Page 1

LPM-08

TWO-STAGE FURNACE, NATURAL GAS TO LP GAS CONVERSION KIT

INSTALLATION INSTRUCTIONS

ATTENTION INSTALLING PERSONNEL

As a professional installer, you have an obligation to know

the product better than the customer. This includes all safety

precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with

this Instruction Manual. Pay special attention to all safety

warnings. Often during installation or repair, it is possible to

place yourself in a position which is more hazardous than

when the unit is in operation.

Remember, it is your responsibility to install the product safely

and to know it well enough to be able to instruct a customer

in its safe use.

Safety is a matter of common sense...a matter of thinking

before acting. Most dealers have a list of specic good safety

practices...follow them.

The precautions listed in this Installation Manual are intended

as supplemental to existing practices. However, if there is a

direct conict between existing practices and the content of

this manual, the precautions listed here take precedence.

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION

DESCRIPTION

This natural gas to L.P. (liquid petroleum) gas conversion

kit allows White-Rodgers gas valve 36G54 (0151F00000P),

36J54 (0151M00027) or Honeywell VR9205Q (0151M00014

/ 0151M00028) to be used on L.P. gas applications.

Use the following parts list to ensure that all parts listed below

are present and in an undamaged condition. IF ANY DOUBT

EXISTS ABOUT THE CONDITIONS OF ANY COMPONENT

WITHIN THIS KIT, DO NOT USE THIS KIT AND CONTACT

YOUR SUPPLIER FOR A NEW KIT.

PARTS LIST

Part

Number

0163F00000P White-Rodgers LP Conversion Kit F92-1008 1

0163M00139 Honeywell LP Conversion Kit 50033841 1

B14933151 Conversion Label 1

B40899125 1.25mm Spud Orice Assembly 1

IO-818 LPM-08 Installation Instructions 1

0151K00000S 36G54 Pressure Check Kit Valve 1

Description Quantity

With the exception of the natural gas burner orices, all of

the fasteners and other components removed to perform

this conversion are to be reused. Any component found to

be damaged due to this conversion must be replaced with

factory authorized replacement parts before this furnace can

be put into o peration.

This furnace is equipped for two-stage heating operation.

The gas valve manifold pressure must be set with rst stage

operating at 6” +/-0.3” W.C. manifold pressure and the second

stage must be set at 10” +/-0.3” W.C. manifold pressure. The

accuracy of these pressures must be checked as shown in

steps 25 and 26 of these instructions.

The gas valve is equipped with a 3-pin polarized plug which

prevents this wiring from being installed incorrectly.

CAUTION

LabeL aLL wires prior to disconnection when servicing

controLs. wiring errors can cause improper and dangerous

operation. verify proper operation after servicing.

NOTE: Do not use power tools for any adjustments on

gas valves.

IO-818

01/2014

Page 2

CONTENTS

CARBON MONOXIDE POISONING HAZARD

B10259-216

Carbon monoxide producing devices (such as an automobile, space

heater, gas water heater, etc.) should not be operated in enclosed areas

such as unventilated garages, utility rooms or parking areas because of

the danger of carbon monoxide (CO) poisoning resulting from the exhaust

emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, utility room or parking area and a carbon monoxide producing

device is operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO poisoning which

can occur if a carbon monoxide producing device continues to operate in

the enclosed area. Carbon monoxide emissions can be (re)circulated

throughout the structure if the furnace or air handler is operating in any

mode.

CO can cause serious illness including permanent brain damage or death.

Special Warning for Installation of Furnaces or Air Handling Units in

Enclosed Areas such as Garages, Utility Rooms or Parking Areas

Important Information ......................................................... 2

Conversion Instructions - WR 36G54 or 36J54 Valves ...... 3

Conversion Instructions - HW VR9205Q Valve .................. 5

NOx Screen Removal ......................................................... 7

Non-Condensing Furnaces & Package Gas-Electric.......... 7

WARNING

carbon monoXide (co) can cause sever personaL

injury or death.

WARNING

The following tools and supplies are required:

• 2 – Pipe wrenches, properly sized to accommodate the

gas piping and connectors

• 1 – 7/16” box wrench or socket wrench

• 1 - 1/4” nut driver

• 1 – 3/16” at blade screwdriver

• 1 – 1/4” at blade screwdriver

• 1 – 3/16” allen wrench

• 1 – manometer to read inlet and outlet pressure of the

gas valve (Minimum range: 0”-20” W.C.)

• Pipe joint compound or pipe thread tape that is approved for use with L.P. gas

• Gas leak detection solution like a soap and water

solution. Always wipe the solution from the joints when

testing is completed.

WARNING

never use an open fLame to check for gas Leaks.

this L.p. (Liquid petroLeum) conversion kit must be

instaLLed by a quaLified service person or agency in

accordance with the manufacturer’s instructions and

aLL appLication codes and requirements of the authority

having jurisdiction. faiLure to foLLow these instructions

eXpLicitLy may cause a fire, eXpLosion or the

production of carbon monoXide (co), which

can cause property damage, personaL

injury or death. the quaLified person performing

this conversion assumes the responsibiLity for the proper

conversion of the appLiance.

Prior to performing this conversion, refer to the National Fuel

Gas Code (NFPA 54-02) or in Canada, CAN/CSA-B149.2-05

to ensure that the installation is in compliance with those

and all local codes.

IMPORTANT INFORMATION

WARNING

high voLtage!

disconnect aLL power before servicing.

muLtipLe power sources may be present. faiLure

do so may cause property damage, personaL

to

or death.

injury

2

Page 3

WHITE-RODGERS 36G54 OR 36J54

CONVERSION INSTRUCTIONS

WARNING

high voLtage!

disconnect aLL power before servicing.

muLtipLe power sources may be present. faiLure

do so may cause property damage, personaL

to

or death.

injury

CAUTION

if noX screens are present, remove as per instructions in

section “noX screen removaL.”

CAUTION

to prevent unsatisfactory furnace operation, the proper

gas conversion kit must be used for the gas vaLve. use the

white-rodgers spring kit onLy with the white-rodgers

gas vaLve.

NOTE: For low NOx models, see table of contents for

NOx screen section.

1. Turn off the gas supply to the furnace.

2. Turn off the electrical power to the furnace.

3. Remove the furnace control access panel.

4. Check for the presence of NOx screen and remove per

NOx instruction.

5. Separate the gas supply union and remove associated

downstream piping.

6. Always use a backup wrench when removing or replacing

piping to avoid any undue strains or rotation of controls.

7. Remove the wires from the gas valve.

8. Remove the 4 sheet metal screws that fasten the manifold/

gas valve assembly to the burner box.

9. Visually inspect orices for damage and drill size (marked

on face with 1.25mm) before installation. Using the 7/16”

wrench, remove all existing natural gas orices and replace with the appropriate 1.25mm L.P. gas orices contained in this kit. Tighten the orices to prevent gas leaks,

but do not overtighten. Retain the natural gas orices for

future reconversion.

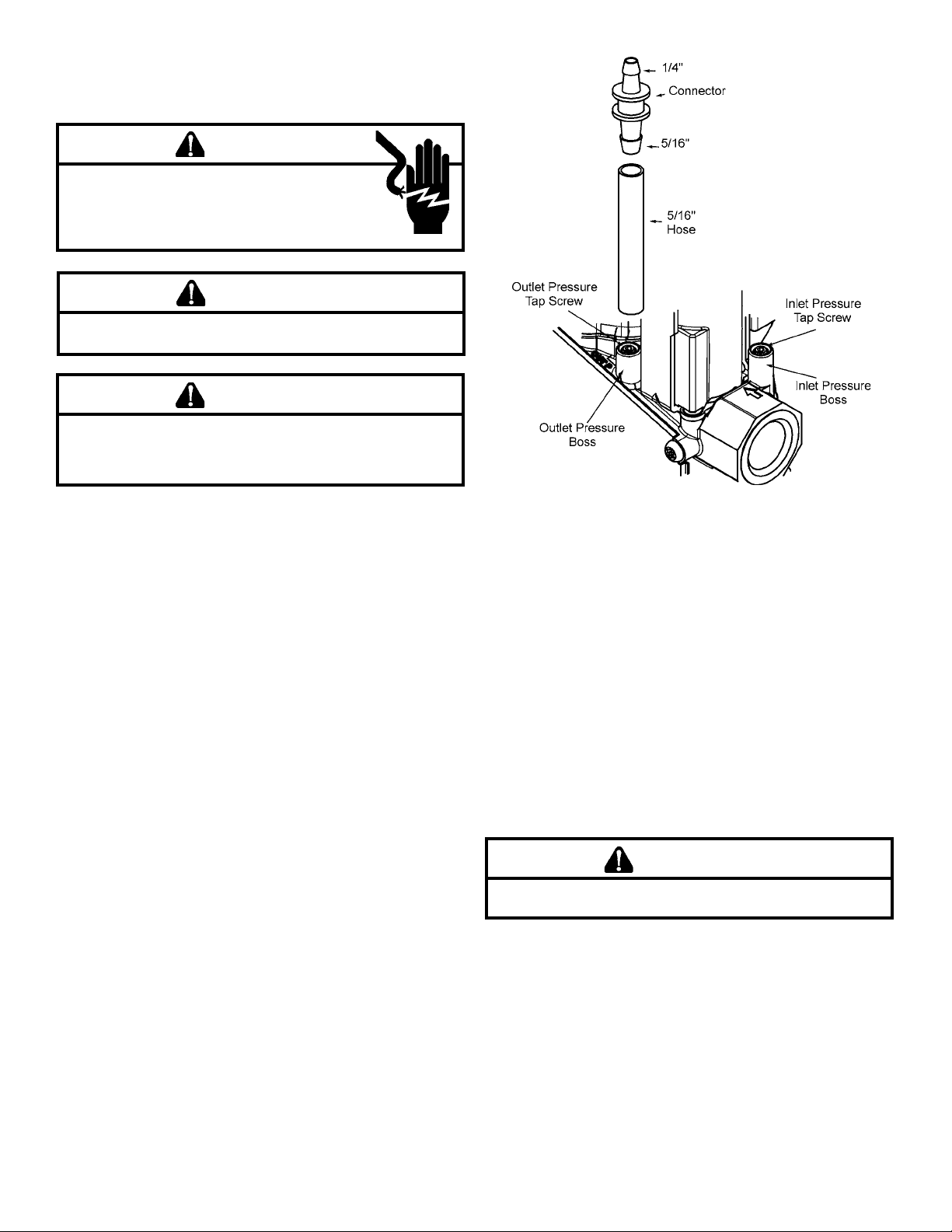

10. Install water manometer using Valve Pressure Check Kit

P/N 0151K00000S included with this kit. Using the included 3/32” hex wrench, rotate outlet pressure tap screw one

revolution counterclockwise. Attach the included 5/16”

hose to the inlet and outlet pressure boss of the valve.

Hose should overlap boss 3/8”. Connect 5/16” side of included connector to the hose on the outlet boss. Connect

1/4” side of the connector to the manometer hose. The

manometer must have a scale range of at least 0” to 20”

of water column.

11. Remove both regulator cover screws.

12. Using a 1/4” at blade screwdriver, remove both regulator

adjustment screws (beneath the cover screws).

13.Remove both Natural Gas regulator springs (color-coded

silver/plain) from regulator sleeves and retain with the

Natural Gas orices for future reconversion.

14. Insert the L.P. regulator springs (provided in the conversion kit and color-coded white) into the regulator sleeves.

15. Replace the High regulator adjustment screw and adjust

approximately 12 turns to the bottom stop.

16. Replace the Low regulator adjustment screw and adjust

approximately 8 turns.

17. Reinstall the manifold/gas valve assembly into the appliance. Rewire the gas valve.

18. Apply a liberal amount of pipe joint compound or pipe

thread tape to the threads and reassemble the piping

previously removed.

WARNING

to prevent the possibiLity of gas Leaks, the pipe joint com-

pound or pipe thread tape must be resistant to L.p. gas.

19. Turn on the gas supply.

20. Using a soap and water solution, check for leaks around

the gas valve/manifold connection.

21. Turn on the electrical supply.

22. Adjust the room thermostat to obtain a rst stage (W1

only) burner operation.

NOTE: for hybrid models, the control board dip switches

need to be set to 2 stg position to set and verify rst stage

heat. (See Installation Instructions supplied with the unit for

dip switch settings)

3

Page 4

WARNING

never use an open fLame to check for gas Leaks.

23. Using a soap and water solution, check for leaks around

the gas valve/manifold connection and the burner orices.

Repair any leaks before continuing.

24. NOTE: Any other gas-red equipment should be ON

before any adjustments are made.

After the furnace has been in operation for 15 minutes,

adjust the gas supply pressure (not manifold pressure) to

obtain a range between 11” and 13” W.C. If the gas inlet

pressure falls outside of this range, then make necessary

L.P. service regulator(s) adjustments; check piping size,

etc., and /or consult with L.P. provider.

25. With the furnace operating in its low-re (W1) condition, the

manifold pressure should be 6” W.C. ± 0.30”. If necessary,

this pressure can be adjusted using the gas valve low

regulator adjustment screw. Turn clockwise to increase

pressure and counterclockwise to decrease manifold

pressure.

26. Readjust the room thermostat to obtain a second stage

call for heat (W2). The manifold pressure for the W2

condition should be 10” W.C. ± 0.30” W.C. Adjustments

to this pressure can be made using the high regulator

adjustment screw.

27. Using the room thermostat to cycle the unit, observe a

minimum of three (3) smooth ignition cycles.

28. Turn off gas and electrical supply to the furnace, remove

the manometer hose from the pressure tap bosses, and

tighten the inlet and outlet pressure tap screws using the

3/32” Allen wrench.

29. Replace both regulator cover screws on the regulator

sleeve.

White-Rodgers 36G54 or 36J54

WARNING

attach the warning LabeL provided in the kit to the gas

vaLve where it can be readiLy seen.

attach the smaLL, round L.p. LabeLs to the top of the

reguLator cover screws.

30. IMPORTANT NOTE: Apply the conversion label (B14933-

151) provided with the conversion kit. This label must be

attached adjacent to the rating plate.

31. For hybrid models, control board switches may need to be

re-set to single stage operation depending on installers

preference of operation.

32. Reinstall the access panels.

33. Turn on the gas and electrical supply.

34. Reset all other appliances so they function normally.

White-Rodgers 36G54 or 36J54

Springs and Regulator Screws

4

Page 5

HONEYWELL VR9205Q

CONVERSION INSTRUCTIONS

WARNING

high voLtage!

disconnect aLL power before servicing.

muLtipLe power sources may be present. faiLure

do so may cause property damage, personaL

to

or death.

injury

CAUTION

if noX screens are present, remove as per instructions in

section “noX screen removaL.”

CAUTION

to prevent unsatisfactory furnace operation, the proper

gas conversion kit must be used for the gas vaLve. use the

honeyweLL spring kit onLy with the honeyweLL gas vaLve.

NOTE: For low NOx models, see table of contents for NOx

screen section.

1. Turn off the gas supply to the furnace.

2. Turn off the electrical power to the furnace.

3. Remove the furnace control access panel.

4. Check for the presence of NOx screen and remove per

NOx instruction.

5. Separate the gas supply union and remove associated

downstream piping.

6. Always use a backup wrench when removing or replacing

piping to avoid any undue strains or rotation of controls.

7. Remove the wires from the gas valve.

8. Remove the 4 sheet metal screws that fasten the manifold/

gas valve assembly to the burner box.

9. Visually inspect orices for damage and drill size (marked

on face with 1.25mm) before installation. Using the 7/16”

wrench, remove all existing natural gas orices and replace with the appropriate 1.25mm L.P. gas orices contained in this kit. Tighten the orices to prevent gas leaks,

but do not overtighten. Retain the natural gas orices for

future reconversion.

10. Remove both the inlet and outlet plugs on the gas valve,

using the 3/16” allen wrench. Install the ttings, which

accompany the manometers, into the 1/8” NPT holes of

the gas valve. Connect the manometers to the barbed

ttings.

Honeywell VR9205Q

11. Remove both regulator cover screws and retain with the

Natural Gas orices for future reconversion.

12. Using a T-25 Torx driver (L Torx tool included in kit) or 3/16”

at head screwdriver, remove both regulator adjustment

screws.

13. Remove both silver colored Natural Gas regulator springs

from the regulator sleeves and retain with the Natural Gas

orices for future reconversion.

14. Insert the L.P. regulator springs (provided in the conversion

kit and color-coded red) into the regulator sleeves.

15. Install the high regulator adjustment screw provided with

the kit by threading all the way down until lightly seated

and then back off 1 1/2 turns.

16. Install the low regulator adjustment screw provided with

the kit by threading all the way down until lightly seated

and then back off 1 1/2 turns.

17. Reinstall the manifold/gas valve assembly into the appliance. Rewire the gas valve.

WARNING

to prevent the possibiLity of gas Leaks, the pipe joint com-

pound or pipe thread tape must be resistant to L.p. gas.

18. Apply a liberal amount of pipe joint compound or pipe

thread tape to the threads and reassemble the piping

previously removed. NOTE: the pipe joint compound must

be resistant to L.P. gas.

19. Turn on the gas supply.

20. Using a soap and water solution, check for leaks around

the gas valve/manifold connection.

21. Turn on the electrical supply.

22. Adjust the room thermostat to obtain a rst stage (W1

only) burner operation.

NOTE: for hybrid models, the control board dip switches

need to be set to 2 stg position to set and verify rst stage

heat. (See Installation Instructions supplied with the unit for

dip switch settings)

5

Page 6

WARNING

WARNING

never use an open fLame to check for gas Leaks.

23. Using a soap and water solution, check for leaks around

the gas valve/manifold connection and the burner orices.

Repair any leaks before continuing.

24. NOTE: Any other gas-red equipment should be ON

before any adjustments are made.

After the furnace has been in operation for 15 minutes,

adjust the gas supply pressure (not manifold pressure) to

obtain a range between 11” and 13” W.C. If the gas inlet

pressure falls outside of this range, then make necessary

L.P. service regulator(s) adjustments; check piping size,

etc., and /or consult with local L.P. provider.

25. With the furnace operating in its low-re (W1) condition,

the manifold pressure should be 6” W.C.± 0.30”. If necessary, this pressure can be adjusted using the low regulator

adjustment screw. Turn clockwise to increase pressure

and counterclockwise to decrease manifold pressure.

26. Readjust the room thermostat to obtain a second stage call

for heat (W2). The manifold pressure for the W2 condition

should be 10” ± 0.30” W.C. Adjustments to this pressure

can be made using the high regulator adjustment screw.

27. Using the room thermostat to cycle the unit, observe a

minimum of three (3) smooth ignition cycles.

28. Turn off gas and electrical supply to the furnace. Remove

the barbed manometer ttings from the 1/8” NPT holes in

the gas valve. Seal inlet and outlet plugs removed earlier

with pipe joint compound or pipe thread tape and reinstall.

to prevent the possibiLity of gas Leaks, the pipe joint

compound must be resistant to L.p. gas.

29. Install the regulator cover screws provided with the conversion kit.

WARNING

instaLL the attention LabeL provided with the conversion

kit to the gas vaLve where it can be readiLy seen.

30. IMPORTANT NOTE: Apply the conversion label (B14933-

151) provided with the conversion kit. This label must be

attached adjacent to the rating plate.

31. For hybrid models, control board switches may need to be

re-set to single stage operation depending on installers

preference of operation.

32. Reinstall the access panels.

33. Turn on the gas and electrical supply.

34. Reset all other appliances so they function normally.

6

Page 7

NOX SCREEN REMOVAL

WARNING

aLL metaL screens must be removed from the heat eXchanger

tubes when using propane gas. faiLure to compLy with this

requirement wiLL aLso void warranty coverage.

NOTE: To prevent premature heat exchanger failure, follow the instructions below to remove all metal screen inserts

from the entrance of heat exchanger tubes during propane conversions. Not all models will have metal screen inserts.

NON-CONDENSING FURNACES AND PACKAGE GAS-ELECTRIC

1. Remove the screws securing the burner box to the partition panel. Separate burner box from unit.

2. Remove the screw(s) securing the NOx screen retention plate and remove the plate.

3. Remove and discard NOx screens.

4. Reinstall the NOx screen retention plate and burner box.

Typical NOx Screen Removal

7

Page 8

NOTE: SPECIFICATIONS AND PERFORMANCE DATA LISTED HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTICE

®

Quality Makes the Difference!

All of our systems are designed and manufactured with the same high quality standards regardless of size or

efciency. We have designed these units to signicantly reduce the most frequent causes of product failure. They

are simple to service and forgiving to operate. We use quality materials and components. Finally, every unit is run

tested before it leaves the factory. That’s why we know. . .There’s No Better Quality.

Visit our website at www.daikincomfort.com, www.goodmanmfg.com or www.amana-hac.com for information on:

• Products

• Warranties

• Customer Services

• Parts

• Contractor Programs and Training

• Financing Options

5151 San Felipe, Suite 500, Houston, TX 77056

© 2014 Goodman Manufacturing Company, L.P.

is a trademark of Maytag Corporation and is used under license. All rights reserved.

8

Loading...

Loading...