Page 1

Installation and Maintenance Manual IM 1110-1

Air-Cooled Scroll Compressor Chiller

Group: Chillers

Part Number: IM1110-1

Date: June 2014

AGZ025D-AGZ190D (REV 0A), Chillers with Pump Packages

R-410A, 60 Hz

© 2014 Daikin Applied

Page 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Manufactured in an ISO-certified facility

©2014 Daikin Applied. Illustrations and data cover the Daikin Applied product at the time of publication and we reserve the right to make

changes in design and construction at anytime without notice.

Selection Procedures . . . . . . . . . . . . . . . . . . . . . . . 8

Pressure Drop Data . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation Information . . . . . . . . . . . . . . . . . . . . . 16

Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Vibration Isolators . . . . . . . . . . . . . . . . . . . . . . . . . 19

Triple Duty Valve . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical Information . . . . . . . . . . . . . . . . . . . . . . 30

Pump Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Start-up and Shutdown . . . . . . . . . . . . . . . . . . . . 52

Setup for BAS Integration . . . . . . . . . . . . . . . . . . 54

System Maintenance . . . . . . . . . . . . . . . . . . . . . . 60

Hazard Identification

DANGER

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage, severe personal injury, or death if not avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or equipment damage if not avoided.

This manual contains information on the optional factory-installed pump packages for

AGZ-D (REV 0A) vintage air-cooled scroll chillers. For other product information, go to

www.DaikinApplied.com.

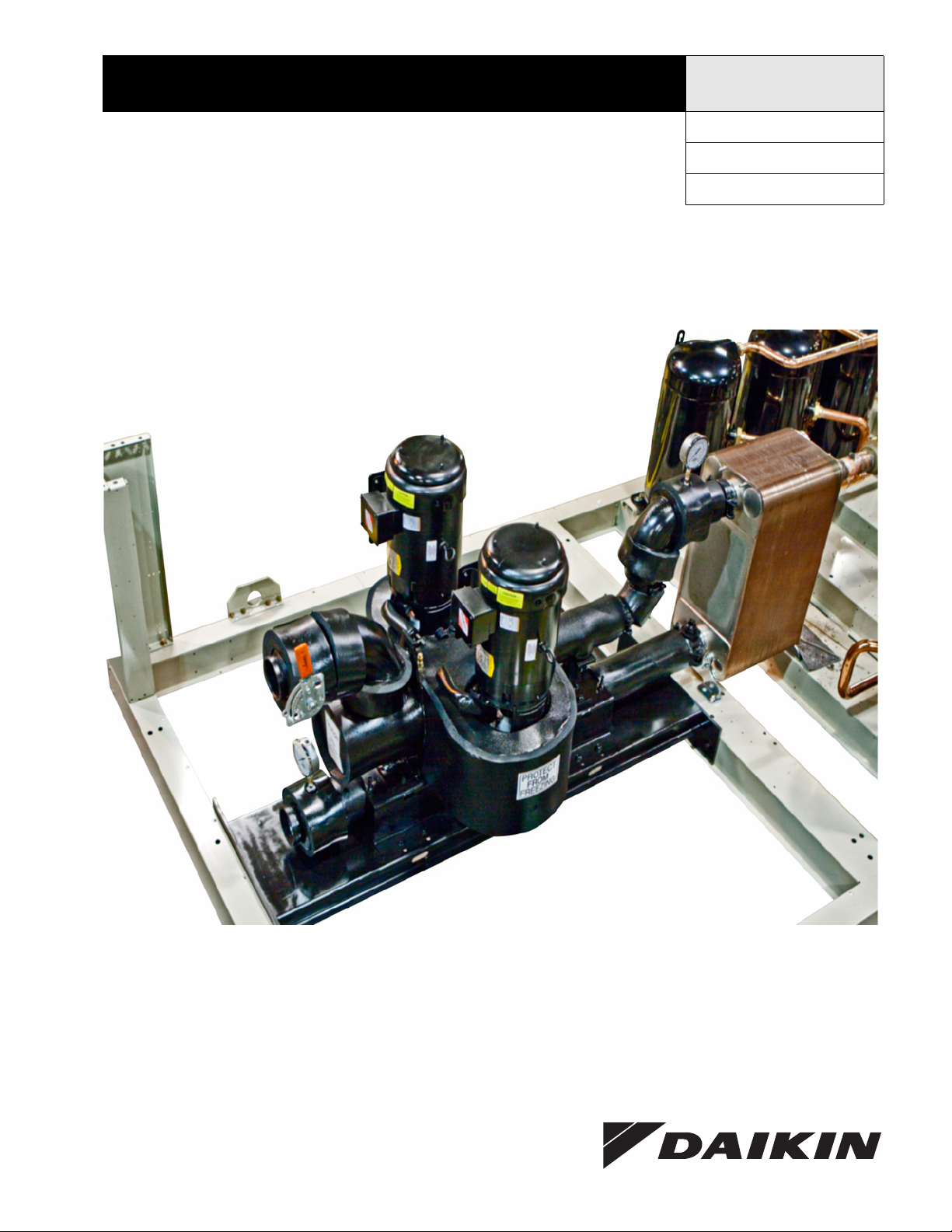

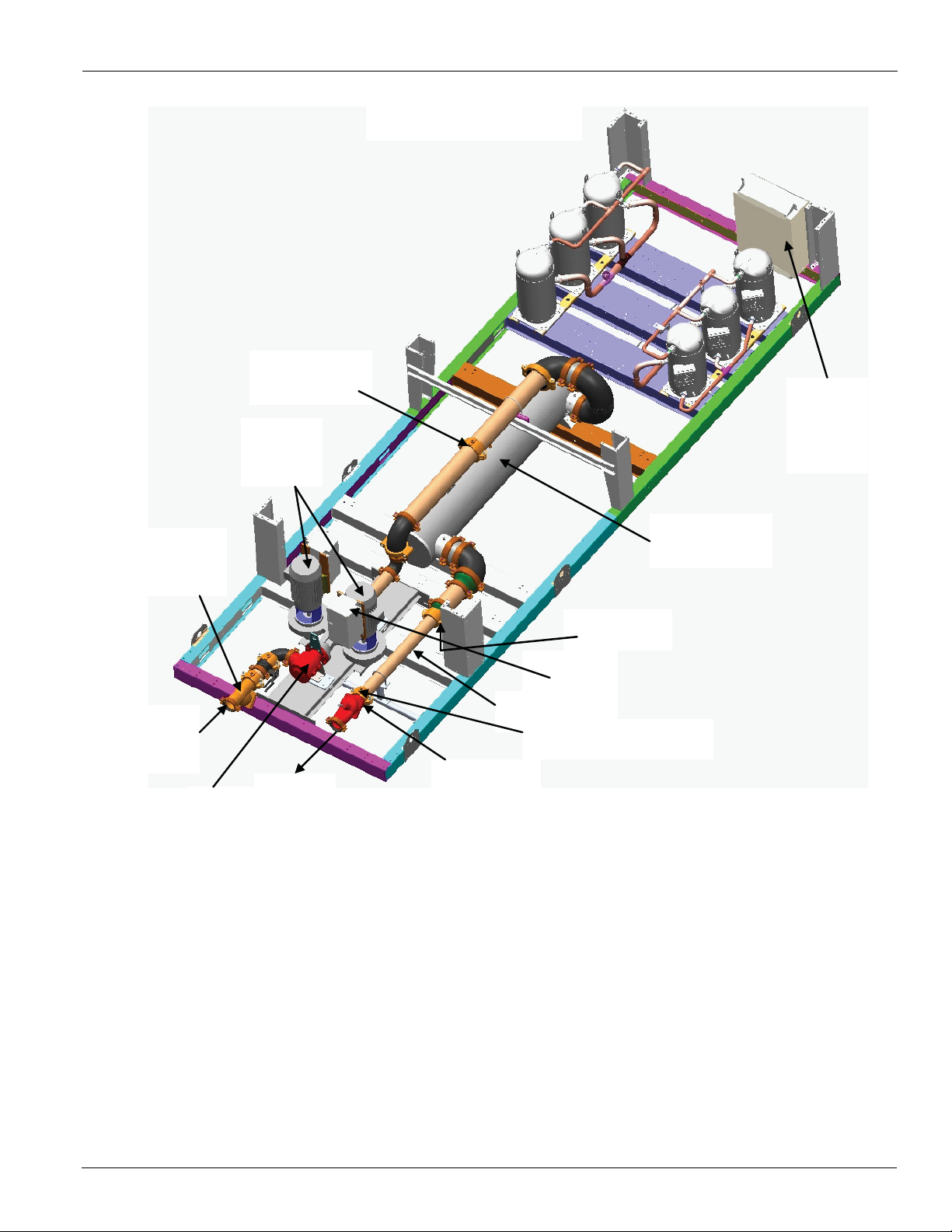

Cover Picture: Pump package shown during manufacture without evaporator insulation installed and without the

shipped loose pump inlet “Y” strainer and outlet triple-duty valve.

2 IM 1110-1

Page 3

Introduction

A

G Z XXX D H

Air-Cooled

Global Design

Scroll Compressor

Nominal Tons

Application

Design Vintage

H = Standard Packaged

Installation is to be performed by qualified personnel who are familiar with local codes and regulations.

Sharp edges on unit and coil surfaces are a potential hazard to personal safety. Avoid contact with them.

Note: Use this manual in conjunction with the current Installation and Maintenance Manual and Operation Manual,

for AGZ-D packaged chillers. Both manuals are available on www.DaikinApplied.com.

General Description

Introduction

WARNING

CAUTION

This manual covers optional on-board, integrated, chilled

water pump package available on all Daikin Model AGZ-D

(REV 0A) chillers. Factory-installed pump packages provide

important benefits:

• Greatly simplify the chilled water system design and

installation

• Provide installation savings by reducing field piping,

wiring and control costs

• Save valuable floor space inside the building

• Reduce project engineering content

• Greatly reduce pump operating cost with the optional

variable flow pump Variable Frequency Drive (VFD)

Standard Components

Single Pump (Model 4380) is a single spring inside seal,

vertical, in-line, radially split-case pump, serviceable without

breaking pipe connections. The motor and pump rotating

assembly can be serviced without removing the pump casing

from the line.

Dual Pumps in a Single Casting (Model 4392) single-spring

inside-seal vertical, in-line, radially split-case pumps, mounted

in a common casing with a common inlet connection and

outlet connection and including a flapper valve to prevent

recirculation when only one pump is operating. An isolation

valve is included that allows one pump to operate when the

other is removed. The pumps are designed for duty/standby,

not parallel operation. All information and performance curves

for the single pump arrangement (Model 4380) can be used for

the dual pump arrangement (Model 4392.)

PLUS

• “Y" type inlet strainer

• Combination triple-duty outlet valve having a drip-tight

discharge shutoff valve, non-slam check valve, and flow

throttling valve

• Combination suction guide with flow stabilizing outlet

vanes and stainless steel strainer with a disposable finemesh strainer for start-up

• Factory power and control wiring from the AGZ-D

chiller to the pump package control panel

• Flow switch mounted and wired

• Interconnecting schedule 40 piping with Victaulic® couplings

• Insulation of all cold surfaces

Options

• Water pressure gauges on the pump suction and discharge

• Expansion tank with size increments from 4.4 to 90 gallons, field installed (small sizes can be factory mounted

• Air separator with air vent, field installed

• Flex piping connections, field installed

• Storage tanks, vertical, insulated. (150, 300, 600, 1000

gallon sizes) with optional immersion heater, field

installed.

IM 1110-1 3

Page 4

Introduction

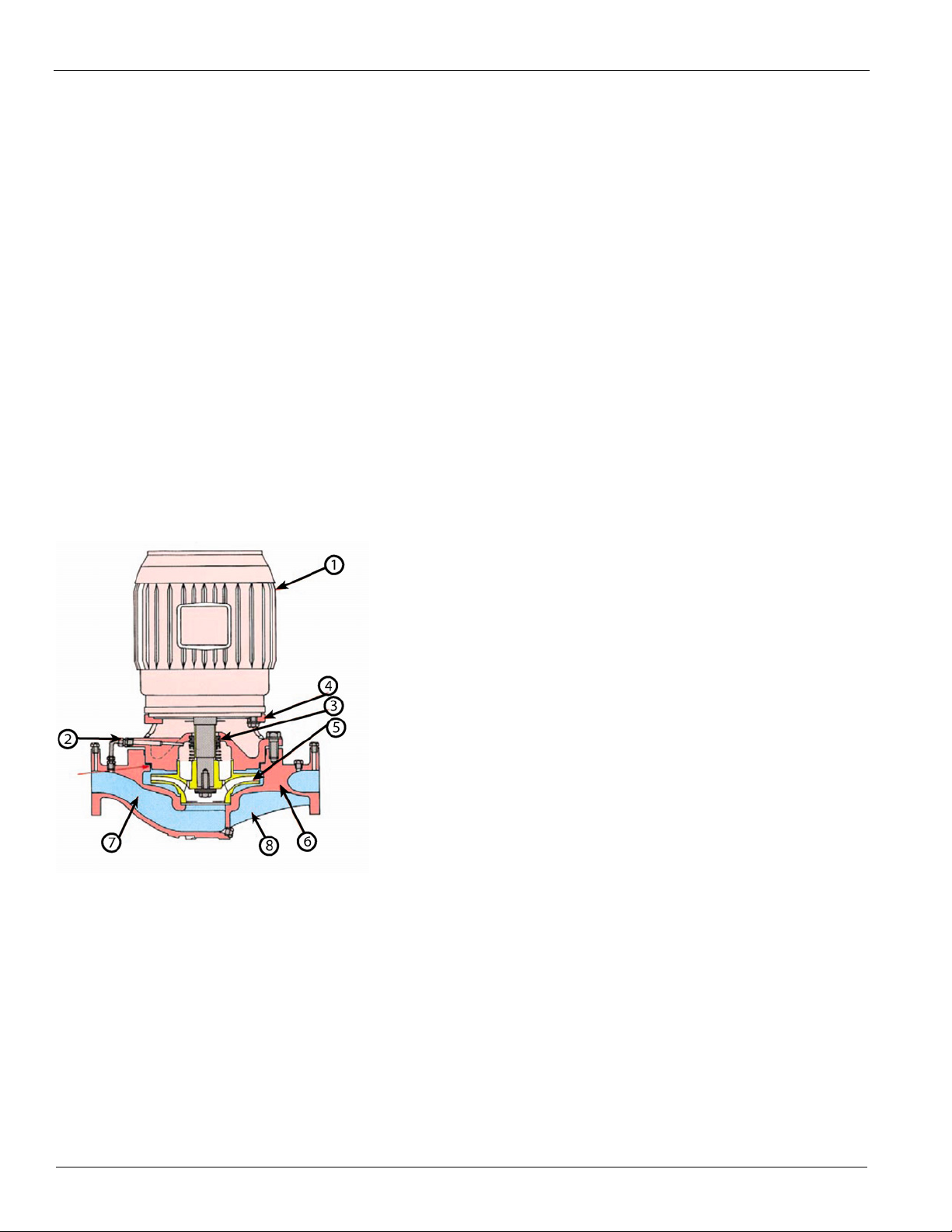

1.Industry standard face mounted motor.

2.Flush and vent connection removes entrained air and ensures

liquid at seal face at all times.

3.Inside type mechanical seal with Silicon Carbide seat,

serviceable without breaking pipe connections.

4.Heavy cylindrical bracket with 360° register on both flanges

provides a rigid union of pump and motor.

5.Dynamically balanced impeller assures smooth vibrationfree operation.

6.Radially split casing with equal suction and discharge flange

sizes. Separate tapped openings for gauge, flush and drain

connections.

7.Liberal inlet passageways and straightening vanes provide

optimum suction performance and quiet operation.

8.Ribs cast integral with casing. Machined surface to accept

floor support when specified.

9.Confined casing gasket to meet stringent industrial

temperature and pressure applications.

Optional Variable Flow VFD

The operating cost savings resulting from using variable

chilled water flow via a pump VFD has been well known for

many years. In the past, however, its usage has been somewhat

limited by the cost and uncertainty of field installing the

required system pressure differential sensors.

Daikin Applied can now offer a variable chilled water flow

system, completely self-contained within the pump package,

by simply ordering the optional pump VFD-no external

sensors required.

Including sensorless operation, there are four operating modes

available with the optional factory-installed variable flow

VFD:

1 Sensorless Pressure Control: Onboard measurements

allow control of the pump speed to optimize chilled

water flow with respect to water system pressure.

External pressure sensors are not required, eliminating

design and installation effort. The unit is factoryconfigured for this mode.

2 BAS Input: The pump speed will be controlled

according to the voltage level from a BAS input signal.

Figure 1: Model 4380 Design Features

3 Locally Selected Constant Speed Control: Operation

of the pump at a constant speed selected on the VFD

control panel. Among other things, this mode allows

selecting a pump speed to match the actual system curve.

4 Remote Sensor Control: The VFD is wired to pressure

sensors mounted in the chilled water piping system. This

is the standard VFD control when a sensorless VFD is

not used.

Pump Description

• Pump casing is cast iron.

• The casing suction and discharge connections are the

same size and have tapped seal vent and pressure gauge

connections.

• The mechanical seal is single-spring inside type with

carbon against silicon carbide faces. EPDM elastomer

with stainless steel and hardware are provided.

• Impellers are bronze, trimmed to design conditions and

then balanced.

• The shaft sleeve is bronze extending the full length of

the seal area.

4 IM 1110-1

Page 5

Component Location

Outlet Valve

Wat er

Inlet

Chilled

Wat er

Outlet

“Y”Type

Inlet

Strainer

Inlet

Guide

Dual

Vertical

Pumps

VFD

Controllers

Pump

Package

Control

Brazed-Plate

Evaporator

Gauge Port

Swt.

Guage Port

Figure 2: Component location for models AGZ025D - AGZ070D

Introduction

Chilled

Optional

Evap In Press.

Panel

Triple-Duty

Flow

Drain

Evap Out Press.

Notes:

1 Dual pumps having a common housing and inlet and outlet connections as shown. An available single pump arrangement can

replace the dual pump and will have a similar piping layout.

2 The inlet strainer and triple-duty valve are shipped separate for field installation.

3 The pump package control panel is located under the main unit control panel. The piping connections are on the left side of

the chiller unit when looking at the control panel.

4 Pump drains are located under the pump casing, ¼ in. NPT.

5 Pipe drains are 1 in. NPT.

IM 1110-1 5

Page 6

Introduction

Dual

Vertical

Pumps

Optional

VFD

Controllers

Chilled

Water

Inlet

Chilled

Water

Outlet

Outlet Valve

Flow Switch

Brazed-Plate

Evaporator

Pump Package

Control Panel

Drain Port

Press. Ga. Port

Evap Out

Press. Ga. Port

Figure 3: Component location for models AGZ075D - AGZ130D

Evap In

“Y” Type Strainer

Notes:

1 Dual pump having a common inlet and outlet shown. An available single pump arrangement can replace the dual pump and

Triple-Duty

will have a similar piping layout.

2 The inlet strainer and triple-duty valve are shipped separate for field installation.

3 The pump package control panel is located under the main unit control panel. The piping connections are at the rear of the

unit, opposite the control panel.

4 Pump drains are located under the pump casing, ¼ in. NPT.

5 Pipe drains are 1 in. NPT.

6 IM 1110-1

Page 7

Figure 4: Component location for models AGZ140D - AGZ190D

Dual

Vertical

Pumps

Optional

VFD

Controllers

Chilled

Water

Inlet

Water

Outlet

Inlet

Guide

Outlet valve

Shell-and-Tube

Evaporator

Pump

Package

Control

Panel

“Y” Type

Inlet

Strainer

Evap In

Press Ga. Port

Evap Out Press. Ga. port

Introduction

Drain Port

Flow Switch

Triple-Duty

Chilled

Notes:

1 Dual pump having a common inlet and outlet shown. An available single pump arrangement can replace the dual pump and

will have a similar piping layout.

2 The inlet strainer and triple-duty valve are shipped separate for field installation.

3 The pump package control panel is located under the main unit control panel. The piping connections are at the rear of the

unit, opposite the control panel.

4 Pump drains are located under the pump casing, ¼ in. NPT.

5 Pipe drains are 1 in. NPT.

IM 1110-1 7

Page 8

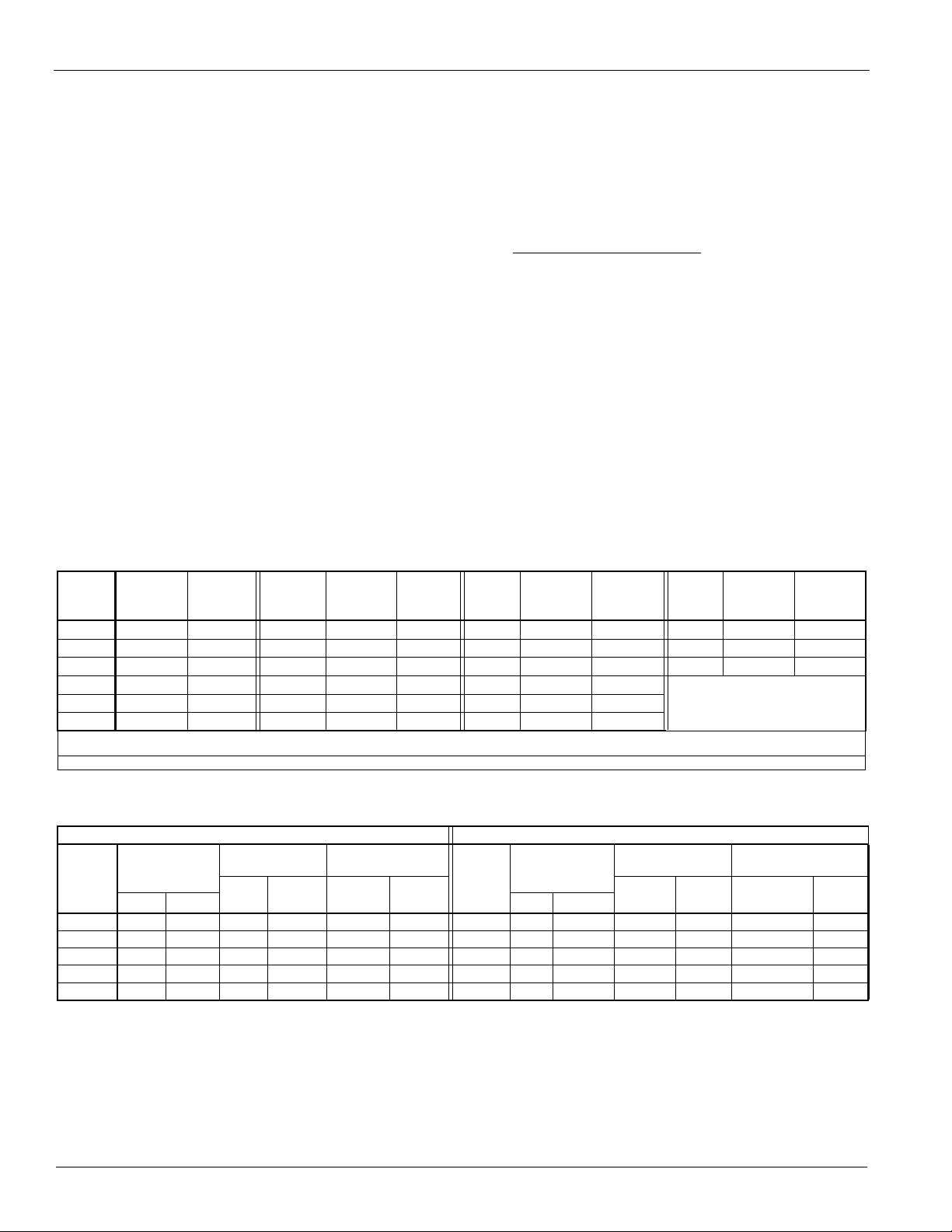

Selection Procedures

Selection Procedures

Selection Procedure

This section provides material to make pump selections. Your

Daikin Applied sales representative can make computerized

selections and provide pricing. The AGZ-D model size, the

chilled water flow, and the total dynamic external system head

are required to select a pump package.

AGZ Model Size

The AGZ-D model size is determined by the selection program

or selected from the current version of the Daikin Applied

catalog available from your local sales representative or

www.DaikinApplied.com.

Chilled Water Flow

The chilled water flow will either be specified or determined

from the AGZ selection program.

Total Dynamic System Head

The total system dynamic head is the sum of three

components:

1 Internal pump package losses from piping, valves and

fittings from Table 1

2 Evaporator pressure drop from the selection program or

from curves on page 15

3 External system pressure drop as determined by the

system designer.

For systems using a glycol solution:

"For the internal package pressure drop, use Table 1 values.

Glycol has no significant impact.

"For the evaporator pressure drop, the Daikin Applied

selection program includes an automatic correction factor. If

the pressure drop is determined from the pressure drop curves,

use the correction factors from Tab le 2 to calculate the water

pressure drop for glycol. Do not use uncorrected table values

for the evaporator.

"The external system pressure drop must also account for

glycol use.

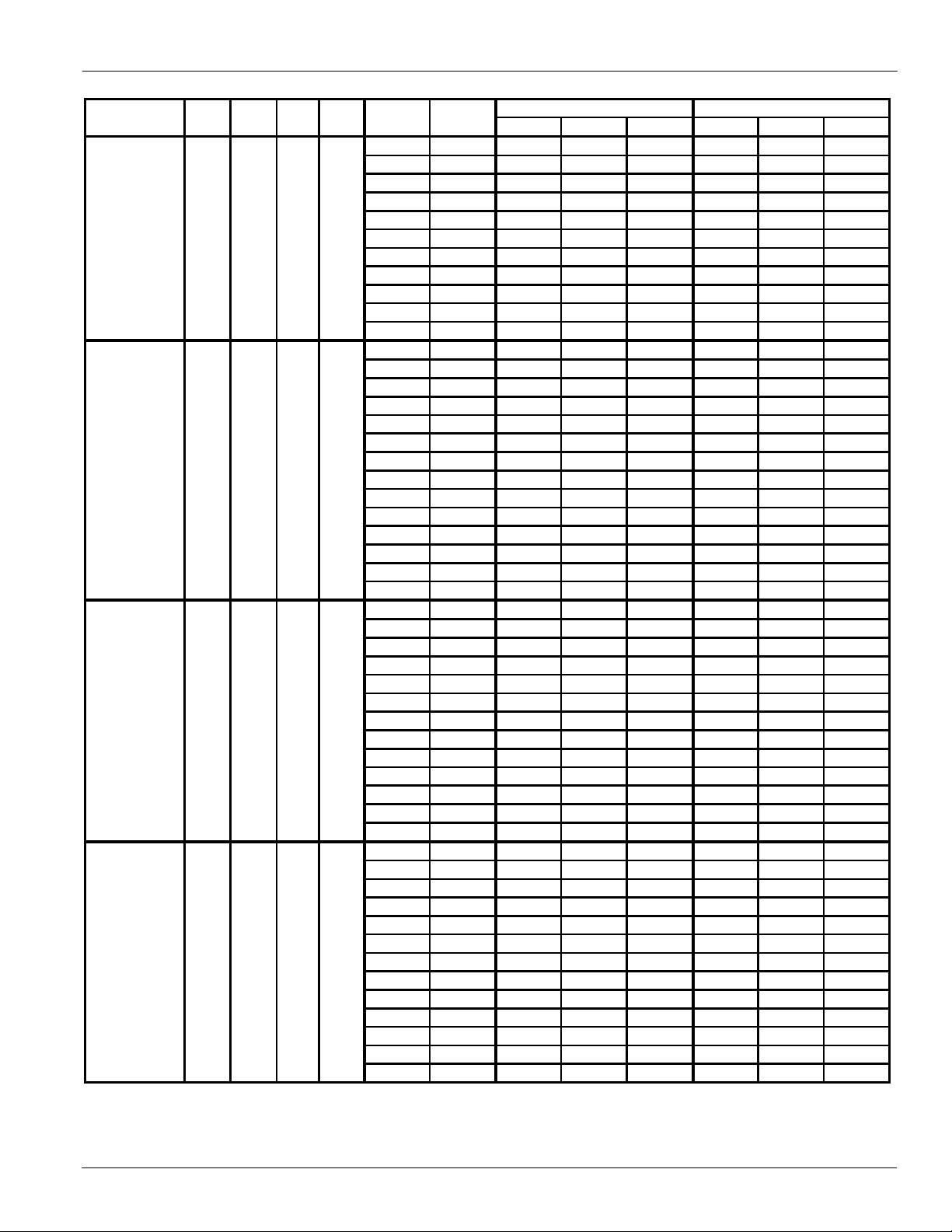

Table 1: Pump Package Internal Pressure Drop and Water Volume

AGZ-D

MODEL

025 3.7 4 055 7.1 6 090 16.3 11 160 12.7 65

030 4.3 4 060 8.0 8 100 10.3 11 180 15.9 65

035 4.6 4 065 8.7 9 110 10.5 12 190 18.4 65

040 4.9 4 070 9.5 9 125 12.9 13

045 5.6 4 075 10.8 9 130 16.0 14

050 6.3 5 080 14.0 9 140 10.0 65

Note: 1.Internal pump package pressure drop is based on the AGZ nominal flow and includes the pipe, fittings and suction guide/strainer. It does not include

Note: 2.Water volume shown is for pump package components, piping and fittings and includes the evaporator.

PRESS

DROP

(ft)

the evaporator pressure drop. Lower flow rates have a negligible affect on the pump selection.

WATER-

VOLUME

(gal.)

AGZ-D

MODEL

PRESS.

DROP

(ft)

WATER

VOLUME

(gal.)

AGZ-D

MODEL

PRESS.

DROP

(ft)

WATER

VOLUME

(gal.)

AGZ-D

MODEL

PRESS.

DROP

(ft)

WATER

VOLUME

(gal.)

Table 2: Glycol Correction Factors

Ethylene Glycol Propylene Glycol

Freeze

% E.G.

10 26 -3.3 1.097 1.097 1.038 1.101 10 26 -3.3 1.016 1.100 1.019 1.097

20 18 -7.8 1.226 1.226 1.063 1.224 20 19 -7.2 1.032 1.211 1.035 1.201

30 7 -13.9 1.369 1.369 1.095 1.358 30 9 -12.8 1.057 1.380 1.059 1.351

40 -7 -21.7 1.557 1.557 1.134 1.536 40 -5 -20.6 1.092 1.703 1.095 1.598

50 -28 -33.3 1.791 1.791 1.184 1.755 50 -27 -32.8 1.140 2.251 1.142 2.039

Point

° F ° C ° F ° C

Model

025-130

Flow PD Flow PD Flow PD Flow PD

Model

140-190

% P.G.

Flow

Freeze Point

Model

025-130

Model

140-190

8 IM 1110-1

Page 9

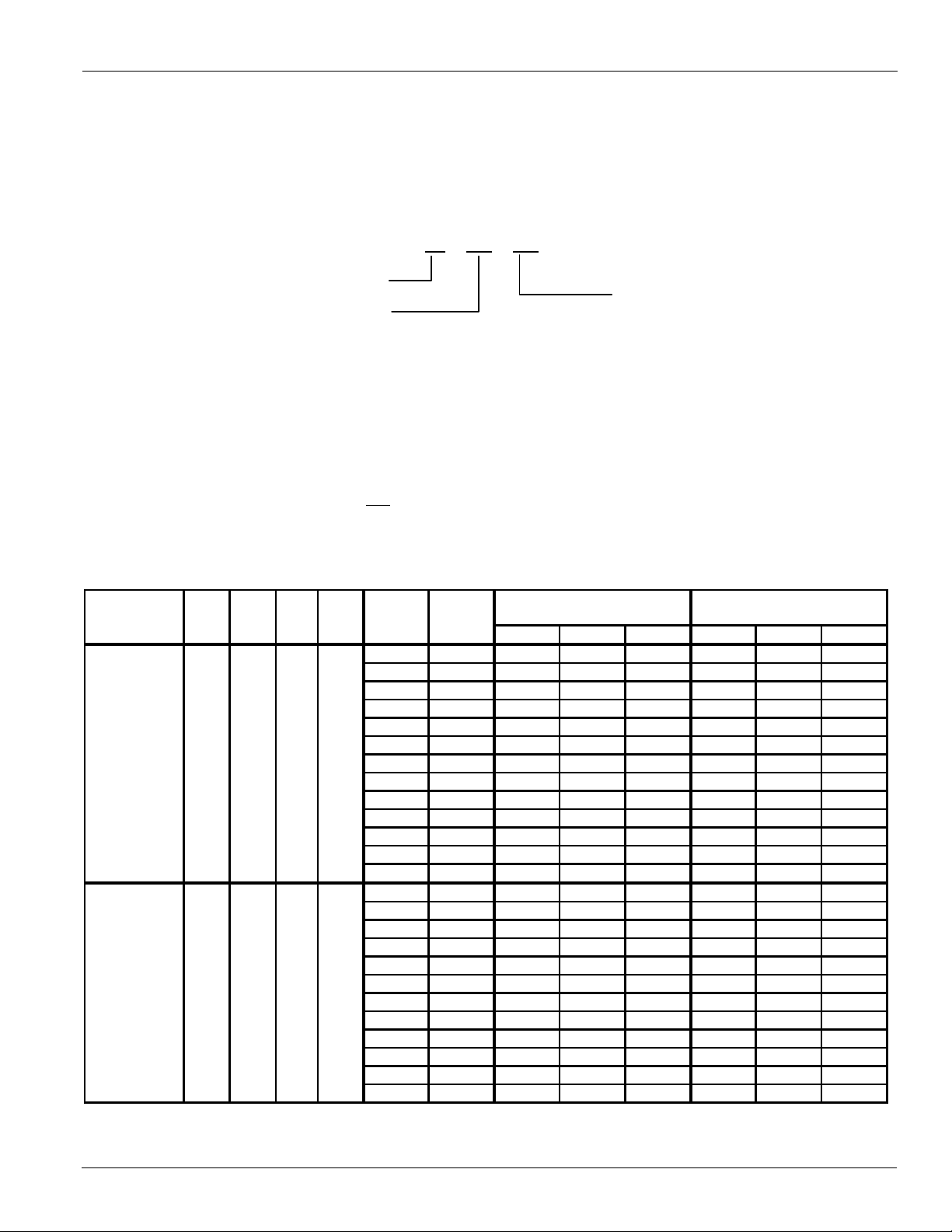

Selection Procedures

Pump Nomenclature

2

x 1.5 x 5.5

Suction Size (in.)

Discharge Size (in.)

Unit Nom. Nom. Min. Max. Unit Tota l

Model Tons gpm gpm gpm gpm Head

ft. Size rpm HP Size rpm HP

41 25 2x2x6 1800 1 2x2x6 1800 1

41 50 1.5x1.5x8 1800 2 2x2x8 1800 3

41 75 1.5x1.5x6 3600 3 2x2x8 3600 5

41 100 1.5x1.5x6 3600 5 2x2x6 3600 5

41 125 1.5x1.5x6 3600 5 - - -

66 25 2x2x6 1800 1 2x2x6 1800 1

66 50 2x2x8 1800 3 2x2x8 1800 3

66 75 1.5x1.5x6 1800 5 3x3x6 1800 5

66 100 1.5x1.5x6 3600 5 2x2x6 3600 5

66 125 1.5x1.5x6 3600 5 - - -

87 25 2x2x6 1800 2 2x2x6 1800 2

87 50 2x2x8 1800 3 2x2x8 1800 3

87 75 2x2x6 3600 5 2x2x6 3600 5

47 25 2x2x6 1800 1 2x2x6 1800 1

47 50 2x2x8 1800 3 2x2x8 1800 3

47 75 1.5x1.5x6 3600 3 2x2x8 3600 5

47 100 1.5x1.5x6 3600 5 2x2x6 3600 5

47 125 1.5x1.5x6 3600 5 - - -

76 25 2x2x6 1800 1 2x2x6 1800 1

76 50 2x2x8 1800 3 2x2x8 1800 3

76 75 1.5x1.5x6 3600 3 2x2x6 3600 5

76 100 1.5x1.5x6 3600 5 - - -

10 1 2 5 3 x3x6 1 80 0 2 3 x3x6 18 00 2

10 1 5 0 2 x2x8 1 80 0 3 2 x2x8 18 00 3

10 1 7 5 2 x2x6 3 60 0 5 2 x2x6 36 00 5

Single Pump Dual Pumps

AGZ 025D

27.3 66 41 109

AGZ 030D

31.6 76 47 126

Pump Selection Procedure

A family of pump sizes has been pre-selected for groups of

AGZ units and shown in Table 3.

Selection Examples

Select: a pump for an AGZ 025-D with 65 gpm of water flow

at a 90 ft external head, dual pumps. From Tab le 1., the

internal pump package pressure drop is 3.7 ft.

From the pressure drop curves on page 15, the evaporator

pressure drop is 9.4 ft.

Internal Pump Package 3.7

Evaporator 9.4

External 90.0

Total Head 103.1

Using the required flow and total system head, select the best

pump from the table. Flow values are shown for minimum,

nominal, and near-maximum flow rates for each AGZ size. For

flow rates falling between these values, check the pump

selection for the higher and lower flow. The impeller will be

trimmed for specific job conditions after order placement.

Impeller Size (in.)

From Table 3., select a dual 2 x 2 x 6 pump, 3600 rpm, 7.5 hp.

Although a 5 hp pump is adequate at design conditions, a 7.5

hp pump will provide non-overloading characteristics.

Table 3: AGZ-D Unit/Pump Combinations

Note: Some unit gpm and head combination do not have a valid selection and are absent from the table.

IM 1110-1 9

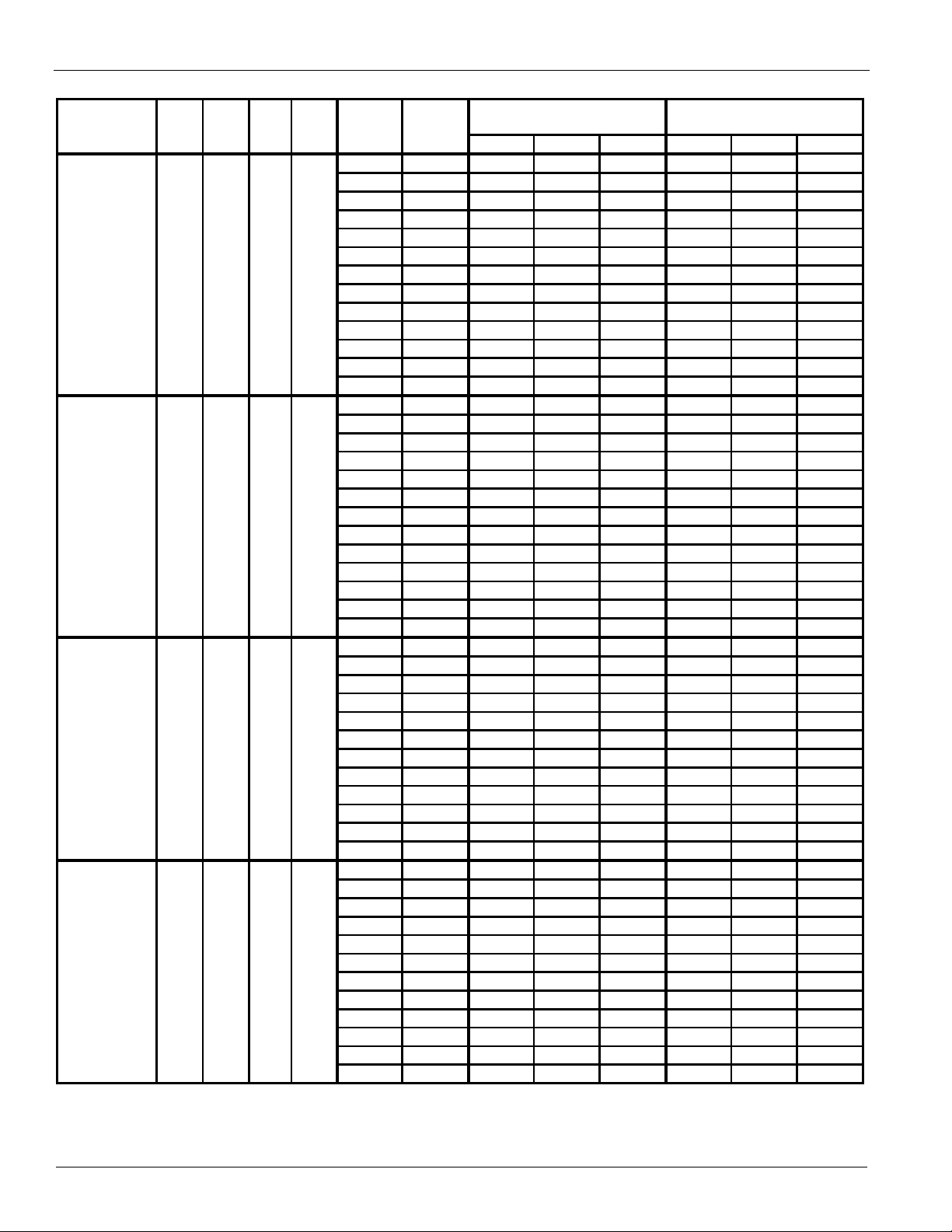

Page 10

Selection Procedures

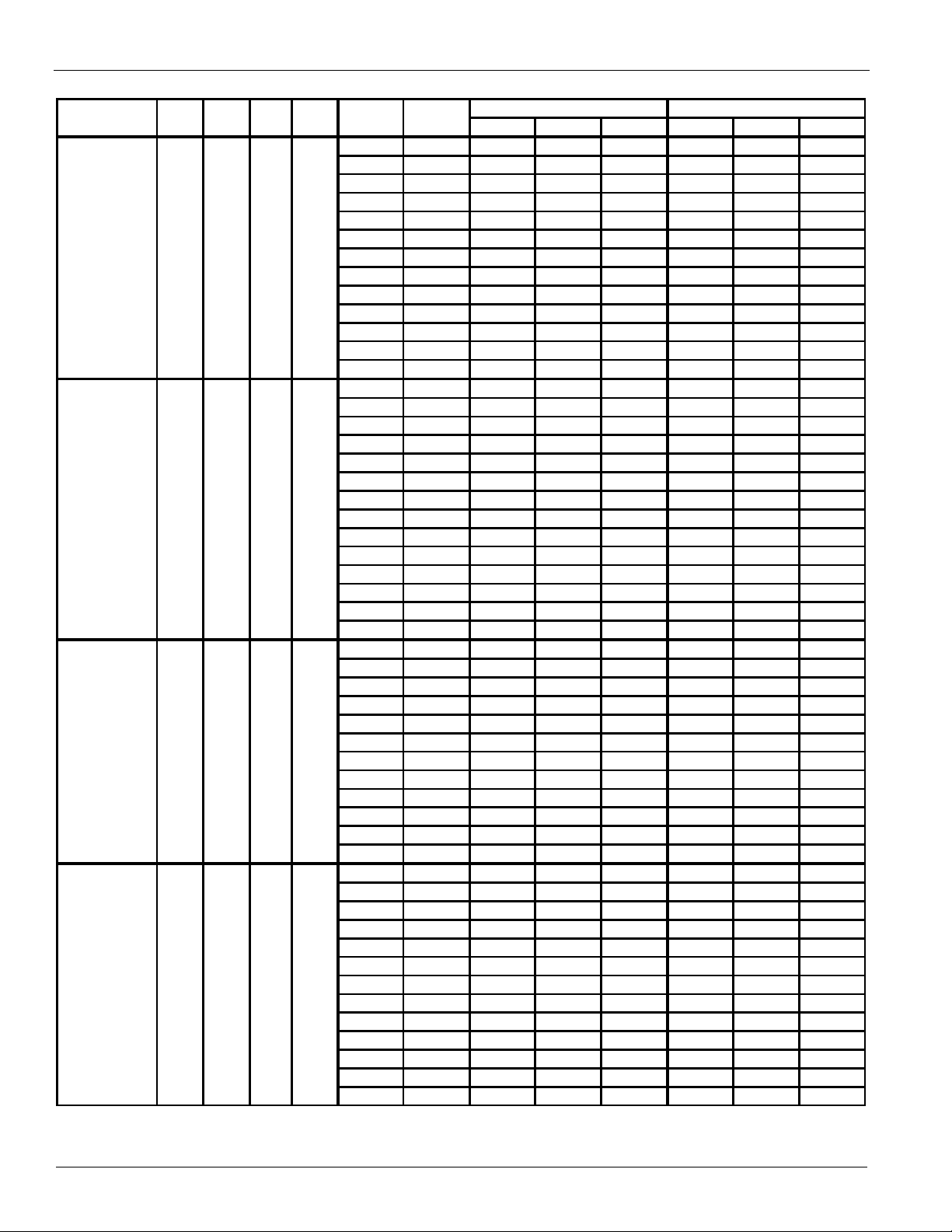

Table 3: AGZ-D Unit/Pump Combinations Continued

Unit Nom . Nom. Min. M a x. Unit Tota l

Model Tons gpm gpm gpm gpm Head

52 50 2x2x8 1800 3 2x2x8 1800 3

52 75 1.5x1.5x6 3600 3 2x2x6 3600 5

52 100 1.5x1.5x6 3600 5 2x2x6 3600 5

52 125 1.5x1.5x6 3600 5 2x2x6 3600 7.5

84 25 2x2x6 1800 2 2x2x6 1800 2

84 50 2x2x8 1800 3 2x2x8 1800 3

AGZ 035D

AGZ 040D

AGZ

045D

AGZ 050D

34.9 84 52

37.9 91 57 152

42.6 102 64 170

48.1 115 72 192

140

84 75 2x2x6 3600 5 2x2x6 3600 5

84 100 1.5x1.5x6 3600 5 2x2x6 3600 7.5

84 125 2x2x6 3600 7.5 2x2x6 3600 7.5

112 25 2x2x8 1800 2 2x2x8 1800 2

112 50 2x2x8 1800 3 2x2x8 1800 3

112 75 2x2x6 3600 5 2x2x6 3600 5

112 100 2x2x6 3600 7.5 2x2x6 3600 7.5

57 50 2x2x8 1800 3 2x2x8 1800 3

57 75 1.5x1.5x6 3600 3 3x3x6 3600 5

57 100 1.5x1.5x6 3600 5 2x2x6 3600 5

57 125 1.5x1.5x6 3600 5 2x2x6 3600 7.5

91 25 2x2x6 1800 2 2x2x6 1800 2

91 50 2x2x8 1800 3 2x2x8 1800 3

91 75 2x2x6 3600 5 2x2x6 3600 5

91 100 2x2x6 3600 7.5 2x2x6 3600 7.5

91 125 2x2x6 3600 7.5 2x2x6 3600 7.5

121 25 3x3x6 1800 2 3x3x6 1800 2

121 50 2x2x8 1800 3 2x2x8 1800 3

121 75 2x2x6 3600 5 2x2x6 3600 5

121 100 2x2x6 3600 7.5 2x2x6 3600 7.5

64 50 2x2x8 1800 3 2x2x8 1800 3

64 75 1.5x1.5x6 1800 5 3x3x6 1800 5

64 100 1.5x1.5x6 3600 5 2x2x6 3600 5

64 125 1.5x1.5x6 3600 5 2x2x6 3600 7.5

102 25 3x3x6 1800 2 3x3x6 1800 2

102 50 2x2x8 1800 3 2x2x8 1800 3

102 75 2x2x6 3600 5 2x2x6 3600 5

102 100 2x2x6 3600 7.5 2x2x6 3600 7.5

136 25 3x3x6 1800 2 3x3x6 1800 2

136 50 2x2x8 1800 5 2x2x8 1800 5

136 75 2x2x6 3600 5 2x2x6 3600 5

136 100 2x2x6 3600 7.5 2x2x6 3600 7.5

72 50 2x2x8 1800 3 2x2x8 1800 3

72 75 1.5x1.5x6 3600 3 2x2x6 3600 5

72 100 1.5x1.5x6 3600 5 2x2x6 3600 7.5

72 125 2x2x6 3600 7.5 2x2x6 3600 7.5

115 25 2x2x8 1800 2 2x2x8 1800 2

115 50 2x2x8 1800 3 2x2x8 1800 3

115 75 2x2x6 3600 5 2x2x6 3600 5

115 100 2x2x6 3600 7.5 2x2x6 3600 7.5

154 25 3x3x6 1800 2 3x3x6 1800 2

154 50 2x2x8 1800 5 2x2x8 1800 5

154 75 2x2x6 3600 7.5 2x2x6 3600 7.5

154 100 2x2x6 3600 7.5 2x2x6 3600 7.5

Single Dual

ft. Size rpm HP Size rpm HP

Note: Some unit gpm and head combination do not have a valid selection and are absent from the table.

10 IM 1110-1

Page 11

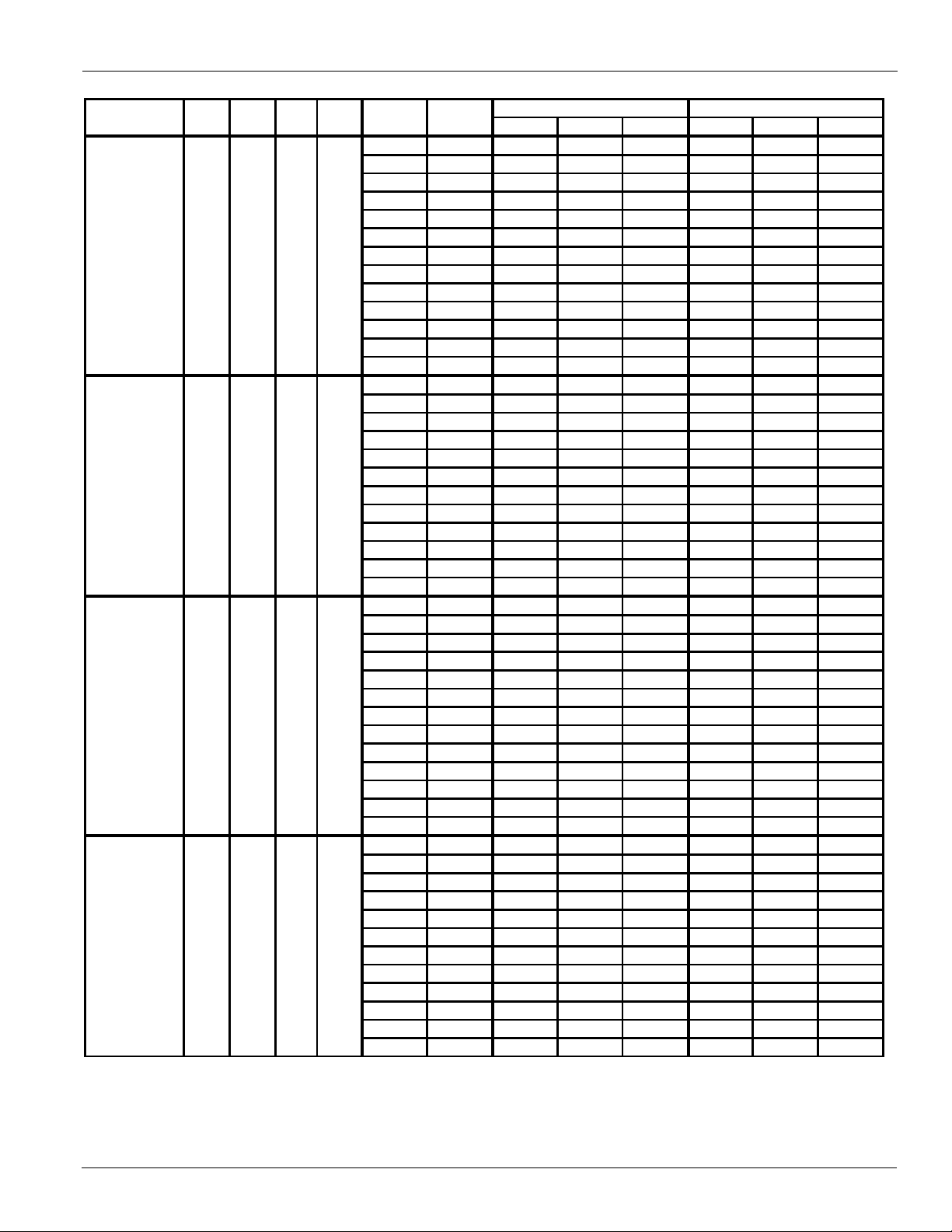

Table 3: AGZ-D Unit/Pump Combinations Continued

Unit Nom. Nom. M in. Ma x . Unit Tota l Head

Model Tons gpm gpm gpm gpm ft. Size RPM HP Size RPM HP

77 50 2x2x8 1800 3 2x2x8 1800 3

77 75 1.5x1.5x6 3600 3 2x2x6 3600 5

77 100 1.5x1.5x6 3600 5 2x2x6 3600 7.5

77 125 2x2x6 3600 7.5 2x2x6 3600 7.5

124 25 3x3x6 1800 2 3x3x6 1800 2

124 50 2x2x8 1800 3 2x2x8 1800 3

124 75 2x2x6 3600 5 2x2x6 3600 5

124 100 2x2x6 3600 7.5 2x2x6 3600 7.5

165 25 3x3x6 1800 2 3x3x6 1800 2

165 50 3x3x8 1800 5 3x3x8 1800 5

165 75 2x2x6 3600 7.5 2x2x6 3600 7.5

84 50 2x2x8 1800 3 2x2x8 1800 3

84 75 2x2x6 3600 5 2x2x6 3600 5

84 100 1.5x1.5x6 3600 5 2x2x6 3600 7.5

84 125 2x2x6 3600 7.5 2x2x6 3600 7.5

135 25 3x3x6 1800 2 3x3x6 1800 2

135 50 2x2x8 1800 5 2x2x8 1800 5

135 75 2x2x6 3600 5 2x2x6 3600 5

135 100 2x2x6 3600 7.5 2x2x6 3600 7.5

135 125 2x2x6 3600 10 2x2x6 3600 10

180 25 3x3x6 1800 2 3x3x6 1800 2

180 50 3x3x8 1800 5 3x3x8 1800 5

180 75 3x3x6 3600 7.5 3x3x6 3600 7.5

180 100 2x2x6 3600 10 2x2x6 3600 10

180 125 2x2x8 3600 10 2x2x8 3600 10

87 50 2x2x8 1800 3 2x2x8 1800 3

87 75 2x2x6 3600 5 2x2x6 3600 5

87 100 2x2x6 3600 7.5 2x2x6 3600 7.5

87 125 2x2x6 3600 7.5 2x2x6 3600 7.5

139 25 3x3x6 1800 2 3x3x6 1800 2

139 50 2x2x8 1800 5 2x2x8 1800 5

139 75 2x2x6 3600 5 2x2x6 3600 5

139 100 2x2x6 3600 7.5 2x2x6 3600 7.5

139 125 2x2x6 3600 10 2x2x6 3600 10

186 25 3x3x6 1800 2 3x3x6 1800 2

186 50 3x3x8 1800 5 3x3x8 1800 5

186 75 3x3x6 3600 7.5 3x3x6 3600 7.5

186 100 2x2x6 3600 10 2x2x6 3600 10

96 50 2x2x8 1800 3 2x2x8 1800 3

96 75 2x2x6 3600 5 2x2x6 3600 5

96 100 2x2x6 3600 7.5 2x2x6 3600 7.5

96 125 2x2x6 3600 10 2x2x6 3600 10

154 25 3x3x6 1800 2 3x3x6 1800 2

154 50 2x2x8 1800 5 2x2x8 1800 5

154 75 2x2x6 3600 7.5 2x2x6 3600 7.5

154 100 2x2x6 3600 7.5 2x2x6 3600 7.5

154 125 1.5x1.5x8 3600 10 2x2x6 3600 10

205 25 3x3x8 1800 3 3x3x8 1800 3

205 50 3x3x8 1800 5 3x3x8 1800 5

205 75 3x3x6 3600 7.5 3x3x6 3600 7.5

205 100 3x3x6 3600 10 3x3x6 3600 10

AGZ 055D

51.6 124 77

Single Pump Dual Pumps

AGZ 065D

58.1 139 87

206

AGZ 060D

56.1 135 84 224

256

AGZ 070D

64.1 154 96

232

Selection Procedures

Note: Some unit gpm and head combination do not have a valid selection and are absent from the table.

IM 1110-1 11

Page 12

Selection Procedures

Unit Nom. Nom. Min. Max. Unit Total Head

Model Tons gpm gpm gpm gpm ft. Size rpm HP Size rpm HP

1 10 5 0 2 x2x8 1 80 0 3 2 x2x8 18 00 3

1 10 7 5 2 x2x6 3 60 0 5 2 x2x6 36 00 5

110 100 2x2x6 3600 7.5 2x2x6 3600 7.5

110 125 2x2x6 3600 10 2x2x6 3600 10

1 75 5 0 3 x3x8 1 80 0 5 3 x3x8 18 00 5

175 75 3x3x6 3600 7.5 3x3x6 3600 7.5

175 100 2x2x6 3600 10 2x2x6 3600 10

175 125 2x2x8 3600 15 2x2x8 3600 15

2 34 2 5 3 x3x8 1 80 0 3 3 x3x8 18 00 3

2 34 5 0 3 x3x8 1 80 0 5 3 x3x8 18 00 5

234 75 3x3x6 3600 7.5 3x3x6 3600 7.5

234 100 2x2x8 3600 15 2x2x8 3600 15

234 125 2x2x8 3600 15 2x2x8 3600 15

1 22 5 0 2 x2x8 1 80 0 3 2 x2x8 18 00 3

1 22 7 5 2 x2x6 3 60 0 5 2 x2x6 36 00 5

122 100 2x2x6 3600 7.5 2x2x6 3600 7.5

122 125 2x2x6 3600 10 2x2x6 3600 10

1 95 2 5 3 x3x6 1 80 0 3 3 x3x6 18 00 3

1 95 5 0 3 x3x8 1 80 0 5 3 x3x8 18 00 5

195 75 3x3x6 3600 7.5 3x3x6 3600 7.5

195 100 2x2x6 3600 10 2x2x6 3600 10

195 125 2x2x8 3600 15 2x2x8 3600 15

2 60 2 5 3 x3x6 1 80 0 3 3 x3x6 18 00 3

2 60 5 0 3 x3x8 1 80 0 5 3 x3x8 18 00 5

260 75 3x3x6 3600 7.5 3x3x6 3600 7.5

260 100 2x2x6 3600 10 2x2x6 3600 10

260 120 2x2x8 3600 15 2x2x8 3600 15

1 34 5 0 2 x2x8 1 80 0 5 2 x2x8 18 00 5

1 34 7 5 2 x2x6 3 60 0 5 2 x2x6 36 00 5

134 100 2x2x6 3600 7.5 2x2x6 3600 7.5

134 125 2x2x6 3600 10 2x2x6 3600 10

2 14 5 0 3 x3x8 1 80 0 5 3 x3x8 18 00 5

214 75 3x3x6 3600 7.5 3x3x6 3600 7.5

214 100 4x4x6 3600 15 4x4x6 3600 15

214 125 2x2x8 3600 15 2x2x8 3600 15

2 85 2 5 4 x4x6 1 80 0 3 4 x4x6 18 00 3

285 50 3x3x8 1800 7.5 3x3x8 1800 7.5

285 75 3x3x6 3600 10 3x3x6 3600 10

285 100 4x4x6 3600 15 4x4x6 3600 15

1 50 5 0 2 x2x8 1 80 0 5 2 x2x8 18 00 5

150 75 2x2x6 3600 7.5 2x2x6 3600 7.5

150 100 2x2x6 3600 7.5 2x2x6 3600 7.5

150 125 2x2x6 3600 15 2x2x6 3600 15

2 40 2 5 3 x3x8 1 80 0 3 3 x3x8 18 00 3

2 40 5 0 3 x3x8 1 80 0 5 3 x3x8 18 00 5

240 75 3x3x6 3600 7.5 3x3x6 3600 7.5

240 100 2x2x8 3600 15 2x2x8 3600 15

240 125 2x2x8 3600 15 2x2x8 3600 15

3 19 2 5 4 x4x6 1 80 0 3 4 x4x6 18 00 3

319 50 3x3x8 1800 7.5 3x3x8 1800 7.5

319 75 3x3x8 3600 10 3x3x8 3600 10

319 100 4x4x6 3600 15 4x4x6 3600 15

Dual Pumps

73.1 175 110 292

Single Pump

324

AGZ 090D

89.2 214 134 357

AGZ 080D

81.1 195 122

AGZ 100D

99.8 240 150 399

AGZ 075D

Table 3: AGZ-D Unit/Pump Combinations Continued

Note: Some unit gpm and head combination do not have a valid selection and are absent from the table.

12 IM 1110-1

Page 13

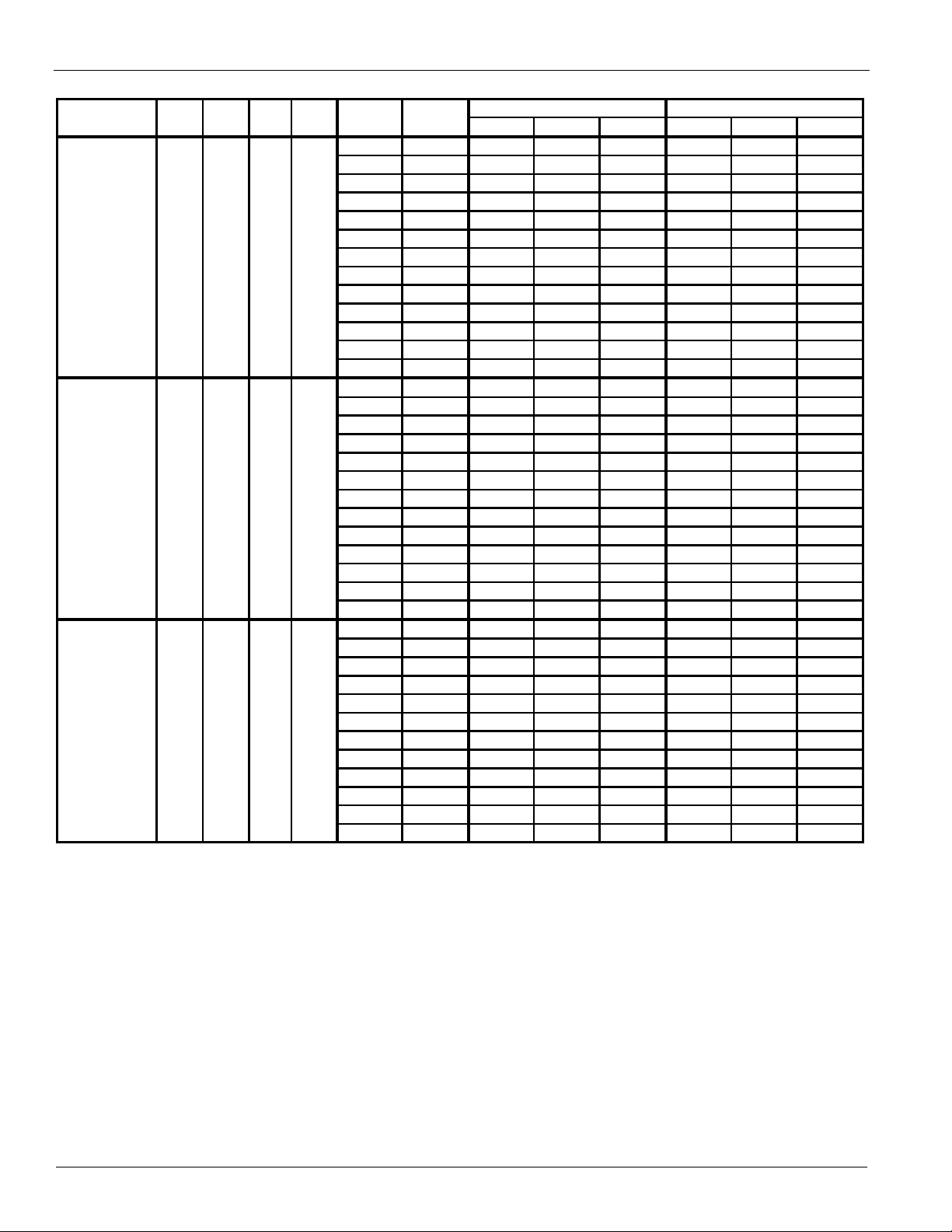

Table 3: AGZ-D Unit/Pump Combinations Continued

Unit Nom . Nom. Min. Max. Unit Tota l Hea d

Model Tons gpm gpm gpm gpm ft. Size rpm HP Size rpm HP

159 50 2x2x8 1800 5 2x2x8 1800 5

159 75 2x2x6 3600 7.5 2x2x6 3600 7.5

159 100 2x2x6 3600 7.5 2x2x6 3600 7.5

159 125 2x2x6 3600 15 2x2x6 3600 15

255 25 3x3x6 1800 3 3x3x6 1800 3

255 50 3x3x8 1800 5 3x3x8 1800 5

255 75 3x3x6 3600 7.5 3x3x6 3600 7.5

255 100 2x2x6 3600 10 2x2x6 3600 10

255 125 2x2x8 3600 15 2x2x8 3600 15

340 25 4x4x6 1800 3 4x4x6 1800 3

340 50 3x3x8 1800 7.5 3x3x8 1800 7.5

340 75 4x4x6 3600 10 4x4x6 3600 10

340 100 4x4x6 3600 15 4x4x6 3600 15

176 50 3x3x8 1800 5 3x3x8 1800 5

176 75 3x3x6 3600 7.5 3x3x6 3600 7.5

176 100 2x2x6 3600 10 2x2x6 3600 10

176 125 2x2x8 3600 15 2x2x8 3600 15

281 25 4x4x6 1800 3 4x4x6 1800 3

281 50 3x3x8 1800 7.5 3x3x8 1800 7.5

281 75 3x3x6 3600 10 3x3x6 3600 10

281 100 4x4x6 3600 15 4x4x6 3600 15

375 25 4x4x6 1800 5 4x4x6 1800 5

375 50 3x3x6 3600 10 4x4x8 3600 10

375 75 4x4x6 3600 15 4x4x6 3600 15

375 100 4x4x6 3600 15 4x4x6 3600 15

194 25 3x3x6 1800 3 3x3x6 1800 3

194 50 3x3x8 1800 5 3x3x8 1800 5

194 75 3x3x6 3600 7.5 3x3x6 3600 7.5

194 100 2x2x6 3600 10 2x2x6 3600 10

194 125 2x2x8 3600 15 2x2x8 3600 15

311 25 4x4x6 1800 3 4x4x6 1800 3

311 50 3x3x8 1800 7.5 3x3x8 1800 7.5

311 75 3x3x8 3600 10 3x3x8 3600 10

311 100 4x4x6 3600 15 4x4x6 3600 15

415 25 3x3x6 3600 7.5 4x4x8 3600 10

415 50 4x4x6 3600 10 4x4x8 3600 10

415 75 4x4x6 3600 15 4x4x6 3600 15

415 100 4x4x6 3600 15 4x4x6 3600 15

204 50 3x3x8 1800 5 3x3x8 1800 5

204 75 3x3x6 3600 7.5 3x3x6 3600 7.5

204 100 3x3x6 3600 10 4x4x6 3600 15

204 125 3x3x6 3600 15 3x3x6 3600 15

327 50 3x3x8 1800 7.5 3x3x8 1800 7.5

327 75 3x3x8 3600 10 3x3x8 3600 10

327 100 4x4x6 3600 15 4x4x6 3600 15

327 125 3x3x8 3600 20 3x3x8 3600 20

436 25 4x4x8 1800 5 4x4x8 1800 5

436 50 4x4x8 1800 10 4x4x8 1800 10

436 75 4x4x6 3600 15 4x4x6 3600 15

436 100 3x3x8 3600 20 3x3x8 3600 20

255 159

Single Pump Dual Pumps

311 194

424

AGZ 125D

117.1 281 176 468

AGZ 110D

106.1

518

AGZ 140D

136.2 327 204 545

AGZ 130D

129.6

Selection Procedures

Note: Some unit gpm and head combination do not have a valid selection and are absent from the table.

IM 1110-1 13

Page 14

Selection Procedures

Unit Nom. Nom. Min. Max. Unit Total Head

Model Tons gpm gpm gpm gpm ft. Size rpm HP Size rpm HP

230 50 3x3x8 1800 5 3x3x8 1800 5

230 75 3x3x6 3600 7.5 3x3x6 3600 7.5

230 100 3x3x6 3600 15 3x3x6 3600 15

230 125 3x3x8 3600 15 3x3x8 3600 15

368 25 4x4x6 1800 5 4x4x6 1800 5

368 50 4x4x8 1800 10 4x4x8 1800 10

368 75 4x4x6 3600 15 4x4x6 3600 15

368 100 4x4x6 3600 15 4x4x6 3600 15

368 125 3x3x8 3600 20 3x3x8 3600 20

491 25 4x4x8 1800 7.5 4x4x8 1800 7.5

491 50 4x4x8 1800 10 4x4x8 1800 10

491 75 4x4x6 3600 15 4x4x6 3600 15

491 100 3x3x8 3600 20 3x3x8 3600 20

258 50 3x3x8 1800 5 3x3x8 1800 5

258 75 3x3x6 3600 7.5 3x3x6 3600 7.5

258 100 4x4x6 3600 15 4x4x6 3600 15

258 125 3x3x8 3600 20 3x3x8 3600 20

413 25 4x4x8 1800 5 4x4x8 1800 5

413 50 4x4x8 1800 10 4x4x8 1800 10

413 75 4x4x6 3600 15 4x4x6 3600 15

413 100 4x4x6 3600 15 4x4x6 3600 15

413 125 3x3x8 3600 20 3x3x8 3600 20

551 25 4x4x8 1800 7.5 4x4x8 1800 7.5

551 50 4x4x8 1800 10 4x4x8 1800 10

551 75 4x4x6 3600 15 4x4x6 3600 15

551 100 4x4x6 3600 20 4x4x6 3600 20

270 50 3x3x8 1800 7.5 3x3x8 1800 7.5

270 75 3x3x6 3600 10 3x3x6 3600 10

270 100 4x4x6 3600 15 4x4x6 3600 15

270 125 3x3x8 3600 20 3x3x8 3600 20

432 25 4x4x8 1800 5 4x4x8 1800 5

432 50 4x4x8 1800 10 4x4x8 1800 10

432 75 4x4x6 3600 15 4x4x6 3600 15

432 100 3x3x8 3600 20 3x3x8 3600 20

576 25 4x4x8 1800 7.5 4x4x8 1800 7.5

576 50 4x4x8 1800 15 4x4x8 1800 15

576 75 4x4x6 3600 15 4x4x6 3600 15

576 100 4x4x6 3600 20 4x4x6 3600 20

Single Pump Dual Pumps

258 689

AGZ 160D

153.3 368 230

720

AGZ 190D

180.1 432 270

613

AGZ 180D

172.2 413

Table 3: AGZ-D Unit/Pump Combinations Continued

Note: Some unit gpm and head combination do not have a valid selection and are absent from the table.

14 IM 1110-1

Page 15

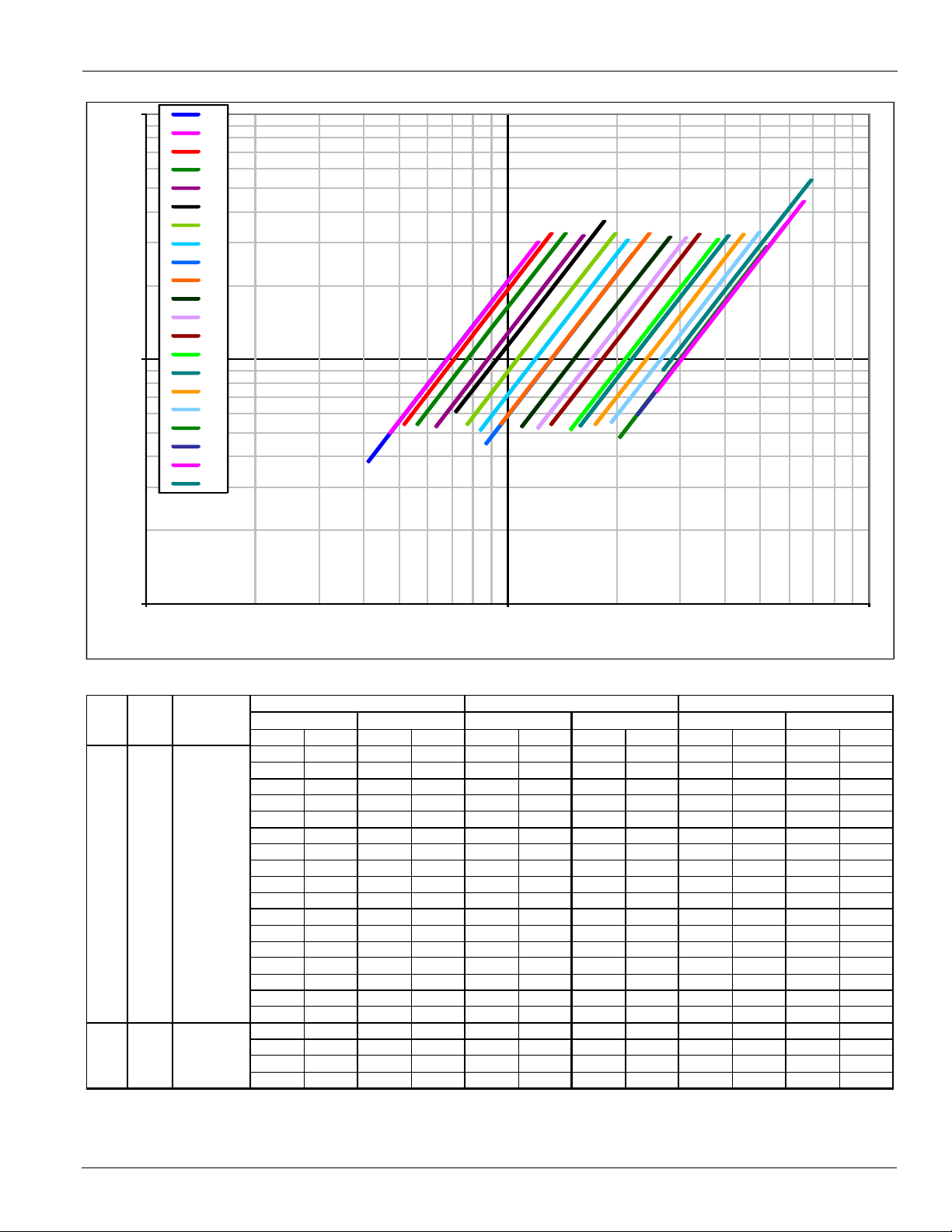

Pressure Drop Data

A

A

B

B

CCD

D

E

E

F

F

G

G

H

H

I

I

J

J

K

K

L

L

M

M

N

N

O

O

P

P

Q

Q

R

R

S

S

T

T

U

U

1

10

100

10 100 1000

D

p

(

f

t

)

Flow Rate (gpm)

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

gpm DP ft. lps DP kpa gpm DP ft. lps DP kpa gpm DP ft. lps DP kpa

A025D

41.3 3.8 2.6 11.5 66.0 9.4 4.2 28.1 105.6 23.0 6.7 68.6

B030D

47.4 5.0 3.0 15.0 75.8 12.3 4.8 36.7 121.3 30.0 7.7 89.7

C035D

51.8 5.4 3.3 16.3 82.8 13.3 5.2 39.7 132.5 32.5 8.4 97.0

D040D

56.4 5.4 3.6 16.3 90.2 13.3 5.7 39.7 144.4 32.5 9.1 97.0

E045D

63.5 5.3 4.0 15.9 101.5 13.0 6.4 38.8 162.4 31.8 10.2 94.8

F050D

72.2 6.1 4.6 18.2 115.4 14.9 7.3 44.5 184.7 36.4 11.7 108.7

G055D

77.4 5.4 4.9 16.3 123.8 13.3 7.8 39.7 198.1 32.5 12.5 97.0

H060D

84.2 5.1 5.3 15.3 134.6 12.5 8.5 37.3 215.4 30.5 13.6 91.2

I065D

87.2 4.5 5.5 13.4 139.4 11.0 8.8 32.8 223.1 26.9 14.1 80.2

J070D

96.2 5.4 6.1 16.3 153.8 13.3 9.7 39.7 246.1 32.5 15.5 97.0

K075D

109.7 5.3 6.9 15.8 175.4 12.9 11.1 38.5 280.7 31.5 17.7 94.1

L080D

121.7 5.2 7.7 15.6 194.6 12.8 12.3 38.2 311.4 31.3 19.7 93.4

M090D

132.3 5.4 8.3 16.1 211.7 13.2 13.4 39.4 338.7 32.2 21.4 96.3

N100D

149.7 5.2 9.4 15.4 239.5 12.6 15.1 37.6 383.2 30.8 24.2 91.9

O110D

159.2 5.3 10.0 15.9 254.6 13.0 16.1 38.8 407.4 31.8 25.7 94.8

P125D

175.7 5.4 11.1 16.1 281.0 13.2 17.7 39.4 449.7 32.2 28.4 96.3

Q130D

194.3 5.5 12.3 16.5 310.8 13.5 19.6 40.3 497.3 33.0 31.4 98.5

R140D

204.3 4.8 12.9 14.4 326.9 11.8 20.6 35.2 523.0 28.8 33.0 86.1

S160D

230.0 5.9 14.5 17.7 367.9 14.5 23.2 43.3 588.7 35.4 37.1 105.8

T180D

258.3 7.4 16.3 22.0 413.3 18.0 26.1 53.7 661.2 44.0 41.7 131.3

U190D

270.2 9.0 17.0 26.9 432.2 22.0 27.3 65.7 691.6 53.7 43.6 160.5

Nominal Flow Rate Maximum Flow Rate

IP SI IP SI IP SI

Brazed Plate

Shell-and-Tube

Model

Ev ap o r a t or

Type

Curve

Re f .

Minimum Flow Rate

Figure 5: Pressure Drop Curves

Pressure Drop Data

Table 4: Pressure Drop Data

IM 1110-1 15

Page 16

Installation Information

Installation Information

This section provides additional information on optional pump

packages factory-mounted on Daikin Model AGZ-D (REV

0A) scroll compressor chillers. The current chiller installation,

operating, and maintenance manuals are available at

www.DaikinApplied.com.

Inspection

When the equipment is received, carefully check all items

against the bill of lading to check for a complete shipment.

Check all units for damage upon arrival. All shipping damage

must be reported to the carrier and a claim must be filed with

the carrier. Check the unit's serial plate before unloading the

unit to be sure that it agrees with the power supply available.

Physical damage to unit after acceptance is not the

responsibility of Daikin Applied.

Note: Installation and maintenance are to be performed only

by qualified personnel who are familiar with local codes and

regulations, and experienced with this type of equipment.

Handling and Rigging

Follow the directions in IM 1100 for locating, handling and

rigging the unit. The addition of the optional pump package

does not change installation procedure. However, vibration

isolator selection and location, lifting and operating weights,

dimensions, and electrical data will differ from units without a

pump package. Refer to dimension drawings for center-ofgravity locations.

Field Water Piping

Piping design must be provided by a qualified Architect or

Systems HVAC Design Engineer familiar with piping design,

as well as local codes and regulations. The manufacturer

recommendations are to be used as a general guide, but do not

replace system design by a qualified professional. All field

piping, wiring, and procedures must be performed in

accordance with ASHRAE, EPA, and industry standards.

Use best practice for piping design with a minimum number of

bends and changes in elevation to keep system cost down and

performance up. See AGZ-D installation manual, IM 1100, for

general unit piping information.

The chilled water piping contains vent and drain connections

as well as taps for inlet and outlet pressure gauges. Install a

manual or automatic vent and a drain valve. Install a single,

valved pressure gauge as shown in the chiller unit installation

manual. The unit inlet and outlet connections are marked. It is

prudent to double check the unit dimension drawing to confirm

the connections.

The inlet guide and the outlet triple duty valve are shipped

separately to protect them from shipping damage. Install on

the unit and support as necessary. Support the chilled water

piping independently from the unit.

Flush the system water piping thoroughly before making

connections to the unit evaporator.

System Water Volume

It is important to have adequate water volume in the system to

provide an opportunity for the chiller to sense a load change,

adjust to the change and stabilize. As the expected load change

becomes more rapid, a greater water volume is needed. The

system water volume is the total amount of water in the

evaporator, air handling products and associated piping. If the

water volume is too low, operational problems can occur

including rapid compressor cycling, rapid loading and

unloading of compressors, erratic refrigerant flow in the

chiller, improper motor cooling, shortened equipment life and

other undesirable occurrences.

For normal comfort cooling where the cooling load changes

relatively slowly, we recommend a minimum system volume

in gallons of 2 to 3 times the flow rate (gpm). For example, if

the design chiller flow rate is 350 gpm, we recommend a

minimum system volume of 700 to 1050 gallons.

Since there are many other factors that can influence

performance, systems can successfully operate below these

suggestions. However, as the water volume decreases below

these suggestions, the possibility of problems increases.

Freeze Protection

In installations where the unit is subject to sub-freezing

temperatures, some method of preventing pipe and component

freezing and subsequent damage is required. The pump will

start on a signal from the chiller controller when either the

chilled water leaving or entering temperature reaches the

chiller freeze point setting to help prevent freeze up. If

constant chilled water circulation is not possible or desired,

one or more of the following procedures must be used:

• Drain the outdoor portion of the system and cap with a

nitrogen charge.

• Heat trace all outdoor components.

• Add sufficient anti-freeze to prevent freezing.

Note: the evaporator is equipped with a water heater to help

protect from freezing. This heater does not protect the pump

package piping or components.

Adding of a concentration of a glycol anti-freeze with a freeze

point 10°F below the lowest expected outdoor temperature will

result in decreased capacity and increased pressure drop in the

chiller. AGZ units are selected to provide the required

capacity with the fluid specified when selected.

Temporary Strainer

The suction guide strainer contains a tempory strainer that

must be removed after startup. See page 81 in the Startup and

Shutdown section. for complete instructions.

.

CAUTION

Do not use automotive grade antifreezes as it contains inhibitors harmful to chilled water systems.

Use only glycols designated for use in building cooling systems

16 IM 1110-1

Page 17

Lifting Locations

CONTROL PANEL

L1

L2

L3

L4

L5

L6

CONTROL PANEL

L1

L2

L3

L4

AGZ190D - Approximate Lifting Locations

See Dimension Drawing for location

AGZ025D-180D - Approximate Lifting Locations

See Dimension Drawing for location

LB S KG LB S KG LB S KG LBS KG LBS KG LB S KG LBS KG LB S KG

AGZ025D

4339 1968 4657

2112

1020 463 1106 502 1062 482 1151 522 - - - -

AGZ030D

4371 1983 4689 2127 1038 471 1098 498 1086 493 1149 521 - - - -

AGZ035D

4376 1985 4694 2129 1046 474 1093 496 1094 496 1143 518 - - - -

AGZ040D

4456 2021 4990 2263 1053 478 1115 506 1111 504 1177 534 - - - -

AGZ045D

4611 2092 5145 2334 1090 494 1155 524 1149 521 1218 552 - - - -

AGZ050D

4686 2126 5220 2368 1113 505 1178 534 1164 528 1231 558 - - - -

AGZ055D

4716 2139 5250 2381 1121 508 1187 538 1169 530 1239 562 - - - -

AGZ060D

4836 2194 5370 2436 1148 521 1228 557 1189 539 1272 577 - - - -

AGZ065D

4866 2207 5502 2496 1154 523 1241 563 1191 540 1281 581 - - - -

AGZ070D

5276 2393 5912 2682 1292 586 1254 569 1385 628 1345 610 - - - -

AGZ075D

6660 3021 7460 3384 1716 778 1611 731 1720 780 1614 732 - - - -

AGZ080D

6750 3062 7550 3425 1757 797 1656 751 1718 779 1620 735 - - - -

AGZ090D

6841 3103 7795 3536 1740 789 1635 742 1787 811 1679 762 - - - -

AGZ100D

6965 3159 7919 3592 1794 814 1707 774 1775 805 1689 766 - - - -

AGZ110D (208/230)

8574 3889 9646 4375 2322 1053 2330 1057 1958 888 1964 891 - - - -

AGZ125D (208/230)

8799 3991 10075 4570 2411 1094 2383 1081 2015 914 1991 903 - - - -

AGZ130D (208/230)

8934 4052 10210 4631 2455 1114 2489 1129 1982 899 2009 911 - - - -

AGZ110D (460/575)

8514 3862 9586 4348 2283 1036 2282 1035 1975 896 1974 895 - - - -

AGZ125D (460/575)

8739 3964 10015 4543 2369 1075 2332 1058 2034 923 2003 909 - - - -

AGZ130D (460/575)

8874 4025 10150 4604 2414 1095 2438 1106 2001 908 2021 917 - - - -

AGZ140D

11147 5056 12743 5780 2636 1196 2767 1255 1698 770 1783 809 1103 500 1158 525

AGZ160D

11297 5124 12893 5848 2716 1232 2803 1271 1734 787 1789 811 1110 503 1146 520

AGZ180D

11462 5199 13058 5923 2769 1256 2903 1317 1740 789 1824 827 1087 493 1140 517

AGZ190D

12308 5583 14223 6451 2032 922 2104 954 2017 915 2089 948 1997 906 2069 938

L1 L2

L IFT I NG W EIG HT BY CORNER ( A L FIN C OIL S)

(SEE NOT E FOR COPPER FI N C OI L S)

NOT E:

To calculate corner lifting w eights f or A GZ 025D-130D (4 lifting points) units w ith copper f in coils add 1/4 of the c opper vs .

aluminum shipping w eight to eac h aluminum cor ner lifting w eight. To calculate cor ner lifting w eights f or AGZ 140D-190D (6 lifting

points) units w ith copper f in coils add 1/6 of the c opper vs . aluminum shipping w eight to each aluminum corner lifting w eight.

AL UM INUM

FIN C OILS

COPPER FIN

COILS

UNIT M ODEL

SHIPPING WEIGHT

L3 L4 L5 L6

Unit Weights

Table 5: Shipping and Lifting Weights

Unit Weights

IM 1110-1 17

Page 18

Unit Weights

L BS KG LBS KG LBS KG LBS KG L BS KG L BS KG L BS KG L BS KG L BS KG L BS KG

AGZ025D

4404 1998 4722

2142

1040 472 1127 511 1074 487 1164 528 - - - - - - - -

AGZ030D

4436 2012 4754 2156 1058 480 1120 508 1097 498 1161 527 - - - - - - - -

AGZ035D

4446 2017 4764 2161 1067 484 1116 506 1106 502 1157 525 - - - - - - - -

AGZ040D

4526 2053 5060 2295 1075 488 1138 516 1123 509 1189 539 - - - - - - - -

AGZ045D

4686 2126 5220 2368 1113 505 1180 535 1162 527 1231 558 - - - - - - - -

AGZ050D

4766 2162 5300 2404 1137 516 1203 546 1178 534 1247 566 - - - - - - - -

AGZ055D

4796 2175 5330 2418 1144 519 1212 550 1184 537 1255 569 - - - - - - - -

AGZ060D

4921 2232 5455 2474 1172 532 1254 569 1206 547 1290 585 - - - - - - - -

AGZ065D

4956 2248 5592 2536 1179 535 1268 575 1209 548 1300 590 - - - - - - - -

AGZ070D

5366 2434 6002 2722 1323 600 1285 583 1400 635 1359 616 - - - - - - - -

AGZ080D

6850 3107 7650 3470 1854 841 1748 793 1672 758 1576 715 - - - - - - - -

AGZ090D

6945 3150 7899 3583 1850 839 1738 788 1731 785 1626 738 - - - - - - - -

AGZ100D

7080 3211 8034 3644 1900 862 1808 820 1728 784 1644 746 - - - - - - - -

AGZ110D (208/230)

8694 3944 9766 4430 1412 640 1416 642 1447 656 1451 658 1482 672 1486 674 - - - -

AGZ125D (208/230)

8929 4050 10205 4629 1470 667 1453 659 1497 679 1479 671 1524 691 1506 683 - - - -

AGZ130D (208/230)

9074 4116 10350 4695 1510 685 1531 694 1502 681 1523 691 1494 678 1514 687 - - - -

AGZ110D (460/575)

8634 3916 9706 4403 1379 626 1378 625 1439 653 1439 653 1500 680 1499 680 - - - -

AGZ125D (460/575)

8869 4023 10145 4602 1435 651 1413 641 1490 676 1467 665 1545 701 1521 690 - - - -

AGZ130D (460/575)

9014 4089 10290 4667 1476 670 1491 676 1495 678 1510 685 1513 686 1528 693 - - - -

AGZ140D

11929 5411 13525 6135 1636 742 1717 779 1524 691 1600 726 1390 630 1459 662 1270 576 1333 605

AGZ160D

12079 5479 13675 6203 1690 767 1744 791 1564 709 1614 732 1413 641 1458 661 1278 580 1319 598

AGZ180D

12244 5554 13840 6278 1731 785 1815 823 1585 719 1661 753 1409 639 1478 670 1252 568 1313 596

AGZ190D

13093 5939 15008 6808 1719 780 1780 807 1650 748 1709 775 1577 715 1633 741 1486 674 1539 698

NOT E:

For AGZ025- 100D (4 mounting points): to calculate cor ner mounting w eights f or units w ith copper f in coils add 1/4 of the copper v s. aluminum operating

w eight to each aluminum mounting w eight. For A GZ110-130D (6 mounting points):: to c alculate c orner mounting w eights f or units w ith copper fin coils add 1/6 of

the copper vs . aluminum operating w eight to each aluminum mounting w eight. For AGZ140-190D (8 Mounting Points) : to calculate corner mounting w eights for

units w ith copper f in coils add 1/8 of the c opper v s. aluminum operating w eight to each aluminum mounting w eight.

M5 M6 M7 M8M1 M2 M3

FIN COIL S

COILS

UNIT MODEL

OPERATING WEIGHT

MOUNTING WEIGHT BY LOCATION (AL FIN COILS)

( SEE NOT E FOR COPPER FI N C OIL S)

M4

Operating Weights & Vibration Isolators

Vibration isolators are recommended for all roof-mounted

installations or wherever vibration transmission is a

consideration. Initially install the unit on shims or blocks at the

"free height" of the isolator. When all piping, wiring, flushing,

charging, etc. is complete, adjust the springs upward to load

them and to provide clearance to free the blocks, which are

then removed.

Table 6: Operating and Mounting Weights

A LUM INUM

COPPER FIN

Installation of spring isolators requires flexible pipe

connections and at least three feet of conduit flex tie-ins.

Support piping and conduit independently from the unit to not

stress connections. Mounting locations are on the unit

dimension drawings beginning on page 23. Isolator selections

are different for AGZ-D units with a pump package than those

without one.

18 IM 1110-1

Page 19

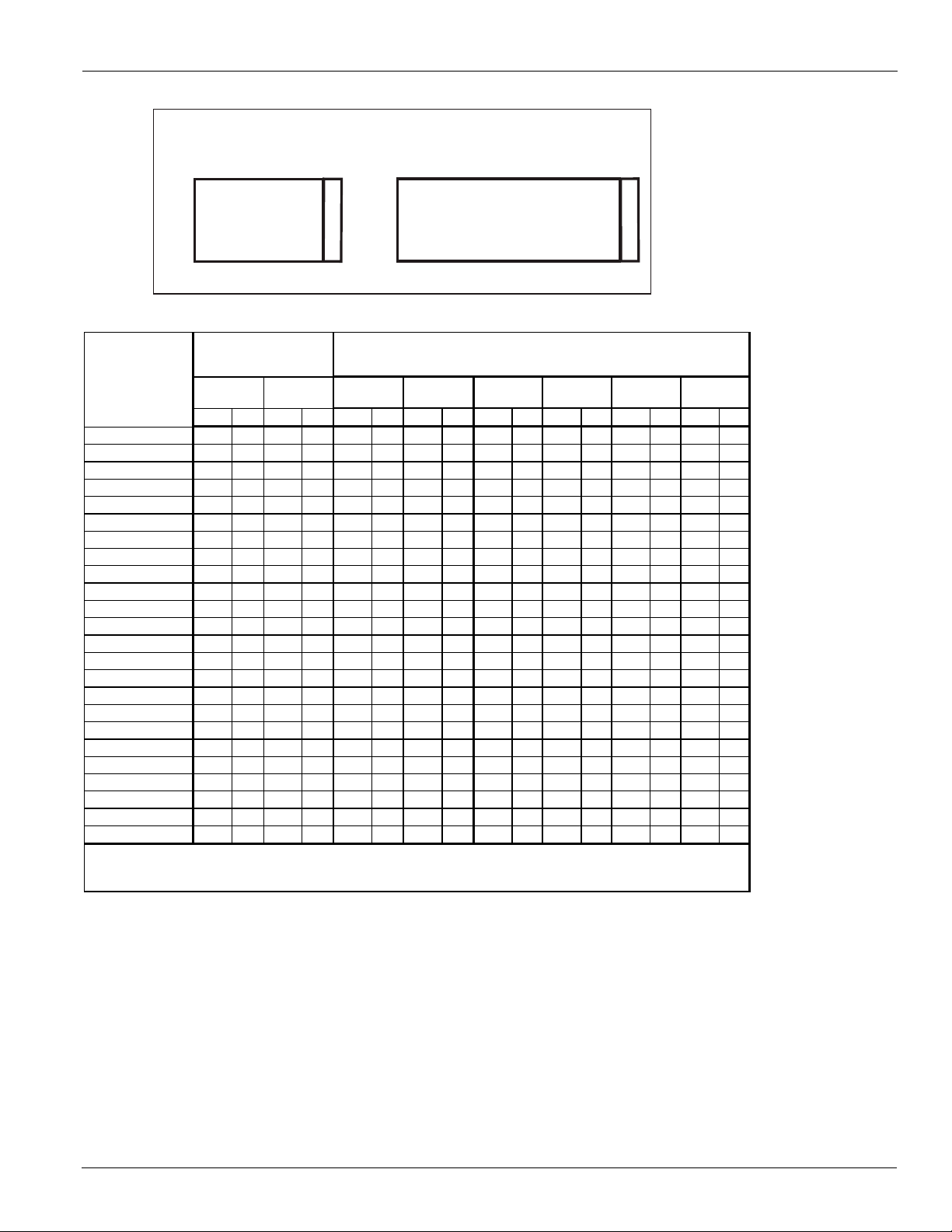

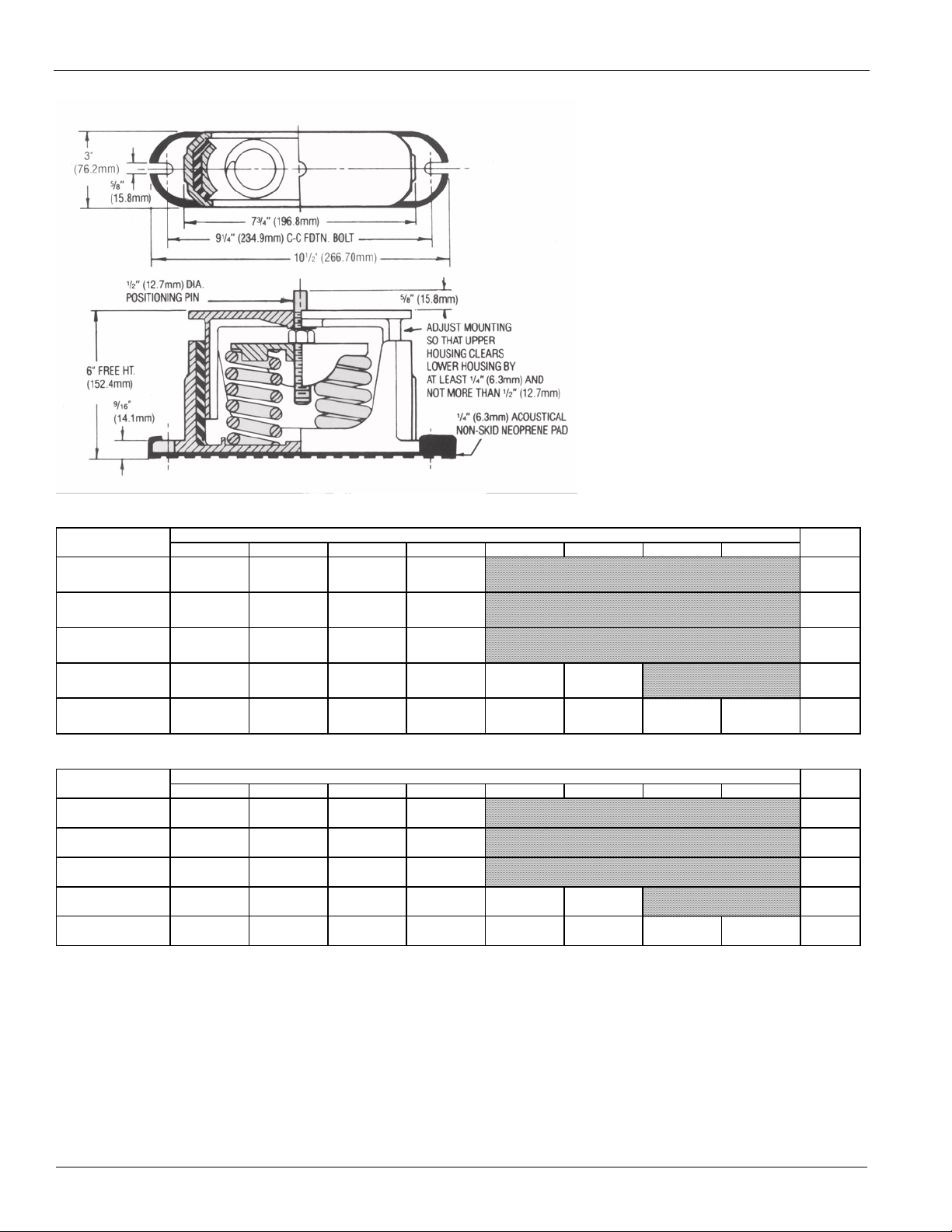

Vibration Isolators

NOTES:

MOUNT MATERIAL TO BE DURULENE RUBBER.1.

MOLDED STEEL AND ELASTOMER MOUNT FOR2.

OUTDOOR SERVICE CONDITIONS.

3. RP-4 MOUNT VERSION WITH STUD IN PLACE.

ALL DIMENSIONS ARE IN DECIMAL INCHES

DRAWING NUMBER 3314814

1.13 ± .25

APPROX.

1.63

.38

DURULENE

MATERIAL

RAISED GRIP RIBS

3.00

3.75

5.00

6.25

3.87

.56 TYP.

4.63

R.28

TYP.

R.250 TYP.

R.750 TYP.

RECESSED

GRIP RIBS

ø .500-13NC-2B

R4

R4

VM&C

VM&C

AG Z - D Un it Kit

Size M1 M2 M3 M4 M5 M6 M7 M8 Number

RP-4 RP- 4 RP-4 RP-4

Brow n Brow n Brow n Brow n

RP-4 RP- 4 RP-4 RP-4

Bric k Brick Br ick Bric k

Red Red Re d Re d

RP-4 RP- 4 RP-4 RP-4 RP- 4 RP- 4

Bric k Brick Br ick Bric k Brick Bric k

Red Red Re d Re d Re d Re d

RP-4 RP- 4 RP-4 RP-4 RP- 4 RP- 4 RP-4 RP-4

Bric k Brick Br ick Bric k Brick Bric k Brick Br ick

Red Red Re d Re d Re d Re d Re d Re d

140, 160, 180, 190

332325110

025, 030, 035, 040,

045, 050

332325107

075, 080, 090, 100

332325108

110, 125, 130

332325109

AGZ-D Unit Ki t

Size M1 M2 M3 M4 M5 M6 M7 M8 Number

RP-4 RP- 4 RP- 4 RP-4

Brow n Brow n Brow n Brow n

RP-4 RP- 4 RP- 4 RP-4

BrickBrickBrickBrick

RedRedRedRed

RP-4 RP- 4 RP- 4 RP-4

Lime Lime Lime Lime

RP-4 RP- 4 RP- 4 RP-4 RP- 4 RP- 4

Brick Brick Brick Brick Brick Brick

Red Red Red Red Red Red

RP-4 RP- 4 RP- 4 RP-4 RP- 4 RP- 4 RP-4 RP-4

Brick Brick Brick Brick Brick Brick Brick Brick

Red Red Red Red Red Red Red Red

RP-4 RP- 4 RP- 4 RP-4 RP- 4 RP- 4 RP-4 RP-4

Lime Lime Lime Lime Lime Lime Lime Lime

332325111

332325107

332325108

332325111

140, 160, 180

190

055. 060, 065, 070

025, 030, 035, 040,

045, 050

075, 080, 090, 100

332325109

332325110

110, 125, 130

Figure 6: RP-4 Rubber-in-Shear Isolator Dimensions

Vibration Isolators

Table 7: Rubber-in-Shear Isolator Locations, Aluminum Fin Coils

RUBBER IN SHEAR I SOL A T ORS - AL UM INUM FIN C OIL S

Table 8: Rubber-in-Shear Isolator Locations, Copper Fin Coils

RUBBER IN SHEAR I SOL A T O RS - Copper FIN COILS

IM 1110-1 19

Page 20

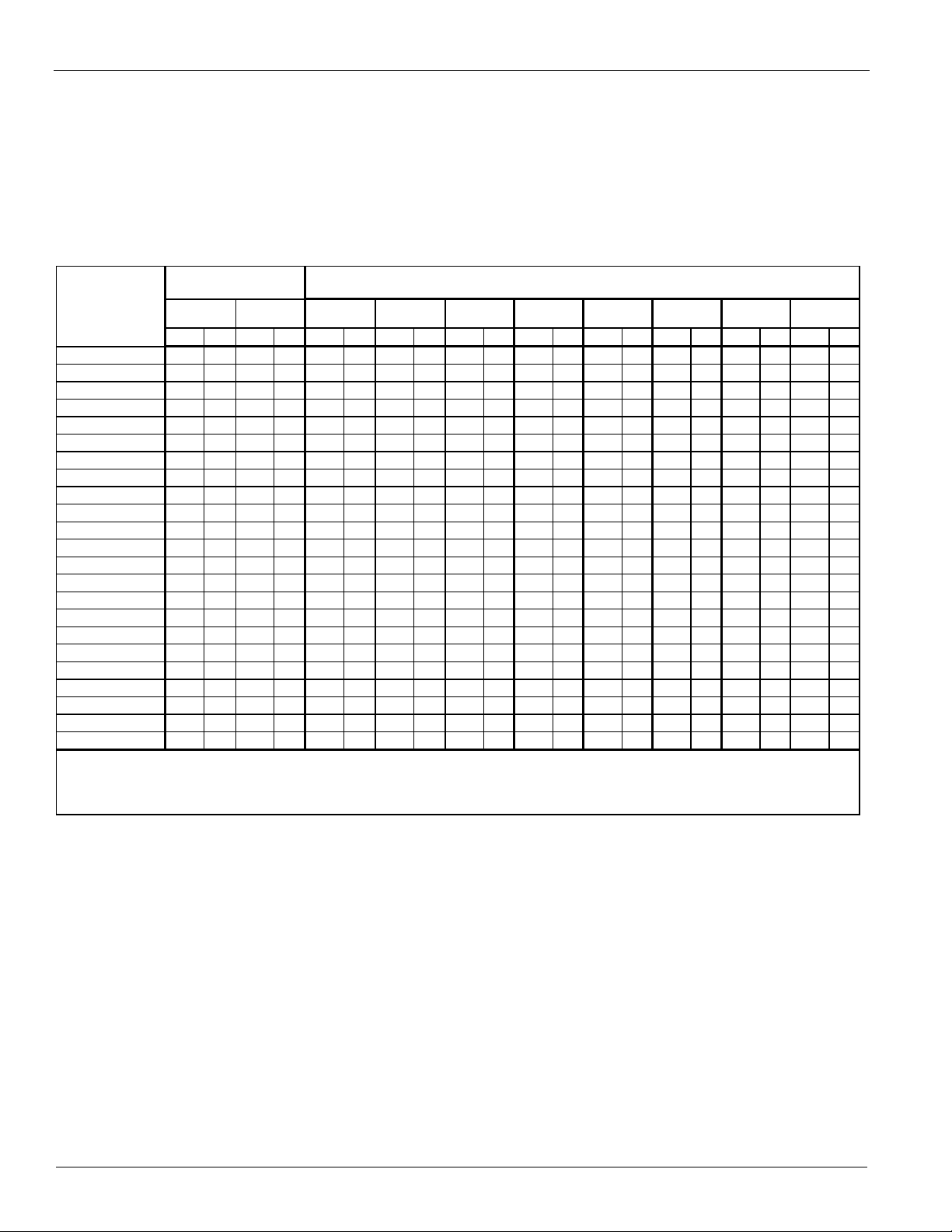

Vibration Isolators

AG Z - D Un i t Kit

Size M1 M2 M3 M4 M5 M6 M7 M8 Number

C2PE-1D-1350 C2PE-1D-1350 C2PE-1D-1350 C2PE-1D-1350

Pu rp le Pur p le Pu r pl e Pur p le

060, 065, 070

C2PE-1D-1800 C2PE-1D-1800 C2PE-1D-1800 C2PE-1D-1800

Green Green Green Green

C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-1800 C2PE-1D-1800

Gray Gray Green Green

C2PE-1D-1800 C2PE-1D-1800 C2PE-1D-1800 C2PE-1D-1800 C2PE-1D-1800 C2PE-1D-1800

Green Green Green Green Green Green

C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400

Gray Gray Gray Gray Gray Gray Gray Gray

025, 030, 035, 040

332320116

332320117

332320118

332320119

075, 080, 090, 100

110, 125, 130

140, 160, 180, 190

332320120

AG Z - D Un i t Kit

Size M1 M2 M3 M4 M5 M6 M7 M8 Number

C2PE-1D-1350 C2PE-1D-1350 C2PE-1D-1350 C2PE-1D-1350

Purple Purple Purple Pur ple

045, 050, 055

C2PE-1D-1800 C2PE-1D-1800 C2PE-1D-1800 C2PE-1D-1800

060, 065, 070

Green Green Green Green

C2PE-1D-2720 C2PE-1D-2720 C2PE-1D-2400 C2PE-1D-2400

White White Gray Gray

C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400

Gray Gray Gray Gray Gray Gray

C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400 C2PE-1D-2400

Gray Gray Gray Gray Gray Gray Gray Gray

025, 030, 035, 040

110, 125, 130

332320122

140, 160, 180, 190

332320120

332320116

332320117

075, 080, 090, 100

332320121

Figure 7: C2P

Table 9: Spring Isolator Locations, Aluminum Fin Coils

SPRING- FL EX I SOL A T ORS - A L UM INUM FI N C OI L S

Table 10: Spring Isolator Locations, Copper Fin Coils

SPRING-FLEX ISOLATORS

20 IM 1110-1

Page 21

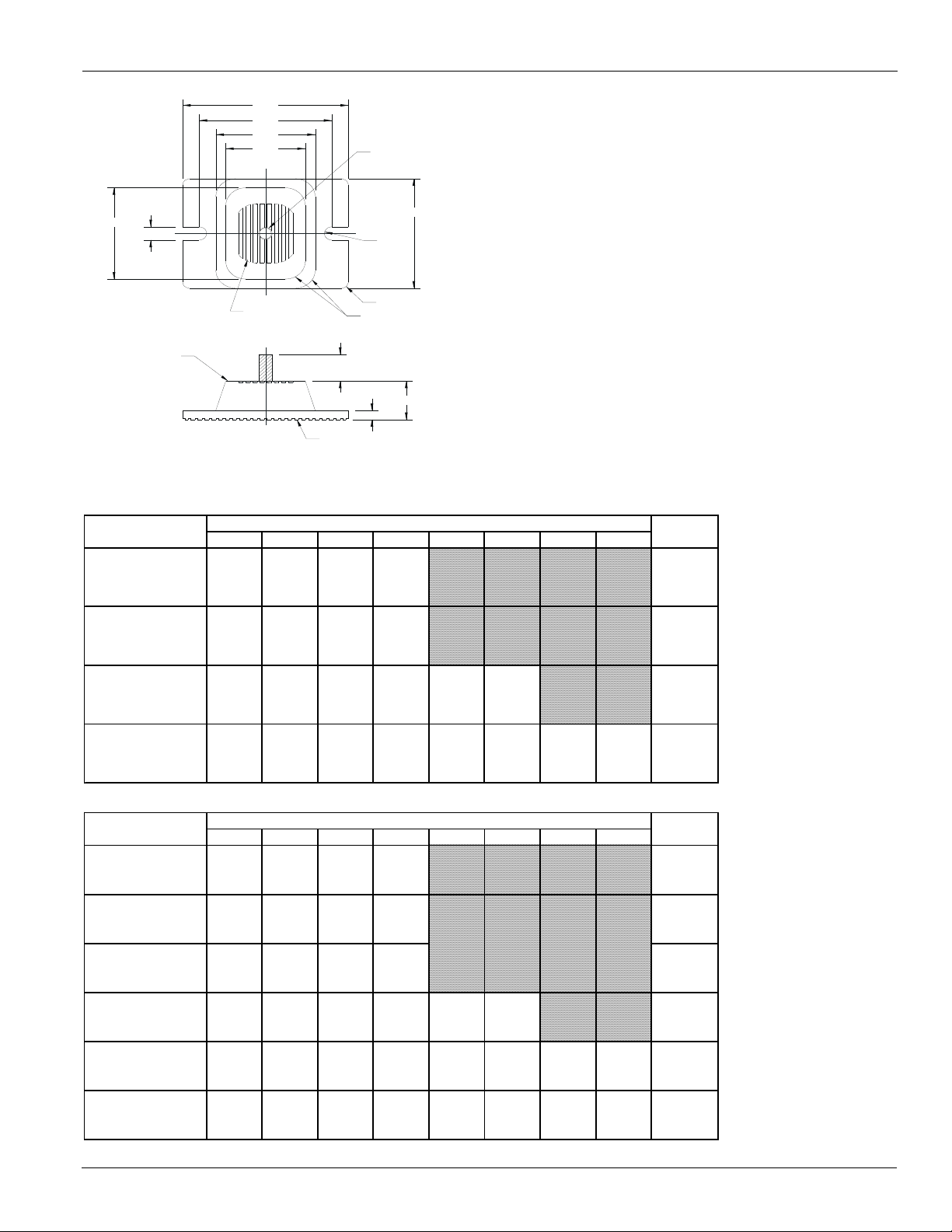

Triple Duty Valve

Flow Indicator

Bonnet “O” Ring

High Strength Resin

Seat EPDM for 8”

and larger

Stainless Steel

Stern

Bronze Disc

Stainless Steel Spring

Flow /Temperate

Measurement orts

Drain Connections

(on opposite side)

Figure 8: Triple Duty Discharge Valve Diagram

Triple Duty Valve

Determining Flow Rate - Valve In Full Open Position

Measure and record the differential pressure across the valve

using a CBDM- 135/60 meter, or pressure gauges with PMP

adapters.

Safety glasses should be used and the probe should not be left

inserted into fittings for prolonged periods of time as leakage

Locate Pressure Differential on left hand side of Performance

Curve (Figure 9) and extend line horizontally across to valve

size being used. Drop line vertically down and read flow rate

from bottom of chart.

Determining Flow Rate - Valve In Throttled Position

Record the size of the valve and stem position using the Flow

Indicator Scale. Calculate percentage of valve opening

referring to table below:

Table 11: Valve Size and Number of Rings

Number of Rings

(valve full open)

Measure and record the differential pressure across the valve

in the throttled position. Project a line vertically up to intersect

with the Valve Curve and from this point project line

horizontally across to the left of the chart and record the

percentage of maximum flow rate.

On the Performance Curve (Figure 9) locate the differential

pressure obtained above and project a line horizontally across

to intercept with Valve Performance Curve. Drop a line

vertically down to read the flow rate at the bottom of the chart.

IM 1110-1 21

CAUTION

from the PMP may occur when probe is removed.

Valve Size 2 1/2 3 4 5 6 8 10 12

5 5 6 9 10 12 18 28

To calculate flow rate of valve in the throttled position,

multiply the flow rate by the percentage flow rate divided by

100.

Example:

• Valve size 4 inch.

• Differential Pressure is 5.4 ft. (1.65 m).

• Number of rings open = 3. Therefore: 3 rings ÷ 6 rings x

100 = 50% throttled.

From the Performance Curve (Figure 9), a 4 inch, valve

with 5.4 ft. pressure drop (1.65 m) represents a flow of 400

USgpm (25.2 l/s).

From Flow Characteristic Curve (Figure 10)., a 4 inch

valve 50% open, represents 34% of maximum flow.

Approximate flow of a 4 inch valve, with a 5.4 ft. (1.65 m)

pressure drop when 50% throttled is:

400 x 34/100 = 136USgpm

or in metric, 25.2 x 34100 = 8.57l/s

Note: To prevent premature valve failure it is not

recommended that the valve operate in the throttled position

with more than 25 ft. pressure differential. Instead the pump

impeller should be trimmed or valves located elsewhere in the

system be used to partially throttle the flow.

Flow Indicator Scale

The valve stem with its grooved

rings and positioning sleeve

indicates the throttled position of

the valve. The quarter turn

graduations on the sleeve, with the

scribed line on the stem provides

for approximate flow measurement.

Note: The valve is shipped in the closed position. The

indicator on the plastic sleeve is aligned with the vertical

scribed line on the stem.

Page 22

Triple Duty Valve

PRESSURE DROP (FT WG)

5

3

1

.5

50

3.0 5.0 10 20 50 100 200 400

100 500 1000 2000 4000 6000

10

20

5.0

2.0

20

10

5.0

2.0

)O HM( PORD ERUSSERP

2

FLOWRATE (USGPM)

FLOWRATE (L/SEC)

Performance Curve

with Valve in Full Open Position

100

80

60

40

20

0

0 20 40 60 80 100

Inherent Flow Characteristic Curve

with Valve in Throttled Position

PERCENT OF MAX FLOW

PERCENT OF FULL OPEN

Figure 9: Performance Curve - Valve in Full Open Position

Figure 10: Flow Characteristic Curve - Valve in Throttled Position

22 IM 1110-1

Page 23

Dimensions

19.9

506

94.3

2396

19.9

506

10.2

260

27.3

693

32.4

823

3.0

EVAP WATER

OUTLET

VICTAULIC

CONNECTION

76

3.0

EVAP WATER

INLET

VICTAULIC

CONNECTION

76

32.2

818

Y

Z

5.0

127

2.0

51

46.7

1186

3.1

80

CG

POWER ENTRY POINTS

ARE ON THE OPPOSITE

SIDE OF CONTROL BOX

.875" KNOCKOUTS

L3

L4

L1

L2

88.0

DIMENSION DOES NOT INCLUDE

LIFTING BRACKETS

2235

94.8

2408

99.9

2538

14.4

366

6.5

165

CONTROL BOX WIDTH

8.1

REF.

205

19.6

498

2.5

64

2.5

64

43.1

1094

43.1

1094

X

POWER ENTRY POINTS

.875" KNOCKOUTS

FRONT OR RIGHT SIDE

FIELD CONTROL

CONNECTIONS

.875" KNOCKOUTS

CG

CONTROL

BOX

PUMP

CONTROL

PANEL

13.3

337

67.8

1721

13.3

337

2.0

52

2.0

52

.75

QTY. 4

19

11.4

290

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

M3 M1

M2M4

L3 L1

L2L4

COMPRESSORS

CIRCUIT #1

COMPRESSORS

CIRCUIT #2

SEE NOTE 1.

PUMPS

EVAP

CERT. DWG, AGZ-D 4 FANS R410A, w/PUMPS

*331749211001*

NOTES:

SUCTION STRAINER, SHUT OFF VALVE AND TRIPLE DUTY VALVE WILL BE SHIPPED LOOSE

FOR FIELD INSTALLATION.

1.

DUE TO VARIATIONS IN PUMP SIZE, OPERATING WEIGHT WITH WATER MAY VARY UP TO

5%.

2.

TO CALCULATE CORNER LIFTING WEIGHTS FOR UNITS WITH COPPER FIN COILS: ADD

1/4 OF THE COPPER

3.

VS. ALUMINUM SHIPPING WEIGHT TO EACH ALUMINUM LIFTING

CORNER WEIGHTS.

Figure 11: AGZ025D - AGZ070D with Pump Package (COG dimensions on page 29 )

Dimensions

IM 1110-1 23

Page 24

Dimensions

24.0

610

134.9

3426

24.0

610

17.4

442

19.4

492

Y

Z

46.7

1186

5.0

127

3.1

80

2.0

51

POWER ENTRY POINTS

OPPOSITE SIDE OF

CONTROL BOX.

.875 KNOCKOUTS

L3

L4

L1

L2

CG

SEE

NOTE 1.

88.0

DIMENSION DOES NOT INCLUDE

LIFTING BRACKETS

2235

95.0

2413

99.9

2537

43.1

1094

14.4

366

6.5

165

CONTROL BOX WIDTH

8.1

REF.

206

43.1

1094

19.6

497

2.5

64

2.5

64

X

FIELD CONTROL

CONNECTIONS

.875 KNOCKOUTS

POWER ENTRY POINTS

.875 KNOCKOUTS

FRONT AND RIGHT SIDE

CONTROL

BOX

CG

PUMP

CONTROL

PANEL

.75

QTY. 4

19

12.4

315

110.1

2796

12.4

315

2.0

52

2.0

52

M3

M1

M2M4

L3 L1

L2L4

COMPRESSORS

CIRCUIT #2

COMPRESSORS

CIRCUIT #1

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

SEE NOTE 1.

PUMPS

EVAP

49.5

1258

11.4

290

31.4

797

3.0

EVAP WATER

INLET

VICTAULIC

CONNECTION

76

3.0

EVAP WATER

OUTLET

VICTAULIC

CONNECTION

76

NOTES:

SUCTION STRAINER, SHUT OFF VALVE AND TRIPLE DUTY VALVE

1.

WILL BE SHIPPED LOOSE FOR FIELD INSTALLATION.

DUE TO VARIATIONS IN PUMP SIZE, OPERATING WEIGHT

2.

WITH WATER MAY VARY UP TO

5%.

TO CALCULATE CORNER LIFTING WEIGHTS FOR UNITS

3.

WITH COPPER FIN COILS: ADD 1/4 OF THE COPPER VS.

ALUMINUM SHIPPING WEIGHT TO EACH ALUMINUM

LIFTING WEIGHT.

CERT. DWG. AGZ-D 6 FANS, R410A w/PUMPS

Sht 1/2 AGZ075D AGZ080D

*3317492120A1*

Figure 12: AGZ075D - AGZ080D with Pump Package (COG dimensions on page 29 )

24 IM 1110-1

Page 25

24.0

610

134.9

3426

24.0

610

17.4

442

19.4

493

Y

Z

46.7

1186

5.0

127

3.1

80

2.0

51

POWER ENTRY POINTS

OPPOSITE SIDE OF

CONTROL BOX.

.875 KNOCKOUTS

L3

L4

L1

L2

CG

SEE

NOTE 1.

88.0

DIMENSION DOES NOT INCLUDE

LIFTING BRACKETS

2235

95.0

2413

99.9

2537

43.1

1094

14.4

366

6.5

165

CONTROL BOX WIDTH

8.1

REF.

206

43.1

1094

19.6

497

2.5

64

2.5

64

X

FIELD CONTROL

CONNECTIONS

.875 KNOCKOUTS

POWER ENTRY POINTS

.875 KNOCKOUTS

FRONT AND RIGHT SIDE

CONTROL

BOX

CG

PUMP

CONTROL

PANEL

.75

QTY. 4

19

12.4

315

110.1

2796

12.4

315

2.0

52

2.0

52

M3

M1

M2M4

L3 L1

L2L4

COMPRESSORS

CIRCUIT #2

COMPRESSORS

CIRCUIT #1

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

SEE NOTE 1.

PUMPS

EVAP

49.5

1258

11.4

290

32.1

816

4.0

EVAP WATER

INLET

VICTAULIC

CONNECTION

102

4.0

EVAP WATER

OUTLET

VICTAULIC

CONNECTION

102

331749212

CERT. DWG. AGZ-D 6 FANS, R410A w/PUMPS

NOTES:

SUCTION STRAINER, SHUT OFF VALVE AND TRIPLE DUTY VALVE

1.

WILL BE SHIPPED LOOSE FOR FIELD INSTALLATION.

DUE TO VARIATIONS IN PUMP SIZE, OPERATING WEIGHT

2.

WITH WATER MAY VARY UP TO

5%.

TO CALCULATE CORNER LIFTING WEIGHTS FOR UNITS

3.

WITH COPPER FIN COILS: ADD 1/4 OF THE COPPER VS.

ALUMINUM SHIPPING WEIGHT TO EACH ALUMINUM

LIFTING WEIGHT.

Figure 13: AGZ090D - AGZ100D with Pump Package (COG dimensions on page 29 )

Dimensions

IM 1110-1 25

Page 26

Dimensions

24.0

610

24.0

610

173.1

4396

5.0

127

2.0

51

Y

Z

47.6

1209

L3

L4

L1

L2

CG

POWER ENTRY POINTS

ARE ON THE OPPOSITE

SIDE OF CONTROL BOX.

.875" KNOCKOUTS

88.0

DIMENSION DOES NOT

INCLUDE LIFTING BRACKETS

2235

95.0

2413

99.9

2538

43.9

1116

6.6

167

6.5

165

11.8

299

2.5

64

2.5

64

43.9

1116

X

EVAP

FIELD CONTROL

CONNECTIONS

.875" KNOCKOUTS

POWER ENTRY POINTS

.875" KNOCKOUTS

FRONT AND RIGHT SIDE

CG

CONTROL

BOX

PUMP

CONTROL

PANEL

25.2

640

67.8

1722

67.7

1719

12.4

315

2.0

52

2.0

52

.75

QTY. 6

19

COMPRESSORS

CIRCUIT #2

COMPRESSORS

CIRCUIT #1

M5 M3 M1

L1L3

L4 L2

M2M4M6

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

PUMPS

SEE NOTE 1.

EVAP

11.4

290

33.1

842

4.0

EVAP WATER

INLET

VICTAULIC

CONNECTION

102

4.0

EVAP WATER

OUTLET

VICTAULIC

CONNECTION

102

44.0

1118

NOTES:

SUCTION STRAINER, SHUT OFF VALVE AND TRIPLE DUTY VALVE

1.

WILL BE SHIPPED LOOSE FOR FIELD INSTALLATION.

DUE TO VARIATIONS IN PUMP SIZE, OPERATING WEIGHT

2.

WITH WATER MAY VARY UP TO

5%.

TO CALCULATE CORNER LIFTING WEIGHTS FOR UNITS

3.

WITH COPPER FIN COILS: ADD 1/4 OF THE COPPER VS.

ALUMINUM SHIPPING WEIGHT TO EACH ALUMINUM

LIFTING WEIGHT.

331749213

CERT. DWG, AGZ-D 8 FANS, R410A, w/PUMPS

Figure 14: AGZ110D - AGZ130D with Pump Package (COG dimensions on page 29 )

26 IM 1110-1

Page 27

Figure 15: AGZ140D - AGZ180D with Pump Package (COG dimensions on page 29 )

268.0

6808

24.0

610

15.5

394

88.7

2252

139.8

3552

2.0

51

5.0

127

Y

Z

3.4

86

47.6

1209

POWER ENTRY POINTS

ARE ON THE OPPOSITE

SIDE OF CONTROL BOX.

.875" KNOCKOUTS

EVAP

L3

L4

L1

L2

CG

50" COILS

L5

L6

SEE NOTE 1.

99.9

2538

95.0

2413

88.0

DIMENSION DOES NOT

INCLUDE LIFTING BRACKETS

2235

43.9

1116

2.5

64

43.9

1116

6.6

167

6.5

165

2.5

64

11.8

298

X

CONTROL

BOX

FIELD CONTROL

CONNECTIONS

.875" KNOCKOUTS

POWER ENTRY POINTS

.875" KNOCKOUTS

FRONT AND RIGHT SIDE

CG

PUMP

CONTROL

PANEL

72.8

1849

81.1

2059

67.7

1719

12.4

315

2.0

52

2.0

52

34.0

863

12.3

313

M5 M3 M1

M2M4M6

L4

L2

L1L3

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

COMPRESSORS

CIRCUIT #2

COMPRESSORS

CIRCUIT #1

M7

M8

L6

L5

SEE

NOTE 1.

NOTES:

SUCTION STRAINER, SHUT OFF VALVE AND TRIPLE DUTY VALVE

1.

WILL BE SHIPPED LOOSE FOR FIELD INSTALLATION.

DUE TO VARIATIONS IN PUMP SIZES, OPERATING WEIGHT

2.

WITH WATER IS APPROXIMATE AND MAY VARY UP TO 5%.

TO CALCULATE L1 THRU L6 LIFTING WEIGHTS FOR UNITS

3.

WITH COPPER FIN COILS: ADD 1/6 OF THE COPPER VS.

ALUMINUM SHIPPING WEIGHT TO EACH L1 THRU L6

ALUMINUM LIFTING WEIGHT.

PUMPS

20.0

508

32.4

822

4.0

EVAP WATER

INLET

VICTAULIC CONNECTION

102

4.0

EVAP WATER

OUTLET

VICTAULIC CONNECTION

102

17.0

432

Dimensions

IM 1110-1 27

Page 28

Dimensions

256.9

6524

37.3

948

110.3

2801

85.2

2165

24.0

610

5.0

127

2.0

51

Z

Y

47.6

1209

3.4

86

POWER ENTRY POINTS

ARE ON THE OPPOSITE

SIDE OF CONTROL BOX.

.875" KNOCKOUTS

EVAP

L5

L6

L3

L4

L1

L2

CG

50"

COILS

99.9

2538

95.0

2413

88.0

DIMENSION DOES NOT

INCLUDE LIFTING BRACKETS

2235

43.9

1116

6.6

167

6.5

165

11.8

299

2.5

64

2.5

64

43.9

1116

X

FIELD CONTROL

CONNECTIONS

.875" KNOCKOUTS

POWER ENTRY POINTS

.875" KNOCKOUTS

FRONT AND RIGHT SIDE

CONTROL

BOX

CG

PUMP

CONTROL

PANEL

.75

QTY. 8

19

14.9

378

90.0

2286

71.9

1826

67.7

1719

12.4

315

2.0

52

2.0

52

M1M3

M2

M5M7

M8

M6 M4

L1

L2

L3

L4

L5

L6

COMPRESSORS

CIRCUIT #2

COMPRESSORS

CIRCUIT #1

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

PUMPS

SEE NOTE 1.

4.0

EVAP WATER

OUTLET

VICTAULIC

CONNECTION

102

30.1

765

17.0

432

4.0

EVAP WATER

INLET

VICTAULIC

CONNECTION

102

24.7

629

NOTES:

SUCTION STRAINER, SHUT OFF VALVE AND TRIPLE DUTY VALVE

1.

WILL BE SHIPPED LOOSE FOR FIELD INSTALLATION.

DUE TO VARIATIONS IN PUMP SIZES, OPERATING WEIGHT

2.

WITH WATER IS APPROXIMATE AND MAY VARY UP TO 5%.

TO CALCULATE L1 THRU L6 LIFTING WEIGHTS FOR UNITS

3.

WITH COPPER FIN COILS: ADD 1/6 OF THE COPPER VS.

ALUMINUM SHIPPING WEIGHT TO EACH L1 THRU L6

ALUMINUM LIFTING WEIGHT.

331749215D0100

AGZD 12 FAN W PUMPS

Figure 16: AGZ190D with Pump Package (COG dimensions on page 29 )

28 IM 1110-1

Page 29

Table 12: Center of Gravity Dimensions

IN M M IN MM IN M M

AGZ025D

45.8 1163 38.6 980 47.7 1212

AGZ030D

45.3 1151 38.3 973 47.8 1214

AGZ035D

45.0 1143 38.1 968 47.8 1214

AGZ040D

45.3 1151 38.7 983 47.9 1217

AGZ045D

45.3 1151 39.6 1006 47.9 1217

AGZ050D

45.2 1148 39.7 1008 47.8 1214

AGZ055D

45.3 1151 39.6 1006 47.7 1212

AGZ060D

45.5 1156 39.6 1006 47.6 1209

AGZ065D

45.6 1158 39.5 1003 47.6 1209

AGZ070D

43.4 1102 37.5 953 48.1 1222

AGZ075D

42.6 1082 40.7 1715 67.5 1715

AGZ080D

42.7 1085 40.5 1702 67.0 1702

AGZ090D

42.6 1082 41.9 1727 68.0 1727

AGZ100D

42.9 1090 41.5 1707 67.2 1707

AGZ110D (208/230)

44.1 1120 40.6 1031 81.2 2062

AGZ125D (208/230)

43.7 1110 39.9 1013 81.0 2057

AGZ130D (208/230)

44.3 1125 39.1 993 79.9 2029

AGZ110D (460/575)

44.0 1118 40.0 1016 82.0 2083

AGZ125D (460/575)

43.7 1110 39.4 1001 81.8 2078

AGZ130D (460/575)

44.2 1123 38.6 980 80.7 2050

AGZ140D

45.1 1146 37.4 950 114.0 2896

AGZ160D

44.7 1135 37.2 945 113.2 2875

AGZ180D

45.0 1143 37.1 942 111.9 2842

AGZ190D

44.8 1138 39.0 991 117.0 2972

UNIT MODEL

CENTER OF GRAV ITY ( COG) L OC ATION

XYZ

Dimensions

IM 1110-1 29

Page 30

Electrical Information

Note: Incoming power and run signals are factory wired.

Note: Single pump panels have only Pump #1

and have a single run signal from the main box.

Electrical Information

Figure 17: Pump Panel Wiring Diagram with Dual Pumps/Dual Control

Power Wiring

As standard, power to the pump package control panel is

factory wired from the chiller electrical panel. When the

optional chiller multi-point power wiring is specified, the

pump power originates from power circuit #1.

There is an option for field power wiring the pumps in lieu of

factory wiring. In this case the necessary electrical data begins

in Table 11 on page 40. In all cases, field power wiring

connections are made to L1, L2, L3 and GND on the pump

panel circuit breaker.

Power wiring to the chiller unit will be as shown in the chiller

catalog and installation manual.

Control Wiring

Control wiring to the chiller unit will be as shown in the chiller

catalog and installation manual except that the flow switch and

pump output signals shown as field wiring will be factory

wired.

Control wiring to start and stop the pump(s) is always factory

wired from the chiller electric panel to the pump package.

Dual pumps have two output signals and single pumps have

one.

The pump panel schematic, Figure 28, shows the standard dual

pump arrangement. Optionally a VFD can be substituted for

the contacts shown. A VFD line reactor can also be added.

A single pump can be ordered, in which case only one run

signal is factory wired in.

VFD Option, the VFD will require field wiring if the optional

BAS control is used or if the VFD is wired to field-mounted

differential switches. The pump BAS protocol will be the same

as specified for the chiller unit. The standard sensorless

arrangement does not require field wiring.

For BAS connection, use RS485 and wire to terminals 68 (+)

and 69 (-) for Modbus, FLN or Metasys protocols. The

terminals are located in the lower-right corner of the pumpmounted VFD enclosure under the keypad.

30 IM 1110-1

Page 31

Table 13: Electrical Data - Single Point

HP FLA

MCA RFS MFS

Pow er Block (1) Disconnect Sw itch (1)

208V 4.6 154 175 175

(1) 2/0 - #14 (2) 300 - 1/0

230V 4.2 153 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 2.1 76 90 90

(1) 2/0 - #14 (1) 1/0 - #14

575V 1.7 66 70 70

(1) 2/0 - #14 (1) 1/0 - #14

208V 6.6 156 175 175 (1) 2/0 - #14 (2) 300 - 1/0

230V 6.0 155 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 3.0 77 90 90

(1) 2/0 - #14 (1) 1/0 - #14

575V 2.4 67 70 70

(1) 2/0 - #14 (1) 1/0 - #14

208V 7.5 157 175 175 (1) 2/0 - #14 (2) 300 - 1/0

230V 6.8 156 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 3.4 78 90 90

(1) 2/0 - #14 (1) 1/0 - #14

575V 2.7 67 70 70

(1) 2/0 - #14 (1) 1/0 - #14

208V 10.6 160 175 175 (1) 2/0 - #14 (2) 300 - 1/0

230V 9.6 159 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 4.8 79 90 90

(1) 2/0 - #14 (1) 1/0 - #14

575V 3.9 68 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 16.7 166 175 175 (1) 2/0 - #14 (2) 300 - 1/0

230V 15.2 164 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 7.6 82 90 90

(1) 2/0 - #14 (1) 1/0 - #14

575V 6.1 70 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 4.6 163 175 175

(1) 2/0 - #14 (2) 300 - 1/0

230V 4.2 156 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 2.1 85 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 1.7 69 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 6.6 165 175 175 (1) 2/0 - #14 (2) 300 - 1/0

230V 6.0 158 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 3.0 86 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 2.4 70 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 7.5 165 175 175 (1) 2/0 - #14 (2) 300 - 1/0

230V 6.8 158 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 3.4 86 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 2.7 70 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 10.6 169 175 175 (1) 600 - #2 (2) 300 - 1/0

230V 9.6 161 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 4.8 87 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 3.9 72 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 16.7 175 200 200 (1) 600 - #2 (2) 300 - 1/0

230V 15.2 167 175 175

(1) 2/0 - #14 (2) 300 - 1/0

460V 7.6 90 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 6.1 74 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 6.6 175 200 200

(1) 600 - #2 (2) 300 - 1/0

230V 6.0 171 200 200

(1) 600 - #2 (2) 300 - 1/0

460V 3.0 88 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 2.4 70 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 7.5 176 200 200 (1) 600 - #2 (2) 300 - 1/0

230V 6.8 172 200 200

(1) 600 - #2 (2) 300 - 1/0

460V 3.4 89 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 2.7 70 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 10.6 179 200 200 (1) 600 - #2 (2) 300 - 1/0

230V 9.6 174 200 200

(1) 600 - #2 (2) 300 - 1/0

460V 4.8 90 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 3.9 72 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 16.7 185 200 200 (1) 600 - #2 (2) 300 - 1/0

230V 15.2 180 200 200

(1) 600 - #2 (2) 300 - 1/0

460V 7.6 93 110 110

(1) 2/0 - #14 (1) 3/0 - #14

575V 6.1 74 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 24.2 193 225 225 (1) 600 - #2 (2) 300 - 1/0

230V 22.0 187 200 200

(1) 600 - #2 (2) 300 - 1/0

460V 11.0 96 110 110

(1) 2/0 - #14 (1) 3/0 - #14

575V 9.0 77 80 80

(1) 2/0 - #14 (1) 1/0 - #14

AGZ035D

PUM P

5.0

3.0

1.5

1.0

2.0

3.0

1.5

2.0

M odel Voltage

Pum p

AGZ025D

PUM P

AGZ030D

PUM P

2.0

1.0

1.5

Lug Range

Ratings

5.0

3.0

5.0

7.5

Electrical Information

Note: Power block and disconnect switch sizes are minimums. Larger sizes may be used, however the lug range must be the same.

IM 1110-1 31

Page 32

Electrical Information

HP FLA

MCA RFS MFS

Pow er Block (1) Disconnect Sw itch (1)

208V 6.6 185 200 200

(1) 600 - #2 (2) 300 - 1/0

230V 6.0 183 200 200

(1) 600 - #2 (2) 300 - 1/0

460V 3.0 91 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 2.4 70 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 7.5 185 200 200

(1) 600 - #2 (2) 300 - 1/0

230V 6.8 183 200 200

(1) 600 - #2 (2) 300 - 1/0

460V 3.4 91 100 100

(1) 2/0 - #14 (1) 1/0 - #14

575V 2.7 70 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 10.6 189 200 200

(1) 600 - #2 (2) 300 - 1/0

230V 9.6 186 200 200

(1) 600 - #2 (2) 300 - 1/0

460V 4.8 93 110 110

(1) 2/0 - #14 (1) 3/0 - #14

575V 3.9 72 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 16.7 195 225 225

(1) 600 - #2 (2) 300 - 1/0

230V 15.2 192 225 225

(1) 600 - #2 (2) 300 - 1/0

460V 7.6 95 110 110

(1) 2/0 - #14 (1) 3/0 - #14

575V 6.1 74 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 24.2 202 225 225

(1) 600 - #2 (2) 300 - 1/0

230V 22.0 199 225 225

(1) 600 - #2 (2) 300 - 1/0

460V 11.0 99 110 110

(1) 2/0 - #14 (1) 3/0 - #14

575V 9.0 77 80 80

(1) 2/0 - #14 (1) 1/0 - #14

208V 6.6 235 250 250

(1) 600 - #2 (1) 600 - #1 & (2) 250 - #1

230V 6.0 234 250 250

(1) 600 - #2 (1) 600 - #1 & (2) 250 - #1

460V 3.0 95 110 110

(1) 2/0 - #14 (1) 3/0 - #14

575V 2.4 79 90 90

(1) 2/0 - #14 (1) 1/0 - #14

208V 7.5 236 250 250

(1) 600 - #2 (1) 600 - #1 & (2) 250 - #1

230V 6.8 235 250 250

(1) 600 - #2 (1) 600 - #1 & (2) 250 - #1

460V 3.4 95 110 110

(1) 2/0 - #14 (1) 3/0 - #14

575V 2.7 79 90 90

(1) 2/0 - #14 (1) 1/0 - #14

208V 10.6 239 250 250