Goodman MBE Series, MBE1200, MBE1600, MBE2000, MBR0800 Installation Instructions Manual

...Page 1

MBE/MBR

BLOWER CABINET

INSTALLATION INSTRUCTIONS

THIS PRODUCT CONTAINS ELECTRONIC COMPONENTS WHICH REQUIRE A

DEFINITE GROUND. PROVISIONS ARE MADE FOR CONNECTION OF THE

GROUND. A DEDICATED GROUND FROM THE MAIN POWER SUPPLY OR

AN EARTH GROUND MUST BE PROVIDED.

INTRODUCTION

This booklet contains the installation and operating instructions for your modular blower cabinet. All warnings and precautions within this booklet must be observed. Improper installation can result in unsatisfactory operation or dangerous

conditions and void the warranty. Read this booklet and any

instructions packaged with accessories prior to installation.

Give this booklet to the user and explain its provisions. The

user should retain this booklet for future reference.

CHECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for damage from shipment.

Claims for damage, either shipping or concealed, should be

filed immediately with the shipping company. Check the unit

model number, specifications, electrical characteristics and

accessories to determine if they are correct. In the event an

incorrect unit is shipped, it must be returned to the supplier

and must NOT be installed. The manufacturer assumes no

responsibility for installation of incorrectly shipped units.

REPLACEMENT PARTS

ORDERING P ARTS

When reporting shortages or damages, or ordering repair parts,

give the complete unit model and serial numbers as stamped

on the unit’s nameplate.

Replacement parts for this appliance are available through your

contractor or local distributor. For the location of your nearest

distributor, consult the white business pages, the yellow page

section of the local telephone book or contact:

SERVICE PARTS DEPARTMENT

GOODMAN MANUFACTURING COMPANY, L.P.

5151 SAN FELIPE, SUITE 500

HOUSTON, TEXAS 77056

(713) 861 – 2500

IMPORTANT SAFETY INSTRUCTIONS

RECOGNIZE SAFETY SYMBOLS, WORDS, AND LABELS

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner’s responsibility to read and comply with all safety information and instructions accompanying these symbols. Failure to heed safety information increases the risk of property

damage, product damage, personal injury or death.

Goodman Manufacturing Company, L.P. © 2004-2009

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com -or- www.amana-hac.com

P/N: IO-239E Date: July 2009

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

Inst a llation and r e pa i r o f th is u n it shoul d be performe d

by individuals meeting the requirements of an

ONLY

“entry level technician” as specified by the Air

Conditioning, Heating, and Refrigeration Institute

(AHRI). Attempting to install or repair this unit without

such ba ckground ma y r es u l t i n p r od uc t dama g e ,

personal injury or death.

CARBON M O NOXIDE POISONING HAZARD

Special Warning for Installation of Furnace or Air Handling Units in

Enclosed Areas such as Garages, Utility Rooms or Parking Areas

Carbon monoxide producing devices (such as an automobile, space

heater, gas water heater, etc.) should not be operated in enclosed areas

such as unventilated garages, utility rooms or parking areas because of

the danger of carbon monoxide (CO) poisoning resulting from the exhaust

emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, utility room or parking area and a carbon monoxide producing

device is operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO poisoning which

can occur if a carbon monoxide producing device continues to operate in

the enclosed area. Carbon monoxide emissions can be (re)circulated

throughout the structure if the furnace or air handler is operating in any

mode.

CO can cause serious illness including permanent brain damage or death.

B10259-216

-

GENERAL INFORMATION

The MBR/MBE Blower Cabinets are used in combination with

a cased evaporator coil. This combination of blower and coil

functions as the indoor part of a split air-conditioning system,

and may be matched with a remote condensing or heat pump

unit. The blower cabinet can also function as an electric furnace when used with an electric heater.

NOTE: The electric heating elements for electric furnace installation are not shipped with the cabinet and are field-installed.

Page 2

Contents

INTRODUCTION ............................................................................................................................................1

CHECKING PRODUCT RECEIVED ..............................................................................................................1

REPLACEMENT PARTS ................................................................................................................................1

ORDERING PARTS......................................................................................................................................................................... 1

IMPORTANT SAFETY INSTRUCTIONS.......................................................................................................1

RECOGNIZE SAFETY SYMBOLS, WORDS, AND LABELS............................................................................................................ 1

GENERAL INFORMATION ............................................................................................................................1

CLEARANCES AND ACCESSIBILITY ............................................................................................................................................ 3

INSULA TION .................................................................................................................................................................................. 3

INSTALLATION INSTRUCTIONS ..................................................................................................................3

BLOWER WITH CASED EVAPORA TOR COIL INSTALLA TION ..................................................................................................... 3

UPFLOW INSTALLA TION .............................................................................................................................................................. 3

COUNTERFLOW INST ALLATION .................................................................................................................................................. 3

HORIZONTAL INSTALLA TION ....................................................................................................................................................... 4

ELECTRICAL CONNECTIONS .....................................................................................................................4

HIGH VOLT AGE WIRING ................................................................................................................................................................ 4

LOW VOL TAGE WIRING................................................................................................................................................................ 5

MISCELLANEOUS ELECTRICAL ................................................................................................................................................... 5

THERMOST AT CONNECTIONS ..................................................................................................................................................... 5

MBE MOTOR ................................................................................................................................................................................. 5

MOTOR SPEED ADJUSTMENT ..................................................................................................................................................... 5

DIPSWITCH FUNCTIONS .............................................................................................................................................................. 5

CF M DE LI VER Y .............................................................................................................................................................................. 5

THERMOSTA T “FAN ONL Y” MODE ............................................................................................................................................... 6

CFM TRIM ADJUST ....................................................................................................................................................................... 6

HUMIDITY CONTROL ..................................................................................................................................................................... 6

TWO STAGE HEA TING................................................................................................................................................................... 6

THERMOSTA T WIRING.................................................................................................................................................................. 6

MBR MOTOR ................................................................................................................................................................................. 6

BLOWER PERFORMANCE DAT A .................................................................................................................................................. 6

SINGLE STAGE COOLING WITH SINGLE OR TWO STAGE HEATING ...................................................9

HEAT PUMP WITH SINGLE OR TWO-STAGE HEATING (OPTIONS FOR EMERGENCY HEAT) ........10

TWO-STAGE COOLING WITH CONVENTIONAL TWO-STAGE THERMOSTA T....................................13

HEAT PUMP WITH SINGLE OR TWO STAGE HEATING WITH CONVENTIONAL THERMOSTAT

(OPTIONS FOR EMERGENCY HEAT) .................................................................................................15

2 SPEED HEAT PUMP WITH SINGLE OR TWO-STAGE HEATING

(OPTIONS FOR EMERGENCY HEAT) WITH CONVENTIONAL TWO-STAGE THERMOSTAT.......17

TWO STAGE COOLING WITH CONVENTIONAL TWO STAGE THERMOSTAT

(ENCLOSED WITH ADD ON 1N006 DIODES) ......................................................................................20

TSTWK01 KIT REQUIRED ..........................................................................................................................20

ENCODED TWO STAGE COOLING WITH GMC THERMOSTAT PART #CHET18-60 TSTWKO1 KIT

REQUIRED..............................................................................................................................................21

TROUBLESHOOTING ENCODED TWO STAGE COOLING THERMOSTATS OPTIONS ....................22

2

Page 3

Systems should be properly sized by heat gain and loss calculations made according to methods of the Air Conditioning

Contractors Association (ACCA) or equivalent. It is the

contractor’s responsibility to ensure the system has adequate

capacity to heat or cool the conditioned space.

CLEARANCES AND ACCESSIBILITY

The unit can be positioned for upflow, counterflow, horizontal

right or horizontal left operation. Zero clearance is allowed on

all sides for combustible materials. Thirty-six inches should be

allotted on the door side for maintenance and service.

To reduce risk of rusting, do not install the unit blower directly

on the ground or on a floor that is likely to be wet. In such

environments, the unit must be elevated by use of a sturdy,

nonporous material.

INSULATION

To ensure efficient operation, review the following precautions.

• If the unit is located in an area with high ambient temperature and/or high humidity, the air handler may be

subject to nuisance sweating of the casing. On these

installations, a wrap of 2” fiberglass insulation with a

vapor barrier is recommended.

• The factory recommends insulating the duct running

through any unconditioned spaces.

To reduce operating sound and vibration transmission use flexible canvas duct connections at the cabinet.

INSTALLATION INSTRUCTIONS

3. Attach supply ductwork. Seal connections between unit

and ductwork as required to reduce/eliminate air leakage.

4. Make electrical connections as specified in “Electrical”

section of this manual.

w

o

l

F

r

i

A

Figure 2 - Upflow Application

COUNTERFLOW INST ALLATION

For counterflow installations, the evaporator coil cabinet must

sit on top of the blower cabinet (Figure 3). NOTE: All panels

should be in place when installing the unit.

BLOWER WITH CASED EVAPORATOR COIL

INST ALLATION

TOP CABINET

BOTTOM CABINET

Figure 1

Secure the coil and blower together with the two connector

plates and screws supplied in the blower bag assembly. Use

one connector plate and six screws on each side of the unit.

If accessory electric heat is to be added, install now per the

instructions shipped with the heater kit.

UPFLOW INST ALLA TION

For upflow installations, the blower cabinet must sit on top of

the coil cabinet (Figure 2). NOTE: All panels should be in

place before installing the cabinet.

1. Place the blower and coil cabinet assembly upright on

the return duct or duct opening. Ensure that there is

ample support for the cabinet assembly and all attached

ductwork.

2. Connect refrigerant and condensate drain connections per

the evaporator coil installation instructions. Ensure refrigerant and drain lines do not interfere with service access to the unit.

w

o

l

F

r

i

A

figure 3 - Counterflow Application

NOTE: Supply ductwork for counterflow applications, must be

Class I. However, if combustible ductwork is used, sheet metal

protection is required.

1. Place the blower and coil cabinet assembly supply outlet

on the supply duct or duct opening. Ensure there is ample

support for the unit and all attached ductwork.

2. Connect refrigerant and condensate drain connections per

the evaporator coil installation instructions. Ensure refrigerant and drain lines do not interfere with service access to the unit.

3. Attach return ductwork. Seal connections between unit

and ductwork as required to reduce/eliminate air leakage.

4. Make electrical connections as specified in “Electrical”

section of this manual.

3

Page 4

HORIZONT AL INST ALLATION

For horizontal installations, the coil cabinet must be upstream

of the blower cabinet (Figures 5 and 6). NOTE: All panels

should be in place when installing the unit.

1. Set the unit near its final installation place. The unit must

be supported along the entire length of the unit. Rubber

isolation pads may be used to reduce sound and vibration

transmission. Ensure there is ample support for the unit

and all attached ductwork.

Blower Cabinet

Air Flow

Support

FIGURE 5 - Attic Installation

Rods

Air Flow

Support

FRONT VIEW

FOR OPTIONAL

SAFETY GND USE

MOUNTING BOLTS

SIDE VIEW

FEMALE CONNECTION S

FIGURE 4 - MBE Motor Orientation

Electrical Connections

Consult the local power company and local codes before installing this unit. All wiring must be in accordance with the

National Electrical Code as well as all local codes. Knockouts

have been provided on side and top of the cabinet for the installation of the electrical conduit. If the knockouts on the cabinet

sides are used for electrical conduit, an adapter ring must be

used in order to meet UL1995 safety requirements. Use Minimum Circuit Ampacity and type of wire to determine proper

wire size. The unit MUST be properly grounded. A ground lug

is provided in the unit.

Check all factory connections before connecting electrical power

to unit to ensure none were loosened or disconnected during

shipping and handling.

FIGURE 6 - Hanging Installation

2. If installed above a finished ceiling or living space, be sure

to put a secondary drain pan under the entire unit, and

pipe the drain separately from the main condensate drain.

3. Connect refrigerant and condensate drain connections per

the coil section installation instructions. Ensure refrigerant and drain lines do not interfere with service access to

the unit.

4. Attach return and supply ductwork. Seal connections.

5. Make electrical connections as specified in “Electrical”

section of this manual.

MBE Only: Counterflow and Horizontal Applications

Loosen motor mount and rotate motor (See Figure 4). Be sure

motor is oriented with the female connections on the casing

pointing down. If the motor is not oriented with the connections pointing down, water will collect in the motor and cause

premature failure.

NOTE: After rotating motor, tighten motor mount to secure

motor. Be sure that the gap between the motor and the insulation is the same as it was before loosening the motor mount.

This will ensure that the blower wheel is properly spaced inside the blower housing.

TO PREVENT PERSONAL INJURY OR DEATH DUE TO ELECTRICAL SHOCK ,

DISCONNECT THE ELECTRICAL POWER BEFORE ELECTRICALLY CONNECTING

THE UNIT.

TO AVOID THE RISK OF PROPERTY DAMA GE, PER SON AL INJURY OR FIRE

USE ONLY COPPER CONDUCTORS.

CAUTION

TO AVOID THE RISK OF PERSONAL INJURY, WIRING TO THE UNIT MUST BE

PROPERLY POLARIZED AND GROUNDED.

WARNING

ALL WI RING MU S T COMPLY WITH APPLI CABLE LOCAL AND NATIONAL C O DES.

TYPE AND LOCATION OF FUSED DISCONNECT SWITCH(ES) MUST COMPLY

WITH ALL APPLICABLE CODES AND PROVIDE OVERCURRENT PROTECTION AS

SHOWN ON THE NAMEPLATE.

HIGH VOL T AGE WIRING

If heater kits will not be installed, remove the proper size knockout for the electrical conduit connection. Connect electrical

conduit to the unit using two washers to make an approved

connection.

The power supply wires must be connected to the red and

black power wiring. Two wire nuts are provided in the bag

assembly for this connection. Wrap the wire nuts with electri-

4

Page 5

cal tape. (Insulated crimp type connectors, field supplied, may

be substituted for the wire nuts and electrical tape provided

proper size connectors are used.) A ground wire MUST be

connected to the ground lug inside the unit.

LOW VOL T AGE WIRING

Low voltage wiring connections are made at the top of the cabinet. See the “Thermostat Wiring” section of this manual for

typical low voltage wiring connections. A minimum 18 AWG

wire must be used for installations up to 50 feet and 16 AWG

wire for installations over 50 feet.

MISCELLANEOUS ELECTRICAL

The unit transformer is factory connected for 240 V operation.

If unit is to operate on 208 V, disconnect the red wires from

terminal 3 of the unit transformer and connect them to terminal

2 of the unit transformer.

INSTALLER: It is important to follow these instructions when

installing the MB series of air handlers.

THERMOST AT CONNECTIONS

The following composite wiring diagrams detail various configurations in which your MB air handler can be used. Examples

include single stage cooling, two stage cooling and heat pump

with single or two stage electric heating. All these configurations can be applied with convenient connections to outdoor

thermostat applications.

The following sections will be detailed:

• Single Stage Cooling (GMC Thermostat part # CHT1860 or equivalent)

• Heat Pump (GMC Thermostat part #HPT18-60 or equivalent)

• Two Stage Cooling with Conventional Two Stage Thermostat (GMC Thermostat part #CHT90-120 or equivalent)

• Two Stage Cooling with Conventional Two Stage Thermostat (Encoded with Add-on Diodes)

• Two Stage Encoded Thermostat from Goodman Manufacturing Part #CHET18-60

Each diagram details the connections between room thermostat and MB air handlers, and the connections between the

MB air handlers and the Condensing Unit (or Heat Pump) with

optional connections to Outdoor Thermostats. For each configuration,

refer to the explanation of the proper jumper(s) to remove for

the corresponding blower speed that will result in the programmed ECM

TM

motor on MBE units.

Important: When matching the MBE air handlers to a single

stage cooling unit or heat pump, remember to connect the “Y/

Y2” thermostat connection on the Variable speed board (VSTB)

to the thermostat. Connecting “Y1” will result in first stage

cooling blower speed.

Note: The two stage configurations are illustrated to detail connections to the two capacity condensing units and heat pumps.

An equivalent thermostat can be used in place of the Goodman

thermostat part number. The GMC thermostats listed are

mercury type.

When utilizing the encoded version of a conventional two stage

cooling and heating electronic thermostat (add-on diodes), a

hard wire “C” (common of 24V secondary voltage) must be

used. This encoded version will not work with a “power robbing”

thermostat (i.e. no common connection). One TSTWK01 kit

is required for the encoded applications on MBE units.

NOTE: When using a conventional two stage thermostat for cooling

or heat pump applications with a two stage compressor, dip switch

#4 must be set to the “OFF” position on MBE units.

MBE MOTOR

This section references the operation characteristics of the

MBE model motor only. The ECM control board is factory set

with the dipswitch #4 in the “ON” position and all other

dipswitches are factory set in the “OFF” position. For most

applications, the settings are to be changed according to

the electric heat size and the outdoor unit selection.

The MBE product uses a General Electric ECM

TM

motor. This

motor provides many features not available on the traditional

PSC motor. These features include:

• Improved Efficiency

• Constant CFM

• Soft Start and Stop

• Improved Humidity Control

MOTOR SPEED ADJUSTMENT

Each ECM™ blower motor has been preprogrammed for operation at 4 distinct airflow levels when operating in Cooling/

Heat Pump mode or Electric Heat mode. These 4 distinct

levels may also be adjusted slightly lower or higher if desired.

The adjustment between levels and the trim adjustments are

made by changing the dipswitch(s) either to an "OFF" or "ON"

position.

DIPSWITCH FUNCTIONS

The MBE air handler motor has an electronic control that contains an eight (8) position dip switch. The function of these

dipswitches are shown in Table 1.

Dipswitch Number Function

1

2

3

4

5

6

7

8

Table 1

Elec tric H e a t

N/A

Indoor Thermostat

Cooling & Heat Pump CFM

CFM Trim Adjust

CFM DELIVERY

Tables 2 and 3 show the CFM output for dipswitch combina-

tions 1-2, and 5-6.

5

Page 6

Model Switch 1 Switch 2 Electric Heat CFM

OFF OFF 1200

MBE1200

ON OFF 1000

OFF ON 800

ON ON 600

OFF OFF 1600

MBE1600

ON OFF 1400

OFF ON 1200

ON ON 1000

OFF OFF 1900

MBE2000

ON OFF 1600

OFF ON 1400

ON ON 1200

Table 2

Model Switch 5 Switch 6 Coo ling/HP CFM

OFF OFF 1200

MBE1200

ON OFF 1000

OFF ON 800

ON ON 600

OFF OFF 1600

MBE1600

ON OFF 1400

OFF ON 1200

ON ON 1000

OFF OFF 2000

MBE2000

ON OFF 1800

OFF ON 1600

ON ON 1200

Table 3

THERMOST A T “FAN ONL Y” MODE

During Fan Only Operations, the CFM output is 30% of the

cooling setting.

CFM TRIM ADJUST

Minor adjustments can be made through the dip switch combination of 7-8. Table 4 shows the switch position for this feature.

NOTE: The airflow will not make the decreasing adjustment in

Electric Heat mode.

CFM Switch 7 Switch 8

+10% ON OFF

-1 5 % O FF O N

TWO ST AGE HEA TING

When using staged electric heat, cut jumper PJ4 on the control board.

THERMOST A T WIRING

Use thermostat wiring diagram Figures 7 through 37 and

those provided with the thermostat when making these connections.

NOTE: If the MBE blower is used with heat pumps, remove the

“Y1-O” production wire.

MBR MOTOR

BLOWER PERFORMANCE DAT A

SPEED

HIGH

MEDIUM

LOW

Exter nal static is for b lower @ 230 vo lts. It doe s not

includ e coi l, air filter or electric heaters .

STATIC

0.1 1240 1500 1800 2160

0.2 1170 1460 1740 2080

0.3 1120 1360 1680 1990

0.4 1060 1280 1610 1890

0.5 980 1200 1520 1790

0.6 900 1110 1430 1690

0.1 900 1380 1540 1730

0.2 850 1320 1490 1670

0.3 790 1270 1450 1590

0.4 740 1200 1400 1520

0.5 680 1140 1350 1420

0.6 605 1040 1280 1320

0.1 650 1170 1130 1520

0.2 590 1130 1100 1450

0.3 540 1080 1070 1360

0.4 500 1020 1030 1290

0.5 430 950 990 1200

0.6 330 830 930 1090

SCFM

MBR0800**-*

SCFM

MBR1200**-*

SCFM

MBR1600**-*

SCFM

MBR2000**-*

Table 4

NOTE: If no adjustment is required, dipswitches 7 & 8 should be left

in the OFF position.

HUMIDITY CONTROL

When using a Humidistat (normally closed), cut jumper PJ6

on the control board. The Humidistat will only affect cooling

airflow by adjusting the Airflow to 85%.

6

Page 7

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

ROOM THER MO ST AT

R

WY

G

#18 GA. 4 WIRES W ITH

COOLING 3 WIRES WITHOUT

MBR UNIT

CONTACT OR

COIL

R

G

W

Y

TO CONDENSING

U NIT 24V. CONNE CTIO N S

#18 GA . 2 W IR ES

RED

GREEN

WHITE

BLUE

Figure 7- Low Voltage Wiring Diagram for Cooling Unit with optional heat kit 10KW and below

ROOM THERM OSTAT

W2

YGR

W

MBR UNIT

#18 G A. 4 WIRE WITH

COOLING 3 WIRE WITHOUT

OUTDOOR

THERMO STAT

(OP T IO NA L )

#18 GA. 2 WIRES

CONTACTOR

COIL

COND EN S ING

UNI T 2 4 V. CON N EC TIO NS

#18 GA. 2 W IRES

Y

W

R

G

RED

GREEN

WHITE

BROWN

BLUE

Figure 8 - Low Voltage Wiring Diagram for Cooling Unit with optional heat kit 15KW and above

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

7

Page 8

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

MBR

SYSTEM COMPOSITE DIAGRAM

800-2000

10 KW & BELOW

HEAT PUMP

W2

O

C

YR

O

W

BL

#18 GA. 5 WIRE

OUTDOOR THERMOSTAT

(OPTIONAL) MAKE ON FALL

CONVENTIONAL

ROOM THERMOSTAT

Y

CW2GRE

O

R

Y

SEE

NOTE

G

3

W

BL

#18 GA. 6 WIRE NEEDED WHEN O T IS USED

FIGURE 9

#18 GA. 7 WIRE

MBR UNIT

RED

R

BR

GREEN

WHITE

BLUE

SYSTEM COMPOSITE DIAGRAM

NOTES

1) OUTDOOR THERMOSTAT (OT-1) SHOULD BE THE

FIRST TO CLOSE AND THE FIRST TO OPEN.

2) IF OUTDOOR THERMOSTAT IS NOT USED. TIE WHITE

AND BROWN WIRES FROM AIR HANDLER TOGETHER.

3) REMOVE WIRE WHEN USING OUTDOOR T-STAT.

#18 GA. 7 WIRE NEEDED WHEN (2) OTs ARE USED

1200-2000

ABOVE 10 KW

C

B

L

U

E

SEE NOTE 1

HEAT PUMP

O

W

H

T

E

W2

I

O

R

A

N

G

E

YR

Y

E

L

L

O

W

BL

R

E

D

R

Y

O

W

OT-1

OT-2

#18 GA. 7 WIRE NEEDED WHEN (2) OTs ARE USED

MBR

CONVENTIONAL

ROOM THERMOSTAT

YOCW2GR

SEE

NOTE

E

G

SEE

3

NOTE

W

1

EHR

3

BL

#18 GA. 5 WIRE

NOMENCLATURE

OT - OUTDOOR THERMOSTAT (OPTIONAL)

MOF - MAKE ON FALL

EHR - EMERGENCY HEAT RELA Y (OP T IONAL)

FIGURE 10

#18 GA. 7 WIRE

MBR UNIT

RED

R

GREEN

2

2

4

WHITE

BROWN

BLUE

COLOR CODES

R - RED O - ORANGE

Y - YELLOW W - WHITE

BL - BLUE PK - PINK

V - VIOLET G - GREEN

BR - BROWN

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

8

Page 9

WARNING

HIGH VOLTAGE!

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

DISCO NNECT ALL POWER BEFORE SERV ICING.

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

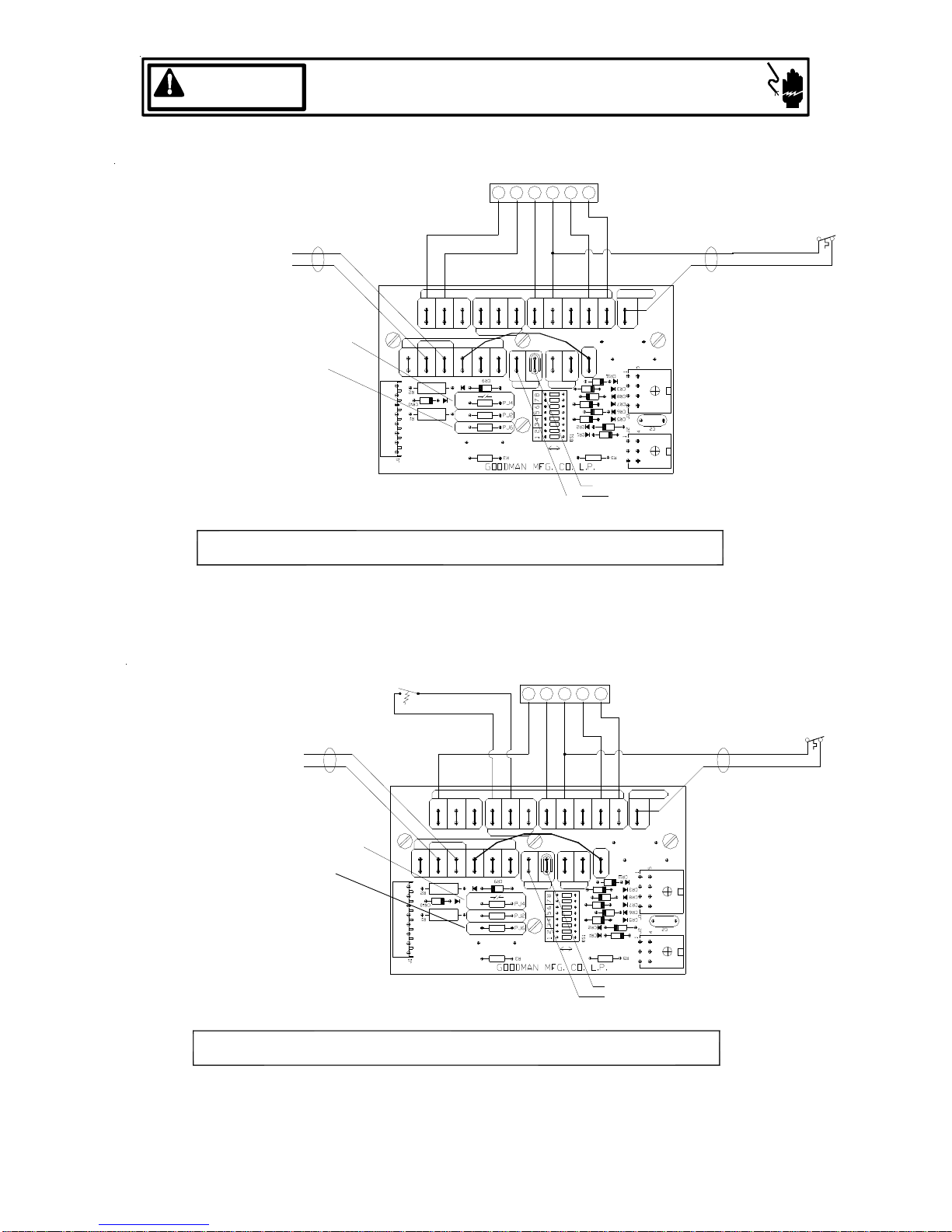

SINGLE ST AGE COOLING WITH SINGLE OR TWO STAGE HEATING

ROOM

THERMOSTAT

W2

W1

RGY

C

CONDENSING

UNIT

NOTES:

1.) Y/Y2 ENABLES HI SPD FAN COOLING

2.) E/W1 ENABLES LO SPD FAN HEATING

W/W2 ENABLES HI SPD FAN HEATING

3.) OT1 PJ4 MUST BE CUT FOR THIS CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.) DIP SWITCH #4 MUST BE IN THE "ON" POSITION

COOLING ONLY - 2 STAGE HEAT THERMOSTAT

CONDENSER

YCON

R

PLEASE REFER

TO MANUAL

FOR PROPER

DIP SWIT CH

CONFIGURATIO N.

OUTDOOR

THERMOSTAT

OTCORCE\W1 W/W2 Y1OT1 OT2

OUTDOOR

HEATPUMP

COM O W2 ED

W1

OT1

OT2

HUM

PN B1368274

(CFM)

Figure 11

THERMOSTATS

W1

HEATER

W2

IF NEEDED

W2

C R

24 VAC

SWITCH

DIP

ON

ROOM

THERMOSTAT

RGY

WC

Y1

OFF

HUMIDISTAT

Y/Y2GHUM

2nd STAGE HEATER

1st STAGE HEATER

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

CONDENSING

UNIT

NOTES:

1.) Y/Y2 ENABLES HI SPD FAN COOLING

2.) E/W1 ENABLES LO SPD FAN HEATING

E/W1 WITH OT CLOSED ENABLES HI SPD FAN HEATING

3.) OT1 PJ4 MUST BE CUT FOR THIS CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.) DIP SWITCH #4 MUST BE IN THE "ON" POSITION

THERMOSTATS

OUTDOOR

HEATPUMP

CONDENSER

YCONR

COM O W2 ED

W1

W2

OT1

OT2

(CFM)

HUM

PN B1368274

PLEASE REFER

TO MANUAL

FOR PROPER

DIP SWIT CH

CONFIGURATION.

1st STAGE ENABLED THRU ROOM T'STAT

2nd STAGE ENABLED THRU CLOSED OT

OT2OT1 Y1W/W2E\W1 C ROOTC

W1 W2

HEATER

IF NEEDED

HUMIDISTAT

HUMGY/Y2

Y1

C R

24 VAC

SWITCH

DIP

ON

OFF

2nd STAGE HEATER

1st STAGE HEATER

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

COOLING ONLY - 2 STAGE HEAT (1st ROOM T'STAT & 2nd OT)

Figure 12

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

9

Page 10

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

CONDENSING

UNIT

NOTES:

1.) Y/Y2 ENABLES HI SPD FAN COOLING

2.) E/W1 ENABLES LO SPD FAN HEATING

W/W2 WITH OT CLOSED ENABLES HI SPD FAN HEATING

3.) OT1 PJ4 MUST BE CUT FOR THIS CONFIGURATION

OT2 PJ2 MUST BE CUT FOR THIS CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HU MI DIT Y RIS E

5.) DIP SWITCH #4 MUST BE IN THE "ON" POSITION

1st STAGE ENABLED TH RU ROOM T'STAT

2nd STAGE ENABLED THRU ROOM T'STAT AND CLOSED OT2

COOLING ONLY - 2 STAGE HEAT (T'STAT ENABLED OT)

OUTDOOR

THERMOSTAT

R

PLEASE REFER

TO MANUAL

FOR PROPER

DIP SWITCH

CONFIGURATION.

E\W1

W/W2 O OTC OT1

HEATPUMP

CONDENSER

YCON

COM OW2W2 ED

OT1

OT2

HUM

(CFM)

Figure 13

OUTDOOR

W1

PN B1368274

ROOM

THERMOSTAT

W1

W2

C

IF NEEDED

THERMOSTATS

OT2 C RY1

W1 W2

HEATER

SWITCH

DIP

RG

CR

24 VAC

ON

Y

Y1

OFF

2nd STAGE HEATER

1st STAGE HEATER

Y/Y2G

HUMIDISTAT

HUM

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

HEAT PUMP WITH SINGLE OR TWO-STAGE HEATING (OPTIONS FOR EMERGENCY HEAT)

REMOVE

PRODUCTION

WIRE Y1-O

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

Figure 14

10

Page 11

WARNING

HIGH VOLTAGE!

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

DISCO NNECT ALL POWER BEFORE SERV ICING.

REMOVE

PRODUCTION

WIRE Y1-O

Figure 15

IF NEED ED

REMOVE

PRODUCTION

WIRE Y1-O

SWITCH

ON

OFF

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

Figure 16

11

Page 12

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

REMOVE

PRODUCTION

WIRE Y1-O

R YCON O W2

3.) OT1 PJ4 AND 0T2 PJ2 MUST BE CUT

FOR THIS CONFIGURATION

Figure 17

O

R

YCON O W2

OT1

OT2

CONFIGURATION.

O

OT2W1OT1OW/W2 OTC

OUTDOOR

W2W1

W2

G

CR

24 VAC

(OPTIO NAL)

GY1RC

REMOVE

PRODUCTION

Y1

WIRE Y1-O

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

Figure 18

12

Page 13

WARNING

(

)

HIGH VOLTAGE!

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

DISCO NNECT ALL POWER BEFORE SERV ICING.

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

TWO-ST AGE COOLING WITH CONVENTIONAL TWO-STAGE THERMOST AT

ROOM

THERMOSTAT

C

W

2-SPD

CONDENSING

C

UNIT

E

E

E

HUMIDISTAT

(OPTIONAL)

NOTES:

1.) Y1 ENABLES LO SPD FAN COOLING

Y/Y2 ENABLES HI SPD FAN COOLING

2.) E/W1 ENABLES HI SPD FAN HEATING

3.) IF OT1 PJ4 JUMPER IS CUT E/W1 ENABLES

LOW SPD FAN HEATING

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.)DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

2 SPD COOLING ONLY - WITH 1 STAGE ELECTRIC HEAT

2-SPD

CONDENSING

UNIT

C

NOTES:

1.) Y1 ENABLES LO SPD FAN COOLING

Y/Y2 ENABLES HI SPD FAN COOLING

2.) E/W1 ENABLES HI SPD FAN HEATING

3.) IF OT1 PJ4 JUMPER IS CUT E/W1 ENABLES

LOW SPD FAN HEATING

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.)DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

Y2

Y1

SEE NOTE 4

CONDENSER

YCON

COM O W2 ED

PLEASE REFER

TO MANUAL

FOR PROPER

CFM

DIP SWITCH

CONFIGURATION.

HEATPUMP

HUM

W1

THERMOSTA TS

OUTDOOR

W2

W1 W2

HEATER

S

WI

DI

P

Y1W/W2EW1 OOTC

24 VAC

O

O

HUMIDISTAT

HUMGY/Y2

Y1

1st STAGE HEATER

Figure 19

ROOM

C

\

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

THERMOSTAT

W

2 SPD COOLING ONLY - WITH 2 STAGE HEAT THERMOSTAT

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

Figure 20

13

1st STAGE HEATER

Page 14

HIGH VOLTAGE!

WARNING

C

NOTES:

1.) Y1 ENABLES LO SPD FAN COOLING

Y/Y2 ENABLES HI SPD FAN COOLING

2.) E/W1 ENABLES HI SPD FAN HEATING

3.) IF OT1 PJ4 JUMPER IS CUT E/W1 ENABLES

LOW SPD FAN HEATING

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.)DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

2-SPD

CONDENSING

UNIT

Y2

Y1

DISCO NNECT ALL POWER BEFORE SERV ICING.

ROOM

C

\

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

THERMOSTAT

W

2 SPD COOLING ONLY - WITH 2 STAGE HEAT THERMOSTAT

2-SPD

CONDENSING

UNIT

NOTES:

1.) Y1 ENABLES LO SPD FAN COOLING

Y/Y2 ENABLES HI SPD FAN COOLING

2.) E/W1 ENABLES LOW SPD FAN HEATING

W/W2 WITH OT CLOSED ENA BLES HI SPD FAN HEATING

3.) OT1 PJ4 MUST BE CUT FOR THIS CONFIGURATION

OT2 PJ2 MUST BE CUT FOR THIS CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.)DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

Figure 21

OUTDOOR

THERMOSTAT

PLEASE REFER

TO MANUAL

FOR PROPER

DIP SWITCH

YCONR

COMW2W2 ED

(CFM)

HEATPUMP

HUM

W1

W1 W2

THERMOSTATS

OUTDOOR

ROOM

THERMOSTAT

R

C

IF NEEDED

C RY1

W1 W2

CR

HEATER

24 VAC

SWITCH

DIP

ON

1st STAGE HEATER

Y1 Y2

G

Y1

OFF

HUMIDISTAT

HUM

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

2 SPD COOLING ONLY - 2 STAGE HEAT (T'STAT ENABLED OT)

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

Figure 22

14

2nd STAGE HEATER

1st STAGE HEATER

Page 15

WARNING

HIGH VOLTAGE!

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

DISCO NNECT ALL POWER BEFORE SERV ICING.

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

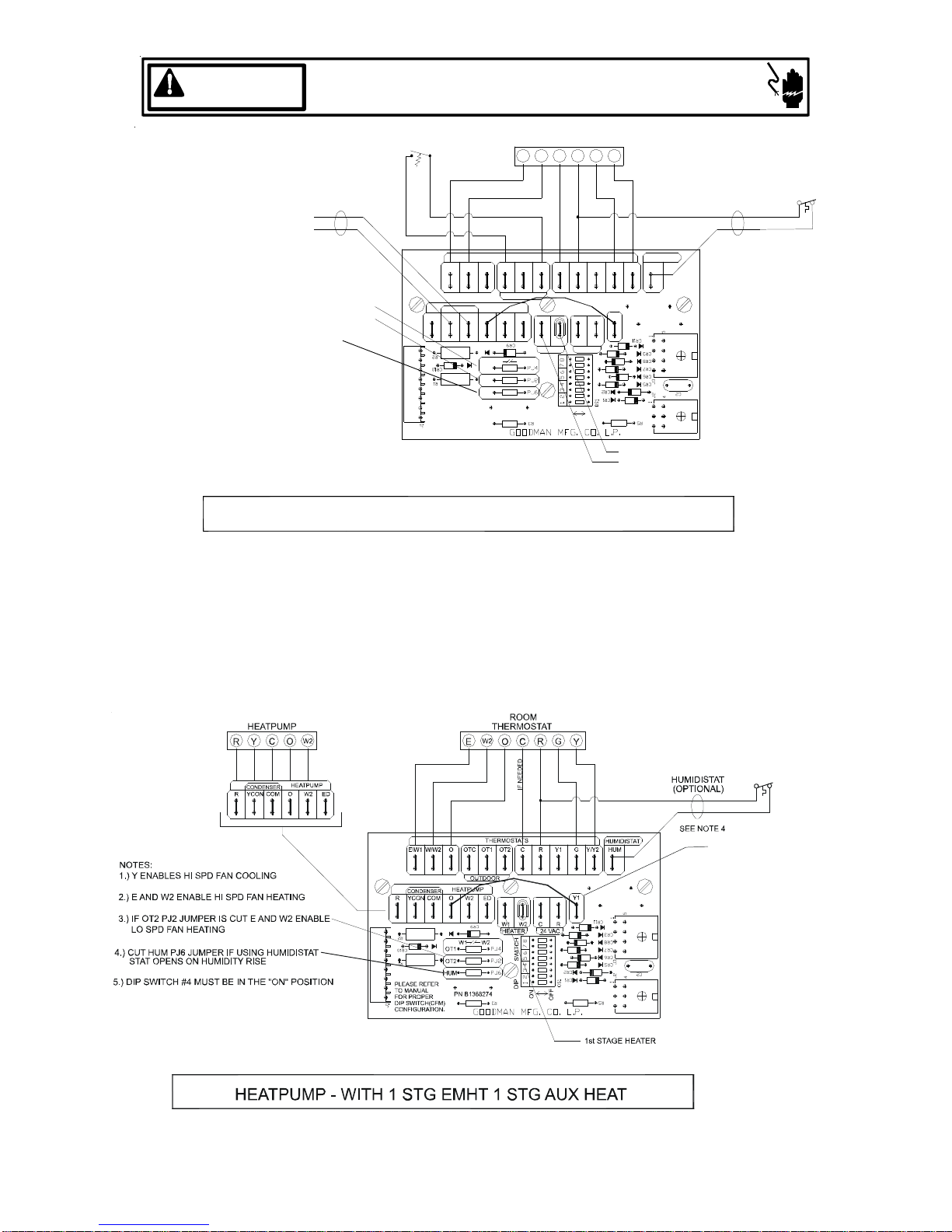

HEAT PUMP WITH SINGLE OR TWO STAGE HEATING WITH CONVENTIONAL THERMOSTAT

(OPTIONS FOR EMERGENCY HEAT)

ROOM

HEATPUMP

RYCO

W2

THERMOSTAT

W2

ECRG

O

Y

HEATPUMP

YCONR COM O W2 ED

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.) E AND W2 ENABLE HI SPD FAN HEATING

3.) IF OT2 PJ2 JUMPER IS CUT E AND W2 ENABLE

LO SPD FAN HEATING

4.)

CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.) DIP SWITCH #4 MUST BE IN THE "ON" POSITION

HEATPUMP - WITH 1 STG EMHT 1 STG AUX HEAT

CO

HEATPUMP

O

W2

W2 ED

YR

CONDENSER

YCON COM

YCONR

COM O W2 ED

PLEASE REFER

TO MANUAL

FOR PROPER

DIP SWITCH

(CFM)

CONFIGURATION.

THERMOSTATS

OUTDOOR

HEATPUMP

W1

W2

OT1

OT2

HUM

Figure 23

E

IF NEEDED

OT2OT1 Y1W/W2E\W1 C ROOTC

W1 W2

HEATER

SWITCH

DIP

THERMOSTAT

W2

O

C R

24 VAC

ON

ROOM

C

IF

N

EE

D

E

HUMIDISTAT

HUMIDISTAT

HUMGY/Y2

(OPTIONAL)

REMOVE

PRODUCTION

Y1

OFF

YG

R

WIRE Y1-O

HUMIDISTAT

(OPTIONAL)

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.)

E ENABLES LOW SPD FAN HEATING

W2 ENABLES HI SPD FAN HEA TI N G

3.) OT1 PJ4 MUST BE CUT FOR THIS CONFIGURATION

4.) CUT HUM PJ6 JUM PER IF USING HUMIDI STAT

STAT OPENS ON HUMIDITY RISE

5.) DIP SWITCH #4 MUST BE IN THE “ON” POSITION

HEATPUMP - 2 STG EMHT 1 STG AU X HEAT

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

CONDENSER

YCON COM

R

R2

CR10

R1

PLEASE REFER

TO MANUAL

FOR PR OPER

DIP SWITCH

J1

CONFIGU RATI O N.

O

W/W2E\W1

HEATPUMP

O

W2 ED

W1 W2

OT1

OT2

HUM

PN B1368274

Figure 24

15

THERMO STATS

OT1OTC

OUTDOOR

CR9

Y1RCGY/Y2OT2 HUM

HUMIDISTAT

SEE NOTE 4

REMOVE

PRODUCTION

Y1

CR

W2W1

24 VAC

S

WI

PJ4

TC

H

PJ2

PJ6

DI

P

R3

CR2

CR1

12345678

DS1

O

O

FF

N

5

1

CR11

CR3

CR8

CR7

CR6

CR5

C2

J2 J3

4

1

2nd STAGE HEATER

1st STAG E H E ATER

WIRE Y1-O

Page 16

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

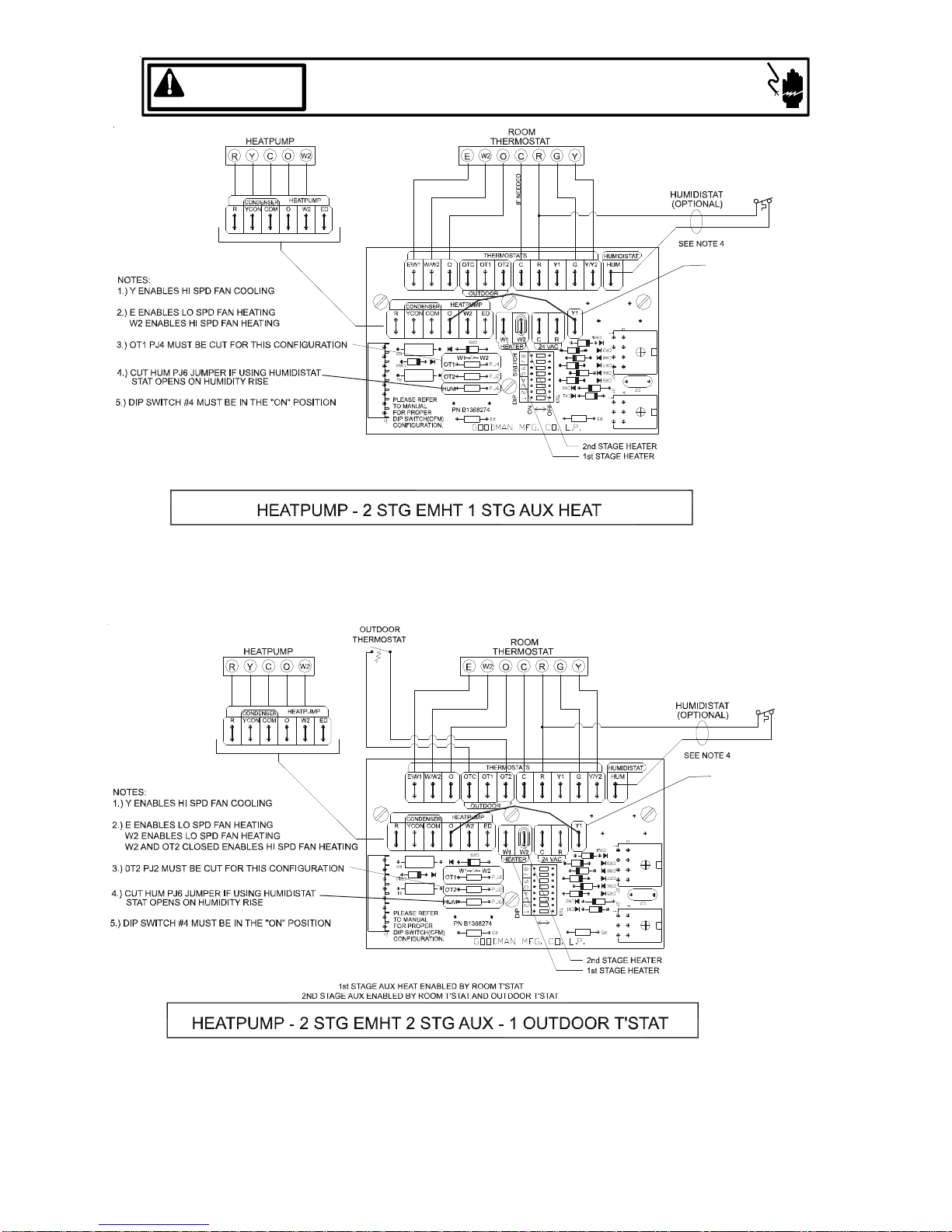

HEATPUMP

W2

HEATPUMP

COM W2

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.) E ENABLES LO SP D FAN HEATING

W2 ENAB LES L O W SPD FAN HEATING

W2 AND OT2 CLOS ED EN A BLES HI SPD FAN H EATING

3.) OT1 PJ2 MUST BE CUT FOR THIS CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.) DIP SWITCH #4 MUST BE IN THE "ON" POSITION

HEATPUMP - 2 STG EMHT 2 STAG AUX - 1 OUTDOOR T-STAT

OUTDOOR

THERMOSTAT

J1

O

W/W2E\W1

HEATPUM P

COM

W1 W2

OT1

OT2

HUM

PN. B1368274

Figure 25

ROOM

THERMOSTAT

W2

IF NEEDED

THERMO STATS

OT1OTC

OUTDOOR

W2

W1

W2

24 VAC

PJ4

PJ2

PJ6

DI

12345678

P

GOODMAN MFG. CO. L.P.

HUMIDISTAT

Y/Y2OT2 HUM

5

1

J2 J3

4

1

2nd STAGE HEATER

1ST STAGE HEATER

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

REMOVE

PRODUCTION

WIRE Y1-O

CONDEN SER

COM

RYCON

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.)

E ENABLES LOW SPD FAN HEATING

W2 AND O T1 CLOSED ENABLES LOW SPD FAN HEATING

W2 AND O T2 CLOSED ENABLES HI SPD FAN HEATING.

3.) IF OT2 PJ4 AND OT2 PJ2 MUST BE CUT FOR THIS

CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

ED

5.) DIP SWITCH #4 MUST BE IN THE “ON” POSITION

NO AUX HEAT IN HEATPUMP MODE UNT IL OUTDOO R T’STAT CLOSES

CONDENSER

RYCONCOM

J1

O

HUM

PN. B13682704

Figure 26

ROOM

THERMOSTATHEATPUMP

IF

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

RC HUM

REMOVE

PRODUCTION

ED

CR

TC

H

DS1

N

5

1

J2 J3

4

1

WIRE Y1-O

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

16

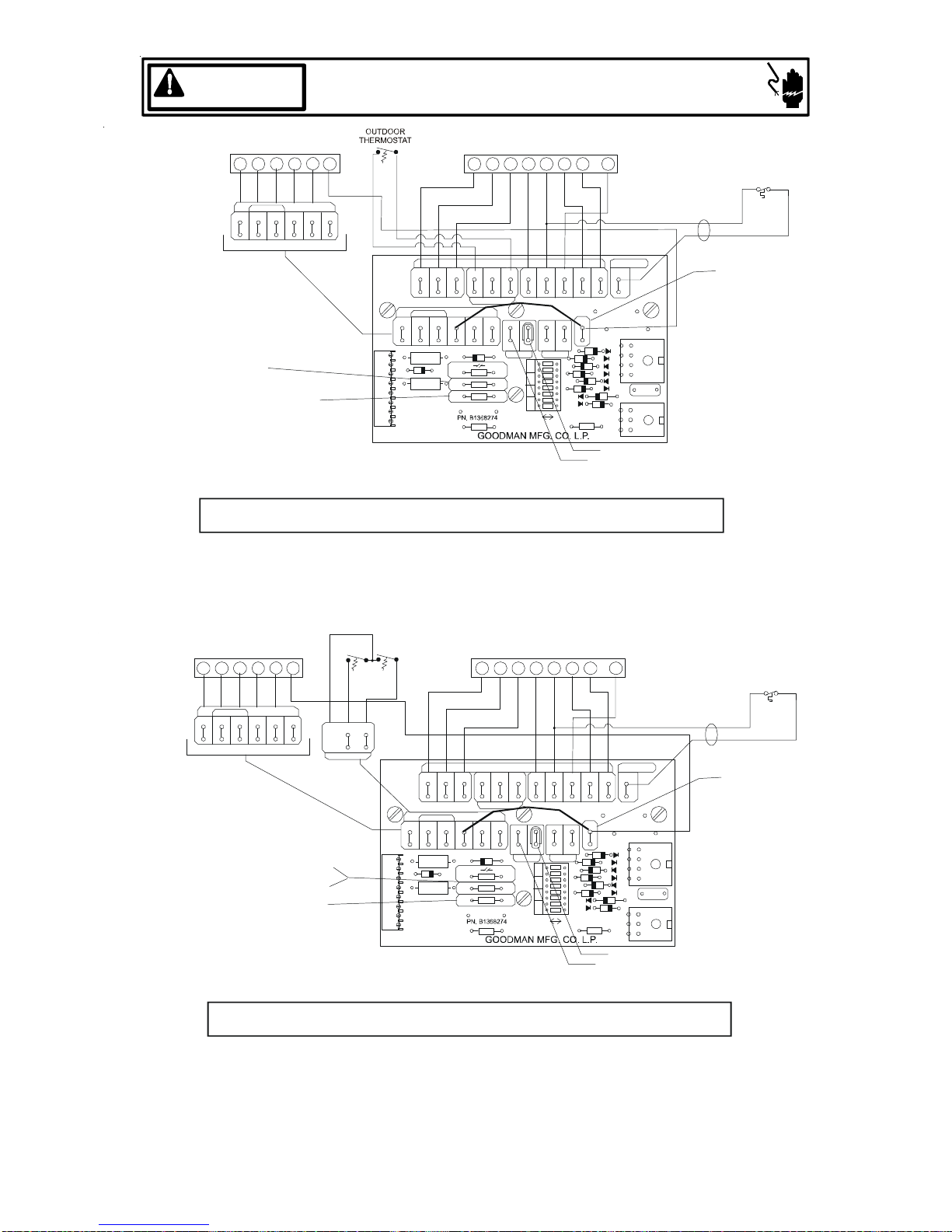

Page 17

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

OUTDOOR

THERMOSTAT

W2

THERMOSTAT

W2

ROOM

HEATPUMP

W2

COM

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.) E ENABLES LO SPD FAN HEATING

W2 AND OT2 CLOSED ENABLES HI SPD FAN HEATING

3.) OT1 PJ4 AND OT2 PJ2 MUST BE CUT

FOR THIS CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.) DIP SWITCH #4 MUST BE IN THE "ON" POSITION

IF NEEDED

THERMOSTATS

W/W2E\W1

COM W2

J1

OT1OTC

O

OUTDOOR

HEATPUMP

W1

W1 W2

PJ4

OT1

PJ2

OT2

PN. B1368274

PJ6

DI

P

HUM

GOODMAN MFG. CO. L.P.

W2

24 VAC

12345678

HUMIDISTAT

Y/Y2OT2 HUM

1

J2 J3

1

2nd STAGE HEATER

1ST STAGE HEATER

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

REMOVE

PRODUCTION

5

4

WIRE Y1-O

HEATPUMP - 2 STG EMHT 1 STG AUX - 1 OUTDOOR T'STAT

Figure 27

2 SPEED HEAT PUMP WITH SINGLE OR TWO-STAGE HEATING

(OPTIONS FOR EMERGENCY HEAT) WITH CONVENTIONAL TWO-STAGE THERMOSTAT

HEATPUMP

COM W2

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.)

E ENABLES LOW SPD FAN HEATING

3.) IF OT2 PJ2 JUMBER IS CUT “E’ AND “W2”

ENABLE LOW SPD FAN HEATING

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.) DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

HEATPUMP - WITH 1 STG EMHT 1 STG AUX HEAT

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

ROOM

W2

O

W/W2E\W1

HEATPUMP

COM

W1 W2

OT1

OT2

HUM

J1

PN. B1368274

THERMOSTAT

W2

IF NEEDED

THERMOSTATS

OT1OTC

OUTDOOR

W2

W2W1

24 VAC

PJ4

PJ2

PJ6

DI

12345678

P

GOODMAN MFG. CO. L.P.

HUMIDISTAT

Y/Y2OT2 HUM

5

1

J2 J3

4

1

2nd STAGE HEATER

1st STAGE HEATER

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

REMOVE

PRODUCTION

WIRE Y1-O

Figure 28

17

Page 18

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

2 SPD HEATPUMP

W2

HEATPUMP

O

W2 ED

Y1

Y2R

CO

CONDENSER

YCON COM

R

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.) E AND W2 ENABLE HI SPD FAN COOLING

3.) IF OT2 PJ2 JUMPER IS CU T “E” AND “W2”

ENABLE LOW SPD FAN HEATING

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.) DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

HEAT PUMP - WITH 1 STG EMHT 1 STG AUX HEAT

W/W2E\W1

CONDENSER

R

YCON

R2

CR10

R1

PLEASE REFER

TO MANUAL

FOR PROPER

DIP SWITCH

J1

CONFIGURATION.

W2

EC

THERMOSTATS

OT1OTC

O

OUTDOOR

HEATPUMP

COMOW2 ED

CR9

W1 W2

OT1

OT2

HUM

Figure 29

ROOM

THERMOSTAT

O

IF NEEDED

W1

W2

S

WI

PJ4

TC

H

PJ2

PJ6

DI

12345678

P

O

N

R3

RY2G

Y1RC G Y/Y2OT2 HUM

R

C

24 VAC

DS1

O

FF

Y1

HUMIDISTAT

Y1

1

CR11

CR3

CR8

CR7

CR6

CR5

CR2

J2 J3

CR1

1

2nd STAGE HEATER

1st STAGE HEATER

5

4

C2

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

REMOVE

PRODUCTION

WIRE Y1-O

2 SPD HEATPUMP

W2 W2

CO

CONDENSER

COMOW2 ED

RYCON

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.)

E ENABLES LOW SPD FAN HEATING

W2 ENABLES HI SPD FAN HEATING

3.) IF OT2 PJ4 MUST BE CUT FOR THIS

CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

Y1 Y1

HEATPUMP

5.) DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

HEAT PUMP - 2 STG EMHT 1 STG AUX HEAT

CONDENSER

RYCON

R2

CR10

R1

PLEASE REFER

TO MANUAL

FOR PROPER

J1

DIP SWITCH

CONFIGURATION.

ECY2R RY2G

O

W/W2E\W1

HEATPUMP

O

W2 ED

COM

W1 W2

OT1

OT2

HUM

Figure 30

THERMOSTATS

OT1OTC

OUTDOOR

CR9

PJ4

PJ2

PJ6

ROOM

THERMOSTAT

O

IF NEEDED

W2W1

C

24 VAC

S

WI

TC

H

DI

12345678

P

O

N

R3

Y1RC G Y/Y2OT2 HUM

Y1

R

CR2

CR1

DS1

O

FF

1st STAGE HEATER

HUMIDISTAT

5

1

CR11

CR3

CR8

CR7

CR6

CR5

C2

J2 J3

4

1

2nd STAGE HEATER

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

REMOVE

PRODUCTION

WIRE Y1-O

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

18

Page 19

WARNING

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

2-SPD HEATPUMP

Y2R

CONDENSER

COM

RYCON

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.)

E ENABLES LOW SPD FAN HEATING

W2 ENABLES LOW SPD FAN HEATING

W2 AND OT2 CLOSED ENABLES HI SPD

FAN HEATING.

3.) IF OT2 PJ4 MUST BE CUT FOR THIS

CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

HEATPUMP

O

W2 ED

Y1

W2

CO

5.) DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

2ND STAGE AUX ENABLED BY ROOM T’STAT AND OUTDOOR T’STAT

HEATPUMP - 2 STG EMHT 2 STG AUX - 1 OUTD OOR T'S TAT

ROOM

THERMOSTAT

W2

E

O

C

R

IF NEEDED

THERMOSTATS

OT1OTC

O

W/W2E\W1

OUTDOOR

HEATPUMP

CONDENSER

RYCONCOMOW2 ED

CR9

W1

C

W2

R2

CR10

R1

PLEASE REFER

TO MANUAL

FOR PROPER

J1

DIP SWITCH

CONFIGURATION.

HUM

OT1

OT2

W1 W2

PJ4

PJ2

PJ6

24 VAC

S

WI

TC

H

DI

12345678

P

O

O

FF

N

R3

1ST STAGE AUX HEAT ENABLED BY ROOM T’STAT

Figure 31

Y2G

Y1

Y1

CR2

CR1

DS1

1st STAGE HEATER

HUMIDISTAT

CR11

2nd STAGE HEATER

Y1RC G Y/Y2OT2 HUM

R

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

REMOVE

PRODUCTION

WIRE Y1-O

5

1

CR3

CR8

CR7

CR6

CR5

C2

J2 J3

4

1

2 SPD HEATPUMP

W2 W2

CO

CONDENSER

COMOW2 ED

RYCON

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.)

E ENABLES LOW SPD FAN HEATING

W2AND OT1 CLOSED ENABLES LOW SPD FAN HEATING

W2 AND OT2 CLOSED ENABLES HI SPD FAN HEATING.

3.) OT1 PJ4 AND OT2 PJ2 MUST BE CUT FOR THIS

CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

Y1 Y1O

HEATPUMP

OT1

OT1 OT2OTC

OUTDOOR

5.) DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

NO AUX HEAT IN HEATPUMP MODE UNTIL OUTDOOR T’STAT CLOSES

HEAT PUMP - 2 STG EMHT 2 STG AUX - 2 OUTDOOR T'STATS

OT2

CONDENSER

RYCON

R2

CR10

R1

PLEASE REFER

TO MANUAL

FOR PROPER

DIP SWITCH

J1

CONFIGURATION.

ECY2R RY2G

OTCW/W2E\W1

O

OUTDOOR

HEATPUMP

COMOW2 ED

W1 W2

OT1

OT2

HUM

Figure 32

ROOM

THERMOSTAT

THERMOSTATS

OT1

CR9

W1

S

WI

PJ4

TC

H

PJ2

PJ6

DI

P

R3

IF NE E DED

W2

12345678

O

N

Y1RC G Y/Y2OT2 HUM

Y1

R

C

24 VAC

CR2

CR1

DS1

O

FF

HUMIDISTAT

5

1

CR11

CR3

CR8

CR7

CR6

CR5

J2 J3

4

1

2nd STAGE HEATER

1st STAGE HEATER

C2

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

REMOVE

PRODUCTION

WIRE Y1-O

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

19

Page 20

WARNING

2-SPD HEATPUMP

CO

Y2R

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

OUTDOOR

THERMOSTAT

W2

Y1

E

ROOM

THERMOSTAT

W2

O

Y2G

C

R

Y1

CONDENSER

RYCON

COM

HEATPUMP

O

W2 ED

IF NEEDED

HUMIDISTAT

(OPTIONAL)

SEE NOTE 4

Y1

CR2

CR1

DS1

1st STAGE HEATER

HUMIDISTAT

5

1

CR11

CR3

CR8

CR7

CR6

CR5

C2

J2 J3

4

1

2nd STAGE HEATER

REMOVE

PRODUCTION

WIRE Y1-O

NOTES:

1.) Y ENABLES HI SPD FAN COOLING

2.)

E ENABLES LOW SPD FAN HEATING

W2 AND OT2 CLOSED ENABLES HI SPD

FAN HEATING

3.) OT1 PJ4 AND OT2 PJ2 MUST BE CUT FOR THIS

CONFIGURATION

4.) CUT HUM PJ6 JUMPER IF USING HUMIDISTAT

STAT OPENS ON HUMIDITY RISE

5.) DIP SWITCH #4 MUST BE IN THE “OFF” POSITION

CONDENSER

RYCON

R2

CR10

R1

PLEASE REFER

TO MANUAL

FOR PROPER

J1

DIP SWITCH

CONFIGURATION.

THERMOSTATS

OT1OTC

O

W/W2E\W1

OUTDOOR

HEATPUMP

O

W2 ED

COM

CR9

W1 W2

PJ4

OT1

PJ2

OT2

PJ6

HUM

R3

W2W1

S

WI

TC

H

DI

P

12345678

C

24 VAC

O

O

FF

N

Y1RC G Y/Y2OT2 HUM

R

NO AUX HEAT IN HEATPUMP MODE UNTIL T’STAT CLOSES

HEATPUMP - 2 STG EMHT 1 ST G AUX - 1 OUTD OOR T'S TAT

Figure 33

TWO STAGE COOLING WITH CONVENTIONAL TWO STAGE THERMOSTAT

(ENCLOSED WITH ADD ON 1N006 DIODES)

TSTWK01 KIT REQUIRED

TO Y ON

TSTWK01 BOARD

1N4005

2 SPD REMOTE

DIODES

CONDENSING

UNIT

TO COMMON ON

24 V

230 V

TSTWK01

TRANSFORMER

TSTWK01 BOARD

TSTWK01

BOARD

ENCODED THERMOSTAT

TEST

ZD3

ZD2

ZD1

PLEASE RE FER

TO MANUAL

FOR PROPER

PN. B136 8271 REV. A

NOTES:

1.) STAT OPENS ON HUMIDITY RISE

2.) DIP SWITCH #4 MUST BE IN THE ON POSITION

DIP SWITCH

CONFIGURATION.

HEATPUMP

HUM

PN. B1368274

THERMOSTATS

PJ4

PJ2

PJ6

Y1 Y/Y2 HUM

24 VAC

CUT OT1 PJ4 FOR 2-STAGE HEAT OPERATION

CUT HUM PJ6 FOR HUMIDISTAT OPERATION

ENCODE D 2 SP D COOLING - WITH 1 OR 2-STG HEAT

HUMIDISTAT

Y1

2ND STAGE HEATER

1ST STAGE HEATER

Figure 34

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

20

HUMIDISTAT

HUMIDISTAT

(OPTIONAL)

(OPTIONAL)

SEE NOTE 1

Page 21

WARNING

R

2 SPD REMOTE

CONDENSING

UNIT

24 V

230 V

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

TO Y ON

TSTWK01 BOARD

OUTDOOR

THERMOSTAT

W1

W2

TO COMMON ON

TSTWK01 BOARD

TSTWK01

BOARD

ENCODED THERMOSTAT

PN. B1368 271 REV. A

NOTES:

1.) OT2 CLOSED AND W2 DEMAND ENABLES

2.) STAT OPENS ON HUMIDITY RISE

3.) DIP SWITCH #4 MUST BE IN THE ON POSITION

OT1

OT2

HUM

OTCE\W1

OUTDOOR

W2

W1 W2

THERMOSTATS

OT1

W1

PJ4

PJ2

PJ6

Y/Y2OT2 HUM

W2

24 VAC

DI

P

2ND STAGE HEATER

1ST STAGE HEATER

CUT OT2 PJ2 FOR THIS CONFIGURATION

CUT HUM PJ6 FOR HUMIDISTAT OPERATION

HUMIDISTAT

HUMIDISTAT

(OPTIONAL)

SEE NOTE 2

TSTWK01

TRANSFORMER

ENCO D ED 2 SPD COO LI NG - WITH 1 OR 2 STG HEAT - 1 OT

Figure 35

ENCODED TWO STAGE COOLING WITH GMC THERMOSTAT PART #CHET18-60

TSTWKO1 KIT REQUIRED

TO Y ON

TSTWK01 BOARD

CHET 18-60

ENCODED

2 SPD REM O T E

CONDENSING

UNIT

24 V

Y1

Y2

TO COMMON ON

TSTWK01 BOARD

TSTWK01

BOARD

Y/Y2

YLO/Y1

C/X

THERMOSTAT

GOODMAN MFG. CO. L.P.

NOTES:

1.) STAT OPENS ON HUMIDITY RISE

2.) DIP SWITCH #4 MUST BE IN THE ON POSITION

CONDENSER

COMOW2 ED

RYCON

PLEASE REFER

TO MAN UAL

FOR PROPER

DIP SWITCH

CONFIGURATION.

THERMOSTATS

OT1OTCW/W2E\W1

OUTDOOR

HEATPUMP

W1

W1 W2

PJ4

OT1

PJ2

OT2

PJ6

HUM

GOODMAN MFG. CO. L.P.

HUMIDISTAT

Y1RC G Y/Y2OT2 H UM

Y1

R

C

W2

24 VAC

S

WI

TC

H

DI

12345678

P

O

O

FF

N

2ND STAGE HEATER

1ST STAGE HEATER

CUT OT2 PJ2 FOR 2-STAGE HEAT OPERATION

CUT HUM PJ6 FOR HUMIDISTAT OPERATION

HUMIDISTAT

(OPTIONAL)

SEE NOTE 1

TSTWK01

TRANSFORME

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

ENCODED 2 SPD COOL ING - WIT H 1 OR 2 STG HEAT

Figure 36

21

Page 22

WARNING

2 SPD REM O T E

CONDENSING

UNIT

TSTWK01

TRANSFORMER

HIGH VOLTAGE!

DISCO NNECT ALL POWER BEFORE SERV ICING.

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

TO Y ON

TSTWK01 BOARD

CHET 18-60

ENCODED

Y1

Y2

TO COMMON ON

TSTWK01 BOARD

TSTWK01

BOARD

Y/Y2

YLO/Y1

C/X

THERMOSTAT

ENCODED THERMOSTAT

ZD3

ZD2

K3

Q2

GOODMAN MFG. CO. L.P.

ZD1

Q1

K1

K2

PN. B1368271 REV. A

NOTES:

1.) OT2 CLOSED AND W2 DEMAND ENABLES

2ND STG HEAT AND HI FAN

2.) STAT OPENS ON HUMIDITY RISE

3.) DIP SWITCH #4 MUST BE IN THE ON POSITION

RYCONCOM

P1

PLEASE REFER

TO MAN UAL

FOR PROPER

DIP SWITCH

J1

CONFIGURATION.

OUTDOOR

THERMOSTAT

W/W2E\W1

OUTDOOR

HEATPUMP

O

W2 ED

W1 W2

OT1

OT2

HUM

GOODMAN MFG. CO. L.P.

THERMOSTATS

OT1OTC

PJ4

PJ2

PJ6

Y1RC G Y/Y2OT2 HUM

RY1W2W1

C

24 VAC

S

WI

TC

H

DI

12345678

P

O

O

FF

N

CUT HUM PJ6 FOR HUMIDISTAT OPERATION

ENCODED 2 SPD COOLING - WITH 1 OR 2 STG HEAT - 1 OT

Figure 37

HUMIDISTAT

(OPTIONAL)

HUMIDISTAT

J2 J3

2ND STAGE HEATER

1ST STAGE HEATER

CUT OT2 PJ2 FOR THIS CONFIGURATION

SEE NOTE 2

INPUT

FROM

THERMOSTAT

POWER

TO

THERMOSTAT

Troubleshooting Encoded Two Stage Cooling Thermostats Options

T

E

S

T

TEST FUNCTION SIGNAL OUT SIGNAL FAN

INDICATION

S1 +

* S1 - *

S1 + -

S2 +

S2 -

S2 + -

S3 +

* S3 - *

* S3 + - *

R + COM

NOTES:

1.) THE TEST SPADE CAN BE CONNECTED TO ANY OTHER TEST SPADE ON EITHER BOARD.

2.) THE + LED WILL BE RED AND WILL LIGHT TO INDICATE + HALF CYCLES.

THE - LED WILL BE GREEN AND WILL LIGHT TO INDICATE - HALF CYCLES.

BOTH RED AND GREEN ILLUMINATED WILL INDICATE FULL CYCLES DENOTED BY + - .

3.) SIGNAL OUT CONDITION FOR W1 , W2 HEATER WILL BE AFFECTED BY OT1 PJ4 AND OT2 PJ2

JUMPERS AND OUTDOOR THERMOSTATS ATTACHED. THE TABLE ABOVE ASSUMES OT1 PJ4 IS

REMOVED AND OT2 PJ2 IS MADE WITH NO OUTDOOR THERMOSTATS ATTACHED.

LOW SPEED COOL

* LO SPEED COOL *

HI SPEED COOL

LO SPEED HEAT

O

LO SPEED HEAT

HI SPEED HEAT

G

N/A

N/A

24 VAC

GND

YCON +

* YCON - *

YCON + -

W1 HEATER

ED -

( FUTURE USE )

W1 HEATER

W2 HEATER

NONE

N/A

N/A

R TO T'STAT

COM TO T'STAT

Y1

* Y / Y2 HI *

Y / Y2

W / W1

O

W / W1

EM / W2

G

N/A

N/A

R

C1 , C2

* ERROR CONDITION ( DIODE ON THERMOSTAT BACKWARDS )

SEE NOTE 3

SEE NOTE 3

* ERROR CONDITION ( S3 CAN ONLY READ + )

* ERROR CONDITION ( S3 CAN ONLY READ + )

The chart above provides troubleshooting for either version of the encoded thermostat option. This provides diagnostic information for the GMC CHET18-60 or a conventional two cool / two stage heat thermostat with IN4005 diodes added as called out in

the above section.

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

22

Page 23

A test lead or jumper wire can be added from the test terminal

to any terminal on the B13682-74 or B13682-71 variable speed

terminal board and provide information through the use of the

LED lights on the B13682-71 VSTB control. Using this chart,

a technician can determine if the proper input signal is being

received by the encoded VSTB control and diagnose any problems that may be relayed to the output response of the B1368274 VSTM control.

Example:

st

The system is calling for 1

stage cooling operation. The proper

input signal from either thermostat option will cause the red “+”

LED light to illuminate when the test terminal and the “S1”

terminal are connected using a test lead or jumper wire. This

verifies proper input from the thermostat. The proper output is

a “YCON” signal to the RSG condensing unit. When a test

lead or jumper is connected between Test and YCON, the red

“+” LED will illuminate. The corresponding response from the

CKTS control will be an illuminated “LOW” LED light and 24V

applied to the Low capacity contactor through the “LOW” terminal output.

This similar procedure can be utilized on any terminal on the

VSTB controls. The chart above indicates the proper input and

LED status as well as the corresponding out signal. Each

mode of operation must be verified during the check out procedure when the units are installed. The LED light provides a

easy method to verify operation without the use of a multimeter.

23

Page 24

All of our systems are designed and manufactured with the same high quality standards regardless of size or efficiency.

We have designed these units to significantly reduce the most frequent causes of product failure. They are simple to

service and forgiving to operate. We use quality materials and components. Finally, every unit is run tested before it

leaves the factory. That’s why we know . . . There’s No Better Quality.

Visit our websites at www.goodmanmfg.com or www.amana-hac.com for information on:

Quality Makes the Difference!

• Products

• Warranties

• Customer Services

• Parts

• Contractor Programs and Training

• Financing Options

© 2004-2009 Goodman Manufacturing Company , L.P .

24

Loading...

Loading...