Page 1

LPLP03

p

LOW PRESSURE PROPANE KIT

INSTALLATION INSTRUCTIONS

Description

This kit is designed for gas-fired units converted to propane

gas use. The Propane Low Pressure (LPLP03) Kit monitors

the gas line pressure with a pressure switch and disables the

unit gas valve if the line pressure drops below acceptable levels.

ATTENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the

product better than the customer. This includes all safety

precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with

this Instruction Manual. Pay special attention to all safety

warnings. Often during installation or repair it is possible to

place yourself in a position which is more hazardous than when

the unit is in operation.

Remember, it is your responsibility to install the product safely

and to know it well enough to be able to instruct a customer in

its safe use.

Safety is a matter of common sense...a matter of thinking before

acting. Most dealers have a list of specific good safety

practices...follow them.

The precautions listed in this Installation Manual are intended

as supplemental to existing practices. However, if there is a

direct conflict between existing practices and the content of

this manual, the precautions listed here take precedence.

Fie l d Suppl ied

1 1/2" x 1-1 / 2" Nippl e

11/2" Tee

1 90 Degree S treet E l b ow

1

NOTE:

installations. See figures inside this IO for application

needs.

1/2" P i pe (length dependent on

model and applic ation)

Field supplied parts are not required for all

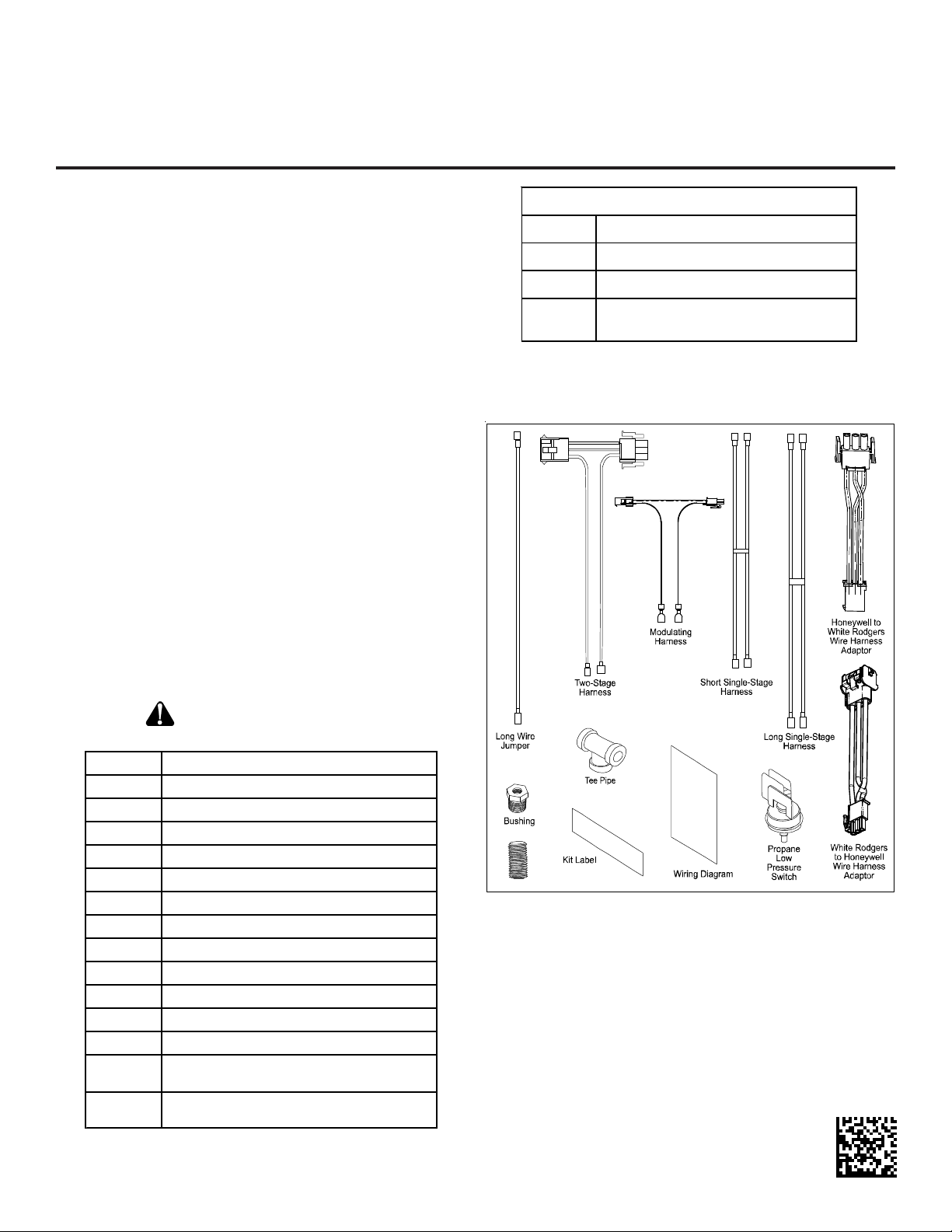

1 Propane Low Pressure Switch

1 1/8" Close Nipple

1 1/ 8" Te e Pi pe

1 1/2" x 1/ 8" Bushing

1 Sho r t Singl e-Stage H arness

1 Long S i ngle - Stage Harness

1 Long Jum per Wire

1 Two-Stag e Harness

1 Modulating Wire Harness

1 Propane Low Pressure Kit Label

1Wiring Diagram

1

1

IO-775C

August 2014

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION

Switch to Gas Valve Piping

Low Pressure Switch Wiring

Honeywell t o White-Ro dgers

Wire Harness Ada

White-Rodgers to Honeywell

Wire Harness Adaptor

tor

Figure 1

Page 2

CONTENTS

Important Information.......................................................... 2

Models Using White-Rodgers 36F & 36E

Gas V alves with 1/8” NPT

Inlet Pressure Port ............................................................. 3

White-Rodgers 36F & 36E V alves

Right Facing Gas Inlet............................................. 3

White-Rodgers 36F & 36E V alves

Left Facing Gas Inlet............................................... 4

White-Rodgers 36G/36J V alve

Right Facing Gas Inlet (Left Facing Similar) ............ 4

Honeywell VR82 and VR9205Q Valves

or VR9205R Modulating V alve on 90%+ models ..... 4

80% Models Using Honeywell VR82, VR92

or White-Rodgers 36G/36J gas valves...................... 4

Honeywell VR82 or VR92 V alve on 80% models ..... 5

LP Low Pressure Switch Wiring

(Single-Stage Models) ............................................. 5

LP Low Pressure Switch Wiring

(T wo-Stage Models White-Rodgers Gas V alve

and Wire Harness Connection) ............................... 5

LP Low Pressure Switch Wiring

(Two-S tage Models with White-Rodgers Gas Valve

with Honeywell Wire Harness Connection) .................. 6

90% Models Using Honeywell VR82, VR9205Q V alves or

VR9205R Modulating V alve or White-Rodgers 36G ..... 6

Short 90% Models Using Honeywell VR82, VR9205Q

V alves or VR9205R Modulating Valve or

White-Rodgers 36J V alve ............................................ 6

Troubleshooting.................................................................. 8

IMPORTANT INFORMA TION

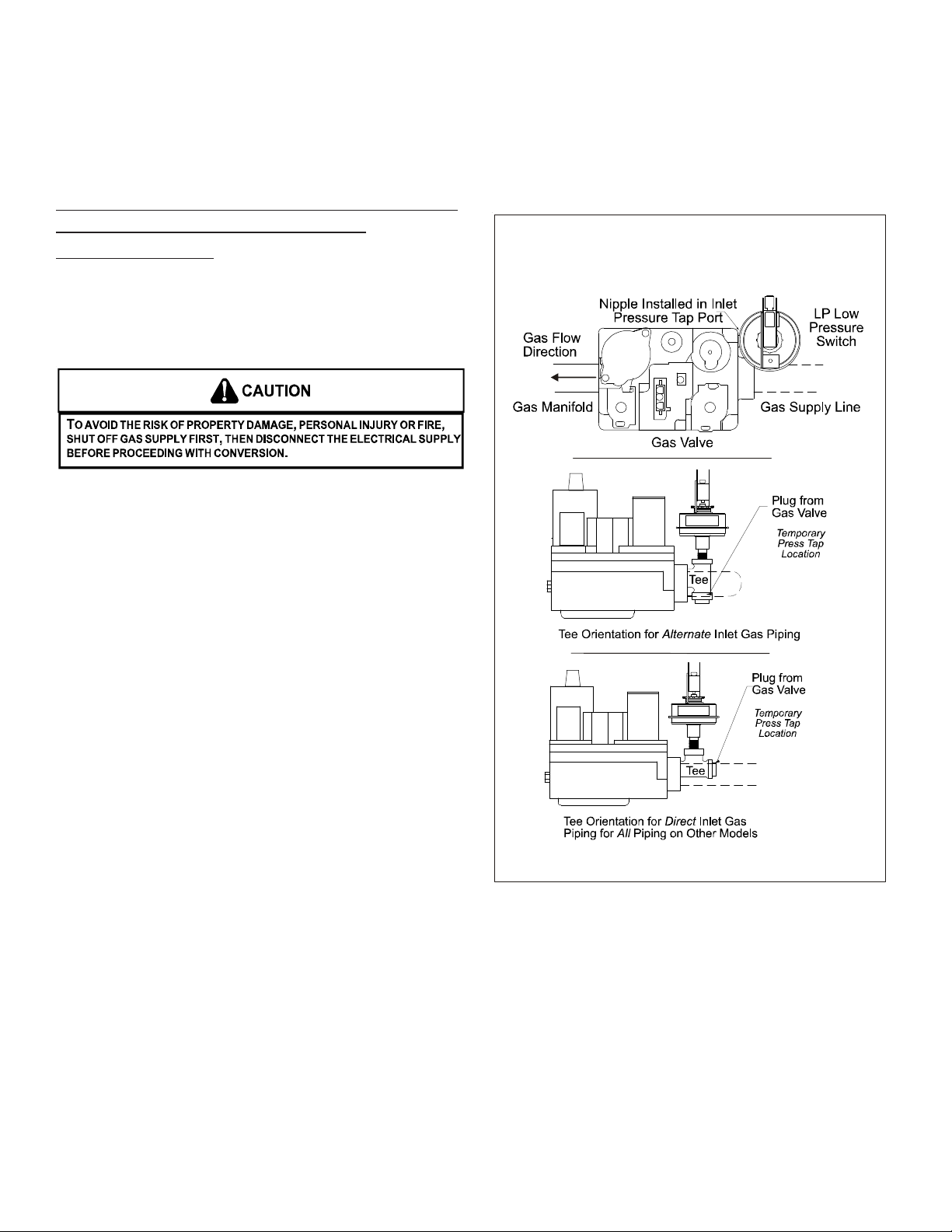

This kit provides control over the unit gas valve by routing the

gas valve wiring through the supplied pressure switch. To enable proper fit-up, the pressure switch kit must be installed

before connecting the gas supply line to the gas valve. For

new unit installations, the kit hardware may be fitted to the gas

valve while the gas manifold is removed for LP gas orifice

conversion. For existing installations, the gas valve line must

be disconnected from the gas valve to allow fitting of kit hardware. Refer to Figures 2, 3, 4, 5 or 6 for a view of kit hardware

as installed in unit. Before proceeding, shut off gas supply

at manual shutoff and turn off power to unit.

Contact a local propane gas supplier

about installing a gas detecting warning device.

2

Page 3

NOTE: T o ensure proper operation, install, operate and main-

tain the unit in accordance with these installation instructions, all local building codes and ordinances. In their absence, follow the latest edition of the National Fuel Gas Code

(NFPA 54/ANSI Z223.1), and/or CAN/CSA B149.1 Installation Codes.

MODELS USING WHITE-RODGERS 36F & 36E

GAS V ALVES WITH 1/8” NPT INLET

PRESSURE PORT

(Alternate method on page 4 may also be used.)

NOTE: All threaded connections must be sealed with Teflon

tape or pipe dope. Pipe sealant must be approved for use

with propane gas.

1. Remove plug from the gas valve inlet pressure tap port.

Save plug.

2. Install the supplied close nipple into the open inlet pressure tap port.

3. Thread the provided tee onto free end of the nipple. Orient

the tee as shown in figure(s).

NOTE: On some models, tee orientation depends on which

side the gas supply line enters.

4. Install pressure switch into the tee.

5. Temporarily fit a field-supplied pressure tap into the remaining leg of the tee. This pressure tap will allow gas

supply line pressure measurement during installation check

out.

6. Attach the pressure tap to a manometer or pressure measurement device before opening gas supply.

7. With gas valve and manifold installed in the unit, connect

gas supply line to the gas valve.

8. Perform installation check out procedure (piping leak check,

line pressure measurement, manifold pressure adjustment,

etc.) as outlined in the unit installation instructions.

9. Turn OFF gas supply .

10. Remove field-supplied pressure tap from tee and insert plug

removed in step 1.

1 1. Turn ON gas supply and leak check inserted plug.

12. Turn OFF power to furnace. Connect jumper harness between LPLP switch and gas valve and gas valve wiring as

indicated in Figure 7 (single-stage models) or Figures 6, 8

or 9 (two-stage models).

13. Turn ON power to furnace. V erify proper unit operation.

14. Remove backing from kit label. Fold label around jumper

harness wire to indicate kit installation.

15. Adhere kit wiring diagram adjacent to existing unit wiring

diagram.

IMPORTANT NOTE: Secure all wires to avoid their contact

with any hot surfaces or moving parts.

White-Rodgers 36F Valve

White-Rodgers 36E Valve

Right Facing Gas Inlet

Figure 2

3

Page 4

White-Rodgers 36F V al ve

White-Rodgers 36E V alv e

Left Facing Gas Inlet

Figure 3

Honeywell VR82, V 9205Q Valves or

VR9205R (Mo dulating ) Valve

Used on 90%+ Models

UPFLOW

R

COUNTERFLOW

White-Rodgers 36G/36J Valve

Right Facing Gas Inlet

(Left Facing Similar)

*If there is interference with the Pressure Switch position,

rotate Pressure Switch 90 degrees.

Figure 4

Figure 5

80% MODELS USING HONEYWELL VR82,

VR9205Q OR WHITE-RODGERS 36G/36J

GAS VALVES

NOTE: All threaded connections must be sealed with Teflon

tape or pipe dope. Pipe sealant must be approved for use

with propane gas.

1. Install field-supplied 90 degree street elbow into gas valve.

2. Install field-supplied 1/2” x length required to exit wrapper

into 90 degree street elbow for left side gas outlet. Install

field supplied 1/2” x length required to exit wrapper on the

right side of the gas outlet (See Figure 6).

3. Place 1/2” tee on pipe.

4. With gas valve and manifold installed in the unit, connect

the gas supply line into 1/2” tee as required (typically opposite of gas valve side).

5. Install 1/2” x 1/8" bushing into 1/2” tee in the remaining

opening.

4

Page 5

6. Install pressure switch in bushing. Pressure switch will be

installed outside of the wrapper (see Figure 6.)

NOTE: Ensure that the switch is upright in all applications.

7. Perform installation check out procedure (piping leak check,

line pressure measurement, manifold pressure adjustment,

etc.) as outlined in the unit installation instructions.

8. Turn OFF gas supply .

9. Turn OFF power to furnace. Connect jumper harness between LPLP switch and gas valve and gas valve wiring as

indicated in Figure 7 (single-stage models - some models

may require the use of long single-stage harness) or Figures 8-1 1 (two-stage models). Some two-stage models may

require the use of long jumper wires to accommodate connection of the switch. (2nd long jumper wire can be taken

from long single stage harness.)

NOTE: Do not run wires through the gas pipe opening if

gas piping is present. Pipe could easily cause damage to

the wires.

10. Turn ON power to furnace. V erify proper unit operation.

1 1. Remove backing from kit label. Fold label around jumper

harness wire to indicate kit installation.

12. Adhere kit wiring diagram adjacent to existing unit wiring

diagram.

IMPORTANT NOTE: Secure all wires to avoid their contact

with any hot surfaces or moving parts.

Honeywell VR82 or Valves

Used on 80% Models

V 9205QR

Honeywell or White-Rodgers Gas Valves

LP Low Pressure Switch Wiring

Single-Stage Models

Gas Valve Wiring

from

Furnace Wiring

Harness

Gas Valve

Brown or Gray Wire

Single-Stage

Jumper Ha rness

White-Rodgers Valve Shown

Figure 7

White-Rodgers Gas Valve

&

Wiring Harness Connection

LP Low Pressure Switch Wiring

Two-Stage Models

Gas Valve Wiring

from

Furnace Wiring

Harness

Kit

Label

LP Low

Pressure

Switch

Figure 6

Two-Stage

Jumper Harness

Gas Valve

Figure 8

Kit

Label

LP Low

Pressure

Switch

5

Page 6

White-Rodgers Gas V alve

With Honeywell

Wiring Harness Connection

LP Low Pressure Switch Wiring

Two-Stage Models

Honeywell Gas Valv e VR9205Q

With White-Rodgers

Wiring Harness Connection

LP Low Pressure Switch Wiring

Two-Stage Models

Two-Stage

Jumper Harness

Gas Valve

Gas Valve Wiring

from

Furnace Wiring

Harness

Kit

Label

Figure 9

Honeywell Gas Valv e VR920 5Q

And

Wiring Harness Connection

LP Low Pressure Switch Wiring

Two-Stage Models

LP Low

Pressure

Switch

Two-Stage

Jumper Harness

Gas Valve Wiring

Gas Valve

from

Furnace Wiring

Harness

Kit

Label

Figure 11

LP Low

Pressure

Switch

Two-Stage

Jumper Harness

Gas Valve

Gas Valve Wiring

from

Furnace Wiring

Harness

Kit

Label

Figure 10

LP Low

Pressure

Switch

6

Page 7

SHORT 90 FURNACES USING

VR82, VR92 and 36J GAS VALVES

NOTE: All threaded connections must be sealed with

Teflon tape or pipe dope. Pipe sealant must be approved

for use with propane gas.

Gas plumbed out the r ight side

of the furnace

Gas Valve

X

Figure 13

1. Install field-supplied ½” x length required to exit wrapper , when the inlet is on left side.

2. For installing the pressure switch, in case of a right side inlet, install field-supplied ½”x 1 ½” required for “C and D” size

cabinet models. “B” cabinet models require a field supplied ½” x length sufficient enough to be clear from any interference from other components. The pressure switch can be installed within or outside the cabinet in case of right side inlet.

3. Place ½” tee on pipe.

4. With gas valve and manifold installed in the unit, connect the gas supply line into 1/2" tee as required (typically opposite

of gas valve side).

5. Install ½” x 1/8" bushing into ½” tee in the remaining opening.

6. Install pressure switch in bushing (See Figure 13).

NOTE: Ensure that the switch is upright in all applications.

7. Perform installation check out procedure (piping leak check, line pressure measurement, manifold pressure adjustment,

etc.) as outlined in the unit installation instructions.

8. Turn OFF gas supply .

9. Turn OFF power to furnace. Connect jumper harness between LPLP switch and gas valve and gas valve wiring as indicated in Figure 7 (single-stage models - some models may require the use of long single-stage harness) or Figures 8-1 1

(two-stage models). Some two-stage models may require the use of long jumper wires to accommodate connection of

the switch. (2nd long jumper wire can be taken from long single stage harness.)

NOTE: Do not run wires through the gas pipe opening if gas piping is present. Pipe could easily cause damage to the

wires.

10. Turn ON power to furnace. V erify proper unit operation.

1 1. Remove backing from kit label. Fold label around jumper harness wire to indicate kit installation.

12. Adhere kit wiring diagram adjacent to existing unit wiring diagram.

IMPORTANT NOTE: Secure all wires to avoid their contact with any hot surfaces or moving parts.

Gas plumbed out the l eft side

of the furnace

Gas Valve

X

7

Page 8

®

TROUBLESHOOTING

If the furnace fails to light after installation of the LP low pressure switch kit, proceed as follows:

Remove jumper harness

from gas valve and gas

valve wiring.

Reconnect furnace wiring

harness to gas valve.

Problem does not

involve the LP low

pressure switc h.

With gas supply on,

measure resistance

between terminals of LP

low pressure switch.

Are

switch contacts

closed?

Check jumper harness

circuits fo r continuity.

NO

Reconnect LP low

pressure switch jumper

harness.

Check gas supply

gas val ve wiring, etc.

NO NO

Is line

pressure above

9.0" w.c.?

Replace faulty LP low

pressure switch.

Reconnect jumper

harness.

Correct insufficient ga s

line pressure problem.

Reconnect jumper

harness.

Continuity

checks OK on

jumper harness?

NO

Jumper ha rness pro blem.

Reconnect jumper

harness . Chec k jump er

harness connections.

NOTE: SPECIFICATIONS AND PERFORMANCE DATA LISTED HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTICE

Visit our website at www.daikincomfort.com, www.goodmanmfg.com or www.amana-hac.com for information on:

• Products • Parts • Customer Services

• Warranties • Financing Options • Contractor Programs and Training

Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

© 2012 - 2014 Goodman Manufacturing Company, L.P.

is a trademark of Maytag Corporation and is used under license. All rights reserved.

8

Loading...

Loading...