Kbtuh

Sens

Kbtuh

Kw

Total

Kbtuh

Sens

Kbtuh

Kw

EVAPORATOR MOTOR HEAT

Horsepower/(kW) BTU/h (KW)

2 (1.49) 4400 (1.29)

3 (2.24) 6200 (1.82)

5 (3.73) 10,500 (3.08)

10 SS-PCB50

Page 11

P

RODUCT

S

PECIFICATIONS

APPLICATION DETAILS AND ACCESSORIES

FACTORY SUPPLIED ACCESSORIES THERMOSTAT (CHT90-120)

Two-stage cool and two-stage heat thermostat with subbase, Manual changeover, Fan ON or AUTO. Note: A variety

of thermostat confi gurations can be used on this equipment based on the application needs. For example our

CHTS36-60 can be used if two-stage cooling and single-stage heat is desired. Our CHT18-60 can be used if singlestage cooling and heating is desired. A single-stage cooling and two-stage heating thermostat can be used.

ROOFTOP LIFT KIT (RLK90-120)

Kit consists of four ½” (12.7mm) shackles that are used to lift the equipment into position on a roof, etc. The

shackles are to be attached to the mounting holes in the base rails. Wire or strap material along with fi eld supplied

spreader bars are employed to complete the lifting assembly (See Rigging detail).

LOW AMBIENT CONTROL (LA-01)

Liquid temperature (or pressure) operated solid state control, which varies the speed of one of the condenser fans.

Low ambient control reduces fan motor RPM as liquid temperature (or pressure) decreases. Caution: If control is

used below 50 °F (10 °C) accumulators should be added to the equipment to avoid slugging of the compressors.

ROOF CURB (PGC-5)

Full perimeter curb for equipment in the down discharge application. Curb includes provisions for duct attachment

prior to setting unit. Curb is shipped knocked down with all necessary hardware and gasket material.

MANUAL AND MOTORIZED FRESH AIR DAMPERS (PGMD-5 & PGMDM-5)

Manual damper is fi xed position type for 0 to 25% fresh air. Motorized damper is a fi eld adjustable mechanical

damper for 0 to 25% fresh air, damper automatically closes when blower stops.

ECONOMIZERS (PGED 090/102-5 & PGED 120/180-5)

Fully modulating, enthalpy controlled economizers shipped with major components pre-assembled. Plug assembly

on equipment and economizer provides easy wiring.

HORIZONTAL DUCT KIT (PGHDK 090/102-5 & PGHDK 120/180-5)

The unit is shipped in the down fl ow (vertical) duct confi guration. The horizontal duct kit must be installed in the

fi eld for horizontal duct confi guration.

PANEL LOUVER KIT (PLK090/102-5 & PLK120/180-5)

Louvered panels for condenser coil protection.

HEAT KIT ACCESSORY

Slide in heat kit from 15 to 30 kW @ 415V, 3Ph, 50 Hz are available. For 380/415V operation the -4 electrical

designation on HKCB heat kits must be used. The heating output is derated as shown by example on page 11 at

both 380V & 415V.

Bulletin illustrations cover the general appearance of Goodman Manufacturing Company, L.P., products at the

time of publication, and we reserve the right to make changes in design and construction at any time without

notice.

SS-PCB50 11

Page 12

P

RODUCT

S

PECIFICATIONS

QUALITY MAKES THE DIFFERENCE!

All of our systems are designed and manufactured with the same high-quality standards, regardless of size or effi ciency. We have designed these units to signifi cantly

reduce the most frequent causes of product failure. They are simple to service and forgiving to operate. We use quality materials and components. Finally, every unit

www.goodmanmfg.com for information on:

Goodman Products • Customer Services • Parts

Goodman Manufacturing Company, L.P., reserves the right to discontinue, or change at any time, specifi cations or designs without notice or without incurring obligations.

Copyright © 2003 Goodman Manufacturing Company, L.P. • Houston, Texas • Printed in the USA. • Goodman products are made proudly in the USA.

12 SS-PCB50

is run-tested before it leaves the factory. That’s why we know...there’s no better quality.

Visit our website at

Goodman Manufacturing Company, L.P.

2550 North Loop West, Suite 400

Houston, Texas 77092 USA

Loading...

Loading...