Goodman R-410A, APH1524M41AA, APH1536M41AA, APH1548M41AA, APH1560M41AA Service Instructions Manual

...Page 1

Service

Instructions

*PH 15 SEER

Multi-Position

Package Heat Pumps

with R-410A Refrigerant

& Accessories

Model numbers

listed on page 6

This manual is to be used by qualified, professionally trained HVAC technicians only.

Goodman does not assume any responsibility for property damage or personal injury

due to improper service procedures or services performed by an unqualified person.

Copyright © 2007 Goodman Manufacturing Company, L.P.

RS6300008 Rev. 1

November 2007

1

Page 2

INDEX

IMPORTANT INFORMATION .......................................................................................................... 4

PRODUCT IDENTIFICATION - *PH15**M4* .................................................................................. 6

ACCESSORIES ............................................................................................................................... 7

GPGHFR101-103 ....................................................................................................................................................... 8

GPH13MFR FILTER RACK ....................................................................................................................................... 9

PGMDD101-103 DOWNFLOW MANUAL FRESH AIR DAMPERS .......................................................................... 10

PGMDMD102-103 DOWNFLOW MOTORIZED FRESH AIR DAMPERS .................................................................. 10

PGMDH102-103 HORIZONTAL MANUAL FRESH AIR DAMPERS .......................................................................... 10

PGMDH102-103 HORIZONTAL MOTORIZED FRESH AIR DAMPERS .................................................................... 10

SQRPG101-103 SQUARE TO ROUND CONVERTER, DOWNFLOW ...................................................................... 11

SQRPGH101-103 SQUARE TO ROUND CONVERTER, HORIZONTAL ................................................................... 11

GPH13MED103 DOWNFLOW ECONOMIZER ......................................................................................................... 12

PGEH102-103 HORIZONTAL ECONOMIZER ........................................................................................................... 12

PGC101-103 ROOF CURBS .................................................................................................................................... 13

PRODUCT DESIGN ...................................................................................................................... 13

LOCATION AND CLEARANCES ............................................................................................................................. 13

COMPRESSEOR ..................................................................................................................................................... 14

INDOOR BLOWER MOTOR .................................................................................................................................... 14

ELECTRICAL WIRING ............................................................................................................................................ 15

LINE VOLTAGE WIRING......................................................................................................................................... 15

SYSTEM OPERATION .................................................................................................................. 16

COOLING ................................................................................................................................................................ 16

COOLING CYCLE ................................................................................................................................................... 16

HEATING CYCLE .................................................................................................................................................... 16

DEFROST CYCLE ................................................................................................................................................... 17

FAN OPERATION .................................................................................................................................................... 17

AIRFLOW ADJUSTMENTS FOR INDOOR BLOWER MOTOR ............................................................................... 17

SCHEDULED MAINTENANCE..................................................................................................... 20

ONCE A MONTH ..................................................................................................................................................... 20

ONCE A YEAR ........................................................................................................................................................ 20

TEST EQUIPMENT ................................................................................................................................................. 20

SERVICING ................................................................................................................................... 22

COOLING /HEAT PUMP- SERVICE ANALYSIS GUIDE .......................................................................................... 21

S-1 CHECKING VOLTAGE ...................................................................................................................................... 22

S-2 CHECKING WIRING ......................................................................................................................................... 23

S-3 CHECKING THERMOSTAT, WIRING, AND ANTICIPATOR ............................................................................... 23

S-3A Thermostat and Wiring .......................................................................................................................... 23

S-3B Cooling Anticipator ................................................................................................................................ 23

S-3C Heating Anticipator ................................................................................................................................ 23

S-4 CHECKING TRANSFORMER AND CONTROL CIRCUIT .................................................................................. 24

S-7 CHECKING CONTACTOR AND/OR RELAYS ................................................................................................... 24

S-8 CHECKING CONTACTOR CONTACTS ............................................................................................................. 24

2

Page 3

INDEX

S-11 CHECKING LOSS OF CHARGE PROTECTOR .............................................................................................. 25

S-15 CHECKING CAPACITOR ................................................................................................................................25

S-15A Resistance Check ................................................................................................................................. 26

S-15B Capacitance Check ............................................................................................................................. 26

S-16 CHECKING MOTORS ..................................................................................................................................... 27

S-16B Checking Fan & Blower Motor (ECM Motors) .................................................................................... 27

S-16C Checking ECM Motor Windings .......................................................................................................... 30

S-16D Checking GEX13™ Motors .................................................................................................................. 30

S-17 CHECKING COMPRESSOR WINDINGS ........................................................................................................ 31

S-17A Resistance Test .................................................................................................................................... 31

S-17B Ground Test .......................................................................................................................................... 31

S-17C Unloader Test Procedure .................................................................................................................... 32

S-17D Operation Test ...................................................................................................................................... 32

S-18 TESTING CRANKCASE HEATER ................................................................................................................... 33

S-21 CHECKING REVERSING VALVE AND SOLENOID ......................................................................................... 33

S-24 TESTING DEFROST CONTROL ..................................................................................................................... 33

S-25 TESTING DEFROST THERMOSTAT ............................................................................................................... 33

S-50 CHECKING HEATER LIMIT CONTROL(S) ...................................................................................................... 33

S-52 CHECKING HEATER ELEMENTS ................................................................................................................... 33

S-100 REFRIGERATION REPAIR PRACTICE.......................................................................................................... 34

S-101 LEAK TESTING (NITROGEN OR NITROGEN-TRACED) ............................................................................... 34

S-102 EVACUATION................................................................................................................................................ 34

S-103 CHARGING ................................................................................................................................................... 35

S-104 CHECKING COMPRESSOR EFFICIENCY .................................................................................................... 36

S-105 THERMOSTATIC EXPANSION VALVE ......................................................................................................... 36

S-106 OVERFEEDING ............................................................................................................................................. 37

S-107 UNDERFEEDING ........................................................................................................................................... 37

S-108 SUPERHEAT ................................................................................................................................................. 37

S-109 CHECKING SUBCOOLING ........................................................................................................................... 38

S-110 CHECKING EXPANSION VALVE OPERATION ............................................................................................. 41

S-112 CHECKING RESTRICTED LIQUID LINE ....................................................................................................... 41

S-113 REFRIGERANT OVERCHARGE .................................................................................................................... 41

S-114 NON-CONDENSABLES ................................................................................................................................. 41

S-115 COMPRESSOR BURNOUT ........................................................................................................................... 41

S-122 REVERSING VALVE REPLACEMENT ........................................................................................................... 42

S-200 CHECKING EXTERNAL STATIC PRESSURE ............................................................................................... 43

S-201 CHECKING TEMPERATURE RISE ................................................................................................................ 43

WIRING DIAGRAMS ................................................................................................................ 44

OT18-60A OUTDOOR THERMOSTAT ..................................................................................................................... 44

OT18-60A OUTDOOR THERMOSTAT ..................................................................................................................... 45

HKR** HEAT KITS.................................................................................................................................................. 46

GPH13MED ECONOMIZER FOR GPH15**M4* ........................................................................................................ 47

3

Page 4

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE

SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

WARNING

T

HIS UNIT SHOULD NOT BE CONNECTED TO. OR USED IN CONJUNCTION WITH, ANY DEVICES THAT ARE NOT DESIGN CERTIFI ED FOR USE WITH THIS UNIT OR HAVE NOT BEEN

TESTED AND APPROVED BY

FROM THE USE OF DEVICES THAT HAVE NOT BEEN APPROVED OR CERTIFED BY

GOODMAN. SERIOUS PROPERTY DAMAGE OR PERSONAL INJURY, REDUCED UNIT PERFORMANCE AND/OR HAZARDOUS CONDITIONS MAY RESULT

GOODMAN.

WARNING

T

O PREVENT THE RISK OF PROPE RTY DAMAGE, PERSONAL INJURY, OR DEATH,

DO NOT STORE COMBUSTIBLE MATE RIALS OR USE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR VAPORS IN THE VICINITY OF THIS APPLIANCE.

WARNING

G

OODMAN WILL NOT BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM IMPROPER SERVICE OR SERVICE PROCEDURES.

I

F YOU INSTALL OR PERFORM SERVICE ON THIS UNIT, YOU ASSUME RESPONSIBILITY FOR ANY PERSONAL INJURY OR PROPERTY DAMAGE WHICH

MAY RESU LT.

M

ANY JURISDICTIONS REQU IRE A LICENSE TO INSTALL OR SERVICE HEATING AN D AIR CONDITIONING EQUIPMENT.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER INFORMATION LINE

GOODMAN® BRAND PRODUCTS

TOLL FREE 1-877-254-4729 (U.S. only)

email us at: customerservice@goodmanmfg.com

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

email us at: hac.consumer.affairs@amanahvac.com

CONSUMER INFORMATION LINE

AMANA® BRAND PRODUCTS

TOLL FREE 1-877-254-4729 (U.S. only)

fax us at: (931) 438- 4362

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500. (Not a technical assistance line for

dealers.) Your telephone company will bill you for the call.

4

Outside the U.S., call 1-931-433-6101. (Not a technical assistance line for

dealers.) Your telephone company will bill you for the call.

Page 5

IMPORTANT INFORMATION

SAFE REFRIGERANT HANDLING

While these items will not cover every conceivable situation, they should serve as a useful guide.

WARNING

REFRIGERANTS ARE H EAVIER THAN AIR . THEY CAN "PUSH OUT" THE

OXYGEN IN YOUR LUNGS OR IN ANY ENCLOSED SPACE.

POSSIBLE DIF FICULT Y IN BREAT HING OR DEATH:

EVER PURGE REFRIGERANT INTO AN ENCLOSED ROOM OR SPACE. BY

•

N

LAW, ALL REFRIGERANTS MUST BE RECLAIMED.

IF AN INDOOR LEAK IS SUSPECTED, THOROUGHLY VENTIL ATE THE AREA

•

BEFORE BEGINNING WORK.

IQUID REFRIGERANT CAN BE VERY COLD. TO AVOID POSSIBLE FROST-

•

L

BITE OR BL INDNESS, AVOID CONTACT WITH REFRIGERANT AND WEAR

I

GLOVES AND GOGGLES.

SKIN OR EYES, SEEK MEDICAL HELP IMMEDIATELY.

A

LWAYS FOLLOW

•

AS POIS ONOUS GAS WILL BE PRODUCED.

F LIQUID REFRIGERANT DOES CONTACT YOUR

EPA

REGULATIONS. NEVER BURN REFRIGERANT,

O AVO ID

T

WARNING

TO AVOID POSSIBLE EXPLOSION:

EVER APPLY FLAME OR STEAM TO A REFRIGERAN T CYLINDER. IF YOU

•

N

MUST HEAT A CYLINDE R FOR FASTER CHARGING, PARTIALLY IMMERSE

IT IN WARM WATER.

NEVER FILL A CYLINDE R MORE THAN 80% FULL OF LIQUID REFRIGERANT.

•

NEVER ADD ANYTHING OTHER THAN R-22 TO AN R-22 CYLINDER OR

•

R-410A TO AN R-410A CYLINDER. THE SERVICE EQUIPMENT USED MUST

BE LISTED OR CERTIF IED FOR THE TYPE OF REFRIGERANT USED.

TORE CYLINDERS IN A CO OL, DRY PLACE. NEVER USE A CYLIND ER

•

S

AS A PLATFORM OR A ROLLER.

WARNING

TO AVOID POSSIBLE EXPLOSION, USE ONLY RETURNABLE (NOT DISPOSABLE)

SERVICE CYLINDERS WHEN REMOVING REFRIGERANT FROM A SYSTEM.

•

ENSURE THE CYLINDER IS FREE OF DAMAGE WHICH COULD LEAD TO A

LEAK OR EX PLOS ION .

•

ENSURE THE HYDROST ATIC TES T DATE DOES NOT EXCE ED 5 YEAR S.

•

ENSURE THE PRESSURE RATING MEETS OR EXCEEDS 400 LBS.

WHEN IN DOUBT, DO NOT USE CYLINDER.

WARNING

WARNING

SYSTEM CONTAMINANTS, IMPROPER SERVICE PROCEDURE AND/OR PHYSICAL

ABUSE AFFECTING HERMETIC COMPRESSOR ELECTRICAL TERMINALS MAY

CAUSE DANGEROUS SYSTEM VENTING.

The successful development of hermetically sealed refrigeration compressors has completely sealed the compressor's

moving parts and electric motor inside a common housing,

minimizing refrigerant leaks and the hazards sometimes associated with moving belts, pulleys or couplings.

Fundamental to the design of hermetic compressors is a

method whereby electrical current is transmitted to the compressor motor through terminal conductors which pass

through the compressor housing wall. These terminals are

sealed in a dielectric material which insulates them from the

housing and maintains the pressure tight integrity of the hermetic compressor. The terminals and their dielectric embedment are strongly constructed, but are vulnerable to careless compressor installation or maintenance procedures and

equally vulnerable to internal electrical short circuits caused

by excessive system contaminants.

T

O AVOID POSSIBLE INJURY, EXPLOSION OR DEATH, PRACTICE SAFE

HANDLING OF REFRIGERANTS.

In either of these instances, an electrical short between the

terminal and the compressor housing may result in the loss

of integrity between the terminal and its dielectric embedment. This loss may cause the terminals to be expelled,

thereby venting the vaporous and liquid contents of the compressor housing and system.

A venting compressor terminal normally presents no danger

to anyone, providing the terminal protective cover is properly

in place.

If, however, the terminal protective cover is not properly in

place, a venting terminal may discharge a combination of

(a) hot lubricating oil and refrigerant

(b) flammable mixture (if system is contaminated

with air)

in a stream of spray which may be dangerous to anyone in

the vicinity. Death or serious bodily injury could occur.

Under no circumstances is a hermetic compressor to be electrically energized and/or operated without having the terminal

protective cover properly in place.

See Service Section S-17 for proper servicing.

5

Page 6

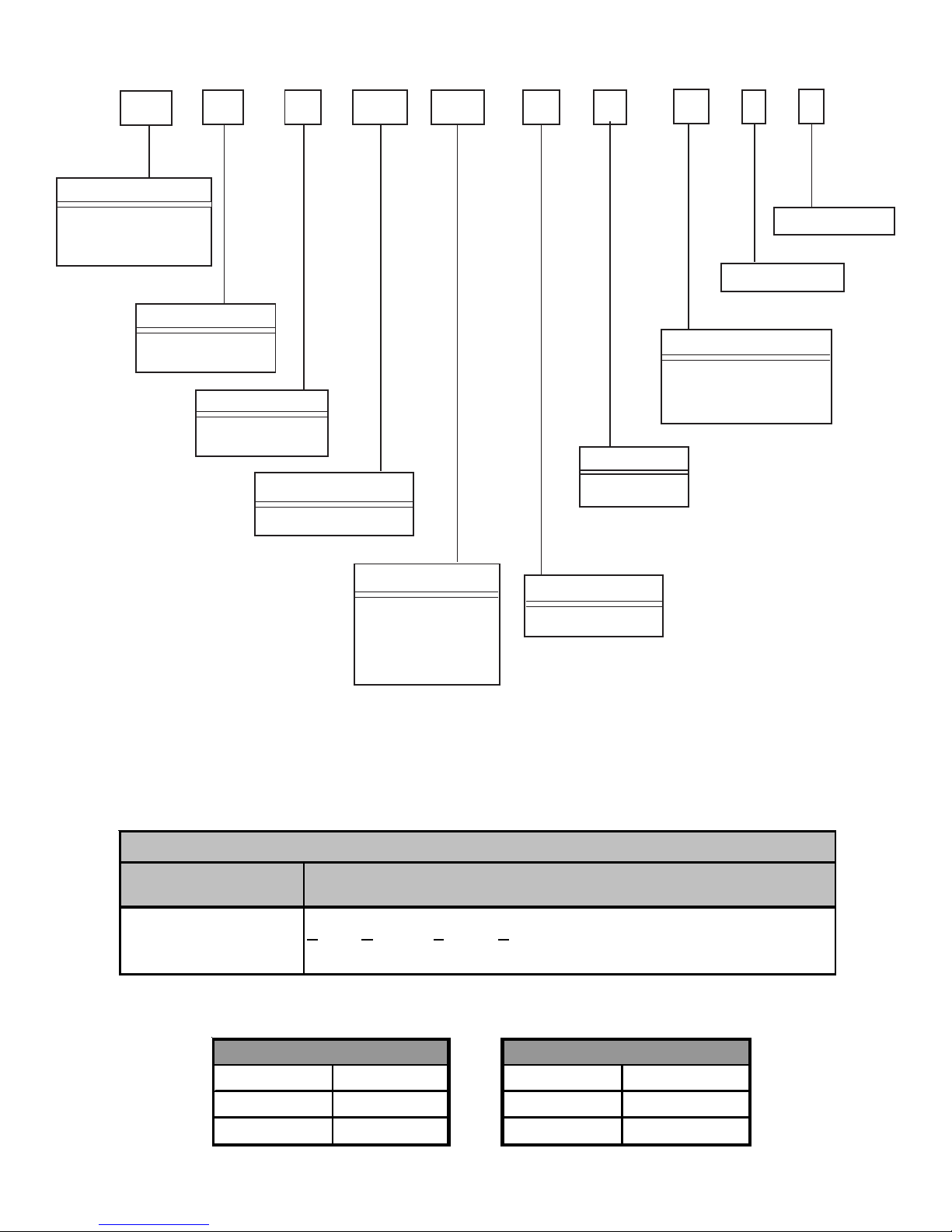

PRODUCT IDENTIFICATION

G P H 15 36 M 4 1 * *

Brand

G: Goodman® Brand

or Distinctions

A: Amana® Brand

Product Type

Package

Cooling/Heating

Product Family

C: Cooling

H: Heat Pump

Minor Revision

Major Revision

Voltage

1: 208-230V/1ph/60Hz

3: 208-230V/3ph/60Hz

4: 460V/3ph/60Hz

Refrigerant

Product Series

15: 15 SEER Rating

Nominal Capacity

24: 24,000 BTUH

36: 36,000 BTUH

48: 48,000 BTUH

60: 60,000 BTUH

Configuration

M: Multi-Position

Single Phase Multiposition Package Heat Pumps

Model # Description

A

A/GPH15**M41AA

mana/Goodman Package Heat Pump 15 Seer R410A Multiposition heat

pump units. Initial release.

4: R-410A

GPH15**M41* APH15**M41*

Chassis Models Chassis Models

Medium 2 - 3 Ton Medium 2 - 3 Ton

Large 4 - 5 Ton Large 4 - 5 Ton

6

Page 7

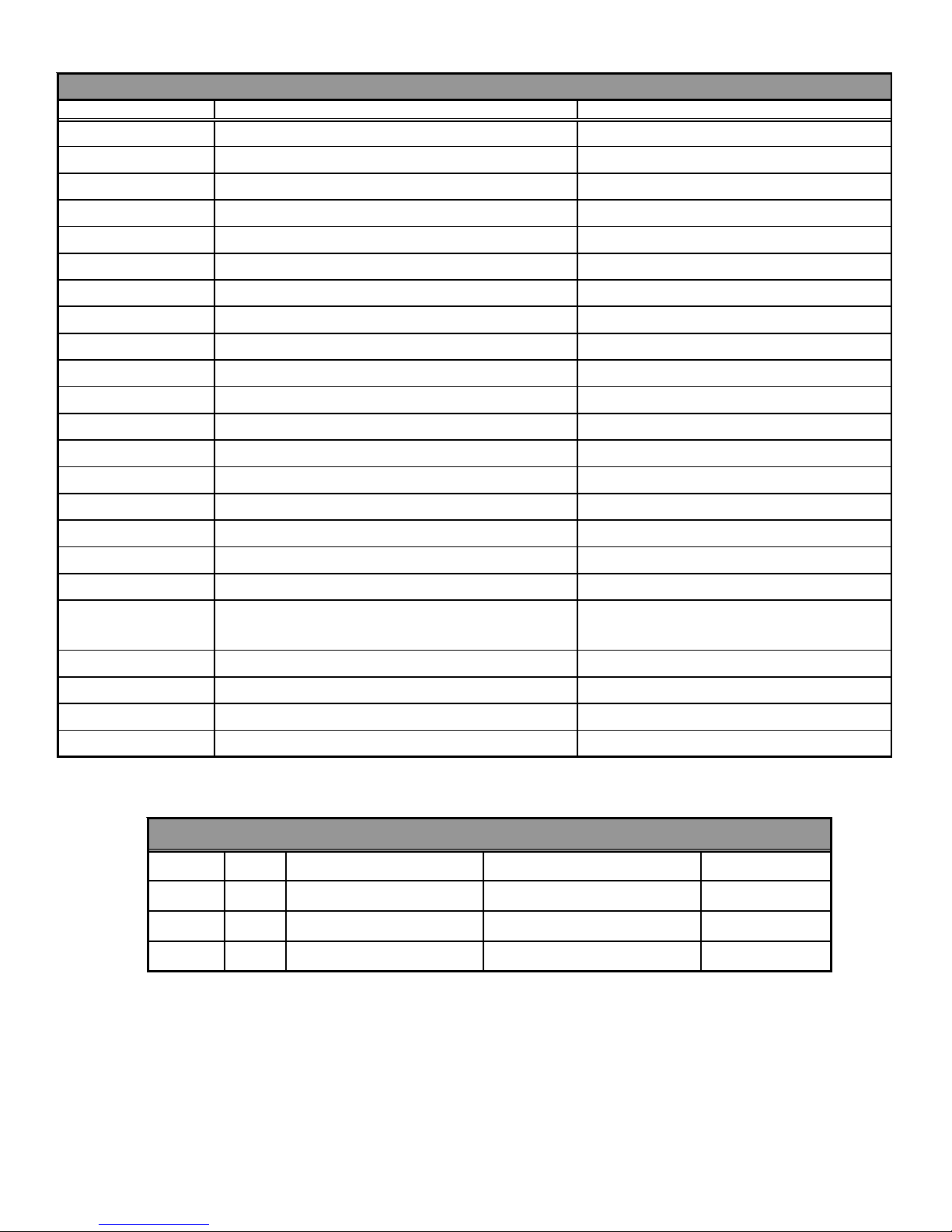

ACCESSORIES

*PH15[24-60]M4*

ACCESSORIES

Part Number Description Fits Models

GPH13MED103 Economizer Downflow All

PGEH102 Economizer Horizontal Medium Chassis

PGEH103 Economizer Horizontal Large Chassis

PGMDD102 Downflow Manual 25% Fresh Air Damper Medium Chassis

PGMDD103 Downflow Manual 25% Fresh Air Damper Large Chassis

PGMDH102 Horizontal Manual 25% Fresh Air Damper Medium Chassis

PGMDH103 Horizontal Manual 25% Fresh Air Damper Large Chassis

PGMDMH102 Horizontal Motorized 25% Fresh Air Damper Medium Chassis

PGMDMH103 Horizontal Motorized 25% Fresh Air Damper Large Chassis

PGMDMD102 Downflow Motorized 25% Fresh Air Damper Medium Chassis

PGMDMD103 Downflow Motorized 25% Fresh Air Damper Large Chassis

SQRPG102 Downflow Square to Round Adapter Medium Chassis

SQRPG103 Downflow Square to Round Adapter Large Chassis

SQRPGH102 Horizontal Square to Round Adapter Medium Chassis

SQRPGH103 Horizontal Square to Round Adapter Large Chassis

PGC101/102/103 Roof Curb All

GPH13MFR Downflow Filter Rack All

GPGHFR101-103 External Horizontal Filter Rack All

OT18-60A

OT/EHR-60A Outdoor Thermostat with Emergency Heat Relay All

HKR05A, 08, 10, CA Heater Kit - Single Phase All GPH15**M41*

HKR15A, CA Heater Kit - Single Phase GPH15(36-60)M41*

HKR20A, CA Heater Kit - Single Phase GPH15(48-60)M41*

Outdoor Thermostat (Required for heat pumps with 0°

outdoor ambient and 50% or higher relative humidity)

All

AMANA® BRAND THERMOSTATS

1213406 Beige Manual/Auto Changeover 5 + 2 Programming Digital 3 Heat - 2 Cool

1213407 White Manual Changeover 5 + 2 Programming Digital 2 Heat - 2 Cool

1213412 White Manual/Auto Changeover 7 Day Programming Digital 3 Heat - 2 Cool

1213431 White Manual/Auto Changeover 7 Day Programming Digital 3 Heat - 2 Cool

7

Page 8

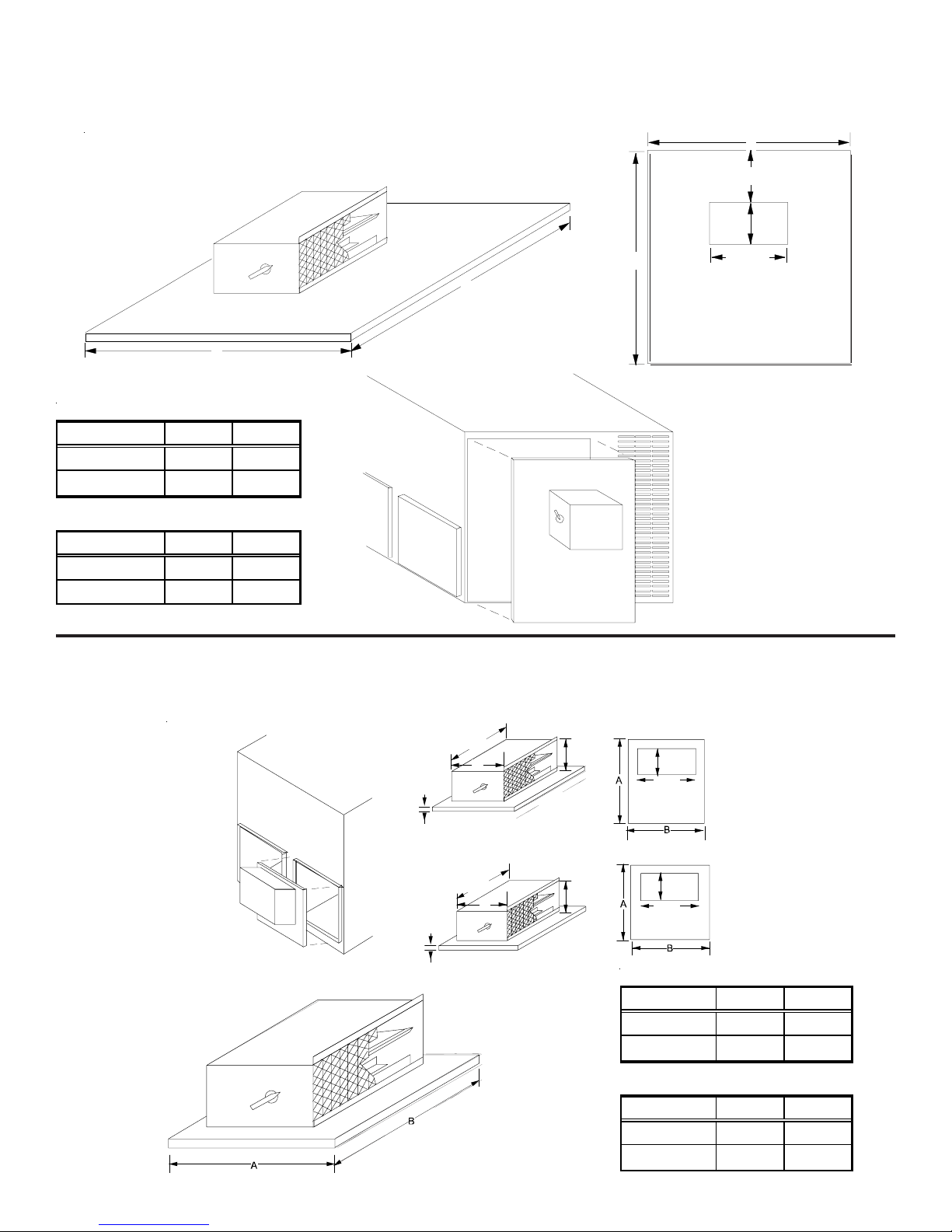

ACCESSORIES

*PH15[24-60]M4*

EXTERNAL HORIZONTAL FILTER RACK

(GPGHFR101-103)

16"

24"

4"

16" x 25" x 2" FILTER

17 1/4"

DOWNFLOW FILTER RACK

PANEL SIDE VIEW

26 1/2"

Filter Size: 16" x 25" x 2"

(Requires 1 filter)

Measurement in inches

(GPH13MFR)

DUCT SIDE VIEW

FILTER PLATFORM

RIGHT SIDE

DOWNFLOW R/A

DUCT OPENING

Filter Size: 14" x 25" x 2" (Requires 2 filters) - Measurement in inches

8

LEFT SIDE

EVAPORATOR

COIL

Page 9

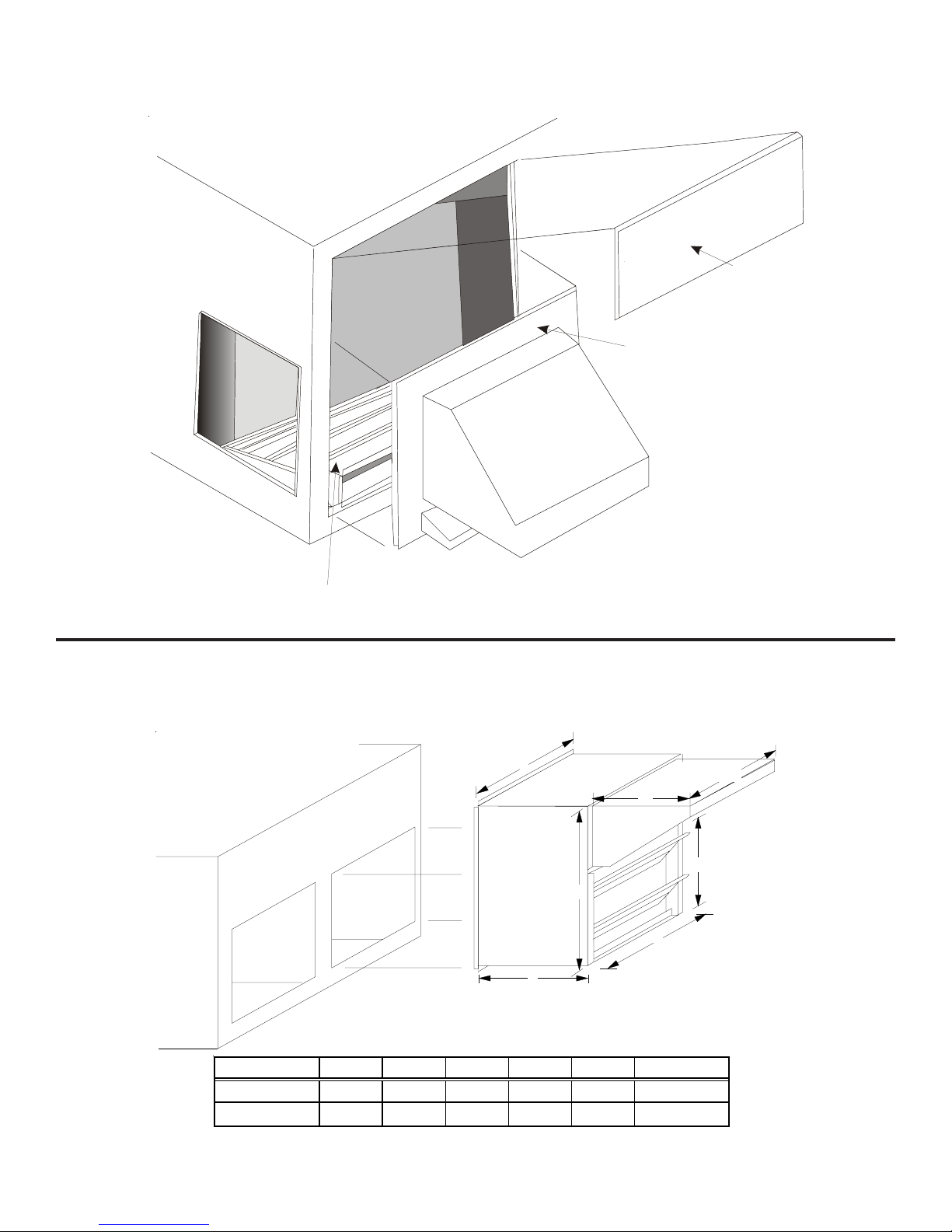

ACCESSORIES

MOTORIZED/MANUAL FRESH AIR DAMPERS -

*PH15[24-60]M4*

(DOWNFLOW APPLICATIONS)

B

7 5/8

5 3/4

A

Manual Fresh Air Dampers

MODEL A B

PGMDD101/102 16 16

PGMDD103 18 16

Motorized Fresh Air Dampers

MODEL A B

PGMDMD102 16 16

PGMDMD103 18 16

MOTORIZED/MANUAL FRESH AIR DAMPERS

B

(HORIZONTAL APPLICATIONS)

A

11 7/8

12 1/8

10

1

PGMDD103

12 1/8

10

1

PGMDD101/102

6

6

BOTTOM VIEW

5 3/4

11 7 /8

BOTTOM VIEW

5 3/4

11 7 /8

Manual Fresh Air Dampers

MODEL A B

PGMDH102 31 1/2 29 3/4

PGMDH103 39 29 3/4

Motorized Fresh Air Dampers

MODEL A B

PGMDMH102 31 1/2 29 3/4

PGMDMH103 39 29 3/4

9

Page 10

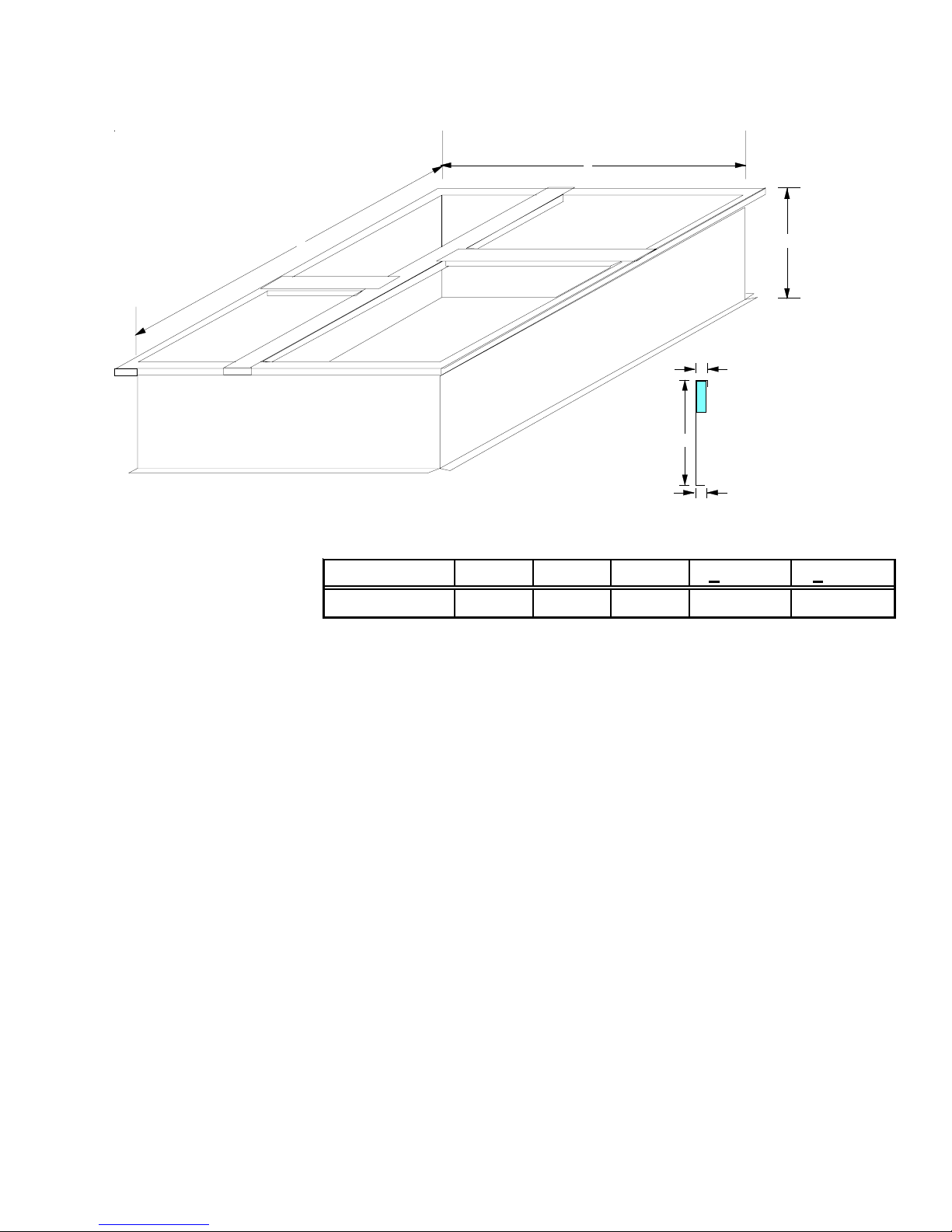

ACCESSORIES

A

*PH15[24-60]M4*

SQUARE TO ROUND CONVERTER

(DOWNFLOW APPLICATIONS)

12 1/4 14 3/4

C

D

S

R

B

MODEL ABCDRETURN SUPPLY

SQRPG101/102 22 3/4 12 1/4 22 1/4 14 3/4 16 16

SQRPG103 22 3/4 12 1/4 22 1/4 14 3/4 18 18

22 3/4 22 1/4

22 3/4 22 1/4

16 ø 16 ø

12 1/4 14 3/4

18 ø 18 ø

SQUARE TO ROUND CONVERTER

(HORIZONTAL APPLICATIONS)

B

C

A

MODEL ABC

SQRPGH101/102 16 16 1/2 16 1/2

SQRPGH103 18 18 1/2 18 1/2

10

Measurements are in inches.

Page 11

ACCESSORIES

*PH15[24-60]M4*

ECONOMIZER GPH13MED103

(DOWNFLOW APPLICATIONS )

Blockoff

External Hood Panel

Louver Assembly

ECONOMIZER PGEH102-103

(HORIZONTAL APPLICATIONS )

B

C

16 1/8

18

D

A

E

MODEL ABCDEFILTER

PGEH102 25 1/4 18 18 18 13 3/4 16 1/8 16 X 25 X1

PGEH103 35 1/4 18 1/8 18 18 1/4 16 1/8 16 X 25 X1

Measurements in inches

11

Page 12

ACCESSORIES

*PH15[24-60]M4*

ROOF CURBS

B

A

PGC101/102/103 46 1/4* 39 3/8* 14 1/2 12 1/2 x 23* 15 x 22 1/2*

R

MODEL A B C RETURN SUPPLY

*Inside Dimensions

S

C

1 5/8

14 1/2

1 3/8

12

Page 13

PRODUCT DESIGN

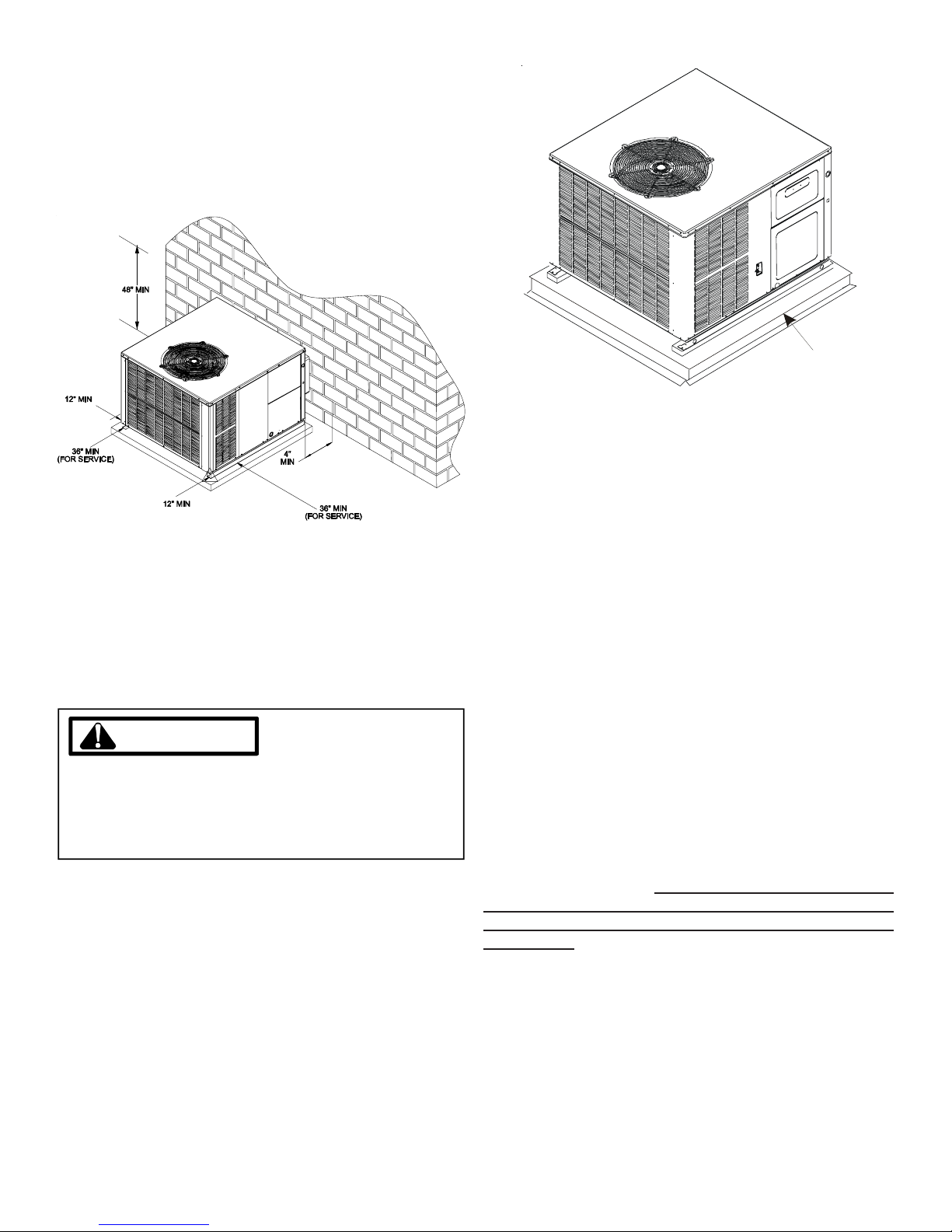

LOCATION & CLEARANCES

In installations where the unit is installed above ground level

and not serviceable from the ground (Example: Roof Top installations) the installer must provide a service platform for the

service person with rails or guards in accordance with local

codes or ordinances.

*PH15[24-60]M41*

NOTE: Roof overhang should be no more than 36" and

provisions made to deflect the warm discharge air out from the

overhang.

Minimum clearances are required to avoid air recirculation and

keep the unit operating at peak efficiency.

WARNING

TO PREVENT POSSIBLE DAMAGE, THE UNIT SHOULD

REMAIN IN AN UPRIGHT POSITION DURING ALL

RIGGING AND MOVING OPERATIONS. TO FACILITATE

LIFTING AND MOVING IF A CRANE IS USED, PLACE

THE UNIT IN AN ADEQUATE CABLE SLIDE.

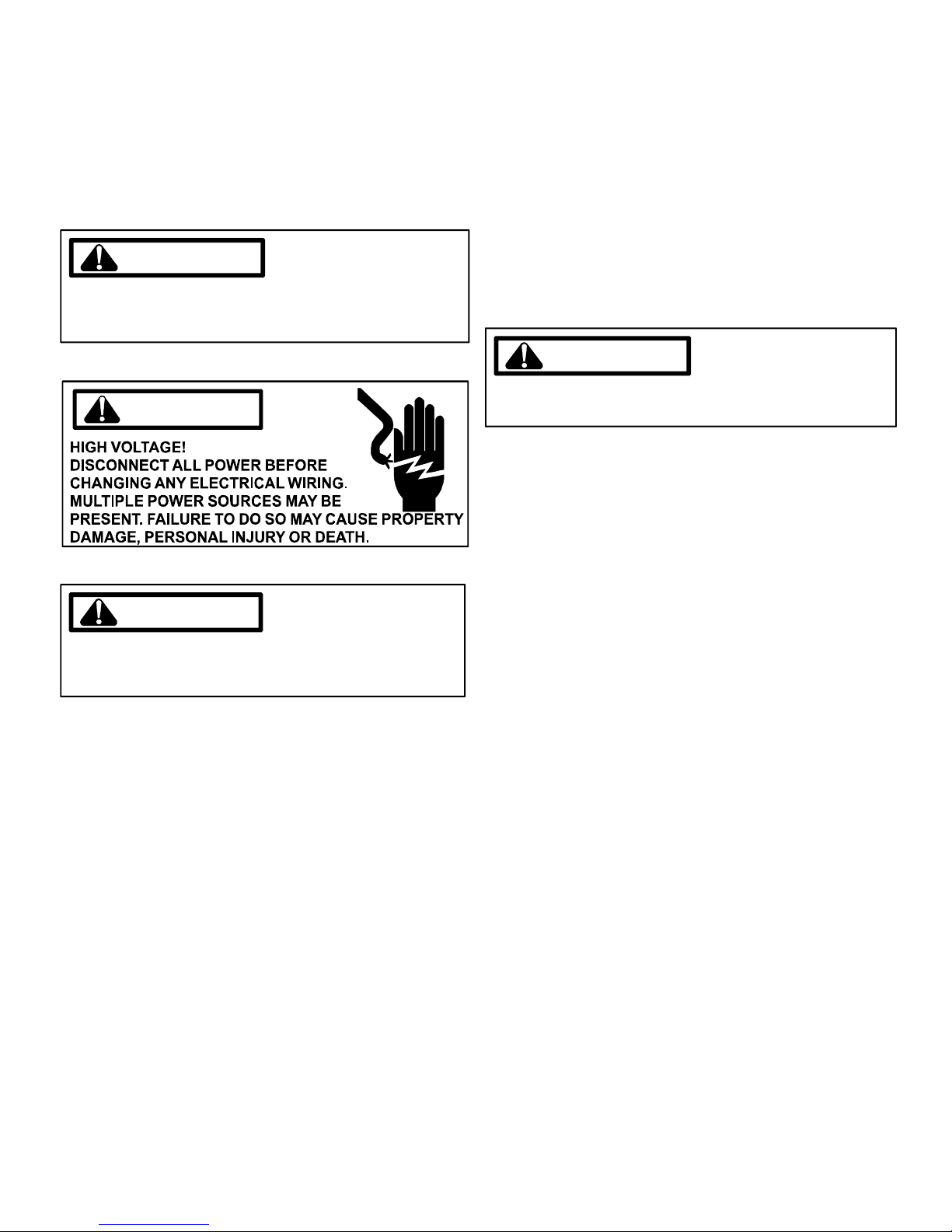

Refer to Roof curb Installation Instructions for proper curb installation. Curbing must be installed in compliance with the

National Roofing Contractors Association Manual.

Lower unit carefully onto roof mounting curb. While rigging

unit, center of gravity will cause condenser end to be lower

than supply air end.

Roof Curb

*PH15[24-60]M4*

*PH Package Units are designed for outdoor installations only

in either residential or light commercial applications.

The connecting ductwork (Supply and Return) can be connected

for horizontal discharge airflow. In the down discharge applications, a matching Roof Curb (PGC101/102/103) is recommended for horizontal models only.

A return air filter must be installed behind the return air grille(s)

or provision must be made for a filter in an accessible location

within the return air duct. An internal filter rack (GPH13MFR102

& 103) and an external filter rack (GPGHFR101-103) are also

available as accessories. The minimum filter area should not

be less than those sizes listed in the Specification Section.

Under no circumstances should the unit be operated without

return air filters.

A 3/4" - 14 NPT drain connector is provided for removal of condensate water from the indoor coil. In order to provide proper

condensate flow, do not reduce the drain line size.

Refrigerant flow control is achieved by use of TXV. These models use the FasTest Access Fitting System, with a saddle that

is either soldered to the suction and liquid lines or is fastened

with a locking nut to the access fitting box (core) and then

screwed into the saddle. Do not remove the core from the

saddle until the refrigerant charge has been removed.

Failure to do so could result in property damage or personal injury.

The single phase units use permanent split capacitors (PSC)

design compressors. Starting components are therefore not

required. A low MFD run capacitor assists the compressor to

start and remains in the circuit during operation.

13

Page 14

PRODUCT DESIGN

The outdoor fan motors are single phase capacitor type motors.

Air for condensing (cooling) is drawn through the outdoor coil

by a propeller fan, and is discharged vertically out the top of

the unit. The outdoor coil is designed for .0 static. No additional restriction (ductwork) shall be applied.

Conditioned air is drawn through the filter(s), field installed,

across the evaporator coil and back into the conditioned space

by the indoor blower.

COMPRESSORS

The *PH15 4 and 5 ton M series package heat pump units use

a two-stage scroll compressor. The two-step modulator has

an internal unloading mechanism that opens a bypass port in

the first compression pocket, effectively reducing the displacement of the scroll. The opening and closing of the bypass port

is controlled by an internal electrically operated solenoid.

The ZPS two-step modulated scroll uses a single step of unloading to go from full capacity to approximately 67% capacity. A single speed, high efficiency motor continues to run while

the scroll modulates between the two capacity steps.

As this motion occurs, the pockets between the two forms are

slowly pushed to the center of the two scrolls while simultaneously being reduced in volume. When the pocket reaches

the center of the scroll form, the gas, which is now at a high

pressure, is discharged out of a port located at the center.

During compression, several pockets are being compressed

simultaneously, resulting in a very smooth process. Both the

suction process (outer portion of the scroll members) and the

discharge process (inner portion) are continuous.

Some design characteristics of the Compliant Scroll compressor are:

• Compliant Scroll compressors are more tolerant of liquid

refrigerant.

NOTE: Even though the compressor section of a Scroll

compressor is more tolerant of liquid refrigerant, continued

floodback or flooded start conditions may wash oil from the

bearing surfaces causing premature bearing failure.

• These Scroll compressors use “POE” or polyolester oil

which is NOT compatible with mineral oil based lubricants

like 3GS. “POE” oil must be used if additional oil is required.

• Compliant scroll compressors perform "quiet" shutdowns

that allow the compressor to restart immediately without

the need for a time delay. This compressor will restart even

if the system has not equalized.

NOTE: Operating pressures and amp draws may differ from

standard reciprocating compressors. This information can

be found in the unit's

Technical Information Manual.

A scroll is an involute spiral which, when matched with a mating scroll form as shown, generates a series of crescent shaped

gas pockets between the two members.

During compression, one scroll remains stationary (fixed scroll)

while the other form (orbiting scroll) is allowed to orbit (but not

rotate) around the first form.

14

INDOOR BLOWER MOTOR

GPH15 M series model package units use a GE X13TM blower

motor The GE X13TM motor is a 3 Phase brushless DC (single

phase AC input), ball bearing construction motor with an integral control module with an internal FCC B EMI filter.

The GE X13TM motor is continuously powered with line voltage.

The switched 24 volt control signal is controlled by the thermostat in the cooling and heat pump mode and the blower relay in

the electric heat mode.

APH15 M series model package units use an ECM blower

motor. These motors offer greater airflow flexibility as well as

dehumidification. The airflow delivery for these models can be

adjusted by changing the position of dip switches on a low

voltage terminal board.

Page 15

PRODUCT DESIGN

ELECTRICAL WIRING

The units are designed for operation at the voltages and hertz

as shown on the rating plate. All internal wiring is complete.

Ensure the power supply to the compressor contactor is brought

to the unit as shown on the supplied unit wiring diagram. The

24V wiring must be connected between the unit control panel

and the room thermostat.

WARNING

TO AVOID PERSONAL INJURY OR DEATH DUE TO

ELECTRIC SHOCK, WIRING TO THE UNIT MUST BE

PROPERLY POLARIZED AND GROUNDED.

WARNING

WARNING

TO AVOID THE RISK OF PROPERTY DAMAGE,

PERSONAL INJURY OR FIRE, USE ONLY COPPER

CONDUCTORS.

LINE VOLTAGE WIRING

Power supply to the unit must be N.E.C. Class 1, and must

comply with all applicable codes. The unit must be electrically

grounded in accordance with the local codes or, in their absence, with the latest edition of the National Electrical Code,

ANSI/NFPA No. 70, or in Canada, Canadian Electrical Code,

C22.1, Part 1. A fused disconnected must be provided and

sized in accordance with the unit minimum circuit ampacity.

The best protection for the wiring is the smallest fuse or breaker

which will hold the equipment on line during normal operation

without nuisance trips. Such a device will provide maximum

circuit protection.

WARNING

DO NOT EXCEED THE MAXIMUM OVERCURRENT

DEVICE SIZE SHOWN ON THE UNIT DATA PLATE.

All line voltage connections must be made through weather

proof fittings. All exterior power supply and ground wiring must

be in approved weather proof conduit. Low voltage wiring from

the unit control panel to the thermostat requires coded cable.

The unit transformer is connected for 230V operation. If the

unit is to operate on 208V, reconnect the transformer primary

lead as shown on the unit wiring diagram.

If it is necessary for the installer to supply additional line voltage wiring to the inside of the package unit, the wiring must

comply with all local codes. This wiring must have a minimum

temperature rating of 105°C. All line voltage splices must be

made inside the unit or heat kit control box.

15

Page 16

SYSTEM OPERATION *PH15[24-60]M41*

SYSTEM OPERATION

COOLING

The refrigerant used in the system is R-410A. It is a clear,

colorless, non-toxic and non-irritating liquid. R-410A is a 50:50

blend of R-32 and R-125. The boiling point at atmospheric

pressure is -62.9°F.

A few of the important principles that make the refrigeration

cycle possible are: heat always flows from a warmer to a

cooler body. Under lower pressure, a refrigerant will absorb

heat and vaporize at a low temperature. The vapors may be

drawn off and condensed at a higher pressure and temperature to be used again.

The indoor evaporator coil functions to cool and dehumidify

the air conditioned spaces through the evaporative process

taking place within the coil tubes.

Heat is continually being transferred to the cool fins and tubes

of the indoor evaporator coil by the warm system air. This

warming process causes the refrigerant to boil. The heat removed from the air is carried off by the vapor.

As the vapor passes through the last tubes of the coil, it

becomes superheated. That is, it absorbs more heat than is

necessary to vaporize it. This is assurance that only dry gas

will reach the compressor. Liquid reaching the compressor

can weaken or break compressor valves.

The compressor increases the pressure of the gas, thus adding more heat, and discharges hot, high pressure superheated

gas into the outdoor condenser coil.

In the condenser coil, the hot refrigerant gas, being warmer

than the outdoor air, first loses its superheat by heat transferred from the gas through the tubes and fins of the coil. The

refrigerant now becomes saturated, part liquid, part vapor and

then continues to give up heat until it condenses to a liquid

alone. Once the vapor is fully liquefied, it continues to give up

heat which subcools the liquid, and it is ready to repeat the

cycle.

HEATING

The heating portion of the refrigeration cycle is similar to the

cooling cycle. By de-energizing the reversing valve solenoid

coil, the flow of the refrigerant is reversed. The indoor coil

now becomes the condenser coil, and the outdoor coil becomes the evaporator coil.

The check valve in the TXV at the indoor coil will open by the

flow of refrigerant letting the now condensed liquid refrigerant

bypass the indoor expansion device. The check valve in the

TXV at the outdoor coil will be forced closed by the refrigerant

flow, thereby utilizing the outdoor expansion device.

COOLING CYCLE

On heat pump models, when the thermostat is switched to

cool, this completes a circuit from R to O energizing the

reversing valve solenoid. When the contacts of the room

thermostat close making terminals R to Y & G, the low voltage

circuit of the transformer is completed. Current now flows

through the magnetic holding coils of the compressor

contactor and fan motor for models with X13 motors and

Variable Speed Terminal Board (VSTB) for models with ECM

motors.

.

This draws in the normally open contact of the contactor,

starting the compressor and condenser fan motors. At the

same time, energizing the X13 motor for models so equipped

and energizing the VSTB for ECM equipped models, starting

the indoor fan motor.

When the thermostat is satisfied, it opens its contacts, breaking the low voltage circuit from R to Y & G, causing the compressor contactor to open, and de-energizing the indoor blower

motor, shutting down the system.

If the room thermostat fan selector switch should be set to

the "on" position, then the indoor blower would run continuous rather than cycling with the compressor.

APH and GPH models energize the reversing valve through

the "O" circuit in the room thermostat. Therefore, the reversing valve remains energized as long as the thermostat subbase is in the cooling position.

HEATING CYCLE

*PH15**M41* Heat Pump Units

On a call for first stage heat, the contacts of the room thermostat close. This energizes terminals R to Y and R to G,

the low voltage circuit to the contactor is completed starting

the compressor and outdoor fan motor. This also energizes

the indoor blower through the VSTB on delay on APH15 M

series units, and instantly on the GPH15 M series units with

the GE X13TM motor.

When the thermostat is satisfied, breaking the circuit between R to Y and R to G, the compressor and outdoor fan

motor will stop. The indoor blower will stop after the 60 second off delay on the APH15 M series units, and after the

programmed 60 second off delay on GPH15 M series units

with the GE X13TM motor. .

When auxiliary electric heaters are used, a two stage heating two stage cooling thermostat would be installed.

Should the second stage heating contacts in the room thermostat close, which would be wired to W1 at the unit low

voltage connections, this would energize the coil(s) of the

electric heat relay(s). Contacts within the relay(s) will close,

bringing on the electric resistance heaters.

If auxiliary electric heaters should be used, they may be controlled by outdoor thermostats (OT18-60A or OT/EHR18-60A).

Emergency Heat Mode (Heat Pumps)

NOTE: The following only applies if the unit has an approved

electric heat kit installed for auxiliary heating.

16

Page 17

SYSTEM OPERATION

*PH15[24-60]M41*

APH15 M Series ECM equipped models only:

With the thermostat set to the emergency heat position and

a call for 2nd stage heat, R to W1 will be energized. This will

energize the electric heat sequencers and also energize W1

on the Variable Speed Terminal Board to start the indoor

blower motor. When the normally open contacts of the heat

sequencers close, this will energize the electric resistance

heat.

GPH15 M Series X13 equipped models only:

With the thermostat set to the emergency heat position and

a call for 2nd stage heat, R to W1 will be energized. This will

energize the electric heat sequencers and the GE X13

motor. The electric heat will be energized through the normally open contacts of the electric heat sequencers. The

indoor blower will be energized through W from the thermostat.

DEFROST CYCLE

Package Heat Pumps

The defrosting of the outdoor coil is jointly controlled by the

defrost control board and the defrost thermostat.

Solid State Defrost Control

During operation the power to the circuit board is controlled

by a temperature sensor, which is clamped to a feeder tube

entering the outdoor coil. Defrost timing periods of 30, 60, or

90 minutes may be selected by connecting the circuit board

jumper to 30, 60, or 90 respectively. Accumulation of time for

the timing period selected starts when the sensor closes

(approximately 34° F), and when the room thermostat calls

for heat. At the end of the timing period, the unit’s defrost

cycle will be initiated provided the sensor remains closed.

When the sensor opens (approximately 60° F), the defrost

cycle is terminated and the timing period is reset. If the defrost cycle is not terminated due to the sensor temperature,

a ten minute override interrupts the unit’s defrost period.

TEST

90

60

30

JUMPE R WIRE

A

CY W2 R R DFT

DF2

DF1

FAN OPERATION

Continuous Fan Mode

GPH15 M Series X13 equipped models only:

If the thermostat calls for continuous fan, the indoor blower

will be energized from the G terminal of the thermostat to the

X13 blower motor.

If a call for heat or cool occurs during a continuous fan call,

TM

the GE X13

motor will always recognize the call for the

highest speed and ignore the lower speed call.

If the thermostat is not calling for heat or cool, and the fan

switch on the thermostat is returned to the automatic position, the fan will stop after the programmed 60 second off

delay on units with the GE X13

TM

TM

motor.

AIRFLOW ADJUSTMENTS FOR INDOOR

BLOWER MOTOR

APH15 M Series ECM equipped models only:

Dip switch 4 must be set to ON for APH1524- 36. Dip switch

4 must be set to OFF for 2-stage compressor models

APH1548-60. Dip switch 4 ON energizes Y1 signal to the

ECM motor anytime Y/Y2 is energized. The indoor motor

will not operate properly if switch is not set correctly for the

model.

ECM Motor

The ECM control board is factory set with the dip switch #4

in the “ON” position for single stage units and to the "OFF"

position for the 2 stage units. All other dip switches are factory set in the “OFF” position. For most applications, the

settings are to be changed according to the electric heat

size.

The ECM motor provides many features not available on the

traditional PSC motor. These features include:

• Improved Efficiency

• Constant CFM

• Soft Start and Stop

• Improved Humidity Control

Motor Speed Adjustment

Each ECM blower motor has been preprogrammed for operation at 4 distinct airflow levels when operating in Cooling/

Heat Pump mode or Electric Heat mode. These 4 distinct

levels may also be adjusted slightly lower or higher if desired. The adjustment between levels and the trim adjustments are made by changing the dip switch(s) either to an

"OFF" or "ON" position.

APH15 M Series ECM equipped models only:

If the thermostat calls for continuous fan, the indoor blower

will be energized through the VSTB at 30% of selected second stage cooling speed on APH15 units.

If the thermostat is not calling for heat or cool, and the fan

switch on the thermostat is returned to the automatic position, the fan will stop after a 60 second delay on APH15

units.

Dip Switch Functions

The ECM motor has an electronic control that contains eight

(8) 2-position dip switches. The function of these dip switches

is shown in Table 1.

17

Page 18

SYSTEM OPERATION

A

Dip Switch Number Function

1

2

3N/A

4 Indoor Thermostat

5

6

7

8

Table 1

Electric Heat

Cooling & Heat Pump CFM

CFM Trim Adjust

CFM Delivery

Tables 2 and 4 show the CFM output for dip switch combinations 1-2 (Electric Heat), and 5-6 (Cooling/Heating).

Tables 3 shows the dip switch settings for 1 and 2-stage

thermostats.

Model Switch 1 Switch 2 Electric Heat CFM

(F)

1050

APH1524

OFF OFF

ON OFF 950

OFF ON 825

ON ON 700

(F)

1250

APH1536

OFF OFF

ON OFF 1100

OFF ON 1000

ON ON 800

(F)

1800

APH1548

OFF OFF

ON OFF 1700

OFF ON 1400

ON ON 1225

(F)

2000

APH1560

OFF OFF

ON OFF 1800

OFF ON 1600

ON ON 1400

(F)

Factory

Table 2

Model Switch 3 Switch 4 Thermostat

APH15**

N/A ON 1-Stage

N/

OFF 2-Stage

Table 3

Model Switch 5 Switch 6 Cooling/HP CFM

(F)

1050

APH1524

OFF OFF

ON OFF 950

OFF ON 825

ON ON 700

(F)

1250

APH1536

OFF OFF

ON OFF 1100

OFF ON 1000

ON ON 800

(F)

1800

APH1548

OFF OFF

ON OFF 1700

OFF ON 1400

ON ON 1225

(F)

2000

APH1560

OFF OFF

ON OFF 1800

OFF ON 1600

ON ON 1400

(F)

Factory

Table 4

Thermostat “Fan Only” Mode

During Fan Only Operations, the CFM output is 30% of the

high stage cooling setting.

CFM Trim Adjust

Minor adjustments can be made through the dip switch combination of 7-8. Table 5 shows the switch position for this

feature.

NOTE: The airflow will not make the decreasing adjustment

in Electric Heat mode.

CFM Switch 7 Switch 8

+10% ON OFF

Normal OFF OFF

-15% OFF ON

Table 5

Humidity Control

When using a Humidistat (normally closed), cut jumper PJ6

on the control board. The Humidistat will only affect both low

stage and high stage cooling airflow by adjusting the Airflow

to 85%.

18

Two Stage Heating

When using staged electric heat, cut jumper PJ4 on the control board.

Thermostat Wiring

Use thermostat wiring diagrams provided with the thermostat

when making these connections.

See Specification Sheet for APH model series for CFM vs

ESP tables.

Page 19

SYSTEM OPERATION

Typical Heat Pump System in Cooling

Reversing Valve

(Energized)

Indoor

Coil

Accumulator

Typical Heat Pump System in Heating

Outdoor

Coil

Indoor

Coil

Accumulator

Reversing Valve

(De-Energized)

Outdoor

Coil

19

Page 20

SCHEDULED MAINTENANCE

Package heat pumps require regularly scheduled maintenance to preserve high performance standards, prolong the

service life of the equipment, and lessen the chances of costly

failure.

In many instances the owner may be able to perform some

of the maintenance; however, the advantage of a service contract, which places all maintenance in the hands of a trained

serviceman, should be pointed out to the owner.

WARNING

ONCE A MONTH

1. Inspect the return filters of the evaporator unit and clean

or change if necessary. NOTE: Depending on operation

conditions, it may be necessary to clean or replace the

filters more often. If permanent type filters are used, they

should be washed with warm water and dried.

2. When operating on the cooling cycle, inspect the condensate line piping from the evaporator coil. Make sure

the piping is clear for proper condensate flow.

ONCE A YEAR

Qualified Service Personnel Only

1. Clean the indoor and outdoor coils.

2. Clean the cabinet inside and out .

3. Motors are permanently lubricated and do not require oiling. TO AVOID PREMATURE MOTOR FAILURE, DO NOT

OIL.

4. Manually rotate the outdoor fan and indoor blower to be

sure they run freely.

5. Inspect the control panel wiring, compressor connections,

and all other component wiring to be sure all connections are tight. Inspect wire insulation to be certain that

it is good.

6. Check the contacts of the compressor contactor. If

they are burned or pitted, replace the contactor.

7. Using a halide or electronic leak detector, check all

piping and etc. for refrigerant leaks.

TEST EQUIPMENT

Proper test equipment for accurate diagnosis is as essential as regular hand tools.

The following is a must for every service technician and

service shop:

1. Thermocouple type temperature meter - measure dry

bulb temperature.

2. Sling psychrometer- measure relative humidity and wet

bulb temperature.

3. Amprobe - measure current.

4. Volt-Ohm Meter - testing continuity, capacitors, motor

windings and voltage.

5. Accurate Leak Detector - testing for refrigerant leaks.

6. High Vacuum Pump - evacuation.

7. Electric Vacuum Gauge, Manifold Gauges and high

vacuum hoses - to measure and obtain proper vacuum.

8. Accurate Charging Cylinder or Electronic Scale - measure proper refrigerant charge.

9. Inclined Manometer - measure static pressure and pressure drop across coils.

Other recording type instruments can be essential in solving abnormal problems, however, in many instances they

may be rented from local sources.

Proper equipment promotes faster, more efficient service,

and accurate repairs with less call backs.

20

Page 21

SERVICING

SERVICING

COOLING /HEAT PUMP- SERVICE ANALYSIS GUIDE

Complaint

No Cooling

Unsatisfact ory Cooling/ Heating

System Opera ting

Pressures

POSSIBLE CAUSE

DOTS IN ANALYSIS GUIDE

INDICATE SYMPTOM

"POSSIBLE CAUSE"

Pow er Failure

Blow n Fuse

Unbalanced Pow er, 3PH

Loose Connection

Shorted or Br oken Wires

Open Fan Overloa d

Faulty Thermos tat

Faulty Transfor mer

Shorted or O pen Capacitor

Internal Compres sor Overload Open

Shorted or G rounded Compressor

Compressor Stuck

Faulty Compres sor Contactor

Compressor High Stage Not W orking

Open Control Cir cuit

Low Voltage

Faulty Evap. Fan Motor

Shorted or G rounded Fan Motor

Improper Cooling Anticipator

Shortage of Refrigerant

Restrict ed Liquid Line

Open Element or Limit on Elec. Heater

Dirty Air Filter

Dirty Indoor Co il

Not enough air acros s Indoor Coil

Too much air acr oss Indoor Coil

Overcharg e of Refrigerant

Dirty Outdoor Coil

Noncondensibles

Recirculation of Condensing Air

Infiltration of Outdoor Air

Improperl y Loc ated Thermostat

Air Flow Unbalanced

System Unders ized

Broken Internal Par ts

Broken Valves

Inefficient Compressor

Loose Hold-dow n B olts

Faulty Reversing Valve

Faulty Defrost Control

Faulty Defrost Thermostat

Flow rator Not Seating Properly

System will not start

Compressor will not start -fan runs

•

• •

•

•

• • • • • •

• • •

• •

•

♦

•

•

•

•

Condenser fan will not start

Evaporator fan will not start

Comp. and Cond. Fan will not start

Compressor runs - goes off on overload

Compressor cycles on overload

Too cool and then too warm

System runs continuously - little cooling/htg

• •

•

•

• •

•

• • •

• •

•

♦

• •

• •

•

•

•

•

• •

•

• •

• •

•

♦

Compressor is noisy

Not cool enough on warm days

System runs -blows cold air in heating

Certain areas too cool, others too warm

♦

Unit will not defrost

Unit will not terminate defrost

Low suction pressure

•

• •

• •

Low head pressure

High suction pressure

♦

High head pressure

•

•

♦ ♦

• • •

• • •

• • •

• •

• •

•

•

•

• • •

•

• •

• •

•

♦

•

♦♦♦ ♦♦♦

•

♦♦♦ ♦ ♦ ♦

•

♦

•

♦

•

♦

•

♦

•

•

•

•

•

♦

♦

♦

•

• •

•

•

•

♦

•

•

•

• •

• •

♦♦♦ ♦ ♦♦♦

•

• •

Test Method Remedy

Test Voltage

Inspect Fuse Size & Type

Test Voltage

Inspect Connect ion - Tighten

Test Circuits With Ohmmeter

Test Continuity of Ove rload

Test continuity of Thermostat & Wiring

Check control ci rcuit w ith voltmeter

Test Capacitor

Test Continuity of Ove rload

Test Motor Windings

Use Test Cord

Tes t cont inuity of Coi l & Contact s

Test Voltage to Unloader Plug, Test Pl ug S-17C

Test Control Circuit w ith Voltmeter

Test Voltage

Repair or Rep lace

Test Motor Windings

Check resi stance of Anticipator

Test For Leak s, Add Refrigerant

Remove Restriction, Replace Restricted Part S-112

Test Heater Element and Controls

Inspect Filt er-Clean or Replace

Inspect Coil - Clean

Check Blow er Speed, Duc t Static Pre ss, Filter S-200

Reduce Blow er Speed

Recover Part of Charge

Inspect Coil - Clean

Recover C harg e, Evacuate, Recharg e

Remove Obstruction to Air Flow

Check Window s, Doors, Vent Fans, Etc.

Relocate Therm ostat

Readjust Air Volume Dampers

Refigure Cooling Lo ad

Replace Com pressor

Test Compressor Efficiency

Test Compressor Efficiency

Tighten Bolts

Replace Valve or Solenoid

Test Contro l

Test Defr ost Thermos tat

Check Flow rator & Seat or Replace Flow rat or S-111

S-1

S-1

S-1

S-2, S-3

S-2, S-3

S-17A

S-3

S-4

S-15

S-17A

S-17B

S-17D

S-7, S-8

S-4, S-11, S- 12

S-1

S-16

S-16A,D

S-3B

S-101,103

S-26,S-27

S-200

S-113

S-114

S-115

S-104

S-104

S-21, 122

S-24

S-25

See Service Procedure Ref.

•

Cooling or Heating Cycle (Heat Pump)

♦

Heating Cycle Only (Heat Pump)

21

Page 22

SERVICING

S-1 CHECKING VOLTAGE

WARNING

1. Remove doors, control panel cover, etc. from unit being

tested.

With power ON:

WARNING

LINE VOLTAGE NOW PRESENT.

2. Using a voltmeter, measure the voltage across terminals

L1 and L2 of the contactor for single phase units, and L3,

for 3 phase units.

3. No reading - indicates open wiring, open fuse(s) no power

or etc. from unit to fused disconnect service. Repair as

needed.

4. With ample voltage at line voltage connectors, energize

the unit.

5. Measure the voltage with the unit starting and operating,

and determine the unit Locked Rotor Voltage.

Locked Rotor Voltage is the actual voltage available at

the compressor during starting, locked rotor, or a stalled

condition. Measured voltage should be above minimum

listed in chart below.

To measure Locked Rotor Voltage attach a voltmeter to

the run "R" and common "C" terminals of the compressor, or to the T1 and T2 terminals of the contactor. Start

the unit and allow the compressor to run for several seconds, then shut down the unit. Immediately attempt to

restart the unit while measuring the Locked Rotor Voltage.

6. Should read within the voltage tabulation as shown. If

the voltage falls below the minimum voltage, check the

line wire size. Long runs of undersized wire can cause

low voltage. If wire size is adequate, notify the local

power company in regards to either low or high voltage.

Unit Supply Voltage

Voltage Min. Max.

460 437 506

208/230 198 253

Three phase units require a balanced 3 phase power supply to

operate. If the percentage of voltage imbalance exceeds 3%

the unit must not be operated until the voltage condition is

corrected.

Max. Voltage Deviation

% Voltage =

Imbalance Average Voltage

To find the percentage of imbalance, measure the incoming

power supply.

L1 - L2 = 240V

L1 - L3 = 232V Avg. V = 710 = 236.7

L2 - L3 = 238V 3

Total 710V

To find Max. deviation: 240 - 236.7 = +3.3

Max deviation was 4.7V

% Voltage Imbalance = 4.7 = 1.99%

If the percentage of imbalance had exceeded 3%, it must be

determined if the imbalance is in the incoming power supply or

the equipment. To do this rotate the legs of the incoming

power and retest voltage as shown below.

L1

L1

By the voltage readings we see that the imbalance rotated or

traveled with the switching of the incoming legs. Therefore the

power lies within the incoming power supply.

If the imbalance had not changed then the problem would lie

within the equipment. Check for current leakage, shorted motors, etc.

From Average Voltage X 100

232 - 236.7 = -4.7

238 - 236.7 = +1.3

236.7

L1 - L2 = 240V

L1 - L3 = 227V

L2 - L3 = 238V

L2

L3

L3L2

Rotate all 3 incoming

legs as shown.

L1 - L2 = 227V

L1 - L3 = 238V

L2 - L3 = 240V

22

Page 23

SERVICING

S-2 CHECKING WIRING

WARNING

1. Check wiring visually for signs of overheating, damaged

insulation and loose connections.

2. Use an ohmmeter to check continuity of any suspected

open wires.

3. If any wires must be replaced, replace with comparable

gauge and insulation thickness.

S-3 CHECKING THERMOSTAT, WIRING, AND

ANTICIPATOR

S-3A THERMOSTAT AND WIRING

WARNING

LINE VOLTAGE NOW PRESENT.

With power ON and thermostat calling for cooling.

1. Use a voltmeter to verify 24 volts present at thermostat

wires C and R.

2. If no voltage present, check transformer and transformer

wiring. If 24 volts present, proceed to step 3.

3. Use a voltmeter to check for 24 volts at thermostat wires C

and Y.

4. No voltage indicates trouble in the thermostat, wiring or

external transformer source.

5. Check the continuity of the thermostat and wiring. Repair

or replace as necessary.

5. No voltage, indicates the trouble is in the thermostat or

wiring.

6. Check the continuity of the thermostat and wiring. Repair

or replace as necessary.

S-3B COOLING ANTICIPATOR

The cooling anticipator is a small heater (resistor) in the thermostat. During the "off" cycle it heats the bimetal element

helping the thermostat call for the next cooling cycle. This

prevents the room temperature from rising too high before the

system is restarted. A properly sized anticipator should maintain room temperature within 1 1/2 to 2 degree range.

The anticipator is supplied in the thermostat and is not to be

replaced. If the anticipator should fail for any reason, the thermostat must be changed.

S-3C HEATING ANTICIPATOR

The heating anticipator is a wire-wound adjustable heater, which

is energized during the "ON" cycle to help prevent overheating

of the conditioned space.

The anticipator is a part of the thermostat and if it should fail for

any reason, the thermostat must be replaced. See the following for recommended heater anticipator setting.

To determine the proper setting, use an amp meter to measure

the amperage on the "W" wire going to the thermostat.

Use an amprobe as shown below. Wrap 10 turns of thermostat

wire around the stationary jaw of the amprobe and divide the

reading by 10.

10 TURNS OF

THERMOSTAT WIRE

(From "W" on thermostat)

STATIONARY JAW

OF AMPROBE

Indoor Blower Motor

With power ON:

WARNING

LINE VOLTAGE NOW PRESENT.

1. Use a voltmeter to verify 24 volts present at thermostat

wires C and R.

2. If no voltage present, check transformer and transformer

wiring. If 24 volts present, proceed to step 3.

3. Set fan selector switch at thermostat to "ON" position.

4. With voltmeter, check for 24 volts at wires C and G.

READS 4 AMPS

CURRENT DRAW

WOULD BE .4 AMPS

Checking Heat Anticipator Amp Draw

23

Page 24

SERVICING

S-4 CHECKING TRANSFORMER AND

CONTROL CIRCUIT

A step-down transformer (208/240 volt primary to 24 volt secondary) is provided with each package unit. This allows ample

capacity for use with resistance heaters.

WARNING

1. Remove control panel cover or etc. to gain access to transformer.

With power ON:

WARNING

LINE VOLTAGE NOW PRESENT.

2. Using a voltmeter, check voltage across secondary voltage

side of transformer (R to C).

3. No voltage indicates faulty transformer, bad wiring, or bad

splices.

4. Check transformer primary voltage at incoming line voltage

connections and/or splices.

5 If line voltage is present at the primary voltage side of the

transformer and 24 volts is not present on the secondary

side, then the transformer is inoperative. Replace.

S-7 CHECKING CONTACTOR AND/OR

RELAYS

The compressor contactor and other relay holding coils are

wired into the low or line voltage circuits. When the control

circuit is energized the coil pulls in the normally open contacts

or opens the normally closed contacts. When the coil is deenergized, springs return the contacts to their normal position.

WARNING

DISCONNECT POWER SUPPLY BEFORE SERVICING.

S-8 CHECKING CONTACTOR CONTACTS

WARNING

DISCONNECT POWER SUPPLY BEFORE SERVICING.

SINGLE PHASE

1. Disconnect the wire leads from the terminal (T) side of the

contactor.

2. With power ON, energize the contactor.

WARNING

LINE VOLTAGE NOW PRESENT.

T2

VOLT/OHM

METER

Ohmmeter for testing holding coil

Voltmeter for testing contacts

TESTING COMPRESSOR CONTACTOR

(Single Phase)

3. Using a voltmeter, test across terminals.

A. L1 to L2 - No voltage. Check breaker or fuses on main

power supply. If voltage present, proceed to step B.

B. T1 to T2 - Meter should read the same as L1 to L2 in

step A. If voltage readings are not the same as step A,

replace contactor.

THREE PHASE

Using a voltmeter, test across terminals:

A. L1-L2, L1-L3, and L2-L3 - If voltage is present, pro-

ceed to B. If voltage is not present, check breaker or

fuses on main power supply..

B. T1-T2, T1-T3, and T2-T3 - If voltage readings are not

the same as in "A", replace contactor.

T1

CC

L1L2

1. Remove the leads from the holding coil.

2. Using an ohmmeter, test across the coil terminals.

If the coil does not test continuous, replace the relay or contactor.

24

Page 25

SERVICING

L2

T1

L1

T3L3T2

CC

VOLT/OHM

METER

Ohmmeter for testing holding coil

Voltmeter for testing contacts

TESTING COMPRESSOR CONTACTOR

(Three-phase)

S-11 CHECKING LOSS OF CHARGE

PROTECTOR

(Heat Pump Models)

The loss of charge protector senses the pressure in the liquid

line and will open its contacts on a drop in pressure. The low

pressure control will automatically reset itself with a rise in

pressure.

The low pressure control is designed to cut-out (open) at approximately 50 PSIG. It will automatically cut-in (close) at

approximately 95 PSIG.

Test for continuity using a VOM and if not as above, replace

the control.

S-12 CHECKING HIGH PRESSURE CONTROL

WARNING

4. Start the system and place a piece of cardboard in front of

the condenser coil, raising the condensing pressure.

5. Check pressure at which the high pressure control cutsout.

If it cuts-out at 610 PSIG ± 10 PSIG, it is operating normally

(See causes for high head pressure in Service Problem Analysis Guide). If it cuts out below this pressure range, replace the

control.

S-15 CHECKING CAPACITOR

CAPACITOR, RUN

A run capacitor is wired across the auxiliary and main windings of a single phase permanent split capacitor motor. The

capacitors primary function is to reduce the line current while

greatly improving the torque characteristics of a motor. This is

accomplished by using the 90° phase relationship between

the capacitor current and voltage in conjunction with the motor

windings so that the motor will give two phase operation when

connected to a single phase circuit. The capacitor also reduces the line current to the motor by improving the power

factor.

CAPACITOR, START

SCROLL COMPRESSOR MODELS

Hard start components are not required on Scroll compressor

equipped units due to a non-replaceable check valve located in

the discharge line of the compressor. However hard start kits

are available and may improve low voltage starting characteristics. Only hard start kits approved by Goodman

should be used. "Kick Start" and/or "Super Boost" kits are not

approved start assist devices.

This check valve closes off high side pressure to the compressor after shut down allowing equalization through the scroll

flanks. Equalization requires only about one or two seconds

during which time the compressor may turn backwards.

®

or Copeland

The high pressure control capillary senses the pressure in the

compressor discharge line. If abnormally high condensing pressures develop, the contacts of the control open, breaking the

control circuit before the compressor motor overloads. This

control is automatically reset.

1. Using an ohmmeter, check across terminals of high pressure control, with wire removed. If not continuous, the contacts are open.

3. Attach a gauge to the dill valve port on the base valve.

With power ON:

WARNING

LINE VOLTAGE NOW PRESENT.

MODELS EQUIPPED WITH A HARD START DEVICE

A start capacitor is wired in parallel with the run capacitor to

increase the starting torque. The start capacitor is of the electrolytic type, rather than metallized polypropylene as used in

the run capacitor.

A switching device must be wired in series with the capacitor

to remove it from the electrical circuit after the compressor

starts to run. Not removing the start capacitor will overheat the

capacitor and burn out the compressor windings.

25

Page 26

SERVICING

These capacitors have a 15,000 ohm, 2 watt resistor wired

across its terminals. The object of the resistor is to discharge

the capacitor under certain operating conditions, rather than

having it discharge across the closing of the contacts within

the switching device such as the Start Relay, and to reduce

the chance of shock to the servicer. See the Servicing Section

for specific information concerning capacitors.

RELAY, START

A potential or voltage type relay is used to take the start capacitor out of the circuit once the motor comes up to speed.

This type of relay is position sensitive. The normally closed

contacts are wired in series with the start capacitor and the

relay holding coil is wired parallel with the start winding. As

the motor starts and comes up to speed, the increase in voltage across the start winding will energize the start relay holding coil and open the contacts to the start capacitor.

Two quick ways to test a capacitor are a resistance and a

capacitance check.

S-15A RESISTANCE CHECK

WARNING

2. Set an ohmmeter on its highest ohm scale and connect

the leads to the capacitor -

A. Good Condition - indicator swings to zero and slowly

returns to infinity. (Start capacitor will bleed resistor will

not return to infinity. It will still read the resistance of the

resistor).

B. Shorted - indicator swings to zero and stops there replace.

C. Open - no reading - replace. (Start capacitor would read

resistor resistance).

S-15B CAPACITANCE CHECK

WARNING

DISCHARGE CAPACITOR THROUGH A 20 TO 30 OHM

RESISTOR BEFORE HANDLING.

Using a hookup as shown below, take the amperage and voltage readings and use them in the formula:

Capacitance (MFD) = 2650 X Amperage

Voltage

1. Discharge capacitor and remove wire leads.

WARNING

DISCHARGE CAPACITOR THROUGH A 20 TO 30 OHM

RESISTOR BEFORE HANDLING.

Volt / Ohm

Meter

r

Capacito

Volt / Ohm

Meter

15 AMP FUSE

AMMETER

TESTING CAPACITANCE

TESTING CAPACITOR RESISTANCE

26

Page 27

SERVICING

A

S-16 CHECKING MOTORS

S-16B CHECKING FAN AND BLOWER MOTOR

(ECM MOTORS)

APH15 M Series Only

An ECM is an Electronically Commutated Motor which offers

many significant advantages over PSC motors. The ECM has

near zero rotor loss, synchronous machine operation, variable

speed, low noise, and programmable air flow. Because of the

sophisticated electronics within the ECM motor, some technicians are intimated by the ECM motor; however, these fears

are unfounded. GE offers two ECM motor testers, and with a

VOM meter, one can easily perform basic troubleshooting on

ECM motors. An ECM motor requires power (line voltage) and

a signal (24 volts) to operate. The ECM motor stator contains

permanent magnet. As a result, the shaft feels "rough" when

turned by hand. This is a characteristic of the motor, not an

indication of defective bearings.

1

2

3

4

5

OUT - OUT +

DJUST +/-

Y1 Y/Y2

COOL

Lines 1 and 2 will be connected

for 12OVAC Power Connector

}

applications only

Gnd

AC Line Connection

AC Line Connection

816

7

15

6

14

5

13

G (FAN)

EM Ht/W2

WARNING

4

12

LINE VOLTAGE NOW PRESENT.

1. Disconnect the 5-pin connector from the motor.

2. Using a volt meter, check for line voltage at terminals #4 &

#5 at the power connector. If no voltage is present:

3. Check the unit for incoming power See section S-1.

4. If line voltage is present, reinsert the 5-pin connector and

remove the 16-pin connector.

5. Check for signal (24 volts) at the transformer.

6. Check for signal (24 volts) from the thermostat to the "G"

terminal at the 16-pin connector.

7. Using an ohmmeter, check for continuity from the #1 & #3

If you do not read voltage and continuity as described, the

problem is in the control or interface board, but not the motor.

If you register voltage as described , the ECM power head is

defective and must be replaced.

DELAY

COMMON2

W/W1

COMMON1 O (REV VALVE)

3

2

19

16-PIN ECM HARNESS CONNECTOR

(common pins) to the transformer neutral or "C" thermostat

terminal. If you do not have continuity, the motor may function erratically. Trace the common circuits, locate and repair the open neutral.

8. Set the thermostat to "Fan-On". Using a voltmeter, check

for 24 volts between pin # 15 (G) and common.

9. Disconnect power to compressor. Set thermostat to call

for cooling. Using a voltmeter, check for 24 volts at pin # 6

and/or #14.

10. Set the thermostat to a call for heating. Using a voltmeter,

check for 24 volts at pin #2 and/or #11.

24 Vac (R)

11

10

HEAT

BK/PWM (SPEED)

27

Page 28

SERVICING

(

y

)

g

I

d

t

d

i

l

gg

d?

Ch

k

f

l

i

fl

(t

h

l

t

t

ity)

Check

for

undercharged

condition

Check

and

plug

leaks

in

return

ducts

cabinet

t

t

N

t

U

i

g

th

g

t

/

t

l

d

l

id

ll

d

t

ti

d

y

d

t

d

lt

y

y

g

g

g

y

y

y

different

have completel

- Turn power OFF prior to repair.

Wait 5 minutes after

disconnecting power before

opening motor.

- Handle electronic motor/control with care.

- Check 230 Vac power at motor.

- Check low voltage (24 Vac R to C) at motor.

- Check low voltage connections

(G, Y, W, R, C) at motor.

- Check for unseated pins in connectors

on motor harness.

Troubleshooting Chart for ECM Variable Speed Air Circulator Blower Motors

28

---- ---- ----

- Manual disconnect switch off or

door switch open.

- Blown fuse or circuit breaker.

- 24 Vac wires miswired.

- Unseated pins in wiring

harness connectors.

- This is normal start-up for

variable speed motor.

- No movement.

Symptom Fault Description(s) Possible Causes Corrective Action Cautions and Notes

- Motor rocks

slightly

when starting.

- Motor won't

- Turn power OFF prior to repair.

- Test with a temporary jumper between R - G.

- Bad motor/control module.

- Moisture present in motor or control module.

start.

Wait 5 minutes after

disconnecting power before

opening motor.

- Handle electronic motor/control with care.

- Check for loose motor mount.

- Make sure blower wheel is tight on shaft.

- Perform motor/control replacement check,

ECM motors only.

- Check line voltage for variation or "sag".

- Turn power OFF prior to repair.

- Check low voltage connections

(G, Y, W, R, C) at

motor, unseated pins in motor

harness connectors.

- Check-out system controls - Thermostat.

- Perform Moisture Check.*

---- ---- ----

- Variation in 230 Vac to motor.

- Unseated pins in wiring harness

connectors.

- Erratic CFM command from

"BK" terminal.

- Improper thermostat connection or setting.

- Loose motor mount.

- Motor rocks,

- Blower wheel not tight on motor shaft.

- Bad motor/control module.

- It is normal for motor to

oscillate with

but won't start.

- Motor

no load on shaft.

oscillates up &

down while

being tested

off of blower.

- Varies up and down

- Moisture present in motor/control module.

or intermittent.

- Motor starts,

but runs

erratically.

- Turn power OFF prior to repair.

.

.

capac

look alike, different modules ma

,

en

a

h the

oo muc

ow

r

modes. Even thou

ow a

or

e harnesses with "drip loop" under motor.

ec

-

- Does removing panel or filter

reduce "puffing"?

- Check/replace filter.

- Check/correct duct restrictions.

- Adjust to correct blower speed setting.

.- Arran

- Incorrect or dirty filter(s).

- Incorrect supply or return ductwork.

- Incorrect blower speed setting.

- "Hunts" or "puffs" at