Page 1

Service Instructions

®

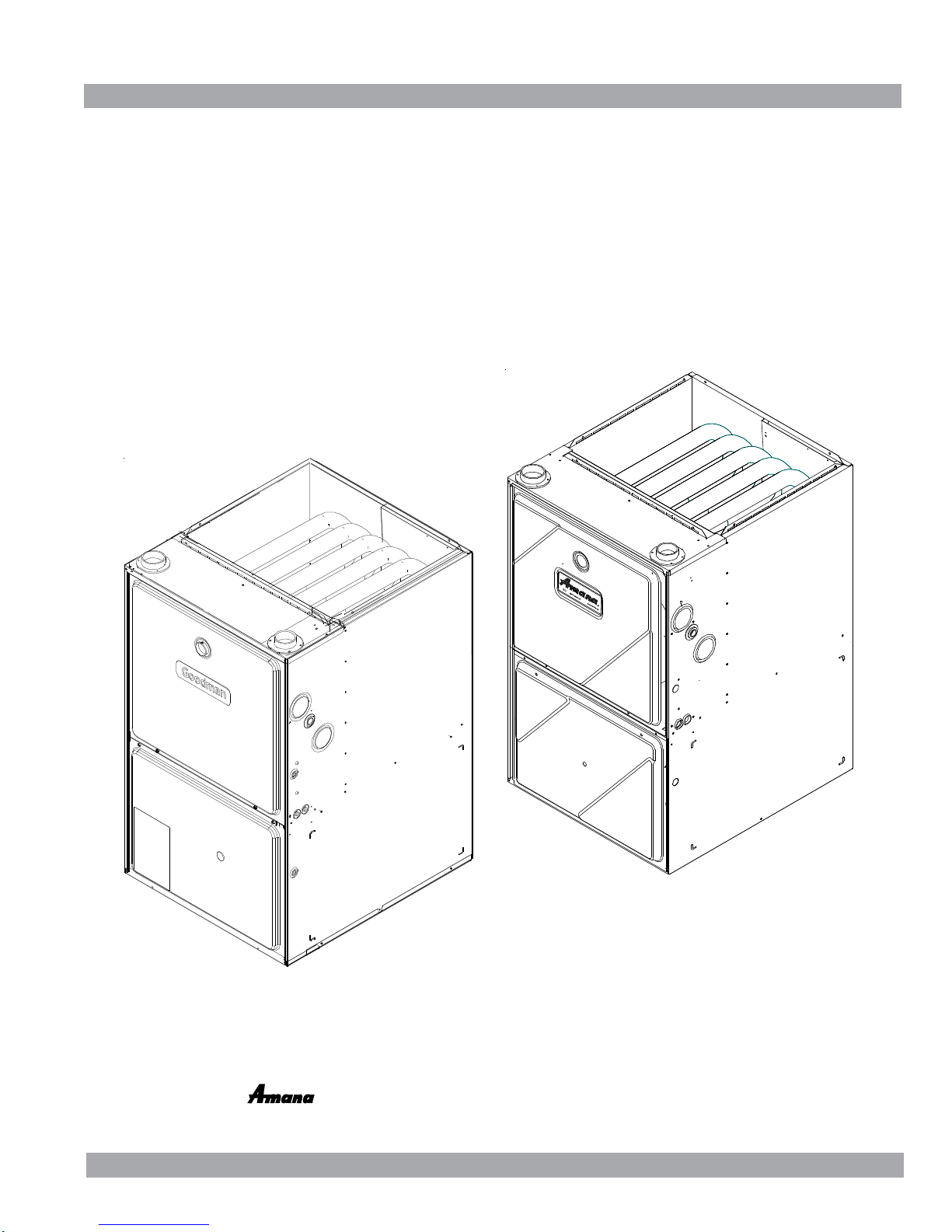

Goodman® Brand GMEC96/GCEC96

& Amana

Two Stage Furnace

with multi-speed ECM Motor

®

Brand AMEC96/ACEC96

This manual is to be used by qualified, professionally trained HVAC technicians only. Goodman does not

assume any responsibility for property damage or personal injury due to improper service procedures or

services performed by an unqualified person. The material in this manual does not supercede manufacturers

installation and operation instructions.

is used under license to Goodman Company, L.P., Houston, TX, USA. All rights reserved.

is a registered trademark of Maytag Corporation or its related companies and

RS6612013r7

November 2017

Copyright© 2014 - 2017 Goodman Company, L.P.

Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION ...............................3

PRODUCT IDENTIFICATION ..............................5

FURNACE SPECIFICATIONS...............................9

OPERATION INSTRUCTIONS............................10

SYSTEM OPERATION. .....................................11

ACCESSORIES.................................................44

SERVICING TABLE OF CONTENTS..................48

SERVICING ........................................................49

MAINTENANCE ..................................................66

WIRING DIAGRAMS ....................................70 -72

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE

SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

O

NLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL, ADJUST, SERVICE OR

REPAIR (HEREINAFTER

MANUAL SHOULD SERVICE THE EQUIPMENT

BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM

IMPROPER SERVICE OR SERVICE PROCEDURES

ASSUME RESPONSIBILITY FOR ANY INJURY OR PROPERTY DAMAGE WHICH MAY

RESULT

. IN

LICENSES TO SERVICE THE EQUIPMENT SPECIFIED IN THIS MANUAL, ONLY

LICENSED PERSONNEL SHOULD SERVICE THE EQUIPMENT

INSTALLATION, ADJUSTMENT, SERVICING OR REPAIR OF THE EQUIPMENT

SPECIFIED IN THIS MANUAL, OR ATTEMPTING TO INSTALL, ADJUST, SERVICE OR

REPAIR THE EQUIPMENT SPECIFIED IN THIS MANUAL WITHOUT PROPER

TRAINING MAY RESULT IN PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH

, “

SERVICE

”)

THE EQUIPMENT SPECIFIED IN THIS

. THE

MANUFACTURER WILL NOT

. IF

YOU SERVICE THIS UNIT, YOU

ADDITION, IN JURISDICTIONS THAT REQUIRE ONE OR MORE

. I

MPROPER

.

WARNING

HIGH VOLTAGE

D

ISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLI NG T HIS UNIT.

BE PRESENT .

DAMAGE, PE RSONAL INJUR Y OR DEATH.

FAILU RE TO DO SO MAY CAUSE P ROPERTY

MULTIPLE P OWER SOURCE S MAY

2

Page 3

IMPORTANT INFORMATION

CO can cause serious illness inc luding permanent brain

damag e or death.

B10259-216

Advertencia especial para la instalación de calentadores ó manejadoras

de aire en áreas cerradas como estacionamientos ó cuartos de servicio.

Las emis iones de monóxido de carbono puede n circular a través

del apa rat o cuando se opera en c ualquier modo.

El monóx ido de carbono puede caus ar enfermedade s se veras

como daño cerebr al permanente ó muerte.

B10259-216

RISQUE D'EMPO ISONNEMENT AU

Cette ventilation est nécessaire pour éviter le danger d'intoxication

au CO pouvant survenir si un appareil produisant du monoxyde

de carb one continue de fonc tionner au sein de la zone confinée.

Le monoxyde de

des

carbone peut causer des maladies graves telles que

dommages permanents au cerveau et mem e la mort.

MONOXYDE DE CARBONE

B10259-216

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER INFORMATION LINE

GOODMAN® BRAND PRODUCTS

TOLL FREE

1-877-254-4729 (U.S. only)

email us at:

customerservice@goodmanmfg.com

fax us at: (731) 856-1821

(Not a technical assistance line for dealers.)

CONSUMER INFORMATION LINE

AMANA® BRAND PRODUCTS

TOLL FREE

1-877-254-4729 (U.S. only)

email us at:

hac.consumer.affairs@amanahvac.com

fax us at: (731) 856-1821

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500.

(Not a technical assistance line for dealers.) Your telephone company will bill you for the call.

3

Page 4

IMPORTANT INFORMATION

A

A

A

A

D

G

N

I

RIVEE

R

U

GAS

I

N

ARRIVE

D

U

S

A

T

L

E

G

Z

A

MAN

A

L

U

G

A

L

E

N

I

E

T

L

E

G

A

Z

MANUA

E

L

R

V

E

O

I

N

N"

"

S

OW

V

"

R

M

"O

L

S

N

E

R

S

H

P

O

O

N

"

S

ARRIVE

O

B

I

T

N

E

A

Z

G

A

P

A

L

,

N

P

N

U

O

S

E

E

E

N

ARC

H

"

M

/

A

S

G

W

N

H

O

O

S

D

A

R

D

MAN

L

IN "

G

A

S

N

I

T

L

E

E

U

G

A

Z

G

A

S

E

I

T

N

L

V

E

E

R

I

G

U

Z

A

MANUA

LE

VER

I

N

N"

"

O

S

U

A

L

G

W

E

V

R

M

"O

N

R

E

H

S

O

O

S

P

O

N

"

A

N

B

I

T

O

A

N

N

L

G

H

S

P

O

Z

E

G

A

P

E

L

E

N

O

S

,

U

RCH

"

/

M

E

S

W

N

O

S

4

Page 5

PRODUCT IDENTIFICATION

The model and manufacturing number are used for positive identification of component parts used in manufacturing.

Please use these numbers when requesting service or parts information.

* M E C 96 60 3 B N A A

12345,67,8,91011121314

Brand Minor Revision

A - Amana

G - Goodman

Configuration Major Revision

M - U p flo w / Ho rizontal A - Initial Release

C - Down flow / Hori zontal B - 1st Revision

Motor NOx

V - V ariab l e Spee d ECM / ComfortNet N - Low NOx

E - M ulti-Speed ECM

S - Single Speed Cabinet Width

Gas Valve B - 17.5"

M - Modulating C - 21"

C - 2 Stage D - 24.5"

S - Single Stage

AFUE 2 - 800 CFM

96 - 96% AFUE 3 - 1200 CFM

92 - 92% AFUE 4 - 1600 CFM

MBTU/h

040 - 40,000 BTU/h

060 - 60,000 BTU/h

® Brand A - Initial Release

® Brand B - 1st Revision

A - 14"

Maximum CFM

5 - 2000 CFM

5

Page 6

PRODUCT IDENTIFICATION

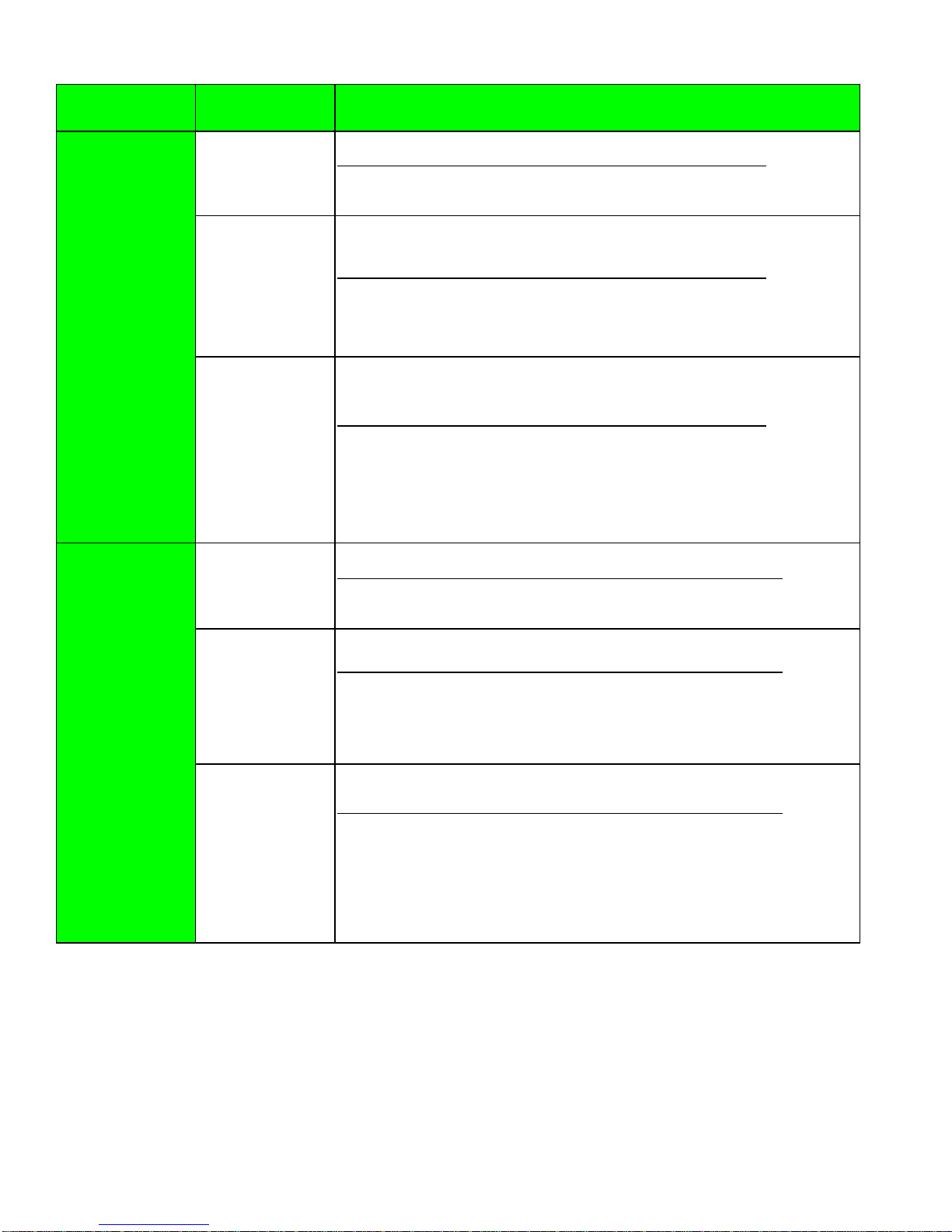

MODEL # MFG. # DESCRIPTION

AMEC960402BNAA

AMEC96

GMEC96

AMEC960603BNAA

AMEC960803BNAA

AMEC961004CNAA

AMEC961205DNAA

AMEC960302BNAB

AMEC960402BNAB

AMEC960603BNAB

AMEC960803BNAB

AMEC961004CNAB

AMEC961205DNAB

AMEC960804CNAB

AMEC961005CNAB

AMEC960303ANAA

AMEC960403ANAA

AMEC960603ANAA

AMEC960302BNAC

AMEC960402BNAC

AMEC960603BNAC

AMEC960803BNAC

AMEC960804CNAC

AMEC961004CNAC

AMEC961005CNAC

AMEC961205DNAC

GMEC960402BNAA

GMEC960603BNAA

GMEC960803BNAA

GMEC961004CNAA

GMEC961205DNAA

GMEC960302BNAB

GMEC960402BNAB

GMEC960603BNAB

GMEC960803BNAB

GMEC961004CNAB

GMEC961205DNAB

GMEC960804CNAB

GMEC961005CNAB

GMEC960303ANAA

GMEC960403ANAA

GMEC960603ANAA

GMEC960302BNAC

GMEC960402BNAC

GMEC960603BNAC

GMEC960803BNAC

GMEC960804CNAC

GMEC961004CNAC

GMEC961005CNAC

GMEC961205DNAC

®

Ama na

flow/Horizontal Left and Right, 34.5" tall, Induced Draft, Nidec multi-speed ECMmotor.

Stainless Steel tubular heat exchanger. 115 volt silicon nitride igniter. Left or right gas.

Ama na

flow/Horizontal Left and Right, 34.5" tall, Induced Draft, Nidec multi-speed ECMmotor.

Stainless Steel tubular heat exchanger. 115 volt silicon nitride igniter. Left or right gas.

Ama na

flow/Horizontal Left and Right, 34.5" tall, Induced Draft, Nidec multi-speed ECMmotor.

Stainless Steel tubular heat exchanger. 115 volt silicon nitride igniter. Left or right gas.

Control board changed from PCBBF137 to PCBBF139. New control feature gives

installer multiple choices for constant fan mode.

Goodman

flow/Horizontal Left and Right, 34.5" tall, Induced Draft, Nidec multi-speed ECMmotor.

Stainless Steel tubular heat exchanger. 115 volt silicon nitride igniter. Left or right gas.

Goodman

flow/Horizontal Left and Right, 34.5" tall, Induced Draft, Nidec multi-speed ECMmotor.

Stainless Steel tubular heat exchanger. 115 volt silicon nitride igniter. Left or right gas.

For Control board part # change to PCBBF137 with heat speed DIP switches.

Goodman

flow/Horizontal Left and Right, 34.5" tall, Induced Draft, Nidec multi-speed ECMmotor.

Stainless Steel tubular heat exchanger. 115 volt silicon nitride igniter. Left or right gas.

For Control board part # change to PCBBF137 with heat speed DIP s witches. Control

board changed from PCBBF137 to PCBBF139. New control feature gives installer

multiple CFM choices for constant fan mode.

Brand 96% Two Stage Heating / Two Stage Cooling Gas Furnace, Up

®

Brand 96% Two Stage Heating / Two Stage Cooling Gas Furnace, Up

®

Brand 96% Two Stage Heating / Two Stage Cooling Gas Furnace, Up

®

Brand 96% Two Stage Heating / Two Stage Cooling Gas Furnace, Up

®

Brand 96% Two Stage Heating / Two Stage Cooling Gas Furnace, Up

®

Brand 96% Two Stage Heating / Two Stage Cooling Gas Furnace, Up

6

Page 7

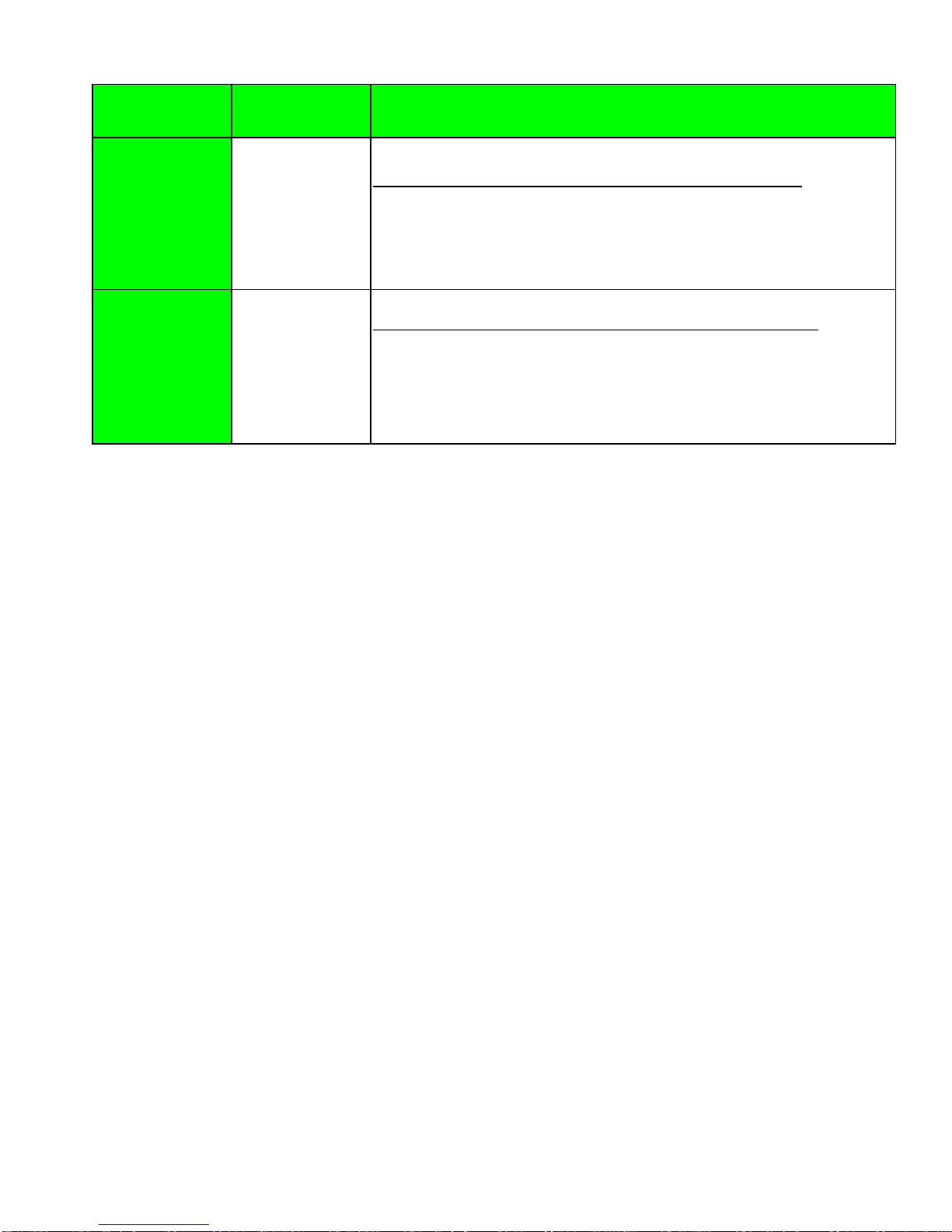

PRODUCT IDENTIFICATION

MODEL # MFG. # DESCRIPTION

®

Brand 96% Two Stage Heating / Two Stage Cooling Gas Furnace, Counter

ACEC96

ACEC960403BNAA

ACEC960603BNAA

ACEC960803BNAA

ACEC961005BNAA

Amana

flow/Horizontal Left and Right, 34.5" tall, Induced Draft, Nidec multi-speed ECM motor.

Stainl ess Steel tubular heat exchanger. 115 volt silicon nitride igniter. Left or right gas.

PCBBF139 Control board which gives installer multiple CFM choices for constant fan

mode.

GCEC96

GCEC960403BNAA

GCEC960603BNAA

GCEC960803BNAA

GCEC961005BNAA

Goodman

flow/Horizontal Left and Right, 34.5" tall, Induced Draft, Nidec multi-speed ECMmotor.

Aluminized Steel tubular heat exchanger. 115 volt si licon nitride igniter. Left or right

gas. PCBBF139 Control board which gives installer multiple CFM choices for constant

fan mode.

®

Brand 96% Two Stage Heating / Two Stage Cooling Gas Furnace, Counter

7

Page 8

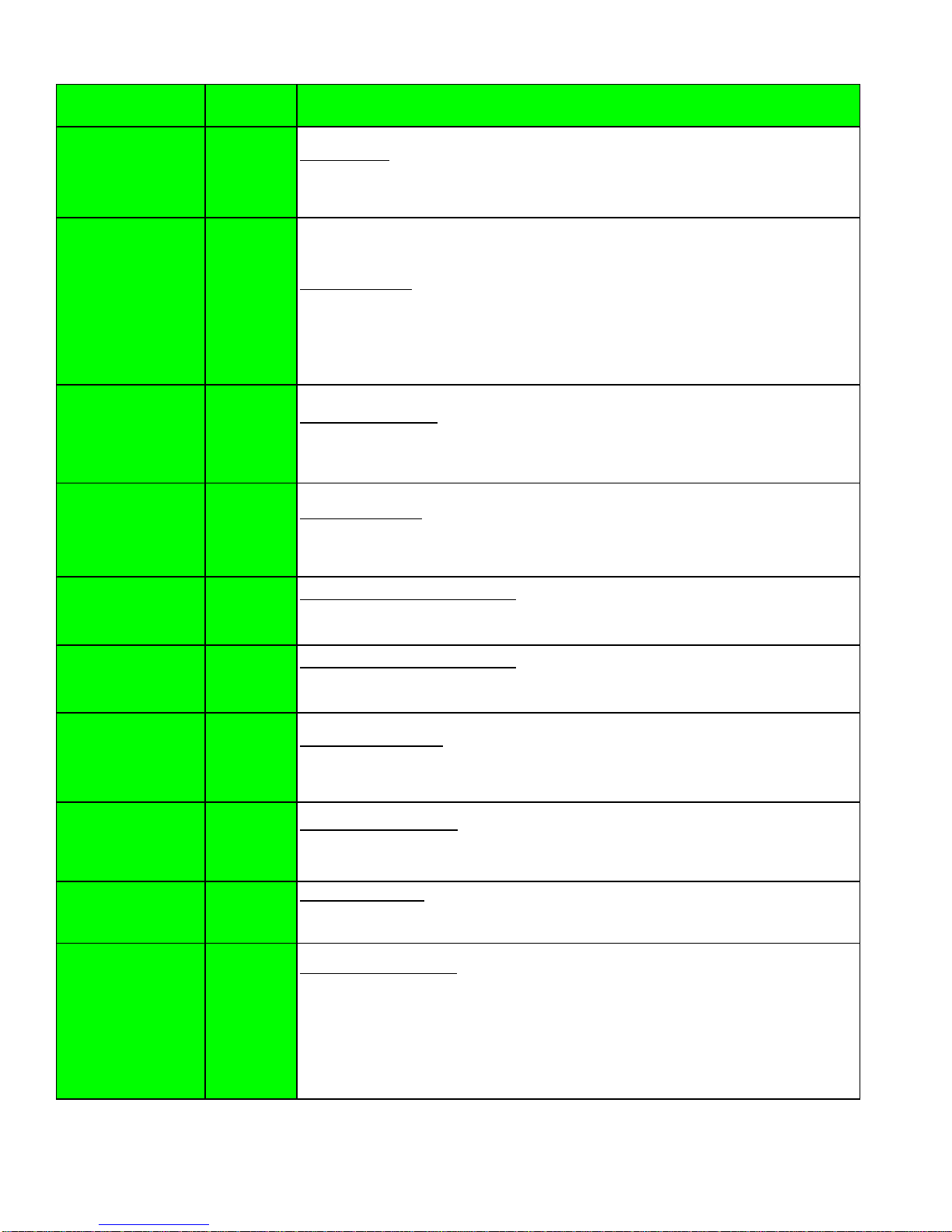

PRODUCT IDENTIFICATION

MODEL # M FG # DESCRI PT ION

AFE18-60A

AMU1620

AMU1625

AMU2020

AMU2025

GMU1620

GMU1625

GMU2020

GMU2025

ASAS-10

ASAS-11

ASAS-12

ASAS-18

DCVK-20 (CVE NT - 2)

DCVK-30 (CVE NT - 3)

0170K00000S

N/A

P1251305F

P1251306F

P1251307F

P1251308F

N/A

P1251301F

P1251302F

P1251303F

P1251304F

P1254001F

P1254002F

N/A

Foss il Fuel Kit.

above/downstream of a gas or f ossil fuel fur nac e when used with a heat pump. It will

operat e with single and two stage heat pumps and single and two stage furnaces

Med ia Air C leaner

efficiency air filtration device designed to remov e dir t, dust, pollen and other microscopic

part ic les fr om the air passing through it . Flexible performance range up t o 2,0

Electronic Air C leaner

cont aminants down to .01 microns. Carbon filters (optional) r emove odors. Dual indicator

lights show unit operat ion at a glance. E lec tronic proving switc h c ycle

Concentric Vent Kit

designed to allow ter minations of a dir ec t vent furnac e to be "c onc entrically" vented through

a wall or roof. T his kit allows a single penetrat ion to support ter min

Side Wall Only Concentric Vent Kit

to be used with 2" - 3" vent sy stems. The vent k it must terminate out side the str uc ture. This

kit is NOT intended f or use with single pipe (indirec t v ent) instal

The AF E 18- 60A c ontrol is designed for use where the indoor c oil is locat ed

. The A mana (AMU*) and G oodman (G MU*) Media Air Cleaner is a high

. The High-Ef ficiency Elec tronic Air Cleaner is designed to remov e air

. For use with Amana® Brand high efficiency f ur nac e models. This kit is

. For use with high efficiency f ur nac e models. This kit is

0170K00001S

EFR02

LPLP03

RF000142

CFSB17

CFSB21

CFSB24

N/A

P1221001

P1221002F

N/A

N/A

N/A

Side Wall Only Concentric Vent Kit

kit is to be used with 2" only vent systems. The vent kit must terminate outside the str uc ture.

This kit is NOT intended f or use with single pipe (indirec t v ent) in

External Filter Rack Kit

casing, f or installation of a permanent filter. The r ac k is mounted over the indoor air blower

compartment ar ea of either side panel, and pr ovide f ilter retentio

LP Gas Low Pressure Kit

80% and 90% single-stage and two- stage gas fired furnace pr oduc ts inst alled on LP gas

listed in this manual. This kit inc ludes harness adaptors to work with White-Rodgers sin

Vent Drain Coupling

the internal elbow is removed. May also be used in the combustion air intak e if

condensation is an issue.

Counterflow Subbase Kit

34.5 furnace model. T hese kit s are available for the following furnace widt h: 17.5" wide

(CF S B 17) , 21" wide (CFSB21, and 24" Wide CF S B 21. The k it must be used to pr event

excessive t emperat ur e from reaching combustible materials, if the fur nac e is installed on

combustible floor . This subbase effect ively separated the furnac e base and plenum from

combustile materials. T o ensure safe installation, do not install the counter flow floor base

directly on c ar peting, tile or other c ombusible mat er ial other t han wood flooring.

. This kit is intended to pr ovide a loc ation, ext er nal t o the fur nac e

. Designed for applic ation on Goodman® and Amana® Brand's

. For use when the fur nac es is installed in horizontal lef t position and

. For use with Amana® Brand, Goodman® brand 96% t wo stage

. For use with high efficiency 90% f ur nac e models. This

8

Page 9

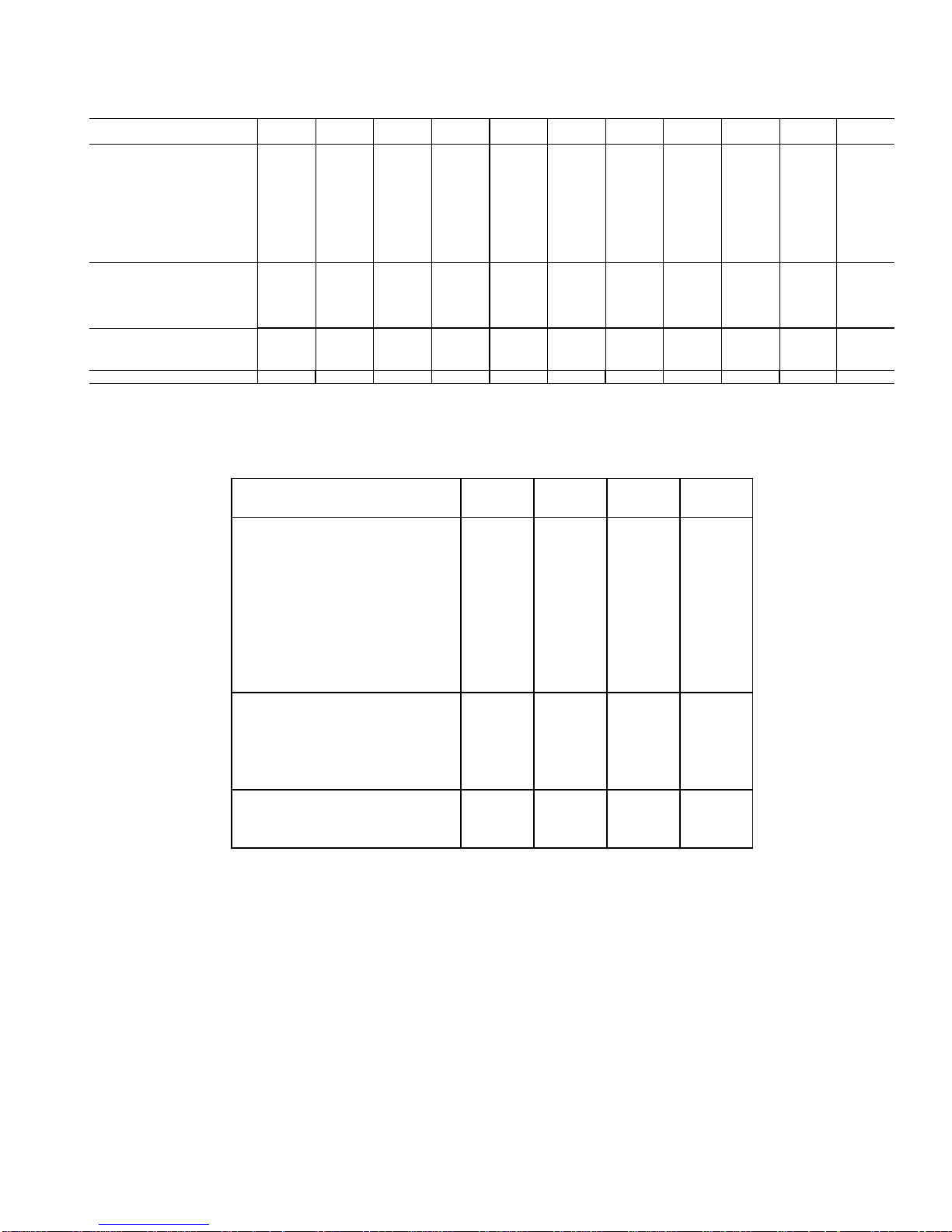

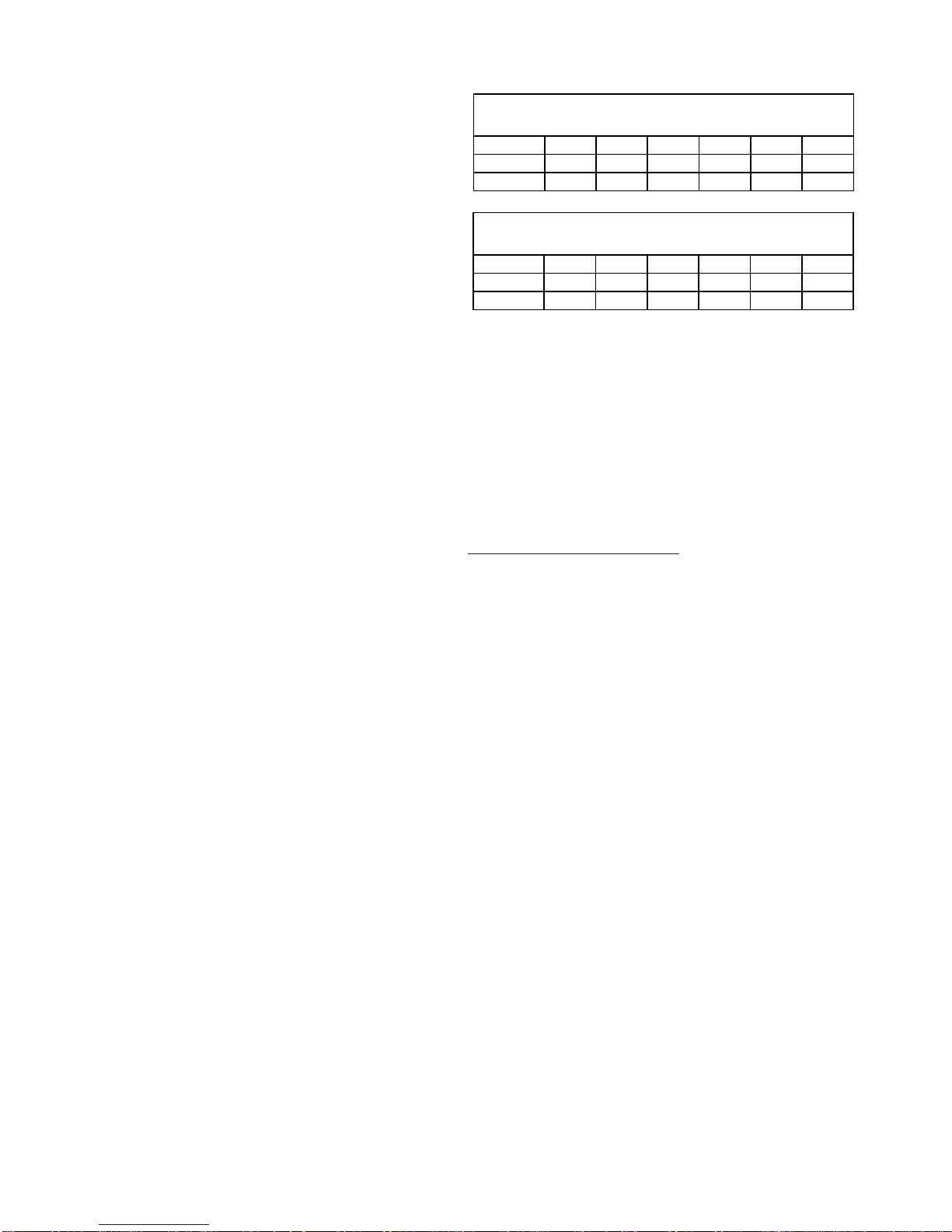

FURNACE SPECIFICATIONS

*MEC96

Heating Data

High Fire Input¹ 30,000 40,000 60,000 30,000 40,000 60,000 80,000 100,000 120,000 80,000 100,000

Hi gh Fi re Outp ut¹ 28,800 38,400 57,600 28,800 38,400 57,600 76,800 96,000 115,200 76,800 96,000

Low-Fire Steady-State Input¹ 21,000 28,000 42,000 21,000 28,000 42,000 56,000 70,000 84,000 56,000 70,000

Low -Fire Stea dy-Sta te Outp ut¹ 20,160 26,880 40,320 20,160 26,880 40,320 53,760 67,200 80,640 53,760 67,200

AFUE² 9696969696969696969696

Tem pera ture Ri se Ra nge (°F) 20 - 50 20 - 50 30 - 60 20 - 50 20 - 50 25 - 55 35 - 65 35 - 65 35 - 65 25 - 55 35 - 65

Ve nt Dia mete r³ 2" - 3" 2" - 3" 2" - 3" 2" - 3" 2" - 3" 2" - 3" 2" - 3" 2" - 3" 2" - 3" 2" - 3" 2" - 3"

No. of Burners 22322345645

Circul a t or Blower

Availa ble AC @ 0.5” ESP 1.5 - 3 1.5 - 3 1.5 - 3 1.5 - 2 1.5 - 3 1.5 - 3 1.5 - 3 1.5 - 4 3 - 5 2.5 - 4 3 - 5

Si ze (D x W) 11" x 6" 11" x 6" 11" x 6" 10" x 8" 10" x 8" 11" x 8" 11" x 8" 11" x 10" 11" x 11" 11" x 10" 11" x 10"

Ho rs epo wer @ 1075 RPM 1/2 1/2 1/2 1/2 1/2 1/ 2 1/2 1 1 3/4 1

Speed 55555555555

Electrical Data

Min. Circuit Ampacity

Max. Overcurrent Device (amps)

Shi ppi ng Weight (lbs)

4

0303ANA

5

8.6 8.6 8.6 8 8 8 8 13. 3 13.3 11.6 13.3

15 15 15 15 15 15 15 15 15 15 15

106 107 110 111 112 115 118 140 154 123 140

*MEC96

0403ANA

*MEC96

0603ANA

*MEC96

0302BNA

0403BN AA

*MEC96

0402BNA

*CEC96

*MEC96

0603BNA

*CEC96

0603BN AA

*MEC96

0803BNA

*CEC96

0803BN AA

*MEC96

1004CNA

*CEC96

1005CNA A

*MEC96

1205DNA

*MEC96

0804CNA

*MEC96

1005CNA

Heating Data

High F ire Input¹ 40,000 60,000 80,000 100,000

High Fi re Output¹ 38,400 57,600 76,800 96,000

Low-Fire Steady-State Input¹ 28,000 42,000 56,000 70,000

Low-Fi re Steady-State Output¹ 26,880 40,320 53,760 67,200

AFUE 96 96 96 96

Tempe rature Rise Range (°F) 25 - 55 25 - 55 40 - 70 36 - 65

Vent Diameterᶾ 2" - 3" 2" - 3" 2" - 3" 2" - 3"

No. of Burners 2345

Circula tor Blower

Available AC @ 0.5 ESP 1.5 - 3 1.5 - 3 1.5 - 3 3 - 5

Size (D x W) 10 x 8 10 x 8 11 x 8 11 x 10

Horsepow er @ 1075 RPM 1/2 1/2 1/2 1 HP

Speed 5555

Elec trical Data

Min. Circuit Ampacity⁴ 88813.3

Max. Overcurrent Device (AMPS)⁵ 15 15 15 15

1

Natural Gas BTU/h

2

DOE AFUE based upon Isolated Combustion System (ICS)

3

Installer must supply one or two PVC pipes: one for

combustion air (optional) and one for the flue outlet (required).

Vent pipe must be either 2" or 3" in diameter, depending upon

furnace input, number of elbows, length of run and installation

(1 or 2 pipes). The optional Combustion Air Pipe is dependent

on installation/code requirements and must be 2" or 3"

diameter PVC.

4

Minimum Circuit Ampacity = (1.25 x Circulator Blower Amps) +

ID Blower amps. Wire size should be determined in

accordance with National Electric Codes. Extensive wire runs

will require larger wire sizes.

5

Maximum Overcurrent Protection Device refers to maximum

recommended fuse or circuit breaker size. May use fuses or

HACR-type circuit breakers of the same size as noted

Notes

• All furnaces are manufactured for use on 115 VAC, 60 Hz,

single-phase electrical supply.

• Gas Service Connection 1/2" FPT

• Important: Size fuses and wires properly and make electrical

connections in accordance with the National Electrical Code

and/or all existing local codes.

• For bottom return: Failure to unfold flanges may reduce

airflow by up to 18%. This could result in performance and

noise issues.

• For servicing or cleaning, a 24" front clearance is required.

Unit connections (electrical, flue and drain) may necessitate

greater clearances than minimum clearances listed above. In

all cases, accessibility clearance must take precedence over

clearances from the enclosure where accessibility clearances

are greater.

9

Page 10

OPERA TIONS INSTRUCTIONS

Introduction

This is a Category lV furnace. This furnace uses a pressurized venting system and must be installed per National and

local codes requirements and the installation manual that

was shipped with the furnace.

The *MEC96 34.5" furnace is one of the products in our

newly redesigned line of shorter chassis furnaces. It is available in the following sizes and suitable for up flow / horizontal installation.

*MEC960303ANA *CEC960402BNAA

*MEC960403ANA *CEC960603BNAA

*MEC960603ANA *CEC960803BNAA

*MEC960302BNA *CEC961005CNAA

*MEC960402BNA Suitable for counter

*MEC960603BNA flow or horizontal

*MEC960803BNA installation.

*MEC960804CNA

*MEC961004CNA

*MEC961005CNA

*MEC961205DNA

Safety

Please adhere to the following warnings and cautions when

installing, adjusting, altering, servicing, or operating the furnace.

WARNING

T

O PREVENT PERSONAL INJURY OR DEATH DUE TO IMPROPER INSTALLATION,

ADJUSTMENT, ALTERATI ON, SERV ICE OR MAINTENANCE, R EFER TO THI S

MANUAL.

QUALIFIED INSTALLE R, SERVICE AGENCY OR THE GAS SUPPLIER.

T

MAY CAUSE SERI OUS ILLNESS OR DEATH AN D WHICH ARE KNOWN TO TH E

S

REPRODUCTIVE HARM.

TO PREVENT POSSIBLE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH

DUE TO ELECTRICAL SHOCK, THE FURNACE MUST BE LOCATED TO PROTECT

THE ELEC TRICA L COMPON ENTS FROM WAT ER.

OR ADDITIONAL ASSISTANCE OR INFORMATION, CONSULT A

F

WARNING

HIS PRODUCT CONTAINS OR PRODUCES A CHEMICAL OR CHEMICALS WHICH

TATE OF CALIFORNIA TO CAUSE CANCER, BI RTH DEFECTS OR OTHER

WARNING

age. By putting the furnace, the control, and the person at

the same electrostatic potential, these steps will help avoid

exposing the integrated control module to electrostatic discharge. This procedure is applicable to both installed and

uninstalled (ungrounded) furnaces.

1. Disconnect all power to the furnace. Do not touch the

integrated control module or any wire connected to the

control prior to discharging your body’s electrostatic

charge to ground.

2. Firmly touch a clean, unpainted, metal surface of the

furnace near the control. Any tools held in a person’s

hand during grounding will be discharged.

3. Service integrated control module or connecting wiring

following the discharge process in Step 2. Use caution

not to recharge your body with static electricity; (i.e., do

not move or shuffle your feet, do not touch ungrounded

objects, etc.). If you come in contact with an ungrounded

object, repeat Step 2 before touching control or wires.

4. Discharge any static electricity from your body to ground

before removing a new control from its container. Follow

Steps 1 through 3 if installing the control on a furnace.

Return any old or new controls to their containers before

touching any ungrounded object.

Product Application

This product is designed for use as a residential home gas

furnace. It is not designed or certified for use in mobile home,

trailer, or recreational vehicle applications.

This furnace can be used in the following non-industrial

commercial applications: Schools, Office buildings, Churches,

Retail stores, Nursing homes, Hotels/motels, Common or

office areas. In such applications, the furnace must be installed

with the

installation instructions.

The *MEC96 furnaces are ETL certified appliances and are

appropriate for use with natural or propane gas. (NOTE: If

using propane gas, a propane conversion kit is required).

*MEC96 furnaces are dual certified.

Dual certification means that the combustion air inlet pipe is

optional and the furnace can be vented as a:

Non-direct vent (single pipe) central forced air furnace

in which combustion air is taken from the installation

area or from air ducted from the outside or,

Direct vent (dual pipe) central forced air furnace in which

all combustion air supplied directly to the furnace burners through a special air intake system outlined in

this manual and the installation instructions.

To ensure proper installation, operation and servicing, thoroughly read the installation and service manuals for specifics pertaining to the installation, servicing and application of

this product.

Charge (ESD) Precautions

NOTE: Discharge body’s static electricity before touching

unit. An electrostatic discharge can adversely affect electrical components.

Use the following precautions during furnace installation and

servicing to protect the integrated control module from dam-

10

WARNING

OSSIBLE PROPERTY D AMAGE, PERSONAL INJ URY OR DEATH DUE TO FIRE,

P

EXPLOSION, SMOKE, S OOT, CONDENSTAION, E LECTRICAL SHOCK OR C ARBON

MONOXIDE MAY RESULT FROM IMPROPER INSTALLATION, RE PAIR, OPERATI ON,

OR MAINTENANCE OF THI S PRODUCT.

Page 11

SYSTEM OPERATION

WARNING

T

O PREVENT PROPERTY DAMAGE, PERSONAL INJ URY OR DEATH D UE TO FIRE,

DO NOT INSTALL T HIS FURNACE IN A MOBILE HOME, TRAILER, OR RECREATIONAL

VEHICLE.

To ensure proper furnace operation, install, operate, maintain and service the furnace in accordance with the installation, operation and service instructions, all local building

codes and ordinances. In their absence, follow the latest

edition of the National Fuel Gas Code (NFPA 54/ANSI

Z223.1), and/or CAN/CGA B149 Installation Codes, local

plumbing or waste water codes, and other applicable codes.

A copy of the National Fuel Gas Code (NFPA 54/ANSI

Z223.1) can be obtained from any of the following:

American National Standards Institute

25 West 43rd Street, 4th Floor

New York, NY 10036

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley

Cleveland, OH 44131

A copy of the CAN/CGA B149 Installation Codes can be

obtained from:

CSA International

178 Rexdale Boulevard

Etobicoke, Ontario, Canada M9W, 1R3

The rated heating capacity of the furnace should be greater

than or equal to the total heat loss of the area to be heated.

The total heat loss should be calculated by an approved

method or in accordance with “ASHRAE Guide” or “Manual

J-Load Calculations” published by the Air Conditioning Contractors of America.

Location Requirements and Considerations

WARNING

O PREVENT POSSIBLE EQUI PMENT DAMAGE, PROPERTY DAMAGE, PERSONAL

T

INJURY OR DEATH, THE FO LLOWING BULLET P OINTS MUST BE OBSERVED

WHEN INSTALLING THE UNIT.

Follow the instructions listed below when selecting a furnace location. Refer also to the guidelines provided in the

Combustion and Ventilation Air Requirements section in

this manual or the installation instructions for details.

• Centrally locate the furnace with respect to the proposed or existing air distribution system.

• Ensure the temperature of the return air entering the

furnace is between 55°F and 100°F when the furnace

is heating.

• If the furnace is installed in an application where the

typical operating sound level of a furnace is deemed

objectionable, an optional sound reduction kit is available. Consult your local distributor for more details.

• Provide provisions for venting combustion products

outdoors through a proper venting system. Special

consideration should be given to vent/flue pipe routing

and combustion air intake pipe when applicable.

90% Furnaces: Refer to the Vent/Flue Pipe and Com-

bustion Air Pipe -Termination Locations section in this

manual or the installation instructions for appropriate

termination locations. Also for 90% furnaces, refer to

the Vent/Flue Pipe and Combustion Air Pipe -Termi-

nation Locations section in this manual or the installation instructions to determine if the piping system

from furnace to termination can be accomplished

within the guidelines given.

NOTE: The length of flue and/or combustion air piping can

be a limiting factor in the location of the furnace.

• Locate the 90% furnace so that the condensate can

be piped at a downward slope away from the furnace

to the drain. Do not locate the furnace or its condensate drainage system in any area subject to below

freezing temperatures without proper freeze protection. Refer to the Condensate Drain Lines and Trap

section in this manual or the installation instructions

for further details.

• Set the 90% furnace on a level floor to enable proper

condensate drainage. If the floor becomes wet or damp

at times, place the furnace above the floor on a

concrete base sized approximately 1-1/2" larger than

the base of the furnace. Refer to the Horizontal Appli-

cations and Considerations section in this manual or

the installation instructions for leveling of horizontal

furnaces.

• Ensure upflow or horizontal furnaces are not installed

directly on carpeting, or any other combustible material. The only combustible material allowed is wood.

• Exposure to contaminated combustion air will result

in safety and performance-related problems. Do not

install the furnace where the combustion air is exposed to the following substances:

chlorinated waxes or cleaners

chlorine-based swimming pool chemicals

water softening chemicals

deicing salts or chemicals

carbon tetrachloride

halogen type refrigerants

cleaning solutions (such as perchloroethylene)

printing inks

paint removers

varnishes

11

Page 12

SYSTEM OPERATION

hydrochloric acid

cements and glues

antistatic fabric softeners for clothes dryers

and masonry acid washing materials

• Isolate a non-direct vent furnace if it is installed near

an area frequently contaminated by any of the above

substances. This protects the non-direct vent furnace

from airborne contaminants. To ensure that the enclosed non-direct vent furnace has an adequate sup-

ply of combustion air, vent from a nearby uncontaminated room or from outdoors. Refer to the Combus-

tion and Ventilation Air Requirements section in this

manual or the installation instructions for details.

• If the furnace is used in connection with a cooling

unit, install the furnace upstream or in parallel with

the cooling unit coil. Premature heat exchanger failure will result if the cooling unit coil is placed in the

return air of the furnace.

• If the furnace is installed in a residential garage, position the furnace so that the burners and ignition

source are located not less than 18 inches (457 mm)

above the floor. Protect the furnace from physical damage by vehicles.

• If the furnace is installed horizontally, the furnace access doors must be vertical so that the burners fire

horizontally into the heat exchanger. Do not install

the unit with the access doors on the “up/top” or “down/

bottom” side of the furnace.

• On counterflow installations, the air conditioning coil

must be downstream on the supply (positive) side of

the furnace heat exchanger.

• Counterflow Installation over a noncombustible floor.

Before setting the furnace over the plenum opening,

ensure the surface around the opening is smooth and

level. A tight seal should be made between the furnace base and floor by using a silicone rubber caulking compound or cement grout.

• Counterflow Installation over a combustible floor. If

installation over a combustible floor becomes necessary, use an accessory sub-base (see Specification

Sheet applicable for your model for details). A special accessory sub-base must be used for upright

counterflow unit installations over any combustible

material including wood. Refer to sub-base instructions for installation details. Follow the instructions

with the sub-base for proper installation. Do not install the furnace directly on carpeting, tile, or other

combustible material other than wood flooring.

(NOTE: The sub-base will not be required if an air

conditioning coil is installed between the supply air

opening on the furnace and the floor.)

*MEC96 M INIMUM CLEA RANCES TO COM BUSTIBLE MATERIALS

POSITION* SIDES REAR FRONT BOTTOM FLUE TOP

Upflow 0" 0" 1" C 0" 1"

Horiz ontal 6" 0" 1" C 0" 6"

*CEC9 6 MINIM UM CLE ARANCE S TO CO MBUSTIB LE MATER IA LS

POSITION* SIDES REAR FRONT BOTTOM FLUE TOP

Counterflow0"0"1"NC0"

Horizontal 6" 0" 1" C 0" 6"

• C = If placed on combustible floor, floor MUST be wood only.

• NC = For installation on non-combustible floors only. A combustible

subbase must be used for installations on combustible flooring.

• For servicing or cleaning, a 24" front clearance is recommended.

• Unit connections (electrical, flue, and drain) may necessitate greater

clearances than the minimum clearances listed above.

• In all cases, accessibility clearance must take precedence over from

the enclosure where accessibility clearances are greater.

• Approved for line contact in the horizontal position.

Clearances and Accessibility

Installations must adhere to the clearances to combustible

materials to which this furnace has been design certified.

The minimum clearance information for this furnace is provided on the unit’s clearance label. These clearances must

be permanently maintained. Refer to Specification Sheet for

minimum clearances to combustible materials. Clearances

must also accommodate an installation’s gas, electrical,

and drain trap and drain line connections. If the alternate

combustion air intake or vent/flue connections are used on

a 90% furnace, additional clearances must be provided to

accommodate these connections. Refer to Vent Flue Pipe

and Combustion Air Pipe section in this manual or the installation instructions for details. NOTE: In addition to the

required clearances to combustible materials, a minimum

of 24 inches service clearance must be available in front of

the unit.

A furnace installed in a confined space (i.e., a closet or

utility room) must have two ventilation openings with a total

minimum free area of 0.25 square inches per 1,000 BTU/hr

of furnace input rating. One of the ventilation openings must

be within 12 inches of the top; the other opening must be

within 12 inches of the bottom of the confined space. In a

typical construction, the clearance between the door and

door frame is usually adequate to satisfy this ventilation

requirement.

12

Page 13

SYSTEM OPERATION

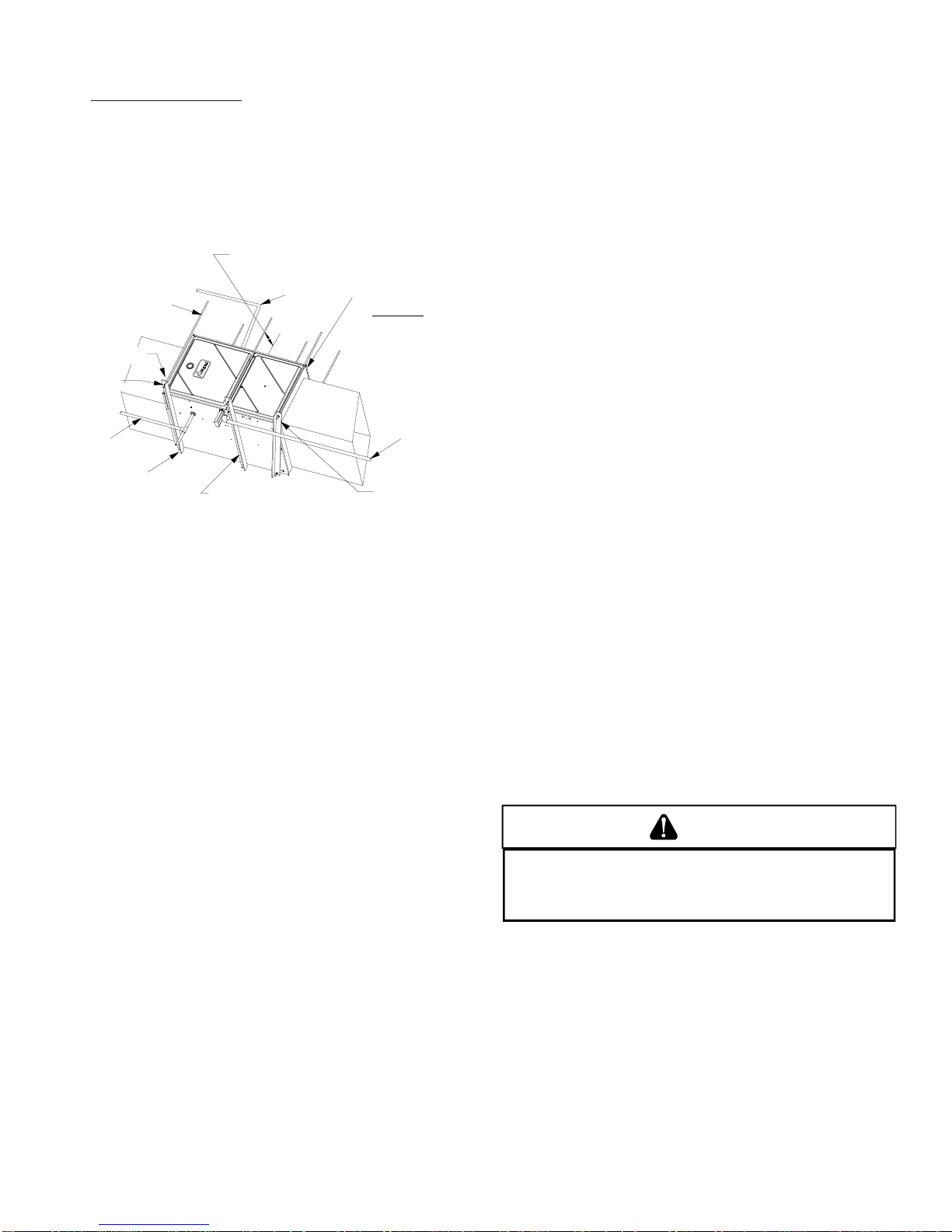

Furnace Suspension

If suspending the furnace from rafters or joist, use 3/8"

threaded rod and 2”x2”x1/8” angle iron as shown in the following figure. If the furnace is installed in a crawl space it

must also be suspended from the floor joist or supported by

a concrete pad. Never install the furnace on the ground or

allow it to be exposed to water. The length of rod will depend on the application and the clearances necessary.

PROVIDE 8" MINIMUM CLEARANCE BETWEEN

CENTER ROD AND FURNACE CABINET

TO ALLOW FOR CIRCULATOR BLOWER REMOVAL.

3/8" DIAMETER

THREADED ROD

(6 PLACES)

HOLD DOWN

NUTS

SUPPORT

NUTS

GAS PIPING

2"X2"X1/8" ANGLE IRON

(3 PLACES)

ALTERNATE

GAS PIPING

POSITION AS CLOSE AS POSSIBLE

TO BLOWER DECK TO ALLOW FOR

CIRCULATOR BLOWER REMOVAL.

ASSURE FURNACE IS LEVEL FROM

END TO END.

ON

90% FURNACES MAKE SURE

THE UNIT HAS A SLIGHT

FORWARD TILT WITH THE FRONT

OF THE FURNACE 0"-3/4"

BELOW THE BACK OF THE FURNACE.

CONDENSATE

DRAIN

TILT OUTWARD TO ALLOW FOR

DOOR AND CIRCULATOR BLOWER

REMOVAL.

90% Suspended Furnace Shown

EXISTING FURNACE REMOVAL

NOTE: When an existing furnace is removed from a venting

system serving other appliances, the venting system may

be too large to properly vent the remaining attached appliances.

The following vent testing procedure is reproduced from the

American National Standard/National Standard of Canada for

Gas-Fired Central Furnaces ANSI Z21.47, latest edition,

CSA-2.3b, latest edition Section 1.23.1.

The following steps shall be followed with each appliance connected to

the venting system placed in operation, while any other appliances

connected to the venting system are not in operation:

a. Seal any unused openings in the venting system;

b. Inspect the venting system for proper size and horizontal pitch,

as required by the National Fuel Gas Code, ANSI Z223.1 or the

CSA B149 Installation Codes and these instructions. Determine

that there is no blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe condition;

c. In so far as practical, close all building doors and windows and

all doors between the space in which the appliance(s) connected

to the venting system are located and other spaces of the building.

Turn on clothes dryers and any appliance not connected to the

venting system. Turn on any exhaust fans, such as range hoods

and

bathroom exhausts, so they shall operate at maximum speed.

Do not operate a summer exhaust fan. Close fireplace dampers;

d. Follow the lighting instructions. Place the appliance being in-

spected in operation. Adjust thermostat so appliance shall

operate continuously;

e. Test for draft hood equipped spillage at the draft hood relief

opening after 5 minutes of main burner operation. Use the flame

of a match or candle;

f. After it has been determined that each appliance connected to the

venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace dampers and any

other gas burning appliance to their previous conditions of use;

g . If improper venting is observed during any of the above tests, the

common venting system must be corrected.

Corrections must be in accordance with the latest edition of

the National Fuel Gas Code NFPA 54/ANSI Z223.1 and/or

CSA B149 Installation Codes.

If resizing is required on any portion of the venting system,

use the appropriate table in Appendix G in the latest edition

of the National Fuel Gas Code ANSI Z223.1 and/or CSA B149

Installation Codes.

Thermostat Requirements

A two stage heat/cool thermostat is recommended. A single

stage heating thermostat may be used. It is recommended

that a high quality thermostat with a "C" terminal is used to

operate the furnace.

Thermostat Location

In an area having good air circulation, locate the thermostat

about five feet high on a vibration-free inside wall. Do not

install the thermostat where it may be influenced by any of

the following:

• Drafts, or dead spots behind doors, in corners, or under cabinets.

• Hot or cold air from registers.

• Radiant heat from the sun.

• Light fixtures or other appliances.

• Radiant heat from a fireplace.

• Concealed hot or cold water pipes, or chimneys.

• Unconditioned areas behind the thermostat and dehumidistat, such as an outside wall.

COMBUSTION AND VENTILATION AIR

REQUIREMENTS

WARNING

OSSIBLE PROPERTY DAMAGE, PERSONAL I NJURY OR DEATH MAY OCCUR

P

IF THE FURNACE I S NOT PR OVIDED WITH ENOUGH FRESH AIR FOR PROPER

COMBUSTION AND VENTIL ATION OF F LUE GASES. MOST HOMES REQUI RE

OUTSIDE AIR BE SUPPLIED TO THE FURNACE AREA.

Improved construction and additional insulation in buildings

have reduced heat loss by reducing air infiltration and escape around doors and windows. These changes have helped

in reducing heating/cooling costs but have created a problem supplying combustion and ventilation air for gas fired

and other fuel burning appliances. Appliances that pull air

out of the house (clothes dryers, exhaust fans, fireplaces,

etc.) increase the problem by starving appliances for air.

When the furnace is installed as a direct ven (2-pipe) furnace, no special provisions for air for combustion are required. However, if this furnace is to be installed in the same

space with other gas appliances, such as a water heater,

13

Page 14

SYSTEM OPERATION

ensure there is an adequate supply of combustion and ventilation air for the other appliances. Refer to the latest edition of the National Fuel Gas Code NFPA 54/ANSI Z223.1

(Section 9.3), or CAN/CGA B149 Installation Codes (Sections 7.2, 7.3, or 7.4), or applicable provisions of the local

building codes for determining the combustion air requirements for the appliances.

Most homes will require outside air be supplied to the furnace area by means of ventilation grilles or ducts connecting directly to the outdoors or spaces open to the outdoors

such as attics or crawl spaces.

The following information on air for combustion and ventilation

is reproduced from the National Fuel Gas Code NFPA 54/ANSI

Z223.1 Section 9.3.

9.3* Air for Combustion and Ventilation.

9.3.1 General.

9.3.1.1 Air for combustion, ventilation, and dilution of flue gases for

appliances installed in buildings shall be obtained by application of one

of the methods covered in 9.3.2 through 9.3.6. Where the requirements

of 9.3.2 are not met, outdoor air shall be introduced in accordance with

methods covered in 9.3.3 through 9.3.6.

Exception No. 1: This provision shall not apply to direct vent appliances.

9.3.1.2 Appliances of other than natural draft design and other than

Category 1 vented appliances shall be provided with combustion, ventilation, and dilution air in accordance with the appliance manufacturer’s

instructions.

9.3.1.3 Appliances shall be located so as not to interfere with proper

circulation of combustion, ventilation, and dilution air.

9.3.1.4 Where used, a draft hood or a barometric draft regulator shall be

installed in the same room or enclosure as the appliance served so as to

prevent any difference in pressure between the hood or regulator and the

combustion air supply.

(1) For appliances other than fan-assisted, calculate using the follow-

ing equation:

Required Volume

(2) For fan-assisted appliances, calculate using the following equation:

Required Volume

where:

I

I

ACH = air change per hour (percent of volume of space exchanged

(3) For purposes of this calculation, an infiltration rate greater than

9.3.2.3 Indoor Opening Size and Location. Openings used to connect indoor spaces shall be sized and located in accordance with the

following:

(1)*Combining spaces on the same story. Each opening shall have a

NOTE: Each opening must have

a free area of not less than one

square inch per 1000 BTU of

the total input rating of all equipment in the enclosure, but not

less than 100 square inches.

= all appliances other than fan-assisted input in Btu per

other

fan

0.60 ACH shall not be used in the equations in 9.3.2.2(1) and

9.3.2.2(2).

minimum free area of 1 in.2/1000Btu/hr (2200 mm2/kW) of the total

input rating of all appliances in the space but not less than 100 in.

(0.60m2). One opening shall commence within 12 in. (300 mm) of

the top, and one opening shall commence within 12 in. (300 mm) of

the bottom, of the enclosure [see Figure A.9.3.2.3(1)]. The minimum dimension of air openings shall be not less than 3 in. (80 mm).

hour

= fan-assisted appliances input in Btu per hour

per hour, expressed as a decimal)

> ________ _________

other

> ________ _________

fan

3

21 ft

ACH 1000 Btu/hr

3

15 ft

ACH 1000 Btu/hr

Chimney or Gas Vent

I

other

(

I

fan

(

)

)

2

9.3.1.5 Makeup air requirements for the operation of exhaust fans, kitchen

ventilation systems, clothes dryers, and fireplaces shall be considered in

determining the adequacy of a space to provide combustion air requirements.

9.3.2 Indoor Combustion Air. The required volume of indoor air shall

be determined in accordance with the method in 9.3.2.1 or 9.3.2.2 except that where the air infiltration rate is known to be less than 0.40

ACH, the method in 9.3.2.2 shall be used. The total required volume

shall be the sum of the required volume calculated for all appliances

located within the space. Rooms communicating directly with the space

in which the appliances are installed through openings not furnished

with doors, and through combustion air openings sized and located in

accordance with 9.3.2.3, are considered a part of the required volume.

9.3.2.1* Standard Method. The minimum required volume shall be 50

ft 3 per 1,000/Btu/hour (4.8m3/kW).

9.3.2.2* Known Air Infiltration Rate Method. Where the air infiltration rate of a structure is known, the minimum required volume shall be

determined as follows:

14

Opening

Water

Heater

Furnace

Opening

Figure A.9.2.3.3.(1) All Combustion Air from Adjacent

Indoor Spaces through Indoor Combustion Air Openings.

(2) Combining spaces in different stories. The volumes of spaces in

different stories shall be considered as communicating spaces where

such spaces are connected by one or more openings in doors or

floors having a total minimum free area of 2 in.2/1000 Btu/hr (4400

mm2/kW) of total input rating of all appliances.

9.3.3 Outdoor Combustion Air. Outdoor combustion air shall be

provided through opening(s) to the outdoors in accordance with the

methods in 9.3.3.1 or 9.3.3.2. The minimum dimension of air openings

shall not be less than 3 in. (80 mm).

Page 15

SYSTEM OPERATION

A

9.3.3.1 Two Permanent Openings Method. Two permanent openings, one commencing within 12 in. (300 mm) of the top and one commencing within 12 in. (300 mm) of the bottom, of the enclosure shall be

provided. The openings shall communicate directly, or by ducts, with

the outdoors or spaces that freely communicate with the outdoors, as

follows:

(1)*Where directly communicating with the outdoors or where commu-

nicating to the outdoors through vertical ducts, each opening shall

have a minimum free area of 1 in.

total input rating of all appliances in the enclosure. [See Figure

A.9.3.3.1(1)(a) and Figure A.9.3.3.1(1)(b).]

Chimney or Gas Vent

Water

Heater

Furnace

lternate

air inlet

Ventilation louvers for

unheated crawl space

Figure A.9.3.3.1(1)(a) All Combustion Air Fr om Outdoors -

Inlet Air from Ventilated Crawl Space and Outlet Air

to Ventilated Attic.

2

/4000 Btu/hr (550 min2/kW) of

Ventilation louvers

(each end of attic)

NOTE: The inlet and outlet a ir

openings must each have a free

area of not less than one square

inch per 4000 BTU of the

total input rating of all equipment

in the enclosure.

Outlet Air

Inlet Air

Chimney or Gas Vent

NOTE: The ai r du ct openings

must have a free area of not

less than one squ are inch per

2000 BTU of the total input

rating of all equipment in the

enclosure*.

Furnace

Water

Heater

Outlet air duct

Inlet air duct

Figure A.9.3.3.1(2) All Combustion Air From Outdoors

through Horizontal Ducts.

9.3.3.2* One Permanent Opening Method. One permanent open-

ings, commencing within 12 in. (300 mm) of the top of the enclosure,

shall be provided. The appliance shall have clearances of at least 1 in.

(25 mm) from the sides and back and 6 in. (150 mm) from the front of

the appliance. The opening shall directly communicate with the outdoors or shall communicate through a vertical or horizontal duct to the

outdoors or spaces that freely communicate with the outdoors (see

Figure A.9.3.3.2) and shall have a minimum free area of the following:

(1) 1 in.

2

/3000 Btu/hr (700 mm2 per kW) of the total input rating of all

appliances located in the enclosure, and

(2) Not less than the sum of the areas of all vent connectors in the

space.

NOTE: The single opening must have

a free area of not less than one

square inch per 3000 BTU of

the total input rating of all equipment in the enclosure, but not less than

the sum of the areas of all vent

connectors in the confin ed spa ce.

Chimney or Gas Vent

Chimney or Gas Vent

Ventilation louvers

(each end of attic)

NOTE: The inlet and outlet air

openings must each have a free

area of not less than one square

inch per 4000 BTU of the

total input rating of all equipmen t

in the enclosure.

Outlet Air

Water

Heater

Furnace

Inlet air duct

[ends 1 ft (300 mm)

above floor]

Figure A.9.3.3.1(1)(b) All Combustion Air

From Outdoors through Ventilated Attic.

(2)*Where communicating with the outdoors through horizontal ducts,

each opening shall have a minimum free area of 1 in.2/2000 Btu/hr

(1100 min2/kW) of total input rating of all appliances in the enclosure. [See Figure A.9.3.3.1(2).]

Opening

Alternate

Opening

Location

Furnace

Water

Heater

Figure A.9.3.3.2 All Combustion Air

From Outdoors through Single Combustion Air Opening.

9.3.4 Combination Indoor and Outdoor Combustion Air. The use

of a combination of indoor and outdoor combustion air shall be in

accordance with (1) through (3) (see example calculation in Annex J]:

(1) Indoor Openings: Where used, openings connecting the interior

spaces shall comply with 9.3.2.3.

(2) Outdoor Opening(s) Location. Outdoor opening(s) shall be lo-

cated in accordance with 9.3.3.

(3) Outdoor Opening(s) Size. The outdoor opening(s) size shall be

calculated in accordance with the following:

(a) The ratio of the interior spaces shall be the available volume

of all communicating spaces divided by the required volume.

(b) The outdoor size reduction factor shall be 1 minus the ratio

of interior spaces.

15

Page 16

SYSTEM OPERATION

(c) The minimum size of outdoor opening(s) shall be the full size

of outdoor opening(s) calculated in accordance with 9.3.3,

multiplied by the reduction factor. The minimum dimension

of air openings shall not be less than 3 in. (80 mm).

9.3.8.4 Ducts shall not serve both upper and lower combustion air

openings where both such openings are used. The separation between

ducts servicing upper and lower combustion air openings shall be maintained to the source of combustion air.

9.3.5 Engineered Installations. Engineered combustion air installations shall provide an adequate supply of combustion, ventilation, and

dilution air and shall be approved by the authority having jurisdiction.

9.3.6 Mechanical Combustion Air Supply . Where all combustion air

is provided by a mechanical air supply system, the combustion air shall

be supplied form outdoors at the minimum rate of 0.35 ft3/min per

1000 Btu/hr (0.034 m3/min per kW) for all appliances located within

the space.

9.3.6.1 Where exhaust fans are installed, additional air shall be provided

to replace the exhausted air.

9.3.6.2 Each of the appliances served shall be interlocked to the mechanical air supply system to prevent main burner operation where the

mechanical air supply system is not in operation.

9.3.6.3 Where combustion air is provided by the building’ s mechanical

ventilation system, the system shall provide the specified combustion

air rate in addition to the required ventilation air.

9.3.7 Louvers, Grilles, and Screens.

9.3.7.1 Louvers and Grilles. The required size of openings for com-

bustion, ventilation, and dilution air shall be based on the net free area

of each opening. Where the free area through a design of louver or grille

or screen is known, it shall be used in calculating the size opening

required to provide the free area specified. Where the louver and grille

design and free area are not known, it shall be assumed that wood

louvers will have 25 percent free area, and metal louvers and grilles will

have 75 percent free area. Nonmotorized louvers and grilles shall be

fixed in the open position.

9.3.7.2 Minimum Scree Mesh Size. Screens shall not be smaller than

1/4 in. mesh.

9.3.7.3 Motorized Louvers. Motorized louvers shall be interlocked

with the appliance so they are proven in the full open position prior to

main burner ignition and during main burner operation. Means shall be

provided to prevent the main burner form igniting should the louver fail

to open during burner startup and to shut down the main burner if the

louvers close during burner operation.

9.3.8 Combustion Air Ducts. Combustion air ducts shall comply with

9.3.8.1 through 9.3.8.8.

9.3.8.1 Ducts shall be constructed of galvanized steel or a material

having equivalent corrosion resistance, strength, and rigidity.

Exception: Within dwellings units, unobstructed stud and joist spaces

shall not be prohibited from conveying combustion air, provided that

not more than one fireblock is removed.

9.3.8.2 Ducts shall terminate in an unobstructed space, allowing free

movement of combustion air to the appliances.

9.3.8.5 Ducts shall not be screened where terminating in an attic space.

9.3.8.6 Horizontal upper combustion air ducts shall not slope down-

ward toward the source of combustion air.

9.3.8.7 The remaining space surrounding a chimney liner, gas vent,

special gas vent, or plastic piping installed within a masonry, metal, or

factory built chimney shall not be used to supply combustion air.

Exception: Direct vent appliances designed for installation in a solid

fuel-burning fireplace where installed in accordance with the

manufacture’s installation instructions.

9.3.8.8 Combustion air intake openings located on the exterior of the

building shall have the lowest side of the combustion air intake openings located at least 12 in. (300 mm) vertically from the adjoining grade

level.

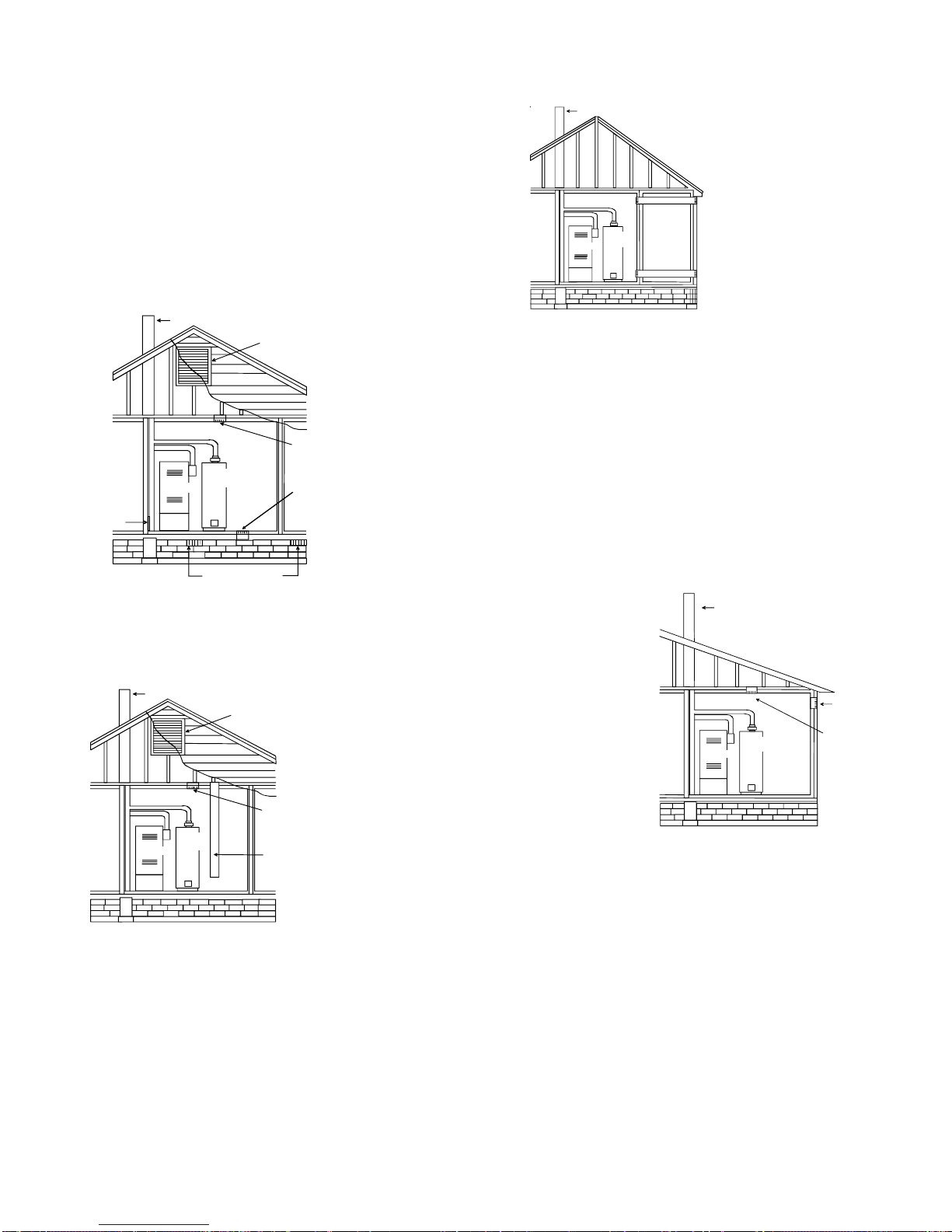

Installation Positions

*MEC96 models may be installed up flow or horizontally

with left or right side down. *CEC96 models may be installed down flow or horizontally with left or right side down.

Do not install any furnace on its back.

Horizontal Applications and Considerations

Horizontal applications, in particular, may dictate many of

the installation’s specifics such as airflow direction, ductwork connections, flue and/or combustion air pipe connections, etc. The basic application of this furnace as a horizontal furnace differs only slightly from an upright installation.

Horizontal Installations

1. Horizontal installations require 5.5" under the furnace

to accommodate the drain trap.

2. Horizontal furnaces must be installed with ¾” slope from

back to front to permit condensate flow towards the

front of the furnace.

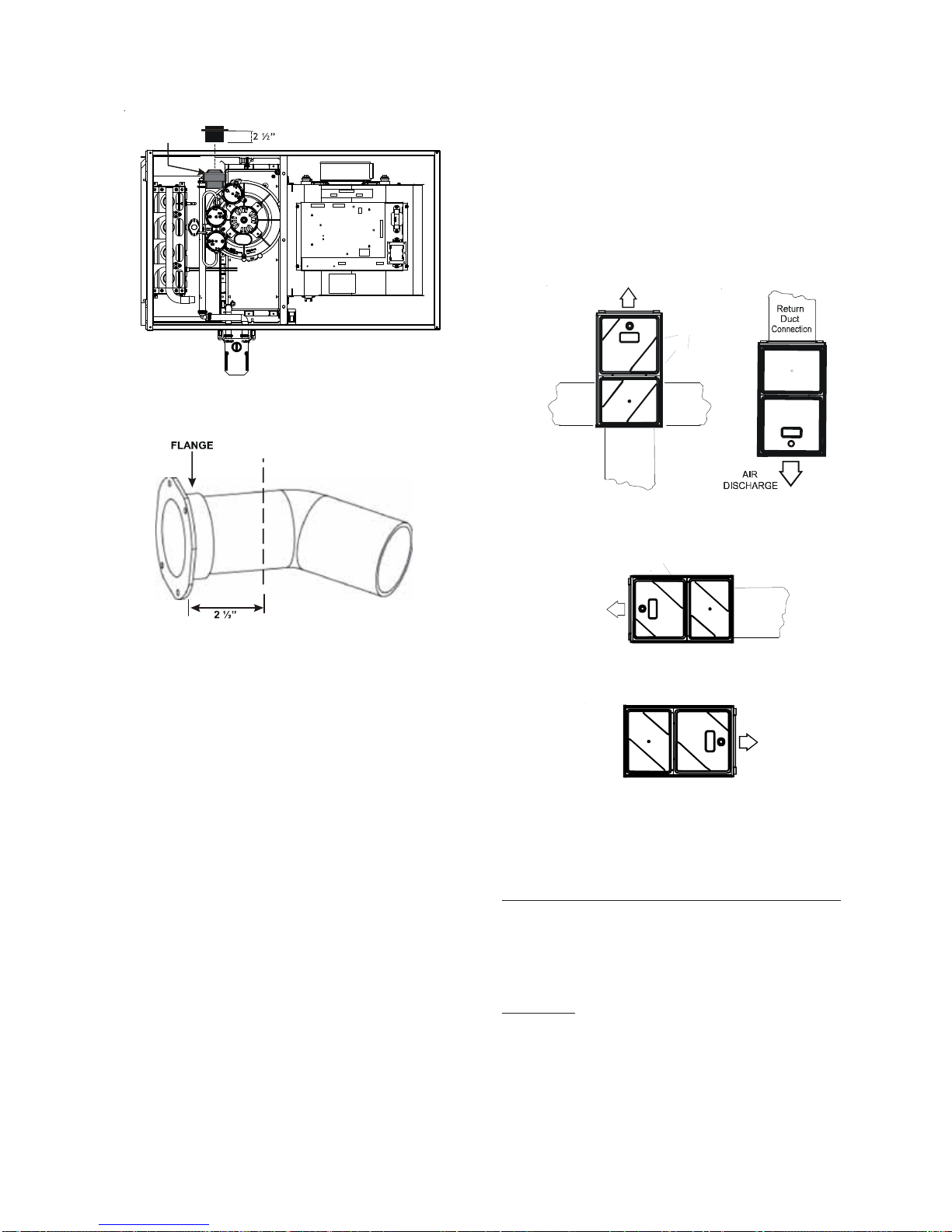

When installing horizontally with the left side down, there

are two options for connecting the vent pipe to the furnace.

1. Venting may be connected to the furnace vent pipe fitting on the original top (now the end) of the furnace

2. The internal vent pipe and elbow may be removed from

the furnace to permit the vent to exit the top (original

side) of the furnace. If this option is used, an RF000142

Vent-Drain coupling must be used to keep condensate

from collecting in the inducer assembly

Refer to the following instructions and illustration.

9.3.8.3 Ducts shall serve a single space.

16

Page 17

SYSTEM OPERATION

A

A

Insert fl ange. Cut 2 ½” long.

R 000142F

Leveling

Leveling ensures proper condensate drainage from the heat

exchanger and induced draft blower. For proper flue pipe

drainage, the furnace must be level lengthwise from end to

end. The furnace should also be level from back to front or

have a slight tilt with the access doors downhill (approximately 3/4") from the back panel. The slight tilt allows the

heat exchanger condensate, generated in the recuperator

coil, to flow forward to the recuperator coil front cover.

IR

DISCHARGE

Figure 9

E

R

E

H

T

U

C

Figure 10

1. Remove screws from the vent flange.

2. Remove the internal elbow and vent pipe

3. Cut 2 1/2" from the flange .

4. Remove cabinet plug adjacent to inducer outlet and

install an original cabinet vent hole.

5. Install RF000142 coupling on inducer outlet.

6. Install flanged vent section removed in step 2 and secure with clamps.

7. Secure flange to cabinet using screws removed in step1.

Drain Trap and Lines

In horizontal applications the condensate drain trap is secured to the furnace side panel, suspending it below the

furnace. A minimum clearance of 5.5" below the furnace

must be provided for the drain trap. Additionally, the appropriate downward piping slope must be maintained from the

drain trap to the drain location. Refer to Condensate Drain

Trap and Lines section in this manual or the installation

instructions for further details. If the drain trap and drain line

will be exposed to temperatures near or below freezing,

adequate measures must be taken to prevent condensate

from freezing. NOTE: The use of insulation and/or heat tape

is recommended. Failure to provide proper condensate drainage can result in property damage.

Side

Return

Duct

Connection

Bottom

Return

Duct

Connection

Side

Return

Duct

Connection

UPFLOW

UPRIGHT

Counterflow

Bottom

Return

Duct

Connection

UPFLOW HORIZONTAL

LEFT AIR DI SCHA RGE

Bottom

Return

Duct

IR

DISCHARGE

UPFLOW HORIZONTAL

RIGHT AIR DISCHARGE

90% Furnace Recommended Installation Positions

Alternate Electrical and Gas Line Connections

The furnaces have provisions allowing for electrical and gas

line connections through either side panel. In horizontal applications the connections can be made either through the

“top” or “bottom” of the furnace.

Drain Pan

A drain pan must be provided if the furnace is installed above

a conditioned area. The drain pan must cover the entire area

under the furnace (and air conditioning coil if applicable).

17

Page 18

SYSTEM OPERATION

Freeze Protection

If the drain trap and drain line will be exposed to temperatures near or below freezing, adequate measures must be

taken to prevent condensate from freezing. NOTE: The use

of insulation and/or heat tape is recommended. Failure to

provide proper condensate drainage can result in property

damage.

Propane Gas and/or High Altitude Installations

WARNING

P

OSSIBLE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH MAY OCCUR IF

THE CORRECT CONVERS ION KI TS ARE NOT I NST ALLED.

MUST BE APPLIED TO INSURE SAFE AND PROPER FURNACE OPERATION.

CONVERSIONS MUST BE PERF ORMED BY A QUALI F IE D INS TALLER O R SERV ICE

AGENCY.

This furnace is shipped from the factory configured for natural gas at standard altitude. Propane gas installations require an orifice change to compensate for the energy content difference between natural and propane gas.

High altitude installations may require both a pressure switch

and an orifice change. These changes are necessary to compensate for the natural reduction in the density of both the

gas fuel and the combustion air at higher altitude.

Refer to the Accessories Charts in this manual or product

Specification Sheet for a tabular listing of appropriate

manufacturer’s kits for propane gas and/or high altitude installations. The indicated kits must be used to insure safe

and proper furnace operation. All conversions must be performed by a qualified installer, or service agency.

VENT/FLUE PIPE AND COMBUSTION AIR PIPE

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN BODILY INJURY OR

DEATH.

ONLY)

CAREFU LL Y RE AD AN D FOL LO W AL L I NST RU CTI ON S GI VEN IN TH IS

SECTION.

WARNING

UPON COMPLETION OF THE FURNACE INSTALLATION, CAREFULLY INSPECT THE

ENTIRE FLUE SYSTEM BOTH INSIDE AND OUTSIDE THE FURNACE TO ASSURE IT

IS PROPERLY SEALED.

PERSONAL INJ URY O R DE ATH DUE TO E XPOSURE TO FLUE PRO DUCTS,

INCLUDING CARBON MONOXIDE.

LEAKS IN THE FLUE SYSTEM CAN RESULT IN SERIOUS

A condensing gas furnace achieves its high level of efficiency

by extracting almost all of the heat from the products of

combustion and cooling them to the point where condensation takes place. Because of the relatively low flue gas temperature and water condensation requirements, PVC pipe is

used as venting material.

This furnace must not be connected to Type B, BW, or L

vent or vent connector, and must not be vented into any

THE APPROPRIATE KIT S

ALL

portion of a factory built or masonry chimney except when

used as a pathway for PVC as described later in this section. Never common vent this appliance with another appliance or use a vent which is used by a solid fuel appliance.

It is the responsibility of the installer to follow the manufacturers’ recommendations and to verify that all vent/flue piping and connectors are compatible with furnace flue products. Additionally, it is the responsibility of the installer to

ensure that all piping and connections possess adequate

structural integrity and support to prevent flue pipe separation, shifting, or sagging during furnace operation.

Materials and Joining Methods

WARNING

O AVOID BODILY INJURY, FIRE OR EXPLOSION, SOLVENT CEMENTS MUST BE

T

KEPT AWAY FROM ALL IGNITION SOURCES (I.E., SPARKS, OPEN FLAMES, AND

EXCESSIVE HEAT) AS THEY ARE COMBUSTIBLE LIQUIDS.

CEMENT VAPORS OR CONTACT WITH SKIN AND/OR EYES.

VOID BREATHING

A

Precautions should be taken to prevent condensate from

freezing inside the vent/flue pipe and/or at the vent/flue

pipe termination. It is our recommendation that all vent/

flue piping exposed to temperatures below 35°F for

extended periods of time should be insulated with 1/2”

thick closed cell foam. Also all vent/flue piping exposed

outdoors in excess of the terminations shown in this manual

(or in unheated areas) should be insulated with 1/2” thick

closed cell foam. Inspect piping for leaks prior to installing

insulation.

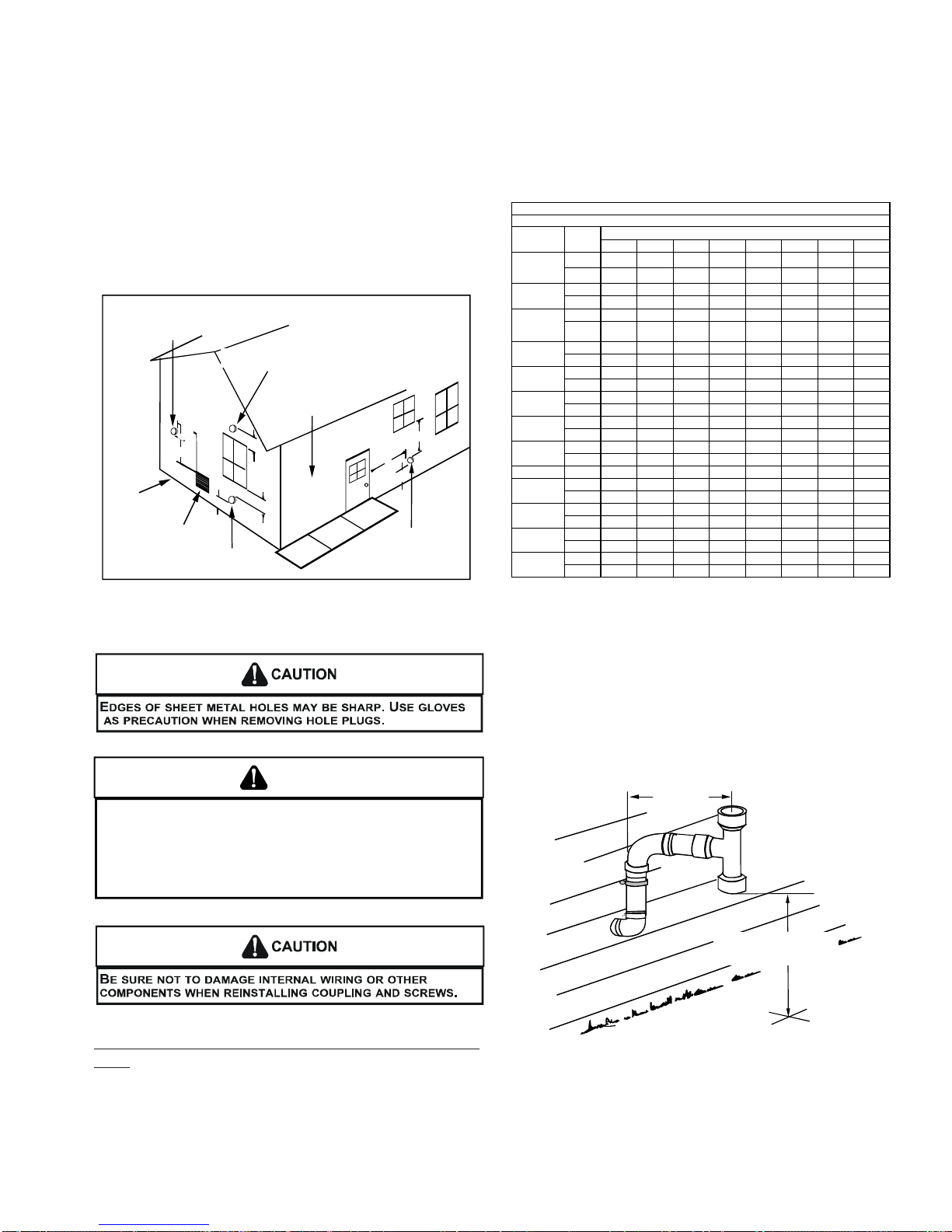

The following bullets and diagram describe the restrictions

concerning the appropriate location of vent/flue pipe and

combustion air intake pipe (when applicable) terminations.

Refer to or the installation instructions for specific details

on termination construction.

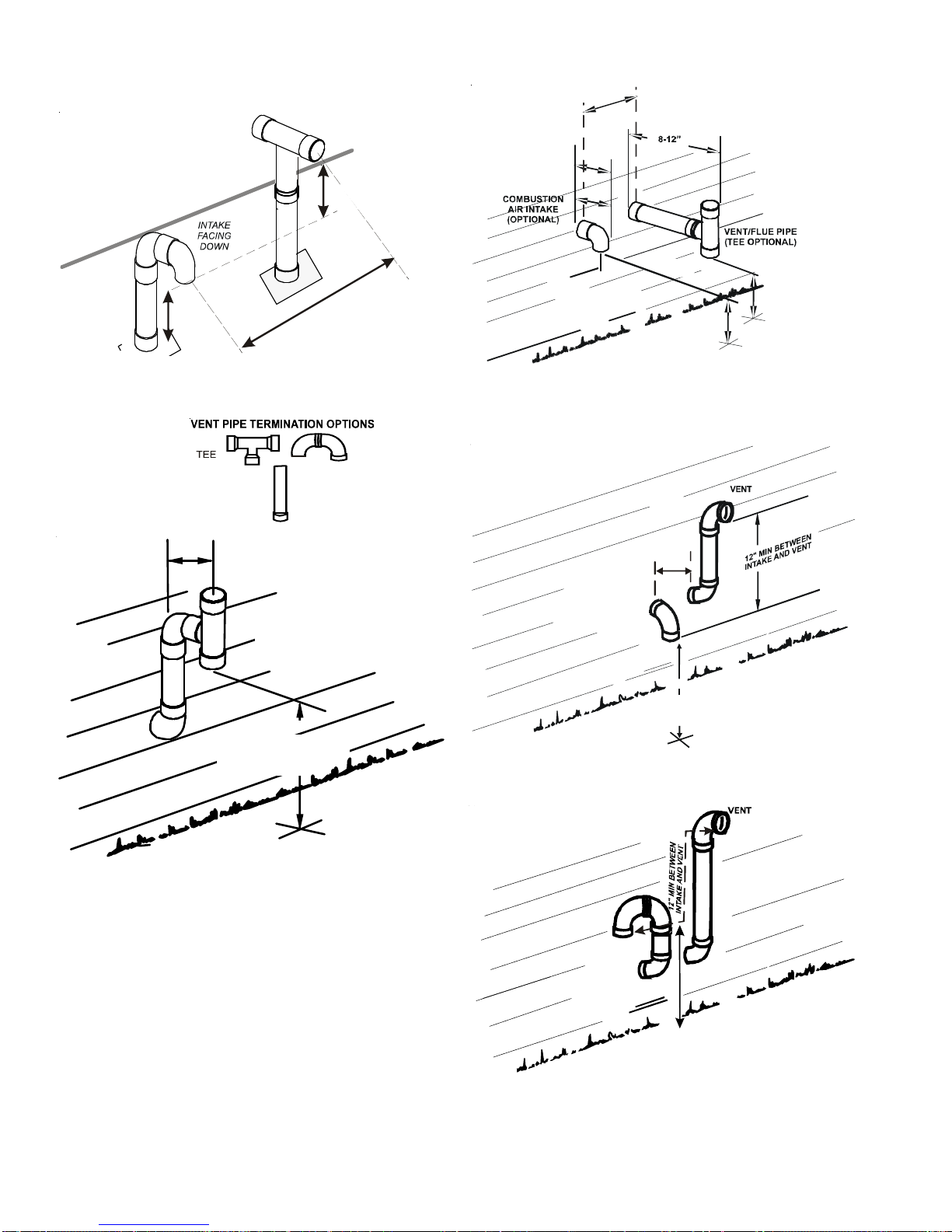

• All terminations must be located at least 12 inches

above ground level or the anticipated snow level.

• Vent terminations must terminate at least 3 feet

above any forced air inlet located within 10 feet.

NOTE: This provision does not apply to the combustion air intake termination of a direct vent application.

• The vent termination of a non-direct vent application

must terminate at least 4 feet below, 4 feet horizontally from, or 1 foot above any door, window, or gravity air inlet into any building.

• The vent termination of a direct vent application must

terminate at least 12 inches from any opening through

which flue gases may enter a building (door, window, or gravity air inlet).

• The vent termination of vent pipe run vertically through

a roof must terminate at least 12 inches above the

roof line (or the anticipated snow level) and be at

least 12 inches from any vertical wall (including any

anticipated snow build up).

18

Page 19

SYSTEM OPERATION

• A vent termination shall not terminate over public walkways or over an area where condensate or vapor

could create a nuisance or hazard or could be detrimental to the operation of regulators, relief valves, or

other equipment.

• The combustion air intake termination of a direct vent

application should not terminate in an area which is

frequently dusty or dirty.

NOTE: In Canada, the B149 Fuel Gas Code takes precedence over the preceding termination restrictions.

OTHER THAN

COMBUSTION AIR

TERMINATION INTAKE

NON-DIRECT VENT

VENT/FLUE TERM I NA TION

NO TERMINATIONS

ABOVE WALKWAY

GRADE OR HIGHEST

ANTICIPATED

SNOW LEV EL

FORCED AIR

INLET

10'

3"

VENT/FLUE TERMINATION

12"

12"

12"

DIRECT VENT

VENT/FLUE TERM INATION

4'

4'

12"

NON-DIRECT VENT

bustion air intake to prevent inadvertent blockage. The tee

or elbows used in the vent/flue termination must be included

when determining the number of elbows in the piping system.

(6)

(3) (5)

MODEL

*MEC960303AN

&

*MEC960403AN

*MEC960603AN

*MEC960302BN

&

*MEC960402BN

*MEC960603BN

*MEC960803BN

*MEC960804CN

*MEC961004CN

*MEC961005CN

*MEC961205DN

*CEC960403BN

*CEC960603BN

*CEC960803BN

*CEC961005CN

*MV C96/*CV C9 6 D irect V ent (2 - Pi p e) and Non-D irect V ent (1- Pi p e)

Maximum Allowable Length of Vent/Flue Pipe

12345678

2 7571676360565248

3 126 120 115 110 105 99 94 89

2 3733302622181511

3 107 102 96 91 86 81 75 70

2 100 95 90 85 80 75 70 65

3 168 161 154 147 140 133 126 119

2 5045403530252015

3 143 136 129 122 115 108 101 94

2 6055504540353025

3 113 106 99 92 85 78 71 64

2 6055504540353025

3 120 113 106 99 92 85 78 71

2 4540353025201510

3 103 96 89 82 75 68 61 54

2 4540353025201510

3 151 144 137 130 123 116 109 102

3 185 178 171 164 157 150 143 136

2 100 95 90 85 80 75 70 65

3 110 103 96 89 82 75 68 61

2 4540353025201510

3 110 103 96 89 82 75 68 61

2 353025201510 5NA

3 103 96 89 82 75 68 61 54

2 4540353025201510

3 110 103 96 89 82 75 68 61

Number of Elbows

^

^

Pipe Size

(4)

(in.)

90% Furnace Vent Termination Clearances

WARNING

HE RUBBER ELBOW IS NOT DESIGNED TO SUPPORAT A LOAD. WHEN THE

T

RUBBER ELBOW IS MOUNTED EXTERNALLY TO THE FURNACE CABINET,

EXTREME CARE MUST BE TAKEN TO ADEQUATELY SUPPORT FIELD-SUPPLIED

VENT/FLUE PIPING, AS DAMAGE CAN RESULT IN LEAKS CAUSING BODILY

INJURY OR DEATH DUE TO EXPOSURE TO FLUE GASES, INCLUDING CARBON

MONOXIDE.

Vent/Flue Pipe Lengths (Non-Direct Vent) and Diameters

Refer to the following tables for applicable length, elbows,

and pipe diameter for construction of the vent/flue pipe system of a non-direct vent installation. In addition to the vent/

flue pipe, a single 90° elbow must be secured to the com-

1) Maximum allowable limits listed on individual lengths for inlet and flue and NOT a combination.

2) Minimum requirement for each vent pipe is five (5) feet in length and one elbow/tee.

3) Tee used in the vent/flue termination must be included when determining the number of elbows in

the piping system.

4) 2 1/2” or 3” diameter pipe can be used in place of 2” diameter pipe.

5) Increased Clearance Configurations using (2) 45 deg. Long Sweep elbows should be considered equivalent to one 90 deg. elbow.

6) One 90° elbow should be secured to the combustion air intake connection.

12" MINIMUM

VENT/FLUE TEE

OR

90° ELBOW TURNED

DOWN

12" MINIMUM ABOVE

HIGHEST ANTICIPATED

SNOW LEVEL

90% Furnace Horizontal Termination (Single Pipe)

Above Highest Anticipated Snow Level

NOTE: Terminate both pipes in the same pressure zone

(same side of roof, no major obstacles between pipes,

etc.).

19

Page 20

SYSTEM OPERATION

d

c

TEE (OPTIONAL)

COMBUSTION AIR INTAKE

(OPTIONAL)

*Not required for

single pipe installation

E

N

I

L

F

O

O

R

X

A

M

”

6

12” MIN TO ROOF OR HIGHEST

ANTICIPATED SNOW LEVEL

9

12” MIN

HEIGHT DIFFERENCE

BETWEEN

INTAKE AND VENT

.

N

I

M

”

3

-

.

10”- 24”

6” MAX

4” MIN

90º OR 45°

ELBOW

12" MIN. TO GRADE OR

HIGHEST ANTICIP AT ED

SNOW LEVEL

Standard Horizontal Terminations (Dual Pipe)

12" MIN.

Horizontal Termination (Single Pipe)

Above Highest Anticipated Snow Level

ELBOWS

STRAIGHT

VENT/FLUE TEE (

TURNED DO W N or

90° ELBOW TURNE D

or

45° ELBOW

DOWN

12" MIN. ABOVE

HIGHEST ANTICI P ATED

SNOW LEVEL

OPTIONAL)

90°

ELBOWS

3” - 24”

12" MIN. ABOVE

HIGHEST ANTICIPA TED

SNOW LEVEL

Alternate Horizontal Vent Termination (Dual Pipe)

90°

ELBOWS

20

3”-24” BETWEEN PIPES

12"MIN.ABOVE

HIGHEST ANTICIPATED

SNOW LEVE L

Combustion Air Intake may also be snorkeled to obtain 12” min groun

learance.

AlternateVentTerminationAboveAnticipated SnowLevel

(DualPipe)

Page 21

SYSTEM OPERATION

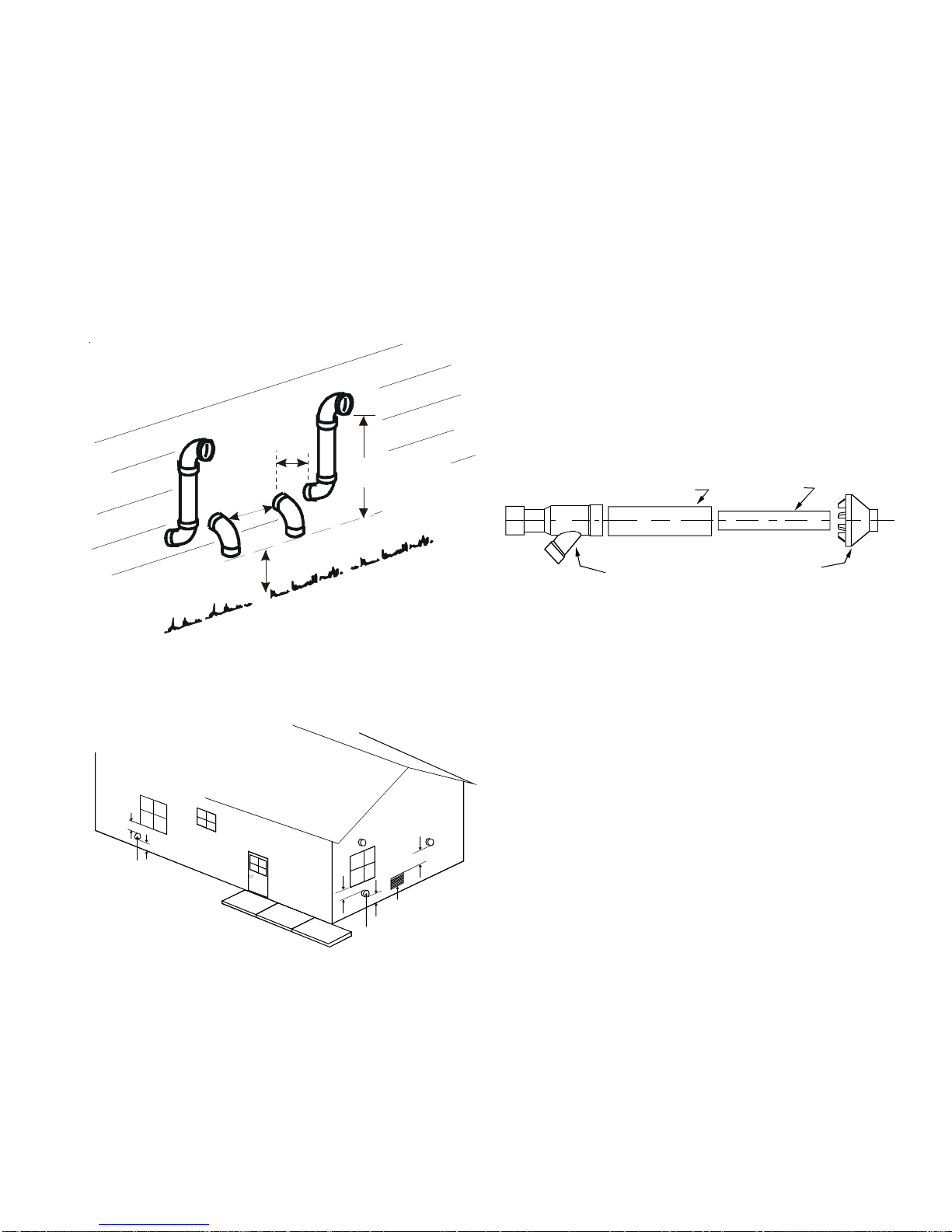

VENT/INTAKE TERMINATIONS FOR INSTALLATION OF MUL-

TIPLE DIRECT VENT FURNACES

If more than one direct vent furnace is to be installed vertically through a common roof top, maintain the same minimum clearances between the exhaust vent and air intake

terminations of adjacent units as with the exhaust vent and

air intake terminations of a single unit.

If more than one direct vent furnace is to be installed horizontally through a common side wall, maintain the clearances as in the following figure. Always terminate all exhaust vent outlets at the same elevation and always terminate all air intakes at the same elevation.

3”MIN

24”MAX

12” MIN SEPARATIO N

3” MIN

1. The vent termination must be located at least 12” above

ground or normally expected snow accumulation levels.

2. Do NOT terminate over public walkways. Avoid areas

where condensate may cause problems such as above

planters, patios, or adjacent to windows where steam

may cause fogging.

3. The vent termination shall be located at least 4’

horizontally from any electric meter, gas meter,

regulator and any relief equipment. These distances

apply ONLY to U.S. Installations.

4. The vent termination shall be located at least 3’ above

any forced air inlet located within 10’; and at least 10’

from a combustion air intake of another appliance,

except another direct vent furnace intake.

5. In Canada, the Canadian Fuel Gas Code takes

precedence over the preceding termination instructions.

3" or 4" Diameter

SDR-26 Pipe

2 or 2 1/2" Diameter

SDR-26 Pipe

12” MIN TO GRADE OR HIGHEST

ANT ICIP ATED SNOW LEVEL

Termination of Multiple Direct Vent Furnaces

9"

12"

Direct Vent

Terminal

50,000 Btuh

or less

12"

Direct Vent Terminal

More than 50,000 Btuh

FIGURE 1

(DCVK) Vent Termination Clearances

12"

Forc e d A ir Inlet

2" or 3" Diameter

2" or 3" Diameter

Y Concentric Fitting

Rain Cap

These kits are for vertical or horizontal termination of the

combustion air inlet and the exhaust vent pipes on Category

IV gas-fired condensing furnaces. The DCVK-30 (CVENT-

3) kit can be used for 3” diameter pipe systems. The DCVK-

20 (CVENT-2) kit can be used for the 2” diameter pipe

system. Both the combustion air inlet and the exhaust vent

pipes must attach to the termination kit. The termination

kit must terminate outside the structure and must be installed

per the instructions outlined below for vertical or horizontal

termination. Vertical termination is preferred. Field supplied

pipe and fittings are required to complete the installation.

3'

D

A

R

G

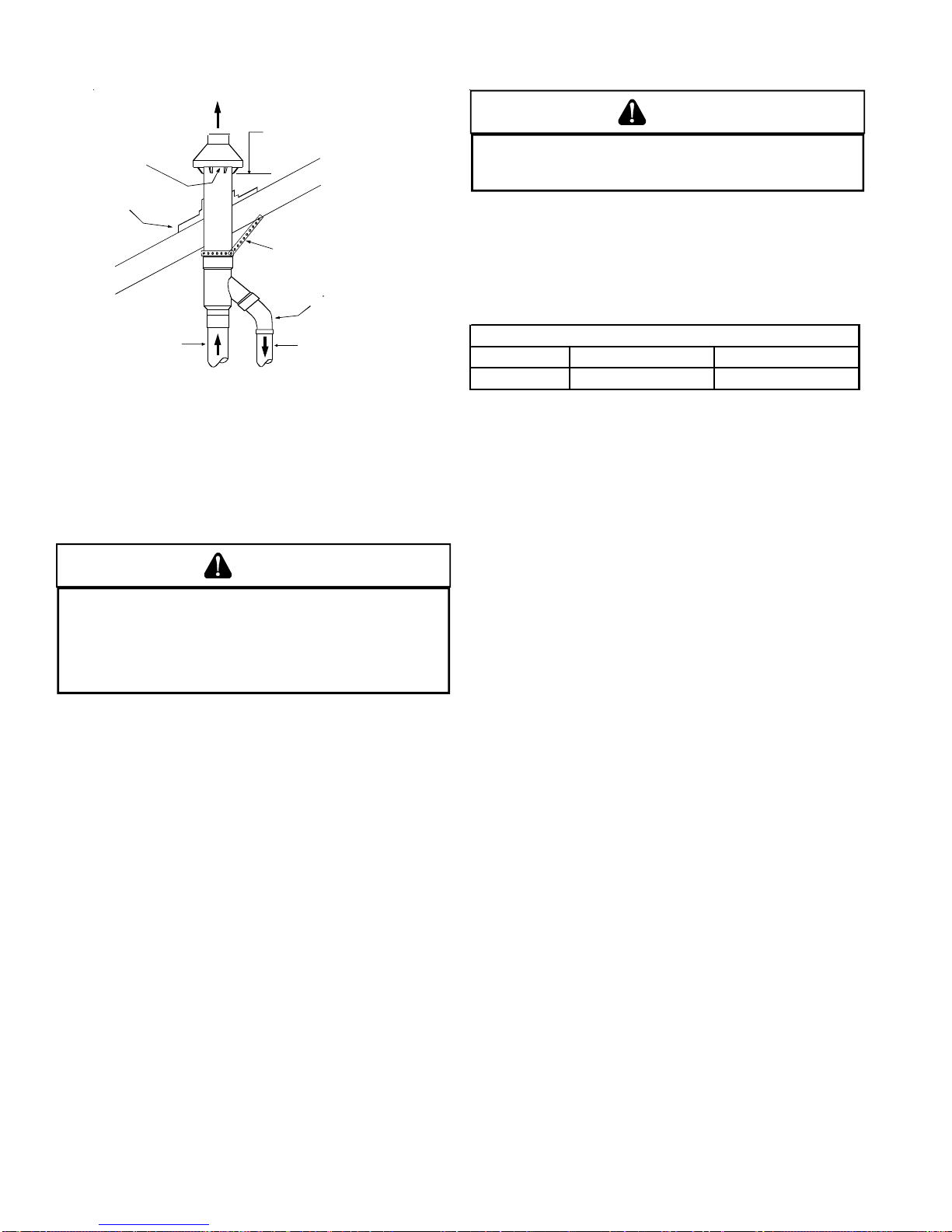

1. Determine the best location for the termination kit. Roof

E

termination is preferred since it is less susceptible to

damage, has reduced intake contaminants and less

visible vent vapors. For side termination, consideration

should be given to:

a. Possible damage from the vapors to plants/shurbs,

other equipment and building materials

b. Possible damage to the terminal from foreign ob-

jects

c. Wind effects that may cause recirculation of flue

products, debris or light snow

d. Visible vent vapors.

21

Page 22

SYSTEM OPERATION

Vent

Maintain 12" (18" for Canada)

minimum clearance above highest

anticipated snow level. Maximum of

Combustion Air

Roof Boot/Flashing

(Field Supplied)

24" above roof.

Support (Field Supplied)

45 Elbow

(Field Supplied)

CAUTION

O PREVENT UNRELI ABLE OPE RATION OR EQUIP MENT DAMAGE, THE INLE T

T

GAS SUPPLY PRESSURE MUST BE AS SPECIFIED ON THE UNIT RATING PLATE

WITH ALL OTHE R HOUSEHOL D GAS FIRED APPLIANCES O PERATING.

Inlet gas supply pressures must be maintained within the

ranges specified below. The supply pressure must be constant and available with all other household gas fired appliances operating. The minimum gas supply pressure must

be maintained to prevent unreliable ignition. The maximum

must not be exceeded to prevent unit overfiring.

Vent

Combustion Air

Condensate Drain Lines and Drain Trap

A condensing gas furnace achieves its high level of efficiency

by extracting almost all of the heat from the products of

combustion and cooling them to the point where condensation takes place. The condensate which is generated must

be piped to an appropriate drain location.

WARNING

N UPRIGHT UPFLOW INS TALLATIONS, THE DRA IN TRAP MUST BE MOUNTED ON

I

THE OPPOSITE S IDE OF THE UNIT FROM THE JUNC TION BOX.

REDUCE THE RIS K OF WATER REACH ING THE JUNCTION BOX I N THE EVENT OF

A BLOCKED DRAIN CONDITION.

CAN RESULT IN PO SSIBLE PROPE RTY DAMAGE, PERS ONAL INJURY, OR DEATH

DUE TO EL ECT RIC AL S HOC K.

AILURE TO FOLLOW THESE I NSTRUCTIONS

F

HIS WILL

T

• If the drain line is routed through an area which may

see temperatures near or below freezing, precautions must be taken to prevent condensate from

freezing within the drain line.

• If an air conditioning coil is installed with the

furnace, a common drain may be used. An open

tee must be installed in the drain line, near the

cooling coil, to relieve positive air pressure from the

coil’s plenum. This is necessary to prohibit any

interference with the function of the furnace’s drain

trap.

GAS SUPPLY AND PIPING

The furnace rating plate includes the approved furnace gas

input rating and gas types. The furnace must be equipped to

operate on the type of gas applied. This includes any conversion kits required for alternate fuels and/or high altitude.

INLET GAS SUPPLY PRESSURE

Natural Gas Minimum: 4.5" w.c. Maximum: 10.0" w.c.

Propane Gas Minimum: 11.0" w.c. Maximum: 13.0" w.c.

HIGH ALTITUDE DERATE