Page 1

VERTICAL MOUNT AIR HANDLERS

INSTALLATION INSTRUCTIONS

Important Safety Instructions

As a professional installer, you have an obligation to know the

product better than the customer. This includes all safety precautions and related items. Prior to actual installation, thoroughly familiarize yourself with this Instruction Manual. Pay

special attention to all safety warnings. Remember, it is your

responsibility to install the product safely and to know it well

enough to be able to instruct a customer in its safe use.

Safety is a matter of common sense...a matter of thinking before acting. Most dealers have a list of specific, good safety

practices...follow them.

The precautions listed in this Installation Manual are intended

as supplemental to existing practices. However, if there is a

direct conflict between existing practices and the content of

this manual, the precautions listed here take precedence.

© 2005-2009 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com -or- www.amana-hac.com

P/N: IO-281J Date: December 2009

Installations and re pair of this un it should be

performed by individuals meeting the

ONLY

require ment s of an “En try Level Techn ician” as

specified by the Air Conditioning, Heating, and

Refrigeration Institute (A HRI). Attemptin g to install

or repair this unit without such background may

result in product damage, personal injury , or death.

This unit should not be connected to, or used in conjunction with, any devices that are not design certified

for use wi th this uni t or h ave not b ee n tes ted an d

approved by Goodm an. Se rious pro perty damage or

personal injury, reduced unit performance and/or

hazardous conditions may result from the use of devices

that ha v e no t be en ap pr o ve d o r c e rt ifi e d b y G o od man .

HIGH VOLTAGE!

Disconnect ALL power before servicing or

installing this unit. Multiple power sources

may be present.

Failure to do so may cause property

damage, personal injury or death.

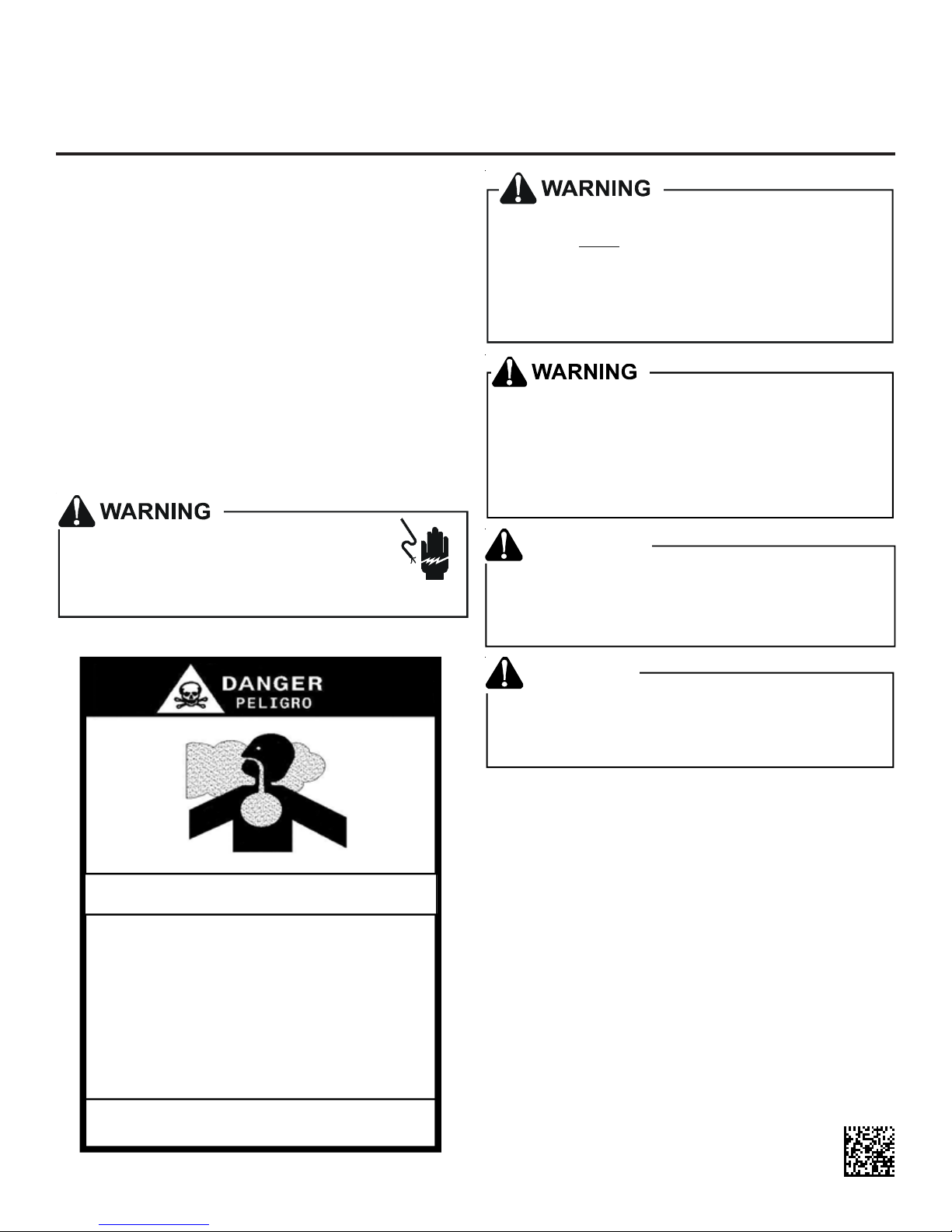

CARBON MONOXIDE POISONING HAZARD

Special Warning for Installation of Furnace or Air Handling Units in

Enclosed Areas such as Garages, Utility Rooms or Parking Areas

Carbon monoxide producing devices (such as an automobile, space

heater, gas water heater, etc.) should not be operated in enclosed areas

such as unventilated gar a ges, utility rooms or parking areas bec ause o f

the danger of carbon monoxide (CO) poisoning resulting from the exhaust

emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, utility room or parki ng area a nd a carbon m onox i de producing

device is operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO poisoning which

can occur if a carbon monoxide prod uc ing device continues to operate in

the enclosed area. Carb on monoxi de emi ss io ns can be (re) c irculated

throughout the structure if the furnace or air handle r is operat ing in any

mode.

CO can cause serious illness including permanent brain damage or death.

B10259-216

WARNING

To prevent the risk of property damage, personal injury,

or death, do not store combustible materials or use

gasoline or other flammable liquids or vapors in the

vicinity of this appliance.

CAUTION

Have your contractor identify all the various cutoff switch es

and devices that service this unit. Know wher e the switc h is

that will cut off ener gy t o the heating sys t e m in the event of

overheating.

Shipping Inspection

Upon receiving the product, inspect it for damage from shipment. Shipping damage, and subsequent investigation is the

responsibility of the carrier. Verify the model number, specifications, electrical characteristics, and accessories are correct prior to installation. The distributor or manufacturer will not

accept claims from dealers for transportation damage or in-

-

stallation of incorrectly shipped units.

Codes & Regulations

This product is designed and manufactured to comply with

national codes. Installation in accordance with such codes and/

or prevailing local codes/regulations is the responsibility of the

installer. The manufacturer assumes no responsibility for equipment installed in violation of any codes or regulations.

Page 2

The United States Environmental Protection Agency (EPA)

has issued various regulations regarding the introduction and disposal of refrigerants. Failure to follow these

regulations may harm the environment and can lead to

the imposition of substantial fines. These regulations may

vary by jurisdiction. A certified technician must perform

the installation and service of this product. Should you

have any questions please contact the local office of the EPA.

Replacement Parts

When reporting shortages or damages, or ordering repair parts,

give the complete product model and serial numbers as stamped

on the product. Replacement parts for this product are available through your contractor or local distributor. For the location of your nearest distributor consult the white business

pages, the yellow page section of the local telephone book or

contact:

SERVICE PARTS DEPARTMENT

GOODMAN MANUFACTURING COMPANY, L.P.

5151 SAN FELIPE, SUITE 500

HOUSTON, TEXAS 77056

(713) 861 – 2500

Installer’s Note:

Replacement air filters can be ordered directly from the supplier:

United Air Filter

Charlotte, NC

Phone: 704-334-5311

AWUF18-24 - Part #BT1369604,14” x 18” x 1”

AWUF36 - Part #BT1369606,16” x 20” x 1”

AWUF31-37 - Part #BT1369608,18” x 20” x 1”

Pre-Installation Instructions

Carefully read all instructions for the installation prior to installing product. Make sure each step or procedure is understood

and any special considerations are taken into account before

starting installation. Assemble all tools, hardware and supplies needed to complete the installation. Some items may

need to be purchased locally. Make sure everything needed to

install the product is on hand before starting.

Before attempting any installation, the following points should

be considered:

IMPORTANT NOTE TO THE OWNER

REGARDING PRODUCT WARRANTY

Your warranty certificate is supplied as a separate document

with the unit installed by your contractor. Read the limited

warranty certificate carefully to determine what is and is not

covered and keep the warranty certificate in a safe place. If you

are unable to locate the warranty certificate please contact

your installing contractor or contact customer service (877254-4729) to obtain a copy.

IMPORTANT: To receive the 10-year Parts Limited Warranty,

online registration must be completed within 60 days of installation. Online registration is not required in California or Quebec.

To register your Goodman brand unit, go to

www.goodmanmfg.com. Click on the word “Warranty” located

on the left side of the home page. Next, click on the word

“Product Registration” located on the left side of the Warranty

page and complete the forms in the manner indicated on the

Product Registration page.

Product limited warranty certificates can be viewed at

www.goodmanmfg.com or www.amana-hac.com. Each product

overview page contains a Product Warranty link; by clicking on

it you will be able to view the limited warranty coverage for that

specific product. To view warranty registration information, click

on the Product Warranty text on the left navigation panel on

the home page of each website. The Online Product Registration pages are located in this same section.

Before using this manual, check the serial plate for proper model

identification.

The installation and servicing of this equipment must be performed by qualified, experienced technicians only.

• Structural strength of supporting members

• Clearances and provision for servicing

• Power supply and wiring

• Air duct connections

• Drain facilities and connections

Application Information

The unit is designed to be installed either recessed into a wall

or hanging in a vertical “upflow” position. If units are recessed

in a wall, use the holes along the inside of the front flange to

attach units to the framing studs. The vertical airhandler comes

equipped with an offset hanging bracket attached to the rear of

the cabinet for hanging applications.

The airhandler also has a bottom and front return. Large chas-

sis installations should be installed as front return only. If

the small chassis airhandler is to be installed in a bottom return application, discard the drain access panel in the bottom

of the unit. If the airhandler is to be installed in a front return

application, remove and discard the front access panel with

insulation. The unit is shipped with a filter rack and filter. Remember to inspect, clean and/or replace the filter monthly.

Units are equipped with both a bottom primary and secondary

drain. Both drains must be trapped. Failure to install a trap

could result in condensation overflowing the drain pan resulting

in substantial water damage to the nearby area.

To prevent potential sweating and dripping on to finished space,

it may be necessary to insulate the condensate drain line located inside the building. Use Armaflex® or similar material.

NOTE: If you intend to install this unit with a “WAD” door

it must be mounted 1/4” behind front edge of stud.

2

Page 3

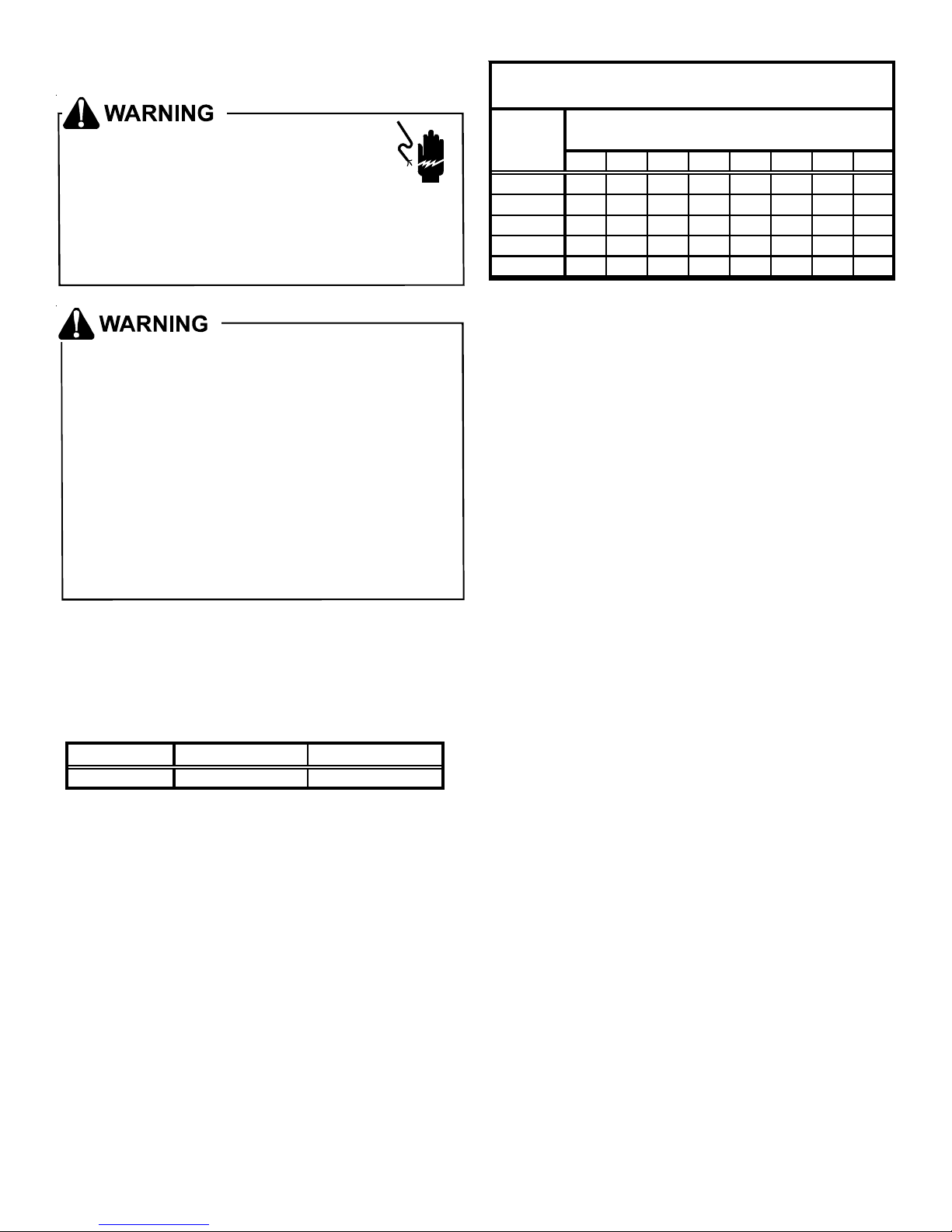

Electrical Supply Wire and MOP

Maximum Allowable Length in Feet

to Limit Volta g e D ro p to 2%*

HIGH VOLTAGE

To avoid the risk of fir e or eq u ipment

dama ge, use only co pp er conducto r s .

Disconnect ALL power before servicing or

insta lling this u nit. Multip le power sou r ces may

be present. Th e ele ctrical power to this unit

MUST be in the OFF position and all power supplies

disconnec t ed. Fail ure to do so may cause pro p e rty

damage, personal injury or death.

The unit MUST have an unin te rru pt ed , un bro ke n

electrical ground to minimize the possibility of

personal injury if an electrical fault should occur. The

electrical ground circuit may consist of an appropriately sized electrical wire connecting the ground lug

in the unit and contro l box wi r e to the bui ldin g’s

electrical service panel. Other methods of grounding

are per mitted if performed in accordance with the

“National Electric Code” (N E C) /”Ameri c an N at ional

Standards Institute” (ANSI)/”National Fire Protection

Association” (NFPA) 70 and local/state codes. In

Canada, elec trical grounding is to be in accordance

with the Canadian Elec tric Code CSA C22.1. Failure

to observe this warning can result in electrical shock

that can cause personal injury or death.

Inspection of the Building Electrical Service

This unit is designed for single-phase electrical supply. DO

NOT OPERATE ON A THREE-PHASE POWER SUPPLY.

Measure the power supply to the unit. The supply voltage

must be in agreement with the unit nameplate power requirements and within the range shown in Table 1.

Wire Size

(AWG)

14 75 50 37 NR NR NR NR NR

12 118 79 59 47 NR NR NR NR

10 188 125 95 75 63 54 NR NR

8 301 201 150 120 100 86 75 68

6 471 314 235 188 157 134 118 110

*Based on NEC 1996

Minimum Circuit Ampacity (M CA)

10 15 20 25 30 35 40 45

Table 2

Maximum Overcurrent Protection (MOP)

Every installation must include an NEC (USA) or CEC (Canada)

approved overcurrent protection device. Also, check with local

or state codes for any special regional requirements.

Protection can be in the form of fusing or HACR style circuit

breakers. The Series and Rating Plate can be used as a guide

for selecting the MAXIMUM overcurrent device.

NOTE: Fuses or circuit breakers are to be sized larger than

the equipment MCA but not to exceed the MOP.

IMPORTANT NOTE: Torch heat required to braze tubes of

various sizes is proportional to the size of the tube. Tubes of

smaller size require less heat to bring the tube to brazing

temperature before adding brazing alloy. Applying too much

heat to any tube can melt the tube. Service personnel must use

the appropriate heat level for the size of the tube being brazed.

NOTE: The use of a heat shield when brazing is recommended

to avoid burning the serial plate or the finish on the unit. Heat

trap or wet rags should be used to protect heat sensitive

components such as service valves and TXV valves.

Nominal Input Minimum Voltage M aximum Voltage

208/230 187 253

Table 1

Wire Sizing

Wire size is important to the operation of your equipment. Use

the following check list when selecting the appropriate wire

size for your unit.

• Wire size must carry the Minimum Circuit Ampacity

(MCA).

• Wire size allows for no more than a 2% voltage drop

from the building breaker/fuse panel to the unit.

Refer to the latest edition of the National Electric Code or in

Canada the Canadian Electric Code when determining the correct wire size. The following table shows the current carrying

capabilities for copper conductors rated at 75oC with a 2%

voltage drop. Use Table 2 to determine the voltage drop per

foot of various conductors.

Electrical Connections – Supply Voltage

USE COPPER CONDUCTORS ONLY.

A knockout is provided on the air handler top panel or side to

allow for the entry of the supply voltage conductors. If the knockouts on the cabinet sides are used for electrical conduit, an

adapter ring must be used in order to meet UL1995 safety

requirements. An NEC or CEC approved strain relief is to be

used at this entry point. The wire is to be sized in accordance

with the “Electrical Wire and MOP” section of this manual.

Some areas require the supply wire to be enclosed in conduit.

Consult your local codes.

3

Page 4

Special Instructions

This airhandler comes equipped with an evaporator coil with a

check style flowrator assembly, an indoor blower and all necessary internal electrical wiring. For most installations with

matching applications, no change to the flowrator orifice is required. However, in mix-matched applications, a flowrator

change may be required. See the Goodman piston kit chart or

consult your local distributor for details regarding mix-matched

orifice sizing. If the mix-match application requires a different

piston size, change the piston in the distributor on the indoor

coil before installing the coil and follow the procedure in this

section.

CAUTION

Excessive torque can cause orifices to stick. Use the proper

torque settings when tightening orifices.

11.Replace suction line insulation.

12. After installation, evacuation and charging of the low side

is complete, check fittings for leaks.

NOTE: With the piston in the distributor, the seal end should

point inside the distributor body and should not be seen when

looking into the end of distributor. Make sure the piston is free

to rotate, and move up and down in the distributor body.

WARNING

The evaporator coil is shipped from the factory with

approximately 90 PSI tracer gas charge. Use caution

when relieving pressure.

CAUTION

To prevent feeder tube damage, hold the distributor body

with a 3/4" open end wrench when removing or replacing

the 13/16" flare nut.

1. Remove the valve core to allow high pressure tracer gas

to escape. No gas indicates a possible leak.

2. Remove the 13/16" flare nut and tailpiece.

3. Unsweat the access fitting on the tailpiece

4. Remove the check piston to verify it is correct and then

replace the piston. See piston kit chart in instructions.

5. Unsweat the cap on the suction line.

6. Slide the 13/16" flare nut over the tailpiece.

7. Braze tailpiece to the lineset liquid tube.

8. Insert the suction line into the connection, slide the insulation at least 18" away from the braze joint. Braze suction line.

MAINTENANCE

Periodic Checkup and Service

This unit is designed to provide many years of dependable,

trouble-free comfort when properly maintained. Proper maintenance will consist of annual checkups and cleaning of the internal electrical and heat transfer components by a qualified

service technician. Failure to provide periodic checkup and

cleaning can result in excessive operating cost and/or equipment malfunction.

9. AFTER THE TAILPIECE HAS COOLED, confirm position of the white Teflon® seal and hand tighten the 13/16"

flare nut.

10. Torque the 13/16" flare nut to 10-25 ft-lbs or tighten 1/6th

turn.

4

Page 5

SUCTIO N LINE

LIQUID LINE

REMOVABLE

SERVICE DOOR

FRONT ACCESS

PANEL

SMALL CHASSIS

BOTTOM PRIMAR Y AND SECONDARY

DRAINS CAN BE ACCESSED THROUGH THE

BO TTO M OF THE UNIT. (3/4" N PT FEMALE

CONNECTION)

NOTE: HAND TIGHTEN ONLY

CABINET DIMENSIONS

LARGE CHASSIS

2.5 & 3.0 TON

A36 36

B 24 20 3/16

C21 16 1/8

D19 7/8 16

E15 7/8 11

5

SMALL CHASSIS

1.5 & 2.0 TON

Page 6

NOTE: SPECIFICATIONS & PERFORMANCE DATA LISTED HEREIN

ARE SUBJECT TO CHANGE WITHOUT NOTICE

NOTE: Thermostat heat anticipator setting is 0.2.

WYG

AWUF18, 24, 30, 36, 37

TAPE

WYG

AWUF31/32

T2

T3

NOTE: T1 Y

Connect to the

going to the outdoor unit.

NOTE:

T1

TAPE

Connect appropriate speed tap

(Pink/Purple/Y ellow) to T1.

Re f e r t o table b elow f or s peed ta p s elec t i o n

T4

T5

T6

WIRE COLOR B TUH N OM INA L CF M

PURPLE 18,000 600

PINK 24,000 800

YELLOW 30,000 950

6

Page 7

BLOWER CHART FOR VERTICAL MOUNT AIR HANDLERS

Model Speed

AWUF18XX1/16A*

AWUF18XX16B*

AWUF24XX1/16A*

AWUF24XX16B*

AWUF30XX1/16A*

AWUF30XX16B*

AWUF310516XX

CFM delivered against External Static Pressure

0.1" 0.2" 0.3" 0.4" 0.5"

High 750 730 690 650 595

Low 710 700 690 635 585

High 755 715 670 615 545

Low 740 700 655 595 535

High 880 845 810 770 735

Low

High 900 870 835 795 760

Low 865 835 800 765 725

High 1250 1195 1135 1085 1010

Low 1110 1055 1020 955 905

High 1255 1120 1100 1020 950

Low 1115 1010 990 900 820

T5 875 865 830 805 765

T4 1005 975 945 920 890

T3

845 815 780 745 705

840 795 785 745 700

AWUF310816XX/

AWUF321016XX

AWUF36XX1/16A*

AWUF36XX16B*

AWUF37XX16A*

AWUF37XX16B*

T2 645 615 550 500 445

T1

T5

T4

T3 840 795 785 745 700

T2 645 615 550 500 445

T1 645 615 550 500 445

High 1280 1190 1110 1010 930

Low 1170 1100 1030 950 890

High 1215 1145 1070 985 890

Low 1120 1065 1000 915 820

High 1326 1284 1232 1181 1115

Low

T5 1385 1205 1130 1045 950

T4 1235 1180 1115 1040 955

T3 1165 1120 1075 1025 945

T2

T1

645 615 550 500 445

1090 1065 1040 1015 985

1005 975 945 920 890

1086 1061 1028 996 950

1050 1010 970 930 860

1050 1010 970 930 860

7

Page 8

THIS PAGE LEFT INTENTIONALLY BLANK

© 2005-2009 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com -or- www.amana-hac.com

8

Loading...

Loading...