Goodman ACNF INSTALLATION INSTRUCTIONS

1

ACNF CEILING MOUNT AIR HANDLER

INSTALLATION INSTRUCTIONS

Important Safety Instructions

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards. It

is the owner’s and installer’s responsibility to read and com-

ply with all safety information and instructions accompany-

ing these symbols. Failure to heed safety information in-

creases the risk of personal injury, property damage, and/or

product damage.

Codes & Regulations

This product is designed and manufactured to comply with

local, national and international laws, codes and regulations.

Installation in accordance with such codes and/or prevailing

local codes/regulations is the responsibility of the installer.

The manufacturer assumes no responsibility for equipment

installed in violation of any codes or regulations.

HIGH VOLT AGE!

D

ISCONNECT

ALL

POWER

BEFORE

SERVICING

OR

INSTALLING

THIS

UNIT

. M

ULTIPLE

POWER

SOURCES

MAY

BE

PRESENT

. F

AILURE

TO

DO

SO

MAY

CAUSE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRIC

SHOCK

.

W

IRING

MUST

CONFORM

WITH

NEC

OR

CEC

AND

ALL

LOCAL

CODES

. U

NDERSIZED

WIRES

COULD

CAUSE

POOR

EQUIPMENT

PERFORMANCE

,

EQUIPMENT

DAMAGE

OR

FIRE

.

G

OODMAN

WILL

NOT

BE

RESPONSIBLE

FOR

ANY

INJURY

OR

PROPERTY

DAMAGE

ARISING

FROM

IMPROPER

SERVICE

OR

SERVICE

PROCEDURES

. I

F

YOU

PERFORM

SERVICE

ON

YOUR

OWN

PRODUCT

,

YOU

ASSUME

RESPONSIBILITY

FOR

ANY

PERSONAL

INJURY

OR

PROPERTY

DAMAGE

WHICH

MAY

RESULT

.

CARBON MONOXIDE POISONING HAZARD

-

Special Warning for Installation of Furnace or Air Handling Units in

Enclosed Areas such as Garages, Utility Rooms or Parking Areas

Carbon monoxide producing devices (such as an automobile, space

heater, gas water heater, etc.) should not be operated in enclosed areas

such as unventilated garages, utility rooms or parking areas because of

the danger of carbon monoxide (CO) poisoning resulting from the exhaust

emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, utility room or parking area and a carbon monox i de produc ing

device is operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO poisoning which

can occur if a carbon monoxide producing device continues to operate in

the enclosed area. Carbon monoxide emissions can be (re)circulated

throughout the structur e if the furnace or air handle r is operating in any

mode.

CO can cause serious illness including permanent brain damage or death.

B10259-216

T

O

PREVENT

THE

RISK

OF

PROPERTY

DAMAGE

,

PERSONAL

INJURY

,

OR

DEATH

,

DO

NOT

STORE

COMBUSTIBLE

MATERIALS

OR

USE

GASOLINE

OR

OTHER

FLAMMABLE

LIQUIDS

OR

VAPORS

IN

THE

VICINITY

OF

THS

APPLIANCE

.

© 2011 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com -or- www.amana-hac.com

IO- 422

10/2011

SHIPPING INSTRUCTIONS ..................................................... 2

APPLICATION INFORMATION ................................................... 2

P

RE-INSTALLATION CONSIDERATIONS ...................................... 2

INSTALLATION ORDER .......................................................... 3

LAYOUT FOR CEILING MOUNT AIR HANDLERS ......................... 3

OUTDOOR UNIT INSTALLATION ............................................... 9

INSTALLING THE CONNECTING PIPE ...................................... 10

REFRIGERANT PIPE CONNECTION ........................................ 11

CONNECTING THE AIR HANDLER TO THE OUTDOOR UNIT ......... 12

CONNECTING THE DRAIN PIPE - INDOOR UNIT ....................... 12

UNITS WITH FRESH AIR DUCT INSTALLATION ......................... 14

MOTOR AND DRAIN PUMP MAINTENANCE ............................. 14

ELECTRICAL WIRING ........................................................ 14

TESTING THE UNIT’S OPERATION ......................................... 15

WIRING DIAGRAMS ........................................................... 18

2

Do not connect to or use any device that is not design

certified by Goodman for use with this unit. Serious

property damage, personal injury, reduced unit

perform ance and/O R haza rdou s cond itio ns m ay resu lt

from the use of such non-approved devices.

WARNING

Have your contractor identify all the various cutoff switches

and devices that service this unit. Know where the switch is

that will cut off energy to the heating system in the event of

overheating.

CAUTION

Special Notes for European Consumers:

Do not dispose of this product as unsorted municipal waste.

Collection of such waste for special treatment is necessary.

It is strictly prohibited to dispose of this unit in domestic

household waste. Disposal options:

1. Some municipalities have established collection systems

to collect electronic waste for disposal.

2. Your purchase point retailer (or manufacturer) may take

back the unit for disposal.

3. Used products contain valuable resources and can be

sold to scrap metal dealers.

Illegal disposal in forests and landscapes endanger your

health and the environment. Hazardous materials leak into

ground water.

SHIPPING INSPECTION

Upon receiving the product, inspect it for damage from ship-

ment. Shipping damage, and subsequent investigation is the

responsibility of the carrier. Verify the model number, speci-

fications, electrical characteristics, and accessories are cor-

rect prior to installation. The distributor or manufacturer will

not accept claims from dealers for transportation damage or

installation of incorrectly shipped units.

Name Shape Qty.

Soundproof/

Insulation sheath

2

Binding Tape 1

Seal Sponge 1

*Orifice 1

Drain joint 1

Seal ring 1

Wire controller

Wire controller

---

1

Owner's Manual

--- 1

Installation Manual

--- 1

* As applicable

Tubes

&

Fittings

Drain Pipe

Fittings for

cooling/heating

Literature

APPLICATION INFORMATION

This ceiling mount air handler is available in cooling capaci-

ties of 1.0, 1.5, 2, 2.5, 3.0, 3.5, 4.0 and 6.0 nominal tons of

cooling. Electric heat models are available in capacities of 0,

5, 6, 8 and 10 kW.

The unit is designed to be installed in a horizontal position

above a dropped ceiling. Do NOT install this unit outside

the structure. These models are designed for INDOOR

USE ONLY.

PRE-INSTALLATION CONSIDERATIONS

Carefully read all instructions for the installation prior to in-

stalling product. Make sure each step or procedure is under-

stood and any special considerations are taken into account

before starting installation. Assemble all tools, hardware

and supplies needed to complete the installation. Some items

may need to be purchased locally. Make sure everything

needed to install the product is on hand before starting.

Before attempting any installation, the following points should

be considered:

• Structural strength of supporting members

• Clearances and provision for servicing

• Power supply and wiring - Routing of wires must be

arranged so the control board cover is fixed properly.

If not, a possibility of overheating, fire or electrical

shock may occur at the connection point of the termi-

nal.

• Air duct connections - Ductwork should be fabricated

in accordance with local codes and sized to accom-

modate 375-425 CFM per ton of cooling with the static

pressure not to exceed 0.5” W.C. Inadequate ductwork

that restricts airflow can result in improper performance

and compressor or heater failure.

• Drain facilities and connections

• Installation of unit must be, at a minimum, of 91” (2.3m)

above the floor.

• Electrical installations must be in accordance with lo-

cal national wiring standards, regulations and this in-

stallation instruction. An independent circuit and single

outlet must be used. If installed without the proper

electrical circuit capacity, or installed defectively, pos-

sibility of electrical shock or fire may occur.

• To ensure proper performance of unit, use the speci-

fied cable, and clamp the cable securely to prevent

disconnection as this will cause overheating or fire at

the connection.

• An all-pole disconnect switch, having a contact sepa-

ration of at least 3mm in all poles, should be con-

nected in the fixed wiring.

3

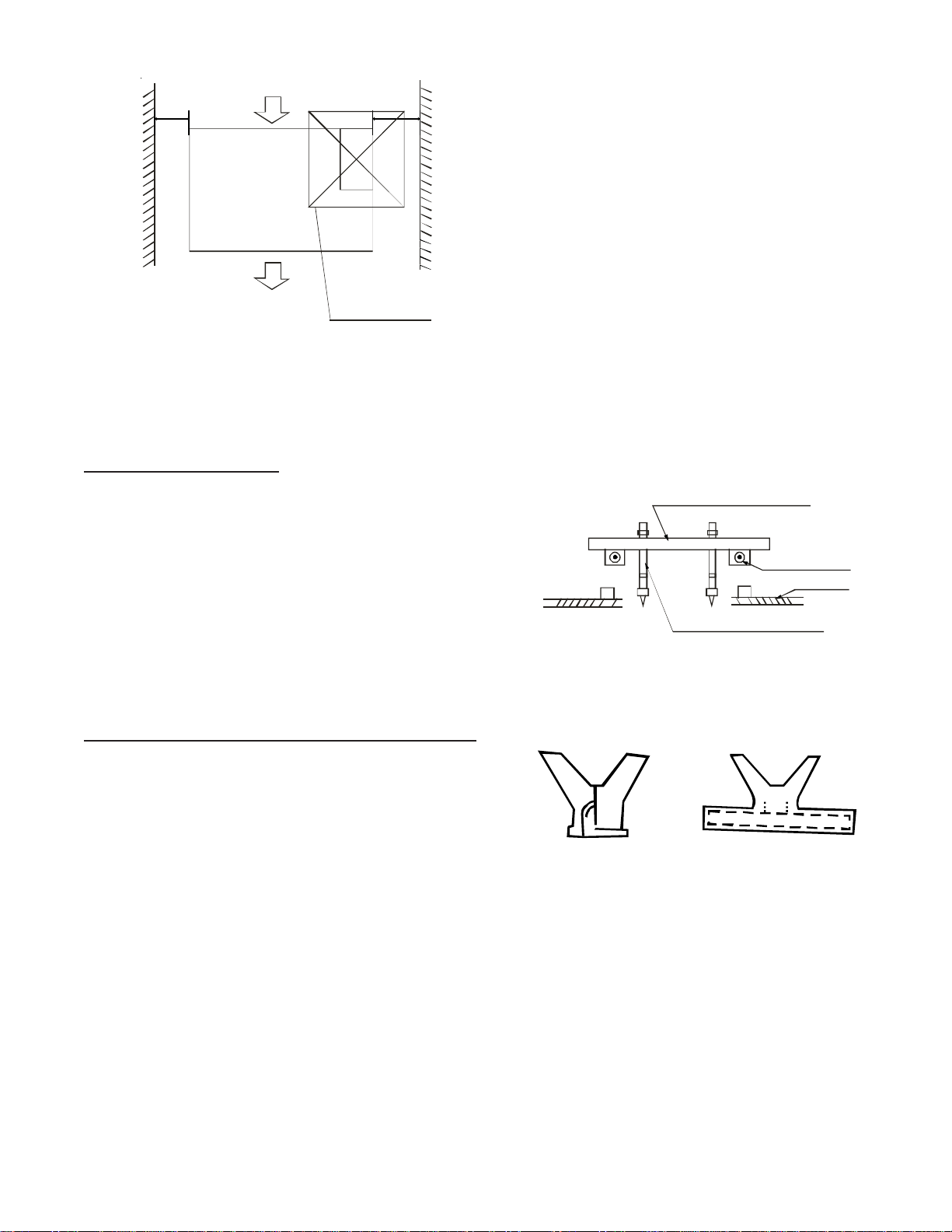

8” (200mm)

or more

12” (300mm)

or more

24” x 24”

(600mm x 600mm)

(Checking orifice)

Figure 1 - Room clearances

NOTE: To prevent interference, keep indoor unit, outdoor

unit, power supply wiring and transmission wiring at

least 39” (1 meter) from televisions and radios.

INSTALLATION ORDER

Install your unit in the following order:

1. Select the mounting locations.

2. Install the indoor unit.

3. Instal the outdoor unit.

4. Install the connecting pipe

5. Connect the drain pipe.

6. Wiring.

7. Test operation.

LAYOUT FOR CEILING MOUNT AIR HANDLERS

NOTE: The location of the unit is based on thorough consid-

eration of the PRE-INSTALLATION CHECK POINTS below:

• Structural strength of supporting members

• Clearances and provision for servicing

• Power supply and wiring

• Air duct connections

• Drain facilities and connections

1. Before locating the unit on the dropped ceiling, ensure

the strength of the ceiling and beams is adequate to

support the weight involved. This is an important step

and the installers responsibility.

Installing the four (4) 3/8” (Ø 10) Hanging Screw Bolts

2. Mount the unit in a horizontal position above a dropped

ceiling of adequate strength with four 3/8” (Ø 10) hang-

ing screw bolts. Refer to the following figures for dis-

tance between the screw bolts.

3. The installation to ceilings varies with construction. Con-

sult construction personnel for the specific procedures.

4. Install pipes and lines in the ceiling after completion of

the installation of the ACNF air handler. The first con-

sideration of installation is to determine the direction of

the pipes. When installing in a ceiling, position the re-

frigerant pipes, drain pipes, indoor and outdoor lines to

the connections before hanging the unit.

5. Install the hanging screw bolts.

6. After the selection of installation location, position the

refrigerant pipes, drain pipes, indoor and outdoor lines

to the connections before hanging the unit.

7. Attach the hanging screw bolts.

NOTE: The minimum drain tilt is at least 1/100.

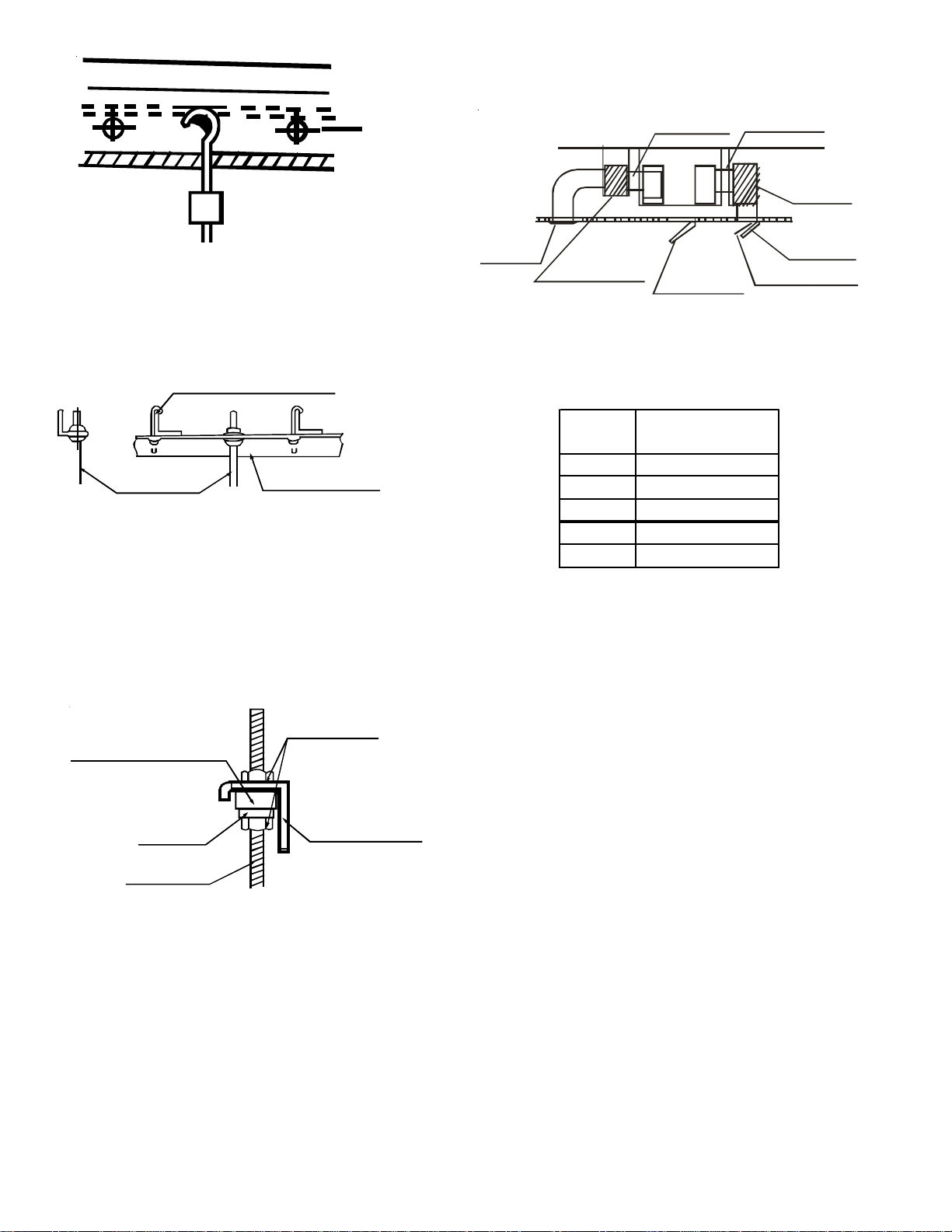

Wooden construction

Put the square timber traversely over the roof beam, then

install the hanging screw bolts.

Timber over the beam

Ceiling

Hanging Screw Bolts

Roof Beam

Figure 2

New Concrete or Bricks

Embedding the screw bolts, Figure 3.

Slide

Insertion

Blade Shape

Insertion

Figure 3

Installation for Existing Concrete Bricks

Use embedding screw bolt, crock and stick harness as shown

in Figure 4.

4

Steel Bar

Embedding screw bolt

(Pipe hanging & embedding screw bolt)

Figure 4

Steel Room Beam Structure

Install directly on the supporting angle steel. See Figure 5.

Hanging Bolts

Hanging Screw Bolt

Hanging Bolts

Supporting Angle Steel

Figure 5

Hanging the Indoor Unit

1. Place the indoor unit onto the hanging screw bolts with

block.

2. Using a level, position the unit to hang flat to prevent

leaks, Figure 6.

Screw Nut

Overhang

Shock-proof cushioningShock-proof cushioningShock-proof cushioning

Hanging Screw Bolt

Washer

Figure 6

Installing the dust proof net and canvas air passage

1. Install the dust proof net according to the installation

manual.

2. Install the canvas air passage underneath the dust proof

net.

Duct Design

1. Air inlet/outlet ducts must be spaced to prevent air from

the outlet from entering the air inlet.

2. A dust filter is located on the indoor unit.

Recommended duct connections:

Canvas tie-in

Canvas tie-in

Air inlet

Isolation

booth

Checking

orifice

Air dust filter

Isolation

booth

Air

outlet

Figure 7

3. It is important to maintain the static pressure below to

alleviate excessive noise, blowing water or other abnor-

malities.

Model

(Kw)

Static Pressure

Inches H

2

0 (Pa)

12 0.16 (40)

18 0.28 (70)

24 0.28 (70)

30-36 0.32 (80)

42-60 0.40 (100)

NOTES:

1. The indoor unit should not bear the connecting duct’s

weight.

2. Use the fire retardant canvas tie-in to prevent vibrating.

3. When connecting the ductwork, install in a location

where maintenance can be done easily.

4. The fan motor static pressure should correspond to the

external static pressure.

5. When installed in a noise-sensitive setting, install an

isolation booth and internal duct underlayer to help muffle

the duct noise. (Figure 7.)

5

Positioning the ceiling hole, indoor unit and hanging screw bolts.

See table below for dimensions.

Air

filter

Electric

control

cabinet

Air

filter

Electric

control cabinet

Figure 8

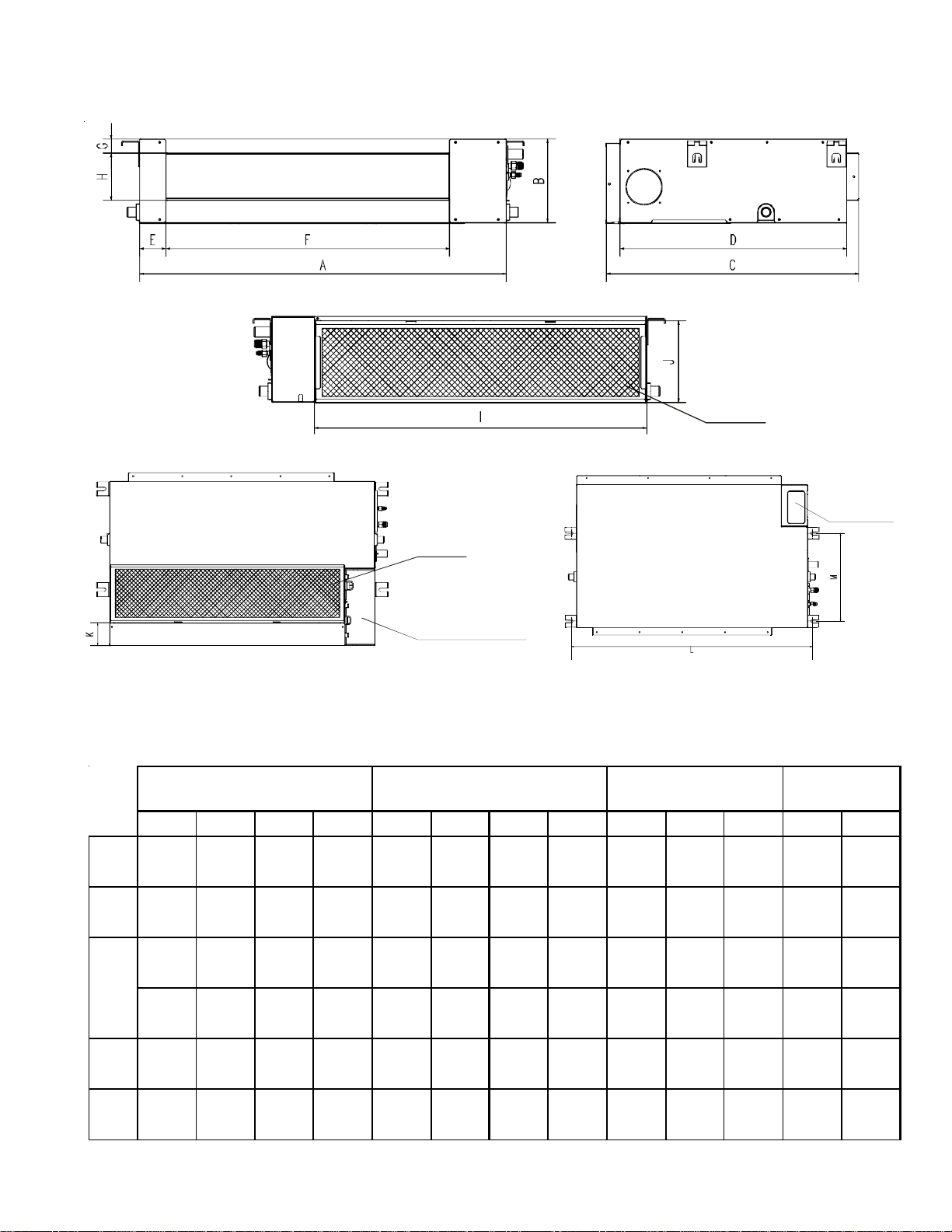

ABCDE FGH I JKLM

12

27 1/2"

700mm

8"

210mm

25"

635mm

22 1/4"

570mm

2 1/2"

65mm

19 1/4"

493mm

1 1/4"

35mm

4 3/4"

119mm

23 1/4"

595mm

8"

200mm

3"

80mm

29"

740mm

13 3/4"

350mm

12, 18

36"

920mm

8"

210mm

25"

635mm

22 1/4"

570mm

2 1/2"

65mm

28"

713mm

1 1/4"

35mm

4 3/4"

119mm

32"

815mm

8"

200mm

3"

80mm

37 3/4"

960mm

13 3/4"

350mm

45"

1140mm

8"

210mm

25"

635mm

22 1/4"

570mm

2 1/2"

65mm

36 3/4"

933mm

1 1/4"

35mm

4 3/4"

119mm

40 3/4"

1035mm

8"

200mm

3"

80mm

46 1/2"

1180mm

13 3/4"

350mm

36"

920mm

10 1/2"

270mm

25"

635mm

22 1/4"

570mm

2 1/2"

65mm

28"

713mm

1 1/4"

35mm

7"

179mm

32"

815mm

10"

260mm

3/4"

20mm

37 3/4"

960mm

13 3/4"

350mm

30-36

45"

1140mm

10 1/2"

270mm

30 1/2"

775mm

28"

710mm

2 1/2"

65mm

36 3/4"

933mm

1 1/4"

35mm

7"

179mm

40 3/4"

1035mm

10"

260mm

3/4"

20mm

46 1/2"

1180mm

19 1/4"

490mm

42-60

47"

1200mm

11 3/4"

300mm

34"

865mm

31 1/2"

800mm

31"

80mm

38"

968mm

1 1/2"

40mm

8"

204mm

43"

1094mm

11 1/4"

288mm

1 3/4"

45mm

48 3/4"

1240mm

19 3/4"

500mm

Size of

mounted lug

24

Outline dimemsion

Air outlet

opening size

Air return

opening size

6

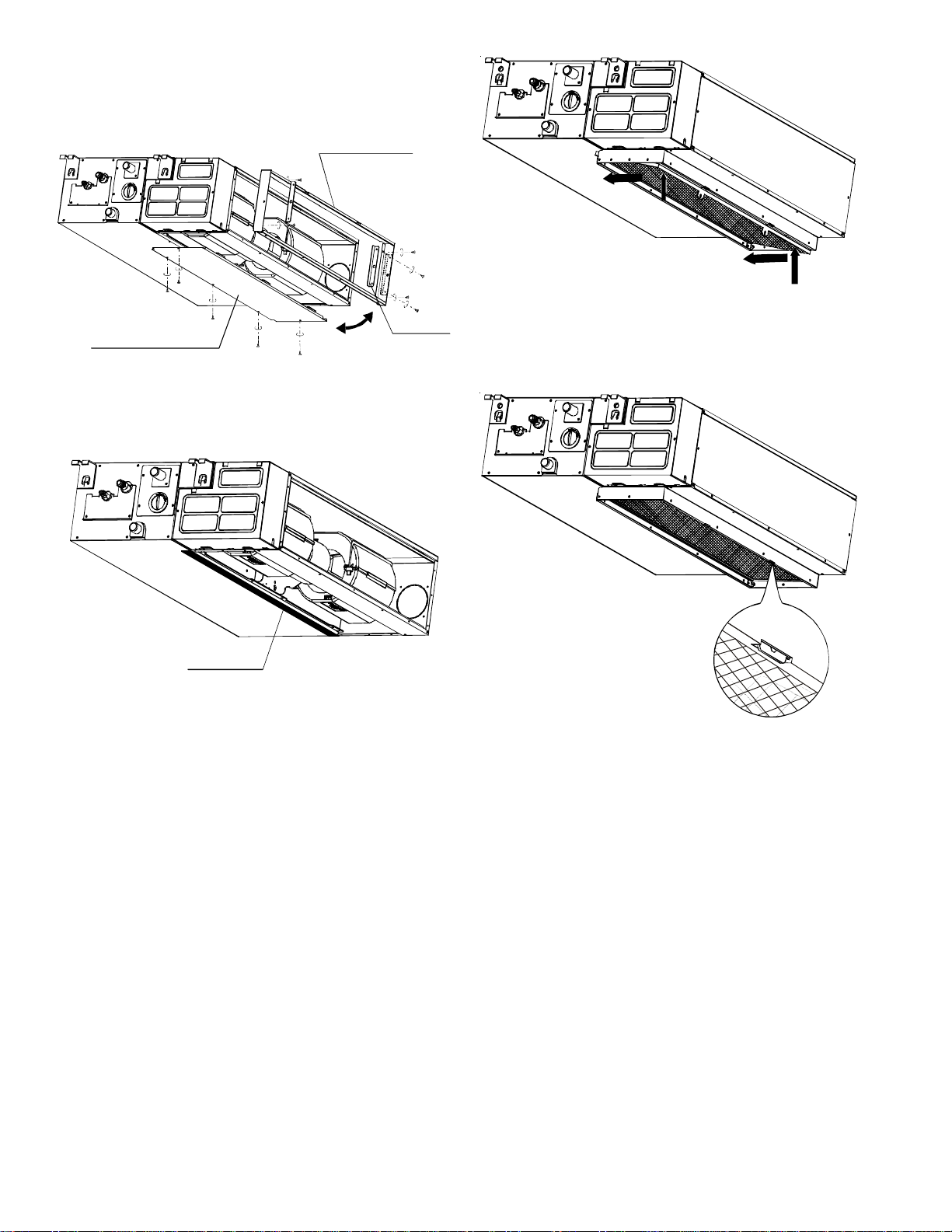

Adjusting the airflow direction

1. Remove the ventilation panel and flange; cut off the

staples at the side rail.

Air return flange

Ventilation panel

Side rail

Figure 9

2. Attach the seal sponge as shown below. Change the

mounting positions of the air return panel and air return

flange.

Seal sponge

Figure 10

3. When installing the filter mesh, place the filter mesh in

the flange and push up to set it in place, as shown by

the arrows in the following Figure 11.

Figure 11

4. Insert the clips in the flange holes as shown in Figure

12.

Figure 12

7

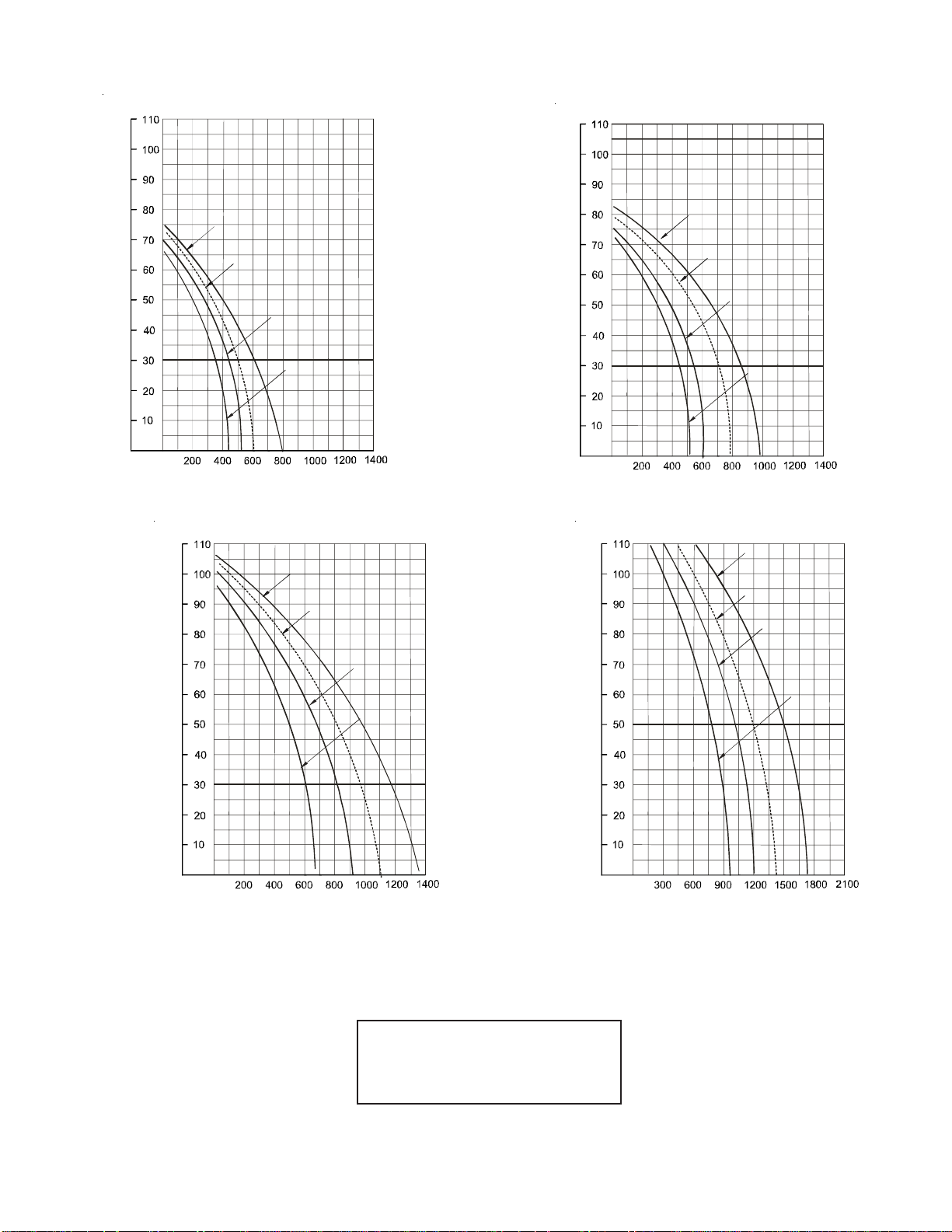

Fan Performance - Stactic Pressure Curve

Model 12

E

x

t

e

r

n

a

l

S

t

a

t

i

c

P

r

e

s

s

u

r

e

(

P

a

)

Super High Speed

High Speed (reserved)

Low Speed

Medium Speed

(Pa)

Air volume (m

3

/h)

Low Speed

Medium Speed

High Speed (reserved)

Super High Speed

Model 18

(Pa)

Air volume (m

3

/h)

E

x

t

e

r

n

a

l

S

t

a

t

i

c

P

r

e

s

s

u

r

e

(

P

a

)

Model 24

Low Speed

Medium Speed

High Speed (reserved)

Super High Speed

(Pa)

Air volume (m

3

/h)

High Speed (reserved)

Super High Speed

Model 30

(Pa)

Low Speed

Medium Speed

Air volume (m

3

/h)

NOTE:

1 m

3

/hr = 0.586 CFM

100 Pa = 0.4015 Inches of water

8

E

x

t

e

r

n

a

l

S

t

a

t

i

c

P

r

e

s

s

u

r

e

(

P

a

)

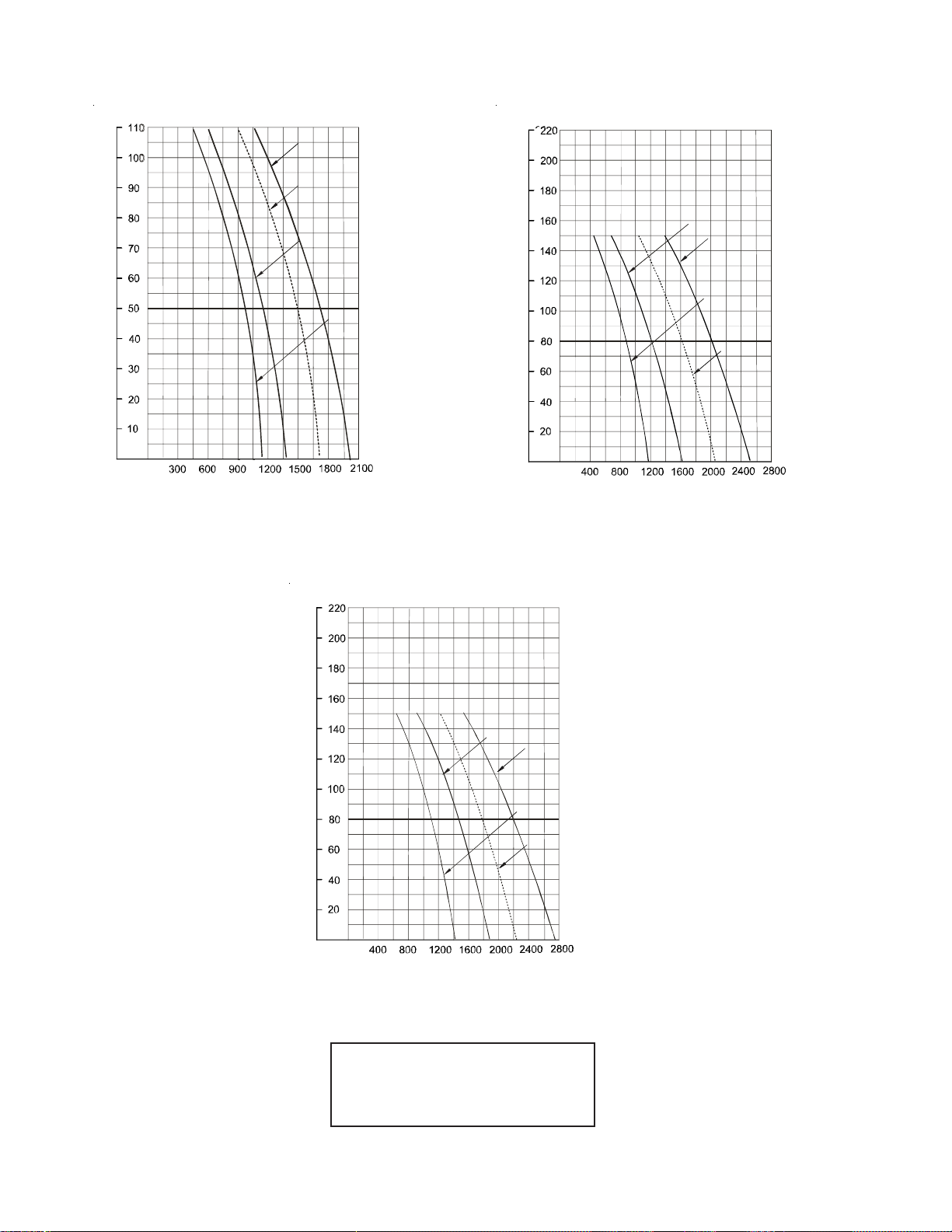

Model 36

(Pa)

Low SpeedLow Speed

Medium Speed

High Speed (reserved)

Super High Speed

Air volume (m

3

/h)

E

x

t

e

r

n

a

l

S

t

a

t

i

c

P

r

e

s

s

u

r

e

(

P

a

)

Super High Speed

High Speed (reserved)

Low Speed

Medium Speed

Model 42-48

(Pa)

Air volume (m

3

/h)

Model 60

(Pa)

E

x

t

e

r

n

a

l

S

t

a

t

i

c

P

r

e

s

s

u

r

e

(

P

a

)

Super High Speed

High Speed (reserved)

Low Speed

Medium Speed

Air volume (m

3

/h)

Fan Performance - Static Pressure Curve

NOTE:

1 m

3

/hr = 0.586 CFM

100 Pa = 0.4015 Inches of water

9

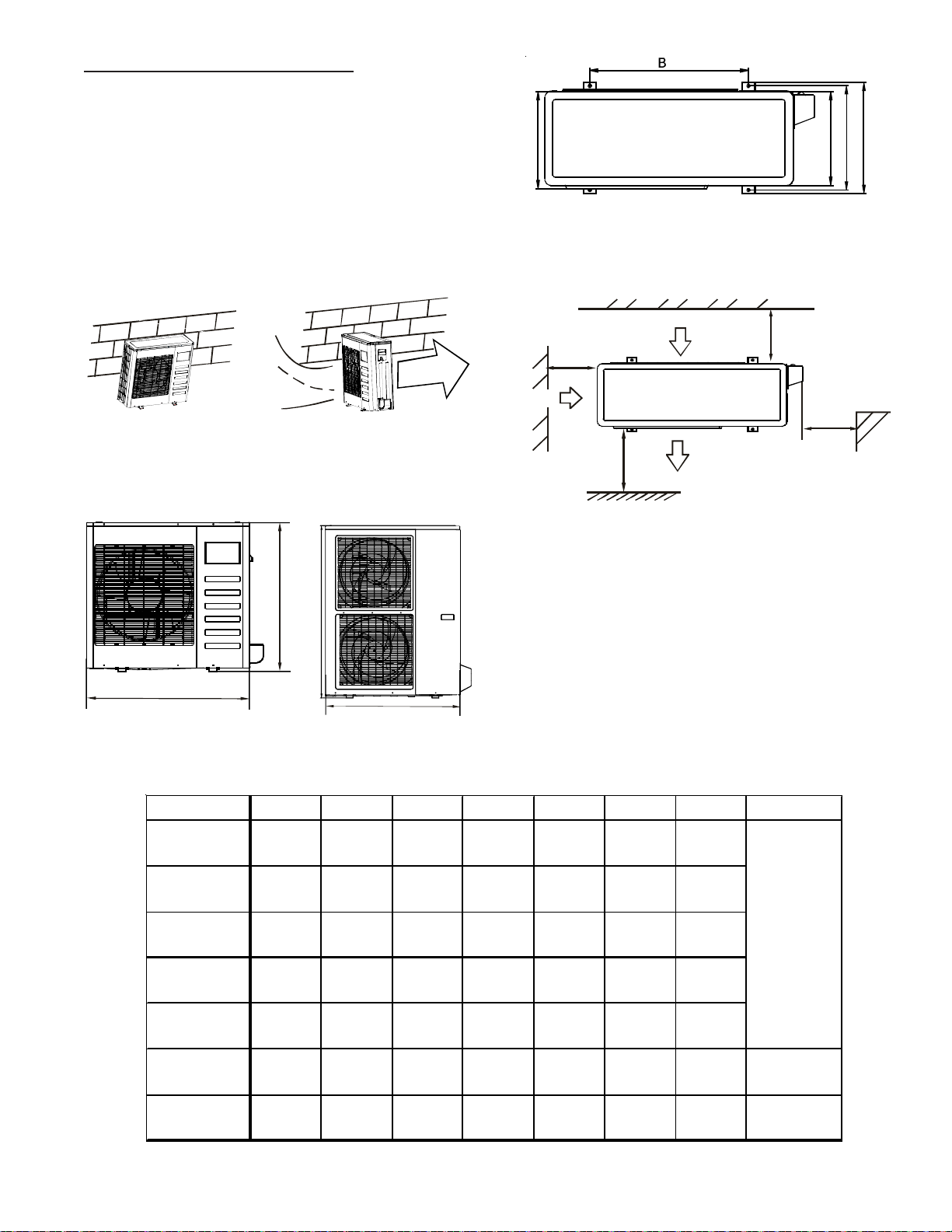

OUTDOOR UNIT INSTALLATION

The following are considerations before installing the out-

door unit.

• Install the outdoor unit on a rigid base to prevent noise

and vibration.

• Place the outdoor unit in such a manner to minimize

restriction of discharge air.

• Protect the unit from prevailing winds. To ensure the

unit operates correctly, place the unit lengthwise along

a wall or use a dust or shield plate.

Figure 13A

Figure 13B

S

T

R

O

N

G

W

I

N

D

• Install in a place where the unit is easily accessible

for installation and maintenance.

A

A

H

Figure 14A Figure 14B

C

E

D

F

Figure 14C

• See Figure 15 for minimum distances to obstacles.

Two of the three must remain unobstructed.

M

P

N

Air Inlet

Wall or obstacle

Air Outlet

Air Inlet

>12”

(30cm)

>

1

2

”

(

3

0

c

m

)

>24”

(60cm)

>

7

9

”

(

2

0

0

c

m

)

Figure 15

Moving and Installation

Notes:

• The inlet of the unit should not be used as a “handle”

when moving the unit.

• Use caution when moving the unit with a sling, since

the center of gravity is not in the unit’s physical cen-

ter.

• The fan should not be touched with hands or any for-

eign objects.

• Do not lean the unit more than 45° or lay it on its side.

ModelABC DEFHFigure Ref.

12,000

R-22 & R-410A

31"

780mm

21 1/2"

548mm

10 1/2"

266mm

11 1/2"

300mm

9 1/2"

241mm

9 1/2"

250mm

21 1/2"

547mm

18,000

R-22 & R-410A

30"

762mm

21"

530mm

11"

290mm

12"

315mm

10 1/2"

270mm

11"

282mm

23"

593mm

24,000

R-22 & R-410A

33"

842mm

22"

560mm

13"

335mm

14"

360mm

12"

312mm

12 1/2"

324mm

27"

695mm

30,000/36,000

R-22 & R-410A

39"

990mm

24 1/5"

624mm

14"

366mm

15 1/2"

396mm

13"

340mm

13 3/4"

354mm

38"

966mm

48,000

R-22 Only

39"

990mm

24 1/5"

624mm

14"

366mm

15 1/2"

396mm

13"

340mm

13 3/4"

354mm

38"

966mm

48,000

R-410A Only

35"

900mm

23"

590mm

14 3/4"

378mm

15 1/2"

400mm

13"

330mm

13 1/4"

340mm

45 3/4"

1167m m

Figure 14B

60,000

R-22 & R-410A

35"

900mm

23"

590mm

14 3/4"

378mm

15 1/2"

400mm

13"

330mm

13 1/4"

340mm

45 3/4"

1167m m

Figure 14B

Figure 14A

Loading...

Loading...