Page 1

I

NSTALLATION INSTRUCTIONS

F

OR

S

ELF

H

-C

EAT

ONTAINED

P

UMP

U

P

NITS

ACKAGE

*PC/*PH15 “M” SERIES

Affix this manual and Users Information Manual adjacent to the unit.

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

ATTENTION INSTALLING PERSONNEL

Prior to installation, thoroughly familiarize yourself with this Installation Manual. Observe all safety warnings. During

installation or repair, caution is to be observed.

It is your responsibility to install the product safely and to educate the customer on its safe use.

These installation instructions cover the outdoor

installation of self contained package air conditioners

and heating units. See the Specification Sheets

applicable to your model for information regarding

accessories.

Goodman Manufacturing Company , L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

IO-394

8/10

www.goodmanmfg.com www.amana-hac.com

© 2010 Goodman Manufacturing Company, L.P.

*NOTE: Please contact your distributor or our

website for the applicable

Specification Sheets referred to in this manual.

Page 2

INDEX

TO THE INSTALLER .............................................................................................................................................. 4

I

MPORTANT NOTE TO THE HOMEOWNER REGARDING PRODUCT WARRANTY ..................................................................... 4

SHIPPING INSPECTION ...................................................................................................................................................... 4

REPLACEMENT P ARTS ....................................................................................................................................................... 4

ORDERING PARTS .............................................................................................................................................. 4

SAFETY INSTRUCTIONS..................................................................................................................................................... 4

CODES AND REGULATIONS ............................................................................................................................................... 5

EP A REGULA TIONS ............................................................................................................................................ 5

N

ATIONAL CODES ............................................................................................................................................... 5

MAJOR COMPONENTS ....................................................................................................................................................... 5

PRE-INSTALLA TION CHECKS ............................................................................................................................................. 5

CLEARANCES AND ACCESSIBILITY........................................................................................................................... 5

U

NIT LOCATION ................................................................................................................................................... 5

G

ROUND LEVEL PRE-INSTALLATION DET AILS............................................................................................................ 5

R

OOF TOP PRE-INSTALLATION DETAILS .................................................................................................................. 6

R

OOF CURB INSTALLATIONS ONLY ......................................................................................................................... 6

R

IGGING DETAILS ............................................................................................................................................... 6

CIRCULA TING AIR AND FILTERS ....................................................................................................................................... 7

AIR FLOW CONVERSION ....................................................................................................................................... 7

D

UCT WORK ....................................................................................................................................................... 7

F

ILTERS ............................................................................................................................................................ 7

PIPING ................................................................................................................................................................................. 8

CONDENSA TE DRAIN ........................................................................................................................................... 8

WIRING ................................................................................................................................................................................ 8

HIGH VOL TAGE WIRING........................................................................................................................................ 8

L

OW VOLTAGE WIRING ........................................................................................................................................ 8

I

NTERNAL WIRING ............................................................................................................................................... 8

ST ARTUP , ADJUSTMENTS, AND CHECKS ......................................................................................................................... 9

COOLING START-UP PROCEDURES ........................................................................................................................ 9

H

EAT PUMP START-UP PROCEDURE ...................................................................................................................... 9

F

INAL SYSTEM CHECKS ...................................................................................................................................... 9

COMPONENTS .................................................................................................................................................................... 9

CONT ACT OR ....................................................................................................................................................... 9

C

RANKCASE HEATER .......................................................................................................................................... 9

C

ONDENSER MOTOR........................................................................................................................................... 9

C

OMPRESSOR ................................................................................................................................................. 10

C

ONTACT OR RELAY........................................................................................................................................... 10

D

EFROST CONTROL .......................................................................................................................................... 10

O

UTDOOR THERMOSTAT ..................................................................................................................................... 10

R

EVERSING VALVE COIL ................................................................................................................................... 10

I

NDOOR BLOWER MOTOR ................................................................................................................................... 10

HEA T PUMP OPERA TION .................................................................................................................................................. 10

COOLING CYCLE .............................................................................................................................................. 10

H

EA TING CYCLE ............................................................................................................................................... 10

D

EFROST CONTROL ...........................................................................................................................................11

A

IR FLOW MEASUREMENT AND ADJUSTMENT .......................................................................................................... 12

A

IR FLOW ADJUSTMENTS FOR INDOOR BLOWER MOTOR .......................................................................................... 12

2

Page 3

APH DIP SWITCH FUNCTIONS ............................................................................................................................ 12

APH CFM D

APH T

APH H

APH T

APH T

E

XPANSION VALVE (TXV) SYSTEM ..................................................................................................................... 13

H

EAT PUMP - HEATING CYCLE ........................................................................................................................... 14

ELECTRICAL ADJUSTMENTS ........................................................................................................................................... 14

MAINTENANCE .................................................................................................................................................................. 15

SERVICE ............................................................................................................................................................................ 15

ELIVERY AND ADJUSTMENTS ............................................................................................................ 12

HERMOSTAT “FAN ONLY” MODE .............................................................................................................. 12

UMIDITY CONTROL .................................................................................................................................. 12

WO-STAGE HEATING ............................................................................................................................... 12

HERMOSTAT WIRING ................................................................................................................................12

COMMON CAUSES OF UNSATISFACTORY OPERATION OF HEAT PUMP ON THE HEATING CYCLE ........................................ 15

NADEQUATE AIR VOLUME THROUGH INDOOR COIL ............................................................................................... 15

I

OUTSIDE AIR INTO RETURN DUCT ..................................................................................................................... 15

UNDERCHARGE .............................................................................................................................................. 15

OOR “TERMINATING” SENSOR CONTACT........................................................................................................... 15

P

MALFUNCTIONING REVERSING VALVE - THIS MAY BE DUE TO: ................................................................................ 15

APPENDIX ......................................................................................................................................................................... 16

TROUBLESHOOTING CHART ................................................................................................................................. 17

GPH15 B

GPC15 B

APH15 B

APH15 CFM O

CFM O

LOWER PERFORMANCE DATA ............................................................................................................... 18

LOWER PERFORMANCE DATA ............................................................................................................... 20

LOWER PERFORMANCE DATA ............................................................................................................... 21

UTPUT AND DIP SWITCH SETTINGS .............................................................................................. 22

UTPUT FOR DIP SWITCH COMBINATIONS 1-2 (ELECTRIC HEAT).................................................................. 22

DIP SWITCH SETTINGS FOR SINGLE AND TWO-STAGE THERMOSTATS ...................................................................... 22

CFM OUTPUT FOR DIP SWITCH COMBINATIONS 5-6 (COOLING/HEATING). ............................................................. 22

ADJUSTMENTS THROUGH DIP SWITCH COMBINATIONS 7-8.................................................................................... 22

3

Page 4

TO THE INSTALLER

Carefully read all instructions for the installation prior to installing

unit. Make sure each step or procedure is understood and any

special considerations are taken into account before starting

installation. Assemble all tools, hardware and supplies needed to

complete the installation. Some items may need to be purchased

locally. After deciding where to install unit, closely look the location

over - both the inside and outside of home. Note any potential

obstacles or problems that might be encountered as noted in this

manual. Choose a more suitable location if necessary.

IMPORTANT NOTE: If a crankcase heater is used, the unit

should be energized 24 hours prior to compressor start up to

ensure crankcase heater has sufficiently warmed the compressor. Compressor damage may occur if this step is not followed.

IMPORTANT NOTE TO THE OWNER REGARDING PRODUCT

WARRANTY

Your warranty certificate is supplied as a separate document

with the unit installed by your contractor. Read the limited

warranty certificate carefully to determine what is and is not

covered and keep the warranty certificate in a safe place. If

you are unable to locate the warranty certificate please contact

your installing contractor or contact customer service (877254-4729) to obtain a copy.

To receive the 10-year Parts Limited Warranty for Goodman

branded products, online registration must be completed within

60 days of installation. Online registration is not required in

California or Quebec. Complete warranty details available at

your local dealer or at www.goodmanmfg.com.

IMPORTANT: To register your Goodman brand unit, go to

www.goodmanmfg.com. Click on the word “Warranty” located

on the left side of the home page. Next, click on the word

“Product Registration” located on the left side of the Warranty

page and complete the forms in the manner indicated on the

Product Registration page.

Product limited warranty certificates for models currently in

production can be viewed at www.goodmanmfg.com. If your

model is not currently in production or does not appear on the

website, please contact your installing contractor or contact

customer service (877-254-4729) to obtain a copy of your

warranty certificate.

Each product overview page contains a Product Warranty link;

by clicking on it you will be able to view the limited warranty

coverage for that specific product. T o view warranty registration

information, click on the Product Warranty text on the left

navigation panel on the home page of each website. The Online

Product Registration pages are located in this same section.

Before using this manual, check the serial plate for proper

model identification.

The installation and servicing of this equipment must be

performed by qualified, experienced technicians only.

SHIPPING INSPECTION

Upon receiving the unit, inspect it for damage from shipment.

Claims for damage, either shipping or concealed, should be filed

immediately with the shipping company. Check the unit model

number, specifications, electrical characteristics and accessories

to determine if they are correct. In the event an incorrect unit is

shipped, it must be returned to the supplier and must NOT be

installed. The manufacturer assumes no responsibility for

installation of incorrectly shipped units.

REPLACEMENT PARTS

O

RDERING PARTS

When reporting shortages or damages, or ordering repair

parts, give the complete unit model and serial numbers as

stamped on the unit’s nameplate.

Replacement parts for this appliance are available through

your contractor or local distributor. For the location of your

nearest distributor, consult the white business pages, the

yellow page section of the local telephone book or contact:

CONSUMER AFFAIRS

GOODMAN MANUFACTURING COMP ANY, L.P .

7401 SECURITY WA Y

HOUSTON, TEXAS 77040

877-254-4729

SAFETY INSTRUCTIONS

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards. It

is the owner’s and installer’s responsibility to read and comply

with all safety information and instructions accompanying

these symbols. Failure to heed safety information increases

the risk of personal injury, property damage, and/or product

damage.

4

Page 5

CODES AND REGULATIONS

The *PH/C M-series heat pumps are designed for OUTDOOR

USE ONLY. *PH M-Series is available in cooling capacities of

2, 2.5 3, 4 and 5 nominal tons of cooling. The GPC is only

available in 2 thru 4 ton. Optional field installed heat kits are

available in 5,8,10,15 and 20 kW. The units can be easily

installed in manufactured or modular homes with existing

high-static duct work. The units can also be easily converted

to accommodate a plenum for normal or low-static

applications. The *PH/C M-series are self contained packaged

units so the only connections needed for installation are the

supply and return ducts, the line and low voltage wiring and

drain connection. The units are ETL listed and AHRI certified.

The information on the rating plate is in compliance with the

FTC & DOE rating for single phase units.

EPA REGULATIONS

IMPORTANT: THE UNITED STATES ENVIRONMENTAL PROTECTION

AGENCY (EP A) HAS ISSUED V ARIOUS REGULATIONS REGARDING THE

INTRODUCTION

AND DISPOSAL OF REFRIGERANTS IN THIS UNIT.

FAILURE TO FOLLOW THESE REGULATIONS MAY HARM THE

ENVIRONMENT

. BECAUSE REGULATIONS MA Y VARY DUE TO PASSAGE OF NEW

FINES

, WE SUGGEST A CERTIFIED TECHNICIAN PERFORM ANY WORK

LAWS

ON THIS UNIT. SHOULD YOU HAVE ANY QUESTIONS PLEASE

DONE

CONTAC T

AND CAN LEAD TO THE IMPOSITION OF SUBSTANTIAL

THE LOCAL OFFICE OF THE EPA.

NATIONAL CODES

This product is designed and manufactured to permit

installation in accordance with National Codes. It is the

installer’s responsibility to install the product in accordance

with National Codes and/or prevailing local codes and

regulations.

PRE-INSTALLATION CHECKS

Before attempting any installation, the following points should be

considered:

• Structural strength of supporting members

• Clearances and provision for servicing

• Power supply and wiring

• Air duct connections

• Drain facilities and connections

• Location may be on any four sides of a home,

manufactured or modular, to minimize noise

CLEARANCES AND ACCESSIBILITY

The unit is designed to be located outside the building with

unobstructed condenser air inlet and discharge. Additionally,

the unit must be situated to permit access for service and

installation. Condenser air enters from three sides. Air

discharges upward from the top of the unit. Refrigerant gauge

connections are made on the right side of the unit as you face

the compressor compartment. Electrical connections can be

made either on the right, bottom or duct panel side of the unit.

The best and most common application is for the unit to be

located 10” from wall (4” minimum) with the connection side

facing the wall. This “close to the wall” application minimizes

exposed wiring.

Close to the wall application assures free, unobstructed air

to the other two sides. In more confined application spaces,

such as corners provide a minimum 12” clearance on all air

inlet sides. Allow 36” minimum for service access to the

compressor compartment and controls. The top of the unit

should be completely unobstructed. If units are to be located

under an overhang, there should be a minimum of 48”

clearance and provisions made to deflect the warm discharge

air out from the overhang.

UNIT LOCATION

Consider the affect of outdoor fan noise on conditioned space

and any adjacent occupied space. It is recommended that

the unit be placed so that condenser air discharge does not

blow toward windows less than 25 feet away. Consideration

should also be given to shade and unit appearance.

Heat pumps require special location consideration in areas of

heavy snow accumulation and/or areas with prolonged continuous subfreezing temperatures. Heat pump unit bases have holes

under the outdoor coil to permit drainage of defrost water accumulation. The unit must be situated to permit free unobstructed drainage of the defrost water and ice. A minimum 2" clearance under

the outdoor coil is required in the milder climates.

GROUND LEVEL PRE-INSTALLATION DETAILS

The unit should be set on a solid, level foundation - preferably

a concrete slab at least 4 inches thick. The slab should be

above ground level and surrounded by a graveled area for

good drainage. Any slab used as a unit’s foundation should

not adjoin the building as it is possible that sound and

vibration may be transmitted to the structure.

MAJOR COMPONENTS

The unit includes a hermetically sealed refrigerating system

(consisting of a compressor, condenser coil, evaporator coil

with flowrator), an indoor blower, a condenser fan and all

necessary internal electrical wiring. The heat pump also

includes a reversing valve, solenoid, defrost thermostat and

control and loss of charge protection. The system is factoryevacuated, charged and performance tested. Refrigerant

amount and type are indicated on rating plate.

5

Page 6

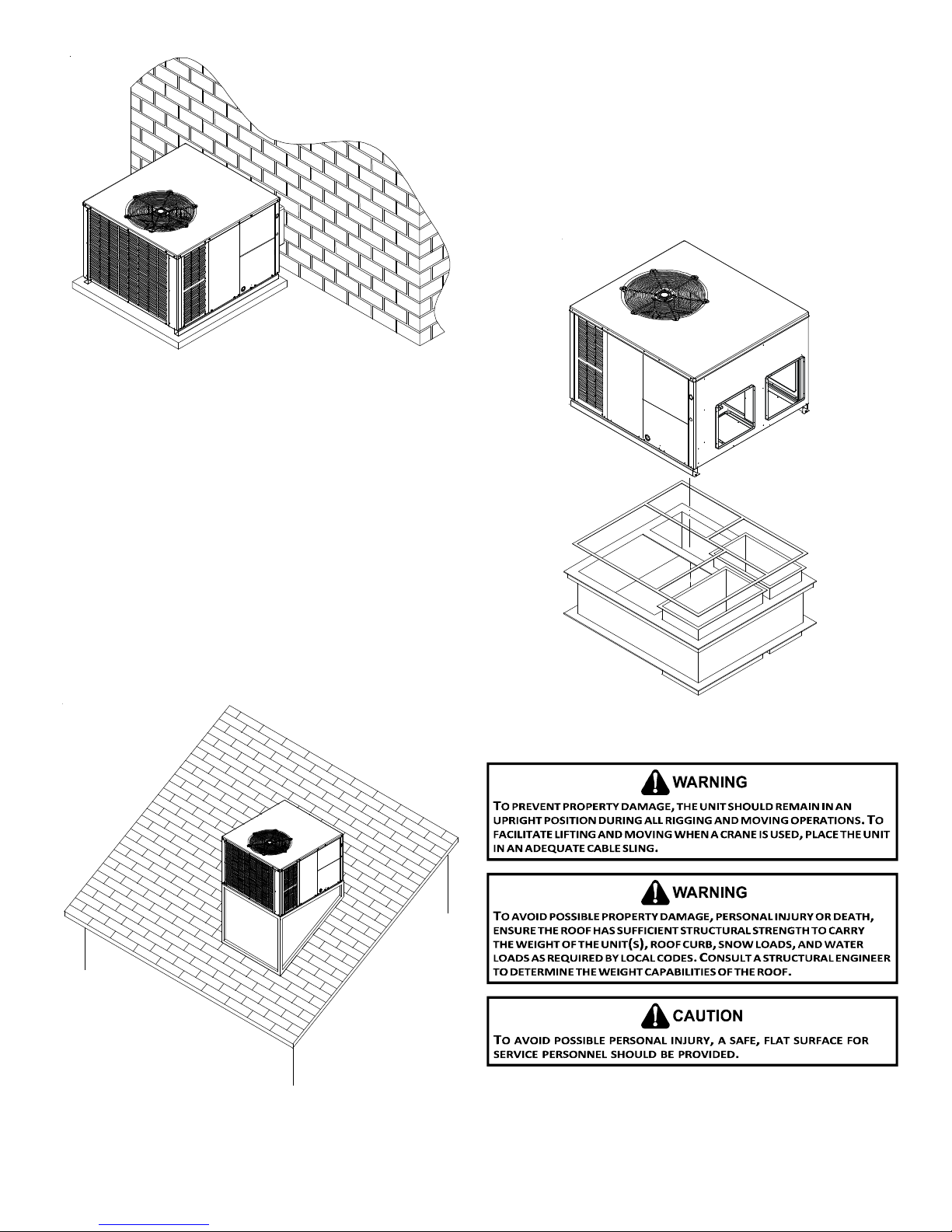

Ground Level Installation

ROOF TOP PRE-INSTALLATION DETAILS

Ensure that the roof is weather tight and allows proper

drainage of condensation. Use steel or treated wood beams

as unit support for load distribution.

NOTE: To ensure proper condensate drainage, unit must be

installed in a level position.

• To avoid possible property damage or personal injury,

the roof must have sufficient structural strength to carry

the weight of the unit(s) and snow or water loads as

required by local codes. Consult a structural engineer to

determine the weight capabilities of the roof.

• The unit may be installed directly on wood floors or on

Class A, Class B, or Class C roof covering material.

• To avoid possible personal injury, a safe, flat surface for

service personnel should be provided.

ROOF CURB INSTALLATIONS ONLY

NOTE: Sufficient structural support must be determined prior

to locating and mounting the curb and package unit.

Curb insulation, cant strips, flashing and general roofing

material are furnished by the contractor.

Curbing must be installed in compliance with the National

Roofing Contractors Association Manual. Construct duct work

using current industry guidelines. The duct work must be

placed into the roof curb before mounting the package unit.

Rooftop Installation

Roof Curb Installation

RIGGING DETAILS

IMPORTANT: If using bottom discharge with roof curb, duct

work should be attached to the curb prior to installing the unit.

Lower unit carefully onto roof mounting curb. While rigging

unit, center of gravity will cause condenser end to be lower

than supply air end.

6

Page 7

Rigging

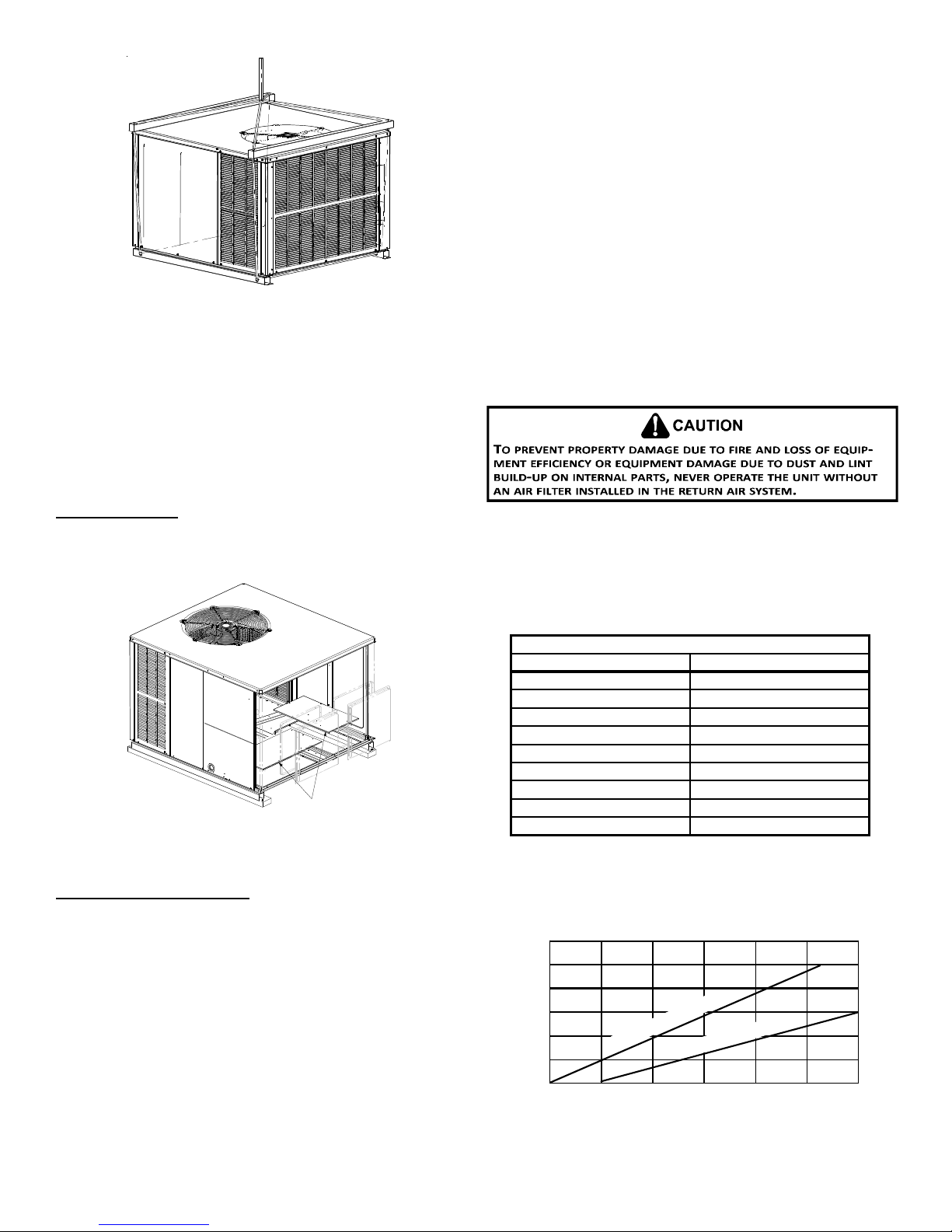

CIRCULA TING AIR AND FILTERS

A

IR FLOW CONVERSION

Units can easily be converted from horizontal to down

discharge air flow delivery. In down discharge or high static

installations, the installer should measure the total external

static and review the blower performance charts before

performing the installation. In some installations it will be

necessary to change the blower speed to provide proper air

flow.

Horizontal Air Flow

Single phase models are shipped without horizontal duct

covers. If needed, these kits may be ordered through

Goodman’s Service Parts department.

Return

Supply

Remove these panels

for downflow duct

applications

Duct Cover Installation

Down Discharge Applications

Cut insulation around bottom openings and remove panels

from the bottom of the unit, saving the screws holding the

panels in place.

NOTE: Single phase models require installation of horizontal

duct kit #20464501PDGK (medium chassis) and

#20464502PDGK (large chassis).

DUCT WORK

Duct systems and register sizes must be properly designed

for the C.F.M. and external static pressure rating of the unit.

Duct work should be designed in accordance with the

recommended methods of Air Conditioning Contractors of

America Manual D (Residential) or Manual Q (Commercial).

All duct work exposed to the outdoors must include a

weatherproof barrier and adequate insulation.

A duct system should be installed in accordance with

Standards of the National Board of Fire Underwriters for the

Installation of Air Conditioning, Warm Air Heating and

Ventilating Systems. Pamphlets No. 90A and 90B.

The supply duct from the unit through a wall may be installed

without clearance. However, minimum unit clearances as

shown in the Appendix must be maintained. The supply duct

should be provided with an access panel large enough to

inspect the air chamber downstream of the heat exchanger. A

cover should be tightly attached to prevent air leaks.

For duct flange dimensions on the unit refer to the Unit

Dimension illustration in the Appendix.

For down discharge applications, the duct work should be

attached to the roof curb prior to installing the unit. Duct work

dimensions are shown in the roof curb installation manual.

If desired, supply and return duct connections to the unit may

be made with flexible connections to reduce possible unit

operating sound transmission.

FILTERS

Filters are not provided with unit and must be supplied and

externally installed in the return duct system by the installer . A

field-installed filter grille is recommended for easy and

convenient access to the filters for periodic inspection and

cleaning. When installing filters, ensure the air flow arrows

on the filter are pointing toward the circulator blower.

Refer to the unit filter size chart below for filter size information.

MINIMUM FILTER SIZE

NOMINAL SIZE (INCHES) NOMINAL AREA (SQ. FT.)

10x20 1.4

14x20 1.9

14x25 2.4

15x20 2.1

16x20 2.2

16x25 2.8

20x20 2.8

20x25 3.5

25x25 4.3

NOTE: Filters must have adequate face area for the rated

quantity of the unit. See the air delivery table below for

recommended filter size. Size the filters in accordance with

their manufacturer recommendations. Throwaway filters must

be sized for a maximum face velocity of 300 feet per minute.

7

a

e

r

6

t

A

e

r

e

e

t

F

l

5

i

e

F

r

l

a

a

u

n

4

q

i

S

m

o

N

3

B

A

S

O

P

S

I

D

2

500 1000 1500 2000 2500 3000 3500

R

E

T

L

I

F

E

L

M

R

E

P

Airflow - SCFM

R

E

T

L

I

F

T

N

E

N

A

7

Page 8

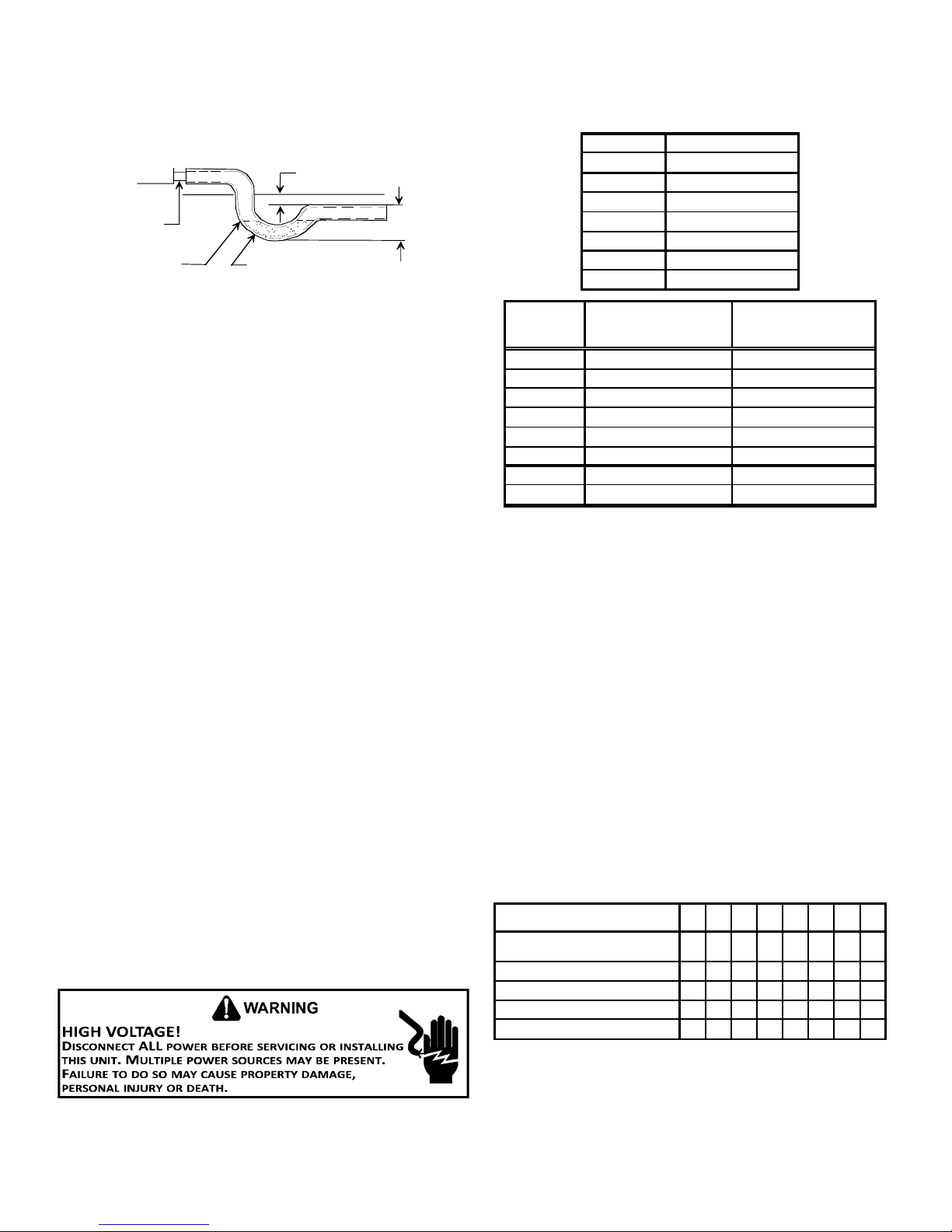

PIPING

(

C

ONDENSATE DRAIN

The condensate drain connection of the evaporator is a half

coupling of ¾” N.P.T. A trap must be provided to have proper

condensate drainage.

Unit

Drain

Connection

Flexible

Tubing-Hose

Or Pipe

Install condensate drain trap as shown. Use ¾ “ drain

connection size or larger. Do not operate without trap. Unit

must be level or slightly inclined toward drain.

A Positive Liquid Seal

Is Required

2" Minimum

3" Minimum

WIRING

NOTE: All wiring should be made in accordance with the

National Electrical Code.

Consult your local Power Company to determine the

availability of sufficient power to operate the unit. Check the

voltage, frequency, and phase at the power supply to ensure

it corresponds to the unit’s RA TED VOL T AGE REQUIREMENT .

In accordance with the N.E.C. or local codes, install a branch

circuit fused disconnect near the unit. Determine wire sizes

and overcurrent protection from the unit nameplate ampacity

and in accordance with the Minimum Filter Size or the N.E.C.

The wiring should never be sized smaller than is

recommended by either of these two sources.

Fuses smaller than that recommended on the rating plate

could result in unnecessary fuse failure or service calls. The

use of protective devices of larger size than indicated could

result in extensive damage to the equipment. The

manufacturer bears no responsibility for damage caused to

equipment as result of the use of larger than is recommended

size protective devices.

All units have undergone a run test prior to packaging for

shipment. This equipment has been started at minimum rated

voltage and checked for satisfactory operation. Do not attempt

to operate this unit if the voltage is not within the minimum

and maximum voltages shown on nameplate.

All exterior wiring must be within approved weatherproof

conduit. The unit must be permanently grounded in

accordance with local codes, or in absence of local codes,

with N.E.C. ANSI/ NFP A NO. 70-1984 or latest edition by using

ground lug in the control box.

Fuses or HACR type circuit breakers may be used where

codes permit.

IMPORTANT NOTE: Some single phase units are equipped

with a single-pole contactor. Exercise caution when servicing

as only one leg of the power supply is broken with the contractor.

LOW VOLTAGE WIRING

• Heat Pumps. Connect 24V wires from the thermostat to

the corresponding wires in the control box using No. 18

AWG as follows:

GPC15

Terminal

Re d

24 - 60

Thermostat

R (24V)

Green G (fan)

White

Brown W2

Yellow

W1 (heat*)

heat*)

Y (cool)

Blue C (24V Common)

[A/G]PH15

Terminal

Red R (24V) R (24V)

Green G (fan) G (fan)

Orange O (rev. valve) O (rev. valve)

White W1 (heat, 2nd) W1 (heat. 2nd)*

Brown W2 (heat, 3rd) W2 (heat, 3rd)*

Purple Not used Y1 (Low cool)

Yellow Y (cool) Y2 (Hi cool)

Blue C (24V Common) C (24V Common)

Thermostats must be set to energize "G" during cooling.

This is default on most all thermostats.

*Optional field installed heat connections.

*PH1549 - *PH1560 have two-stage cooling and require

two-stage heat/cool with optional third stage electric heat

thermostat.

24 - 4 3

Thermostat

49 - 60

Thermostat

INTERNAL WIRING

A diagram detailing the internal wiring of this unit is located

on the electrical box cover. If any of the original wire supplied

with the appliance must be replaced, the wire gauge and

insulation must be the same as the original wiring.

Transformer is wired for 230 volts on the 208/230 models.

See wiring diagram for 208 volt wiring.

1. For branch circuit wiring (main power supply to unit

disconnect), the minimum wire size for the length of run

can be determined using the circuit ampacity found on the

unit rating plate and the table below. From the unit

disconnect to the unit, the smallest wire size allowable

may be used for the ampacity , as the disconnect must be

in sight of the unit.

BRANCH CIRCUIT AMPA CITY

SUPPLY WIRE LENGTH -

FEET

200 64443322

150 86644433

100 108866644

50 141210108866

15 20 25 30 35 40 45 50

HIGH VOLTAGE WIRING

• Single Phase. Connect two leads to terminals L1 & L2 in

the electrical control section, using wire sizes specified

in wiring table.

2. Wire size based on 60°C rated wire insulation and 30°C

Ambient Temperature (86°F).

3. For more than three conductors in a raceway or cable, see

the N.E.C. for derating the ampacity of each conductor.

8

Page 9

STARTUP, ADJUSTMENTS, AND CHECKS

COOLING START-UP PROCEDURES

With power turned off at all disconnects:

1. Turn thermostat system switch to “COOL” and fan switch

to “AUTO”. Next, turn the temperature setting as high as it

will go.

2. Inspect all registers and set them to the normal open

position.

3. Turn on the electrical supply at the disconnect.

4. Turn the fan switch to the “ON” position. The blower should

begin ramping up immediately.

5. Turn the fan switch to “AUTO” position. The blower should

begin ramping down after an approximate 60-second

delay.

6. Slowly lower the cooling temperature until the unit starts.

The compressor, blower and fan should now be operating.

Allow the unit to run 10 minutes, make sure cool air is

being supplied by the unit.

7. Turn the temperature setting to the highest position,

stopping the unit. The indoor blower will continue to run

for approximately 60-seconds.

8. Turn the thermostat system switch to “OFF” and disconnect

all power when servicing the unit.

HEAT PUMP START-UP PROCEDURE

1. Check the cooling mode for the heat pump in the same

manner as above. The reversing valve is energized when

the thermostat is placed in the cooling position. A clicking

sound should be noticeable from the reversing valve. By

lowering the temperature setting to call for cooling, the

contractor is energized. The compressor, blower and fan

should then be running. Af ter the cooling mode is checked

out, turn the thermostat system switch to “OFF”.

2. Turn the thermostat system switch to “HEA T” and fan switch

to “AUTO”.

3. Slowly raise the heating temperature setting. When the

heating first stage makes contact, stop raising the

temperature setting.. The compressor, blower and fan

should now be running with the reversing valve in the deenergized (heating) position. After giving the unit time to

settle out, make sure the unit is supplying heated air.

4. If the outdoor ambient is above 80°F, the unit may trip on

its high pressure cut out when on heating. The compressor

should stop. The heating cycle must be thoroughly

checked, so postpone the test to another day when

conditions are more suitable. DO NOT FAIL TO TEST.

5. If the outdoor ambient is low and the unit operates properly

on the heating cycle, you may check the pressure cutout

operation by blocking off the indoor return air until the unit

trips.

6. If unit operates properly in the heating cycle, raise the

temperature setting until the heating second stage makes

contact. Supplemental resistance heat, if installed should

now come on. Ensure all heaters energize.

NOTE: *PH1542-60 have two stages of compressor heat.

During resistance heat test, increase temperature setting

until third stage heat is energized.

If outdoor thermostats are installed, the outdoor ambient

must be below the set point of these thermostats for the

heaters to operate. It may be necessary to jumper these

thermostats to check heater operation if outdoor ambient

is mild.

7. THERMOSTA TS WITH EMERGENCY HEA T . For thermostats

with an emergency heat switch, raise the temperature

setting until the heating second stage makes contact. The

emergency heat switch is located at the bottom of the

thermostat. Move the switch to emergency heat. The heat

pump will stop, the blower will continue to run, all heaters

will come on and the thermostat emergency heat light will

come on.

8. If checking the unit in the wintertime, when the outdoor coil

is cold enough to actuate the defrost control, observe at

least one defrost cycle to make sure the unit defrosts

completely.

FINAL SYSTEM CHECKS

1. Ensure all supply and return air grilles are adjusted and

the air distribution system is balanced for the best

compromise between heating and cooling.

2. Ensure there are no air leaks in the duct work.

3. Check air flow and refrigerant charge. See Sections on

Air Flow Measurement and Adjustment and Checking

Charge.

4. Ensure the unit is free of “rattles”, and the tubing in the unit

is free from excessive vibration. The tubes or lines should

not rub against sheet metal surfaces, edges or each other.

5. Ensure the Owner is instructed on the unit operation, filter,

servicing, correct thermostat operation, etc.

Set the thermostat at the appropriate setting for cooling and

heating or automatic changeover for normal use.

NOTE: The “Cooling Start-up Procedure” is a recommended

step as it serves as an system indicator that the unit will operate

normally.

COMPONENTS

Contactor

This control is activated (closed) by the room thermostat for

both heating and cooling. The contactor has a 24V coil and

supplies power to the compressor and outdoor fan motor.

Crankcase Heater

This item is “ON” whenever power is supplied to the unit and

the crankcase heater thermostat is closed. Crankcase heater

thermostat closes at 67° and opens at 85°. It warms the

compressor crankcase thereby preventing liquid migration

and subsequent compressor damage. The insert type heater

is self regulating. It is connected electrically to the contactor

L1 and L2 terminals.

Condenser Motor

This item is activated by the contactor during heating and

cooling, except during defrost and emergency heat operation.

On 460V heat pumps, the condenser motor is activated by the

CMR.

9

Page 10

Compressor

This item is activated by the contactor for heating and cooling,

except during emergency heat. It is protected by an internal

overload.

Contactor Relay

This control is activated by the thermostat (24V coil) and

supplies power to the contactor.

Defrost Control

The Defrost Control provides time/temperature initiation and

termination of the defrost cycle. When a defrost cycle is

initiated, the Defrost Control shifts the reversing valve to

“COOLING” mode, stops the outdoor fan and brings on

supplemental heat. Normally, a defrost cycle will take only 23 minutes unless system is low on refrigerant charge or

outdoor conditions are severe (i.e. windy and cold). The defrost

control also provides for a 3 minute off cycle compressor

delay.

Outdoor Thermostat

These optional controls are used to prevent full electric heater

operation at varying outdoor ambient (0°F to 45°F). They are

normally open above their set points and closed below to

permit staging of indoor supplement heater operation. If the

outdoor ambient temperature is below 0°F (-18°C) with 50%

or higher RH, an outdoor thermostat (OT) must be installed

and set at (0°) on the dial. Failure to comply with this

requirement may result in damage to the product which may

not be covered by the manufacturer’s warranty.

Reversing Valve Coil

This coil is activated by the thermostat, in the cooling mode

and during defrost. It positions the reversing valve pilot valve

for cooling operation.

Indoor Blower Motor

This is activated by the room thermostat by COOLING or FAN

ON position. For GPC/GPH models, the motor is energized

directly by the room thermostat for X-13 motors. X-13 motors

are constant torque motors with very low power consumption.

For APH models, the motor is energized by the fan control

board for ECM motors. ECM motors are constant CFM motors

with very low power consumption. This motor is energized by

a 24V signal from the thermostat. (See Air Flow Measurement

and Adjustment for speed adjustment instructions).

The following figures show a schematic of a heat pump on

the cooling cycle and the heating cycle. In addition to a

reversing valve, a heat pump is equipped with an expansion

device and check valve for the indoor coil, and similar

equipment for the outdoor coil. It is also provided with a defrost

control system.

The expansion devices are flowrator distributors and perform

the same function on the heating cycle as on the cooling

cycle. The flowrator distributors also act as check valves to

allow for the reverse of refrigerant flow.

When the heat pump is on the heating cycle, the outdoor coil

is functioning as an evaporator. The temperature of the

refrigerant in the outdoor coil must be below the temperature

of the outdoor air in order to extract heat from the air. Thus, the

greater the difference in the outdoor temperature and the

outdoor coil temperature, the greater the heating capacity of

the heat pump. This phenomenon is a characteristic of a

heat pump. It is a good practice to provide supplementary

heat for all heat pump installations in areas where the

temperature drops below 45°F. It is also a good practice to

provide sufficient supplementary heat to handle the entire

heating requirement should there be a component failure of

the heat pump, such as a compressor, or refrigerant leak, etc.

Since the temperature of the refrigerant in the outdoor coil on

the heating cycle is generally below freezing point, frost forms

on the surfaces of the outdoor coil under certain weather

conditions of temperature and relative humidity. Therefore, it

is necessary to reverse the flow of the refrigerant to provide

hot gas in the outdoor coil to melt the frost accumulation. This

is accomplished by reversing the heat pump to the cooling

cycle. At the same time, the outdoor fan stops to hasten the

temperature rise of the outdoor coil and lessen the time

required for defrosting. The indoor blower continues to run

and the supplementary heaters are energized.

HEAT PUMP OPERATION

C

OOLING CYCLE

When the heat pump is in the cooling cycle, it operates exactly

as a Air Conditioner unit.

HEATING CYCLE

The heat pump operates in the heating cycle by redirecting

refrigerant flow through the refrigerant circuit external to the

compressor. This is accomplished with through the reversing

valve. Hot discharge vapor from the compressor is directed to

the indoor coil (evaporator on the cooling cycle) where the

heat is removed, and the vapor condenses to liquid. It then

goes through the expansion device to the outdoor coil

(condenser on the cooling cycle) where the liquid is

evaporated, and the vapor goes to the compressor.

When the solenoid valve coil is operated either from heating

to cooling or vice versa, the piston in the reversing valve to the

low pressure (high pressure) reverse positions in the

reversing valve.

10

Page 11

COOLING

SERVICE VALVE

SERVICE PORT

REVERSING VALVE

R

O

T

A

R

O

P

A

V

E

INDOOR

CHECK VALVE

COIL

HEATING

SERVICE VALVE

R

E

S

N

E

D

N

O

C

INDOOR

CHECK VALVE

COIL

SERVICE PORT

COMPRESSOR

DISTRIBUTOR

EXPANSION DEVICE

ORIFICE

DISTRIBUTOR

ORIFICE

SERVICE

VALVE

COMPR ESSOR

SERVICE

VALVE

SERVICE PORT

ACCUMULATOR

SERVICE PORT

CHECK VALVE

ORIFICE

ACCUMULATO R

SERVICE PORT

CHECK VALVE

ORIFICE

OUTDOOR

REVERSING VALVE

DISTRIBUTOR

OUTDOOR

DEFROST CONTROL

During operation the power to the circuit board is controlled

by a temperature sensor, which is clamped to a feeder tube

entering the outdoor coil. Defrost timing periods of 30, 60 and

90 minutes may be selected by setting the circuit board jumper

to 30, 60 and 90 respectively. Accumulation of time for the

timing period selected starts when the sensor closes

(approximately 34°F), and when the wall thermostat calls for

heat. At the end of the timing period, the unit’s defrost cycle

will be initiated provided the sensor remains closed. When

the sensor opens (approximately 60°F), the defrost cycle is

terminated and the timing period is reset. If the defrost cycle

is not terminated due to the sensor temperature, a twelve

minute override interrupts the unit’s defrost period.

COIL

COIL

R

E

S

N

E

D

N

O

C

R

O

T

A

R

O

P

A

V

E

Suggested Field Testing/Trouble Shooting

1. Run unit in the heating mode (room thermostat calling for

heat).

2. Check unit for proper charge. NOTE: Bands of frost on the

condenser coil indicate low refrigerant charge.

3. Shut off power to unit.

4. Disconnect outdoor fan by removing the outdoor fan motor

wire from “DF2” on defrost control.

5. Restart unit and allow frost to accumulate.

6. After a few minutes of operation, the unit’s defrost

thermostat should close. To verify this, check for 24 volts

between “DFT” and “C” on board. If the temperature at the

thermostat is less than 28°F and the thermostat is open,

replace the unit’s defrost thermostat, as it is defective.

7. When the unit’s defrost thermostat has closed, short the

test pins on the defrost board until the reversing valve

shifts, indicating defrost. This should take up to 21

seconds depending on what timing period the control is

set on. After defrost initiation, the short must instantly be

removed or the unit’s defrost period will only last 2.3

seconds.

8. The control is shipped from the factory with the compressor

delay option selected. This will de-energize the

compressor contactor for 30 seconds on defrost initiation

and defrost termination. If the jumper is set to Normal, the

compressor will continue to run during defrost initiation

and defrost termination. The control will also ignore the

low pressure switch connected to R-PS1 and PS2 for 5

minutes upon defrost initiation and 5 minutes after defrost

termination.

9. After the unit’s defrost thermostat has terminated, check

the defrost thermostat for 24 volts between “DFT” and “C”.

The reading should indicate 0 volts (open sensor).

10. Shut off power to unit.

11. Replace outdoor fan motor lead to terminal “DF2” on defrost

board and turn on power.

11

Page 12

AIR FLOW MEASUREMENT AND ADJUSTMENT

Please review the Duct Work section before proceeding

with the airflow measurements and adjustments in this

section.

Unit blower curves (see Specification Sheets) are based on

external static pressure (ESP per in/W .C.). The duct openings

on the unit are considered internal static pressure. As long as

ESP is maintained, the unit will deliver the proper air up to the

maximum static pressure listed for the CFM required by the

application (i.e. home, building, etc.)

In general, 400 CFM per ton of cooling capacity is a rule of

thumb. Some applications depending on the sensible and

latent capacity requirements may need only 350 CFM or up to

425 CFM per ton. Check condition space load requirements

(from load calculations) and equipment expanded ratings data

to match CFM and capacity.

After unit is set and duct work completed, verify the ESP with a

1-inch inclined manometer with pilot tubes or a Magnahelic

gauge and confirm CFM to blower curves in the Specification

Sheets.

NOTE: Never run CFM below 350 CFM per ton, evaporator

freezing or poor unit performance is possible.

AIR FLOW ADJUSTMENTS FOR INDOOR BLOWER MOTOR

X-13 Motor

Adjust the CFM by changing the 24V low voltage lead at the

speed terminal block on the motor. (T1-Low Speed, T2 and

T3-Medium Speed, T4 and T5-High Speed).

NOTE: Factory set T1 (G , fan), T2 (cool/Hi cool), T3 (W2 electric

heat), T4 and T5 reserved for high static (cool/Hi cool) and

W2. GPH1548M41 and GPH1560M41 low cool Y1 will run at G

speed.

ECM Motor

The ECM control board is factory set with the dip switch #4 in

the “ON” position for single stage units and to the "OFF"

position for the 2 stage units. All other dip switches are factory

set in the “OFF” position. For most applications, the settings

are to be changed according to the electric heat size.

The ECM motor provides many features not available on the

traditional PSC motor. These features include:

• Improved Efficiency

• Constant CFM

• Soft Start and Stop

• Improved Humidity Control

ECM Motor Speed Adjustment

Each ECM blower motor has been preprogrammed for

operation at 4 distinct air flow levels when operating in Cooling/

Heat Pump mode or Electric Heat mode. These 4 distinct

levels may also be adjusted slightly lower or higher if desired.

The adjustment between levels and the trim adjustments are

made by changing the dip switch(s) either to an "OFF" or "ON"

position.

APH DIP SWITCH FUNCTIONS

The ECM motor has an electronic control that contains eight

(8) 2-position dip switches. The function of these dip switches

is shown in Table 1.

DIP SWITCH NUMBER FUNCTION

1

2

3N/A

4 Indoor Thermostat

5

6

7

8

Table 1

For APH1524-43 models, dip switch 4 must be set to ON. Dip

switch 4 must be set to OFF for two-stage compressor models

APH1549-60. Dip switch 4 ON energizes Y1 signal to the

ECM motor anytime Y/Y2 is energized. The indoor motor will

not operate properly if switch is not set correctly for the model.

Electric Heat

Cooling & Heat Pump CFM

CFM Trim Adjust

APH CFM DELIVERY AND ADJUSTMENTS

See Appendix for CFM Output, Adjustments and DIP switch

settings.

APH THERMOSTAT “FAN ONLY” MODE

During Fan Only Operations, the CFM output is 50% of the high

stage cooling setting.

APH HUMIDITY CONTROL

When using a Humidistat (normally closed), cut jumper PJ6 on the

control board. The Humidistat will only affect both low stage and

high stage cooling air flow by adjusting the Air flow to 85%.

APH TWO-STAGE HEATING

When using staged electric heat, cut jumper PJ4 on the control

board.

APH THERMOSTAT WIRING

Use thermostat wiring diagrams provided with the thermostat

when making these connections.

See Appendix for Blower Performance tables.

SUPERHEAT CAN BE DETERMINED AS FOLLOWS:

1. Read suction pressure. Determine Saturated Suction

Temperature from tables or pressure gauge saturated

temperature scale (R-410A).

2. Read suction line temperature.

3. Use the following formula:

SUPERHEAT = SUCTION LINE TEMP - SAT. SUCTION TEMP

See Appendix for Blower Performance Data tables.

12

Page 13

p

SATURATED SUCTION PRESSURE

p

TEMPERATURE CHART

Suction

Pressure

Saturated Suction

Tem

erature °F

PSIG R-410A

50 1

52 3

54 4

56 6

58 7

60 8

62 10

64 11

66 13

68 14

70 15

72 16

71 17

76 19

78 20

80 21

SUBCOOLING = SAT. LIQUID TEMP. - LIQUID LINE TEMP.

SATURATED LIQUID PRESSURE

TEMPERATURE CHART

Liquid

Pressure

Saturated Liquid

Tem

erature °F

PSIG R-410A

200 70

210 73

220 76

225 78

235 80

245 83

255 85

265 88

275 90

285 92

295 95

305 97

325 101

355 108

375 112

405 118

EXPANSION VALVE (TXV) SYSTEM

Single Speed Application (*PH1524/43 and GPC15)

1. Purge gauge lines. Connect service gauge manifold to

access fittings. Run system at least 10 minutes to allow

pressure to stabilize.

2. Temporarily install thermometer on liquid (small) line near

liquid line access fitting with adequate contact and insulate

for best possible reading.

3. Check subcooling and superheat. Systems with TXV

application should have a subcooling of 10 + 2°F and

superheat of 15 to 18ºF.

a. If subcooling and superheat are low, adjust TXV to 15

- 18ºF then check subcooling.

b. If subcooling is low and superheat is high, add charge

to raise subcooling to 10 ± 2ºF then check superheat.

c. If subcooling and superheat are high, adjust TXV valve

to 15 - 18ºF then check subcooling.

d. If subcooling is high and superheat is low, adjust TXV

valve to 15 to 18ºF superheat and remove charge to

lower the subcooling to 10 ± 2ºF.

The TXV should NOT be adjusted at light load conditions 55º

to 60ºF, under such conditions only the subcooling can be

evaluated. This is because suction pressure is dependent

on indoor air flow, and wet bulb temperature.

NOTE: Do NOT adjust charge based on suction pressure

unless there is a gross undercharge.

4. Disconnect manifold set. Installation is complete.

Two Speed Application (*PH1549/60)

Run the unit on low stage cooling for 10 minutes until

refrigerant pressures stabilize. Follow the guidelines and

methods below to check unit operation and ensure that the

refrigerant charge is within limits. Charge the unit on low

stage.

1. Purge gauge lines. Connect service gauge manifold to

access fittings. Run system at least 10 minutes to allow

pressure to stabilize.

2. Temporarily install thermometer on liquid (small) line near

liquid line access fitting with adequate contact and insulate

for best possible reading.

3. Check subcooling and superheat. Two stage systems

running on low stage with TXV application should have a

subcooling of 5 to 7 ºF and superheat of 15 to 18ºF.

a. If subcooling and superheat are low, adjust TXV to 15

to 18ºF superheat, then check subcooling.

NOTE: To adjust superheat, turn the valve stem

clockwise to increase and counter clockwise to

decrease.

b. If subcooling is low and superheat is high, add charge

to raise subcooling to 5 to 7 ºF then check superheat.

c. If subcooling and superheat are high, adjust TXV valve

to 15 to 18ºF superheat, then check subcooling.

d. If subcooling is high and superheat is low, adjust TXV

valve to 15 to 18ºF superheat and remove charge to

lower the subcooling to 5 to 7 ºF.

NOTE: Do NOT adjust the charge based on suction

pressure unless there is a gross undercharge.

4. Disconnect manifold set, installation is complete.

Refrigerant Charge Check (Units with Fixed Orifice Devices)

After completing airflow measurements and adjustments the

unit’s refrigerant charge must be checked. The unit comes

factory charged, but this charge is based on 325 CFM per ton

and minimum ESP per ARI test conditions (generally between

.15 -.25 ESP). When air quantity or ESP is different than above,

the refrigerant charge must be adjusted to the proper amount.

All package units with fixed orifice devices are charged using

the super heat method at the compressor suction line.

For charging in the warmer months, 8 ± 3ºF superheat at the

compressor is required at conditions 95ºF outdoor ambient

(dry bulb temperature), 80ºF dry bulb / 67ºF wet bulb indoor

ambient, approximately 50% humidity. This superheat varies

when conditions vary from the conditions described.

13

Page 14

After superheat is adjusted it is recommended to check unit sub-cooling at the condenser coil liquid line out. In most operating

conditions 10 - 15ºF of sub-cooling is adequate.

HEAT PUMP - HEATING CYCLE

The proper method of charging a heat pump in the heat mode is by weighing the charge according to the total charge listed on the

rating plate.

ELECTRICAL ADJUSTMENTS

This series of electric cooling and, heat pump package equipment is designed to accept a field installed electric heat kit. The unit

is equipped to easily install the HKR Series Electric Heat Kit. Full Installation Instructions are included in this kit. Please use this

document for guidance in field equipping the package unit with electric heat.

Choose the heat kit that fits the application for the specific installation. Permanently mark the unit’s nameplate with the model

being installed. High and low voltage connections are detailed in the heat kit instructions.

Indoor Blower motor speed tap selection may need to be modified to accommodate normal continuous operation to prevent a

nuisance trip. See tables below.

EL EC T R I C H EA T kW

ELECTRIC HEAT kW

5

MODE L

GPC1524M41 3 3 3 x x

GPC1530M41 3 3 3 3 x

GPC1536M41 3 3 3 3 x

GPC1542M41 3 3 3 3 x

GPC1548M41 3 3 3 3 3

All mod el s are fac tory shipped at T3 speed

8 10 1 5

20

MODEL

GPH1524M41

GPH1530M41

GPH1536M41 3333x

GPH1543M41

GPH1549M41

GPH1560M41 33333

All models are factory shippe d at T3 speed

5 8 10 15 20

333xx

3333x

3333x

33333

MODEL

APH1524M41

APH1530M41

APH1536M41

APH1543M41

APH1549M41

APH1560M41

ELEC TR IC H EA T k W

5 8 10 15 20

XXX

XXXX

XXXX

XXXX

XXXXX

XXXXX

14

Page 15

MAINTENANCE

The Self Contained Package Air Conditioner and Heat Pump

should operate for many years without excessive service calls

if the unit is installed properly. However it is recommended

that the homeowner inspect the unit before a seasonal start

up. The coils should be free of debris so adequate air flow is

achieved. The return and supply registers should be free of

any obstructions. The filters should be cleaned or replaced.

These few steps will help to keep the product up time to a

maximum. The Troubleshooting Chart (see Appendix) should

help in identifying problems if the unit does not operate

properly.

Refer to Blower Performance section in the Appendix - Higher

air flow lowers temperature rise.

Lower air flow raises temperature rise.

SERVICE

THE FOLLOWING INFORMA TION IS FOR USE BY

QUALIFIED SERVICE AGENCY ONLY : OTHERS SHOULD

NOT A TTEMPT TO SERVICE THIS EQUIPMENT .

COMMON CAUSES OF UNSATISFACTORY OPERATION OF HEAT

PUMP ON THE HEATING CYCLE

INADEQUATE AIR VOLUME THROUGH INDOOR COIL

When a heat pump is in the heating cycle, the indoor coil is functioning as a condenser. The return air filter must always be clean,

and sufficient air volume must pass through the indoor coil to

prevent excessive discharge pressure, and high pressure cut out.

OUTSIDE AIR INTO RETURN DUCT

Do not introduce cold outside air into the return duct of a heat

pump installation. Do not allow air entering the indoor coil to drop

below 65°F. Air below this temperature will cause low discharge

pressure, thus low suction pressure, and excessive defrost cycling resulting in low heating output. It may also cause false defrosting.

UNDERCHARGE

An undercharged heat pump on the heating cycle will cause low

discharge pressure resulting in low suction pressure and frost

accumulation on the outdoor coil.

POOR “TERMINATING” SENSOR CONTACT

The unit’s defrost terminating sensor must make good thermal

contact with the outdoor coil tubing. Poor contact may not terminate the unit’s defrost cycle quickly enough to prevent the unit from

cutting out on high discharge pressure.

MALFUNCTIONING REVERSING VALVE - THIS MAY BE DUE TO:

1. Solenoid not energized - In order to determine if the

solenoid is energized, touch the nut that holds the solenoid

cover in place with a screwdriver. If the nut magnetically

holds the screwdriver, the solenoid is energized and the

unit is in the cooling cycle.

2. No voltage at unit’s solenoid - Check unit voltage. If no

voltage, check wiring circuit.

3. Valve will not shif t:

a. Undercharged - check for leaks;

b. Valve Body Damaged - Replace valve;

c. Unit Properly Charged - If it is on the heating cycle,

raise the discharge pressure by restricting air flow

through the indoor coil. If the valve does not shift, tap it

lightly on both ends with a screwdriver handle. DO NOT

T AP THE V ALVE BODY. If the unit is on the cooling cycle,

raise the discharge pressure by restricting air flow

through the outdoor coil. If the valve does not shift after

the above attempts, cut the unit off and wait until the

discharge and suction pressure equalize, and repeat

above steps. If the valve does not shift, replace it.

15

Page 16

APPENDIX

16

Page 17

TROUBLESHOOTING CHART

g

g

g

g

g

HIGH VOLT AGE!

Disconnect ALL power before servicing or installing this unit. Multiple

power sources may be present. Failure to do so may cause property

damage, personal injury or death.

SYMPTOM

High head - low suction a. Restriction in liquid line or

High head - high or normal suction a. In Cooling: Dirty condenser coil a. Clean coil

Low head - high suction

Unit will not r un

Condenser f an runs,

compressor doesn't

Low suction - cool compressor a. In Cooling: Low indoor airflow a.

Iced evaporator coil In Heating: Dirty outdoor coil, de fective

Com pressor short cycle s

Registers sweat Low airflow

High suction pressure

Insufficient cooling

TXV not functioning

In Heating: Dirty filter, Dirty indoor coil

b. Overchar

c. In Coolin

c. In Heating: Indoor blower not running c. Repair or Replace

a. Incorrect TXV. a. Replace with correct TXV

b. Defective compressor valves b. Replace compressor

c. TXV not functioning properly c. Check for debris in TXV or deformed TXV.

d. Incorrect TXV setting d. Check Super Heat

a. Power off or loose electrical connection a. Check for unit voltage at contactor in unit

b. Thermostat out of calibration set too high b. Reset

c. Defective contactor c. Check for 24 volts at contactor coil replace if

d. Blown fuses or tripped breaker d. Replace fuse or reset breaker

e. Transformer defective

f. High or low pressure control open

(Optional)

g. Compressor overload contacts open g. Replace compressor

a. Loose connection a. Check for unit voltage at compressor check &

b. Compressor stuck, grounded or open

winding open internal overload

c. Low voltage connection c. At compressor terminals, voltage must be within

d. Capacitor weak, open, or shorted d. Check capacitor. If defective, replace.

defrost thermostat, defective defrost

control board, outdoor fan not runnin

refrigerant charge.

b. Low airflow b. Check - should be approximately 400 CFM per

c. Low refrigerant charge c. Properly charge unit

d. Operatin

outdoor temperature

a. Defective overload protector a. Replace - check for correct voltage

b. Unit cycling on low pressure control b. Check refrigerant charge and / or airflow

c. High pressure switch cuts out c. Check airflow (indoor & outdoor),

a. a. Increase speed of blower or reduce restriction

a. Excessive load a. Recheck load calculation

b. Defective compressor b. Replace

c. Reversing valve not seating properly. c. Replace

a. Improperly sized unit a. Recalculate load

b. Improper airflow b. Check - should be approximately 400 CFM per ton

ed b. Correct System charge

: Condenser fan not runnin

unit in cooling mode below 65°F

a. Remove or replace with proper size TXV.

Remove debris or replace TXV.

contacts are open

e.

Check wiring - replace transformer

f. Check high pressure control or check unit

charge

High pressure control opens at 610 psig

Low pressure control opens at 22 psig

NOTE: Wait at least 2 hours for overload to reset

t ighten all conn ec tions

b. Wait at least 2 hours for overload to reset If still

open, replace the compressor.

10 % of nameplate volts when unit is operating

Increase speed of blower or reduce restriction replace air filters

, low

ton, dirty air filters, all duct outlets open

d. Install or check low ambient control, should be

open below 65°F outdoor temperature

check expansio n device

replace air filters

REMEDYPOSS IBLE CAUSE

c. Incorrect refrigerant charge. c. Charge per procedure attached to unit service

panel

d. Incorrect voltage d. At compressor terminals, voltage must be within

10% of nameplate volts when unit is operating

17

Page 18

GPH15 BLOWER PERFORMANCE DATA

Model Spe ed Volts

GPH 1524M41*

T1 (G)

T2 / T3

(W2)

T4 / T5 (Y)

230

230

230

T1 (G) 230

T2 / T3

(W2)

GPH1530M41*

T4 / T5 (Y) 230

T1 (G)

T2 / T3

(W2)

GPH1536M41*

T4 / T5 (Y)

230

230

230

230

E. S.P (In. of H

O)

2

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

CFM 882 808 727 649 545 --- --- - --

WATTS 82 86 92 102 108 --- -- - ---

CFM 933 873 810 733 637 584 --- ---

WATTS 93 103 109 120 126 135 --- ---

CFM 1058 1012 945 896 816 723 672 ---

WATTS 124 136 142 153 168 172 179 - --

CFM 893 824 752 665 575 --- --- ---

WATTS 87 95 101 111 115 --- --- ---

CFM 1132 1070 1011 959 889 827 733 669

WATTS 153 162 168 179 184 195 206 208

CFM 1287 1236 1165 1123 1066 1012 958 857

WATTS 211 217 228 239 244 255 265 272

CFM 852 764 711 592 545 --- --- ---

WATTS 80 82 86 95 99 --- -- - ---

CFM 1232 1190 1131 1082 1023 966 889 819

WATTS 202 214 221 229 235 246 258 264

CFM 1267 1213 1162 1120 1058 1009 932 841

WATTS 218 226 236 245 247 260 272 275

NOTES:

• Dat a sh ow n is dry coil . Wet coil pres su r e drop is approxi mately 0.1" H

0.2" H

0, for three- row indoor coil ; and 0.3" H20, for four-row indoor coil.

2

2

• Data shown does not incl ude filter pressure drop, approximately 0.08" H

• ALL MODELS SHOULD RUN NO LESS THAN 350 CFM/TON .

• Reduce airflow by 2% for 208-volt operation.

0 , fo r two-row i ndoor c oi l;

0.

2

18

Page 19

GPH15 BLOWER PERFORMANCE DATA

Model Spe ed Volts

T1 (G) 23 0

GPH1543M41*

T2 (Y) / T3

(W2)

T4 / T5

(HS)

230

230

T1 (G) 23 0

T2 (Y) 23 0

T3 (W2) 2 30

GPH1549M41*

T4 (YHS)

T5

(W2HS)

230

230

E. S.P (In. of H

O)

2

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

CFM 1199 1138 1085 1017 957 889 820 755

WA TTS 162 173 185 1 93 211 219 232 245

CFM 1359 1322 1262 1214 1165 1119 1080 1039

WA TTS 200 214 218 2 33 243 254 267 283

CFM 1598 1559 1525 1483 1441 1398 1353 1314

WATTS 332 343 360 365 384 385 404 414

CFM 1199 1138 1085 1017 957 889 820 755

WA TTS 162 173 185 1 93 211 219 232 245

CFM 1 418 1383 1349 1312 1275 1228 1178 1141

WATTS 242 258 273 282 299 308 320 338

CFM 1799 1745 1698 1658 1610 1560 1522 1450

WA TTS 480 493 508 5 21 531 545 550 547

CFM 1799 1745 1698 1658 1610 1560 1522 1450

WA TTS 480 493 508 5 21 531 545 550 547

CFM 1 921 1865 1818 1780 1719 1667 1579 1483

WATTS 582 585 602 625 627 621 595 569

T1 (G)

230

CFM 1390 1325 1282 1223 1180 1134 1066 1011

WATTS 231 240 253 262 277 292 300 316

CFM 1900 1843 1801 1762 1723 1672 1577 1482

WATTS 543 559 569 583 600 603 577 554

CFM 2094 2039 1981 1907 1819 1731 1628 1497

GPH1560M41*

T2 / T3

(W2)

T4 / T5 (Y)

230

230

WATTS 724 727 720 701 671 653 611 569

NOTES:

• Dat a sh ow n is dry coil. Wet co i l pres su r e drop is approxi mately 0.1" H20 , fo r two-r ow in door c oi l ;

0, for three- row indoor coil ; and 0.3" H20, for four-row indoor coil.

0.2" H

2

• Data shown does not include filter pressure drop, approximately 0.08" H

0.

2

• ALL MODELS SHOULD RUN NO LESS THAN 350 CFM /TON.

• Reduce airflow by 2% for 208-volt operat i on.

19

Page 20

GPC15 BLOWER PERFORMANCE DATA

Model Speed Volts

230

230

230

GPC1524M41*

T1 (G)

T2 / T3

T4 / T5

T1 (G) 230

T2 / T3 230

GPC 1530M41*

T4 / T5 230

230

230

230

GPC1536M41*

T1 (G)

T2 / T3

T4 / T5

T1 (G) 230

T2 / T3 230

GPC1542M41*

T4 / T5 230

T1 (G)

T2 / T3

GPC 1548M41*

T4 / T5

230

230

230

E.S.P (In. of H

O)

2

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

CFM 882 808 727 649 545 --- --- ---

WATTS 82 86 92 102 108 --- --- ---

CFM 933 873 810 733 637 584 --- ---

WATTS 93 103 109 120 126 135 --- ---

CFM 1058 1012 945 896 816 723 672 ---

WATTS 124 136 142 153 168 172 179 ---

CFM 893 824 752 665 575 --- --- ---

WATTS 87 95 101 111 115 --- --- ---

CFM 1132 1070 1011 959 889 827 733 669

WATTS 153 162 168 179 184 195 206 208

CFM 1287 1236 1165 1123 1066 1012 958 857

WATTS 211 217 228 239 244 255 265 272

CFM 852 764 711 592 545 --- --- ---

WATTS8082869599---------

CFM 1232 1190 1131 1082 1023 966 889 819

WATTS 202 214 221 229 235 246 258 264

CFM 1267 1213 1162 1120 1058 1009 932 841

WATTS 218 226 236 245 247 260 272 275

CFM 1123 1070 1025 984 942 894 839 774

Watts 162 170 182 193 204 216 229 242

CFM 1437 1390 1354 1318 1281 1243 1204 1165

Watts 310 317 331 342 355 366 377 389

CFM 1528 1490 1450 1410 1383 1348 1312 1267

Watts 372 379 391 403 416 427 439 451

CFM 1199 1138 1085 1017 957 889 820 755

WATTS 162 173 185 193 211 219 232 245

CFM 1799 1745 1698 1658 1610 1560 1522 1450

WATTS 480 493 508 521 531 545 550 547

CFM 1921 1865 1818 1780 1719 1667 1579 1483

WATTS 582 585 602 625 627 621 595 569

NOTES:

• Data shown is dry coil. Wet c o il pressure drop is approximately 0.1" H20 , fo r two-r ow i ndoor c oi l ;

0.2" H

0, for three- row indoor coil ; and 0.3" H20, for four-row ind oor coil.

2

• Dat a sh ow n do es not include fi l ter pres sure d r op, app r ox ima tely 0.08" H

• ALL MODELS SHOULD RUN NO LESS THAN 350 CFM/TON . See Repair Parts list.

• Reduce airflow by 2% for 208-volt operatio n.

20

0.

2

Page 21

APH15 BLOWER PERFORMANCE DATA

APH1530 M41APH1524M41

Cooling/HP

Speed

D Minus 630 D Minus 630 D Minus 720 D Minus 720

D Normal 700 D Normal 700 D Normal 800 D Normal 800

D Plus770 D Plus770 D Plus880 D Plus880

C Minus 743 C Minus 743 C Minus 900 C Minus 900

C Normal 825 C Normal 825 C Normal 1,000 C Normal 1,000

C Plus 908 C Plus 908 C Plus 1,100 C Plus 1,100

B Minus 855 B Minus 855 B Minus 990 B Minus 990

B Normal 950 B Normal 950 B Normal 1,100 B Normal 1,100

B Plus 1,045 B Plus 1,045 B Plus 1,210 B Plus 1,210

A Minus 945 A Minus 945 A Minus 1,125 A Minus 1,125

A Normal1,050 A Normal1,050 A Normal1,250 A Normal1,250

A Plus 1,155 A Plus 1,155 A Plus 1,375 A Plus 1,375

* @ 0.1 - 0.5 ESP * @ 0.1 - 0.5 ESP

Cooling/HP

Speed

D Minus 720 D Minus 720 D Minus 1,103 D Minus 1,103

D Normal 800 D Normal 800 D Normal 1,225 D Normal 1,225

D Plus 880 D Plus 880 D Plus*** 1,348 D Plus 1,348

C Minus 900 C Minus 900 C Minus** 1,260 C Minus** 1,260

C Normal1,000 C Normal1,000 C Normal1,400 C Normal1,400

C Plus 1,100 C Plus 1,100 C Plus 1,540 C Plus 1,540

B Minus 990 B Minus 990 B Minus 1,530 B Minus 1,530

B Normal1,100 B Normal1,100 B Normal1,700 B Normal1,700

B Plus 1,210 B Plus 1,210 B Plus 1,870 B Plus 1,870

A Minus 1,125 A Minus 1,125 A Minus 1,620 A Minus 1,620

A Normal1,250 A Normal1,250 A Normal1,800 A Normal1,800

A Plus 1,375 A Plus 1,375 A Plus 1,980 A Plus*** 1,980

* @ 0.1 - 0.5 ESP * @ 0.1 - 0.5 ESP

Adjust

Tap

Adjust

Tap

CFM*

APH1536M41

CFM*

Electric

Heat

Electric

Heat

Adjust

Tap

Adjust

Tap

CFM*

CFM*

Cooling/HP

Speed

Cooling/HP

Speed

** DENO TES FACTO RY SETTING FOR APH1543M4 1

*** DENOTES FA CTORY SETTING FOR APH1549M41

Adjust

Tap

APH1543M41 APH1549M41

Adjust

Tap

CFM *

CFM *

Electric

Heat

Electric

Heat

Adjust

Tap

Adjust

Tap

CFM*

CFM*

APH1560M41

Cooling/HP

Speed

D Minus 1,260 D Minus 1,260

D Normal1,400 D Normal1,400

D Plus1,540 D Plus1,540

C Minus 1,440 C Minus 1,440

C Normal1,600 C Normal1,600

C Plus1,760 C Plus1,760

B Minus 1,620 B Minus 1,620

B Normal1,800 B Normal1,800

B Plus1,980 B Plus1,980

A Minus 1,800 A Minus 1,800

A Normal2,000 A Normal2,000

A Plus2,200 A Plus2,200

* @ 0.1 - 0.5 ESP

Adjust

Tap

CFM*

Electric

Heat

Adjust

Tap

CFM*

21

Page 22

APH15 CFM OUTPUT AND DIP SWITCH SETTINGS

CFM Output for DIP Switch Combinations 1-2

(Electric Heat)

MODEL

APH1524

APH1530

APH1536

APH1543

APH1549

APH1560

(F)

Factory Setting

SPE ED

TAP

SWITCH1SWITCH2 ELECTRIC

A

B

C

D

A

B

C

D

A

B

C

D

A

B

C

D

A

B

C

D

A

B

C

D

Off Off

On Off 950

Off On 825

On On 700

Off Off

On Off 110 0

Off On 1000

On On 800

Off Off

On Off 110 0

Off On 1000

On On 800

Off Off 1800

On Off 170 0

Off On

On On 1225

Off Off

On Off 170 0

Off On 1400

On On 1225

Off Off

On Off 180 0

Off On 1600

On On 1400

HE AT (CFM)

1050

1250

1250

1400

1800

2000

(F)

(F)

CFM Output for DIP Switch Combinations 5-6

(Cooling/Heating).

MODEL

APH1524

(F)

APH1530

(F)

APH1536

APH1543

(F)

APH1549

(F)

APH1560

(F)

Factory Setting

SPE ED

TAP

SWITCH5SWITCH6COOLING/HP

A

B

C

D