Goodman RS6100004, RS6200006, ARUF 14 series, ARPT 14 series, ASPT 14 series Technical Manual

...Page 1

TECHNICAL MANUTECHNICAL MANU

TECHNICAL MANU

TECHNICAL MANUTECHNICAL MANU

ALAL

AL

ALAL

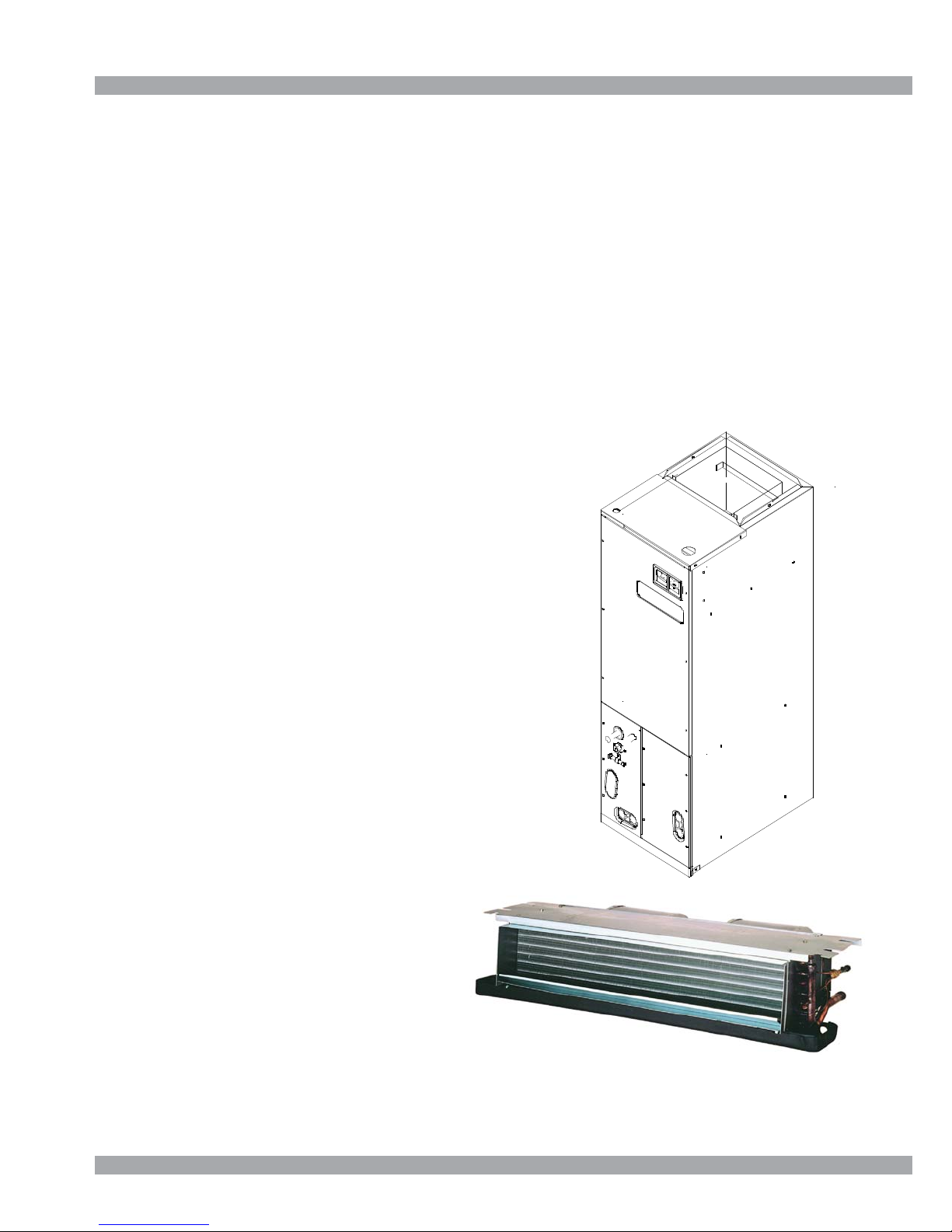

ACNF , ADPF , AEPF , ARPF , ARUF ,

ASPF, ATUF, A WUF Air Handlers

• Refer to Service Manual RS6100004 & RS6200006 for installation, operation & troubleshooting information.

• All safety information must be followed as provided in the Service Manual.

• Refer to the appropriate Parts Catalog for part number information.

• Models listed on page 3.

This manual is to be used by qualified, professionally trained HVAC technicians only. Goodman

does not assume any responsibility for property damage or personal injury due to improper

service procedures or services performed by an unqualified person.

Copyright © 2007-2013 Goodman Company, L.P.

RT6121000r20

September 2013

Page 2

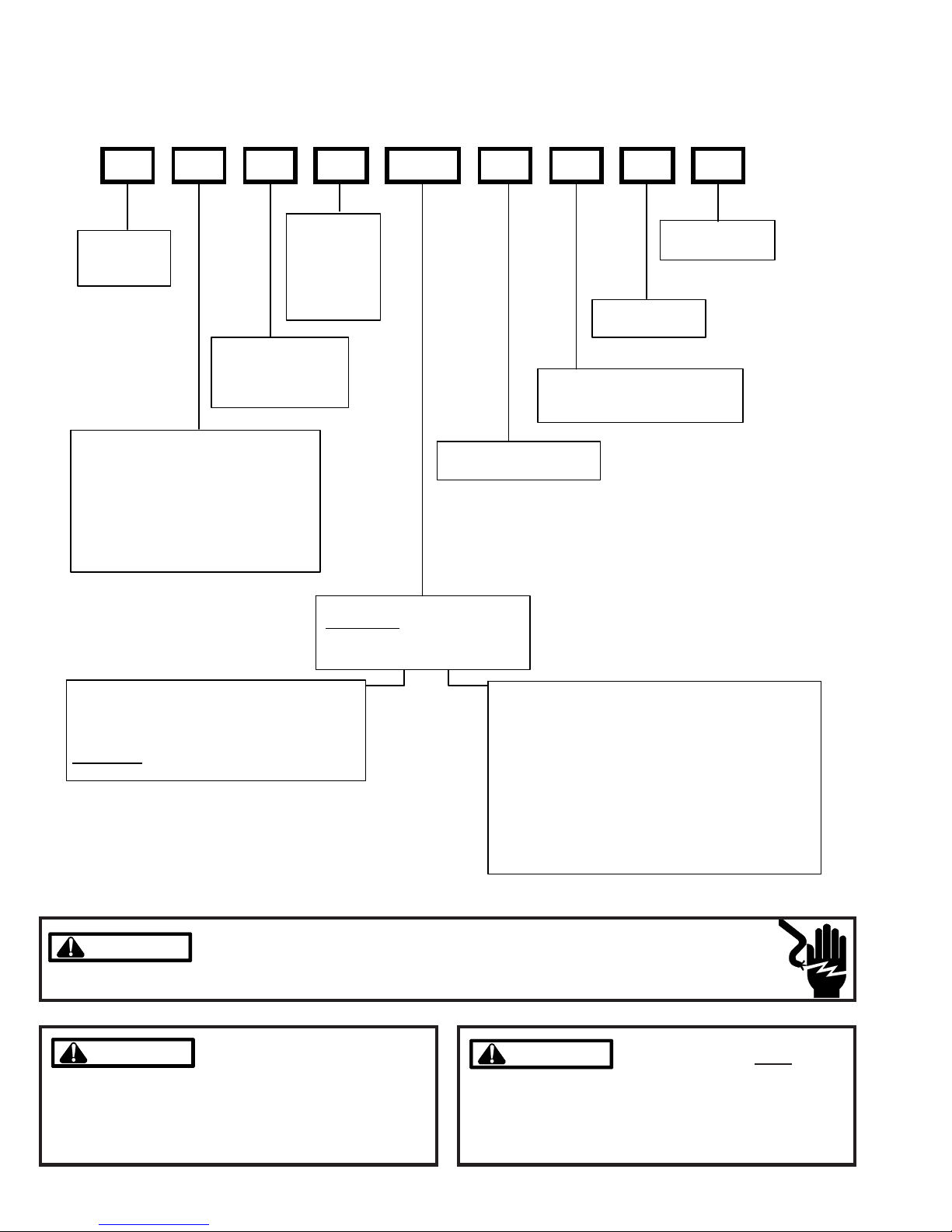

PRODUCT IDENTIFICATION

)

The model number is used for positive identification of component parts used in manufacturing. Please use this number

when requesting service or parts information.

A W U F 3642 1 6 A A

EXPANS ION

PRODUCT

TYPE:

A: Air Handler

CA BINET FI NISH:

U: Unpainted

P: Painted

N : Uncased

APPLICATION

C: C eiling Mount PS C Motor

D: Do wn flo w P S C M otor

E: Multi-P osition Varible Speed Motor

S: Energy-Efficient Motor

R: Multi-Position PSC Motor

T: Coated Coils

W: Wall Mount PSC Motor

DEV ICE :

F: Flowrat er

T: TXV

(Expansion

Device)

MINOR

REVISION*

MAJOR

REVISION*

REFRIGERANT CHARGE:

No Digit: R-22 Only

6: R-410A or R-22

ELECTRICAL:

1: 208 - 230 V / 1ph/60Hz

NOM INAL CA PACITY RANGE:

@ 13 SEER

Dedicated Appl icat ion

36 36 : 3 Tons

Multi- P osition & Downflow Ap plication s

3137: 3 Tons

3642: 3 - 3 1/2 Tons

183 0 : 1 1/2 - 3 1/ 2 T o ns

@10 SEER

172 9 : 1 1/2 - 2 1/ 2 T o ns (for export systems

All Airhandlers use DIRECT DRIVE MOTORS. Power supply is AC 208-230v, 60 hz, 1 phase.

HIGH VOLTAGE!

WARNING

WARNING

WARNING

WARNING

arising from improper service or service procedures. If

you install or perform service on this unit, you assume

responsibility for any personal injury or property damage

which may result. Many jurisdictions require a license to

install or service heating and air conditioning equipment.

Disconnect ALL power before servicing or installing this unit. Multiple power

sources may be present. Failure to do so may cause property damage, personal

injury or death.

Goodman will not be responsible

for any injury or property damage

Ceiling M o unt & Wall Mount Applicatio ns

(Nomin al Cooling Capacity/E lectric Heat kW)

1803 : 1 1/2 To ns Co o li n g / 3 kW Elec tric He at

1805 : 1 1/2 To ns Co o li n g / 5 kW Elec tric He at

2405: 2 Tons Cooling / 5 kW Electric Heat

3608: 3 Tons Cooling / 8 kW Electric Heat

310 5: 1.5 - 2. 5 Tons Co oling / 5k W Ele c tric Hea t

3210: 2 - 2.5 Tons Cooling / 10kW Electric Heat

3705: 3 Tons Cooling / 5 kW Electric Heat

3708: 3 Tons Cooling / 8 kW Electric Heat

3710: 3 Tons Cooling / 10 kW Electric Heat

WARNING

WARNING

ments of an "entry level technician", at a minimum, as

specified by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI). Attempting to install or repair this

unit without such background may result in product

damage, personal injury or death.

Installation and repair of this unit

should be performed

dividuals meeting the require-

ONLY by in-

2

Page 3

PRODUCT IDENTIFICATION

The model number is used for positive identification of component parts used in manufacturing. Please use this number

when requesting service or parts information.

ACNF18001**

ACNF18051**

ACNF18061**

ACNF18081**

ACNF24001**

ACNF24051**

ACNF24061**

ACNF24081**

ACNF24101**

ACNF30001**

ACNF30051**

ACNF30061**

ACNF30081**

ACNF30101**

ACNF180016D*

ACNF180516D*

ACNF180616D*

ACNF180816D*

ACNF240016D*

ACNF240516D*

ACNF240616D*

ACNF240816D*

ACNF241016D*

ACNF300016D*

ACNF300516D*

ACNF300616D*

ACNF300816D*

ACNF301016D*

ADPF18241**

ADPF30421**

ADPF48601**

ADPF182416

ADPF304216**

ADPF486016**

AEPF18301**

AEPF30361**

AEPF31371**

AEPF42601**

ARPF18241**

ARPF30301**

ARPF37431**

ARPF48601**

ARPF182416**

ARPF193116**

ARPF303016**

ARPF363616**

ARPF364216**

ARPF374316**

ARPF486016**

ARPF496116**

ARUF18241**

ARUF30301**

ARUF36421**

**

ARUF37431**

ARUF48601**

ARUF172916**

ARUF182416**

ARUF193116**

ARUF303016**

ARUF363616**

ARUF364216**

ARUF374316**

ARUF486016**

ARUF496116**

ASPF183016*

ASPF303616*

ASPF313716*

ASPF426016*

ATUF182416**

ATUF193116**

ATUF303016**

ATUF363616**

ATUF364216**

ATUF374316**

ATUF486016**

AWUF18051**

AWUF18081**

AWUF24051**

AWUF24081**

AWUF24101**

AWUF30051**

AWUF30081**

AWUF30101**

AWUF36051**

AWUF36081**

AWUF36101**

AWUF37051**

AWUF37081**

AWUF37101**

AWUF180316**

AWUF240316**

AWUF300316**

AWUF240316B*

AWUF240516B*

AWUF240816B*

AWUF241016B*

AWUF310516A*

AWUF310816A*

AWUF321016A*

WARNING

WARNING

WARNING

WARNING

Serious property damage, personal injury, reduced unit

performance and/or hazardous conditions may result

from the use of such non-approved devices.

The United States Environmental Protection Agency (“EPA”) has issued various regulations regarding the introduction and disposal of refrigerants introduced into this unit. Failure to follow

these regulations may harm the environment and can lead to the imposition of substantial fines.

These regulations may vary by jurisdiction. Should questions arise, contact your local EPA office.

Do not connect or use any device

that is not design certified by

Goodman for use with this unit.

WARNING

WARNING

do not store combustible materials or use gasoline or

other flammable liquids or vapors in the vicinity of this

appliance.

To prevent the risk of property

damage, personal injury, or death,

3

Page 4

PRODUCT DESIGN

WARNING

When installing or servicing this equipment, safety

clothing, including hand and eye protection, is

strongly advised. If installing this equipment in an

area that has special safety requirements (hard hats

etc.), observe these requirements. To protect the

unit when brazing close to the painted surfaces,

the use of a quenching cloth is strongly advised to

prevent scorching or marring of the equipment finish.

WARNING

The unit MUST have an uninterrupted, unbroken

electrical ground to minimize the possibility of personal injury if an electrical fault should occur. The

electrical ground circuit may consist of an appropriately sized electrical wire connecting the

ground lug in the unit control box to the building

electrical service panel. Other methods of grounding are permitted if performed in accordance with

the “National Electric Code” (NEC)/“American National Standards Institute” (ANSI)/“National Fire

Protection Association” (NFPA) 70 and local/state

codes. In Canada, electrical grounding is to be in

accordance with the Canadian Electric Code CSA

C22.1. Failure to observe this warning can result

in electrical shock that can cause personal injury

or death.

AIR HANDLERS

*See Air Handler Specification Sheet for Proper Combinations.

ALL AIR HANDLERS USE DIRECT DRIVE MOTORS. POWER SUPPLY IS 220-240 V, 60 HZ, 1

PHASE

Installation

Before installing this appliance insure that it is properly sized

and adequate power is available.

This appliance can be installed in the vertical or right horizon-

tal position without modification. The horizontal left and

downflow positions require product modification.

This product is designed for zero inches (0 inches) clearance; however, adequate access for service or replacement

must be considered without removing permanent structure.

This unit can be installed on a platform when deemed necessary.

In an attic installation a secondary drain pan must be provided by the installer and placed under the entire unit with a

separate drain line properly sloped and terminated in an area

visible to the owner. This secondary drain pan is required in

the event that there is a leak or main drain blockage. Closed

cell insulation should be applied to the drain lines in unconditioned spaces where sweating may occur.

Appliances installed in garages, warehouses or other areas

where they may be subjected to mechanical damage must

be suitably guarded against such damage by installing behind protective barriers, being elevated or located out of the

normal path of vehicles. When installed on a base, the base

must also be protected by similar means.

Heating and cooling equipment located in garages, which

may generate a glow, spark or flame capable of igniting flammable vapors, must be installed with the ignition source at

least 18"[46cm] above the floor level.

When more than one appliance is installed in a building it

shall be permanently identified as to the area or space serviced by the equipment.

When this product is installed in the downflow installation in

an unconditioned space, remove the horizontal drain pan and

install the following insulation kit

WARNING

If this appliance is installed in an enclosed area

such as a garage or utility room with any carbon

monoxide (CO) producing appliance (i.e. automobile, furnace, water-heaters, etc.), ensure the area

is properly ventilated.

4

ARUF, ATUF

or A RPF M odel

1729

1824

3030

1931

3636

3642 3036

3743

4860

4961

This kit is used to prevent sweating on the vertical drain pan.

AEPF / ASPF Insulation Kit

N/A

1830

3137

4260

DPI18-30/20

DPI36-42/20

DPI48-61/-20

Page 5

PRODUCT DESIGN

To prevent the horizontal drain pan from sweating in high

humidity applications, it is recommended that a DPIH

insulation accessory kit be used. NOTE: The DPIH insulation kit is not supplied with this product and must be

purchased separately.

See Chart below for the correct DPIH kit.

A RUF, ATUF

or ARPF Model

1729

1824

3030

1931

3636

3642 3036

3743 3137

4860

4961

ACNF AC electric heat air handlers are designed for ceiling

mounting and have a direct drive, multi-speed motor. They

are available in 1-1/2, 2 and 2 1/2 ton sizes.

AWUF is a vertical stud or wall-mount electric heat air handler and features a direct drive, multi-speed motor. The AWUF

has a check flowrater for cooling only and heat pump operation, with sequence controlled heating elements of 5, 8, and

10 kW. The AWUF is available in 1 1/2 to 3 ton sizes.

ADPF is a dedicated downflow, multi-speed air handler and

is available in 1 1/2 to 5 ton sizes. Electric heat kits are

available as a field-installed option.

AEPF / ASPF Ins ulation Kit

N/A

1830

4260

DPIH18-32

DPIH36-42

DPIH48-61

*ARPF air handlers are multi-position, multi-speed with direct drive motors. They are available in 1 1/2 to 5 ton sizes

with optional 3 kW to 21kW electric heat kits available for

field installation. (See note below.)

ARUF is a multi-position air handler and can be used with R410A or R-22 (models ending in 1/16) and features a direct

drive, multi-speed motor. The ARUF has a check flowrater for

cooling-only and heat pump operation. The ARUF is available in 1 1/2 to 5 ton sizes.

*AEPF is a multi-position, variable-speed air handler and can

be used with R-410A or R-22 (models ending in 1/16). The

unit's blower design includes a variable-speed DC motor and

is compatible with heat pumps and variable-capacity cooling

applications. (See note below.)

*ASPF is a multi-position air handler that can be used with R410A or R-22 and it features a energy efficient motor. This

motor is a constant torque motor with very low power

consumption and it is energized by a 24V signal. The energy

efficient motor features an integrated control module and is

compatible with heat pumps and cooling applications. (See

note below.)

*NOTE: Factory-sealed to achieve a 2% or less leakage rate

at 1.0" water gauge external duct static pressure.

Complies with the Factory-sealed Air Handling Credit as

listed in the 2001 Florida Building Code, Chapter 13, Section

610.2.A.2.1.

5

Page 6

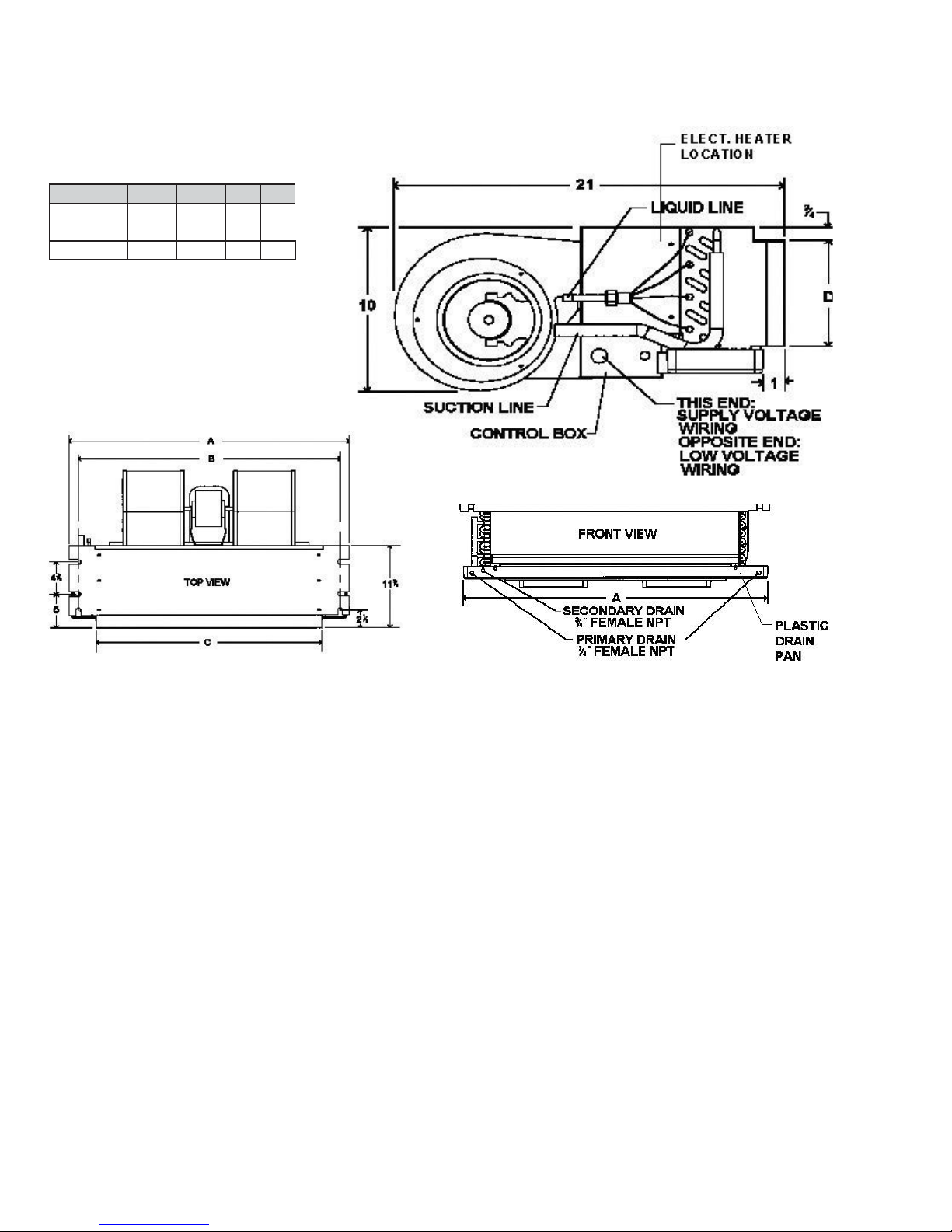

PRODUCT DIMENSIONS

D

IMENSIONS

ACNF

Model A B C D

ACNF18 37¼” 34

ACNF24 43¼” 40

ACNF30 49¼” 46

AC18 37¼” 34

AC30 43¼” 40

AC36 49¼” 46

11

/16” 30” 6½”

11

”

36” 6½”

/

16

11

/16” 42” 6½”

11

/16” 30” 6½”

11

”

36” 6½”

/

16

11

/16” 42” 6½”

6

Page 7

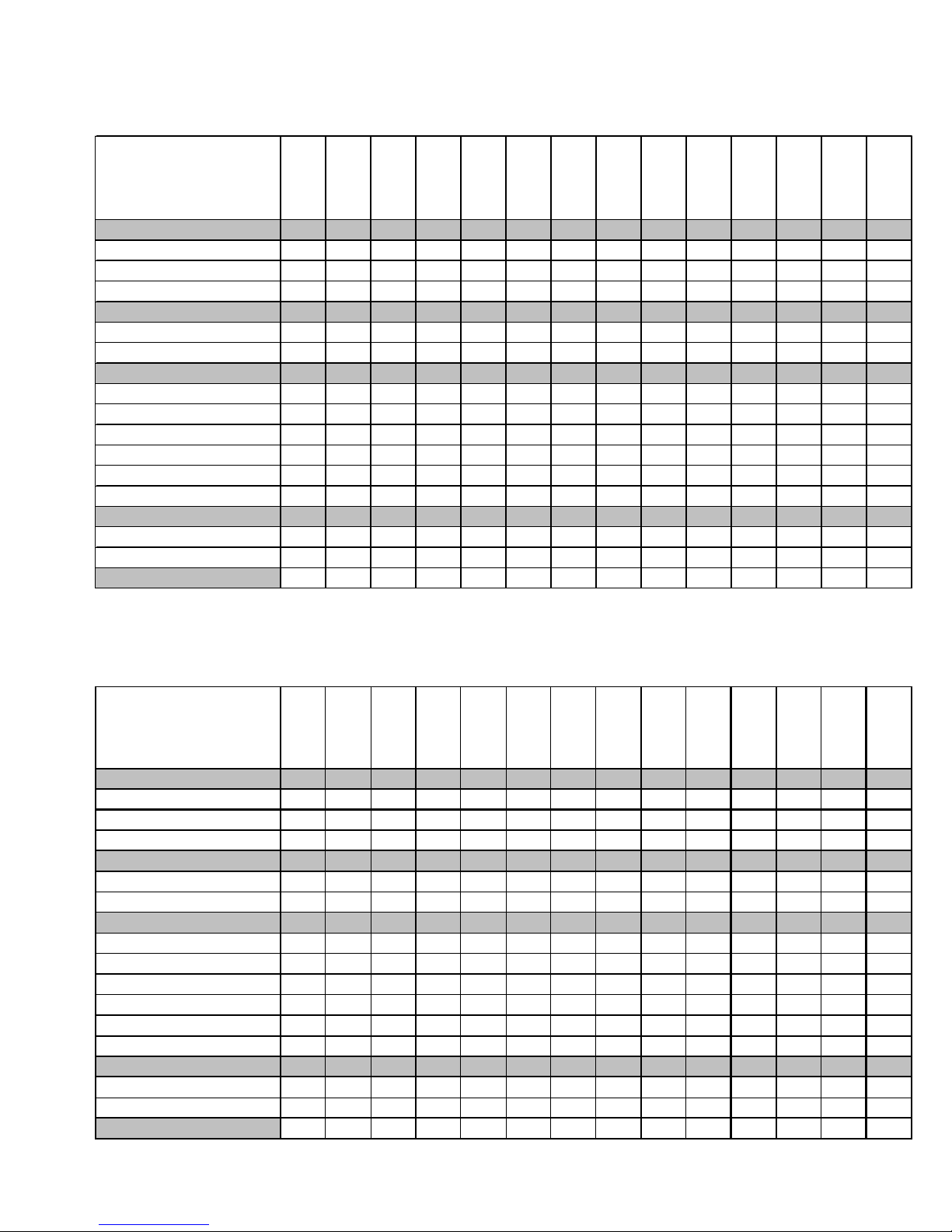

PRODUCT SPECIFICA TIONS

ACNF*****AA/AB (copper coils)

ACNF

ACNF18001

ACNF18051

ACNF18061

ACNF18081

ACNF24001

ACNF24051

ACNF24061

Blower

Diam eter 5.75 5.75 5.75 5.75 6.31 6.31 6.31 6.31 6.31 6.75 6.75 6.75 6.75 6.75

Width 6.75 6.75 6.75 6.75 8.25 8.25 8.25 8.25 8.25 8.25 8.25 8.25 8.25 8.25

Coil Dr a in Connection FPT 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3 /4" 3/4" 3/4" 3/4" 3/4"

Lineset Connection Size

Liquid 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8"

Suction 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4 " 3/4"

Electrical Data

Min. Circuit Ampacity @ 240V 0.9 27 33.5 40.5 1.68 27.8 34.3 41.3 54.9 1.68 27.8 34.3 41.3 54.9

Min. Circuit Ampacity @ 208V 0.9 2405 30.5 36.8 1.68 25.3 31.36 37.6 49.8 1.68 25.3 31.3 37.6 49

Max. Overcurrent Device 240V 15 30 40 50 15 30 40 50 60 15 30 40 50 8

Max. Overcurrent Device @ 208V 15 30 40 40 15 30 40 40 50 15 30 40 40 60

Minimum VAC 197 197 197 197 197 197 197 197 197 197 197 197 197 50

Maximum VAC 253 253 253 253 253 253 253 253 253 253 253 253 253 253

Blower Motor

FLA 0.72 0.72 0.72 0.72 1.34 1.34 1.34 1.34 1.34 1.34 1.34 1.34 1.34 1.34

HP 1/81/81/81/81/41/41/41/41/41/41/41/41/41/4

Ship Weight (lbs)

59 59 59 59 69 69 69 69 69 79 79 79 79 79

ACNF24081

ANF24101

ACNF30001

ACNF30051

ACNF30061

ACNF30081

ACNF30101

ACNF*****DA (with aluminum coils)

ACNF180016

ACNF180516

ACNF180616

ACNF180816

ACNF240016

ACNF240516

ACNF240616

Blower

Diameter 5.75 5.75 5.75 5.75 6.31 6.31 6.31 6.31 6.31 6.75 6.75 6.75 6.75 6.75

Width 6.756.756.756.758.258.258.258.258.258.258.258.258.258.25

Coil Drain Connection FPT 3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"

Lineset Connect ion Size

Liquid 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8"

Suction 3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"3/4"

Electrical Data

Min. Circuit Am pacity @ 240V 0. 9 27 33.5 40.6 1.68 27. 8 34.3 41.3 54. 9 1.68 27.8 34. 3 41.3 54.9

Min. Circuit Am pacity @ 208V 0. 9 23.5 29.2 35.3 1.68 24. 3 36.1 47. 8 49.8 1.68 24. 3 29.9 36.1 47. 8

Max. Overcurrent Device 240V 15 30 35 45 15 30 45 50 60 15 30 35 45 8

Max. Overcurrent Device @ 208V 15 25 30 40 15 25 40 40 50 15 25 30 40 60

Minimum VAC 197 197 197 197 197 197 197 197 197 197 197 197 197 50

Maxi m um V A C 253 25 3 253 253 25 3 253 253 25 3 253 25 3 253 253 253 25 3

Bl ower Mot o r

FLA 0.720.720.720.721.341.341.341.341.341.341.341.341.341.34

HP 1/81/81/81/81/41/41/41/41/41/41/41/41/41/4

Ship Weight (lbs)

54 57 57 57 61 64 64 64 64 65 68 68 68 68

ANF241016

ACNF240816

ACNF300016

ACNF300516

ACNF300616

ACNF300816

ACNF301016

7

Page 8

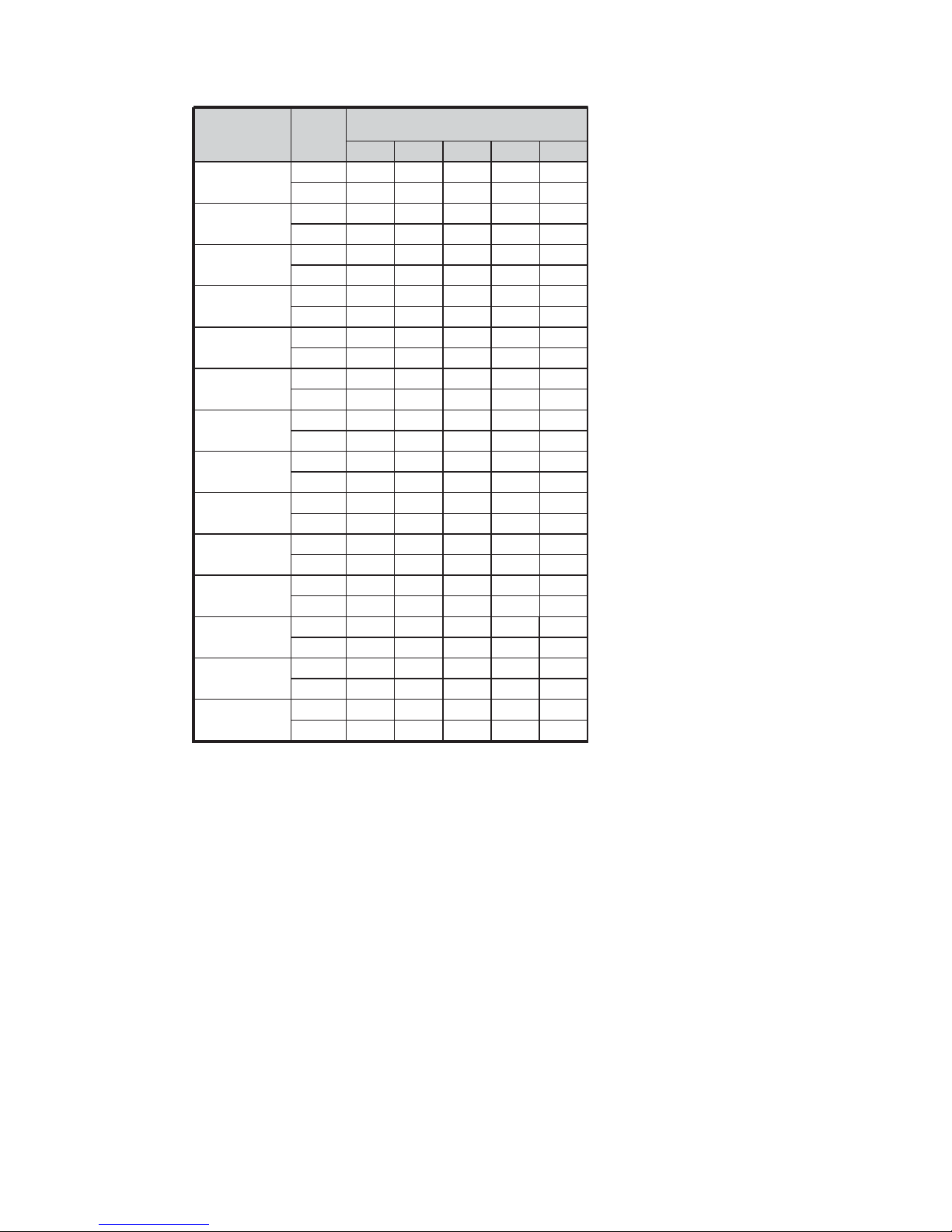

BLOWER PERFORMANCE DATA

CFM delivered against External

Model Speed

ACNF18001

ACNF18051

ACNF18061

ACNF18081

ACNF24001

ACNF24051

ACNF24061

ACNF24081

ACNF24101

ACNF30001

ACNF30051

ACNF30061

ACNF30081

ACNF30101

High 780 710 625 520 440

Low 675 585 510 460 400

High 780 710 625 520 440

Low 675 585 510 460 400

High 780 710 625 520 440

Low 675 585 510 460 400

High 780 710 625 520 440

Low 675 585 510 460 400

High 935 880 810 735 675

Low 720 680 630 565 490

High 935 880 810 735 675

Low 720 680 630 565 490

High 935 880 810 735 675

Low 720 680 630 565 490

High 935 880 810 735 675

Low 720 680 630 565 490

High 935 880 810 735 675

Low 720 680 630 565 490

High 1,075 1,015 945 865 770

Low 830 785 720 665 605

High 1,075 1,015 945 865 770

Low 830 785 720 665 605

High 1,075 1,015 945 865 770

Low 830 785 720 665 605

High 1,075 1,015 945 865 770

Low 830 785 720 665 605

High 1,075 1,015 945 865 770

Low 830 785 720 665 605

0.1” 0.2” 0.3” 0.4” 0.5”

Static Pressure

ACNF

Note: Assumes dry coil with filter in place; 208-volt operation x .96

8

Page 9

BLOWER PERFORMANCE DATA

ACNF*****DA (with aluminum coils)

CFM deli ve rd agains t External Static Pressu re

Model Speed

0.1" 0.2" 0.3" 0.4" 0.5"

ACNF

ACNF180016

ACNF180516

ACNF180616

ACNF180616

ACNF240016

ACNF240516

ACNF240616

ACNF240816

High 610 525 480 400 320

Low 545 470 400 340 250

High 610 525 480 400 320

Low 545 470 400 340 250

High 610 525 480 400 320

Low 545 470 400 340 250

High 610 525 480 400 320

Low 545 470 400 340 250

High 945 860 800 725 670

Low 850 800 725 680 600

High 945 860 800 725 670

Low 850 800 725 680 600

High 945 860 800 725 670

Low 850 800 725 680 600

High 945 860 800 725 670

Low 850 800 725 680 600

ACNF241016

ACNF300016

ACNF300516

ACNF300616

ACNF300816

ACNF31016

High 945 860 800 725 670

Low 850 800 725 680 600

High 1,060 985 895 805 720

Low 905 845 780 710 625

High 1,060 985 895 805 720

Low 905 845 780 710 625

High 1,060 985 895 805 720

Low 905 845 780 710 625

High 1,060 985 895 805 720

Low 905 845 780 710 625

High 1,060 985 895 805 720

Low 905 845 780 710 625

Heating Capacity/kW Correction Factor

Supply Voltage 240 230 220 210 208

C orrect i o n Factor 1.08 1. 0 0 0.92 0.84 0.82

9

Page 10

PRODUCT DIMENSIONS

ADPF

2 ȹ”

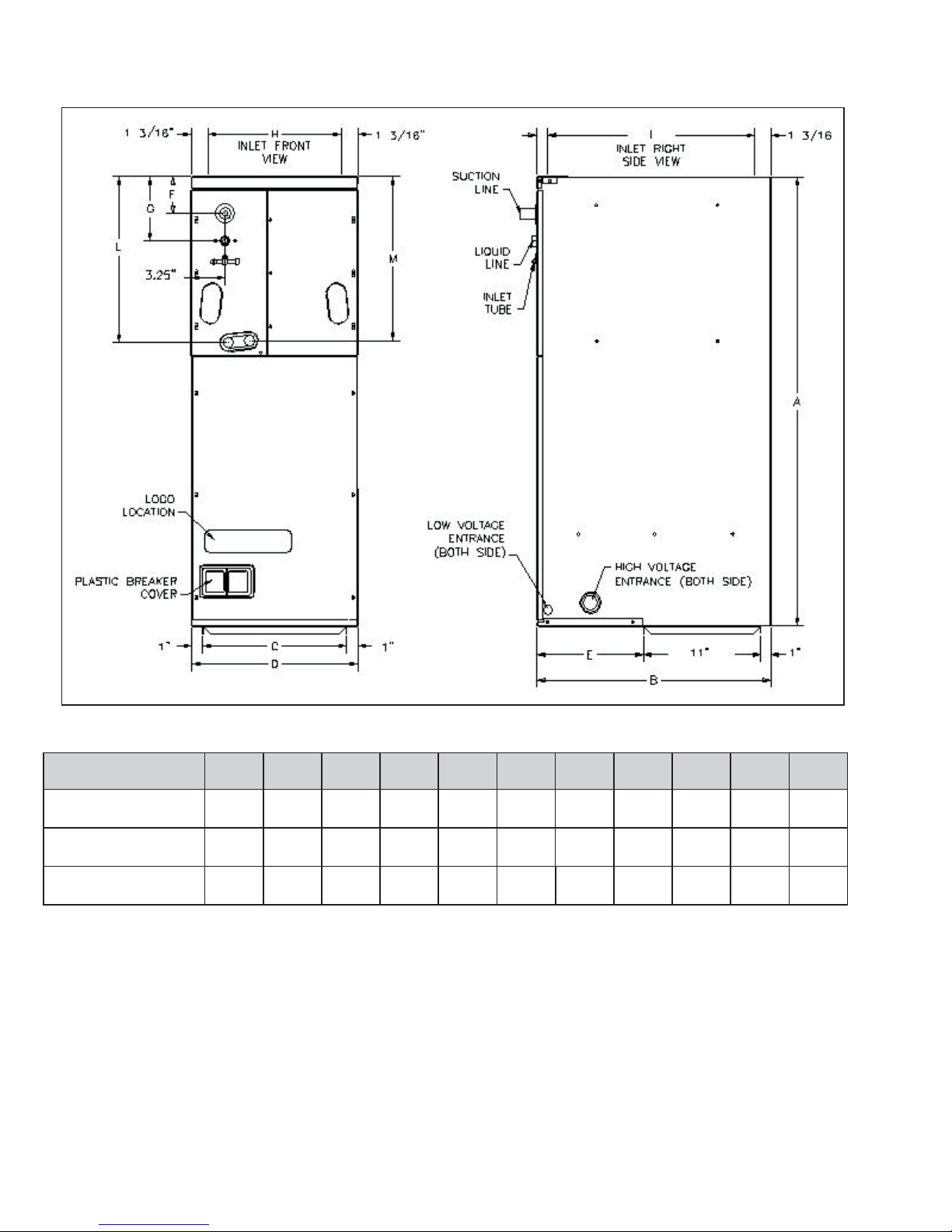

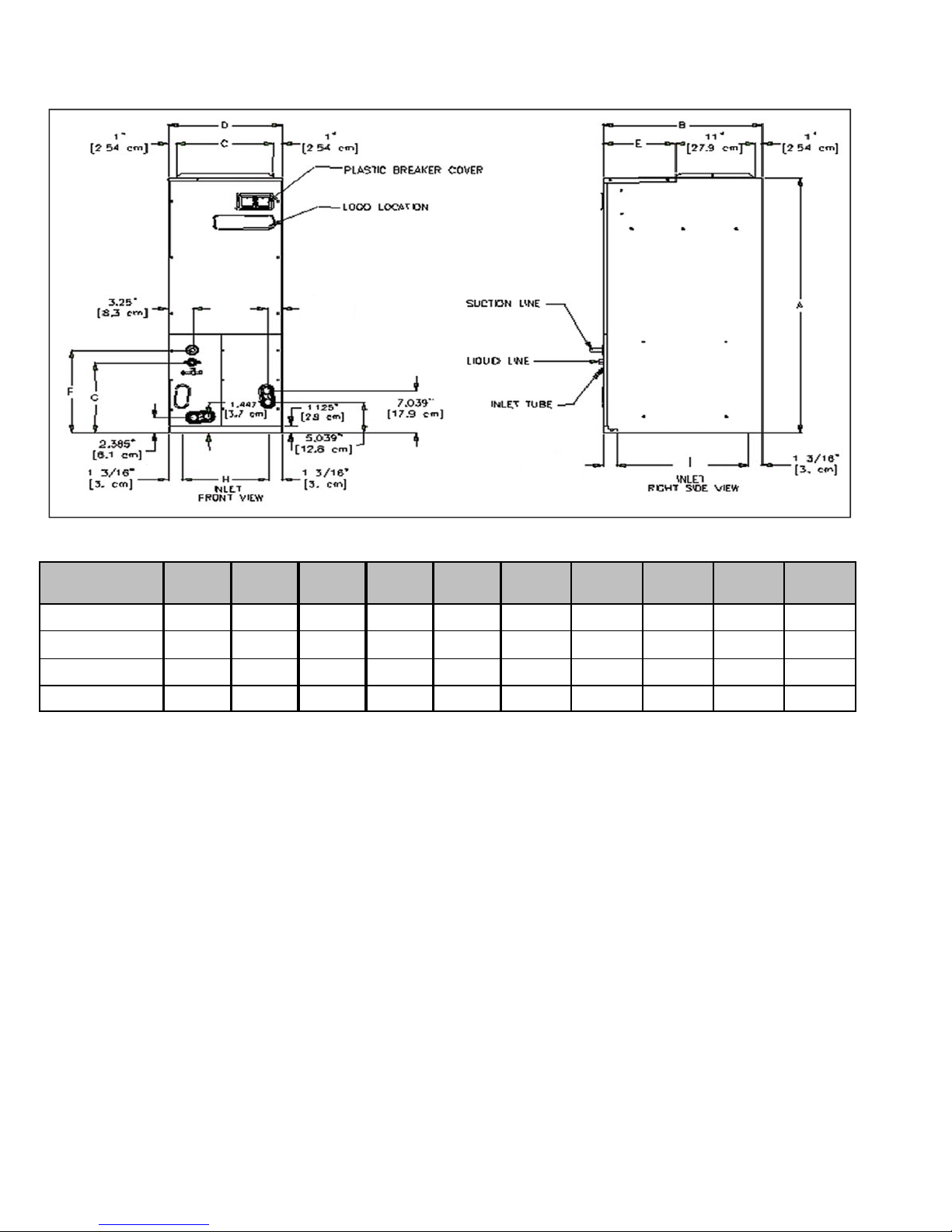

Model A B C D E F G H I L M

ADPF18241/16 42ȶ” 22” 13½” 15½” 10” 3½” 6

ADPF30421/16 53¼” 24” 20” 22” 12” 9¼” 11

ADPF48601/16 53¼” 24” 20” 22” 12” 9¼” 11

10

1

/16”13ȶ”1715/16”15½” 155/16”

13

/16”19ȸ”1915/16”217/16”21¼”

13

/16”19ȸ”1915/16”217/16”21¼”

Page 11

PRODUCT SPECIFICA TIONS

ADPF

ADPF18 24

1/16

Blower

Diameter 9 1/2" 10 5/8" 10 5/8"

Width 6" 8" 10 5/8"

Coil Drain Connection FPT 3/4" 3/4" 3/4"

Lineset Connection Size

Liquid 3/8" 3/8 " 3/8"

Suction 3/4" 7/8" 7/8"

Electrical Data

Voltage 208/240 208/240 208/240

Min. Circuit Ampacity* 2.1/2.1 3.7/3.7 5.4/5.4

Max. Overcurrent Device (amps)* 15/15 15/15 15/15

Minimum VAC 197 197 197

Maximum VAC 253 253 253

Blower Motor

FLA 1.70 2.95 4.30

HP 1/3 1/2 3/4

Ship Weight (lbs)

100 131 160

ADPF304 2

1/16

ADPF4860

1/16

* @ 208V/ 240V

BLOWER PERFORMANCE DAT A

Model Spe ed

High 1,155 1,090 1,025 950 895

AD PF18241/16 Med. 940 890 860 815 755

Low 695 665 650 610 550

High 1,700 1,660 1,625 1,545 1,505

AD PF30421/16 Med. 1,500 1,440 1,400 1,350 1,345

Low 1,370 1,300 1,250 1,230 1,220

High 2,150 2,120 2,070 2,000 1,940

AD PF48601/16 Med. 1,940 1,930 1,905 1,860 1,790

Low 1,610 1,600 1,590 1,575 1,550

CFM deliver d against External Static Pressure

0.1" 0.2" 0.3" 0.4" 0.5"

ADPF

Note: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208V/240V)

11

Page 12

PRODUCT DIMENSIONS

J

2 ȹ”

[7.30 cm]

AEPF

Model A B C D E F G H I J

AEPF18301/16

AEPF30361/16

AEPF31371/16

AEPF42601/16

46 3/4" 2 2" 17 1/ 2" 1 9 1/2" 1 0' 14 1/2" 11 15/16" 17 1/8" 17 15/16" 2"

53 1/4" 2 4" 20" 22" 1 2 " 19 5/ 8" 11 15/16" 19 5/8" 19 15/16" 1 13/16"

53 1/4" 2 4" 20" 22" 1 2 " 19 5/ 8" 11 15/16" 19 5/8" 19 15/16" 1 13/16"

53 1/4" 2 4" 20" 22" 1 2 " 19 5/ 8" 11 15/16" 19 5/8" 19 15/16" 1 13/16"

12

Page 13

PRODUCT SPECIFICA TIONS

AEPF183016* AEPF303616* AEPF313716* AEPF426016*

Blower

Dia m eter 9 1/2" 10 5/ 8" 10 5/8" 10 5/8"

Width 8" 10 5/8" 10 5/8" 10 5/8"

C oi l Drain Connec ti on FPT 3 / 4 " 3 /4" 3/4" 3/ 4 "

Lineset Connection Size

Liquid 3/8" 3/8" 3/8" 3/8"

Suction 3/4"7/8"7/8"7/8"

Electrical Data

Voltage 208/240 208/240 208/240 208/ 240

Min. Circui t Ampacity* 2 .5 /2 . 5 3.1/3.1 3.1/ 3. 1 7. 8/7.8

Max. Ov ercu rrent De v i ce (am ps)* 1 5/15 15 /15 15 / 1 5 1 5/15

Minimum VAC 197 197 197 197

Maximum VAC 253 253 253 253

Bl o wer Mot o r

FLA 2.002.502.506.20

HP 1/2 3/4 3/4 3/4

Ship Weight (lbs)

125 176 176 195

AEPF

13

Page 14

BLOWER PERFORMANCE DATA

H

1830

AEPF

The AEPF air handler blower motor is pre-programmed for operation at four distinct airflow levels when operating in

the Cooling, Heat Pump heating, Backup heating (Electric Heating), and Backup + Heat Pump heating modes. Each

modes has four levels to deliver different CFM. Simply flip the dipswitch for a different CFM combination.

Setting the Motor

O

N

O

F

F

12345678

Dipswitch

Number

1 Electric Heat Mode

2 Electric Heat Mode

3N/AN/A

4Thermostat Mode

5 Coolin g /He a t P ump M o de Fin d t h e a ir flow for y ou r app licatio n in th e t able s (D ip s wit ch 5/ 6 & 7 /8) b elow.

6 Cooling/Heat Pump Mo de Set up the motor based on the ou tdo or u nit capacity tons.

7

8

Dipswitch 1/2 & 7/8

AEPF 1830

eating

Element

(kw)

UP TO 10 OF F OFF OFF OFF 11 0 0 121 0

UP TO 10 ON OFF OFF OFF 890 935

5 OFF ON OFF OFF 700 770

Function Instructions

Se lect t h e t ap s allow in t h e t able s (d ip sw itch 1/2 & 7/8) b e lo w

ON = The system operates with single-stage units using a single-stage

c o oling o r h eat p u mp ther mo s tat . (fac t o r y d efault)

OFF = The system o perates with two-stage units with either a conventional

tw o -st age coo ling/h e at p u mp t h e r mo sat o r w ith an enc oded t w o -s tag e

co nd en sin g un it in r et r ofit a p plicat ions wh er e n ot en ough e x isting w ire s a r e

available fo r co n n e ct io n s to th e in d o

Trim CFM Adjust Mode

Trim CFM Adjust Mode

Switch

Position

1278

Switch

Position

Increase or decrease your selec ted airflow to fit your requirement.

O N-O FF = In crease s s e lect e d Coo l/He at P u mp air flow b y 10%

O FF-ON = De cr e as e s s e lect e d co ol/He at P u mp airflow b y 15%

NOTE: Other setting have no effec t on the set airflow.

Emergency

Backup

Heat Pump

With Back up

Dipswitch 5/6 & 7/8

AEPF

Switch

Position

5678CoolingHeat Pump

OFF OFF OFF OFF 1100 1100

ON OFF OFF OFF 800 800

OFF ON OFF OFF 600 600

Switch

Position

Indoor Airflow

AEPF303 6 / 31 37 / 4260

Heating

Element

(kw)

UP TO 20 OF F OFF OFF OFF 20 5 0 215 0

UP TO 20 ON OF F OF F OF F 17 5 0 1835

UP TO 15 OF F ON OF F OFF 16 0 0 168 0

UP TO 10 ON ON OFF OFF 12 00 12 60

UP TO 10 ON ON OFF ON 1020 1070

NOTE: When applying a humidistat (normally closed), refer to the installation and operating instructions. The humidstat can adjust the

cooling airflow to 85%.

Switch

Position

1278

Switch

Position

Emergency

Backup

Heat Pump

With Back up

AEPF303 6 / 31 37 / 4260

Switch

Position

5678CoolingHeat Pump

OFF OFF OFF OFF 1800 1800

ON OFF OFF OFF 1580 1580

OFF ON OFF OFF 1480 1480

ON ON OFF OFF 1200 1 200

ON ON OFF ON 1020 1020

Switch

Position

Indoor Airflow

14

Page 15

PRODUCT DIMENSIONS

A

ARPF

D

C

SUCTION

LINE

LIQUID

LINE

INLET

TUBE

F

G

H

INLET

(FRONT VIEW)

B

E

I

INLET

(RIGHT SIDE VIEW)

Model A B C D E F G

H

IJ

ARPF18241* 42 1/8" 22" 13 1/2" 15 1/2" 10" 14 1/2" 11 15/16" 13 1/8" 17 15/16" 2"

ARPF19311* 46 3/4" 22" 17 1/2" 19 1/2" 10" 14 1/2" 11 15/16" 17 1/8" 17 15/16" 2"

ARPF30301* 46 3/4" 22" 17 1/2" 19 1/2" 10" 14 1/2" 11 15/16" 17 1/8" 17 15/16" 2"

ARPF36361* 46 3/4" 22" 17 1/2" 19 1/2" 10" 14 1/2" 11 15/16" 17 1/8" 17 15/16" 2"

ARPF36421* 53 1/4" 24" 20" 22" 12" 14 1/2" 11 15/16"

ARPF37431* 53 1/4" 24" 20" 22" 12" 14 1/2" 11 15/16"

ARPF48601* 53 1/4" 24" 20" 22" 12" 14 1/2" 11 15/16"

ARPF49611* 53 1/4" 24" 20" 22" 12" 14 1/2" 11 15/16"

19 5/8"

19 5/8"

19 5/8"

19 5/8"

19 15/16" 1 13/16"

19 15/16" 1 13/16"

19 15/16" 1 13/16"

19 15/16" 1 13/16"

15

Page 16

PRODUCT SPECIFICA TIONS

s

ARPF

ARPF18241* ARPF19311* ARPF30301* ARPF36361*

Blower

Diameter 9 1/2" 9 1/2" 9 1/2" 9 1/2"

Width 6"6"8"6"

Coil Drain Connection FPT 3/4" 3/4" 3/4" 3/4"

Lineset Connection Size

Liquid 3/8" 3/8" 3/8" 3/8"

Suction 3/4" 7/8" 3/4" 3/4"

Electrical Data

Voltage 208 / 240 208 / 240 208 / 240 208 / 240

Min. Circuit Ampacity 2.1 / 2. 1 1.9 / 1.9 3.3 / 3.3 3.3 / 3.3

Max. Overcurrent Device ( amps) 15 / 15 15 / 15 15 / 15 15 / 15

Minimum VAC 197 197 197 197

Maximum VAC 253 253 253 253

Blower M otor

FLA 1.701.482.642.64

HP 1/3 1/4 1/3 1/3

Ship Weight (lbs)

120 155 144 164

ARPF36421* A RPF37431* ARPF48601* A RPF49611*

Blower

Diameter 10 5/8" 11 15/16" 10 5/8" 10 5/8"

Width 8" 10 11/16" 10 5/8" 10 5/8"

Coil Drain Connection FPT 3/4" 3/4" 3/4" 3/4"

Linese t C onn ection Size

Liquid 3/8" 3 /8" 3/8" 3/8"

Suction 7/8"7/8"7/8"7/8"

Electrical D ata

Voltage 208 / 240 208 / 240 208 / 240 208 / 240

Min. Circ uit Ampacity 3.7 / 3 .7 4.2 / 4 .2 5.4 / 5.4 5.4 / 5 .4

Max. O vercurrent D evice (a mp

Minim um VAC 197 197 197 197

Maximum VAC 253 253 253 253

Blower Motor

FLA 2.953.394.304.30

HP 1 /2 1/2 3/4 3/4

S hip W eight ( lbs)

15 / 15 15 / 15 15 / 15 15 / 15

160 195 192 192

16

Page 17

BLOWER PERFORMANCE DATA

ARPF

Model Speed

High 1155 1090 1025 950 895

ARPF18241* M ed . 940 890 860 815 755

Low 695 665 650 610 550

High 1135 1085 1025 965 915

ARPF19311* M ed . 860 825 780 750 680

Low 600 570 545 500 465

High 1385 1315 1240 1155 1065

ARPF30301* M ed . 1340 1290 1230 1140 1050

Low 1075 1030 980 910 840

High 1310 1240 1155 1090 1020

ARPF36361* M ed . 1270 1210 1140 1075 980

Low 1045 1005 955 885 805

High 1700 1660 1625 1545 1505

ARPF36421* M ed . 1500 1440 1400 1350 1345

Low 1330 1300 1250 1230 1220

High 2065 2000 1925 1860 1780

ARPF37431* M ed . 1685 1635 1550 1470 1410

Low 1490 1425 1345 1280 1205

High 2150 2120 2070 2000 1940

ARPF48601* M ed . 1940 1930 1905 1860 1790

Low 1610 1600 1590 1575 1550

High 2150 2105 2040 1970 1880

ARPF49611* M ed . 1960 1935 1895 1825 1750

Low 1670 1625 1585 1525 1455

CFM d e l i ve rd agai n st E x t e rn al St at i c P re ssu re

0.1" 0.2" 0.3" 0.4" 0.5"

Note: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208V/240V)

17

Page 18

PRODUCT DIMENSIONS

J

ARUF

2 ȹ”

[7.30 cm]

Model A B C D E F G

ARUF172 916 4 2 1/8" 22" 13 1/2" 1 5 1/2" 1 0" 14 1/2" 11 15 /16" 13 1/8" 17 15/16" 2"

ARUF182 416 4 2 1/8" 22" 13 1/2" 1 5 1/2" 1 0" 14 1/2" 11 15 /16" 13 1/8" 17 15/16" 2"

ARUF193 116 4 6 3/4" 22" 17 1/2" 1 9 1/2" 1 0" 14 1/2" 11 15 /16" 17 1/8" 17 15/16" 2"

ARUF303 016 4 6 3/4" 22" 17 1/2" 1 9 1/2" 1 0" 14 1/2" 11 15 /16" 17 1/8" 17 15/16" 2"

ARUF363 616 4 6 3/4" 22" 17 1/2" 1 9 1/2" 1 0" 14 1/2" 11 15 /16" 17 1/8" 17 15/16" 2"

ARUF364 216 5 3 1/4" 24" 20" 22" 12" 14 1/2" 11 15 / 16"

ARUF374 316 5 3 1/4" 24" 20" 22" 12" 14 1/2" 11 15 / 16"

ARUF486 016 5 3 1/4" 24" 20" 22" 12" 14 1/2" 11 15 / 16" 19 5/8 " 19 15/16" 1 13/ 16"

ARUF496 116 5 3 1/4" 24" 20" 22" 12" 14 1/2" 11 15 / 16" 19 5/8 " 19 15/16" 1 13/ 16"

H

1 9 5/8"

1 9 5/8"

IJ

1 9 15/16" 1 13/ 16"

1 9 15/16" 1 13/ 16"

18

Page 19

PRODUCT SPECIFICA TIONS

ARUF172916 ARUF182416 ARUF193116 ARUF303016

Blower

Diameter 9 1/2" 9 1/2" 9 1/2" 9 1/2"

Width 6"6"6"8"

Coil Drain Connection FPT 3/4" 3/4" 3/4" 3/4"

Lineset Connection Size

Liquid 3/8" 3/8" 3/8" 3/8"

Suction 3/4" 7/8" 3/4" 3/4"

Electrical Data

Voltage 208 / 240 208 / 240 208 / 240 208 / 240

Min. Circuit Ampacity 2.1 / 2.1 2.1 / 2.1 1.9 / 1.9 3.3 / 3.3

Max. Overcurrent Device (amps) 15 / 15 15 / 15 15 / 15 15 / 15

Minimum VAC 197 197 197 197

Maximum VAC 253 253 253 253

Blower Motor

F LA 1.70 1.70 1.48 2.64

HP 1/3 1/3 1/4 1/3

Ship Weight (lbs)

110 120 155 144

ARUF

ARUF363616 ARUF364216 ARUF374316 ARUF486016 ARUF496116

Blower

Diameter 9 1/2" 10 5/8" 11 15/16" 10 5/8" 10 5/8"

Width 6" 8" 10 11/16" 10 5/8" 10 5/8"

Coil D ra in Connection FPT 3/4" 3/4" 3/4" 3/4" 3/4"

Lineset Conne ction Size

Liquid 3/8" 3/8" 3/8" 3 /8" 3/8"

Suction 3/4"7/8"7/8"7/8"7/8"

Electrical Data

Voltage 208 / 240 208 / 240 208 / 240 208 / 240 208 / 240

Min. Circuit Ampacity 3.3 / 3.3 3.7 / 3.7 4.2 / 4.2 5.4 / 5.4 5.4 / 5.4

Max. O ver current Device (amps ) 15 / 15 15 / 15 15 / 15 1 5 / 15 15 / 15

Minim um VAC 197 197 197 197 197

Maximum VAC 253 253 253 253 253

Blower Motor

FLA 2.642.953.394.304.30

HP 1/3 1/2 1/2 3/4 3/4

Ship Weight (lbs)

164 160 195 192 19 2

19

Page 20

BLOWER PERFORMANCE DATA

ARUF

Model Speed

High 1155 1090 1025 950 895

ARUF172916 Med. 940 890 860 815 755

Low 695 665 650 610 550

High 1155 1090 1025 950 895

ARUF182416 Med. 940 890 860 815 755

Low 695 665 650 610 550

High 1135 1085 1025 965 915

ARUF193116 Med. 860 825 780 750 680

Low

High 1385 1315 1240 1155 1065

ARUF303016 Med. 1340 1290 1230 1140 1050

Low 1075 1030 980 910 840

High 1310 1240 1155 1090 1020

ARUF363616 Med.

Low

High 1700 1660 1625 1545 1505

CFM d e li ve rd agai n st Exte rnal S tat i c P re ssu re

0.1" 0.2" 0.3" 0.4" 0.5"

600 570 545 500 465

1270 1210 1140 1075 980

1045 1005 955 885 805

ARUF364216 Med. 1500 1440 1400

Low 1330 1300 1250

High 2065 2000 1925 1860 1780

ARUF374316

ARUF486016

ARUF496116 Med. 1960 1935 1895 1825 1750

Note: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208V/240V)

Med. 1685 1635 1550 1470 1410

Low 1490 1425 1345 1280 1205

High 2150 2120 2070 2000 1940

Med. 1940 1930 1905 1860 1790

Low 1610 1600 1590 1575 1550

High 2150 2105 2040 1970 1880

Low 1670 1625 1585 1525 1455

1350 1345

1230 1220

20

Page 21

PRODUCT DIMENSIONS

J

2 ȹ”

[7.30 cm]

ASPF

Model ABCDE F G H I J

ASPF183016*

ASPF303616*

ASPF313716*

ASPF426016*

4 6 3/ 4" 22" 17 1/2" 1 9 1/ 2" 10' 14 1 /2 " 11 15/16" 17 1/8" 17 15/ 16" 2 "

53 1/4" 24" 20" 22" 12" 19 5/8" 1 1 15/16" 19 5/8" 19 15/16" 1 13/ 16"

53 1/4" 24" 20" 22" 12" 19 5/8" 1 1 15/16" 19 5/8" 19 15/16" 1 13/ 16"

53 1/4" 24" 20" 22" 12" 19 5/8" 1 1 15/16" 19 5/8" 19 15/16" 1 13/ 16"

21

Page 22

PRODUCT SPECIFICA TIONS

AS P F183016* AS PF 303616* AS PF313716* ASPF 426016*

Blower

Diameter 9 1/2" 10 5/8" 10 5/8" 10 15/16"

Width 8" 10 5/8" 10 5/8" 10 11/16"

C o il D r a in Con n e ction FPT 3 /4" 3/4" 3/4 " 3/4 "

Lineset Connection Size

Liqu id 3/8" 3 /8 " 3 /8" 3/8"

S u ction 3/4" 7 /8 " 7 /8" 7/8"

Ele c trical Data

Voltag e 2 08 / 23 0 20 8 / 2 3 0 20 8 / 230 2 0 8 / 230

Min. Circ u it Ampacity 3. 6 / 3.6 3.8 / 3 .8 3.9 / 3.9 6.4 / 6. 4

Max. Overcurrent Device (am ps) 15 / 15 15 / 15 15 / 15 15 / 15

Minim um VAC 197 197 197 197

Maximum VAC 253 253 253 253

Blower Motor

FL A 2.9 3.0 3.1 5 .1

HP 1/2 3/4 3/4 3/4

Ship Weight (lbs)

125 176 176 195

ASPF

22

Page 23

BLOWER PERFORMANCE DATA

ASPF

Model

AS PF183016 3 920 900 850 840 815

AS PF303616 3 1165 1070 1020 960 915

AS PF313716 3 1165 1070 1020 960 915

Motor

Speed Tap

1 700 670 650 595 510

2 820 785 765 745 705

4 1075 1055 1015 975 960

5 1130 1115 1085 1040 1000

1 1060 86 5 600 515 420

2 1105 91 0 795 745 690

4 1285 1240 1195 1140 1100

5 1435 1395 1350 1315 1265

1 1060 86 5 600 515 420

2 1105 91 0 795 745 690

CFM del i ve rd agai n st E x t e rnal S tat i c P re ss ure

0.1" 0.2" 0.3" 0.4" 0.5"

4 1285 1240 1195 1140 1100

5 1435 1395 1350 1315 1265

1 1445 1275 1175 940 855

2 1545 1405 1325 1260 1145

AS PF426016 3

4

5

Notes: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208/240V)

All ASPF models are shipped from the factory with the speed tap set on T4.

1660 1610 1555 1490 1415

1905 1870 1810 1750 1695

2115 2070 2000 1965 1915

Notes: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208/240V)

All ASPF models are shipped from the factory with the speed tap set on T4.

23

Page 24

PRODUCT DIMENSIONS

J

ATUF

2 ȹ”

[7.30 cm]

Model A B C D E F G

ATUF182 416 4 2 1/8" 22" 13 1/2" 1 5 1/2" 1 0" 14 1/ 2" 11 15/16" 13 1/8 " 17 15/16" 2"

ATUF193 116 4 6 3/4" 22" 17 1/2" 1 9 1/2" 1 0" 14 1/ 2" 11 15/16" 17 1/8 " 17 15/16" 2"

ATUF303 016 4 6 3/4" 22" 17 1/2" 1 9 1/2" 1 0" 14 1/ 2" 11 15/16" 17 1/8 " 17 15/16" 2"

ATUF363 616 4 6 3/4" 22" 17 1/2" 1 9 1/2" 1 0" 14 1/ 2" 11 15/16" 17 1/8 " 17 15/16" 2"

ATUF364 216 5 3 1/4" 24" 20" 22 " 12" 14 1/2" 11 15 /16"

ATUF374 316 5 3 1/4" 24" 20" 22 " 12" 14 1/2" 11 15 /16"

ATUF486 016 5 3 1/4" 24" 20" 22 " 12" 14 1/2" 11 15 /16" 19 5/8" 19 15/ 16" 1 13/16"

H

1 9 5/8"

1 9 5/8"

IJ

1 9 15/16" 1 13/ 16"

1 9 15/16" 1 13/ 16"

24

Page 25

PRODUCT SPECIFICA TIONS

ATUF182416 AT UF193116 ATUF303016 ATUF363616

Blower

Dia met er 9 1/2 " 9 1/ 2" 9 1/2" 9 1/2"

Width 6"6"8"6"

Coil Dr ain Connection FPT 3/4" 3/4" 3/4" 3/4"

Lineset Connection Size

Liquid 3/8" 3/8" 3/8" 3/8"

Suction 7/8" 3/4" 3/4" 3/4"

Electrical Data

Volt age 208 / 240 2 08 / 24 0 2 08 / 240 208 / 240

Min. Circu it Ampa city 2.1 / 2.1 1.9 / 1.9 3.3 / 3.3 3.3 / 3.3

Max . Ove rc urrent Devi ce (amps) 15 / 15 15 / 15 15 / 15 15 / 15

Minimum VAC 19 7 197 197 197

Maximum VAC 253 2 53 25 3 25 3

Bl o wer Motor

FLA 1.70 1.48 2.64 2.64

HP 1/31/41/31/3

Ship Weight (lbs)

120 155 144 164

ATUF

ATUF364216 AT UF374316 ATUF486016

Blower

D ia m et e r 10 5/ 8" 11 15/16 " 1 0 5/8"

Wi dth 8" 10 11 /16" 10 5 / 8 "

Coil Dr ain Connection FPT 3/4" 3/4" 3/4"

Lineset Connection Size

Liquid 3/8" 3/8" 3/8"

Suction 7/8" 7/8" 7/8"

Electrical Data

Volt age 208 / 240 2 08 / 24 0 2 08 / 240

Min. Circu it Ampa city 3.7 / 3.7 4.2 / 4.2 5.4 / 5.4

Max. Overcurrent Device (amps) 15 / 15 15 / 15 15 / 15

Minimum VAC 19 7 197 197

Maximum VAC 253 2 53 25 3

Bl o wer Motor

FLA 2.95 3.39 4.30

HP 1/2 1/2 3/4

Ship Weight (lbs)

173 195 192

25

Page 26

BLOWER PERFORMANCE DATA

ATUF

Model Speed

High 1,155 1,090 1,025 950 895

ATUF182416 Med. 875 830 790 750 715

Low 640 610 570 535 490

High 1,135 1,085 1,025 965 915

ATUF193116 Med. 860 825 780 750 680

Low 600 570 545 500 465

High 1,455 1,385 1,330 1,205 1,090

ATUF303016 Med. 1,340 1,290 1,230 1,140 1,050

Low 1,075 1,030 980 910 840

High 1,345 1,290 1,230 1,150 1,070

ATUF363616 Med. 1,270 1,210 1,140 1,075 980

Low 1,045 1,005 955 885 805

High 1,700 1,680 1,645 1,610 1,535

ATUF364216 Med. 1,500 1,480 1,440 1,380 1,325

Low 135 1,320 1,275 1,230 1,195

CFM deliverd against External Static Pressure

0.1" 0.2" 0.3" 0.4" 0.5"

High 2,065 2,000 1,925 1,860 1,780

ATUF374316

ATUF486016

Note: Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208V/240V)

Med. 1,685 1,635 1,550 1,470 1,410

Low 1,490 1,425 1,345 1,280 1,205

High 2,135 2,080 1,985 1,900 1,805

Med. 1,975 1,935 1,875 1,775 1,675

Low 1,715 1,670 1,650 1,590 1,530

26

Page 27

PRODUCT DIMENSIONS

AWUF

Small Chassis

AWUF 18 & 24

A 36" A 36"

B 20 3/8" B 24"

C 16 1/8" C 21"

D 16" D 19 7/8"

E 11" E 15 7/8"

FILTER 14" X 18" X 1" FILTER 16" X 20" X 1"

Large Chassis

AWUF 30 BB & 3 6 BB

A 36"

B 24"

C 21"

D 19 7/8"

E 15 7/8"

FILTER 18" X 20" X 1"

Large Cha s s is

AWUF 30 BA & 36 BA

Large Chassis

AWUF 31,32 & 37

A 36"

B 24"

C 21"

D 19 7/8"

E 15 7/8"

FILTER 18" X 20 " X 1"

27

Page 28

PRODUCT SPECIFICA TIONS

AWUF[18-37]A*

Heating Cap acity

Ac tu al kW @ 240 volt s 3.0 4.8 7 . 3 3.0 4.8 7.3 9.8 3. 0 4.8 7.3 9.8

BTU /h @ 240 volts 1 0,240 16 ,3 90 24,92 5 10,240 16,3 90 24,925 33,460 10,2 40 16,390 24,925 33,460

Blow er

Diameter 9" 9" 9" 10" 10" 10" 10" 9" 9" 9" 9"

Width 6"6"6"6"6"6"6"8"8"8"8"

Coil Drain Connection FPT 3/4" 3/4" 3/4" 3/4" 3 /4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4"

Lineset Connection Siz e

Liquid 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8"

Suction 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 3/4" 3/4" 3/4" 3/4"

Electrical Data

Min. Cir cuit Ampacity* 15.1/17.3 26.7/23.3 39.7/34.2 15.1/17.3 26.7/23.3 39.7/34.2 52.7/45.6 15.5/17.6 27.0/23.6 40.0/34.9 53.0/46.2

Max. Overcurrent Device (amps)* 20/ 20 30/30 40/40 20/20 30/30 40/40 60/50 20/20 30/25 40/35 60/50

Minimum VAC 197 197 197 197 197 197 197 197 197 197 197

Maxi m um VAC 253 253 253 253 253 253 2 53 253 253 253 2 53

Blo wer Motor

FLA 1.30 1 .35 1.35 1.30 1.35 1.35 1.35 1.58 1.58 1.58 1.58

HP 1/5 1/5 1/5 1/5 1/5 1/5 1/5 1/3 1/3 1/3 1/3

Ship Weight (lbs)

* @ 240V/208V

AWUF18031**

84 84 84 84 84 84 84 93 93 93 93

AWUF18051

AWUF18081

AWUF24031**

AWUF24051

AWUF24081

AWUF24101

AWUF30031**

AWUF30051

AWUF30081

AWUF30101

AWUF310516

Heating Cap acity

Ac tu al kW @ 240 volt s

BTU /h @ 240 volts 1 6,390 24 ,9 25 33,46 0 16,390 24,9 25 33,460 16,390 24,9 25 33,460

Blow er

Diameter 10" 10" 10" 9" 9" 9" 10" 10" 10"

Width 8"8"8"8"8"8"8"8"8"

Coil Drain Connection FPT 3/4" 3/4" 3/4" 3/4" 3 /4" 3/4" 3/4" 3/4" 3/4"

Lineset Connection Siz e

Liquid 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8"

Suction 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4"

Electrical Data

Min. Cir cuit Ampacity* 30.1/26.8 43.1/38.1 56.2/49.4 27.0/23.6 40.0/34.9 53.0/46.2 30.1/26.8 43.1/38.1 56.2/49.4

Max. Overcurrent Device (amps)* 35/ 30 45/40 60/50 30/25 40/35 60/50 35/30 45/40 60/50

Minimum VAC 197 197 197 197 197 197 197 197 197

Maxi m um VAC 253 253 253 253 253 253 2 53 253 253

Blo wer Motor

FLA 4.1 4.1 4.1 1.58 1.58 1.58 4.1 4.1 4.1

HP

Ship Weight (lbs)

4.8 7.3 9.8

1/2 1/2 1/2

96 96 96

AWUF310816

AWUF321016

AWUF36051

4.8 7.3 9.8

1/3 1/3 1/3

96 96 96

AWUF36081

AWUF36101

AWUF37051

4.8 7.3 9.8

1/2 1/2 1/2

96 96 96

AWUF37081

AWUF37101

28

Page 29

PRODUCT SPECIFICA TIONS

AWUF[18-24]**16B*

He at ing Capaci t y

Actual kW @ 240 volts 4.8 7.3 3.0 4.8 7.3 9.8

BTU/h @ 240 vo lts 1 6, 390 24,9 25 10, 240 16, 390 24,925 33,460

Blow er

Diameter 9" 9" 10" 10" 10" 10"

Width 6" 6" 6"6"6"6"

Coil Drain Connection FPT 3/4" 3/4" 3/4" 3/4" 3/4" 3 /4"

Lineset Connection Siz e

Liquid 3/8" 3/8" 3/8" 3/8" 3/8" 3/8"

Suction 5/8" 5/8" 5/8" 5/8" 5/8" 5 /8"

Electrica l Data

Min. Circuit Ampacity* 26.6/23.3 39.6/34.6 15.1/17.3 26.7/23.3 39.7/34.2 52.7/45.6

Ma x. Overcu rrent De vice (a m ps)* 30/25 40/3 5 20/2 0 30/ 30 40 /40 60 /50

Mi nimum VAC 197 197 197 197 197 197

Maximum VAC 253 253 253 253 253 253

Blower Motor

FLA 1.30 1.30 1.30 1.35 1.35 1.35

HP 1/5 1/5 1/5 1/5 1/5 1/5

Ship Weight (lbs)

* @ 240V /208V

AWUF180516B*

84 84 84 84 84 84

AWUF180816B*

AWUF240316B*

AWUF240516B*

AWUF240816B*

AWUF241016B*

29

Page 30

BLOWER PERFORMANCE DATA

AWUF

Model Speed

AWUF18XX1/16A*

AW U F18 XX16B*

AWUF24XX1/16A*

AW U F24 XX16B*

AWUF30XX1/16A*

AW U F30 XX16B*

AWUF310516XX

High

Low

High

Low

High

Low

High

Low

High

Low

High

Low

T5

T4

T3

C FM deli ve rd agains t Exter na l St atic Pres su re

0.1" 0.2" 0.3" 0.4" 0.5"

750 730 690 650 595

710 700 690 635 585

755 715 670 615 545

740 700 655 595 535

880 845 810 770 735

845 815 780 745 705

900 870 835 795 760

865 835 800 765 725

1250 1195 1135 1085 1010

1110 1055 1020 955 905

1255 1120 1100 1020 950

1115 1010 990 900 820

875 865 830 805 765

1005 975 945 920 890

840 795 785 745 700

AWUF310816XX/

AWUF321016XX

AWUF36XX1/16A*

AW U F36 XX16B*

AW U F37 XX16A*

AW U F37 XX16B*

T2

T1

T5

T4

T3

T2

T1

Hig h 1280 1190 1110 1010 930

Low 1170 1100 1030 950 890

Hig h 1215 1145 1070 985 890

Low 1120 1065 1000 915 820

High

Low

T5

T4

T3

645 615 550 500 445

645 615 550 500 445

1090 1065 1040 1015 985

1005 975 945 920 890

840 795 785 745 700

645 615 550 500 445

645 615 550 500 445

1326 1284 1232 1181 1115

1086 1061 1028 996 950

1385 1205 1130 1045 950

1235 1180 1115 1040 955

1165 1120 1075 1025 945

T2

T1

Note:

Assumes dry coil with filter in place; SCFM correction for wet coil = 4% (208V/240V)

30

1050 1010 970 930 860

1050 1010 970 930 860

Page 31

WIRING DIAGRAMS

ACNF

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT . FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

31

Page 32

WIRING DIAGRAMS

ADPF, ARPF, ARUF, A TUF

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT . FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

FL

FL

FL

FL

BL

YL

RD

BK

BK

L2L1 L1 L2

208/240 VOLTS

EM

LO

HI

SEE NOTE 1

3

TL

HTR1

HTR2

HTR3

HTR4

BK

M1

M2

RD

BK

TL

RD

TL

YL

TL

BL

BK

1

PU

RD

BL

M3

M7

M5

M6

M4

M8

R1

R2

YL

BL

BK

RD

2

3

RD

BL

4

5

BR

6

WH

7

8

9

L2

2

PLM

PLF

EBTDR

COM

2

NO

3

NC

M1

M2

PLM

PLF

FL

TLHTR2

FL

HTR1 TL

BK

RD

M1M2M3

R

RD

BK

BK

RD

L2L1

L2

L1

RD

BK

2

1

2

1

BK

RD

RD

BK

BK

BL

M4

WH

1

2

RD

3

PU

4

5

6

7

8

9

EQUIPMENT GROUND

EQUIPMENT GROUND

USE COPPER OR ALUMINUM WIRE

USE COPPER WIRE

GRD

3

4 5 678 9

3

4 5WH67489

PU

BR

BL

SEE

NOTE

BK

RD

L1

FL

FL

FL

YL

L2 L1 L2

HTR1

TL

BK

HTR2

TL

RD

HTR3

TL

RD

BK

M1

M3

M1

M4

M2

M2

R1

BK

RD

YL

BK

RD

BK

1

YL

PU

BL

R2

2

3

RD

BL

4

5

BR

6

WH

7

8

9

L1

1

PLM

1

PLF

RC

1

2

FL

HTR1

TL

BK

BK

L1 L2

BK

M1

R

M2

BK

BK

RD

BL

WH

1

2

RD

3

PU

4

5

6

7

8

9

ONE (1) ELEMENT ROWS TWO (2) ELEMENT ROWS THREE (3) ELEMENT ROWS FOUR (4) ELEMENT ROWS

NOTE: WHEN INSTALLING HEATER KIT, ENSURE SPEED TAP DOES NOT EXCEED MI NIMUM BLOWER SPEED ( M BS ) SP ECIFIED F OR THE AIRHANDLER/HEA T ER

KIT COMBINATION ON THIS UNIT'S S&R PLATE. AFTER INSTALLING OPTIONAL HEAT KIT, MARK AN "X" IN THE PROVIDED ABOVE.

MARK A CCORDING TO NUMBER OF HEATER ELEMENT RO WS INSTALLED. NO MARK INDICATES NO HEAT KIT INSTALLED.

TERMINAL BLOCK SHOW N

FOR 50HZ MO DELS ONLY

WH

RD GR

BL

BR

SR

SEE

NOTE

2

BR

WH

TR

GR

RD

BL

COPPER OR ALUMINUM

COPPER POWER SUPPLY

POWER SUPPLY

(SEE RATING PLATE)

(SE E RATING PLATE)

USE MIN. 75°C FIELD WIRE

USE MIN. 75°C FIELD WIRE

IF RE PL AC E M ENT OF THE O R IG INA L WIRES

SUPPLIED WITH THIS ASSEMBLY IS NECESSARY,

USE WIRE THAT CONFORMS TO THE

NATIONAL ELECTRIC CODE.

XFMR-R

XFMR-C

RD

BL

SPEEDUP

THREE SPEED MOTOR WIRING

(SELE CT M ODELS ONL Y)

G

R

C

EBTDR

SEE NOTE 3

SEE NOTE 5

K1

COM

K1

M1

M2

RD

NO

NC

SEE

NOTE

R G

BK

PU

RD

BK

PU

3

(M1) RD LOW

BL

(M2)

MEDIUM

(COM) BK

(TR 1)

PU

HIGH

PU

BR

RC

C

EM

3 SPEED

1 2

5

BL

24V

RD

3

4

RD

SEE NOTE 1

240

TR

BL

RC

RD

COLOR CODE

BK

BLACK

RD

RED

YELLOW

BLYLBLUE

COMPONENT CODE

EM

EVAPORATOR MOTOR

RC

RUN CAPACITOR

SR

PU

BK

RD

BR

EM

BR

Notes:

1) Red wires to be on transformer terminal "3" for 240 volts and on terminal "2" for 208 volts.

2) See composite wiring diagrams in installation instructio ns

for proper low voltage wiring connections.

3) Confirm speed tap selected is appropriate for application. If speed tap needs

to be changed, connect appropriate motor wire (Red for low, Blue for medium,

and Black for high speed) on "COM" connection of the EBTDR.

Inactive motor wires should be connected to "M1 or M2" on EBTDR.

4) Brown and white wires are used with Heat Kits only.

5)

EBTDR has a 7 second on delay when "G" is energized and a 65 second off

delay when "G" is de-energized.

STRAIN RELIEF

RRELAY

EBTDR

ELECTRONIC BLOWER TIME

DELAY RELAY

EBTDR

24V

4

5

5

4

WH6BR

GREEN

GR

PURPLE

PU

BROWN

BR

WHITEWH

C

EBTDR

PLF

BL

WIRING CODE

FACTORY WIRING

HIGH VOLTAGE

LOW VOLTAGE

FIELD WIRING

HIGH VOLTAGE

LOW VOLTAGE

TR

TRANSFORMER

FEMALE PLUG CONNECTOR

PLF

MALE PLUG CONNECTOR

PLM

FL FUSE LINK

THERMAL LIMIT

TL

HTR HEAT ELEMENTS

GR

NOTE 2

0140M00037

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

32

Page 33

WIRING DIAGRAMS

ADPF, ARPF, ARUF, A TUF

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT . FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

FL

BL

YL

RD

BK

L2L1 L1 L2

208/240 VOLTS

EM

EM

HI

HI

LO

LO

3

3

FL

HTR1

HTR2

FL

HTR3

FL

HTR4

BK

RD

M1

M2

BK

RD

M1

M1

M2

M2

SEE NOTE 1

SEE NOTE 1

TL

TL

TL

TL

BL

PU

M5

M3

M4

M6

R1

YL

BL

BK

RD

3 2

NC

NC

BK

RD

YL

EBTDR

EBTDR

COM

COM

PLF

BK

1

2

BL

M7

M8

R2

3

RD

BL

4

5

BR

6

WH

7

8

9

L2

2

PLM

NO

NO

PLM

PLF

FL

TL

HTR2

FL

TL

HTR1

BK

RD

M1M2M3

R

RD

BK

BK

RD

L2L1

L2

L1

RD

BK

23

1

2

1

BK

BK

RD

RD

RD

BK

BK

1

2

RD

3

PU

BL

M4

WH

4

5

6

7

8

9

TWO (2) ELEMENT ROWS THREE (3) ELEMENT RO W S FOUR (4) ELEMENT ROWS

EQUIPMENT GROUND

USE COPPER WIRE

GRD

4 5 678 9

4 5WH6789

3

PU

PU

BL

BL

WH

BR

BR

SEE

SEE

NOTE 4

NOTE 4

BK

L1

RD

FL

FL

FL

YL

BK

L2 L1 L2

TL

HTR1

HTR2

HTR3

BK

M1

M2

RD

BK

TL

RD

TL

RD

M3

M1

M4

M2

R1

YL

BK

RD

BK

1

YL

PU

BL

R2

2

3

RD

BL

4

5

BR

6

WH

7

8

9

L1

1

PLM

1

PLF

RC

RC

1

1

2

2

FL

TL

HTR1

BK

BK

L1 L2

BK

M1

R

M2

BK

BK

BL

WH

RD

1

2

RD

3

PU

4

5

6

7

8

9

ONE (1) ELEMENT ROWS

NOT E: W HEN INSTALLING HEATER KI T, ENSURE SPEED TAP DOES NOT EX CEED MINIMUM BL OWER SPEED (MBS) SPECIFIED FOR THE AIRHANDLER/HEATER

KIT COMBINAT ION ON TH I S UNIT'S S&R PL ATE. A F TE R INSTALLING OPTIONAL HE AT KIT, MARK A "X" IN THE PROV IDED ABOV E.

MARK ACCORDING TO NUMBER OF HEA TER ELEMENT ROWS INSTALLED. NO MARK INDICA TES NO HEAT KIT INSTALLED.

BL

SEE NOTE 2

RD GR

WH

TE RMINAL BLOCK SHOW N

FOR 50HZ MODELS ONLY

BR

SR

BR

BR

WH

WH

TR

GR

RD

BL

G

EBTDR

R

XFMR-R

RD

XFMR-C

C

BL

SPEEDUP

COPP ER PO WER SUPPLY

(SEE RATING PLATE)

USE MIN. 75°C FIELD WIRE

THREE SPEED MOTOR WIRING

(SELECT MODELS ONLY)

SEE NOTE 3

IF REPLACEMENT OF THE ORIGINAL WIRES

SUPPLIED WITH THIS ASSEMBLY IS NECESSARY

USE WIRE THAT CONFORMS TO THE

NATIONAL ELECTRIC C OD E.

SEE NOTE 5

NO

K1

COM

K1

NC

M1

M2

BK

NOTE 3

SEE

RD

PU

(TR 1)

PU

RD

(COM) RD LOW

(M2)

BL

(M1) BK

PU

RC

BK

MEDIUM

HIGH

BR

PU

C

EM

3 SPEED

123

5

24V

BL

RD

4

RD

SEE NOTE 1

240

TR

BL

RC

BR

BR

R G

EBTDR

24V

4

5

5

RD

WH6BR

COLORCODE

BK

BLACK

RD

RED

YELLOW

BLYLBLUE

GREEN

GR

PURPLE

PU

BROWN

BR

WHITEWH

COMPONENT CODE

EM

EVAPORATOR MOTO R

RC

RD

PU

N

OTES:

BK

EM

1) RED WIRES TO BE ON TRANSFORMER TERMINAL "3 " FOR 240 VOLTS AND

ON TERMINAL "2" FOR 208 VOLTS

2) SEE COMPOSITE WIRING DIAGRAMS IN INSTALLATION INSTRUCTIONS FOR PROPER

LOW VOLTAGE WIRING CONNECTIO NS

3) CONFIRM SPEED T AP SEL ECT ED IS APPROPRIATE FOR APPLICATION . IF SPEED TAP

NEEDS TO BE CHANGED, CONNECT APPROPRIATE MOTOR WIRE (RED FOR LOW,

BLUE FOR MEDIUM,AND BLACK FOR HIGH SPEED) ON "COM" CONNECTION OF THE EBTDR

INACTIVE MOTOR WIRES SHOULD BE CONNECTED TO "M1 OR M2" ON EBTDR.

4) BROWN AN D WH ITE WIRES ARE USED WITH HEAT KITS ONL Y.

5) EBTDR HAS A 7 SEC O N D O N DE LAY WHEN "G" IS ENERGIZED AND A 65 SECOND OFF

DELAY WHEN "G" IS DE-ENERGIZED.

RUN CAP ACITOR

SR

STRAIN RELIEF

RRELAY

EBTDR

ELECTRONIC BLOWER TIME

DELAY RELAY

C

EBTDR

4

PLF

BL

WIRING CODE

FACTORY WIRING

HIGH VOLT AGE

LOW VOLTAGE

FIELD WI RING

HIGH VOLT AGE

LOW VOLTAGE

TR

TRANSFORMER

FEMALE PLU G CONNECTOR

PLF

MALE PLU G CONNECT OR

PLM

FL FUSE LINK

TL

THERMAL LI MIT

HTR HEAT ELEMENTS

GR

0140M00170-E

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

33

Page 34

WIRING DIAGRAMS

A

AEPF

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT . FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

R

BK

6

W1

PJ4

W1

FL

FL

HTR2

FL

HTR3

FL

HTR4

BL

BK

M1

Y

M2

BK

R

L2L1 L1 L2

TO LOW V OLTAGE

TERMINAL BOARD

PL2

YCON

IN4005

DIODE

Y1YY2

SEE NOTE 1

FACT ORY WI RI NG

HIGH VOLTAGE

LOW VO LTAGE

FIELD W IRIN G

HIGH VOLTAGE

LOW VO LTAGE

THERM AL LIMIT

TL

HEAT ELEMENT

HTR

RELAY

R

TLHTR1

TL

TL

TL

R

M3

M4

R1

Y

BK

R

W

BK

R

Y

BL

PU

M5

M6

BL

SEE

NOTE 4

NOTE DIODE

ON VSTB

G

*SEE N O TE 7

IRING CODE

BL

M7

M8

R2

W

1

1PL2

BK

R

PL1

4

PL2

C

0140A00000P

1

2

3

BL

4

5

BR

6

7

8

9

FL

TL

HTR1

BK

BK

1

2

R

PU

BK

L1 L2

M1

R

M2

BK

BK

BL

W

R

3

4

5

6

7

8

9

ONE (1) ELEMENT RO WS TWO (2) ELEMENT ROWS THREE (3) ELEMENT ROWS FOUR (4) ELEMENT ROWS

AFTER INSTALLING OPTIONAL HEAT KIT, MARK AN "X" IN THE PROVIDED ABOVE.

* SEE NOTE 7

LOW VOLTAGE

FIELD CO N NECTION

BOX

PN. B1368270 REV. A

J1

COPPER

POWER SUPPLY

(SEE RATING PLATE)

CONTROLS SHOW N WITH UTILITIES IN "ON" POSITION AND THERMOSTAT IN "OFF" POSITION.

IF REPLAC EM ENT OF THE ORIGINAL WIRES SUPPLIED WITH THIS ASSEMBLY IS NECESSAR Y, USE 105°C. W IRE. SIZE TO CONFORM TO THE NATIONA L ELECTRIC CODE.

R

YCON

HUM

PJ6

DS1

CONDENSER

OT2

OT1

COM W2OED

W1

HEATPUMP

W2

PJ2

PJ4

HEATER

W1

W2

W

24 VAC

CR

BR

BL

R

Y1

J3J2

TO

CONDENSER

W/W2

OTC OT1 COT2OE\W1

OUTDO OR

THERMOST

TS

R Y1 G

Y/Y2

HUMIDISTAT

HUM

YCON

R

R

Y

BL

O

BR

BL

THERMOSTAT

W1

O

W2 R

C

W2

Y

O

BL

BR

BR

W

BR

R

PU

G

Y

EQUIPMENT GRO UND

FL

TL

HTR2

FL

TL

HTR1

BK

R

M1M2M3

R

R

BK

BK

R

L2L1

MARK ACCORDING TO NUMBER OF HEATER ELEMENT ROWS INSTALLED

R

BK

BK

BL

M4

W

1

2

R

3

PU

4

5

6

7

8

9

NO MARK INDICATES NO HEAT KIT INSTALLED

BK

R

L1

FL

FL

FL

Y

L2 L1 L2

TL

HTR1

HTR2

HTR3

BK

M1

M2

BK

R

BK

TL

R

TL

Y

R

BL

M3

M1

M4

M2

R2

R1

Y

BK

R

TO

Y1C

Y/Y2

G

O

BL

PUW

RYG

O

R

BL

BR

W

USE COPPER WIRE

BK

PL1

PL2

1R23

312

BR

SEE NOTE 8

4567 89

456789

BK

BL

R

240

208

COM

1

2

3

R

W

BK

R

EM

TR

4

BL

R

24V

5

BL

G

N

OTES:

1. FOR HEAT PUM P APPLICATIONS REMOVE ORANGE JUMP ER WIRE BETWEEN O & Y1.

2. FOR TWO S TAGE ELECTRIC HEAT APPLICATIONS CUT PJ4. (USE ONLY ON 15 & 20 KW MODE LS).

3. FOR OUTDOOR THERMOSTAT OPERATION OF SECOND STAGE HEAT, CUT PJ2 & ADD OT18-60 TO OTC & OT2.

4. FOR SINGLE STAGE COOLING APPLICATIONS CONNECT TH ERMOST AT TO Y/Y2 ONLY,

TAPE OR REMOVE Y1 CONNECTION. CONNECT CONDENSING UNIT TO YCON & C.

5. W HEN HUMIDSTAT IS PROVIDED CUT PJ 6. THER MOSTAT OPEN S ON HUMIDITY RISE.

6. RED WIRES TO BE O N TRANSFORMER TERMINAL 3 FOR 2 40 VOLTS AND ON TERMINAL 2 FOR 208 VOLTS.

7. SE E COMPOSITE WIRING DIAGRAMS IN I NSTALLATION INSTRUCTIONS FOR PROPER LO W VOLTAGE

CONNECTIONS AN D DETAILS ON CO MPATIBLE THERMOS TATS AND THEIR CONNECTIONS.

8. DISCARD ORIGINAL "PL1" PLUG CONNECTOR WHEN INSTALLING OPTIONAL HEAT KIT.

SEE NOTE 5

PJ6

HUM

R

SEE NOTE 3

PL1

PL2

5 PL2

W2

PJ2

2OT1

PJ2,PJ4,PJ6

TR

W WHITE

R

Y

BL

EM

PL

FL FUSE LINK

BK

1

2

PU

3

R

BL

4

5

BR

6

W

7

8

9

2

2

EM

2

3

1

5

24 VOLT

4

OT

OT

O

C

W2W E

SEE NOTE 2

COLOR COD E

BLACKBK

RED

YELLOW

BLUE

EVAPORATOR MOTOR

PLUG

PRO GRA M JU MPER

VARIABLE SPEED TRANSFORMERVSTB TR

PU PURPLE

0

PK

TERMINAL BOARD

GREENG

BROWNBR

ORANGE

PINK

COMP

208/240 VOLTS

ONENT CODE

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

34

Page 35

WIRING DIAGRAMS

A

A

AEPF******CA

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT . FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

RD

BK

6

W1

PJ4

W1

FL

HTR 1

FL

HTR 2

FL

HTR 3

FL

HTR 4

BL

RD

BK

M1

YL

M2

BK

RD

L1L1 L2 L2

TO LOW VOLTAGE

TERMINAL BOARD

PL2

YCON

IN4005

DIODE

Y1

Y Y2

SEE NOTE 1

FACT ORY WIRING

HI GH VOLT AGE

LOW VOLTAGE

FIELD WI RING

HI GH VOLT AGE

LOW VOLTAGE

TL

THERMAL LI MIT

HTR

HEAT ELEMENT

RELAY

R

TL

TL

TL

TL

PU

M3

M5

M6

M4

R1

YL

BL

BK

RD

NOTE DIODE

ON VSTB

WIRING CODE

BK

RD

YL

BL

BL

M7

M8

R2

1

1

SEE

NOTE 4

G

*SEE NOTE 7

PL 1

BK

RD

BL

BR

WH

PL1

PL2

4

PL2

C

0140A00041-B

1

2

3

4

5

6

7

8

9

FL

HTR 1

BK

R

BK

L1 L2

* SEE NOTE 7

LOW VOLTAGE

FIELD CONNECTION

BOX

PN. B1368270 REV. A

J1

VSTB

TL

BK

M1

M2

BK

RD

PL 1

1

BK

2

RD

PU

BL

WH

3

4

5

6

7

8

9

ONE (1) ELEMENT ROWS TWO (2) ELEMENT ROWS THREE (3) ELEMENT ROWS FOUR (4) ELEMENT ROWS

FTER INSTALLING OPTIONAL HEAT KIT, MARK A "X" IN THE PROVIDED ABOVE.

TO

FOR HEAT

PUMPS ONLY

HUM

OT2

OT1

PJ2

PJ6

PJ4

WH

BR

DS1

J3J2

CONDENSER

O

RD

R

YCON

COM W2OED

W1

W2

W1

W2

CR

BL

RD

YL

CONDE NSER

W/W2

HEATPUMP

OTC OT1 COT2OE\W1

THERMOST

OUTDOOR

HEATER

TS

O

24 VA C

RY1G

Y1

Y/Y2

HUMIDISTAT

HUM

RD

OR

YCON

R

BL

WH

BR

BL

THERMOSTAT

W1

C

W2

W2

YL

OR

BL

BR

BR

BR

RD

PU

GR

YL

FL

TL

HTR 1

FL

TL

HTR 2

RD

BK

M1M2M3

R

BK

RD

BK

RD

L1 L2

MARK ACCORDING TO NUMBER OF HEATER ELEMENT ROWS INSTALLED

BK

RD

M4

WH

PL 1

1

BK

2

RD

3

PU

BL

4

5

6

7

8

9

NO MARK INDICATES NO HEA T KIT INSTALLED

TO

Y1C

Y/Y2

R

G

SEE NOT E 8

BL

TR

RD

240

1

208

2

3

COM

PUWHBL

RDYLGR

BK

PL1

PL2

1RD23

312

456789

456789

BK

RD

WH

BK

EQUIPMENT GROUND

USE COPPER WIRE

RD

BR

RD

BL

BR

WH

EM

COPPER

POWER SUPPLY

(SEE RATING PLATE)

CONTROLS SHOWN WITH UTILITIES IN "ON" POSITION AND THERMOSTAT IN "OFF" POSITION.

FL

TL

BK

TL

RD

TL

RD

YL

BL

M3

M1

M4

M2

R2

R1

YL

BK

RD

PL 1

1

BK

2

PU

3

RD

4

BL

5

BR

6

WH

7

8

9

RD

BK

L1 L2 L2L1

HTR 1

FL

HTR 2

FL

HTR 3

YL

BK

M1

M2

BK

RD

208/240 VOLTS

PL1

2

PL2

2

EM

EQUIPMENT GROUND

USE COPPER WIRE

1

2

3

TR

5

24 VOLT

4

BL

RD

24V

5

BL

SEE NOTE 5

PJ6

HUM

R

SEE NOTE 3

GR

EQUIPMENT GROUND

USE COPPER WIRE

PJ2,PJ4,PJ6

NOTES:

1. FOR HEAT PU

2. FOR TWO STAGE ELECTRIC HEAT APPLICATIONS CUT PJ4. (USE ONLY ON 15 & 20 KW MODELS).

3. FOR OUTDOOR THERMOSTAT OPERATION OF SECOND STAGE HEAT, CUT PJ2 & ADD OT18-60 TO OTC & OT2.

4. FOR SINGLE STAGE COOLING APPLICATIONS CONNECT THERMOSTAT TO Y/Y2 ONLY,

5. WHEN HUMIDSTAT IS PROVIDED CUT PJ6. THERMOSTAT OPENS ON HUMIDITY RISE.

6. RED WIRES TO BE ON TRANSFORMER TERMINAL 3 FOR 240 VOLTS AND ON TERMINAL 2 FOR 208 VOLTS.

7. SE E COMPOSITE WIRING DIAGRAMS IN INSTALLATION INSTRUCTIONS FOR PROPER LOW VOLTAGE

8. DISCARD ORIGINAL "PL1" PLUG CONNECTOR WHEN INSTAL LING OPTIONAL HEAT KIT.

MP APPLICATIONS REMOVE ORANGE JUMPER WIRE BETWEEN O & Y1.

TAPE OR REMOVE Y1 CONNECTION. CONNE CT CONDENSING UNIT TO YCON & C.

CONNECTIONS AND DETAILS ON COMPATIB LE THERMOSTATS AND THEIR CONNECTIONS.

4

5

PL2

W2

PJ2

OT

OT

2OT1

C

COLOR CODE

WH WHITE

BLACKBK

RD

RED

YL

YELLOW

BLUE

BL

EM

EVAPORATOR MOTOR

PL

PLUG

PROGRAM JUMPER

VARI ABLE SPEED TRANSFORMERVSTB TR

TERMINAL BOARD

FL FUSE LINK

O

SEE NOT E 2

PU PURPLE

0R

PK

W2W E

GREENGR

BROWNBR

ORANGE

PINK

COMPONENT CODE

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

35

Page 36

WIRING DIAGRAMS

ASPF******AA

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT . FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

BK

TL

HTR1

FLFLFL

BK

TL

HTR1

FLFLFL

TLHT R2

FL

FL

4

6

1

3

2

BL

BK

RD

BL

RD

YL

TLTLTL

HTR3

HTR2

FL

RD

TL

HTR2

M7R2M8

BL

M5

PU

M3

RD

HTR4

BK

M1

BL

YL

2

BL

BK

RD

PU

BL

YL

M2

M1

TL

HTR3

M4

M3

RD

BK

M1

M2

YL

RD

897

5

BR

WH

M6

BL

BK

R1

M4

M2

RD

56341

BR

R2

R1

BK

RD

YL

RD

BK

BK

978

WH

BK

RD

YL

RD

BK

L2L1 L1 L2

L2 L1 L2

L1

COM

NO NC

EBTDR

G

R

XFMR-C

XFMR-R

C

C

EM

1

243

5

CR

7 4

2

2

L2

PLM

PLF

B

SEE NOTE 1

208/2 40 VOLTS

EM

C LGN

PLF

PLM

1

1

L1

3

2

1

PLF

4

5

5

6

24V

4

TR

WIRING COD E

HIGH VOLTAGE

FACTORY W IRI NG

PURPLE

GREEN

W2R W1C G 4Y1 OY2 1DH 32 5

PU

GR

COLOR CODE

RED

BLACK

BKRDBL

FEMALE P L UG CONNECTOR

MALE PL U G CONN E CT OR

THERMAL LIMIT

TRANSFORMER

FL FUSE LINK

TL

TR

LOW VOLTAGE

HIGH VOLTAGE

LOW VOLTAGE

FIELD WIR ING

PLF

HTR HEAT ELEMENTS

PLM

BROWN

WHITEWH

BR

YELLOW

YL

BLUE

RELAY

DELAY RELAY

EVAPORATO R M O TO R

ELECTRONIC BLOWER TIME

TERMINA L BOARD

R

TB

COMPONENT CODE

EM

CR CONT ROL RELAY

EBTDR

for proper low voltage wiring connections.

Notes:

3) Confirm speed tap selected is appropr iate fo r application. If speed tap needs

1) Red wires to be on t ransformer t erminal "3" for 240 volts and on terminal "2" for 208 volts.

2) See composite wiring diagrams in installation instructions

0140A00034

to be changed, connect red wire from terminal 4 of CR relay to appropriate t ap

at TB

4) Brown and white wires are used with He at Kits only.

NC GL

EM

21 43 5

NOTE 4

6

2

453

1

BK

RD

PU

RD

HTR1 TL

BL

BK

M3

M1

BK

RD

897

WH

M4

RD

M2

BK

RD

R

BK

L2L1

EQUIPMENT GROUND

USE COPPER WIRE

EQUIPMENT GROUND

USE COPPER OR ALUMINUM WIRE

4 5 678 9

GRD

3

2

RD

L2

1

BK

L1

PLM

SEE

6789

WH

BR

4 5

BL

3

2

RD

1

BK

SEE NOTE 1

RD

BK

BK

BL

240

TR

4

RD

24V

5

1 2 3

BL

C

RD

RD

PLF

RD

BL

NOTE 3

SEE

BL

BK

RD

4

1

BK

BK

TL

HTR1

FL

563

2

RD

PU

BL

M1

M2

R

BK

987

WH

RD

BK

BK

ONE (1) ELEMENT ROWS TWO (2) ELEM ENT ROW S THREE (3) ELEMENT ROWS FOUR (4) ELEMENT ROWS

L1 L2

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

36

17

41 32 5DH

FOR 50HZ MODELS ONLY

TERMINAL BLOCK SHOWN

BR

WH

SEE NOTE 2

MARK ACCO RDING TO NUMBER OF HEATER ELEMENT ROWS INSTALLED. NO MARK INDICATES NO HEAT KIT INSTALLED.

KIT CO MBINATION ON THI S UNIT'S S&R PL AT E. AFTER I NSTALLING OPTIONAL HEAT KIT, MARK AN "X" IN THE PROVIDED ABOVE.

RCGW1W2 Y2Y1 O

RD

NOTE: WHEN INSTALLIN G HEATER KIT, ENSURE SPEED TAP DOE S NOT EXCEED MINIMUM BLOWER SPEED (MBS) SPECIFIED FOR THE AIRHAND LER/HEAT ER

RD

BL

4

BL

CR

BL

COM

GR

RD

XFMR-R

A B

RD

GR

RD

RD

BL

NO NC

EBTDR

R

XFMR-C

BL

G

C

POWER SUPPLY

(SEE RATING PLATE)

(SEE RATING PLATE)

COPPER OR ALUMINUM

COPPER POWER SUPPLY

USE MIN. 75°C FIELD WIRE

GR

USE MIN. 75°C FIELD WIRE

IF REPLACEMENT OF THE OR IGINA L W IRES

USE W IRE THAT CONF O RMS TO THE

SUPPLIED WITH THIS ASSEMBLY IS NECESSARY,

NA TIONAL ELECT RIC CODE.

Page 37

WIRING DIAGRAMS

4

5

3

2

1

PLM

BK

RD

BK

YL

TL

TLTLTL

HTR3

HTR2

HTR1

FL

FL

FL

FL

FL

FL

PLM

BK

RD

TL

TL

TL

HTR2

HTR1

HTR3

FL

FL

FL

PLM

RD

TLHT R2

HTR1 TL

FL

1

PLM

BK

BK

TL

HTR1

BL

BL

PU

RD

HTR4

BK

BL

2

3

1

BK

RD

PU

BL

YL

RD

BK

YL

2

3

1

BK

RD

PU

BK

BK

4

3

2

RD

PU

BL

M1

BK

6

897

BR

BL

RD

WH

M7R2M8

M6

M5

R1

M4

M3

M1

M2

YL

RD

4

5

BR

BL

R2

M2

M1

M4

R1

M3

M1

M2

BK

RD

4

5

BL

M4

M3

M1

M2

R

RD

5

6

M2

R

BL

RDBKYL

RD

BK

BK

6

BK

WH

978

WH

BK

RD

YL

RD

6

897

WH

RD

BK

RD

BK

9

8

7

RD

BK

BK

ASPF******BA

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT . FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

C

EM

1

243

5

5

FOUR (4) ELEMENT ROWS

L2L1 L1 L2

2

2

L2

PLM

PLF

208/240 VOLTS

L2 L1 L2

L1

EQUIPMENT GROUND

EQUIPMENT GROUND

USE COPPER OR ALUMINUM WIRE

L2

L1

L2L1

FOR 50HZ MODELS ONL Y

TERMINAL BLOCK SHOWN

SEE NOTE 2

ONE (1) ELEM ENT ROWS TWO (2) ELEMENT ROWS THREE (3) EL EMENT ROWS

MARK ACCORDING TO NUMBER OF HEATER ELEMENT ROWS INSTALLED. NO MARK INDICATES NO HEAT KIT INSTALLED.

KIT COMBINATION ON THIS UNIT'S S&R PLATE. AFTER INSTALLING OPTIONAL HEAT KIT, MARK AN "X" IN THE PROVIDED ABOVE.

L1 L2

EM

C LGN

PLF

PLM

1

1

L1

6789

USE COPPER WIRE

4 5

4 5 678 9

GRD

3

2

23

RD

1

1

BK

PLF

PLM

W2R W1CG 4Y1 OY2 1DH 32 5

RD

WH

BR

BK

NOTE: WHEN INSTALLING HEATER KIT, ENSURE SPEED TAP DOES NOT EXCEED MINIMUM BLOWER SPEED (MBS) SPECIFIED FOR THE AIRHANDLER/HEATER

4

CR

2

FEMALE PLUG CONNECTOR

MALE PLUG CONNECTOR

WIRING CODE

FACTORY WIRING

TRANSFORMER

TR

FIELD WIRING

HIGH VOLTAGE

LOW VOLTAGE

HIGH VOLTAGE

LOW VOLTAGE

PLF

PLM

3 1

SEE NOTE 1

3

2

1

NOTE 4

SEE

BL

RD

PLF

4

5

5

6

24V

4

TR

PU

W2R W1C G 4Y1 OY2 1DH 32 5

HOLDER

FUSE

SEE NOTE 1

3

RD

1 2

BK

BK

SEE

NOTE 3

WH

4

CR

BR

WH

GR