Page 1

Installation and Maintenance Manual IM 1240-1

Group: Controls

Part Number: 910166126

Date: November 2015

Intelligent Equipment™ for

Daikin Trailblazer™

Models: AGZ-D, AGZ-E

Page 2

Table of ConTenTs

Introduction..................................3

Revision History .............................3

Reference Documents ........................3

Limited Warranty .............................3

General Information ..........................3

Product Description...........................3

Hazardous Information Messages ...............3

Components ................................4

Machine-to-Machine (M2M) Gateway ...........4

Antennas .................................4

Energy Management Module (EMM) ............4

Current Transformers (CT’s) ..................4

Power Supply..............................4

Fuse Block ................................4

USB-to-Ethernet Adapter .....................4

Installation...................................5

Unpacking ..................................5

Material shipped loose .......................5

Necessary Tools............................5

Retrot Installation ...........................5

Installing M2M Gateway......................6

Installing Energy Management Module ..........8

Installing Power Supply ......................8

Installing Fuse Block ........................8

Control Cabinet Penetrations..................9

Wiring interconnections.......................10

Table of ConTenTs

M2M Connection to MTIII ...................10

M2M Connection to EMM ...................10

Connection of Power Supply .................11

Connection of EMM to CT’s ..................11

Installing CT’s.............................12

Connection of EMM to Line Voltage............12

Connection of M2M and EMM to Ground .......13

Antenna Installation..........................14

Mounting ................................14

Wiring of Antennas .........................14

Verify Time Zone Information ..................15

Cellular Conguration ........................17

Wi-Fi Conguration ..........................19

Conguration for Hard-Wired Connection .........22

Troubleshooting .............................25

Potential issues:...........................25

Appendix ...................................26

Appendix A ................................26

Wi-Fi or Hardwired LAN Ethernet connection Pre-

Start-up Form.............................26

IM 1240-1 • INTELLIGENT EQUIPMENT 2 www.DaikinApplied.com

Page 3

Revision History

InTroduCTIon

InTroduCTIon

Hazardous Information Messages

Literature Number Release Date Action

IM 1240-1 November 2015 Revised LAN conguration

IM 1240 May 2015 Initial release

instructions

Reference Documents

Number Company Title Source

OM 1241 Daikin Applied

Operation and

Maintenance

Manual

www.

daikinapplied.com

Limited Warranty

Consult your local Daikin representative for warranty details. To

nd your local Daikin representative, go to www.DaikinApplied.

com.

General Information

This manual contains the information you need to install and

congure the Intelligent Equipment solution on MicroTech® III

Air-Cooled Chiller models: AGZ-D and AGZ-E. For installation

Technical Support, please contact the Daikin Applied

Controls Support Group at (866) 462-7829.

Recognize Safety Symbols, Words and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner and installer’s responsibility to read and comply with

all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the

risk of property damage and/or product damage, serious

personal injury or death. Improper installation, operation and

maintenance can void the warranty.

CAUTION

Cautions indicate potentially hazardous situations, which can

result in personal injury or equipment damage if not avoided.

Static sensitive components. Can cause equipment damage.

Discharge any static electrical charge by touching the bare

metal inside the control panel before performing any service

work. Never unplug cables, circuit board terminal blocks, or

power plugs while power is applied to the panel.

WARNING

Warnings indicate potentially hazardous situations, which can

result in property damage, severe personal injury, or death if

not avoided.

Product Description

The Daikin Applied Intelligent Equipment™ Software-asa-Service (SaaS) solution provides facility and equipment

management, monitoring, control, analysis, and decisionmaking via a secure, cloud-communicating machine-tomachine gateway that captures, analyzes and delivers building

and equipment information, and third party content (i.e. weather, utility, and CRM data), to a user device (smart phone,

tablet, etc.) via wireless (cellular, Wi-Fi) or local area network

(LAN) connection.

Intelligent Equipment provides real-time power monitoring

of the site and individual equipment. The user can view unit

statuses, modes, temperatures, pressures and setpoints, and

make adjustments to modes, schedules and temperature

setpoints. Messages and alarms can be viewed, acknowledged

and cleared.

User accounts are role-based, and user interaction, including

setpoint changes and clearing of alarms, is logged for later

reporting. System updates can be delivered automatically from

the cloud. Built-in trending tools provide easy access to unit

performance history. The subscription-based SaaS is available

with three interface options: Owner View, Technical View,

and Owner/Technical View. Hardware components consist

of: one Machine to Machine (M2M) Gateway, one Energy

Management Module (EMM), two Antennas, and three Current

Transformers (CT’s).

DANGER

Dangers indicate a hazardous situation which will result in

death or serious injury if not avoided. Electric shock hazard.

Can cause personal injury or equipment damage. This

equipment must be properly grounded. Connections and

service to the MicroTech III Air-Cooled Chiller Controller,

Machine-to-Machine Gateway and Energy Management

Module must be performed only by personnel knowledgeable

in the operation of the equipment being controlled.

NOTICE

This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with this instruction manual, may cause interference to radio

communications. It has been tested and found to comply with

the limits for a Class A digital device, pursuant to part 15 of the

FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct

the interference at his or her own expense. Daikin disclaims

any liability resulting from any interference or for the correction

thereof.

www.DaikinApplied.com 3 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 4

Components

InTroduCTIon

Machine-to-Machine (M2M) Gateway

The M2M Gateway is a factory tested and commissioned

device, which analyzes and delivers data to the cloud

via wireless (Wi-Fi, cellular) or local area network (LAN)

connection. The M2M Gateway implements security, including

data delivery via secure HTTPS using SSL, and whitelisting

protection. In the case of a unit ordered with Intelligent

Equipment, the M2M gateway will be factory-installed in the

unit control panel. For installation in retrot applications, see

document section titled, Installing M2M Gateway on page

6.

Antennas

Two Cellular/Wi-Fi antennas are provided with the Intelligent

Equipment solution, and must be eld-mounted, regardless

of whether the Daikin Applied Intelligent Equipment solution

was ordered as part of the chiller, or for retrot installation. In

most cases, only one of the two antennas will be installed and

connected to the M2M Gateway. The second antenna is used

in situations where both cellular and Wi-Fi are used to deliver

data to the cloud. Both antennas are shipped with a magnetic

base, which is suitable for directly mounting to the unit control

panel or case.

Energy Management Module (EMM)

The EMM is a factory tested and commissioned device, which

monitors unit voltage, current, and power and transmits this

data to the M2M Gateway for delivery to the cloud. In the case

of a unit ordered with Intelligent Equipment, the EMM will be

factory-installed in the unit control panel. For installation in

retrot applications, see document section titled, Installing

Energy Management Module on page 8.

Current Transformers (CT’s)

Three Current Transformers (CT’s) are supplied with the

Intelligent Equipment solution. At the time of order, the Maximum

Current Ampacity (MCA) for the unit is specied, thereby driving

selection of appropriately-sized CT’s (See Table 1 for CT sizing

and specications). In the case of a unit ordered with Intelligent

Equipment, the CT’s will be factory-installed within the unit

control panel. For installation of the CT’s in retrot applications,

see document section titled, Installing CT’s on page 12.

Power Supply

A 24 VDC Power Supply is provided to power the M2M

Gateway. In the case of a unit ordered with Intelligent

Equipment, the power supply will be factory-installed in the

unit control panel. For installation of the power supply in

retrot applications, see document section titled, Installing

Power Supply on page 8.

Fuse Block

A Fuse Block is provided to provide over-current protection for

the Energy Management Module (EMM). Replaceable 5Amp

fuses are pre-installed in the Fuse Block. In the case of a unit

ordered with Intelligent Equipment, the Fuse Block will be

factory-installed in the unit control panel. For installation of the

Fuse Block in retrot applications, see document section titled,

Installing Fuse Block on page 8.

USB-to-Ethernet Adapter

For installations where a Local Area Network (LAN) connection

is to be used, a USB-to-Ethernet adapter is included in all

shipments. The adapter is necessary because the M2M

Gateway has a single Ethernet plug, which is connected to

the MicroTech III controller, and, therefore, unavailable for

connection to the LAN.

Table 1: CT Sizing and Specications.

Key Specications 50A Model 100A Model 200A Model 600A Model 1000A Model

Window Size 0.4ʺ (10 mm) 1ʺ (25 mm) 1ʺ (25 mm) 1.25ʺ (31.8 mm) 2ʺ (50.8 mm)

Current Range 0.25 – 80A AC 1 - 200A AC 1 – 300A AC 12 – 780A AC 20 – 1300A AC

Output 333 mV at rated current 333 mV at rated current 333 mV at rated current 333 mV at rated current 333 mV at rated current

Ratio Error

Phase Error

<0.5% from 0.25 – 80A AC

(typical)

<1.5° from 1 – 80A AC

<2° from 0.25 – 1A AC

<0.3% from 1 - 200A AC

(typical)

<0.5° from 1 - 200A AC <0.5° from 1 – 300A AC <2° from 12 – 780A AC <2° from 20 – 1300A AC

<1.0% from 1 – 300A AC

(typical)

<1% from 12 – 780A AC

(typical)

<1% from 20 – 1300A AC

(typical)

IM 1240-1 • INTELLIGENT EQUIPMENT 4 www.DaikinApplied.com

Page 5

Unpacking

Material shipped loose

Factory Installed IE

If the Intelligent Equipment solution was ordered with the chiller,

it shipped with the M2M, EMM, CT’s, Powers Supply and Fuse

Block already installed in the control enclosure, and associated

interconnections already made. The antenna ags and Ethernet

adapter ship inside the schematics envelope for the unit. The

antenna(s) and Ethernet adapter are eld-installed.

Retrot IE

When the Intelligent Equipment solution is ordered for retrot

installation, the following components will ship loose:

• M2M Gateway

• Power Supply

• EMM

• Fuse Block (with 5A Fuses pre-installed).

• Antenna ags and bases

• Three Current Transformers (CT’s)

• 3' USB cable

• 6' Ethernet Patch cable

• USB-to-Ethernet Adapter

• 6" EMM Wiring Harness

• 6' EMM Wiring Harness

• Hardware packet, including (1) patch plate with two

watertight grommets pre-installed, (1) 0.875" grommet,

(2) grounding harnesses, (1) 3-wire voltage harness,

wire ties, wire tie hangers, (12) self-tapping sheet metal

screws, (1) section of 600V-rated heat shrink tubing.

Upon receiving, verify that all components are present, and

notify the supplier of any shortage.

Necessary Tools

• Corded (or powerful cordless) Drill

• Drill Bit set, including sizes 7/64", 1/8", and 5/32" suitable

for drilling through metal enclosure)

• Multimeter

• 25' Fish tape

• Wire strippers

• SAE hex wrench set

• Precision screwdriver set

• #2 Phillips screwdriver

• #2 Flat screwdriver

• 5/16" Nut driver

• Hammer

• Pliers

InsTallaTIon

InsTallaTIon

Retrot Installation

DANGER

Electric shock hazard. Can cause personal injury or

equipment damage.

Prior to installing Intelligent Equipment hardware, power must

be removed from the unit. This means removing power at the

breaker panel serving the unit, and following proper lockout/

tagout procedures at said breaker panel for the duration of

the install. Power should not be reapplied until all electrical

interconnections have been made and veried.

This equipment must be properly grounded. Connections

and service to the MicroTech III Air-Cooled Chiller Controller,

Machine-to-Machine Gateway and Energy Management

Module must be performed only by personnel knowledgeable

in the operation of the equipment being controlled.

CAUTION

Static sensitive components. Can cause equipment

damage.

Discharge any static electrical charge by touching the bare

metal inside the control panel before performing any service

work. Never unplug cables, circuit board terminal blocks, or

power plugs while power is applied to the panel.

WARNING

Sharp edges on sheet metal and fasteners can cause

personal injury. This equipment must be installed, operated,

and serviced only by an experienced installation company

and fully trained personnel.

CAUTION

To avoid damaging wires or components, verify clearance in

and around the point of penetration prior to any drilling

During any drilling, ensure that resultant metal shavings are

not allowed to contact unit electronics.

Subsequent to any drilling, remove all resulting metal shavings

from the control enclosure.

www.DaikinApplied.com 5 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 6

Installing M2M Gateway

Prior to installing any Intelligent Equipment components, power

must be removed from the unit. Power must be removed at

the breaker panel serving the unit, and proper lockout/tagout

procedures should be followed for the duration of the install.

After removing unit power at the breaker panel, the installer

must verify the absence of power at the unit using a multimeter.

Only if power has been veried absent, should the technician

begin the install. The retrot kit is shipped with the M2M

gateway shipped loose.

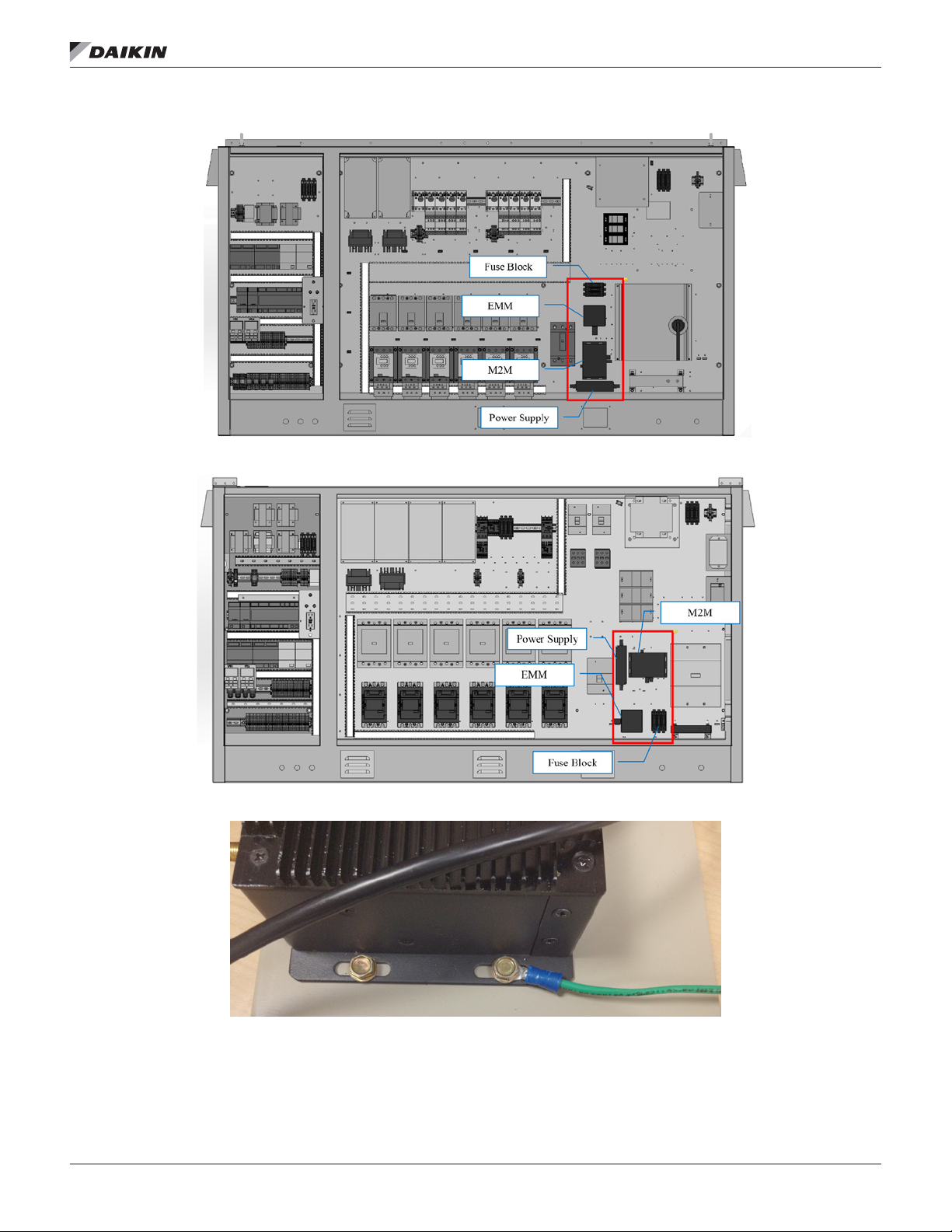

Figure 1: Component locations – AGZ-D & E Small Panel

InsTallaTIon

The M2M gateway must be installed inside the unit control

panel. The installation location will vary depending on the unit

model and size of the control enclosure (see Figure 1 through

Figure 4 for correct component locations). Begin by positioning

the M2M gateway on the backplane of the enclosure and

marking the screw holes. Next, drill pilot holes, through the

marks just created, using a 7/64" drill bit. Finally, attach the

M2M gateway to the backplane using (4) of the provided #6

sheet metal screws (5/16" head). Install the ring terminal on

one end of the M2M ground conductor under one of the(4)

sheet metal screws (Figure 5). The M2M ground conductor has

ring terminals at both ends. Termination for the other end of

this conductor is described in the section entitled, Connection

of M2M and EMM to Ground on page 13.

Figure 2: Component locations – AGZ-D & E Medium Panel

IM 1240-1 • INTELLIGENT EQUIPMENT 6 www.DaikinApplied.com

Page 7

Figure 3: Component locations – AGZ-D Large Panel

Figure 4: Component locations – AGZ-E Large Panel

InsTallaTIon

Figure 5: Installation of Grounding Ring to M2M Gateway

www.DaikinApplied.com 7 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 8

InsTallaTIon

Installing Energy Management Module

Prior to installing any Intelligent Equipment components, power

must be removed from the unit. Power must be removed

at the breaker panel serving the unit, and proper lockout/

tagout procedures should be followed for the duration of the

install. After removing unit power at the breaker panel, the

installer must verify the absence of power at the unit using a

multimeter. Only if power has been veried absent, should the

technician begin the install. The retrot kit is shipped with the

EMM shipped loose. The EMM must be installed inside the unit

control panel.

The installation location will vary depending on the unit model

and size of the control enclosure (see Figure 1 through Figure

4 for correct component locations). Begin by positioning the

EMM on the backplane of the enclosure and marking the screw

holes. Next, drill pilot holes, through the marks just created,

using a 7/64" drill bit. Finally, attach the EMM to the backplane

using (4) of the provided #6 sheet metal screws (5/16" head).

Installing Power Supply

Prior to installing any Intelligent Equipment components, power

must be removed from the unit. Power must be removed at

the breaker panel serving the unit, and proper lockout/tagout

procedures should be followed for the duration of the install.

After removing unit power at the breaker panel, the installer

must verify the absence of power at the unit using a multimeter.

Only if power has been veried absent, should the technician

begin the install.

The retrot kit is shipped with the power supply shipped loose.

The power supply must be installed inside the unit control

panel. The installation location will vary depending on the unit

model and size of the control enclosure (see Figure 1 through

Figure 4 for correct component locations).

Begin by positioning the power supply on the backplane of the

enclosure and marking the screw holes. Next, drill pilot holes,

through the marks just created, using a 7/64" drill bit. Finally,

attach the power supply to the backplane using (2) of the

provided #6 sheet metal screws (5/16" head).

Installing Fuse Block

Prior to installing any Intelligent Equipment components, power

must be removed from the unit. Power must be removed at

the breaker panel serving the unit, and proper lockout/tagout

procedures should be followed for the duration of the install.

After removing unit power at the breaker panel, the installer

must verify the absence of power at the unit using a multimeter.

Only if power has been veried absent, should the technician

begin the install. The retrot kit is shipped with the fuse block

shipped loose. The fuse block must be installed inside the unit

control panel. The installation location will vary depending on

the unit model and size of the control enclosure (see Figure 1

through Figure 4 for correct component locations).

Begin by removing the fuse covers and fuses from the fuse

block (Figure 6). Prior to removal, make note of fuse orientation

within the fuse block. Then, position the fuse block on the

backplane of the enclosure and mark the screw holes. Next,

drill pilot holes, through the marks just created, using a 1/8"

drill bit.

Finally, attach the fuse block to the backplane using (2) of the

provided #8 sheet metal screws (5/16" head). Fuses can be

reinstalled, but the covers should remain off for subsequent

install of necessary wiring.

Figure 6: Fuse Block with Covers and Fuses Removed

IM 1240-1 • INTELLIGENT EQUIPMENT 8 www.DaikinApplied.com

Page 9

Control Cabinet Penetrations

Only the antenna cable(s) must be routed to the outside of

the control enclosure; all other terminations remain within

the control enclosure. This is done using a specic available

knockout. The location of the correct knockout will vary

depending on the unit model and size of the control enclosure

(see Figure 7 through Figure 9 for knockout locations).

First, determine the correct knockout to remove, then remove

it using a hammer, at screwdriver and pliers. Use the hammer

to gently tap the at blade of a screwdriver into the open slit

of the knockout. Once enough separation is gained between

the knockout and the panel, use the pliers to fully remove the

knockout. Insert the provided 0.875" grommet into the control

enclosure from the outside. The knockout is now prepared for

routing of the antenna cable(s).

InsTallaTIon

Figure 8: AGZ Medium Enclosure Knockout Location (Rear

of Enclosure)

Figure 7: AGZ Small Enclosure Knockout Location (Rear

of Enclosure)

Figure 9: AGZ Large Enclosure Knockout Location (Rear

of Enclosure)

www.DaikinApplied.com 9 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 10

Wiring interconnections

InsTallaTIon

DANGER

Electric shock hazard. Can cause personal injury or

equipment damage.

Prior to installing Intelligent Equipment hardware, power must

be removed from the unit. This means removing power at the

breaker panel serving the unit, and following proper lockout/

tagout procedures at said breaker panel for the duration of

the install. Power should not be reapplied until all electrical

interconnections have been made and veried.

This equipment must be properly grounded. Connections

and service to the MicroTech III Air-Cooled Chiller Controller,

Machine-to-Machine Gateway and Energy Management

Module must be performed only by personnel knowledgeable

in the operation of the equipment being controlled.

CAUTION

Static sensitive components. Can cause equipment damage.

Discharge any static electrical charge by touching the bare

metal inside the control panel before performing any service

work. Never unplug cables, circuit board terminal blocks, or

power plugs while power is applied to the panel.

M2M Connection to MTIII

The M2M Gateway is connected to the MicroTech III unit

controller via Ethernet. Connect one end of the provided 6'

Ethernet Patch cable to the M2M port marked, “ETH”, and the

other end to the MicroTech III Unit controller port marked, “TIP”

(Figure 10).

M2M Connection to EMM

The M2M Gateway is connected to the EMM via USB. Connect

the type-A end of the provided 3' USB cable to the M2M port

marked, “USB1”, and the type-B end of the same cable to the

USB port of the EMM (Figure 11).

Figure 11: USB Connections

Figure 10: ‘ETH’ and ‘TIP’ Ports

IM 1240-1 • INTELLIGENT EQUIPMENT 10 www.DaikinApplied.com

Page 11

InsTallaTIon

Connection of Power Supply

The M2M Gateway is powered by a 120VAC (primary) to

24VDC (secondary) power supply. The 24 VDC connection

is made via a pre-fabricated, keyed plug coming from the low

voltage end of the power supply. Connect this plug to the M2M

Gateway receptacle marked, “Power Input” (Figure 12).

The 120VAC cable has the jacket and insulation pre-stripped,

with the ends of both the Line and Neutral wires tinned.

On a MicroTech III AGZ-D or AGZ-E unit, connect the Line

(brown) conductor to terminal TB1-11B and the Neutral (blue)

conductor to terminal TB1-32B (Figure 13).

Figure 12: M2M Power Input

Connection of EMM to CT’s

The high voltage side of the EMM has a hinged cover, which

must be opened. First, remove the two installation screws

(Figure 14), then ip the cover open. The EMM uses an open

style hinge, so it may be easier to completely remove the

hinged door while installing conductors.

The CT’s have built-in output conductors, which must be

connected to the EMM. Each black conductor must be

connected to an EMM terminal labeled, “CT”, while each white

conductor must be connected to the corresponding terminal

labeled, “A”, “B”, or “C”. The two conductors from each CT

must be connected to the same terminal set, i.e. – “CT” and

“A”, “CT” and “B”, or “CT” and “C”. For each CT, the white wire

must go to terminal labeled ‘CT’ and the black wire must go to

the associated lettered terminal (Figure 15).

Figure 14: Hinged Cover Screw Locations

Figure 13: AGZ-D and AGZ-E 120VAC Wiring

Figure 15: Connection of EMM to CT’s

www.DaikinApplied.com 11 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 12

InsTallaTIon

Installing CT’s

Current Transformers (CT’s) are split-core type, to make

installation easier. Snap split-core CT connected to EMM

terminal CT_A on phase L1, snap split-core CT connected

to EMM terminal CT_B on phase L2, and snap split-core CT

connected to EMM terminal CT_C on phase L3 (Figure 16).

Ensure that the “Load” indicator on the CT is oriented correctly.

Figure 16: CT Installation

Connection of EMM to Line Voltage

The EMM is connected to Line Voltage through the Fuse

Block. Begin by removing the fuse covers and fuses from the

Fuse Block. Prior to removal, make note of fuse orientation

within the fuse block. Next, using the provided 6" wiring

harness, connect the “VinA” (Tan), “VinB” (Violet), and “VinC”

(Orange) terminals on the EMM to the “Load” terminals on the

Fuse Block (Figure 17).

Next, remove the plastic protective shield from Power

Distribution Block 1 (PD1).Using the provided 6' wiring

harness, connect the corresponding “Line” terminals on the

Fuse Block to the control panel (PD1) terminals “T1”, “T2”,

and “T3”, such that EMM terminal “VinA” (Tan) is connected

to PD1-T1, “VinB”(Violet) is connected to PD1-T2, and “VinC”

(Orange) is connected to PD1-T3 (Figure 18).

Figure 17: EMM Connection to Fuse Block

Figure 18: Fuse Block Connected to Line Voltage

IM 1240-1 • INTELLIGENT EQUIPMENT 12 www.DaikinApplied.com

Page 13

Connection of M2M and EMM to Ground

One end of the M2M ground conductor should already be

connected to the M2M case (see section entitled, “Installing

M2M Gateway”). Connect the tinned end of the EMM ground

conductor to the “GND” terminal on the EMM itself (Figure 19).

Connect the free ring terminals for both the M2M and EMM to

the nearest available grounding lug in the control enclosure

(Figure 20).

Once all connections are made to the line voltage side of the

EMM, close the hinged cover, and reinstall the screws. Figure

21 depicts an EMM with all high voltage terminations made and

the hinged cover reinstalled.

Figure 19: Ground Wire Connected to EMM

InsTallaTIon

Figure 20: Typical Grounding Lug

Figure 21: EMM Following Reinstallation of Hinged Cover

www.DaikinApplied.com 13 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 14

Antenna Installation

InsTallaTIon

DANGER

Electric shock hazard. Can cause personal injury or

equipment damage.

Prior to installing Intelligent Equipment hardware, power must

be removed from the unit. This means removing power at the

breaker panel serving the unit, and following proper lockout/

tagout procedures at said breaker panel for the duration of

the install. Power should not be reapplied until all electrical

interconnections have been made and veried.

This equipment must be properly grounded. Connections

and service to the MicroTech III Air-Cooled Chiller Controller,

Machine-to-Machine Gateway and Energy Management

Module must be performed only by personnel knowledgeable

in the operation of the equipment being controlled.

CAUTION

Static sensitive components. Can cause equipment damage.

Discharge any static electrical charge by touching the bare

metal inside the control panel before performing any service

work. Never unplug cables, circuit board terminal blocks, or

power plugs while power is applied to the panel.

WARNING

Sharp edges on sheet metal and fasteners can cause

personal injury. This equipment must be installed, operated,

and serviced only by an experienced installation company

and fully trained personnel.

Mounting

The antennas provided with the Daikin Applied Intelligent

Equipment solution (Figure 22) are omni-directional, and utilize

a swiveling base that allows the antenna to be oriented to

avoid interference from structures or other antennas. For initial

installation, it is recommended to install the antenna on top

of the chiller, with enough clearance from the edge to avoid

accidental contact or damage. The antenna is held in place by

its magnetic base. You will nd more information about aiming

antennas in the, “Cellular Conguration”, “Wi-Fi Conguration”,

and “Troubleshooting” sections of this document.

Figure 22: Wireless Antenna on Magnetic Mounting Base

Wiring of Antennas

As described previously, the antenna cable must be fed from

the outside of the unit through the control enclosure and up

to the mounting bracket with the M2M Gateway, EMM, power

supply, and fuse block. The connection is made by screwing

the SMA coaxial connector onto the appropriate M2M SMA

coaxial connector; “3G/GPRS” for cellular or “WLAN” for Wi-Fi.

(Figure 23).

Figure 23: 3G and WLAN Connections

IM 1240-1 • INTELLIGENT EQUIPMENT 14 www.DaikinApplied.com

Page 15

Verify Time Zone Information

The M2M Gateway comes pre-congured from the factory

with the Time and Time Zone set based on the location of the

installation site. However, the installer should conrm that

the factory setting is accurate, and ensure that the correct

information is also set in the MicroTech III Chiller controller.

1. Using a laptop computer and Ethernet cable, connect

to the “ETH” port of the M2M Gateway (you will need to

temporarily disconnect the Ethernet cable between the

M2M Gateway and the MicroTech III controller, to make

use of the “ETH” port on the M2M Gateway).

a. The Cellular strength of the M2M Gateway is

veried using an HTML Interface page in an

HTTP server.

b. In order to access this page, your computer must

be on the same subnet as the M2M Gateway,

which is shipped set to a default IP subnet mask

(255.255.0.0) and IP address (172.31.255.1). You

must change the computer’s network settings to

match the subnet (the signal strength verication

process is the same regardless of the operating

system on your computer).

c. Navigate to your laptop’s Local Area Connection

settings screen and change the IP subnet mask to

255.255.0.0, and the IP address to be compatible

with the default M2M Gateway IP address

listed above (example: 172.31.255.7). For more

information on how to change your computer’s IP

settings, consult the Operating System’s “Help” les.

d. Temporarily disable the wireless adapter(s) on the

computer, as these may prevent accessing the

HTML Interface page.

2. Open a web browser page and type, 172.31.255.1, then

press enter.

a. When prompted, enter the User Name: “root”

b. Enter the Password: “root”

c. This opens the Gateway home page.

3. Click the ‘System’ tab (Figure 24 on page 16).

a. Select the ‘Settings’ tab

b. Under ‘Time Zone’, verify that the indicated Time

Zone is accurate. If so, continue to step 5.

4. If the Time Zone is inaccurate, use the list to select the

correct Time Zone, then click, ‘Save Changes’.

a. After saving changes, the screen will refresh.

InsTallaTIon

5. Click, ‘Apply Changes’ to write the change to the

Gateway’s conguration le.

a. After applying changes, the screen will briey

indicate that the conguration is being updated,

then will refresh to display the new time zone.

6. You will notice that the time in the upper right corner of

the webpage will now reect accurately based on the

selected Time Zone (Figure 25).

7. Once the Time Zone is veried in the M2M Gateway, you

will verify the time in the MicroTech III Chiller controller.

Begin by entering the password of 6363. Next, from the

main menu of the unit controller (Figure 27), turn the

knob clockwise until ‘View/Set Unit’ is highlighted, then

depress the knob to enter the ‘View/Set Unit’ menu.

a. Press in on the knob to enter the ‘View/Set Unit’

menu

8. From the ‘View/Set Unit’ menu, turn the knob

clockwise until ‘Date/Time/Schedules’ is highlighted.

Depress the knob to enter the ‘Date/Time/Schedules’

menu. Verify that the ‘Time’, ‘Date’, and ‘UTC Diff’

(Figure 26) are all correct. If any require a change,

simply use the knob to highlight that eld, then press in

on the knob to select, which makes the item adjustable.

Use the knob to increase/decrease the value, then

press in on the knob to enter

9. Once the ‘Time’, ‘Date’, and ‘UTC Diff’ are all correct,

press the BACK button to return to the main menu.

NOTE: For more information on navigating the MicroTech III

rooftop unit controller keypad display, please see the

appropriate operation manual for the unit model.

www.DaikinApplied.com 15 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 16

Figure 24: System Tab

InsTallaTIon

Figure 25: Time Updated to Time Zone Figure 26: Date/Time/Schedules Menu

Figure 27: Keypad Controls

IM 1240-1 • INTELLIGENT EQUIPMENT 16 www.DaikinApplied.com

Page 17

Cellular Conguration

The following procedures should be used to congure the

Intelligent Equipment solution for Cellular connectivity:

1. Mount and connect the wireless antenna per the

instructions included in document section, Antenna

Installation on page 14.

2. Using a laptop computer and Ethernet cable, connect

to the “ETH” port of the M2M Gateway (you will need to

temporarily disconnect the Ethernet cable between the

M2M Gateway and the MicroTech III controller, to make

use of the “ETH” port on the M2M Gateway).

a. The Cellular strength of the M2M Gateway is

veried using an HTML Interface page in an

HTTP server.

b. In order to access this page, your computer must

be on the same subnet as the M2M Gateway,

which is shipped set to a default IP subnet mask

(255.255.0.0) and IP address (172.31.255.1). You

must change the computer’s network settings to

match the subnet (the signal strength verication

process is the same regardless of the operating

system on your computer).

c. Navigate to your laptop’s Local Area Connection

settings screen and change the IP subnet mask to

255.255.0.0, and the IP address to be compatible

with the default M2M Gateway IP address

listed above (example: 172.31.255.7). For more

information on how to change your computer’s IP

settings, consult the Operating System’s “Help” les.

d. Temporarily disable the wireless adapter(s) on the

computer, as these may prevent accessing the

HTML Interface page.

3. Open a web browser page and type, 172.31.255.1, then

press enter.

a. When prompted, enter the User Name: “root”

b. Enter the Password: “root”

c. This opens the Gateway home page (Figure 28 on

page 18).

InsTallaTIon

4. Click the ‘Status’ tab

a. Select the ‘WWAN Modem’ tab

b. Under “Signal Quality, verify cellular signal strength

(Figure 29).

5. Adjust antenna as necessary to establish a strong

cellular connection

a. For reliable operation, signal quality and power

should both be in the good or excellent range.

b. As the antenna is adjusted, be mindful that

signal strength is impacted by structures or other

antennas. As much as practically possible, make

efforts to avoid such interference while adjusting

the antenna.

6. Once a strong cellular connection is obtained, close the

web browser, and disconnect the Ethernet cable between

the laptop and M2M Gateway.

7. Reconnect the Ethernet cable between the M2M

Gateway and the MicroTech III controller.

8. Feed excess antenna cable into the control enclosure,

then tighten waterproof grommet.

9. Add a bead of silicone around the perimeter of the

waterproof grommet penetration into the control

enclosure.

10. On inside of enclosure, secure excess antenna cable

using zip ties.

www.DaikinApplied.com 17 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 18

Figure 28: M2M Gateway Home Page

InsTallaTIon

Figure 29: Verify Cellular Signal Strength

IM 1240-1 • INTELLIGENT EQUIPMENT 18 www.DaikinApplied.com

Page 19

Wi-Fi Conguration

The following procedures should be used to congure the

Intelligent Equipment solution for Wi-Fi connectivity:

1. Mount and connect the wireless antenna per the

instructions included in document section, Antenna

Installation on page 14.

2. Using a laptop computer and Ethernet cable, connect

to the “ETH” port of the M2M Gateway (you will need to

temporarily disconnect the Ethernet cable between the

M2M Gateway and the MicroTech III controller, to make

use of the “ETH” port on the M2M Gateway).

a. The Wi-Fi settings of the M2M Gateway are

congured using HTML Interface pages in an

HTTP server.

b. In order to access these pages, your computer

must be on the same subnet as the M2M Gateway,

which is shipped set to a default IP subnet mask

(255.255.0.0) and IP address (172.31.255.1). You

must change the computer’s network settings to

match the subnet (the Wi-Fi conguration process

is the same regardless of the operating system on

your computer).

c. Navigate to your laptop’s Local Area Connection

settings screen and change the IP subnet mask to

255.255.0.0, and the IP address to be compatible

with the default M2M Gateway IP address

listed above (example: 172.31.255.7). For more

information on how to change your computer’s IP

settings, consult the Operating System’s “Help”

les.

d. Temporarily disable the wireless adapter(s) on the

computer, as these may prevent accessing the

HTML Interface pages.

3. Open a web browser page and type, 172.31.255.1, then

press enter.

a. When prompted, enter the User Name: “root”

b. Enter the Password: “root”

c. This opens the Gateway home page (Figure 30 on

page 20).

4. If the M2M Gateway will be using DHCP, skip to step 6.

If the M2M Gateway will be using a Static IP address, go

to step 5.

InsTallaTIon

5. Click the ‘Network’ tab

a. Under wlan0 Conguration (Figure 31), select

‘Static IP’ for Connection Type

b. Enter the IP, Subnet, and Gateway address

information

c. Under wlan0 DNS Servers enter the primary DNS

server and click ‘Add’

d. If a secondary DNS server address is to be

entered, enter it after the page has reloaded and

click ‘Add’ and enter the secondary address.

e. Click ‘Save’.

6. Click the ‘Wireless’ tab ( Figure 32)

a. Enter the ESSID of the network

b. If Wi-Fi security is enabled enter in Wi-Fi network

SSID and password and security type

7. Click the ‘Save Changes’ button in the lower right corner

of the page.

8. Click the System tab, then click the Reboot tab.

a. Click the ‘Yes, really reboot now’ button

b. The gateway will automatically refresh after several

minutes.

9. Click the ‘Status’ tab

a. Under ‘WLAN’, verify Wi-Fi signal strength (Figure

33).

10. Adjust antenna as necessary to establish a strong Wi-Fi

connection

a. For reliable operation, signal level should be 60

dBm or lower and link quality power should be

50/70 or higher.

b. As the antenna is adjusted, be mindful that

signal strength is impacted by structures or other

antennas. As much as practically possible, make

efforts to avoid such interference while adjusting

the antenna.

11. Once a strong Wi-Fi connection is obtained, close the

web browser, and disconnect the laptop and Ethernet

cable from the M2M Gateway.

12. Reconnect the Ethernet cable between the M2M

Gateway and the MicroTech III controller.

13. Feed excess antenna cable into the control enclosure,

then tighten waterproof grommet.

14. Add a bead of silicone around the perimeter of the

waterproof grommet penetration into the control

enclosure.

15. On inside of enclosure, secure excess antenna cable

using zip ties.

www.DaikinApplied.com 19 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 20

Figure 30: M2M Gateway Home Page

InsTallaTIon

Figure 31: Wireless LAN Conguration

IM 1240-1 • INTELLIGENT EQUIPMENT 20 www.DaikinApplied.com

Page 21

Figure 32: Wireless Conguration Screen

InsTallaTIon

Figure 33: Wireless Signal Strength

www.DaikinApplied.com 21 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 22

Conguration for Hard-Wired Connection

The M2M Gateway is congured using a set of HTML interface

pages within the Wind River Intelligent Device Platform.

The table below indenties the Wind River conguration

parameters, along with the corresponding physical port

on the M2M Gateway. For reference, it also includes the

corresponding device connection to the M2M Gateway.

Wind River

conguration

parameter

LAN ETH (which is eth0) MTIII Unit Controller

wan USB2 (which is eth1) Local Network

wlan0 WLAN WiFi

wwan 3G/GPRS Cellular

M2M Gateway port Device Connection

The following procedures should be used to congure the

Intelligent Equipment solution for hard-wired Local Area

Network (LAN) connectivity (note: it is the “wan” interface in the

gateway that will be congured):

1. Remove the USB-to-Ethernet converter from the

envelope and connect it to an open USB port on the

M2M Gateway (this is necessary because the M2M

Gateway has a single Ethernet plug, which is connected

to the MicroTech III controller, and, therefore, unavailable

for the purpose of connecting to the local network).

a. Connect the provided Ethernet patch cable to the

USB-to-Ethernet adapter and to the local network

(DHCP is enabled by default).

2. Using a laptop computer and Ethernet cable, connect

to the “ETH” port of the M2M Gateway (you will need to

temporarily disconnect the Ethernet cable between the

M2M Gateway and the MicroTech III controller, to make

use of the “ETH” port on the M2M Gateway).

a. The hard-wired Local Area Network (LAN) settings

of the M2M Gateway are congured using HTML

interface pages in an HTTP server.

b. In order to access these pages, your computer

must be on the same subnet as the M2M Gateway,

which is shipped set to a default IP subnet mask

(255.255.0.0) and IP address (https://172.31.255.1).

You must change the computer’s network settings to

match the subnet.

c. Navigate to your laptop’s Local Area Connection

settings screen and change the IP subnet mask to

255.255.0.0, and the IP address to be compatible

with the default M2M Gateway IP address

listed above (example: 172.31.255.7). For more

information on how to change your computer’s

IP settings, consult your PC operating system’s

“Help” les.

d. Temporarily disable the wireless adapter(s) on the

computer, as these may prevent accessing the

HTML Interface pages.

3. Open a web browser and type, https://172.31.255.1, then

NOTE: If you will use DHCP for your local network

4. Click the ‘Network’ tab

5. Locate the ‘wan Conguration’ section (Figure 35 on

6. Click the ‘Save Changes’ button in the lower right corner

7. Click the ‘Apply Changes’ button in the lower right-hand

8. Click the ‘Multiwan’ tab

9. Once created, set “ICMP hosts” of new interface to

10. Under ‘Priority Interface’, set to “wan”

InsTallaTIon

press enter.

a. When prompted, enter the User Name: “service”.

b. Enter the unique password that was provided with

the Gateway hardware and press ENTER.

c. This opens the Wind River Intelligent Device

Platform conguration page in the gateway (Figure

34 on page 23).

conguration, please proceed to step 8.

page 24)

a. Under wan Conguration select ‘Static IP’ for

Connection Type

b. Ensure that Interface = eth1

c. Enter the IP, Subnet, and Gateway address

information

d. Under wan DNS Servers enter your network’s

primary DNS server and click ‘Add’ (NOTE: If you

prefer to use a public DNS server, use 8.8.8.8 or

4.2.2.2)

e. If a secondary DNS server address is to be

entered, enter it after the page has reloaded and

click ‘Add’ and enter the secondary address.

of the page.

a. IMPORTANT: Allow the page to refresh

b. Conrm that there is number in parentheses next

to “Review Changes”. If so, proceed to step 7; if

not, repeat steps 5 and 6.

corner of the screen. The page will automatically refresh

when complete (this can take as much as two minutes).

a. Scroll to the bottom of the page and Click ‘Add

New Interface’ (Figure 36 on page 24)

b. Name the interface, “wan” (must match the name

of the interface congured in step 5.

c. Click ‘Add new interface’

“disable”

IM 1240-1 • INTELLIGENT EQUIPMENT 22 www.DaikinApplied.com

Page 23

InsTallaTIon

11. Click ‘Save changes’ button

a. IMPORTANT: Allow the page to refresh

b. Conrm that there is number in parentheses next

to “Review Changes”. If so, proceed to step 12; if

not, repeat steps 8-11.

12. Remove ‘wwan’ interface

13. Remove ‘wlan0’ interface

14. Click the ‘Save Changes’ button

a. IMPORTANT: Allow the page to refresh

b. Conrm that there is number in parentheses next

to “Review Changes”. If so, proceed to step 15; if

not, repeat steps 8-14.

15. Click the ‘Apply Changes’ button in the lower right-hand

corner of the screen. The page will automatically refresh

when complete (this can take as much as two minutes).

Figure 34: M2M Gateway Home Page

16. Conrm that ‘ICMP host’ of “wan” interface is still set to

“disable”

a. If so, go to step 17.

b. If not, set to “disable”

c. Click ‘Save changes’ button

i. IMPORTANT: Allow the page to refresh

ii. Conrm that there is number in parentheses

next to “Review Changes”. If so, proceed to step

17; if not, repeat steps 8-16.

d. Click the ‘Apply Changes’ button in the lower

right-hand corner of the screen. The page will

automatically refresh when complete (this can take

as much as two minutes).

17. Click the ‘System’ tab, then click the Reboot button.

18. Reconnect the Ethernet cable between the M2M

Gateway and the MicroTech III controller. Procedure

complete.

NOTE: Be certain that the IT staff has allowed incoming and

outgoing internet trafc on TCP ports 80, 443, 3197,

3199, 5222, 5223 and 8080.

www.DaikinApplied.com 23 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 24

Figure 35: WAN Conguration Settings

Figure 36: ‘Add New Interface’ Selection

InsTallaTIon

IM 1240-1 • INTELLIGENT EQUIPMENT 24 www.DaikinApplied.com

Page 25

Potential issues:

Gateway does not power up (LED does not illuminate)

• Verify 120V at TB1

• Verify that power supply wires are properly installed in

terminals 1 and 3

• Verify that power supply is properly connected to the

Gateway

• Contact Daikin Applied

Energy Management Module does not power up

• Verify USB cable connection to Gateway and Energy

Management Module

• Verify that Gateway has power

• Contact Daikin Applied

Cell connection cannot be established

• Check antenna connection to magnetic base

• Check antenna connection to 3G/GPRS connection on

Gateway

• Check signal strength through WebIF

• Verify APN settings

• Verify that neither a LAN or Wi-Fi connection has been

established

• Conrm SIM card installation and recognition by gateway

• Contact Daikin Applied

TroubleshooTIng

TroubleshooTIng

Wi-Fi connection cannot be established

• Check antenna connection to magnetic base

• Check antenna connection to WLAN connection on

Gateway

• Check signal strength through WebIF

• Verify Wi-Fi IP addressing, ESSID, and login credentials

match customer supplied Wireless LAN requirements

• Connect to Wi-Fi network and try to ping the Gateway’s

WLAN IP address

• Verify that neither a LAN or Cell connection has been

established

• Contact Daikin Applied

LAN connection cannot be established

• Conrm proper installation of USB to Ethernet adapter

• Verify LED activity on USB to Ethernet adapter

• Verify LAN addressing through Web IP

• Connect to LAN and try to ping the Gateway’s LAN IP

address

• Verify that neither a Wi-Fi or Cell connection has been

established

• Contact Daikin Applied

MicroTech III Data Not Showing Up In User Interface

• Conrm Ethernet cable is plugged into ‘ETH’ port on

Gateway

• Conrm Ethernet cable is plugged into ‘TIP’ port on

MicroTech III controller

• Check for LED activity on Gateway’s ETH port

• Verify IP address of Eth0 on the Gateway is 192.168.1.40

• Verify IP address of the MicroTech III controller is

192.168.1.42

— View/Set Unit —> Ctrlr IP Setup

• Contact Daikin Applied

www.DaikinApplied.com 25 IM 1240-1 • INTELLIGENT EQUIPMENT

Page 26

Appendix A

Wi-Fi or Hardwired LAN Ethernet connection Pre-Start-up Form

appendIx

appendIx

The Intelligent Equipment gateway is capable of

communicating via cellular connection, Wi-Fi Ethernet

connection, or hardwired LAN Ethernet connection. For either

Ethernet connection the gateway supports DHCP to have an IP

address assigned automatically, or it can be eld programmed

with a static IP address.

If an Ethernet connection is to be used for either type, the

customer’s LAN Administrator should review and supply the

following information (as necessary) prior to going to the

jobsite and commissioning the gateway.

1. IT Group must allow incoming and outgoing internet trafc on TCP ports 80, 443, 3197, 3199, 5222, 5223 and 8080 for

hardwired LAN connections.

2. If the gateway will be required to use a static IP address the following information will need to be supplied:

Internal LAN Static IP Address: — — — (required)

IP Subnet Mask: — — — (required)

Default Gateway: — — — (required)

DNS Server (primary): — — — (required)

DNS Server (secondary): — — — (if applicable)

Proxy Server IP Address: — — — (if applicable)

Proxy Server Port Number: (if applicable)

A CAT 5E Ethernet communication cable with an extra:

feet of coiled cable and a RJ45 connector on the

free end has been run per local codes from the customer’s

LAN to the unit main control box of each unit with an Intelligent

Equipment gateway.

3. For Wi-Fi Ethernet connections the following information will be required as well:

Wi-Fi network SSID:

Wi-Fi network password:

Wi-Fi encryption type:

Wi-Fi Mode:

Preferred Wi-Fi channel:

IM 1240-1 • INTELLIGENT EQUIPMENT 26 www.DaikinApplied.com

Page 27

Page 28

Daikin Applied Training and Development

Now that you have made an investment in modern, efcient Daikin equipment, its care should be a high

priority. For training information on all Daikin HVAC products, please visit us at www.DaikinApplied.com

and click on Training, or call 540-248-9646 and ask for the Training Department.

Warranty

All Daikin equipment is sold pursuant to its standard terms and conditions of sale, including Limited

Product Warranty. Consult your local Daikin Applied representative for warranty details. To nd your

local Daikin Applied representative, go to www.DaikinApplied.com.

Aftermarket Services

To nd your local parts ofce, visit www.DaikinApplied.com or call 800-37PARTS (800-377-2787).

To nd your local service ofce, visit www.DaikinApplied.com or call 800-432-1342.

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.DaikinApplied.com.

Products manufactured in an ISO Certied Facility.

IM 1240-1 (11/15) ©2015 Daikin Applied | (800) 432–1342 | www.DaikinApplied.com

Loading...

Loading...