Goodman ACVC950714CXAD, ACVC950915DXAD, ACVC950714CXBA, ACVC950915DXBA, ACVC951155DXAA Technical Manu Technical Manualal

...Page 1

TECHNICAL MANUTECHNICAL MANU

®

TECHNICAL MANU

TECHNICAL MANUTECHNICAL MANU

TM

ACVC9/AMVC95

GCVC9/GMVC95

ALAL

AL

ALAL

90%

• Refer to Service Manual RS6612002 for troubleshooting information.

• Refer to the appropriate Parts Catalog for part number information.

• Models listed on page 3.

UP TO

96% Gas Furnace Unit s

This manual is to be used by qualified, professionally trained HVAC technicians only. Goodman does

not assume any responsibility for property damage or personal injury due to improper service

procedures performed by an unqualified person.

®

is a registered trademark of Maytag Corporation or its related companies and is used under license to

Goodman Company, L.P., Houston, TX. All rights reserved.

RT6612025r5

November 2013

Copyright ©2012-2013 Goodman Company, L.P.

Page 2

PRODUCT IDENTIFICATION

The model and manufacturing number are used for positive identification of component parts used in manufacturing.

Please use these numbers when requesting service or parts information.

GCVC90704CXAA

PRODUCT

TYPE:

G : Goodman®

A: Ama na ®

Brand Gas

SUPPLY TYPE:

C: Counterflow/

Horizontal

M: Up flow/

Horizontal

FURNACE TYPE:

V: Variable Speed

AFUE

9: 90%

95: 95%

COMMUNICATION

FEA TURE:

C: 4-wire

Co mm un icati on

Ready

AIRFLOW

CAPABILITY:

3: 1200

4: 1600

5: 2000

NOMINA L IN PUT:

0 45: 45,000 Btuh

0 70: 70,000 Btuh

071: 70,000 Btuh

0 90: 90,000 Btuh

0 91: 90,000 Btuh

1 15: 115,000 Btuh

CABINET

WIDTH:

B: 17 - 1/2 "

C: 21"

D: 24-1/2"

ADDITIONAL

FEATURES:

N: Natural Gas

X: Low NOx

A: Initial R el ease

MINOR

REVISION

LEVEL

A: Ini tial Re l e a se

MAJOR

REVISION

LEVEL

WARNING

WARNING

WARNING

WARNING

service procedures. If you install or perform service on

this unit, you assume responsibility for any personal

injury or property damage which may result. Many jurisdictions require a license to install or service heating

and air conditioning equipment.

Disconnect ALL power before servicing or installing this unit. Multiple power

sources may be present. Failure to do so may cause property damage, personal

injury or death.

Goodman will not be responsible

for any injury or property damage

arising from improper service or

2

HIGH VOLTAGE!

WARNING

WARNING

viduals meeting the requirements of an "entry level technician", at a minimum, as specified by the Air-Conditioning,

Heating, and Refrigeration Institute (AHRI). Attempting to

install or repair this unit without such background may

result in product damage, personal injury or death.

Installation and repair of this unit

should be performed

ONLY by indi-

Page 3

PRODUCT IDENTIFICATION

The model and manufacturing number are used for positive identification of component parts used in manufacturing.

Please use these numbers when requesting service or parts information.

ACVC950714CXAD

ACVC950915DXAD

ACVC950714CXBA

ACVC950915DXBA

ACVC951155DXAA

GCVC951155DXAE

GCVC950714CXAD

GCVC950915DXAD

GCVC950714CXBA

GCVC950915DXBA

AMVC950453BXAE

AMVC950704CXAE

AMVC950905CXAD

AMVC950905DXAE

AMVC951155DXAE

AMVC950453BXBA

AMVC950704CXBA

AMVC950905CXBA

AMVC950905DXBA

AMVC951155DXBA

GMVC950453BXAE

GMVC950704CXAE

GMVC950905CXAD

GMVC950905DXAE

GMVC951155DXAE

GMVC950453BXBA

GMVC950704CXBA

GMVC950905CXBA

GMVC950905DXBA

GMVC951155DXBA

Earlier revisions of these units can be found in RT6612021*

WARNING

WARNING

WARNING

WARNING

Serious property damage, personal injury, reduced unit

performance and/or hazardous conditions may result

from the use of such non-approved devices.

The United States Environmental Protection Agency (“EPA”) has issued various regulations regarding the introduction and disposal of refrigerants introduced into this unit. Failure to follow

these regulations may harm the environment and can lead to the imposition of substantial fines.

These regulations may vary by jurisdiction. Should questions arise, contact your local EPA office.

Do not connect or use any device

that is not design certified by

Goodman for use with this unit.

WARNING

WARNING

do not store combustible materials or use gasoline or

other flammable liquids or vapors in the vicinity of this

appliance.

To prevent the risk of property

damage, personal injury, or death,

3

Page 4

PRODUCT DESIGN

A

General Operation

Models covered by this manual come with a new 4-wire communicating PCB. When paired with a compatible communicating indoor unit and a CTK0* communicating thermostat,

these models can support 4-wire communication protocol

and provide more troubleshooting information. These models are also backward compatible with the legacy thermostat wiring.

The GCVC9, GCVC95, GMVC95, AMVC95 and ACVC95

furnaces are equipped with an electronic ignition device to

light the burners and an induced draft blower to exhaust

combustion products.

An interlock switch prevents furnace operation if the blower

door is not in place. Keep the blower access doors in place

except for inspection and maintenance.

These furnaces are also equipped with a self-diagnosing electronic control module. In the event a furnace component is

not operating properly, the control module's dual 7-segment

LED's will display an alpha-numeric code, depending upon

the problem encountered.

For information regarding diagnostics and LED codes refer

to the Installation Instructions shipped with the furnace or

the service manual .PDF available at www.goodmanmfg.com

or www.amana-hac.com.

The rated heating capacity of the furnace should be greater

than or equal to the total heat loss of the area to be heated.

The total heat loss should be calculated by an approved

method or in accordance with “ASHRAE Guide” or “Manual

J-Load Calculations” published by the Air Conditioning Contractors of America.

*Obtain from: American National Standards Institute 1430

Broadway New York, NY 10018

Location Considerations

• The furnace should be as centralized as is practical

with respect to the air distribution system.

• Do not install the furnace directly on carpeting, tile, or

combustible material other than wood flooring.

• When suspending the furnace from rafters or joists,

use 3/8" threaded rod and 2” x 2” x 1/8” angle as

shown in the Installation and Service Instructions. The

length of the rod will depend on the application and

clearance necessary.

• When installed in a residential garage, the furnace

must be positioned so the burners and ignition source

are located not less than 18 inches (457 mm) above

the floor and protected from physical damage by vehicles.

Notes:

1. Installer must supply one or two PVC pipes: one for combustion air (optional) and one for the flue outlet (required).

Vent pipe must be either 2” or 3” in diameter, depending

upon furnace input, number of elbows, length of run and

installation (1 or 2 pipes). The optional Combustion Air

Pipe is dependent on installation/code requirements and

must be 2” or 3” diameter PVC.

2. Line voltage wiring can enter through the right or left side

of the furnace. Low voltage wiring can enter through the

right or left side of furnace.

3. Conversion kits for propane gas and high altitude natural

and propane gas operation are available. See High Altitude Derate chart for details.

4. Installer must supply the following gas line fittings, depending on which entrance is used:

Left -- Two 90° Elbows, one close nipple, straight pipe

Right -- Straight pipe to reach gas valve.

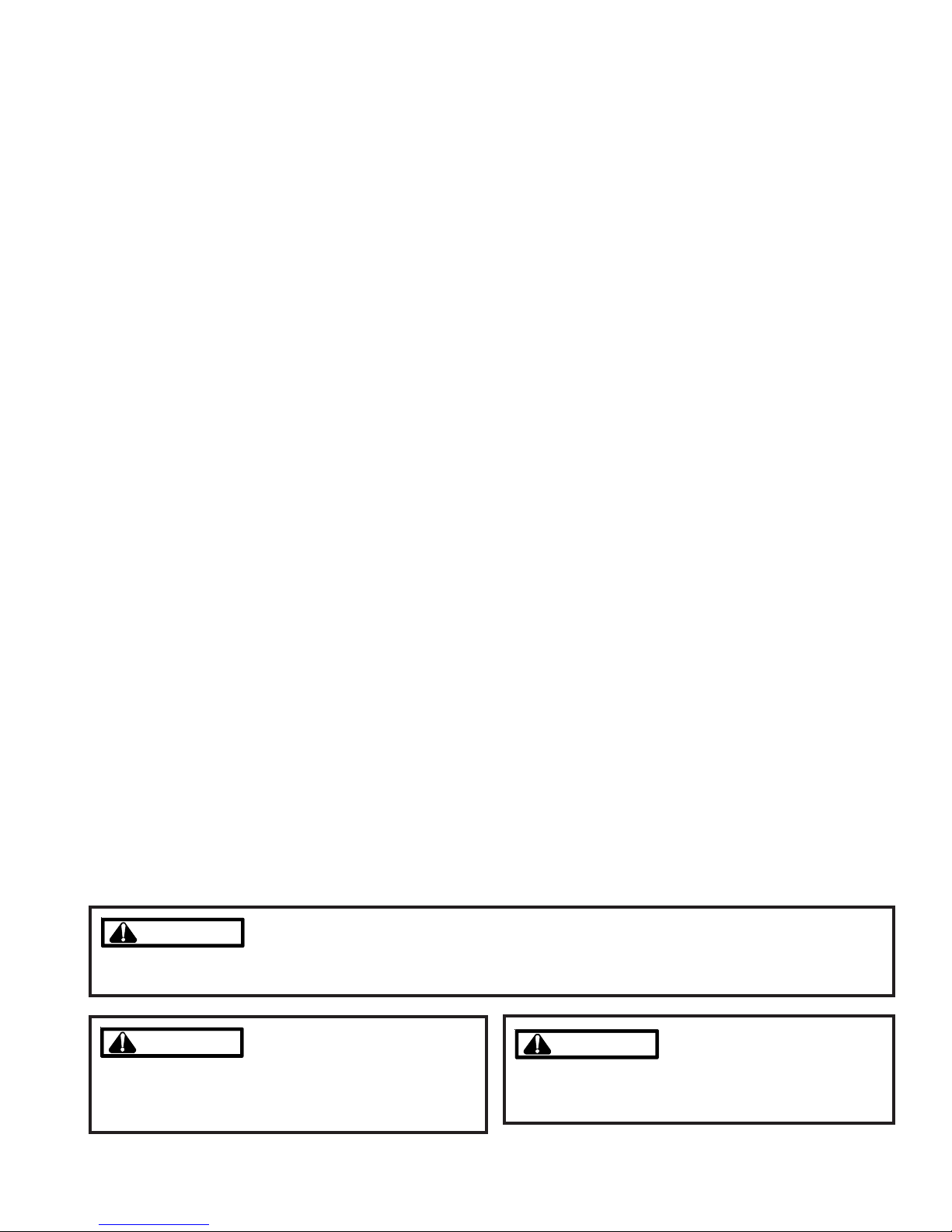

Accessibility Clearances (Minimum)

*MVC 95* MINIMUM CLEARANCES TO COMBUSTIBLE MATERIAL S

(INCHES)

POSITION* FRONT SIDES REAR TOP FLUE FLOOR

Upflow30010 C

Horizontal Alcove 6 0 4 0 C

*= All pos i tioni ng is determi ned as i nst alled unit is viewe d from the fron t.

C= If place d on combusti bl e floor, floor MUST be wood only.

NC= For insta laltion on non-c ombust i bl e floor s only. A c om bust i ble

subbase m ust be used for i nst allations on combu stible flooring .

*CVC9 MINIMUM CLEARANCES TO COMBUSTIBL E MATERIALS

POSITION* FRONT SIDES REAR TOP FLUE FLOOR

Upflow10010NC

Horizontal Alcove 6 0 4 0 C

*= All pos i tioni ng is determi ned as i nst alled unit is viewe d from the fron t.

C= If place d on combusti bl e floor, floor MUST be wood only.

NC= For insta laltion on non-c ombust i bl e floor s only. A c om bust i ble

subbase m ust be used for i nst allations on combu stible flooring .

(INCHES)

Alcove Illustration

REAR

S

I

E

D

I

S

LCOVE

D

E

4

24" at front is required for servicing or cleaning.

Note: In all cases accessibility clearance shall take

precedence over clearances from the enclosure where

accessibility clearances are greater. All dimensions are

given in inches.

Page 5

PRODUCT DESIGN

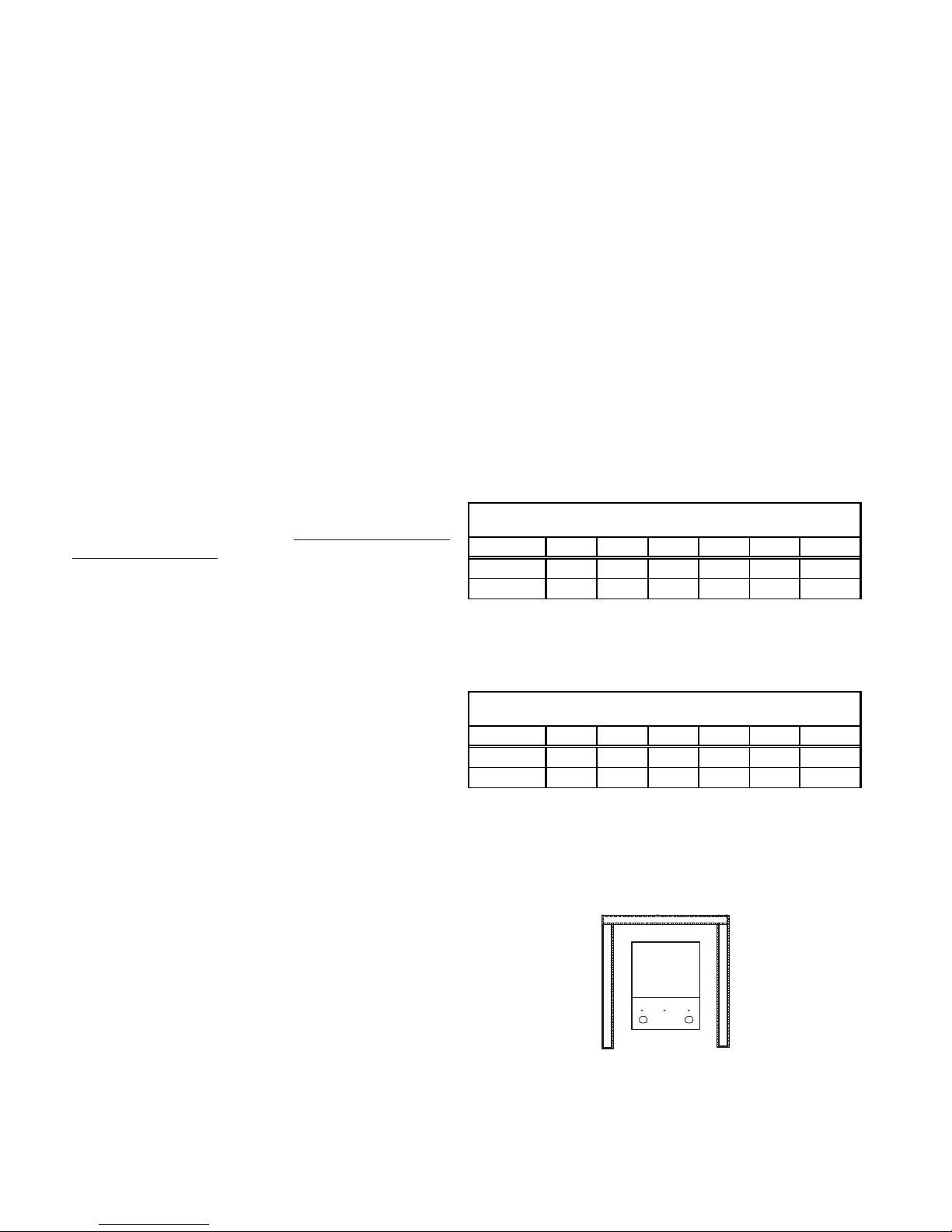

High Altitude Derate

When this furnace is installed at high altitude, the appropriate High Altitude orifice kit must be installed. This is required due to the natural reduction in the density of both the

gas fuel and combustion air as altitude increases. The kit

will provide the proper design certified input rate within the

specified altitude range.

High altitude kits are purchased according to the installation altitude and usage of either natural or propane gas. Refer

to the chart below for a tabular listing of appropriate altitude

ranges and corresponding manufacturer’s high altitude Natural Gas and Propane Gas kits. For a tabular listing of appropriate altitude ranges and corresponding manufacturer's High

Altitude Pressure Switch kits, refer to either the Pressure

Switch Trip Points & Usage Chart in this manual or the Accessory Charts in Service Instructions.

0 - 7, 000 Feet (Standard Altitude) 7,001 - 9,000 Feet

Gas Orifices

Furnace

Natural

GMVC950453BX*

GMVC950704CX*

AMVC950453BX*

AMVC950704CX*

GMVC950905CX*

AMVC950905CX*NoC hange

GMVC950905DX*

GMVC951155DX*

AMVC950905DX*

AMVC951155DX*

GCVC91155DX*

ACVC951155DX*NoC hange

No

C hange

No

C hange

e

Propan

LPM-06*

#55 Orifice

LPM-06*

#55 Orifice

LPM-06*

#55 Orifice

LPM-06*

#55 Orifice

"STANDARD" and "HIGH ALTITUDE" KITS

Gas Orifices

Pressure

e

Natural

HANG13

#44

Orifice

N/A N/A N/A N/A N/A N/A

HANG13

#44

Orifice

HANG13

#44

Orifice

Propan

HALP11

#56

Orifice

HALP11

#56

Orifice

HALP11

#56

Orifice

(1)

(1)

(1)

(1)

ID Blwr

Pressure

Switch

No

Change

No

Change

No

Change

No

Change

ID Blwr

Switch

HAPS28

HAPS29

HAPS29

9,001 - 11,000 Feet

Gas Orifices

Natural

HANG14

#45

Orifice

HANG14

#45

Orifice

HANG14

#45

Orifice

HALP11

#56

Orifice

HALP11

#56

Orifice

HALP11

#56

Orifice

Propan

e

ID Blwr

Pressure

Switch

HAPS28

HAPS29

HAPS31

GCVC950714CX*

GCVC950915DX*

ACVC950714CX*

ACVC950915DX*

1

LPM-06* supports Honeywell and White-Rodgers 2-stage valves

No

C hange

LPM-06*

#55 Orifice

(1)

No

Change

N/A N/A N/A N/A N/A N/A

5

Page 6

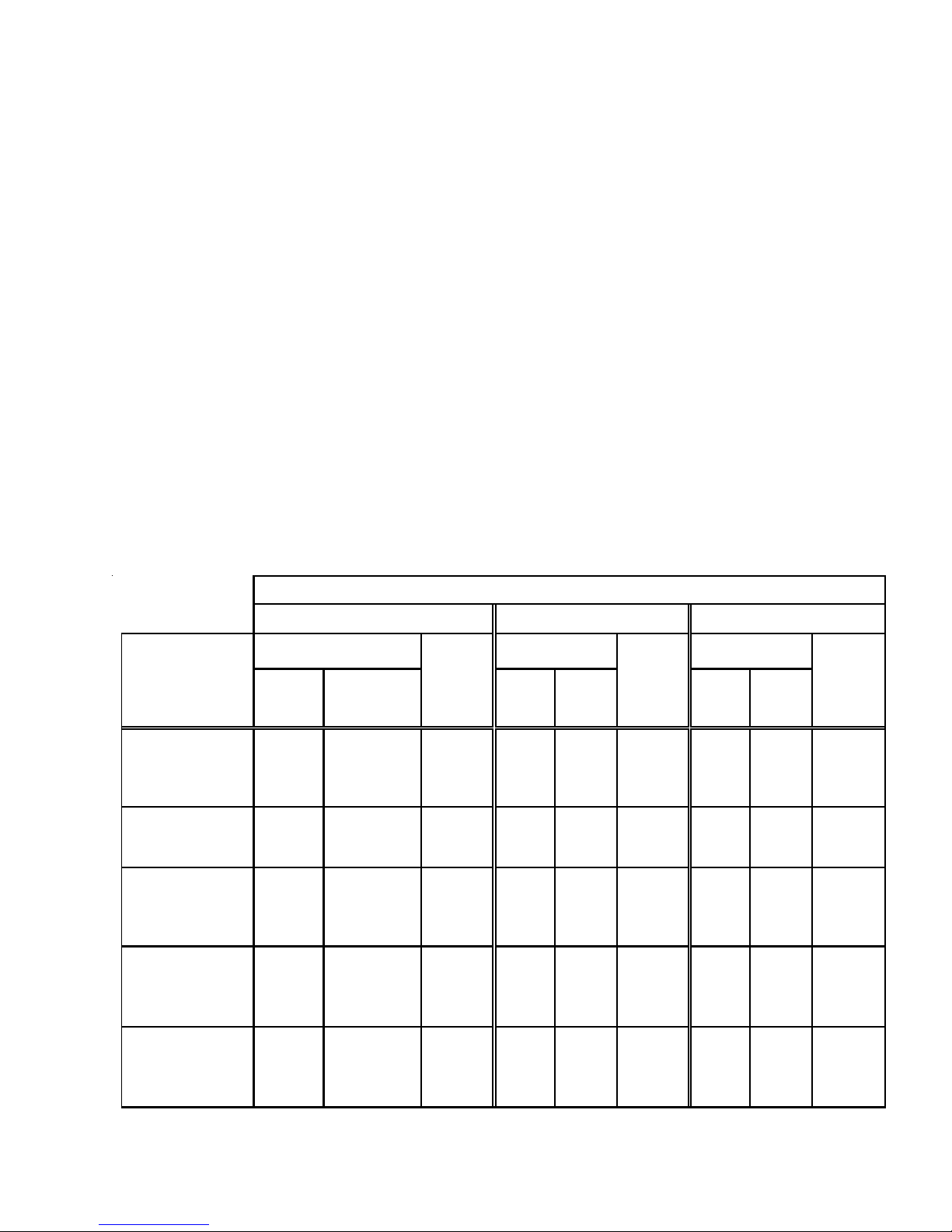

COMPONENT IDENTIFICATION

ections-Left Side

ections-Left Side

ections

de

0

NOTICE

Horizontal Conn

Horizontal Conn

-Right Si

140F00821

NOTICE

This fitting is specially designed to

drain water from the flue asse mbl y

Horizontal Conn

Horizontal Connections-Right Side 0140F00821

E

C

1 Two-Stage Gas Valve

2 Gas Line Entrance (Alternate)

3 Pressure Switch(es)

4 Gas Manifold

5 Combustion Air Intake Connection

6 Hot Surface Igniter

7 Rollout Limit

8 Burners

9 Flame Sensor

10 Flue Pipe Connection

11 Flue Pipe

12 Primary Limit

13 Gas Line Entrance

14 Flue Pipe Connection (Alternate)

15 Rubber Elbow

16 Two-Speed Induced Draft Blower

17 Electrical Connection Inlets (Alternate)

Counterflow /HorizontalUpflow/Horizontal

18 Coil Front Cover Pressure Tap

19 Coil Front Cover Drain Port

20 Drain Line Penetrations

21 Drain Trap

22 Blower Door Interlock Switch

23 Inductor (Not All Models)

24 Two-Stage Integrated Control Module

(with fuse and diagnostic LED)

25 24 Volt Thermostat Connections

26 Transformer (40 VA)

27 ECM Variable Speed Circulator Blower

28 Auxiliary Limit

29 Junction Box

30 Electrical Connection Inlets

31 Coil Front Cover

32 Combustion Air Inlet Pipe (*CVC9/95 only)

6

Page 7

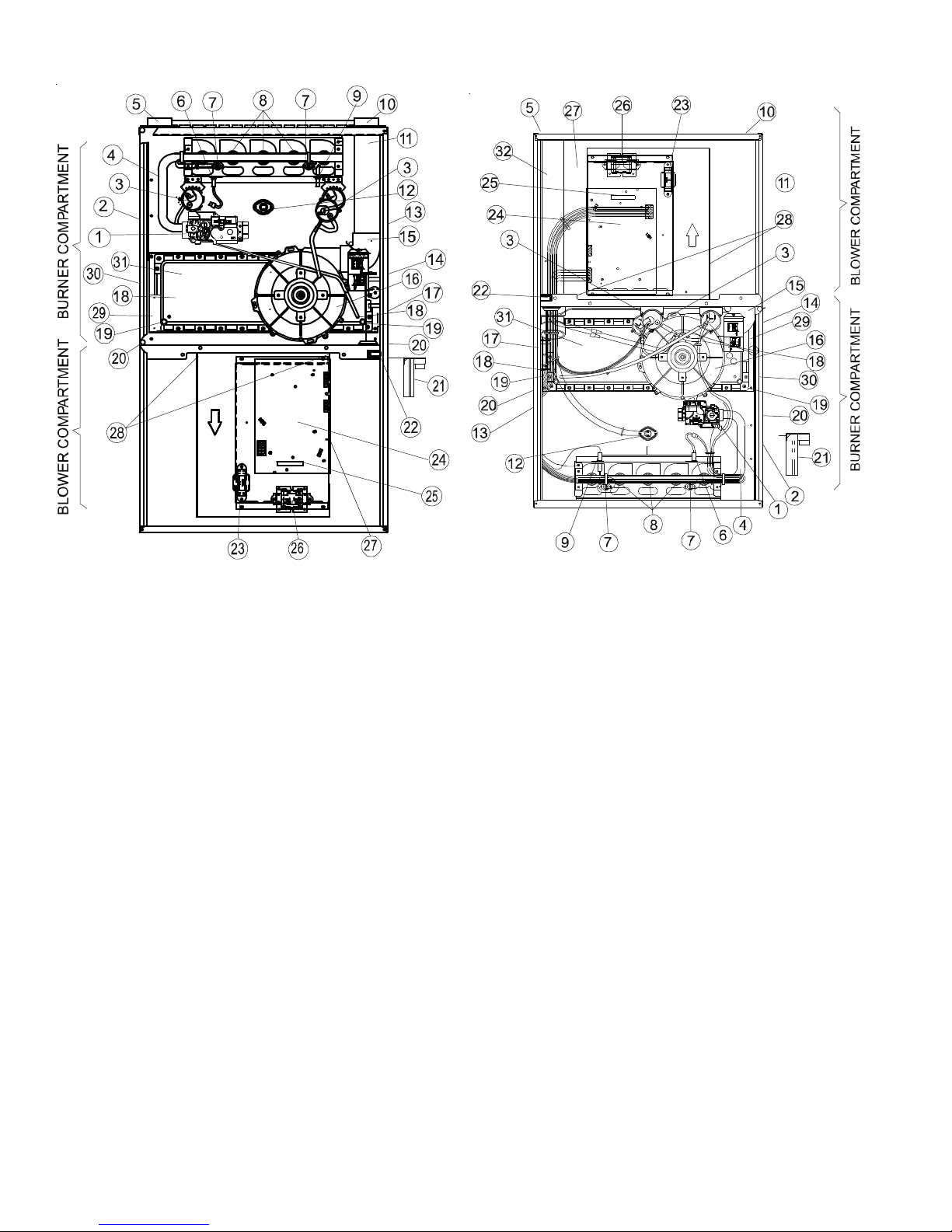

PRODUCT DIMENSIONS

SIZE

UNITS A B C D

SM ALL 0453BX* 17 1/2 15 12 3/ 8 12 5/8

MEDIUM

0704CX*

0905CX*

21 19 16 3/8 14 5/8

LARG E

0905DX*

1155DX*

24 1/2 23 20 3/ 8 18 5/8

All dimens ions are in inc hes .

®Ù

®Ý«Ù¦

/Äã»>Êã®ÊÄ

½ãÙÄã®Ù

&½ç>Êã®ÊÄ

½ãÙÄãsÄã

Z®¦«ãͲ^®

,®¦«Ͳsʽã¦

^ãÄÙ'Ý^çÖÖ½ù

½ãÙ®½Kçã½ã

ϲЯΗ

Ù®Ä>®Ä

dÙÖ

Ù®Ä

>ÊóͲsʽã¦

½ãÙ®½Kçã½ã

^®çãͲKçã

1¾"

GMVC95/AMVC95___X*

RIGHT SIDE VIEW

sÄã&½çW®Ö

¾"

;®Ý«Ù¦Ϳ

¾"

ϮΗWs

ϮЩІЋΗ

ϮϷϷШІЋΗ

ÊÄÄÝã

Ù®ÄãÙÖ

óвΗWs

ϰЯΗ

;Ù®¦«ãÊÙ

®Ý«Ù¦

ϮϰϿШІЋΗ

½¥ãÝ®Ϳ

40"

ϮзΗ

ϮϳЯΗ

ϭϵϹШІЋΗ

30¼"

11¾"

ϯϮϷϹШІЋΗ

ϭϲзΗ

2"

E

D

D

Bottom Knock-Out

&ʽ&½Ä¦Ý

hĥʽ&½Ä¦Ý

FRONT VIEW

ϮΗWs

®Ù/Äã»W®Ö

2½"

ϳдΗ

®Ù

®Ý«Ù¦

28¾"

ϭϵиΗ

^çÖÖ½ù

½ãÙÄã'Ý

¾"

30¼"

1¾"

,®¦«Ͳsʽã¦

½ãÙ®½Kçã½ã

>¥ãͲ^®Ù®Ä>®Ä

23"

1½"

ϮзΗ

Ù®ÄdÙÖ

21¼"

>ÊóͲsʽã¦

ІЋ"

ϭϵϹШ

11¾"

D

1¾"

^®çãͲKçã

½ãÙ®½Kçã½ã

14"

ϮϮЩІЋΗ

ϮϯϿШІЋΗ

&ʽ&½Ä¦Ý

Bottom Knock-Out

hĥʽ&½Ä¦Ý

1"

ϭзΗ

CABINET

LEFT SIDE VIEW

NOTE: Airflow area will be reduced by approximately 18% if duct flanges are not unfolded. This could cause performance issues and noise issues.

7

Page 8

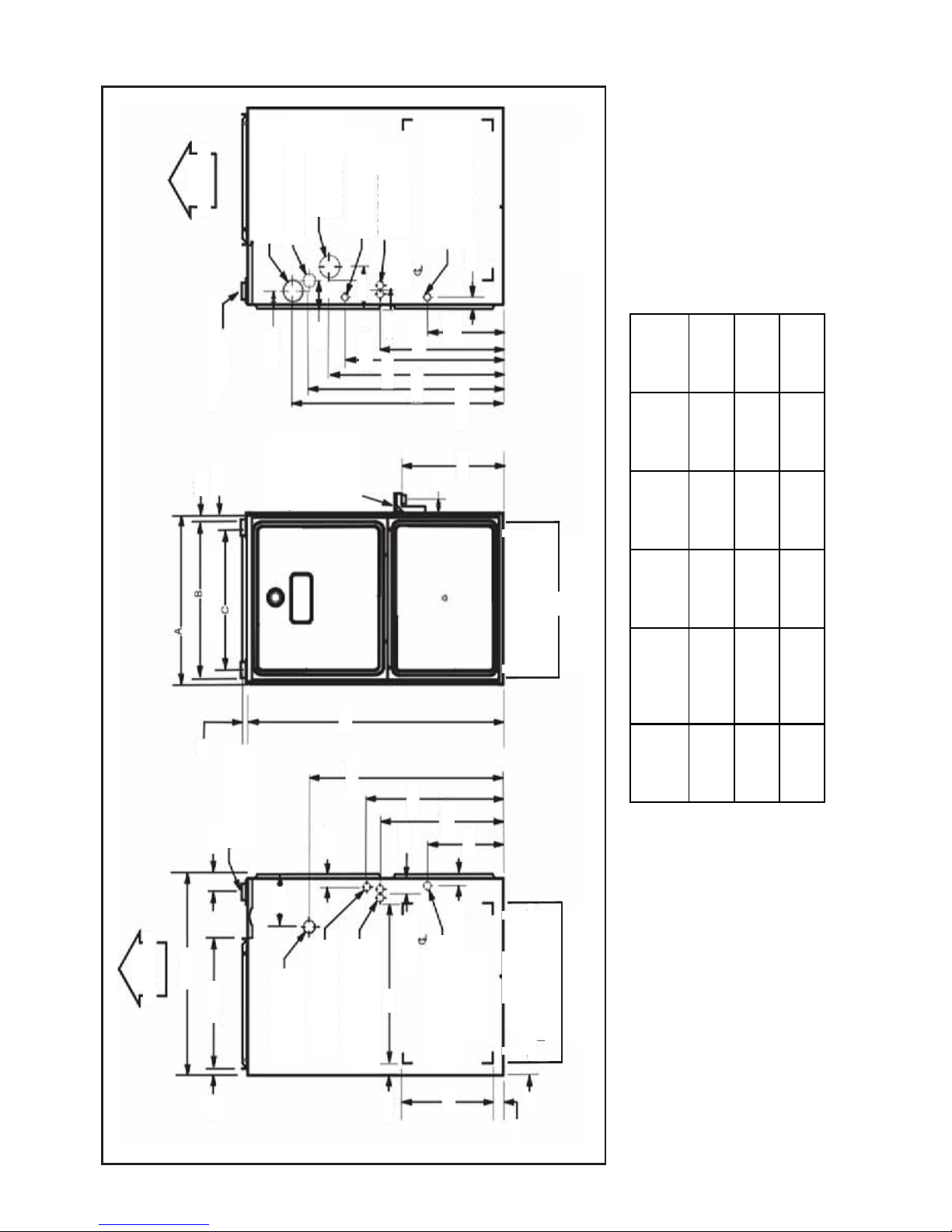

PRODUCT DIMENSIONS

&½ç>Êã®ÊÄ

½ãÙÄãsÄã

/Äã»>Êã®ÊÄ

Ù®ÄdÙÖ

RIGHT SIDE VIEWLEFT SIDE VIEW FRONT VIEW

>ÊóͲsʽã¦

½ãÙ®½Kçã½ã

,®¦«Ͳsʽã¦

½ãÙ®½Kçã½ã

½ãÙÄã®Ù

ϮзΗ

Z®¦«ãͲ^®

Ù®Ä>®Ä

½ãÙÄã'Ý

ϳдΗ

^çÖÖ½ù>Êã®ÊÄ

GCVC9/ACVC9_____X*

®Ù

®Ý«Ù¦

ϮΗWs

sÄã&½çW®Ö

¾"

;ZãçÙÄͿ

¾"

ϮЩІЋΗ

ÊÄÄÝã

1¾"

Ù®ÄãÙÖ

óвΗWs

;Ù®¦«ãÊÙ

®Ý«Ù¦

40"

ϲЯΗ

ϮϴϻШІЋΗ

½¥ãÝ®Ϳ

ϮϷϷШІЋΗ

ϭϵиΗ

ϭϴϷϹШІЋΗ

14"

ϭϭзΗ

2"

9¾"

8¼"

All dimensions are in inches.

&ʽ&½Ä¦Ý

/^,Z'

hĥʽ&½Ä¦Ý

24 1/2 23 20 3/8 18 5/8 20 7/8

ϮϴϻШІЋΗ

ϮΗWs

®Ù/Äã»W®Ö

2½"

28¾"

20¼"

¾"

1¾"

>ÊóͲsʽã¦

½ãÙ®½Kçã½ã

,®¦«Ͳsʽã¦

½ãÙ®½Kçã½ã

8

Ù®ÄdÙÖ

ϮзΗ

ϭϱЪΗ

>¥ãͲ^®

11½"

ϵϷϹШІЋΗ

^ãÄÙ

Ù®Ä>®Ä

ϰЯΗ

'Ý^çÖÖ½ù

ϭϴзΗ

&ʽ&½Ä¦Ý

ϮϬϻШЈЇΗ

UNITSABCDE

SIZE

CABINET

®Ù

®Ý«Ù¦

hĥʽ&½Ä¦Ý

MEDIUM 0714CX* 21 19 16 3/8 14 5/8 17 1/2

0915DX*

1155DX*

LARGE

NOTE: Airflow area will be reduced by approximately 18% if duct flanges are not unfolded. This could cause performance issues and noise issues.

Page 9

PRODUCT DESIGN

PRES S U RE S WI TCH TR IP P O IN TS AND USAG E CH AR T

NEGAT IVE P RESSURE

ID BLOWER

WITH FLUE

MODEL

GMVC950453BX*

GMVC950704CX*

AMVC950453BX*

AMVC950704CX*

GMVC950905CX*

AMVC950905CX*

GMVC950905DX*

GMVC951155DX*

AMVC950905DX*

AMVC951155DX*

GCVC950714CX*

ACVC950714CX*

GCVC950915DX*

ACVC950915DX*

GCVC91155DX*

ACVC951155DX*

(1) Data given is least negative pressure required for pressure switch to close.

(2) Data given is least negative pressure required for pressure switch to remain closed.

Note: The typical sea level negative pressure data represents the minimum pressures expected. S horter length of flue pipe or single pipe systems compared to

dual pipe syste ms should show higher (greater ne gative) press ures.

N O T FI RIN G

TYP ICA L S E A LE VEL

LOW FIRE HI GH FI RE LO W FIRE HIGH FIRE L OW FIRE HI GH FI RE LO W FIRE HI G H FI RE

-0.45 -0.92 -0.30 -0.75 -0.25 -0.25 -0.10 -0.10

-0.75 -1.60 -.060 -1.40 -0.25 -0.25 -0.10 -0.10

-0.65 -1.27 -0.50 -1.10 -0.25 -0.25 -0.10 -0.10

-0.95 -1.80 -0.80 -1.60 -0.25 -0.25 -0.10 -0.10

-0.95 -1.80 -0.80 -1.60 -0.25 -0.25 -0.10 -0.10

-0.35 -0.70 -0.20 -0.55 -0.52 -0.52 -0.37 -0.37

DATA

(1)

NEGATI VE PRESSU RE

ID BLOWER

WITH FLUE

FIRING

TYPICA L SEA L EVE L

DATA

(2)

NEGATIVE PRESSURE

COI L COV E R

WITH FL UE

NOT FIRING

T Y P I CA L SE A LEVE L

DATA

(1)

NE GATIVE P RESSURE

COI L COVER

WITH FLUE

FIRING

TYPICAL SEA LEVEL

DATA

(2)

9

Page 10

PRODUCT DESIGN

KIT

HIGH

ALTITUDE

HIGH

SWITCH

PRESSURE

TR IP P OINT

ID BLOWER

7,001 ft. t o 11,000 f t.

PRESSURE

TRIP P O INT

COI L COVER

LOW

HIGH

SWITCH

LOW

FIRE

FIRE

FIRE

FIRE

HAPS28

11177115

HAPS29

11177116

PRE SSURE SWITCH TRIP POINTS AND US AGE CHART

PART #

SWITCH

PRESSURE

ID BLOWER

FIRE

HIGH

SWITCH

PRESSURE

TR IP PO IN T

ID BLOWER

0 to 7,000 ft.

COIL COVER

PRESSURE

TR IP P O INT

COIL COVER

LOW

FIR E

PART #

SWITCH

PRESSURE

FIRE

HIGH

SWITCH

LOW

FIRE

-0.10 -0.10 20197308 -0.30 -0.75 11177113 -0.10 -0.10 -0.22 -0.55

-0.10 -0.10 20197308 -0.60 -1.40 0130F00251 N/A N/A N/A N/A N/A

-0.10 -0.10 20197308 -0.50 -1.10 11177114 -0.10 -0.10 -0.38 -0.82

-0.10 -0.10 0130F00070 -0.80 -1.60 0130F00100 N/A N/A N/A N/A N/A

-0.10 -0.10 0130F00070 -0.80 -1.60 0130F00100 N/A N/A N/A N/A N/A

-0.37 -0.37 20197313 -0.20 -0.55 11177118 -0.37 -0.37 -0.15 -0.30 HAPS31

MODEL

10

Replacement pressure switch number is listed below high altitude kit number.

All installations above 7,000 ft. require a pressure switch change. For in stallations in Canada the *MVC95 & *CVC9/95 furnaces are cert ified only to 4500 ft.

ACVC91155DX*

AMVC950453BX*

GMVC950453BX*

AMVC950704CX*

GMVC950704CX*

AMVC950905CX*

GMVC950905CX*

AMVC950905DX*

AMVC951155DX*

GCVC950714CX*

GMVC950905DX*

GMVC951155DX*

ACVC950714CX*

GCVC950915DX*

ACVC950915DX*

GCVC91155DX*

Note:

All negative pressure readings are in i nches of wate r column (" w.c.).

Note:

Note:

Page 11

PRODUCT DESIGN

PRIM ARY LIM IT

Part Number

Open Setting (°F)

GMVC950453BX*

AMVC950453BX*

GMVC950704CX*

AMVC950704CX*

GMVC950905CX*

AMVC950905CX*

GMVC950905DX*

AMVC950905DX*

GMVC951155DX*

AMVC951155DX*

GCVC950714CX*

ACVC950714CX*

GCVC950915DX*

ACVC950915DX*

GCVC91155DX*

ACVC951155DX*

Part Number 10123 512 1012 3517 101 23518 1 0123533 10123534 10 123537

Open Setting (°F) 325 210 170 200 220 190

GMVC950453BX*

AM V C950453BX*

GMVC950704CX*

AM V C950704CX*

GMVC950905CX*

AM V C950905CX*

GMVC950905DX*

AM V C950905DX*

GMVC951155DX*

AM V C951155DX*

20162903 20162904 201629 05 2 0162907 20162908 0130F001 05

160 150 145 155 170 130

--- --- 1 --- --- ---

--- --- --- 1 --- ---

--- --- --- --- --- 1

--- --- 1 --- --- ---

--- 1 --- --- --- ---

--- 1 --- --- --- ---

--- --- --- --- --- 1

---- ---- 1 ---- ---- ---

ROLLO UT LI MIT S WIT C H ES

--- --- 1 --- --- ---

--- --- --- 2 --- ---

--- --- --- 2 --- ---

--- --- --- --- --- 2

--- --- --- 2 --- ---

GCVC950714CX*

ACVC950714CX*

GCVC950915DX*

ACVC950915DX*

GCVC91155DX*

ACVC951155DX*

---- 2 ---- ---- ---- ----

--- 2 --- --- --- ---

---- 2 ---- ---- ---- ---

A UXILIARY LIMIT SWITCHES

Part Number 10123534 10123535 10123537 10123536 10123533 0130F00038

Ope n Sett ing (° F)

GMVC950453BX*

AMVC950453BX*

GMVC950704CX*

AMVC950704CX*

GMVC950905CX*

AMVC950905CX*

GMVC950905DX*

AMVC950905DX*

GMVC951155DX*

AMVC951155DX*

GCVC950714CX*

ACVC950714CX*

GCVC950915DX*

ACVC950915DX*

GCVC91155DX*

ACVC951155DX*

220 150 190 180 200 120

--- 2 --- --- --- ---

--- --- 2 --- --- ---

--- --- --- 2 --- ---

--- --- --- 2 --- ---

--- --- --- ---

--- --- --- --- --- 2

--- --- --- --- --- 2

--- --- --- --- --- 2

2 ---

11

Page 12

PRODUCT DESIGN

Thermostats:

ComfortNet™ CTK0* Thermostat Kit

Filters:

Filters are required with this furnace and must be provided by the installer. The filters used must comply with UL900 or

CAN/ULCS111 standards. Installing this furnace without filters will void the unit warranty

Upflow Filters

Return air filters may be installated at the furnace side and/or bottom return openings. The furnace bottom return opening

and side openings will accommodate the following filter sizes depending on cabinet size:

Si de Re tu rn O p e n in g(s) Bottom Re tu rn Op e n i ng

Cabinet

Width

(in.)

All 16 x 25 x 1 400 17-1/2 14 x 25 x 1 350

Nomi nal

Filter Size

(in.)

Approx.

Flow Area

2

(in

)

Cabinet

Width

(in.)

21 16 x 25 x 1 400

24-1/2 20 x 25 x 1 500

Nominal

Filter S ize

(in.)

Refer to Minimum Filter Area tables to determine filter area requirement. NOTE: Filters can also be installed elsewhere in

the duct system such as a central return.

Approx.

Flow Area

(in2)

UPFLOW

COOL ING AI RF LOW REQUIRE ME NT ( C FM)

600 800 1000 1200 1400 1600 1800 2000

0453__X* 415* 415* 480 576 --- --- --- --0704__X* --- --- 636* 636* 672 768 --- --0905__X* --- --- --- 826* 826* 826* 864 960

Input__Airflow

1155__X* --- --- --- 875* 875* 875* 875* 960

COUNTERFLOW

COOL ING AI RF LOW REQUIRE ME NT ( C FM)

600 800 1000 1200 1400 1600 1800 2000

0714__X* --- --- 634* 634* 672 768 --- ---

0915__X* --- --- --- 819* 819* 819* 864 960

Input

Airflow

1155__X* --- --- --- 860* 860* 860* 864 960

*Minimum filter area dictated by heating airflow requirement.

Disposable Minimum Filter Area (in2)

[Based on a 300 ft/min filter face velocity]

12

Page 13

PRODUCT DESIGN

0453__X* 207* 207* 240 288 --- --- --- --0704__X* --- --- 318* 318* 336 384 --- --0905__X* --- --- --- 413* 413* 413* 432 480

Inp ut__Airflow

1155__X* --- --- --- 437* 437* 437* 432 480

0714__X* --- --- 316* 316* 336 384 --- ---

0915__X* --- --- --- 409* 409* 409* 432 480

Input

Airflow

UPFLOW

COO L IN G AI RF LOW REQU IR EM EN T ( C FM)

600 800 1000 1200 1400 1600 1800 20 00

COUNTERFLOW

COO L IN G AI RF LOW REQU IR EM EN T ( C FM)

600 800 1000 1200 1400 1600 1800 20 00

1155__X* --- --- --- 430* 430* 430* 432 480

*Minimum filter area dictated by heating airflow requirement.

Disposable Minimum Filter Area (in2)

[Based on a 600 ft/min filter face velocity]

Counterflow Filters

Return air filters may be installated at the at the counterflow top return. A field supplied center filter support must be provided

by the installer in order to use the top return. The furnace will accommodate the following counterflow top return filter sizes

depending on cabinet size:

Coun terflow To p R eturn

Optional

Access

Door

Return Air

"A"

Min

Cabinet Width

17 1/ 2 14. 2

21 13.0

24 1/ 2 11. 3

17 1/ 2 19. 7

21 18.8

24 1/ 2 17. 7

17 1/ 2 25. 0

21 24.3

24 1/ 2 23. 4

Filter Area

2

)

(in

600 2 15 X 20 X 1

800 2 20 X 20 X 1

1 000 2 25 X 20 X 1

Qty

Filter Size

(in)

Dimen sion "A"

(in)

Refer to Minimum Filter Area tables to determine filter area requirement. NOTE: Filters can also be installed elsewhere

in the duct system such as a central return.

13

Page 14

FURNACE SPECIFICATIONS

A/GMVC95

MODEL

BTUH

Natural Gas Input (High Fire) 45,000 68,000 90,000 90,000 113,000

Natural Gas Output (High Fire) 43,200 65,300 86,500 86,500 108,600

LP Gas Input (High Fire) 40,500 61,200 81,000 81,000 101,700

LP Gas Output (High Fire) 38,900 58,800 77,800 77,800 97,700

A.F.U.E. 96.1% 96.1% 96.1% 96.1% 96.1%

Rated External Static (" w.c.) .20 - .50 .20 - .50 .20 - .50 .20 - .50 .20 - .50

Temperature Rise (°F) 30 - 60 30 - 60 30 - 60 30 - 60 35 - 65

ID Blower Pressure Switch Trip Point (" w.c.) -0.75 -0.75 -1.40 -1.10 -1.10

Front Cover Pressure Switch Trip Point (" w.c.) -0.10 -0.10 -0.10 -0.10 -0.10

Blower Wheel (D" x W") 10 x 8 10 x 10 11 x 10 11 x 10 11 x 10

Blower Horsepower 1/2 3/4 1 1 1

Blower Speeds

Max CFM @ 0.5 E.S.P.

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Minimum Circuit Ampacity (MCA)

Maximum Overcurrent Device

Transformer (VA) 40 40 40 40 40

Primary Limit Setting (°F) 145 155 130 145 150

Auxiliary Limit Setting (°F) 150 190 180 180 200

Rollout Limit Setting (°F) 170 200 200 190 200

Fan Delay On Heating 30 secs. 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating

Fan Delay On Cooling 5 sec 5 sec 5 sec 5 sec 5 sec

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Natural/Propane) ("w.c.) 7 / 11 7 / 11 7 / 11 7 / 11 7 / 11

Manifold Pressure (Natural/Propane) ("w.c.) 3.5 / 10 3.5 / 10 3.5 / 10 3.5 / 10 3.5 / 10

Orifice Size (Natural/Propane) 43 / 55 43 / 55 43 / 55 43 / 55 43 / 55

Number of Burners 2 3 4 4 5

Vent Connector Diameter (inches)

Combustion Air Connector Diameter (inches)

Shipping Weight (lbs.) 123 142 150 155 165

NOTE: Low fire input is 70% of high fire input

(3)

(1)

(2)

(4)

(5)

*MVC950453

BX*

11.3 14.1 14.4 14.4 14.4

15.0 15.0 15.0 15.0 15.0

150 secs. 150 secs. 150 secs. 150 secs. 150 secs.

22222

22222

*MVC950704

CX*

*MVC950905

CX*

Refer to Blower CFM Charts

*MVC950905

DX*

*MVC951155

DX*

1. These furnaces are manufactured for natural gas operation. Optional Kits are available for conversion to propane gas operation.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not be derated, orifice

changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method in accordance with the

"A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total

heat loss calculated should be equal to or less than the heating capacity. Output based on D.O.E. test procedures, steady state efficiency times

output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

14

Page 15

FURNACE SPECIFICATIONS

A/GCVC9

MODEL

GCVC91155

DX*

ACVC951155

DX*

*CVC950714

CX*

*CVC950915

DX*

BTUH

Natural Gas Input (High Fire) 1 13,000 113,000 68,000 90,000

Nat ural Gas Output (High Fire) 105,10 0 105,100 64,600 85,500

LP Gas Input (High Fire) 101,70 0 101,700 61,200 81,000

LP Gas Out put (High Fire) 94, 600 94,600 58,100 77, 000

A.F.U.E. 93.0% 93.0% 95.0% 95.0%

Rated External Static (" w.c.) .20 - .50 .20 - . 50 .20 - .50 .20 - .50

Temperature Rise (°F) 40 - 70 40 - 70 25 - 55 25 - 55

ID Blower Press ure Switch High FireTrip Point (" w.c.) -0 .55 -0.55 -1.60 -1.60

Fro n t C ove r Pre ssur e S wi tch Tri p P o int (" w. c.) -0. 3 7 -0 .37 -0. 1 0 -0.10

Blower Wheel (D" x W") 11 x 10 11 x 10 10 x 10 11 x 10

Blower Horsepower 1 1 3/4 1

Blower Speeds

Refer to Blower CFM Chart s

Max CFM @ 0.5 E.S.P.

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1

Minimum Circuit Ampacit y (MCA)

Maximum Overcurrent Devi ce

(2)

(1)

14.4 14.4 11.2 15.0

15.0 15.0 15.0 15.0

Transformer (VA) 40 40 40 40

Primary Limit Setting (°F ) 145 145 150 13 0

Auxiliary Limit Sett i ng (°F) 120 120 120 120

Rollout Lim it Sett ing (°F) 210 210 210 21 0

Fan Delay On Heating 30 secs. 30 secs. 30 secs. 30 secs.

Of f Heating

(3)

150 secs. 150 secs. 150 secs . 150 s ecs.

Fa n D elay On Cooling 5 sec 5 sec 5 s ec 5 sec

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Natural/Pro pane) ("w .c. ) 7 / 11 7 / 11 7 / 11 7 / 11

Manifold Pressure (Nat ural/Propane) ("w.c.) 3.5 / 10 3.5 / 10 3.5 / 10 3.5 / 10

Orifice Size (Natural/Propane) 43 / 55 43 / 55 43 / 55 43 / 55

Number of Burners 5 5 3 4

Vent Connec tor Diameter (inches)

(4)

Combustion Air Connector Diam eter (inc hes)

(5)

2222

2222

Shipping Weight (lbs.) 160 160 139 158

NO TE : Lo w fi r e inp ut is 70% o f h i gh f ir e inp ut

1. These furnaces are manufactured for natural gas operation. Optional Kits are available for conversion to propane gas operation.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not be derated, orifice

changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method in accordance with the

"A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total

heat loss calculated should be equal to or less than the heating capacity. Output based on D.O.E. test procedures, steady state efficiency times

output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

15

Page 16

BLOWER PERFORMANCE SPECIFICATIONS

*MVC950453BX Cooling/Heating Speed Charts

*MVC950453BX

Cooling Speed

( @ .1" - .8" w.c. ESP)

Tap Adjust

Minus 10% 540 351 Minus 10% 713 495 57

Minus 5% 570 371 Minus 5% 752 523 49

A

B

C

DD

Normal 6 00 390 Normal 792 550 41

Plus 5% 630 410 P l us 5% 832 578 43

Plus 10% 660 429 Plus 10% 871 605 46

Minus 10% 720 468 Minus 10% 778 540 52

Minus 5% 760 494 Minus 5% 821 570 49

Normal 8 00 520 Normal 864 600 47

Plus 5% 840 546 P l us 5% 907 630 45

Plus 10% 880 572 Plus 10% 950 660 43

Minus 10% 900 585 Minus 10% 842 585 48

Minus 5% 950 618 Minus 5% 889 618 45

Normal 1,000 650 Normal 936 650 4 3

Plus 5% 1,050 683 Plus 5% 983 683 4 1

Plus 10% 1,100 715 Plus 10% 1,030 715 39

Minus 10% 1,080 702 Minus 10% 907 630 4 5

Minus 5% 1,140 741 Minus 5% 958 665 42

Normal 1,200 780 Normal 1,008 700 40

Plus 5% 1,260 819 Plus 5% 1, 058 735 38

Plus 10% 1,320 858 Plus 10% 1,109 770 36

High-Stage

CFM

Low-Stage

CFM

(@ .1" - .5" w.c. ESP; Rise Range: 30 - 60°F)

Tap Adjust

A

B

C

*MVC950453BX

Heating Speed

High-Stage

CFM

Low-Stage

CFM

Rise

(°F)

*MVC950704CX Cooling/Heating Speed Charts

*MVC950704CX

Cooling Speed

( @ .1" - .8" w.c. ESP)

Tap Adjust

Minus 10% 540 35 1 Minus 10% 1,089 756 56

Minus 5% 570 371 Minus 5% 1,150 798 53

A

B

C

DD

Normal 600 390 Normal 1,210 840 50

Plus 5% 630 410 Plus 5% 1,271 882 48

Plus 10% 660 429 Plus 10% 1,331 924 46

Minus 10% 720 46 8 Minus 10% 1,193 828 51

Minus 5% 760 494 Minus 5% 1,259 874 48

Normal 800 520 Normal 1,325 920 46

Plus 5% 840 546 Plus 5% 1,391 966 44

Plus 10% 880 572 Plus 10% 1,458 1,012 42

Minus 10% 990 64 4 Minus 10% 1,296 900 47

Minus 5% 1,045 679 Minus 5% 1,368 950 44

Normal 1,100 715 Normal 1,440 1,000 42

Plus 5% 1,155 751 Plus 5% 1,512 1,050 40

Plus 10% 1,210 78 7 Plus 10% 1,584 1,100 38

Minus 10% 1,286 83 6 Minus 10% 1,400 972 43

Minus 5% 1,358 883 Minus 5% 1,477 1,026 41

Normal 1,429 929 Normal 1,555 1,080 39

Plus 5% 1,500 975 Plus 5% 1,633 1,134 37

Plus 10% 1,572 1,022 Plus 10% 1,711 1, 188 35

High-Stage

CFM

Low-Stage

CFM

*MVC950704CX

Heating Speed

(@ .1" - .5" w.c. ESP; Rise Range: 30 - 60°F)

Tap Adjust

A

B

C

High-Stage

CFM

Low-Stage

CFM

Rise

(°F)

1. All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

2. For most jobs, about 400 CFM per ton when cooling is desirable.

3. Do not operate above .5" w.c. ESP in heating mode. Operating CFM between .5" and .8" w.c. is tabulated for cooling purposes only.

4. Continuous fan speeds of 25%, 50%, 75% of maximum cooling airflow are available when using a communicating thermostat and 25%, 50%, 75%, 100%

of maximum cooling airflow are available in legacy mode by setting dip switches

16

Page 17

BLOWER PERFORMANCE SPECIFICATIONS

*MVC950905CX Cooling/Heating Speed Charts

*MVC950905CX

Cooling Speed

( @ .1" - .8" w.c. ESP)

Tap Adjust

Minus 10% 729 495 Minus 10% 1,341 945 60

Minus 5% 770 523 Minus 5% 1,416 998 57

A

B

C

D

Normal 810 550 Normal 1,490 1,050 54

Plus 5% 851 578 Plus 5% 1,565 1,103 51

Plus 10% 891 605 Plus 10% 1,639 1,155 49

Minus 10% 990 693 Minus 10% 1,413 1,008 57

Minus 5% 1,045 732 Minus 5% 1,492 1,064 54

Normal 1,100 770 Normal 1,570 1,120 51

Plus 5% 1,155 80 9 Plus 5% 1,64 9 1,176 49

Plus 10% 1,210 847 Plus 10% 1,727 1,232 47

Minus 10% 1,323 900 Minus 10% 1,521 1,080 53

Minus 5% 1,397 950 Minus 5% 1,606 1,140 50

Normal 1,470 1,000 N o r m a l 1,690 1,200 48

Plus 5% 1,544 1,050 Plus 5% 1, 775 1,260 45

Plus 10% 1,617 1,100 Plus 10% 1,859 1,320 43

Minus 10% 1,629 1,125 Minus 10% 1,602 1,125 50

Minu s 5% 1, 720 1,188 Minus 5% 1,691 1,188 47

Normal 1,810 1,250 N o r m a l 1,780 1,250 45

Plus 5% 1,901 1,313 Plus 5% 1, 869 1,313 43

Plus 10% 1,991 1,375 Plus 10% 1,958 1,375 41

High-Stage

CFM

Low-Stage

CFM

(@ .1" - .5" w.c. ESP; Rise Range: 30 - 60°F)

Tap Adjust

A

B

C

D

*MVC950905CX

Heating Spe e d

High-Stage

CFM

Low-Stage

CFM

Rise

(°F)

*MVC950905DX Cooling/Heating Speed Charts

*MVC950905DX

Cooling Speed

( @ .1" - .8" w.c. ESP)

Tap Adjust

Minus 10% 720 468 Minus 10% 1,458 1,013 55

Minus 5% 760 494 Minus 5% 1,539 1,069 52

A

B

C

D

1. All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

2. For most jobs, about 400 CFM per ton when cooling is desirable.

3. Do not operate above .5" w.c. ESP in heating mode. Operating CFM between .5" and .8" w.c. is tabulated for cooling purposes only.

4. Continuous fan speeds of 25%, 50%, 75% of maximum cooling airflow are available when using a communicating thermostat and 25%, 50%, 75%, 100%

of maximum cooling airflow are available in legacy mode by setting dip switches

Normal 800 5 20 Normal 1,620 1,125 50

Plus 5% 840 546 Plus 5% 1,701 1,181 47

Plus 10% 880 572 Plus 10% 1,782 1,238 45

Minus 10% 900 644 Minus 10% 1,549 1,076 52

Minus 5% 950 679 Minus 5% 1,635 1,135 49

Normal 1,000 715 Normal 1,721 1,195 47

Plus 5% 1,050 751 Plus 5 % 1,807 1,255 45

Plus 10% 1,100 787 Plus 10% 1,893 1,315 43

Minus 10% 1,260 819 Minus 10% 1,640 1,139 49

Minus 5% 1,330 865 Minus 5% 1,731 1,202 46

Normal 1,400 910 Normal 1,822 1,265 44

Plus 5% 1,470 956 Plus 5 % 1,913 1,328 42

Plus 10% 1,540 1,001 Plus 10% 2,004 1,392 40

Minus 10% 1,620 1,053 Minus 10% 1,730 1,202 47

Minus 5% 1,710 1,112 Minus 5% 1,826 1,268 44

Normal 1,800 1,170 Normal 1,922 1,335 42

Plus 5% 1,890 1,229 Plus 5% 2,018 1,402 40

Plus 10% 1,980 1,287 Plus 10% 2,114 1,469 38

High-Stage

CFM

Low-Stage

CFM

(@ .1" - .5" w.c. ESP; Rise Range: 30 - 60°F)

Tap Adjust

A

B

C

D

*MVC950905DX

Heati ng Spee d

High-Stage

CFM

Low-Stage

CFM

Rise

(°F)

17

Page 18

BLOWER PERFORMANCE SPECIFICATIONS

*MVC951155DX Cooling/Heating Speed Charts

*MVC951155DX

Cooling Speed

( @ .1" - .8" w.c. ESP)

Tap Adjust

Minus 10% 720 468 Minus 10% 1,594 1,107 63

Minus 5% 760 494 Minus 5% 1,682 1,169 60

A

B

C

D

Normal 800 520 Normal 1,771 1,230 57

Plus 5% 840 546 Plus 5% 1,860 1,292 54

Plus 10% 880 572 Plus 10% 1,948 1,353 52

Minus 10% 990 644 Minus 10% 1,640 1,139 62

Minus 5% 1,045 679 Minus 5% 1,731 1,202 59

Normal 1,100 715 Normal 1,822 1,265 56

Plus 5% 1,155 751 Plus 5% 1,913 1,328 53

Plus 10% 1,210 787 Plus 10% 2,004 1,392 50

Minus 10% 1,260 819 Minus 10% 1,685 1,170 60

Minus 5% 1,330 865 Minus 5% 1,778 1,235 57

Normal 1,400 910 Normal 1,872 1,300 54

Plus 5% 1,470 956 Plus 5% 1,966 1,365 51

Plus 10% 1,540 1,001 Plus 10% 2,059 1,430 49

Minus 10% 1,620 1,053 Minus 10% 1,730 1,202 58

Minus 5% 1,710 1,112 Minus 5% 1,826 1,268 55

Normal 1,800 1,170 Normal 1,922 1,335 53

Plus 5% 1,890 1,229 Plus 5% 2,018 1,402 50

Plus 10% 1,980 1,287 Plus 10% 2,114 1,469 48

High-Stage

CFM

Low-Stage

CFM

(@ .1" - .5" w.c. ESP; Rise Range: 35 - 65°F)

Tap Adjust

A

B

C

D

*MVC951155DX

Heating Speed

High-Stage

CFM

Low-Stage

CFM

Rise

(°F)

1. All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

2. For most jobs, about 400 CFM per ton when cooling is desirable.

3. Do not operate above .5" w.c. ESP in heating mode. Operating CFM between .5" and .8" w.c. is tabulated for cooling purposes only.

4. Continuous fan speeds of 25%, 50%, 75% of maximum cooling airflow are available when using a communicating thermostat and 25%, 50%, 75%, 100%

of maximum cooling airflow are available in legacy mode by setting dip switches

18

Page 19

BLOWER PERFORMANCE SPECIFICATIONS

*CVC950714CX Cooling/Heating Speed Charts

*CVC950714CX

Cooling Speeds

( @ .1" - .8" w.c. ESP)

Tap Adjust

Minus 10% 594 324 Minus 10% 1,107 783 77

Minus 5% 627 342 Minus 5% 1,169 827 73

A

B

CC

DD

Normal 660 360 Normal 1,230 870 69

Plus 5% 693 378 Plus 5% 1,292 914 66

Plus 10% 726 396 Plus 10% 1, 353 957 63

Minus 10% 747 468 Minus 10% 1,215 855 71

Minus 5% 789 494 Minus 5% 1,283 903 68

Normal 830 520 Normal 1,350 950 64

Plus 5% 872 546 Plus 5% 1,418 998 61

Plus 10% 913 572 Plus 10% 1, 485 1,045 58

Minus 10% 1,017 702 Minus 10% 1,323 936 65

Minus 5% 1,074 741 Minus 5% 1,397 988 61

Normal 1,130 780 Normal 1,470 1,040 58

Plus 5% 1,187 819 Plus 5% 1,544 1,092 55

Plus 10% 1,243 858 Plus 10% 1,617 1,144 53

Minus 10% 1,314 864 Minus 10% 1,440 1,017 59

Minus 5% 1,387 912 Minus 5% 1,520 1,074 56

Normal 1,460 960 Normal 1,600 1,130 53

Plus 5% 1,533 1,008 Plus 5% 1,680 1,187 51

Plus 10% 1,606 1,056 Plus 10% 1,760 1,243 49

High-Stage

CFM

Low-Stage

CFM

(@ .1" - .5" w.c. ESP; Rise Range: 25 - 55°F)

Tap Adjust

A

B

*CVC950714CX

Heating Speed

High-Stage

CFM

Low-Stage

CFM

Rise

*CVC950915DX Cooling/Heating Speed Charts

*CVC950915DX

Cooling Speeds

( @ .1" - .8" w.c. ESP)

Tap Adjust

Minus 10% 729 504 Minus 10% 1,458 1,008 80

Minus 5% 770 532 Minus 5% 1,539 1,064 76

A

Normal 810 560 Normal 1,620 1,120 72

Plus 5% 851 588 Plus 5% 1,701 1,176 68

Plus 10% 891 616 Plus 10% 1,782 1,232 65

Minus 10% 999 666 Minus 10% 1,575 1,098 73

Minus 5% 1,055 703 Minus 5% 1,663 1,159 69

BB

Normal 1,110 740 Normal 1,750 1, 220 66

Plus 5% 1,166 777 Plus 5% 1,838 1,281 63

Plus 10% 1,221 814 Plus 10% 1,925 1,342 60

Minus 10% 1,287 828 Minus 10% 1,674 1,152 70

Minus 5% 1,359 874 Minus 5% 1,767 1,216 66

CC

D

1. All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

2. For most jobs, about 400 CFM per ton when cooling is desirable.

3. Do not operate above .5" w.c. ESP in heating mode. Operating CFM between .5" and .8" w.c. is tabulated for cooling purposes only.

4. Continuous fan speeds of 25%, 50%, 75% of maximum cooling airflow are available when using a communicating thermostat and 25%, 50%, 75%, 100%

of maximum cooling airflow are available in legacy mode by setting dip switches

Normal 1,430 920 Normal 1,860 1, 280 63

Plus 5% 1,502 966 Plus 5% 1,953 1,344 60

Plus 10% 1,573 1,012 Plus 10% 2,046 1,408 57

Minus 10% 1,674 1,071 Minus 10% 1,773 1,206 67

Minus 5% 1,767 1,131 Minus 5% 1,872 1,273 63

Normal 1,860 1,190 Normal 1,970 1, 340 60

Plus 5% 1,953 1,250 Plus 5% 2,069 1,407 57

Plus 10% 2,046 1,309 Plus 10% 2,167 1,474 55

High-Stage

CFM

Low-Stage

CFM

(@ .1" - .5" w.c. ESP; Rise Range: 25 - 55°F)

Tap Adjust

A

D

*CVC950915DX

Heating Speed

High-Stage

CFM

Low-Stage

CFM

Rise

19

Page 20

BLOWER PERFORMANCE SPECIFICATIONS

GCVC951155DX Cooling/Heating Speed Charts

GCVC91155DX*

ACVC951155DX*

Cooling Speeds

(@.1" -.8" w.c. ESP)

Tap Adjust

Minu s 10% 705 457 Min us 10% 1,583 1,0 93 63

Minus 5% 744

AA

BB

Normal 783

Plus 5% 822

Plus 10% 861

Minu s 10% 982

Minus 5% 1,036

Normal 1,091

Plus 5%

Plus 10% 1,200

Minu s 10% 1,265

Minus 5% 1,336

CC

DD

Normal 1,406 906 Normal 1,838 1,2 96 54

Plus 5% 1,476

Plus 10% 1,547

Minu s 10% 1,628

Minus 5% 1,719

Normal 1,809

Plus 5% 1,899

Plus 10% 1,990 1,282 Plus 10% 2,066 1,4 32 48

High-Stage

CFM

1,146

Low-Stage

CFM

483

508

533

559

621

656

690

725

759

815

861

951

997

1,049

1,107

1,165

1,223

Tap Adjust

(@.1" -.5" w.c. ESP; Rise Range: 40 - 70° F)

Minus 5% 1,671

Normal 1,759

Plu s 5% 1,847

Plus 10% 1,935

Min us 10% 1,612

Minus 5% 1,701

Normal 1,791

Plu s 5% 1,881

Plus 10% 1,970

Min us 10% 1,654

Minus 5% 1,746

Plu s 5% 1,930

Plus 10% 2,022

Min us 10% 1,690

Minus 5% 1,784

Normal 1,878

Plu s 5% 1,972

GCVC91155DX*

ACVC95 1155DX*

Heating Speeds

High-Stage

CFM

Low-Stage

CFM

1,1 53 59

1,2 14 56

1,2 75 53

1,3 35 51

1,1 06 61

1,1 68 58

1,2 29 55

1,2 90 52

1,3 52 50

1,1 66 60

1,2 31 57

1,3 61 51

1,4 26 49

1,1 72 59

1,2 37 56

1,3 02 53

1,3 67 50

Rise

1. All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

2. For most jobs, about 400 CFM per ton when cooling is desirable.

3. Do not operate above .5" w.c. ESP in heating mode. Operating CFM between .5" and .8" w.c. is tabulated for cooling purposes only.

4. Continuous fan speeds of 25%, 50%, 75% of maximum cooling airflow are available when using a communicating thermostat and 25%, 50%, 75%, 100%

of maximum cooling airflow are available in legacy mode by setting dip switches

20

Page 21

BLOWER PERFORMANCE SPECIFICATIONS

f

Circulator Blower Speed Adjustment Switches

Switc h Bank Purpose F unction

90 Off Off

120

150 Off On

180 On On

2 St age Stat

2 St age Stat On Off

S1

Hea ti ng O ff Delay

Ther mostat Set up

1 Stg Stat 5 min delay Off Of f

1 Stg Stat aut o del ay Off O n

AOffOff

Cooling Airflow

S3

Trim

BOnOff

COffOn

D

Add 5%

Mi nus 5% On Off

Add 10% Off On

Minus 10 % On On

A

Ramping Prof ile

S4

Hea ti ng Air flow

BOnOff

COffOn

DOnOn

AOffOff

B

COffOn

DOnOn

Dehum

Trim

S5

Continuous Fan

Di sabled

Enable d On

Di sabled

Enable d On

25% Off Off

50%

75% Off On

100% On On

Dip Switch

1234

On Off

On On

On On

Off Off

Off Off

On Off

Of

Off

On Off

Note: There are dual 7-segment LED's adjacent to the selection dipswitches. The airflow (rounded to the nearest 100 CFM) is

displayed on the dual 7-segment LED's. The CFM display alternates with the operating mode.

Example:

If the airlfow demand is 1230 CFM, the LED's will display 12. If the airflow demand is 1275 CFM, the LED's will display 13.

Note: The optional usage of a dehumidistat allows the furnace’s circulator blower to operate at a slightly lower speed (85% of

desired speed) during a combined thermostat call for cooling and dehumidistat call for dehumidification. This can be done

through an independent dehumidistat or through a thermostat’s DEHUM terminal (if available). This lower blower speed enhances

dehumidification of the conditioned air as it passes through the AC coil. For proper function, a dehumidistat applied to this furnace

must operate on 24 VAC and utilize a switch which opens on humidity rise.

1. All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

2. For most jobs, about 400 CFM per ton when cooling is desirable.

3. Do not operate above .5" w.c. ESP in heating mode. Operating CFM between .5" and .8" w.c. is tabulated for cooling purposes only.

4. Continuous fan speeds of 25%, 50%, 75% of maximum cooling airflow are available when using a communicating thermostat and 25%, 50%, 75%, 100%

of maximum cooling airflow are available in legacy mode by setting dip switches

21

Page 22

BLOWER PERFORMANCE SPECIFICATIONS

Ramping Profile

Note: The multi-speed circulator blower also offers several custom ON/OFF ramping profiles. These profiles may be used

to enhance cooling performance and increase comfort level. The ramping profiles are selected using DIP switches 5 and

6. Refer to the following figure for switch positions and their corresponding taps. Refer to the bullet points below for a

description of each ramping profile. Verify CFM by noting the number displayed on the dual 7-segment LED display.

OFF

100% CFM 100% CFM

1 min

Profile A: provides only an OFF delay of one (1)

minute at 100% of the cooling demand airflow.

OFF

50% CFM

1/2 min

100% CFM

100% CFM

1 min

Profile B: ramps up to full cooling demand airflow by first

stepping up to 50% of the full demand for 30 seconds. The

motor then ramps to 100% of the required airflow. A one (1)

minute OFF delay at 100% of the cooling airflow is provided.

OFF

100% CFM

OFF

OFF

OFF

Profile C: ramps up to 85% of the full cooling demand airflow

and operates there for approximately 7 1/2 minutes. The motor

then steps up to the full demand airflow. Profile C also has a

one (1) minute 100% OFF delay.

OFF

OFF

Profile D: ramps up to 50% of the demad for 1/2 minute,

then ramps to 85% of the full cooling demand airflow and

operates there for approximately 7 1/2 minutes. The motor

then steps up to the full demand airflow. Profile D has a 1/

2 minute at 50% airflow OFF delay.

1. All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

2. For most jobs, about 400 CFM per ton when cooling is desirable.

3. Do not operate above .5" w.c. ESP in heating mode. Operating CFM between .5" and .8" w.c. is tabulated for cooling purposes only.

4. Continuous fan speeds of 25%, 50%, 75% of maximum cooling airflow are available when using a communicating thermostat and 25%, 50%, 75%, 100%

of maximum cooling airflow are available in legacy mode by setting dip switches

22

Page 23

WIRING DIAGRAMS

BR

PU

YL

OR

GY

2

1

RD

WH

C

E

H

A

WH

WH

WH

T

H

O

O

L

S

A

U

C

E

R

F

P

E

R

T

N

I

G

I

E

R

I

C

2

N

C

O

O

W

T

A

G

S

N

H

O

(

WH

RD

T

C

U

I

R

N

O

E

C

T

H

A

E

G

S

T

C

E

V

V

A

L

E

)

W

Y

L

E

L

M

P

A

N

M

N

T

C

O

L

B

R

E

O

A

U

T

T

I

M

I

L

3

2

1

B

U

R

N

E

M

C

R

O

M

E

W

C

O

O

B

R

L

BK

HUM-

OUT

EAC

W

H

W

H

GN

U

P

L

Y

R

B

3

1

Y

G

0

1

K

P

7

R

O

4

U

P

W

H

/

1

OR

PK

V

4

2

A

3

U

F

S

E

R

T

M

M

R

N

E

S

S

L

B

G

Y

R

D

4

K

B

3

2

1

R

O

U

T

R

C

L

C

A

I

*CVC9/*MVC95_A*

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

O

T

N

D

G

5

1

I

S

W

R

E

I

F

W

C

R

E

S

S

U

R

N

C

H

S

T

W

I

R

O

3

I

U

P

2

B

R

1

Y

G

N

O

U

O

L

E

U

A

L

L

R

O

S

R

E

T

C

E

S

O

N

N

I

L

G

(

S

L

R

O

U

)

B

k

T

5

4

K

P

P

A

R

S

I

R

Y

M

E

T

L

R

O

C

O

N

T

H

W

R

D

B

K

E

N

T

P

M

A

R

T

E

P

N

T

M

A

R

T

A

U

M

N

A

L

E

R

S

E

T

A

U

X

I

L

I

A

R

Y

L

I

I

T

L

M

T

O

C

N

R

O

HUM-

IN

HUM

E

N

W

H

F

S

E

I

N

L

BK

C

BK

BK

C

O

O

H

E

D

E

H

U

T

R

I

M

4

1

5

1

C

O

2

1

1

1

H

E

A

T

9

8

6

5

3

2

S

E

E

BR

5

N

O

T

E

OR

R

2Y11

C

GY

V

4

2

T

H

M

E

R

Y

B

S

L

E

A

C

H

M

S

T

I

H

U

.

2

M

4

V

R

O

C

O

C

P

I

M

I

L

T

O

L

R

O

T

U

P

N

D

G

U

L

T

A

R

L

B

A

F

O

O

L

%

M

T

R

I

L

P

R

F

L

A

F

A

T

A

E

M

B

L

N

E

E

N

A

B

E

L

F

A

N

N

T

D

Y

L

O

F

F

S

A

T

T

T

-

W1

W2

G

S

O

T

A

T

C

O

O

N

Y

G

R

V

C

O

E

R

N

T

O

F

R

T

N

C

E

T

S

W

S

I

S

E

U

R

N

R

O

D

N

I

U

C

E

D

T

D

R

A

F

E

W

O

B

R

L

U

P

L

Y

WH

5 CIRCUIT CONNEC TOR

5

4

3

2

1

4 CIRCUIT MOTOR

CONNECTOR

4

3

DIP SWITCHES

2

1

0

4

T

R

INTEGRATED

TWO-STAGE

CONTROL

MODULE

D

I

A

G

C

N

O

S

T

I

E

L

D

'

S

DEHUM

Y2

O

E

C

S

N

N

T

I

O

BK

5

K

B

4

W

H

3

R

G

2

P

1

W

L

O

E

B

R

N

G

D

K

WH

YL

K

B

R

E

I

H

G

F

H

I

P

R

E

S

S

E

U

R

OR

C

H

S

T

I

W

H

BR

PK

WH

RD

BK

OR

RD

L

B

Y

G

K

B

R

D

V

A

A

N

S

F

E

R

M

R

O

4

2

V

A

C

5

1

1

V

A

C

BK

W

H

W

H

S

D

C

I

O

N

PU

A

E

M

L

F

S

E

N

S

R

O

D

B

W

M

P

G

CHASSIS GROUND

BL

GN

INTEGRATED CONTROL MODULE

BR

PK

24V THERMOSTAT CONNECTIONS

OR

GY

24V HUM.

W

H

K

B

K

B

B

E

L

W

R

O

O

P

C

M

A

T

E

T

R

M

N

C

O

S

R

I

D

T

H

W

O

(

O

P

E

E

H

N

W

N

D

P

O

O

E

)

R

O

N

N

1

1

A

1

5

C

V

O

T

/

Ø

R

E

C

V

O

U

W

:

A

G

R

N

N

I

O

P

N

O

S

C

N

C

I

T

E

C

E

I

O

R

F

V

E

E

R

S

T

N

I

U

O

T

N

R

G

I

I

E

R

P

O

P

B

E

T

U

S

N

D

A

D

E

Z

R

L

I

A

O

N

R

D

D

U

.

O

E

R

D

O

O

S

I

T

W

C

H

I

N

D

U

T

C

O

R

7

0

k

B

T

U

,

9

0

k

1

1

5

k

B

T

M

U

O

N

O

L

Y

U

H

M

L

I

N

E

U

U

-

H

O

M

T

U

H

M

E

A

C

N

I

G

F

S

L

I

N

E

F

U

S

E

3

A

T

R

V

+

D

C

T

O

Y

W

W

Y

G

E

D

C

I

N

H

1

P

1

P

2

P

T

O

C

R

M

O

I

2

H

O

M

U

H

M

M

M

G

T

T

O

G

R

+

R

T

O

T

I

C

M

R

O

A

T

E

G

R

A

E

T

D

C

O

N

T

R

O

P

JUNCTION BOX

R

U

E

R

E

S

E

S

A

G

S

T

-

W

O

E

W

T

O

B

R

D

L

1

P

O

V

O

P

R

L

W

P

S

N

T

E

C

R

W

N

I

R

C

B

D

-

I

I

H

O

L

S

S

S

2

H

I

G

P

R

L

V

V

V

N

R

N

V

X

X

U

L

M

P

T

A

W

O

E

P

R

H

6

0

Z

/

C

R

E

P

T

O

N

R

T

E

N

G

D

L

R

E

.

G

L

Y

J

U

N

C

T

N

I

O

O

T

E

N

I

N

M

O

1

I

L

H

C

D

D

D

(

X

I

L

U

,

L

S

I

N

R

D

O

O

A

I

R

C

C

I

R

U

L

A

T

O

B

L

R

W

S

6

E

E

T

N

E

O

U

I

D

H

M

I

F

I

E

R

M

U

I

D

H

I

F

I

E

R

E

L

E

C

T

O

I

C

R

N

A

L

C

E

I

R

A

E

N

R

N

D

I

H

I

D

B

L

R

W

D

L

O

H

T

O

S

R

U

F

A

C

E

N

I

G

I

T

E

R

F

L

A

E

M

S

E

N

S

R

O

1

1

5

V

A

C

(

4

)

V

A

C

4

2

R

E

A

S

E

N

I

T

U

L

A

L

A

U

X

I

C

O

N

T

R

O

S

L

)

0

1

(

(

7

)

.

H

U

M

V

4

2

(

2

)

O

N

O

N

)

2

1

(

F

I

H

R

E

C

H

T

I

E

S

S

S

W

.

(

1

)

N

(

1

3

)

F

C

P

(

1

4

)

(

8

)

(

5

)

(

1

1

)

(

4

)

(

C

1

)

I

N

O

D

(

2

)

A

I

R

C

L

I

R

U

C

3

)

B

L

W

O

D

E

U

L

Z

H

0

6

/

Ø

V

1

A

C

/

E

W

S

H

R

U

P

P

T

W

Y

L

I

E

R

C

U

R

R

E

T

N

E

C

I

E

D

N

V

O

I

E

C

T

T

O

A

R

W

O

E

R

U

O

R

O

N

D

U

P

S

O

I

T

B

X

O

R

A

R

Y

C

M

A

N

I

L

M

O

R

O

N

R

E

S

S

R

O

A

T

O

R

N

E

N

O

S

N

D

C

C

N

G

I

I

:

T

E

E

O

F

B

R

R

E

N

R

G

W

I

I

N

C

.

I

G

I

V

E

B

T

U

M

S

T

N

I

R

E

P

R

G

O

L

Y

P

N

D

E

N

N

N

4

0

V

A

T

A

R

N

A

U

I

L

T

M

I

U

A

L

T

C

I

O

C

O

V

T

U

R

E

G

N

D

R

D

P

E

Z

O

R

L

A

L

I

Y

U

N

D

E

D

.

H

T

W

I

C

E

I

V

D

I

S

C

N

O

N

E

C

T

N

G

D

N

E

U

T

R

A

L

INTEGRATED CONTROL MODULE

E

N

U

T

R

A

L

E

N

U

T

R

A

L

E

U

T

R

A

L

E

T

U

R

A

L

E

T

N

U

R

A

L

E

S

M

R

F

R

O

T

O

M

A

P

R

Y

R

R

I

E

S

E

T

C

O

N

T

R

T

O

M

L

I

I

L

R

E

F

I

P

R

E

S

S

.

O

L

W

I

S

W

T

C

H

C

R

E

S

E

T

R

O

O

L

L

U

T

N

T

R

O

S

L

P

M

E

R

I

S

W

T

C

H

I

H

C

G

A

S

V

V

A

E

L

T

O

E

N

S

:

1

.

S

E

T

E

H

A

T

A

T

I

N

P

I

C

A

N

O

T

R

R

O

O

O

2

.

M

F

A

U

A

T

R

N

C

U

E

3

.

I

F

A

F

N

O

Y

T

E

H

I

S

T

U

T

M

B

E

R

E

P

$

C

A

T

L

E

S

A

T

1

0

5

4

.

N

U

I

T

M

S

U

T

B

P

E

5

.

E

A

T

R

C

L

O

L

T

H

E

R

O

O

E

M

F

R

T

A

2

H

N

I

D

6

M

I

.

U

F

R

H

I

E

I

N

S

E

H

A

T

C

A

L

L

(

C

M

O

M

T

E

M

R

I

N

A

L

S

T

R

O

U

L

E

A

Y

G

O

C

E

M

D

)

O

S

E

T

U

P

I

S

D

N

O

E

W

F

1

0

0

4

1

0

M

'

S

R

S

P

E

C

I

F

D

I

E

E

R

P

A

I

I

N

L

G

E

R

I

R

W

O

A

S

I

T

H

I

R

W

I

L

A

E

W

C

D

.

U

S

P

E

O

N

P

C

O

E

C

R

E

M

R

A

N

E

T

N

L

Y

R

G

O

L

A

S

T

6

F

A

L

U

T

S

,

M

I

L

E

E

O

D

S

C

N

S

H

W

T

A

L

L

A

T

N

I

P

O

O

T

N

I

O

I

C

N

A

U

R

T

O

G

L

I

N

E

I

F

I

U

E

D

R

R

H

M

N

U

I

D

R

I

N

D

E

P

N

E

D

E

T

N

L

Y

H

I

T

I

N

N

C

M

U

O

I

M

C

A

B

-

1

0

2

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

I

L

O

I

N

C

U

T

R

D

C

O

7

0

k

B

U

T

,

9

0

k

B

T

,

U

1

1

5

k

B

D

L

O

T

S

E

M

U

O

L

Y

N

T

S

H

O

T

E

M

A

R

T

A

T

0

.

7

A

M

P

S

L

A

E

E

T

C

M

N

S

P

U

P

L

I

E

D

N

M

G

A

T

E

R

D

C

U

T

O

R

S

U

D

N

E

D

N

A

S

O

T

R

E

E

C

N

I

S

A

D

N

N

T

B

S

:

U

S

E

U

H

A

Y

G

O

C

M

D

H

G

I

E

N

A

T

F

E

H

R

A

M

O

T

T

G

I

H

N

E

R

.

P

A

T

R

S

U

M

S

T

B

E

U

S

D

E

E

H

I

T

W

H

I

A

L

H

A

O

L

N

Y

N

D

O

C

T

T

O

Y

(

N

O

T

M

E

R

E

S

)

.

U

A

C

L

L

(

T

C

A

L

M

S

O

T

W

T

H

E

F

R

A

E

U

U

N

C

M

S

B

V

I

.

F

L

E

T

M

S

E

C

L

A

T

T

N

A

G

E

T

M

P

E

A

R

T

U

R

E

M

R

.

O

T

E

N

.

O

.

C

A

D

N

A

H

I

O

(

S

T

R

E

C

N

,

D

E

T

E

P

R

E

M

S

R

O

T

A

I

N

T

P

T

U

S

I

D

A

N

L

T

R

N

O

U

H

M

U

H

M

U

-

I

N

A

D

N

H

U

-

O

M

M

M

A

U

I

C

T

N

I

N

G

O

M

T

M

G

I

N

N

C

M

U

I

O

C

M

A

)

C

L

O

C

R

O

O

D

:

E

N

S

E

R

.

V

G

I

N

I

C

E

R

E

P

C

D

L

A

E

,

R

A

T

I

N

O

G

F

L

O

A

C

L

C

O

D

E

S

.

E

S

S

C

S

I

T

H

W

)

I

F

R

G

I

I

E

N

D

R

U

T

U

D

E

R

O

O

L

E

-

N

Y

D

O

S

L

O

N

K

I

P

K

P

R

B

W

H

L

B

Y

G

R

D

L

Y

R

O

U

P

N

G

K

B

L

O

R

W

O

B

N

H

W

I

E

T

H

B

G

R

Y

O

P

G

B

I

L

U

E

H

Y

R

A

D

E

L

W

L

O

E

N

R

E

G

A

U

L

R

E

P

N

I

E

R

N

E

C

L

A

K

(

2

4

V

E

G

A

L

T

O

V

W

L

E

I

F

E

G

A

L

T

O

V

W

(

)

1

1

5

V

I

E

T

P

V

E

G

O

L

T

A

L

D

E

I

F

V

E

G

O

L

T

A

J

U

N

C

T

R

M

E

T

N

L

E

T

I

A

R

N

C

D

O

N

R

E

G

T

T

A

C

L

U

N

G

O

N

I

T

E

C

I

D

M

I

U

F

H

I

E

R

G

N

N

D

T

E

M

P

U

Q

I

)

D

N

O

I

L

N

A

I

O

T

R

L

O

N

O

E

L

N

G

D

E

D

I

F

C

L

L

S

I

D

E

P

E

I

F

)

C

.

T

H

P

I

W

M

(

S

E

T

R

E

T

N

G

I

I

C

(

T

.

R

P

H

S

E

I

W

S

)

S

R

C

E

U

V

O

R

R

E

N

T

C

E

I

V

D

E

R

.

T

O

P

23

Page 24

SCHEMATICS

)

LIMIT

RESET

MANUAL

LIMIT

RESET

MANUAL

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

TAB TERMINAL