Goodman AGZ075DB Installation Manual

Installation and Maintenance Manual IM 1165-1

Air-Cooled Scroll Compressor Chiller

Group: Chillers

Part Number: IM1165-1

Date: June, 2015

AGZ075DH - AGZ190DH (Rev 0A), Packaged Chillers

AGZ075DB - AGZ190DB (Rev 0A), Chillers with Remote Evaporators

R-410A, 50/60 Hz

.

© 2015 Daikin Applied

Installation and Application Information . . . . . . . . 3

Modbus

*AHRI Certification and ETL Listing apply to 60Hz models only

©2015 Daikin Applied. Illustrations and data cover the Daikin Applied product at the time of publication and we reserve the right to make

changes in design and construction at anytime without notice.

Remote Evaporators . . . . . . . . . . . . . . . . . . . . . . . 13

Dimensions - Packaged . . . . . . . . . . . . . . . . . . . . . 21

Dimensions - Remote Evaporator Models . . . . . . 26

Lifting and Mounting Weights . . . . . . . . . . . . . . . . 31

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Physical Data - Remote Evaporator . . . . . . . . . . . 40

Pressure Drop Data. . . . . . . . . . . . . . . . . . . . . . . . 44

Electrical Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Field Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . 46

Electrical Information . . . . . . . . . . . . . . . . . . . . . . 48

Startup and Shutdown Procedures and Component

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Warranty Registration Form (Scroll) . . . . . . . . . . 57

Hazard Identification

DANGER

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage, severe personal injury, or death if not avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or equipment damage if not avoided.

2 IM 1165-1

©2015 Daikin Applied Form SF01017 P/N 331977001 22APR2015

Pre-Start Checklist – Scroll Compressor Chillers

Must be completed, signed and provided to Daikin Applied at least 2 weeks prior to requested start date.

Job Name

Installation Location

Customer Order Number

Model Number(s)

G.O. Number(s)

Chilled Water

Yes

No

N/A

Initials

Piping Complete

Water strainer : Shell & Tube Evaporators 0.125”(3.2mm) or smaller perforations

Brazed Plate Evaporator 0.063” (1.6mm) or smaller perforations

Water System filled, flushed and vented

Pumps installed and operational (rotation checked, strainers cleaned)

Controls operational (3-way valves, face/bypass dampers, bypass valves, etc.)

Water system operated and tested; flow meets unit design requirements

Flow switch installed and wired

Vent installed on evaporator

Glycol at design %

Electrical

Yes

No

N/A

Initials

Building controls operational

*Power leads connected to power block or optional disconnect

Power leads have been checked for proper phasing and voltage

All interlock wiring complete and compliant with Daikin specifications

Power applied at least 24 hours before startup

Oil heaters energized at least 24 hours before startup

Chiller components (EXV Sensors Transducers) installed and wired properly.

*Wiring complies with National Electrical Code and local codes (See Notes)

Remote EXV wired with shielded cable

Miscellaneous

Yes

No

N/A

Initials

Unit control switches all off

Remote Evaporator /Condenser Piping factory reviewed

All refrigerant components/piping leak tested, evacuated and charged

Thermometers, wells, gauges, control, etc., installed

Minimum system load of 80% capacity available for testing/adjusting controls

Document Attached: Technical Breakdown from Selection Software

Document Attached: Final Order Acknowledgement

Document Attached: Remote piping approval

Notes: The most common problems delaying start-up and affecting unit reliability are:

1.

Field installed compressor motor power supply leads too small. Questions: Contact the local

Daikin sales representative*. State size, number and

type of conductors and conduits installed:

a. From Power supply to chiller

* Refer to NEC Article

430-22 (a)

2.

Remote Evaporator piping incomplete or incorrect. Provide approved piping diagrams.

3. Items on this list incorrectly acknowledged resulting in delayed start and possible extra expenses incurred by return trips.

Contractor Representative

Daikin Applied Sales Representative

Signed:

Signed:

Name:

Name:

Company:

Company:

Date:

Date:

Phone/Email:

Phone/Email:

Installation and Application Information

A

G Z XXX D H

Air-Cooled

Global Design

Scroll Compressor

Nominal Tons

Application

Design Vintage

H = Standard Packaged

B = Remote Evaporator

Blocking is required

across full width

All rigging loc ation s

mu st be used.

Spreader ba rs

required

(u se cautio n)

Number of fans may vary

from this diagram. The lifting

method will remain the same.

Spreader ba rs

required

(u se cautio n)

Installation and Application Information

Chiller Nomenclature

WARNING

Installation is to be performed by qualified personnel who are familiar with local codes and regulations.

CAUTION

Sharp edges on unit and coil surfaces are a potential hazard to personal safety. Avoid contact with them.

General Description

Daikin air-cooled water chillers are complete, self-contained,

automatic chiller units designed for outdoor installation.

Packaged units are completely assembled, factory wired,

charged, and tested. Remote evaporator units require field

refrigerant piping, pressure testing, evacuation, charging with

field-supplied refrigerant and field control wiring.

The electrical control center includes all equipment protection

and operating controls necessary for dependable automatic

operation.

Additional Manuals

This manual covers the installation, of dual circuit, AGZ-DH

packaged, scroll compressor chillers using R-410A.

Operating and maintenance information is contained in the

current version of operating manual OMM 1166, available at

www.DaikinApplied.com.

Inspection

Check all items carefully against the bill of lading. Inspect all

units for damage upon arrival. Report shipping damage and

file a claim with the carrier. Check the unit nameplate before

unloading, making certain it agrees with the power supply

available. Daikin Applied is not responsible for physical

damage after the unit leaves the factory.

Figure 1: Suggested Pushing Arrangment

Figure 2: Required Lifting Arrangement

Handling

Be careful to avoid rough handling of the unit. Do not push or

pull the unit from anything other than the base. Block the

pushing vehicle away from the unit to prevent damage to the

sheet metal cabinet and end frame (see Figure 1).

To lift the unit, 2-1/2" (64mm) diameter lifting eyes are

provided on the base of the unit. Arrange spreader bars and

cables to prevent damage to the condenser coils or cabinet (see

Figure 2).

IM 1165-1 3

CAUTION

All lifting locations must be used to prevent damage to unit.

Installation and Application Information

Operating and Standby Limits

Table 1: Operating Limits

Maximum standby ambient temperature 130°F (55°C)

Maximum operating ambient temperature 105°F (40°C)

-with optional high ambient package (see information under High Ambient Operation‚ page 11 125°F (52°C)

Minimum operating ambient temperature (standard control) 35°F (2°C)

Minimum operating ambient temperature (with optional low-ambient control) -10°F (-23°C)

Leaving chilled water temperature 40°F to 60°F (2°C to 16°C)

Leaving chilled fluid temperatures (with anti-freeze) - Unit unloading is not permitted with fluid

leaving temperatures below 25°F (-4°C). When ambient air temperature is above 100º F, minimum

leaving chilled fluid temperature (with antifreeze) is 25°F (4°C)

Operating chilled water delta-T range 6°F to 16°F (3.3°C to 8.9°C)

Maximum evaporator operating inlet fluid temperature 76°F (24°C)

Maximum evaporator non-operating inlet fluid temperature 100°F (38°C)

15°F to 60°F (-9°C to 16°C)

Unit Placement

AGZ units are for outdoor applications and can be mounted

either on a roof or at ground level. For roof mounted

applications, install the unit on a steel channel or I-beam frame

to support the unit above the roof. For ground level

applications, install the unit on a substantial base that will not

settle. Use a one-piece concrete slab with footings extended

below the frost line. Be sure the foundation is level within 0.5”

(13mm) over its length and width. The foundation must be

strong enough to support the weights listed in the Physical

Data Tables beginning on page 36.

Service Clearance

Sides: Minimum of 4 feet (1.22 m)

Control panel end: Minimum of 4 feet

Opposite control panel:

• Minimum 4 feet on models 075 to 130;

• 12 feet on models 140-190 (allows clearance to remove

the evaporator ).

Air Clearance

Daikin's advanced “W” coil design and open air-passage ends

allow very close unit spacing and a small installation footprint.

The AGZ-D fans are canted inward and reduce recirculation

by directing discharge air to the center of the unit, reducing the

tendency to flow outward and spill over into the coil inlet.

Sufficient clearance must be maintained between the unit and

adjacent walls or other units to allow the required unit air flow

to reach the coils. Failure to do so will result in a capacity

reduction and an increase in power consumption. No

obstructions are allowed above the unit at any height.

Spacing Requirements

In general, with a small performance penalty in some cases,

AGZ-D units can be spaced at four feet from other units or a

wall. Curves on the following pages give the minimum

clearance for different types of installations and also capacity

reduction and power increase if closer spacing is used.

4 IM 1165-1

Installation and Application Information

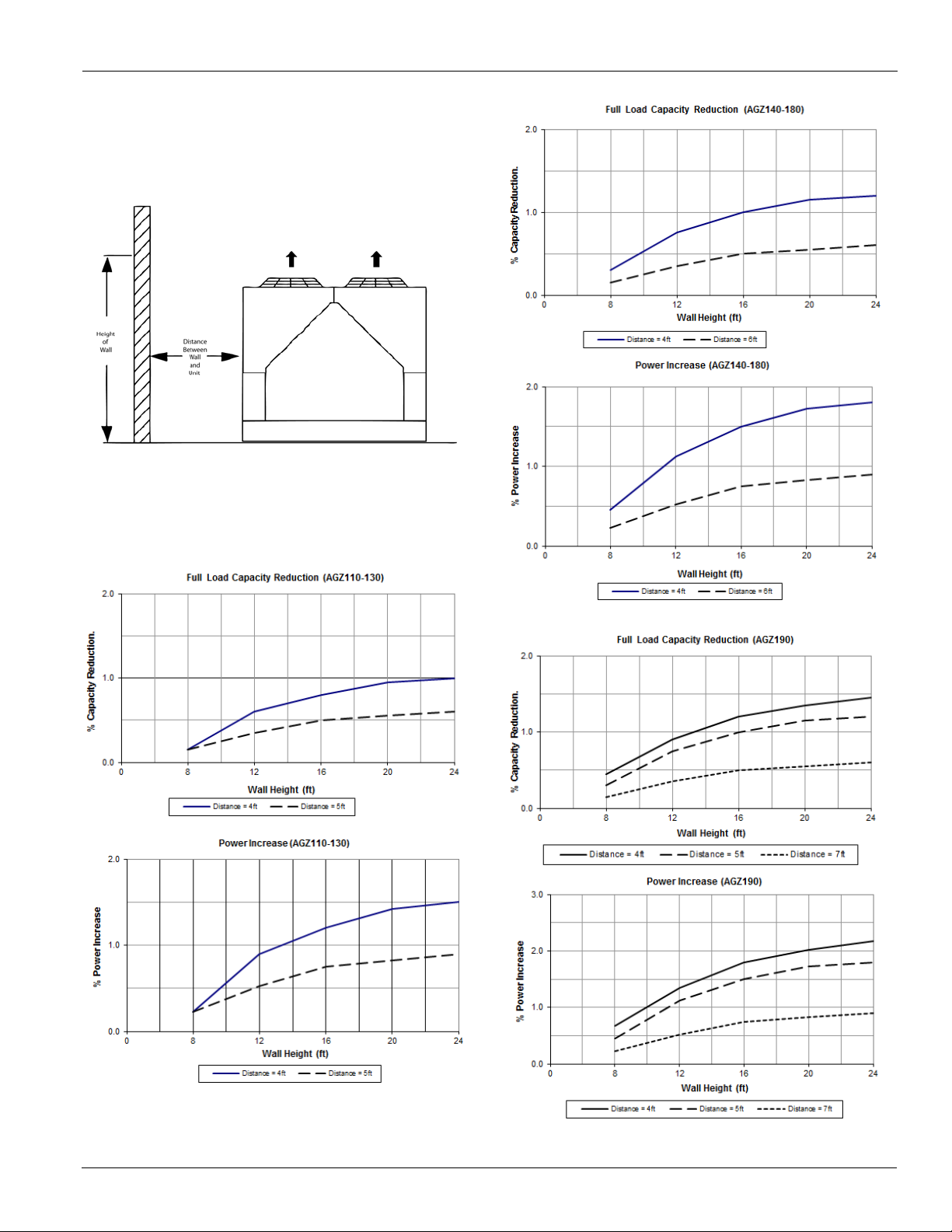

Case 1: Wall on One Side

In this case a solid wall up to 24-feet is considered. (For walls

higher than 24 ft., use the 24-foot values.) Also use these

charts for an adjacent building. For perforated screening walls,

use Case 4. Spacing is differentiated by unit size families.

Figure 3: Wall on One Side of Unit

Note: Maintain a minimum of 4-feet on all sides; except models

140-190, which require 12-feet opposite the control

panel to remove the evaporator.

For models AGZ 075-100: use 4 feet from any height wall. For

models 110-190, use Performance Adjustment curves below.

Figure 4: Case 1 Adjustment Factors (AGZ110D-130D)

Figure 5: Case 1 Adjustment Factors (AGZ140D-180D)

Figure 6: Case 1 Adjustment Factors (AGZ190D)

IM 1165-1 5

Installation and Application Information

Case 2: Two Units, Side-by-Side

Maintain a minimum of 6-feet on all sides; except models 140190, which require 12-feet opposite the control panel to

remove the evaporator.

Figure 7: Case 2 - Two units side by side

For models AGZ 075-100: use 4 feet between units. For

models 110-190, use Performance Adjustment chart in

Figure 8.

Figure 8: Case 2 Adjustment Factors

Case 3: Three or More Units, Side-by-Side

Maintain a minimum of 6-feet on all sides; except models 140190, which require 12-feet opposite the control panel to

remove the evaporator. For more than three units, allow an

additional 2-feet clearance between units.

Figure 9: Case 3 - 3 units side by side

Data is for the middle unit - with a unit on each side. See Case

2, page 6 for Adjustment Factors for the two outside units.

Figure 10: Case 3 Adjustment Factors

6 IM 1165-1

Installation and Application Information

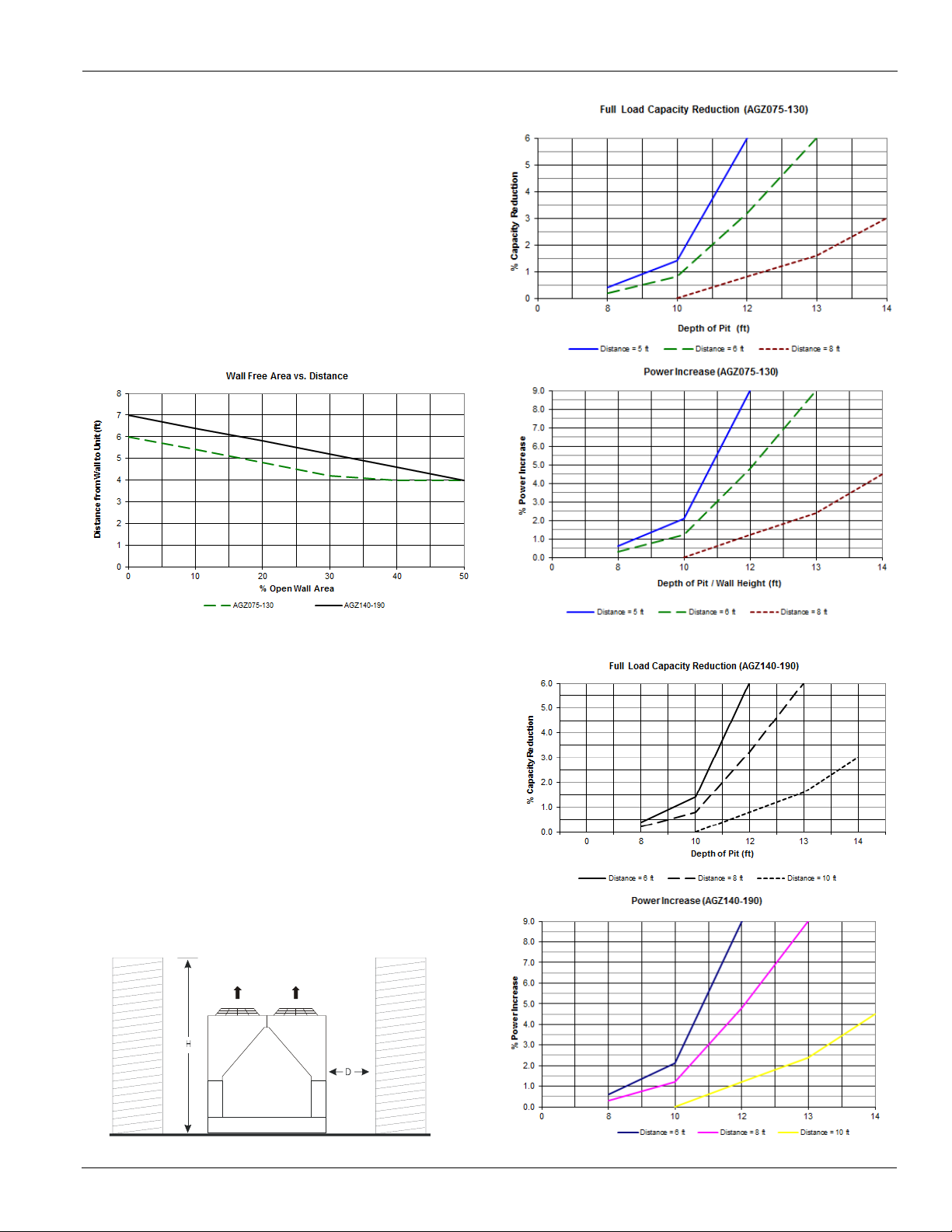

Case 4: Open Screening Walls

Decorative screening walls are often used to help conceal a

unit either on grade or on a rooftop. Design these walls such

that the combination of their open area and distance from the

unit do not require performance adjustment. It is assumed that

the wall height is equal to or less than the unit height when

mounted on its base support. If the wall height is greater than

the unit height, see Case 5, Pit Installation. The distance from

the sides of the unit to the side walls must be sufficient for

service, such as opening control panel doors. For uneven wall

spacing, the distance from the unit to each wall can be

averaged providing no distance is less than 4 feet. Values are

based on walls on all four-sides.

Figure 11: Case 4 Adjustment Factor

Figure 13: Case 5 Adjustment Factors (AGZ075D-130D)

Case 5: Pit Installation

Figure 14: Case 5 Adjustment Factors (AGZ140D-190D)

Pit installations can cause operating problems from air

recirculation and restriction, and require care that sufficient air

clearance is provided, safety requirements are met and service

access is provided. Pit covers must have abundant open area at

least equal to the chiller footprint. A solid wall surrounding a

unit is essentially a pit and this data should be used.

Steel grating is sometimes used to cover a pit to prevent

accidental falls or trips into the pit. The grating material and

installation design must be strong enough to prevent such

accidents, yet provide abundant open area to avoid

recirculation problems. Have any pit installation reviewed by

the Daikin Applied sales representative prior to installation to

ensure it has sufficient air-flow characteristics, and approved

by the installation design engineer to avoid risk of accident.

Figure 12: Case 5 - Pit Installation

IM 1165-1 7

Installation and Application Information

Chilled Water Piping

CAUTION

To prevent damage to the evaporator and potential chiller

failure, a supply strainer is required in the inlet water piping

which connects to this evaporator. This strainer must be

installed prior to operation of the chilled liquid pumps.

Field installed water piping to the chiller must include:

• A cleanable strainer installed at the water inlet to the

evaporator to remove debris and impurities before they

reach the evaporator. Install cleanable strainer within 5

feet (1500 mm) of pipe length from the evaporator inlet

connection and downstream of any welded connections

(no welded connections between strainer and evaporator). See Inlet Strainer Guidelines for more information

including required perforation size.

• A water flow switch must be installed in the horizontal

piping of the supply (evaporator outlet) water line to

avoid evaporator freeze-up under low or no flow conditions. The flow switch may be ordered as a factoryinstalled option, a field-installed kit, or may be supplied

and installed in the field. See page 11 for more informa-

tion.

• Piping for units with brazed-plate evaporators must have

a drain and vent connection provided in the bottom of

the lower connection pipe and to the top of the upper

connection pipe respectively, see Figure 16. These evaporators do not have drain or vent connections due to their

construction. Shell-and-tube evaporators have a drain

located on the bottom of the evaporator. They are

drained of water in the factory and shipped with evaporator drain plugs removed, stored in the control panel or

with an open ball valve in the drain holes. Be sure to

replace plugs or close the valves prior to filling the shelland-tube evaporator with fluid.

• Purge air from the water system before unit start-up to

provide adequate flow through the evaporator.

• Adequate piping support, independent from the unit, to

eliminate weight and strain on the fittings and connections.

• Method to read temperatures and pressures entering and

leaving the evaporator for service and performance verifications.

It is recommended

chiller include:

• Thermometers at the inlet and outlet connections of the

evaporator.

that the field installed water piping to the

• Water pressure gauge connection taps and gauges at the

inlet and outlet connections of the evaporator for measuring water pressure drop.

• Shutoff valves are necessary to isolate the unit from the

piping during unit servicing.

• Minimum bends and changes in elevation to minimize

pressure drop.

• An expansion tank or regulating valve to maintain adequate water pressure

• Vibration eliminators in both the supply and return water

lines to reduce transmissions to the building, required

when the unit is mounted on spring isolators.

• Flush the system water piping thoroughly before making

connections to the unit evaporator.

• Piping insulation, including a vapor barrier, helps prevent condensation and reduces heat loss.

• Regular water analysis and chemical water treatment for

the evaporator loop is recommended immediately at

equipment start-up.

Inlet Strainer Guidelines

An inlet water strainer kit must be installed in the chilled water

piping before the evaporator inlet. A few paths are available to

meet this requirement:

1 A field-installed kit shipped-loose with the unit is

available for all unit sizes and consists of:

• Y-type area strainer with 304 stainless steel perforated

basket, Victaulic pipe connections and strainer cap.

• Extension pipe with (2) Schrader fittings that can be

used for a pressure gauge and thermal dispersion flow

switch. The pipe provides sufficient clearance from the

evaporator for strainer basket removal.

• ½-inch blowdown valve

• Two grooved clamps

The strainer is sized per Tab le 2 and with the pressure drop

shown in the Strainer Pressure Drop graph. Connection sizes

are given in the Dimensions and Weights section on page 21.

2 A field-supplied strainer that meets specification and

installation requirements of this manual.

Table 2: Strainer Data

AGZ-D Model

075-130 3.0 (76) 0.063 (1.6)

140-190 8.0 (203) 0.125 (3.175)

Strainer Size

in. (mm)

Minimum perforation size

in. (mm)

8 IM 1165-1

Installation and Application Information

Air

Vent

Flow

Switch

Vibration

Eliminators

Drain

Outlet

Inlet

P

Isolation

Valves

Strainer

LEAVING FLUID

TEMP. SENSOR

VENT

3/8” PIPE PLUG

VIBRATION

ELIMINATOR

FLOW

SWITCH

GATE

VALV E

FLOW

FLOW

GATE

VALV E

OUTLET

DRAIN

BALANCING

VALV E

VIBRATION

ELIMINATOR

WATER

STRAINER

VALVED

PRESSURE

GAUGE

PROTECT ALL FIELD PIPING

AGAINST FREEZING

INLET

Figure 15: Strainer Pressure Drop

Water Flow Limitations

Constant Evaporator Flow

The evaporator flow rates and pressure drops shown on page

page 44 are for full load design purposes. The maximum flow

rate and pressure drop are based on a 6°F temperature drop.

Avoid higher flow rates with resulting lower temperature drops

to prevent potential control problems resulting from very small

control bands and limited start up/shut off temperature

changes.

The minimum flow and pressure drop is based on a full load

evaporator temperature drop of 16°F. Evaporator flow rates

below the minimum values can result in laminar flow causing

freeze-up problems, scaling and poor control. Flow rates above

the maximum values will result in unacceptable pressure drops

and can cause excessive erosion, potentially leading to failure.

Variable Evaporator Flow

Reducing evaporator flow in proportion to load can reduce

system power consumption. The rate of flow change should be

a maximum of 10 percent of the flow per minute. For example,

if the maximum design flow is 200 gpm and it will be reduced

to a flow of 140 gpm, the change in flow is 60 gpm. Ten

percent of 200 gpm equals 20 gpm change per minute, or a

minimum of three minutes to go from maximum to minimum.

Do not reduce flow lower than the minimum flows listed in the

evaporator pressure drop section, page 44. The water flow

through the evaporator must remain between the minimum and

maximum values listed on page 44. If flow drops below the

minimum allowable, large reductions in heat transfer can

occur. If the flow exceeds the maximum rate, excessive

pressure drop and tube erosion can occur.

Figure 16: Typical Piping, Brazed-Plate Evaporator (models AGZ075D-130D)

Figure 17: Typical Piping, Shell and Tube Evaporator (models AGZ140D-190D)

IM 1165-1 9

Installation and Application Information

System Water Volume Considerations

All chilled water systems need adequate time to recognize a

load change, respond to that load change and stabilize, without

undesirable short cycling of the compressors or loss of control.

In air conditioning systems, the potential for short cycling

usually exists when the building load falls below the minimum

chiller plant capacity or on close-coupled systems with very

small water volumes. Some of the things the designer should

consider when looking at water volume are the minimum

cooling load, the minimum chiller plant capacity during the

low load period and the desired cycle time for the

compressors. Assuming that there are no sudden load changes

and that the chiller plant has reasonable turndown, a rule of

thumb of "gallons of water volume equal to two to three times

the chilled water gpm flow rate" is often used. A storage tank

may have to be added to the system.

BAS should enable chiller only when there is a cooling

demand.

Evaporator Freeze Protection

Evaporator freeze-up can be a concern in the application of aircooled water chillers. To protect against freeze-up, insulation

and electric heaters are furnished with the unit. Models 140

through 190 have immersion heaters with a thermostat; models

075 through 130 have an external plate heater and thermostat.

They protect the evaporator down to -20°F (-29°C) ambient air

temperature; however, see Chilled Water Pump section for

more information. Although the evaporator is equipped with

freeze protection, it does not protect water piping external to

the unit or the evaporator itself if there is a power failure or

heater cable burnout, or if the chiller is unable to control the

chilled water pumps. Use one of the following

recommendations for additional protection:

1 If the unit will not be operated during the winter, drain

evaporator and chilled water piping and flush with

glycol. Drain and vent connections are provided on the

evaporator to ease draining.

2 Add a glycol solution to the chilled water system to

provide freeze protection. Freeze point should be

approximately 10

temperature.

3 The addition of thermostatically controlled heat and

insulation to exposed piping.

The evaporator heater cable is factory wired to the 115 volt

circuit in the control box. This power should be supplied from

a separate source, but it can be supplied from the control

circuit. Operation of the heaters is automatic through the

ambient sensing thermostat that energizes the evaporator

heaters for protection against freeze-up. Unless the evaporator

is drained in the winter or contains an adequate concentration

ºF below minimum design ambient

of anti-freeze, the disconnect switch to the evaporator heater

must not be open.

Chilled Water Pump

It is important that the chilled water pumps be wired to, and

controlled by, the chiller's microprocessor. When equipped

with optional dual pump output, the chiller controller has the

capability to selectively send the signal to a pump relay (by

others) to start pump A or B or automatically alternate pump

selection and also has standby operation capability. The

controller will energize the pump whenever at least one circuit

on the chiller is enabled to run, whether there is a call for

cooling or not. This helps ensure proper unit start-up sequence.

The pump will also be turned on when the water temperature

goes below the Freeze Setpoint for longer than a specified time

to help prevent evaporator freeze-up. Connection points are

shown in the Field Wiring Diagram on page 46.

CAUTION

Adding glycol or draining the system is the recommended method of

freeze protection. If the chiller does not have the ability to control the

pumps and the water system is not drained in temperatures below

freezing, catastrophic evaporator failure may occur.

Failure to allow pump control by the chiller may cause the

following problems:

1 If any device other than the chiller attempts to start the

chiller without first starting the pump, the chiller will

lock out on the No Flow alarm and require manual reset.

2 If the chiller evaporator water temperature drops below

the “Freeze setpoint” the chiller will attempt to start the

water pumps to avoid evaporator freeze. If the chiller

does not have the ability to start the pumps, the chiller

will alarm due to lack of water flow.

3 If the chiller does not have the ability to control the

pumps and the water system is not to be drained in

temperatures below freezing, the chiller may be subject

to catastrophic evaporator failure due to freezing. The

freeze rating of the evaporator is based on the immersion

heater and pump operation. The immersion heater itself

may not be able to properly protect the evaporator from

freezing without circulation of water.

Low Ambient Operation

Compressor staging is adaptively determined by system load,

ambient air temperature, and other inputs to the MicroTech III

control. A low ambient option with fan VFD allows operation

down to -10° F (-23° C). The minimum ambient temperature is

based on still conditions where the wind is not greater than

five mph. Greater wind velocities will result in reduced

discharge pressure, increasing the minimum operating ambient

temperature.

10 IM 1165-1

Installation and Application Information

FactorCorrectionFlow

T

CapacitykW

×

(l/s) Flow Glycol

High Ambient Operation

AGZ-D units for high ambient operation (105ºF to 125ºF,

40.1ºC to 51.7ºC) require the addition of the optional high

ambient package that includes a small fan with a filter in the

air intake to cool the control panel.

All units with the optional VFD low ambient fan control

automatically include the high ambient option.

Flow Switch

All chillers require a chilled water flow switch to check that

there is adequate water flow through the evaporator and to shut

the unit down if there isn't. There are two options for meeting

this requirement.

1 A factory-mounted thermal dispersion flow switch.

2 A "paddle" type flow switch is available from Daikin

Applied for field mounting and wiring. Wire from switch

terminals Y and R to the unit control panel terminals

shown on the field wiring diagrams, beginning on

page 46. Mount the flow switch in the leaving water line

to shut down the unit when water flow is interrupted. A

flow switch is an equipment protection control and

should never be used to cycle a unit.

Installation should be per manufacturer's instructions included

with the switch . Flow switches should be calibrated to shut off

the unit when operated below the minimum listed flow rate for

the unit as listed on page 44.

There is also a set of normally closed contacts on the switch

that can be used for an indicator light or an alarm to indicate

when a "no flow" condition exists. Freeze protect any flow

switch that is installed outdoors. Differential pressure switches

are not recommended for outdoor installation. They can freeze

and not indicate a no-flow conditions.

Grooved Coupling/Flow Switch Warning

On units with shell-and-tube vessels and with factory-mounted

flow switches and where flange connections (grooved-toflange adaptors or weld-on flanges) are to be used, relocating

the flow switch is required to allow for possible future

replacement. The flange will interfere with unscrewing the

switch. The following procedure is recommended before

installing a flange to avoid interference:

Glycol Solutions

The use of a glycol/water mixture in the evaporator to prevent

freezing will reduce system capacity and efficiency, as well as

increase pressure drop. The system capacity, required glycol

solution flow rate, and pressure drop with glycol may be

calculated using the following formulas and tables.

Delta

−×=18.4

1 Capacity - Multiply the capacity based on water by the

Capacity correction factor from Tab le 3 to Table 6.

2 Flow - Multiply the water evaporator flow by the Flow

correction factor from Table 3 to Ta ble 6 to determine

the increased evaporator flow due to glycol. If the flow is

unknown, it can be calculated from the following

equation:

3 Pressure drop - Multiply the water pressure drop from

Tabl e 2 7 by Pressure Drop correction factor from Tabl e 3

to Table 6. High concentrations of propylene glycol at

low temperatures may cause unacceptably high pressure

drops.

4 Power - Multiply the water system power by Power

correction factor from Tabl e 3 to Table 6.

Test coolant with a clean, accurate glycol solution hydrometer

(similar to that found in service stations) or refractometer to

determine the freezing point. Obtain percent glycol from the

freezing point table below. It is recommended that a minimum

of 25% solution by weight be used for protection against

corrosion or that additional compatible inhibitors be added.

Concentrations above 35% do not provide any additional burst

protection and should be carefully considered before using.

CAUTION

Do not use an automotive-grade antifreeze. Industrial grade

glycols must be used. Automotive antifreeze contains

inhibitors which will cause plating on the copper tubes within

the chiller evaporator. The type and handling of glycol used

must be consistent with local codes.

1.Remove the flow switch and plug the switch opening in the

nozzle.

2.Install the grooved-to-flange adaptor or weld on flange.

3.Relocate the flow switch in the water piping outside the

flange, close enough to it that the wire leads will reach and the

switch can still be unscrewed.

IM 1165-1 11

Installation and Application Information

!

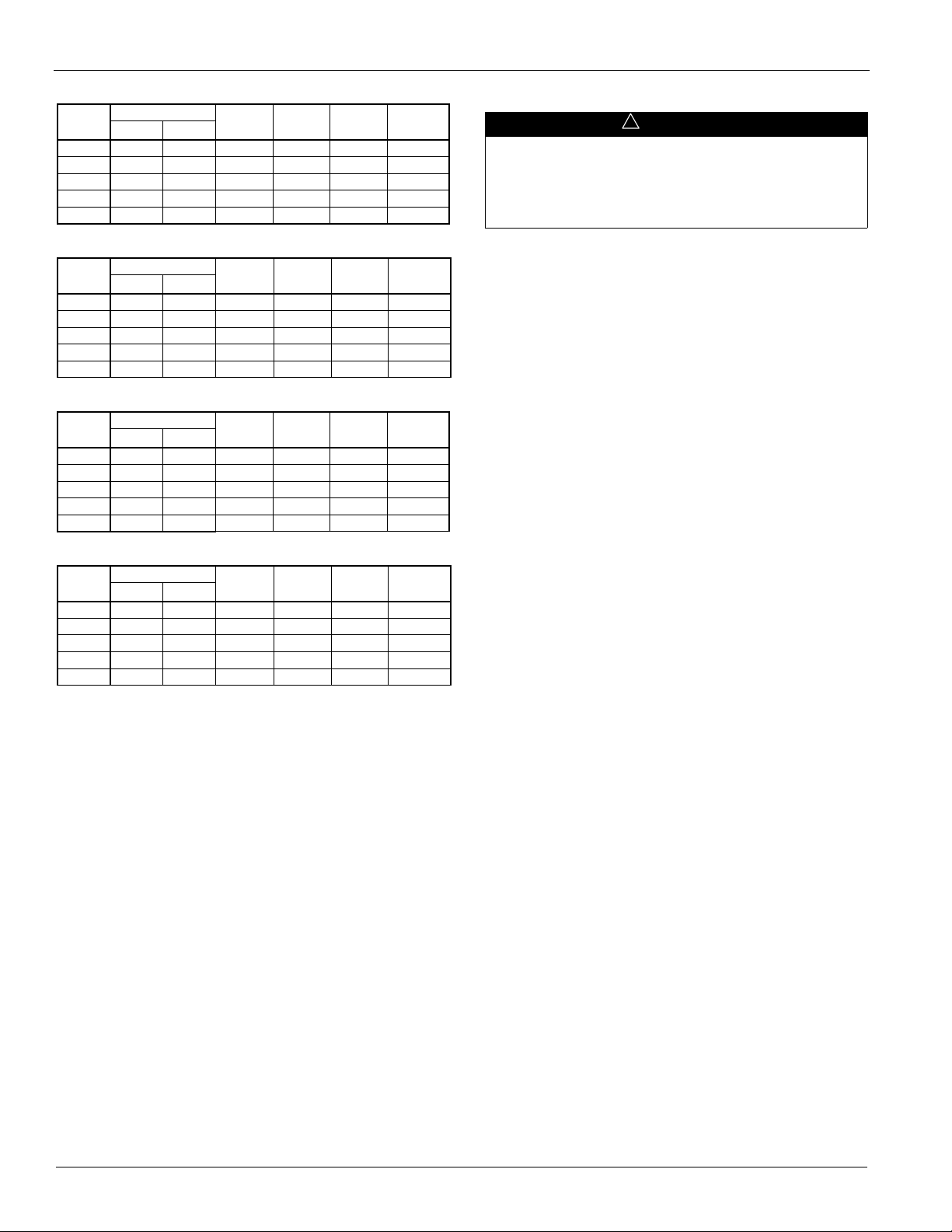

Table 3: Ethylene Glycol Factors-Brazed Plate Evaporator

% E.G.

10 26 -3.3 0.998 0.998 1.036 1.097

20 18 -7.8 0.993 0.997 1.060 1.226

30 7 -13.9 0.987 0.995 1.092 1.369

40 -7 -21.7 0.980 0.992 1.132 1.557

50 -28 -33.3 0.973 0.991 1.182 1.791

Freeze Point

o

o

F

Capacity Power Flow PD

C

Table 4: Propylene Glycol Factors-Brazed Plate Evaporator

% P.G.

10 26 -3.3 0.995 0.997 1.016 1.100

20 19 -7.2 0.987 0.995 1.032 1.211

30 9 -12.8 0.978 0.992 1.057 1.380

40 -5 -20.6 0.964 0.987 1.092 1.703

50 -27 -32.8 0.952 0.983 1.140 2.251

Freeze Point

o

o

F

Capacity Power Flow PD

C

Table 5: Ethylene Glycol Factors-Shell & Tube Evaporator

% E.G.

10 26 -3.3 0.996 0.997 1.036 1.097

20 18 -7.8 0.988 0.994 1.061 1.219

30 7 -13.9 0.979 0.991 1.092 1.352

40 -7 -21.7 0.969 0.986 1.132 1.532

50 -28 -33.3 0.958 0.981 1.182 1.748

Freeze Point

o

o

F

Capacity Power Flow PD

C

Table 6: Propylene Glycol Factors-Shell & Tube Evaporator

% P.G.

10 26 -3.3 0.991 0.996 1.016 1.092

20 19 -7.2 0.981 0.991 1.032 1.195

30 9 -12.8 0.966 0.985 1.056 1.345

40 -5 -20.6 0.947 0.977 1.092 1.544

50 -27 -32.8 0.932 0.969 1.140 1.906

Freeze Point

o

o

F

Capacity Power Flow PD

C

POE Lubricants

WARNING

POE oil must be handled carefully using proper protective

equipment (gloves, eye protection, etc.) The oil must not

come in contact with certain polymers (e.g. PVC), as it may

absorb moisture from this material. Also, do not use oil or

refrigerant additives in the system.

POE type oil is used for compressor lubrication. This type of

oil is extremely hydroscopic which means it will quickly

absorb moisture if exposed to air and may form acids that can

be harmful to the chiller. Avoid prolonged exposure of POE oil

to the atmosphere to prevent this problem. For more details on

acceptable oil types, contact your Daikin Applied service

representative.

It is important that only the manufacturer’s recommended oils

be used. Acceptable POE oil types are:

• CPI/Lubrizol Emkarate RL32-3 MAF

• Copeland Ultra 32-3 MAF

• Parker Emkarate RL32-3MAF

• Virginia LE323MAF

• Nu Calgon 4314-66

12 IM 1165-1

Remote Evaporators

SO FIELD MUST USE MIN 45% SILVER BRAZE ROD.

BRAZE CONNECTIONS ON EVAP ARE STAINLESS STEEL,

CIR. #2

LIQUID

CIR. #1

LIQUID

TEMP SENSOR

LOCATION

CIR. #2

SUCTION

CIR. #1

SUCTION

ENTERING WATER

STAINLESS STEEL

PIPE PLUG

Remote Evaporators

Piping and Application

AGZ-D units have two circuits, each with either two or three

compressors. These circuits must be kept separated throughout

the entire refrigerant piping system. Pipe all lines (suction,

liquid and hot gas bypass, if used) of each evaporator circuit to

a circuit on the outdoor unit. Be careful not to cross-pipe lines.

Evaporator circuit #1 must be piped to the circuit #1

condensing unit . Evaporator circuit #2 must be piped to the

circuit #2 condensing unit.

CAUTION

Refrigerant circuits must be kept isolated from eather

throughout the entire system. For braze plateevaporators, note

that the Circuit #1 Suction Line is located diagonally from

Circuit #1 Liquid Line, and the same for Circuit #2 Liquid and

Suction Lines. See Figure 18.

Figure 18: Location of Connections

The primary concerns related to piping are refrigerant pressure

drop; a solid liquid feed to the expansion valves, continuous

oil return and properly sized refrigerant specialties.

AGZ-D Unit Performance is negatively affected by Suction

Line Pressure Drop Losses. Distance between the AGZ-D unit

and the Remote Evaporator should be kept as short as possible

to minimize the performance derate.

Table 7: Remote Evaporator Piping Limitations

Maximum measured piping distance between the

unit and the remote evaporator

Maximum equivalent Feet of Distance between

the unit and evaporator including elbows and traps

Note: For Installations with Distances exceeding these values Daikin

Applied Technical Responce Center (TRC) must be consulted for

approval of the piping design for factory warranty to be valid

90 ft.

150 ft.

Refrigerant piping is permitted to be installed below ground

provided the following conditions are met:

• Piping or pipe insulation is NOT in contact with the

ground

• Piping is installed in an open or enclosed chase that

allows for inspection and leak testing

• Piping is sized and installed per ASHRAE guidelines

Piping Recommendations

IMPORTANT: Refrigerant piping design must be provided by

a qualified Architect or Systems HVAC Design Engineer

familiar with piping design, as well as local codes and

regulations. The manufacturer recommendations provided here

are to be used as a general guide, but do not replace system

design by a qualified professional. All field piping, wiring, and

procedures must be performed in accordance with ASHRAE,

EPA, local codes, and industry standards.

Proper refrigerant piping can make the difference between a

reliable system and an inefficient, problematic system. See the

recommended field pipe sizes shown in Table 8 and Tabl e 1 0.

For additional information about refrigerant piping techniques

and sizing, see the Daikin Refrigerant Piping Design Guide,

AG 31-011, which can be found on www.DaikinApplied.com.

IM 1165-1 13

WARNING

Improper installation can cause refrigerant migration, flood

back, oil loss, line corrosion, or mechanical failures.

For Installations where the evaporator is installed either above

or below the unit - the following recommendations apply:

Evaporator installed below outdoor unit:

• 30 ft. Maximum Vertical Distance

• Only single riser suction tubing is to be used - Double riser

installations are not permitted

• A suction line trap must be installed at the bottom of the

riser and a second trap at 20 ft. height

Evaporator installed above the AGZ-D Outdoor unit:

• 30 ft. Vertical Distance is the recommended maximum to

prevent loss of liquid subcooling

Installation Guidelines

Insulate the suction line to reduce excessive superheat buildup. Insulate the liquid line, where located in areas above

ambient temperature, to prevent loss of subcooling and

consequent liquid flashing.

The installer must leak test the remote piping with nitrogen at

150 psig maximum pressure, then properly evacuate the piping

systemto 500 microns or below and provide the operating

charge of R-410A. A holding charge of nitrogen/helium is

Remote Evaporators

Unit Model Nom inal Tubing Re commended Suction Line Sizes, OD Copper -based on Eq. ft. Length Max. Suct.

AGZ-DB Tons Per Conn. Riser Line Size

(Rem ote Evap) Circuit Size for Vertical

At Unit Size

F

Size

F

Size

F

Siz e

F

Size

F

Up flo w t o Co m pr .

AGZ075DB

36 2 5/8

2 1/8 0.5 2 1/8 0.8 2 1/8 1.1 2 1/8 1.4 2 1/8 1.6

2 1/8

AGZ080DB

40 2 5/8

2 1/8 0.7 2 1/8 1.0 2 1/8 1.3 2 1/8 1.7 2 1/8 2.0

2 1/8

AGZ090DB

45 2 5/8

2 1/8 0.8 2 1/8 1.2 2 1/8 1.6 2 1/8 2.1 2 1/8 2.5

2 1/8

AGZ100DB

50 2 5/8

2 1/8 1.0 2 1/8 1.5 2 1/8 2.0 2 1/8 2.5 2 1/8 3.0

2 1/8

AGZ110DB

53 2 5/8

2 1/8 1.1 2 1/8 1.7 2 5/8 0.8 2 5/8 1.0 2 5/8 1.2

2 1/8

AGZ125DB

58 2 5/8

2 1/8 1.3 2 1/8 1.9 2 5/8 0.9 2 5/8 1.2 2 5/8 1.4

2 1/8

AGZ130DB

65 2 5/8

2 1/8 1.6 2 5/8 0.9 2 5/8 1.1 2 5/8 1.4 2 5/8 1.7

2 5/8

AGZ140DB

68 2 5/8

2 1/8 1.7 2 5/8 0.9 2 5/8 1.2 2 5/8 1.6 2 5/8 1.9

2 5/8

AGZ160DB

76 2 5/8

2 5/8 0.8 2 5/8 1.1 2 5/8 1.5 2 5/8 1.9 3 1/8 1.0

2 5/8

AGZ180DB

86 2 5/8

2 5/8 1.0 2 5/8 1.4 2 5/8 1.9 2 5/8 2.4 3 1/8 1.2

2 5/8

AGZ190DB

90 2 5/8

2 5/8 1.0 2 5/8 1.5 2 5/8 2.1 2 5/8 2.6 3 1/8 1.3

2 5/8

No te s :

1. PD °F is Press ure Dro p sho wn in degrees F. M ultiply by 2.25 for ps i. Exam ple: 1°F pres sure dro p = 2.2 5 psi.

2. Fo r equivalent lengt hs between t he table values , use t he colum n higher than t he length and calc ulate the pres sure dro p based o n the direct ratio

o f the lengt h com pared to the co lumn value. Example: Fo r 90 ft equivalent leng th, use the c olumn v alue fo r 100 ft t imes 90/ 100 fo r the press ure drop

3. No minal to ns fo r mo dels 80, 125, and 160 units are averaged per c ircuit.

Up to

50 Equiv. Ft 75 Equiv. Ft 100 Equiv. Ft 125 Equiv. Ft 150 Equiv. Ft

Up to Up to Up to Up to

provided for the outdoor section. The brazed-plate evaporators

on Models 075 to 130 have no charge and are not sealed. The

shell-and-tube evaporators on Models 140 to 190 have a

nitrogen holding charge. Holding charges must be removed

prior to the R-410a charging procedure.

The use of double risers for vertical gas risers is not allowed.

Size the vertical riser per Tabl e 8 . Follow ASHRAE

procedures.

Slope the refrigerant lines 1" per 10 feet of horizontal run in

the direction of refrigerant flow to assist oil return.

Avoid using hot gas bypass (or provide condenser fan VFDs)

for applications when operation in ambient temperature below

40ºF is expected. This is necessary to maintain adequate

condensing pressures and liquid refrigerant at the expansion

valve when condenser capacities are at their maximum.

Interconnecting refrigerant piping and total system refrigerant

charge are field supplied and installed. The outdoor unit and

remote evaporator are shipped with a nitrogen holding charge

that must be removed and replaced with R 410A.

Pressure drops in the refrigerant lines should be maintained at

the equivalent feet calculation shown in Tab le 8 and should not

exceed 3°F and line lengths should be made as short as

possible. Follow ASHRAE recommendations. Exceeding these

recommendations will decrease performance and could impact

reliability.

Use caution in sizing the liquid line in applications where the

evaporator is above the outdoor section. The weight of the

liquid refrigerant in the vertical column will decrease the

pressure at the top of the riser (0.43 psi per foot of vertical

rise) allowing some of the refrigerant to flash to a gas.

Adequate refrigerant subcooling is needed at the expansion

valve for proper operation.

Care should be taken while designing piping system to avoid

the draining of condensed refrigerant to the lower component

when normal shutdown procedures do not occur (such as a

power failure).

Location of Liquid Line Filter Drier, Solenoid Valve and

Expansion Valve

These components must be installed adjacent to the Remote

evaporator. The expansion valves must be installed within 12

inches of the Evaporator Inlet Connection and the outlet piping

of the Expansion valve must go directly into the Evaporator

with no bends in between.

The Liquid line Solenoid valves must be installed within 3 ft.

of the evaporator. The Liquid line Solenoid Valve must be

connected to the AGZ cable using a junction box to extend the

wiring to the length required to reach the solenoid.

The Liquid line Filter Drier must be installed at the Remote

Evaporator - upstream of the Liquid Solenoid Valve and

Expansion Valve

A small trap must be provided at the base of each major

vertical gas riser to assist in the collection of oil. If vertical

risers exceed more than 20 feet, install a small trap at the

midpoint and at a maximum of 20 foot intervals.

How to determine performance derate:

Using the model size and the equivalent feet of piping between

the unit and the evaporator, find the Pressure Drop in °F from

Tabl e 8 . Cross-reference the Pressure Drop in °F to Tab le 9 to

find the capacity, power, and EER derate factor.

Table 8: Recommended Horizontal or Downflow Suction Line Size, R-410A

PD

°

14 IM 1165-1

PD

°

PD

°

PD

°

PD

°

Table 9: Performance Derate Factors for Suction Line Pressue Drop

Suction Line Unit Unit

Press. Drop Capacity Power

°F % %

0°F 100.0 100.0

1.0°F 98.5 99.5

2.0°F 97.1 98.9

3.0°F 95.6 98.4

4.0°F 94.1 97.9

5.0°F 92.6 97.4

No te: Data at AH RI Standard Chiller Rat ing Condit ion o f 54.0 F/ 44.0 F

Chiller Inlet and Outlet Wat er Temps and 95.0 F Outdo or A ir Temperature.

Unit

EER

100.0

99

%

98.2

97.2

96.1

95.1

Unit Model Nominal Tubing Re comme nded Liquid Line Sizes, OD Copper

AGZ-DB Tons Conn.

(Remote Evap) Per Size

Circuit At Unit Size

Size

Size

Size

Size

AGZ075DB

36

1 1/8 1 1/8 0.3 1 1/8 0.5 1 1/8 0.6 1 1/8 0.8 1 1/8 1.0

AGZ080DB

40

1 1/8 1 1/8 0.4 1 1/8 0.6 1 1/8 0.8 1 1/8 1.0 1 1/8 1.2

AGZ090DB

45

1 1/8 1 1/8 0.5 1 1/8 0.7 1 1/8 1.0 1 1/8 1.2 1 1/8 1.5

AGZ100DB

50

1 1/8 1 1/8 0.6 1 1/8 0.9 1 1/8 1.2 1 1/8 1.5 1 1/8 1.8

AGZ110DB

53

1 1/8 1 1/8 0.7 1 1/8 1.0 1 1/8 1.3 1 1/8 1.6 1 1/8 2.0

AGZ125DB

58

1 1/8 1 1/8 0.8 1 1/8 1.1 1 1/8 1.5 1 1/8 1.9 1 1/8 2.3

AGZ130DB

65

1 1/8 1 1/8 0.9 1 1/8 1.4 1 1/8 1.9 1 1/8 2.3 1 1/8 2.8

AGZ140DB

68

1 3/8 1 3/8 0.4 1 3/8 0.6 1 3/8 0.8 1 3/8 0.9 1 3/8 1.1

AGZ160DB

76

1 3/8 1 3/8 0.5 1 3/8 0.7 1 3/8 0.9 1 3/8 1.1 1 3/8 1.4

AGZ180DB

86

1 3/8 1 3/8 0.6 1 3/8 0.9 1 3/8 1.1 1 3/8 1.4 1 3/8 1.7

AGZ190DB

90

1 3/8 1 3/8 0.6 1 3/8 0.9 1 3/8 1.2 1 3/8 1.6 1 3/8 1.9

Note s :

1. PD°F is P ressure Drop s hown in degrees F. M ultiply by 4.75 for psi. Exam ple: 1 F degree pressure drop = 4.75 ps i.

2. For equiv alent lengths between the table values, use the co lumn higher than the length and calc ulate the press ure drop based on t he direct ratio

o f the length co mpared to the co lumn value. Example: For 90 f t equivalent length, use the c olumn v alue fo r 100 ft tim es 90/100 for the pressure dro p

3. Nominal to ns fo r models 80, 125, and 160 units are averaged per circuit.

150 Equiv. Ft

Up to

50 Equiv. Ft 75 Equ iv. Ft 100 Equiv. Ft 125 Equiv. Ft

Up to Up to Up to Up to

Table 10: Recommended Liquid Line Size, R-410A

Remote Evaporators

PD°F

Wiring for AGZ-Remote Evaporators

Refrigerant Specialties Kit

Remote Evaporator units include a Refrigerant Specialties Kit

which supplies the following field-installed components:

• Charging valves

• Expansion valves

• Models 075-130 use Thermal Expansion Valves (TXV),

EXV is option

• Models 140-190 use Electronic Expansion Valves (EXV)

and includes M12 cable

• Liquid line solenoid valves and cable

• Liquid line filter driers with filter drier core, clamp, and felt

• Liquid line sight glasses (and saddle adapter for AGZ140-

• Ball valves

• Suction temperature sensor tubes

• Schrader fittings and Schrader core for suction transducers

gasket

190D)

IM 1165-1 15

PD°F

PD°F

Sensor Wiring

The Remote Evaporator AGZ-D Units come with long sensor

wires for the remote evap installation. These wires allow the

evaporator to be installed up to 90 ft. from the AGZ-D unit

without splicing these wires. The sensor wires to the

evaporator include the following :

• Evaporator Water Inlet and Outlet Temperature Sensor

• Suction Line Temperature Sensors for Piping at the

Evaporator for both Circuit #1 and #2

• Suction Transducer Wiring for Installation on Evaporator

Suction Piping for both Circuit #1 and #2

For AGZ140-190D units with Electric Expansion Valves, the

wiring to the evaporator must be spliced using #14 wire gauge

shielded wire.

The factory supplied cable with #18 ga wire is suitable for 30

ft. maximum length. For installations where the evaporator

will be located more than 30 ft from the outdoor unit, the

sensors must be relocated to the Suction Line piping at the

Evaporator for proper unit operation. If the evaporator is

located within 30 linear feet of piping from the outdoor unit,

the two suction temperature sensors can be left on the outdoor

PD°F

PD°F

Remote Evaporators

ADDRESS=3

T1 T3

T2

T4

E.E.X.V.1

123456

ON

ADDRESS=5

T1 T3

T2

T4

E.E.X.V.2

123456

ON

BRN

WHT

BLU

BLK

RED

GRN

WHT

BLK

RED

GRN

WHT

BLK

BLU

BLK

WHT

BRN

M16

902

900

M26

906

901

POL94E.00/MCQ

D01A

C1

D01B

DI1

R1

T3-M

X3

+5V

X1

T3-M

X2

M1-

M2+

M2-

M1+

+24V

24VGNDB-A+

A+ B-

GND

24V

POL94E.00/MCQ

D01A

C1

D01B

DI1

R1

T3-M

X3

+5V

X1

T3-M

X2

M1-

M2+

M2-

M1+

+24V

24VGNDB-A+

A+ B-

GND

24V

W1

W1

W2

W2

EXV-1

1

2

3

4

GTB5

W1

W1

W2

W2

EXV-2

1

2

3

4

GTB5

A2 A1

M16

(438)

(439)

(440)

NC

NO

903

A2 A1

M26

(538)

(539)

(540)

NC

NO

907

(847) (847) (847) (847)

(848) (848) (848) (848)

(863) (863) (863) (863)

/(756)

/(659)

/(756)

/(659)

unit factory suction line as shipped only if TXVs are used.

EXVs require sensors be located at the evaporator.

There are two evaporator water temperature sensors with 90

feet of cable coiled in the unit behind the control panel for

extension to the evaporator and insertion in fitting located on

the inlet and outlet nozzle on AGZ-D models 140 to 190. For

models AGZ 075 to 130 with brazed-plate evaporators, the

sensors are inserted into back of heat exchanger, opposite the

water connections, at the designated inlet and outlet water

temperature sensor locations.

There is one suction line refrigerant temperature sensor per

circuit installed on suction line with 90 feet of cable coiled

behind the unit control panel, intended for extension to the

evaporator. Place the sensor in a brazed well (provided in kit,

installed in the field) on the suction line in a straight-flat area,

close to the suction line pressure transducer. Install with heat

conductive compound and insulate well. If installed on a

horizontal pipe run, locate between the 2-4 o'clock positions,

or, on a TXV, locate the bulb and equalizer line on suction line

at the 3 or 9 o’clock position.

There is one suction line pressure transducer per circuit with

90 feet of cable coiled, installed on the suction line behind the

unit control panel for extension to the evaporator. Mount the

transducer in the suction line, 1-2 feet from the evaporator

head, on the top or side of the pipe. Connection is ¼-inch flare

with a flare Schrader.

40-feet of the evaporator, and up to 60 additional feet of 14GA

shielded wire connected from the cable to the unit, allowing up

to a total distance of 100 feet.

Figure 19: EXV Field Wiring

One solenoid valve per circuit must be wired to the unit

control panel. They come equipped with an 8-foot cable that

must be added to. See the wiring diagram on page 65 for

connection points at unit.

Expansion Valve Wiring

AGZ-D models 075-130 use Thermal Expansion Valves

(TXV standard, EXV optional). These valves must be located

within 12 inches of the evaporator liquid line connections and

the expansion valve bulbs. The 1/4” equalizer lines must be

attached to the suction pipes near the evaporator outlet.

AGZ-D models 140-190 use Electronic Expansion Valves

(EXV). The EXV has a 1 ft. cable attached with an M12

Threaded Connector. A 15 ft. cable is supplied with the kit to

attach to the 1 ft cable at the valve.

The field must supply #14 ga. shielded wires to extend this

cable to run back and connect to the Expansion Valve control

module located inside the AGZ-D control box. When splicing

is required the connections must be soldered together and

individually shrink wrapped to be made water resistant. The

expansion valve wiring cannot run in conduit with other wiring

that is over 24 Volts AC. Shielding must cover the wiring from

the unit to the EXV, including the splice connection.

The electronic expansion valve has a 40-foot long cable

attached and can be used, when the outdoor unit is less than 40

feet away. Beyond that, a junction box must be located within

16 IM 1165-1

Liquid Line Solenoid Valve Wiring

The Liquid Line Solenoid valves are supplied as part of the

Specialties Kit. These valves must be located within 3 feet of

the evaporator. Included with the Liquid Line Solenoids are

wiring cables which are 10 ft. long. These cables must be

connected to the termfinal block inside the AGZ-D control box

via a field-supplied junction box and #14 ga. wiring. This

24volt wiring should be run in conduit, or at a minimum, twowire cable with a protective covering must be used. See Field

Wiring Diagram included in unit, or Typical Field Wiring

Diagram on page 46 and page 47 for wiring schematic.

Pumpdown

The pumpdown capacity of AGZ units is given in the Physical

Data Tables starting on page 36. Care should be exercised to

include all equipment and lines when calculating the system

charge relative to the unit's pumpdown (storage) capacity. The

AGZ-D remote evaporators have an insignificant operating

charge. It is mandatory that the liquid line solenoid valve be

located close to the evaporator so that pump down does not

have to remove and store a large quantity of liquid refrigerant

from the liquid line.

Figure 20: Remote Evaporator Piping Models 075-130

(FIELD SUPPLIED)

30 FEET FROM THE OUTDOOR UNIT, THEN

THE SUCTION TEMPERATURE SENSORS AND

1. FOR FILTER DRIER SERVICE:

THE EVAPORATOR AS SHOWN.

TRANSDUCERS MUST BE RE-LOCATED AT

(FIELD SUPPLIED)

(INCLUDED IN KIT)

CIR. #2

LIQUID

EXPANSION VALVE (INCLUDED IN KIT)

CIR. #1

LIQUID CIR. #2

LIQUID

CIR. #2

SUCTION

CIR. #1

SUCTION

FILTER DRIER CLAMP

IF EVAPORATOR IS LOCATED MORE THAN

SIGHT GLASS (INCLUDED IN KIT)

LIQUID

CIR. #1

SOLENOID VALVE (INCLUDED IN KIT)

FILTER DRIER SHELL

SCHRADER FITTINGS

NOTES:

ROUTE COPPER TUBE PIPING

APPROXIMATELY AS SHOWN

FELT GASKET KIT

FILTER DRIER CORES

WATER

(FIELD SUPPLIED)

REQUIRED

OUTLET

WATER STRAINER

(ALL INCLUDED IN KIT)

BALL VALVE

SCHRADER FITTINGS (FIELD SUPPLIED)

WATER INLET

2. LIQUID LINE SOLENOID & FILTER DRIER MUST

LINE BALL VALVE LOCATED NEXT TO DRIER.

SO FIELD MUST USE MIN 45% SILVER BRAZE ROD.

BRAZE CONNECTIONS ON EVAP ARE STAINLESS STEEL,

SCHRADER FITTINGS

AGZ075-130D (6-8) FAN UNITS

(6 FAN UNIT SHOWN)

PUMP DOWN SYSTEM USING LIQUID

3. SUPPORT FIELD PIPING AS REQUIRED.

COMPRESSORS

CIRCUIT #1

COMPRESSORS

CIRCUIT #2

OPTIONAL HOTGAS BYPASS LINE MUST ENTER FROM VERTICAL POSITION AS SHOWN

BE LOCATED AT REMOTE EVAP.

CIR. #1

HOTGAS BYPASS

OPTION

BYPASS CIR. #2

OPTION HOTGAS

BLK#2 TO TB2 93

GND TO CONNECT WITH GND WIRE

RUN SOLENOID VALVE CABLE INTO BACK

OF CONTROL BOX AND CONNECT TO:

CIR#1

BLK#1 TO TB2 91

BLK#2 TO TB2 93

GND TO CONNECT WITH GND WIRE

CIR#2

BLK#1 TO TB2 92

SOLENOID VALVE CABLES

(INCLUDED IN KIT)

R331738201 0B

(INCLUDED IN KIT)

PIPE ASSEMBLY

TEMP. SENSOR

LEAVING WATER

LEAVING WATER

VALVE CORE

(INCLUDED IN KIT)

FOR EQUALIZER LINE

CHARGING VALVE

SCHRADER FITTINGS

0.25" DIAMETER HOLE

TO EXPANSION VALVE

(INCLUDED IN KIT)

FOR SUCTION

NEAR EVAPORATOR)

SUCTION

CIR. 2

(INCLUDED IN KIT)

TRANSDUCERS

SUCTION TEMPERATURE

SENSOR TUBE (LOCATED

EXPANSION

VALVE BULB

SUCTION

CIR. 1

CIR. #2

LIQUID

CIR. #1

LIQUID

TEMP SENSOR

LOCATION

CIR. #2

SUCTION

CIR. #1

SUCTION

ENTERING WATER

STAINLESS STEEL

PIPE PLUG

Remote Evaporators

IM 1165-1 17

Loading...

Loading...