Page 1

Installation, Operating and Maintenance Manual

Optional Pump Packages for

AGZ 030C – AGZ 190C

IOMM AGZ-C

PUMP PACKAGE

SUPPLEMENT

Group: Chiller

Part Number: 331975401

Date: August 2009

Supersedes: New

Page 2

Table of Contents

Introduction........................................3

General Description................................... 3

Inspection .................................................. 3

Installation .........................................3

Field Water Piping..................................... 3

System Water Volume ............................... 4

Freeze Protection....................................... 4

Weights & Vibration Isolators ................... 4

Pump Control ............................................ 8

Freeze Protection....................................... 8

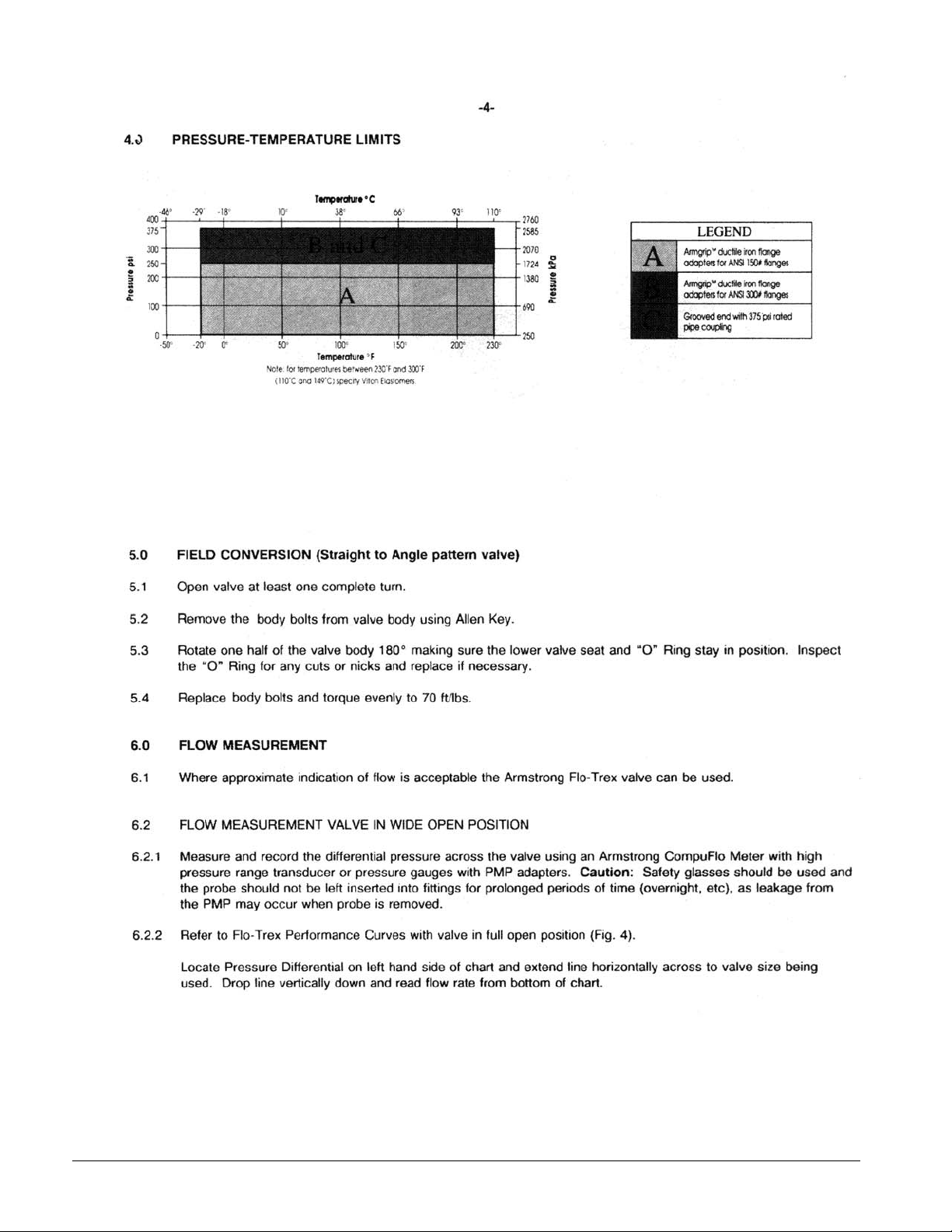

Triple-Duty Valve ............................10

Component Location........................16

Dimensions ......................................18

Pump Curves....................................23

Manufactured in an ISO Certified Facility

HAZARD IDENTIFICATION INFORMATION

Wiring Diagrams..............................33

Electrical Data..................................36

Sequence of Operation

S

tart-up.............................................56

.....................55

System Maintenance........................56

Lubrication.............................................. 56

Electrical Terminals................................. 56

Preventative Maintenance Schedule ....... 57

Warranty Statement..........................57

Service

.............................................57

!

DANGER

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

!

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage, severe

personal injury, or death if not avoided.

!

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or

equipment damage if not avoided.

©2008 McQuay International. Illustrations and data cover the McQuay International product at the time

of publication and we reserve the right to make changes in design and construction at anytime without

notice. ™® The following are trademarks or registered trademarks of their respective companies:

FanTrol, MicroTech II, Open Choices, and SpeedTrol from McQuay International.

2 IOMM AGZC Pump Pkg

Page 3

Introduction

General Description

This manual provides additional information on optional pump packages, factory mounted on McQuay

Model AGZ-C scroll-compressor chillers. Follow the directions in the chiller installation and

operating manuals, IMM AGZC and OM AGZC, for installation and operation of the entire unit.

Inspection

When the equipment is received, carefully check all items against the bill of lading to check for a

complete shipment. Check all units for damage upon arrival. All shipping damage must be reported

to the carrier and a claim must be filed with the carrier. Check the unit’s serial plate before unloading

the unit to be sure that it agrees with the power supply available. Physical damage to unit after

acceptance is not the responsibility of McQuay International.

Installation

Installation and maintenance are to be performed only by qualified personnel who are familiar with

local codes and regulations, and experienced with this type of equipment.

Follow the directions in IMM AGZC for installation of the unit. The addition of the optional pump

package does not change installation procedure. However, vibration isolator selection and location,

unit weights, dimensions and electrical data will differ from units without a pump package.

Field Water Piping

Due to the variety of piping practices, follow the recommendations of local authorities. They can

supply the installer with the proper building and safety codes required for a proper installation.

Design the piping with a minimum number of bends and changes in elevation to keep system cost

down and performance up. It should contain:

1. Vibration eliminators to reduce vibration and noise transmission to the building.

2. Shutoff valves to isolate the unit from the piping system during unit servicing. The pump

package has suction and discharge service shutoff valves for each pump.

3. Manual or automatic air vent valves at the high points of the system and drains at the low

parts in the system. The evaporator should not be the highest point in the piping system.

4. Some means of maintaining adequate system water pressure (i.e., expansion tank or

regulating valve).

5. Water temperature and pressure indicators located at the unit to aid in unit servicing.

6. A strainer to is provided in the package to remove foreign matter from the water before it

enters the pump and chiller. The use of a strainer will prolong pump life and help maintain

high system performance levels. The strainer must be cleaned after system flushing is

completed.

7. Any water piping to the unit must be protected to prevent freeze-up if below freezing

temperatures are expected.

8. If the unit is used with a replacement chiller on a previously existing piping system, flush

the system thoroughly prior to unit installation.

Make a preliminary leak check prior to insulating the water piping and filling the system.

Include a vapor barrier with the piping insulation to prevent moisture condensation and

possible damage to the building structure. It is important to have the vapor barrier on the

outside of the insulation to prevent condensation within the insulation on the cold surface of

the pipe.

IOMM AGZC Pump Pkg 3

Page 4

System Water Volume

It is important to have adequate water volume in the system to provide an opportunity for

the chiller to sense a load change, adjust to the change and stabilize. As the expected load

change becomes more rapid, a greater water volume is needed. The system water volume is

the total amount of water in the evaporator, air handling products and associated piping. If

the water volume is too low, operational problems can occur including rapid compressor

cycling, rapid loading and unloading of compressors, erratic refrigerant flow in the chiller,

improper motor cooling, shortened equipment life and other undesirable occurrences.

For normal comfort cooling applications where the cooling load changes relatively slowly,

we recommend a minimum system volume in gallons of 2 to 3 times the flow rate (gpm).

For example, if the design chiller flow rate is 350 gpm, we recommend a minimum system

volume of 700 to 1050 gallons.

Since there are many other factors that can influence performance, systems can successfully

operate below these suggestions. However, as the water volume decreases below these

suggestions, the possibility of problems increases.

Freeze Protection

In installations where the unit is subject to sub-freezing temperatures, some method of

preventing pipe and component freezing and subsequent damage must be employed. The

pump package has an outdoor air thermostat (TH1) that will start the pump at 40F to help

prevent freeze up. It is recommended that one or more of the following strategies also be

employed:

If chilled water circulation is not possible or desired, one or more of the following

procedures must be used.

1. Drain the outdoor portion of the system and cap with a nitrogen charge.

2. Heat trace all outdoor components.

3. Add sufficient anti-freeze to prevent freezing.

Adding of a concentration of a glycol anti-freeze with a freeze point 10 degrees F below the

lowest expected outdoor temperature will result in decreased capacity and increased

pressure drop in the chiller. AGZ units are selected to provide the required capacity with the

fluid specified, water or antifreeze.

Note: Do not use automotive grade antifreezes as it contains inhibitors harmful to chilled

water systems. Use only glycols designated for use in building cooling systems.

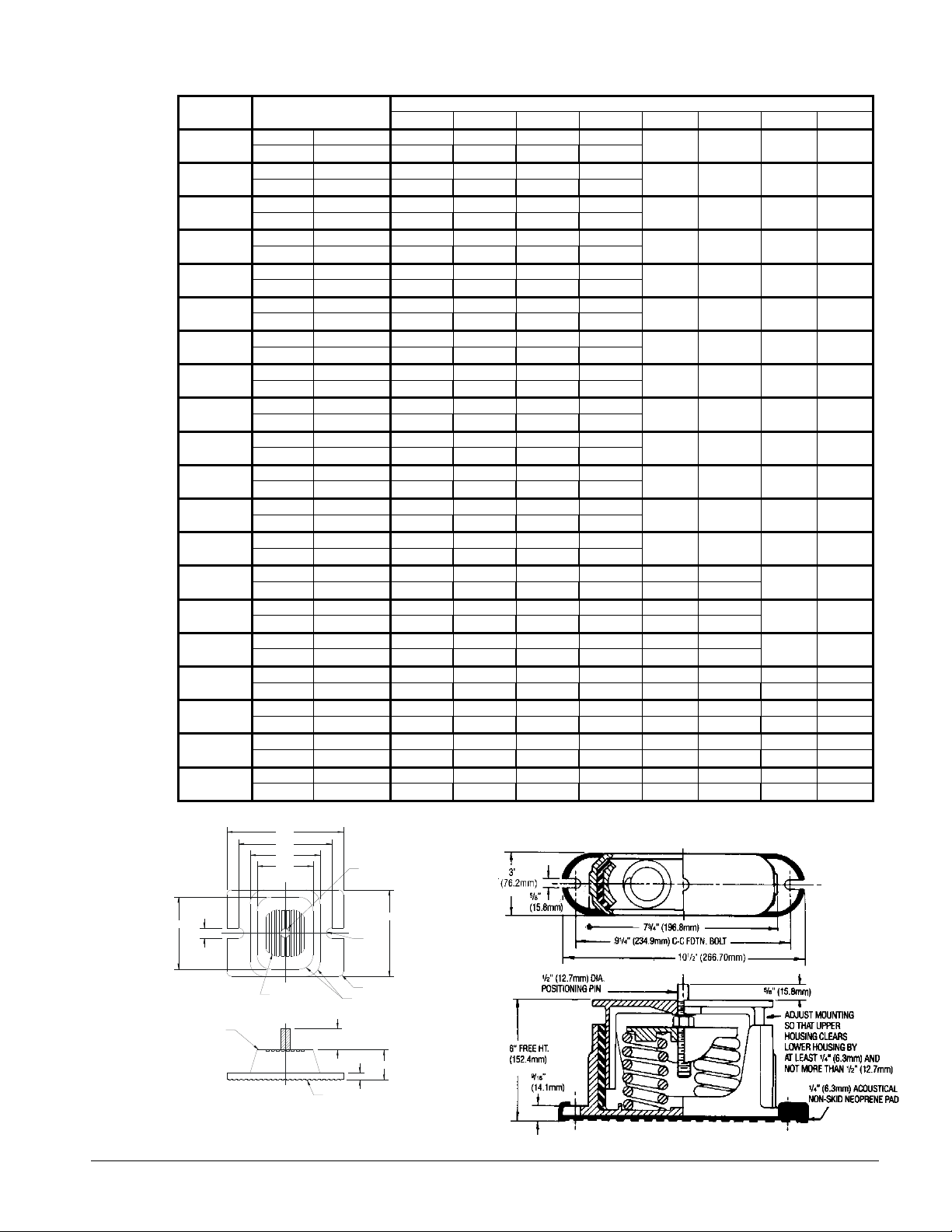

Weights & Vibration Isolators

Vibration isolators are recommended for all roof-mounted installations or wherever

vibration transmission is a consideration. If the pump package is installed adjacent to a

chiller that is mounted on springs, it is essential that flexible piping connections be

employed between the two units.

Initially install the unit on shims or blocks at the "free height" of the isolator. When all

piping, wiring, flushing, charging, etc. is complete, adjust the springs upward to load them

and to provide clearance to free the blocks, which are then removed.

Installation of spring isolators requires flexible pipe connections and at least three feet of

conduit flex tie-ins. Support piping and conduit independently from the unit to not stress

connections.

See pages 18 through 22 for the for mounting hole locations.

4 IOMM AGZC Pump Pkg

Page 5

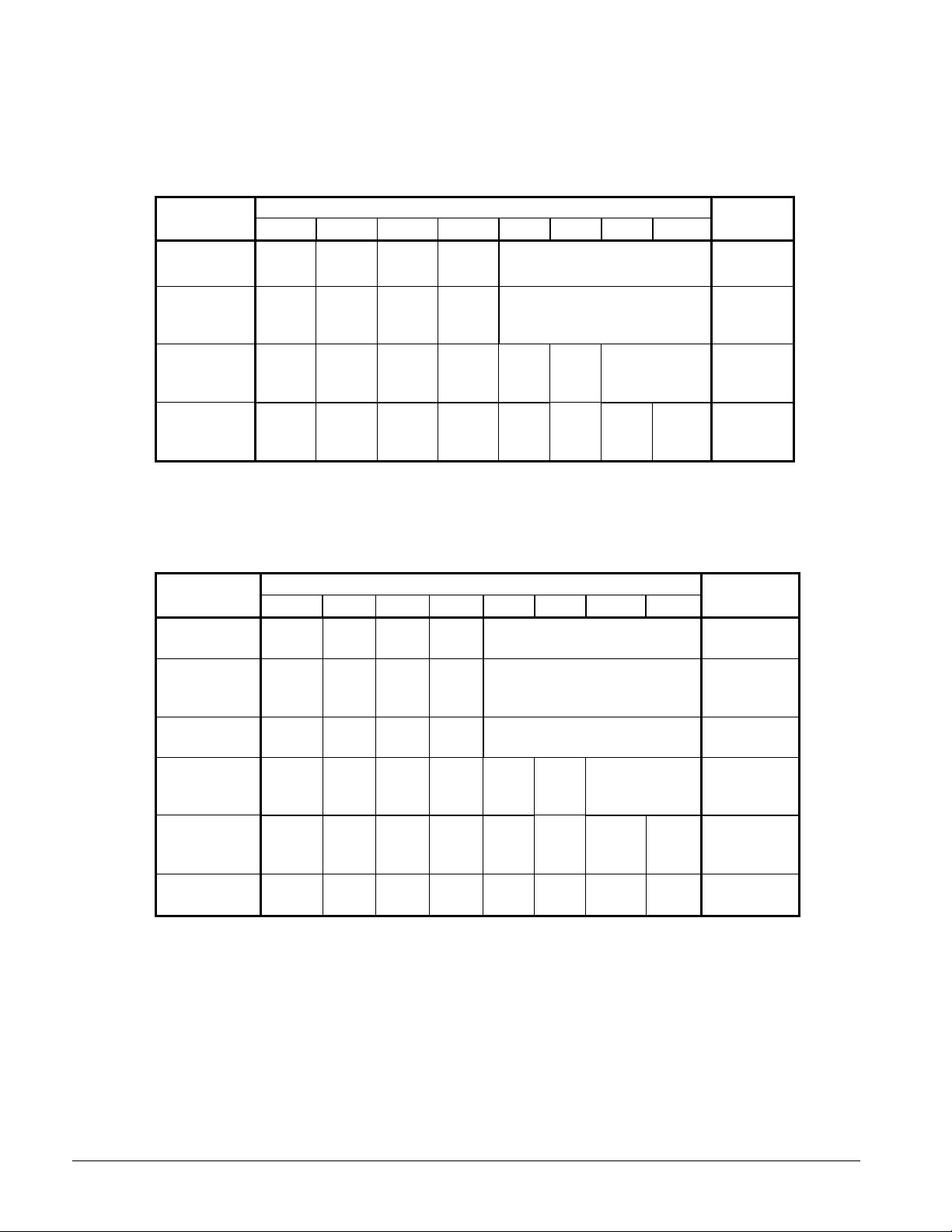

Table 1, Mounting Weights

2

A

SIZE

030

035

040

045

050

055

060

065

070

075

080

090

100

110

125

130

140

160

180

190

OPERATING.

WEIGHT lbs kg

M1 M2 M3 M4 M5 M6 M7 M8

lbs 4035 1089 1060 956 930

kg 1832 494 481 434 422

lbs 4090 1100 1084 960 946

kg 1857 499 492 436 429

lbs 4205 1123 1112 990 980

kg 1909 510 505 450 445

lbs 4335 1123 1179 992 1041

kg 1968 510 535 450 473

lbs 4465 1179 1190 1043 1053

kg 2027 535 540 474 478

lbs 4405 1176 1214 991 1023

kg 2000 534 551 450 465

lbs 4690 1212 1332 1022 1124

kg 2129 550 605 464 510

lbs 4725 1206 1335 1036 1147

kg 2145 548 606 470 521

lbs 5280 1357 1270 1370 1283

kg 2397 616 577 622 582

lbs 6690 1733 2003 1370 1583

kg 3037 787 910 622 719

lbs 6775 1800 2088 1336 1550

kg 3076 817 948 607 704

lbs 6658 1759 2030 1332 1537

kg 3023 798 922 605 698

lbs 6792 1761 2053 1375 1603

kg 3084 800 932 624 728

lbs 8650 1405 1551 1370 1513 1336 1475

kg 3927 638 704 622 687 606 670

lbs 8800 1437 1559 1407 1526 1377 1494

kg 3995 653 708 639 693 625 678

lbs 8945 1479 1627 1420 1562 1361 1497

kg 4061 672 739 645 709 618 679

lbs 13062 1613 1664 1610 1660 1605 1656 1602 1652

kg 5930 732 756 731 754 729 752 727 750

lbs 13092 1594 1604 1617 1627 1645 1655 1670 1680

kg 5944 724 728 734 739 747 751 758 763

lbs 13213 1616 1647 1628 1660 1643 1675 1656 1688

kg 5999 734 748 739 753 746 760 752 766

lbs 14834 1793 1835 1814 1857 1851 1894 1873 1917

kg 6735 814 833 824 843 840 860 850 870

MOUNTING WEIGHTS, LBS KG AGZ-C

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

RP-4, Rubber-in-Shear Isolator Dimension C2PE, Spring Isolator Dimensions

6.25

3.87

.56 TYP.

5.00

3.75

3.00

R4

VM&C

ø .500-13NC-2B

VM&C

R.28

TYP.

4.63

N/A N/A

N/A N/A

N/A N/A

R4

RECESSED

GRIP RIBS

DURULENE

MATERIAL

NOTES:

MOUNT MATERIAL TO BE DURULENE RUBBER.1.

MOLDED STEEL AND ELASTOMER MOUNT FOR

.

OUTDOOR SERVICE CONDITIONS.

3. RP-4 MOUNT VERSION WITH STUD IN PLACE.

DRAWING NUMBER 3314814

ALL DIMENSIONS ARE IN DECIMAL INCHES

R.250 TYP.

R.750 TYP.

1.13 ± .25

PPROX.

.38

RAISED GRIP RIBS

1.63

IOMM AGZC Pump Pkg 5

Page 6

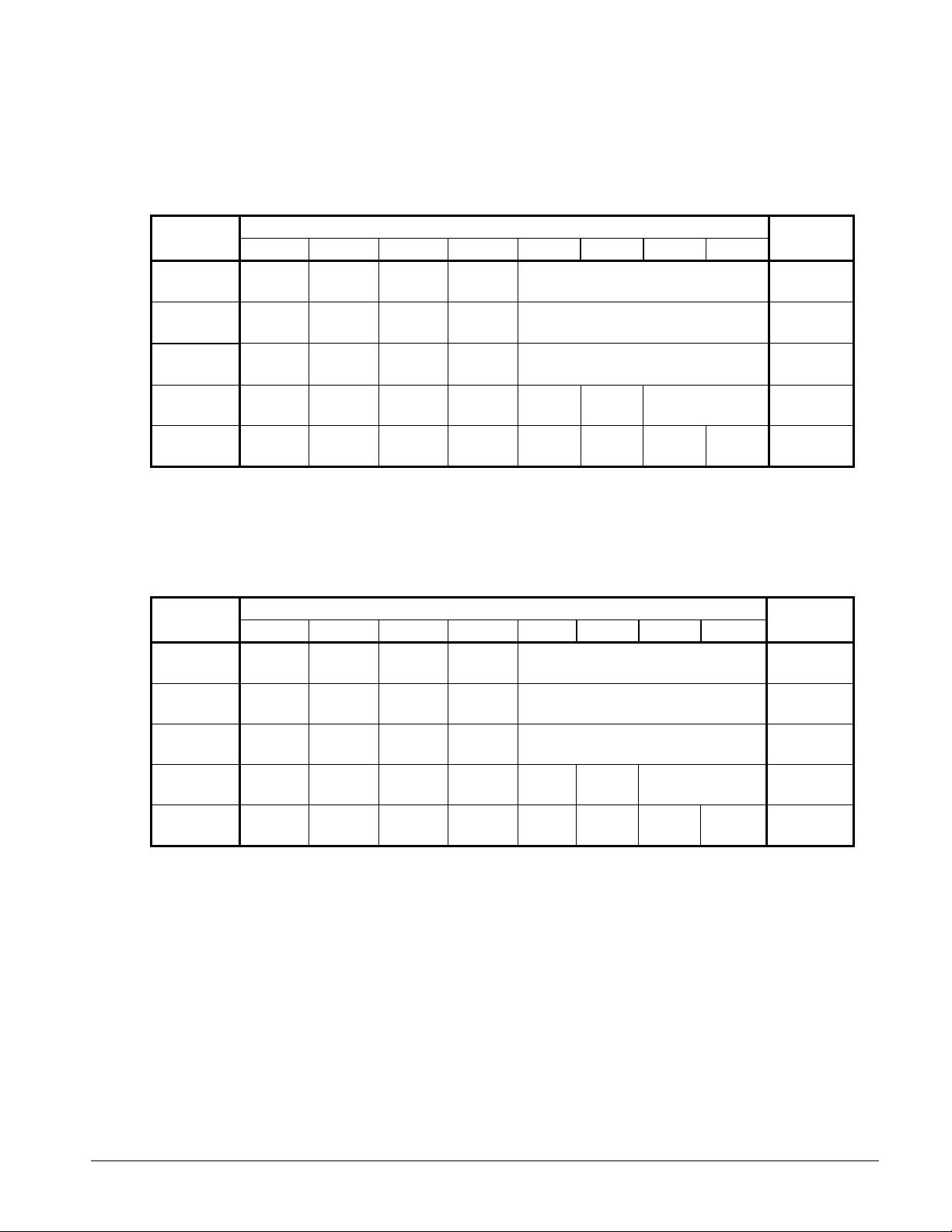

Rubber-In- Shear Isolators

Table 2, Rubber-in-Shear Isolator Locations, Aluminum Fin

Mounting hole location dimensions are on the unit dimension drawings beginning on page 18. The

isolator selections are different for AGZ units with pump packages than those without.

AGZ-C

Size

030, 035, 040

045. 050, 055

060, 065, 070

075, 080, 090

100

110, 125, 130

140, 160, 180

190

M1 M2 M3 M4 M5 M6 M7 M8

RP-4 RP-4 RP-4 RP-4

Brown Brown Brown Brown

RP-4 RP-4 RP-4 RP-4

Brick

Red

RP-4 RP-4 RP-4 RP-4 RP-4 RP-4

Brick

Red

RP-4 RP-4 RP-4 RP-4 RP-4 RP-4 RP-4 RP-4

Brick

Red

Brick

Red

Brick

Red

Brick

Red

RUBBER-IN-SHEAR ISOLATORS

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Table 3, Rubber-in-Shear Isolator Locations, Copper Fin

Mounting hole location dimensions are on the unit dimension drawings beginning on page 18. The

isolator selections are different for AGZ units with pump packages than those without.

AGZ-C

Size

030, 035, 040

045, 050

055, 060, 065

070

075, 080, 090

100

110, 125, 130

140, 160, 180

190

M1 M2 M3 M4 M5 M6 M7 M8

RP-4 RP-4 RP-4 RP-4

Brown Brown Brown Brown

RP-4 RP-4 RP-4 RP-4

Brick

Red

RP-4 RP-4 RP-4 RP-4

Lime Lime Lime Lime

RP-4 RP-4 RP-4 RP-4 RP-4 RP-4

Brick

Red

RP-4 RP-4 RP-4 RP-4 RP-4 RP-4 RP-4 RP-4

Brick

Red

RP-4 RP-4 RP-4 RP-4 RP-4 RP-4 RP-4 RP-4

Lime Lime Lime Lime Lime Lime Lime Lime

Brick

Red

Brick

Red

Brick

Red

RUBBER-IN-SHEAR ISOLATORS

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

Brick

Red

KIT

NUMBERS

332325107

332325108

332325109

332325110

KIT

NUMBERS

332325107

332325108

332325111

332325109

332325110

332325112

6 IOMM AGZC Pump Pkg

Page 7

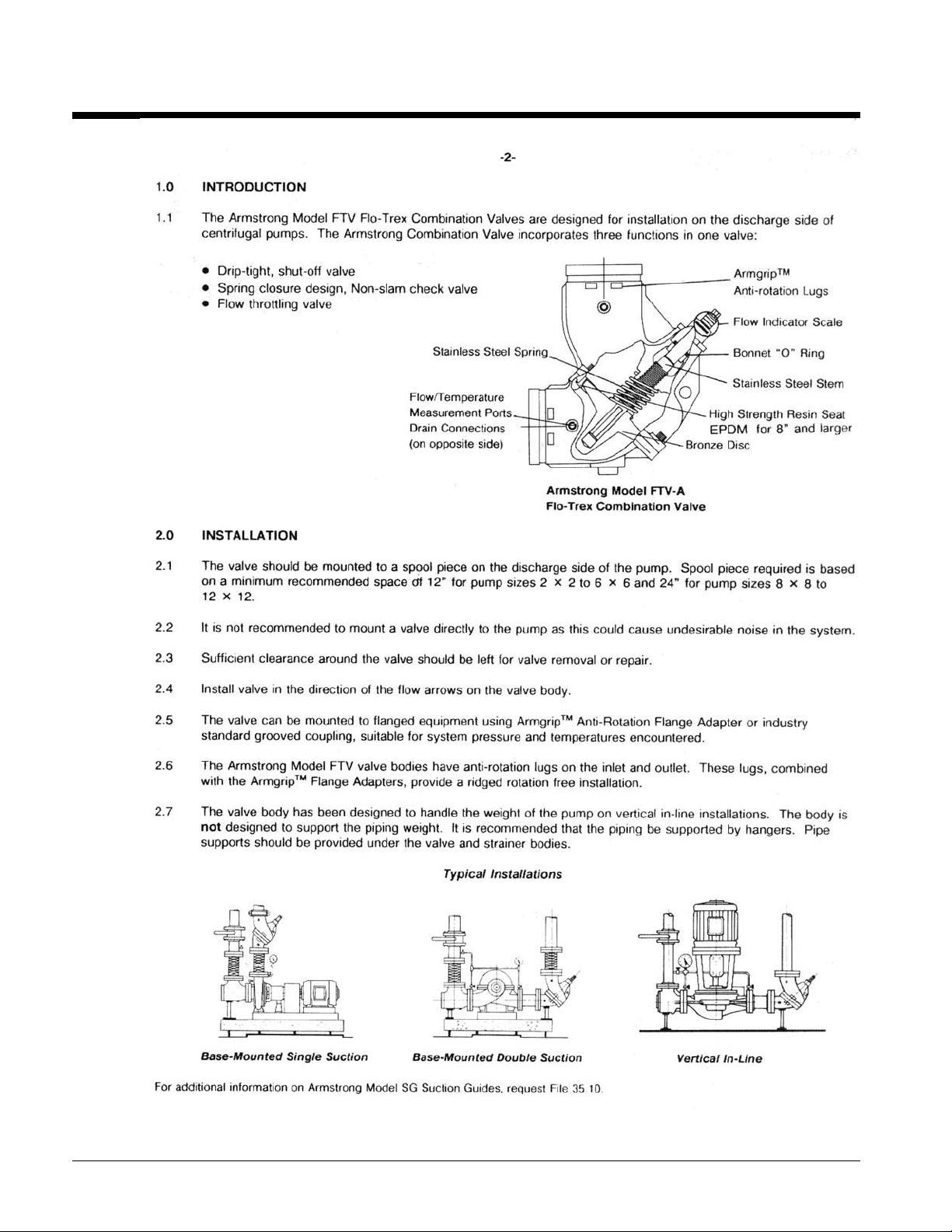

Spring Isolators

Table 4, Spring Isolator Locations, Aluminum Fin

Mounting hole dimensions are on the unit dimension drawings beginning on page 18. The vibration isolators

are different for AGZ units with pump packages than those without. All isolators have two springs per housing

(C2PE).

AGZ-C

Size

030, 035, 040

045, 050, 055

060, 065, 070

075, 080, 090

100

110, 125, 130

140, 160, 180

190

M1 M2 M3 M4 M5 M6 M7 M8

1D-1350 1D-1350 1D-1350 1D-1350

Purple Purple Purple Purple

1D-1800 1D-1800 1D-1800 1D-1800

Green Green Green Green

1D-2400 1D-2400 1D-1800 1D-1800

Gray Gray Green Green

1D-1800 1D-1800 1D-1800 1D-1800 1D-1800 1D-1800

Green Green Green Green Green Green

1D-2400 1D-2400 1D-2400 1D-2400 1D-2400 1D-2400 1D-2400 1D-2400

Gray Gray Gray Gray Gray Gray Gray Gray

SPRING-FLEX ISOLATORS

NUMBERS

332320116

332320117

332320118

332320119

332320120

KIT

Table 5, Spring Isolator Locations, Copper Fin

Mounting hole dimensions are on the unit dimension drawings beginning on page 18. The vibration isolators

are different for AGZ units with pump packages than those without. All isolators have two springs per housing

(C2PE).

AGZ-C

Size

030, 035, 040

045, 050, 055

060, 065, 070

075, 080, 090

100

110, 125, 130

140, 160, 180

190

M1 M2 M3 M4 M5 M6 M7 M8

1D-1350 1D-1350 1D-1350 1D-1350

Purple Purple Purple Purple

1D-1800 1D-1800 1D-1800 1D-1800

Green Green Green Green

1D-2720 1D-2720 1D-2720 1D-2720

White White Gray Gray

1D-2720 1D-2720 1D-2720 1D-2720 1D-2720 1D-2720

Gray Gray Gray Gray Gray Gray

1D-2720 1D-2720 1D-2720 1D-2720 1D-2720 1D-2720 1D-2720 1D-2720

Gray Gray Gray Gray Gray Gray Gray Gray

SPRING-FLEX ISOLATORS

NUMBERS

332320116

332320117

332320121

332320122

332320120

KIT

IOMM AGZC Pump Pkg 7

Page 8

Pump Control

There are three possible pump control arrangements:

1. Single Pump/Single Control; the standard single digital output from the chiller’s

microprocessor control starts and stops the pump.

2. Dual Pump/Single Control; the standard single digital output controls the pumps. Pump

operation is automatically selected by an alternating relay arrangement. The panel has a

selector switch allowing selection of pump A, pump B, or automatic (using relays).

3. Dual Pump/Dual Control; an optional second chiller digital output must be supplied and

operation of the pumps is controlled by settings in the microprocessor as follows:

The pump output used is determined by the Evap Pump Control setpoint. This setting

allows the following configurations:

#A only – Pump A will always be used

#B only – Pump B will always be used

Auto – The primary pump is the one with the least run hours, the other is used as a

backup

#A Primary – Pump A is used normally, with pump B as a backup

#B Primary – Pump B is used normally, with pump A as a backup

Primary/Standby Pump Staging

The pump designated as primary will start first. If the evaporator state is START for a

time greater than the RECIRCULATE TIMEOUT setpoint and there is no flow, then the

primary pump will shut off and the standby pump will start. When the evaporator is in

the RUN state, if flow is lost for more than half of the FLOW PROOF setpoint value,

the primary pump will shut off and the standby pump will start. Once the standby pump

is started, the FLOW LOSS alarm logic will apply if flow cannot be established in the

evaporator START state, or if flow is lost in the EVAPORATOR RUN state.

Auto Control

If AUTO pump control is selected, the primary/standby logic above is still used. When

the evaporator is not in the RUN state, the run hours of the pumps will be compared.

The pump with the least hours will be designated as the primary at this time.

Freeze Protection

In installations where the unit is subject to sub-freezing temperatures, some method of

preventing pipe and component freezing and subsequent damage must be employed.

The pump package has an outdoor air thermostat (TH1) that will start the pump at 40F

to help prevent freeze up.

If the chiller is valved out of the building circulation system during freezing

temperatures, a valved bypass must be installed between the supply and return lines, on

the pump side of the chiller isolation valves.

If operation of the chilled water pump during freezing weather is not desired, one or

more of the following strategies must be employed:

4. Drain the portion of the system subject to freezing and cap with a nitrogen charge.

If the system will be drained, the pump(s) and the interconnecting piping also have

to be drained. A drain plug is provided at the very bottom of the pump housing and

at the bottom of the evaporator barrel or package piping. Open the appropriate

vents to assist in draining. A nitrogen head is recommended to decrease corrosion

in the drained portion of the piping

8 IOMM AGZC Pump Pkg

Page 9

5. Heat trace all outdoor piping and components. If the system is to have field-installed

heat tracing, the factory pipe insulation will have to be removed and replaced after the

installation of the tracing.

6. Add sufficient anti-freeze to prevent freezing. If an anti-freeze solution is to be used,

additional anti-freeze must be added to protect the water in the pump package.

Adding of a concentration of a glycol anti-freeze with a freeze point 10 degrees F below

the lowest expected outdoor temperature will result in decreased capacity and increased

pressure drop in the chiller. AGZ units can be selected to provide the required capacity

with the fluid specified, water or antifreeze.

Note: Do not use automotive grade antifreezes as they contain inhibitors harmful to

chilled water systems. Use only glycols specifically designated for use in building

cooling systems.

IOMM AGZC Pump Pkg 9

Page 10

Triple-Duty Valve

10 IOMM AGZC Pump Pkg

Page 11

IOMM AGZC Pump Pkg 11

Page 12

12 IOMM AGZC Pump Pkg

Page 13

IOMM AGZC Pump Pkg 13

Page 14

14 IOMM AGZC Pump Pkg

Page 15

IOMM AGZC Pump Pkg 15

Page 16

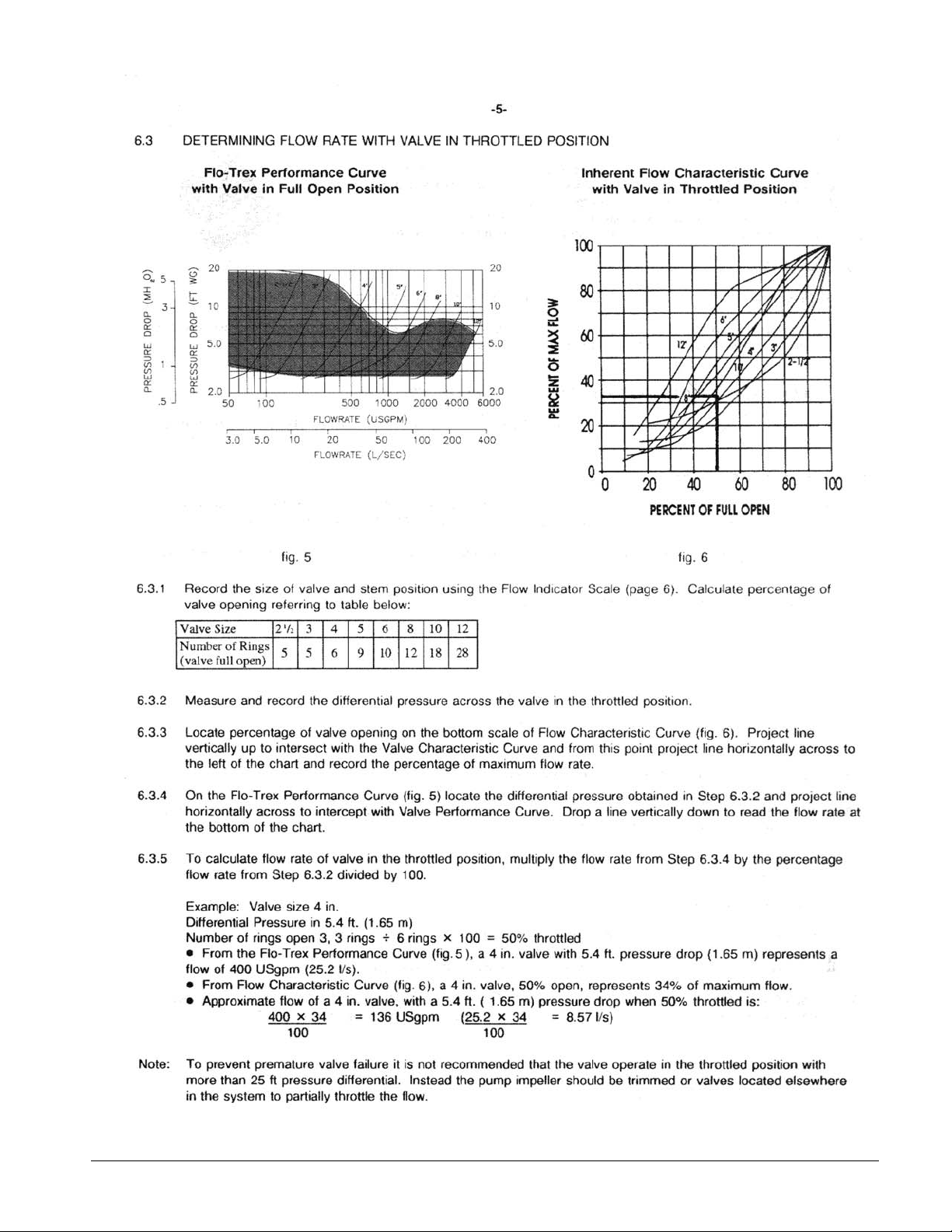

Component Location

Table 6 ,Standard Pump Package Components

Commponent AGZ 030-070 AGZ 075-130 AGZ 140-190

Strainer Y Strainer w/ B-D Valve Inlet Guide Inlet Guide (1)

Suction S-O Valve 1 per Pump 1 per Pump 1 per Pump

Discharge Check 1 per Pump 1 per Pump 1 per Pump

Discharge S-O Valve 1 per Pump 1 per Pump 1 per Pump

Flow Switch 1 per Unit 1 per Unit 1 per Unit

Triple-Duty Valve 1 per Unit 1 per Unit 1 per Unit

Pump(s) 1 or 2 1 or 2 1 or 2

Control Panel Mounted on the pump package base, not shown below for clarity.

NOTES:

1. Field Installed

2. All cold surfaces are insulated.

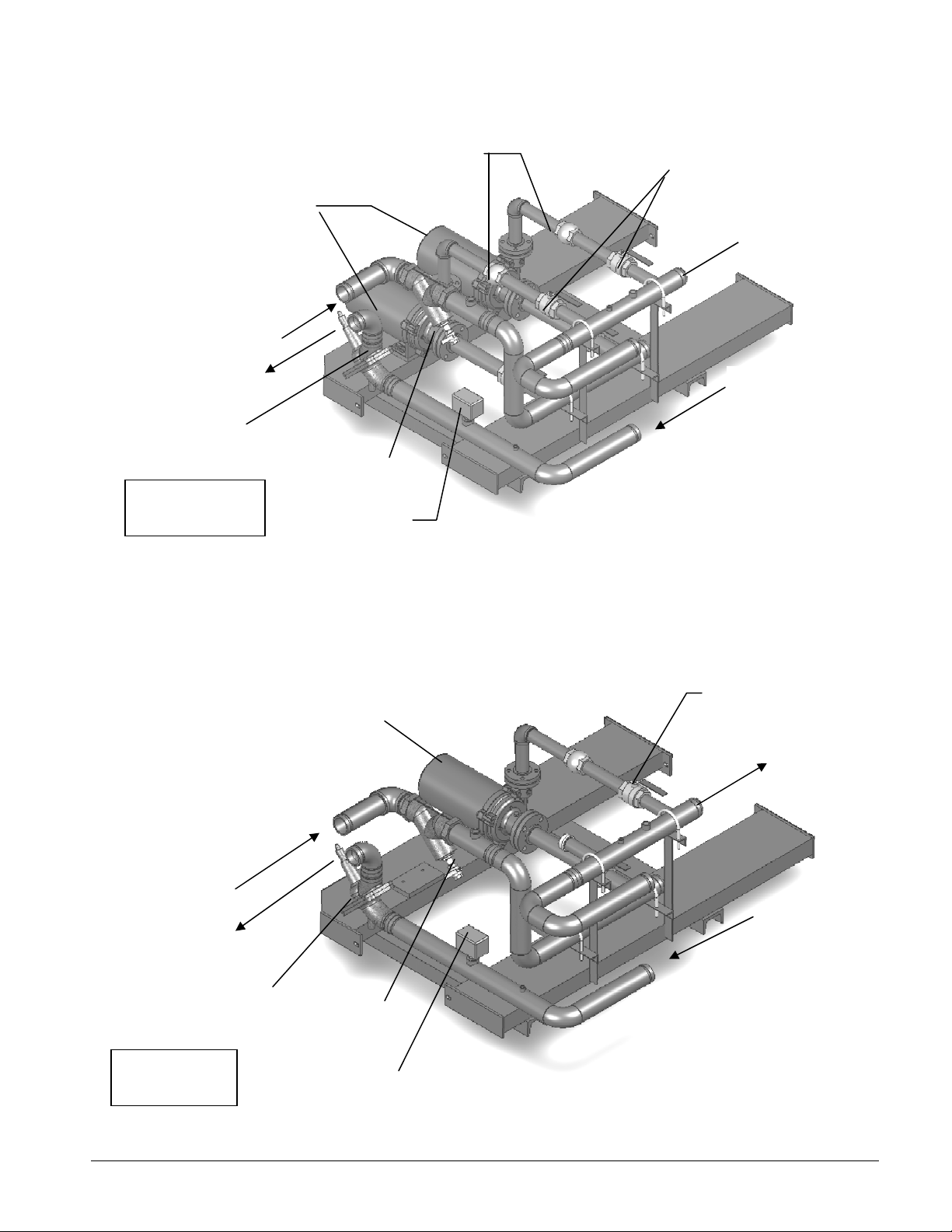

Figure 1, Standard Components, AGZ 110C to 130C, Dual Pumps

Control panel not shown for clarity.

To Evaporator

(Factory)

From Evaporator

(Factory)

Flow Switch

Discharge Check

Pumps

Triple Duty Valve

Discharge S O

Valves (2)

Suction S O

Valves (2)

Inlet Guide

(Strainer)

System Inlet Conn.

System Outlet Conn.

BACK OF

UNIT

16 IOMM AGZC Pump Pkg

Page 17

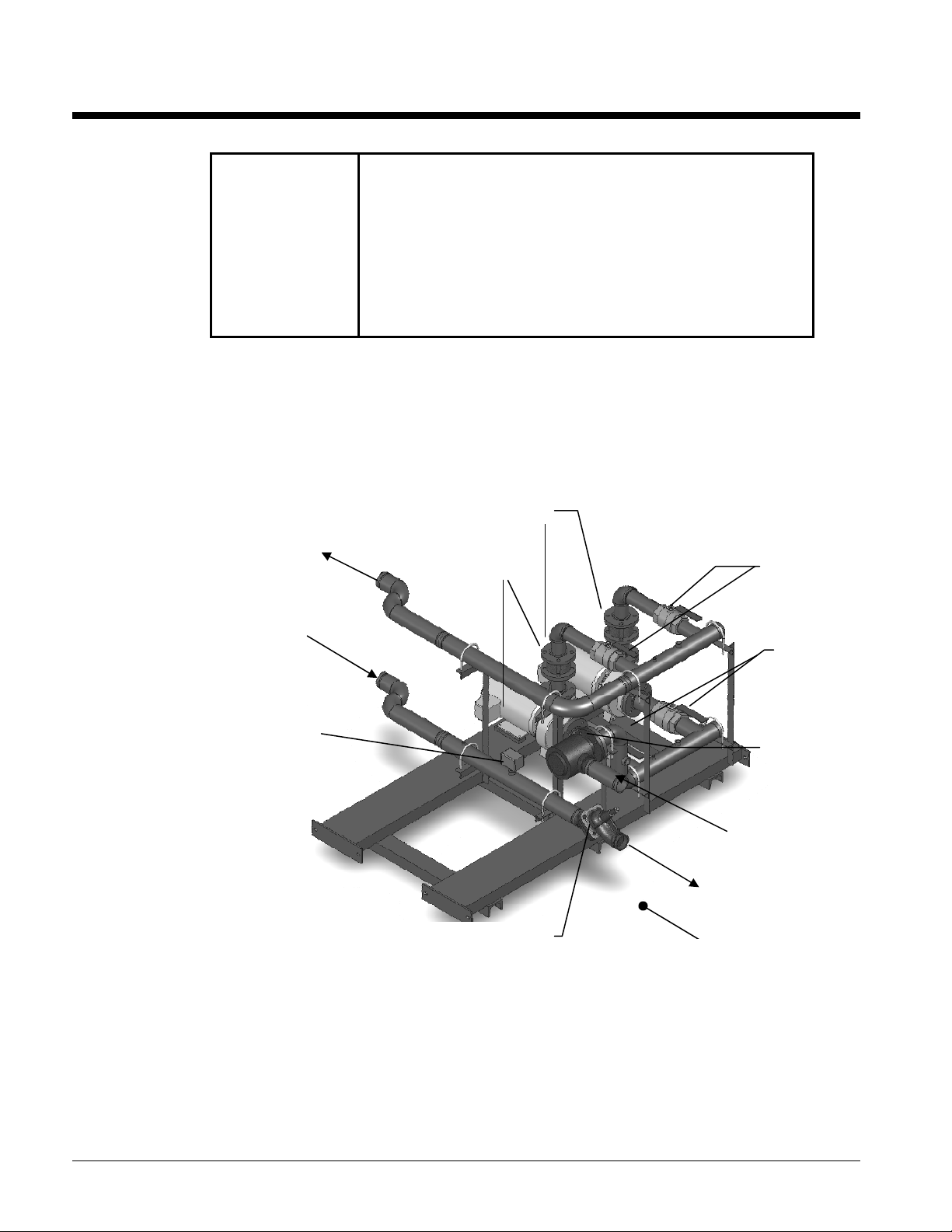

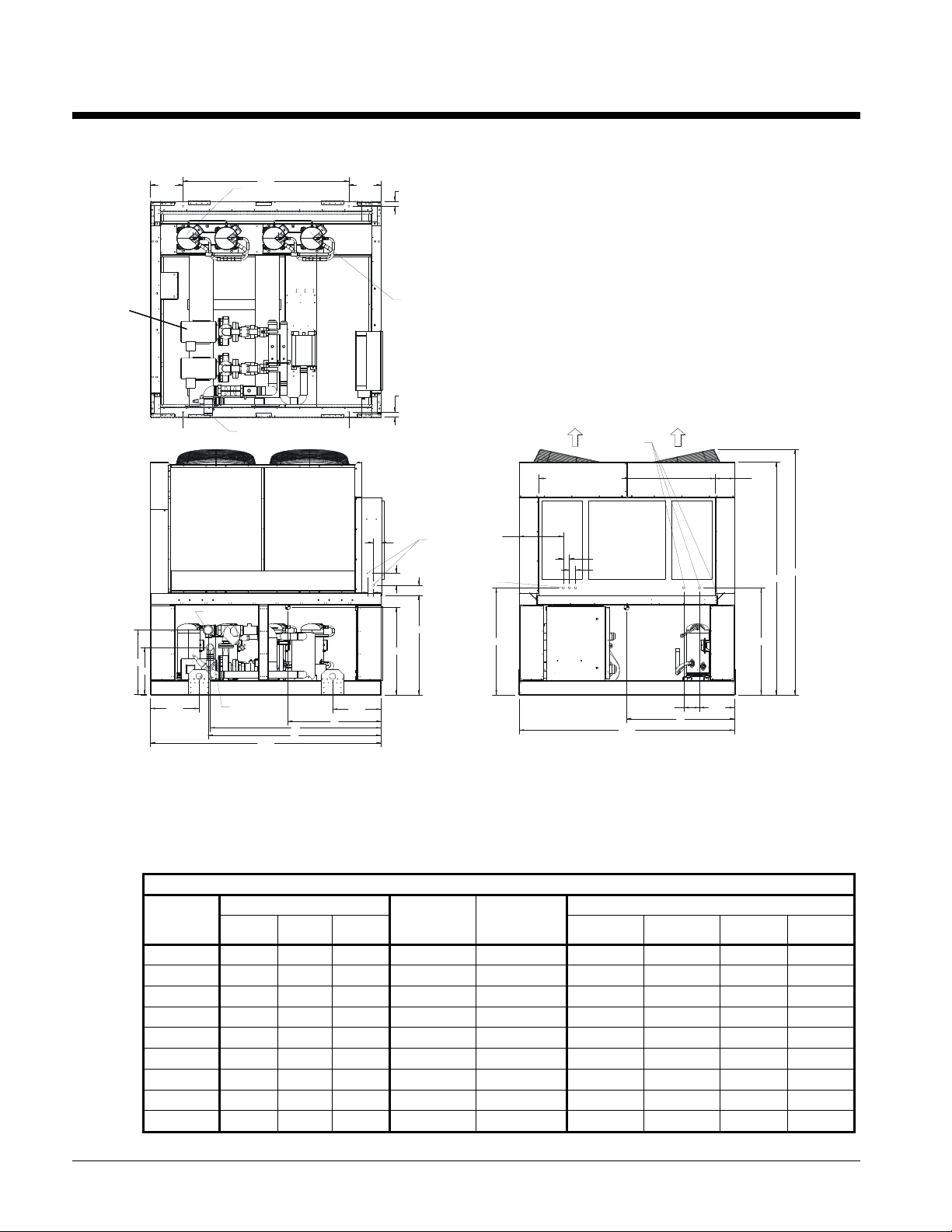

Figure 2, Standard Components, AGZ 030C to 070C, Dual Pumps

(2)

Control panel not shown for clarity.

Pumps

System Inlet

System Outlet

Triple-Duty

Outlet Valve

LEFT SIDE

Of UNIT

Discharge Check Valves

Y- St r ai n e r

Flow Switch

Figure 3, Standard Components, AGZ 030C to 070C, Single Pump

Control panel not shown for clarity.

Shut-Off

Va l ve s

To Evaporator

From

Evaporator

System Inlet

System Outlet

Triple-Duty

Outlet Valve

LEFT SIDE

Of UNIT

Shut Off Valve

Pump

To Evaporator

From

Evaporator

Y- St r ai n e r

Flow Switch

IOMM AGZC Pump Pkg 17

Page 18

Dimensions

Figure 4, AGZ 030C to 070C Dimensions with Pump Package

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

13.3

L3

67.8

COMPRESSOR

CIRCUIT #2

M1M3

13.3

L1

2.0

COMPRESSOR

CIRCUIT #1

2.0

NOTE:

1. DUE TO VARIATIONS IN PUMP SIZES, OPERATING WEIGHT WITH WATER IS

APPROXIMATE AND MAY INCREASE UP TO 5%

CG

EVAP

D

B

L2

M2M4

POWER

3.4

CONNECTIONS

OPPOSITE SIDE

OF CONTROL BOX

5.0

2.0

4.0

18.0

FIELD CONTROL

CONNECTION

POWER ENTRY POINT

.875 KNOCK OUTS

FRONT OR SIDE

CONTROL BOX WIDTH

CONTROL

PAN EL

2.5

2.5

8.0

REF.

94.9

100.2

CG

40.7

Y

L1

19.9

L2

Z

43.7

PUMP

COMTROL

PAN EL

88.0

6.4

14.4

X

ALL DIMENSIONS ARE IN DECIMAL INCHES

SCALE

*331779021001*

NONE

43.7

L4

EVAP PIPING

CONNECTIONS

EVAP WATER

INLET

A

C

19.9

EVAP WATER

L3

L4

OUTLET

94.3

NOTES:

1. The dimension drawing depicts the dual-pump option; a single pump is also available. Water connections are

in the same location with either arrangement.

2. See following page for additional dimensions and pump information.

3. Due to variations in pump sizes, operating weight with water is approximate, and may increase up to 5%. The

mounting weights are shown on page 5.

AGZ-C, 4-FAN UNIT, WEIGHTS AND CG (with PUMPS)

AGZ-C

MODEL

030C 43.4 37.8 45.0 4020 4035 1101 1072 936 911

035C 43.7 37.7 44.9 4070 4090 1112 1095 939 925

040C 43.8 37.9 45.0 4185 4205 1134 1122 970 959

045C 45.1 40.0 45.1 4310 4335 1133 1189 971 1018

050C 44.2 38.7 45.1 4435 4465 1187 1198 1020 1030

055C 44.7 38.8 44.3 4375 4405 1191 1229 962 993

060C 46.1 38.2 44.3 4640 4690 1222 1343 989 1087

065C 46.2 38.2 44.6 4670 4725 1213 1342 1004 1111

070C 42.6 36.6 47.3 5225 5280 1341 1255 1358 1271

CG LOCATION (in.) LIFTING WEIGHT BY CORNER (lbs))

X Y Z

SHIPPING

WEIGHT (lbs)

OPERATING

WEIGHT (lbs)

L1 L2 L3 L4

18 IOMM AGZC Pump Pkg

Page 19

EVAP

WATER

CONNECTION

Figure 5, AGZ 075C to 100C Dimensions with Pump Package

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

12.4 12.4110.1

L3

EVAP

L4

TOP VIEW

M1M3

L1

2.0

COMPRESSOR

CIRCUIT #2

EVAP. WATER

INLET

COMPRESSOR

CIRCUIT #1

B

C

L2

M2M4

2.0

EVAP. WATER

OUTLET

BACK VIEW

POWER ENTRY POINT

.875 KNOCK OUTS

FRONT AND SIDE

A

49.5

43.7

8.0

REF.

24.0

POWER

CONNECTIONS

OPPOSITE SIDE

OF CONTROL BOX

2.0

CG

5.0

EVAP

L3

L4

134.9

L1

24.0

L2

Z

3.4

4.0

40.7

FIELD CONTROL

Y

18.0

CONNECTION

43.7

SIDE VIEW

CONTROL BOX WIDTH

CONTROL

BOX

2.5

2.5

CG

PUMP

CONTROL

PAN EL

FRONT VIEW

88.0

6.4 14.4

X

NOTES:

1. The dimension drawing depicts the optional dual-pump arrangement, a single pump is standard.

2. See following page for additional dimensions and pump information.

3. Due to variations in pump sizes, operating weight with water is approximate, and may increase up to 5%. The

mounting weights are shown on page 5.

AGZ-C, 6-FAN UNIT, WEIGHTS AND CG (with PUMPS)

CG LOCATION (in.) LIFTING WEIGHT BY CORNER (lbs) AGZ-C

MODEL X Y Z

SHIPPING

WEIGHT

(lbs)

OPERATING

WEIGHT

(lbs)

L1 L2 L3 L4

95.0

100.2

075C 47.2 38.1 61.0 6640 6690 1769 2044 1312 1516

080C 47.3 39.7 59.3 6720 6775 1847 2143 1264 1466

090C 47.2 40.0 59.8 6595 6660 1800 2075 1262 1457

100C 47.4 39.6 60.7 6730 6795 1797 2093 1311 1529

IOMM AGZC Pump Pkg 19

Page 20

C

A

Figure 6, AGZ 110C to 130C Dimensions with Pump Package

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

25.2 67.8 67.7 12.4

L1

EVAP

L4

EVAP

WATER

ONNECTIONS

M6 M4 M2

TOP VIEW

M1M3M5

L1L3

2.0

COMPRESSOR

CIRCUIT #2

EVAP. WATER

COMPRESSOR

CIRCUIT #1

L2

INLET

2.0

B

C

EVAP. WATER

OUTLET

BACK VIEW

CONTROL BOX WIDTH

POWER ENTRY POINTS

.875 KNOCK OUTS

FRONT OR SIDE

50.0

REF.

8.0

CG

L3

L4

24.0 24.0

NOTES:

1. DUE TO VARIATIONS IN PUMP SIZES, OPERATING WEIGHT WITH WATER

SIDE VIEW

173.1

Z

IS AP PROXIMATE AND MAY INCREASE UP TO 5%.

POWER

CONNECTIONS

OPPOSITE SIDE

40.7

3.4

4.0

Y

OF CONTROL BOX

5.0

FIELD CONTROL

CONNECTIONS

43.7

2.0

L1

L2

PUMP

CONTROL

PANE L

CONTROL

BOX

2.518.1

CG

2.5

6.4 14.4

SCALE

*331779023001*

NONE

X

88.0

FRONT VIEW

ALL DIMENSIONS ARE IN DECIMAL INCHES

43.7

NOTES:

1. The dimension drawing depicts the optional dual-pump arrangement, a single pump is standard.

2. See following page for additional dimensions and pump information.

3. Due to variations in pump sizes, operating weight with water is approximate, and may increase up to 5%. The

mounting weights are shown on page 5.

AGZ-C, 8-FAN UNIT, WEIGHTS AND CG (with PUMPS)

AGZ-C

MODEL

CG LOCATION (in.) LIFTING WEIGHT BY CORNER (lbs)

X Y Z

SHIPPING

WEIGHT

(lbs)

110C 46.2 38.6 79.0 8580 8650 2284 2522 1794 1981

OPERATING

WEIGHT

(lbs)

L1 L2 L3 L4

95.0

100.2

125C 45.8 39.7 79.2 8720 8800 2337 2534 1847 2002

130C 46.1 40.7 78.3 8850 8945 2386 2624 1829 2012

20 IOMM AGZC Pump Pkg

Page 21

Figure 7, AGZ 140C to 180C Dimensions with Pump Package

2

A

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

M7

34.17 72.80

L5

M5

L3

81.1 67.7 12.4

M3

M1

L1

2.0

COMPRESSOR

CIRCUIT #2

COMPRESSOR

CIRCUIT #1

31.97

L6

M8

85.89

8"

VICTAULIC

CONNECTION

L5

L6

15.50

NOTE:

1. DUE TO VARIATIONS IN PUMP SIZES, OPERATING WEIGHT WITH

104.2

17.00

EVAP

WATER

OUTLET

NOTES:

1. The dimension drawing depicts the optional dual-pump arrangement, a single pump is standard.

2. See following page for additional dimensions and pump information.

3. Due to variations in pump sizes, operating weight with water is approximate, and may increase up to 5%. The

mounting weights are shown on page 5.

EVAP

L4

M6

TOP VIEW

CG

M4

Y

EVAP

L3

L4

268.0

SIDE VIEW

WATER IS APPROXIMATE AND MAY INCREASE UP TO 5%.

L2

M2

2.00

L1

L2

Z

24.0

2.0

POWER CONNECTIONS

OPPOSITE SIDE OF

CONTROL BOX

3.40

FIELD CONTROL

CONNECTIONS

5.00

4.80

41.62

44.0

WATER

INLET

POWER ENTRY POINTS

.875 KNOCK OUTS

FRONT OR SIDE

CONTROL

PAN EL

2.511.8

2.5

PUMP

CONTROL

PANE L

88.0

FRONT VIEW

43.04

BACK VIEW

CG

6.5 6.6

X

ALL DIMENSIONS ARE IN DECIMAL INCHES

SCALE

*331779024001*

NONE

95.0

44.0

100.

AGZ-C, 10-FAN UNIT, WEIGHTS AND CG (with PUMPS)

AGZ-C

MODEL

CG LOCATION (in.) LIFTING WEIGHT BY CORNER (lbs)

X Y Z

SHIPPING

WEIGHT

(lbs)

OPERATING

WEIGHT (lbs)

L1 L2 L3 L4 L5 L6

140C 44.7 39.6 121.7 12580 13062 2784 2872 1964 2026 1444.4 1489.8

160C 44.1 37.4 123.3 12610 13092 2776 2794 2000 2013 1508.2 1517.8

180C 44.4 35.2 122.7 12731 13213 2805 2859 2004 2043 1495.9 1524.7

IOMM AGZC Pump Pkg 21

Page 22

Figure 8, AGZ 190C Dimensions with Pump Package

A

W

(

(

)

ISOLATOR MOUNTING HOLE LOCATIONS ON BOTTOM SURFACE OF UNIT BASE

119. 272.834.2

L5

L6

17.0

L3

L4

TOP VIEW

Y

EVAP

32.1

L7

L8

8"

VICTAULIC

CONNECTION

124.25

M1M3M5M7

12.4067.7

L1

2.0

COMPRESSOR

CIRCUIT #2

COMPRESSOR

CIRCUIT #1

L2

2.00

2.0

M2M4M6M8

POWER CONNECTIONS

OPPOSITE SIDE OF

3.40

5.00

41.62

CONTROL BOX

4.80

FIELD CONTROL

CONNECTIONS

11. 8

44.00

EVAP

WATER

INLET

POWER ENTRY POINTS

.875 KNOCK OUTS

FRONT OR SIDE

2.50

PUMP

CONTROL

PANE L

CONTROL

PAN EL

2.50

CG

43.04

BACK VIEW

44.0

95.0

100.2

6.5

X

88.00

*R331779025001*

EVAP

WATER

OUTLET

306.19

SIDE VIEW

24.085.2392.7788.6815.50

Z

ALL DIMENSIONS ARE IN DECIMAL INCHES

SCALE

NONE

NOTES:

1. The dimension drawing depicts the optional dual-pump arrangement, a single pump is standard.

2. Due to variations in pump sizes, operating weight with water is approximate, and may increase up to 5%.

AGZ-C, 12-FAN UNIT, WEIGHTS AND CG (with PUMPS)

AGS-C

MODEL

CG LOCATION (in.) LIFTING WEIGHT BY CORNER

SHIPPING

WEIGHT

X Y Z

lbs)

OPERATING

WEIGHT

lbs

L1 L2 L3 L4 L5 L6 L7 L8

190C 44.5 36.8 142.7 14352 14834 2098 2147 1889 1934 1661 1700 1445 1478

6.6

FRONT VIE

22 IOMM AGZC Pump Pkg

Page 23

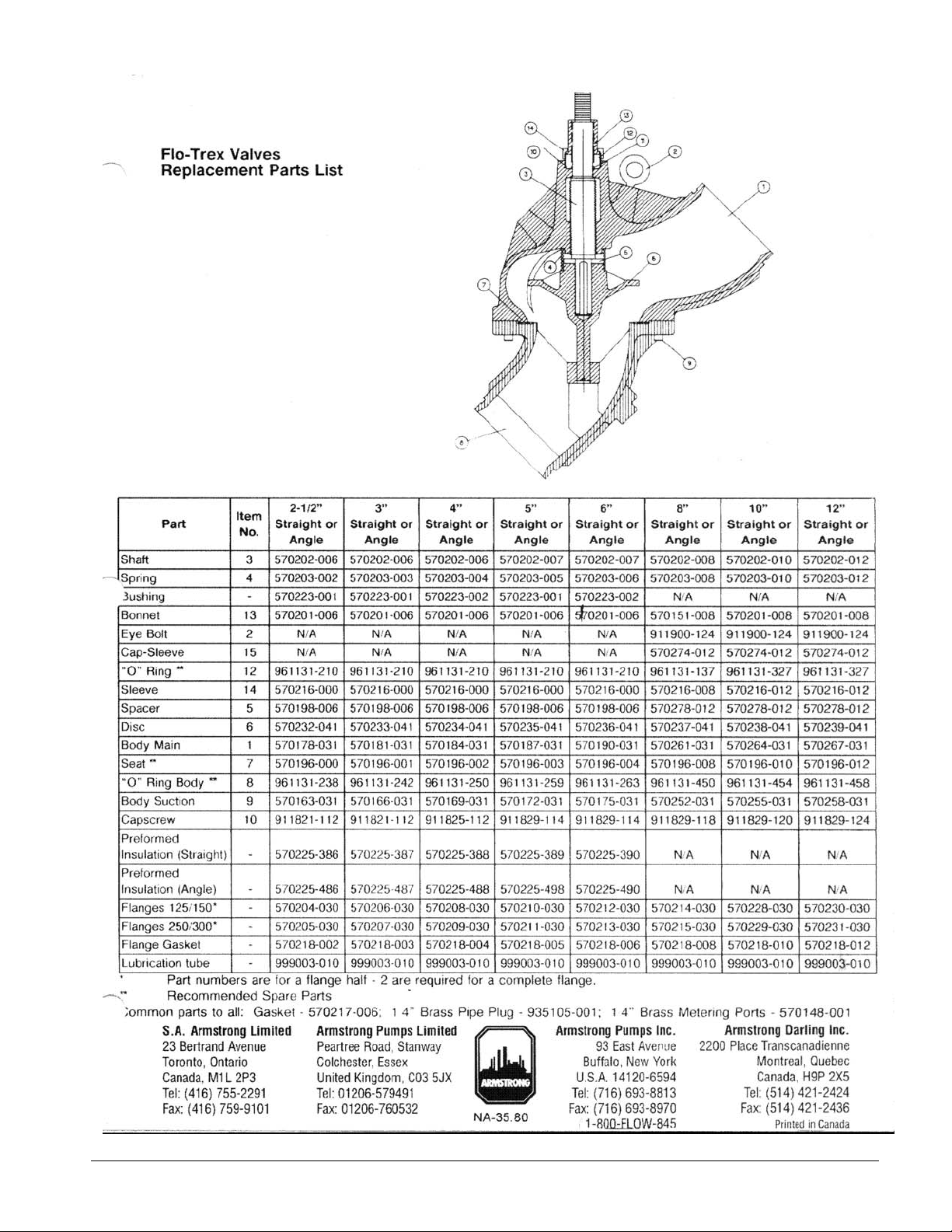

Pump Curves

The impeller of each pump is cut to meet the project’s design flow and head, and it is not practical to include

so many of them in this manual. However, a close approximation of the job’s specific pump can be made as

follows:

1. Using the pump nameplate as a reference, find the generic pump curve in this section.

2. Using the project’s design information, find the system design flow and head

3. Mark this flow and head on the pump curve and using the point as a reference point, draw in curve

parallel to the curve above and below it.

4. For example, if the design conditions were 90 gpm at a 90 ft. head, the point would be as shown below.

Draw a curve through it and parallel to the 5.50 in. and the 5.00 in. impeller curves.

Figure 9, Series 4270, 2x1.5x5.5, 3600 RPM

Hea d (m ) ft

(36.6) 120

(27.4) 90

(18.3) 60

(9. 1) 30

(0. 0) 0

Wa t e r, sg = 1 . 00

5.50 in

5.00 in

4.50 in

4.00 in

3.50 in

0

0.00

3600 RPM

43

55

62

67

70

71

71

71

70

67

62

55

5 hp

3 hp

2 hp

N

P

0.5 hp

0.75 hp

1 hp

S

H

r

NPSHr

30

1.89

60

3.79

1.5 hp

90

5.68

120

7.57

150

9.46

(usgpm)

(lp s)

Fl o w

CURVE NO.

PT32-1-7-3600

SERIES

4270

SIZE

2x1.5x5.5

RPM

3600

BHP based on

sho wn Flu id 's sp . g r.

4270

All Rating s

A

V

A

I

L

A

B

I

L

Design Operating Point

IOMM AGZC Pump Pkg 23

Page 24

Figure 10, Series 4280, 3x1.5x6, 3600 RPM

Head (m) ft

(45.7)

(36.6)

(27.4) 90

(18.3) 60

(9.1) 30

(0.0) 0

Water, sg= 1.00

150

120

0

0.00

6.19 in

5.63 in

5.25 in

4.88 in

4.50 in

N

P

S

H

r

NPSHr

60

3.79

49

58

65

69

71

2 hp

120

7.57

CURVE NO.

3600 RPM

PT49-2-0-3600

SERIES

71

71

7272

3 hp

69

5 hp

65

58

49%

7.5 hp

15 hp

10 hp

4030

4280

SIZE

3x1.5x6

RPM

3600

BHP based on

shown Fluid's sp. gr.

4030

All Ratings

4280

All Ratings

A

(lps)

Flow

V

A

I

L

A

B

I

L

180

11. 36

240

15.14

(usgpm)

Figure 11, Series 4280, 3x1.5x6, 1800 RPM

Head (m) ft

(12.2) 40

(9.8) 32

(7.3) 24

(4.9) 16

(2.4) 8

(0.0) 0

Water, sg= 1.00

0

0.00

6.19 in

5.63 in

5.25 in

4.88 in

4.50 in

N

P

S

H

r

NPSHr

50

30

1.89

60

67

71

72

0.25 hp

60

3.79

73

0.333 hp

72

0.5 hp

90

5.68

71

0.75 hp

1800 RPM

67

60

1 hp

120

7.57

1.5 hp

(usgpm)

(lps)

Flow

CURVE NO.

PT48-2-0-1800

SERIES

4030

4280

SIZE

3x1.5x6

RPM

1800

BHP based on

shown Fluid's sp. gr.

4030

All Ratings

4280

All Ratings

A

V

A

I

L

A

B

I

L

24 IOMM AGZC Pump Pkg

Page 25

4

4

C

3

R

AVAILAB

I

L

S

S

1

4

4

C

3

R

AVAIL

A

B

I

L

S

S

3

Figure 12, Series 4280, 3x1.5x8, 1800 RPM

Head (m) ft

(19.5) 64

(14.6) 48

(9.8) 32

(4.9) 16

(0.0) 0

Water, sg= 1.00

8.19 in

7.50 in

7.00 in

6.50 in

6.00 in

0

0.00

N

P

S

H

r

NPSHr

36

49

58

64

67

69

1 hp

0.75 hp

40

2.52

80

5.05

69

49%

1.5 hp

120

7.57

URVE NO.

1800 RPM

69

67

64

58

5 hp

PT50-1-0-1800

ERIES

030

280

IZE

x1.5x8

3 hp

PM

800

2 hp

BHP based on

shown Fluid's sp. gr.

4030

All Ratings

4280

All Ratings

160

10.09

(usgpm)

(lps)

Flow

Figure 13, Series 4280, 3x2x6, 3600 RPM

Head (m) ft

(36.6)

(27.4) 90

(18.3) 60

(9.1) 30

Water, sg= 1.00

120

(0.0) 0

6.19 in

5.63 in

5.25 in

4.88 in

4.50 in

0

0.00

49

59

66

N

P

S

H

r

NPSHr

80

5.05

160

10.09

URVE NO.

71

74

74

74

3600 RPM

71

66

15 hp

PT63-1-0-3600

ERIES

030

280

IZE

x2x6

PM

600

BHP based on

4030

49%

10 hp

59%

7.5 hp

shown Fluid's sp. gr.

5 hp

All Ratings

3 hp

240

15.14

320

20.19

(usgpm)

(lps)

4280

All Ratings

Flow

IOMM AGZC Pump Pkg 25

Page 26

Figure 14, Series 4280, 3x2x6, 1800 RPM

4

4

C

3

R

S

S

1

4

4

C

3

R

S

S

1

Head (m) ft

6.19 in

37

49

59

67

(9.8) 32

5.63 in

(7.3) 24

5.25 in

4.88 in

4.50 in

(4.9) 16

(2.4) 8

(0.0) 0

Water, sg= 1.00

0

0.00

N

P

S

H

NPSHr

r

40

2.52

80

5.05

URVE NO.

1800 RPM

72

74

75

74

72

67

1.5 hp

59%

PT62-1-0-1800

ERIES

030

280

IZE

x2x6

PM

800

1 hp

49%

0.75 hp

BHP based on

shown Fluid's sp. gr.

4030

All Ratings

0.5 hp

0.333 hp

120

7.57

160

10.09

(usgpm)

(lps)

Flow

A

V

A

I

L

A

B

I

L

4280

All Ratings

Figure 15, Series 4280, 3x2x8, 1800 RPM

Head (m) ft

(18.3) 60

(14.6) 48

(11.0) 36

(7.3) 24

(3.7) 12

Water, sg= 1.00

(0.0) 0

0

0.00

8.13 in

7.63 in

7.13 in

6.63 in

5.88 in

N

P

S

H

r

NPSHr

36

50

60

67

72

1 hp

60

3.79

120

7.57

74

1.5 hp

74

2 hp

180

11. 36

URVE NO.

1800 RPM

74

72

67

60

5 hp

PT64-1-0-1800

ERIES

030

280

IZE

x2x8

PM

3 hp

800

BHP based on

shown Fluid's sp. gr.

4030

All Ratings

4280

All Ratings

A

(lps)

Flow

V

A

I

L

A

B

I

L

240

15.14

(usgpm)

26 IOMM AGZC Pump Pkg

Page 27

Figure 16, Series 4280, 3x2.5x8, 1800 RPM

4

4

3

R

S

S

1

4

4

C

3

R

A

V

AIL

ABI

L

S

S

3

Head (m) ft

(18.3) 60

(14.6) 48

8.19 in

7.38 in

6.75 in

40

5353%

63

70

74

76

76

CURVE NO.

1800 RPM

PT56-1-0-1800

ERIES

76

74

70

63

7.5 hp

030

280

IZE

x2.5x8

(11.0) 36

6.13 in

5.50 in

(7.3) 24

2 hp

1.5 hp

240

15.14

(3.7) 12

(0.0) 0

Water, sg= 1.00

0

0.00

N

P

S

NPSHr

H

r

80

5.05

1 hp

160

10.09

Figure 17, Series 4280, 3x2.5x6, 3600 RPM

Head (m) ft

150

(45.7)

(36.6)

(27.4) 90

120

6.19 in

5.63 in

5.25 in

4.88 in

4.50 in

39

52

62

69

74

3 hp

76

320

20.19

76

5 hp

76

PM

800

BHP based on

shown Fluid's sp. gr.

4030

All Ratings

4280

All Ratings

A

(lps)

Flow

V

A

I

L

A

B

I

L

400

25.24

(usgpm)

URVE NO.

3600 RPM

PT55-1-0-3600

ERIES

030

280

IZE

74

69

62

x2.5x6

PM

600

(18.3) 60

(9.1) 30

15 hp

10 hp

N

P

S

H

NPSHr

r

3 hp

7.5 hp

5 hp

BHP based on

shown Fluid's sp. gr.

4030

All Ratings

4280

All Ratings

(0.0) 0

0

0.00

100

6.31

200

12.62

300

18.93

400

25.24

500

31.54

(usgpm)

(lps)

Flow

Water, sg= 1.00

IOMM AGZC Pump Pkg 27

Page 28

Figure 18, Series 4280, 3x2.5x6, 1800 RPM

Head (m) ft

6.19 in

(9.8) 32

5.63 in

5.25 in

37

51

61

68

72

75

(7.3) 24

4.88 in

4.50 in

(4.9) 16

(2.4) 8

(0.0) 0

Water, sg= 1.00

0

0.00

N

P

NPSHr

S

H

r

60

3.79

0.333 hp

120

7.57

0.5 hp

75

180

11.36

75

51%

0.75 hp

72

68

1 hp

1800 RPM

61

2 hp

1.5 hp

240

15.14

(usgpm)

CURVE NO.

PT54-1-0-1800

BHP based on

shown Fluid's sp. gr.

A

V

A

I

(lps)

L

A

Flow

B

I

L

SERIES

4030

4280

SIZE

3x2.5x6

RPM

1800

4030

All Ratings

4280

All Ratings

Figure 19, Series 4382, 3x3x8, 1800 RPM

Head (m) ft

8.19 in

36

48

57

63

67

(19.5) 64

7.50 in

7.00 in

(14.6) 48

6.50 in

6.00 in

(9.8) 32

(4.9) 16

(0.0) 0

Water, sg= 1.00

0

0.00

N

P

S

H

NPSHr

r

40

2.52

80

5.05

0.75 hp

7.57

1 hp

120

69

48%

69

1.5 hp

69

2 hp

160

10.09

1800 RPM

67

63

3 hp

12.62

200

CURVE NO.

PT30-1-0-1800

SERIES

4302

4382

SIZE

57

5 hp

3x3x8

RPM

1800

BHP based on

shown Fluid's sp. gr.

4302

All Ratings

4382

All Ratings

A

(lps)

Flow

V

A

I

L

A

B

I

L

(usgpm)

28 IOMM AGZC Pump Pkg

Page 29

Figure 20, Series 4280, 4x3x6, 3600 RPM

4

4

4

R

S

S

3

4

4

4

R

S

S

1

Head (m) ft

(45.7)

(36.6)

(27.4) 90

(18.3) 60

150

120

6.19 in

5.63 in

5.25 in

4.88 in

4.50 in

35

49

61

71

77

CURVE NO.

3600 RPM

PT78-1-0-3600

ERIES

030

82

83

82

77

71

30 hp

25 hp

20 hp

15 hp

280

IZE

x3x6

PM

600

BHP based on

shown Fluid's sp. gr.

0

0.00

N

P

S

H

NPSHr

r

160

10.09

320

20.19

480

30.28

(9.1) 30

(0.0) 0

Water, sg= 1.00

Figure 21, Series 4280, 4x3x6, 1800 RPM

Head (m) ft

(9.8) 32

(7.3) 24

(4.9) 16

Water, sg= 1.00

(2.4) 8

(0.0) 0

0

0.00

6.19 in

5.63 in

5.25 in

4.88 in

4.50 in

N

P

S

H

r

NPSHr

35

80

5.05

49

61

71

77

160

10.09

5 hp

82

240

15.14

7.5 hp

1 hp

0.75 hp

10 hp

83

640

40.38

82

1.5 hp

320

20.19

800

50.47

1800 RPM

77

71

3 hp

2 hp

25.24

400

(usgpm)

(lps)

Flow

5 hp

(usgpm)

(lps)

Flow

4030

All Ratings

4280

All Ratings

A

V

A

I

L

A

B

I

L

CURVE NO.

PT78-1-0-1800

ERIES

030

280

IZE

x3x6

PM

800

BHP based on

shown Fluid's sp. gr.

4030

All Ratings

4280

All Ratings

IOMM AGZC Pump Pkg 29

Page 30

Figure 22, Series 4382, 4x4x10, 1800 RPM

R

R

Head (m) ft

(30.5)

(24.4) 80

10.16 in

100

9.38 in

8.75 in

8.13 in

5441

64

70

73

75

CURVE NO.

1800 RPM

75

75

73

70

64

15 hp

PT66-2-0-1800

SERIES

4302

4382

SIZE

4x4x10

(18.3) 60

7.50 in

(12.2) 40

(6.1) 20

(0.0) 0

Water, sg= 1.00

0

0.00

N

P

S

H

NPSHr

r

80

5.05

160

10.09

2 hp

15.14

Figure 23, Series 4382, 6x6x6, 3600 RPM

Head (m) ft

150

(45.7)

(36.6)

(27.4) 90

120

6.19 in

5.63 in

5.25 in

4.88 in

4.50 in

42

55

66

74

79

82

(18.3) 60

0

0.00

N

P

S

NPSHr

H

r

200

12.62

400

25.24

37.85

(9.1) 30

(0.0) 0

Water, sg= 1.00

3 hp

240

600

83

5 hp

5 hp

82

7.5 hp

20.19

10 hp

50.47

320

79

800

7.5 hp

66%

15 hp

74

20 hp

10 hp

400

(usgpm)

25.24

3600 RPM

25 hp

1000

63.09

(usgpm)

shown Fluid's sp. gr.

A

V

A

I

(lps)

L

A

Flow

B

I

L

PT86-1-0-3600

shown Fluid's sp. gr.

A

V

A

I

(lps)

L

A

Flow

B

I

L

PM

1800

BHP based on

4302

All Ratings

4382

All Ratings

CURVE NO.

SERIES

4302

4382

SIZE

6x6x6

PM

3600

BHP based on

4302

All Ratings

4382

All Ratings

30 IOMM AGZC Pump Pkg

Page 31

Figure 24, Series 4382, 6x6x6, 1800 RPM

4

4

C

6

R

AVAILAB

I

L

S

S

1

4

4

C

6

R

AVAILAB

I

L

S

S

1

Head (m) ft

(9.8) 32

(7.3) 24

(4.9) 16

Water, sg= 1.00

(2.4) 8

(0.0) 0

6.19 in

5.63 in

5.25 in

4.88 in

4.50 in

0

0.00

44

58

68

76

80

83

N

P

NPSHr

S

H

r

100

6.31

200

12.62

0.5 hp

18.93

300

83

1 hp

0.75 hp

URVE NO.

1800 RPM

PT85-1-0-1800

ERIES

302

382

83

80

76

68

3 hp

2 hp

1.5 hp

IZE

x6x6

PM

800

BHP based on

shown Fluid's sp. gr.

4302

All Ratings

4382

All Ratings

400

25.24

500

31.54

(usgpm)

(lps)

Flow

Figure 25, Series 4382, 6x6x8, 1800 RPM

Head (m) ft

(18.3) 60

(14.6) 48

(11.0) 36

(7.3) 24

(3.7) 12

Water, sg= 1.00

(0.0) 0

8.19 in

7.50 in

7.00 in

6.50 in

6.00 in

0

0.00

35

48

59

67

73

N

P

NPSHr

S

H

r

160

10.09

320

20.19

30.28

77

480

3 hp

URVE NO.

1800 RPM

PT87-1-0-1800

ERIES

78

77

73

67

15 hp

302

382

IZE

x6x8

PM

5 hp

59%

7.5 hp

10 hp

800

BHP based on

shown Fluid's sp. gr.

4302

All Ratings

4382

All Ratings

640

40.38

800

50.47

(usgpm)

(lps)

Flow

IOMM AGZC Pump Pkg 31

Page 32

Figure 26, Series 4382, 6x6x10, 1800RPM

4

4

6

R

S

S

1

4

4

8

R

S

S

1

Head (m) ft

(30.5)

(24.4) 80

(18.3) 60

100

10.19 in

9.50 in

9.00 in

8.50 in

8.00 in

36

48

57

64

69

CURVE NO.

1800 RPM

71

72

71

69

64

57

15 hp

PT81-1-0-1800

ERIES

302

382

IZE

x6x10

PM

800

(12.2) 40

0

0.00

N

P

S

H

NPSHr

r

100

6.31

200

12.62

(6.1) 20

(0.0) 0

Water, sg= 1.00

Figure 27, Series 4382, 8x8x10, 1800RPM

Head (m) ft

(30.5)

(24.4) 80

(18.3) 60

100

10.19 in

9.50 in

9.00 in

8.50 in

8.00 in

56

68

76

81

3 hp

300

18.93

83

10 hp

7.5 hp

5 hp

BHP based on

shown Fluid's sp. gr.

4302

All Ratings

4382

All Ratings

A

(lps)

Flow

V

A

I

L

A

B

I

L

400

25.24

500

31.54

(usgpm)

CURVE NO.

1800 RPM

PT104-1-0-1800

ERIES

84

83

81

76

68

302

382

IZE

x8x10

PM

800

BHP based on

shown Fluid's sp. gr.

4302

All Ratings

4382

All Ratings

(12.2) 40

(6.1) 20

(0.0) 0

Water, sg= 1.00

0

0.00

56

25 hp

20 hp

15 hp

10 hp

5 hp

600

37.85

7.5 hp

800

50.47

1000

63.09

(usgpm)

(lps)

Flow

A

V

A

I

L

A

B

I

L

N

P

S

H

NPSHr

r

200

12.62

400

25.24

32 IOMM AGZC Pump Pkg

Page 33

Wiring Diagrams

Figure 28, Wiring Diagram with Dual Pumps/Single Control

IOMM AGZC Pump Pkg 33

Page 34

Figure 29, Wiring Diagram with Dual Pumps/Dual Control

C

\L1\PPU

\L2\PPU

DUAL CONTROL AND DUAL MOTOR

CBM

16 AWG

RED

8

15

16

17

18

1L1

1L2

1L3

14 AWG

GRN

16 AWG

YEL

16 AWG

WHT/YEL

16 AWG

YEL

16 AWG

WHT/YEL

12 AWG

BLK

T1

2.5

FU3

500VA

12

7

120VAC

FU6

FUSES INTEGRAL TO TRANS.

6

PUMP A

RUN

PUMP B

RUN

FU4

TS1-1

1L21L1

2.5

16 AWG

WHT

M1

A1 A2

M2

A1 A2

CLOSED <40F\POPEN

BLK

(MTD L-SIDE ENCL.)

1L1

1L2

1L3

4

4

43

TH1

>40\U+00B0F

BLK

PUMP A

PUMP B

INCOMING POWER

USTOMER SUPPLIED

3

3

(MTD L-SIDE ENCL.)

RUN SIGNAL

(120VAC)

RUN SIGNAL

(120VAC)

L1

L2

L3

PE

GND1 ENCL. DOOR

CR1

74

TS1-4 TS1-5

TH1

CR3

74

2

1

1

2

14 AWG

GRN

RED

TS1-3

GRN

16 AWG

GRN

1L1 1L2 1L3

TS1-2

G

}

See

Below

STANDARD LEGEND

WIRE NODE SYMBOL MAY

HAVE TERMINAL BLOCK

BENSHAW SUPPLIED

TERMINAL BLOCK

TERMINAL STRIP

POWER CONNECTION

PC BOARD TERMINALS

TWISTED PAIR

TWISTED SHIELDED PAIR

SHIELDED WIRE

FIELD WIRING

BLK

1L1 1L2 1L3

331480401rev0C

NOTES:

1

. TIGHTEN CONTROL TERMINALS TO 4.4 IN.\LBS (.5Nm)

2

. CUSTOMER CONNECTIONS SHALL USE COPPER WIRE

ONLY WITH A MINIMUM RATING OF 60C.

sheet 7

MSP1

CIRCUIT BREAKER

BLK

M1 CONTACTOR

13

14 222121436532

1L1A 1L2A 1L3A

1T1 1T2 1T3

M

MP MOTOR #1

43

31

44

TERMINATE TO

GND1 LUG

MOTOR GND

MSP2

CIRCUIT BREAKER

A1

X

A2

BLK

2L1A 2L2A 2L3A

M2 CONTACTOR

13

14 222121436532

TERMINATE TO

GND1 LUG

2T1 2T2 2T3

MOTOR GND

M

31

MP MOTOR #2

43

44

34 IOMM AGZC Pump Pkg

A1

A2

Page 35

Figure 30, Wiring Diagram with Single Pump/Single Control

Y

INCOMING POWER

CUSTOMER SUPPLIED

PE

RUN SIGNAL

(120VAC)

CBM

L1

L2

L3

14 AWG

GRN

GND1 ENCL. DOOR

16 AWG

CR1

74

TS1-4

TH1

1

RED

TS1-5

2

TB1

15

15

TB1

16

16

3

3

CLOSED <40F\POPEN

>40\U+00B0F

(MTD L-SIDE ENCL.)

1L1

1L2

1L3

16 AWG

GRN

12 AWG

BLK

T1

2.5

FU3

7

FU6

FUSES INTEGRAL TO TRANS.

6

TS1-3

16 AWG

YEL

16 AWG

WHT/YEL

500VA

12

120VAC

95 96

G

CR1

AB

SINGLE CONTROL AND SINGLE MOTOR

1L21L1

2.5

FU4

OL1

6A

PUMP

RUN

M1

A1 A2

1L1

1L2

1L3

16 AWG

WHT

4

4

BLK

PUMP A

14 AWG

GRN

1L1A 1L2A 1L3A

See

}

Below

STANDARD LEGEND

WIRE NODE SYMBOL MA

HAVE TERMINAL BLOCK

BENSHAW SUPPLIED

TERMINAL BLOCK

TERMINAL STRIP

POWER CONNECTION

PC BOARD TERMINALS

TWISTED PAIR

TWISTED SHIELDED PAIR

SHIELDED WIRE

FIELD WIRING

NOTES:

1

. TIGHTEN CONTROL TERMINALS

TO 4.4 in.\lbs (.5Nm)

. CUSTOMER CONNECTIONS SHALL

2

USE COPPER WIRE ONLY WITH A

MINIMUM RATING OF 60C

331480401rev0C

sheet 4

M1 CONTACTOR

13

14 222121436532

31

TERMINATE TO

GND1 LUG

MOTOR GND

M\L1\PPUMP MOTOR #1

IOMM AGZC Pump Pkg 35

Page 36

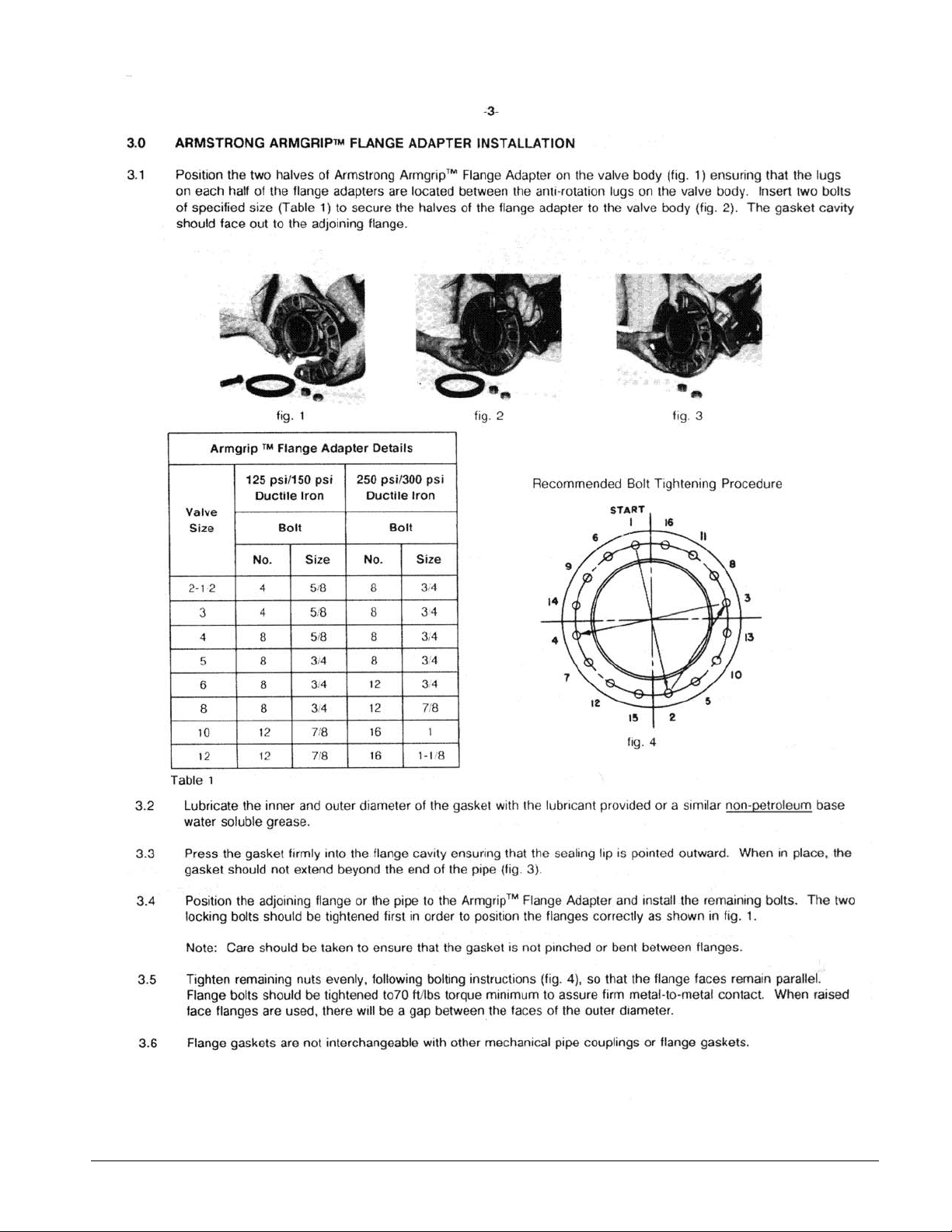

Electrical Data

Table 7, Unit Amp Draw

AGZ-C

SIZE

030

030

030

035

035

035

035

040

040

040

040

VOLTS

208 31.6 31.6 -- 31.6 31.6 -- 225 225 -- 225 225 -- 4 5.8 23.3 None -230 30.1 30.1 -- 30.1 30.1 -- 225 225 -- 225 225 -- 4 5.8 26.1 None -460 16.7 16.7 -- 16.7 16.7 -- 114 114 -- 114 114 -- 4 2.8 13.0 None -575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 None -208 31.6 31.6 -- 31.6 31.6 -- 225 225 -- 225 225 -- 4 5.8 23.3 2.0 7.5

230 30.1 30.1 -- 30.1 30.1 -- 225 225 -- 225 225 -- 4 5.8 26.1 2.0 6.8

460 16.7 16.7 -- 16.7 16.7 -- 114 114 -- 114 114 -- 4 2.8 13.0 2.0 3.4

575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 2.0 2.7

208 31.6 31.6 -- 31.6 31.6 -- 225 225 -- 225 225 -- 4 5.8 23.3 3.0 10.6

230 30.1 30.1 -- 30.1 30.1 -- 225 225 -- 225 225 -- 4 5.8 26.1 3.0 9.6

460 16.7 16.7 -- 16.7 16.7 -- 114 114 -- 114 114 -- 4 2.8 13.0 3.0 4.8

575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 3.0 3.9

208 31.6 31.6 -- 36.3 36.3 -- 225 225 -- 239 239 -- 4 5.8 23.3 None -230 30.1 30.1 -- 36.0 36.0 -- 225 225 -- 239 239 -- 4 5.8 26.1 None -460 16.7 16.7 -- 17.9 17.9 -- 114 114 -- 125 125 -- 4 2.8 13.0 None -575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 None -208 31.6 31.6 -- 36.3 36.3 -- 225 225 -- 239 239 -- 4 5.8 23.3 2.0 7.5

230 30.1 30.1 -- 36.0 36.0 -- 225 225 -- 239 239 -- 4 5.8 26.1 2.0 6.8

460 16.7 16.7 -- 17.9 17.9 -- 114 114 -- 125 125 -- 4 2.8 13.0 2.0 3.4

575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 2.0 2.7

208 31.6 31.6 -- 36.3 36.3 -- 225 225 -- 239 239 -- 4 5.8 23.3 3.0 10.6

230 30.1 30.1 -- 36.0 36.0 -- 225 225 -- 239 239 -- 4 5.8 26.1 3.0 9.6

460 16.7 16.7 -- 17.9 17.9 -- 114 114 -- 125 125 -- 4 2.8 13.0 3.0 4.8

575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 3.0 3.9

208 31.6 31.6 -- 36.3 36.3 -- 225 225 -- 239 239 -- 4 5.8 23.3 5.0 16.7

230 30.1 30.1 -- 36.0 36.0 -- 225 225 -- 239 239 -- 4 5.8 26.1 5.0 15.2

460 16.7 16.7 -- 17.9 17.9 -- 114 114 -- 125 125 -- 4 2.8 13.0 5.0 7.6

575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 5.0 6.1

208 36.3 36.3 -- 36.3 36.3 -- 239 239 -- 239 239 -- 4 5.8 23.3 None -230 36.0 36.0 -- 36.0 36.0 -- 239 239 -- 239 239 -- 4 5.8 26.1 None -460 17.9 17.9 -- 17.9 17.9 -- 125 125 -- 125 125 -- 4 2.8 13.0 None -575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 None -208 36.3 36.3 -- 36.3 36.3 -- 239 239 -- 239 239 -- 4 5.8 23.3 2.0 7.5

230 36.0 36.0 -- 36.0 36.0 -- 239 239 -- 239 239 -- 4 5.8 26.1 2.0 6.8

460 17.9 17.9 -- 17.9 17.9 -- 125 125 -- 125 125 -- 4 2.8 13.0 2.0 3.4

575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 2.0 2.7

208 36.3 36.3 -- 36.3 36.3 -- 239 239 -- 239 239 -- 4 5.8 23.3 3.0 10.6

230 36.0 36.0 -- 36.0 36.0 -- 239 239 -- 239 239 -- 4 5.8 26.1 3.0 9.6

460 17.9 17.9 -- 17.9 17.9 -- 125 125 -- 125 125 -- 4 2.8 13.0 3.0 4.8

575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 3.0 3.9

208 36.3 36.3 -- 36.3 36.3 -- 239 239 -- 239 239 -- 4 5.8 23.3 5.0 16.7

230 36.0 36.0 -- 36.0 36.0 -- 239 239 -- 239 239 -- 4 5.8 26.1 5.0 15.2

460 17.9 17.9 -- 17.9 17.9 -- 125 125 -- 125 125 -- 4 2.8 13.0 5.0 7.6

575 13.0 13.0 -- 13.0 13.0 -- 80 80 -- 80 80 -- 4 3.0 14.0 5.0 6.1

CIRCUIT #1 CIRCUIT #2 CIRCUIT #1 CIRCUIT #2

#1 #3 #5 #2 #4 #6 #1 #3 #5 #2 #4 #6

Continued on next page.

RATED LOAD AMPS LOCK ROTOR AMPS FAN MTRS PUMP MTRS

FLA

Qty

(EA)

LRA

(EA)

HP

FLA

(EA)

36 IOMM AGZC Pump Pkg

Page 37

Table 7, Unit Amp Draw, Continued

AGZ-C

SIZE

045

045

045

045

050

050

050

050

055

055

055

055

RATED LOAD AMPS LOCK ROTOR AMPS FAN MTRS. PUMP MTRS.

VOLTS

208 48.1 48.1 -- 48.1 48.1 -- 245 245 -- 245 245 -- 4 5.8 23.3 None -230 48.1 48.1 -- 48.1 48.1 -- 245 245 -- 245 245 -- 4 5.8 26.1 None -460 18.9 18.9 -- 18.9 18.9 -- 125 125 -- 125 125 -- 4 2.8 13.0 None -575 15.1 15.1 -- 15.1 15.1 -- 100 100 -- 100 100 -- 4 3.0 14.0 None -208 48.1 48.1 -- 48.1 48.1 -- 245 245 -- 245 245 -- 4 5.8 23.3 2.0 7.5

230 48.1 48.1 -- 48.1 48.1 -- 245 245 -- 245 245 -- 4 5.8 26.1 2.0 6.8

460 18.9 18.9 -- 18.9 18.9 -- 125 125 -- 125 125 -- 4 2.8 13.0 2.0 3.4

575 15.1 15.1 -- 15.1 15.1 -- 100 100 -- 100 100 -- 4 3.0 14.0 2.0 2.7

208 48.1 48.1 -- 48.1 48.1 -- 245 245 -- 245 245 -- 4 5.8 23.3 3.0 10.6

230 48.1 48.1 -- 48.1 48.1 -- 245 245 -- 245 245 -- 4 5.8 26.1 3.0 9.6

460 18.9 18.9 -- 18.9 18.9 -- 125 125 -- 125 125 -- 4 2.8 13.0 3.0 4.8

575 15.1 15.1 -- 15.1 15.1 -- 100 100 -- 100 100 -- 4 3.0 14.0 3.0 3.9

208 48.1 48.1 -- 48.1 48.1 -- 245 245 -- 245 245 -- 4 5.8 23.3 5.0 16.7

230 48.1 48.1 -- 48.1 48.1 -- 245 245 -- 245 245 -- 4 5.8 26.1 5.0 15.2

460 18.9 18.9 -- 18.9 18.9 -- 125 125 -- 125 125 -- 4 2.8 13.0 5.0 7.6

575 15.1 15.1 -- 15.1 15.1 -- 100 100 -- 100 100 -- 4 3.0 14.0 5.0 6.1

208 52.8 52.8 -- 52.8 52.8 -- 300 300 -- 300 300 -- 4 5.8 23.3 None -230 52.8 52.8 -- 52.8 52.8 -- 300 300 -- 300 300 -- 4 5.8 26.1 None -460 23.1 23.1 -- 23.1 23.1 -- 150 150 -- 150 150 -- 4 2.8 13.0 None -575 19.9 19.9 -- 19.9 19.9 -- 109 109 -- 109 109 -- 4 3.0 14.0 None -208 52.8 52.8 -- 52.8 52.8 -- 300 300 -- 300 300 -- 4 5.8 23.3 2.0 7.5

230 52.8 52.8 -- 52.8 52.8 -- 300 300 -- 300 300 -- 4 5.8 26.1 2.0 6.8

460 23.1 23.1 -- 23.1 23.1 -- 150 150 -- 150 150 -- 4 2.8 13.0 2.0 3.4

575 19.9 19.9 -- 19.9 19.9 -- 109 109 -- 109 109 -- 4 3.0 14.0 2.0 2.7

208 52.8 52.8 -- 52.8 52.8 -- 300 300 -- 300 300 -- 4 5.8 23.3 3.0 10.6

230 52.8 52.8 -- 52.8 52.8 -- 300 300 -- 300 300 -- 4 5.8 26.1 3.0 9.6

460 23.1 23.1 -- 23.1 23.1 -- 150 150 -- 150 150 -- 4 2.8 13.0 3.0 4.8

575 19.9 19.9 -- 19.9 19.9 -- 109 109 -- 109 109 -- 4 3.0 14.0 3.0 3.9

208 52.8 52.8 -- 52.8 52.8 -- 300 300 -- 300 300 -- 4 5.8 23.3 5.0 16.7

230 52.8 52.8 -- 52.8 52.8 -- 300 300 -- 300 300 -- 4 5.8 26.1 5.0 15.2

460 23.1 23.1 -- 23.1 23.1 -- 150 150 -- 150 150 -- 4 2.8 13.0 5.0 7.6

575 19.9 19.9 -- 19.9 19.9 -- 109 109 -- 109 109 -- 4 3.0 14.0 5.0 6.1

208 52.8 52.8 -- 56.6 56.6 -- 300 300 -- 340 340 -- 4 5.8 23.3 None -230 52.8 52.8 -- 55.8 55.8 -- 300 300 -- 340 340 -- 4 5.8 26.1 None -460 23.1 23.1 -- 26.9 26.9 -- 150 150 -- 172 172 -- 4 2.8 13.0 None -575 19.9 19.9 -- 23.7 23.7 -- 109 109 -- 132 132 -- 4 3.0 14.0 None -208 52.8 52.8 -- 56.6 56.6 -- 300 300 -- 340 340 -- 4 5.8 23.3 2.0 7.5

230 52.8 52.8 -- 55.8 55.8 -- 300 300 -- 340 340 -- 4 5.8 26.1 2.0 6.8

460 23.1 23.1 -- 26.9 26.9 -- 150 150 -- 172 172 -- 4 2.8 13.0 2.0 3.4

575 19.9 19.9 -- 23.7 23.7 -- 109 109 -- 132 132 -- 4 3.0 14.0 2.0 2.7

208 52.8 52.8 -- 56.6 56.6 -- 300 300 -- 340 340 -- 4 5.8 23.3 3.0 10.6

230 52.8 52.8 -- 55.8 55.8 -- 300 300 -- 340 340 -- 4 5.8 26.1 3.0 9.6

460 23.1 23.1 -- 26.9 26.9 -- 150 150 -- 172 172 -- 4 2.8 13.0 3.0 4.8

575 19.9 19.9 -- 23.7 23.7 -- 109 109 -- 132 132 -- 4 3.0 14.0 3.0 3.9

208 52.8 52.8 -- 56.6 56.6 -- 300 300 -- 340 340 -- 4 5.8 23.3 5.0 16.7

230 52.8 52.8 -- 55.8 55.8 -- 300 300 -- 340 340 -- 4 5.8 26.1 5.0 15.2

460 23.1 23.1 -- 26.9 26.9 -- 150 150 -- 172 172 -- 4 2.8 13.0 5.0 7.6

575 19.9 19.9 -- 23.7 23.7 -- 109 109 -- 132 132 -- 4 3.0 14.0 5.0 6.1

CIRCUIT #1 CIRCUIT #2 CIRCUIT #1 CIRCUIT #2

#1 #3 #5 #2 #4 #6 #1 #3 #5 #2 #4 #6

Qty.

FLA

(EA)

LRA

(EA)

HP

FLA

(EA)

IOMM AGZC Pump Pkg 37

Page 38

Table 7, Unit Amp Draw, Continued

AGZ-C

SIZE

060

060

060

060

060

065

065

065

065

065

VOLTS

208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 5.8 23.3 None -230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 5.8 26.1 None -460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 2.8 13.0 None -575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 None -208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 5.8 23.3 3.0 10.6

230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 5.8 26.1 3.0 9.6

460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 2.8 13.0 3.0 4.8

575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 3.0 3.9

208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 5.8 23.3 5.0 16.7

230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 5.8 26.1 5.0 15.2

460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 2.8 13.0 5.0 7.6

575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 5.0 6.1

208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 5.8 23.3 7.5 24.2

230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 5.8 26.1 7.5 22.0

460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 2.8 13.0 7.5 11.0

575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 7.5 9.0

208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 5.8 23.3 10.0 30.8

230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 5.8 26.1 10.0 28.0

460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 2.8 13.0 10.0 14.0

575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 10.0 11.0

208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 7.8 31.7 None -230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 7.8 35.6 None -460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 3.6 17.8 None -575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 None -208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 7.8 31.7 3.0 10.6

230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 7.8 35.6 3.0 9.6

460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 3.6 17.8 3.0 4.8

575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 3.0 3.9

208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 7.8 31.7 5.0 16.7

230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 7.8 35.6 5.0 15.2

460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 3.6 17.8 5.0 7.6

575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 5.0 6.1

208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 7.8 31.7 7.5 24.2

230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 7.8 35.6 7.5 22.0

460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 3.6 17.8 7.5 11.0

575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 7.5 9.0

208 56.6 56.6 -- 56.6 56.6 -- 340 340 -- 340 340 -- 4 7.8 31.7 10.0 30.8

230 55.8 55.8 -- 55.8 55.8 -- 340 340 -- 340 340 -- 4 7.8 35.6 10.0 28.0

460 26.9 26.9 -- 26.9 26.9 -- 172 172 -- 172 172 -- 4 3.6 17.8 10.0 14.0

575 23.7 23.7 -- 23.7 23.7 -- 132 132 -- 132 132 -- 4 3.0 14.0 10.0 11.0

Continued on next page.

RATED LOAD AMPS LOCK ROTOR AMPS FAN MTRS. PUMP MTRS.

CIRCUIT #1 CIRCUIT #2 CIRCUIT #1 CIRCUIT #2

#1 #3 #5 #2 #4 #6 #1 #3 #5 #2 #4 #6

QTY.

FLA

(EA)

LRA

(EA)

HP

FLA

(EA)

38 IOMM AGZC Pump Pkg

Page 39

Table 7, Unit Amp Draw, Continued

AGZ-C

SIZE

070

070

070

070

070

075

075

075

075

075

VOLTS

208 56.6 74.5 -- 56.6 74.5 -- 340 505 -- 340 505 -- 4 7.8 31.7 None -230 55.8 74.5 -- 55.8 74.5 -- 340 505 -- 340 505 -- 4 7.8 35.6 None -460 26.9 33.0 -- 26.9 33.0 -- 172 225 -- 172 225 -- 4 3.6 17.8 None -575 23.7 25.2 -- 23.7 25.2 -- 132 180 -- 132 180 -- 4 3.0 14.0 None -208 56.6 74.5 -- 56.6 74.5 -- 340 505 -- 340 505 -- 4 7.8 31.7 3.0 10.6

230 55.8 74.5 -- 55.8 74.5 -- 340 505 -- 340 505 -- 4 7.8 35.6 3.0 9.6

460 26.9 33.0 -- 26.9 33.0 -- 172 225 -- 172 225 -- 4 3.6 17.8 3.0 4.8

575 23.7 25.2 -- 23.7 25.2 -- 132 180 -- 132 180 -- 4 3.0 14.0 3.0 3.9

208 56.6 74.5 -- 56.6 74.5 -- 340 505 -- 340 505 -- 4 7.8 31.7 5.0 16.7

230 55.8 74.5 -- 55.8 74.5 -- 340 505 -- 340 505 -- 4 7.8 35.6 5.0 15.2

460 26.9 33.0 -- 26.9 33.0 -- 172 225 -- 172 225 -- 4 3.6 17.8 5.0 7.6

575 23.7 25.2 -- 23.7 25.2 -- 132 180 -- 132 180 -- 4 3.0 14.0 5.0 6.1

208 56.6 74.5 -- 56.6 74.5 -- 340 505 -- 340 505 -- 4 7.8 31.7 7.5 24.2

230 55.8 74.5 -- 55.8 74.5 -- 340 505 -- 340 505 -- 4 7.8 35.6 7.5 22.0

460 26.9 33.0 -- 26.9 33.0 -- 172 225 -- 172 225 -- 4 3.6 17.8 7.5 11.0

575 23.7 25.2 -- 23.7 25.2 -- 132 180 -- 132 180 -- 4 3.0 14.0 7.5 9.0

208 56.6 74.5 -- 56.6 74.5 -- 340 505 -- 340 505 -- 4 7.8 31.7 10.0 30.8

230 55.8 74.5 -- 55.8 74.5 -- 340 505 -- 340 505 -- 4 7.8 35.6 10.0 28.0

460 26.9 33.0 -- 26.9 33.0 -- 172 225 -- 172 225 -- 4 3.6 17.8 10.0 14.0

575 23.7 25.2 -- 23.7 25.2 -- 132 180 -- 132 180 -- 4 3.0 14.0 10.0 11.0

208 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 31.7 None -230 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 35.6 None -460 33.0 33.0 -- 33.0 33.0 -- 225 225 -- 225 225 -- 6 3.6 17.8 None -575 25.2 25.2 -- 25.2 25.2 -- 180 180 -- 180 180 -- 6 3.0 14.0 None -208 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 31.7 5.0 16.7

230 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 35.6 5.0 15.2

460 33.0 33.0 -- 33.0 33.0 -- 225 225 -- 225 225 -- 6 3.6 17.8 5.0 7.6

575 25.2 25.2 -- 25.2 25.2 -- 180 180 -- 180 180 -- 6 3.0 14.0 5.0 6.1

208 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 31.7 7.5 24.2

230 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 35.6 7.5 22.0

460 33.0 33.0 -- 33.0 33.0 -- 225 225 -- 225 225 -- 6 3.6 17.8 7.5 11.0

575 25.2 25.2 -- 25.2 25.2 -- 180 180 -- 180 180 -- 6 3.0 14.0 7.5 9.0

208 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 31.7 10.0 30.8

230 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 35.6 10.0 28.0

460 33.0 33.0 -- 33.0 33.0 -- 225 225 -- 225 225 -- 6 3.6 17.8 10.0 14.0

575 25.2 25.2 -- 25.2 25.2 -- 180 180 -- 180 180 -- 6 3.0 14.0 10.0 11.0

208 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 31.7 15.0 46.2

230 74.5 74.5 -- 74.5 74.5 -- 505 505 -- 505 505 -- 6 7.8 35.6 15.0 42.0

460 33.0 33.0 -- 33.0 33.0 -- 225 225 -- 225 225 -- 6 3.6 17.8 15.0 21.0

575 25.2 25.2 -- 25.2 25.2 -- 180 180 -- 180 180 -- 6 3.0 14.0 15.0 17.0

CIRCUIT #1 CIRCUIT #2 CIRCUIT #1 CIRCUIT #2

#1 #3 #5 #2 #4 #6 #1 #3 #5 #2 #4 #6

Continued on next page.

RATED LOAD AMPS LOCK ROTOR AMPS FAN MOTORS PUMP MTRS

FLA

QTY>

(EA)

LRA

(EA)

HP

FLA

(EA)

IOMM AGZC Pump Pkg 39

Page 40

Table 7, Unit Amp Draw, Continued

AGZ-C

VOLTS

SIZE

208 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 31.7 None --

080

080

080

080

080

090

090

090

090

090

230 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 35.6 None -460 33.0 33.0 -- 44.5 44.5 -- 225 225 -- 272 272 -- 6 3.6 17.8 None -575 25.2 25.2 -- 32.1 32.1 -- 180 180 -- 218 218 -- 6 3.0 14.0 None -208 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 31.7 5.0 16.7

230 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 35.6 5.0 15.2

460 33.0 33.0 -- 44.5 44.5 -- 225 225 -- 272 272 -- 6 3.6 17.8 5.0 7.6

575 25.2 25.2 -- 32.1 32.1 -- 180 180 -- 218 218 -- 6 3.0 14.0 5.0 6.1

208 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 31.7 7.5 24.2

230 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 35.6 7.5 22.0

460 33.0 33.0 -- 44.5 44.5 -- 225 225 -- 272 272 -- 6 3.6 17.8 7.5 11.0

575 25.2 25.2 -- 32.1 32.1 -- 180 180 -- 218 218 -- 6 3.0 14.0 7.5 9.0

208 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 31.7 10.0 30.8

230 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 35.6 10.0 28.0

460 33.0 33.0 -- 44.5 44.5 -- 225 225 -- 272 272 -- 6 3.6 17.8 10.0 14.0

575 25.2 25.2 -- 32.1 32.1 -- 180 180 -- 218 218 -- 6 3.0 14.0 10.0 11.0

208 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 31.7 15.0 46.2

230 74.5 74.5 -- 89.1 89.1 -- 505 505 -- 544 544 -- 6 7.8 35.6 15.0 42.0

460 33.0 33.0 -- 44.5 44.5 -- 225 225 -- 272 272 -- 6 3.6 17.8 15.0 21.0

575 25.2 25.2 -- 32.1 32.1 -- 180 180 -- 218 218 -- 6 3.0 14.0 15.0 17.0

208 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 31.7 None -230 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 35.6 None -460 44.5 44.5 -- 44.5 44.5 -- 272 272 -- 272 272 -- 6 3.6 17.8 None -575 32.1 32.1 -- 32.1 32.1 -- 218 218 -- 218 218 -- 6 3.0 14.0 None -208 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 31.7 5.0 16.7

230 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 35.6 5.0 15.2

460 44.5 44.5 -- 44.5 44.5 -- 272 272 -- 272 272 -- 6 3.6 17.8 5.0 7.6

575 32.1 32.1 -- 32.1 32.1 -- 218 218 -- 218 218 -- 6 3.0 14.0 5.0 6.1

208 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 31.7 7.5 24.2

230 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 35.6 7.5 22.0

460 44.5 44.5 -- 44.5 44.5 -- 272 272 -- 272 272 -- 6 3.6 17.8 7.5 11.0

575 32.1 32.1 -- 32.1 32.1 -- 218 218 -- 218 218 -- 6 3.0 14.0 7.5 9.0

208 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 31.7 10.0 30.8

230 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 35.6 10.0 28.0

460 44.5 44.5 -- 44.5 44.5 -- 272 272 -- 272 272 -- 6 3.6 17.8 10.0 14.0

575 32.1 32.1 -- 32.1 32.1 -- 218 218 -- 218 218 -- 6 3.0 14.0 10.0 11.0

208 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 31.7 15.0 46.2

230 89.1 89.1 -- 89.1 89.1 -- 544 544 -- 544 544 -- 6 7.8 35.6 15.0 42.0

460 44.5 44.5 -- 44.5 44.5 -- 272 272 -- 272 272 -- 6 3.6 17.8 15.0 21.0

575 32.1 32.1 -- 32.1 32.1 -- 218 218 -- 218 218 -- 6 3.0 14.0 15.0 17.0

Continued on next page.

RATED LOAD AMPS LOCK ROTOR AMPS FAN MTRS PUMP MTRS

CIRCUIT #1 CIRCUIT #2 CIRCUIT #1 CIRCUIT #2

#1 #3 #5 #2 #4 #6 #1 #3 #5 #2 #4 #6

QTY

FLA

(EA)

LRA

(EA)

HP

FLA

(EA)

40 IOMM AGZC Pump Pkg

Page 41

Table 7, Unit Amp Draw, Continued

AGZ-C

SIZE

100

100

100

100

100

110

110

110

110

110

VOLTS

208 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 31.7 None -230 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 35.6 None -460 43.0 54.5 -- 43.0 54.5 -- 272 310 -- 272 310 -- 6 3.6 17.8 None -575 32.1 44.5 -- 32.1 44.5 -- 218 239 -- 218 239 -- 6 3.0 14.0 None -208 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 31.7 5.0 16.7

230 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 35.6 5.0 15.2

460 43.0 54.5 -- 43.0 54.5 -- 272 310 -- 272 310 -- 6 3.6 17.8 5.0 7.6

575 32.1 44.5 -- 32.1 44.5 -- 218 239 -- 218 239 -- 6 3.0 14.0 5.0 6.1

208 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 31.7 7.5 24.2

230 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 35.6 7.5 22.0

460 43.0 54.5 -- 43.0 54.5 -- 272 310 -- 272 310 -- 6 3.6 17.8 7.5 11.0

575 32.1 44.5 -- 32.1 44.5 -- 218 239 -- 218 239 -- 6 3.0 14.0 7.5 9.0

208 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 31.7 10.0 30.8

230 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 35.6 10.0 28.0

460 43.0 54.5 -- 43.0 54.5 -- 272 310 -- 272 310 -- 6 3.6 17.8 10.0 14.0

575 32.1 44.5 -- 32.1 44.5 -- 218 239 -- 218 239 -- 6 3.0 14.0 10.0 11.0

208 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 31.7 15.0 46.2

230 89.1 115.5 -- 89.1 115.5 -- 544 599 -- 544 599 -- 6 7.8 35.6 15.0 42.0