Page 1

I

NSTALLATION INSTRUCTIONS

C

OMMERCIAL

H

EATING

& C

F

OR

OOLING

3 T

ON

- 6 T

ON

P

CPG S

ACKAGE

ERIES

G

AS

U

C

NIT

®

US

This Forced Air Central Unit Design Complies With

Requirements Embodied in The American National

Standard / National Standard of Canada Shown

Below.

ANSI Z21.47•CSA-2.3 Central Furnaces

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

ATTENTION INSTALLING PERSONNEL

Prior to installation, thoroughly familiarize yourself with this Installation Manual. Observe all safety warnings.

During installation or repair, caution is to be observed.

It is your responsibility to install the product safely and to educate the customer on its safe use.

All information contained herein is subject to change without notice.

Goodman Manufacturing Company, L.P .

IO-353C 5151 Felipe, Suite 500, Houston, TX 77056

11/10 www.goodmanmfg.com www.amana-hac.com

© 2009-2010 Goodman Manufacturing Company, L.P.

Page 2

Index

REPLACEMENT PARTS

Replacement Parts ........................................................2

Safety Instructions ........................................................2

General Information ......................................................3

Unit Location ................................................................. 4

Clearances .....................................................................5

Roof Curb Post-Installation Checks ............................ 6

Roof Top Duct Connections .........................................6

Rigging Details ..............................................................7

Electrical Wiring ............................................................9

Gas Supply Piping.......................................................10

Propane Gas Installations ..........................................12

Circulating Air and Filters...........................................13

Venting ......................................................................... 13

Condensate Drain Connection ...................................13

Startup, Adjustment s, and Checks ............................14

Normal Sequence Of Operation ................................. 19

Troubleshooting ..........................................................20

Input Rating .................................................................21

Air flow Adjustments................................................... 22

ORDERING PARTS

When reporting shortages or damages, or ordering repair

parts, give the complete unit model and serial numbers

as stamped on the unit’s nameplate.

Replacement parts for this appliance are available

through your contractor or local distributor. For the

location of your nearest distributor, consult the white

business pages, the yellow page section of the local

telephone book or contact:

CONSUMER AFFAIRS

GOODMAN MANUFACTURING COMPANY, L.P.

7401 SECURITY WAY

HOUSTON, TEXAS 77040

(877) 254-4729

SAFETY INSTRUCTIONS

TO THE INSTALLER

Before installing this unit, please read this manual to

familiarize yourself on the specific items which must be

adhered to, including maximum external static pressure

to unit, air temperature rise, minimum or maximum CFM

and motor speed connections.

Keep this literature in a safe place for future reference.

WARN ING

Motor Sheave Adjustments ........................................ 22

Maintenance ................................................................22

Appendix A Blower Performance Tables................... 25

Direct Drive .............................................................. 25

CPG036 Down Shot and Horizontal...................25

CPG048 Down Shot and Horizontal...................26

CPG060 Down Shot............................................. 27

CPG060 Horizontal ..............................................28

Belt Drive ................................................................. 29

Standard Down Shot...........................................29

Standard Horizontal ............................................30

High Static Down Shot........................................31

Belt Drive - High Static Horizontal ..................... 32

Appendix B Electrical Data......................................... 33

Appendix C Unit Dimensions ..................................... 34

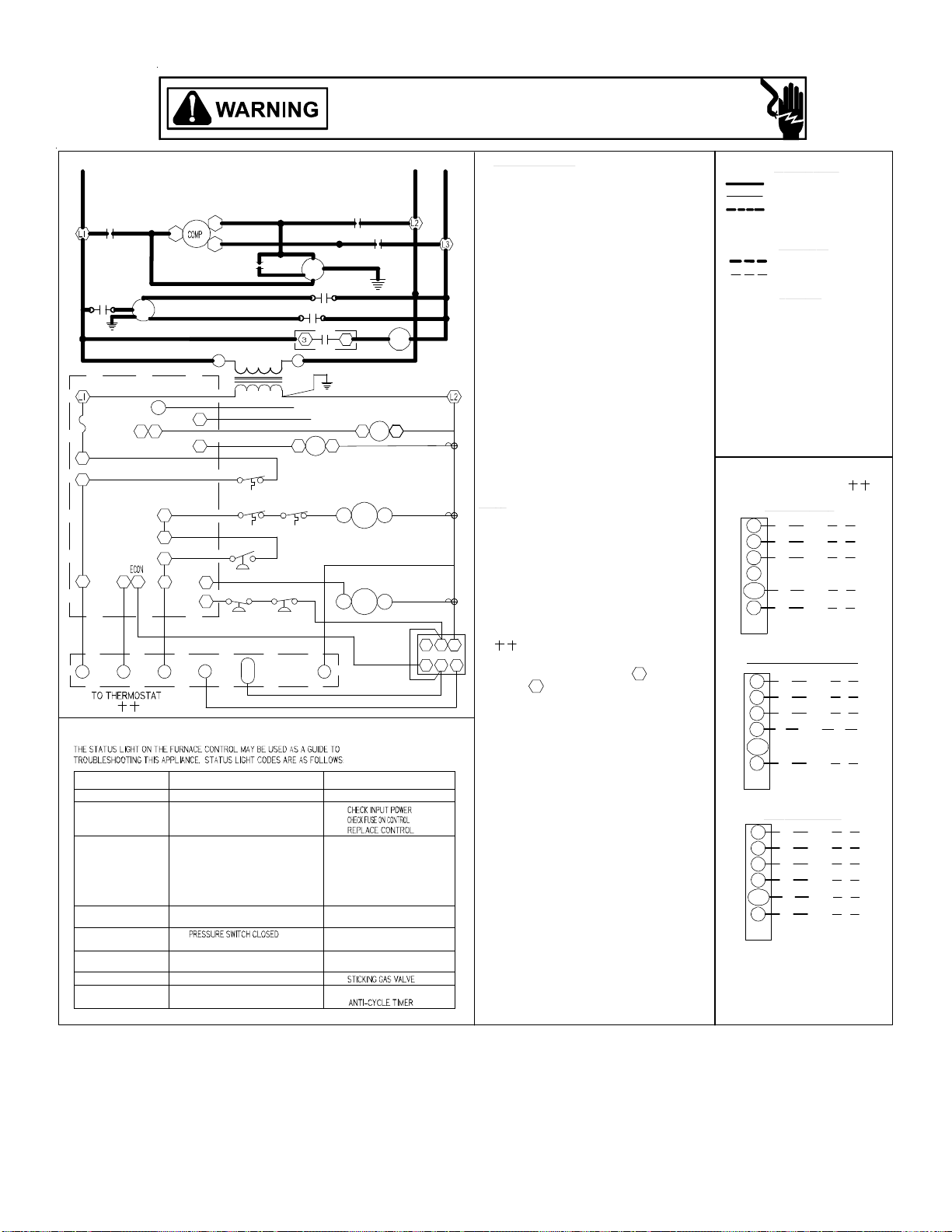

Appendix D Wiring Diagrams .....................................35

IF

THE INFORMATION IN THESE INSTRUCTIONS IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY

DAMAGE, PERSONAL INJURY OR LOSS OF LIFE

- D

O NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

- WHAT T O D O IF YO U SMELL GA S:

- I

* D

O NOT TRY TO LIGHT ANY APPLIANCE

O NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT USE

* D

ANY PHONE IN YOUR BUILDING

* I

MMEDIATELY CALL YOUR GAS SUPPLIER FROM A

NEIGHBORS PHONE

INSTRUCTIONS

* I

F YOU CANNOT REACH YOUR GAS SUPPLIER, CALL THE

NSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED

INSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER

FIRE DEPARTMENT

. F

OLLOW THE GAS SUPPLIERS

.

.

.

.

.

.

WARNING

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO SHUT OFF, TURN

OFF THE MANUAL GAS SHUTOFF VALVE EXTERNAL TO THE FURNACE BEFORE

TURNING OFF THE ELECTRICAL SUPPLY.

CAUTION

S

HEET METAL PARTS, SCREWS, CLIPS AND SIMILAR ITEMS INHERENTLY

HAVE SHARP EDGES, AND IT IS NECESSARY THAT THE INSTALLER AND

SERVICE PERSONNEL EXERCISE CAUTION

.

2

Page 3

WARN ING

DO

NOT CONNECT TO OR USE ANY DEVICE THAT IS NOT DESIGN

CERTIFIED BY GOODMAN FOR USE WITH THIS UNIT

PROPERTY DAMAGE, PERSONAL INJURY, REDUCED UNIT

PERFORMANCE AND

FROM THE USE OF SUCH NON-APPROVED DEVICES

/OR

HAZARDOUS CONDITIONS MAY RESULT

. S

.

ERIOUS

WARNING

HIS PRODUCT CONTAINS OR PRODUCES A CHEMICAL OR CHEMICALS WHICH

T

MAY CAUSE SERIOUS ILLNESS OR DEATH AND WHICH ARE KNOWN TO THE

S

TATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM.

WARNING

WARNING

CARBON MONOXIDE POISONING

HAZARD

FAILUR E TO KEEP THIS CO MPARTMENT CLOS ED

EXCEPT WHEN SERVICING COULD RESULT IN

CARBON MONOXIDE POISONING OR DEATH.

THIS COMPARMENT MUST BE CLOSED EXCEPT

WHEN SERVICING

A VERTISSEMENT

RISQUE D'EMPOISONNEMENT AU

MONOXYDE DE CARBONE

SI CE COMPARTMENT N'EST PAS FERME EN

TOUT TEMPS, SAU F EN CAS D E REPARATION, IL Y

A RISQUE D'EM POISONNEME NT OU MONOXYDE

DE CARBON E OU DE MORT.

CE COMPARTIMENT DO IT ETRE FE RME SAUF AU

MOMENT DE L'ENTRETIEN.

O AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DO NOT USE

T

I

THIS UNIT IF ANY PART HAS BEEN UNDER WATER.

QUALIFIED SERVICE TECHNICIAN TO INSPECT THE FURNACE AND TO REPLACE

ANY PART OF THE CONTROL SYSTEM AND ANY GAS CONTROL HAVING BEEN

UNDER WATER.

T

HIS UNIT MUST NOT BE USED AS A "CONSTRUCTION HEATER

DURING THE FINISHING PHASES OF CONSTRUCTION ON A NEW

STRUCTURE

FAILURE OF THE UNIT DUE TO EXTREMELY LOW RETURN AIR

TEMPERATURE AND EXPOSURE TO CORROSIVE OR VERY

DIRTY

. T

HIS TYPE OF USE MAY RESULT IN PREMATURE

ATMOSPHERES

.

MMEDIATELY CALL A

"

WARN ING

HIGH VOLTAGE!

ISCONNECT ALL POWER BEFORE SERVICI NG OR

D

INSTALLING THIS UNIT

BE PRESENT

DAMAGE, PERSONAL INJURY OR DEATH

. F

. M

AILURE TO DO SO MAY CAUSE PROPERTY

ULTIPLE POWER SOURCES MAY

.

WARNING

TO PREVENT THE RISK OF PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH,

DO NOT STORE COMBUSTIBLE MATERIALS OR USE GASOLINE OR OTHER

FLAMMABLE LIQUI DS OR VAPORS I N THE V ICINIT Y OF THI S APPL IANCE.

ADVERTENCIA

PELIGRO MONOXIDO DE CARBONO

TOXICO

EL FRACASO DE NO MANTENER

COMPARTIMIENTO CERRADO MENOS DURANTE,

ATENDER, PODRIA TENER COMO RESULTADO

ENVENENAR DE MONOXIDO DE CARBONO O

MUERTE.

ESTE COMPARTIMIENTO DEBE CERRADO MENOS

AL A TEN DER

GENERAL INFORMA TION

WARNING

O PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DUE TO FIRE,

T

EXPLOSIONS, SMOKE, SOOT, CONDENSATION, ELECTRIC SHOCK OR CARBON

MONOXIDE, THIS UNIT MUST BE PROPERLY INSTALLED, REPAIRED, OPERATED,

AND MAINTAINED.

This unit is approved for outdoor installation ONLY. To

assure that your unit operates safely and efficiently, it must

be installed, operated, and maintained in accordance with

these installation and operating instructions, all local building

codes and ordinances, or in their absence, with the latest

edition of the National Fuel Gas Code NFP A54/ANSI Z223.1

and National Standard of Canada CAN/CSA B149 Installation Codes.

-

0140L00106

WARN ING

HIGH VOLTAGE!

INSTALLATION AND REPAIR OF THIS UNIT SHOULD BE

PERFORMED

REQUIREMENTS OF AN

SPECIFIED BY THE AIR CONDITIONING AND

R

EFRIGERATION INSTITUTE

INSTALL OR REPAIR THIS UNIT WITHOUT SUCH

BACKGROUND MAY RESULT IN PRODUCT DAMAGE

PERSONAL INJURY OR DEATH

ONLY BY

INDIVIDUALS MEETING THE

“E

NTRY LEVEL TECHNICIAN” AS

(ARI). A

TTEMPTING TO

.

,

The heating and cooling capacities of the unit should be

greater than or equal to the design heating and cooling loads

of the area to be conditioned. The loads should be calculated

by an approved method or in accordance with ASHRAE Guide

or Manual J - Load Calculations published by the Air Conditioning Contractors of America.

Obtain from:

American National Standards Institute

1430 Broadway

New York, NY 10018

System design and installation should also, where applicable,

follow information presented in accepted industry guides such

as the ASHRAE Handbooks. The manufacturer assumes no

3

Page 4

responsibility for equipment installed in violation of any code

or regulation. The mechanical installation of the packaged

roof top units consists of making final connections between

the unit and building services; supply and return duct connections; and drain connections (if required). The internal

systems of the unit are completely factory-installed and tested

prior to shipment.

Units are generally installed on a steel roof mounting curb

assembly which has been shipped to the job site for installation on the roof structure prior to the arrival of the unit. The

model number shown on the unit’s identification plate identifies the various components of the unit such as refrigeration

tonnage, heating input and voltage.

Carefully inspect the unit for damage including damage to

the cabinetry . Any bolts or screws which may have loosened

in transit must be re-tightened. In the event of damage, the

receiver should:

1. Make notation on delivery receipt of any visible

damage to shipment or container.

2. Notify carrier promptly and request an inspection.

3. In case of concealed damage, carrier should be

notified as soon as possible-preferably within 5 days.

4. File the claim with the following supporting documents:

a. Original Bill of Lading, certified copy, or indemnity

bond.

b. Original paid freight bill or indemnity in lieu thereof.

c. Original invoice or certified copy thereof, showing

trade and other discounts or reductions.

d. Copy of the inspection report issued by carrier

representative at the time damage is reported to the

carrier. The carrier is responsible for making prompt

inspection of damage and for a thorough

investigation of each claim. The distributor or

manufacturer will not accept claims from dealers for

transportation damage.

NOTE: When inspecting the unit for transportation damage,

remove all packaging materials. Recycle or dispose of the

packaging material according to local codes.

PRE-INSTALLATION CHECKS

Carefully read all instructions for the installation prior to installing unit. Ensure each step or procedure is understood

and any special considerations are taken into account before starting installation. Assemble all tools, hardware and

supplies needed to complete the installation. Some items may

need to be purchased locally.

UNIT LOCA TION

WARNING

O PREVENT POSSIBLE EQUIPMENT DAMAGE, PROPERTY DAMAGE, PERSONAL

T

INJURY OR DEATH, THE FOLLOWING BULLET POINTS MUST BE OBSERVED

WHEN INSTALLING THE UNIT.

IMPORTANT NOTE: Remove wood shipping rails prior to

installation of the unit.

ALL INSTALLATIONS:

NOTE: Appliance is shipped from factory for vertical duct

application.

Proper installation of the unit ensures trouble-free operation.

Improper installation can result in problems ranging from

noisy operation to property or equipment damages, dangerous conditions that could result in injury or personal property

damage and could void the warranty . Give this booklet to the

user and explain it’s provisions. The user should retain these

instructions for future reference.

• For proper flame pattern within the heat exchanger

and proper condensate drainage, the unit must be

mounted level.

• The flue outlet must be at least 12 inches from any

opening through which flue gases could enter a

building, and at least three feet above any forced air

inlet located within ten feet. The economizer/manual

fresh air intake/motorized fresh air intake and

combustion air inlet mounted on the unit are not

affected by this restriction.

• To avoid possible corrosion of the heat exchanger,

do not locate the unit in an area where the outdoor air

(i.e. combustion air for the unit) will be frequently

contaminated by compounds containing chlorine or

fluorine. Common sources of such compounds include

swimming pool chemicals and chlorine bleaches, paint

stripper, adhesives, p aints, varnishes, sealers, waxes

(which are not yet dried) and solvents used during

construction and remodeling. V arious commercial and

industrial processes may also be sources of chlorine/

fluorine compounds.

• To avoid possible illness or death of the building

occupants, do NOT locate outside air intake device

(economizer, manual fresh air intake, motorized fresh

air intake) too close to an exhaust outlet, gas vent

termination, or plumbing vent outlet. For specific

distances required, consult local codes.

• Allow minimum clearances from the enclosure for fire

protection, proper operation, and service access (see

unit clearances). These clearances must be

permanently maintained.

• The combustion air inlet and flue outlet on the unit

must never be obstructed. If used, do not allow the

economizer/manual fresh air damper/ motorized fresh

air damper to become blocked by snow or debris. In

some climates or locations, it may be necessary to

elevate the unit to avoid these problems.

• When the unit is heating, the temperature of the return

air entering the unit must be between 50° F and 100°

F.

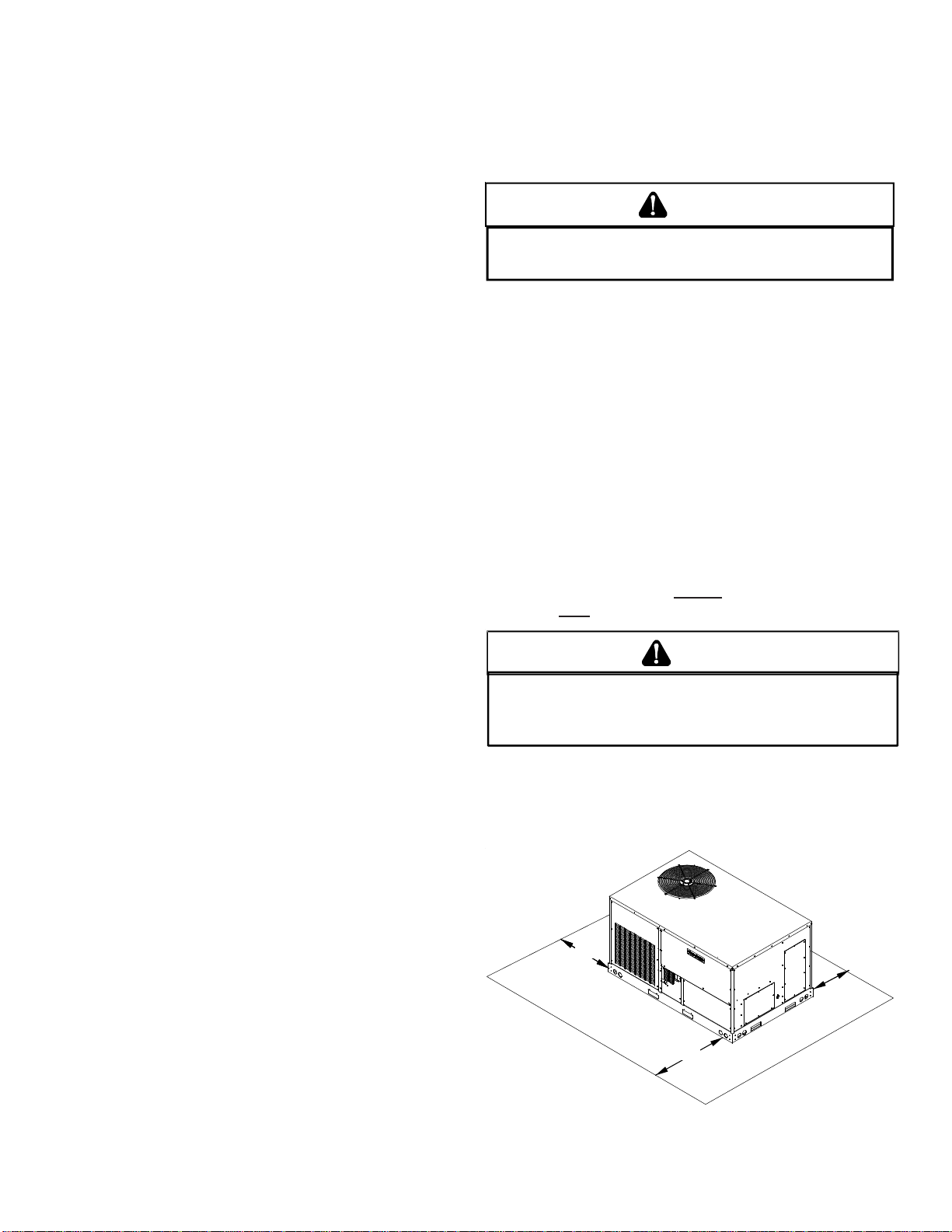

GROUND LEVEL INSTALLATIONS ONLY:

• When the unit is installed on the ground adjacent to

the building, a level concrete (or equal) base is

recommended. Prepare a base that is 3” larger than

the package unit footprint and a minimum of 3” thick.

4

Page 5

• The base should also be located where no runoff of

water from higher ground can collect in the unit.

ROOF TOP INSTALLATIONS ONLY:

• T o avoid possible property damage or personal injury ,

the roof must have sufficient structural strength to carry

the weight of the unit(s) and snow or water loads as

required by local codes. Consult a structural engineer

to determine the weight capabilities of the roof.

• The unit may be installed directly on wood floors or

on Class A, Class B, or Class C roof covering material.

• To avoid possible personal injury, a safe, flat surface

for service personnel should be provided.

• As indicated on the unit data plate, a minimum

clearance of 36” to any combustible material is

required on the furnance access side of the unit. All

combustible materials must be kept out of this area.

• This 36” clearance must also be maintained to insure

proper combustion air and flue gas flow. The

combustion air intake and furance flue discharge must

not be blocked for any reason, including blockage by

snow.

• Adequate clearances from the furnace flue discharge

to any adjacent public walkways, adjacent buildings,

building openings or openable windows must be

maintained in accordance with the latest edition of

the National Fuel Gas Code (ANSI Z223.1)

• Minimum horizontal clearance of 48” from the furnace

flue discharge to any electric meters, gas meters,

regulators and relief equipment is required.

UNIT PRECAUTIONS

• Do not stand or walk on the unit.

• Do not drill holes anywhere in panels or in the base

frame of the unit. Unit access panels provide

structural support.

• Do not remove any access panels until unit has been

installed on roof curb or field supplied structure.

• Do not roll unit across finished roof without prior

approval of owner or achitect.

• Do not skid or slide on any surface as this may

damage unit base. The unit must be stored on a

flat, level surface. Protect the condenser coil

because it is easily damaged.

Full perimeter roof curbs are available from the factory and

are shipped unassembled. Field assembly, squaring, leveling and mounting on the roof structure are the responsibility

of the installing contractor . All required hardware necessary

for the assembly of the sheet metal curb is included in the

curb accessory.

WARNING

O PREVENT POSSIBLE EQUIPMENT DAMAGE, PROPERTY DAMAGE, PERSONAL

T

INJURY OR DEAT H, THE FOL LOWING BU LLET POINTS MUST BE OB SERVED

WHEN INSTALLING THE UNIT.

• Sufficient structural support must be determined prior

to locating and mounting the curb and package unit.

• Ductwork must be constructed using industry

guidelines. The duct work must be placed into the

roof curb before mounting the package unit. Our full

perimeter curbs include duct connection frames to be

assembled with the curb. Cantilevered type curbs

are not available from the factory.

• Curb insulation, cant strips, flashing and general

roofing material are furnished by the contractor.

The curbs must be supported on parallel sides by roof members. The roof members must not penetrate supply and return duct opening areas as damage to the unit might occur.

NOTE: The unit and curb accessories are designed to allow

vertical duct installation before unit placement. Duct

installaton after unit placement is not recommended.

CAUTION

ALL

CURBS LOOK SIMILAR

POSITIONING, CHECK JOB PLANS CAREFULLY AND VERIFY MARKINGS

ON CURB ASSEMBLY

SUPERSEDES INFORMATION SHOWN

See the manual shipped with the roof curb for assembly and

installation instructions.

. TO

AVOID INCORRECT CURB

. I

NSTRUCTIONS MAY VARY IN CURB STYLES AND

.

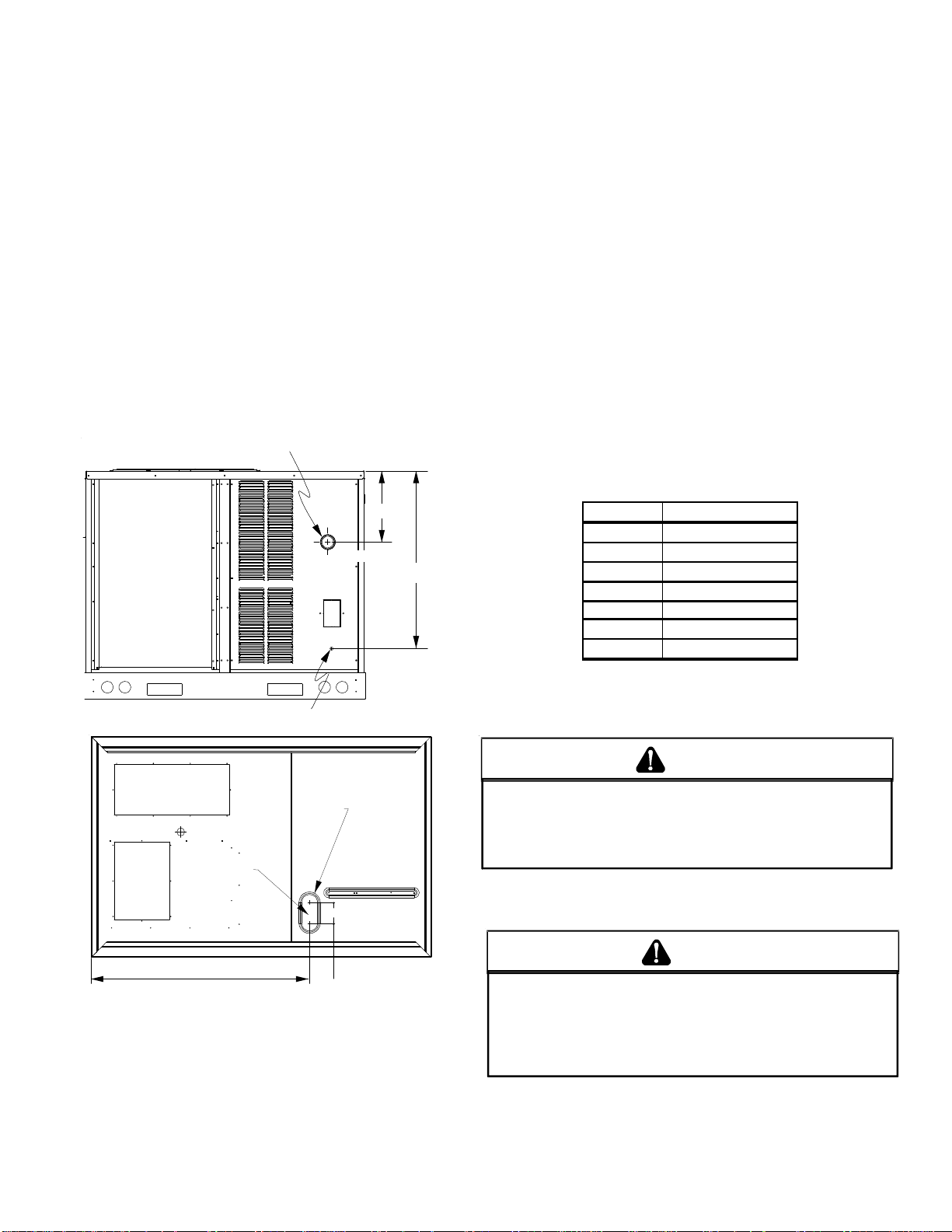

CLEARANCES

ROOF CURB INSTALLATIONS ONLY:

Curb installatons must comply with local codes and should

be done in accordance with the established guidelines of the

National Roofing Contractors Association.

Proper unit installation requires that the roof curb be firmly

and permanently attached to the roof structure. Check for

adequate fastening method prior to setting the unit on the

curb.

48”

48”

75”

Unit Clearances

5

Page 6

Adequate clearance around the unit should be kept for safety ,

service, maintenance, and proper unit operation. A total clearance of 75” on the main control panel side of the unit is recommended to facilitate possible fan shaft, coil, electric heat

and gas furnace removal. A clearance of 48” is recommended

on all other sides of the unit to facilitate possible compressor

removal, to allow service access and to insure proper ventilation and condenser airflow. The unit must not be installed

beneath any obstruction. The unit should be installed remote from all building exhausts to inhibit ingestion of exhaust

air into the unit fresh air intake.

CAUTION

IF

PROTRUSIONS EXIST, DO NO ATTEMPT TO SET UNIT ON CURB

.

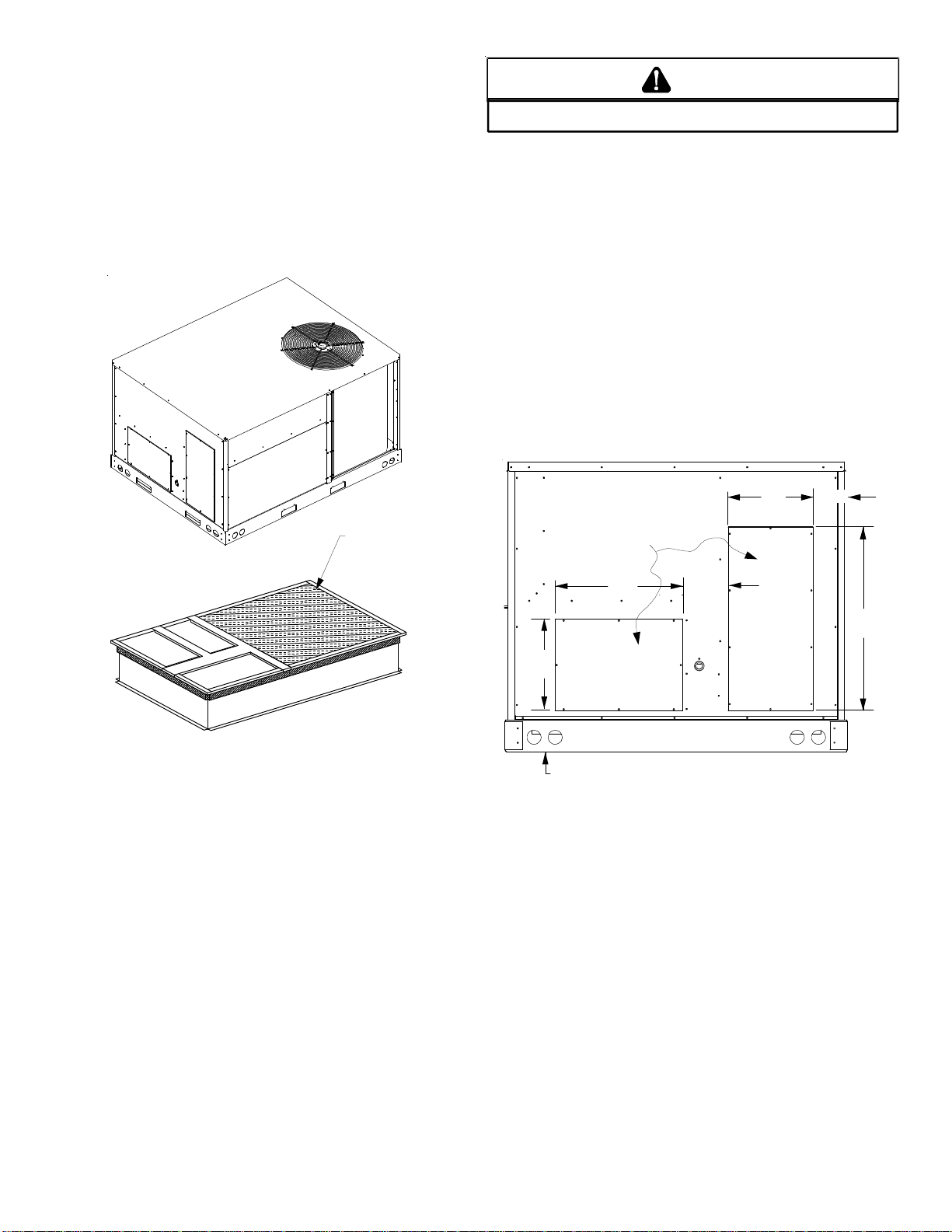

ROOF TOP DUCT CONNECTIONS

Install all duct connections on the unit before placing the unit

on rooftop.

HORIZONTAL DISCHARGE

For horizontal discharge, remove the supply and return duct

covers and place them over the vertical discharge return and

supply openings. Install with insulation facing up, using the

longer screws provided in the literature package.

Ensure that the top of the duct connection frame is flush with

the top of the roof curb.

Flexible duct connectors between the unit and ducts are recommended. Insulate and weatherproof all external ductwork

and joints as required and in accordance with local codes.

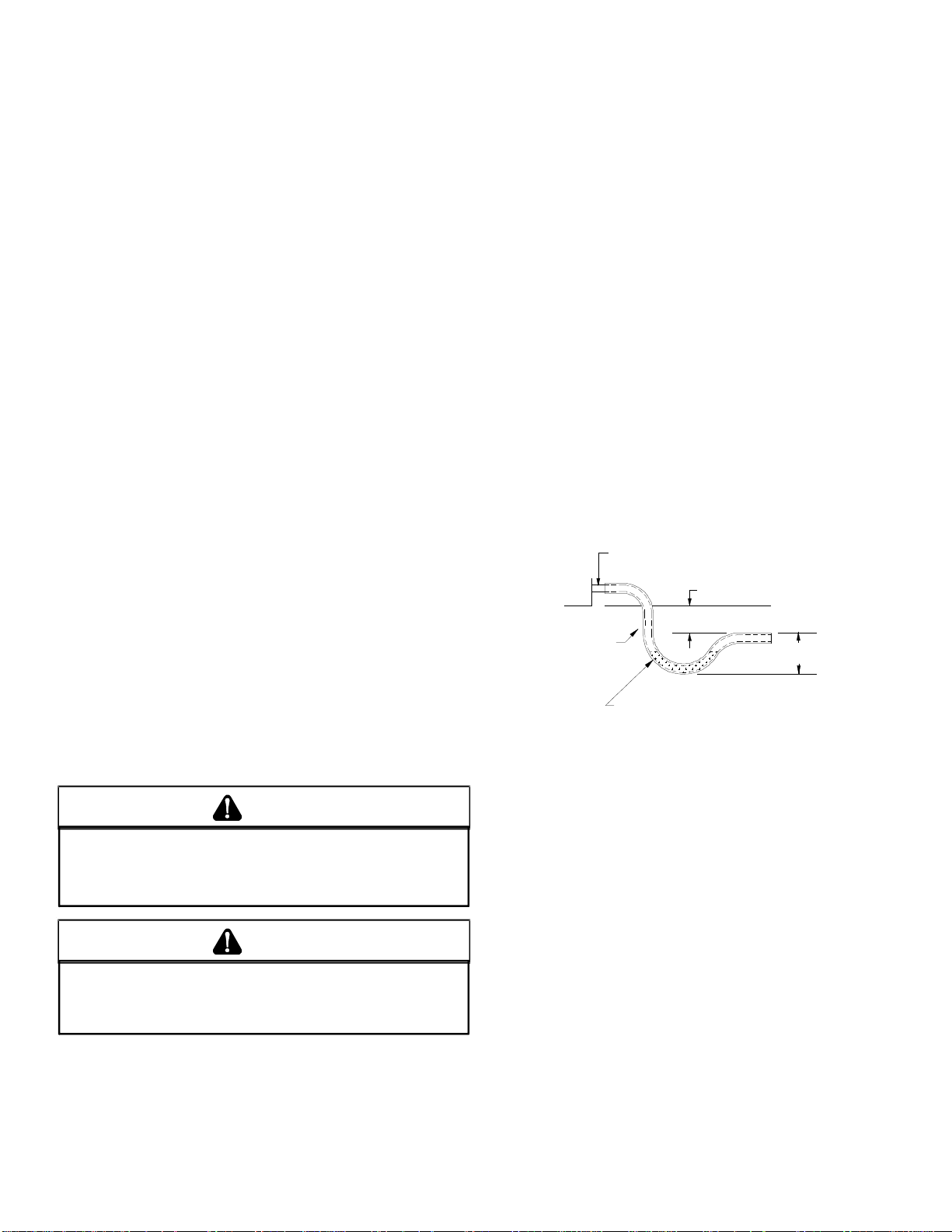

11” 4 7/8””

INSULATED

PANELS

Roof Curb Installation

ROOF CURB POST-INST ALLA TION CHECKS

After installation, check the top of the curb, duct connection

frame and duct flanges to make sure gasket has been applied properly. Gasket should be firmly applied to the top of

the curb perimeter, duct flanges and any exposed duct connection frame. If gasket is loose, re-apply using strong

weather resistant adhesive.

PROTRUSION

Inspect curb to ensure that none of the utility services (electric) routed through the curb protrude above the curb.

REMOVE

COVERS

17” 7 3/8”

12”

SUPPL Y

6 3/16”

Horizontal Discharge Duct Connections

25”

6

Page 7

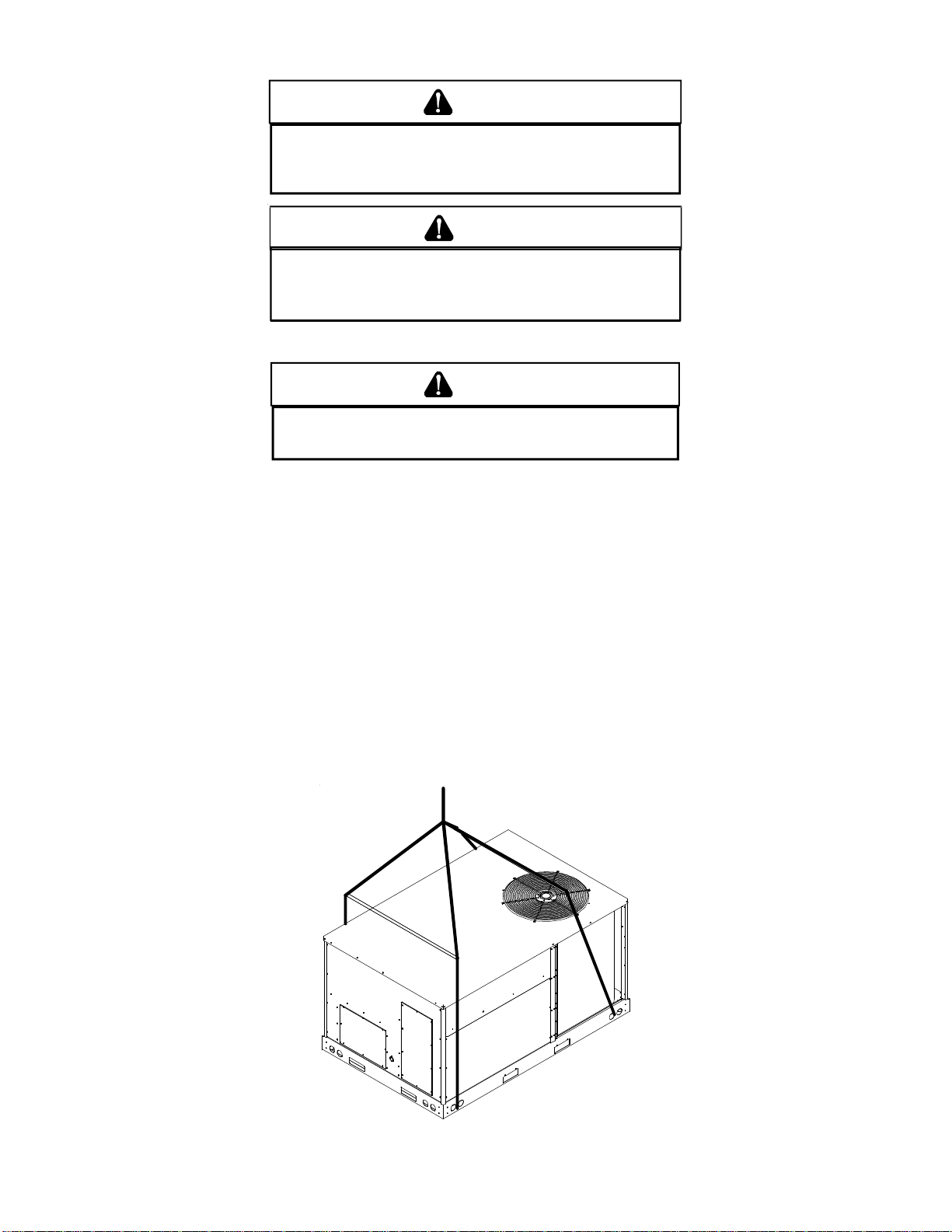

RIGGING DET AILS

WARNING

O PREVENT PROPERTY DAMAGE, THE UNIT SHOULD REMAIN IN AN UPRIGHT

T

T

POSITION DURING ALL RIGGING AND MOVING OPERATIONS.

LIFTING AND MOVING WHEN A CRANE IS USED, PLACE THE UNIT IN AN

ADEQUATE CABLE SLING.

O FACILITATE

CAUTION

IF

UNITS ARE LIFTED TWO AT A TIME, THE FORK HOLES ON THE

CONDENSER END OF THE UNIT MUST NOT BE USED

LENGTH IS

IS RECOMMENDED

42” TO

PREVENT DAMAGE TO THE UNIT; HOWEVER

.

. M

INIMUM FORK

, 48”

Provisions for forks have been included in the unit base frame. No other fork locations are approved.

WARNING

O PREVENT POSSIBLE EQUIPMENT DAMAGE, PROPERTY DAMAGE, PERSONAL

T

INJURY OR DEATH, THE FOLLOWING BULLET POINTS MUST BE OBSERVED

WHEN INSTALLING THE UNIT.

• Unit must be lifted by the four lifting holes located at the base frame corners.

• Lifting cables should be attached to the unit with shackles.

• The distance between the crane hook and the top of the unit must not be less than 60”.

• Two spreader bars must span over the unit to prevent damage to the cabinet by the lift cables. S preader bars must

be of sufficient length so that cables do not come in contact with the unit during transport. Remove wood struts

mounted beneath unit base frame before setting unit on roof curb. These struts are intended to protect unit base

frame from fork lift damage. Removal is accomplished by extracting the sheet metal retainers and pulling the struts

through the base of the unit. Refer to rigging label on the unit.

Important: If using bottom discharge with roof curb, ductwork should be attached to the curb prior to installing the unit.

Ductwork dimensions are shown in Roof Curb Installation Instructions.

Refer to the Roof Curb Installation Instructions for proper curb installation. Curbing must be installed in compliance with the

National Roofing Contractors Association Manual.

Lower unit carefully onto roof mounting curb. While rigging unit, center of gravity will cause condenser end to be lower than

supply air end.

To assist in determining rigging requirements, unit weights are shown as follows:

7

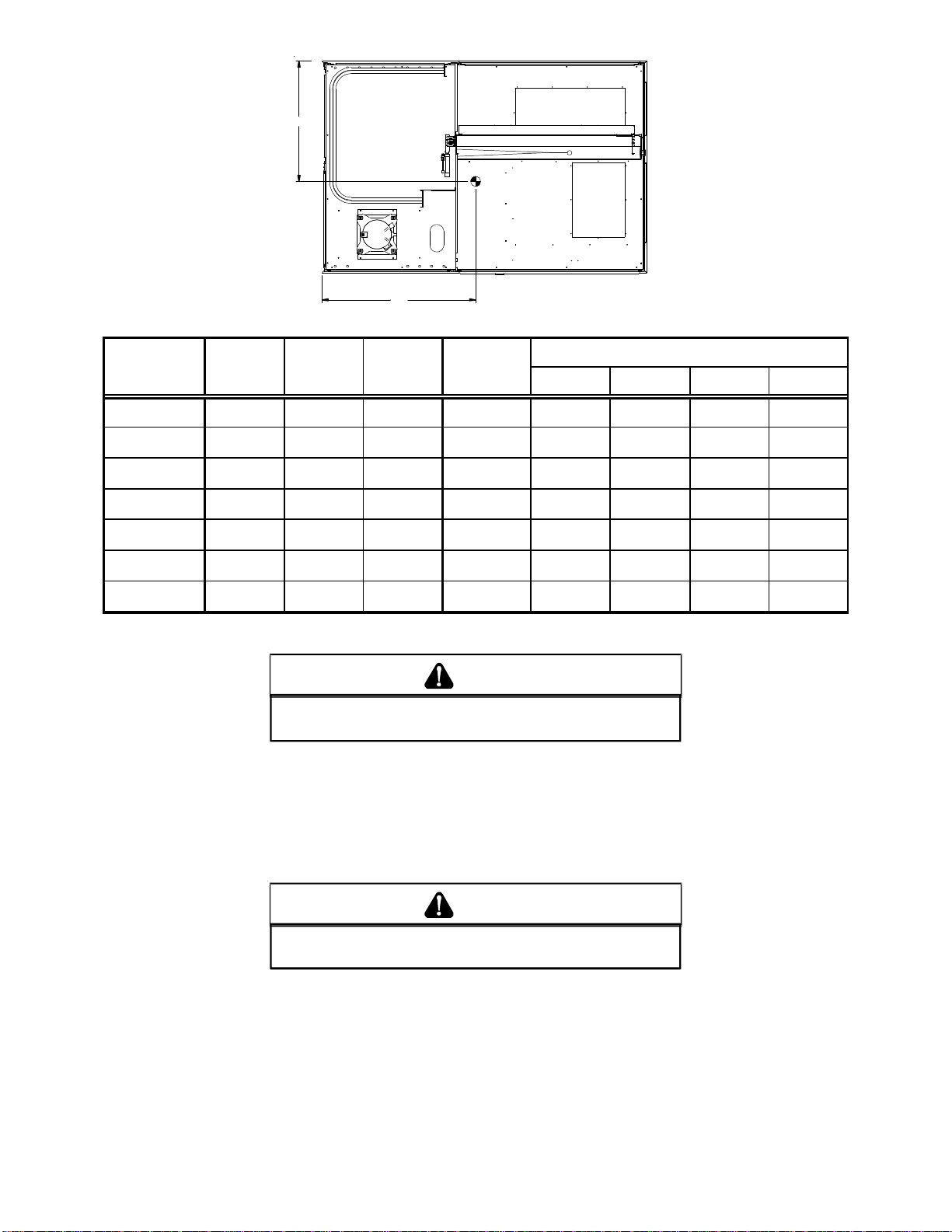

Page 8

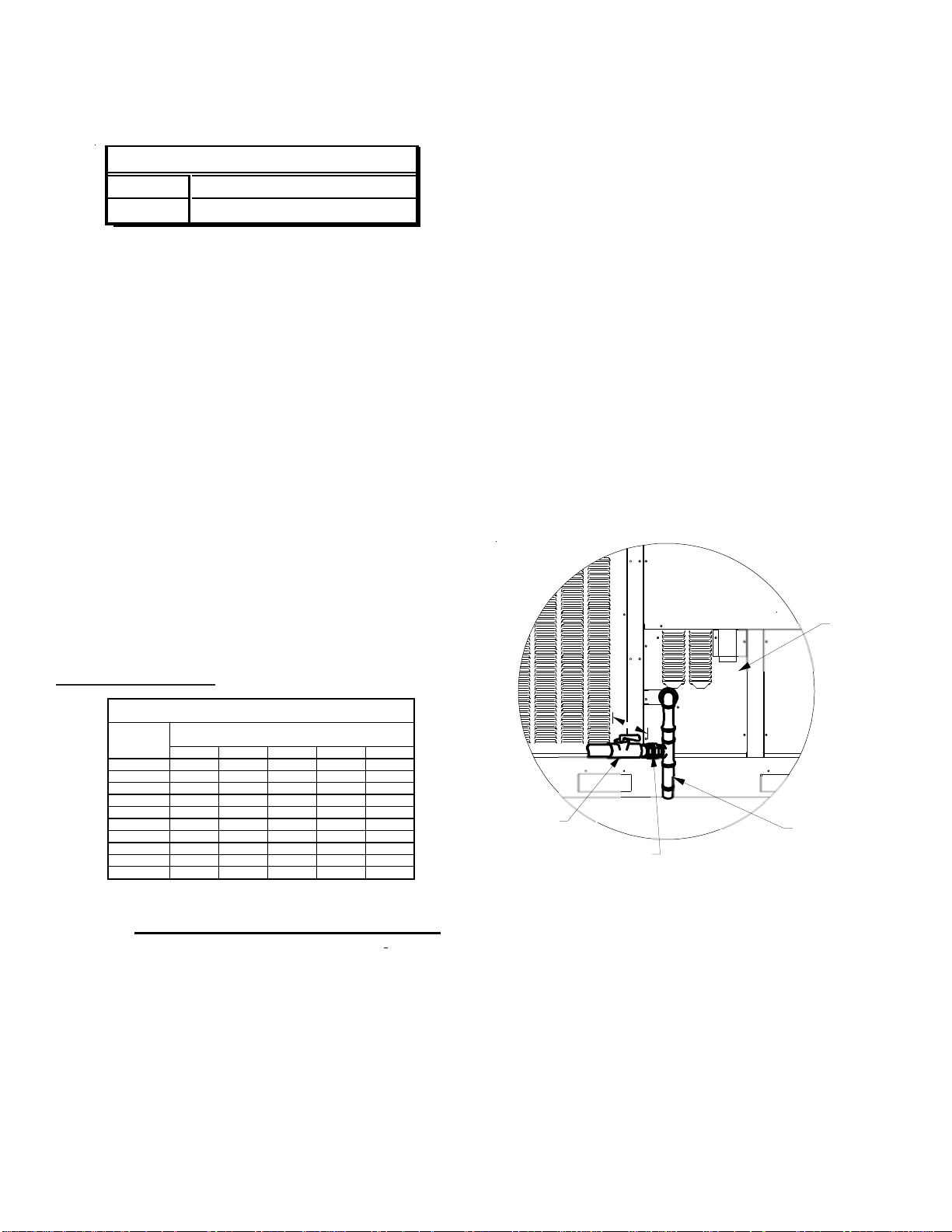

A

C

Y

B

CONDENSER

COIL

COMPRESSOR

X

CG

RETURN

EVAPOR ATOR COIL

SUPPL Y

D

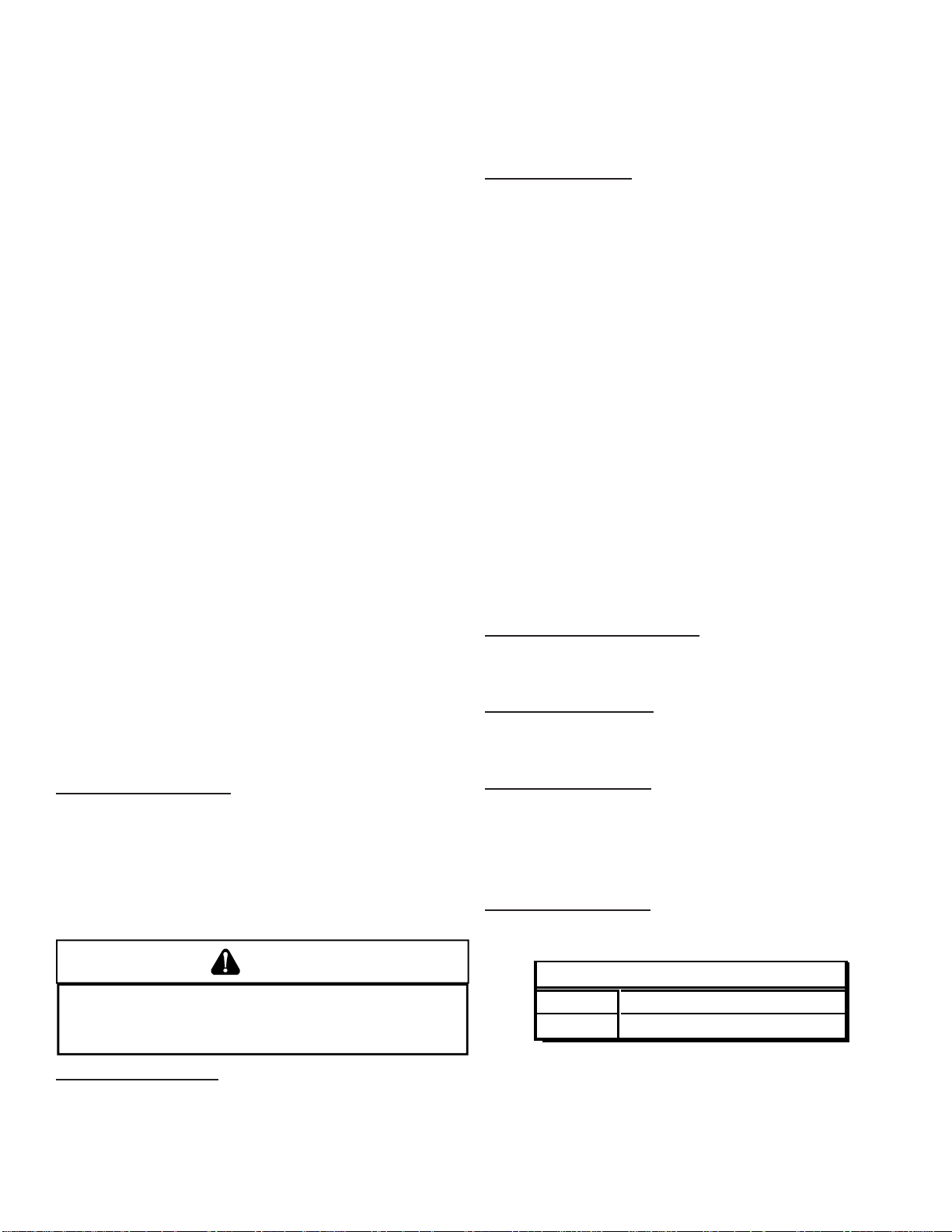

Corner & Center of Gravity Locations

Operating

Weight

(lbs)

Corner Weights ( lbs )

ABCD

Model

X

(in)

Y

(in)

Shipping

Weight

(lbs)

CPG036045* 37 30 550 525 100 165 100 165

CPG036090* 37 30 560 535 100 170 100 170

CPG048090* 37 30 600 575 110 180 110 180

CPG048115* 37 30 605 580 110 180 110 180

CPG060090* 37 30 645 620 115 190 120 195

CPG060140* 37 30 655 630 120 195 120 195

CPG072140* 37 30 715 690 130 215 130 215

* Weights shown are belt drive with no accessories.

CAUTION

TO

PREVENT SEVERE DAMAGE TO THE BOTTOM OF THE UNIT, DO NOT

FORK LIFT UNIT AFTER WOOD STRUTS HAVE BEEN REMOVED

.

Bring condenser end of unit into alignment with the curb. With condenser end of the unit resting on curb member and using

curb as a fulcrum, lower opposite end of the unit until entire unit is seated on the curb. When a rectangular cantilever curb

is used, care should be taken to center the unit. Check for proper alignment and orientation of supply and return openings

with duct.

RIGGING REMOVAL

CAUTION

TO

PREVENT DAMAGE TO THE UNIT, DO NOT ALLOW CRANE HOOKS

AND SPREADER BARS TO REST ON THE ROOF OF THE UNIT

Remove spreader bars, lifting cables and other rigging equipment.

.

8

Page 9

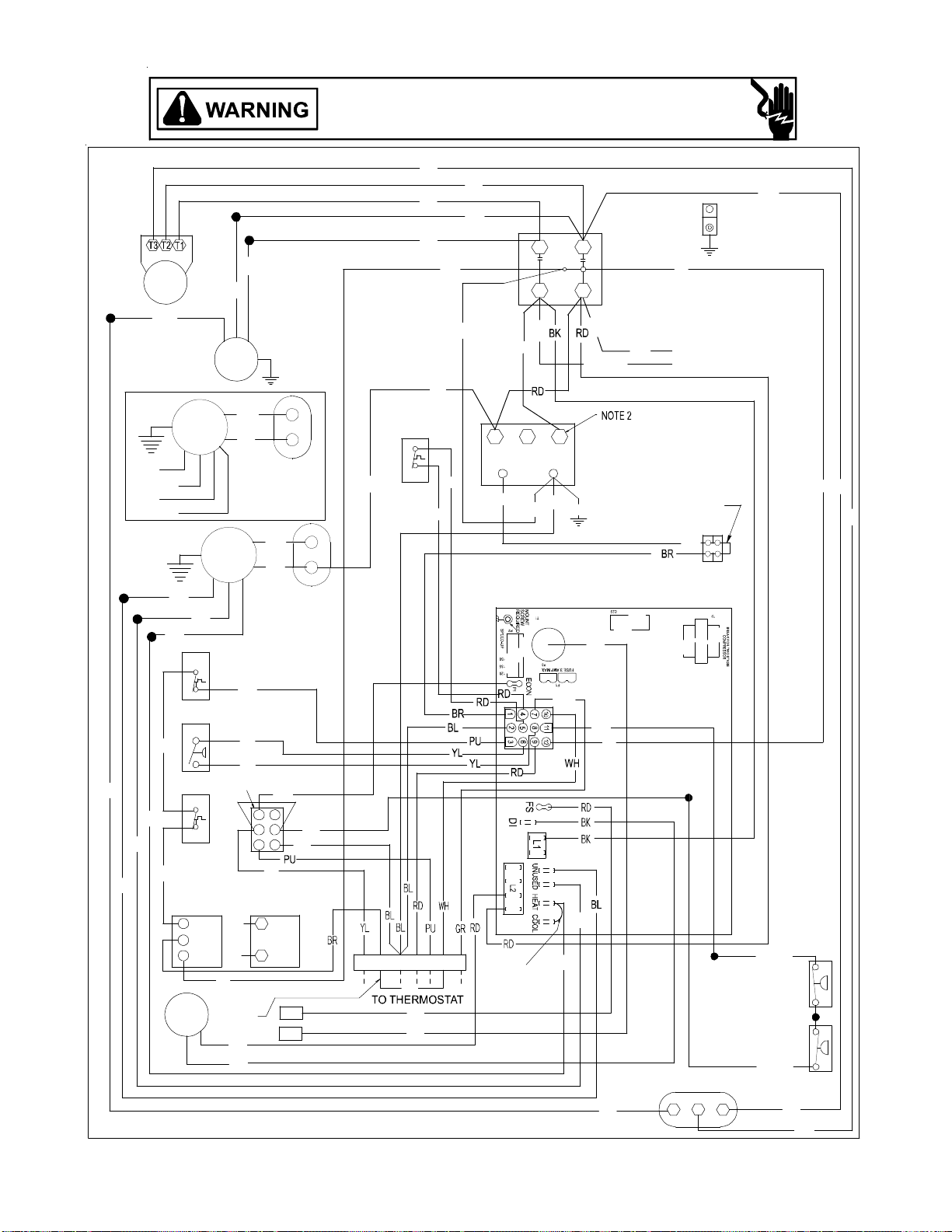

ELECTRICAL WIRING

WARN ING

HIGH VOLTAGE!

ISCONNECT ALL POWER BEFORE SERVICI NG OR

D

INSTALLING THIS UNIT

BE PRESENT

DAMAGE, PERSONAL INJURY OR DEATH

. F

. M

AILURE TO DO SO MAY CAUSE PROPERTY

ULTIPLE POWER SOURCES MAY

.

Electrical Code. If long wires are required, it may be necessary to increase the wire size to prevent excessive voltage

drop. Wires should be sized for a maximum of 3% voltage

drop.

O AVOID PROPERTY DAMAGE OR PERSONAL INJURY DUE TO FIRE, USE

T

ONLY COPPER CONDUCTORS.

CAUTION

WARN ING

HIGH VOLTAGE!

O AVOID PERSONAL INJURY OR DEATH DUE TO

T

ELECTRICAL SHOCK, DO NOT TAMPER WITH FACTORY

WIRING

. THE

OF THESE UNITS ARE FACTORY-INSTALLED AND HAVE

BEEN THOROUGHLY TESTED PRIOR TO SHIPMENT

ONTACT YOUR LOCAL REPRESENTATIVE IF

C

ASSISTANCE IS REQUIRED

INTERNAL POWER AND CONTROL WIRING

.

.

CAUTION

TO

PREVENT DAMAGE TO THE WIRING, PROTECT WIRING FROM

SHARP EDGES

LOCAL CODES AND ORDINANCES

REMOVABLE ACCESS PANELS

. F

OLLOW NATIONAL ELECTRICAL CODE AND ALL

. DO

NOT ROUTE WIRES THROUGH

.

CAUTION

C

ONDUIT AND FITTINGS MUST BE WEATHER-TIGHT TO PREVENT

WATER ENTRY INTO THE BUILDING

.

For unit protection, use a fuse or HACR circuit breaker that is

in excess of the circuit ampacity , but less than or equal to the

maximum overcurrent protection device. DO NOT EXCEED

THE MAXIMUM OVERCURRENT DEVICE SIZE SHOWN

ON UNIT DATA PLATE.

All line voltage connections must be made through weatherproof fittings. All exterior power supply and ground wiring

must be in approved weatherproof conduit.

CAUTION

O PREVENT IMPROPER AND DANGEROUS OPERATION DUE TO WIRING ERRORS,

T

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS.

ERIFY PROPER OPERATION AFTER SERVICING.

V

NOTE: A weather-tight disconnect switch, properly sized for

the unit total load, must be field installed. An external field

supplied disconnect may be mounted on the exterior panel.

Ensure the data plate is not covered by the field-supplied

disconnect switch.

• Some disconnect switches are not fused. Protect the

power leads at the point of distribution in accordance

with the unit data plate.

• The unit must be electrically grounded in accordance

with local codes or, in the absence of local codes,

with the latest edition of the National Electrical Code

(ANSI-NFPA 70). A ground lug is provided for this

purpose. Size grounding conductor in accordance

with T able 250-95 of the National Electrical Code. Do

not use the ground lug for connecting a neutral

conductor.

• Connect power wiring to the compressor contactor

closest to the entrance located within the main control

box.

MAIN POWER

LOW VOLTAGE

BLOCK

The main power supply wiring to the unit and low voltage

wiring to accessory controls must be done in accordance with

these instructions, the latest edition of the National Electriacl

Code (ANSI/NFPA 70), and all local codes and ordinances.

All field wiring shall conform with the temperature limitations

for Type T wire (63°F/35°C rise).

The main power supply for the CPG036XXX3,4,7 through

CPG072 shall be three-phase, three wire. The power supply for the CPG036XXX1 through CPG060 shall be singlephase, two wire. The unit is factory wired for the voltage shown

on the unit’s data plate.

NOTE: If supply voltage is 208V, lead on primary of transformer TRANS1 must be moved from the 230V to the 208V

tap.

Main power wiring should be sized for the minimum wire

ampacity shown on the unit’s database. Size wires in accordance with the ampacity tables in Article 310 of the National

LOW VOLTAGE

ENTRANCE

POWER THRU

THE CURB

Power and Low Voltage Block Connections

WARN ING

F

AILURE OF UNIT DUE TO OPERATION ON IMPROPER LINE VOLTAGE

OR WITH EXCESSIVE PHASE UNBALANCE CONSTITUTES PRODUCT

ABUSE AND WILL VOID YOUR WARRANTY AND MAY CAUSE SEVERE

DAMAGE TO THE UNIT ELECTRICAL COMPONENTS

9

.

Page 10

Areas Without Convenience Outlet

(Hig

)

It is recommended that an independant 115V power source

be brought to the vicinity of the roof top unit for portable lights

and tools used by the service mechanic.

UNITS INSTALLED ON ROOF TOPS

Main power and low voltage wiring may enter the unit through

the condenser end of unit or through the roof curb. Install

conduit connectors at the desired entrance locations. External connectors must be weatherproof. All holes in the unit

base must be sealed (including those around conduit nuts)

to prevent water leakage into building. All required conduit

and fittings are to be field supplied.

Supply voltage to roof top unit must not vary by more than

10% of the value indicated on the unit data plate. Phase

voltage unbalance must not exceed 2%. Contact your local

power company for correction of improper voltage or phase

unbalance.

HIGH VOLTAGE ENTRANCE

(REMOVE PLUG)

2. Locate thermostat or remote sensor in the conditioned

space where it will sense average temperature. Do

not locate the device where it may be directly exposed

to supply air, sunlight or other sources of heat. Follow

installation instructions packaged with the thermostat.

3. Use #18 AWG wire for 24V control wiring runs not

exceeding 75 feet. Use #16 A WG wire for 24V control

wiring runs not exceeding 125 feet. Use #14 AWG

wire for 24V control wiring runs not exceeding 200

feet. Low voltage wiring may be National Electrical

Code (NEC) Class 2 where permitted by local codes.

4. Route thermostat wires from sub-base terminals to

the unit. Control wiring should enter through the

condenser end of unit or through curb. Connect

thermostat and any accessory wiring to low voltage

terminal block TB1 in the main control box.

NOTE: Field-supplied conduit may need to be installed

depending on unit/curb configuration. Use #18 AWG solid

conductor wire whenever connecting thermostat wires to

terminals on sub-base. DO NOT use larger than #18 AWG

wire. A transition to #18 AWG wire may be required before

entering thermostat sub-base.

12 3/8”

30 1/4”*

47 1/2”

1:4

LOW VOLTAGE ENTRANCE

3.5 DIA.

4 1/2”

7 1/2”

* (6 Ton - 34 1/4”)

Electrical Entrance and Thru Curb

POWER THRU

THE CURB

Unit is equipped with a Low Voltage Terminal Block and has

Single Point wiring to the contactor.

LOW VOLTAGE CONTROL WIRING

1. A 24V thermostat must be installed for unit operation.

It may be purchased with the unit or field -supplied.

Thermostats may be programmable or

electromechanical as required.

LEAD THERMOSTAT

Re d R (24V)

Green G (Fan)

Yellow Y1 (High Cool)

Purple Y2 (Low Cool)

Blue C om m on ( if req'd)

White W1 (Heat)

Brown W2

CPG 036 Thru 072 (Gas Heat)

h Heat

GAS SUPPL Y PIPING

WARN ING

TO

PREVENT PERSONAL INJURY OR DEATH DUE TO IMPROPER

INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE, REFER TO THIS MANUAL

ASSISTANCE OR INFORMATION, CONSULT A QUALIFIED INSTALLER

SERVICE AGENCY OR THE GAS SUPPLIER

. FOR

.

ADDITIONAL

IMPORTANT NOTE: This unit is factory set to operate on

natural gas at the altitudes shown on the rating plate.

WARN ING

TO

AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH WHEN

EITHER USING PROPANE GAS ALONE OR AT HIGHER ALTITUDES

OBTAIN AND INSTALL THE PROPER CONVERSION KIT(S

DO SO CAN RESULT IN UNSATISFACTORY OPERATION AND/OR

EQUIPMENT DAMAGE

NSTALLATIONS ONLY AND ARE NOT APPROVED FOR USE IN CANADA

I

. H

IGH ALTITUDE KITS ARE FOR

). F

U.S.

AILURE TO

The rating plate is stamped with the model number, type of

gas and gas input rating. Make sure the unit is equipped to

operate on the type of gas available. Conversion to propane

10

,

,

.

Page 11

(LP) gas is permitted with the use of the factory authorized

p

)

g

)

conversion kit (see the unit Technical Manual for the appropriate kit). For High Altitude derates, refer to the latest edition

of the National Fuel Gas Code NFPA 54/ANSI Z223.1.

INLET GAS PRESSUR E

NATURAL

PROPANE

IInlet Gas Pressure Must Not Exceed the Maximum Value Shown in Table

Above.

Min. 5.0" W .C. , Max . 10 .0" W.C.

Min. 11.0" W .C. , M ax . 14 .0" W .C.

The minimum supply pressure should not vary from that

shown in the table above because this could prevent the unit

from having dependable ignition. In addition, gas input to the

burners must not exceed the rated input shown on the rating

plate. Overfiring of the unit could result in premature heat

exchanger failure.

PIPING

IMPORT ANT NOTE: T o avoid possible unsatisfactory opera-

tion or equipment damage due to under firing of equipment,

do not undersize the natural/propane gas piping from the

meter/tank to the unit. When sizing a trunk line, include all

appliances on that line that could be operated simultaneously .

The rating plate is stamped with the model number, type of

gas and gas input rating. Make sure the unit is equipped to

operate on the type of gas available. The gas line installation

must comply with local codes, or in the absence of local codes,

with the latest edition of the National Fuel Gas Code NFPA

54/ANSI Z223.1.

4. Install a drip leg to trap dirt and moisture before it can

enter the gas valve. The drip leg must be a minimum

of three inches long.

5. Use two pipe wrenches when making connection to

the gas valve to keep it from turning.

6. Install a manual shut-off valve in a convenient location

(within six feet of unit) between the meter and the

unit.

7. Tighten all joints securely.

8. The unit must be connected to the building piping by

one of the following methods:

• Rigid metallic pipe and fittings

• Semirigid metallic tubing and metallic fittings

(Aluminum alloy tubing must not be used in exterior

locations)

• Listed gas appliance connectors used in accordance

with the terms of their listing that are completely in

the same room as the equipment

• In the prior two methods above the connector or

tubing must be protected from physical and thermal

damage. Aluminum alloy tubing and connectors must

be coated to protect against external corrosion when

in contact with masonry, plaster or insulation or are

subject to repeated wettings by liquids (water - not

rain water, detergents or sewage).

BURNER

DOOR

Natural Gas Connection

Natural Gas Capaci ty of Pipe

in Cubic Feet of Gas Per H our (C FH)

Length of

Pipe in Feet

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 980

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

100 38 79 150 305 460

Pressure = .50 PSIG or less and Pressure Drop of 0.3" W.C. (Based

CFH =

Heatin

Nominal Black Pipe Si ze (i nches)

1/2 3/4

on 0.60 S

BTUH Furnace Input

Va lu e o f Ga s (BTU/Cubic Foot

1

ecific Gravity Gas

1 1/4 1 1/2

Refer to the Proper Piping Practice drawing for the general

layout at the unit. The following rules apply:

1. Use black iron pipe and fittings for the supply piping.

The use of a flex connector and/or copper piping is

permitted as long as it is in agreement with local

codes.

2. Use pipe joint compound on male threads only. Pipe

joint compound must be resistant to the action of the

fuel used.

3. Use ground joint unions.

TBD

MANUAL

SHUT-OFF

GROUND JOINT

UNION

DRIP

LEG

Proper Piping Practice

NOTE: The unit gas supply entrance is factory sealed with

plugs. Keep plugs in place until gas supply is ready to be

installed. Once ready, replace the plugs with the supplied

grommets and install gas supply line.

11

Page 12

GAS PIPING CHECKS

CAUTION

T

O PREVENT PROPERTY DAMAGE OR PERSONAL INJURY DUE TO FIRE, THE

FOLLOWING INSTRUCTIONS MUST BE PERFORMED REGARDING GAS

CONNECTIONS AND PRESSURE TESTING:

HE UNIT AND ITS GAS CONNECTIONS MUST BE LEAK TESTED BEFORE

•

T

PLACING IN OPERATION.

FIRE, NEVER USE A MATCH OR OPEN FLAME TO TEST FOR LEAKS.

EXCEED SPECI FIED PRES SURES FOR TESTI NG.

DAMAGE GAS VALV E AND CAUSE OVERFIRING WHICH MAY RESULT IN

PREMATURE HEAT EXCHANGE FAILURE.

HIS UNIT AND ITS SHUT-OFF VALVE MUST BE DISCONNECTED FROM

•

T

THE GAS S UPPLY DURING ANY PRESSURE TESTING OF THAT SYSTEM AT

TEST PRESSUR E S IN EX CES S OF 1/2

HIS UNI T MUST BE I SOLAT ED FROM THE GAS SUPPL Y SYS TEM BY

•

T

CLOSING ITS MANUAL SHUT-OFF VALVE DURING ANY PRESSURE

TESTING OF THE GAS SUPPLY PI PING SYSTEM AT TEST PRESSURE S

EQUAL TO OR LESS THAN 1/2

ECAUSE OF THE DANGER OF EXPLOSION OR

B

IGHER PRESSURE MAY

H

(3.48 KPA).

PSIG

(3.48 KPA).

PSIG

WARNING

N

EVER

1. Vaporization rate, which depends on (a) temperature

of the liquid, and (b) wetted surface area of the

container or containers.

2. Proper pressure regulation.

3. Pressure drop in lines between regulators, and

between second stage regulator and the appliance.

Pipe size required will depend on length of pipe run

and total load of all appliances.

TANKS AND PIPING

Complete information regarding tank sizing for

vaporization, recommended regulator settings and pipe

sizing is available from most regulator manufacturers and

propane gas suppliers.

Since propane gas will quickly dissolve white lead or most

standard commercial compounds, special pipe dope

must be used. Shellac base compounds resistant to the

actions of liquefied petroleum gases such as Gasolac®,

Stalactic®, Clyde’s® or John Crane® are satisfactory.

See below for typical propane gas piping.

O AVOID PROPERTY DAMAGE OR PERSONAL INJURY

T

NO OPEN FLAME IN THE VICINITY DURING AIR BLEEDING.

, BE SURE THERE IS

There will be air in the gas supply line after testing for leaks

on a new installation. Therefore, the air must be bled from

the line by loosening the ground joint union until pure gas is

expelled. Tighten union and wait for five minutes until all gas

has been dissipated in the air. Be certain there is no open

flame in the vicinity during air bleeding procedure. The unit is

placed in operation by closing the main electrical disconnect

switch for the unit.

PROP ANE GAS INST ALLA TIONS

WARNING

O AVOID PROPERTY DAMAGE, PERSONAL INJURY O R DEATH DUE TO FIR E

T

OR EXPLOSION CAUSED BY A PROPANE GAS LEAK, INSTALL A G AS

DETECTING WARNING DE VICE.

OF ODORANT IN PROPANE GAS, A GAS DETECTING W ARNING DEVICE

IS THE ONLY RELIABLE WAY TO DETECT A PROPANE GAS LEAK.

ONTACT A LOCAL PROPANE GAS SUPPLIER ABOUT INSTALLING A

C

GAS DETECTING WARNING DEVICE.

INCE RUST CAN REDUCE THE LEVEL

S

First Stage

Regulator

200 PSIG

Maximum

5 to 15 PSIG

(20 PSIG Max.)

Continuous

Second Stage

Regulator

11" W.C.

Typical Propane Gas Piping

ROOF TOP LOCATION AND INSTALLATION

The gas supply piping location and installation for roof top

units must be in accordance with local codes or, in the absence of locals codes, with ordinances of the latest edition of

the National Fuel Gas Code (ANSI Z223.1).

A manual gas shutoff valve must be field inst alled external to

the roof top unit. In addition, a drip leg must be installed near

the inlet connection. A ground joint union connection is required between the external shutoff valve and the unit connection to the gas valve to permit removal of the burner assembly for servicing.

IMPORTANT NOTE: Propane gas conversion kits must be

installed to convert units to propane gas. NOx screens must

be removed before converting to LP. Remove burner

assembly and pull NOx screens from each burner tube. When

all the screens are out, reassemble the burner assembly

without the screens.

All propane gas equipment must conform to the safety

standards of the National Board of Fire Underwriters (See

NBFU Manual 58).

For satisfactory operation, propane gas supply pressure must

be within 9.7 - 10.3 inches W.C. at the manifold with all gas

appliances in operation. Maintaining proper gas pressure

depends on three main factors:

1. Route gas piping to unit so that it does not interfere

with the removal of access panels. Support and align

piping to prevent strains or misalignment of the

manifold assembly.

2. All units are furnished with standard female NPT pipe

connections. Connection pipe sizes for CPG036

through 072 units is 1/2" NPT on 045 to 140 mBH

units. The size of the gas supply piping to the unit

must be based on length of run, number of units on

the system, gas characteristics, BTU requirement and

available supply pressure. All piping must be done in

accordance with local codes or, in the absence of local

codes, with the latest edition of the National Fuel Gas

Code (ANSI Z223.1).

12

Page 13

NOTE: The gas connection size at the unit does NOT

establish the size of the supply line.

3. These units are designed for either natural or propane

(LP) gas and are specifically constructed at the factory

for only one of these fuels. The fuels are NOT

interchangeable. However, the furnace can be

converted in the field from natural gas to LP gas with

the appropriate factory kit (see unit Technical Manual

for the appropriate kit). Only a qualified contractor,

experienced with natural and propane gas systems,

should attempt conversion. Kit instructions must be

followed closely to assure safe and reliable unit

operation.

4. With all units on a common line operating under full

fire, natural gas main supply pressure should be

adjusted to approximately 7.0" w.c., measured at the

unit gas valve. If the gas pressure at the unit is greater

than 10.5" w.c., the contractor must furnish and inst all

an external type positive shutoff service pressure

regulator. The unit will not function satisfactorily if

supply gas pressure is less than 5.5" w.c. or greater

than 10.5" w.c..

NOTE: A minimum horizontal distance of 48"

between the regulator and the furnace flue discharge

is required.

5. With all units on a common line operating under full

LP gas main supply pressure should be at least 1 1.0"

w.c. and must be no greater than 13.0" w .c., measured

at the unit gas valve. Unit will not function satisfactorily

if supply gas pressure is less than 1 1.0" w.c. or greater

than 13.0" w.c..

6. All pipe connections should be sealed with a pipe

thread compound, which is resistant to the fuel used

with the furnace. A soapy water solution should be

used to check all joints for leaks. A tap is located on

the entering side of the gas valve for test gauge

connection to measure supply (main) gas pressure.

Another tap is provided on the manifold side of the

gas valve for checking manifold pressure.

WARN ING

T

HIS UNIT AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE

DISCONNECTED

PRESSURE TESTING OF THAT SYSTEM AT TEST PRESSURES IN

EXCESS OF

1/2 PSIG (13.8” W.C.).

FROM THE GAS SUPPLY SYSTEM DURING ANY

CIRCULA TING AIR AND FILTERS

DUCTWORK

The supply duct should be provided with an access panel

large enough to inspect the air chamber downstream of the

heat exchanger. A cover should be tightly attached to prevent air leaks.

Ductwork dimensions are shown in the roof curb installation

manual.

If desired, supply and return duct connections to the unit may

be made with flexible connections to reduce possible unit

operating sound transmission.

VENTING

NOTE: Venting is self-contained.

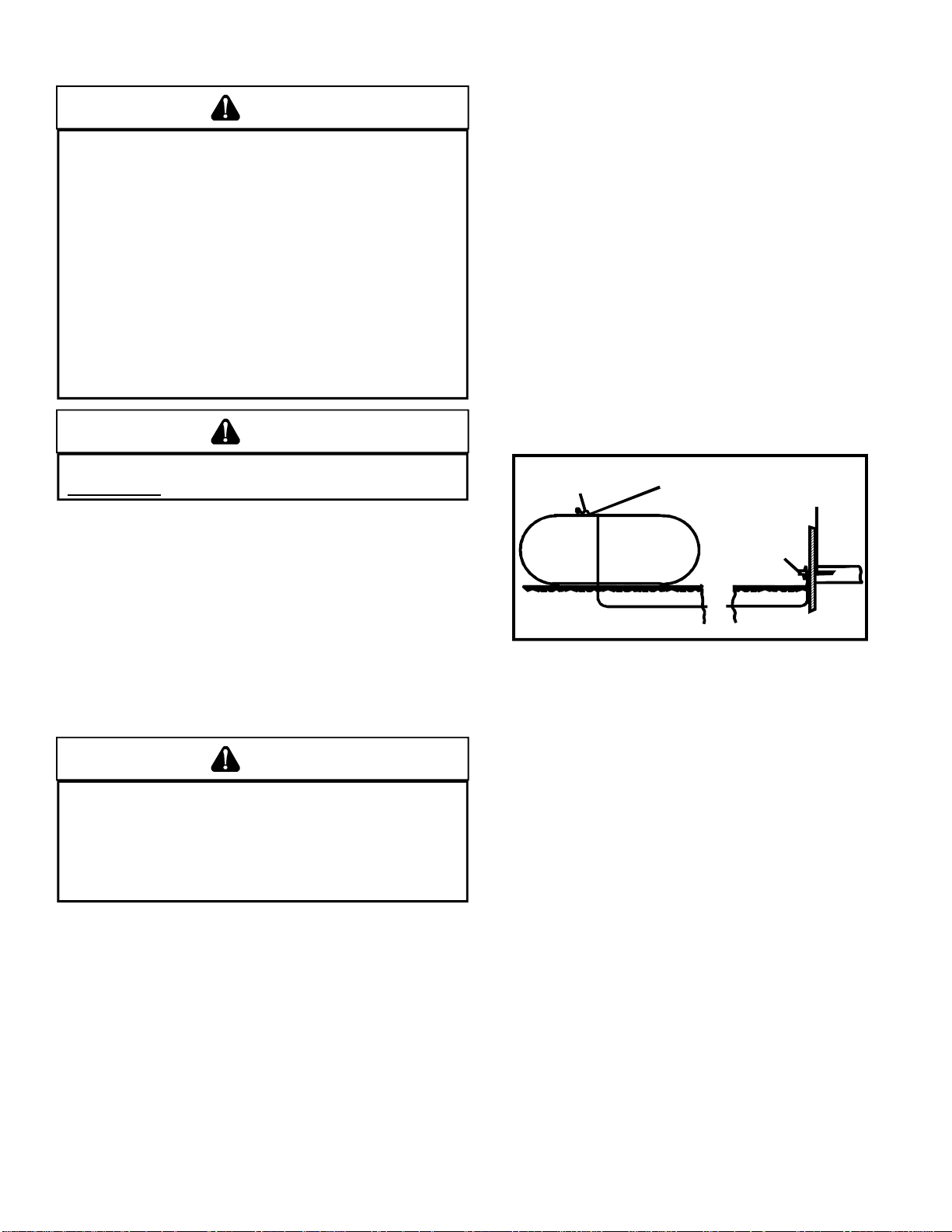

CONDENSA TE DRAIN CONNECTION

CONDENSATE DRAIN CONNECTION

A 3/4” NPT drain connection is supplied for condensate piping. An external trap must be inst alled for proper condensate

drainage.

DRAIN

CONNECTION

UNIT 2" MINIMUM

FLEXIBLE

TUBING-HOSE

OR PIPE

A POSITIVE LIQUID

SEAL IS REQUIRED

Drain Connection

3" MIN IMUM

Install condensate drain trap as shown. Use 3/4" drain line

and fittings or larger. Do not operate without trap.

HORIZONTAL DRAIN

Drainage of condensate directly onto the roof may be acceptable; refer to local code. It is recommended that a small

drip pad of either stone, mortar , wood or metal be provided to

prevent any possible damage to the roof.

CAUTION

T

HIS UNIT MUST BE

SYSTEM BY CLOSING ITS INDIVIDUAL MANUAL SHUTOFF VALVE

DURING ANY PRESSURE TESTING EQUAL TO OR LESS THAN

PSIG.

ISOLAT ED

FROM THE GAS SUPPLY PIPING

1/2

7. There must be no obstruction to prevent the flow of

combustion and ventilating air. A vent stack is not

required and must never be used. The power venter

will supply an adequate amount of combustion air as

long as the air passageways are kept free of any

obstructions and the recommended external unit

clearances are maintained.

CLEANING

Due to the fact that drain pans in any air conditioning unit

will have some moisture in them, algae and fungus will

grow due to airborne bacteria and spores. Periodic cleaning is necessary to prevent this build-up from plugging the

drain.

13

Page 14

ST ARTUP , ADJUSTMENTS, AND CHECKS

WARN ING

HIGH VOLTAGE!

O AVOID PERSONAL INJURY OR DEATH DUE TO

T

ELECTRICAL SHOCK, B

THE BUILDING ELECTRICAL GROUND BY USE OF THE

GROUNDING TERMINAL PROVIDED OR OTHER

ACCEPTABLE MEANS

SERVICING OR INSTALLING THIS UNIT

OND THE FRAME OF THIS UNIT TO

. D

ISCONNECT ALL POWER BEFORE

.

TOOLS REQUIRED

Refrigeration gauge and manifold

Voltmeter

Clamp-on ammeter

Ohmmeter

Test lead

(Minimum #16 AWG with insulated alligator clips)

Manometer for verifying gas pressure 0 to 20" w.c.

Air temperature measuring device

General refrigeration mechanics’ tools

PRE-STARTUP INSTRUCTIONS

CAUTION

TO

PREVENT PROPERTY DAMAGE OR PERSONAL INJURY

START THE UNIT UNTIL ALL NECESSARY PRE-CHECKS AND TESTS

HAVE BEEN PERFORMED

.

, DO

NOT

Prior to the beginning of Startup, Adjustments, and Checks

procedures, the following steps should be completed in the

building.

THERMOSTAT. Set the thermostat in the conditioned

space at a point at least 10°F below zone temperature.

Set the thermostat system switch on COOL and the

fan switch on AUTO.

WARN ING

MOVING MACHINERY HAZARD!

O PREVENT POSSIBLE PERSONAL INJURY OR DEATH, DISCONNECT

T

POWER TO THE UNIT AND PADLOCK IN THE

SERVICNG FANS

.

“OFF”

POSITION BEFORE

HEATING STARTUP

This unit is equipped with an electronic ignition device to automatically light the main burners. It also has a power vent

blower to exhaust combustion products.

On new installations, or if a major component has been replaced, the operation of the unit must be checked.

TEMPORARY HEATING OR COOLING

If the unit is to be used for temporary heating or cooling, a

“Startup, Adjustments, and Checks” must first be performed

in accordance with this manual. Failure to comply with this

requirement will void the warranty. After the machines are

used for temporary heating or cooling, inspect the coils, fans,

and motors for unacceptable levels of construction dust and

dirt and install new filters.

CONTRACTOR RESPONSIBILITY

The installing contractor must be certain that:

• All supply and return air ductwork is in place and

corresponds with installation instructions.

• All thermostats are mounted and wired in accordance

with installation instructions.

• All electric power, all gas, hot water or steam line

connections, and the condensate drain installation

have been made to each unit on the job. These main

supply lines must be functional and capable of

operating all units simultaneously.

ROOF CURB INSTALLATION CHECK

Inspect the roof curb for correct installation. The unit and curb

assembly should be level. Inspect the flashing of the roof

mounting curb to the roof, especially at the corners, for good

workmanship. Also check for leaks around gaskets. Note any

deficiencies in a separate report and forward to the contractor.

Check unit operation as outlined in the following instructions.

If any sparking, odors, or unusual sounds are encountered,

shut off electrical power and recheck for wiring errors, or obstructions in or near the blower motors. Duct covers must

be removed before operating unit.

The Startup, Adjustments, and Checks procedure provides a

step-by-step sequence which, if followed, will assure the

proper startup of the equipment in the minimum amount of

time. Air balancing of duct system is not considered part of

this procedure. However, it is an important phase of any air

conditioning system startup and should be performed upon

completion of the Startup, Adjustments, and Checks procedure. The Startup, Adjustments, and Checks procedure at

outside ambients below 55°F should be limited to a readiness check of the refrigeration system with the required final

check and calibration left to be completed when the outside

ambient rises above 55°F.

OBSTRUCTIONS, FAN CLEARANCE AND WIRING

Remove any extraneous construction and shipping materials that may be found during this procedure. Rotate all fans

manually to check for proper clearances and that they rotate

freely . Check for bolts and screws that may have jarred loose

during shipment to the jobsite. Retighten if necessary. Retighten all electrical connections.

PRE-STARTUP PRECAUTIONS

It is important to your safety that the unit has been properly

grounded during installation. Check ground lug connection

in main control box for tightness prior to closing circuit breaker

or disconnect switch. Verify that supply voltage on line side

of disconnect agrees with voltage on unit identification plate

and is within the utilization voltage range as indicated in

Appendix C Electrical Data.

14

Page 15

System Voltage - That nominal voltage value assigned to a

circuit or system for the purpose of designating its voltage

class.

Nameplate Voltage - That voltage assigned to a piece of

equipment for the purpose of designating its voltage class

and for the purpose of defining the minimum and maximum

voltage at which the equipment will operate.

Utilization Voltage - The voltage of the line terminals of the

equipment at which the equipment must give fully satisfactory performance. Once it is established that supply voltage

will be maintained within the utilization range under all system conditions, check and calculate if an unbalanced condition exists between phases. Calculate percent voltage unbalance as follows.

Three Phase Models Only

2) MAXIMUM VOLTAGE DEVIATIONS

3) PERCENT VOLTAGE

UNBALANCE

HOW TO USE THE FORMULA:

EXAMPLE: With voltage of 220, 216, and 213

1) Average Voltage = 220+216+213=649 / 3 = 216

2) Maximum Voltage Deviation s fro m Average Voltage = 220 - 216 = 4

3) Percent Voltage Unbalance = 100 x = = 1.8%

Percent voltage unbalance MUST NOT exceed 2%

= 100 X

FROM AVERAGE VOLT AG E

1) AVERAGE VOLTAGE

4

216

400

216

.

SET EVAPORATOR FAN RPM

Actual RPM’s must be set and verified with a tachometer or

strobe light. Refer to Appendices A and B for basic unit fan

RPM. Refer also to “Airflow” section of this manual. With

disconnect switch open, disconnect thermostat wires from

terminals Y and W . This will prevent heating and mechanical

cooling from coming on. Place a jumper wire across terminals R and G at TB1 terminal block. Close disconnect switch;

evaporator fan motor will operate so RPM can be checked.

For gas heat units, the airflow must be adjusted so that the

air temperature rise falls within the ranges given stated on

Data Plate (see Appendix A - Blower Performance).

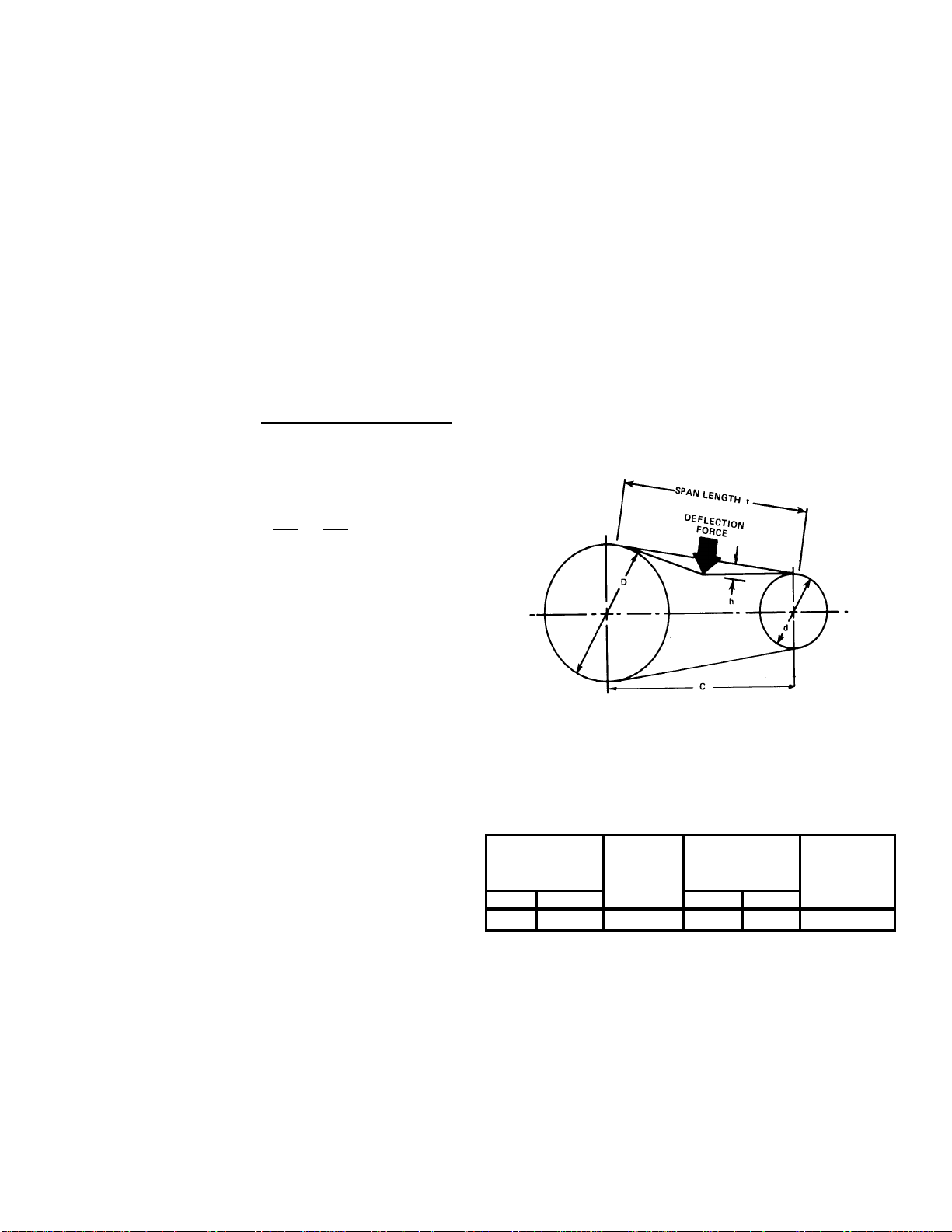

TENSION AND ALIGNMENT ADJUSTMENT

Correct belt tension is very important to the life of your belt.

Too loose a belt will shorten its life; too tight, premature motor and bearing failure will occur. Check you belt drive for

adequate “run-in” belt tension by measuring the force required

to deflect the belt at the midpoint of the span length. Belt

tension force can be measured using a belt tension gauge,

available through most belt drive manufacturers.

FIELD DUCT CONNECTIONS

Verify that all duct connections are tight and that there is no

air bypass between supply and return.

CONTROL VOLTAGE CHECK

With disconnect switch in the open “OFF” position, disconnect blue wire from low voltage transformer TRANS1. Close

the disconnect switch to energize TRANS1 control transformer. Check primary and secondary (24V) of control transformer TRANS1.

THERMOSTAT PRELIMINARY CHECK

With disconnect switch open and blue wire disconnected from

TRANS1 transformer, att ach one lead of ohmmeter to terminal R on TB1 terminal block. Touch, in order, the other ohmmeter lead to terminals Y1, Y2 and G at TB1 terminal block.

There must be continuity from terminal R to terminals Y and

G. R to Y indicates cool. R to G indicates fan (auto). Replace

blue wire on TRANS1 transformer.

FILTER SECTION CHECK

Remove filter section access panels and check that filters

are properly installed. Note airflow arrows on filter frames.

BELT DRIVE MODELS ONLY

BEARING CHECK

Prior to energizing any fans, check and make sure that all

setscrews are tight so that bearings are properly secured to

shafts.

Belt Tension Adjustment

t = Span length, inches

C = Center distance, inches

D = Larger sheave diameter, inches

d = Smaller sheave diameter, inches

h = Deflection height, inches

SMALL

TYPE DEFLECTION

BELT DRIVE USED NEW

AX Standard 3.0 to 4.0 4.2 ± 0.5 5.5 ± 0.5 0.313

Recommended Pounds of Force Per Belt

SHEAVE

DIAMETER

(in)

DEFLECTION

FORCE (lbs)

(in)

New V-belts will drop rapidly during the first few hours of use.

Check tension frequently during the first 24 hours of operation. T ension should fall between the minimum and maximum

force. To determine the deflection distance from a normal

position, measure the distance from sheave to sheave using

a straightedge or a cord. This is your reference line. On multiple belt drives, an adjacent undeflected belt can be used as

a reference.

15

Page 16

EVAPORATOR FAN ROTATION CHECK (THREE PHASE MODELS

ONLY)

Check that fan rotates clockwise when viewed from the drive

side of unit and in accordance with rotation arrow shown on

blower housing. If it does not, reverse any two incoming power

cables at Single Point Power Block. In this case, repeat bearing check.

Do not attempt to change load side wiring. Internal wiring

assures all motors and compressors will rotate in correct direction once evaporator fan motor rotation check has been

made.

ELECTRICAL INPUT CHECK

Make preliminary check of evaporator fan ampere draw and

verify that motor nameplate amps are not exceeded. A final

check of amp draw should be made upon completion of air

balancing of the duct system (see Appendix C).

RESTORING CONNECTIONS

With disconnect switch open, remove jumper wire from terminals R and G at TB1 terminal block, and reconnect thermostat wires to terminals Y and W.

REFRIGERATION SYSTEM CHECKS

Ensure the hold-down bolts on the compressor are secure

and have not vibrated loose during shipment. Check that vibration grommets have been installed. Visually check all piping and clamps. The entire refrigeration system has been

factory charged and tested, making it unnecessary to field

charge. Factory charges are shown in Appendix C and on

the unit nameplate.

Install service manifold hoses. Gauges should read saturation pressure corresponding to ambient temperature. Charge

should be checked to obtain 12° to 15° of sub-cooling per

system (i.e. compressor circuits).

If the power to the unit is interrupted during the heating cycle,

it may cause the secondary limit to trip. Once the blower compartment temperature drops below the limit reset temperature, the limit will automatically reset. The unit will restart

after one (1) hour.

Pre-Operation Checks

1. Close the manual gas valve external to the unit.

2. Turn off the electrical power supply to the unit.

3. Set the room thermostat to its lowest possible setting.

4. Remove the heat exchanger door on the side of the

unit by removing screws.

5. This unit is equipped with an ignition device which

automatically lights the main burner. DO NOT try to

light burner by any other method.

6. Move the gas control valve switch to the OFF position.

Do not force.

7. Wait five minutes to clear out any gas.

8. Smell for gas, including near the ground. This is

important because some types of gas are heavier than

air. If you have waited five minutes and you do smell

gas, immediately follow the warnings on page 3 of

this manual. If having waited for five minutes and no

gas smell is noted, move the gas control valve switch

to the ON position.

9. Replace the heat exchanger door on the side of the

unit.

10.Open the manual gas valve external to the unit.

11. Turn on the electrical power supply to the unit.

12.Set the thermostat to desired setting.

Gas Supply And Manifold Check

Gas supply pressure and manifold pressure with the burners

operating must be as specified on the rating plate.

Gas Inlet Pressure Check

Gas inlet pressure must be checked and adjusted in accordance to the type of fuel being consumed.

Rollout Protection Control

The rollout protection device opens, cutting power to the

gas valve, if the flames from the burners are not properly

drawn into the heat exchanger. The rollout protection

device is located on the burner bracket. The reason for

elevated temperatures at the control should be

determined and repaired prior to resetting this manual

reset control.

WARNING

O AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH DUE TO FIRE

T

OR EXPLOSION, A QUALIFIED SERVICER MUST INVESTIGATE THE REASON FOR

THE ROLLOUT PROTECTION DEVICE TO OPEN BEFORE MANUALLY RESETTING

THE ROLLOUT PROTECTION DEVICE.

Secondary Limit Control

The secondary limit control is located on the top of the blower

scroll assembly . This control opens when elevated temperatures are sensed. Elevated temperatures at the control are

normally caused by blower failure. The reason for the opening should be determined and repaired prior to resetting.

With Power And Gas Off:

1. Connect a water manometer or adequate gauge to

the inlet pressure tap of the gas valve.

Inlet gas pressure can also be measured by removing

the cap from the dripleg and installing a predrilled cap

with a hose fitting.

With Power And Gas On:

2. Put unit into heating cycle and turn on all other gas

consuming appliances.

INLET GAS PRESSUR E

NATURAL

PROPANE

Min. 5.0" W .C. , Max . 10 .0" W.C.

Min. 11.0" W .C. , Max . 14.0" W .C.

NOTE: Inlet Gas Pressure Must Not Exceed the Maximum

Value Shown.

If operating pressures differ from above, make necessary

pressure regulator adjustments, check piping size, etc., and/

or consult with local utility.

16

Page 17

Manifold Pressure Check

The gas valve has a tapped opening to facilitate measurement of the manifold pressure. A “U” Tube manometer having a scale range from 0 to 12 inches of water should be

used for this measurement. The manifold pressure must be

measured with the burners operating.

1. With disconnect switch open, remove field connected

thermostat wire from terminal R, W1 and W2 on TB1.

Place jumper wire between R, W1 and W2 to engage

high stage heat. (note on 045 kbtu/hr units W2 is not

used, only jumper R to W1).

2. See Figure in input rating section for gas valve

adjustment.

T o adjust the pressure regulator , remove the adjustment screw

or cover on the gas valve. Turn out (counterclockwise) to

decrease pressure, turn in (clockwise) to increase pressure.

Only small variations in gas flow should be made by means

of the pressure regulator adjustment. In no case should the

final manifold pressure vary more than plus or minus 0.3

inches water column from the specified nominal pressure.

Any major changes in flow should be made by changing the

size of the burner orifices. The measured input rate to the

furnace must not exceed the rating specified on the unit rating plate.

For natural gas, the high stage manifold pressure must be

between 3.2 and 3.8 inches water column (3.5 nominal). Low

stage manifold pressure must be between 1.7 to 2.3 inches

water column (2.0 nominal).

3. To set low fire rate on 090, 1 15 and 140 kbtu/hr: Open

disconnect switch, and remove jumper from R to W2.

T o set low fire manifold pressure, repeat steps above.

Refer to Figure in input rating section for location of

high and low stage adjustment.

For propane gas, the manifold pressure must be between

9.7 and 10.3 inches water column (10.0 nominal). Low stage

manifold must be between 5.7 and 6.3 inches water column

(6.0 nominal).

4. Relight all other appliances turned off in step 1. Be

sure all pilot burners are operating.

Main Burner Flame Check

Flames should be stable, soft and blue (dust may cause orange tips but they must not be yellow) and extending directly

outward from the burner without curling, floating or lifting off.

NOx Screen Check

Verify that the alignment of the NOx screens is at 6 o' clock.

In jurisdictions that do not require low NOx emissions, NOx

screens may be removed.

Temperature Rise Check

Check the temperature rise through the unit by placing thermometers in supply and return air registers as close to the

unit as possible. Thermometers must not be able to sample

temperature directly from the unit heat exchangers, or false

readings could be obtained.

1. All registers must be open; all duct dampers must be

in their final (fully or partially open) position and the

unit operated for 15 minutes before taking readings.

2. The temperature rise must be within the range specified

on the rating plate.

NOTE: Air temperature rise is the temperature difference

between supply and return air.

With a properly designed system, the proper amount of temperature rise will normally be obtained when the unit is operated at rated input with the recommended blower speed.

If the correct amount of temperature rise is not obtained, it

may be necessary to change the blower speed. A higher

blower speed will lower the temperature rise. A slower blower

speed will increase the temperature rise.

NOTE: Blower speed MUST be set to give the correct air

temperature rise through the unit as marked on the rating

plate.

Gas Input (Natural Gas Only) Check

To measure the gas input use a gas meter and proceed

as follows:

1. Turn off gas supply to all other appliances except the

unit.

2. With the unit operating, time the smallest dial on the

meter for one complete revolution. If this is a 2 cubic

foot dial, divide the seconds by 2; if it is a 1 cubic foot

dial, use the seconds as is. This gives the seconds

per cubic foot of gas being delivered to the unit.

3. INPUT=GAS HTG VALUE x 3600 / SEC. PER CUBIC

FOOT

Example: Natural gas with a heating value of 1000 BTU per

cubic foot and 34 seconds per cubic foot as determined by

Step 2, then:

Input = 1000 x 3600 / 34 = 106,000 BTU per Hour.

NOTE: BTU content of the gas should be obtained

from the gas supplier. This measured input must not

be greater than shown on the unit rating plate.

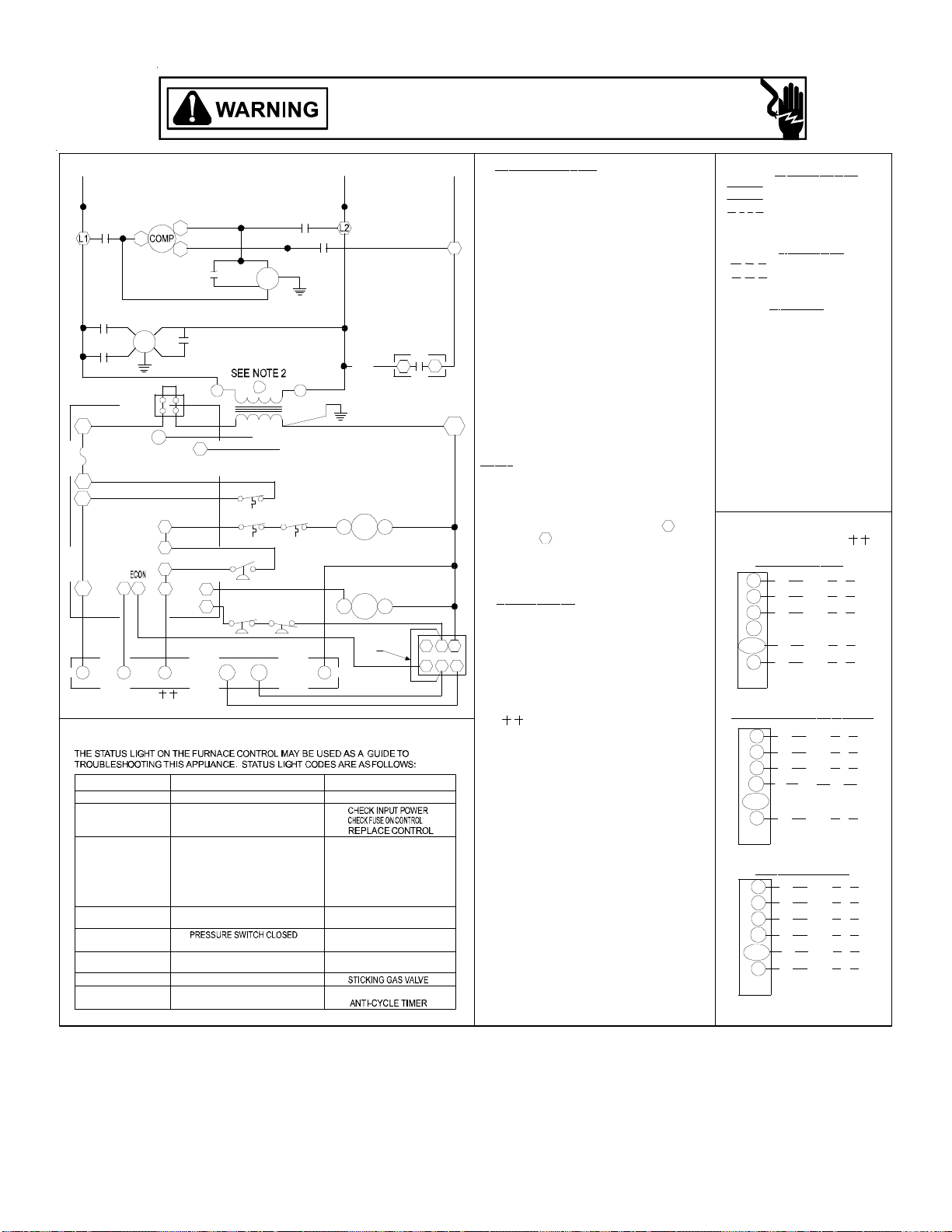

REFRIGERATION SEQUENCE CHECK

With the disconnect switch open, remove the field connected

thermostat wire from terminal R on TB1 terminal block. Place

a jumper across terminals R and G, and across R and Y on

TB1 terminal block. Close the disconnect switch. The following operational sequence should be observed.

1. Current through primary winding of transformer

TRANS1 energizes the 24-volt control circuit.

2. To simulate a mechanical call for cooling from the wall

thermostat, place a jumper across terminals R and Y

of terminal block TB1. The cooling is energized when

the room temperature is above the thermostat setpoint for cooling. The thermostat makes R to Y.

3. UNIT WITH ECONOMIZER OPTION: The

compressor circuit is interlocked through terminals 3

and 4 of the economizer module. If the outdoor air

enthalpy (temperature and humidity) is not suitable

for cooling, the economizer terminals will be closed

permitting compressor to be energized.

17

Page 18

4. The belt drive blower contactor closes its contacts L1,

L2 and L3 to T1, T2 and T3 to provide power to the

supply fan motor.

PSC Motor

Adjust the CFM for the unit by changing the speed

tap of the indoor blower motor at the EBTDR “com”

connection with one of the speed taps on “M1” or “M2”.

(Black-High Speed, Blue-Medium Speed, Red-Low

Speed.)

EEM Motor

Adjust the CFM for the unit by changing the position

of the low voltage leads on the motor terminal block.

White is for fan only and gas heat, Y ellow is for cooling.

Refer to Appendix A for blower performance at each

speed tap. NOTE: If more than one lead is energized

simultaneously , the motor will run at the higher speed.

5. Check supply fan rotation. If the supply fan is rotating

in the wrong direction, disconnect and lock off Single

Point Power Block. Do not attempt to change load

side wiring. Internal wiring is set at the factory to assure

that the supply fan and compressors all rotate in the

proper direction. Verification of correct supply fan

rotation at initial startup will also indicate correct

compressor rotation. Reconnect power and check for

proper operation.

6. Compressor contactor closes its contacts L1, L2 and

L3 to T1, T2 and T3 to provide power to the

compressor motor COMP . 1. In addition, cont actor C1

closes its contact L3 to T3 , energizing the condenser

fan motor.

WARN ING

7. Disconnecting the jumper wire between R and Y and

between R and G on TB1 terminal block will simulate

a satisfied thermostat. The compressor will cycle off

and IIC (pin 12) will initiate its time delay cycle. The

compressor and the supply fan will cycle off.

8. After a time delay of approximately 3 minutes, the

compressor control circuits will be ready to respond

to a subsequent call for cooling from the wall

thermostat.

9. Open disconnect switch. Reconnect the field

thermostat wire at terminal R on terminal block TB1.

REFRIGERATION PERFORMANCE CHECK

Under normal summertime (full load) operating conditions,

superheat should be between 8°F and 12°F and sub-cooling

measured at the condenser outlet should be 15°F (nominal).

A 25°F to 35°F temperature difference should exist between

the entering condenser air and the temperature corresponding to the compressor saturated discharge pressure. Check

that compressor RLA corresponds to values shown in Appendix C. RLA draw can be much lower than values listed at

low load conditions and low ambient condensing temperatures. Values in Appendix C can slightly exceed at high load

conditions and high ambient condensing temperatures.

GAS SUPPLY PRESSURES & REGULATOR ADJUSTMENTS

WARN ING

S

HOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO SHUT

OFF, TURN OFF THE MANUAL GAS SHUTOFF VALVE EXTERNAL TO THE

UNIT BEFORE TURNING OFF THE ELECTRICAL SUPPLY

.

DO NOT T OUCH! DISCHARGE LINE MAY BE HOT!

BURN HA Z ARD!

7. Check that the compressor is operating correctly. The

scroll compressors in these units MUST operate in

the proper rotation. To ensure the compressors are

operating in the correct direction, check the

compressor discharge line pressure or temperature

after the compressor is started.

The discharge pressure and discharge line

temperature should increase. If this does not occur

and the compressor is producing an exceptional

amount of noise, perform the following checks.

• Ensure all compressors and the supply fan motor

are operating in the proper direction. If a single motor

is operating backwards, check the power wiring for

that motor and correct any leads that have been

interchanged at the contactor or at the motor.

• If all of the motors are operating backward,

disconnect the unit power supply and lock it in the

“OFF” position. Switch two leads of the power supply

at the unit Single Point Power Block. Reconnect

power and check for compressor and supply fan

motor operation.

6. With all safety devices closed, the system will continue

cooling operation until the thermostat is satisfied.

WARN ING

TO

AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DO

NOT FIRE GAS UNIT WITH FLUE BOX COVER REMOVED

.

NOTE: Except during brief periods when gas pressures are

being measured by qualified service personnel, the furnace

access panel must always be secured in place when the

furnace is in operation. An inspection port in the access p anel

is provided to monitor the flame.

The first step in checking out the gas-fired furnace is to test

the gas supply piping to the unit for tightness and purge the

system of air using methods outlined in the latest edition of

the National Fuel Gas Code ANSI Z223.1. Verify that the

disconnect switch is in the “OFF” position. A soapy water

solution should be used to check for gas leaks. Since the unit

is subject to considerable jarring during shipment, it is extremely important that all gas connections and joints be tested

for tightness. Gas piping downstream from the unit inlet should

be checked for leaks during the subsequent sequence check.

The supply gas pressure should be adjusted to 7.0" w.c. on

natural gas and 1 1.0" on LP gas with the gas burners operating. If there is more than one unit on a common gas line, the

pressures should be checked with all units under full fire. A

18

Page 19

supply pressure tap is provided on the upstream side of the

gas valve. A manifold pressure tap is provided on the gas

valve. The normal manifold pressure for full input is 3.5" w .c.

on natural gas and 9.5" w.c. for propane gas. Low fire natural gas 2.0” w.c., 6.0” low fire propane gas. Minimum gas

supply pressure is 5.5" w.c. for natural gas and 11.0" for propane gas. In order to obtain rating, gas supply pressure must

be 11.0" w.c. for propane gas.

3. Remove the heat exchanger door on the side of the

unit by removing screws.

4. Move the gas control valve switch to the OFF position.

Do not force.

5. Close manual gas shutoff valve external to the unit.

6. Replace the heat exchanger door on the unit.

7. If cooling and/or air circulation will be desired, turn

ON the electrical power.

The pressure regulator on LP gas models is adjusted for 9.5"

w.c. manifold pressure and is intended to prevent over-firing

only . Do not attempt adjustment of the built-in pressure regulator unless the supply pressure is at least 7.0" w.c. on natural gas or 13.0" w.c. on propane gas. Check the location of

the ignition electrode and the flame sensor for correct gap

setting.

Flame Sensor and Ignition Electrode Location

MAXIMUM

INPUT

(BTUH)

45,000 2 23,000 #43 #55

115,000 5 23,000 #43 #55

140,000 6 23,000 #43 #55

90,000 4 23,000 #43 #55

NUMBER

of

BURNERS

Heat Exchanger and Burner Orifice Specifications

MAXIMUM

BTUH/BURNER

GAS ORIFICES

NATURAL

(Dia)

PROPANE (LP)

(Dia)

NOTE: Gas appliances located more than 2000 feet above

sea level must be derated 4% per 1000 feet of total elevation

and that variance in gas heating value and specific gravity