Page 1

LPT-03

NA TURAL GAS TO LP GAS CONVERSION KIT(S)

INSTALLATION INSTRUCTIONS

ATTENTION INSTALLING PERSONNEL

As a professional installer, you have an obligation to know the

product better than the customer. This includes all safety

precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with

this Instruction Manual. Pay special attention to all safety

warnings. Often during installation or repair, it is possible to

place yourself in a position which is more hazardous than

when the unit is in operation.

Remember, it is your responsibility to install the product safely

and to know it well enough to be able to instruct a customer in

its safe use.

Safety is a matter of common sense...a matter of thinking

before acting. Most dealers have a list of specific good safety

practices...follow them.

The precautions listed in this Installation Manual are intended

as supplemental to existing practices. However, if there is a

direct conflict between existing practices and the content of

this manual, the precautions listed here take precedence.

Prior to performing this conversion refer to the National Fuel

Gas Code (ANSI Z223.1) or in Canada, CAN/CGA-B149.2M91 to ensure that the installation is in compliance with those

and all local codes.

PLEASE READ AND FOLLOW THESE INSTRUCTIONS

CAREFULLY.

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION

Description

This Natural Gas to L.P. Gas conversion kit allows the 36G22

(B1282628), 36J22( 0151M00037) and VR-8215 (0151M00013)

Series gas valves to be used on L.P. gas applications. This

conversion kit is for use on all single stage maximum

regulation valves.

Require d Tools for Kit Installation

Pipe Wrenches, properly sized

2

to accom modate the gas piping and connectors

7/16" box wrench or socket wrench

1

5/16" Nut driv er

1

1/4" regular (flatblade) screwdriver

1

3/32" Al len wrench

1

Manom eters to read inlet & outlet press ure of the

2

gas valve (M inimum range: 0" - 15" W .C.)

1 3/16" Al len wrench

2 1/8" NPT hose barb

Pipe joint compound or pipe thread tape that is

approved for use with L.P. gas

Gas leak detection solution, like a soap and

water solution. Always wipe the solution from the

joints when testing is complete.

Kit Contents

Using the following parts list, ensure that all parts included in

this list are present and in an undamaged condition.

Quantity Part Numb er D e scri pt i on

1 B10259108 Conversion Label

1 B1880007

1 0163M00078

1 B408995 5 Bur ner Orifice

1 IO- 734C Inst allation I n str uctions

Whi te-Ro dger s 36G22 Valve

Spring Kit f or

Spring Kit for

Honeywell V R8215 Valv e

IO-734C

3/2014

Page 2

CARBON MONOXIDE POISONING HAZARD

CONTENTS

A

Important Information.......................................................... 2

Conversion Instructions - WR 36G22 / 36J22 Valve ........... 3

Conversion Instructions - HW VR8215 V alve....................... 5

NOx Screen Removal ......................................................... 6

Non-Condensing Furnaces & Package Gas-Electric........... 6

IMPORTANT INFORMA TION

WARNING”

“This conversion k it shall be installed by a qualified

service agency in accordance with the

manufacturer’s instructions an d all app licabl e

codes and requirements of the authority having

jurisdiction. If the information in these instructions

is not followed exactly, a fire, explosion or

production of carbon monoxide may result causing

property damage, personal injury or loss of life. The

qualified service agency is responsible for the

proper installation of this kit. The installation is not

proper and complete until the operation of the

converted appliance is checked as specified in the

manufacturer’s instructions supplied with the kit.”

Special Warning for Installat ion of Furnaces or Air Handling Units in

Enclose d A r eas such as Garages, Utility Rooms or Parking Areas

Carbon monoxide producing dev ices (suc h as an automobile, spac e

heater, gas water heater, etc.) s hould not be operated in enclos ed ar eas

such as unventilated garages, utility rooms or par k ing areas because of

the danger of carbon monoxide (CO) poisoni ng result ing f r om the exh aus t

emission s . If a furnac e or air handl er is instal led in an enclo sed area such

as a garage, utility r oom or parking area and a c ar bon monoxide producing

device is operated therein, ther e must be ad equate, direct outside

ventilation.

WARNING

TO

AVOID PERSONAL INJURY, PROPERTY DAMAGE OR DEATH, DUE

TO LEAKING GAS, CONTACT YOUR PROPANE SUPPLIER ABOUT

INSTALLING A GAS DETECTING WARNING DEVICE

CAN REDUCE THE LEVEL OF ODORANT IN PROPANE GAS

DETECTING DEVICE IS THE ONLY RELIABLE METHOD TO DETECT A

PROPANE GAS LEAK

.

. I

RON OXIDE (RUST

. A

GAS

BEFORE BEGINNING CONVERSION:

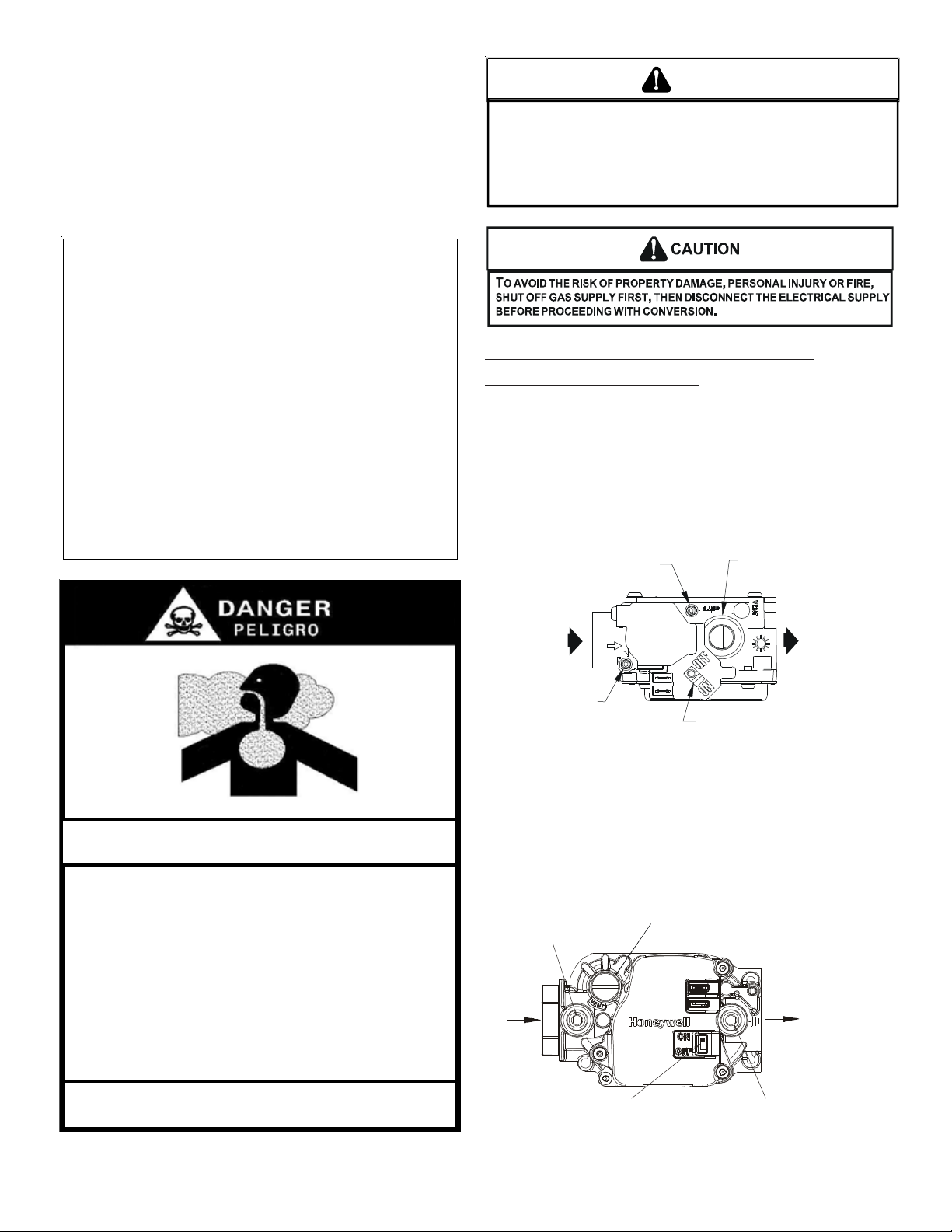

VALVE IDENTIFICATION

Before beginning conversion, the type valve you have must be

identified. Compare the gas valve presently on the equipment

to the drawing below to identify the correct valve you are

working with. Page numbers for the instructions for that valve

are below each drawing.

White-Rodgers 36G22 / 36J22

Outlet Pressure

Tap

INLET

Inlet Pressure

Tap

Instructions for these valves start on page 3.

Honeywell VR82 15

Regulator Pressure

djustment (Under Cap

Screw), Turn Clockwise to

Inlet Pressure Tap

1/8 NPT 3/16 Allen

Increase Pressure, Turn

Pressure Regulator

Adjustment

(Under Cap Screw)

OUTLET

Gas Valve

On/Off

Selector

Switch

)

This venti lation is necessary to avoid the danger of CO poisoning which

can occur if a c ar bon monoxide producing dev ic e c ontinues to operate in

the enclosed area. Carbon mon ox ide emis s ions can be (r e) c irculated

througho ut the struct ur e if the fur nace or air handler is oper ating in any

mode.

CO can cause serious illness inc luding permanent brain damag e or death.

B10259-216

FLOW DIRECTION

Gas Valve

ON/OFF S elect o r

Outlet Pre ssure

Tap 1/8 NPT 3/16

Instructions for this valve start on page 5.

2

Page 3

WHITE-RODGERS 36G22 / 36J22

CONVERSION INSTRUCTIONS

NOTE: For low NOx models, see page 6 for NOx screens.

1. Turn off gas supply to the furnace.

2. Turn off the electrical power to the furnace.

3. Remove the furnace control access panel.

4. Separate the gas supply union and remove associated downstream piping.

NOTE: Always use a backup wrench when removing or

replacing piping to avoid any undue strains or rotation of

controls.

5. Remove the wires from the gas valve.

6. Remove the 4 sheet metal screws that fasten the manifold/

gas valve assembly to the burner box.

7. Visually inspect orifices for damage and drill size (marked

on face with a 55) before installation. Using the 7/16"

wrench, remove all existing natural gas orifices and replace

with the appropriate marked 55 L.P. gas orifices contained

in this kit. Tighten the orifices to prevent gas leaks, but do

not overtighten. Retain the natural gas orifices for future

reconversion.

8. Reinstall the manifold/gas valve assembly into the appliance. Rewire the gas valve.

9. Using a 3/32” Allen wrench, loosen the inlet and outlet pressure tap screw one (1) turn only (DO NOT REMOVE). Attach a length of 5/16” hose to each of the pressure taps.

Connect the 5/16” hose to two (2) separate manometers or

other adequate gauges having a scale range of at least 0”

to 15” of water column.

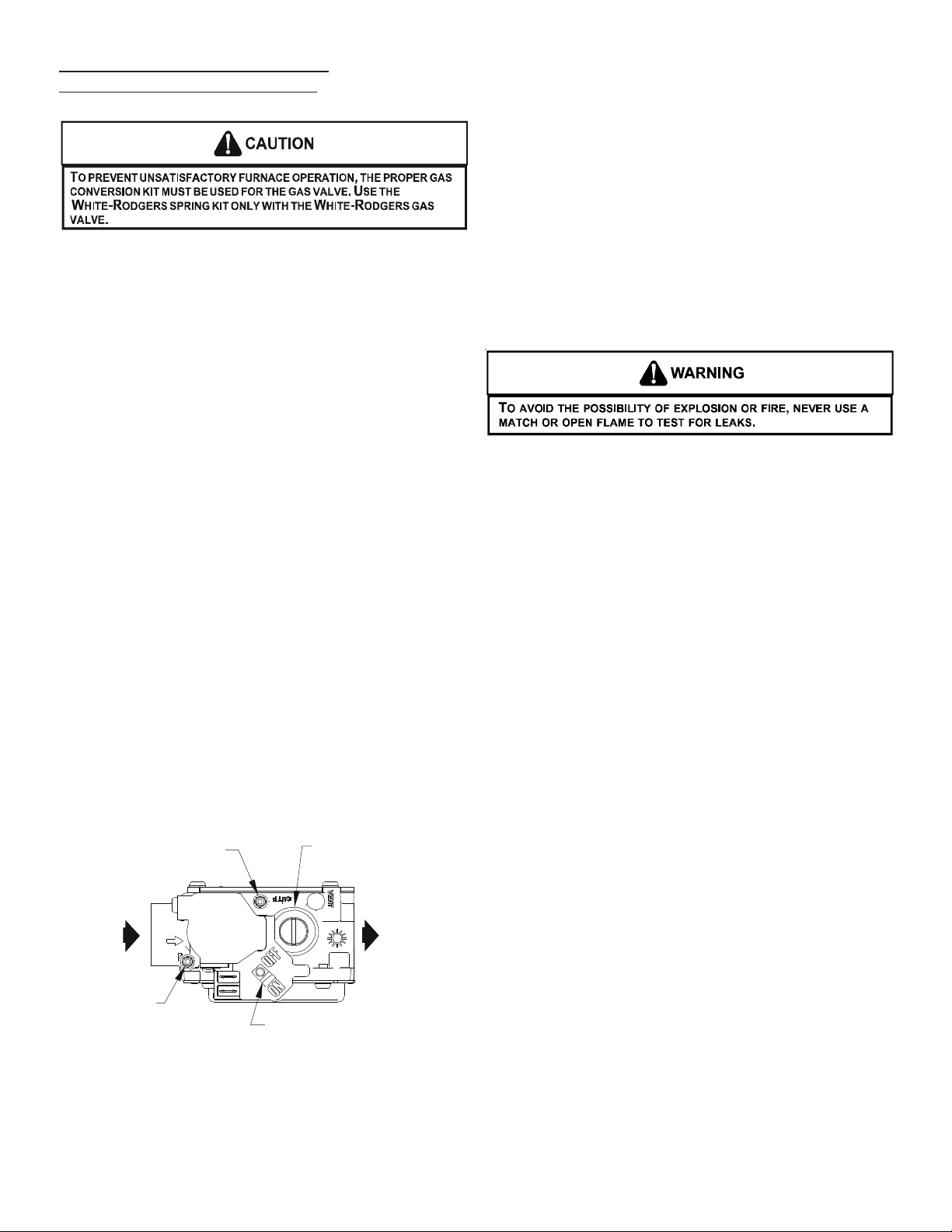

Outlet Pressure

Tap

INLET

Pressure Regulator

Adjustment

(Under Cap Screw)

OUTLET

10.Using a flat blade screwdriver, remove the regulator cover

screw.

11. Using a flat blade screwdriver, remove plastic regulator adjustment screw located beneath the cover screw.

12. Remove the natural gas regulator spring from the regulator

sleeve.

13. Insert the kit (P/N B1880007, WR F92-0999) provided L.P.

regulator spring into the regulator sleeve.

14.Replace the regulator adjustment screw.

15. Apply a liberal amount of pipe joint compound or pipe thread

tape to the threads and reassemble the piping previously

removed. Note: the pipe joint compound or pipe thread tape

must be resistant to L.P. gas.

16.Turn on the gas supply and check for leaks.

17.Turn on the electrical supply.

18. Adjust the room thermostat to allow for constant operation.

19. If you have the correct manifold pressure and the burn-

ers do not light, there may be air trapped in the lines.

Follow these instructions:

To check for air trapped in the supply line: Verify line

pressure is in the correct range. If manifold pressure is

indicated during the ignition trial, the valve is opening and

air may be in the line.

Units with hot surface ignitors: The valve will not open

until the ignitor is at the proper temperature (glowing

brightly).

Units with spark ignition: The valve will open as soon as

the spark starts. If no manifold pressure is indicated during the trial for ignition, please return to step 13 to ensure

the correct spring was used and to ensure the regulator

adjustment is near the bottom of the adjustment range.

20.If gas inlet pressure falls outside the range of 11” and 13”

W.C. after the unit has been in operation for 15 minutes,

adjust the gas supply pressure (not manifold pressure),

check piping size, etc., and/or consult with local utility.

NOTE: Any other gas-fired equipment should be ON before

any adjustments are made.

21.Check manifold pressure. For propane gas, the manifold

pressure must be between 9.5” and 10” W.C.

Inlet Pressure

Tap

Gas Valve

On/Off

Selector

Switch

White-Rodgers 36G22 / 36J22

3

Page 4

22. Turn adjustment screw out (counterclockwise) to decrease

pressure, turn in (clockwise) to increase pressure. Only

small variations in gas flow should be made by means of

the pressure regulator adjustment. In no case should the

final manifold pressure vary more than plus or minus 0.3”

water column from the specified nominal pressure. Any

major changes in flow should be made by changing the

size of the burner orifices. The measured input rate to the

furnace must not exceed the rating specified on the unit

rating plate.

23. Reset all other appliances so they function normally.

24. Turn off gas and electrical supply to the furnace, remove

the manometer hose from the pressure taps, and tighten

the inlet and outlet pressure tap screws using the 3/32”

Allen wrench (clockwise 7 in-lb minimum).

25. If regulator adjustment screw (removed in step 11) is white,

the gasket supplied with the kit must be installed on the

regulator cover screw. The gasket is not required if the

regulator adjustment screw is black.

26. Replace the regulator cover screw on the regulator sleeve.

27. Attach the kit provided WARNING label to the gas valve

where it can be readily seen. Also attach the small round

L.P. label to the top of the regulator cover screw.

28. Turn on the gas and electrical supply, energize the appliance and recheck for leaks.

29. Observe at least 3 ignition cycles to assure quick and

smooth ignition and burner operation.

30. Reinstall the access panels.

Regulator

Cover Screw

Gasket (From

Conversion K it)

Plastic Regulator

Adjustment Screw

Regulator

Spring

Regulator

Sleeve

36G22 / 36J22 MODEL

Note: Conversion instructions for the Honeywell

VR8215 gas valve begin on the following page.

4

Page 5

HONEYWELL VR8215

A

CONVERSION INSTRUCTIONS

NOTE: For low NOx models, see page 6 for NOx screens.

1. Turn off gas supply to the furnace.

2. Turn off the electrical power to the furnace.

3. Remove the furnace control access panel.

4. Separate the gas supply union and remove associated down-

stream piping.

NOTE: Always use a backup wrench when removing or

replacing piping to avoid any undue strains or rotation of

controls.

Regulator Pressure

djustment (Under Cap

Screw), Turn Clockwise to

Inlet Pressure Tap

1/8 N PT 3/ 16 Allen

ON/OFF Selector

Increase Pressure, Turn

Gas V al ve

FLOW

DIRECTION

Outlet Pressure

Tap 1/8 NPT 3/16

Honeywel l VR8215

5. Remove the wires from the gas valve.

6. Remove the 4 sheet metal screws that fasten the manifold/

gas valve assembly to the burner box.

7. Visually inspect orifices for damage and drill size (marked

on face with a 55) before installation. Using the 7/16"

wrench, remove all existing natural gas orifices and replace

with the appropriate marked 55 L.P. gas orifices contained

in this kit. Tighten the orifices to prevent gas leaks, but do

not overtighten. Retain the natural gas orifices for future

reconversion.

8. Reinstall the manifold/gas valve assembly into the appli-

ance. Rewire the gas valve.

9. Remove both the inlet and outlet plugs on the gas valve,

using the 3/16” Allen wrench. Install the fittings which accompany the manometers into the 1/8” taped holes of the

gas valve. Connect the manometers to the barbed fittings.

10.Using a flat blade screwdriver, remove the regulator cover

screw.

11. Using a flat blade screwdriver, remove plastic regulator adjustment screw located beneath the cover screw.

12. Remove the natural gas regulator spring from the regulator

sleeve.

13.Insert the kit (P/N 0163M00078, Honeywell P/N 396221)

provided L.P. regulator spring into the regulator sleeve.

14.Replace the natural gas regulator adjustment screw with

the L.P. regulator adjustment screw included in the kit.

NOTE: The LP regulator should be adjusted near the bottom of the adjustment range. DO NOT OVER-TIGHTEN.

15. Apply a liberal amount of pipe joint compound or pipe thread

tape to the threads and reassemble the piping previously

removed.

NOTE: the pipe joint compound or pipe thread tape must

be resistant to L.P. gas.

16.Turn on the gas supply and check for leaks.

17.Turn on the electrical supply.

18. Adjust the room thermostat to allow for constant operation.

19. To check for air trapped in the supply line: Verify line

pressure is in the correct range. If manifold pressure is

indicated during the ignition trial, the valve is opening and

air may be in the line.

Units with hot surface ignitors: The valve will not open

until the ignitor is at the proper temperature (glowing

brightly).

Units with spark ignition: The valve will open as soon as

the spark starts. If no manifold pressure is indicated during the trial for ignition, please return to step 13 to ensure

the correct spring was used and to ensure the regulator

adjustment is near the bottom of the adjustment range.

20.If gas inlet pressure falls outside the range of 11” and 13”

W.C. after the unit has been in operation for 15 minutes,

adjust the gas supply pressure (not manifold pressure),

check piping size, etc., and/or consult with local utility.

NOTE: Any other gas-fired equipment should be ON before

any adjustments are made.

21.Check manifold pressure. For propane gas, the manifold

pressure must be between 9.5” and 10” W.C.

5

Page 6

22. Turn adjustment screw out (counterclockwise) to decrease

pressure, turn in (clockwise) to increase pressure. Only

small variations in gas flow should be made by means of

the pressure regulator adjustment. In no case should the

final manifold pressure vary more than plus or minus 0.3”

water column from the specified nominal pressure. Any

major changes in flow should be made by changing the

size of the burner orifices. The measured input rate to the

furnace must not exceed the rating specified on the unit

rating plate.

23. Reset all other appliances so they function normally.

24. Turn off the gas and electrical supply to the appliance,

remove the pressure taps at the gas valve, reinstall the

plugs using pipe joint compound or tape.

25. Replace the regulator cover screw on the regulator sleeve.

26. Attach the kit provided A TTENTION label to the gas valve

where it can be readily seen.

27. Turn on the gas and electrical supply, energize the appliance and recheck for leaks.

28. Observe at least 3 ignition cycles to assure quick and

smooth ignition and burner operation.

29. Reinstall the access panels.

NON-CONDENSING FURNACES

AND PACKAGE GAS-ELECTRIC

1. Remove the screws securing the burner box to the partition panel. Separate burner box from unit.

2. Remove the screw(s) securing the NOx screen retention

plate and remove the plate.

3. Remove and discard NOx screens.

4. Reinstall the NOx screen retention plate and burner box.

PAR TITION PANEL

RETENTION PL ATE

BURN ER BOX ASSY.

SCREENS

Typical Nox Screen Remo val

NOx SCREEN REMOVAL

NOTE: To prevent premature heat exchanger failure, follow the

instructions in the NON-CONDENSING FURNACES AND

PACAKGE GAS-ELECTRIC section to remove all metal

screen inserts from the entrance of heat exchanger tubes

during propane conversions. Not all models will have metal

screen inserts.

6

Page 7

THIS PAGE LEFT INTENTIONALLY BLANK

7

Page 8

NOTE: SPECIFICATIONS AND PERFORMANCE DATA LISTED HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTICE

Quality Makes the Difference!

All of our systems are designed and manufactured with the same high quality standards regardless of size or efficiency. We have designed these units to significantly reduce the most frequent causes of product failure. They are

simple to service and forgiving to operate. We use quality materials and components. Finally, every unit is run tested

before it leaves the factory . That’ s why we know. . .There’s No Better Quality.

Visit our website at www.daikincomfort.com, www.goodmanmfg.com or www.amana-hac.com for information on:

• Products

• Warranties

• Customer Services

• Parts

• Contractor Programs and Training

• Financing Options

© 2009-2010, 2013 - 2014 Goodman Manufacturing Company, L.P.

is a registered trademark of Maytag Corporation or its related companies and is used under license. All rights reserved.

8

Loading...

Loading...