Goodman AGZ120E Installation Manual

Installation, Operation,

IOM 1206-6

and Maintenance Manual

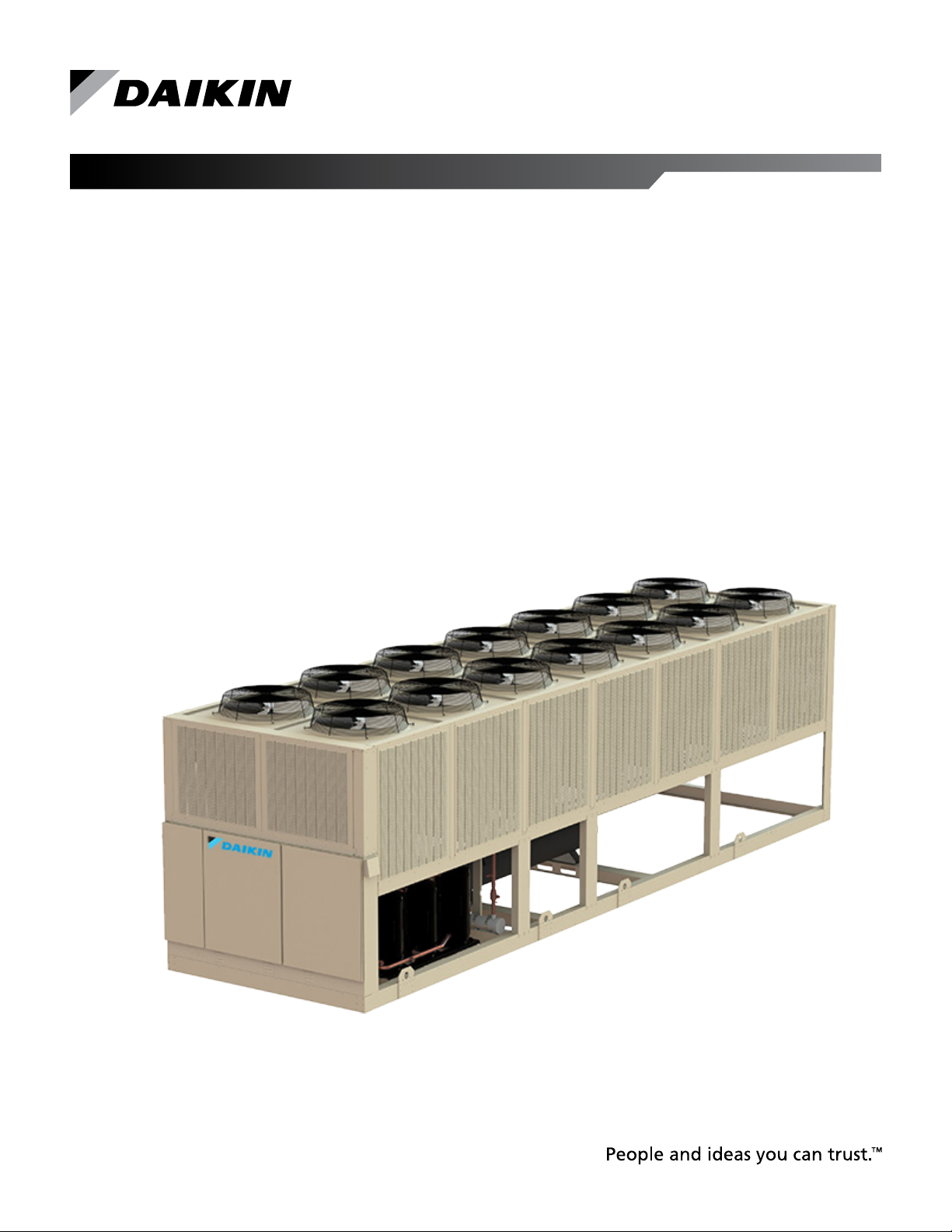

Trailblazer™

Air-Cooled Scroll Chillers

Model AGZ, E Vintage

30 to 240 Tons (100 to 840 kW)

HFC-410A Refrigerant

50/60 Hz

Group: Chiller

Part Number: IOM1206-6

Date: December 2015

Table of ConTenTs

Table of ConTenTs

Installation and Application Information ..........3

Dimensions and Weights - Packaged Units ......15

Refrigerant Charge...........................23

Isolator Information ..........................24

Pressure Drop Data ..........................27

Electrical Data...............................29

Unit Controller Operation .....................38

Sequence of Operation .......................49

Unit Functions ..............................56

Circuit Functions ............................65

Table of ConTenTs

Alarms .....................................74

Using the Controller..........................78

Optional Low Ambient Fan VFD ................81

Startup and Shut-down Procedures .............87

Component Operation ........................89

Unit Maintenance ............................91

Troubleshooting Chart .......................97

Warranty Registration Form (Scroll).............99

Manufactured in an ISO 9001 & ISO 14001 certied facility

©2015 Daikin Applied. Illustrations and data cover the Daikin Applied product at the time of publication and we reserve the right to

make changes in design and construction at any time without notice.

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 2 www.DaikinApplied.com

Job Name

Installation Location

Customer Order Number

Model Number(s)

G.O. Number(s)

Chilled Water

Yes

No

N/A

Initials

Piping Complete

Water strainer : Shell & Tube Evaporators 0.125”(3.175mm) or smaller perforations

Brazed Plate Evaporator 0.063” (1.6mm) or smaller perforations

Water System filled, flushed and vented

Pumps installed and operational (rotation checked, strainers cleaned)

Controls operational (3-way valves, face/bypass dampers, bypass valves, etc.)

Water system operated and tested; flow meets unit design requirements

Flow switch installed and wired

Vent installed on evaporator

Glycol at design %

Electrical

Yes

No

N/A

Initials

Building controls operational

*Power leads connected to power block or optional disconnect

Power leads have been checked for proper phasing and voltage

All interlock wiring complete and compliant with Daikin specifications

Power applied at least 24 hours before startup

Oil heaters energized at least 24 hours before startup

Chiller components (EXV Sensors Transducers) installed and wired properly.

*Wiring complies with National Electrical Code and local codes (See Notes)

Remote EXV wired with shielded cable

Miscellaneous

Yes

No

N/A

Initials

Unit control switches all off

Remote Evaporator /Condenser Piping factory reviewed

All refrigerant components/piping leak tested, evacuated and charged

Thermometers, wells, gauges, control, etc., installed

Minimum system load of 80% capacity available for testing/adjusting controls

Document Attached: Technical Breakdown from Selection Software

Document Attached: Final Order Acknowledgement

Document Attached: Remote piping approval

Notes: The most common problems delaying start-up and affecting unit reliability are:

3. Items on this list incorrectly acknowledged resulting in delayed start and possible extra expenses incurred by return trips.

Contractor Representative

Daikin Applied Sales Representative

Signed:

Signed:

Name:

Name:

Company:

Company:

Date:

Date:

Phone/Email:

Phone/Email:

Pre-Start Checklist – Scroll Compressor Chillers

Must be completed, signed and provided to Daikin Applied at least 2 weeks prior to requested start date.

1. Field installed compressor motor power supply leads too small. Questions: Contact the local Daikin sales representative*. State size, number and

type of conductors and conduits installed:

Cut Here

a. From Power supply to chiller

* Refer to NEC Article 430-22 (a)

2. Remote Evaporator piping incomplete or incorrect. Provide approved piping diagrams.

©2013 Daikin Applied Form SF01017 P/N 331977001 22OCT2013

InsTallaTIon and applICaTIon InformaTIon

General Description

Daikin Trailblazer™ air-cooled water chillers are complete, selfcontained, automatic chillers designed for outdoor installation.

Packaged units are completely assembled, factory wired,

charged, and tested.

NOMENCLATURE

A G Z XXX E D SM

Air-Cooled

Global Design

Scroll Compressor

Nominal Tons

Design Vintage

WARNING

Installation is to be performed by qualied personnel who are

familiar with local codes and regulations.

CAUTION

Sharp edges on unit and coil surfaces are a potential hazard

to personal safety. Avoid contact with them.

InsTallaTIon and applICaTIon InformaTIon

The electrical control center includes all equipment protection

and operating controls necessary for dependable automatic

operation.

Application

SM = Standard Efciency Packaged Unit

HM = High Efciency Packaged Unit

# of Compressors

D = Tandem per Circuit

T = Trio per Circuit

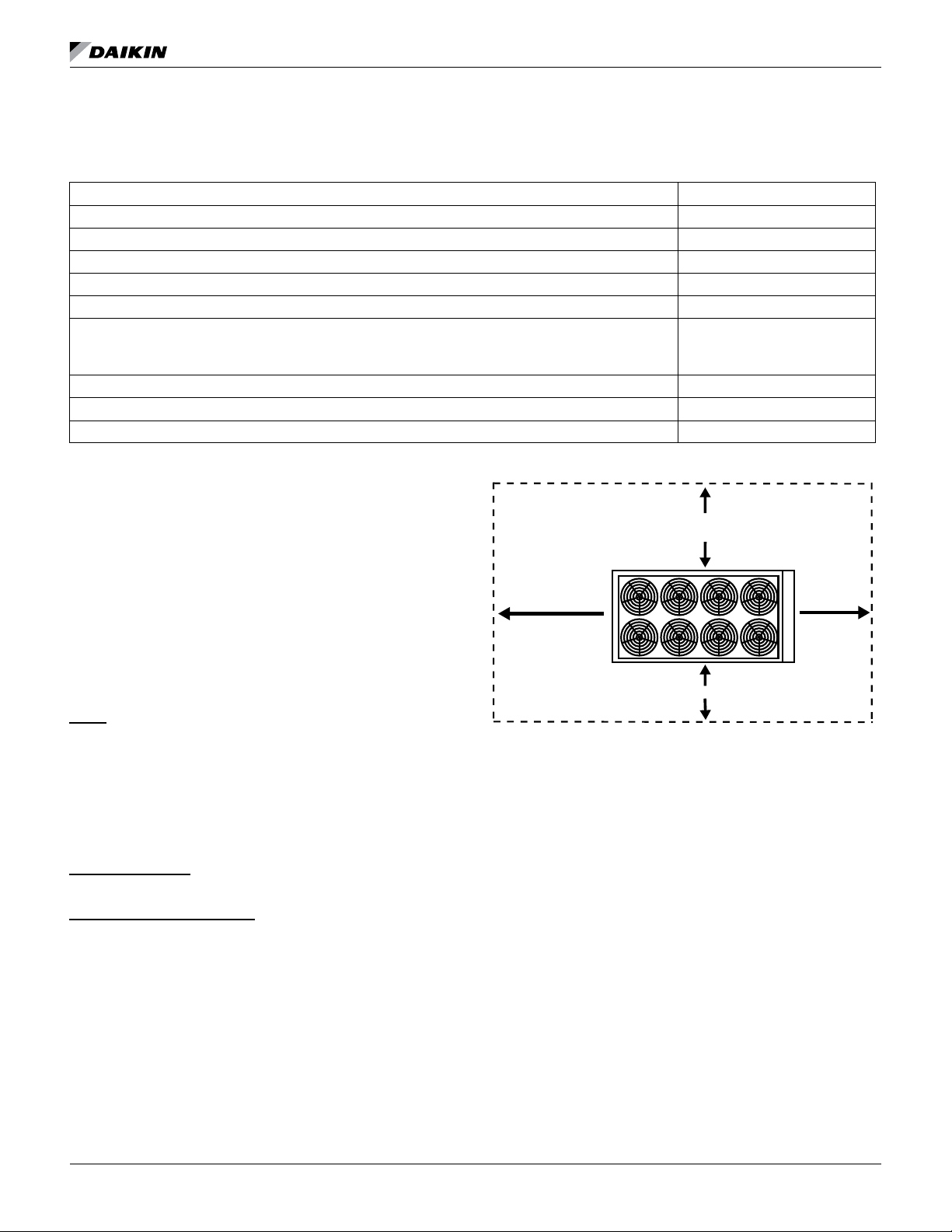

Figure 1: Suggested Pushing Arrangment

Blocking is required

across full width

Additional Manual

This manual covers the installation, of dual circuit, AGZ-EH

packaged, scroll compressor chillers using R-410A.

Information for units with either the pump package or remote

evaporator options can be found at www.DaikinApplied.com.

Inspection

Check all items carefully against the bill of lading. Inspect

all units for damage upon arrival. Report shipping damage

and le a claim with the carrier. Check the unit nameplate

before unloading, making certain it agrees with the power

supply available. Daikin Applied is not responsible for physical

damage after the unit leaves the factory.

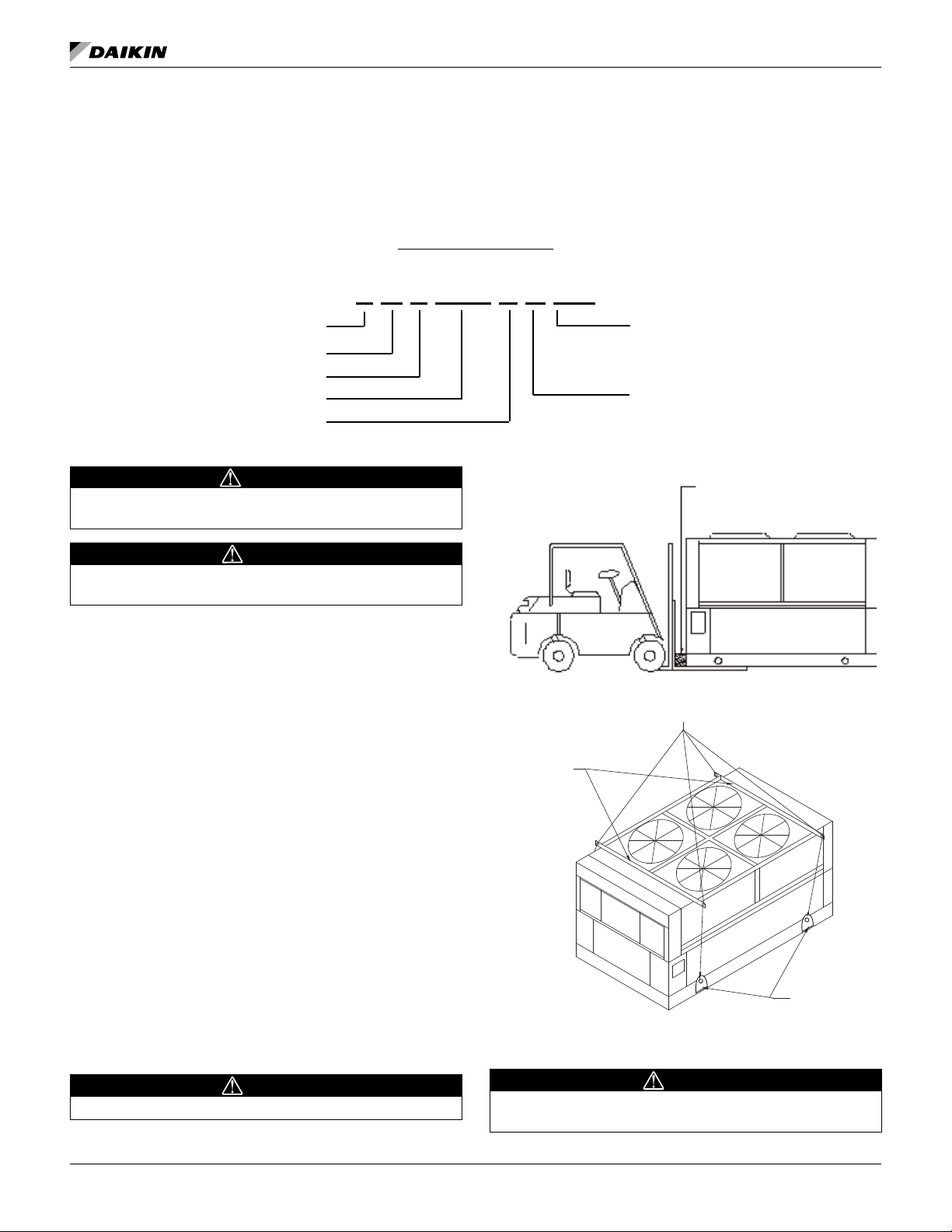

Handling

Be careful to avoid rough handling of the unit. Do not push

or pull the unit from anything other than the base. Block the

pushing vehicle away from the unit to prevent damage to the

sheet metal cabinet and end frame (see Figure 1).

To lift the unit, 2-1/2” (64mm) diameter lifting eyes are provided

on the base of the unit. Arrange spreader bars and cables to

prevent damage to the condenser coils or cabinet (see Figure

2).

CAUTION

All lifting locations must be used to prevent damage to unit.

Figure 2: Required Lifting Arrangement

Number of fans and

rigging holes may vary

SPREADER BARS

REQUIRED FOR

EACH PAIR OF

LIFTING LUGS

(USE CAUTION)

from this diagram.

The lifting method will

remain the same.

MUST USE THESE

RIGGING HOLES

(BE AWARE OF

CONTROL BOX

LOCATION)

DANGER

Do not stand beneath the unit while it is being lifted or

installed.

www.DaikinApplied.com 3 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

InsTallaTIon and applICaTIon InformaTIon

Operating and Standby Limits

Table 1: Operating Limits

Maximum standby ambient temperature 131°F (55°C)

Maximum operating ambient temperature 105°F (41°C)

-with optional high ambient package (see information under High Ambient Operation) 125°F (52°C)

Minimum operating ambient temperature (standard control) 32°F (0°C)

Minimum operating ambient temperature (with optional low-ambient control) -10°F (-23°C)

Leaving chilled water temperature 40°F to 65°F (4°C to 18°C)

Leaving chilled uid temperatures (with anti-freeze) - Note that in cases of high ambient

temperature, the lowest leaving water temperature settings may be outside of the chiller

operating envelope; consult Daikin Tools to ensure chiller is capable of the required lift.

Operating chilled water delta-T range 6°F to 16°F (3.3°C to 8.9°C)

Maximum evaporator operating inlet uid temperature 81°F (27°C)

Maximum evaporator non-operating inlet uid temperature 100°F (38°C)

15°F to 65°F (-9°C to 18°C)

Unit Placement

Trailblazer™ units are for outdoor applications and can be

mounted either on a roof or at ground level. For roof mounted

applications, install the unit on a steel channel or I-beam

frame to support the unit above the roof. For ground level

applications, install the unit on a substantial base that will not

settle. Use a one-piece concrete slab with footings extended

below the frost line. Be sure the foundation is level within 0.5”

(13 mm) over its length and width. The foundation must be

strong enough to support the unit weight - see “Dimensions

and Weights - Packaged Units” on page 15.

Service Clearance

Sides

• 30-70 Ton Models: Minimum of 4 feet (1.2 meters)

• 75-240 Ton Models: It is highly recommended to

provide a minimum of 8 feet (2.4 meters) on one side to

allow for coil replacement. Coils can be removed from

the top, allowing a minimum of 4 feet (1.2 meters) of

side clearance; however, the unit performance may be

derated.

Control Panel End

• All Models: Minimum of 4 feet (1.2 meters)

Opposite Control Panel End

• 30-70 Ton Models with Microchannel Coils: Minimum

of 7.5 feet (2.3 meters)

• 75-180 Ton Models: Minimum of 4 feet (1.2 meters)

• 190-240 Ton Models: Minimum of 8 feet (2.4 meters) for

evaporator removal

Figure 3: Service Clearance

075-240 Ton Models: 8ft (2.4 m) recommended on one side

Minimum = 7.5 ft (2.3 m)

for models 030-070

with Microchannel Coils

Minimum = 4 ft (1.2 m)

for models 075-180

Minimum = 8 ft (2.4 m)

for models 190-240

Minimum = 4 ft (1.2 m)

Minimum = 4 ft (1.2 m)

Minimum = 4 ft

(1.2 m)

Control Panel

Spacing Requirements

Sufcient clearance must be maintained between the unit

and adjacent walls or other units to allow the required unit air

ow to reach the coils. Failure to do so will result in a capacity

reduction and an increase in power consumption. No solid

obstructions are allowed above the unit at any height, see page

7 for details.

Graphs on the following pages give the minimum clearance

for different types of installations and also capacity reduction

and power increase if closer spacing is used. The clearance

requirements shown are a general guideline and cannot

account for all scenarios. Such factors as prevailing winds,

additional equipment within the space, design outdoor air

temperature, and numerous other factors may require more

clearance than what is shown.

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 4 www.DaikinApplied.com

InsTallaTIon and applICaTIon InformaTIon

D

% Capacity Reduction

AGZ190-210E AGZ225-240E

AGZ190-210E AGZ225-240E

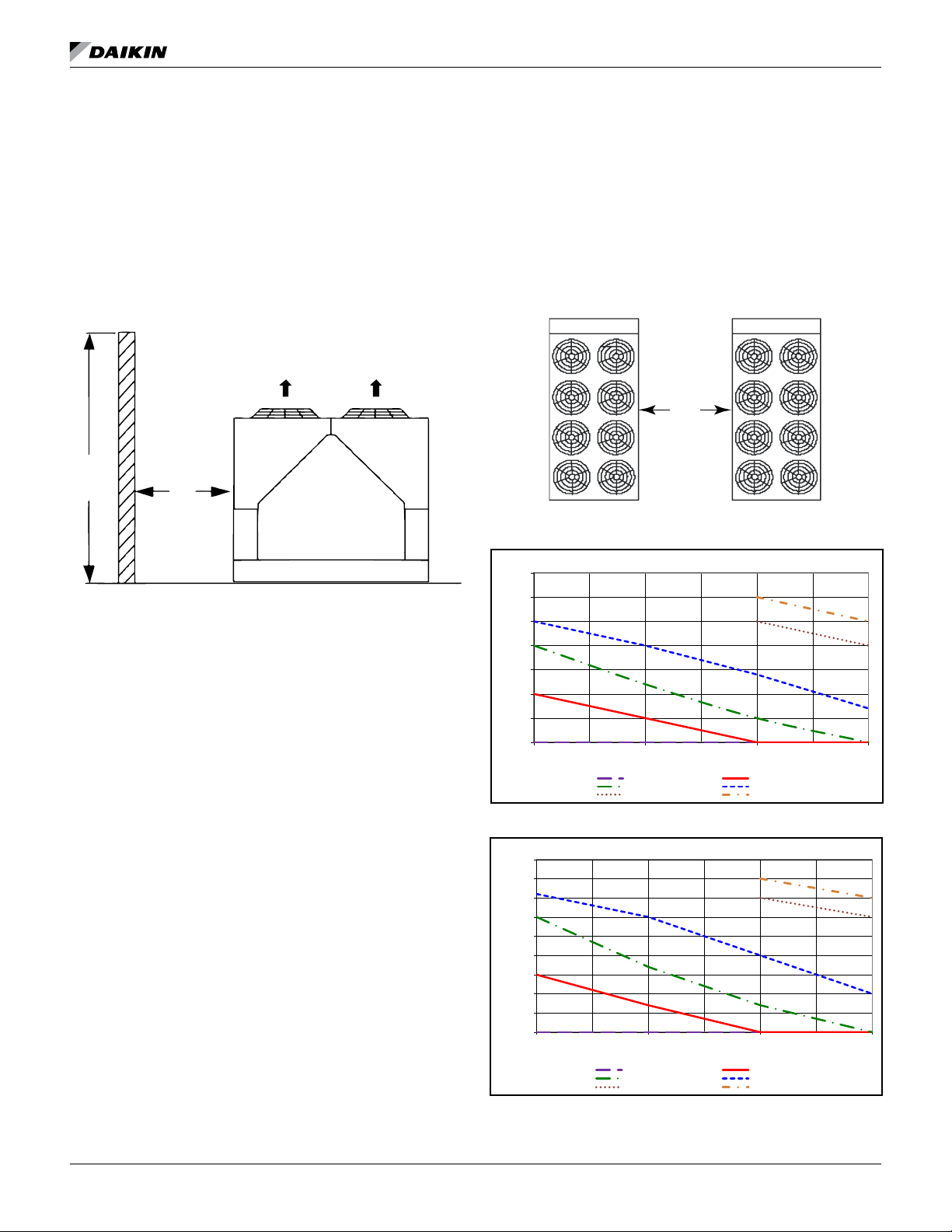

Case 1: Building or Wall on One Side of Unit

NOTE: Assumes a solid height wall taller than unit. Refer to

Case 4 for partial wall openings.

For models AGZ030-100E, maintain a 4 feet minimum from a

wall of any height.

For models AGZ110-130E, maintain a 6 feet minimum from a

wall of any height.

For models AGZ140-240E, maintain a 8 feet minimum from a

wall of any height.

Figure 4: Building or Wall on One Side of Unit

Height

of

Wall

Distance

Between

Wall

and

Unit

Case 2: Two Units, Side-by-Side

For models 030-180, there must be a minimum of 4 feet

between two units placed side-by-side; however, performance

may be affected at this distance. For models 190-210,

the minimum is 6 feet as closing spacing may cause air

recirculation and elevated condenser pressure. Assuming

the requirement of one side having at least 8 feet of

service clearance is met, Case 2 gures show performance

adjustments as the distance between two units increases.

Figure 5: Two Units, Side-by-Side

Figure 6: Case 2 - Full Load Capacity Reduction

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

4 5 6 8

Full Load Capacity Reduction

Distance Between Units (ft)

AGZ030-070E AGZ075-100E

AGZ110-130E AGZ140-180E

Figure 7: Case 2 - Power Increase

4.5

4.0

3.5

3.0

2.5

2.0

1.5

% Power Increase

1.0

0.5

0.0

4 5 6 8

Power Increase

Distance Between Units (ft)

AGZ030-070E AGZ075-100E

AGZ110-130E AGZ140-180E

www.DaikinApplied.com 5 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

InsTallaTIon and applICaTIon InformaTIon

Distance from Wall to Unit (ft)

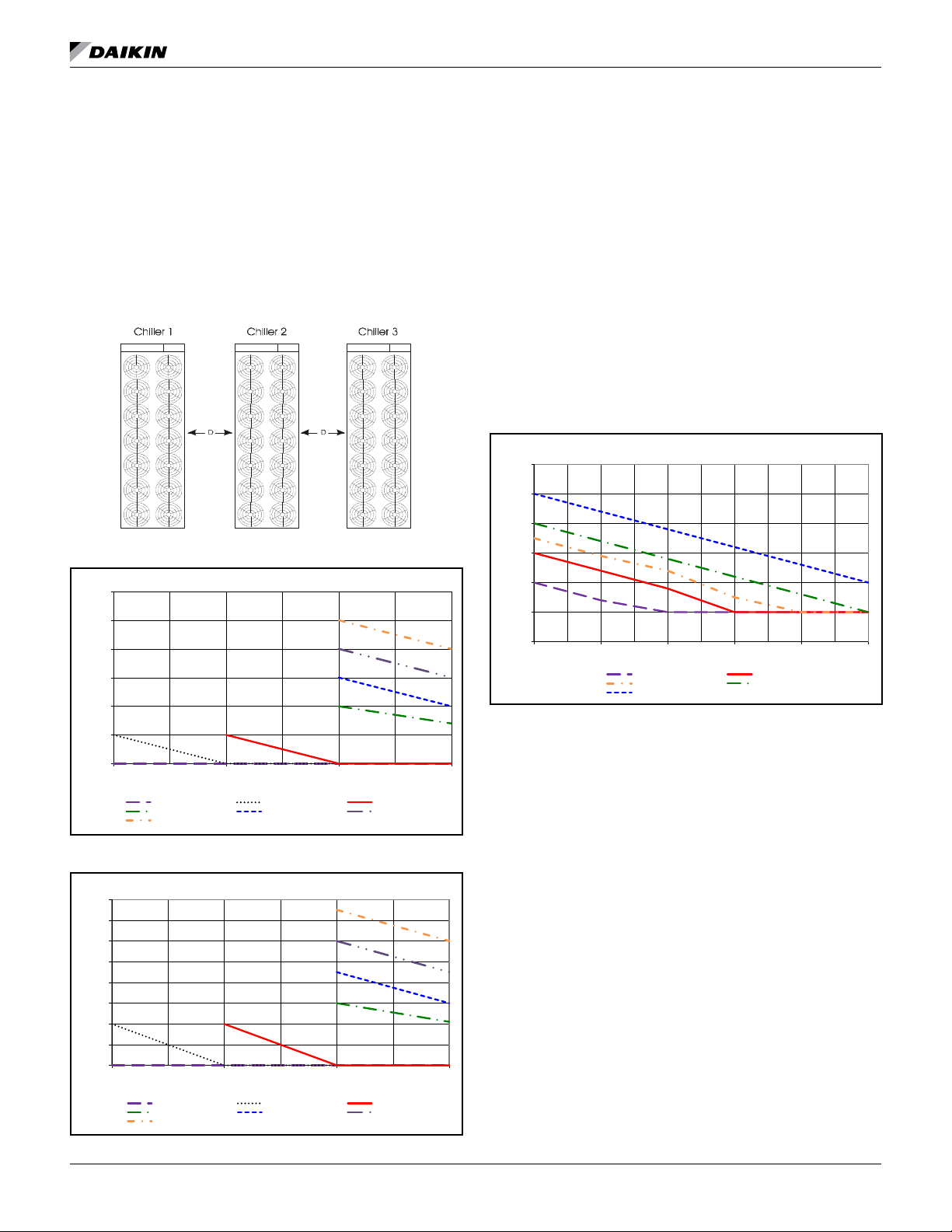

Case 3: Three or More Units, Side-by-Side

For all models, there must be a minimum distance between

any units placed side-by-side; however, performance may be

affected at this distance. Minimum distances are: models 030

to 070 - 4 feet, models 075 to 100 - 5 feet, models 110 to 240

- 6 feet. Figure 9 and Figure 10 depict Case 3 performance

adjustments as the distance between units increases.

NOTE: Data in Figure 9 and Figure 10 is for the middle unit

with a unit on each side. See Case 2 adjustment

factors for the two outside units.

Figure 8: Three or More Units, Side-by-Side

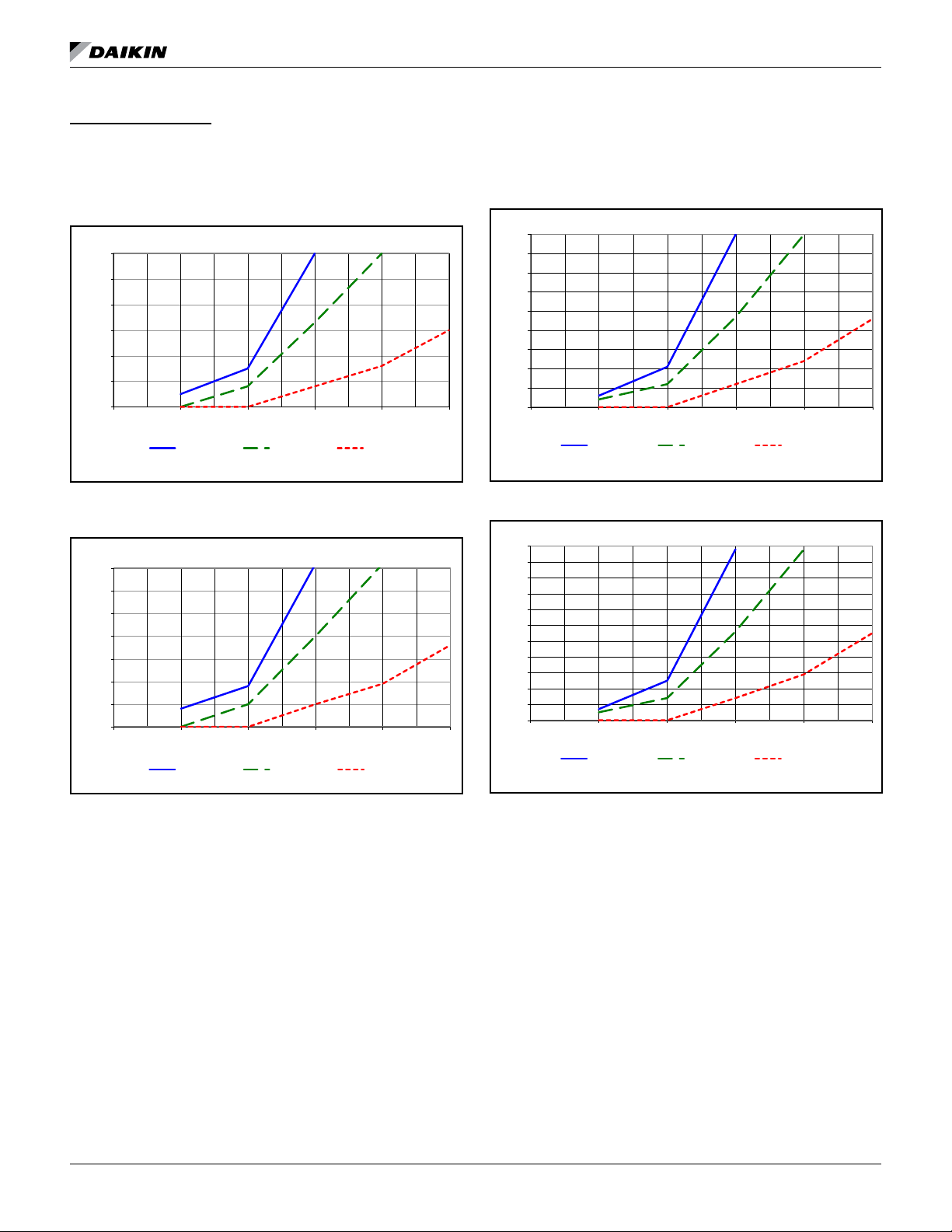

Figure 9: Case 3 - Full Load Capacity Reduction

6.0

5.0

4.0

3.0

2.0

% Capacity Reduction

1.0

0.0

4 5 6 8

Full Load Capacity Reduction

Distance Between Units

AGZ030-035E AGZ040-070E AGZ075-100E

AGZ0110-130E AGZ140-180E AGZ190-210E

AGZ225-240E

Case 4: Open Screening Walls

Decorative screening walls are often used to help conceal a

unit either on grade or on a rooftop. When possible, design

these walls such that the combination of their open area

and distance from the unit (see Figure 11) do not require

performance adjustment. If the wall opening percentage is less

than recommended for the distance to the unit, it should be

considered as a solid wall. It is assumed that the wall height is

equal to or less than the unit height when mounted on its base

support. If the wall height is greater than the unit height, see

Case 5: Pit Installation for performance adjustment factors.

The distance from the sides of the unit to the side walls must

be sufcient for service, such as opening control panel doors.

For uneven wall spacing, the distance from the unit to each

wall can be averaged providing no distance is less than 4 feet.

Values are based on walls on all four sides.

Figure 11: Case 4 - Allowable Wall Open Area

Wall Free Area vs. Distance

9.0

8.0

7.0

6.0

5.0

4.0

3.0

0 10 20 30 40 50

% Open Wall Area

AGZ030-070E AGZ075-100E

AGZ110-130E AGZ140-180E

AGZ190-240E

Figure 10: Case 3 - Power Increase

8.0

7.0

6.0

5.0

4.0

3.0

% Power Increase

2.0

1.0

0.0

4 5 6 8

AGZ030-035E AGZ040-070E AGZ075-100E

AGZ0110-130E AGZ140-180E AGZ190-210E

AGZ225-240E

Power Increase

Distance Between Units (ft)

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 6 www.DaikinApplied.com

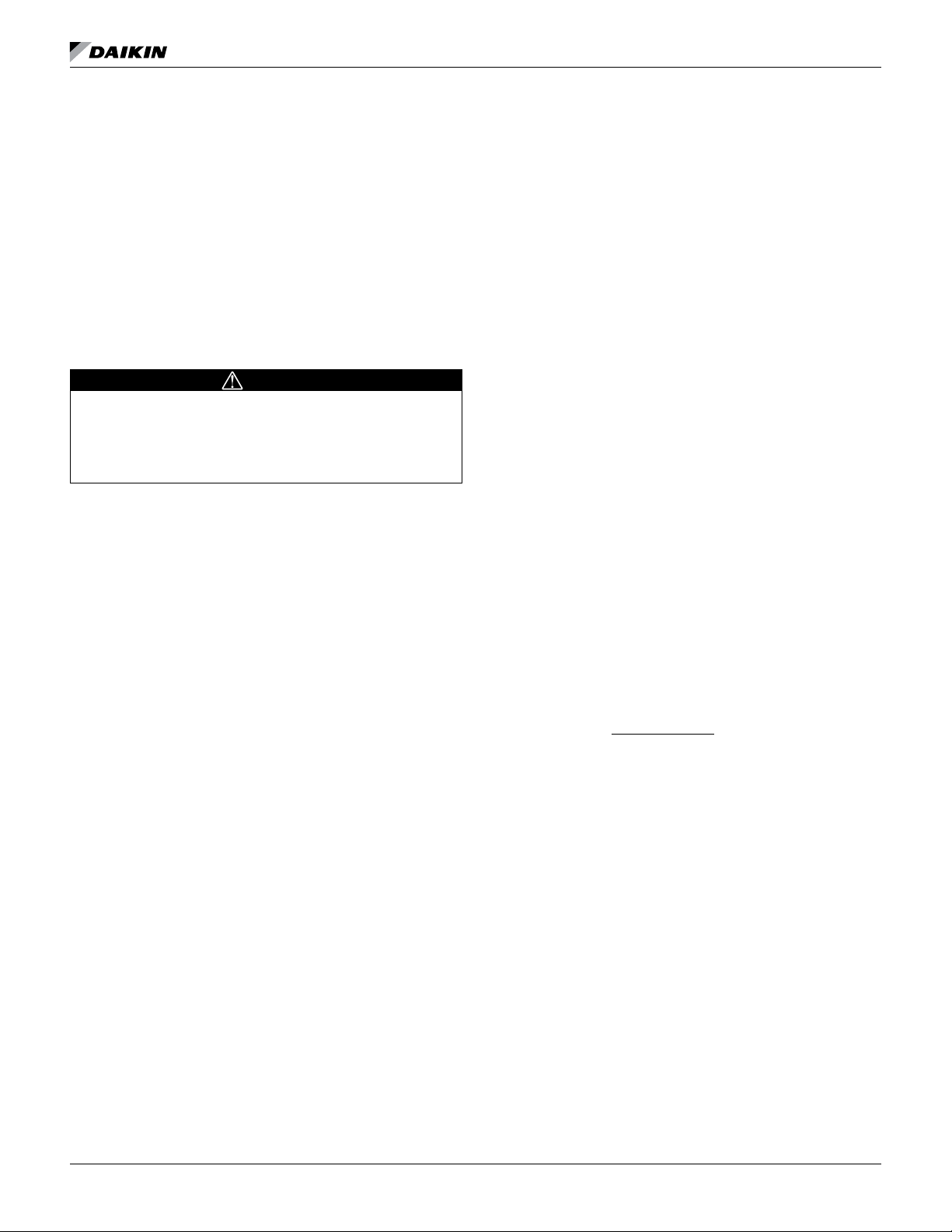

InsTallaTIon and applICaTIon InformaTIon

0.0

1.0

2.0

3.0

4.0

5.0

6.0

08101213

14

% Capacity Reduction

Depth of Pit / Wall Height (ft)

Full Load Capacity Reduction (AGZ030-070E)

Dis tance = 4 ft

Dis tance = 5 ft

Dis tance = 6 ft

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

08101213

14

% Pow er Incr ease

Depth of Pit / Wall Height (ft)

Power Increase (AGZ030-070E)

Dis tance = 4 ft

Dis tance = 5 ft

Dis tance = 6 ft

0.0

1.0

2.0

3.0

4.0

5.0

6.0

08101213

14

% Capacity Reduction

Depth of Pit / Wall Height ft)

Full Load Capacity Reduction (AGZ075

-130E)

Dis tance = 5 ft

Dis tance = 6 ft

Dis tance = 8 ft

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

08101213

14

% Pow er Incr ease

Depth of Pit / Wall Height (ft)

Power Increase (AGZ075-130E)

Dis tance = 5 ft

Dis tance = 6 ft

Dis tance = 8 ft

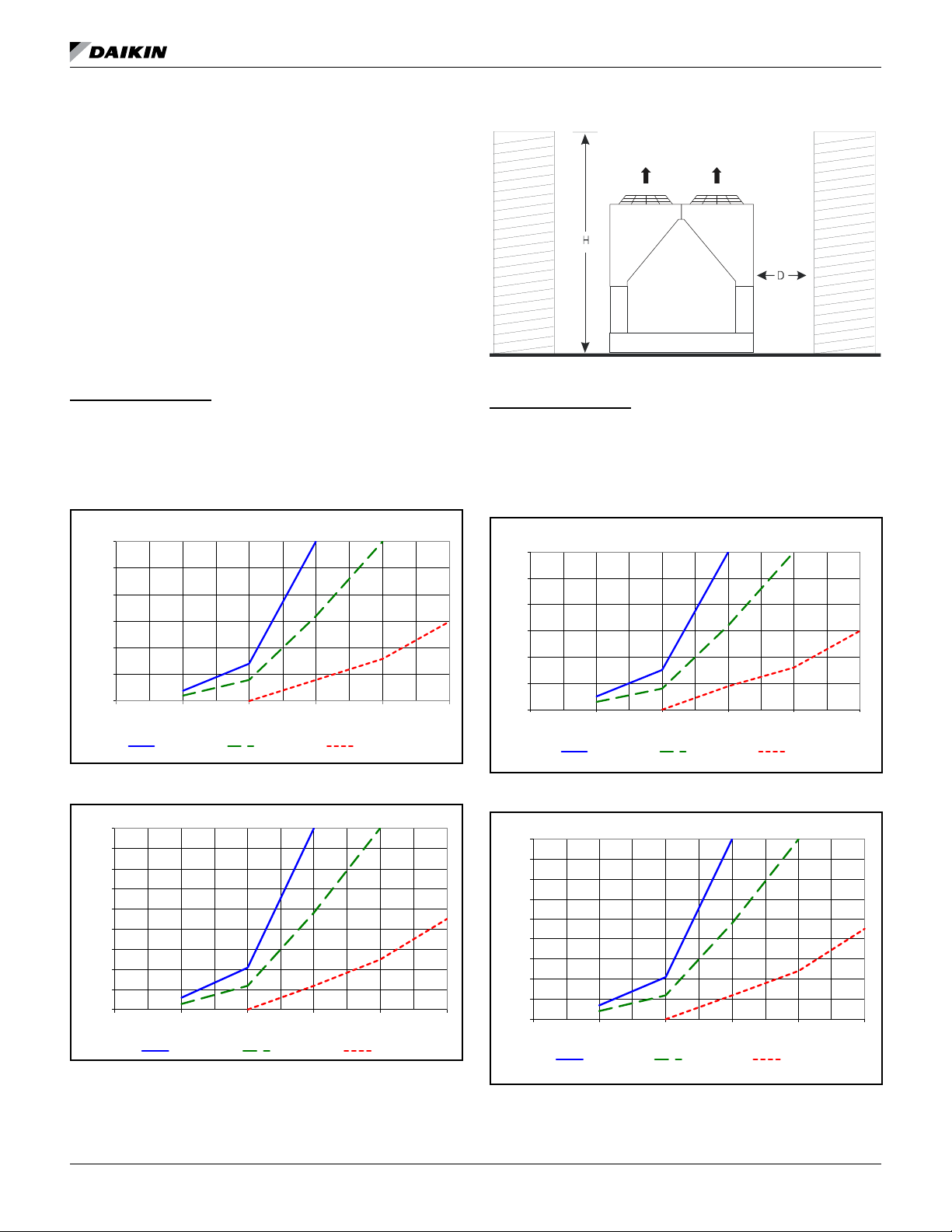

Case 5: Pit Installation

Pit installations can cause operating problems resulting from

air recirculation and restriction and require care that sufcient

air clearance is provided, safety requirements are met and

service access is provided. A solid wall surrounding a unit is

substantially a pit and this data should be used.

Steel grating is sometimes used to cover a pit to prevent

accidental falls or trips into the pit. The grating material

and installation design must be strong enough to prevent

such accidents, yet provide abundant open area to avoid

recirculation problems. Have any pit installation reviewed by

the Daikin Applied sales representative prior to installation to

ensure it has sufcient air-ow characteristics and approved by

the installation design engineer to avoid risk of accident.

Models AGZ030-070E:

The Case 5 gures for models AGZ030-070E show adjustment

factors for pit/wall heights of 4 feet, 5 feet, and 6 feet.

Figure 12: Case 5 - Full Load Capacity Reduction

(AGZ030E-070E)

Figure 14: Case 5 - Pit Installation

Models AGZ075-130E:

The Case 5 gures for models AGZ075-130E show adjustment

factors for pit/wall heights of 5 feet, 6 feet, and 8 feet.

Figure 15: Case 5 - Full Load Capacity Reduction

(AGZ075-130E)

Figure 13: Case 5 - Power Increase (AGZ030-070E)

www.DaikinApplied.com 7 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

Figure 16: Case 5 - Power Increase (AGZ075-130E)

Models AGZ140-240E:

% Capacity Reduction

% Capacity Reduction

The Case 5 gures for models AGZ140-240E show adjustment

factors for pit/wall heights of 6 feet, 8 feet, and 10 feet.

InsTallaTIon and applICaTIon InformaTIon

Figure 17: Case 5 - Full Load Capacity Reduction

(AGZ140-180E)

6.0

5.0

4.0

3.0

2.0

1.0

0.0

Full Load Capacity Reduction (AGZ140-180E)

0 8 10 12 13 14

Depth of Pit / Wall Height (ft)

Distance = 6 ft Distance = 8 ft Di stance = 10 ft

Figure 18: Case 5 - Full Load Capacity Reduction

(AGZ190-240E)

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

Full Load Capacity Reduction (AGZ190-240E)

0 8 10 12 13 14

Depth of Pit / Wall Height (ft)

Distance = 6 ft Distance = 8 ft Distance = 10 ft

Figure 19: Case 5 - Power Increase (AGZ140-210E)

9.0

8.0

7.0

6.0

5.0

4.0

3.0

% Power Increase

2.0

1.0

0.0

0 8 10 12 13 14

Power Increase (AGZ140-210E)

Depth of Pit / Wall Height (ft)

Distance = 6 ft Distance = 8 ft Distance = 10 ft

Figure 20: Case 5 - Power Increase (AGZ225-240E)

11.0

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

% Power Increase

2.0

1.0

0.0

0 8 10 12 13 14

Power Increase (AGZ225-240E)

Depth of Pit / Wall Height (ft)

Distance = 6 ft Distance = 8 ft Distance = 10 ft

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 8 www.DaikinApplied.com

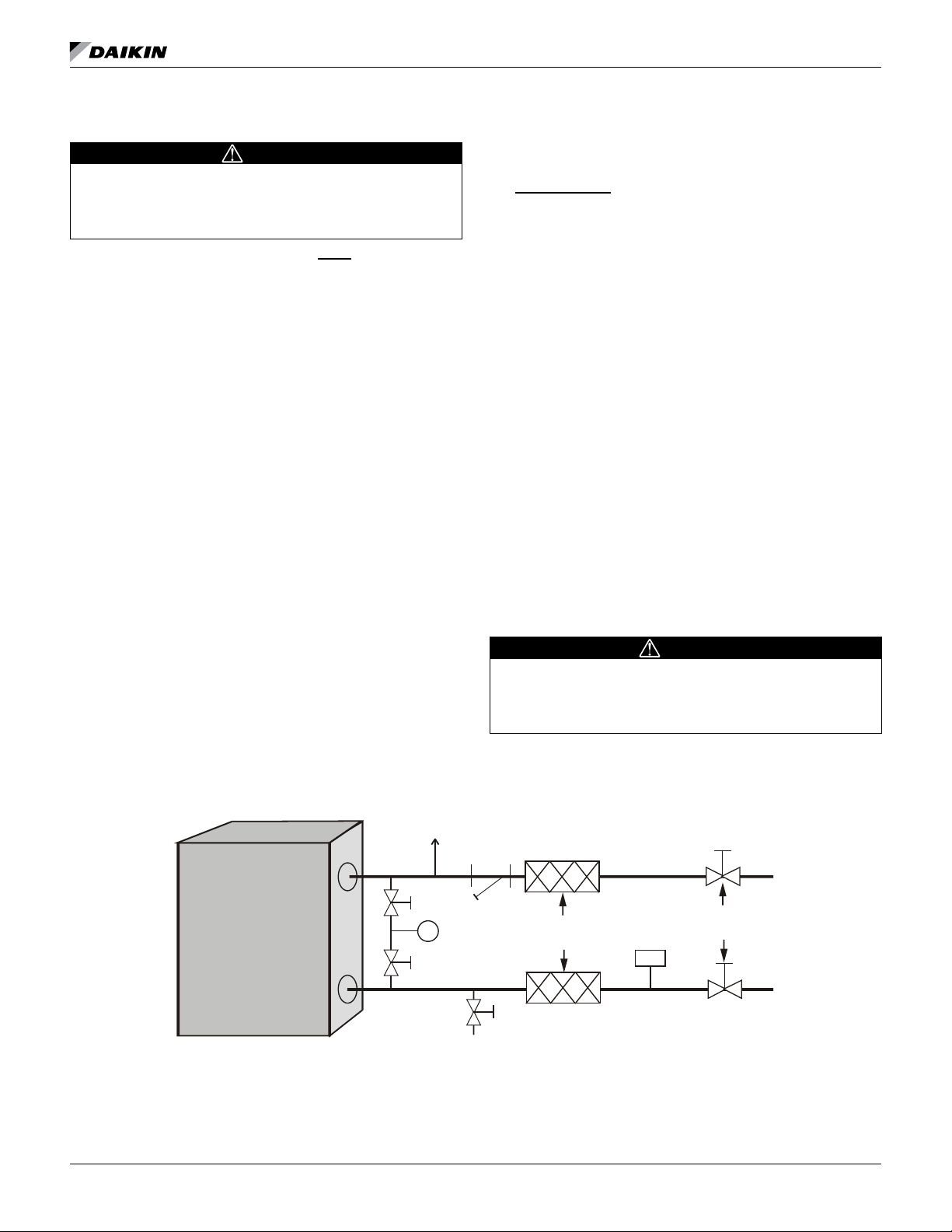

Chilled Water Piping

CAUTION

To prevent damage to the evaporator and potential chiller

failure, a supply strainer is required in the inlet water piping

which connects to this evaporator. This strainer must be

installed prior to operation of the chilled liquid pumps.

Field installed water piping to the chiller must include:

• A cleanable strainer installed at the water inlet to the

evaporator to remove debris and impurities before they

reach the evaporator. Install cleanable strainer within

5 feet (1500 mm) of pipe length from the evaporator

inlet connection and downstream of any welded

connections (no welded connections between strainer

and evaporator).

• AGZ-E models 030-180 require a strainer with

perforations no larger than 0.063” (1.6 mm) diameter and

models 190-240 require a strainer with perforations no

larger than 0.125” (3.175 mm) diameter. See the Inlet

Strainer Guidelines on page 10 for more information.

• A water ow switch must be installed in the horizontal

piping of the supply (evaporator outlet) water line to avoid

evaporator freeze-up under low or no ow conditions. The

ow switch may be ordered as a factory-installed option,

a eld-installed kit, or may be supplied and installed in the

eld. See page 12 for more information.

• Piping for units with brazed-plate evaporators must have

a drain and vent connection provided in the bottom of

the lower connection pipe and to the top of the upper

connection pipe respectively, see Figure 21. These

evaporators do not have drain or vent connections due

to their construction. Purge air from the water system

before unit start-up to provide adequate ow through the

evaporator.

• Adequate piping support, independent from the unit,

InsTallaTIon and applICaTIon InformaTIon

to eliminate weight and strain on the ttings and

connections.

It is recommended that the eld installed water piping to the

chiller include:

• Thermometers at the inlet and outlet connections of the

evaporator.

• Water pressure gauge connection taps and gauges at

the inlet and outlet connections of the evaporator for

measuring water pressure drop.

• Shutoff valves are necessary to isolate the unit from the

piping during unit servicing.

• Minimum bends and changes in elevation to minimize

pressure drop.

• An expansion tank or regulating valve to maintain

adequate water pressure

• Vibration eliminators in both the supply and return water

lines to reduce transmissions to the building.

• Flush the system water piping thoroughly before making

connections to the unit evaporator.

• Piping insulation, including a vapor barrier, helps prevent

condensation and reduces heat loss.

• Regular water analysis and chemical water treatment

for the evaporator loop is recommended immediately at

equipment start-up.

NOTE: Failure to follow these measures may result in

performance and reliability issues.

WARNING

Daikin Applied recommends against the use of PVC and

CPVC piping for chilled water systems. In the event the pipe

is exposed to POE oil used in the refrigerant system, the pipe

can be chemically damaged and pipe failure can occur. .

Figure 21: Typical Piping, Brazed-Plate Evaporator

Air

Vent

Strainer

Inlet

P

Vibration

Eliminators

Isolation

Valves

Outlet

Flow

Switch

Drain

WELDED PIPE CONNECTIONS ARE NOT ALLOWED

BETWEEN THE STRAINER AND EVAPORATOR DUE

TO THE CHANCE OF SLAG ENTERING THE EVAPORATOR

www.DaikinApplied.com 9 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

Typical Piping, Shell and Tube Evaporator

CHANCE OF SLAG ENTERING THE EVAPORATOR

InsTallaTIon and applICaTIon InformaTIon

VENT

3/8” PIPE PLUG

OUTLET

INLET

VIBRATION

ELIMINATOR

DRAIN

PROTECT ALL FIELD PIPING

AGAINST FREEZING

WELDED PIPE CONNECTIONS ARE NOT ALLOWED

BETWEEN THE STRAINER AND EVAPORATOR DUE TO THE

WATER

STRAINER

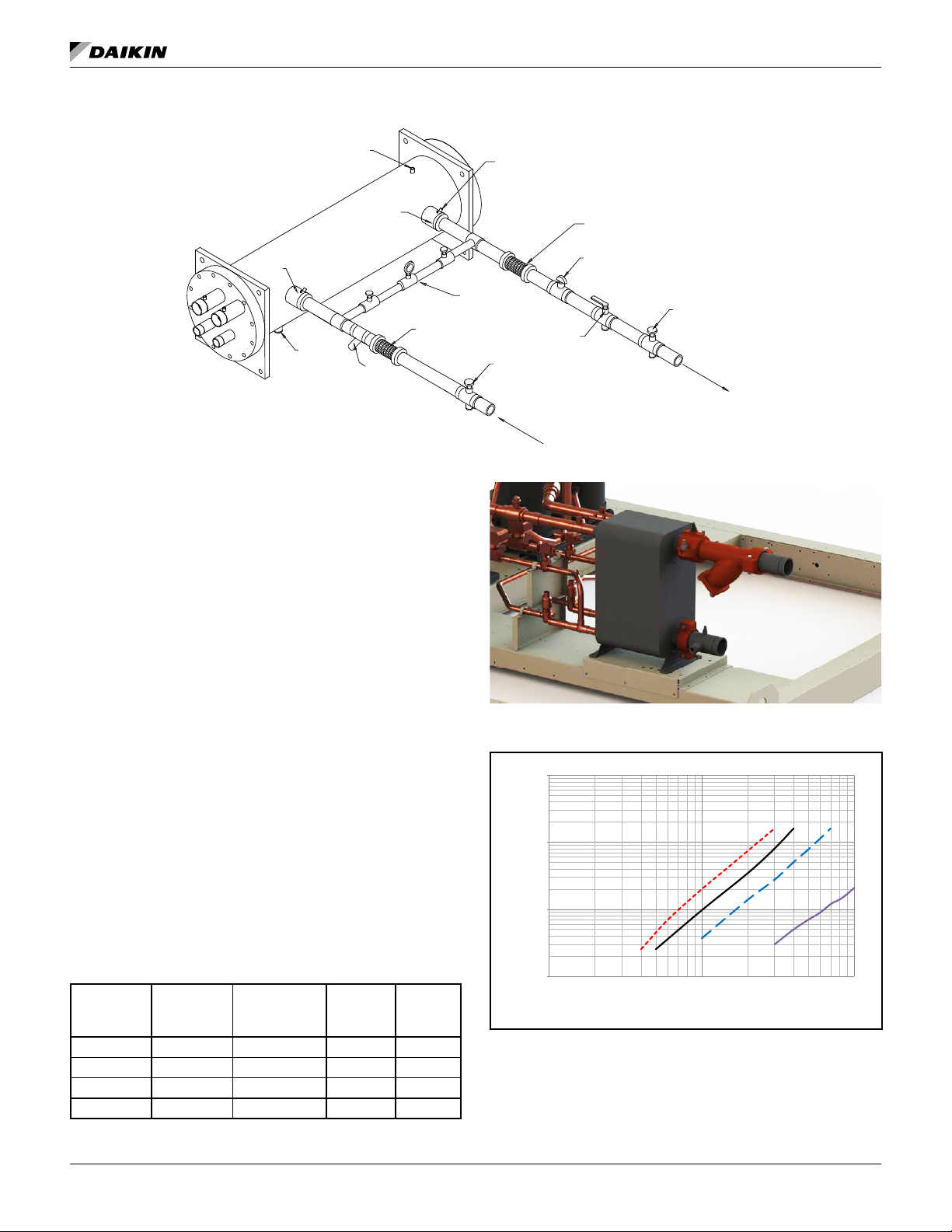

Inlet Strainer Guidelines

An inlet water strainer kit must be installed in the chilled water

piping before the evaporator inlet. Several paths are available

to meet this requirement:

1. Factory installed option is available - models 030 to 180.

2. A eld-installed kit shipped-loose with the unit is available

for all unit sizes and consists of:

• Y-type area strainer with 304 stainless steel perforated

basket, Victaulic pipe connections and strainer cap [a

strainer with perforations no larger than 0.063” (1.6

mm) diameter for AGZ-E models 030-180, a strainer

with perforations no larger than 0.125” (3.175 mm)

diameter for AGZ-E models 190-240].

• Extension pipe with two Schrader ttings that can be

used for a pressure gauge and thermal dispersion ow

switch. The pipe provides sufcient clearance from the

evaporator for strainer basket removal.

• ½-inch blowdown valve

• Two grooved clamps

Both are sized per Table 2 and with the pressure drop shown in

the Strainer Pressure Drop graph. Connection sizes are given

in the Dimensions and Weights section on page 15.

3. A eld-supplied strainer that meets specication and

installation requirements of this manual.

LEAVING FLUID

TEMP. SENSOR

VIBRATION

ELIMINATOR

FLOW

VALVED

PRESSURE

GAUGE

GATE

VALV E

BALANCING

FLOW

SWITCH

VALV E

Figure 22: Factory Installed Strainer

Figure 23: Strainer Pressure Drop

100.0

10.0

Pressure Drop ( ft)

1.0

GATE

VALV E

FLOW

2.5 in

3.0 in

4.0 in

8.0 in.

Table 2: Strainer Data

Trailblazer™

Model

030-070E 2.5 (64) 0.063 (1.6) Y Y

075-130E 3.0 (76) 0.063 (1.6) Y Y

140-180E 4.0 (102) 0.063 (1.6) Y Y

190-240E 8.0 (203) 0.125 (3.175) N Y

Strainer Size

in (mm)

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 10 www.DaikinApplied.com

Minimum

perforation size

in (mm)

Factory

Installed

Option

Field

Installed

Option

0.1

10.0 100.0 1000.0

Flow Rate (gpm)

InsTallaTIon and applICaTIon InformaTIon

Water Flow Limitations

Constant Evaporator Flow

The evaporator ow rates and pressure drops shown on page

28 for various system designs. The maximum ow rate and

pressure drop are based on a 6°F temperature drop. Flow

rates above the maximum values will result in unacceptable

pressure drops and can cause excessive erosion, potentially

leading to failure.

The minimum ow and pressure drop is based on a full load

evaporator temperature drop of 16°F. Evaporator ow rates

below the minimum values can result in laminar ow causing

low pressure alarms, scaling and poor temperature control.

Variable Evaporator Flow

Reducing evaporator ow in proportion to load can reduce

system power consumption. The rate of ow change should be

a maximum of 10 percent of the ow per minute. For example,

if the maximum design ow is 200 gpm and it will be reduced to

a ow of 140 gpm, the change in ow is 60 gpm. Ten percent of

200 gpm equals 20 gpm change per minute, or a minimum of

three minutes to go from maximum to desired ow. The water

ow through the evaporator must remain between the minimum

and maximum values listed in Table 11 on page 28. If ow

drops below the minimum allowable, large reductions in heat

transfer can occur. If the ow exceeds the maximum rate,

excessive pressure drop and tube erosion can occur. See unit

set point information in See Variable Evaporator Flow on page

56

System Water Volume Considerations

All chilled water systems need adequate time to recognize

a load change, respond to the change and stabilize to avoid

undesirable short cycling of the compressors or loss of

temperature control. In air conditioning systems, the potential

for short cycling usually exists when the building load falls

below the minimum chiller plant capacity or on close-coupled

systems with very small water volumes. Some of the things

the designer should consider when looking at water volume

are the minimum cooling load, the minimum chiller plant

capacity during the low load period and the desired cycle time

for the compressors. Assuming that there are no sudden load

changes and that the chiller plant has reasonable turndown,

a rule of thumb of “gallons of water volume equal to two to

three times the chilled water gpm ow rate” is often used. A

storage tank may have to be added to the system to reach the

recommended system volume. Refer to AG 31-003 for method

of calculating “Minimum Chilled Water Volume”.

BAS should enable chiller only when there is a cooling

demand.

Evaporator Freeze Protection

Evaporator freeze-up can be a concern in the application of

air-cooled water chillers in areas experiencing below freezing

temperatures. To protect against freeze-up, insulation and an

electric heater are furnished with the evaporator. Models 030

through 180 have an external plate heater and thermostat.

Models 190 through 240 have immersion heaters with a

thermostat. These heaters help protect the evaporator down to

-20°F (-29°C) ambient air temperature. The evaporator heater

cable is factory wired to the 115 volt control circuit transformer

in the control box. A 115V power source for the heater and

controls may also be supplied from a separate power feed to

maximize unit protection if desired. Refer to the eld wiring

diagram on page 30 for additional information on supplying a

separate 115V power feed.

Operation of the heaters is automatic through the sensing

thermostat that energizes the evaporator heaters for protection

against freeze-up. Unless the evaporator is drained in the

winter or contains an adequate concentration of anti-freeze, the

disconnect switch to the evaporator heater must not be open.

Although the evaporator is equipped with freeze protection,

it does not protect water piping external to the unit or the

evaporator itself if there is a power failure or heater burnout, or

if the chiller is unable to control the chilled water pumps. Use

one of the following recommendations for additional freeze

protection:

1. If the unit will not be operated during the winter, drain the

evaporator and chilled water piping and ush with glycol.

2. Add a glycol solution to the chilled water system. Burst

protection should be approximately 10°F below minimum

design ambient temperature.

3. Insulate the exposed piping.

4. Add thermostatically controlled heat by wrapping the

lines with heat tape.

5. When glycol is added to the water system for freeze

protection, the refrigerant suction pressure will be lower,

cooling performance less, and water side pressure drop

greater. If the percentage of glycol is high, or if propylene

is used instead of ethylene glycol, the added pressure

drop and loss of performance could be substantial. When

Glycol or Ice are selected as Unit Mode, the MicroTech®

III control will automatically reset the available range

for the Leaving Water Temperature, Freezestat and

Evaporator Pressure settings.

www.DaikinApplied.com 11 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

InsTallaTIon and applICaTIon InformaTIon

Chilled Water Pump

It is important that the chilled water pumps be wired to, and

controlled by, the chiller’s microprocessor. When equipped

with optional dual pump output, the chiller controller has the

capability to selectively send the signal to a pump relay (by

others) to start pump A or B or automatically alternate pump

selection and also has standby operation capability. The

controller will energize the pump whenever at least one circuit

on the chiller is enabled to run, whether there is a call for

cooling or not. This helps ensure proper unit start-up sequence.

he pump will also be turned on when the water temperature

goes below the Freeze Setpoint for longer than a specied time

to help prevent evaporator freeze-up. Connection points are

shown in the Field Wiring Diagram beginning on page 30.

CAUTION

Adding glycol or draining the system is the recommended

method of freeze protection. If the chiller does not have

the ability to control the pumps and the water system is

not drained in temperatures below freezing, catastrophic

evaporator failure may occur.

Failure to allow pump control by the chiller may cause the

following problems:

1. If any device other than the chiller attempts to start the

chiller without rst starting the pump, the chiller will lock

out on the No Flow alarm and require manual reset.

2. If the chiller evaporator water temperature drops below

the “Freeze setpoint” the chiller will attempt to start the

water pumps to avoid evaporator freeze. If the chiller

does not have the ability to start the pumps, the chiller

will alarm due to lack of water ow.

3. If the chiller does not have the ability to control the

pumps and the water system is not to be drained in

temperatures below freezing or contain glycol, the chiller

may be subject to catastrophic evaporator failure due to

freezing. The freeze rating of the evaporator is based on

the evaporator heater and pump operation. The external

brazed plate heater or shell and tube immersion heater

itself may not be able to properly protect the evaporator

from freezing without circulation of water.

Flow Switch

All chillers require a chilled water ow switch to check that

there is adequate water ow through the evaporator ant to shut

the unit down if there isn’t. There are two options for meeting

this requirement.

1. A factory-mounted thermal dispersion ow switch.

2. A “paddle” type ow switch is available from Daikin

Applied for eld mounting and wiring. Wire from switch

terminals Y and R to the unit control panel terminals

shown on the eld wiring diagrams, page 30 and page

31. Mount the ow switch in the leaving water line to

shut down the unit when water ow is interrupted. A ow

switch is an equipment protection control and should

never be used to cycle a unit.

Installation should be per manufacturer’s instructions included

with the switch. Flow switches should be calibrated to shut off

the unit when operated below the minimum listed ow rate for

the unit as listed on page 28.

There is also a set of normally closed contacts on the switch

that can be used for an indicator light or an alarm to indicate

when a “no ow” condition exists. Freeze protect any ow

switch that is installed outdoors. Differential pressure switches

are not recommended for outdoor installation. They can freeze

and not indicate a no-ow conditions.

Glycol Solutions

The use of a glycol/water mixture in the evaporator to prevent

freezing will reduce system capacity and efciency, as well

as increase pressure drop. The system capacity, required

glycol solution ow rate, and pressure drop with glycol may be

calculated using the following formulas and tables.

Glycol Flow Rate = Capacity Tons X Flow Correction Factor

(gpm) 0.00429 x ΔT

1. Capacity - Multiply the capacity based on water by the

Capacity correction factor from Table 3 or Table 4.

2. Flow - Multiply the water evaporator ow by the Flow

correction factor from Table 3 or Table 4 to determine

the increased evaporator ow due to glycol. If the ow is

unknown, it can be calculated from the above equation.

3. Pressure drop - Multiply the water pressure drop from

Table 11 by Pressure Drop correction factor from Table

3 or Table 4. High concentrations of propylene glycol at

low temperatures may cause unacceptably high pressure

drops.

4. Power - Multiply the water system power by Power

correction factor from Table 3 or Table 4.

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 12 www.DaikinApplied.com

InsTallaTIon and applICaTIon InformaTIon

Test coolant with a clean, accurate glycol refractometer to

determine the freezing point. Obtain percent glycol from the

freezing point table below. It is recommended that a minimum

of 25% solution by weight be used for protection against

corrosion or that additional compatible inhibitors be added.

Concentrations above 35% do not provide any additional burst

protection and should be carefully considered before using.

Reset the freezestat setting to 6 °F (3.3 °C) below the leaving

chilled water setpoint temperature after the glycol percentage

is veried safe for the application.

CAUTION

Do not use an automotive-grade antifreeze. Industrial

grade glycols must be used. Automotive antifreeze contains

inhibitors which will cause plating on the copper tubes within

the chiller evaporator. The type and handling of glycol used

must be consistent with local codes.

Table 3: Ethylene Glycol Factors

E.G. Freeze Point

% °F °C

10 26 -3.3 0.997 0.999 1.028 1.090

20 18 -7.8 0.993 0.997 1.059 1.216

30 7 -14 0.987 0.995 1.094 1.379

40 -7 -22 0.981 0.993 1.132 1.557

50 -28 -33 0.972 0.990 1.174 1.811

Cap Power Flow PD

Low Ambient Operation

Compressor staging is adaptively determined by system load,

ambient air temperature, and other inputs to the MicroTech® III

control. The standard minimum ambient temperature is 32°F

(0°C). A low ambient option with fan VFD allows operation

down to -10°F (-23°C). The minimum ambient temperature

is based on still conditions where the wind is not greater

than 5 mph. Greater wind velocities will result in reduced

discharge pressure, increasing the minimum operating

ambient temperature. Field installed louvers are available and

recommended to help allow the chiller to operate effectively

down to the ambient temperature for which it was designed.

High Ambient Operation

Trailblazer™ units for high ambient operation (105°F to 125°F,

40°C to 52°C) require the addition of the optional high ambient

package that includes a small fan with a lter in the air intake

to cool the control panel.

All units with the optional VFD low ambient fan control

automatically include the high ambient option. Note that in

cases of high ambient temperature, capacity could be reduced

or the lowest leaving water temperature settings may be

outside of the chiller operating envelope; consult Daikin Tools

to ensure chiller is capable of the required lift.

Table 4: Propylene Glycol Factors

P.G. Freeze Point

% °F °C

10 26 -3.3 0.995 0.998 1.011 1.025

20 19 -7.2 0.988 0.995 1.030 1.150

30 9 -13 0.979 0.992 1.056 1.375

40 -5 -21 0.968 0.988 1.090 1.701

50 -27 -33 0.955 0.983 1.131 2.128

Cap Power Flow PD

www.DaikinApplied.com 13 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

InsTallaTIon and applICaTIon InformaTIon

Condenser Coil Options and Coating

Considerations

The standard coils on the Trailblazer™ chiller are an all

aluminum alloy microchannel design with a series of at

tubes containing multiple, parallel ow microchannels layered

between the refrigerant manifolds. The microchannel coils are

designed to withstand 1000+ hour acidied synthetic sea water

fog (SWAAT) test (ASTM G85-02) at 120°F (49°C) with 0% n

loss and develop no leaks.

Should the standard microchannel coil not meet the corrosion

requirements for the application, additional coil options are

available.

Aluminum n/copper tube coils consist of 3/8 inch (10 mm)

seamless copper tubes mechanically bonded into plate-type

aluminum ns. The ns have full drawn collars to completely

cover the tubes. The aluminum n/copper tube option is best

suited for non-corrosive environments, and can be repaired

onsite. This option is only available for models AGZ030-070E.

Figure 24: Aluminum Fin/Copper Tube Coils

BlackFin™ coils include aluminum ns pre-coated with a

durable phenolic epoxy coating. In addition to providing a

durable coating on the n material, the BlackFin™ coils provide

and epoxy barrier between the aluminum n stock and the

copper tube, to prevent the galvanic corrosion that can occur

between the dissimilar metals. This option will provide a 1000+

hour salt spray rating per ASTM B117-90. The BlackFin™

option provides enhanced protection in mildly corrosive

environments. This option is only available for models AGZ030070E.

Copper-n coils consist of 3/8 inch (10 mm) seamless copper

tubes mechanically bonded into plate-type copper ns. The ns

have full drawn collars to completely cover the tubes. Since

the n and the tube materials are similar, the opportunity for

galvanic corrosion is eliminated. The copper n/copper tube

option may be used in marine environments; however this

option is not well suited for industrial or chemical atmospheric

contamination. This option is only available for models

AGZ030-070E.

ElectroFin® coil coating is a water-based extremely exible

and durable epoxy polymer coating uniformly applied to all

coil surfaces through a multi-step, submerged electrostatic

coating process. ElectroFin® condenser coils provide a 5000+

hour salt spray resistance per ASTM B117-90, applied to both

the coil and the coil frames. The ElectroFin® coated coils also

receive a UV-resistant urethane top-coat to provide superior

resistance to degradation from direct sunlight. This coil coating

option provides the best overall protection against corrosive

marine, industrial or combined atmospheric contamination.

This coating option may be applied to any of the untreated coil

options offered, to provide excellent longevity and resistance to

corrosion.

Table 5: Coil/Coating Selection Matrix

Coil Option

Standard Microchannel +++ - - -

Alum. Fin/Copper Tube

Copper Fin/Copper Tube

™5

BlackFin

ElectroFin

®

Non-

Corrosive

5

+++ - - -

5

+++ +++ - -

+++ + + -

+++ +++ +++ ++

Unpolluted

1

Marine

2

Industrial

Combined

3

Marine-

Industrial

NOTE:

1. Non-corrosive environments may be estimated by the

appearance of existing equipment in the immediate area

where the chiller is to be placed.

2. Marine environments should take into consideration

proximity to the shore as well as prevailing wind

direction.

3. Industrial contaminants may be general or localized,

based on the immediate source of contamination (i.e.

diesel fumes due to proximity to a loading dock).

4. Combined marine-industrial are inuenced by proximity

to shore, prevailing winds, general and local sources of

contamination.

5. Available for models AGZ030-070E only.

4

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 14 www.DaikinApplied.com

dImensIons and WeIghTs - paCkaged UnITs

BLANK PANELS ARE

M1 - M4, ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

COMPRESSORS

LOCATIONS

TOP VIEW WITH

COILS AND

OPERATING

WEIGHT

LBS (KG) LBS (KG) L1 L2 L 3 L4 M1 M2 M3 M4

AGZ030E 2947 (1337) 2960 (1343) 1011 (459) 799 (362) 635 (288) 502 (228) 980 (445) 775 (352) 673 (305) 532 (241)

AGZ035E 2873 (1303) 2887 (1310) 1051 (477) 861 (391) 528 (240) 433 (196) 1005 (456) 824 (374) 581 (264) 476 (216)

PACKAGE UNITS WITH MICROCHANNEL COILS

LIFTING (SHIPPING) WEIGHT BY CORNER LBS (KG) MOUNTING (OPERATING) WEIGHT LBS (KG)

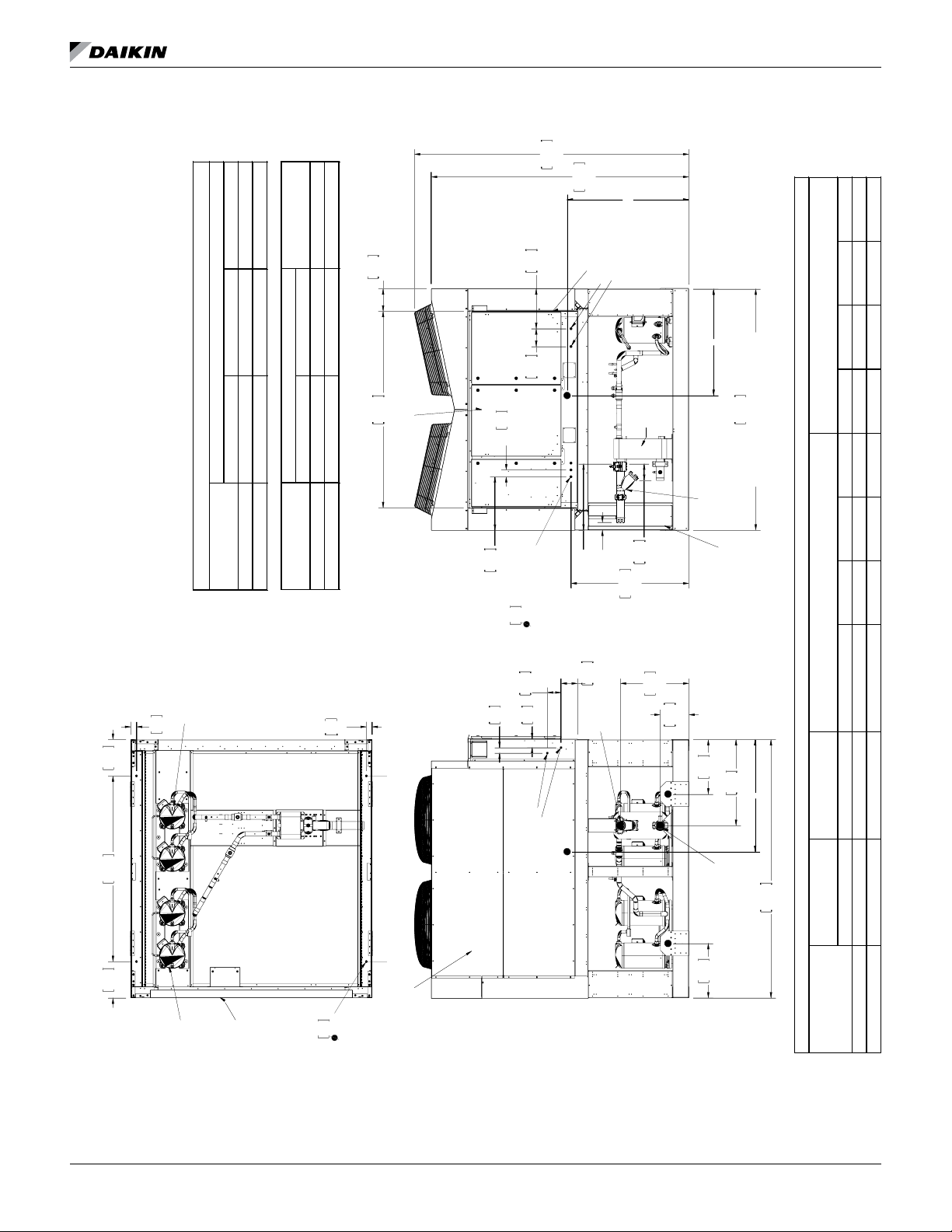

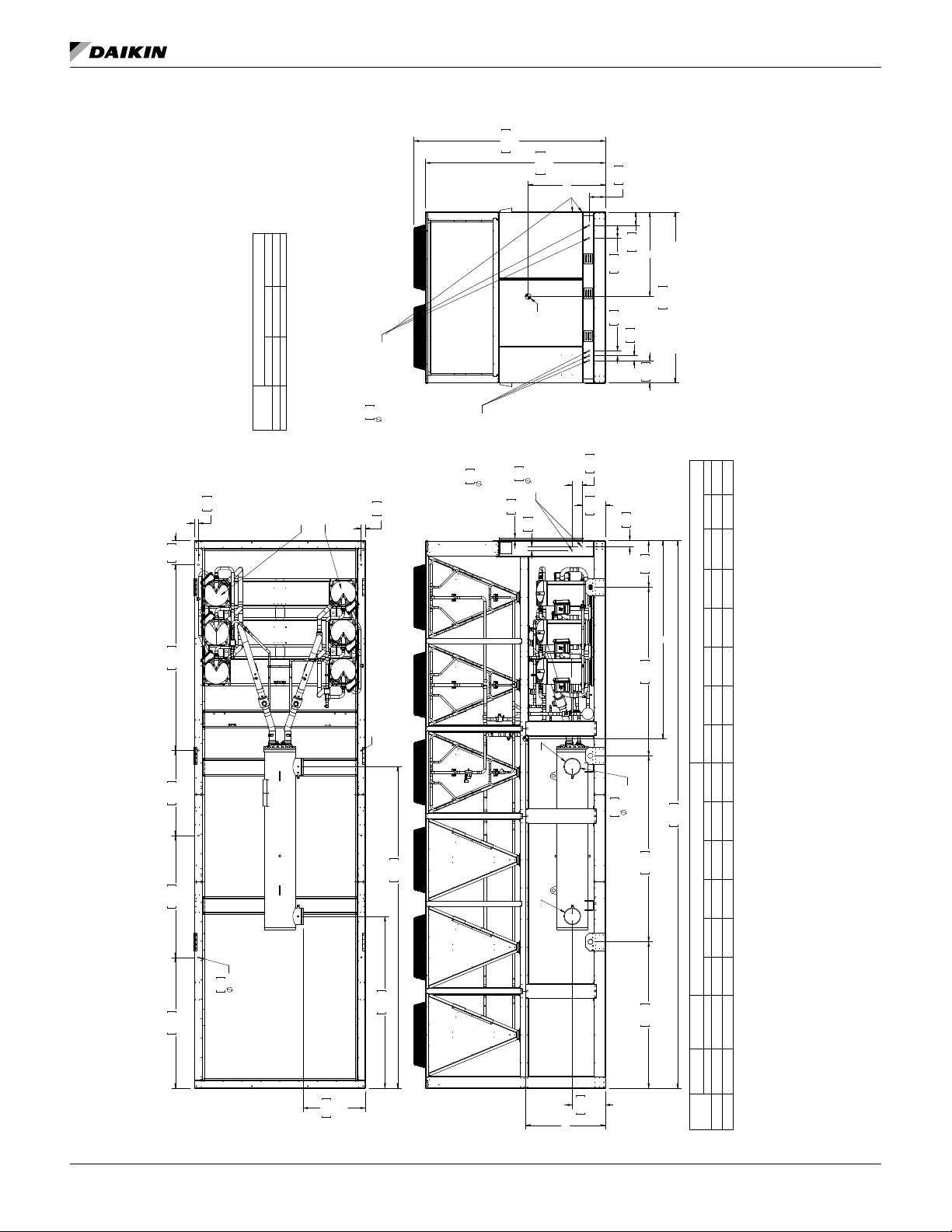

Figure 25: AGZ030E - AGZ035E

CG LOCATION, IN (MM)

X Y Z

0B

334547101

AGZ-E, 4 FANS

MOUNTING WEIGHTS ARE BASED ON UNIT OPERATING WEIGHT WITH EVAPORATOR WATER INCLUDED.

NOTE: LIFTING WEIGHTS ARE BASED ON UNIT SHIPPING WEIGHTS.

SHIPPING AND OPERATING WEIGHTS DO NOT INCLUDE THE WEIGHTS OF ANY OPTIONS OR ACCESSORIES.

PACKAGE UNITS WITH MICROCHANNEL COILS

AGZ030E 38.9 (988) 44.5 (1130) 40.9 (1039)

AGZ035E 39.7 (1008) 45.5 (1156) 38.1 (968)

UNIT MODEL

dImensIons and WeIghTs - paCkaged UnITs

2546

100.2

94.1

2389

(VICTAULIC)

497

64

19.6

2.5

2X

22

370

165

KNOCKOUTS

.875

8.2

209

REF.

71.8

A B

1822

CONTROL

BOX

EVAP. DIMENSIONS IN (MM) CONNE CTION SIZE

AGZ030E 24.2 (615) 2.9 (74) 2.5 (64)

AGZ035E 23.5 (597) 2.2 (56) 2.5 (64)

UNIT MODEL

[22]

14.6

6.5

QTY. 3

CONNECTIONS

FIELD CONTROL

Ø.875

KNOCKOUTS

POWER ENTRY

B

A

Y

FRONT OR

RIGHT SIDE

EVAP.

153

43.1

1094

X

88.0

2235

LIFTING BRACKETS

DIMENSION DOES NOT INCLUDE

WYE-STRAINER

REQUIRED

(FACTORY OR FIELD

INSTALLED OPTION)

6.0

FRONT LEFT

CORNER POST

PURPOSELY

HIDDEN

M3 M1

337

1721

337

13.3

L1L3

67.8

13.3

52

2.0

COMPRESSORS

CIRCUIT #1

CIRCUIT #2

FANS REMOVED

6.0

5.0

127

51

52

2.0

M2M4

2.0803.2

152

EVAP.

WATER

INLET

635

25.0

266

10.5

506

19.9

797

31.4

L1

L2

Z

EVAP.

WATER

OUTLET

[22]

Ø.875 KNOCKOUTS

POWER ENTRY KNOCKOUTS

ARE ON THE OPPOSITE

SIDE OF CONTROL BOX

L3

L1 - L4,

LIFTING

L4

506

19.9

L4 L2

.750

19

QTY. 4

USED ON UNIT SIDES.

SLOPED 50" COILS

USED ON INSIDE.

2396

94.3

SHIPPING WEIGHT

UNIT MODEL

www.DaikinApplied.com 15 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

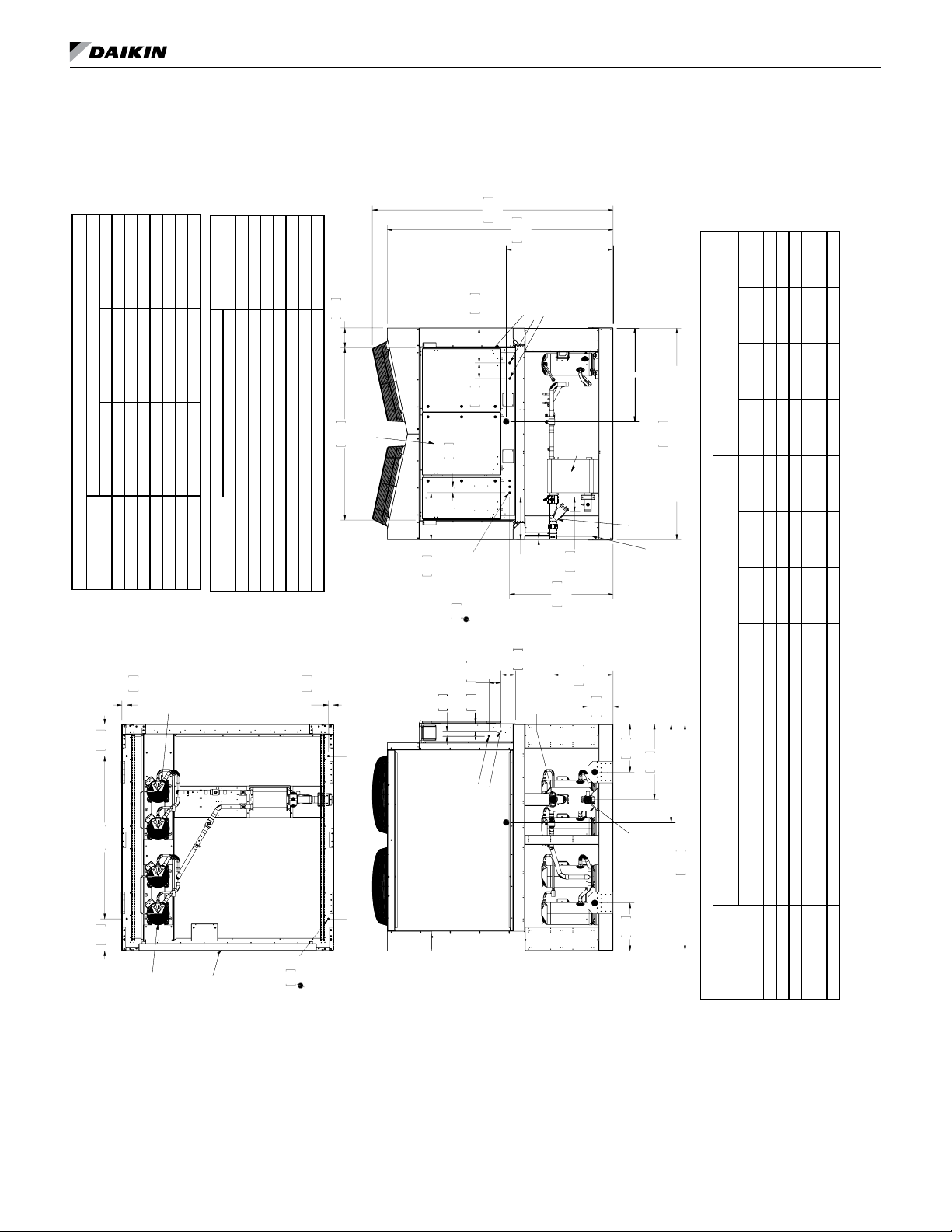

Figure 26: AGZ040E - AGZ070E

LOCATIONS

COILS AND

FANS REMOVED

2948 (1337) 2964 (1345) 1067 (484) 881 (400) 548 (249) 453 (206) 1022 (464) 844 (383) 601 (273) 496 (225)

3094 (1403) 3112 (1412) 1051 (477) 832 (377) 676 (307) 535 (243) 1021 (463) 809 (367) 715 (324) 567 (257)

3093 (1403) 3114 (1413) 1049 (476) 837 (380) 671 (304) 536 (243) 1020 (463) 814 (369) 712 (323) 568 (258)

3106 (1409) 3128 (1419) 1052 (477) 840 (381) 675 (306) 539 (245) 1023 (464) 817 (371) 716 (325) 572 (260)

3130 (1420) 3155 (1431) 1059 (480) 851 (386) 676 (307) 543 (246) 1031 (468) 828 (376) 718 (326) 577 (262)

3130 (1420) 3155 (1431) 1059 (480) 851 (386) 676 (307) 543 (246) 1031 (468) 828 (376) 718 (326) 577 (262)

3472 (1575) 3497 (1586) 1180 (535) 847 (384) 842 (382) 604 (274) 1157 (525) 830 (377) 880 (399) 631 (286)

LIFTING (SHIPPING) WEIGHT BY CORNER LBS (KG) MOUNTING (OPERATING) WEIGHT LBS (KG)

NOTE: LIFTING

SHIPPING AND OPERATING WEIGHTS DO NOT INCLUDE THE WEIGHTS OF ANY OPTIONS OR ACCESSORIES.

(VICTAULIC)

CG LOCATION, IN (MM)

208

dImensIons and WeIghTs - paCkaged UnITs

2546

100.2

94.0

2389

Y

[22]

Ø.875

FRONT OR

370

165

14.6

6.5

8.2

REF.

RIGHT SIDE

KNOCKOUTS

POWER ENTRY

0B

334547101

AGZ-E, 4 FANS

X

WYE-STRAINER

REQUIRED

(FACTORY OR FIELD

INSTALLED OPTION)

FRONT LEFT

CORNER POST

PURPOSELY

19.9

797

31.4

L2

WATER

OUTLET

L4

19.9

88.0

2235

LIFTING BRACKETS

DIMENSION DOES NOT INCLUDE

HIDDEN

PACKAGE UNITS W ITH MICROCHANNEL COILS

Z

2396

94.3

WEIGHT

OPERATING

SHIPPING WEIGHT

LBS (KG) LBS (KG) L1 L2 L3 L4 M1 M2 M3 M4

WEIGHTS ARE BASED ON UNIT SHIPPING WEIGHTS.

71.8

X Y Z

A B

EVAP. DIMENSIONS IN (MM) CONNECTION SIZE

1822

CONTROL

BOX

64

2.5

2X

EVAP.

PACKAGE UNITS WITH MICROCHANNEL COILS

B

AGZ040E 39.8 (1011) 45.9 (1166) 38.4 (975)

AGZ045E 38.9 (988) 44.5 (1130) 41.2 (1047)

AGZ050E 39.1 (993) 44.9 (1141) 41.2 (1047)

AGZ055E 39.1 (993) 44.8 (1138) 41.2 (1047)

AGZ060E 39.2 (996) 44.6 (1133) 41.1 (1044)

AGZ065E 39.2 (996) 44.6 (1133) 41.1 (1044)

UNIT MODEL

52

2.0

337

13.3

L1L3

67.8

1721

M3 M1

337

13.3

AGZ070E 36.8 (935) 41.8 (1062) 42.6 (1082)

COMPRESSORS

CIRCUIT #1

AGZ040E 22.8 (579) 1.5 (38) 2.5 (64)

AGZ045E 21.4 (544) 0.11 (3) 2.5 (64)

AGZ050E 20 (508) 2.7 (69) 2.5 (64)

AGZ055E 19.3 (490) 2.0 (51) 2.5 (64)

AGZ060E 17.6 (447) 0.3 (8) 2.5 (64)

AGZ065E 17.6 (447) 0.3 (8) 2.5 (64)

UNIT MODEL

AGZ070E 17.6 (447) 0.3 (8) 2.5 (64)

52

2.0

M2M4

L4 L2

497

19.6

KNOCKOUTS

.875

22

51

2.0803.2

[22]

Ø.875 KNOCKOUTS

127

A

QTY. 3

CONNECTIONS

FIELD CONTROL

6.0

152

5.0

EVAP.

WATER

INLET

POWER ENTRY KNOCKOUTS

ARE ON THE OPPOSITE

SIDE OF CONTROL BOX

1094

43.1

153

635

6.0

25.0

266

10.5

506

L1

EVAP.

L3

506

AGZ045E

AGZ050E

AGZ055E

AGZ060E

AGZ065E

AGZ070E

UNIT MODEL

AGZ040E

.750

19

QTY. 4

M1 - M4, ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

COMPRESSORS

CIRCUIT #2

TOP VIEW WITH

L1 - L4,

LIFTING

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 16 www.DaikinApplied.com

MOUNTING WEIGHTS ARE BASED ON UNIT OPERATING WEIGHT WITH EVAPORATOR WATER INCLUDED.

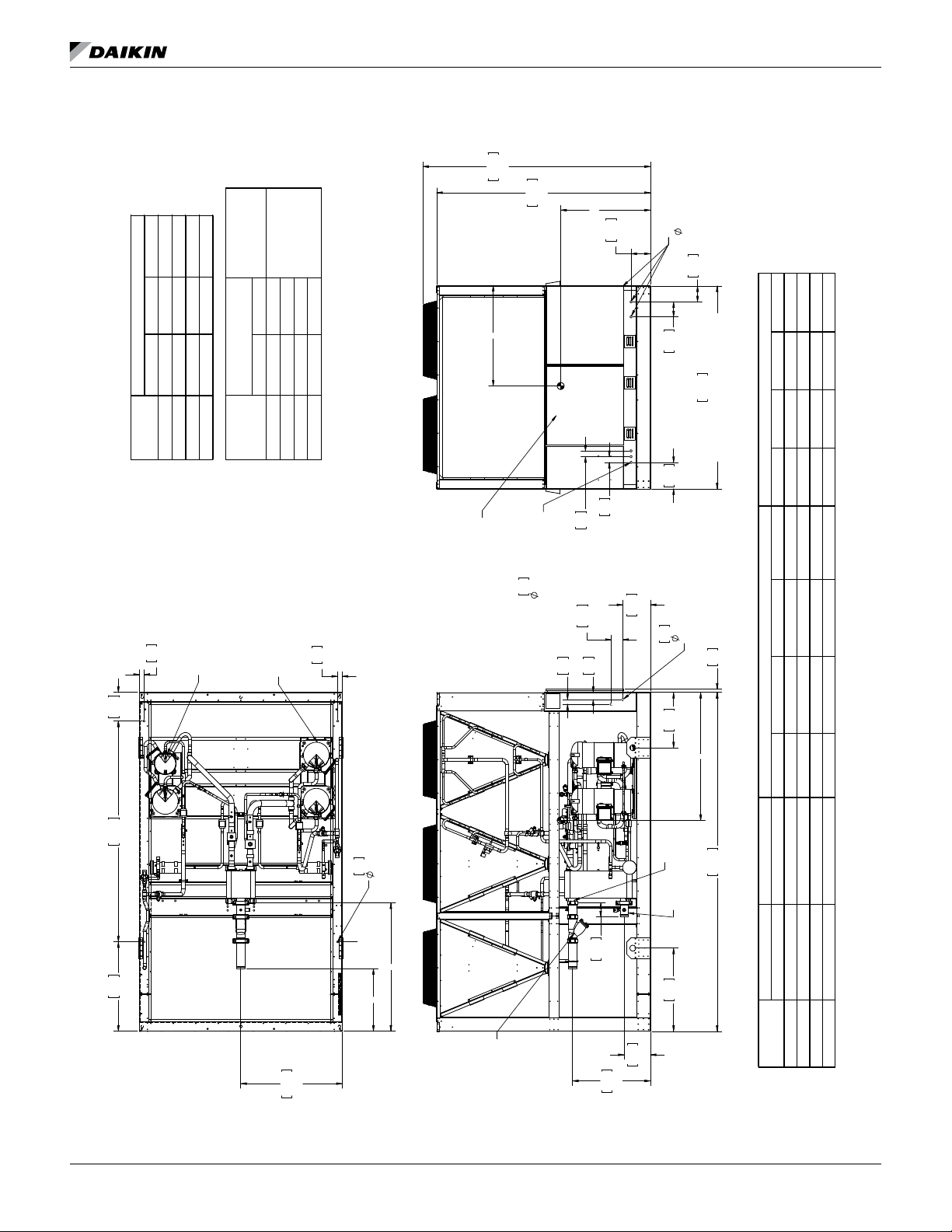

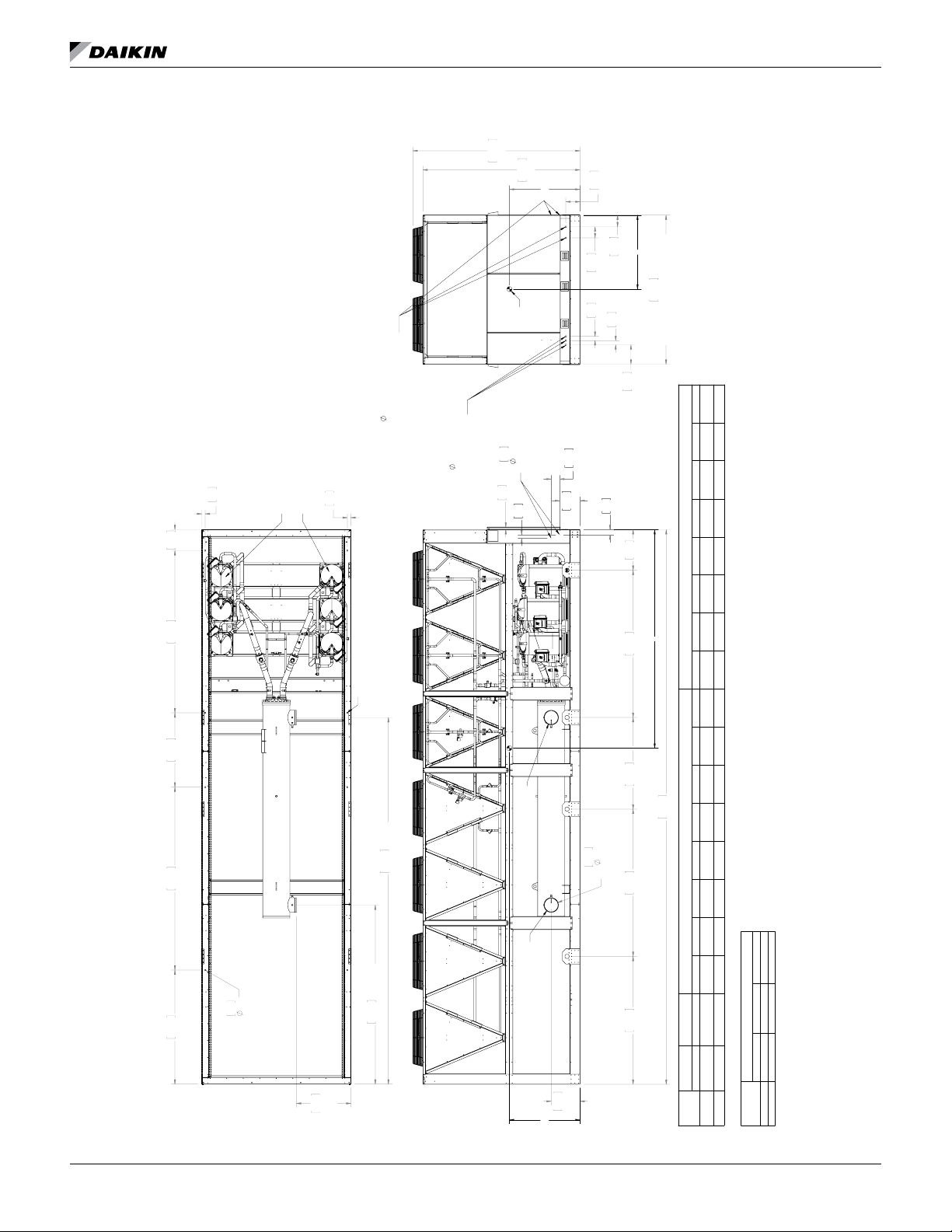

Figure 27: AGZ075E - AGZ100E

(FACTORY OR FIELD

INSTALLED OPTION)

WYE-STRAINER

REQUIRED

LOCATIONS

LIFTING

L1 - L4,

NOTE: LIFTING WEIGHTS ARE BASED ON UNIT SHIPPING WEIGHTS.

MOUNTING WEIGHTS ARE BASED ON UNIT OPERATING WEIGHT WITH EVAPORATOR WATER INCLUDED.

SHIPPING AND OPERATING WEIGHTS DO NOT INCLUDE THE WEIGHTS OF ANY OPTIONS OR ACCESSORIES.

M1 - M4, ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE.

TOP VIEW WITH

COILS AND FANS

REMOVED

SHIPPING WEIGHT OPERATING WEIGHT

4451 (2019) 1341 (608) 1420 (644) 790 (358) 837 (380) 1173 (532) 1242 (563) 989 (449) 1047 (475)

4579 (2077) 1407 (638) 1418 (643) 840 (381) 846 (384) 1232 (559) 1241 (563) 1049 (476) 1057 (479)

4609 (2091) 1456 (660) 1466 (665) 806 (366) 812 (368) 1276 (579) 1285 (583) 1020 (463) 1028 (466)

4780 (2168) 1505 (683) 1480 (671) 863 (391) 848 (385) 1322 (600) 1299 (589) 1089 (494) 1070 (485)

LIFTING (SHIPPING) WEIGHT BY CORNER, LBS (KG) MOUNTING (OPERATING) WEIGHT, LBS (KG)

dImensIons and WeIghTs - paCkaged UnITs

CG LOCATION, IN (MM)

XYZ

45.3 (1151) 38.6 (980) 56.2 (1427)

44.2 (1122) 39.2 (995) 56.5 (1435)

44.2 (1122) 39.2 (995) 55.0 (1397)

43.6 (1108) 38.9 (988) 55.7 (1415)

UNIT

MODEL

AGZ0 75E

AGZ0 80E

AGZ0 90E

AGZ1 00E

52

2.0

COMPR.

CIRCUIT 2

3.0 (76)

SIZE, IN.

CONNE CTION

IN (MM)

AB

EVAP. DIMENSIONS

55.6 (1412) 27.1 (688)

54.4 (1382) 25.9 (658)

54.4 (1382) 25.9 (658)

UNIT

MODEL

AGZ075E

AGZ080E

AGZ090E

CIRCUIT 1

COMPR.

51.6 (1311) 23.1 (587)

AGZ100E

52

175

FRONT OR RIGHT SIDE

ARE ON THE OPPOSITE SIDE

6.9

2235

OF THE CONTROL BOX

88.0

DIMENSION DOES NOT INCLUDE

37

1.5

00

334547111

AGZ-E, 6 FANS

LIFTING BRACKETS

98.6

2506

92.7

2355

X

BOX

CONTROL

.875 KNOCKOUTS

22

FIELD CONTROL

2.0

CONNECTIONS

QTY. 3

2.0513.1

64

127

Y

8.4

213

64

2.5

2.5

305

5.0

80

.875 POWER ENTRY

[22]

KNOCKOUTS

6.5

165

292

11.5

12.0

.875 KNOCKOUTS

22

POWER ENTRY KNOCKOUTS

M1

M3

315

2433

984

12.4

L1

95.8

L3

38.7

44.0

1118

M2

L2

L4

609

24.0

Z

L1

WATER

INLET

290

EVAP.

L3

11.4

L4 L2

916

EVAP.

WATER

36.1

OUTLET

3733

147.0

LBS (KG) LBS (KG ) L1 L2 L3 L4 M1 M2 M3 M4

4510 (2046)

4540 (2059)

4696 (2130)

4388 (1990)

AGZ080E

AGZ090E

AGZ100E

AGZ075E

UNIT M ODEL

.750

19

QTY. 4

M4

A

B

153

6.0

858

33.8

www.DaikinApplied.com 17 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

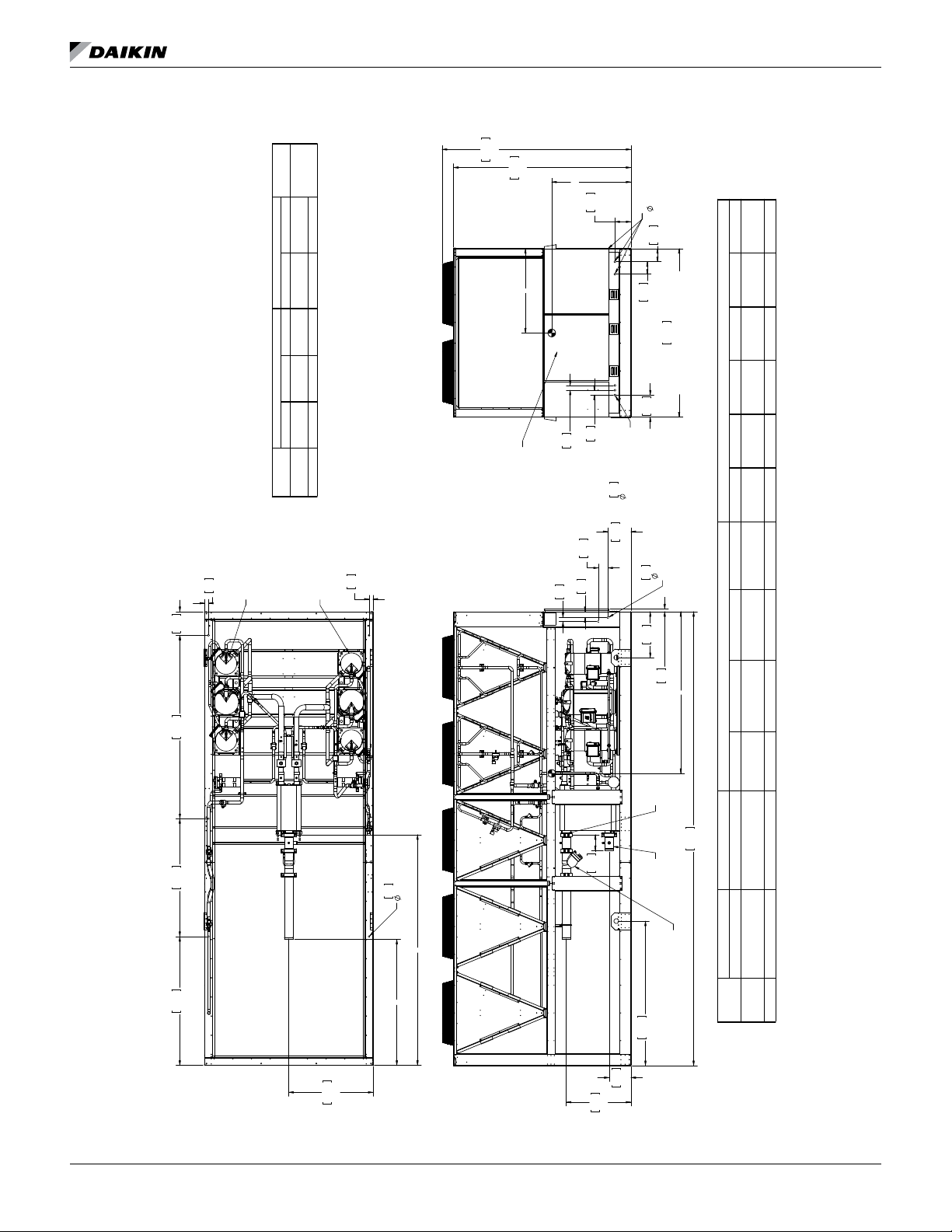

Figure 28: AGZ110E - AGZ130E

FIELD INSTALLED

OPTION)

LIFTING

LOCATIONS

WYE-STRAINER

REQUIRED

(FACTORY OR

NOTE: LIFTING WEIGHTS ARE BASED ON UNIT SHIPPING WEIGHTS.

MOUNTING WEIGHTS ARE BASED ON UNIT OPERATING WEIGHT WITH EVAPORATOR WATER INCLUDED.

SHIPPING AND OPERATING WEIGHTS DO NOT INCLUDE THE WEIGHTS OF ANY OPTIONS OR ACCESSORIES.

M1 - M6, ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE.

TOP VIEW WITH

COILS AND FANS

REMOVED.

SHIPPING WEIGHT OPERATING WEIG HT

AGZ110E

5528 (2508) 1762 (799) 1769 (802) 951 (431) 955 (433) 1424 (646) 1430 (649) 845 (383) 849 (385) 489 (222) 491 ( 223)

AGZ120E

5796 (2629) 1907 (865) 1915 (869) 935 (424) 939 (426) 1548 (702) 1555 (705) 878 (398) 882 (400) 465 (211) 467 ( 212)

AGZ130E

5903 (2678) 1941 (880) 1863 (845) 1015 (460) 974 (442) 1575 ( 714) 1511 (685) 920 (417) 883 (401) 517 (235) 49 6 (225)

LIFT ING (SHIPPI NG) WEIGHT BY CORNER, LBS (KG) MOUNTING (OPERATING) W EIGHT, LBS (KG)

dImensIons and WeIghTs - paCkaged UnITs

98.6

2506

92.7

2355

3.0 (76)

SIZE, IN.

CONNECTION

213

Y

8.4

.875 POWER ENTRY

[22]

KNOCKOUTS

FRONT OR RIGHT SIDE

175

334547121

AGZ-E 8 FANS

6.9

X

CG LOCATION, IN (MM)

X Y Z

44.1 (1120) 42.1 (1069) 69.0 (1753)

44.1 (1120) 43.3 (1100) 66.4 (1687)

UNIT

MODEL

AGZ110E

AGZ120E

52

2.0

COMPR.

CIR. 2

315

12.4

M1

95.824.8

2433

43.1 (1095) 41.0 (1041) 68.3 (1735)

AGZ130E

A B

95.5 (2426) 69.1 (1755)

93.9 (2385) 67.5 (1715)

EVAP. DIMENSIONS, I N (MM)

UNIT

COMPR.

92.0 (2337) 65.5 (1664)

MODEL

AGZ110E

AGZ120E

AGZ130E

64

64

2.5

2.5

BOX

CONTROL

52

2.0

CIR. 1

M2

L2M4L 4M 6

QTY. 3

CONNECTIONS

.875 KNOCKOUTS

22

FIELD CONTROL

5.0

127

51

2.0

80

3.1

305

6.5

165

88.0

2235

LIFTING BRACKETS

DIMENSION DOES NOT INCLUDE

292

11.5

12.0

.875 KNOCKOUTS

22

POWER ENTRY KNOCKOUTS

ARE ONTHE OPPOSITE SIDE

37

1.5

609

24.0

L1

Z

OF THE CONTROL BOX

WATERL2INLET

EVAP.

4879

192.1

M3

59.0

1499

L3 L1

M5

630

44.0

1118

A

B

.750

19

QTY. 6

153

6.0

858

OUTLET

WATER

EVAP.

L4

L3

996

39.2

290

11.4

33.8

L1 - L4,

LBS (KG) LBS (KG) L1 L2 L3 L4 M1 M2 M3 M4 M5 M6

5792 (2627)

5696 (2584)

5437 (2466)

UNIT

MODE L

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 18 www.DaikinApplied.com

Figure 29: AGZ140E - AGZ161E

TOP VIEW WITH

COILS AND FANS

M1 - M4, ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE.

REMOVED

NOTE: LIFTING WEIGHTS ARE BASED ON UNIT SHIPPING WEIGHTS.

MOUNTING WEIGHTS ARE BASED ON UNIT OPERATING WEIGHT WITH EVAPORATOR WATER INCLUDED.

SHIPPING AND OPERATING WEIGHTS DO NOT INCLUDE THE WEIGHTS OF ANY OPTIONS OR ACCESSORIES.

LOCATIONS

LIFTING

1862 (845) 1868 (847) 1410 (640) 1415 (642) 1411 (640) 1416 (642) 1070 (485) 1074 (487) 850 (386) 853 (387)

1888 (856) 1881 (853) 1426 (647) 1421 (645) 1433 (650) 1428 (648) 1085 (492) 1081 (490) 861 (391) 858 (389)

1917 (870) 1876 (851) 1453 (659) 1422 (645) 1456 (660) 1425 (646) 1104 (501) 1080 (490) 878 (398) 859 (390)

LIFTING (SHIP PING) WEIGHT BY COR NER, LBS (KG) M OUNTING (OPERATING) WEIGHT, LBS (KG)

SIZE, IN.

4.0 (102)

CONNECTION

65.9 (1674)

67.51 (1715)

2506

dImensIons and WeIghTs - paCkaged UnITs

98.6

92.7

2355

Y

213

8.4

.875

[22]

POWER ENTRY

KNOCKOUTS FRONT

OR RIGHT SIDE

6.9

175

EVAP. DIMENSIONS, IN (MM)

X

165

6.5

88.0

2235

LIFTING BRACKETS

DIMENSION DOES NOT INCLUDE

CG LOCATION, IN (MM)

44.1 (1120) 42.6 (1083) 83.3 (2117) 122.1 (3102)

43.9 (1116) 42.4 (1077) 83.3 (2115) 120.5 (3062)

43.5 (1105) 42.3 (1074) 83.4 (2117) 120.5 (3062) 65.9 (1674)

CONTROL

UNIT

MODEL X Y Z A B

AGZ140E

AGZ150E

AGZ161E

AGZ-E 10FANS

334547131

52

2.0

COMPR.

CIR. 2

315

12.4

M1

L1

52

2.0

CIR. 1

COMPR.

M2

L2

BOX

64

2.5

64

2.5

5.0

127

80

3.1

51

2.0

292

11.5

QTY. 3

CONNECTIONS

.875 KNOCKOUTS

22

FIELD CONTROL

305

12.0

.875 KNOCKOUTS

22

POWER ENTRY KNOCKOUTS

ARE ON THE OPPOSITE SIDE

OF THE CONTROL BOX

609

24.0

37

L1

L2

1.5

Z

95.8

2433

INSTALLED OPTION)

6025

L1 L2 L3 L4 M1 M2 M3 M4 M5 M6

237.2

6674 (3027)

6745 (3059)

LBS (KG) LBS (KG)

6555 (2973)

6617 (3001)

6668 (3025) 6802 (3085)

SHIPPING W EIGHT OPERATING W EIGHT

UNIT

MODEL

AGZ140E

AGZ150E

AGZ161E

WATER

INLET

EVAP.

M3

61.6

1564

L3

M5

67.4

1711

M4

8.3

210

WATER

EVAP.

OUTLET

.750

19

QTY. 6

L 4M 6

L4

L3

A

75.5

(FACTORY OR FIELD

WYE-STRAINER

REQUIRED

B

1919

290

858

11.4

33.8

L1 - L4

1118

44.0

www.DaikinApplied.com 19 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

Figure 30: AGZ170E - AGZ180E

NOTE: LIFTING WEIGHTS ARE BASED ON UNIT SHIPPING WEIGHTS.

MOUNTING WEIGHTS ARE BASED ON UNIT OPERATING WEIGHT WITH EVAPORATOR WATER INCLUDED.

SHIPPING AND OPERATING WEIGHTS DO NOT INCLUDE THE WEIGHTS OF ANY OPTIONS OR ACCESSORIES.

LIFTING

LOCATIONS

M1 - M4, ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE.

REMOVED

TOP VIEW WITH

COILS AND FANS

SHIPPING WEIGHT OPERATING WEIGHT

CONNECTI ON

dImensIons and WeIghTs - paCkaged UnITs

98.6

2506

92.7

4.0 (102)

SIZE, IN.

2355

Y

213

8.4

.875

[22]

POWER ENTRY

KNOCKOUTS FRONT

OR RIGHT SIDE

6.9

175

954 (433)

920 (417)

119 (3022)

83.6 (2123) 64.3 (1634)

40.4 (1025)

39.4 (1000) 82.8 (2103) 117 (2971) 62.4 (1584)

CG LOCATION, IN ( MM) EVAP. DIMENSIONS, IN (MM)

X Y Z A B

43.2 (1096)

44.1 (1119)

AGZ170E

AGZ-E 10FANS

334547131

52

2.0

CIR. 2

COMPR.

315

12.4

M1

L1

AGZ180E

UNIT MODEL

52

2.0

COMPR.

CIR. 1

M 2L 2M4L 4M 6

X

64

2.5

64

2.5

CONTROL

BOX

5.0

127

80

3.1

51

2.0

6.5

165

88.0

2235

LIFTING BRACKETS

DIMENSION DOES NOT INCLUDE

292

11.5

MOUNTING (OPERATING) W EIGHT, LBS (KG)

QTY. 3

CONNECTIONS

.875 KNOCKOUTS

22

305

FIELD CONTROL

12.0

.875 KNOCKOUTS

22

POWER ENTRY KNOCKOUTS

ARE ON THE OPPOSITE SIDE

OF THE CONTROL BOX

609

24.0

L2

L1

37

1.5

Z

M1 M2 M3 M4 M5

1466 (665) 1471 (667) 1136 (515) 1140 (517) 924

1613 (732) 1617 (733) 1210 (549) 1214 (551) 951 (431)

1571 (713) 1512 (686) 1197 (543) 1152 (523) 956 (434)

2127 (965) 1580 (717) 1584 (718)

95.8

2433

LIFTI NG (SHIPPIN G) WEIGHT BY CORNER, LBS (KG)

1941 (880)

2072 (940)

2121 (962)

EVAP.

WATER

INLETOUTLET

M3

6025

237.2

7307 (3314) 1995 (905) 1581 (717) 1522 (690)

LBS (KG) L BS (KG) L1 L2 L3 L4 M6

MODE L

7560 (3429)

6937 (3147)

7170 (3252)

7412 (3362)

AGZ170E

AGZ180E

8.3

61.6

1564

L3

M5

67.4

1711

44.0

1118

.750

19

QTY. 6

A

B

210

EVAP.

WATER

L3

L4

WYE-STRAINER

REQUIRED

(FACTORY OR FIELD

INSTALLED OPTION)

UNIT

75.5

1919

290

11.4

858

33.8

L1 - L4

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 20 www.DaikinApplied.com

Figure 31: AGZ190E - AGZ210E

ISOLATOR MOUNTING HOLE LOCATIONS ARE ON BOTTOM SURFACE OF UNIT

TOP VIEW

WITH COILS

AND FANS

REMOVED

MODEL

LIFTING (SHIPPING) WEIGHT BY CORNER, LBS (KG)

LBS (KG) LBS (KG) L1 L2 L3 L4 L5 L6 M1 M2 M3 M4 M5 M6 M7 M 8

AGZ190E

8548 (3877) 9022 (4092) 1707 (774) 1687 (765)1442 (654) 1426 (647)1150 (522) 1137 (516)1587 (720)1569 (712) 1191 (540)1177 (534) 1009 (458) 998 (453) 749 (340) 741 (336)

AGZ210E

8584 (3894) 9058 (4109) 1714 (777) 1703 (772)1445 (655) 1435 (651)1147 (520) 1140 (517)1594 (723)1584 (718) 1193 (541)1186 (538) 1010 (458) 1003 (455) 747 (339)742 (337)

Z

102.1 (2592)

39.8 (1011)

CG LOCATION IN (MM)

X Y

43.8 (1111)

UNIT

MODEL

AGZ190E

52

2.0

101.9 (2587)

39.8 (1011)43.9 (1114)

AGZ210E

dImensIons and WeIghTs - paCkaged UnITs

98.6

2506

92.7

2355

Y

CG

BOX

CONTROL

.875 KNOCKOUTS

22

WEIGHTS ARE BASED ON UNIT OPERATING WEIGHT WITH EVAPORATOR

LIFTING WEIGHTS ARE BASED ON UNIT SHIPPING WEIGHTS. MOUNTING

THE WEIGHTS OF ANY OPTIONS OR ACCESSORIES.

WATER INCLUDED. SHIPPING AND OPERATING WEIGHTS DO NOT INCLUDE

NOTE:

COMPRESSORS

CIRCUIT #1

CIRCUIT #2

COMPRESSORS

FRONT & RIGHT SIDE

POWER ENTRY POINTS

.875 KNOCKOUTS

22

CONNECTIONS

.875 KNOCKOUTS

22

FIELD CONTROL

52

2.0

ARE ON OPPOSITE

POWER ENTRY POINTS

SIDE OF CONTROL BOX

37

1.5

51

2.0

127

305

8.4

213

6.9

175

X

6.5

165

88.0

2235

64

2.5

64

2.5

DIMENSION DOES NOT

INCLUDE LIFTING BRACKETS

292

11.5

5.0

12.0

80

3.1

LEFT HAND EVAPORATOR VIEWS SHOWN. SEE CERTIFIED

DRAWING FOR VIEWS WITH RIGHT HAND EVAP.

1.

NOTES:

315

12.4

M1

L1

2433

M3

L3L5

43.8 95.8

1114

M5

62.9

1596

M7

.75

19

QTY 8

67.4

1711

M2

M4

L4

M6 L2

4210

165.7

L6

M8

88.6

2249

CG

EVAPORATOR

WATER OUTLET WATER INLET

609

24.0

L2L4

L1L5

Z

86.9

MOUNTING (OPERATING) WEIGHT, LBS (KG)

L3

8.0

203

L6

7171

CONN. TYP.

2436

1919 2207

282.3

95.9

75.5

WEIGHT

OPERATING

VICTAULIC

814

32.1

TYP.

www.DaikinApplied.com 21 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

432

17.0

TYP.

Y

WEIGHT

SHIPPING

UNIT

Figure 32: AGZ225E - AGZ240E

ISOLATOR MOUNTING HOLE LOCATIONS ARE ON BOTTOM SURFACE OF UNIT.

LIFTING WEIGHTS ARE BASED ON UNIT SHIPPING WEIGHTS. MOUNTING

WEIGHTS ARE BASED ON UNIT OPERATING WEIGHT WITH EVAPORATOR

WATER INCLUDED. SHIPPING AND OPERATING WEIGHTS DO NOT INCLUDE

TOP VIEW

WITH COILS

AND FANS

REMOVED

MODEL

AGZ225E

43.7 (1110) 40.7 (1034)

AGZ240E

43.8 (1113) 40.8 (1036)

MODEL

LBS (KG) LBS (KG)

L1 L2 L3 L4 L5 L6 L7 L8

AGZ225E

1419 (644) 1403 (636)1248 (566) 1234 (560)1141 (518) 1128 (512)

AGZ240E

1443 (655) 1433 (650)1260 (572) 1251 (567)1146 (520) 1138 (516)

52

2.0

52

COMPRESSORS

CIRCUIT #1

COMPRESSORS

CIRCUIT #2

2.0

.875 KNOCKOUTS

POWER ENTRY POINTS

FRONT AND RIGHT SIDE

[22]

.875 KNOCKOUTS

FIELD CONTROL

CONNECTIONS

[22]

98.6

2506

92.7

2355

BOX

CG

CONTROL

KNOCKOUTS

.875

22

ARE ON OPPOSITE

POWER ENTRY POINTS

37

1.5

51

2.0

dImensIons and WeIghTs - paCkaged UnITs

8.4

305

127

12.0

213

6.9

175

X

6.5

165

88.0

2235

64

2.5

64

2.5

5.0

80

3.1

292

11.5

DIMENSION DOES NOT

INCLUDE LIFTING BRACKETS

LEFT HAND EVAPORATOR VIEWS SHOWN. SEE SHEET 2 FOR

VIEWS WITH RIGHT HAND EVAP.

NOTES:

1.

PART NUMBER

334547141

Y

SIDE OF CONTROL BOX

315

12.4

M1

L1

95.8

2433

M3

L3

43.8

1114

M5

L5L7

2743

108.0

M7

.75

19

67.4

1711

QTY 8

814

32.1

TYP.

M2

L2

M4

L4

M6

L6L8

INLET

5496

216.4

M8

OUTLET

2685

105.7

CG

INLET

WATER

WATER

OUTLET

EVAPORATOR

432

17.0

TYP.

Y

609

L1

L3

L5

203

L7

24.0

L2

MOUNTING (OPERATING) WEIGHT, LBS (KG)

Z

86.9

2207

L4

54.1

1375

L6

8.0

VICTAULIC

CONN. TYP.

L8

8317

327.4

86.9

2207

LIFTING (SHIPPING) WEIGHT BY CORNER, LBS (KG)

75.5

1919

WEIGHT

OPERATING

WEIGHT

SHIPPING

UNIT

INSTR,CERTIFIED DWG,AGZ-E 14 FANS

M1 M2 M3 M4 M5 M6 M7 M8

1410 (640) 1394 (632)1309 (594) 1294 (587)1262 (572) 1248 (566)1148 (521) 1135 (515)

1433 (650) 1422 (645)1320 (599) 1310 (594)1269 (576) 1259 (571)1141 (518) 1133 (514)

970 (440) 959 (435)

963 (437) 956 (434)

NOTE:

Z

10200 (4627)

10288 (4667)

CG LOCATION IN (MM)

X Y

9501 (4310)

9589 (4349)

UNIT

THE WEIGHTS OF ANY OPTIONS OR ACCESSORIES.

126.6 (3216)

125.9 (3198)

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 22 www.DaikinApplied.com

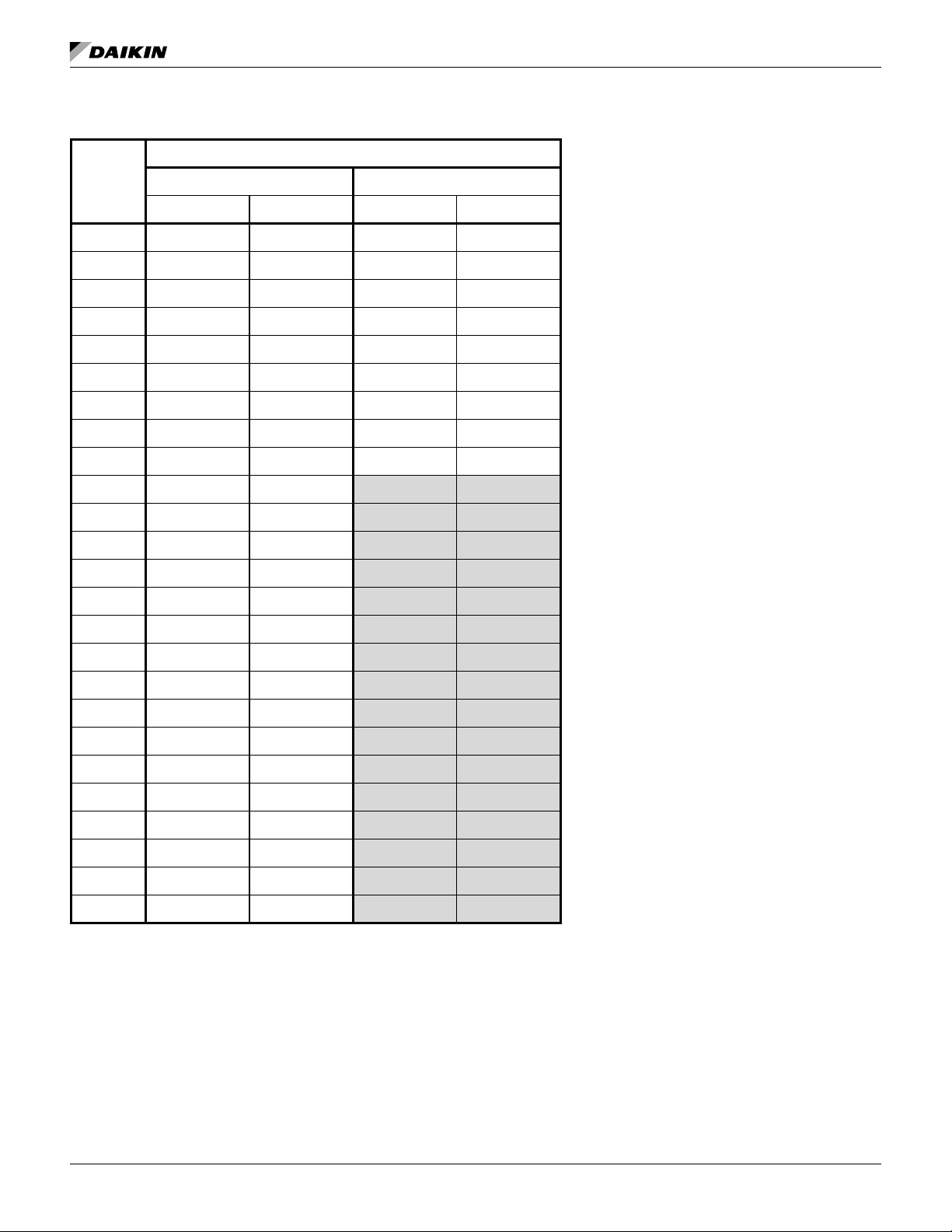

Table 6: Refrigerant Charge - Microchannel Units

Microchannel Coil Unit Operating Charge - lbs (kg)

Unit

Models

030E 17 (7.7) 17 (7.7) 15 (16.8) 15 (16.8)

035E 16 (7.3) 16 (7.3) 14 (6.4) 14 (6.4)

040E 23 (10.5) 23 (10.5) 21 (9.5) 21 (9.5)

045E 23 (10.5) 23 (10.5) 21 (9.5) 21 (9.5)

050E 23 (10.5) 23 (10.5) 21 (9.5) 21 (9.5)

055E 23 (10.5) 23 (10.5) 21 (9.5) 21 (9.5)

060E 23 (10.5) 23 (10.5) 21 (9.5) 21 (9.5)

065E 23 (10.5) 23 (10.5) 21 (9.5) 21 (9.5)

070E 23 (10.5) 23 (10.5) 21 (9.5) 21 (9.5)

075E 46 (20.9) 46 (20.9)

Replaceable Core Filter Drier Sealed Filter Drier

Circuit 1 Circuit 2 Circuit 1 Circuit 2

refrIgeranT Charge

refrIgeranT Charge

080E 46 (20.9) 46 (20.9)

090E 48 (21.8) 48 (21.8)

100E 49 (22.3) 49 (22.3)

110E 64 (29.1) 64 (29.1)

120E 65 (29.5) 65 (29.5)

130E 65 (29.5) 65 (29.5)

140E 76 (34.5) 76 (34.5)

150E 76 (34.5) 76 (34.5)

161E 78 (35.4) 78 (35.4)

170E 80 (36.3) 80 (36.3)

180E 80 (36.3) 80 (36.3)

190E

210E

225E 110 (49.9) 110 (49.9)

240E 114 (51.8) 114 (51.8)

90 (40.9) 90 (40.9)

94 (42.7) 94 (42.7)

www.DaikinApplied.com 23 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

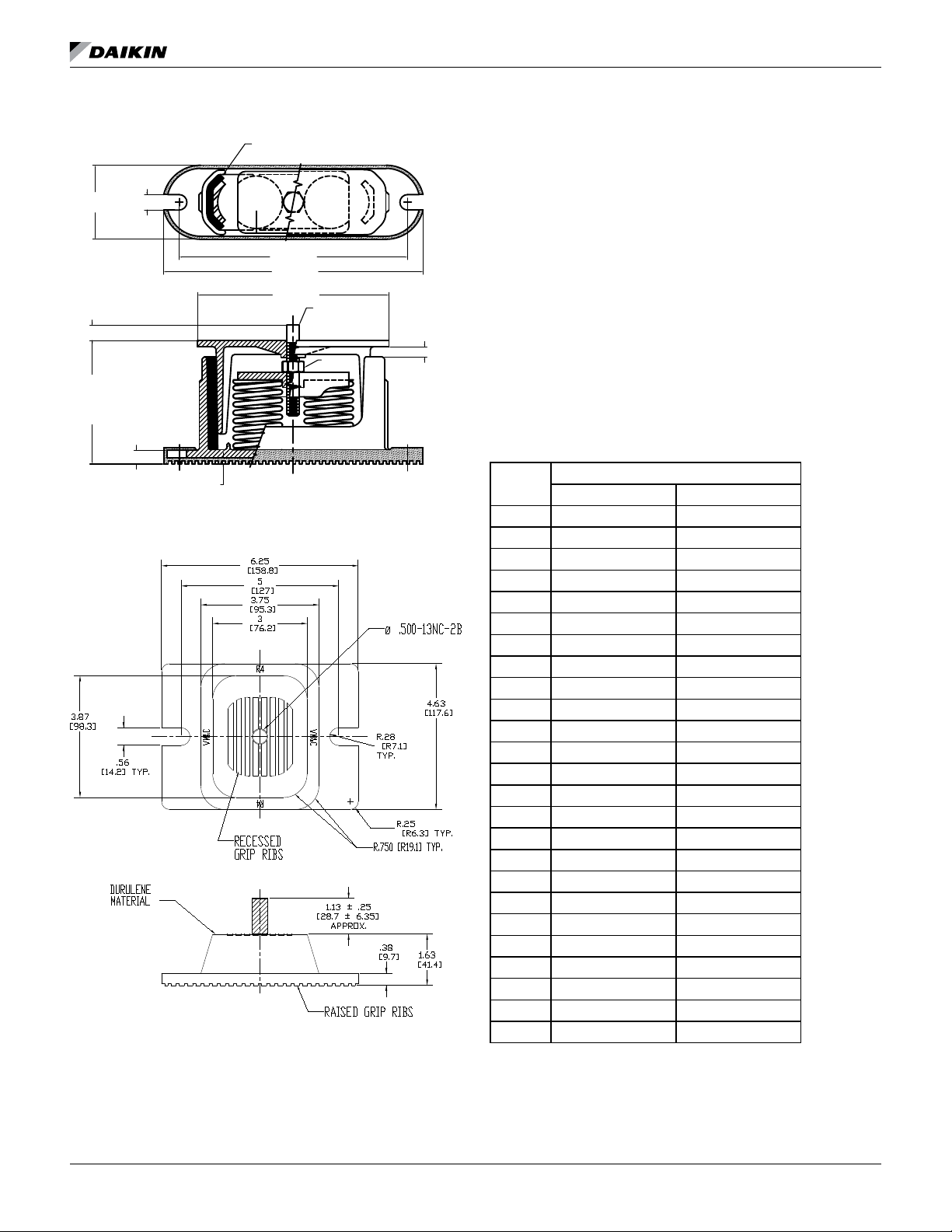

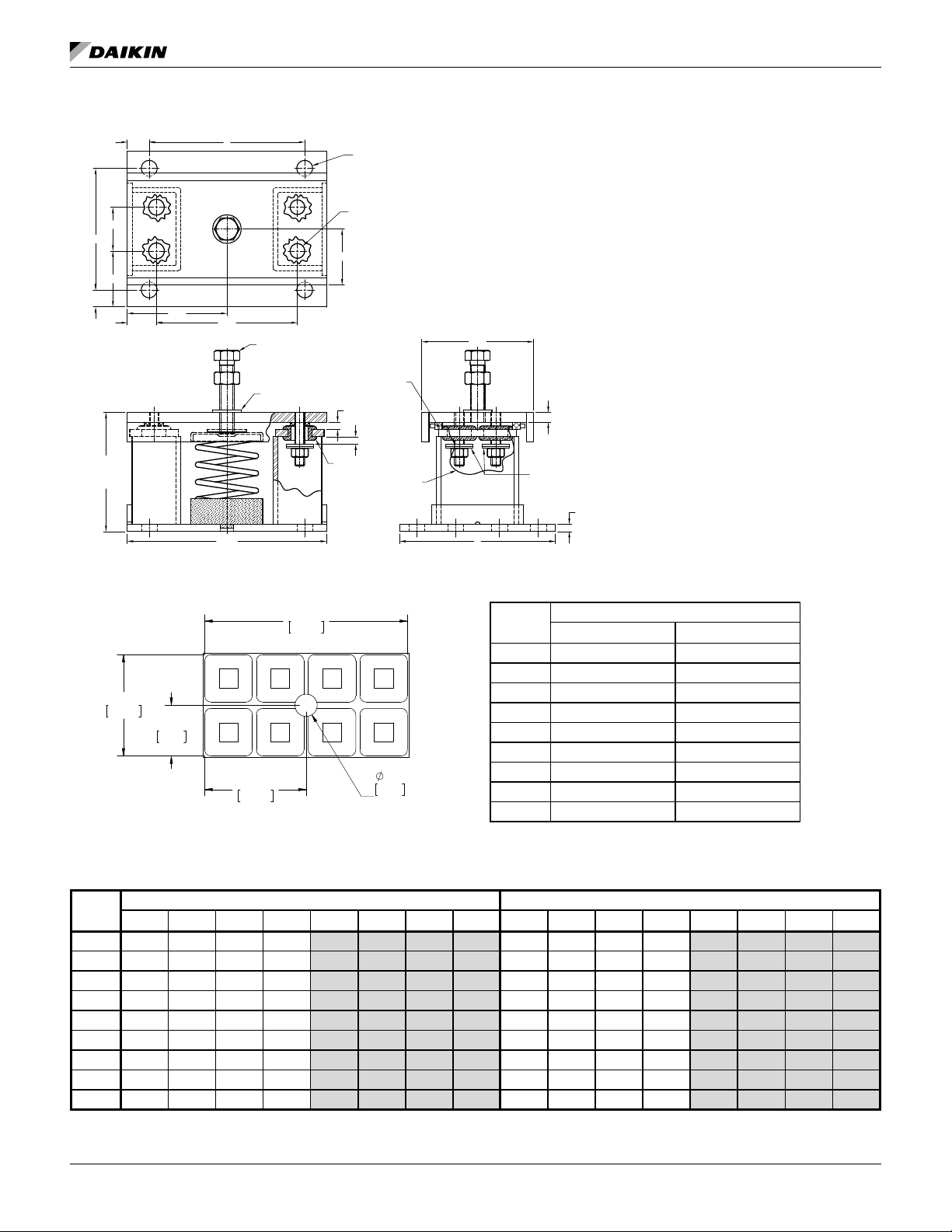

Figure 33: Spring Isolator

OPER. HT.

ELASTOMERIC PAD

.25 TO .5 GAP

3

.62 [15.8]

[76.2]

.625

[15.9]

5

6.2

[127.0]

FREE HT.

5\X [127.0]

ELASTOMERIC

SNUBBER

9.25 [235.0]

10.5 [266.7]

7.75 [196.9]

.5 [12.7] DIA.

POSITIONING

PIN

ADJ. BOLT

[6.4 to 12.7]

IsolaTor InformaTIon

IsolaTor InformaTIon

In all cases, set the unit in place and level. When spring

isolators are required, install springs running under the main

unit supports. Unit should be installed on blocks or shims at the

listed free height. Isolator springs should not be loaded until the

installation is complete, then adjust the springs to the vendor

listed compression for the load point.

Installation of spring isolators requires exible piping

connections and at least three feet of exible electrical conduit

to avoid straining the piping and transmitting vibration and

noise.

Mounting locations for each model can be found in the

“Dimensions and Weights - Packaged Units” section of this

document, starting on page 15.

Optional seismic isolator information begins on page 26

Contact a Daikin Applied sales representative for isolator

information related to units with other n materials.

.56 [14.3]

.25 [6.4]

Figure 34: Rubber-in-Shear (RIS) Isolator

Table 7: Isolator Kits

AGZ-E

Model

030 332320102 332325101

035 332320102 332325101

040 332320102 332325101

045 332320132 332325101

050 332320132 332325101

055 332320132 332325101

060 332320132 332325101

065 332320132 332325101

070 332320132 332325101

075 332320117 332325101

080 332320117 332325101

090 332320117 332325101

100 332320117 332325101

110 332320123 332325113

120 332320124 332325113

130 332320124 332325113

140 332320106 332325113

150 332320106 332325113

161 332320111 332325113

170 332320111 332325113

180 332320111 332325113

190 332320108 332325114

210 332320108 332325114

225 332320126 332325114

240 332320126 332325114

Microchannel - Packaged Units

Spring Isolators RIS Isolators

IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS 24 www.DaikinApplied.com

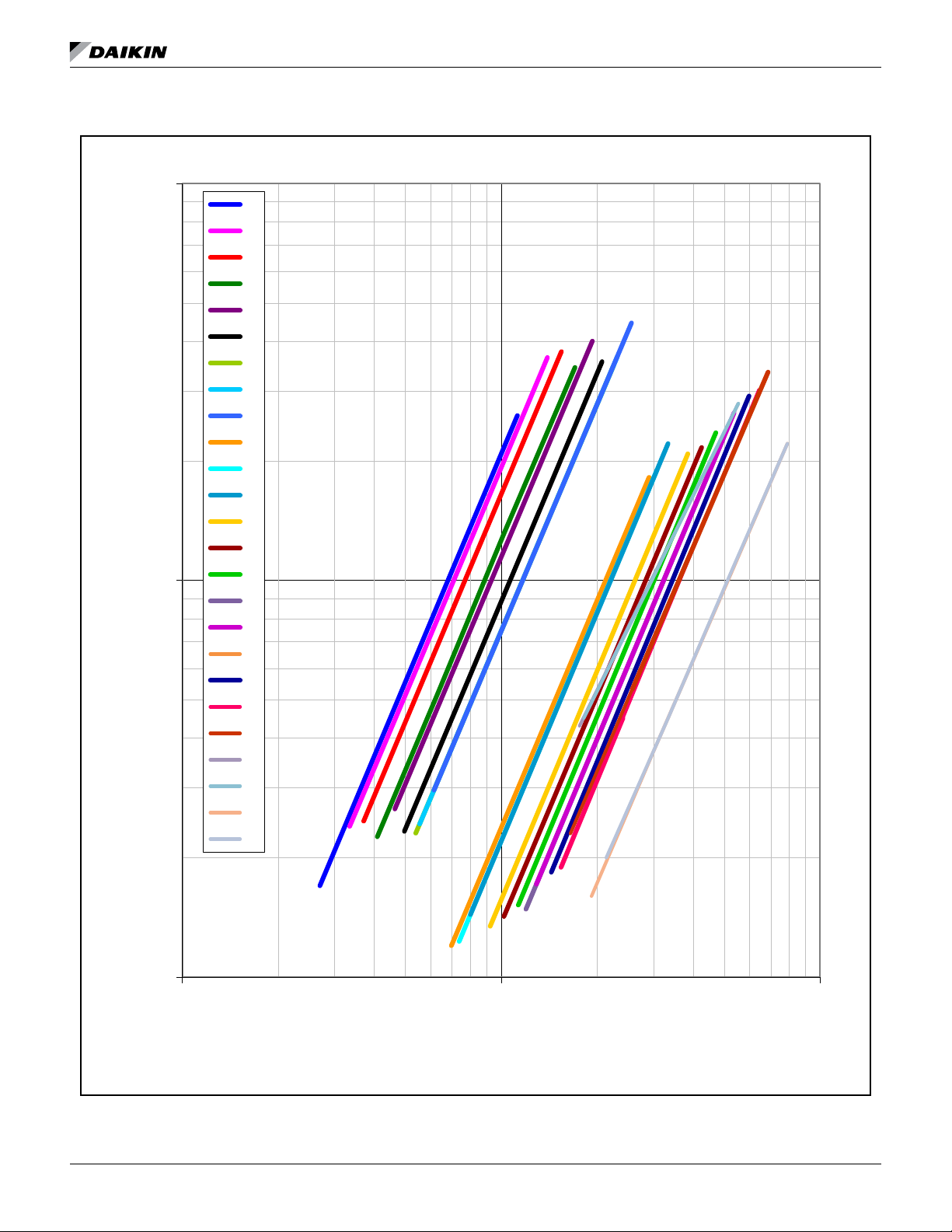

Table 8: Isolator Information - Microchannel Units

AGZ-E

Model

030

035

040

045

050

055

060

065

070

075

080

090

100

110

120

130

140

150

161

170

180

190

210

225

240

M1 M2 M3 M4 M5 M6 M7 M8 M1 M2 M3 M4 M5 M6 M7 M8

Brown Brown Brown Brown Dark Grn Dk Prple Black Black

Brown Brown Brown Brown Dark Grn Dk Prple Black Black

Brown Brown Brown Brown Dark Grn Dk Prple Black Black

Brown Brown Brown Brown Dark Grn Dk Prple Dk Prple Black

Brown Brown Brown Brown Dark Grn Dk Prple Dk Prple Black

Brown Brown Brown Brown Dark Grn Dk Prple Dk Prple Black

Brown Brown Brown Brown Dark Grn Dk Prple Dk Prple Black

Brown Brown Brown Brown Dark Grn Dk Prple Dk Prple Black

Brown Brown Brown Brown Dark Grn Dk Prple Dk Prple Black

Brown Brown Brown Brown Dark Grn Dark Grn Dark Grn Dark Grn

Brown Brown Brown Brown Dark Grn Dark Grn Dark Grn Dark Grn

Brown Brown Brown Brown Dark Grn Dark Grn Dark Grn Dark Grn

Brown Brown Brown Brown Dark Grn Dark Grn Dark Grn Dark Grn

Red Red Brown Brown Brown Brown Dark Grn Dark Grn Dk Prple Dk Prple Red Red

Red Red Brown Brown Brown Brown Gray Gray Dk Prple Dk Prple Red Red

Red Red Brown Brown Brown Brown Gray Gray Dk Prple Dk Prple Red Red

Red Red Brown Brown Brown Brown Dark Grn Dark Grn Dark Grn Dark Grn Dk Prple Dk Prple

Red Red Brown Brown Brown Brown Dark Grn Dark Grn Dark Grn Dark Grn Dk Prple Dk Prple

Red Red Brown Brown Brown Brown Gray Gray Dark Grn Dark Grn Dark Grn Dark Grn

Red Red Brown Brown Brown Brown Gray Gray Dark Grn Dark Grn Dark Grn Dark Grn

Red Red Brown Brown Brown Brown Gray Gray Dark Grn Dark Grn Dark Grn Dark Grn

Red Red Brown Brown Brown Brown Brown Brown Gray Gray Dark Grn Dark Grn Dark Grn Dark Grn Black Black

Red Red Brown Brown Brown Brown Brown Brown Gray Gray Dark Grn Dark Grn Dark Grn Dark Grn Black Black

Red Red Brown Brown Brown Brown Brown Brown Gray Gray Dark Grn Dark Grn Dark Grn Dark Grn Dark Grn Dark Grn

Red Red Brown Brown Brown Brown Brown Brown Gray Gray Dark Grn Dark Grn Dark Grn Dark Grn Dark Grn Dark Grn

Rubber-In-Shear (RIS) Mounts Spring Isolator Mountings

IsolaTor InformaTIon

www.DaikinApplied.com 25 IOM 1206-6 • TRAILBLAZER™ MODEL AGZ CHILLERS

Figure 35: Seismic Spring Isolators

2 1/4 [57]

6 1/4 [159]

2 7/8 [73]

7/8 [22]

6 1/8 [156]

FREE &

OPERATING

HEIGHT

1 1/8

[29]

5 1/8

[130]

[38]

[203]

7 1/41 1/2

[184]

8

3/4 [19] REMOVABLE

ADJUSTING BOLT

3/4 [19] STD.WASHER

(BY OTHERS)

[21]

13/16 DIA HOLE FOR

ATTACHMENT TO

CONCRETE (6 TYP)

(BASE PLATE)

[19]

3/4 DIA HOLE FOR

ATTACHMENT TO

STEEL (4 TYP)

(VIEW CUT AWAY FOR CLARITY)

2 7/8 [73]

STEEL SHIM

(REMOVE AFTER

SPRING ADJUSTMENT)

3/8 [10] GAP

1/4 - 3/8 [6 - 10]

ELASTOMERIC

SNUBBER

SHIPPING SPACER

ASSY STRAP

(NOT SHOWN

IN OTHERVIEWS

FOR CLARITY )

5 3/4

[146]

1/2 [13]

LIMIT STOPS

(NOT SHOWN

IN TOP VIEW

FOR CLARITY )

IsolaTor InformaTIon

3/8 [10]

10 1/4 8

[260]

[203]

Figure 36: Seismic Neoprene Isolation Pads Table 9: Seismic Isolator Kit Numbers

Packaged Unit - Aluminum Fins

Neoprene Pads Spring Isolators

4.00

101.6

2.00

50.8

4.00

101.6

8.00

203.2

.875

22.2

THRU

ALL

AGZ-E

Model

030 334549001 334548801

035 334549001 334548801

040 334549001 334548801

045 334549001 334548801

050 334549001 334548801

055 334549001 334548801

060 334549001 334548801

065 334549001 334548801

070 334549001 334548802

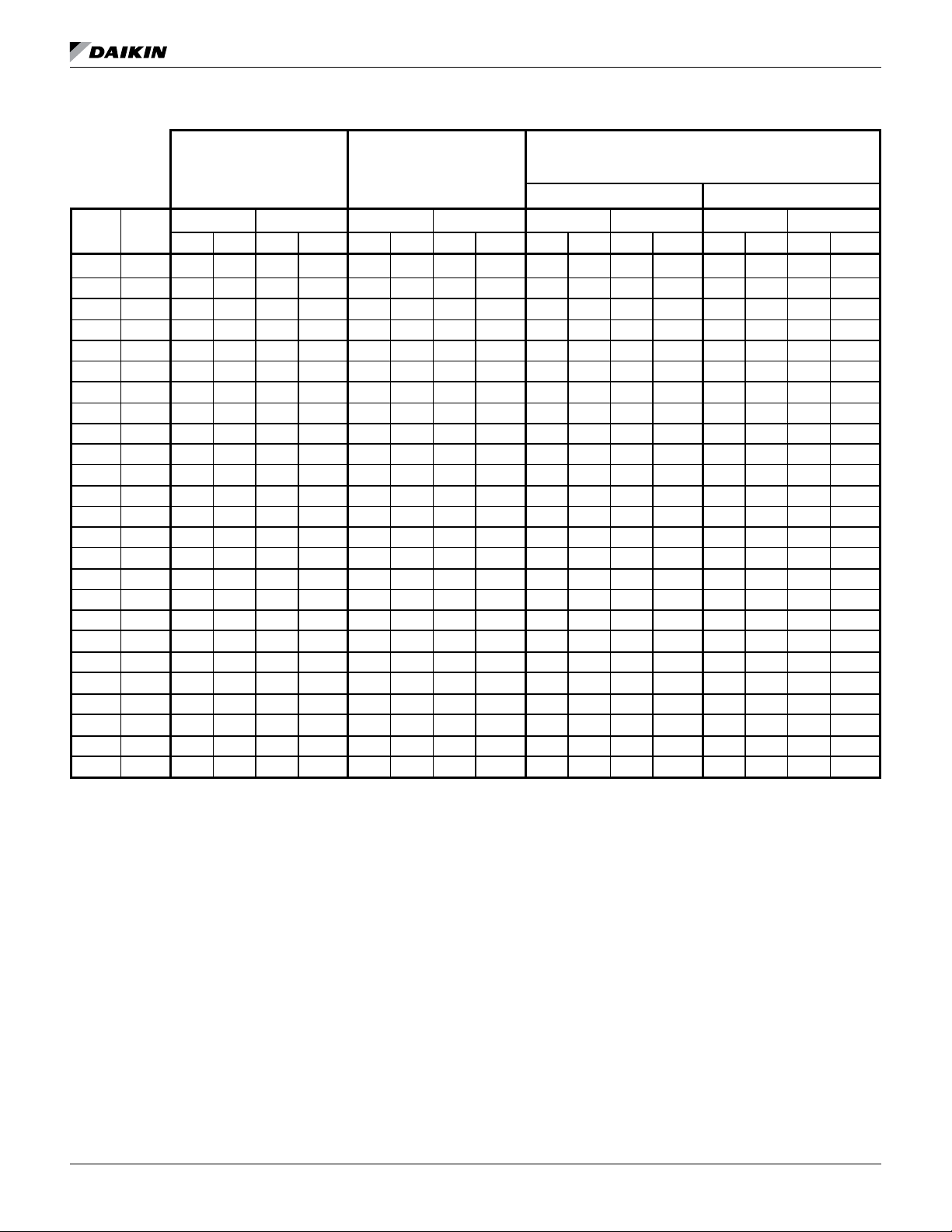

Table 10: Seismic Isolator Information

AGZ-E

Model

030

035

040

045

050

055

060

065

070

M1 M2 M3 M4 M5 M6 M7 M8 M1 M2 M3 M4 M5 M6 M7 M8

Brown Brown Brown Brown Pink Pink Tan Tan