Page 1

Installation, Operation and Maintenance Manual

Group: Chiller

Part Number: 331975001

Effective: March 2012

Supersedes: January 2012

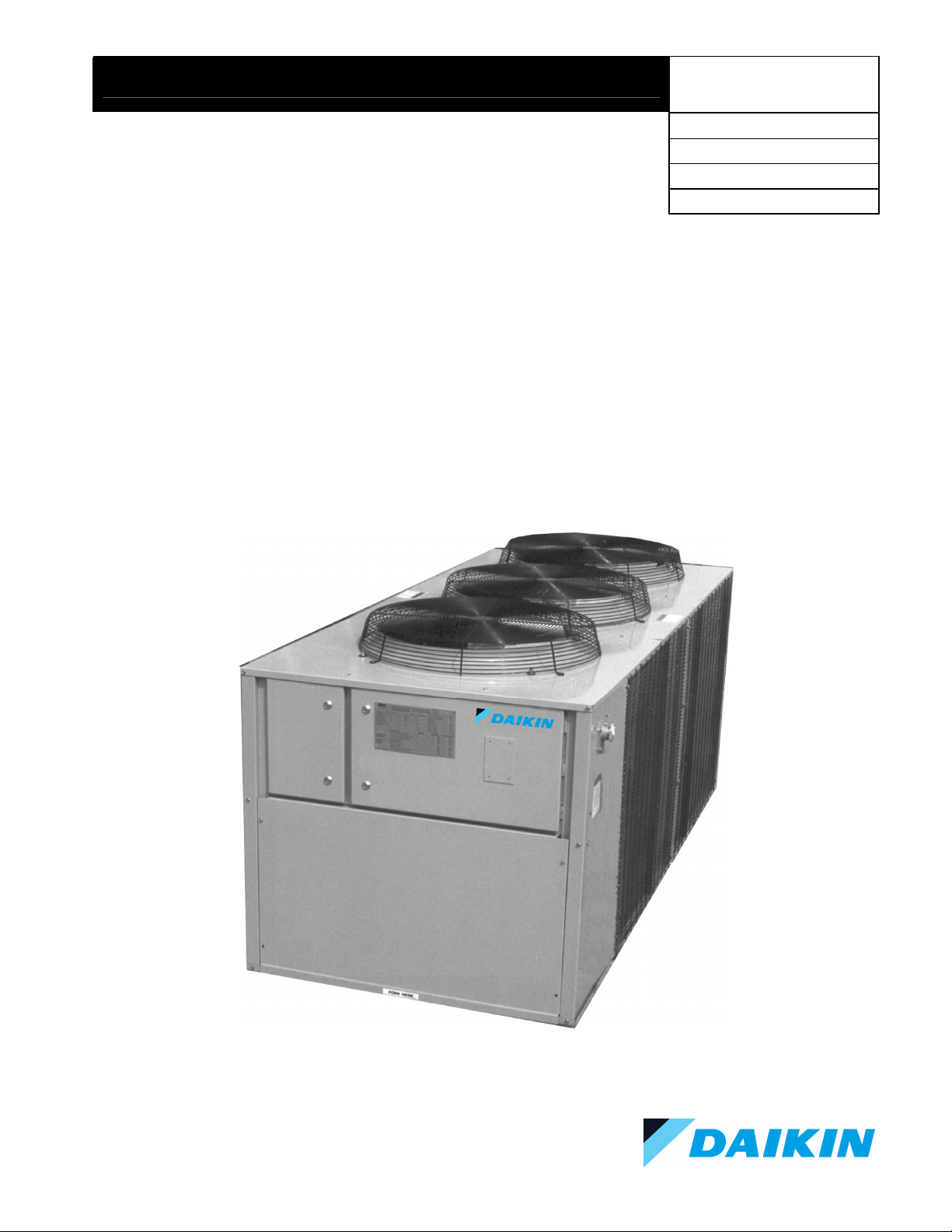

Air-Cooled Scroll Compressor Water Chillers

AGZ 010BS – AGZ 034BS, Packaged Chiller

AGZ 010BM – AGZ 034BM, Remote Evaporator

10 to 34 Tons, 35 to 120 kW

R-407C

60 Hertz

Software Version AGZSU0102D

IOMM 1155

Page 2

Table of Contents

Introduction........................................3

General Description...................................3

Inspection ..................................................3

Installation .................................................3

Handling ....................................................3

Location.....................................................4

Service Access...........................................4

Vibration Isolators .....................................5

Chilled Water System ................................9

Water Connections...................................11

Refrigerant Charge ..................................11

Unit Component Location .......................11

Glycol Solutions......................................12

Evaporator Water Flow and Pressure Drop12

R-407C Units ....................................14

Control Layout and Operation.......16

Control Center .........................................16

Start-up and Shutdown....................16

Pre Start-up..............................................16

Start-up ....................................................16

Sequence of Operation ............................17

Physical Data ....................................18

AGZ-BS, R-407C....................................18

AGZ-BM, R-407C...................................20

Electrical Data..................................22

Field Wiring.............................................22

R-407C ....................................................22

Notes for Electrical Data .........................25

Dimensions & Weights.....................27

Remote Evaporators ................................29

ACZ/AGZ Dimensions and Weights .......30

Lubrication.............................................. 31

Electrical Terminals ................................ 31

Condensers.............................................. 31

Refrigerant Sight glass............................ 31

Standard MicroTech II Controller. 32

Table of Contents .................................... 32

Overview................................................. 33

General Description ................................ 33

Setpoint Security..................................... 37

Equipment Protection Alarms ................. 37

Control Functions and Definitions.......... 38

Unit Enable ............................................. 39

Unit Mode............................................... 39

Power Up Start Delay ............................. 40

Ice Mode Start Delay .............................. 40

Unit State ................................................ 40

Evaporator Water Pump State Control .... 41

Condenser Fans....................................... 43

Low OAT Start........................................ 43

Circuit Capacity Overrides ..................... 43

Maximum LWT Rate .............................. 44

Low Ambient Lockout ............................ 44

Compressor Control................................ 44

Using the Controller................................ 47

Menu Screens.......................................... 48

BAS Interface................................... 60

Service............................................... 61

Thermostatic Expansion Valve ............... 61

Filter-Driers............................................. 61

Liquid Line Solenoid .............................. 61

Optional Controls.................................... 62

Troubleshooting Chart ............................ 65

System Maintenance ........................31

General ....................................................31

©2012 Daikin. Illustrations and data cover the Daikin product at the time of publication and we reserve the right to make

changes in design and construction at anytime without notice. ™® The following are trademarks or registered trademarks of

their respective companies: BACnet from ASHRAE; LONMARK, LonTalk, LONWORKS, and the LONMARK logo are managed,

granted and used by LONMARK International under a license granted by Echelon Corporation; Compliant Scroll from Copeland

Corporation; ElectroFin from AST ElectroFin Inc.; Modbus from Schneider Electric; FanTrol, MicroTech II, Open Choices, and

SpeedTrol from Daikin.

2 AGZ 010B through 034B IOMM 1155

Page 3

Introduction

General Description

Daikin air-cooled water chillers are complete, self-contained automatic refrigerating units. Every

unit is completely assembled, factory wired, charged, and tested. Each unit consists of air-cooled

condensers, Copeland Compliant Scroll hermetic compressor, brazed plate-to-plate evaporator,

and complete refrigerant piping. Liquid line components include sight-glass/moisture indicator,

solenoid valve, and thermal expansion valve. Other features include a compressor heater, and

evaporator heater for chilled water freeze protection.

The electrical control center includes all equipment protection and operating controls necessary for

automatic operation. Condenser fan motors are three-phase (except single-phase on No. 1 fan with

SpeedTrol option) and started by their own contactors and have inherent overload protection. Each

compressor has solid-state motor protection for inherent thermal overload protection except Model

AGZ 010 that has internal line breakage.

Software Version

This manual is based on software version AGZSU0102D. The software version can be displayed by

pressing the Enter and Menu keys simultaneously. Exit by pressing Menu.

Inspection

Check all items carefully against the bill of lading. Inspect all units for damage upon arrival. Report

shipping damage and file a claim with the carrier. Check the unit nameplate before unloading to be

sure it agrees with the power supply available. Units are shipped FOB factory and Daikin is not

responsible for physical damage after unit leaves the factory.

Note: Unit shipping and operating weights are listed on pages 18 and 19.

Installation

Note: Installation must be performed by trained, experienced personnel who are familiar

with local codes and regulations, especially concerning refrigerant release to the

atmosphere.

!

WARNING

Sharp edges and coil surfaces can cause personal injury. Avoid contact with them.

Handling

Be careful to avoid rough handling of the unit. Do not push or pull the unit from anything other than

the base. Block the pushing vehicle away from the unit to prevent damage to the sheet-metal cabinet

and end frame (see Figure 1). To lift the unit, lifting slots are provided in the base of the unit.

Arrange spreader bars and cables to prevent dam

HAZARD IDENTIFICATION INFORMATION

Warnings indicate potentially hazardous situations, which can result in property damage, severe personal

injury, or death if not avoided.

age to condenser coils or cabinet (see Figure 2).

!

WARNING

!

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or equipment

damage if not avoided.

IOMM 1155 AGZ 010B through 034B 3

Page 4

Figure 1, Suggested Pushing Arrangement

BLOCKING REQUIRED

ACROSS FULL WIDTH

Figure 2, Suggested Lifting Arrangement

SPREADER BAR (2)

NOTE:: The fork lift slots can be used for

lifting by inserting sufficiently strong pipe

through them as shown in Figure 2.

Use the outboard slots on three-fan units

and the only two on two-fan units.

PIPE SLUNG THRU

OPENINGS IN LEGS (2)

Location

Unit Placement

AGZ units are for outdoor applications and can be mounted on a roof or at ground level. Set units on

a solid and level foundation. For roof-mounted applications, install the unit on a steel channel or Ibeam frame to support the unit above the roof. For ground level applications, install the unit on a

substantial base that will not settle. A one-piece concrete slab with footings extended below the frost

line is recommended. Be sure the foundation is level (within 1/2” [13 mm] over its length and width).

The foundation must support the operating weights listed in the Physical Data Tables on pages 18 and

19. It is recommended that the unit be raised a few inches with a suitable support, located at least

under the m

ounting locations, to allow

under it.

Since its operation is affected by wind, the unit should be located so that its length is parallel with the

prevailing wind. If this is not practical, use field fabricated wind deflectors.

water to drain from under the unit and to facilitate cleaning

Service Access

Each end of the unit must be accessible after installation for periodic service. Compressors, filterdriers, and liquid line solenoid valve are accessible from the end of the unit. High-pressure, lowpressure, and motor protector controls are on the compressor. Most operating, equipment protection,

and starting controls are located in the unit control box.

The fan deck with the condenser fans and motors can be removed from the top of the unit.

4 AGZ 010B through 034B IOMM 1155

Page 5

Clearances

The flow of air to and from the

condenser coil must not be limited.

Restricting airflow or allowing air

recirculation will result in a decrease in

unit performance and efficiency. There

must be no obstruction above the unit

that would deflect discharge air

downward where it could be

recirculated back to the inlet of the

condenser coil. The condenser fans are

propeller type and will not operate with

ductwork on the fan outlet.

Install the unit with enough side

clearance for air entrance to the coil and

for servicing. Provide service access to

the evaporator, compressors, electrical

control panel and piping components as

shown in Figure 3. Do not block access to

the unit with piping or conduit.

Do not allow debris to accumulate near the

unit. Air movement may draw debris into

the condenser coil causing air starvation.

Give special consideration to low ambient

operation where snow can accumulate.

Keep condenser coils and fan discharge free

of snow or other obstructions to permit

adequate airflow.

Sound Isolation

The low sound levels of the AGZ chiller are

suitable for most applications. When

additional sound reduction is necessary,

locate the unit away from sound sensitive

areas. Avoid locations beneath windows or

between structures where normal operating

sounds may be objectionable. Reduce

structurally transmitted sound by isolating

water lines, electrical conduit and the unit

itself. Use wall sleeves and rubber isolated

piping hangers to reduce transmission of

water or pump noise into occupied spaces.

Use flexible electrical conduit to isolate

sound through electrical conduit. Spring

isolators are effective in reducing the low

amplitude sound generated by the Discus

semi-hermetic compressors and for unit

isolation in sound-sensitive areas.

Figure 3, Clearance requirements

4 Ft. (1220mm)

Clearance for Air Inlet

4 Ft.

(1220mm)

Clearance for

Service Access

4 Ft. (1220mm)

Clearance for Air Inlet

The recommended minimum side clearance between two units

is 8 feet (2440mm).

The unit must not be installed in a pit or enclosure that is

deeper or taller than the height of the unit unless extra space

is provided. The minimum clearance on each side of the

unit is 6 feet (1828mm) when installed in a pit. The pit cannot

be deeper than the unit.

The minimum clearance to a side wall or building taller than

the unit height is 6 feet (1828mm) provided no solid wall

above 6 feet (1828mm) tall is closer than 12 feet (3658mm)

to the opposite side of the unit.

4 Ft.

(1220mm)

Clearance for

Service Access

Vibration Isolators

Vibration isolators are recommended for

all roof-mounted installations or wherever vibration transmission is a consideration.

IOMM 1155 AGZ 010B through 034B 5

Page 6

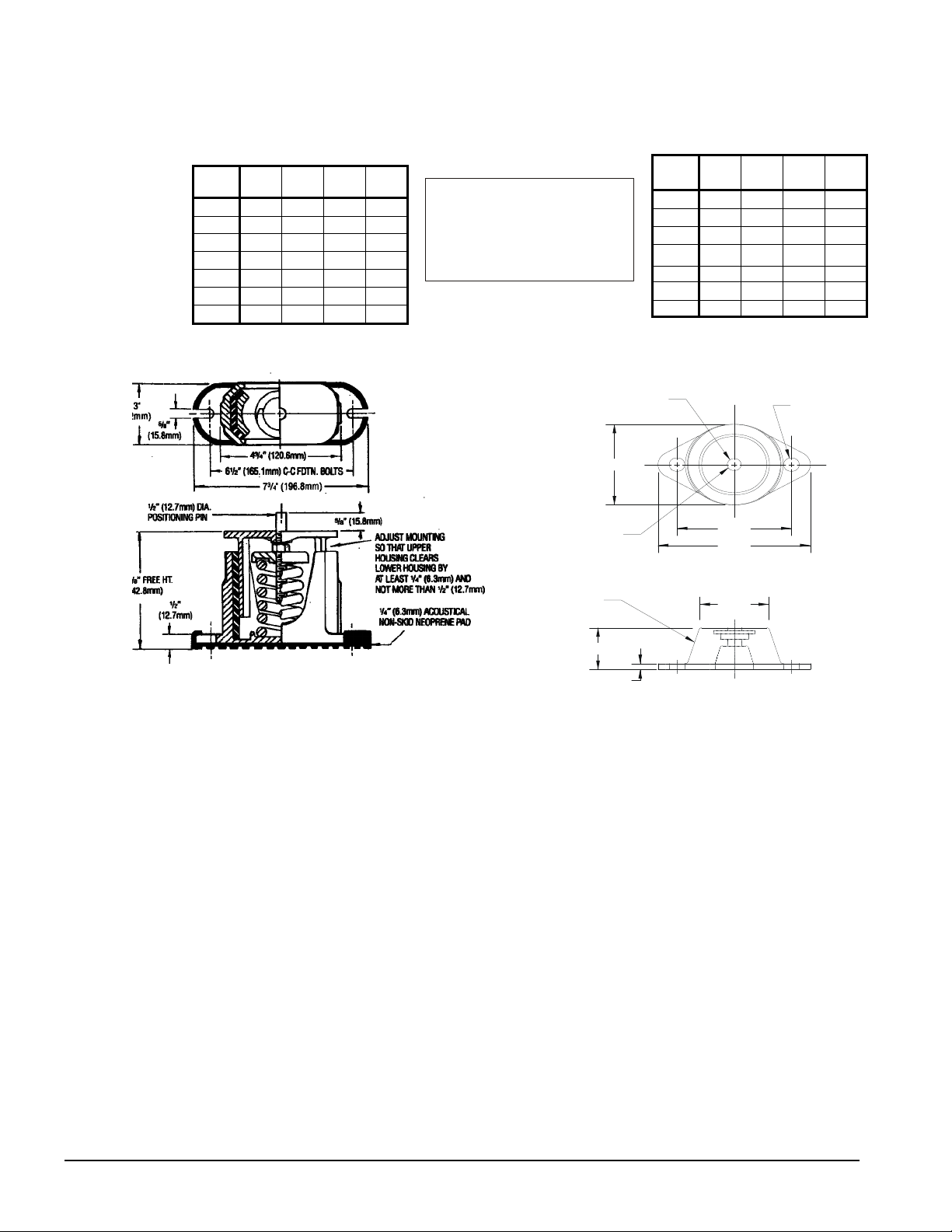

The unit should be initially placed on shims or blocks at the listed free height. When all piping,

wiring, flushing, charging, etc. is completed, the springs are adjusted upward to loosen the blocks

or shims that are then removed.

A rubber anti-skid pad is part of the isolator. Installation of spring isolators requires flexible

piping connections and at least three feet of flexible conduit to avoid straining the piping and

transmitting vibration and noise. These units cannot be bolted to isolators.

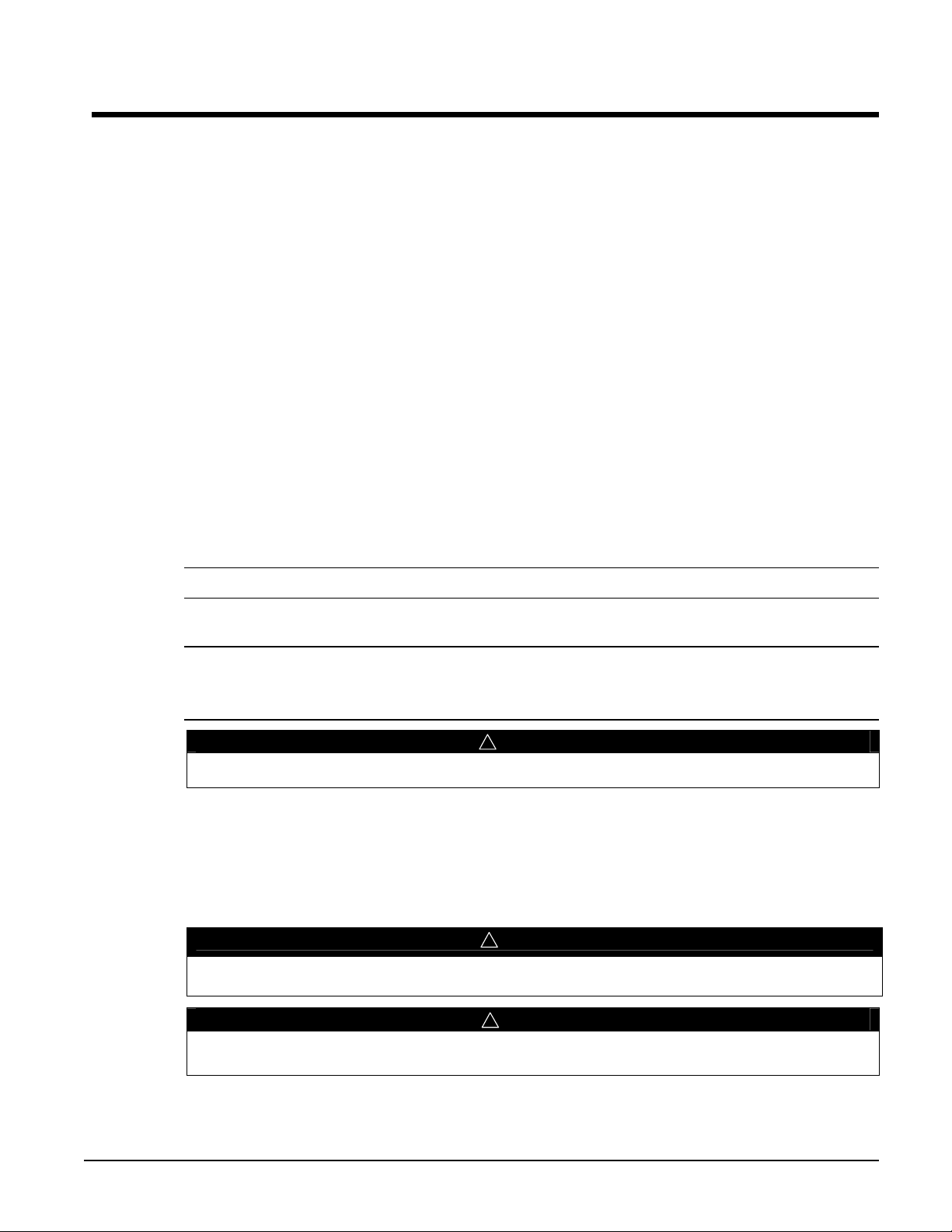

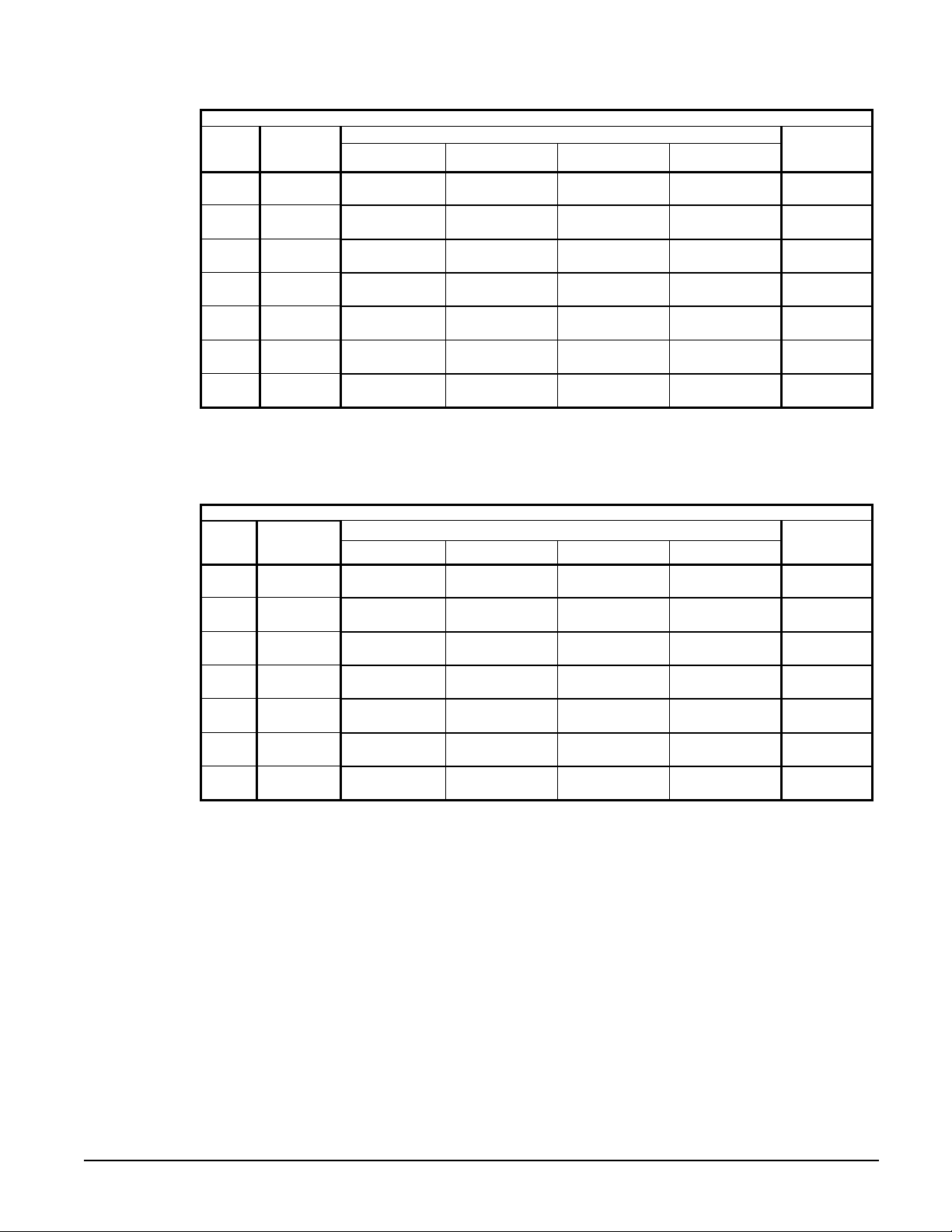

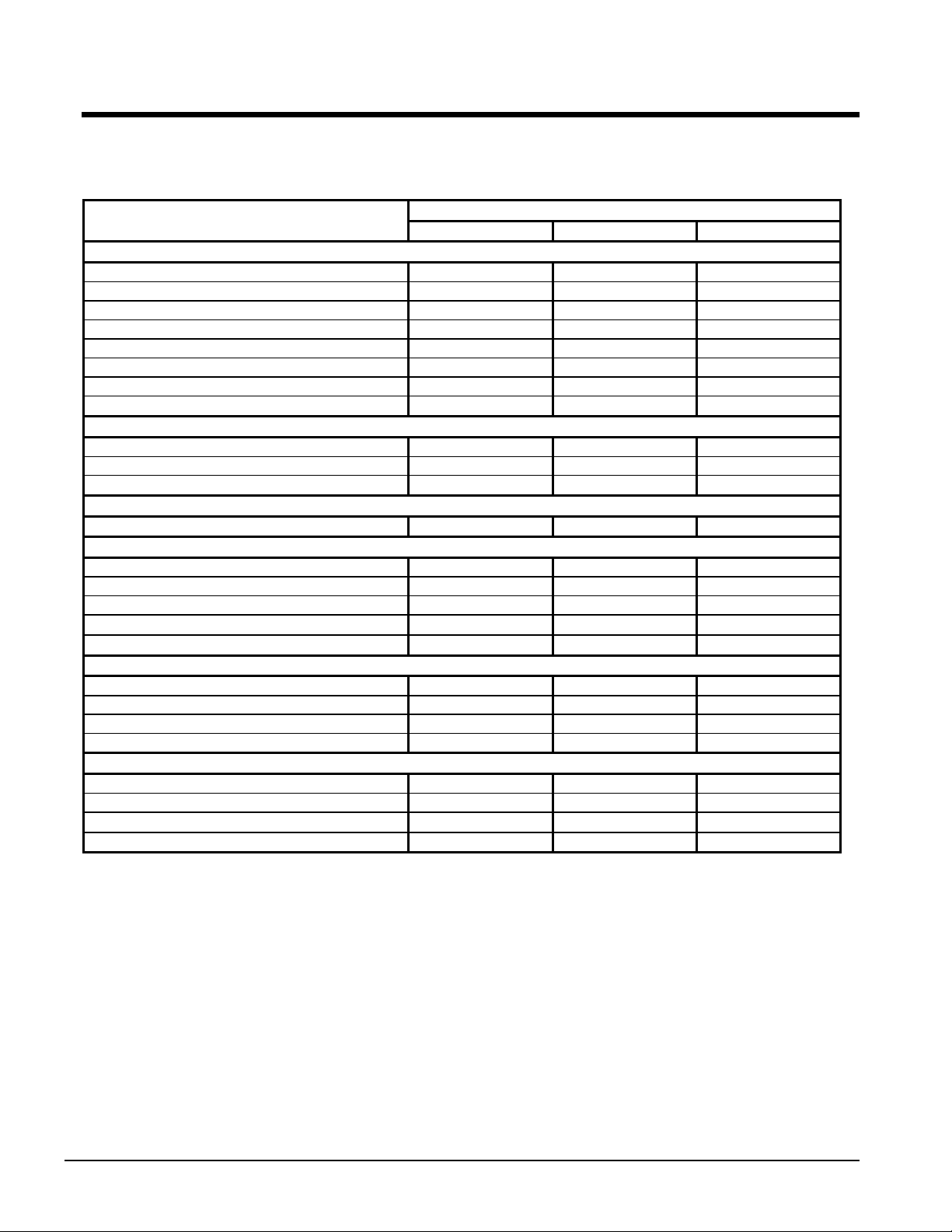

Table 1, Packaged & Remote Evaporator, R-I-S Isolator Locations, Aluminum Fins

UNIT

SIZE

010

013

017

020

025

029

034

OPER.

WGT

LBS.

1085

1170

1280

1505

1610

1800

2270

LF RF LB RB

RP-3 RP-3 RP-3 RP-3

Brick Red Brick Red Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Brick Red Brick Red Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Brick Red Brick Red Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Lime Lime Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Lime Lime Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Lime Lime Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Charcoal Charcoal Brick Red Brick Red

Note: See dimension drawing for location of isolators.

R-I-S, ALUMINUM FINS

MOUNTING LOCATION

KIT PART

NUMBER

332325001

332325001

332325001

332325002

332325002

332325002

332325003

Table 2, Packaged & Remote Evaporator, R-I-S Isolator Locations, Copper Fins

UNIT

SIZE

010

013

017

020

025

029

034

OPER.

WGT

LBS.

1085

1170

1280

1505

1610

1800

2270

LF RF LB RB

RP-3 RP-3 RP-3 RP-3

Brick Red Brick Red Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Brick Red Brick Red Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Brick Red Brick Red Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Lime Lime Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Lime Lime Brick Red Brick Red

RP-3 RP-3 RP-3 RP-3

Charcoal Charcoal Lime Lime

RP-3 RP-3 RP-3 RP-3

Charcoal Charcoal Lime Lime

Note: See dimension drawing for location of isolators.

R-I-S, COPPER FINS

MOUNTING LOCATION

KIT PART

NUMBER

332325001

332325001

332325001

332325002

332325002

332325004

332325004

6 AGZ 010B through 034B IOMM 1155

Page 7

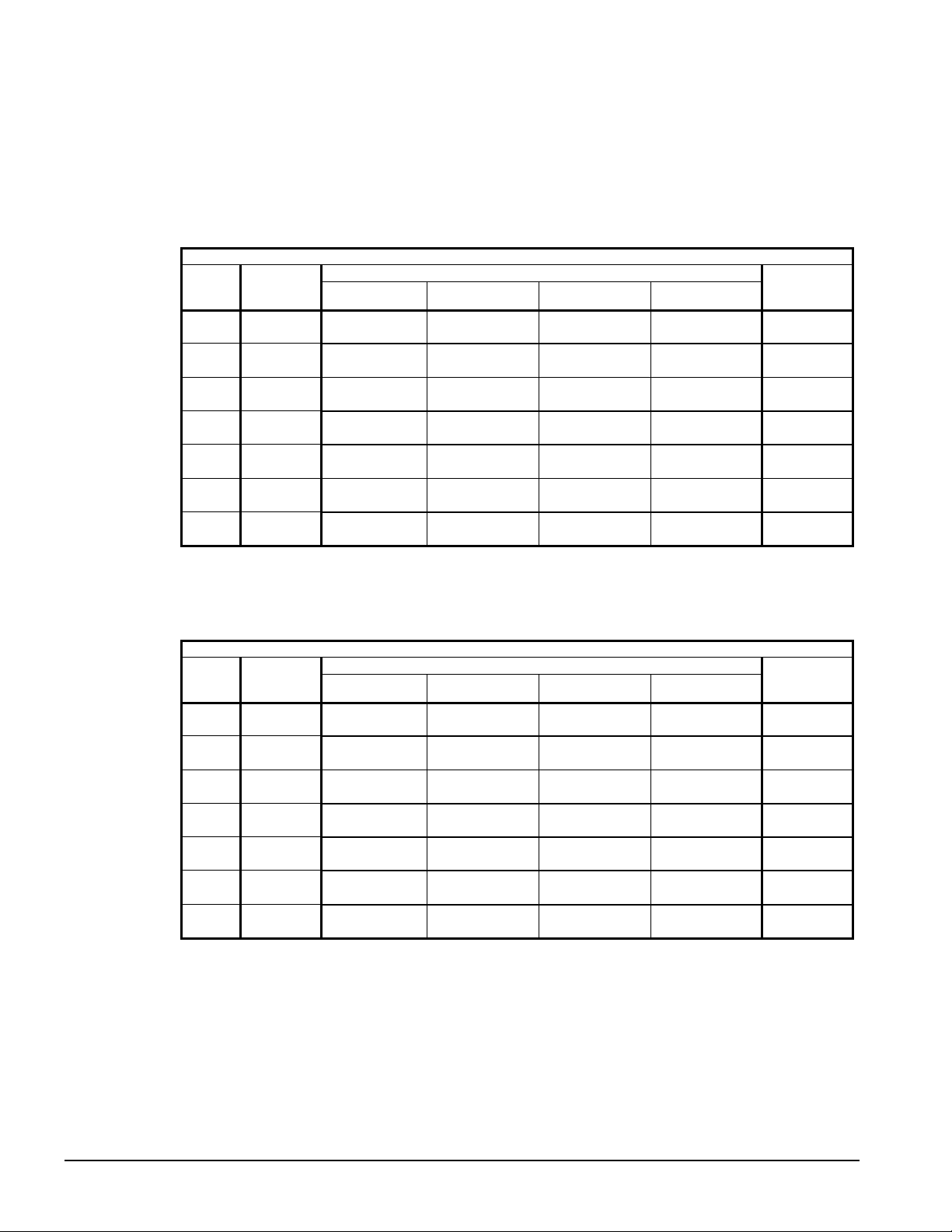

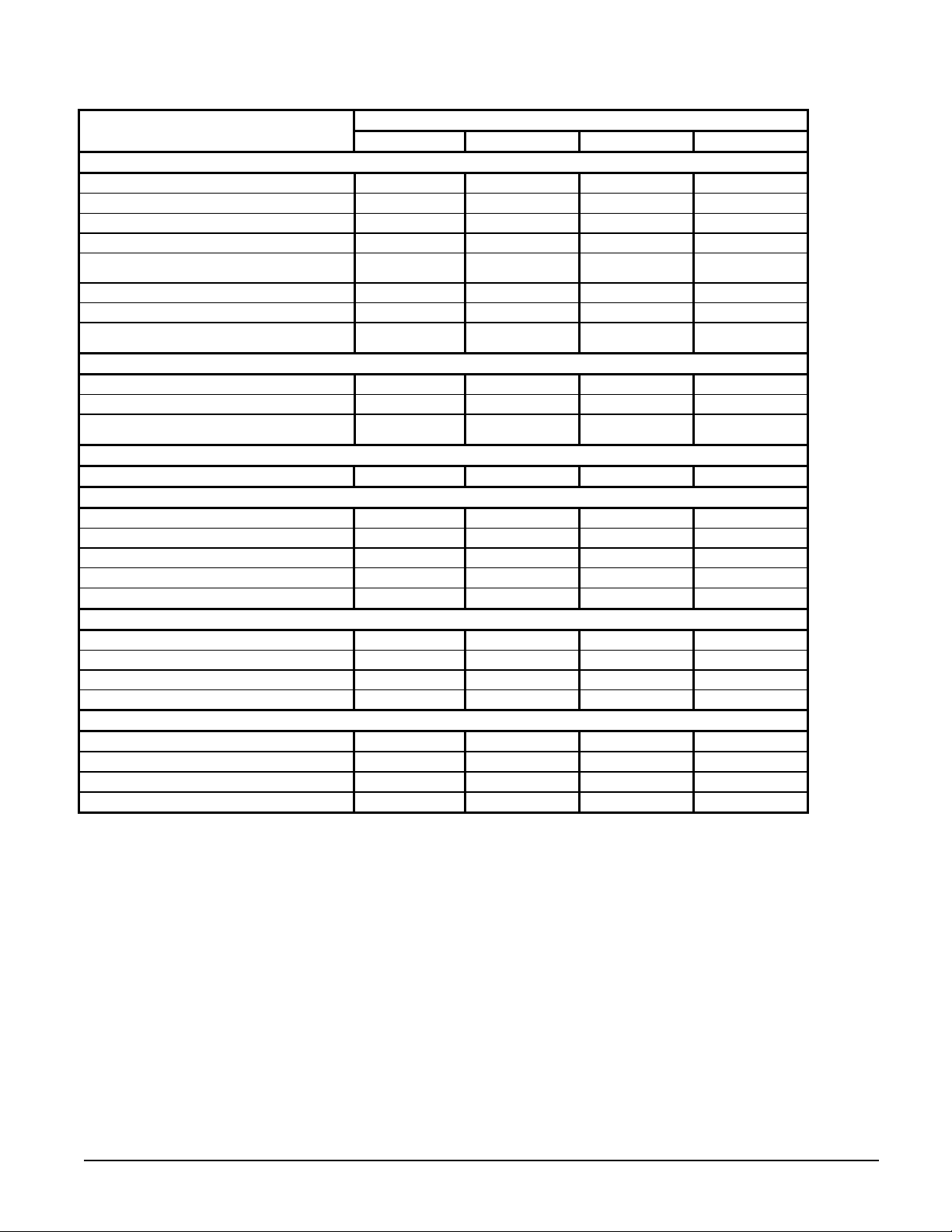

Table 3, Packaged & Remote Evaporator, Spring Isolator Locations, Al. Fins

,

UNIT

SIZE

010

013

017

020

025

029

034

OPER.

WGT

LBS.

1085

1170

1280

1505

1610

1800

2270

LF RF LB RB

C1PE-1D-340 C1PE-1D-340 C1PE-1D-340 C1PE-1D-340

Red Red Red Red

C1PE-1D-340 C1PE-1D-340 C1PE-1D-340 C1PE-1D-340

Red Red Red Red

C1PE-1D-510 C1PE-1D-510 C1PE-1D-510 C1PE-1D-510

Black Black Black Black

C1PE-1D-675 C1PE-1D-675 C1PE-1D-340 C1PE-1D-340

Dark Purple Dark Purple Red Red

C1PE-1D-675 C1PE-1D-675 C1PE-1D-340 C1PE-1D-340

Dark Purple Dark Purple Red Red

C1PE-1D-900 C1PE-1D-900 C1PE-1D-510 C1PE-1D-510

Dark Green Dark Green Black Black

C1PE-1D-900 C1PE-1D-900 C1PE-1D-510 C1PE-1D-510

Dark Green Dark Green Black Black

Note:

1. See dimension drawing for location of isolators.

2. C1PE designates one spring per housing.

SPRINGS, ALUMINUM FINS

MOUNTING LOCATION

KIT PART

NUMBER

332320001

332320001

332320003

332320004

332320004

332320006

332320006

Table 4, Packaged & Remote Evaporator, Spring Isolator Locations, Cu. Fins

SPRINGS

UNIT

SIZE

010

013

017

020

025

029

034

OPER.

WGT

LBS.

1085

1170

1280

1505

1610

1800

2270

LF RF LB RB

C1PE-1D-340 C1PE-1D-340 C1PE-1D-340 C1PE-1D-340

Red Red Red Red

C1PE-1D-510 C1PE-1D-510 C1PE-1D-510 C1PE-1D-510

Black Black Black Black

C1PE-1D-510 C1PE-1D-510 C1PE-1D-510 C1PE-1D-510

Black Black Black Black

C1PE-1D-900 C1PE-1D-900 C1PE-1D-510 C1PE-1D-510

Dark Green Dark Green Black Black

C1PE-1D-900 C1PE-1D-900 C1PE-1D-510 C1PE-1D-510

Dark Green Dark Green Black Black

C1PE-1D-900 C1PE-1D-900 C1PE-1D-675 C1PE-1D-675

Dark Green Dark Green Dark Purple Dark Purple

C1PE-1D-1200 C1PE-1D-1200 C1PE-1D-900 C1PE-1D-900

Gray Gray Dark Green Dark Green

Note:

1. See dimension drawing for location of isolators.

2. C1PE designates one spring per housing.

COPPER FINS

MOUNTING LOCATION

KIT PART

NUMBER

332320001

332320003

332320003

332320006

332320006

332320007

332320008

IOMM 1155 AGZ 010B through 034B 7

Page 8

.

S

S

Corner Weights

Packaged Chiller

AGZ-

010A

013A

017A

020A

025A

029A

034A

RF LF RB LB

BS

279 275 267 263

315 297 288 271

344 323 316 297

502 475 271 257

531 496 301 282

583 238 353 326

779 761 369 361

RBI

LBI

Control

Panel

RFI

LFI

Remote Evaporator

AGZ-

BM

010A

013A

017A

020A

025A

029A

034A

LF RF LB RB

257 264 236 243

290 286 246 243

312 309 266 263

446 443 241 240

453 449 245 243

488 487 296 295

656 703 297 318

CP-1, Spring Isolator RP-3, Rubber-in-Shear Isolator

1/2-13 TAP

ø3.38

LOCATING PIN TO

BE INSTALLED HERE

MOUNTING MOLDED IN

DURULENE. WEATHER

RESISTANT (WR)

1.75 (R)

4.13

5.50

2.50

ø.56DIA

2 HOLES

.25

DRAWING NUMBER 3319880

ALL DIMENSION

ARE IN DECIMAL INCHE

8 AGZ 010B through 034B IOMM 1155

Page 9

Chilled Water System

Water Piping

Local authorities can supply the installer with the proper building and safety codes required

for proper installation.

Install piping with minimum bends and changes in elevation to minimize pressure drop.

Consider the following when installing water piping:

1. Vibration eliminators to reduce vibration and noise transmission to the building.

2. Shutoff valves to isolate the unit from the piping system during unit servicing.

3. Manual or automatic air vent valves at the high points of the system. Install drains at

the lowest points in the system.

4. Maintaining adequate system water pressure (expansion tank or regulating valve).

5. Temperature and pressure indicators located at the unit to aid in unit servicing. Pressure

gauge taps must be installed in the chilled water inlet and outlet piping or as shown in

Figure 4.

6. A strainer or other means of removing foreign matter from the water before it enters the

pump. Place the strainer far enough upstream to prevent cavitation at the pump inlet

(consult pump manufacturer for recommendations). The use of a strainer can prolong

pump life and keep system performance up.

7. A 40-mesh strainer is required in the water line just before the inlet of the evaporator.

This will help prevent foreign material from entering and decreasing the performance of

the evaporator.

!

CAUTION

If a separate disconnect is used for the 110V supply to the evaporator heating cable,

mark the disconnect clearly so the disconnect is not accidentally shut off during cold

seasons. Failure to do so can cause a failure of the evaporator.

8. The brazed plate evaporator has a thermostat and heating cable to prevent freeze-up

down to -20F (-29C). The heating cable should be wired to a separate 110V supply

circuit. As shipped from the factory, the heating cable is wired to the control circuit.

Protect all water piping to the unit from freezing.

9. If the unit is used as a replacement chiller on a previously existing piping system, flush

the system thoroughly before unit installation. Perform regular water analysis and

chemical water treatment on the evaporator immediately at equipment start-up.

10. When glycol is added to the water system for freeze protection, the refrigerant suction

pressure will be lower, cooling performance less, and water side pressure drop greater.

If the percentage of glycol is high, or if propylene is used instead of ethylene glycol, the

added pressure drop and loss of performance could be substantial. Reset the freezestat

and low leaving water alarm temperatures. The freezestat is factory set to default at

38F (3.3C). Reset the freezestat setting to approximately 4 to 5 degrees F (2.3 to 2.8

degrees C) below the leaving chilled water setpoint temperature. See the section titled

“Glycol Solutions” on page 12 for additional information concerning glycol.

11. Perform

a prelim

inary leak check before insulating the piping and filling the system.

12. Include a vapor barrier on the piping insulation to prevent condensation and possible

damage to the building structure.

IOMM 1155 AGZ 010B through 034B 9

Page 10

Figure 4, Typical Field Evaporator Water Piping

Ai

r

Vent

Strainer

Inlet

P

Outlet

Drain

NOTES:

1. Chilled water piping within the unit enclosure must be insulated in the field.

2. Support piping independently of the unit and install per local codes.

Vibration

Eliminators

Flow

Switch

Isolation

Val ves

System Volume

It is important to have adequate water volume in the system to provide an opportunity for

the chiller to sense a load change, adjust to the change and stabilize. As the expected load

change becomes more rapid, a greater water volume is needed. The system water volume is

the total amount of water in the evaporator, air handling products and associated piping. If

the water volume is too low, operational problems can occur, including rapid compressor

cycling, rapid loading and unloading of compressors, erratic refrigerant flow in the chiller,

improper motor cooling, shortened equipment life and other undesirable occurrences.

For normal comfort cooling applications, where the cooling load changes relatively slowly,

we recommend a minimum system volume of three to four times the flow rate (GPM). For

example, if the design chiller flow rate is 120 GPM, we recommend a minimum system

volume of 360 to 480 gallons.

Since there are many other factors that can influence performance, systems may

successfully operate below these suggestions. However, as the water volume decreases

below these suggestions, the possibility of problems increases.

Variable Chilled Water flow

Variable chilled water flow systems are not recommended for this class of equipment due to

limited unloading capability.

Flow Switch

Mount a water flow switch in the leaving water line to shut down the unit when water flow

is interrupted.

A flow switch is available from Daikin

(part number 017503300). It is a

“paddle” type

switch and adaptable to

pipe sizes down to 1 1/4” (32mm)

nominal. Certain minimum flow rates

are required to close the switch and are

listed in Table 5. Install the switch as

shown in Figure 5. Connect the

normally open contacts of the flow

switch in the unit control center

at terminals 4 and 5. There is also a

set of normally closed contacts on the

switch that can be used for an indicator

light or an alarm to indicate when

a “no-flow” condition exists. Freeze

protect any flow switch that is installed

outdoors. Follow

10 AGZ 010B through 034B IOMM 1155

Figure 5, Flow Switch Installation

Page 11

installation instructions provided with the flow switch. Calibrate the flow switch to open at

one-half of nominal flow rate.

NOTE: Differential pressure switches are not recommended for outdoor

installation. They are subject to damage from freezing.

Table 5, Flow Switch Settings

(NOTE !)

Min.

Adjst.

Max.

Adjst.

Flow

Flow Lpm 0.8 1.1 2.2 2.8 4.3 11.4 22.9 35.9 38.6

Flow

Flow Lpm 2.8 4.1 6.1 7.3 11.4 27.7 53.4 81.8 90.8

NOTES:

1. A segmented 3-inch paddle (1, 2, and 3 inches) is furnished mounted, plus a 6-inch paddle loose.

2. Flow rates for a 2-inch paddle trimmed to fit the pipe.

3. Flow rates for a 3-inch paddle trimmed to fit the pipe.

4. Flow rates for a 3-inch paddle.

5. Flow rates for a 6-inch paddle.

inch 1 1/4 1 1/2 2 2 1/2 3 4 5 6 8 Pipe Size

mm 32 (2) 38 (2) 51 63 (3) 76 102 (4) 127 (4) 153 (4) 204 (5)

gpm 5.8 7.5 13.7 18.0 27.5 65.0 125.0 190.0 205.0

Lpm 1.3 1.7 3.1 4.1 6.2 14.8 28.4 43.2 46.6

gpm 3.7 5.0 9.5 12.5 19.0 50.0 101.0 158.0 170.0

No

gpm 13.3 19.2 29.0 34.5 53.0 128.0 245.0 375.0 415.0

Lpm 3.0 4.4 6.6 7.8 12.0 29.1 55.6 85.2 94.3

gpm 12.5 18.0 27.0 32.0 50.0 122.0 235.0 360.0 400.0

No

Water Connections

The unit has 3-inch holes for the chilled water piping to enter the unit. The connections are

made to the evaporator water connections located within the unit. Chilled water piping

within the unit must be insulated.

Refrigerant Charge

All units are designed for R-407C and are shipped with an operating charge. The operating

charge for each unit is shown in the Physical Data Tables on pages 18 and 19.

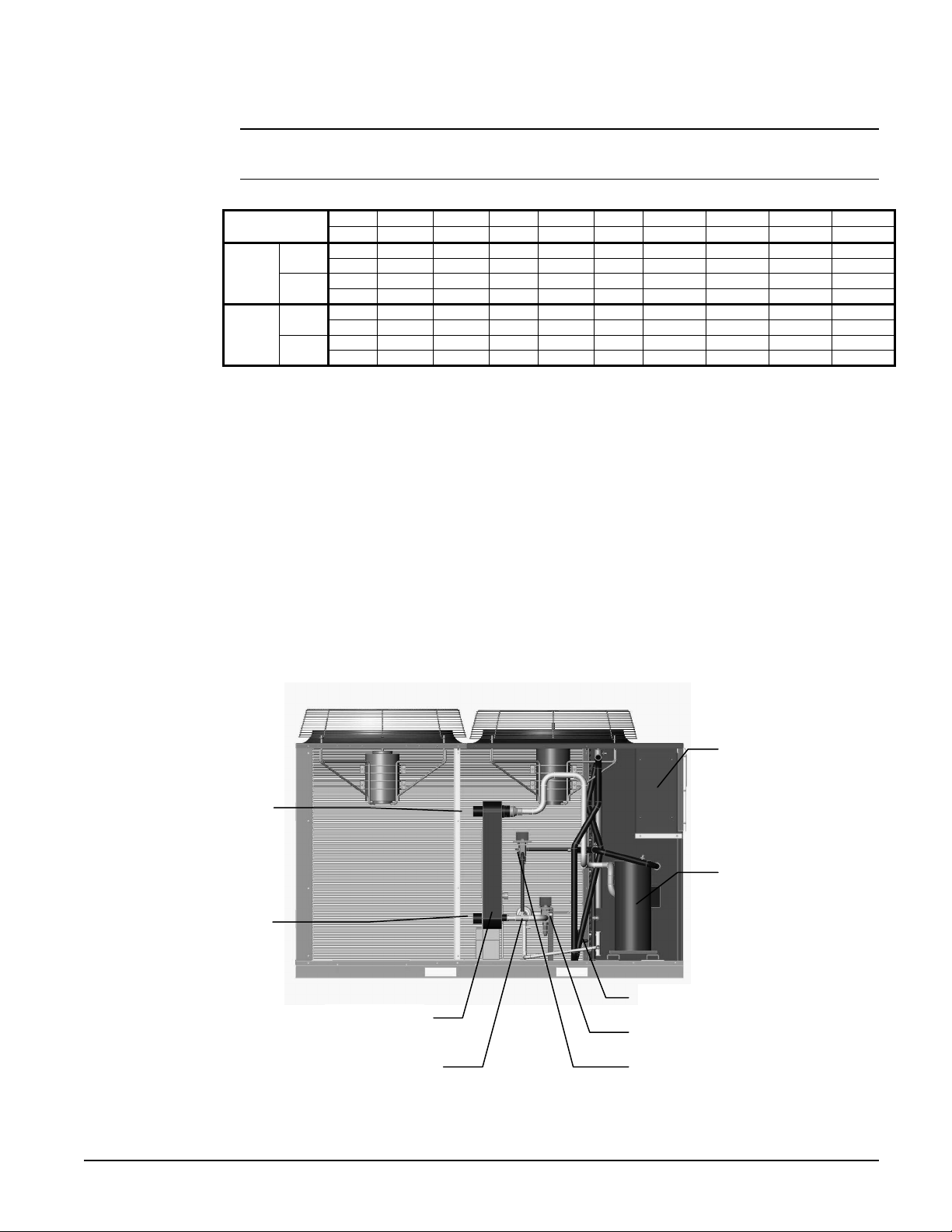

Unit Component Location

Chilled Water

Inlet Connection

Chilled Water

Outlet Connection

Evaporator

Control Panel

Tandem Scroll

Compressors

Charging Valve

Solenoid Valve, Expansion Valve

Optional Hot Gas Bypass Valve Filter Drier

IOMM 1155 AGZ 010B through 034B 11

Page 12

Glycol Solutions

The use of glycol antifreeze solutions will decrease unit capacity and increase the pressure

drop through the cooler. See Product Manual Catalog ACZAGZB1 for specific ratings and

correction factors.

!

CAUTION

Do not use automotive grade antifreeze. Industrial grade glycols must be used. Automotive

antifreeze contains inhibitors that will cause plating on the copper tubes within the chiller

evaporator. The type, storage, disposal, and handling of glycol used must be consistent

with local codes.

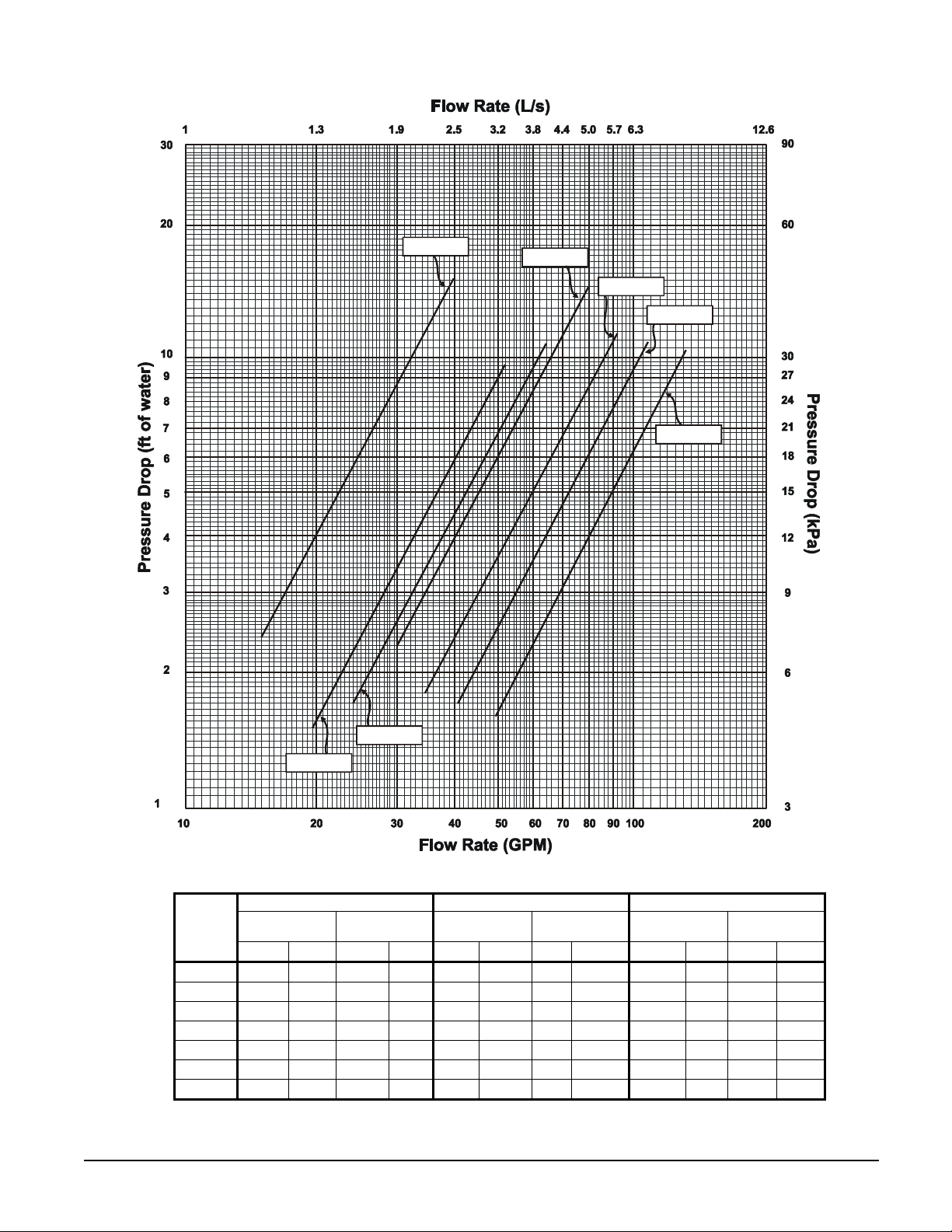

Evaporator Water Flow and Pressure Drop

Evaporator flow rate must fall between the minimum and maximum values shown in the

evaporator pressure drop curve, Figure 6. Flow rates outside of these limits result in a

chilled water Delta-T

Measure the chilled water pressure drop through the evaporator at field-installed pressure

taps. It is important not to include the effect of valves or strainers in these readings.

Do not vary the chilled water flow through the evaporator while the compressors are

operating.

outside the operating range of the controller

.

12 AGZ 010B through 034B IOMM 1155

Page 13

Figure 6, Evaporator Water Pressure Drop Curves

A

A

A

A

AGZ 010

GZ 020

GZ 025

GZ 029

GZ 034

AGZ 017

AGZ 013

Minimum Flow Nominal Flow Maximum Flow

AGZ

Model

010

013

017

020

025

029

034

Flow Rate

gpm L/s ft. kPa gpm L/s ft. kPa gpm L/s ft. kPa

15.0 0.9 2.4 7.1 24.0 1.5 5.8 17.3 40.0 2.5 15.2 45.5

19.5 1.2 1.5 4.5 31.2 2.0 3.7 11.0 52.0 3.3 9.6 28.9

24.0 1.5 1.7 5.0 38.4 2.4 4.1 12.2 64.0 4.0 10.7 32.1

30.0 1.9 2.3 6.8 48.0 3.0 5.6 16.7 80.0 5.0 14.5 43.4

34.5 2.2 1.8 5.3 55.2 3.5 4.3 13.0 92.0 5.8 11.4 34.3

40.7 2.6 1.7 5.0 65.0 4.1 4.0 12.1 108.4 6.8 10.9 32.6

49.8 3.1 1.6 4.7 79.7 5.0 3.9 11.7 132.8 8.4 10.4 31.2

Pressure

Drop

Flow Rate

Pressure

Drop

Flow Rate

Pressure

Drop

IOMM 1155 AGZ 010B through 034B 13

Page 14

R-407C Units

AGZ chillers are available with R-407C refrigerant as non-ARI certified units. R-407C is a

zeotropic blend of three compounds, and as such exhibits the characteristic of glide. It does not

behave as one substance like R-22 does. Glide is the difference (in degrees F) between the

beginning and end phase-change process in either the evaporator or condenser. During these

processes, different ratios of the refrigerant’s components change phase from the beginning to the

end of the process. The following functions, conditions and settings will differ from units charged

with R-22.

1. Different physical data and electrical data

2. Polyolester lubricants are used instead of mineral oil.

3. The saturated pressure/temperature relationship

4. Control and alarm settings

5. Charging procedures

1. Lubrication. The units are factory-charged with polyoester (POE) lubricant and one of the

following lubricants must be used if lubricant is to be added to the system:

POEs are very hygroscopic and will quickly absorb moisture if exposed to air. Pump the

lubricant into the unit through a closed transfer system. Avoid overcharging the unit.

Copeland Ultra 22 CC

Mobil EAL Arctic 22 CC

ICI EMKARATE RL RL 32CF

2. Pressure/temperature relationship. See Table 6 on page 15 for the saturated pressure-

erature chart. Due to refrigerant glide, use the following procedures for superheat and

p

tem

subcooling measurement.

To determine superheat, only vapor must be present at the point of measurement, no liquid.

Use the temperature reading, the pressure reading and the Saturated P/T Chart. If the

pressure is measured at 78 psig, the chart shows the saturated vapor

50.6F. If the temperature is measured at 60F, the superheat is 9.4 degrees F.

To determine subcooling, only liquid must be present, no vapor. Use the temperature

reading, the pressure reading and the Saturated P/T Chart. If the pressure is measured at 250

psig, the chart shows the saturated liquid

measured at 98F, the subcooling is 10.2 degrees F.

3. Control and alarm settings. The software that controls the operation of the unit is factory-

set for operation with R-407C.

4. Charging procedure. Packaged units are factory-charged with R-407C. Remote evaporator

units have a nitrogen/helium holding charge, which must be removed prior to system

charging procedure. Use the following procedure if recharging in the field is necessary:

Whether topping off a charge or replacing the circuit’s entire charge, always remove the

refrigerant from the charging vessel as a liquid. Many of the cylinders for the newer

refrigerants have a dip tube so that liquid is drawn off when the cylinder is in the upright

position. Do not vapor charge out of a cylinder unless the entire contents will be charged into

the system.

temperature to be 108.2F. If the temperature is

temperature to be

With the system in a 250-micron or lower vacuum, liquid can be charged into the high side.

Initially charge about 80 percent of the system total charge.

Start the system and observe operation. Use standard charging procedures (liquid only) to

top off the charge.

14 AGZ 010B through 034B IOMM 1155

Page 15

It may be necessary to add refrigerant through the compressor suction. Because the

refrigerant leaving the cylinder must be a liquid, exercise care to avoid damage to the

compressor. A sight glass can be connected between the charging hose and the compressor.

It can be adjusted to have liquid leave the cylinder and vapor enter the compressor.

Table 6, R-407C Pressure/Temperature Chart

Pressure

(PSIG)

20 -10.7 1.5 150 74.8 84.9

22 -8.2 4.0 155 76.8 86.8

24 -5.7 6.4 160 78.7 88.7

26 -3.4 8.7 165 80.6 90.5

28 -1.1 11.0 170 82.5 92.3

30 1.1 13.1 175 84.3 94.0

32 3.2 15.2 180 86.1 95.8

34 5.3 17.2 185 87.8 97.5

36 7.3 19.2 190 89.6 99.1

38 9.2 21.0 195 91.3 100.7

40 11.1 22.9 200 92.9 102.3

42 12.9 24.7 205 94.6 103.9

44 14.7 26.4 210 96.2 105.4

46 16.4 28.1 215 97.7 107.0

48 18.1 29.7 220 99.3 108.4

50 19.7 31.3 225 100.8 109.9

52 21.3 32.9 230 102.3 111.4

54 22.9 34.4 235 103.8 112.8

56 24.4 35.9 240 105.3 114.2

58 25.9 37.4 245 106.7 115.6

60 27.4 38.8 250 108.2 116.9

62 28.8 40.2 255 109.6 118.2

64 30.2 41.6 260 111.0 119.6

66 31.6 43.0 265 112.3 120.9

68 33.0 44.3 270 113.7 122.1

70 34.3 45.6 275 115.0 123.4

72 35.6 46.9 280 116.3 124.7

74 36.9 48.1 285 117.6 125.9

76 38.2 49.3 290 118.9 127.1

78 39.4 50.6 295 120.2 128.3

80 40.6 51.8 300 121.4 129.5

82 41.9 52.9 305 122.7 130.7

84 43.0 54.1 310 123.9 131.8

86 44.2 55.2 315 125.1 133.0

88 45.4 56.3 320 126.3 134.1

90 46.5 57.4 325 127.5 135.2

92 47.6 58.5 330 128.7 136.3

94 48.7 59.6 335 129.8 137.4

96 49.8 60.7 340 131.0 138.5

98 50.9 61.7 345 132.1 139.6

100 51.9 62.7 350 133.2 140.6

105 54.5 65.2 355 134.3 141.7

110 57.0 67.7 360 135.4 142.7

115 59.5 70.0 365 136.5 143.7

120 61.8 72.3 370 137.6 144.7

125 64.1 74.6 375 138.7 145.7

130 66.4 76.7 380 139.8 146.7

135 68.5 78.8 385 140.8 147.7

140 70.7 80.9 390 141.8 148.7

145 72.8 82.9 395 142.9 149.6

Liquid Temp

(°F)

Vapor Temp

(°F)

Pressure

(PSIG)

Liquid Temp

(°F)

Vapor Temp

(°F)

IOMM 1155 AGZ 010B through 034B 15

Page 16

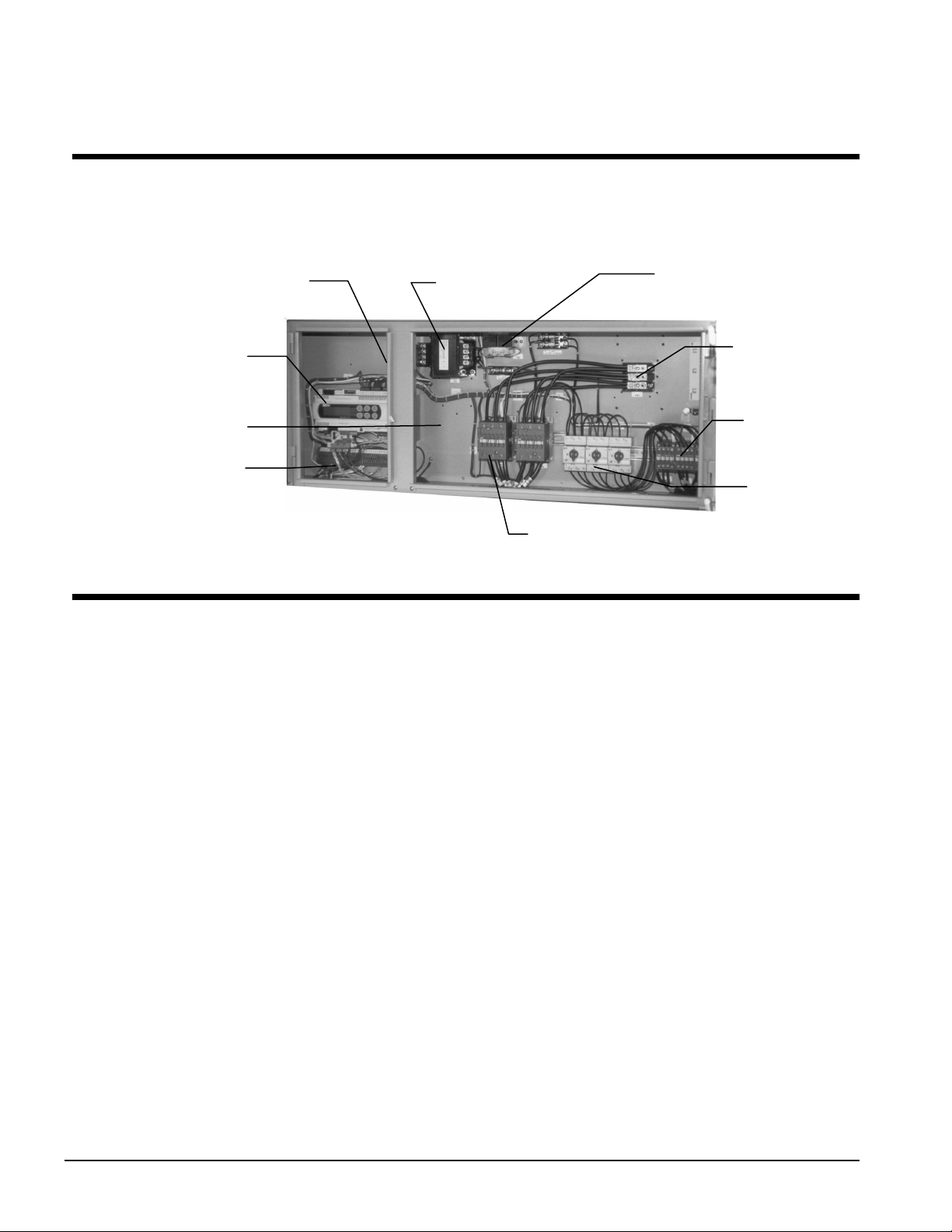

Control Layout and Operation

Control Center

All electrical controls are enclosed in a weatherproof control center with tool-locked, hinged

access doors. The left-hand section contains the microprocessor controller and control input and

output terminals. All high-voltage components are located on the right side of the panel.

ON/OFF Switch

MicroTech II

Controller

SpeedTrol Location

Field Connection

Termin als

Start-up and Shutdown

Pre Start-up

1. The chilled-water system should be flushed and cleaned. Proper water treatment is required to

prevent corrosion and organic growth.

2. Open all electric disconnects and check all electric connections for tightness.

3. Inspect all water piping for flow direction and correct connections at the evaporator.

4. Verify thermostat water temperature sensor is installed in the leaving water line (supply to

building). On all AGZ units the sensor well and sensor are factory mounted.

5. Check compressor oil level. The oil level should be visible in the oil sight glass.

6. Check voltage of the unit power supply and make certain voltage is within 10% of nameplate

rating. Check unit power supply wiring for proper ampacity and a minimum insulation

temperature of 75C. Check for proper phasing using a phase sequence meter.

7. Verify all mechanical and electrical inspections have been completed according to local codes.

8. Open control stop switch S1(off). Turn on the main power and control disconnect switches.

This will energize crankcase heaters. Wait at least 24 hours before starting up unit.

9. Open all water flow valves and start the chilled water pump. Check all piping for leaks and

vent the air from the evaporator as well as from the system piping. Flush the evaporator and

system piping to obtain clean, noncorrosive water in the evaporator.

Control

Transformer

24-Volt Trans.

Non-Fused Disc.

or

Power Block

Fan

Contactors

Fan

Protection

Compressor Contactors

Start-up

1. Set temperature controller to the desired chilled water temperature. Set the chilled water

Delta-T.

2. Start auxiliary equipment by turning on the following: time clock (if present), ambient

thermostat and/or remote on/off switch, chilled water pump.

3. If the controller calls for cooling, the unit will begin the start-up sequence.

16 AGZ 010B through 034B IOMM 1155

Page 17

4. After running the unit for a short time, check the oil level in the compressor (1/4 to 1/3

of the glass), rotation of fans, and flashing in refrigerant sight glass.

5. Verify superheat temperature is at the factory setting of 8 to 12 degrees F (4.4 to 6.7

degrees C).

After system performance has stabilized, complete the current AGZ Start-Up Form

6.

(obtainable from

benefits. Return the form to Daikin through your sales representative.

the local Daikin sales office) to establish inception of warranty

Sequence of Operation

Start-Up

With the control circuit power on, 115V power is applied through the control circuit fuse F1

to the compressor crankcase heaters, the compressor motor protections and the primary of

the 24V control circuit transformer. The 24V transformer provides power to the

microprocessor controller.

When a remote time clock, manual switch, or the unit controller turns on the chilled water

pump, the flow switch closes and satisfies the flow requirement. If the chilled water

temperature is above the stage-on temperature, and all equipment protection devices are

closed, the unit will start. The controller will operate the unit in response to the leaving

chiller water temperature or reset signals that may be present.

Equipment Protection Alarms

The following conditions will shut down the unit and activate the alarm circuit:

No evaporator water flow Low evaporator pressure

High condenser pressure Motor protection system

Phase voltage protection (Optional) Outside ambient temperature

Evaporator freeze protection Sensor failures

The following alarms will limit unit operation:

Condenser pressure stage down, unloads unit at high discharge pressures

Low ambient lockout, shuts off unit at low ambient temperatures

Low evaporator pressure hold, holds stage #1 until pressure rises

Low evaporator pressure unload, shuts off stage #2

Unit Enable Selection

Enables unit operation from local keypad, digital input, or Building Automation System.

Unit Mode Selection

Selects standard cooling, ice, glycol, or test operation mode.

Condenser fan control

Control of condenser fans is provided by the MicroTech II controller. The control steps

condenser fans based on discharge pressure.

Shutdown

As the leaving water control is satisfied, it will stage off the lag compressor unloading the

unit. The second stage will de-energize the liquid line solenoid valve SV1 and shut off the

lead compressor. The compressor crankcase heaters will energize when the compressors

shut off, keeping the small amount of refrigerant in the plate heat exchanger from migrating

to the compressor. See page 55 for detailed explanation of compressor staging.

IOMM 1155 AGZ 010B through 034B 17

Page 18

Physical Data

AGZ-BS, R-407C

Table 7, Physical Data, AGZ 010BS through 017BS, Packaged, R-407C

PHYSICAL DATA

BASIC DATA

Unit Capacity @ ARI Conditions (1), Tons (kW) 10.0 (36.2) 13.7 (48.2) 15.8 (55.6)

Number Of Refrigerant Circuits 1 1 1

Unit Operating Charge, R-407C Lb. (kg) 22.0 (10.0) 24.0 (10.9) 31.0 (14.1)

Cabinet Dimensions, LxWxH, In. 73.6 x 46.3 x 50.8 73.6 x 46.3 x 50.8 73.6 x 46.3 x 50.8

Cabinet Dimensions, LxWxH, (mm) (1869) x (1176) x (1289) (1869) x (1176) x (1289) (1869) x (1176) x (1289)

Unit Operating Weight, Lb. (kg) 1095 (498) 1190 (541) 1300 (591)

Unit Shipping Weight, Lb. (kg) 1085 (493) 1170 (532) 1280 (582)

Add'l Weight If Copper Finned Coils, Lb. (kg) 176 (80.0) 176 (80.0) 264 (120.0)

COMPRESSORS

Type Scroll Scroll Scroll

Nominal Horsepower 6.0 / 6.0 7.5 / 7.5 9.0 / 9.0

Oil Charge Per Compressor of a Tandem Set, oz. (g) 60 (1701) 85 (2410) 110 (3119)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DSPLACEMENT

Standard Staging 0 – 50 – 100 0 – 50 – 100 0 – 50 – 100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area, One of Two Sides, Sq. Ft. (M2) 30.3 (2.8) 30.3 (2.8) 30.3 (2.8)

Finned Height x Finned Length, In. 84 x 52 84 x 52 84 x 52

Finned Height x Finned Length, (mm) (2134) x (1321) (2134) x (1321) (2134) x (1321)

Fins Per Inch x Rows Deep: 16 x 2 16 x 2 16 x 3

Pumpdown Capacity Lb. (kg) 35.3 (16.0) 35.3 (16.0) 52.9 (24.0)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 2 – 26 (660) 2 – 26 (660) 2 – 26 (660)

Number Of Motors - HP (kW) 2 – 1.0 (0.75) 2 – 1.0 (0.75) 2 – 1.0 (0.75)

Fan And Motor RPM, 60 Hz 1140 1140 1140

60 Hz Total Unit Airflow, CFM (l/s) 13950 (6584) 13950 (6584) 12000 (5664)

DIRECT EXPANSION EVAPORATOR - BRAZED PLATE-TO-PLATE

Connection Size Victaulic, In. (mm) 2 (51) 2 (51) 2 (51)

Water Volume, Gallons (L) 0.9 (3.6) 1.7 (6.3) 2.0 (7.6)

Maximum Refrigerant Working Pressure, psig (kPa) 450 (3103) 450 (3103) 450 (3103)

Maximum Water Pressure, psig (kPa) 350 (2413) 350 (2413) 350 (2413)

NOTE: Nominal capacity based on 95°F ambient air and 54°F/44°F water range.

010B 013B 017B

AGZ MODEL NUMBER

18 AGZ 010B through 034B IOMM 1155

Page 19

Table 8, Physical Data, AGZ 020BS through 034BS, Packaged, R-407c

PHYSICAL DATA

BASIC DATA

Unit Capacity @ ARI Conditions (1), Tons (kW) 20.6 (72.4) 22.7 (79.8) 27.7 (97.5) 34.0 (119.5)

Number Of Refrigerant Circuits 1 1 1 1

Unit Operating Charge, Lb. (kg) 38.0 (17.3] 42.0 (19.1) 47.0 (21.3) 50.0 (22.7)

Cabinet Dimensions, LxWxH, In. 106.2x 46.3 x 50.8 106.2x 46.3 x 50.8 106.2x 46.3 x 58.8 106.2x 46.3 x 58.8

Cabinet Dimensions, LxWxH, (mm)

Unit Operating Weight, Lbs. (kg) 1590 (723) 1635 (743) 1830 (832) 2315 (1052)

Unit Shipping Weight, Lbs. (kg) 1570 (714) 1610 (732) 1800 (818) 2270 (1032)

Add'l Weight If Copper Finned Coils, Lb. (kg)

COMPRESSORS

Type Scroll Scroll Scroll Scroll

Nominal Horsepower 12.0 / 12.0 13.0 / 13.0 15.0 / 15.0 20.0 / 20.0

Oil Charge Per Compressor of a Tandem Set,

oz. (g)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging 0 –50 - 100 0 – 50 – 100 0 – 50 – 100 0 – 50 – 100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area, One of Two Sides, Sq. Ft. (M2) 49.0 (4.6) 49.0 (4.6) 58.3 (5.4) 58.3 (5.4)

Finned Height x Finned Length, In. 84 x 84 84 x 84 100 x 84 100 x 84

Finned Height x Finned Length, (mm) (2134) x (2134) (2134) x (2134) (2545 ) x (2134) (2545 ) x (2134)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3

Pumpdown Capacity, Lb. (kg) 85.4 (38.8) 85.4 (38.8) 101.6 (46.2) 101.6 (46.2)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 3 – 26 (660) 3 – 26 (660) 3 – 26 (660) 3 – 26 (660)

Number Of Motors - HP (kW) 3 – 1.0 (0.75) 3 – 1.0 (0.75) 3 – 1.0 (0.75) 3 – 1.0 (0.75)

Fan And Motor RPM, 60 Hz 1140 1140 1140 1140

60 Hz Total Unit Airflow, CFM (l/s) 20925 (9877) 20925 (9877) 19800 (9346) 19800 (9346)

DIRECT EXPANSION EVAPORATOR - BRAZED PLATE-TO-PLATE

Connection Size Victaulic, In. (mm) 2 (51) 2 (51) 2 (51) 2 (51)

Water Volume, Gallons (L) 2.2 (8.2) 3.0 (11.5) 4.0 (15.1) 5.6 (21.0)

Max. Refrigerant Working Pressure, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

Maximum Water Pressure, psig (kPa) 350 (2413) 350 (2413) 350 (2413) 350 (2413)

NOTE: Nominal capacity based on 95°F ambient air and 54°F/44°F water range.

020B 025B 029B 034B

(2697) x (1176) x

(1289)

426 (194) 426 (194) 508 (231) 508 (231)

110 (3119) 110 (3119) 110 (3119) 158 (4479)

AGZ MODEL NUMBER

(2697) x (1176) x

(1289)

(2697) x (1176) x

(1493)

(2697) x (1176) x

(1493)

IOMM 1155 AGZ 010B through 034B 19

Page 20

AGZ-BM, R-407C

Table 9, Physical Data, AGZ 010BM through 017BM, Remote Evaporator, R-407C

PHYSICAL DATA

BASIC DATA

Unit Capacity @ ARI Conditions (1), Tons (kW) 10.0 (36.2) 13.7 (48.2) 15.8 (55.6)

Number Of Refrigerant Circuits 1 1 1

Unit Operating Charge, Lb. (kg) 13 (5.9) 14 (5.3) 17 (7.7)

Cabinet Dimensions, LxWxH, In. 73.6 x 46.3 x 50.8 73.6 x 46.3 x 50.8 73.6 x 46.3 x 50.8

Cabinet Dimensions, LxWxH, (mm) (1869) x (1176) x (1289) (1869) x (1176) x (1289) (1869) x (1176) x (1289)

Unit Operating Weight, Lb. (kg) 950 (431) 1276 (579) 1278 (580)

Unit Shipping Weight, Lb. (kg) 1025 (465) 1350 (613) 1363 (619)

Add'l Weight If Copper Finned Coils, Lb. (kg) [176 (80.0) [176 (80.0) [264 (120.0)

COMPRESSORS

Type Scroll Scroll Scroll

Nominal Horsepower 6.0 / 6.0 7.5 / 7.5 9.0 / 9.0

Oil Charge Per Compressor of a Tandem Set, oz. (g) 60 (1701) 85 (2410) 110 (3119)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DSPLACEMENT

Standard Staging 0 – 50 – 100 0 – 50 – 100 0 – 50 – 100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area, One of Two Sides, Sq. Ft. (M2) 30.3 (2.8) 30.3 (2.8) 30.3 (2.8)

Finned Height x Finned Length, In. 84 x 52 84 x 52 84 x 52

Finned Height x Finned Length, (mm) (2134) x (1321) (2134) x (1321) (2134) x (1321)

Fins Per Inch x Rows Deep [16 x 2 16 x 2 16 x 3

Pumpdown Capacity Lb. (kg) 35.3 (16.0) 35.3 (16.0) 52.9 (24.0)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 2 – 26 (660) 2 – 26 (660) 2 – 26 (660)

Number Of Motors - HP (kW) 2 – 1.0 (0.75) 2 – 1.0 (0.75) 2 – 1.0 (0.75)

Fan And Motor RPM, 60 Hz 1140 1140 1140

60 Hz Total Unit Airflow, CFM (l/s) 13950 (6584) 13950 (6584) 12000 (5664)

REMOTE DIRECT EXPANSION EVAPORATOR - BRAZED PLATE-TO-PLATE

Water Connection Size Victaulic, In. (mm) 2 (51) 2 (51) 2 (51)

Water Volume, Gallons (L) 0.9 (3.6) 1.7 (6.3) 2.0 (7.6)

Liquid Line Conn. Braze, inches 1.125 1.125 1.125

Suction Line Conn. Braze, Inches 2.125 2.125 2.125

Temperature Sensor Conn. NPT, Inches 0.75 0.75 0.75

Dry Weight, lbs (kg) 50 (22) 75 (34) 87 (39)

Operating Weight, lbs (kg) 58 (26) 88 (40) 109 (49)

Maximum Refrigerant Working Pressure, psig (kPa) 450 (3103) 450 (3103) 450 (3103)

Maximum Water Pressure, psig (kPa) 450 (3103) 450 (3103) 450 (3103)

Vent and Drain Conn. Field Field Field

NOTE: Nominal capacity based on 95°F ambient air and 54°F/44°F water range and does not take field-installed lines into account.

010B 013B 017B

AGZ MODEL NUMBER

20 AGZ 010B through 034B IOMM 1155

Page 21

Table 10, Physical Data, AGZ 020BM through 034BM, Remote Evaporator, R-407C

PHYSICAL DATA

BASIC DATA

Unit Capacity @ ARI Conditions (1), Tons (kW) 20.6 (72.4) 22.7 (79.8) 27.7 (97.5) 34.0 (119.5)

Number Of Refrigerant Circuits 1 1 1 1

Unit Operating Charge, Lb. (kg) 38.0 (17.3) 42.0 (19.1) 47.0 (21.3) 50.0 (22.7)

Cabinet Dimensions, LxWxH, In. 106.2x 46.3 x 50.8 106.2x 46.3 x 50.8 106.2x 46.3 x 58.8 106.2x 46.3 x 58.8

Cabinet Dimensions, LxWxH, (mm)

Unit Operating Weight, Lbs. (kg) 1459 (662) 1478 (671) 1622 (737) 1817 (825)

Unit Shipping Weight, Lbs. (kg) 1558 (707) 1576 (716) 1719 (780) 1914 (869)

Add'l Weight If Copper Finned Coils, Lb. (kg) 426 (194) 426 (194) 508 (231) 508 (231)

COMPRESSORS

Type Scroll Scroll Scroll Scroll

Nominal Horsepower 12.0 / 12.0 13.0 / 13.0 15.0 / 15.0 20.0 / 20.0

Oil Charge Per Compressor of a Tandem Set,

oz. (g)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging 0 –50 - 100 0 – 50 – 100 0 – 50 – 100 0 – 50 – 100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area, One of Two Sides, Sq. Ft. (M2) 49.0 (4.6) 49.0 (4.6) 58.3 (5.4) 58.3 (5.4)

Finned Height x Finned Length, In. 84 x 84 84 x 84 100 x 84 100 x 84

Finned Height x Finned Length, (mm) (2134) x (2134) (2134) x (2134) (2545 ) x (2134) (2545 ) x (2134)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3

Pumpdown Capacity, Lb. (kg) 85.4 (38.8) 85.4 (38.8) 101.6 (46.2) 101.6 (46.2)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 3 – 26 (660) 3 – 26 (660) 3 – 26 (660) 3 – 26 (660)

Number Of Motors - HP (kW) 3 – 1.0 (0.75) 3 – 1.0 (0.75) 3 – 1.0 (0.75) 3 – 1.0 (0.75)

Fan And Motor RPM, 60 Hz 1140 1140 1140 1140

60 Hz Total Unit Airflow, CFM (l/s) 20925 (9877) 20925 (9877) 19800 (9346) 19800 (9346)

REMOTE DIRECT EXPANSION EVAPORATOR - BRAZED PLATE-TO-PLATE

Connection Size Victaulic, In. (mm) 2 (51) 2 (51) 2 (51) 2 (51)

Water Volume, Gallons (L) 2.2 (8.2) 3.0 (11.5) 4. 0 (15.1) 5.6 (21.0)

Liquid Line Conn. Braze, inches 1.125 1.125 1.375 1.375

Suction Line Conn. Braze, Inches 2.125 2.125 2.125 2.125

Temperature Sensor Conn. NPT, Inches 0.75 0.75 0.75 0.75

Dry Weight, lbs (kg) 92 (42) 124 (56) 156 (71) 211 (96)

Operating Weight, lbs (kg) 110 (50) 148 (67) 188 (85) 255 (116)

Max. Refrigerant Working Pressure, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

Maximum Water Pressure, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

Drain and Vent Connections Field Field Field Field

NOTE: Nominal capacity based on 95°F ambient air and 54°F/44°F water range and does not take field-installed lines into account.

020B 025B 029B 034B

(2697) x (1176) x

(1289)

110 (3119) 110 (3119) 110 (3119) 158 (4479)

AGZ MODEL NUMBER

(2697) x (1176) x

(1289)

(2697) x (1176) x

(1493)

(2697) x (1176) x

(1493)

IOMM 1155 AGZ 010B through 034B 21

Page 22

Electrical Data

Field Wiring

Wiring must comply with all applicable codes and ordinances. Warranty is void if wiring is

not in accordance with specifications. Copper wire is required for all power lead

terminations at the unit.

AGZ 010B through AGZ 034B units have single point power connection. A single field

supplied fused disconnect is required. The control transformer is factory mounted.

If the evaporator heater is on a separate disconnect switch from the main unit power supply,

the unit may be shut down without defeating the freeze protection provided by the

evaporator heater.

R-407C

Table 11, Electrical Data, R-407C

AGZ

Unit

Size

010B

013B

017B

020B

025B

029B

034B

NOTE: See page 25 for all Electrical Data notes.

Volts

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

Minimum

Circuit

Ampacity

(MCA)

58

54

27

22

77

77

39

30

82

80

41

33

113

113

51

41

129

129

61

51

148

139

72

58

187

182

85

73

Power Supply

Field Wire

Quantity

3 6 AWG 1 1.00 (25)

3 6 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 4 AWG 1 1.00 (25)

3 4 AWG 1 1.00 (25)

3 8 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 4 AWG 1 1.00 (25)

3 4 AWG 1 1.00 (25)

3 8 AWG 1 1.00 (25)

3 10 AWG 1 1.00 (25)

3 2 AWG 1 1.25 (32)

3 2 AWG 1 1.25 (32)

3 6 AWG 1 1.00 (25)

3 8 AWG 1 1.00 (25)

3 1 AWG 1 1.25 (32)

3 1 AWG 1 1.25 (32)

3 6 AWG 1 1.00 (25)

3 6 AWG

3 1/0 AWG 1 1.50 (38)

3 1/0 AWG 1 1.50 (38)

3 4 AWG 1 1.00 (25)

3 6 AWG 1 1.00 (25)

3 3/0 AWG 1 2.00 (51)

3 3/0 AWG 1 2.00 (51)

3 4 AWG 1 1.00 (25)

3 4 AWG

Wire

Gauge

75C

Hub (Conduit

Connection)

Quantity

1 1.00 (25)

1 1.00 (25)

Nominal

Size

In. (mm)

Field Fuse

or Breaker Size

Recommended Maximum

70 70

60 70

30 35

25 25

90 100

90 100

45 50

35 40

110 110

90 100

50 50

40 40

125 150

125 150

60 60

50 50

150 175

150 175

70 80

60 60

175 200

175 175

80 100

80 80

250 250

250 250

100 110

100 100

22 AGZ 010B through 034B IOMM 1155

Page 23

Table 12, Compressor & Fan Motor Amps, R-407C

AGZ

Unit

Size

010B

013B

017B

020B

025B

029B

034B

NOTE: See page 25 for all Electrical Data notes.

Volts

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

Rated Load Amps Locked Rotor Amps

Compressors Compressors

No. 1 No. 2

20.3 20.3

18.6 18.6

9.2 9.2

7.4 7.4

28.8 28.8

28.8 28.8

14.7 14.7

10.8 10.8

31.2 31.2

30.1 30.1

15.5 15.5

12.1 12.1

42.3 42.3

42.3 42.3

18.6 18.6

14.6 14.6

49.4 49.4

49.4 49.4

23.1 23.1

19.2 19.2

57.9 57.9

53.8 53.8

28.2 28.2

22.4 22.4

75.0 75.0

73.1 73.1

34.0 34.0

28.8 28.8

F.L. Amps

Fan

Motor

(Each)

5.8 2 21.4 156 156

5.8 2 23.7 156 156

2.8 2 10.7 75 75

2.5 2 11.0 54 54

5.8 2 21.4 195 195

5.8 2 23.7 195 195

2.8 2 10.7 95 95

2.5 2 11.0 80 80

5.8 2 21.4 225 225

5.8 2 23.7 225 225

2.8 2 10.7 114 114

2.5 2 11.0 80 80

5.8 3 21.4 245 245

5.8 3 23.7 245 245

2.8 3 10.7 125 125

2.5 3 11.0 100 100

5.8 3 21.4 300 300

5.8 3 23.7 300 300

2.8 3 10.7 150 150

2.5 3 11.0 109 109

5.8 3 21.4 340 340

5.8 3 23.7 340 340

2.8 3 10.7 173 173

2.5 3 11.0 132 132

5.8 3 21.4 505 505

5.8 3 23.7 505 505

2.8 3 10.7 225 225

2.5 3 11.0 180 180

No. of

Fans

Motor

(Each)

Fan

Across-The-Line

No. 1 No. 2

IOMM 1155 AGZ 010B through 034B 23

Page 24

Table 13, Field Wiring Data, R-407C

AGZ

Volts

Unit

Size

208 175

230 175

010B

460 175

575 175

208 175

230 175

013B

460 175

575 175

208 175

230 175

017B

460 175

575 175

208 175

230 175

020B

460 175

575 175

208 175

230 175

025B

460 175

575 175

208 175

230 175

029B

460 175

575 175

208 335 6 AWG – 400 kcmil

230 335 6 AWG – 400 kcmil

034B

460 175 14 AWG – 2/0

575 175 14 AWG – 2/0

NOTE:

1. High Interruptor or HSCCR Circuit Breakers are not available in these sizes

2. "Size" is the maximum amperage rating for the terminals or the main electrical device.

3. "Size" is the disconnect part number and not the amperage rating for the terminals or the main electrical device.

4. "Connection" is the range of wire sizes that the terminals on the electrical device will accept.

5. See page 25 for additional electrical notes.

Standard Power Block Terminal

Maximum

Terminal Amps

Wiring to

Connector Wire

Range

(Copper Wire Only)

14 AWG – 2/0 60

14 AWG – 2/0 60 14 AWG – 1 AWG 80 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 40 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 35 10 AWG - 1/0

14 AWG – 2/0 100

14 AWG – 2/0 100

14 AWG – 2/0 60 14 AWG – 1 AWG 60 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 50 10 AWG - 1/0

14 AWG – 2/0 100

14 AWG – 2/0 100

14 AWG – 2/0 60 14 AWG – 1 AWG 70 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 50 10 AWG - 1/0

14 AWG – 2/0 125

14 AWG – 2/0 125

14 AWG – 2/0 60 14 AWG – 1 AWG 80 10 AWG - 1/0

14 AWG – 2/0 60 14 AWG – 1 AWG 70 10 AWG - 1/0

14 AWG – 2/0 225

14 AWG – 2/0 225

14 AWG – 2/0 100

14 AWG – 2/0 60

14 AWG – 2/0 225

14 AWG – 2/0 225

14 AWG – 2/0 100

14 AWG – 2/0 100

Optional Disconnect Switch

Disconnect

Size

225

225

100

100

Wiring to

Connector Wire

Range

(Copper Wire Only)

14 AWG – 1 AWG

8 AWG - 1/0

8 AWG - 1/0

8 AWG - 1/0

8 AWG - 1/0

3 AWG – 3/0

3 AWG - 3/0

2 AWG - 4/0

2 AWG - 4/0

8 AWG - 1/0

14 AWG – 1 AWG

2 AWG - 4/0

2 AWG - 4/0

8 AWG - 1/0

8 AWG - 1/0

2 AWG - 4/0

2 AWG - 4/0

8 AWG - 1/0

8 AWG - 1/0

Wiring to High Interrupt

or HSCCR Circuit Breaker

Max.

Amps

125 3 AWG - 3/0

125 3 AWG - 3/0

125 3 AWG - 3/0

125 3 AWG - 3/0

175 6 AWG - 350 kcmil

175 6 AWG - 350 kcmil

200 6 AWG - 350 kcmil

200 6 AWG - 350 kcmil

100 10 AWG - 1/0

225 6 AWG - 350 kcmil

225 6 AWG - 350 kcmil

125 3 AWG - 3/0

N/A Note 1

N/A Note 1

150 6 AWG - 350 kcmil

125 3 AWG - 3/0

Connector Wire

(Copper Wire Only)

90 10 AWG - 1/0

80 10 AWG - 1/0

90 10 AWG - 1/0

Range

24 AGZ 010B through 034B IOMM 1155

Page 25

Notes for Electrical Data

A

1. Unit wire size ampacity (MCA) is equal to 125% of the largest compressor-motor RLA

plus 100% of RLA of all other loads in the circuit.

2. The control transformer is furnished and no separate 115V power supply is required.

3. If a separate 115V power supply is used for the control circuit, then the wire sizing

amps is 10 amps for all unit sizes.

4. Recommended power lead wire sizes for three conductors per conduit are based on

100% conductor ampacity in accordance with NEC. Voltage drop has not been included.

Therefore, it is recommended that power leads be kept short. All terminal block

connections must be made with copper wire.

5. “Recommended Fuse Sizes” are selected at approximately 175% of the largest

compressor RLA, plus 100% of the RLA of all other loads in the circuit.

6. “Maximum Fuse or breaker size” is selected at approximately 225% of the largest

compressor RLA, plus 100% of all other loads in the circuit.

7. The recommended power lead wire sizes are based on an ambient temperature of 86°F

(30°C). Ampacity correction factors must be applied for other ambient temperatures.

Refer to the National Electrical Code Handbook.

8. Units must be electrically grounded according to national and local electrical codes.

Voltage Limitations:

Within 10 percent of nameplate rating

Important: Voltage unbalance not to exceed 2% with a resultant current unbalance of 6 to

10 times the voltage unbalance per NEMA MG-1, 1998 Standard. This is an important

restriction that must be adhered to.

Notes for “Compressor and Condenser Fan Amp Draw”:

1. Compressor RLA values are for wiring sizing purposes only but may not reflect normal

operating current draw at rated capacity.

2. Fan motor FLA values are approximate fan motor amp values at rated voltage.

Notes for “Field Wiring Data”

1. Requires a single disconnect to supply electrical power to the unit. This power supply

must either be fused or use a circuit breaker.

2. All field wiring to unit power block or optional non-fused disconnect switch must be

copper.

3. All field wire size values given in table apply to 75°C rated wire per NEC.

Standard Panel Ratings (kA)

Voltage

208-230

460

575

AGZ 010-017 AGZ 025-029 AGZ 034

5 10 10

5 5 10

5 5 5

GZ-B Model Size

Circuit Breakers

The circuit breaker used in the High Short Circuit panel option may have a higher trip rating

than the unit Maximum Overload Protection (MOP) value shown on the unit nameplate.

The circuit breaker is installed as a service disconnect switch and does not function as

branch circuit protection, mainly that the protection device must be installed at the point of

origin of the power wiring. The breaker (disconnect switch) is oversized to avoid nuisance

trips at high ambient temperature conditions.

IOMM 1155 AGZ 010B through 034B 25

Page 26

Figure 7, AGZ 010A through AGZ 034A, Typical Field Wiring Diagram

B

A

G

G

UNIT MAIN

TERMINAL

BLOCK

GND LUG

TO COMPRESSOR(S)

AND FAN MOTORS

3 PHASE

POWER

SUPPLY

DISCONNECT

(BY OTHERS)

NOTE: ALL FIELD WIRING

TO BE INSTALLED AS NEC

CLASS 1 WIRING SYSTEM

WITH CONDUCTOR RATED

600 VOLTS

120VAC

CONTROL POWER

SEPARATE EVAP.

HEATER POWER

FIELD WIRED

FACTORY SUPPLIED ALARM

ALARM

BELL

OPTION

REMOTE STOP

SWITCH

(BY OTHERS)

ICE MODE

SWITCH

(BY OTHERS)

FIELD WIRED

ALARM BELL RELAY

CHW FLOW SWITCH

N

120VAC

(BY OTHERS)

HOT GAS BYPASS SOLENOID

TIME

CLOCK

---MANDATORY–(BY OTHERS)

4-20MA FOR

CHW RESET

(BY OTHERS)

FUSED CONTROL

TRANSFORMER

DISCONNECT

(BY OTHERS)

(BY OTHERS)

DISCONNECT

(BY OTHERS)

N

LIQUID LINE SOLENOID

120 VAC 1.0 AMP MAX

SV1

SV5

120 VAC 1.0 AMP MAX

CHW PUMP RELAY

(BY OTHERS)

120 VAC 1.0 AMP MAX

AUTO

ON

MANUAL

NOR. OPEN PUMP AUX.

CONTACTS (OPTIONAL)

AUTO

ON

MANUAL

CIRCUIT

10A

FUSE

(BY OTHERS)

OFF

+

-

OFF

FUSE

120

VAC

TB1-20

TB1

CONTROL

1

10A

2

6

15

13

16

14

12

17

11

17

CIRCUIT

GZ REMOTE EVAP ONLY

FUSE

N

MJ

IF SEPARATE EVAPORATOR

HEATER POWER OPTION

MJ

IS USED - REMOVE

MECHANICAL JUMPER

BETWEEN TB1-5 AND TB1-6

& TB1-15 AND TB1-16.

120 VAC

120 VAC

120 VAC

120 VAC

GND

TB2

IF REMOTE STOP

CONTROL IS USED,

843

REMOVE LEAD 843

FROM TERM. 25 TO 35.

GND

ALARM BELL

RELAY

COM NO

BELL

12

ALARM BELL OPTION

24VAC

25

35

22

31

26

36

22

33

34

28

38

FIELD WIRIN

FACTORY WIRIN

LABEL DWG. 330538401 REV.0

Note: See control and power wiring diagrams on unit control panel for specific unit information.

26 AGZ 010B through 034B IOMM 1155

Page 27

Dimensions & Weights

3.00

9

Figure 8, AGZ 010BS - 017BS, Packaged (See page 29 for additional dimensions and weights)

ACCESS

PANEL

QTY.2

EVAP.

INLET

31.70

11.27

EVAP.

OUTLET

14.66

5.17

POWER ENTRY

KNOCKOUT

(OTHER SIDE)

2.61

40.18

24.57

.875

.875

CONTROL

ELECTRICAL

KNOCKOUT

ACCESS DOORS

Y

CONTROL BOX

ACCESS

DOOR

POWER

ENTRY

51.00

46.18

49.06

L1, L2L3, L4

3.00

QTY.2

EVAP.

INLET

31.70

11.27

21.18

X

4.00

MOUNTING HOLES

DIA. 1.00 INCH

QTY. 4

DIM. A = AGZ020-025 = 24.6"

AGZ029-034 = 33.0"

DIM. B = AGZ020-025 = 40.2"

AGZ029-034 = 48.7"

Z

31.15

MOUNTING

HOLES

46.42

7.64

NOTE:

L2 & L4 ARE LOCATED ON1.

OPPOSITE SIDE OF UNIT.

ALL WEIGHTS ARE IN POUNDS.2.

R331987001

CERTIFIED, 2 FAN, AGZ-

00

Figure 9, AGZ 020BS - 034BS, Packaged (See page 29 for additional dimensions and weights)

ACCESS

PANEL

73.80

EVAP.

OUTLET

14.66

49.06 49.06

84.95

106.23

5.17

L1, L2L3, L4

X

21.18

.875

POWER ENTRY

KNOCKOUT

(OTHER SIDE)

2.67

.875

CONTROL

ELECTRICAL

KNOCKOUT

B

A

Y

CONTROL PANEL

ACCESS DOORS

ACCESS

DOOR

Z

31.10

MOUNTING

HOLES

46.38

R331987101

POWER

ENTRY

AGZ020-025 =51

AGZ029-034 = 5

7.64

CERTIFIED, 3 FAN, AGZ-B

IOMM 1155 AGZ 010B through 034B 27

Page 28

Figure 10, AGZ 010 - 017BM Remote Evap. (See page 29 for additional dimensions and weights

T

DIM. A

ACZ025-028

6"

9

ACCESS

PANEL

NOTE:

L2 & L4 ARE LOCATED ON1.

OPPOSITE SIDE OF UNIT.

ALL WEIGHTS ARE IN POUNDS.2.

5.17

HOT GAS

BYPASS

L1, L2L3, L4

Figure 11, AGZ 020BM - 034BM (See page 29 for additional dimensions and weights

ACCESS

PANEL

46.18

49.06

73.80

21.18

X

DIM. B = ACZ025-028 = 40.2"

DIM. C = ACZ025-033 = 18.8"

DIM. D = ACZ025-033 = 4.5"

18.84

9.19

4.56

5.06

8.86

4.00

MOUNTING HOLES

DIA. 1.00 INCH

=

ACZ033-039 = 33.0"

ACZ033-039 = 48.7"

ACZ039 = 12.6"

ACZ039 = 7.5"

POWER ENTRY

KNOCKOUT

(OTHER SIDE)

SUCTION

20.79

LIQUID

.875

.875

CONTROL

ELECTRICAL

KNOCKOUT

24.57

= 24.

CONTROL BOX

ACCESS DOORS

ACCESS

DOOR

31.15

MOUNTING

HOLES

46.42

R331987401

NOTE:

L2 & L4 ARE LOCATED ON1.

OPPOSITE SIDE OF UNIT.

ALL WEIGHTS ARE IN POUNDS.2.

00

POWER

ENTRY

51.00

Y

Z

7.64

CERTIFIED, 2 FAN, AGZ-B REMO

49.06 49.06

106.23

28 AGZ 010B through 034B IOMM 1155

.875

POWER ENTRY

KNOCKOUT

(OTHER SIDE)

84.95

5.17

HOT GAS BYPASS

.875

CONTROL

ELECTRICAL

KNOCKOUT

D

2.67

SUCTION

C

9.19

L1,L2L3,L4

21.18

X

LIQUID

5.06

8.86

20.79

B

A

R331987501

CONTROL PANEL

ACCESS DOORS

POWER

ENTRY

ACCESS

DOOR

Z

31.10

MOUNTING

HOLES

46.38

CERTIFIED, 3 FAN, AGZ-B REMOTE

Y

7.64

ACZ025-028 =51

ACZ033-039 = 5

Page 29

Remote Evaporators

Figure 12, Remote Evaporators, for AGZ 010BM – 034BM

Suction

30.2

(767)

8.2 (208)

10.2 (260)

1.2

(30)

.35

(9)

3.5

(90)

A

3.5

(90)

Te mp Se n so r

1.2

(30)

Liquid

W1

Inlet

W2

Outlet

AGZ

Model

010

013

017

020

025

029

034

Liquid Line Conn.

Brazed, in (L).

1.125 2.125 0.75 2.0 3.6 (91)

1.125 2.125 0.75 2.0 6.0 (153)

1.125 2.125 0.75 2.0 7.1 (181)

1.125 2.125 0.75 2.0 7.7 (195)

1.125 2.125 0.75 2.0 10.6 (271)

1.375 2.125 0.75 2.0 13,8 (351)

1.375 2.125 0.75 2.0 19.0 (483)

Suction Line Conn.

Brazed, in (S).

Temp. Sensor

NPT, in. (TS)

Victaulic

Water Conn.

In. (W)

Dimension

“A”

in. (mm)

IOMM 1155 AGZ 010B through 034B 29

Page 30

ACZ/AGZ Dimensions and Weights

Table 14, Packaged Chiller, Dimensions and Weights

AGZ

UNIT

SIZE

010B

013B

017B

020B

025B

029B

034B

CENTER OF GRAVITY

28.00 21.50 23.40 1085 1095 398 392 149 147 2 279 275 267 263

27.40 21.40 23.90 1170 1190 452 426 150 141 2 315 297 288 271

27.50 21.60 24.00 1280 1300 493 463 167 157 2 344 323 316 297

38.50 21.80 23.90 1505 1525 564 534 209 198 2 502 475 271 257

39.50 19.40 24.00 1610 1635 593 554 239 224 2 531 496 301 282

41.00 22.75 24.20 1800 1830 645 595 291 269 2 583 538 353 326

35.60 23.70 23.50 2270 2315 890 869 259 253 2 779 761 369 361

(IN.)

X Y Z

SHIP WT.

(LBS)

OPN. WT.

(LBS)

Table 15, Remote Evaporator, Dimensions and Weights

AGZ

REMOTE

EVAP.

010B

013B

017B

020B

025B

029B

034B

CENTER OF GRAVITY

(IN.)

X Y Z

27.50 21.70 22.90 1000 1015 369 379 124 128 1.125 0.875 0.625

26.50 21.60 23.40 1065 1090 421 416 115 113 1.625 0.875 0.625

26.60 21.80 23.30 1150 1190 454 449 124 123 1.625 0.875 0.625

38.50 21.90 23.30 1370 1420 501 498 186 185 1.625 0.875 0.625

38.50 19.10 23.30 1390 1445 508 505 189 188 1.625 0.875 0.625

41.00 23.00 23.30 1565 1625 540 538 244 243 1.625 0.875 0.875

34.60 24.00 22.40 1975 2050 753 807 201 215 2.125 0.875 0.875

SHIP

WT.

(LBS)

OPN.

WT.

(LBS)

LIFTING CORNER WEIGHTS

(LBS)

L1 L2 L3 L4

LIFTING CORNER WEIGHTS

(LBS)

L1 L2 L3 L4 SUCTION LIQUID

EVAP.

CONN.

(IN.)

VICTAULIC

CONNECTION SIZES (IN. O.D.)

MOUNTING CORNER

WEIGHTS (LBS.)

M1 M2 M3 M4

HOT GAS

BYPASS

Table 16, Mounting Weights

REMOTE

EVAP

010B

013B

017B

020B

025B

029B

034B

MOUNTING CORNER WEIGHTS (LBS.)AGZ

M1 M2 M3 M4

257 264 236 243

290 286 246 243

312 309 266 263

446 443 241 240

453 449 245 243

488 487 296 295

656 703 297 318

30 AGZ 010B through 034B IOMM 1155

Page 31

System Maintenance

General

On initial start-up and periodically during operation, it will be necessary to perform certain

routine service checks. Among these are taking electric leg readings. Some readings are

readily available on the MicroTech II controller’s display.

Lubrication

No routine lubrication is required on the AGZ units. The fan motor bearings are of the

permanently lubricated type and require no lubrication.

Electrical Terminals

Electric shock hazard. Disconnect and tag out all sources of power to the unit before

continuing with following service or severe personal injury or death can result.

Normal heating and cooling of the wire will cause terminals to loosen. Retighten all power

electrical terminals every six months.

Condensers

Condensers are air-cooled and constructed with 3/8” (9.5mm) O.D. internally finned copper

tubes bonded in a staggered pattern into slit aluminum fins. No maintenance is ordinarily

required except the occasional removal of dirt and debris from the outside surface of the

fins. Use locally purchased foaming condenser coil cleaners for periodic cleaning of the

coil. Condenser cleaners may contain harmful chemicals, be careful when using cleaners.

Care should be taken not to damage the fins during cleaning. All chemical cleaners should

be thoroughly rinsed from the coils.

!

WARNING

Refrigerant Sight glass

Observe the refrigerant sight glass monthly. A clear glass of liquid indicates adequate subcooled refrigerant charge in the system to ensure proper feed through the expansion valve.

Bubbling refrigerant in the sight glass indicates the system is short of refrigerant charge.

Sub-cooling should be verified to prevent overcharging. Refrigerant gas flashing in the

sight glass could also indicate an excessive pressure drop in the line, possibly due to a

clogged filter-drier or a restriction elsewhere in the system. The sight glass indicates what

moisture condition corresponds to a given element color. If the sight glass does not indicate

a dry condition after about 12 hours of operation, the refrigerant or oil should be tested for

moisture.

IOMM 1155 AGZ 010B through 034B 31

Page 32

Standard MicroTech II Controller

Table of Contents

Overview...............................................................................33

General Description...............................................................33

Compressor Motor Description ........................................33

FanTrol Head Pressure Control

Inputs/Outputs .................................................................

Setpoints ..........................................................................34

Equipment Protection Alarms...........................................36

Control Functions and Definitions....................................38

Limit Alarms....................................................................38

Control Functions ............................................................38

Unit Enable ......................................................................39

Unit Mode Selection ........................................................39

Unit State.........................................................................40

Evaporator Pump state .....................................................41

Condenser Fans................................................................43

Compressor Control .........................................................44

Using the Controller ..............................................................38

Display and Keyboard......................................................47

........................................33

34

Getting Started ......................................................................47

Menu Screens...................................................................48

Menu Matrix ....................................................................50

View Screens Defined ......................................................51

Alarm Screens Defined ....................................................53

Set Screens Defined .........................................................54

Softwar

32 AGZ 010B through 034B IOMM 1155

e Version AGZSU0102D

Page 33

Overview

The MicroTech II controller’s state-of-the-art design will not only permit the chiller to run

more efficiently, but will also simplify troubleshooting if a system failure occurs. Every

MicroTech II controller is programmed and tested prior to shipment to contribute to a

trouble-free start-up.

Release Version

This manual covers Software Release AGZ SU0102D

Operator-friendly

The MicroTech II controller’s menu structure is separated into three distinct categories,

which provide the operator or service technician with a full description of current unit

status, control parameters, and alarms. Security protection prevents unauthorized changing

of the setpoints and control parameters.

The MicroTech II controller continuously performs self-diagnostic checks, monitoring