Page 1

LAKT01 & LAKT03

LOW AMBIENT KITS

INSTALLATION INSTRUCTIONS

ATTENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the product better than the customer. This includes all safety precautions

and related items.

Prior to actual installation, thoroughly familiarize yourself with this

Instruction Manual. Pay special attention to all safety warnings.

Often during installation or repair it is possible to place yourself in

a position which is more hazardous than when the unit is in operation.

Remember, it is your responsibility to install the product safely

and to know it well enough to be able to instruct a customer in its

safe use.

Safety is a matter of common sense...a matter of thinking before

acting. Most dealers have a list of specific good safety practices...

follow them.

The precautions listed in this Installation Manual are intended as

supplemental to existing practices. However, if there is a direct

conflict between existing practices and the content of this manual,

the precautions listed here take precedence.

DESCRIPTION

The LAKT01 and LAKT03 low ambient kits (for Light Commercial

Models and Residential Splits) are temperature sensitive fan motor speed controls designed to regulate the outdoor section head

pressure by varying the air volume through the outdoor coil and

are required when operating below 55

is achieved by sensing the liquid temperature at the coil by means

of a thermistor probe. The probe provides an input signal to the

control to increase the fan motor speed in relation to changes in

the liquid temperature. Ensure all parts are included before beginning. If parts are missing from the kit contact the distributor where

the kit was purchased.

NOTE: These kits are not approved for any 16 and 18 SEER outdoor units that utilize an ECM condenser fan motor.

°

F outdoor temperature. This

The following accessories must be installed on all condensers and

remote heat pumps when equipped with low ambient kits.

1. Crankcase heater must be installed if not factory installed.

2. Hard start kit for single phase units. (See Spec Sheet for

Accessories)

3. TXV kit installed on indoor evaporator coil, if not factory installed.

4. FSK01A - Freeze protection kit must be installed on indoor

coil.

o

5. Wind buffer must be installed for temperatures below 0

areas with high prevailing winds. Wind buffer can be a wall

fabricated from wood or masonry material that will prevent

the prevailing wind from causing the outdoor fan to rotate.

NOTE: When wind buffer is installed, it is necessary to use

minimum 4" risers to elevate the unit off of the pad to provide

better airflow for moderate and high ambient temperatures.

F or

NOTE: SPECIFICATIONS AND PERFORMANCE DATA LISTED HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTICE

Quality Makes the Difference!

All of our systems are designed and manufactured with the same high quality standards regardless of size or

efficiency. We have designed these units to significantly reduce the most frequent causes of product failure.

They are simple to service and forgiving to operate. We use quality materials and components. Finally, every

unit is run tested before it leaves the factory. That’s why we know. . .There’s No Better Quality.

Visit our website at www.daikincomfort.com, www.goodmanmfg.com or www.amana-hac.com for information on:

• Products • Parts

• Warranties • Contractor Programs and Training

• Customer Services • Financing Options

IO-826

7/2014

is a registered trademark of Maytag Corporation or its related companies and is used under license to

© 2014 Goodman Manufacturing Company, L.P.

Goodman Company, L.P., Houston, TX, USA. All rights reserved.

Page 2

PARTS LIST FOR KITS

Item Part No. Qty.

Pres sure Control & Probe LAKT01 0130M00058 1

Pres sure Control & Probe LAKT03 0130M00059 1

Wire As sembly LAKT01 --- 8

Wire As sembly LAKT03 --- 6

Terminals LAKT01 --- 4

Terminals LAKT03 --- 7

Wire Ties LAKT01 --- 3

Wire Ties LAKT03 --- 4

Mount ing Bracket

LAKT01 & LAKT03

0121M00047 1

Inst allation Instruc tions IO-826 1

KIT INSTALLATION

Figure 1A

1. Disconnect all sources of power to the unit.

2. Remove access panels to blower compartment and control

box.

3. Using the screws provided, secure the control to the mounting bracket provided (see Figure 1A). Secure the new assembly on the condenser evaporator partition panel in the

blower section of the unit.

For 3 to 12.5 ton light commercial, secure 2 inches below

the hole where the fan and compressor leads exit the blower

section. See Figure 1B.

For 15 to 20 ton light commercial, secure to the right of

the capacitor assembly, located on the partition panel. See

Figure 1C.

For residential 3 phase models, secure ICM to the control

panel. See Figure 1D. (Do not use mounting bracket in this

application.)

NOTE: Do not install the control in areas where the mounting screws can come into contact with the condenser coil or

tubing.

Figure 1B

Figure 1C

2

Page 3

Figure 1D

4. Connect the electrical wiring as shown in the wiring diagrams

on pages 5 - 8.

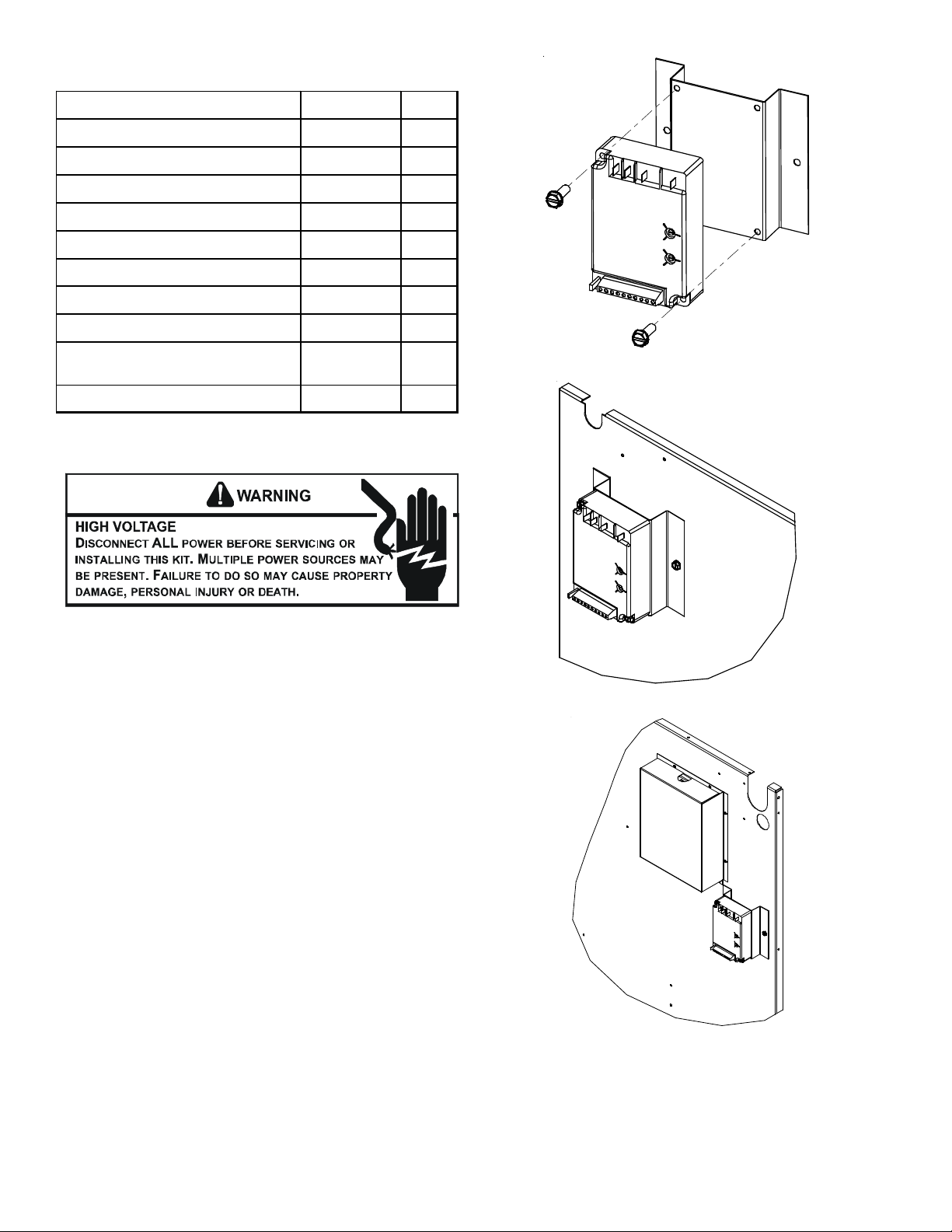

5. For light commercial, install temperature probe between

the fins, at the middle to upper section of the condenser coil

(see Figure 2).

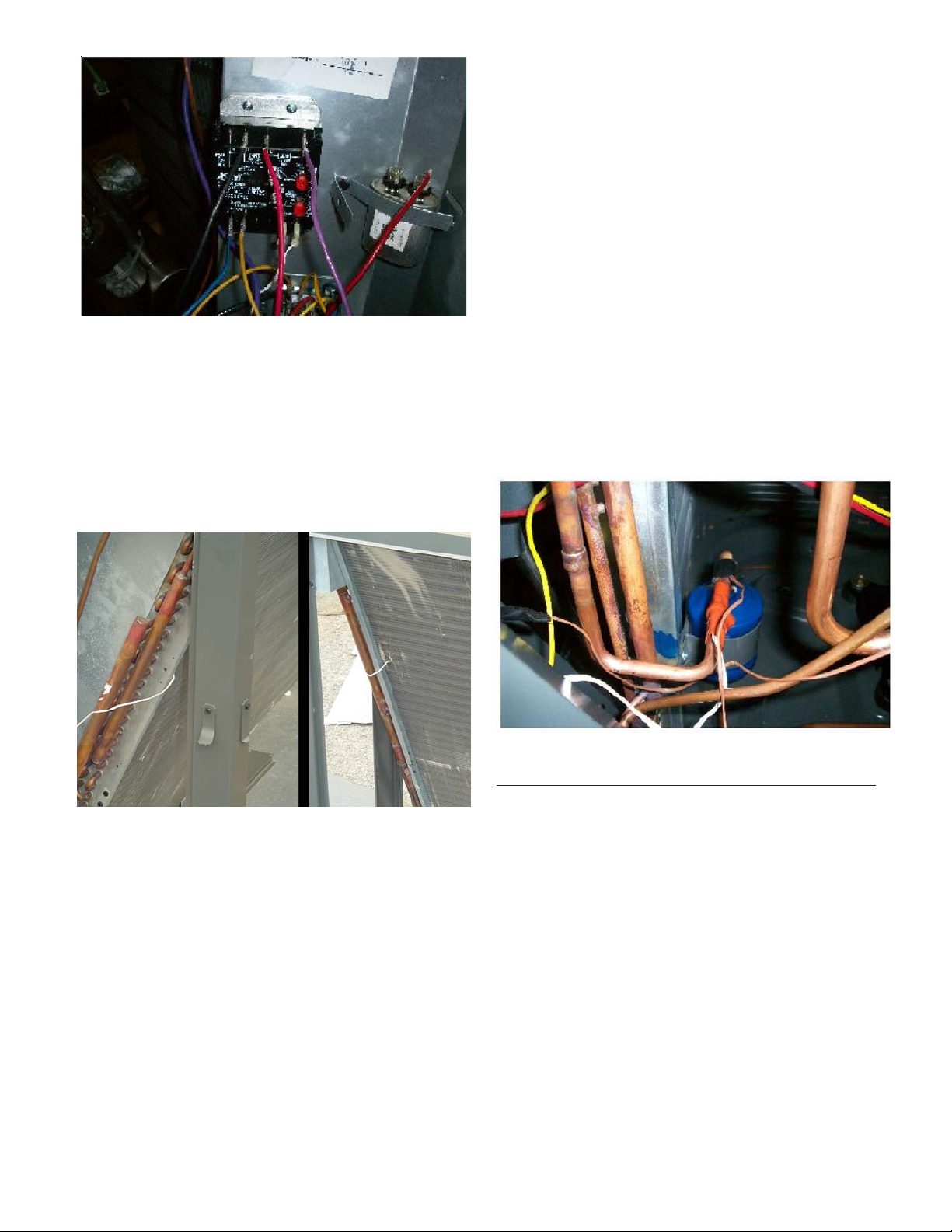

For Residential Split Condensers and heat pumps,

install the probe on the liquid line before the filter/dryer.

Ensure the probe body is completely attached to the body of

the liquid tube before securing with the tape (See Figure 3).

LAKT01 (3 thru 6 tons)

Wiring Diagram 0140M00108 - use with AC and HP units, three

phase and single phase application.

For residential 3 phase condensers, connect wires per 0140M00108

wiring diagram.

For residential 3 phase heat pumps, connect wires per 0140R00167

wiring diagram.

LAKT03 (7 ½ tons thru 12 ½ tons)

Wiring Diagram 0140L03520A - use with AC and HP units, three

phase application.

LAKT03 (15 tons and up)

Wiring Diagram 0140L01008 - use with AC units.

(a) Wiring diagrams show the controller connection for 120/

277 volts supply. For 480/600 volts application, connect

the power supply leads to the 480/600 VAC terminal.

NOTE: The low ambient kit is pre-set at the factory and re-

quires no further adjustment. Altering the setting may

greatly reduce motor life.

Figure 2

6. Connect the probe leads to the terminal marked PROBE S1.

For systems with multiple refrigeration circuits, attach the

second probe to PROBE S2 or PROBE S3. The LAKT03 is

shipped with two probes. See control instruction manual for

multiple probe connection and operation.

WIRING DIAGRAMS AND APPLICATION

The LAKT01 and LAKT03 kits are shipped with wiring diagram

included. Affix the low ambient kit wiring diagram on the control

box door next to the unit wiring diagram.

Figure 3

WIRING PROCEDURE FOR LAKT01 (REMOTE AC & HP):

1. Connect the wiring as shown on page 6.

2. Attach supplied wiring diagram adjacent to existing wiring

diagram. Follow the system calibration instruction provided

in the control instruction manual for sleeve bearing motors.

Verify wiring is correct.

3. Use provided wire ties to secure wire leads away from all

moving parts and warm refrigeration tubing.

4. Reinstall access panel.

5. Restore power and verify system operation.

3

Page 4

WIRING PROCEDURE FOR LAKT03 (7½ thru 12 ½ tons):

WIRING PROCEDURE FOR LAKT03 (15 tons & up):

1. Find the three (3) fan motor leads (purple, black & brown)

from condenser motor circuit #2. (These leads pass through

the partition panel just above the area where the controller

is mounted.) Disconnect the leads at the junctions.

2. From the kit, install one of the “Y” push-on terminal adapters onto the controller terminal marked Motor 2 and another

onto terminal Line 1/Motor 1.

NOTE: Make sure the correct voltage tap is selected.

3. Connect the black wire from condenser motor circuit #2 to

one side of the connector on the Motor 2 terminal of the

controller. Using the male/female black adapter wire from

the kit, connect the black wire coming from the control box to

the Line 2 terminal on the controller.

4. Connect the male/female purple adapter wire from the kit to

the purple wire coming from the control box and to one side

of the Line 1/Motor 1 terminal on the controller.

5. Find the three fan motor leads (purple, black & brown) going

to condenser motor circuit #1. (These leads exit through the

partition panel on the opposite side of the controller.) Cut

the black and purple wires so that those leads will connect

to the controller. Attach the provided terminals to each of the

leads and connect the purple lead to the Line 1/Motor 1

terminal. Attach the black wire to the other side of the “Y”

push-on terminal adapters on the Motor 2 terminal on the

controller.

6. Remove or tape up the ends of the cut purple and black

wires.

7. Locate the red wire connecting FC1 (fan capacitor #1) to T2

of the compressor contactor #1. Disconnect the wire from

T2 and connect it to the terminal on FC2 (fan capacitor #2)

that has three black wires. Remove the black wire from FC1

(fan capacitor #1) and connect to T2 of the compressor

contactor 1.

1. Remove the cover on the capacitor assembly that is located

next to the controller. Disconnect the red and black leads

that are coming form the control box assembly. They are

connected to the furthest right capacitor and the terminal

block respectively.

2. From the kit, install one of the Y push on terminal adapters

onto the controller terminal marked Line 1 / Motor 1.

3. Connect the disconnected black wire to Line 2 terminal on

the controller. Connect the disconnected red wire onto one

of the Y push on terminals now located on the Line 1 / Mo-

tor 1 terminal of the controller.

4. From the kit, connect the red wire between the remaining Y

terminal on Line 1 / Motor 1 and the location on the furthest

right capacitor where the red wire had previously been removed.

5. From the kit, connect the black wire between the Motor 2

terminal on the controller and the terminal block where the

black wire had previously been removed.

6. Connect the blue wire and the yellow wire to the controller on

the 24 VAC connection as shown on the diagram.

7. Route wires along tubing, under evaporator, and into the

bottom opening of control box. Connect the yellow wire to

Y1 on the low voltage terminal strip and the blue wire to C.

8. Attach supplied wiring diagram adjacent to existing wiring

diagram. Follow the system calibration instruction provided

in the control instruction manual for sleeve bearing motors.

Verify wiring is correct.

9. Use provided wire ties to secure wire leads away from all

moving parts and warm refrigeration tubing.

10. Reinstall access panel.

11. Restore power and verify system operation.

8. Connect YL and BL wire to 24 vac connection on the controller and then to YI and C respectively, on the terminal block

in the control box.

9. Attach supplied wiring diagram adjacent to existing wiring

diagram. Follow the system calibration instruction provided

in the control instruction manual for sleeve bearing motors.

Verify wiring is correct.

10. Use provided wire ties to secure wire leads away from all

moving parts and warm refrigeration tubing.

11. Reinstall access panel.

12. Restore power and verify system operation.

4

Page 5

WIRING DIAGRAM

WARNING

LAKT01

CONNECT PARALLEL TO

REVER SING VALVE 24 VAC

( IF USED ) SEE NOTE 2

O.D. MOTOR

( IF USED )

SEE NOTE 3

MODELS: GSX**090*, GSX**120*, DX**090*,

DX**120* & DC*036-072

YL

VAC

PUMP

S1

S2

S3

BR

N.C. HEAT PUMP

24

HEAT

PROBE

PROBE

START

HARD

PROBE

BK

SPEED

CONTROLS

CUT OUT

RD

ICM

FULL

SPEED

VAR IABL E

SPPED

PU

L

I

N

480-600

VAC

E

1

/

M

120-277

VAC

O

T

O

R

1

10 AMP

MAX

MOTOR 2LINE 2

BK

PU

FAN

RUN

CAPACITOR

T2 L2

T1

RD

COMP

BK

COMP

HERM

C

CONNECT TO TERMINAL BLOCK

Y (CALL FOR COOL)

BL (COMMON)

C

L1

LEGEND

RETURN BEND END

OF CONDENSER COIL

RD RED

BK BLACK

PU PURPLE

BR BROWN

CONTACTOR

B BLUEL

NOTES:

1. USE COPPER CONDUCTORS ONLY.

SENSOR

2. ALTERNATE WIRING FOR HEAT PUMP APPLICATION, MAKE A

PARALLEL CONNECTION FROM THE REVERSING VALVE 24 VAC

POWER SUPPLY TO THE HEAT PUMP TERMINALS ON THE CONTROL.

THE SELECT JUMPER MUST BE IN THE NORMALLY CLOSED

POSITION FOR NON-ENERGIZED REVERSING VALVE DURING HEATING.

3. ALTERNATE WIRING FOR SINGLE PHASE APPLICATION; THREE PHASE

MODELS DOES NOT REQUIRE A DUAL RUN CAPACITOR.

4. WIRING DIAGRAM SHOWS CONTROLLER CONNECTION FOR 120 TO

277 VOLTS SUPPLY; FOR 480-600 VOLT APPLICATION,

CONNECT POWER SUPPLY BETWEEN LINE 2 AND THE 480-600

VAC TERMINALS.

0140M00 108 REV B

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

5

Page 6

WIRING DIAGRAM

WARNING

DEFRO ST BOARD

LVDR

W2

O O R R

C Y

OR

BK

RD COMP

BK COMP

BK

BK

RD

T2

T3

T1

L1

L2

L3

CONTACTOR

DF2

H

V

D

R

DF1

DFT

REVERSING VALVE

BK

MODELS: GSZ**090* & GSZ**120*

DZ**090* & DZ**120*

BK

BK

BK

BK

ICM

PU

PU

HERM

FAN

C

CAPACITOR

RD

PU

2

LOAD

X

X

BR

PU

OD FAN MOTOR

CUT OUT TEMP

HARD START

LAKT01

BK

24V

HP

YL

BL

BK

OR

CONNECT PARALLEL TO

24V REVERSING VALVE

FIGURE 3

SENSOR

NOTE

1. THE HEAT PUMP TERMINALS ACCEPT THE 24VAC SIGNAL FROM

THE RV HOLDING COIL . MAKE PARALLEL CONNECTION FROM RV

TO HP TERMINALS.

2. THE HEAT PUMP SELECT JUMPER WIRE MUST BE IN THE ( N.C.)

POSITION.

3. ENSURE THE BODY OF THE SENSOR PROBE IS COMPLETELY

ATTACHED TO THE BODY OF LIQUID TUBE BEFORE SECURING

WITH THE TAPE.

4. USE COPPER CONDUCTORS ONLY.

5. WIRING DIAGRAM SHOWS CONTROLLER CONNECTION FOR 120 TO 277 VOLTS SUPPLY.

FOR 480-600 VOLT APPLICATION, CONNECT POWER SUPP LY BETWEEN

LINE 2 AND THE 480-600VAC TERMINALS.

LIQUID LINE

BEFORE

FILTER DRIER

CONNECT WITH

BL

YL (CALL FOR COOL )

YL

BL ( COMMON)

T-STAT L EADS

RETURN BEND END

OF CONDENSER COIL

( OR )

FILTER DRIER

LEGEND

RD RED

BK BLACK

PU PURPLE

BR BROWN

YL YELLOW

BL BLUE

OR ORANGE

0140R00167

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

6

Page 7

WIRING DIAGRAM

WARNING

BK

BK

BK

YL

YL

YL

BK

BK

BK

BL

BL

BL

MODELS: DC*090 - DC*150

MODELS: DC*090 - DC*150

MODELS: DC*090 - DC*150

VAC

VAC

VAC

24

24

24

PUMP

PUMP

PUMP

HEAT

HEAT

HEAT

PROBE

PROBE

PROBE

S1

S1

S1

PROBE

PROBE

PROBE

S2

S2

S2

PROBE

PROBE

PROBE

S3

S3

S3

O.D. MOTOR

O.D. MOTOR

O.D. MOTOR

N.C. HEAT PUMP

N.C. HEAT PUMP

N.C. HEAT PUMP

START

START

START

HARD

HARD

HARD

BK

BK

BK

BR

BR

BR

FAN

FAN

FAN

RUN

RUN

RUN

CAPACITOR

CAPACITOR

CAPACITOR

CUT OUT

SPEED

CUT OUT

SPEED

CUT OUT

SPEED

C

C

C

ICM

ICM

ICM

CONTROLS

CONTROLS

CONTROLS

USE ONE TERMINAL ONLY

480-600

VAC

480-600

VAC

480-600

VAC

LINE 1 / MOTOR 1

VAC

VAC

VAC

120-277

120-277

120-277

LINE 2

LINE 2

LINE 2

FULL

SPEED

FULL

SPEED

FULL

SPEED

10 AMP

MAX

10 AMP

MAX

10 AMP

MAX

VARIABLE

SPPED

VARIABLE

SPPED

VARIABLE

SPPED

MOTOR 2

MOTOR 2

MOTOR 2

PU

PU

PU

SEE NOTE 2

PU

PU

PU

PU

PU

PU

RD

RD

RD

BK

BK

BK

PU

PU

PU

BK

BK

BK

BK

BK

BK

O.D. MOTOR

O.D. MOTOR

O.D. MOTOR

BR

BR

BR

RUN

RUN

RUN

CAPACITOR

CAPACITOR

CAPACITOR

C

C

FAN

FAN

FAN

C

RD

RD

RD

CONTACTOR

CONTACTOR

CONTACTOR

LAKT03

BK

BK

BK

O (HEAT PUMP ONLY)

O (HEAT PUMP ONLY)

C (HEAT PUMP ONLY)

C (HEAT PUMP ONLY)

T1 T2

T1 T2

T1 T2

L1 L2

L1 L2

L1 L2

CONNECT TO TERMINAL BLOCK

Y1 (CALL FOR COOL)

CONNECT TO TERMINAL BLOCK

Y1 (CALL FOR COOL)

C (COMMON)

C (COMMON)

SENSOR

SENSOR

SENSOR

CIRCUIT #1

CIRCUIT #1

CIRCUIT #1

RD

RD

RD

T1

T1

T1

L1

L1

L1

CMC

CMC

CMC

T2

T2

T2

L2

L2

L2

HEAT

PUMP ONLY

(SEE NOTE "2")

INSERT PROBE 2/3

INSERT PROBE 2/3

INSERT PROBE 2/3

UP IN FIN PACK ON

UP IN FIN PACK ON

SENSOR

SENSOR

SENSOR

CIRCUIT #2

CIRCUIT #2

CIRCUIT #2

UP IN FIN PACK ON

HEADER END OF

HEADER END OF

HEADER END OF

COIL

COIL

COIL

NOTES:

1. USE COPPER CONDUCTORS ONLY.

2. ALTERNATE WIRING FOR HEAT PUMP APPLICATION, CONNECT

TO THE HEAT PUMP TERMINALS ON THE CONTROL.

THE SELECT JUMPER MUST BE IN THE NORMALLY CLOSED

POSITION FOR NON-ENERGIZED REVERSING VALVE DURING HEATING.

PURPLE WIRE IS CONNECTED TO T1 OF CMC, AND NOT TO C TERMINAL

OF CAPACITOR.

3. WIRING DIAGRAM SHOW S CONTROLLER CONNECTION FOR 120 TO

277 VOLTS SUPPLY; FOR 480-600 VOLT APPLICATION,

CONNECT POWER SUPPLY BETWEEN LINE 2 AND THE 480-600

VAC TERMINALS.

T3

T3

T3

L3

L3

C

C

C

LEGEND

LEGEND

LEGEND

RD RED

RD RED

RD RED

BK BLACK

BK BLACK

BK BLACK

PU PURPLE

PU PURPLE

PU PURPLE

BR BROWN

BR BROWN

BR BROWN

YL YELLOW

YL YELLOW

YL YELLOW

BL BLUE

BL BLUE

BL BLUE

L3

0140L03520-A

0140L03520-A

0140L03520-A

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

7

Page 8

WIRING DIAGRAM

WARNING

CONNECT PARALLEL TO

REVERSING VALVE 24 VAC

( IF USED ) SEE NOT E 2

LAKT03

L2L1

L2L1

L3

N.C. HEAT PUMP

VAC

24

PUMP

HEAT

PROBE

S1

PROBE

S2

START

HARD

PROBE

S3

ICM

CONTROLS

CUT OU T

SPEED

SPEED

SPPED

L

I

480-600

VAC

N

E

1

/

120-277

VAC

M

O

T

O

R

1

FULL

10 AMP

MAX

VARIA BLE

MOTOR 2LINE 2

RD

CC2

RD

BK

CC1

RD

L3

T2T1

T3

T2T1

T3

RD

L2L1

L3

RD

T2T1

T3

SENSOR

SENSOR

CIRCUIT #2

CIRCUIT #1

CONNECT TO TERMINAL BLOCK

Y (CALL FOR COOL)

BL (COMMON)

INSERT PR OBE 2/3

UP IN FIN PACK ON

HEADER END OF

COIL

BK

PU

BR

PU PU

BR BR

PU

PU

PU

BR

BR

BR

PU

PU

BR

BR

FC1

FC2

FC3

TB2

CM3

CM2

CM1

C

RD

F

C

RD

F

C

F

BK

BK

BK

BK

BK

BK

BK

LEGEND

RD RED

BK BLACK

PU PURPLE

BR BROWN

YL YELLOW

BL BLUE

NOTES:

1. USE COPPER CONDUCTORS ONLY.

2. ALTERNATE WIRING FOR HEAT PUMP APPLICATION, MAKE A

PARALLEL CONNECTION FROM THE REVERSING VALVE 24 VAC

POWER SUPPLY TO THE HEAT PUMP TERM INALS ON THE CONTROL.

THE SELECT JUMPER MUST BE IN THE NORMALLY CLOSED

POSITION FOR NON-ENERGIZED REVERSING VALVE DURING HEATING.

3. WIRING DIAGRAM SHOWS CONTROLLER CONNECTION FOR 120 TO

277 VOLTS SUPPLY; FOR 480-600 VOLT APPLICATION,

CONNECT POWER SUPPLY BETWEEN LINE 2 AND THE 480-600

VAC TERMINALS.

0140L 01008 REV B

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

8

Loading...

Loading...